Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Philips Lighting Signs New Partnership Agreement With Greenhouse Specialist ST Solution for Russian Horticulture Market

February 28, 2018

Philips Lighting Signs New Partnership Agreement With Greenhouse Specialist ST Solution for Russian Horticulture Market

Eindhoven, the Netherlands – Philips Lighting (Euronext: LIGHT), the world leader in lighting, today announced the official Philips LED Horti partnership agreement with ST Solution, a Russian specialist in turnkey greenhouse solutions.

This partnership, made official at the HortiContact fair (February 20-22) in the Netherlands, came after the two companies worked together on an enormous new horticultural project at Agro-Inwest, a horticultural innovator located 350 km southwest of Moscow. The collaboration is part of a larger initiative in which Philips Lighting is developing a network of Russian partners.

“We are sharing our knowledge and investing in training programs for Russian experts,” said Udo van Slooten, Business Leader Horticulture at Philips Lighting. ST Solution’s personnel have already completed multi-stage training programs in Russia and at Philips Lighting’s headquarters in Eindhoven.

Valentin Shchenikov, Technical Director of ST Solution, said that it made sense to partner with Philips Lighting in both the short- and long-term. “If you want to be the best you should work with the best producers,” he said. “We appreciate the Philips system approach. Because it’s not just luminaries selling, it's an ROI-philosophy with quality service at each project stage: from business planning to agronomic support during growing. For us Philips is an example of genuine teamwork.”

ST Solution provides smart horticultural systems and greenhouse constructions for greenhouse projects throughout Russia. It has a Dialux certified design team and skillful installation team. Most recently they have been working with several new investors and on greenhouse projects in Russia, including the largest LED project worldwide at Agro-Inwest.

Agro-Inwest is one of Russia’s most innovative greenhouse produce companies. In 2017-2018 ST Solution built its greenhouses the size of 40 football fields, more than 25 hectare, for growing tomatoes and cucumbers. ST Solution helped install 120,000 GreenPower LED interlighting and GreenPower LED toplighting modules in less than three months in Russian winter time.

“We wanted to work with ST Solution because it has demonstrated sharp implementation times in Russia,” said Van Slooten. “The successful Agro-Inwest installation proved that ST Solution could deliver the local high level of service support that we look for in a partner.”

We are hiring: Business Development Manager CEE/Russia

Lighting Research Spotlight

Thinking of adding or upgrading supplemental grow lights in your greenhouse? Then the article “How Many Light Fixtures Do I Need?” written by GLASE Principal Investigator Dr. Neil Mattson and published in the e-Gro Edible Alert is a must read.

Lighting Research Spotlight

How many light fixtures do you need in a greenhouse?

Thinking of adding or upgrading supplemental grow lights in your greenhouse? Then the article “How Many Light Fixtures Do I Need?” written by GLASE Principal Investigator Dr. Neil Mattson and published in the e-Gro Edible Alert is a must read.

Mattson walks you through estimating how many fixtures you need if you know your target light intensity in micromoles per square meter per second (µmol/m2/s) and the light output in micromoles per second (µmol/s) from a given fixture. You can also estimate your annual electricity bill from using the lights if you know the power consumption of a fixture (in Watts) and an estimate of how many hours it will be operating during the year.

To further lower implementation and operational costs of horticultural LED lighting systems, GLASE is developing controlled environment agriculture (CEA)-specific technologies. The goal of these technologies is to improve lighting design recommendations and to support growers during the decision-making process to define an optimal system.

New technologies serving commercial lighting companies include the development of integrated CEA buildings, energy simulation engines, integrated control system simulations, and investigations of light distribution patterns in tall plant canopies. The development of a framework to compare energy and cost impacts of various lighting systems designed for horticultural applications will assist CEA growers in determining an optimal technology to fit their specific needs.

For more information, please visit the GLASE website at www.glase.org

Picture courtesy of Tessa Pocock

Dubai Chef Offers Tours of His Greenhouse

Buenaventura grows several different kinds of lettuce, a range of herbs, tomatoes, peppers, aubergines and edible flowers in a space that can’t be much bigger than 40 square metres.

Dubai Chef Offers Tours of His Greenhouse

UAE restaurant Cuisinero Uno has begun to grow its own organic vegetables. Gather around and join the fun at this urban farm

March 1, 2018

Keith J Fernandez, Group Editor - GulfNews.Com

John Martho Buenaventura shows off his baby eggplant with all the pride of a father. “I’m so happy,” he trills, talking to Gulf News tabloid!on the deck outside his second-floor restaurant at Dubai’s Business Bay. “Come back in two weeks and we’ll have a lovely crop!”

Rather improbably, we’re standing in a greenhouse bang in the middle of a dense cluster of high rises, in a very Dubai take on the heightened trend for organic produce and locavore eating. “A lot of people have been growing their own food, but we’re the first restaurant to actually do so on our terrace,” he says.

Buenaventura grows several different kinds of lettuce, a range of herbs, tomatoes, peppers, aubergines and edible flowers in a space that can’t be much bigger than 40 square metres. The results are served in his modern tapas restaurant Cuisinero Uno at the Steigenberger Hotel Business Bay.

Diners can tour the greenhouse anytime. Until March 9, as part of Dubai Food Festival, the restaurant is hosting a tour and tasting session each Friday. Interested visitors can take part in an experiential planting session and learn how to make healthy smoothies and mocktails — and taste some of this food. We loved the fantastic burratini salad with homegrown cherry tomatoes — the tomatoes juicy, fresh and sharp, the basil nice and peppery.

“My food costs have gone down between 3 and 5 percent, and the food tastes better because it’s locally sourced and organic,” Buenaventura tells me. The volumes from his terrace farm are nowhere near enough to sustain the restaurant, but as he says, at least he’s doing something to create a greener world and be sustainable. “In our own small way, we want to do a farm-to-table experience and we want to showcase that you don’t have to spend a lot of money for good food.”

And although he faced high installation and set-up costs for this urban farm, these will be amortised over time. He is now also experimenting with making his own compost.

The greenhouse uses a combination of hydroponics and aquaponics. The former is simply growing plants in water and is largely responsible for the spurt in locally grown produce now available in UAE supermarkets. Aquaponics is a system of aquaculture, where plants live off used water from aquariums. The plant beds subsequently purify the water, which loops back into the fish tanks. Nutrients are automatically added as required.

In March last year, Gulf News reported how the UAE Ministry of Climate Change and Environment has prioritised the use of hydroponic technology on farms as part of its food security strategy. The number of greenhouses in the country has grown from 50 in 2009 to over 1,000 in 2016, official figures show.

Buenaventura wants to take that one step further. He hopes to inspire similar projects and seed a discussion about sustainable habits. “The UAE is a hot country and not a lot of crops grow here. But if it was mandated by the government that all buildings in Dubai had to dedicate one floor to vertical farming, nobody would go hungry,” he says. “What do we eat in Dubai? Tomatoes, lettuce, cucumber, lemon, aubergine — we spend a lot of money on those, but we can grow these ourselves.”

He acknowledges that apartment residents won’t achieve the volumes needed to feed their families with a small balcony garden, but he says it’s a viable business model for those looking at alternative sources of income. “In a bigger set-up, like a grow truck — about the size of a trailer truck — you can grow 3,000 heads of organic lettuce in a month with hydroponics, which shortens the grow time by up to 30 per cent. So that’s a good business.”

For the moment, Buenaventura is happy to be making a difference in his own small way.

What Are The Production And Training Issues Facing Controlled Environment Agriculture Growers?

What Are The Production And Training Issues Facing Controlled Environment Agriculture Growers?

Exclusives from Urban Ag News

Ohio State University professor Chieri Kubota is focused on helping to resolve the production and training challenges facing controlled environment growers.

Trying to produce vegetables in hot, humid conditions can be difficult for controlled environment growers whether growing in a greenhouse or a warehouse.

“The challenges of greenhouse growing in Ohio and the Midwest are different than the challenges faced by growers in Arizona,” said Ohio State University horticulture professor Chieri Kubota. Kubota, who joined the faculty at Ohio State this past June will continue the controlled environment agriculture research she was doing while at the University of Arizona.

“Some people think I’m an expert at dealing with heat stress because I was doing my research in an Arizona greenhouse,” she said. “But in Arizona growers don’t really have to worry about the heat inside a greenhouse if they are using an evaporative cooling system to lower the temperature. In Arizona, the outside temperature can be 110ºF, but the temperature in the greenhouse can be lowered to 75ºF-80ºF (25ºC-27ºC) as long as the air is dry enough and water is available. In Arizona the dryness can be a challenge, causing tip burn on sensitive crops such as lettuce and strawberry.

