Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

US (MA): Lettuce Grower Decreases Crop Cycle by 30%

Fresh Roots Greenhouse is a hydroponic lettuce, herb and leafy greens grower based in Chelmsford, Massachusetts. After 40 years in the pharmaceutical industry, Fresh Roots’ owner Bill Evans wanted to give back to his community during his retirement years. He found himself drawn to how cooperative-run greenhouses like Evergreen Cooperatives and WellSpring Cooperative created jobs for underserved members in addition to providing local produce, which inspired him to build Fresh Roots Greenhouse. Fresh Roots’ state-of-the-art Harnois greenhouse uses an AmHydro Nutrient Film Technique (NFT) system to grow arugula, kale, basil, and several varieties of lettuce.

The potential to direct plant growth

Since Bill’s goal is to run his greenhouse year-round, he needed the most energy-efficient lighting system possible. His experiences growing with HPS and fluorescent lights at other facilities had been suboptimal. While the fixtures grew plants, Bill could tell that the plants were not growing as quickly and that the red varieties were not coloring up as expected. Bill felt that LEDs were the most practical financial choice – while LEDs cost a bit more up front, they would save him money on electricity and labor in the long run. After Bill learned about spectrum and LumiGrow through Melanie Yelton, Vice President of LumiGrow Research, at a hydroponic tomato growing course at the University of Arizona, he was eager to learn more and stayed in touch. He was impressed with LumiGrow Research’s depth of knowledge and hands-on approach to helping customers implement the latest lighting strategy research. As a result, LumiGrow was top of mind for Bill when he began to search for the right LED lighting system for Fresh Roots Greenhouse.

“I really believe in the promise of spectral science,” says Bill, “From the time I met Melanie [at University of Arizona] and learned about LED lighting’s potential to direct plant growth, I’ve wanted to work with LumiGrow.”

Extending photoperiod to maximize growth

Bill implemented LumiGrow fixtures across the Fresh Roots entire greenhouse. He uses them for all NFT stages of plant growth. Bill was eager to start growing and immediately began using the lights to extend his plants’ photoperiod to 21 hours.

“Keeping the light on for 21 hours keeps the plants awake,” explains Bill, “If they’re kept awake, we maximize their growth period.”

Fresh Roots lettuce varieties reach harvest size about 30% faster than their typical light exposure seen in soil farming. The seed manufacturer reports a typical harvest after 50-55 days, whereas the LumiGrow-lit lettuce is ready after about 35-40 days. Bill has had success growing a wide variety of lettuces, from green butterhead to green leaf to romaine. Depending on the variety, the finished lettuce heads weigh between 7-10 oz. Each variety grows a bit differently under the LumiGrow lights.

Bill has also successfully reduced his basil’s crop cycle by over 35-40%. The basil plants reach harvest size in 35-42 days – unlit greenhouse-grown basil can take up to 56-68 days as reported by the seed manufacturer.

Additional savings using smartPAR Light Sensors

Bill has moved past simple daylight extension and is using LumiGrow fixtures to automate his lighting strategy to improve production. Bill is using LumiGrow smartPAR Light Sensors to constantly monitor the light levels inside the greenhouse and adjust the fixture intensity to achieve a daily light integral (DLI) of 17 μmol·m−2·s−1 over the course of each 21-hour photoperiod. Once the target DLI is reached, the LumiGrow smartPAR Wireless Control System turns down the fixtures’ light intensity to minimize electricity use while keeping the plants awake for the full photoperiod. Bill is happy to see that his plants are thriving under the LumiGrow fixtures.

Bill was even happier to discover that in addition to consistently reaching his lighting goals, the smartPAR Light Sensors are maximizing his LumiGrow fixtures’ energy efficiency. After Fresh Roots’ smartPAR Light Sensors were installed, Bill noticed that his electricity bill was significantly lower than when he was simply turning the fixtures on at the end of the day to extend photoperiod. Bill can rest easy knowing that he can rely on his smart lighting to deliver the appropriate amount of light every day while saving him money each month.

Bill also appreciates the flexibility that LumiGrow adjustable spectrum offers. While Bill prefers to use his LumiGrow smartPAR Light Sensors to automate his greenhouse’s lighting, he likes that the LumiGrow smartPAR Wireless Control System also gives him the option to adjust each spectral channel to create custom spectral strategies. His LumiGrow fixtures’ versatility and user-friendly software make it simple to fine-tune his spectral programs as leafy greens research continues to develop. Bill likes that smartPAR enables him to easily create new lighting zones, which opens the possibility of growing new varieties of leafy greens under different ratios of light spectrum

In the meantime, Bill will continue to provide high-quality, locally-grown leafy greens to the local community in Massachusetts and share his passion for LumiGrow technology.

“I love sharing the many properties of these lights with people, particularly the science and engineering behind them,” says Bill, “Year-round supplemental lighting is not something a lot of greenhouses in this area have yet.”

For more information:

LumiGrow

800-514-0487

info@lumigrow.com

www.lumigrow.com

France: "Local Cultivation Is More Than The Right Postal Code"

Le Maraîchers du Mont Saint-Michel

"The French market is a very good market to cultivate for. There is a demand for a clean, sustainably cultivated quality product: the tomatoes must be red and of good taste." This is what Jean Marc Paimblanc from the French tomato nursery Le Maraîchers du Mont Saint-Michel is saying. Recently, Havecon completed the company's 17 hectare greenhouse.

Upscaling

The greenhouse is up and about, the heating system and the water systems are completed. At the end of January, the first plants will be moved into the greenhouse and next year Le Maraîchers du Mont Saint-Michel (the growers of the Mont Saint-Michel) hope to get the first tomatoes from their new greenhouse. There will be quite a lot of them: already in their first year, there will be cultivation on 17 hectares. "That's new for the French market, where the average nursery has an acreage of a few hectares," confirms Jean Marc Paimblanc, director of the company. "Customers would like to cooperate more intensively with cultivation companies. That is where this size fits: it allows you to deliver in a customer-specific way."

Diffuse glass

The greenhouse is divided into three blocks of almost 6 hectares each and is equipped with diffuse glass to make optimum use of the available sunlight. The construction photos of Havecon, which is realizing the entire project in collaboration with the French CMF, show very well how the light is spread. At the company a processing room has been realized to have the tomatoes packaged to size and delivered to the customer. Also a number of CHPs have been installed.

"The people in France remain very modest but this really is a state of the art construction project in beautiful Normandy", according to Ramon Bol, responsible for the sales in Europe within Havecon.

Location

Le Maraîchers du Mont Saint-Michel are focusing on the local market. "The demand for local product is rising", says Jean Marc. "It is not only about the postal code of the company. A French tomato also ought to have the right quality and provide the right experience: the consumer wants a cleanly grown, red and tasty tomato, cultivated by a company from the region. All this gives value to the concept of local."

