Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

GE Appliances Shows Off Future Kitchen Technology At CES

Louisville-based GE Appliances, a Haier Company, will reveal its reimagination of the home at CES 2020, which comes in the form of two new kitchen concepts: “Shift,” and “Home Grown.”

The Home Grown Kitchen employs three different gardening systems for consumers to cultivate their own trees and produce in-home. It additionally comes with guides to assist the user from seeding, harvesting, and preparation of produce.

By Sarah Shadburne – Reporter, Louisville Business First

Jan 8, 2020

Louisville-based GE Appliances, a Haier Company, will reveal its reimagination of the home at CES 2020, which comes in the form of two new kitchen concepts: “Shift,” and “Home Grown.”

"At GE Appliances, our driving force is to eliminate the distance between what we make and what our consumers need, and it propels us to imagine what's to come," said Shawn Stover, vice president of SmartHome Solutions, GE Appliances, in a news release.

CES, the brainchild of the Consumer Technology Association, hosts its annual event this week as tech trailblazers from around the world make the pilgrimage to Las Vegas for a three-day showcase of their innovations.

GE’s thesis statement is one of personalized kitchen convenience for all members of the home, the release said.

As many homes become multigenerational and house people with varying physical abilities, GE said it sought to create kitchens that empower their users.

“Shift” is a technological kitchen which utilizes face and voice recognition technology to determine features applicable to its user, which include height adjustments for wheelchair users, to update the space in real-time.

The “Home Grown” offering features three different gardening systems so users can grow foods directly in their homes. The gardening system utilizes aeroponics, hydroponics, and soil to enable in-kitchen growth for trees and produce and is regulated by a user interface which guides the user from growth to harvest to food preparation.

At the conference Tuesday, GE was named Smart Appliance Company of the Year for the second year in a row through the IoT Breakthrough Awards program. The program attracted 3,700 nominations this year and seeks to recognize innovators, leaders, and visionaries in internet-of-things (IoT) categories such as industrial and enterprise, connected home and home automation and more.

“GE Appliances was the first manufacturer to offer a full suite of connected products for the home and they continue to define what’s possible, responding to consumer needs and preferences with “breakthrough” products that deliver real-world results,“ said James Johnson, managing director at IoT Breakthrough, in a news release. “GE Appliances is redefining the appliance industry by creating appliances that get smarter over time with software updates and upgrades. Making continued investments in research and development of compelling and useful smart appliance features and products, GE Appliances proves it is the leader year-after-year in the smart appliance segment. We congratulate them once again and look forward to continued leadership and innovation in the smart appliance arena.”

GE will also host Tech Talks at its booth #16006 daily through the conference from 10 a.m. to 3 p.m. The Haier section of the booth will highlight its work to create a fully connected IoT living space, from Smart Kitchen to Smart Living Room to Smart Closet.

Locally, GE is the second largest manufacturer in Louisville, with 6,000 full-time employees and 12,500 companywide. They operate the Appliance Park at 4000 Buechel Bank Road.

LG's Herb Fridge Is A Full-Size Indoor Gardening Center

You've heard of wine and beer fridges, but what about an herb fridge? LG thinks this full-size greens grower will be the next big thing

You've heard of wine and beer fridges, but what about an herb fridge? LG thinks this full-size greens grower will be the next big thing.

December 25, 2019

When you think of growing herbs indoors (calm down, not that kind), most people image terra cotta pots lined neatly on a window sill. Smart indoor gardening has so far been predominantly gadget-size, like the countertop herb growing machines from MiracleGro and Click and Grow. Now, LG is taking on the green indoors with a full-size appliance in 2020. Today, the company announced an "indoor gardening appliance" and "indoor vegetable cultivator," tentatively called the LG Harvester, and plans to exhibit it at CES in January.

The built-in, column style refrigerator uses light, temperature and water controls to create the best environment for gardening in your kitchen. A non-circulating water supply system distributes the right amount of water for each plant type and prevents algae growth. Flexible modules replicate the best outdoor conditions by matching the temperature in the cabinet with the time of day. There are LED lights, forced air circulation, and a wick-based water management system.

The fridge will work with a line of all-in-one seed packages and with a monitoring app to keep watch over your garden from anywhere, manage settings and give you gardening tips along the way.

You'll be able to grow up to 24 seed packages of vegetables and herbs in one appliance. Each package contains seeds, peat moss, and fertilizer. Initial packages will include 20 varieties, including romaine, other types of lettuce, arugula, chicory, and basil.

Vertical farming, smart indoor planters, and micro-gardening are changing the way city dwellers pick their parsley. There are other herb fridge models, out there. Most are wine-fridge-size appointments, like the ones from Viking and Urban Cultivator.

This LG model certainly doesn't look space-saving, so you'll need to really love your leafy greens to be on board. Still, taking the garden full-size is an exciting idea.

Miele Acquires Consumer Indoor Vertical Farm Company Agrilution

Agrilution’s Plantcubes look like wine fridges that are meant to be built directly into home kitchens. The automated systems regulate the lighting, climate, and water levels plants receive, all key parts of delivering the right “recipe” of nutrients to crops grown in vertical farms

Miele announced today that it has acquired the assets of the German company, Agrilution, makers of the Plantcube indoor vertical farm. Terms of the deal were not disclosed.

Agrilution’s Plantcubes look like wine fridges that are meant to be built directly into home kitchens. The automated systems regulate the lighting, climate, and water levels plants receive, all key parts of delivering the right “recipe” of nutrients to crops grown in vertical farms. Plantcubes cost €2,979 (~$3,300 USD) and are capable of growing a number of different greens including kale, leaf lettuce, basil and more.

According to the press announcement, Miele came on board after Agrilution failed to raise more financing and filed for insolvency on Dec. 1. Agrilution will become a subsidiary of Miele, and almost all of Agrilution’s employees will be transferred over to Miele.

Having an in-kitchen grow system makes a lot of sense for people wanting to reduce their carbon footprint as well as have more transparency into and control over the food that they eat. These small farms could be especially appealing to those that don’t have the space, inclination or talent to grow their greens outside. In fact, building hydroponic grow systems directly into cabinets was a trend predicted during a panel on the future of the kitchen at our recent Smart Kitchen Summit.

The acquisition of Agrilution also seems like a smart play for Miele. Since Agrilution was in insolvency, the assets for the company probably weren’t that expensive. Miele has also shown that it isn’t afraid to shake up the traditional kitchen with new appliances like its solid state RF oven, its own meal delivery service, and investments in digital recipe startups like Plant Jammer and KptnCook.

A big player like Miele could also help push indoor farming systems more into the mainstream. Miele has the market muscle other in-home farming startups like Seedo, SproutsIO, or Ponix just can’t match. The only question remains is whether in a world of on-demand food delivery, people will have the patience to grow their own greens.

AIPLUS, A Developer of Smart Home Farming Appliance

Just as every home has a refrigerator, all households may have a smart home farming appliance in the future. AIPLUS is seeking to open a new frontier in agriculture and create another blue ocean in the home appliance industry.

#Power of Businesses l 2019-10-21

© AIPLUS

The 2019 Korea Electronics Show was held at COEX, in southern Seoul, from October 8th to 11th. To mark the 60th anniversary of Korea’s electronics sector, this year’s event was joined by 750 companies both from Korea and abroad to showcase prospective products and technologies of the Fourth Industrial Revolution, with 16 brilliant products receiving the “2019 KES Innovation Award.” For this week’s show, we’ll talk about one of the innovative products and companies that shined at this year’s KES. The company we’ll introduce is called AIPLUS. Let’s hear from its co-founder and CEO, Kwon Oh-yong.

Our home farming appliance, PLANTBOX, can be described as a kitchen garden in the form of consumer electronics. Those who have ever tended a vegetable patch will certainly understand how difficult the job is. It is necessary to learn about vegetables and take great care of them constantly. Many people just give up on the onerous work, so we wondered how to come up with a convenient and stylish tool to ease the hassle. We developed a smart home farming appliance and displayed it at this year’s KES.