“I really didn’t have to deal with heat stress much in Arizona. But there are other parts of the country like the Midwest and East Coast that have to deal with hot, humid summer conditions and very cold winters. I would like to work on those issues and develop technologies, including climate control strategies that can mitigate the issues of growing crops year-round. In Ohio and the Midwest summer heat stress is a major issue for crops causing all kinds of physiological disorders including incomplete pollination and fruit ripening disorders. During the winter, heating and humidity can also be an issue. There is also an issue with low light levels so supplemental lighting is more important.”

Ohio State University horticulture professor Chieri Kubota is planning to continue the controlled environment research she started at the University of Arizona and plans to expand her program to study LED lighting and new crops.

Photos courtesy of Chieri Kubota, Ohio St. Univ.

Because of the limited optimum growing season in greenhouses in the Midwest, Kubota said using indoor productions systems makes more sense compared to Arizona.

“In this part of the country it is very difficult to maintain the optimum temperature range year round,” she said. “And because of the increased interest in vertical farming, I expect to put more effort in warehouse production systems, including the use of LED lighting.”

Improving vegetable grafting

Some of the projects Kubota started at the University of Arizona that she will continue to work on our vegetable grafting and hydroponic strawberry production. She is a member of a research team led by North Carolina State University plant pathologist Frank Louws that is working on vegetable grafting.

“I am continuing my research on improving grafting methods and the handling of grafted plants so that they can be shipped long distances,” Kubota said. “I am also creating a simple tool for growers to schedule grafted plant production. Having the grafted plants ready at exactly the same size is always a challenge for growers. The research group is working to develop a simple plant growth model based on environmental conditions to predict how many days are needed to finish a grafted crop.”

Kubota said the grafting research team is looking at a variety of plants, including tomato, watermelon, cucumber, eggplant, pepper, and muskmelon.

“Growers are commercially producing grafted tomato and watermelon plants, but there are many more crops that can use grafting technology to reduce loss from soil-borne diseases and to increase yields. My program is looking at all of these potential crops.”

Kubota said the grafting research also has application to greenhouse crops.

“The grafting technology was originally developed for soil-based production, but greenhouse vegetable growers discovered that even though they are doing soilless production, using grafted plants can increase crop yields,” she said. “In North America, greenhouse growers were the first group who started using grafting technology. The field growers are now more interested since they have fewer means to control disease. In terms of potential market, field production in the U.S. is much larger in terms of number of plants.

“Currently tomato accounts for the majority of grafted plants in greenhouses. Increased tomato yields have been the driver for greenhouse growers to use grafted plants. Some greenhouse growers have been trialing grafted cucumbers and some research has shown that grafted eggplants can increase yields.”

Improving strawberry production

Kubota who has been working on greenhouse strawberry production for nine years will continue working on this crop with an interest in the use of LEDs.

Chieri Kubota will continue her greenhouse strawberry research with an interest in increasing yields using supplemental light.

“Strawberry fruit production is not as productive as leafy greens or tomatoes in terms of dollars of return relative to the input of light,” she said. “I’m interested in studying the increase in yields relative to the increase in light. What is the dollar value of that increase of yield by adding for example, 1 mole of light? Unless there is an improvement in lighting technology, it may not make sense to grow strawberries under supplemental lighting.

“I would like to come up with a smart lighting system to reduce the lighting cost based on the understanding of strawberry physiology and how plants are grown in a greenhouse. I think we could reduce lighting energy use and costs quite a bit by doing that. Strawberries are physiologically unique in terms of light saturation and also in terms of the sink-and-source relationship of how much sugar can be translocated from the leaves so that the photosynthetic rate can be maximized.”

Developing new crops

Another area that Kubota would like to expand for CEA production is the development of new crops.

“Controlled environment growers whether they are growing in greenhouses or warehouses need to diversify and increase the number of crops they are producing,” she said. “Although I don’t have any new crop projects coming up, I am particularly interested in small fruits. Since Ohio and the Midwest have a cold climate, there may be an opportunity to do more with small fruit crops like raspberries, blueberries, blackberries and other berry crops for greenhouse production.”

Kubota is also interested in revisiting the study of spinach production in greenhouse and warehouses.

“Controlled environment growers seem to have a particularly difficult time managing diseases including Pythium on spinach,” she said. “I am interested in determining if there is a practical way to manage these diseases. Cornell University researchers had previously done a lot of studies on this issue years ago. I wanted to see what the difference was between the successful hydroponic growing of spinach in Asia and other countries and why U.S. growers can’t do that too.”

Expanding professional training, research programs

As part of her extension efforts at Ohio State, Kubota wants to expand the opportunities for growers to receive professional training.

“I want this training to go beyond Ohio and to go nationwide and even international,” she said. “I’m interested in training professionals with online courses and other programs at a reasonable cost.

“The heart of the horticulture industry is in this part of the country. There are many different types of growers, supporting vendors and technology providers here. They are well connected.”

Chieri Kubota said having an extensive group of CEA researchers and extension specialists at Ohio State will enable her to expand training programs for growers not only in the state but potentially worldwide.

Kubota said at the University of Arizona research in the plant science department was focused more on basic science such as how a particular gene functions in plants, but not necessarily horticultural plants.

“Here at Ohio State I am in the horticulture and crop science department so the other faculty members understand what horticulture is,” she said. “There are a number of people here working on controlled environment agriculture including horticulture, which covers floriculture, hydroponics, and high tunnels, and ag engineering, entomology, plant pathology and food safety. There is a complete set of researchers and extension specialists who can work on a variety of controlled environment agriculture issues related to horticulture crops. This makes it advantageous for not only developing research projects together, but also professional training for commercial growers.”

For more: Chieri Kubota, The Ohio State University, Department of Horticulture and Crop Science, kubota.10@osu.edu; http://u.osu.edu/cepptlab; https://hcs.osu.edu/our-people/dr-chieri-kubota; https://www.facebook.com/CEPPTLAB.

Increased Consumer Demand Drives Strawberry And Lettuce Greenhouse Expansion

Ontario, Canada

February 26, 2018

Increased Consumer Demand Drives Strawberry And Lettuce Greenhouse Expansion

Mucci Farms is in the third year as well as the third expansion phase of its greenhouse grown strawberry program. Smuccies™ was commercially launched in 2016 on a 12-acre site. “We completed phase two this past October, bringing us to a total of 24 acres of greenhouse grown strawberries,” says Bert Mucci, CEO of Mucci Farms.

The final 12-acre expansion will be completed this summer and will include grow lights, allowing the company to offer high-quality local berries year-round, also during the winter months. The first harvest from the final 12 acres will be in October of this year. The 36-acre site is the largest strawberry farm in North America under glass.

Strawberry greenhouse

Consistent flavor and quality

What drives the expansion into a 36-acre site? “An increased demand from consumers and retailers,” shared Joe Spano, Vice President of Sales & Marketing. “Strawberries are consistently ranked at the top of the ‘dirtiest fruit’ lists yearly and we have responded by offering the market the cleanest strawberries grown in the cleanest environment, which is free of pesticides. High demand confirms we are fulfilling a need.”

Not only are the strawberries pesticide free, but Spano remarks how they are the most flavorful strawberries available in the market. “Due to the control we have over the growing conditions, we offer the most consistent and flavorful strawberries. This is a significant benefit as strawberry quality tends to vary based on season.”

Reduced travel time

Smuccies are grown in Kingsville, ON, a region that typically brings in strawberries from California. “We are offering a product with significantly less travel miles. Reduced travel miles increase shelf-life as well as quality of this extremely delicate berry,” Spano commented.

Lettuce expansion

In addition to the success story for strawberries, Mucci Farms is also in the process of expanding its lettuce acreage. “We are consistently sold out of lettuce and have more retailers that are interested in our product,” mentioned Bert Mucci. “We are currently harvesting 30,000 heads of lettuce per week out of a roughly two-acre facility. To accommodate increased demand, we are in the process of expanding to eight acres, allowing us to harvest 200,000 – 250,000 heads per week.” The six-acre expansion will be completed this fall. As with the initial two acres, the expanded facility will also be equipped with state-of-the-art proprietary automation and robotics, allowing for maximum production and yield.

The expansion is mainly driven by the popularity of Naked Leaf™ Living Lettuce. “It comes with the root intact, allowing leaves to stay fresh and continue to grow if placed in a cup of water,” Mucci said. Consumers are interested in a pesticide-free and long-shelf life product. “Living Lettuce lasts for up to 14 days.” In addition to the current Naked Leaf™ Living Lettuce offering, Mucci Farms is in the process of developing Naked LeafTM Salad Kits.