Although the postal code of the company may not be the most important for the sales, the location is of course important: the company is unique in the region, has a strong sales market here and even has the metropolis of Paris, at less than 300 km distance in a straight line. The fact that this location is less than twenty kilometers away from the well-known Mont Saint-Michel, is really a great advantage. There is a reason why they have incorporated the French icon into their company name. "The Mont Saint-Michel is a household name domestically and outside of France", Jean Marc concludes. "They receive thousands of tourists a day - only the Louvre and the Eiffel Tower attract more visitors. And in this region, no comparable tomato nursery has been established yet, so that is a great opportunity. In the coming years we hope to supply regional parties with our local production."

For more information:

Havecon

Lorentzstraat 8

2665 JH Bleiswijk

Netherlands

Tel. +31(0)10 266 32 70

Fax +31(0)10 266 32 71

info@havecon.com

www.havecon.com

NatureFreshTM Farms Gives Back to Leamington & Delta Communities This Holiday Season

Leamington, ON & Delta, OH (December 19th, 2018) –During the 2018 holiday season, the NatureFreshTM Farms team was busy spreading good will by volunteering with local partners, spreading cheer at holiday events, helping deserving families, and donating food to feed people in need. Giving back to the communities they grow in is an integral part of the NatureFreshTM Farms identity!

NatureFreshTM Farms kicked off the season of giving by sending a group of volunteers to Southwestern Ontario Gleaners, a charitable organization in Leamington, ON that distributes nutritious food to people in need both locally and internationally. NatureFreshTM Farms regularly donates Bell Peppers to this organization so that they can create healthy soup mix bags for charitable distribution. In one volunteer session, the NatureFreshTM Farms team was able to prepare roughly 25,000 servings of soup!

Leamington’s Annual Christmas Parade, which took place on November 24th this year, presented the NatureFreshTM Farms team with an opportunity to spread holiday cheer in a community they have called home for twenty years. The team gave their Greenhouse Education Center trailer a festive makeover for the event, and Peter Quiring, Matt Quiring, John Ketler, and dozens of their NatureFreshTM Farms employees accompanied the float, wishing happy holidays to families watching the parade.

To help their neighbors have a happy holiday season, NatureFreshTM Farms also ran a Holiday Sweepstakes campaign in Fulton County, Ohio, calling members of the community to nominate five deserving families to receive a helping hand. Cornelius Neufeld, Operations Manager at NatureFreshTM Farms USA, explained how this initiative got started: “Our employees in Ohio really drove this initiative – a lot of them knew neighbors or friends who would benefit from a helping hand during the holidays. They came to us asking what NatureFreshTM could do to support their community – so that’s where it all began.” The families who are chosen will each receive $500 grocery gift cards and NatureFreshTM Farms food baskets – they should expect the delivery of their care packages before Christmas Day.

All year long, NatureFreshTM Farms feeds their communities with healthy, flavorful Tomatoes, Bell Peppers, and Cucumbers, but their team decided to take things a step further this year and run a cross-company food drive during the holidays.

Collectively, they were able to gather 6,330 non-perishable food items for donation! Donations were made to The Salvation Army in Leamington, ON and The Open Door in Delta, OH, and they were made in Peter Quiring’s name – a gesture that he says was very humbling: “These donations were given in my name as a gift from my team – it was incredibly humbling to see how everyone was inspired to give back to people in need in our communities in such a meaningful way.”

One more initiative that NatureFreshTM Farms supported this holiday season was Talking Over Turkey. This Leamington-based initiative will bring hundreds of food boxes to families in need this holiday season throughout the Leamington, ON area. Through the donations of South Essex Fabricating, NatureFreshTM Farms, and NatureFreshTM Farms Sales, approximately 200 Leamington-based families will receive a healthy holiday food box.

Connecting with the communities they grow in is always a top priority at NatureFreshTM Farms, whether it’s the holiday season or not – as far as their team is concerned, year-round growing is just as important as year-round giving!

-30-

About NatureFreshTM Farms

NatureFreshTM Farms has grown to become one of the largest independent, vertically integrated greenhouse vegetable growers in North America. Growing in Leamington, ON and Delta, OH, NatureFreshTM Farms prides itself on exceptional flavor & quality. Family owned since 1999, NatureFreshTM Farms ships fresh greenhouse grown produce year-round to key retailers throughout North America.

SOURCE:

NatureFreshTM Farms | info@naturefresh.ca

T: 519 326 1111 | www.naturefresh.ca

On The 5th & 6th of December, The Third Annual International Investment Forum Greenhouse Complexes Russia 2018 Was Held With Great Success

On the 5th & 6th of December, the Third Annual International Investment Forum Greenhouse Complexes Russia 2018 was held with great success, drawing participation from over 700 leaders and executives of agricultural holdings, greenhouse complexes, initiators of investment projects, investors, trading networks, government representatives, producers and installers of equipment and related services for the greenhouse industry.

The event hosted delegates from 20 countries. Throughout the course of the forum, over 500 meetings were conducted.

PHOTO GALLERY

First Deputy Minister of Agriculture of the Russian Federation Dzhambulat Khatuov spoke at a plenary session of the Forum, noting that thanks to effective support on the part of the Russian government, a consistently fast pace of construction in new, high-tech greenhouse complexes has been achieved: We observe a stable rise in investment volume in the industry, alongside a stable and positive dynamic in production volumes that began already several years ago. New projects are regularly launched to full production capacity, and with each year we increase gross harvests of fresh vegetables. Total harvests of closed-field vegetables from domestic agricultural organisations exceeded 920 000 tonnes last year, and this year, forecasts predict a result above 1 million tonnes – both successive records for the industry. Thanks to recent successes in greenhouse vegetable cultivation, the level at which domestic market demands are met by domestic greenhouse production has now risen to 57% versus 40% in 2015. Khatuov further asserted that the chosen dynamic and realisation of government support measures should continue to provide significant results in the industry for the future – it is therefore important to develop not only the domestic market, but also to consider the possibility of future export growth in connection with future goals and tasks to be established by the President.

The second day of the Forum was divided into three streams – the Conference; Focus Day: Storage, Processing, Logistics; Agronomists’ Day.

During the Conference stream sessions, banks alongside forum guests discussed questions of preferred credit financing, and project financial management. A separate session was dedicated to energy-efficiency at greenhouse complexes, in which Agrocomplex Churilovo offered a range of practical experience. The session on production planning and sales strategies featured experts’ experiences with plant varieties, the broader panel of available varieties, assessment of sales markets, marketing, and innovations in sorting and packaging. Dinko Gadzhev, Commercial Director, Fruit and Vegetables at O’KEI discussed strategies for collaboration among trading networks and greenhouse operators. Driss Dehbi, Managing Director, Suhool Arabia Investment, invited producers of fruit and vegetables to collaborate on exports to the UAE.

The conference concluded with a round table led by Galina Lishinaya, Acting Provost for Academic and Scientific Work, Russian Academy for Agricomplex Personnel, who led the institution’s educators along with business representatives in a discussion of the most pertinent questions relevant to providing greenhouse enterprises with qualified personnel.