© AIPLUS

PLANTBOX is a smart indoor veggie farming solution that won the Best Design award at this year’s KES. It looks like a small refrigerator, unlike conventional vegetable-growing boxes that typically take up a lot of space in apartment balconies. Once users plug in the seed capsules, the machine automatically sets the optimal level of light, temperature, moisture and nutrition for the plants so the users can grow vegetables easily. AIPLUS, a startup that was founded last year, is a spin off from Samsung Electronics’ in-house venture nurturing program.

I entered Samsung Electronics in 2004 and worked at the wireless business department to develop mobile phones. The co-founder of AIPLUS, Choi Seon-muk(최선묵), also worked at Samsung Electronics from 2006, but his job was related to consumer electronics. We thought that my experience in the Internet of Things or IoT and his expertise in home appliances could be combined to create something new.

The idea began to take shape when Choi went to a weekend farm with his children. As I said before, farming is laborious work. They had to work hard, catching bugs, in the hot sun. Exhausted, he stopped visiting the farm. He wondered how to grow vegetables in an easier way. Having heard about his story, I recalled my parents who used to cultivate vegetables and herbs on a rooftop garden.

We thought it would be interesting and meaningful to ease the inconvenience of home farming by using our own respective technology.

So, the idea of the new home farming appliance started from Choi’s painful experience at a local farm. Many people visit weekend farms or grow vegetables in a small patch in their apartment balconies in the hopes of eating fresh vegetables they have cultivated themselves. But most of them give up after some time because it is quite challenging for urban farmers to invest large amounts of time and control the damage caused by harmful insects.

To resolve the problems of home farming effectively, Kwon and Choi used their own knowledge about IoT and consumer electronics, respectively, and developed a new product.

© AIPLUS

In addition to adjusting the temperature and moisture, PLANTBOX uses light-emitting diode or LED lighting to ensure the best wavelengths of light for photosynthesis.

Just like humans, leafy greens need to sleep when the sun sets. In the box, artificial lights appear slowly, just as the sun rises, so the indoor environment can be as similar to nature as possible. Apart from the physical conditions for greens to grow, human touch is also needed. Of course, this is the most challenging part. First, users stick smart seed capsules inside the box, which automatically identifies what kinds of vegetables are put in and sets the best environment for the plants. The indoor environment is connected to the users’ smartphone app through IoT. An alarm will sound on the app to remind them to water the veggies or replace some supplies. That’s all the users have to do, and PLANTBOX will do everything else.

PLANTBOX, a combination of agriculture, home appliance and IoT technology, enables people to raise veggies at home easily without special knowledge or extensive experience in vegetable cultivation.

The inside of the machine consists of three compartments. The bottom part is for watering, replacing consumables and checking the overall conditions. It is the other two compartments in the upper section where plants grow. We call them trays, which serve as a field. When smart seed capsules are put in the trays, nutrients are automatically mixed with the culture fluid on the trays. The plants absorb the nutrients and keep growing on the two trays. Of course, the machine ensures appropriate levels of temperature, moisture and LED lighting. The door can be opened and closed, just like a refrigerator, and is tightly sealed to block the vegetables from outside contaminants. So, users can grow fresh veggies regardless of the season or the weather.

Some companies have produced home farming tools before. But the market response was not very good since they were rather inconvenient to use. Also, there were design and flavor issues.

AIPLUS, a late starter, took a different approach by using a hydroponic cultivation method in a refrigerator-shaped electric appliance and adopting IoT technology. PLANTBOX enables people to enjoy delicious vegetables in their freshest state without using any pesticides. It only occupies 0.2 square meters but produces the same amount of veggies grown in a 3.3 square-meter garden. Users can water the plants just four or five times a month, and some vegetables are fully grown in 25 days. The company has applied for eight patents for the product.

Numerous people who visited AIPLUS’ booth at the recent electronics show were amazed to see the remarkable product. AIPLUS plans to commercialize next year to take the first step in bringing about a major change in the industry.

Currently, refrigerators, air conditioners, TV sets and washing machines comprise a major axis in the home appliance market, while air purifiers, clothing-care systems and body massage chairs are becoming popular these days as well. When a new product is released, market observers generally expect that the market will expand to invigorate the economy.

But what we really want is for PLANTBOX to help people change their lifestyle in a healthier way. Users of the product will realize that vegetables can be so fresh and even tasty, although they may not like veggies very much. They will then consume more vegetables and enhance their nutritional balance. After all, good nutrition and a balanced diet will keep them healthy, possibly preventing and curing high blood pressure, diabetes and obesity over the long term. We hope to provide a product that will bring about a positive change in people’s lifestyles.

Just as every home has a refrigerator, all households may have a smart home farming appliance in the future. AIPLUS is seeking to open a new frontier in agriculture and create another blue ocean in the home appliance industry. We’ll have to wait and see how the company’s innovative product will perform in the market.

Homefarm In 2019

In August, Homefarm had the privilege of partnering with South African premier kitchen design firm Slavin at the Decorex Johannesburg Design show. It was an opportunity to showcase another example of a built-In Homefarm 'double-stack' in a stunning kitchen

In August, Homefarm had the privilege of partnering with South African premier kitchen design firm Slavin at the Decorex Johannesburg Design show. It was an opportunity to showcase another example of a built-In Homefarm 'double-stack' in a stunning kitchen

The Homefarm+Slavin stand really looked incredible, and the organizers agreed; awarding the stand as Best Kitchen Stand of Decorex 2019. The show was a fantastic opportunity for Homefarm and served as the public unveiling of our new Anthracite Grey product edition.

Homefarm also developed an Exclusive Black edition in 2019 when it partnered with another premium kitchen design company; Blu_Line. Homefarm now offers 3 color SKUs; White, Grey, and Black. This means that the Homefarm appliance can now seamlessly fit into your kitchen's color scheme.

Homefarm Product Development in 2019

At Homefarm, we never stop innovating and improving our product.

So far in 2019, since launching the product, we have released major improvements to the Homefarm App and on-board software. We have launched an improved watering system, various gardening merchandise, and the Homefarm Grow Pod System.

Homefarm Grow Pod System

The Homefarm Grow Pod System enables Homefarm users to grow, propagate and clone a variety of different garden crops. Some of our users are using the System to germinate and grow out-of-season, while others are using it to clone their prized plants.

A single Homefarm can grow up to 24 individual plants. Depicted above is a Homefarm growing basil clone cuttings as well as basil seedlings (in the foreground) grown from seed.

Homefarm is currently available for only R8499 from the Homefarm website.

If you enjoy eating fresh, healthy, home-grown food every day or you enjoy gardening; Homefarm is the product for you. It makes a great gift for family and loved ones. Why not treat yourself to one of the most gratifying products on the South African market today.

If you order now, your Homefarm can be delivered to your door, anywhere in South Africa within 1 week. You can email us at info@myhomefarm.io with any queries or to request a product catalog.

The Homefarm Team

MIT Media Lab Director Joi Ito Resigns Amid Epstein Funding Fallout

The director of the Massachusetts Institute of Technology’s Media Lab stepped down on Saturday after a New Yorker magazine article revealed the lab tried to conceal donations from disgraced late financier Jeffrey Epstein, the university said

REUTERS September 7, 2019

Former MIT Media Lab director Joi Ito - Image Credit: MIT Media Lab

(Reuters) — The director of the Massachusetts Institute of Technology’s Media Lab stepped down on Saturday after a New Yorker magazine article revealed the lab tried to conceal donations from disgraced late financier Jeffrey Epstein, the university said.

“This afternoon, Joi Ito submitted his resignation as Director of the Media Lab and as a professor and employee of the Institute,” MIT President Rafael Reif said in a letter posted online.