Lettuce farm

Southern Exposure

The team at Mucci Farms is looking forward to this week's Southern Exposure show. “As we do every year, we have fun with the SEPC theme. Since “Produce is King” alludes to Elvis, we chose to put a spin on “Jailhouse Rock” by naming our theme “Greenhouse Rock”. We’ve created a custom booth to reflect the time period and used vinyl records, an old school microphone and creative artwork to bring it to life,” says Ajit Saxena, Digital Media Coordinator at Mucci Farms. “Jailhouse Rock” was re-written as “Greenhouse Rock” and an authentic theme song was recorded, highlighting Mucci’s products and presence at the SEPC. Visit booth #448 to see how “Produce is King”.

For more information:

Ajit Saxena

Mucci Farms

Tel: (+1) 519-326-8881

Publication date: 2/26/2018

Author: Marieke Hemmes

Copyright: www.freshplaza.com

Four Growers: Farming For The Future

Four Growers: Farming For The Future

Senior mechanical engineering major Dan Chi promotes Four Growers, a company started by Chi and his friend Brandon Contino that is devoted to creating tomato-harvesting robots to work in greenhouses. (Photo courtesy of Karen Woolstrum)

BRIAN SALVATO | Staff Writer

February 13, 2018

Imagine being able to open a door and go from biting winds and snow to a warm, climate-controlled greenhouse that carries the aroma of fresh tomatoes — being harvested by robots roaming through the aisles.

For Brandon Contino and Daniel Chi, this fantasy is turning into a reality through their company Four Growers, as they aim to develop automated tomato harvesting robots to work in greenhouses.

Contino, CEO of Four Growers and a Pitt 2016 alumnus, takes the spokesperson role for the company, while senior mechanical engineering major Chi focuses on the technical side. The idea developed in April of 2017 when Contino and Chi began talking to tomato growers and associations.

“Dan and I knew we wanted to do something in an indoor farming or hydroponic growing place, so we decided to learn from those who were successful at it,” Contino said.

The two saw firsthand the issues facing modern-day tomato growing when they had their first greenhouse visit a month later with MightyVine — a sustainable tomato growing company in the Chicago area. These issues include weather variability, crop loss and population growth.

Contino’s conversation with the tomato growers made it clear that greenhouses are becoming the future of produce farming. The pair say greenhouse growing is more sustainable, versatile and efficient than traditional farming.

“They require 90 percent less water and provide consistent, yearlong, local, high-yield production with near-zero herbicide and pesticide use,” Contino said. “In fact, over 50 percent of fresh U.S. tomatoes are greenhouse grown.”

Despite the advantages greenhouse farming can provide, Contino said the largest limiting factors growers face are the cost, accessibility and reliability of their labor force.

“There are increasing shortages in workers, and the workers that they are able to find are inconsistent,” Contino said. “Growers desperately need automation to keep providing healthy, local produce at competitive rates.”

This is where Contino hopes Four Growers can provide a solution. Once fully developed, Contino said the automated harvesting robot could replace the role of a human.

“The tomato harvesting robot is able to go down greenhouse aisles, accurately identify ripe versus unripe clusters, harvest them from the plant without damaging them and place them in a cart to get sent back to the packhouse,” Contino said.

The robot — according to Contino’s estimates — will be able to harvest as much as a human, but do it more consistently at a lower cost.

While implementing robots could be more efficient, Four Growers also had to consider what it would mean to replace human labor. But they say that their robot would enable farmers to expand labor resources.

“By enabling this industry we’ll be able to increase the amount of fresh, … pesticide free, local produce greenhouse farms can produce,” Contino said. “It’s a win for the consumer, the greenhouse and the worker.”

So far, the company has developed a vision system for the robot that allows it to learn using artificial intelligence as it works. The two are currently refining a prototype, which they hope to test at major greenhouses.

“We are working with six different farms who wish to beta test our robot, and these farms collectively represent 20 percent of the U.S. and Canadian greenhouse tomato acreage,” Contino said.

For Contino and Chi, reaching the next stage is possible with continued support from Pitt’s Innovation Institute. Susan Dorff — manager for student programs at the Innovation Institute — worked alongside Four Growers since their inception. She said the company became involved with the Institute through student programming.

“We help [students] practice, learn, compete and get funding to continue with their idea,” she said.

Four Growers has been involved with several of the Innovation Institute’s programs, as well as competitions such as the Randall Family Big Idea Competition — an experience-based learning opportunity for Pitt students with big ideas that offers $100,000 in cash prizes.

Babs Carryer — the director of education and outreach at the Innovation Institute — said she has noticed distinct qualities in Contino and Chi’s approach between now and when she first met them.

“I think that the entrepreneurial lead is really important. I view Brandon [Contino] as sort of the driver of this project,” Carryer said. “A lot of student projects don’t quite have that strong a driver. Brandon’s really committed to doing this.”

Carryer said she was amazed by the amount of customer discovery the duo had done and the interest from tomato growers they received. Usually, Carryer sees entrepreneurs get nonspecific, general interest from companies that acknowledge their idea but never move beyond that. She believes the difference in Four Growers is their passion.

“They haven’t just been sitting on their laurels thinking about this. They’ve been actually out there really doing the deep work that’s necessary to advance an idea towards reality,” Carryer said.

As with any early product, there are still more hurdles on the road to completion. Carryer pointed out the challenge of realistically getting a robot to consistently harvest tomatoes without a problem, as well as Four Growers likely having to expand their team as their idea grows. Nevertheless, she believes in what Contino and Chi can do.

“I think they should be one of our leading student spinout companies, and I can’t wait to keep working with them on that,” Carryer said. “They definitely have what it takes.”

e-GRO Launches Nutritional Monitoring of Floriculture Crops Website

e-GRO Launches Nutritional Monitoring of Floriculture Crops Website

e-GRO, a collaborative team of university floriculture specialists and educators, launches a nutritional monitoring website for greenhouse, floriculture and vegetable crops.

January 31, 2018 by W. Garrett Owen, Michigan State University Extension

Figure 1. The collaborative group of greenhouse and floriculture specialists and educators, e-GRO, launched a Nutritional Monitoring of Floriculture Crops website.

Nutritional disorders are among the many challenges greenhouse growers encounter during crop production. Nutritional disorders often occur when substrate pH or soluble salts, referred to as electrical conductivity (EC), drifts above or below optimal ranges for plant uptake. To assist greenhouse growers in addressing nutritional disorders, the collaborative group of greenhouse and floriculture specialists and educators, e-GRO, has launched a Nutritional Monitoring of Floriculture Crops website, www.fertdirtandsquirt.com (Fig 1.), led by W. Garrett Owen of Michigan State University Extension and Brian Whipker of North Carolina State University.

The Nutritional Monitoring of Floriculture Crops, sponsored by the American Floral Endowment, will assist growers in establishing an in-house monitoring program and serve as an information and education center. The website is accessible by computer (Fig 2A), tablet (Fig 2B) or mobile device (Fig 2C).

Figure 2. The Nutritional Monitoring of Floriculture Crops website is accessible by computer (A), tablet (B) or mobile device (C). Pictured is the website homepage viewed on each device.

The Nutritional Monitoring of Floriculture Crops website provides growers crop-specific nutritional factsheets of seven annual bedding plants including marigolds, geraniums, petunia, calibrachoa, gerbera, New Guinea impatiens(Fig 3) and dahlias. In the future, it will also provide nutritional factsheets for perennials, potted flowering plants, edible and herb crops. These crop-specific nutritional factsheets provide the optimal crop-specific fertility requirements, pH and EC values reported by the 1:2 Dilution, Saturated Media Extraction (SME) and PourThru methods, fertility management, corrective procedures for high and low pH and EC, and nutritional disorder photos.

Figure 3. Example of a nutritional factsheet that provides optimal crop-specific fertility requirements, pH and EC values reported by the 1:2 Dilution, Saturated Media Extraction (SME) and PourThru methods, fertility management, corrective procedures for high and low pH and EC, and nutritional disorder photos. Pictured here is the New Guinea impatiens nutritional factsheet.

The new website will also provide growers with instructional “How To” videos and guides. For instance, instructional “How To” videos and guides for determining substrate pH and EC by either 1:2 Dilution, Saturated Media Extraction (SME) and PourThru methods will be available. Sampling methods to determine pH and EC of annual bedding and perennial plants, plugs, liners, flats, pots and hanging baskets will be posted. Other videos and guides include properly collecting plant tissue for analysis, sampling irrigation water and injector calibration.

As a continuous effort to provide growers with nutritional information, please check the Nutritional Monitoring of Floriculture Cropswebsite for updates and new postings of crop-specific nutritional factsheets, videos and guides.