Leading experts during Agronomists’ Day were Marite Gailite, Latvia and Jenny Harris and Joe Schwartz, USA, who held professional master classes on contemporary approaches to growing tomatoes, cucumbers, and salad greens.

Focus Day was used to address questions of storage, reprocessing, and realisation of agricultural production. Leading industry figures took part in special parallel sessions: executives of major agricultural parks, wholesale distribution and logistics centres, agricultural holdings and other agricultural enterprises, initiators of investment projects, experts in agricultural logistics – RosAgroMarket Holding, Agroproduction Park Kazan, Agroproduction Park Samara, ORC Magistral, UK Grando, Nord-Ovosh, PRODO, Businovsky MPK, Razdolye, Agrocomplex Eseninsky, YugOvoshSbyt, Yugagroholding, FOOD CITY, AGROCITY, Victoria Estate, Romex Group and many others. A special stream was also visited by over 90 companies involved in investment projects in the industry: construction of vegetable and fruit storage facilities, grain storage and elevators, and wholesale distribution centers.

During the specialised exhibition, innovative developments were presented by major producers of equipment and technologies in Russia, the CIS, Europe, and Africa.

Forum Sponsors:

Gold Sponsor: Grodan;

Silver Sponsors: Signify, SVETOGOR, Green Automation Group, BLV, C-LED;

Bronze Sponsors: Royal Brinkman, AWETA, Lider-Pak, Mir Stekla, Rijk Zwaan;

Video Sponsors: Richel Group, 3DSmartGarden, OHK «URALCHEM»;

Evening guests were also offered an outstanding opportunity to make new acquaintances and strengthen existing business connections in an informal setting at the gala dinner, which also included a formal awards ceremony to recognise leaders of the Russian greenhouse agriculture industry for 2018.

Nothing Is Wasted In This Greenhouse Restaurant

It has been there for a while, restaurant the Green House in the center of Utrecht (Netherlands). On April 9, the restaurant opened its doors, and since then the visitors have been able to enjoy food which is harvested above their heads in the greenhouse. The video below gives a good overview of the restaurant.

For more information, read the article published before on Horti Daily.

For more information:

The Green House

Croeselaan 16, 3521 CA Utrecht

Netherlands

+31 (0)6 2213 1447

info@thegreenhouserestaurant.nl

www.thegreenhouserestaurant.nl

Publication date : 12/13/2018

Appleton, WI Greenhouse To Grow Industrial Hemp

It's industrial hemp, and it's growing in popularity in Wisconsin. And after an experimental growing season, an Appleton greenhouse is now making room to meet the expected demand.

by Eric Peterson, FOX 11 News

December 4, 2018 (WLUK/Eric Peterson)

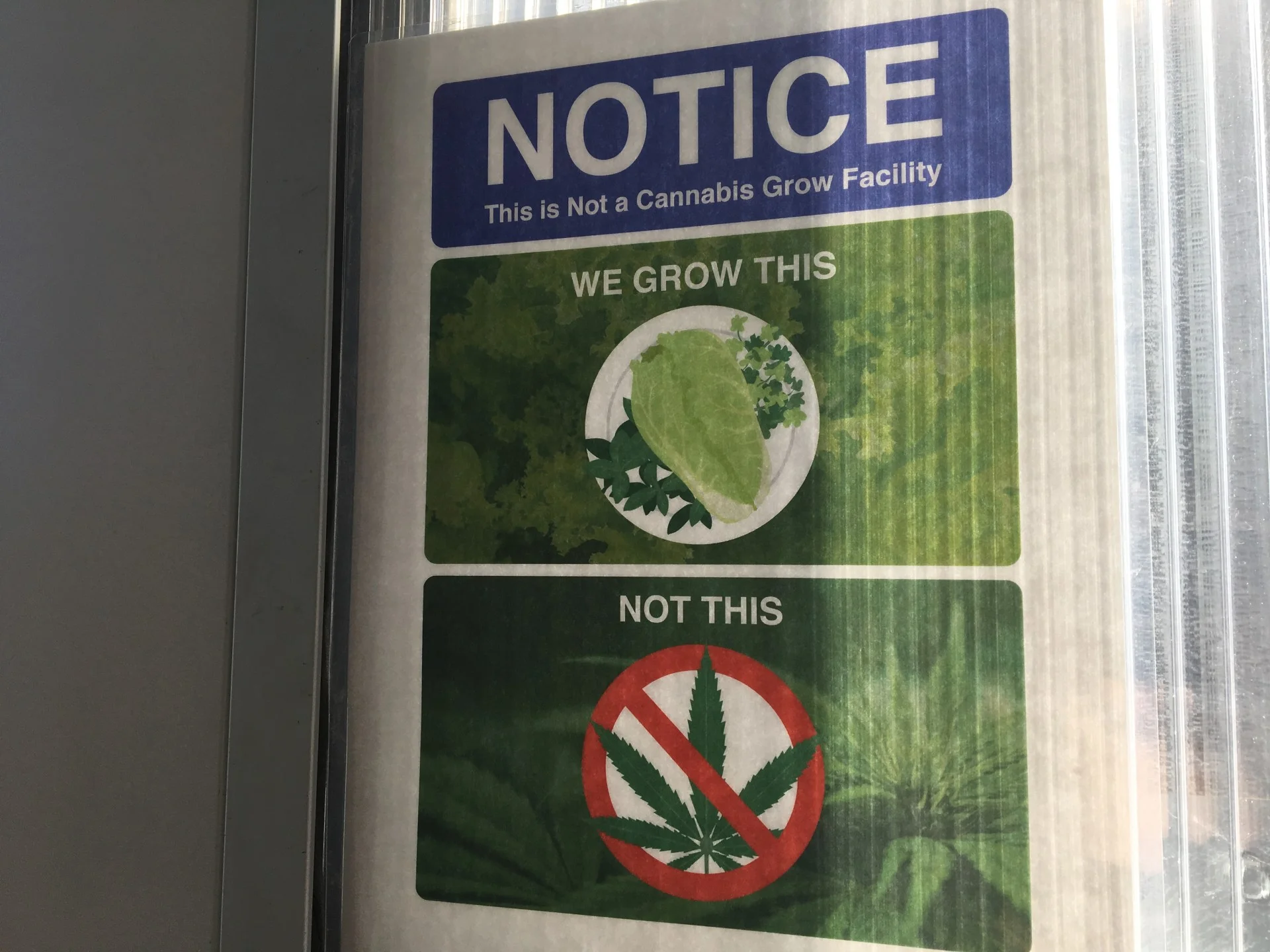

APPLETON, Wis. (WLUK) -- It looks like marijuana, but it's not.

It's industrial hemp, and it's growing in popularity in Wisconsin.

And after an experimental growing season, an Appleton greenhouse is now making room to meet the expected demand.