Ito could not be reached for immediate comment. The New York Times and New Yorker reported he said in an internal email, “After giving the matter a great deal of thought over the past several days and weeks, I think that it is best that I resign as director of the media lab and as a professor and employee of the Institute, effective immediately.”

Last month, Reif said the elite university would review its process for accepting donations after taking about $800,000 from foundations controlled by Epstein, who committed suicide while in jail awaiting trial on sex trafficking charges.

The New Yorker article uncovered deeper fundraising ties between the Media Lab and Epstein and said the institution had actively tried to conceal the extent of its connections with the disgraced financier.

On Saturday, Reif described the acceptance of contributions from Epstein as a “mistake of judgment” and said he had instructed MIT’s general counsel to bring in a prominent law firm to investigate the matter.

“Because the accusations in the (New Yorker) story are extremely serious, they demand an immediate, thorough and independent investigation,” Reif said.

Ito previously apologized for having accepted donations from Epstein and had said he would raise an amount equivalent to the donations the lab received from foundations controlled by Epstein and “direct those funds to nonprofits that focus on supporting survivors of trafficking.”

The New Yorker said Ito disclosed this week he received a further $1.2 million from Epstein for investment funds under Ito’s control and $525,000 for the lab. Epstein also secured $7.5 million in donations for the lab from other wealthy individuals.

On Saturday, Ito also resigned from the board of directors of The New York Times Co and of PureTech, a biotechnology firm, according to statements from the two companies.

Mini Greenhouse For Microgreens

The fully automated "Plantcube" greenhouse from Munich-based company Agrilution offers a closed ecosystem for plants and, according to the manufacturer, optimal growth conditions. Irrigation is done automatically

Automated Ecosystem From Agrilution

The fully automated "Plantcube" greenhouse from Munich-based company Agrilution offers a closed ecosystem for plants and, according to the manufacturer, optimal growth conditions. Irrigation is done automatically.

The fully automated greenhouse "Plantcube" / Image: Agrilution

The high nutrient density ensures an intense aroma and pronounced textures. Currently, 17 different lettuces, microgreens and herbs can be selected from the Agrilution range, among which there are unusual varieties such as red Pak Choi or Wasabina leaf mustard. The system is controlled by the Agrilution Cloud and a user-friendly app provides insight into the growth process and notes on maintenance and harvesting. The "Plantcube" is the size of a small refrigerator.

For more information:

Agrilution GmbH

Centa-Hafenbrädl-Str. 61

81249 München

Telefon: +49 89 230 292 92

E-Mail: info@agrilution.com

www.agrilution.com

Publication date: 9/19/2019

MIT Built A Theranos For Plants

The prestigious multidisciplinary MIT Media Lab built a “personal food computer” that worked so poorly that demos had to be faked Theranos-style, per a weekend report in Business Insider

September 8, 2019

The MIT Media Lab’s failed “personal food computer.” Screenshot: Seeker (YouTube)

The prestigious multidisciplinary MIT Media Lab built a “personal food computer” that worked so poorly that demos had to be faked Theranos-style, per a weekend report in Business Insider. Word of the project’s troubles comes as the Media Lab’s attempts to cover up its extensive financial ties to late financier and alleged sex trafficker Jeffrey Epstein have seriously damaged its credibility and led to resignation of its director, Joichi Ito.

According to Business Insider, the project—a plastic hydroponic grow box filled with “advanced sensors and LED lights” that would supposedly make it possible to replicate crop conditions from any part of the global—was a sham, with MIT’s Open Agriculture Initiative director Caleb Harper resorting to faking demos:

Ahead of big demonstrations of the devices with MIT Media Lab funders, staff were told to place plants grown elsewhere into the devices, the employees told Business Insider.

In another instance, one employee was asked to purchase herbs at a nearby flower market, dust off the dirt in which they were grown, and place them in the boxes for a photoshoot, she said... The aim was to make it look like the devices lived up to Harper’s claims, the employees said. Those claims, which included assertions that the devices could grow foods like broccoli four times faster than traditional methods, landed Harper and his team articles in outlets ranging from the Wall Street Journal to Wired and National Geographic.

All told, Business Insider’s sources said, the “personal food computers” amounted to hydroponic boxes that don’t work. Dietitian and former Open Agriculture Initiative project manager Paula Cerqueira told the site that the devices she worked on were “glorified grow boxes... with some sensors for collecting data,” and that on multiple occasions staff filled them with store-bought plants that had to be washed of dirt before presentations with funders. The boxes also weren’t air-tight, Cerqueira added, meaning that users couldn’t control for things like carbon dioxide levels or temperature and humidity.

Cerqueira told Business Insider that out of dozens of units sent to schools in the Boston region, only a handful ever worked. On one occasion, the Media Lab sent 30 of them to schools, and “It’s fair to say that of the 30-ish food computers we sent out, at most two grew a plant,” Cerqueira told the site. On another, the Media Lab couldn’t make the boxes work in time for a demo with a representative from the Bezos Family Foundation, something Cerqueira told Business Insider was “super embarrassing.”

In other words, this sounds a hell of a lot like Theranos, the disastrously failed startup that also promised a magical technology box (though in their case, it was fake blood-testing technology that helped the company achieve a valuation of $9 billion.) The food computer certainly doesn’t come anywhere the scale of Theranos, but Harper touted it with similarly grandiose claims: In a March 2019 video by Seeker, Harper stated that “You think Star Trek or Willy Wonka, that’s exactly what we’re going for.”

According to Business Insider, Harper directed an email requesting comment to an MIT spokesperson, who “didn’t provide a comment.”

Explore Future of Food In Virtual Reality At University of Cambridge Festival of Ideas

Did you know that only 20 per cent of the fish we harvest each year actually ends up in our stomachs? Now Natural Machines is using its Foodini 3D printing technology to create an edible product from offcuts that would otherwise be wasted

By Paul Brackley- paul.brackley@iliffemedia.co.uk

08 September 2019

Did you know that only 20 percent of the fish we harvest each year actually ends up in our stomachs?

Now Natural Machines is using its Foodini 3D printing technology to create an edible product from offcuts that would otherwise be wasted.

Future Kitchen VR workshop in the Botanic Garden's classroom, Esme Booth with a device being placed on Emanuel Bernardo. Picture: Keith Heppell. (15994444)

And, in an immersive virtual reality video that you can see at the University of Cambridge’s Festival of Ideas, you can go inside the 3D printer as it operates.

It is one of an extraordinary series of food technology videos released on FoodUnfolded.com, created by an international team involving the university.

Designed to show how food tech can improve the sustainability of our food and transform ways it is produced, the series of videos in the ‘Future Kitchen’ project gives viewers a 360-degree, fully immersive experience that makes them feel like they are part of the story

.Dr Holly T Kristinsson, consultant for innovation and market analysis at Matis and co-ordinator of the Future Kitchen project, says: “We are trying to explore the potential of virtual reality to connect people with food tech more effectively.

“With consumer trust in the food system at an all-time low, we need to step up, reconnect with people and inspire them.”

Another video explores how farmers in Iceland are able to grow tomatoes despite the sub-zero temperatures outside. Viewers get to look around the greenhouses, powered by geothermal or hydropower energy. Bees are brought in to pollinate the tomato plants - and no pesticides are required.

“When we are using the bees, we get something like a 90-95 per cent yield from the plants, which is an enormous increase from a farmer’s point of view,” horticulturalist and biologist Guðríður Helgadóttir tells viewers.

A third video explores Plantcube, an intelligent vertical farming system for the home, created by Agrilution.

The German company was founded by Max Loessl and mechatronics engineer Philipp Wagner to bring the freshest vegetables, salads and herbs to the home, grown without pesticides and as close and to the place of consumption as possible. The Plantcube - which will set you back 2,979 euros - provides an indoor garden for growing lettuce, microgreens and herbs on eight ‘fields’, with automated watering, optimal LED lighting and sensor-based climate control.