The e-GRO team would like to thank the American Floral Endowment for support.

This article was published by Michigan State University Extension. For more information, visit http://www.msue.msu.edu. To have a digest of information delivered straight to your email inbox, visit http://www.msue.msu.edu/newsletters. To contact an expert in your area, visit http://expert.msue.msu.edu, or call 888-MSUE4MI (888-678-3464).

Hydroponics And Aquaponics Systems To Expand On Campus

Hydroponics And Aquaponics Systems To Expand On Campus

ELIAS OLSEN/THE ITHACAN

The hydroponics system located in Terrace Dining Hall allows herbs grown to become ingredients for meals in the dining hall.

By Emily Snyder — Staff Writer

Ithaca College’s student-run hydroponics and aquaponics systems are receiving materials to improve and expand within the next few months.

Paula Turkon, assistant professor in the Department of Environmental Studies and Sciences, oversees seven undergraduate student researchers who maintain the hydroponics and aquaponics systems in the Center for Natural Sciences and the hydroponics system in Terrace Dining Hall. Hydroponics is a method of cultivating plants through the nutritious water beneath them. Aquaponics incorporates fish into the hydroponics system.

Turkon said hydroponics is an efficient method because the plants receive nutrients directly from the water. The traditional medium, soil, takes longer to distribute nutrients to the plants.

Materials have been ordered to expand the systems into the greenhouse from the growing room in CNS, Turkon said. The greenhouse allows for more natural light and space for additional crops, she said. However, using an uncontrolled environment generates more challenges. She said it is necessary to regulate the temperature in the greenhouse because the tilapia and plants demand temperatures of about 85 degrees.

To deal with these complications, Turkon plans to grow cold–weather plants in the winter and warm–weather plants in the summer.

Turkon also said the team faces challenges with aquaponics because it has to accommodate the fish. Although aquaponics is more natural than hydroponics because the waste the fish produce provides nutrients for the plants, aquaponics is not completely sustainable because the fish in the system are fed fish meal, Turkon said.

Turkon and the project team have been researching more sustainable and locally available food for the fish as a way to improve the system.

Turkon said bringing aquaponics to campus in the spring of 2013 was important to her because fresh produce could be made available to the campus year-round. The hydroponics system was installed the following semester.

“The overall benefit is to try to provide some local produce,” Turkon said. “It can’t get any more local than this.”

Junior Jennifer Skala manages the hydroponics system in Terrace Dining Hall in addition to tending to the systems in CNS.

“We use the system to demonstrate our alternative grow methods to the broader campus community and provide the kitchen with healthy and local herbs for use in their meals,” Skala said.

Because the water in the hydroponics cycle is renewable, the system can be beneficial to regions like New York state that have colder climates or areas that struggle with water shortages, Turkon said.

Turkon, who has experience performing archaeological research in Mesoamerica, was inspired by floating gardens called “chinampas.” Chinampas are a traditional Aztec agricultural method that requires a plot of fertile land to float on freshwater lakes.

“Aquaponics is actually a modern technological version of a prehistoric technology,” Turkon said. “It’s this continuous process that’s adding nutrients to the soil. The soil is supporting the plants and cleaning the water as well.”

Turkon learned about aquaponics from Miles Crettien ’09, who co-founded VertiCulture, an aquaponics farm in New York City. Turkon also received guidance from local aquaponics farmer Steven Austin in the system’s beginning stages.

Herbs grown in Terrace Dining Hall become ingredients for meals in the dining hall.

The hydroponics system allows chefs to garnish dishes with herbs from the garden, Jeff Scott, general manager of dining services on campus, said. The hydroponics system serves to educate both students dining at Terraces and the members of the project on sustainability.

“It’s a reminder of our commitment to sustainability,” Scott said.

Scott said that further expansion of the system has been discussed and that he is eager to hear proposals of agricultural methods from students.

Scott is seeking students who can implement innovative growing methods such as growing vertically or growing in the courtyards.

Integrating hydroponics and aquaponics systems on campus allows students to assist Turkon in the project and receive research credits. Senior Lauren Saylor became involved with the project as a freshman when Turkon introduced the project in her environmental seminar. In addition to maintaining the CNS system each week, Saylor is conducting independent research on pathogenic contamination in aquaponics and hydroponics systems.

“This system benefits the researchers most directly,” Saylor said. “I believe that this will educate the campus on sustainable food production — we do this already at Terraces to a small degree.”

Skala hopes to increase the productivity of the Terraces hydroponics system to produce more fresh food for the dining hall. In the future, Skala wants to continue researching innovative fertilizers and nutrient disorders in crops.

Sophomore Carmen Liberatore recently joined the team and said she is adjusting to the maintenance procedures that include cleaning the water filters, feeding the fish and pruning the plants.

“It’s such a niche interest, and it’s cool to have the chance to dig into it,” Liberatore said.

Searching For Profits With Fish, Vegetables And A Greenhouse

Searching For Profits With Fish, Vegetables And A Greenhouse

- BARRY ADAMS badams@madison.com

-

- February 18, 2018 | 5 min to read

Mike Knight, co-founder of Clean Fresh Food near Paoli shows off some of the nearly full-grown lettuce grown in his greenhouse that is part of an aquaponics system located on a former dairy farm. The system, which holds 55,000 gallons of heated well water, uses the waste from tilapia, growing in an adjacent building, to fertilize the crops in the greenhouse. Knight, who founded and later sold Third Wave Research Group and now owns Customer Analytics, is working with his wife, Dagny, and a small staff to determine the best way to profitably grow leafy greens and microgreens year round.

STEVE APPS, STATE JOURNAL

Town of Primrose, Wisconsin — The farmland along Sun Valley Parkway east of Paoli is still fertile soil for corn, soybeans, alfalfa and other traditional crops.

But a 120-acre farm established in the 1800s along a rail line that is now the Badger State Trail is trying to make a year-round business out of lettuce, herbs and micro greens, thanks to a greenhouse, tanks of tilapia and the entrepreneurial drive of its owners and small staff.

Clean Fresh Foods is the creation of Mike and Dagny Knight, who are skipping the dirt. Instead, their aquaponics farm uses tanks and troughs of well water in an attempt to reach profitability, capitalize on the local food movement and provide fresh greens to restaurants, grocery stores and institutions, even when their Dane County property is smothered in February snow.

Jo-Ann O'Brien-Schorr, a former nurse who lives near Farm Fresh Foods in the town of Primrose, transfers young lettuce plants to a raft that will float in a trough of water fertilized by the waste of tilapia. The farm harvests about 12,000 head of lettuce a month, which is sold to grocery stores and restaurants.

STEVE APPS, STATE JOURNAL

“I think we’re just on the edge of profitability,” said Dagny Knight, a former nurse. “If we can figure out this micro greens piece and get into the farmers market niche, that would be a good step in the right direction. We’re just so close to breaking through that profitability mark.”

Aquaponics is a combination of hydroponics and aquaculture in which fish waste from the aquaculture system is broken down by bacteria into dissolved nutrients that is then fed into a hydroponics system to grow vegetables or other plants. The nutrient removal improves water quality for the fish but also decreases overall water consumption by limiting the amount released as effluent, according to a 2017 report by D. Allen Porttillo, an extension and outreach fisheries specialist at Iowa State University.

Like hydroponics, aquaponics systems require less land and water than conventional crop production methods, increase growth rates and allow for year- round production.

Aquaponics is a combination of hydroponics and aquaculture in which fish waste from the aquaculture system is broken down by bacteria into dissolved nutrients that is then fed into a hydroponics system to grow vegetables or other plants. The nutrient removal improves water quality for the fish but also decreases overall water consumption by limiting the amount released as effluent.

STEVE APPS, STATE JOURNAL

Aquaponics farms across Wisconsin

Aquaponics farms are dotted throughout the state. They include Lake Orchard Farm Aquaponics near Sheboygan, which harvests 1,100 heads of lettuce a week and also sells tilapia. Floating Gardens Aquaponics near the La Crosse County community of Mindoro opened in 2017 and sells lettuce, kale, basil, chive, lavender, cilantro and other greens to grocery stores and other retailers in western Wisconsin and eastern Minnesota.

In nearby Jackson County, Superior Fresh has one of the largest aquaponics systems in the world. The massive facility in Northfield, just south of the intersection of Interstate 94 and Highway 121, has a 1.3 million-gallon system, a 123,000-square-foot greenhouse designed to produce 1.8 million pounds of leafy greens annually and a 40,000-square-foot fish house that is home to thousands of Atlantic salmon and rainbow trout.