For nearly a century, Memorial Florists & Greenhouses has grown plants of all kinds, but a new look at an old variety has president Bob Aykens very interested.

"They came in as cuttings, and they're in the process of being rooted and propagated," said Aykens, the business's president.

Aykens says through a lease agreement with Colorado-based company Front Range Biosciences, a 15,000 square foot greenhouse will soon grow hemp.

"Our production plan says 250,000 clones will go out of here for next spring," he said.

The greenhouse will be fitted with lights, a network of nozzles will spray the plants on a regular basis. Farmers will place their orders, and the hemp will be delivered from the bio-secure area to the producers in the field.

"I think to have that ability for a farmer to come in, and have the confidence of what they're planting, is is going to succeed, and prosper here in the state," said Rob Richard, Wisconsin Farm Bureau Federation Senior Director of Governmental Relations.

Richard represents hemp farmers around the state. He says last year, there were more than 200 licensed producers. He calls the first season a success, and expects that number to grow.

Aykens agrees. He says a quarter of a million hemp plants is a good start.

"That probably won't meet the demand, I'm going to guess. But we'll be looking at expanding upon what those needs are, once we know what they are," said Aykens.

Wisconsin's Department of Agriculture Trade, and Consumer Protection oversees the hemp industry.

Industrial hemp licensing applications are available for the 2019 season. You have until the end of the year to apply.

Altius Farms Is Supplying Local Restaurants

High-Tech Urban Greenhouse Takes Local Farming To A New Level In Denver

December 14, 2018

By: Liz Gelardi

DENVER -- People walking or driving by Altius Farms have picked up their phone to call and ask about the greenhouse at 25th and Lawrence. The glass-enclosed structure houses an urban farm that is using advanced technology to change the way we think about growing food.

"This is our mission, is to bring urban farming back into our communities," said Altius Farms Founder and CEO Sally Herbert.

Photos: Altius Farms uses vertical farming to supply local Colorado restaurants and stores

The farm is already supplying about 20 local restaurants and Marczyk's Fine Foods with fresh produce. Herbert hopes to introduce a community-supported agriculture (CSA) program where people will be able to buy directly from the farm.

"People can know their farmer. These restaurateurs and their customers will understand where their food is coming from every day," said Herbert.

Herbert gave Denver7 a tour of the facility, starting with the steps everyone has to take to in order to enter the greenhouse's controlled environment. She started by rinsing her shoes, washing her hands and putting on gloves. Then she explained the control panels that essentially run the 8,000 square-foot building.

"It really does most of the work for us – everything from nutrients to the plants to CO2 production," said Herbert.

Sensors on the inside and outside of the greenhouse check the environment every 90 seconds. If the temperature or humidity is off, adjustments are made automatically. Panels on the side of the building open and close to let cool air in. The greenhouse almost feels like it's breathing when the roof opens to let warm air out.

The plants seem to be thriving in the environment. Twenty-eight different varieties are currently growing inside, including herbs, a variety of lettuces and edible flowers.

The vertical towers give them the ability to maximize the space, allowing them to produce 10 times as much as conventional farming while using only 10 percent of the water. The seedlings get their start with supplemental light but the rest of the greenhouse utilizes Colorado's natural sunlight.

Altius Farms uses vertical farming to supply local Colorado restaurants and stores and gives you home growing tips

As Herbert walks around, she samples some fresh arugula and parsley. She's fairly new to the agriculture business and got her start after a career in corporate America. She served on the board of an organization called Veterans to Farmers, where the idea to start her own farm was born. Herbert is also a veteran and is now hiring vets to help grow the business.

“I can’t say enough about this team. This team makes it happen," said Herbert.

Company Finds New Way to Grow Lettuce, Cut Risk of Foodborne Illness

One rooftop greenhouse company in Chicago says their lettuce is safer and longer-lasting.

3:25 PM, Dec 5, 2018

4:16 PM, Dec 6, 2018

The romaine lettuce outbreak has many consumers thinking about where their crops are grown.

One rooftop greenhouse company in Chicago says their lettuce is safer and longer-lasting.

Jenn Frymark, the chief agriculture officer and manager of Gotham Greens, pulls out a head of lettuce and immediately starts to eat it.

"No, you don't need to wash it,” Frymark says. “We don't have that on our package, but there's no reason for me to wash it. I never wash any of our lettuce at home. It's amazing; nothing touches it; it’s so clean.”

Here at Gotham Greens, lettuce is grown differently.

They do it hydroponically. That means it’s grown without soil, but in a nutrient-rich water. Instead of a traditional farm field, this lettuce is grown on rooftop greenhouses.

Their space on Chicago's south side is the largest rooftop greenhouse in the country. Because of the controlled environment, crops can grow in a third of the time of a traditional field.

“We're giving this plant everything it wants: the right day temp, the right night temp, the nutrients, CO2 levels, air circulation, the water,” Frymark explains. “I mean, these are very coddled plants and they have everything they need, and they can just grow in this perfect environment and reach maturity very quickly.”

Gotham Greens sells to grocery stores in the Chicago and New York metro areas, as well as select Whole Foods stores. The product goes from the greenhouse directly to grocery shelves in a day and a half.

The company’s lettuce also lasts longer than the traditional grocery lettuce out here. Frymark says their product can last up to two to three weeks in the fridge. Additionally, Gotham Greens prices are comparable to other organic produce.

Frymark also says their method dramatically lowers the risk for foodborne illness.

“There [are] no manures, there’s no water sources that could be contaminants,” she says. “We don't have birds and animals getting into the field.”

She says the company is expanding and plans to open more rooftop greenhouses in the near future.

What's In Your Water?

Posted by Zack Foust, Sales Representative on 12/4/2018

One aspect of farming that is often overlooked is the quality of source water being used for crop production. For many greenhouse growers, winter provides a break to clean up and analyze data after a long growing season. Having a sample of your source water analyzed from time to time provides important information for realizing patterns and planning for the next growing season.

Results from a water analysis provide the following information:

Electrical conductivity (expressed in mS) – total concentration of salts dissolved in your water

pH – acidity or alkalinity of your water; pure water has a pH of 7.0

Concentration of ions dissolved in water – narrowed down to essential elements for plant nutrition. Read about these important elements here.

Presence of carbonates and bicarbonates (“hardness” of your water) – concentration of bicarbonates (up to pH 8.2) and/or carbonates (pH of 8.3+) that increase pH buffering capacity

It is important to take action once you receive your results so you could potentially improve your production by:

Adjusting the EC so as not to exceed the set points appropriate for any given time of the year

Meeting nutrient targets for the crop being grown; saving money by switching from a pre-mixed fertilizer to a custom recipe which prevents over-feeding your crop nutrients already found in your source water.

Properly adjusting pH to keep the nutrient solution closer to your set point based on the hardness of your water and the presence of individual ions

Contact CropKing for options to have your water sample analyzed. We also offer an interpretation service for water and tissue samples, and can make recommendations based on the results.