Future Kitchen VR workshop in the Botanic Garden's classroom, Esme Booth with a device. Picture: Keith Heppell. (15994450)

This vertical farming system even notifies you via an app of the perfect time to harvest to your food.

The VR project is funded by EIT Food, Europe’s leading food innovation initiative, and is a response to the need to connect, and reconnect, people with food.

While technology in a food context tends to have negative connotations among the public, the series aims to show how it can be used to improve sustainability.

The makers believe it could act as a pilot for the food industry to help engage consumers as well as entice those interested in food-related careers.

Further videos are coming, which will introduce viewers to future kitchen devices, explore the origin of food, robotics, metabolomics, personalised nutrition, macro and micro algae processing and novel food processing, including how alternative proteins are made.

Regular focus group lunchtime sessions are being held in Cambridge where visitors can view the videos and share their thoughts.

After watching the Foodini video, one University of Cambridge student said: “I never knew how 3D printing food worked, and to be immersed in the whole process is fascinating.”

And at the Festival of Ideas - supported by the Cambridge Independent once more this year - two sessions will be held at the Alison Richard Building on West Road on Saturday October 19 to introduce members of the public to the videos. Bookings open on September 23.

This Brilliant Hydroponic System Puts A Whole Garden On Your Countertop

Growing your own food is one of life’s great pleasures—plus it’s good for you and for the environment. But in increasingly tight, urban homes, we don’t all have room for gardens

08.19.19

It’s Not Just A Garden—It’s A Work of Art

[Photos: courtesy Bace]

Growing your own food is one of life’s great pleasures—plus it’s good for you and for the environment. But in increasingly tight, urban homes, we don’t all have room for gardens. And hydroponic systems, as appealing as they may be, often appear to be a whole lot of hardware for only a bit of actual green. Some fresh arugula would be nice for dinner, but who wants giant plastic box taking up half their kitchen to get a few leaves?

[Photo: courtesy Bace]

The Rotofarm, by an Australian company called Bace (which appears to have produced skincare products in a past life), is a space-friendly hydroponic system, and it doubles as a beautiful sculpture in your home. With a circular design, which rotates plants like a Ferris wheel through the day, the Rotofarm is able to fit nearly five feet of growing area inside a countertop footprint of just 11 inches. Water is dispersed through the nutrient and water reservoir in the stainless steel base, and a bright LED grow light lives in the middle like a tiny sun. Then to harvest, you can tilt the farm 180-degrees and pull off its clear cover. You take what you want (kale, mint, lettuce, spinach, or, yes, marijuana), and close it back up.

Of course, you might be wondering, will it work? Can you grow plants upside down? In fact, you can. NASA has discovered that root systems understand how to grow just fine in zero gravity. Meanwhile, existing rotary systems like the Omega Garden contend that moments of flipped gravity can actually help plants grow and flower, but you wouldn’t want the Omega Garden’s giant drums in your apartment. “The rotary design has been around in agriculture for a while, but these are things that take up a whole room with giant troughs of water underneath,” says Bace’s founder Toby Farmer (yes, his name is “farmer”). “Rotofarm is the first concept that really belongs inside the home.”

[Photo: courtesy Bace]

The Rotofarm is supposed to debut on Kickstarter next month. Despite connecting with Farmer on email, we’re left with all sorts of questions about its true feasibility. Will you need to buy the special, potentially expensive fertilizer packets for the machine seen in the teaser video? What’s the monthly power usage like? How will some teased automation features—from misting to overgrowth sensors—actually work? And of course, what will the whole thing cost?

As a prototype, the Rotofarm is intriguing. As a product, it has all sorts of everyday execution details that need to be just right for the system to be a productive joy rather than a big, annoying, green lamp. That said, so far, so good. Rotofarm offers a convincing thesis on the future of urban gardening. Now we’ll see if the Bace product team can deliver it.

ABOUT THE AUTHOR

Mark Wilson is a senior writer at Fast Company who has written about design, technology, and culture for almost 15 years. His work has appeared at Gizmodo, Kotaku, PopMech, PopSci, Esquire, American Photo and Lucky Peach

The Epstein-Funded MIT Lab Has An Ambitious Project That Purports To Revolutionize Agriculture. Insiders Say It’s Mostly Smoke And Mirrors

Ahead of big demonstrations with MIT Media Lab funders, staff were told to place plants grown elsewhere into the devices, the insiders said. In other instances, devices delivered to local schools simply didn’t work. “It’s fair to say that of the 30-ish food computers we sent out, at most two grew a plant,” one person said

Erin Brodwin, Business Insider US

September 7, 2019

Shutterstock

Insiders told Business Insider that MIT Media Lab faked key elements of its “personal food computer” project (not pictured), which aimed to grow plants without soil.

An ambitious MIT project that purported to turn anyone into a farmer with a single tool is scraping by with smoke-and-mirror tactics, employees told Business Insider.

Ahead of big demonstrations with MIT Media Lab funders, staff were told to place plants grown elsewhere into the devices, the insiders said.

In other instances, devices delivered to local schools simply didn’t work.

“It’s fair to say that of the 30-ish food computers we sent out, at most two grew a plant,” one person said.

MIT didn’t provide a comment for this story.

An ambitious project that purported to turn anyone into a farmer with a single tool is scraping by with smoke-and-mirror tactics, employees told Business Insider.

The “personal food computer,” a device that MIT Media Lab senior researcher Caleb Harper presented as helping thousands of people across the globe grow custom, local food, simply doesn’t work, according to two employees and multiple internal documents that Business Insider viewed. One person asked not to be identified for fear of retaliation.

Harper is the director of MIT’s Open Agriculture Initiative and leads a group of seven people who work on transforming the food system by studying better methods of growing crops.

The food computers are plastic boxes outfitted with advanced sensors and LED lights and were designed to make it possible for anyone, anywhere to grow food, even without soil, Harper has said. Instead of soil, the boxes use hydroponics, or a system of farming that involves dissolving nutrients in water and feeding them to the plant that way.

“We design CO2, temperature, humidity, light spectrum, light intensity, and the minerality of the water, and the oxygen of the water,” Harper said.

On Saturday, Joi Ito, the director of the MIT Media Lab, resigned following a lengthy expose in the New Yorker about the Media Lab’s financial ties with late financier Jeffrey Epstein. Epstein died by suicide while in jail and faced sex-trafficking charges.

Staff placed food grown elsewhere into the devices for demos and photoshoots, they say

Ahead of big demonstrations of the devices with MIT Media Lab funders, staff were told to place plants grown elsewhere into the devices, the employees told Business Insider.

In another instance, one employee was asked to purchase herbs at a nearby flower market, dust off the dirt in which they were grown, and place them in the boxes for a photoshoot, she said.

Harper forwarded an email requesting comment on this story to an MIT spokesperson. The spokesperson didn’t provide a comment.

The aim was to make it look like the devices lived up to Harper’s claims, the employees said. Those claims, which included assertions that the devices could grow foods like broccoli four times faster than traditional methods, landed Harper and his team articles in outlets ranging from the Wall Street Journal to Wired and National Geographic.

Harper’s vision for the personal food computer is bold: “You think Star Trek or Willy Wonka, that’s exactly what we’re going for,” he said in a March 2019 YouTube video produced by the news site Seeker.

Harper’s coworkers told Business Insider a different story. They said the devices are basic hydroponic setups and do not offer the capabilities Harper outlines. In addition, they simply don’t work, they said.

MIT Media Lab’s Caleb Harper speaks at TEDGlobal Geneva. James Duncan Davidson/TED

‘They were always looking for funding’

Paula Cerqueira, a researcher and dietitian who worked as a project manager at the Open Agriculture Initiative for two years, told Business Insider that the personal food computers she worked with were “glorified grow boxes.”