Clean Fresh Food near Paoli isn't a fish farm but needs fish, like this tilapia, to grow vegetables in the adjacent greenhouse. The tilapia are raised in 1,200-gallon tanks, and the nutrient-rich water from the tanks is circulated into troughs where vegetables are grown year-round.

STEVE APPS, STATE JOURNAL

The first commercial aquaponics farm in the state opened in 2009 near North Freedom in Sauk County.

Donna Meunier has a 9,000-square-foot greenhouse that is fed by 10 1,200-gallon tanks brimming with tilapia. Her KP Simply Fresh facility grows 15 to 20 varieties of lettuce for area nursing homes and hospitals and, over the past few years, she’s been experimenting with growing cucumbers, cherry tomatoes, kale and radishes.

She battles aphids from nearby alfalfa fields, has lost crops due to cold and early on had to replace her copper pipes leading from the well with PVC because copper is toxic to fish.

“We’ve expanded twice to meet the needs of what people are asking for,” said Meunier, who for years had run with her husband one of the largest amusement game companies in the state. “I know we will get to the point were we will make a consistent profit each month, but we’re just not there yet. This entire business is very expensive. I know of several people who have gone into it and are now out of it because it’s too much work.”

‘Entrepreneurial ADD’

The Knights are well aware of the challenges but are determined to find the right system and business model.

They purchased the farm in 2011 and a year later started construction on their $250,000 aquaponics operation, which includes a 7,200-square-foot greenhouse and 2,700-square-foot fish building. They began growing fish in four 50-gallon tanks in an old milk house in October 2012, harvested their first vegetables in summer 2013 and harvested their first fish around Thanksgiving of that year, Dagny Knight said.

Mike Knight holds the root and a grow-plug made of rock wool from a recently harvested lettuce plant that was grown on a floating raft.

STEVE APPS, STATE JOURNAL

The farm now produces about 12,000 head of lettuce a month. But other crops like mustard and carrot greens, basil and arugula are also being grown in the system that uses six troughs, each 8 feet wide, 100 feet long and about a foot deep, each with 100 floating Styrofoam mats.

The water in the 55,000-gallon system is fertilized naturally by the tilapia who swim in 12 1,200-gallon plastic tanks in a building adjacent to the greenhouse. The water, the vast majority of which is recycled through the system, comes from the well and is warmed with an outdoor furnace that in 2017 went through 40 cords of wood harvested from the farm.

“This is the result of entrepreneurial ADD,” Mike Knight said. “I didn’t grow up on a farm. I grew up on military bases. My whole thing is trying to make this sustainable on its own. If we can do this in this climate, growing these fresh green vegetables, what’s it mean to remote locations around the world and further northern climates?”

Knight, 62, who grew up in Utah and is a graduate of Utah State, has a drive for entrepreneurial ventures and has a deep business background. He is the former director of the Applied Population Lab at UW-Madison and in 1993 founded Third Wave Research Group, a company that provides insights from customers for other businesses, customer-based marketing strategies and behavior-based marketing services. He sold the company in 2010 and now heads Customer Analytics, a company with 365 employees that provides data-mining services for non-health care companies looking to expand their business.

Zak Buell plants arugula, a micro green that could help turn a better profit for Clean Fresh Food, an aquaponics farm in southwestern Dane County.

STEVE APPS STATE JOURNAL

Lettuce, micro greens sold in Madison

The lettuce and micro greens grown at Clean Fresh Foods are sold to the two Metcalfe’s Markets in Madison, restaurants at Memorial Union and the business school at UW-Madison and to the Downtown Madison restaurants Lucille and Merchant. The tilapia, prolific at fish counters and one of the most consumed foods in the world, are not part of the business plan and are periodically harvested and either composted or given away to family and friends every 12 to 18 months.

But the Knights, who have received guidance from UW-Stevens Point and Roth Fresh Farms in Boscobel, a company that uses tilapia to grow lettuce, micro greens, and edible flowers, may switch to bluegill. The beloved panfish would still provide the needed fertilizer but could be more marketable to Wisconsin restaurants known for their fish fries and customers with an appetite for the sweet-tasting fish.

Mike Knight explains his tank farm that hold hundreds of tilapia. The fish are given away to family and friends once they are mature since their is little profit in selling the fish. But Knight is considering switching to blue gill, which could be more desirable for area restuarants, grocery stores and fish markets.

STEVE APPS STATE JOURNAL

The Knights are also looking at ways to increase profits with the vegetables, which could mean focusing more on herbs and microgreens, which could bring in higher prices and generate more revenue. Each 2-foot-by-4-foot floating raft can grow about $45 worth of lettuce but about $56 worth of microgreens. They also want to grow food without government subsidies, are considering adding more troughs and would like to partner with a company to create a brand of herbs. They also want to explore dedicating some troughs to specific businesses that could customize their crops.

“I’m not sure what the exact model is, but I know it’s not just delivering lettuce to restaurants,” Mike Knight said. “At some point, we’re going to go back to more of a regional model. We’ve already done it with beer and whiskey. Just look at all the distillers and breweries. I think it’s the right trend.”

Philips Lighting Announces First Russian LED Cucumber Project With Agrokultura Group and New Partner Svetogor

Philips Lighting Announces First Russian LED Cucumber Project With Agrokultura Group and New Partner Svetogor

Philips Lighting today announced it has installed its first LED grow light project for cucumber cultivation in Russia with Agrokultura Group, LLC, and its new business partner Svetogor. Agrokultura is a large supplier of greenhouse grown cucumbers and tomatoes located near Moscow. The company is trialing a hybrid installation with HID top lighting and GreenPower LED interlighting on 7,550 square meters with the aim of increasing its yields, predictability and reducing energy costs.

“We use lighting from September to April in our cucumber greenhouse for about 4,000 hours. Reducing the electricity costs for our lighting system could significantly increase the profitability of the greenhouse,” says Vladimir Chernyshev, CEO of Agrokultura Group, LLC. “Besides reducing energy costs, we are expecting to see an increase in yields which would allow us to pay back the LED modules within the first three to four years of their use. The return on investment we achieve in the trial will be crucial for helping us decide whether to switch our full 30 hectares of greenhouse to LED lighting. We are partnering with Philips Lighting because of its high-quality technical solutions and ability to supply big orders in a relatively fast time frame.”

“Our recent participation in Russian projects like LLC Agro-Invest, the largest LED project in the world for cucumbers and tomatoes, has created a lot of interest across Russia and other parts of the world,” said Udo van Slooten, Business Leader Horticulture at Philips Lighting. “We know that lighting costs make up a significant share of operational costs for Russian growers, and we are eager to help Agrokultura increase its yields and reduce its energy consumption with the use of our LED technologies.”

This project is being implemented by Svetogor, a turnkey project lighting and horticultural lighting company headquartered in Moscow. Svetogor produces its own innovative HID lighting fixtures for greenhouses and has built up a great deal of experience in LED technologies based on its implementation of more than 100 large-scale projects with LED lighting in the last five years.

The partnership with Philips Lighting was announced on Wednesday morning @ Fruit Logistica, the fresh produce trade show in Berlin, February 7-9, 2018

Anchorage Wants To Make It Easier To Build Rooftop Greenhouses

Anchorage Wants To Make It Easier To Build Rooftop Greenhouses

February 12, 2018 | Author: Devin Kelly

Artist rendering: Baxter Senior Living, a planned senior housing project in East Anchorage, included rooftop greenhouses as part of its initial plans, but that piece is on hold until the city approves new regulations. (Provided by J.R. Wilcox / Baxter Senior Living)

As part of plans to build senior housing in East Anchorage, the development company Baxter Senior Living wanted to give residents a place to garden — and settled on rooftop greenhouses.

But the idea ran into trouble at the city's permitting office. The greenhouses would have made the building too tall.

It was a wrinkle for a new project — but it also fed into a larger conversation in Anchorage about making it easier for people to grow and even sell their own food. Now, a few years later, there's a proposal from the administration of Mayor Ethan Berkowitz to make rooftop greenhouses easier to build.

The proposal would allow developers to build rooftop greenhouses 10 feet above height limits. It's aimed at new construction for large apartment, commercial and industrial buildings, said city planner Ryan Yelle.

The measure, being introduced to the Anchorage Assembly Tuesday, is one of several efforts by the city to ease regulations farmers and food advocates have called burdensome. In the past two years, the city has adopted laws that cut fees for farmers markets, eased the sale of cottage foods like bread and jam, and allowed the markets to be located on parkland.

For the greenhouses, a land use permit and inspection would be required, because of how much a greenhouse weighs and holds water. The greenhouse also can't block sunlight for neighbors between 9 a.m. and 3 p.m. in the winter.