For more information on our custom fertilizer recipes, click here!

Bonus: Sending plant tissue samples to a lab and having them analyzed is also an important step in improving your operation. Tissue analyses provide a breakdown of elements present in the sampled crops. Growers receive the greatest benefit from tissue analyses by:

Sending samples before and after altering fertilizer and/or pH regimes

Provides quantitative data to show how changes affect crop nutrition

Submitting multiple samples throughout the growing season to quickly catch imbalances

Compiling results and identifying patterns to improve future production

Category: News and Updates

Backyard Farms’ Northeast Expansion Sets Record

December 04, 2018

Mastronardi Produce Ltd. is expanding the Backyard Farms brand with the introduction of a high-tech greenhouse in New York, one the largest-ever single builds in North America.

“This expansion allows us to meet the incredible loyal consumer and retailer demand for this brand," said Paul Mastronardi, president, chief executive officer and the fourth-generation family member to lead Mastronardi Produce. “It also ensures that all Northeasterners can enjoy what New Englanders have come to expect: fresh-from-the-vine Backyard Farms tomatoes delivered within hours.”

The 71.6-acre glass greenhouse is only Phase I of the company’s mission to satisfy customer appetites — and exceed flavor expectations — for locally grown Backyard Farms tomatoes.

The new, industry-leading greenhouse more than doubles Backyard Farms’ greenhouse growing acreage and increases Mastronardi Produce’s internal greenhouse network to seven locations across the United States. In total, Mastronardi produces and delivers fresh, flavorful produce to retailers from more than 4,000 productive acres of growing capacity.

New-York-grown Backyard Farms tomatoes are planned to hit stores in Fall 2019

Tomatoes And Microgreens In Space

We Have Lift-Off

Originally scheduled for November 19, the Eu:CROPIS mission, featuring life support system greenhouses that are to demonstrate that growing tomatoes in space is possible using urine, was launched December 3 and is now in orbit.

In other space news, December 5 will see another satellite launch, this time from Cape Canaveral Air Force Station. Space Tango customer payloads will be making their departure for the International Space Station for the SpaceX Commercial Resupply Services-16 (CRS-16) mission. Included in the mission are two horticulture projects.

„Test of outside cameras and Payload No.4 (SCORE) successfully accomplished. The images show the inside view of the non-deployed solar panels”

#SSOA #SmallSatExpress @DLR_de @UniFAU @SpaceX @elonmusk @DLRWeaselWorks @Lizzard07 @nohka @SpaceflightInc @DLR_next

Aeroponic Farming in Microgravity

The Aeroponic Farming in Microgravity payload will evaluate an aeroponic system designed for use in a microgravity environment. The primary payload objective is observing the behavior of mist immediately after it is ejected from its source and how it moves thereafter. The secondary objective is to observe how a sample plant grows using the aeroponic system.

In order to examine the feasibility of using small-scale aeroponics systems in microgravity, this experiment features a chamber with an ultrasonic fogger unit. The mist is sprayed onto material containing microgreen seeds and the resulting germination and growth are imaged. Research data collected should provide a helpful model for future plant growth studies on the ISS.

Growth of Assorted Microgreens in Microgravity

The Growth of Assorted Microgreens in Microgravity payload studies the morphology and physiology of the germination of four different microgreens within modular growth chambers in microgravity.

The seeds are placed under automatic growth lighting conditions to provide day and night lighting cycles that simulate successful terrestrial lighting. While imaging and numerous environmental sensors provide an incremental evaluation of the plant growth on the International Space Station, multiple terrestrial control experiments will be conducted for comparison.

The Growth of Assorted Microgreens in Microgravity experiment demonstrates modular, autonomous and retrievable crop research in space by contributing to the understanding of plant cultivation in service of food, oxygen and other habitat requirements on long-term space missions. This experiment also provides insight on plants grown under unusual conditions and can inform crop science, basic biology and horticultural applications on Earth.

Publication date : 12/5/2018

Shareholders Still Stuck With Worthless Greenhouse And Aquariums

In July the project went bankrupt, after which the curator tried to continue the vegetable cultivation and the fish breeding

Netherlands: The financial failure of The Hague's urban greenhouse

Urban farms may one day form an integral part of the future megalopolis, but it's clear the concept still needs some refinement. The experiment in The Hague, a 1200 m2 greenhouse on top of the building De Schilde, proves to be a financial failure as its backers stand to lose money even after the farm shut down.

"Assuming that the disposal costs of the greenhouse and the aquariums will be very high and with the uncertainty about their current condition, the value of the goods is very low and possibly even negative," says a recently released bankruptcy report about the project in the Hague.

In July the project went bankrupt, after which the curator tried to continue the vegetable cultivation and the fish breeding. The activities of Urban Farmers were losing them money from the start, as costs were high and revenue too low.However, no interested parties were found that wanted to continue the current activities.

The Fonds Ruimte en Economie Den Haag, shareholder of one third of the building, will take over the greenhouse and try to minimize financial losses. No more (public) activities will take place at the urban greenhouse.

Read the bankruptcy report here (in Dutch).

Publication date : 11/26/2018

Rooftop Greenhouse Teaches, Nourishes and Empowers Students

The nation’s first student-run rooftop greenhouse with the capacity for year-round food production helps stock the UA Campus Pantry.

By Emily Dieckman, UA College of Engineering

Nov. 20, 2018

Gene Giacomelli, left, former director of the UA's Controlled Environment Agriculture Center, talks tomatoes with Todd Millay, director of the Arizona Student Unions, in the greenhouse on the Student Union roof.

EXTRA INFO

The UA Campus Pantry has food distribution days from noon to 7 p.m. on Wednesdays and from 11 a.m. to 3 p.m. during the academic year. Tours of the rooftop garden are available on Wednesday mornings at 10 a.m. and can be signed up for at the Arizona Student Unions information desk.

Stacy Tollefson, project and production manager for the greenhouse and a professor of practice in the Department of Biosystems Engineering, tends the crops in the greenhouse atop the UA student union building.

Twice a week in the basement of the Student Union Memorial Center, about 500 students, faculty and staff pick up free groceries at the University of Arizona Campus Pantry.

Twice a week on the roof of the student union, UA students and future commercial growers harvest cucumbers, tomatoes and bell peppers from the Rooftop Greenhouse and send the vegetables down to the Campus Pantry. This student-designed, and mostly student-run, controlled-environment facility is the first rooftop campus greenhouse in the nation that can produce food year-round, with 10 times the productivity of an outdoor garden.

“We harvest on the same days the campus pantry does distribution and bring the food right down, so the produce is super fresh,” said Stacy Tollefson, project and production manager for the greenhouse and a professor of practice in the Department of Biosystems Engineering, as well as an expert vegetable grower for the UA’s nationally recognized Controlled Environment Agriculture educational program.