Cerqueira was part of a team that, on several occasions, delivered the personal food computers to schools. She also helped demonstrate the boxes to big-name MIT Media Lab investors.

During the organization’s “Members Weeks” – once-a-semester events that drew donors including Google, Salesforce, Citigroup, and 21st Century Fox – Cerqueira and her coworkers would show investors how the technology worked.

On one occasion, Cerqueira said, her coworkers were told to fetch basil grown from a nearby location and place it into the personal food computers to make it look like it had been grown inside the boxes.

“They wanted the best looking plants in there,” Cerqueira told Business Insider. “They were always looking for funding.”

Cerqueira said in another instance, she was told by another MIT Media Labs manager to buy edible lavender plants from a nearby flower’s market and place them in the boxes for a photoshoot, she said. Before any photos were taken, she carefully dusted off the tell-tale soil on the plants’ roots.

The boxes simply didn’t work, one employee told Business Insider

The central problem with the personal food computer was that it simply didn’t work, Cerqueira and another person with knowledge of the matter told Business Insider.

“It’s essentially a grow box with some sensors for collecting data,” Cerqueira, a dietitian who worked as a project manager at the Open Agriculture Initiative for two years, told Business Insider. Cerqueira left her post after becoming increasingly frustrated with working conditions at the Media Lab, she said.

The boxes were not air-tight, so staff couldn’t control variables like the levels of carbon dioxide and even basic environmental factors like temperature and humidity, Cerqueira and the other person said.

Other team members were aware of these issues, according to several internal emails that Business Insider viewed.

One email, on which Harper is copied, also said that team members weren’t given the chance to test the devices’ functionality for themselves. Another person with knowledge of the matter also described these issues to Business Insider.

‘Of the 30-ish food computers we sent out, at most two grew a plant’

In the Spring of 2017, Cerqueira was part of a pilot program that delivered three of Harper’s devices to local schools in the Boston area. Initially, the idea was for the students to put the devices together themselves. But Cerqueira said that didn’t work – the devices were too complex for the students to construct on their own.

“They weren’t able to build them,” Cerqueira said.

In response, Cerqueira’s team sent three MIT Media Lab staff to set up the computers for them. Of the three devices the staff members tried to setup, only one was able to grow plants, she said. That one stopped working after a few days, however.

When Cerqueira and her coworkers would visit the school, students would joke that the plants they were growing in plastic cups were growing better than the ones in the personal food computers, she said. The pilot ended shortly thereafter.

On another occasion, her team sent two dozen of the devices to classrooms across greater Boston as part of a curriculum being designed by one of MIT Media Lab’s education partners.

“It’s fair to say that of the 30-ish food computers we sent out, at most two grew a plant,” Cerqueira said.

No one knew exactly what was wrong, but in general, the team was aware that the devices weren’t functioning as they should be. In a last-ditch attempt to make the devices deliver, Cerqueira’s team sent new packages of fresh seedlings to the school. When that didn’t work, they tried it again. No matter what, the plants just kept dying, according to Cerqueira.

At one point, a representative from the Bezos Family Foundation, a private nonprofit foundation cofounded by Jackie and Mike Bezos, stopped by the school for a visit, Cerqueira said. Harper had been hoping to entice the group to help fund a new foundation that he was just getting off the ground. Even then, the devices wouldn’t work.

“It was super embarrassing,” said Cerqueira.

Want to tell us about your experience with MIT Media Lab? Email the author at ebrodwin@businessinsider.com.

Heliponix Capturing Innovation And Hearts In Indiana's Great Southwest

Heliponix is an Agriculture Technology company that sells the GroPod to consumers. The GroPod is a revolutionary smart appliance that grows fresh produce in your home any time of year with an organic seed-pod subscription without any preservatives or pesticides

See The First GroPod One In-Person At The Purdue University Graduate Student Plant Science Symposium on August 1 At The Beck Agricultural Center.

Heliponix is an Agriculture Technology company that sells the GroPod to consumers. The GroPod is a revolutionary smart appliance that grows fresh produce in your home any time of year with an organic seed-pod subscription without any preservatives or pesticides.

The business model is similar to the keurig k-cup model, but is also a practical solution to counter the environmental damage wreaked by conventional soil agriculture since it uses hydroponics which grows produce faster with 95% less water. This is important because the human population will reach 9.8 Billion in the year 2050 which will increase food demand by 70%. This will likely not be met with current agriculture practices in the US accounting for almost 80% of all freshwater consumption and 50% of land use.

Heliponix was co-founded by Southern Indiana natives, Scott Massey and Ivan Ball. Although they did not know each other before completing their respective engineering degrees at Purdue University, they met each other as co-working on a NASA funded research study at Purdue.

There, there research energy efficent LED lighting spectrum optimization to reduce the energy consumption of the hydroponic growing systems on the International Space Station. As undergraduate students, they had the idea to create an IoT (internet of things) appliance that would automate the complex process of hydroponics so every-day consumers would have the ability to grow their own produce at home. They then competed in business plan competitions at various universities and research institutions to raise several hundred thousand dollars in funding to commercialize their proprietary technology. Purdue University was among their first investors through their venture division focused on innovations within the agricultural and biological engineering domain.

Heliponix won first place in the Evansville Regional Pitch Competition after debuting considerable traction bringing the GroPod to market as well as the their first production model from their manufacturing facility that will have the capability to produce several thousand GroPods.

Scott Massey said: “We considered many other cities when deciding where to locate a high-tech appliance company such as Heliponix. Fortunately, the Ohio River Valley is fertile in engineering talent and manufacturing plants to produce our exact product. We will continue creating high-paying jobs as we define an entirely new frontier for agriculture. In the not so distant future, the majority of culinary herbs, microgreens, and leafy green vegetables will be grown indoors as consumers favor the flavor, health, and food safety benefits of fresher food. That’s why we are excited to advance to the state finals since our company truly has so much growth potential for our region.”

Indoor Garden Works’ (IGWorks™) iHarvest Kickstarter Introduces A Beautiful, Soilless Indoor Garden For Growing Big Fruits And Vegetables At Home

IGWorks™ announces the April 16th launch of their Kickstarter campaign for the patent pending iHarvest™: a beautiful hydroponic system that will reinvent vegetable gardening

April 14, 2019 | San Clemente, California

IGWorks™ announces the April 16th launch of their Kickstarter campaign for the patent pending iHarvest™: a beautiful hydroponic system that will reinvent vegetable gardening.

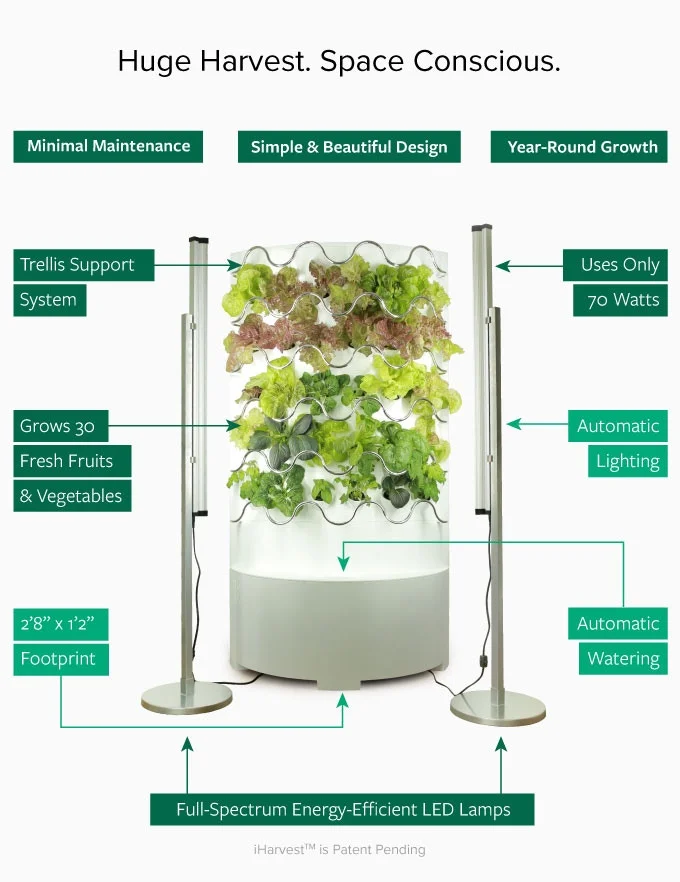

“All the existing systems were either too small to grow real food or too ugly to enjoy with your family and friends,” shared founder and CEO Dave Stevens. The solution was a hydroponic, automated and fully self-contained system that simultaneously grows up to 30 fruits and vegetables, all within 2.5 sq. feet of floor space.