Anchorage, like all other towns and villages in Alaska, is vulnerable to disruptions in the food supply network. The state imports nearly all of its food, mostly on container ships. A mechanical problem on a ship in Seattle can mean that milk, eggs or bananas don't make it to Anchorage shelves.

The rooftop greenhouse proposal isn't meant to fix Anchorage's supply shortage, Yelle said. He framed it as an extra way for developers to offer gardening to people who live and work in Anchorage.

City restrictions haven't entirely stopped rooftop greenhouses from sprouting up in Anchorage. But the current laws make it more difficult, Yelle said.

J.R. Wilcox is the president of Baxter Senior Living, a senior housing facility being built in East Anchorage. The plans call for 116 apartment units for seniors, including services for residents with Alzheimer's and dementia.

The company's architect came up with the idea of putting greenhouses on the roof, Wilcox said. Renderings of the project show transparent structures with slanted tops.

"This is something really nice in assisted living, for people to be able to garden," Wilcox said.

But the greenhouse would have exceeded the height limit for the building, Wilcox said. The developers would have had to remove an entire story to make it work. After talking to the city, it turned out that changing the law itself was easier than granting an exception to the rule, Wilcox said.

Rooftop gardens are ubiquitous in New York City and other cities around the U.S. and Canada. Yelle, the Anchorage planner, said he looked at regulations in New York and Montreal while drafting the city's proposal.

"It's a very popular thing throughout the north," Wilcox said.

More than a year ago, the Alaska Food Policy Council, a nonprofit coalition that advocates for more self-reliance in statewide food production, began floating the rooftop greenhouse idea to city planners and economic development officials.

Danny Consenstein, a board member of the council, said there's a business argument for changing regulations that otherwise make it difficult to garden on a small scale.

A few months ago, the Food Policy Council and the Berkowitz administration announced "mini-grants" for local food projects. Consenstein said he's been impressed while reading through the applications. Many came from schools and involve hydroponics, the process of growing plants indoors in water, Consenstein said.

Consenstein said rooftop gardening is another piece of that puzzle.

"There are exciting, good things going on at the school level, the apartment complex level, at the community garden level," Consenstein said.

When applying for its building permit, Baxter Senior Living excluded a greenhouse from the plans.

But Wilcox said the building is months from being finished, and it's been engineered so a greenhouse can be added if the Berkowitz administration's proposal becomes law.

The Anchorage Assembly is expected to hold a hearing on the proposal on Feb. 27.

About this Author

Devin Kelly covers Anchorage city government and general assignments.

Pure Flavor® Georgia Greenhouse Construction Project Coming to Life

Pure Flavor® Georgia Greenhouse Construction Project Coming to Life

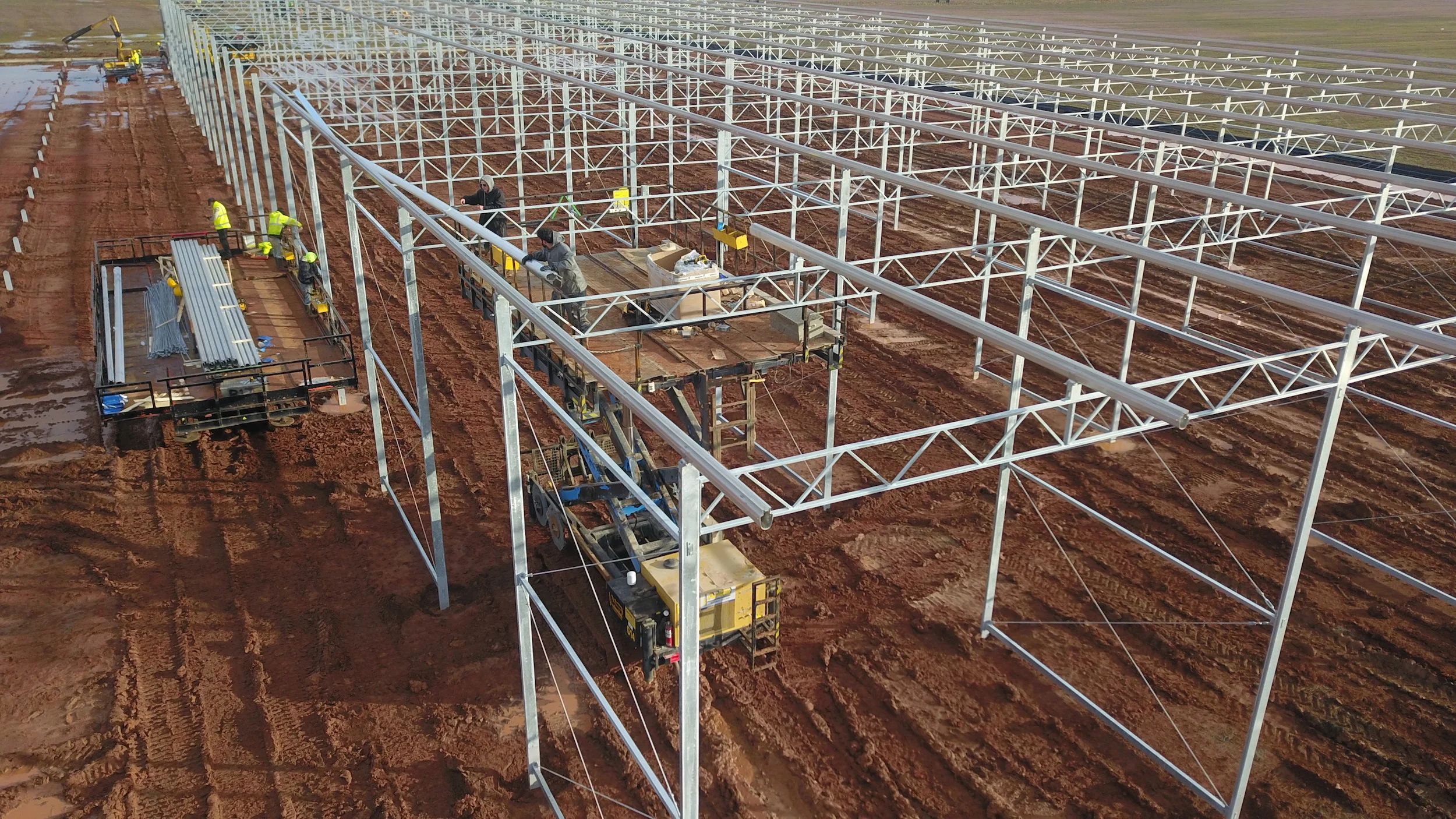

Fort Valley, GA (February 14th, 2018) – Cooperation with Mother Nature for good weather this winter has spurned a fury of activity at the site of Pure Flavor®’s greenhouse project in Georgia. Ground leveling completed in late fall lead to a smooth start of construction of the company’s new 75-acre high tech greenhouse facility in Peach County.

Over the course of the last few weeks once post holes were dug and backfilled, Dutch greenhouse builder Havecon began erecting the main structure with full-scale implementation now underway. From a timing standpoint, the project is on track for completion by late summer with the first crop of tomatoes & seedless cucumbers to be planted shortly thereafter.

“Building a high-tech greenhouse in Georgia was part of our growth strategy to extend our reach across North America. Being strategically located in Peach County allows us in some instances to have same day & next day deliveries in the southeast region”, stated Matt Mastronardi, Executive Vice-President. Pure Flavor® researched more than 400 sites throughout North America before settling on Peach County, GA. The 75-acre greenhouse project broke ground in September 2017 and will be built in 3 phases of 25 acres. Phase 1 is expected to be completed in late Summer 2018.

“Greenhouse tomatoes & seedless cucumbers grown in Georgia will help breathe new life in to the category. It will help our retail (& foodservice partners) in the region to have fresher product on store shelves while maintaining consistent quality and availability year-round. In the end, it is the consumer who will benefit from great product grown in the state of Georgia”, said Mastronardi.

Retail partners & consumers can follow the progress in photos of the Georgia greenhouse construction on a weekly basis by visiting the Pure Flavor® Georgia Photo Gallery: https://goo.gl/s5UCgc

“We are connecting our customers with the project in every way possible with frequent updates via social media, the photo gallery, and video stories shot by drone”, said Chris Veillon, Chief Marketing Officer. A custom website was built just before the groundbreaking in September 2017 to announce the project, the page now serves as the central resource for everything to do with the Georgia project. “A connected customer is an informed customer, we can’t wait to get our first plants in the greenhouse later this summer”, commented Veillon. Pure Flavor® expects the first crops to be picked in early Fall 2018.