Seed of an Idea

Student volunteer Maggie Lacross, UA Campus Pantry operations chair, offers some nutrition guidelines.

When Todd Millay became director of the Arizona Student Unions in December 2016, he was excited to see there was a small outdoor garden on the roof being run by staff. When he heard about the Campus Pantry, which was serving about 30-40 people every few weeks, he offered pantry volunteers a central campus location in the Student Union, but noticed they weren’t receiving many fresh produce donations. The potential for connection seemed clear.

“Why don’t we just make a better garden on the roof and send the food down?” he thought. “And maybe instead of Student Union employees figuring out how to do this, we could ask students how to build it.”

Millay and some Student Union colleagues partnered with the UA Office of Student Engagement and launched a four-month competition. Twenty-five groups of five students each were given a hypothetical $50,000 budget to design a cost-effective, productive and sustainable system to grow fresh produce for the Campus Pantry. Coca Cola, Shamrock Farms, the UA Student Union, the UA Student Services Fees Grant and the UA Green Funds Grant helped finance the competition and the eventual greenhouse.

The winning team, composed of four UA College of Engineering students and one UA College of Agriculture and Life Sciences student, proposed a 750-square-foot temperature-controlled greenhouse that would grow tomatoes, cucumbers and bell peppers. Design advice from Gene Giacomelli, a professor of biosystems engineering and the former director of the Controlled Environment Agriculture program, combined with donations from companies like Autogrow, Formflex, Grodan, Wadsworth Control Systems and Polytex Inc., led to the greenhouse’s construction in 2018.

The Tech Behind the Tomatoes

The greenhouse is temperature-controlled and could yield produce year-round, but the team harvests for nine months and takes the summer off to prepare for new student recruits and start afresh. In those nine months, Tollefson expects the greenhouse to yield 3,000 pounds of cucumbers, 1,200 pounds of tomatoes, 800 pounds of cherry tomatoes and 250 pounds of bell peppers.

The plants don’t get their nutrients from soil, but from two large tanks of solution with just the right mix of nitrogen, phosphorous, potassium and other nutrients. Any solution that isn’t absorbed by the greenhouse’s four rows of plants is recirculated back into the tanks, revitalized and fed back to the plants.

“We’re saving tons of water with this recirculating hydroponic system because we’re only losing maybe 5 percent to evaporation, and we’re saving tons of nutrients,” Tollefson said.

In addition to conserving water and nutrients, the recirculation system ensures that no fertilizer water is discharged into the environment. Another hi-tech feature is that the greenhouse climate and irrigation control systems are connected to the internet: The greenhouse team can log in and monitor the nutrient solution for pH, electrical conductivity and temperature from their phones.

Efforts Bearing Fruit

Tollefson, who has a Ph.D. in agricultural and biosystems engineering, said working at the greenhouse has been an excellent learning experience, even for her – this is the first time she has grown hydroponic tomatoes while recirculating the nutrient solution, so both she and the students are learning how to manage plant nutrition more efficiently. Student interns are learning hydroponic cultivation techniques and greenhouse management techniques that translate to valuable career skills.

“There’s a tremendous demand out in the industry for people who know how to operate these greenhouses because of the recent interest in locally grown and urban agriculture,” Giacomelli said.

Tollefson oversees two interns – plant sciences major Chris Patzke and veterinary science major Tyler Rodriquez – and full-time greenhouse manager Quinn Waltz, a senior majoring in agricultural technology management.

The greenhouse team makes frequent visits to the greenhouse to check on the hydroponic system, care for the plants and monitor the environmental conditions, and harvest, weigh and deliver the crops to the Campus Pantry. The idea is to make sure everything is running smoothly – and it certainly is. This fall, the cucumber plants were growing about 2 feet a week, and the tomato plants about 18 inches. The tomatoes and bell peppers are just starting to ripen, but they’re already delivering about 50 pounds of cucumbers to the pantry each week.

“We keep the conditions just right,” Patzke said. “Happy plants grow really fast.”

The students in the greenhouse say they love knowing their work is making a difference in the Wildcat community.

“It’s inspiring and humbling to know we are the first ones working on this project,” Waltz said. “We are setting the foundation for future students who want to be a part of something that impacts others, and want to learn about how and where their food comes from.”

NatureFresh Farms Ohio-Based Greenhouse Growing Strong Throughout The Winter

Delta, OH (December 5th, 2018)

With the last weeks of 2018 still ahead of us, NatureFresh Farms is in the thick of a third winter growing season at their Ohio- based facility. Located in the northwestern community of Delta, OH, the NatureFresh Farms USA greenhouse will be picking, packing, and shipping fresh and flavorful Tomatoes throughout the coldest months of the year – good news for retailers looking to add NatureFresh Farms products to their store shelves all year long!

Since 2015, NatureFresh Farms USA has experienced great success with consistently healthy crops and high fruit yields every season. This year, the greenhouse grower is producing Tomatoes-on-the-Vine, Beefsteak Tomatoes, and a large variety of Specialty Tomatoes across 45 acres.

The Delta-based greenhouse was strategically built in the northwestern region of the Buckeye state to allow for quick transport of products to all the company’s North American retail partners.

The Delta facility is using High-Pressure Sodium (HPS) lighting fixtures, a powerful grow light technology which allows for winter Tomato production. Paul Schockman, Sales Manager, shares that the Delta greenhouse gave NatureFresh Farms the opportunity to produce locally-grown Tomatoes at a time of year when traditional farms are not in operation: “Our retail partners within the northeastern region of the United States can now provide high-value Ohio-grown products to their customers when locally-grown food is typically not available. With such an effective arrangement, it wouldn’t surprise me if we add more acreage in Ohio in the future.”

Growing in the state of Ohio has also provided the NatureFreshTM Farms team with the opportunity to develop a strong partnership with the Ohio Proud program. Featuring the Ohio Proud sticker on all Tomato products grown and packed at the NatureFresh Farms USA location ensures consumers know they are purchasing Ohio-grown products, creates support for local growers, and promotes local agriculture, the number one industry in Ohio.

With exciting plans for market growth, as well as various expansion projects to look forward to, NatureFresh Farms is positioned to reach incredible new heights in 2019 and beyond.

-30-

About NatureFresh Farms

NatureFresh Farms has grown to become one of the largest independent, vertically integrated greenhouse vegetable growers in North America. Growing in Leamington, ON and Delta, OH, NatureFresh Farms prides itself on exceptional flavor & quality. Family owned since 1999, NatureFresh Farms ships fresh greenhouse grown produce year-round to key retailers throughout North America.

SOURCE: NatureFresh Farms

info@naturefresh.ca

T: 519-326-1111

Leafy Greens From A Growing Machine

Advancements In Automated Commercial Scale Vertical Farming

Growing produce automated or nearly automated and in any possible location are some of the advantages often supplied by the vertical farming industry. The Canadian company CubicFarms shows how also traditional greenhouse companies can benefit from indoor farming techniques.