The iHarvest™ makes it easy for the indoor home gardener to grow a wide variety of fruits and vegetables, including cucumbers, strawberries, beans and more, while saving up to $1,000 a year on groceries.

The Perfect Garden for Small Spaces

Smaller indoor and outdoor spaces, limited time, harsh seasons and unpredictable climates can make it increasingly challenging to grow healthy produce at home. “We knew that the answer lied in hydroponics; however, the existing systems were either unattractive, cumbersome, costly or challenging to use,“ said Stevens. “I wanted an attractive, indoor garden that could easily fit into the smallest apartment, while also providing enough produce to help feed a family year-round.”

Realizing that there was nothing on the market that met his needs, Stevens enlisted a team of individuals, including engineers and business advisors, to bring iHarvest™ and IGWorks™ to life. The result was an eye-catching self-contained growing wall that enhances spaces with a burst of greenery and light.

Experience how iHarvest™ will reinvent indoor gardening:

Faster Growing Time – Harvest your produce 30-50% faster than traditional vegetable gardens

Fresh, Healthy Produce –Grow your food precisely the way that you want it including zero pesticides, zero herbicides, and without GMO’s.

Automated LED Lights – High-efficiency, visually pleasing, full spectrum LED lights allow the user to predetermine when the sun rises and sets while using the same amount of energy (72W) of a standard lightbulb.

95% Less Water – Requires 20 X less water than traditional growing methods

Vertical Design – Fits in the smallest of spaces, while the included trellis easily accommodates hanging vegetation.

Easily Assembled - Simply add seeds to the medium, place into the pod, add water and grow.

Early Kickstarter supporters will receive the iHarvest™ for a substantially reduced price, $449 versus the projected retail price of $850, a 47% savings. “This innovative system will reinvent the way that consumers look at indoor gardening, making it easy to grow fresh produce in every home,” said Stevens. “By supporting iHarvest™ on Kickstarter, supporters can help bring the future of gardening to market.”

Visit the iHarvest™ pre-release Kickstarter page, learn more about what inspired the product, and see how iHarvest™ will transform the way that we look at indoor produce gardening.

Lettuce Grow’s Subscription Service Promises to Make Texas Gardening Much Simpler

Actress Zooey Deschanel at the Lettuce Grow launch party. Photo by: Julia Keim.

BY PAULA FORBES

March 13, 2019

Growing plants in Texas involves a steep learning curve. Even if you grew up seeding and weeding at the side of a knowledgable green thumb, there’s a lot of collective wisdom to internalize before you’re harvesting your own vegetables. Our warmer winters mean an entirely different planting schedule than is suggested on the backs of seed packets. Scorching hot summers require vigilant water management. Plus, the bugs more than live up to that old cliche that everything is bigger in our state.

Lettuce Grow, a startup from Emmy- and Grammy-nominated actor and singer Zooey Deschanel (known for New Girl, 500 Days of Summer, and the musical duo She & Him) and her husband, entrepreneur Jacob Pechenik, is an attempt to make that curve a little less steep. On March 10, 2019, at the South Congress Hotel, they hosted a launch party for the Austin-based company, which will begin shipping to its first subscribers soon.

The couple, who have two young children, split their time between Austin and Los Angeles and are familiar with the peculiar challenges of growing veggies here. “In a place like Texas, you have these [weather] extremes,” Pechenik says. With their backyard hydroponic system and accompanying subscription service, he claims, they want to enable people to “grow twenty percent of their food.” It’s an ambitious goal, but Lettuce Grow automates many aspects of gardening, effectively giving its customers a shortcut to homegrown produce. “You might not have a green thumb,” Deschanel says. “We want to do all the extra work that might stop people from growing a garden at their house.”

Here’s how it works: When you sign up, Lettuce Grow ships you one of their “farms.” Made from ocean-bound plastic (plastic that wouldn’t have been recycled otherwise), the farms are vertical hydroponic gardening systems. Hydroponics is a method of growing plants without soil. You set the grower in a sunlit area, fill it with nutrient-enriched water, plug it in, and then add the seedlings that Lettuce Grow ships you monthly. That’s it, more or less.

Deschanel and Pechenik in front of two of Lettuce Grow’s “farms” at the launch party on Sunday, March 10, 2019. Photo: Laura Hajar

The plant varieties have been selected to work well based on your geographic location, and the types of plants Texans can expect to receive through the subscription service will be tailored to the seasons and the weather. Lettuce Grow works with local farms to grow the seedlings. In Austin that farm is Agua Dulce, owned by Deschanel and Pechenik’s Farm Project. Varieties are tested and chosen for flavor, yield, insect resistance, climate compatibility, and more.

The goal is to get your Lettuce Grow farm to a point where it’s producing enough vegetables that you can harvest some every day. That way, says Pechenik, “you can start to build a lifestyle around eating at home, cooking at home.” The company has an accompanying app that advises when to harvest; advises when to clean, add nutrients, or add water to the Farm; and provides recipes and tips for eating your bounty. You can even send in photos of your plants if they seem to be struggling, and they’ll offer advice—or change the variety of plants in your subscription box to some better suited to your space.

All of this hand-holding comes at a price: Farms range from $399 to $469 depending on size, and the accompanying subscriptions cost between $49 and $69 monthly. But Lettuce Grow claims that, at peak season, the smallest farm produces $78 worth of produce a month—so if you stick with it, you’ll eventually save money. For those who want to garden and can afford the system, it removes plenty of hurdles to starting a garden. (Lettuce Grow also donates one farm and accompanying membership to “a school or community-based organization” for every ten subscriptions it sells.)

Pechenik discusses one of the company’s hydroponic growing systems.

Laura Hajar

“I am drinking the Kool-Aid,” says Stephanie Scherzer of Austin’s Rain Lily Farm, who has worked closely with Lettuce Grow in selecting varietals and growing seedlings. She admires the system for being accessible to children and the elderly as well as its performance. Scherzer says she’s been able to grow watermelon, eggplant, and peppers in her prototype farm and that the cooling properties of the hydroponics system extended the Texas growing season for crops like thyme, watercress, and kale. (For now, the service sends members mostly greens and herbs, but greater variety is planned.)

Deschanel says she’s enthusiastic about Lettuce Grow because “it’s really such an advantage to grow your own food.” She notes that freshly picked vegetables retain the most nutrients and that picking only as much food as you need to eat can reduce food waste. She adds that her daughter loves picking the vegetables, and the Lettuce Grow system provides a starting point to get kids involved in gardening. “It’s a great way to explore the food you’re eating and explore healthier options too.”

Lettuce Grow is taking preorders for its first round of subscriptions. Farms begin shipping in three to five weeks, and it’s available nationwide.

Continuously Growing Microgreens At Home

The perfect present for a food-loving tech nerd should be an innovation that can be labeled as smart, urban and sustainable. Well, the Mizzle microgreen cultivator ticks all the boxes.