Pure Flavor® will be exhibiting at the upcoming Southern Exposure Trade Show & Convention in Tampa, FL March 3rd. Visitors are encouraged to visit Booth #605 to learn more about the Georgia project.

To learn more about the Pure Flavor® Georgia greenhouse project, please visit GeorgiaGrownFlavor.com.

-30-

About Pure Flavor®

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise.

We are the next generation of vegetable growers, inspired to put quality, flavor, and customers first by providing greenhouse-grown vegetables from our farms that are strategically located throughout North America.

SOURCE: Chris Veillon | chris@pure-flavor.com

Chief Marketing Officer | Pure Flavor®

T: 519 326 8444

VIDEO: https://youtu.be/f6mXwHRuzMo

GALLERY: https://goo.gl/s5UCgc

Spread The Love With Valentine’s Strawberries

Spread The Love With Valentine’s Strawberries

Valentine’s Day is a perfect opportunity for Driscoll’s to reach out to consumers by offering the best quality strawberries, large in size, light red in color and with exceptional flavor in a premium packaging. Berries are an emotional category driven by impulse. The valentine’s punnet is the perfect way to tap into this. The company believes that celebrating the special moments in the lives of consumers can contribute to building the berry category even further.

Driscoll’s is the world’s true expert in the breeding, production, and sales of strawberries, raspberries, blackberries, and blueberries. With over 100 year experience in the farming of berries, Driscoll’s is the true berry expert of the world.

The development of unique varieties is one of Driscoll’s top priorities. A nice intense color, exceptional flavor, and a long-lasting shelf life differentiate Driscoll’s berries from other varieties. Driscoll’s is working with independent growers from all around the world and by choosing the regions with the best-growing conditions Driscoll’s can deliver berries all year round.

Publication date: 2/14/2018

Under The Lights: $15M Makeover Means Greenhouse Strawberries In Time For Valentine's Day

Under The Lights: $15M Makeover Means Greenhouse Strawberries In Time For Valentine's Day

SHARON HILL, WINDSOR STAR

February 5, 2018

Strawberry plants replaced cucumbers in a Leamington greenhouse this summer when DelFrescoPure made a $15-million switch to grow and sell fresh strawberries through the winter.

It costs 30 to 40 per cent more to grow strawberries because of the extra expenses such as added lighting that tricks the everbearing strawberry plants to grow like it’s a long summer day.

“We took a big chance putting these lights in,” Carl Mastronardi, president and one of the owners of the Kingsville-based Del Fresco Produce, said Monday. “It’s working.”

The immediate payoff could be Valentine’s Day sales but in the long run for the greenhouse industry and for consumers, the move a couple of Leamington and Kingsville growers have made to greenhouse berries could be a game-changer.

“This could be a lot bigger than we think,” Mastronardi said of having fresh, local berries that are grown using less chemicals because of the beneficial insects greenhouses use to kill pests.

“This opens up a realm of trying a whole bunch of new things.”

Next on the list are raspberries, he said.

The strawberries are marketed as YES!Berries Your Every Day Snack! and are sold for $3.99 to $5.99 for a 12-ounce container. They can be found in local grocery stores including Metro, Sobeys, Walmart and Remark Farms.

“It’s a taste of summer all year round,” said marketing manager Fiona McLean. “Once you start you can’t stop.”

YES!Berries are picked almost 100 per cent ripe, are sweet and consistent, and can be in grocery stores sometimes as fast as the next morning, Mastronardi said. Florida and California berries are not picked ripe and take days for them to reach Ontario stores.

Strawberries are packaged at the Del Fresco Produce Ltd. strawberry greenhouse, Monday, February 5, 2018. DAX MELMER / WINDSOR STAR

Other local greenhouses have tried strawberries. Orangeline Farms in Leamington won a 2016 Premier’s Award for Agri-Food Innovation Excellence for its strawberries.

In October, Mucci Farms in Kingsville announced it was spending $12 million in addition to its $24-million greenhouses built just for strawberries to become the largest strawberry grower in North America under glass. It will have 36 acres.

Mastronardi doesn’t have the most indoor strawberry acres here but figures, for now, his 10 acres are likely the most under grow lights.

The electricity costs would have been too expensive so the greenhouse uses two natural gas generators to produce electricity and then heat, as a byproduct, which is distributed to the greenhouses through pipes as hot water, Mastronardi said.

Lights are used at the Del Fresco Produce Ltd. strawberry greenhouse, Monday, February 5, 2018.DAX MELMER / WINDSOR STAR

DelFrescoPure grows about 100 acres of tomatoes, peppers, cucumbers, beans and eggplant in its greenhouses. Strawberries could be harvested year-round but the season will run from late October to July because Mastronardi expects his berries grown with beneficial insects to kill pests can compete with field-grown berries.

He expects to have the most greenhouse strawberries available in local grocery stores this Valentine’s Day. Each acre has 43,000 strawberry plants with berries ripening daily.

There will be opportunities to try YES!Berries this weekend in some Sobeys stores in Ontario including the Amherstburg store and then the demos will be in some Metro stores in Windsor, London, and Sarnia Feb. 15 to 18.

Is Personalized, Next-Day Delivery the Future of Urban Farming?

Canadian Prime Minister Justin Trudeau and Lauren Rathmell in Lufa Farms' Anjou greenhouse in March 2017 Lufa Farms

Is Personalized, Next-Day Delivery the Future of Urban Farming?

February 9, 2018 | SARAH TRELEAVEN

A rooftop-farming venture in Montreal has found success with a model that’s part CSA, part Amazon Prime.

Canadians have grown accustomed to seeing Prime Minister Justin Trudeau pop up in unlikely photos, sometimes shirtless or in athletic gear. But Trudeau was wearing a suit for a planned photo op when he toured Lufa Farms, a 63,000-square-foot rooftop greenhouse in Montreal, last March. During his visit, Trudeau took a moment to harvest a bag of greens for his family.

One of Canada’s largest urban farming projects, Lufa Farms is the brainchild of Mohamed Hage and Lauren Rathmell. Back in 2011, Hage and Rathmell—partners in business and life—opened the world’s first commercial rooftop greenhouse, a 31,000-square-foot space atop an old Montreal warehouse. They now oversee three hydroponic greenhouses, each placed on a sturdy, low-rise building, with a combined 138,000 square feet.

The rooftop greenhouse in Montreal’s Ahuntsic neighborhood (Lufa Farms)

The enterprise is part of a wider movement to bring rooftop gardens and greenhouses to North American cities. Gotham Greens operates a 75,000-square-foot rooftop greenhouse in Chicago, said to be the world’s biggest. In Brooklyn, a 65,000-square-foot greenhouse is planned to open on top of a building in the Navy Yard later this year. The concept is suited to a range of environments. Cold-weather cities like Montreal and Chicago have limited growing seasons, which a greenhouse can extend. A rooftop garden maximizes space in a dense urban area and uses less water than traditional agriculture, an advantage in a city or region with a limited water supply.

Whereas many urban farms sell to restaurants or grocery stores, or via farmer’s markets, Lufa has a key point of differentiation: its direct-to-consumer business model. On its website, shoppers can customize baskets of fresh food, which are then delivered to more than 300 pick-up points across the city, or to their homes for an added fee. It’s like community-supported agriculture (CSA) or a farm share merged with the personalization and convenience of Uber Eats or Amazon Prime. “We decided that we needed to give people the option to order what they wanted, and that we would figure out how to get those items to them,” Rathmell said.

In order to serve customers year-round, Lufa Farms pulls in other partners, including more conventional farmers. This helps it prevent seasonal defection (as can happen with some CSAs, once winter arrives and turnips become dispiritingly abundant). Shoppers start with a base basket—suggestions that are automatically included but can be removed. The website offers everything from locally baked bread and Florida citrus to blood sausage and pork pies, quinoa tabbouleh, and organic face wash.

Customers receive an email on Friday to notify them that the marketplace is open, and they have until Sunday night at midnight to lock in their order for a basket to be delivered the next day. From there, the Lufa Farms team gets to work—notifying suppliers, picking the appropriate produce, and channeling it all through a central distribution team that sends the baskets out late Monday morning to pickup points (such as cafes and yoga studios) via electric vehicles.

Part of Lufa’s delivery fleet (Lufa Farms)

Lufa has a checklist of criteria that partner farms and suppliers—numbering in the hundreds—must meet, including no synthetic pesticides, herbicides, or fungicides. An organic certification is common, but not required; Lufa Farms’ own produce is not organic, since hydroponic growing methods are not eligible for the certification in Canada.