DelFresco Pure recently chose CubicFarm Systems to grow leafy greens alongside their greenhouse production of peppers, cucumbers, tomatoes and strawberries.

CubicFarms has a background in greenhouse horticulture. The British Columbia, Canada based company has developed a indoor growing system based on a conveyer rotation method, allowing indoor farming to become scalable. It is quite a mouthful, but they explain their produce to be grown safe, sustainable and self-sufficient, cost-effective and on commercial scale.

Currently CubicFarms Systems Corp. is expanding and growing with both sales of systems, and sales of produce grown in CubicFarms.

CubicFarm installation in full swing in Pitt Meadows, BC

This summer, CubicFarms finished construction of their first full-scale, completely operational, 11 machine CubicFarm System in Pitt Meadows, BC.

"With the capacity to grow over 1.5 million of heads of lettuce, or over 9 million basil plants, or over 150,000 pounds of microgreens each year, or any combination thereof, we quickly became one of the largest producers of living lettuce, herbs, and microgreens in Canada", they explain.

Plans are already in place to expand the site by 10 fold over the next 12 months.

CubicFarms in Ontario, Canada

CubicFarms recently exhibited at the PMA 2018 show in Florida with its newest customer, DelFresco Pure, of Leamington, Ontario.

DelFresco Pure recently chose CubicFarm Systems to grow leafy greens alongside their greenhouse production of peppers, cucumbers, tomatoes and strawberries. "Our system will allow DelFresco Pure to bring additional produce into their local market without disturbing their current greenhouse operations. Installation has begun and are expected to be completed by the end of January, 2019."

A mini demonstration CubicFarm growing machine was built to display in DelFresco’s huge booth at the Orlando PMA. Strawberry Sundaes with CubicFarm growing micro basil was the big flavour hit at the show.

CubicFarms in Central Alberta

CubicFarms has also recently partnered with Swiss Leaf Farms near Edmonton, Alberta. Swiss Leaf chose CubicFarms’ automated growing machines to bring local, fresh leafy greens to central Alberta.

"The machines have just been installed and will commence growing in December. Swiss Leaf will be utilising CubicFarm’s “Thriiv Local Garden” produce brand to market and sell living lettuce, herbs and microgreens."

Thriiv Local Garden

And there's more. CubicFarms' launched their lettuce, basil and microgreens into Fresh Street Market stores in October, under their proprietary “Thriiv Local Produce” brand.

"We received positive responses from customers enjoying the freshest possible produce. Their living lettuce heads are available in 3 different blends (Springtime Trio, Butter Blend and Merlot Medley) and are sold in their proprietary packaging that allows lettuce to stay alive and fresh on the windowsill or in the fridge for weeks", they explain.

The microgreens have a variety of blends, including the spicy “Fire and Ice” and “Chef’s Blend”.

Carl Mastronardi Wins Produce Person of The Year From OPMA

During the annual OPMA Gala on November 9, Carl Mastronardi, President of DelFrescoPure® was the proud recipient of the OPMA Cory Clack-Streef Produce Person of the Year Award. Mastronardi received this prestigious award for his diligence and dedication to the greenhouse strawberry program.

“This is one of the most unforgettable events of my life. To be recognized by OPMA, my peers and the experts in the produce sector is a highlight that I treasure with abundant gratitude!” expressed Carl. “I was completely unaware that OPMA was considering me for this award, so it came as a complete surprise!”

Back in July of 2016, Carl Mastronardi and his partner, Jamie D’Alimonte, decided to test run the growing of one acre of strawberries in their greenhouse. Upon completion of the trial, the analysis of the growth within the greenhouse micro-climate environment coupled with favorable feedback from local and national retailers, had Carl convinced that they had tapped into an important niche market.

By September of 2017, ten acres of cucumber greenhouses were retrofitted to grow strawberries using high-pressure sodium grow lights enabling the strawberries to grow all year long. Production was scheduled for January 2018. "We were the first greenhouse grower in Ontario to offer greenhouse-grown strawberries during the winter season," said Mastronardi. With support from local and national retail partners, the strawberry program was a huge success and drove the further expansion of six acres for a total of seventeen acres of strawberry growing – all year round.

DelFrescoPure® said its strawberry program marketing and communication plan includes: a social media campaign with a local registered dietitian, promoting the ‘locally grown’ and ‘buy local’ message for strawberry sales, a double-sided billboard rental spot at the Ontario Food Terminal, social media outreach with Produce Made Simple, TV segments with RT and other influencers, featured ads with retail partners throughout the year, in-store demos with consumer-facing POS materials about how they grow, editorials in the Windsor Star, multiple interviews with the media, a video on “How We Grow Greenhouse Strawberries”, and outreach with trade publications promoting YES!Berries Your Everyday Snack™ strawberries.

During the launch of our new YES!Berries Your Everyday Snack™ strawberries product, the initiation of these communication plans resulted in multiple compliments for Carl regarding consumer education outreach throughout various social media platforms, according to the company.

“I would like to congratulate our president, Carl Mastronardi, on winning the OPMA ‘Cory Clack-Streef Produce Person of the Year Award’ and our DelFrescoPure® team in achieving the vision we both had in creating a truly unique, fresh and flavorful product that’s available year-round!” Expressed Jamie D’Alimonte, Chief Operation Officer for Del Fresco Produce Ltd. “To all of our staff from our greenhouses, warehouses, distribution, sales and marketing as well as our many loyal retail partners, we could not have done this without you! A sincere thank you is extended to all of them.”

For more information:

Fiona McLean

DelFrescoPure

Tel: +1 (519) 733-6101

news@DelFrescoPure.com

www.delfrescopure.com

Publication date : 11/28/2018

"Educator Greenhouses Foster The Perfect Learning Environment"

GrowSpan Commercial Educator Greenhouses provide a growing environment to encourage hands-on learning. The American-made structures offer an economical growing solution for instructors looking to enhance their program and teach horticulture throughout the year.

The Commercial Educator Greenhouses are 14’ wide and built to various lengths, tailoring the size of each structure to the program’s specific needs. The durable frame is made from triple-galvanized steel to prevent corrosion over time, while the clear, UV-resistant Twin-wall polycarbonate cladding is 12 times lighter than glass and accompanied by a 10-year warranty. GrowSpan is able to customize Educator Greenhouses with complete environmental control systems, including lighting, heating, ventilation and hydroponics systems as desired.

Starmont High School utilizes a GrowSpan Educator Greenhouse to take this learning a step further by organizing an annual plant sale to incorporate commerce and business experience into their program. As a GrowSpan customer, their educational program finds immeasurable value in the knowledge their students gain while working in the greenhouse.

GrowSpan understands the benefits of agricultural education for people of all ages. These greenhouses are suitable for primary and secondary schools, colleges and universities, research institutions, correctional facilities and more.