The concept, which is not for sale yet, is a product of designers Gökhan Cetinkaya & Deniz Ibanoğlu and a winner of the iF Design Talent Award. The duo designed a smart aeroponic kitchen for consumers to grow microgreens at home.

The Mizzle is divided into three compartments: the first one is for germination in a dark, closed space. The seeds are placed in a tray and once ready they can be pushed to the next compartment, where the microgreens can grow under sunlight or LED light. Once the third compartment has been fully harvested, a new growing pad with seeds can be placed in the tray and can be slid into the germination cell. This way the system allows the consumer to produce microgreens continuously.

What is even more convenient is that the user can install a specially designed app to follow the growing cycles and to get notified when they have to add water.

Read this article from Designboom to get more information.

Publication date : 2/22/2019

Author: Jobke den Hertog

© HortiDaily.com

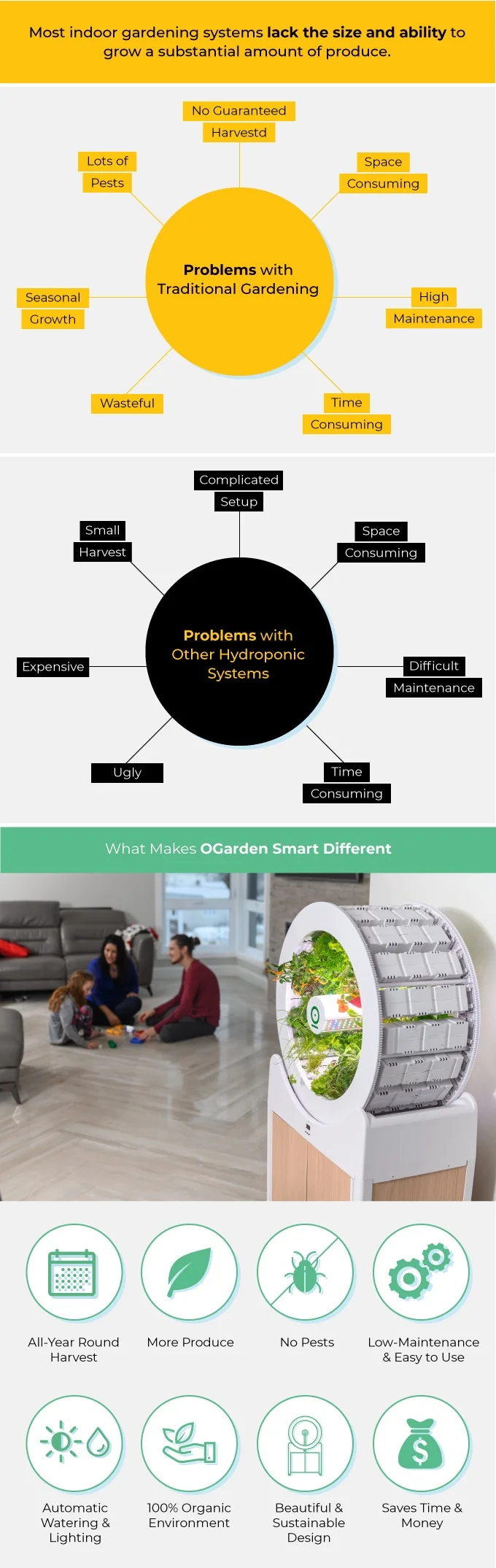

OGarden Smart: Grow An Indoor Garden of 90 Fruits & Veggies

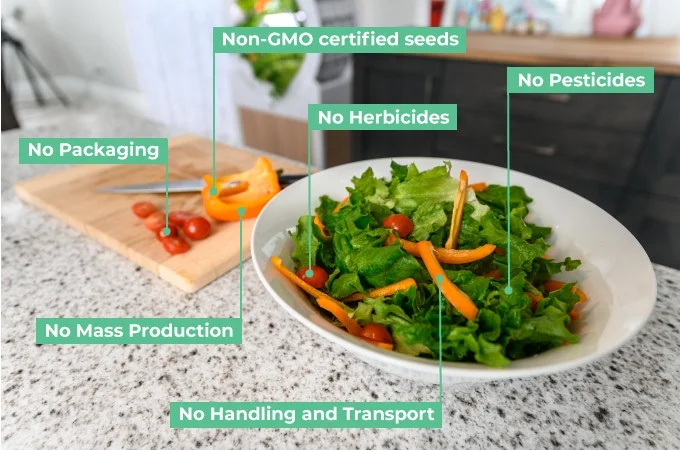

The OGarden Smart can grow up to 90 fruits, veggies and delicious aromatic herbs at once, so you can enjoy an abundance of super fresh food.

Automatic watering makes using OGarden Smart virtually effortless, and the automatic low energy consumption LEDs simulate the perfect amount of sunlight, offering optimal year round growth (and will automatically turn on and off for convenience and energy conservation)

All you need to do is plant a seed, make sure there is enough water in the tank (only once a week), and you can harvest your produce 30 to 40 days later, that’s it! And don’t forget to send the roots to the compost bin and start the life cycle again.

There are 90 available spots, so with a good rotation, you can have 2-4 large vegetables a day, every day.

Why is OGarden’s growth so efficient? And why is it so easy?

The key is in the cup of seeds. Made with organic soil and fed with all the organic fertilizer it needs, our seed cups create the perfect environment for the plant to grow. they’re also super clean! No spilled dirt or fuss. With a 100% biodegradable membrane, the seed cups stay in place without any mess.

OGarden Smart’s LEDs simulate the perfect amount of sunlight that your produce needs to thrive. No more worrying about which seasons to grow your produce in. No matter the conditions outside, OGarden Smart will grow up to 90 fruits and veggies at once, with 20 different varieties to choose from.

Is your favorite vegetable or fruit not on the list? No problem! With the Empty seed cup, you can sprout your own seeds. Have fun and grow your own original plants. We'd love to see what you grow! Take photos of your harvest and share them with the Ogarden Smart community.

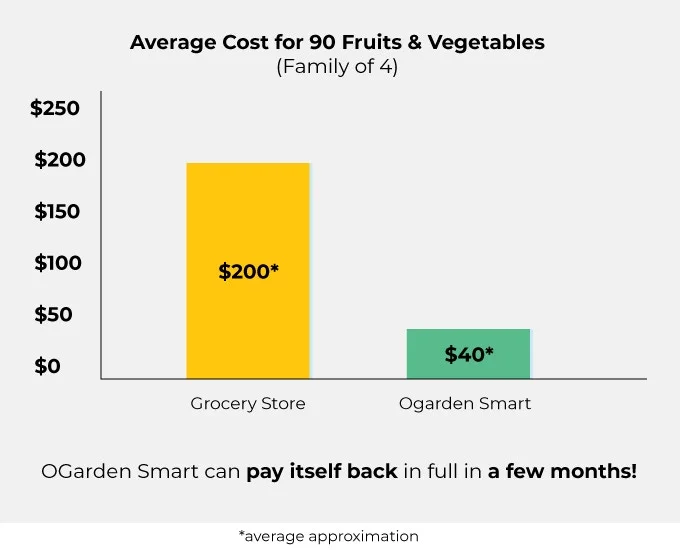

According to the U.S. Department of Agriculture, it costs a family of four an average of $850 per month for groceries*. OGarden Smart can save you up to 80% on your veggie expenses - allowing you to cut down your grocery bill.

*Official USDA Food Plans: U.S. Average, November 2017

With OGarden, you can get fully grown, pesticide-free veggies for as low as $0.45 cents!

By producing your vegetables, fruits, and herbs directly at home, you know the quality of the air, the water and environment they grow in. Have peace of mind knowing that all of your fresh produce is grown in a 100% organic environment.