Currently, Lufa supplies about 25 percent of the food it sells, although that proportion goes up in the middle of winter when more conventional growers have to contend with Quebec’s frozen ground. Rathmell and Hage anticipate the share will increase with their newly opened third greenhouse. “We’re continuing to scale up, and we want to grow as much as we can ourselves,” said Rathmell. The company grows lettuce, bok choy, tomatoes, cucumbers, peppers, eggplants, zucchini, and many kinds of greens. Lufa also offers foods from other growers that consumers are surprised to see in the middle of a Montreal winter, like locally-grown strawberries.

“If you can grow a strawberry in January, you can charge whatever you want.”

The idea of growing strawberries in Montreal in January may seem, to put it in produce terms, bananas. But Aaron Fox, an assistant professor of urban and community agriculture at California State Polytechnic University, Pomona, in California, said it makes good business sense to focus on these kinds of coveted items: “If you can grow a strawberry in January, you can charge whatever you want.” Urban farmers, he noted, often end up growing boutique crops because they offer a better financial return than cheaper staples like corn and potatoes, which are not cost-effective with a small yield.

While many urban farmers struggle to make a living, Lufa Farms is shaping up to be a success. It now delivers more than 10,000 baskets of food every week in the Greater Montreal, Trois-Rivieres, and Quebec City corridor, feeding about 2 percent of the population in that area. Launched with some $1.6 million from the founders, it has since received $2.8 million in venture capital, and broke even in 2016. Districts in Montreal are competing to host the next greenhouse, and loyal customers have dubbed themselves “Lufavores.”

Rathmell described Lufa as a “local food engine,” and said the plan is eventually to replicate it in other seasonal food deserts. (The company was recently in discussions to expand into New England, but it is focusing on Quebec for now.) “We’ve created a scalable model for urban agriculture that can theoretically make cities self-sufficient in their food production by growing year-round in greenhouses,” Rathmell said.

For now, though, what makes Lufa work is not strict self-sufficiency, but partnering with suppliers far and wide, and giving the customer exactly what she wants—not a box full of rutabagas.

About the Author

Sarah Treleaven Sarah Treleaven is a Canadian journalist who divides her time between Toronto and Jerusalem.

lef Farms Launches New Clamshell Packaging To Meet Overwhelming Customer Demand

lef Farms Launches New Clamshell Packaging To Meet Overwhelming Customer Demand

(LOUDON, NH) – While lef Farms may be a new name to some, it has already earned a strong reputation in New England’s retail and food service community by providing the most unique blends of locally grown, fresh baby greens on the market. That recognition didn’t come by accident. It came by applying the knowledge from its founders’ 40 years of growing experience, paying close attention to market trends and, most importantly, listening to what its customers have to say. And what they were saying loud and clear throughout 2017 was “We want clamshells!”

To answer that passionate call, lēf Farms is excited to introduce its newly designed clamshell packaging. While the fresh and tasty contents of its packages won’t be changing, lef has adopted this much more popular packaging format by going to clamshells.

“There’s no doubt that everyone loves our baby greens that, up until now, were available in distinctive black bags. Consumers expressed to us they were having difficulty finding our products in a consistent location within their local stores, as produce managers often placed them away from the traditional salad wall,” begins lef Sales & Marketing Manager, Donald Grandmaison.

With the improved clamshell packaging, retailers are now able to consistently incorporate lēf products into their store planograms in a location where consumers are more apt to look for tasty local greens. Switching over to clams also helps reduce the amount of food waste by protecting our greens during transit, as well as during the stocking and restocking of product dispensers at store level.

“Within the baby greens space,” Grandmaison continues, “our retailer partners indicated they were much more in favor of clamshells because they were easier to attractively stack, load, and restock product as compared to bags. So, to us, putting our greens into clamshells made perfect sense.”

Beyond the ease of displaying our greens at retail, the new lef clamshells also protect our delicate greens as they make their way to the homes of salad lovers all across New England. The clams also provide consumers with more convenience, as they stack easily inside any refrigerator. Plus, the re-sealable closure helps reduce wilting and food waste by keeping the greens as fresh as when they first came home from the store.

Like the original bags, lef’s new clamshells carry a clean and simple design, accented by a color band to differentiate each of the unique blends offered. So, lef’s Smooth greens, which are a buttery blend of baby romaine, oakleaf lettuce, pac choi, and mizuna, will continue to have a blue band. Its Spice mix, a robust mix of baby arugula, red mustard, leaf lettuce, mizuna, and cress, will still carry a red band. And lef Balance, a delicate blend of red and green baby kale with a subtle, sweet flavor, will still have the same tan color band as before.

lef’s new design also takes advantage of unique clear labeling, allowing consumers to see more of its scrumptious baby greens before they buy.

“This was another important area for us to address in our repackaging efforts,” states Grandmaison. “Consumers are passionate about their produce. And they want to see as much of what’s inside the packages before they buy. This knowledge helped shape our approach to the graphic design of our new clams. The more open our design, the more customers can see how much our locally grown greens visually outperform any product out there,” smiles Grandmaison. “Our new clamshells offer nearly 95% product visibility, which literally speaks about our commitment to transparency in everything we do.”

As with all of lef’s business decisions, the move to clamshells also needed to take into consideration environmental implications. Although its initial bags were recyclable, lef’s new clamshells are made of a much more commonly recycled material, food-grade PETE 1 (polyethylene terephthalate) – making them more easily recovered by most community programs.

lef Farms is a 75,000-sq. ft. greenhouse growing facility, producing nearly than 1.5 million pounds annually of the freshest and healthiest baby greens for New England. www.lef-farms.com

# # #

BrightFarms Innovates With A Crunchy Iceberg Baby Leaf!

BrightFarms Innovates With A Crunchy Iceberg Baby Leaf!

A new take on a salad classic, BrightFarms Sunny Crunch is now on shelves in partner retailers.

New York, (February 2, 2018) – BrightFarms is announcing the launch of Sunny Crunch, a packaged salad that features a unique baby leaf iceberg not typically found in US supermarkets.

With a mild flavor profile that’s aimed at families and kids, Sunny Crunch combines the crisp texture of iceberg with the flavor and color of a leafy green. BrightFarms’ innovation team spent months researching and testing non-traditional lettuce varieties before landing on Sunny Crunch. It will be grown and distributed to local supermarkets from each of the company’s current greenhouse facilities.

“Iceberg lettuce is an American classic that continues to command a strong position in the salad category,” said Abby Prior, BrightFarms VP of Marketing. “Sunny Crunch adds a new level of flavor and excitement to a variety that many of us grew up with. We’re very excited to be introducing it to our retail partners as an exclusive offering.”

Through the use of controlled hydroponic growing systems, BrightFarms is able to bring innovative products to market in a relatively short amount of time. The company is testing a number of other leafy greens and herbs and plans to roll out additional new products this spring.

For more information about BrightFarms and Sunny Crunch, please visit www.brightfarms.com.

About BrightFarms

BrightFarms grows local produce, nationwide. BrightFarms finances, builds, and operates local greenhouse farms in partnership with supermarkets, cities, capital sources, and vendors, enabling it to quickly and efficiently eliminate time, distance, and costs from the food supply chain. BrightFarms’ growing methods, a model for the future of scalable, sustainable local farming, uses far less energy, land and water than conventional agriculture. Fast Company recognizes BrightFarms as “One of World’s 50 Most Innovative Companies” and one of the “Top 10 Most Innovative Companies in Food” in the world. For more information, please visit www.brightfarms.com.

###

Media Inquiries:

Megan Foard

Abel Communications for BrightFarms

Big Greenhouse Project At Eastman Business Park Nears Groundbreaking, A Year Later Than Promised

Big Greenhouse Project At Eastman Business Park Nears Groundbreaking, A Year Later Than Promised

Steve Orr, @SOrr1 | Feb. 1, 2018

(Photo: Steve Orr/Staff photographer)

Construction should begin this spring on a large hydroponic greenhouse at Eastman Business Park where organic leafy greens will be grown year-round.

Clearwater Organic Farms' ground-breaking is tentatively set for April, nearly a year later than originally promised. Company officials and others say extra time was needed to finalize financing and other aspects of the deal.

"It’s still coming. It's very close. We’re very excited about it," said Alex Wasilov, the company's chairman.

If all goes as planned, the operation could be up and running by the fall. It will be the largest hydroponic greenhouse growing leafy greens in the country.

Clearwater expects to hire about 30 people initially, Wasilov said. Envisioned expansions should push employment over 100, he said.

The 475,000-square-foot greenhouse will sit on 13 acres at the business park's western edge. Clearwater will lease the site from Lidestri Food & Drink, which has a compound of buildings on adjacent parcels.