For more information:

GrowSpan Greenhouse Structures

1395 John Fitch Blvd

South Windsor, Connecticut 06074

Toll-free USA: (800) 476 9715

International: +1 860 528 9550

info@growspan.com

Publication date : 12/4/2018

Technological Supplier THORILEX Is Looking For Partners And Distributors

THORILEX launched several new products this summer including reusable THORILEX Hydroponics baskets for an automatic vertical THORILEX Hydroponics system and the company is looking for partners and distributors now.

“We can see a huge opportunity on the vertical farming market that is still moving forward with a significant growth at a CAGR of 22%. The vertical farming market is projected to grow from present 2,45 billion € to 6.54 billion € till the year 2023. We would like to find great partners and distributors to grow.” Explains Marek Hrstka from THORILEX

“I know that we have truly great products that are now placed in the THORILEX Farm in the biggest glass house complex in our country and it is possible to visit the farm to see the products in operation. Finding truly great partners or distributors is important to achieve our strategy.”

“It will take some time to find the right one. We are looking for someone who haS similar thoughts, likes, innovations and have experience in the horticulture industry. It can be a big or a small company or even an individual.

We are looking for a win-win situation where both sides are prospering from mutual cooperation.” Concludes Marek

Romaine Lettuce Scare Has Montreal Clients Turning To Local Greenhouses

With no romaine lettuce in stores or restaurants because of the E. coli outbreak, some are turning to local greenhouses for safer greens.

MICHELLE LALONDE, MONTREAL GAZETTE

November 27, 2018

As food safety authorities in Canada and the U.S continue to warn against eating romaine lettuce because of the recent E. coli outbreak, many consumers seem to be turning to local, hydroponically grown greens as a safer way of getting their salad fix.

Lufa Farms, which operates three rooftop greenhouses in the region, has seen a significant bump in new clients ordering their weekly baskets of local products. Lufa Farms co-founder and marketing director Lauren Rathmell said it seems likely the increase is because of the romaine shortage.

While Rathmell said she has no evidence that a direct correlation can be made with the increase in members to Lufa Farms with the romaine lettuce shortage, she said, “I would certainly say that the past week and a bit have been our record weeks to date by far.”

She said clients have been calling to ask specifically about the safety of Lufa’s hydroponically grown romaine lettuce at its Anjou site.

News of the E. coli outbreak has prompted most grocery stores and restaurants in the U.S. and Canada to remove romaine lettuce from shelves and menus, since the first public health notice was issued on Nov. 20.

Lauren Rathmell of Lufa Farms with bok choy that will soon be ready for harvest at the third, and newest, commercial rooftop greenhouse built for the urban farming organization, this one in Anjou. PIERRE OBENDRAUF /MONTREAL GAZETTE

The Public Health Agency of Canada and the Canadian Food Inspection Agency continue to collaborate with U.S. agencies to try to find the source of the most recent outbreak.

In the U.S., 32 people in several states have so far been confirmed sick from E. coli contaminations after consuming romaine lettuce, and 13 have been hospitalized. In Canada, there have been 22 confirmed cases so far, including 17 in Quebec, four in Ontario, and one in New Brunswick. Eight Canadians have been hospitalized, and one has contracted hemolytic-uremic syndrome, a severe complication that can cause ongoing kidney problems or death.

The news has some people seeking out greenhouse-grown vegetables, where there is less chance of contamination from contact with feces from infected animals.

“When you grow hydroponically in greenhouses like we do, its soil-less,” Rathmell said. “So there is no manure, and there are no other contaminants coming in from outside. So there is very, very little risk. We can’t say there is no risk … but there is virtually none.”

Founded in 2011, Lufa now has rooftop greenhouses in Laval, Ahuntsic and Anjou. The company partners with local farms to provide food baskets containing not only rooftop grown vegetables but also fresh, locally produced meats, dairy products, bread, pasta, etc. Clients customize their baskets online and pick them up from locations around the city.

Rathmell said Lufa ships baskets of produce to about 14,000 clients a week, and that number has been growing, generally, by a few hundred per week. She declined to give exact recent numbers but said that in the past couple of weeks, the increase has been “in the higher hundreds rather than the lower hundreds, if I had to give you a ball park.”

Experts say there is no such thing as no risk of contamination, since seeds can be contaminated before planting and post-harvest handling by humans can also transmit harmful pathogens, but food grown in greenhouses without soil is definitely lower risk.

“There is very little handling,” Rathmell said. “The Anjou site is remarkable. It’s basically this sea of greens when you walk in. So there is almost no handling or walkways in between the crops. You plant a seedling, and about four to five weeks later it’s ready to harvest and there is just one step. We take that lettuce, roots and all, we put it in a bag and it goes straight to the customer within a day. So there are no entry points” for pathogens, she said.

But for another local hydroponic producer, the romaine lettuce shortage has not been particularly beneficial.

Martin Desrochers (left) and Sylvain Terrault of Hydro-Serre Mirabel with its water-grown Boston lettuce. Terrault says it is producing at capacity and can’t satisfy the demand for more lettuce. MARIE FRANCE COALLIER/ MONTREAL GAZETTE FILES

Sylvain Terrault, president and CEO of Hydroserre Mirabel, said his company is already producing various greens — mainly Boston lettuce, but also oakleaf lettuce, swiss chard, mâche, etc. — at capacity in its three greenhouse complexes in the region.

The company does not produce romaine, but his clients, mainly grocery store chains in Canada and the U.S., have been calling to demand more of the greens Mirabel does produce to fill the void left by romaine.

“It has had an impact, but not necessarily an agreeable one, in the sense that our clients want a lot (more greens), and we can’t satisfy (the demand), and a client not satisfied is not a happy client,” he said, adding his company has a policy of not increasing prices as a function of a punctual shortage, so there hasn’t really been an upside.

RELATED

Inspired Greens Producing To Meet Frantic Demand For Clean, Safe, Local Lettuce

Innovative Alberta greenhouse offers lettuce grown in pristine conditions

COALDALE – A $60 million investment into the world’s most innovative greenhouse technology was based on a fundamental premise: clean means clean.

With North American retailers and consumers paying heightened attention to food safety – specifically related to romaine lettuce – Inspired Greens offers greenhouse-grown lettuce varieties grown with triple-filtrated water in a closed, environmentally safe and secure environment.

“Retailers and consumers have a heightened awareness of food safety, quality and taste,” said David Karwacki, Chief Executive Officer of The Star Group of Companies, which built the Inspired Greens greenhouses. “We invested this cutting-edge clean technology to ensure we can unequivocally deliver clean, fresh, healthy lettuce with no concerns about contamination.”

The Inspired Greens greenhouses opened in Coaldale, AB, in June 2017 and can produce up to 12 million heads annually. It is the first North American greenhouse to use this advanced technology, with plants untouched by human hands from seed to harvest. In April 2018, Inspired Greens announced plans to double its production capacity based on strong industry and consumer demand.

Inspired Greens and Inspired Leaves are available in grocery stores across Western Canada and in select markets in the western United States