WHAT COMES IN THE BOX:

● The Ogarden Smart (disassembled) ;

● 30 Empty seed cups;

● 3 packs of seeds (Basil, Chinese cabbage Tat-soi, Lettuce Green Oak Leaf)

Additional Empty cups and multiple varieties of seeds are available on the online shop.

NOW ON KICKSTARTER (Feb.12th)

Grow Strong: African Farmers, Entrepreneurs Revamp Agriculture Norms Through Purdue Partnership

Scott Massey, a Purdue University graduate and founder of Heliponix, a company that makes an appliance that fits under a kitchen counter and grows produce year-round, is hoping to change that by bringing sustainable agriculture methods in Cameroon.

January 28, 2019

Scott Massey, founder of hydroponics startup Heliponix, discusses agricultural innovations with Togonese students as a part of his first Mandela Washington Fellowship. In 2019, Massey will workshop at Cameroonian universities, empowering students interested in agricultural innovation and entrepreneurship. (Photo provided) Download image

WEST LAFAYETTE, Ind. – Many farmers in the Republic of Cameroon usually grow just enough food to feed their families due to limited fertilizer and high-yield seeds, coupled with poor soil quality and lack of irrigation.

Scott Massey, a Purdue University graduate and founder of Heliponix, a company that makes an appliance that fits under a kitchen counter and grows produce year-round, is hoping to change that by bringing sustainable agriculture methods in Cameroon.

Massey has been selected for a second Mandela Washington Fellowship to lead educational workshops at Cameroonian universities this month. Approximately 200 million hectares of suitable land remains unfarmed across Africa, causing many observers to wonder how African nations can unlock their full agricultural potential.

The Mandela Washington Fellowship seeks to promote agricultural development through the academic and entrepreneurial empowerment of African peoples.

“African entrepreneurs have immeasurable economic opportunities to market solutions using new agricultural technologies,” Massey said. “Our overall goal is to provide these resilient people the means to their own production and permanently break the cycle of dependency on foreign aid.”

Massey has used his extensive knowledge in hydroponic systems and agricultural engineering to develop GroPod, an in-home appliance that grows produce year-round. His background also gives him the unique expertise to teach innovative and sustainable farming techniques in Cameroon.

“In these workshops, we are implementing a new vertical farming technique that utilizes an adaption of the proprietary vertical farming technology also used in GroPod,” Massey said. “Not only will we be teaching the students about these advanced technologies that they can use to start their own businesses, but we will also be building model farms that they can incorporate into their curriculums to grow clean food.”

On this trip, Massey will travel with Daliwa Joseph Bainamndi, another Mandela Washington fellow, to give Cameroonian farmers vital information on developing and incorporating innovative farming practices into their work. The pair will lead lectures on hydroponic farming, entrepreneurship, 3D printing and computer-assisted design at the University of Ngaoundéré, University of Ngoa-ékélé and the agriculture school of Institut Superieur des Sciences et Techniques de Yaounde.

In general, African farmers struggle against nonexistent agricultural infrastructure and poor farming conditions, making subsistence farming the most advantageous practice. However, Massey and Bainamndi’s work could empower Cameroonian students and farmers to expand operations sustainably and successfully through entrepreneurship and innovation.

Massey’s work aligns with Purdue's Giant Leaps celebration of the university’s global advancements made in health, space, artificial intelligence and sustainability as part of Purdue’s 150th anniversary. Those are the four themes of the yearlong celebration’s Ideas Festival, designed to showcase Purdue as an intellectual center solving real-world issues.

Massey received his first Mandela Washington Fellowship in 2018 when he traveled to Togo, Africa, to teach farmers there about the farming usages of hydroponics systems. Read more about his first trip here.

“This diplomatic humanitarian mission will fight the war against hunger on its front line and expand the addressable technology market to maximize global impact,” he said. “I look forward to the day that Africa becomes an environmentally and economically sustainable farming model.”

About Purdue Foundry

The Purdue Foundry is an entrepreneurship and commercialization accelerator in Discovery Park's Burton D. Morgan Center for Entrepreneurship whose professionals help Purdue innovators create startups. Managed by the Purdue Research Foundation, the Purdue Foundry was co-named a top recipient at the 2016 Innovation and Economic Prosperity Universities Designation and Awards Program by the Association of Public and Land-grant Universities for its work in entrepreneurship. For more information about funding and investment opportunities in startups based on a Purdue innovation, contact the Purdue Foundry at foundry@prf.org.

Writer: Kelsey Henry, 765-588-3342, kehenry@prf.org

Purdue Research Foundation Contact: Tom Coyne, 765-558-1044, tjcoyne@prf.org

Source: Scott Massey, scott@heliponix.com

Evansville, A Home For Business

Back text: “E — Scenic View of Ohio River, V — Reitz Memorial High School, A — Vandenburgh County Courthouse, N — Adm. Bldg., Evansville College, S — Evansville National Guard Armory, V — Dade Park Race Track, I — Electric Fountain, Garvin Park, L — Greyhound Bus Station, L — Lions Den, Mesker Park Zoo, E — Dress Plaza”

After graduating from Purdue University in May 2017, I continued to rent co-work space on campus in West Lafayette working for Heliponix full-time until my apartment lease ended at August 2017. At the time, I was hyper focused on the engineering design tasks at hand for Heliponix to debut a new prototype GroPod™ at the Forbes AgTech Summit. After the summit ended, I brought all of my possessions back to Evansville. It occurred to me I was once again living in Evansville only after I had moved back home. Upon moving back, I was asked to speak at Evansville’s Tech on Tap weekly entrepreneurial meetup where I was asked why I came back. I answered, “Evansville is home, and I can continue working on my company without paying myself by living with my parents.” This seemingly obvious answer spurred a new found sense of urgency that if I were to scale a technology company, than I must leave southern Indiana for greener pastures. I then began to look for every possible reason why I should move away from Evansville for the benefit of Heliponix. I identified the following four reasons why I could not headquarter Heliponix in Evansville, Indiana.

Early adopter customers for new technologies do not live in the midwest.

Tech companies need investors. Evansville did not have venture funds.

Tech companies need top tier software engineering talent. Evansville did not have individuals with this skill set on hand.

Hardware companies such as Heliponix need to manufacture overseas to be cost competitive in the marketplace.

Customers

Heliponix (formerly Hydro Grow) team picture after winning first place at the Schurz Innovation Prize at Purdue University. Left to Right: Scott Massey (CEO), Jimmy Carlson (Software Engineering Intern), Ivan Ball (CTO)

Starting a company without experience or the money needed is comparable to charging into a battle unarmed and unaware of the terrain with dangers ahead. I was acutely aware of my limitations, and spent my senior year at Purdue University delivering newspapers at night for about $9/hour, and competing in business plan competitions between classes for cash awards. Although we were very lucky to have successfully secured over $80k over the course my senior year and a little under $100k from competitions post graduation, the money was the second most valuable aspect of winning these pitch competitions. For every competition we won, at least two or three articles from local media publications would cover the story with our name on the front title. We jumped at every opportunity to showcase our prototypes at schools, STEM career fairs, and also leveraged my position as the lowly delivery boy to publish articles in the Exponent to grasp as much publicity as possible for an early stage company.

Scott Massey giving a STEAM (Science, technology, engineering, agriculture, and math) career talk about indoor agriculture to middle and high school students Our Lady of Providence School in New Albany, Indiana.

For every article and interview that was published, I received an email from random Indiana residents interested in purchasing a GroPod when it became available for purchase. I kept a running list of these potential customers, and reached out to collect a $500 pre-order deposit when we had finally landed on a GroPod design that worked reliably. We had definitively proven that a pre-revenue startup company could launch an expensive product in Indiana if they are able to achieve enough publicity to convert impressions into executed sales. Although there are many more wealthy individuals in major cities who could buy an early stage product; we did not yet have the production capabilities to meet this demand, and still had product development to refine before we would be ready for a massive user base.

Funding

Inside Indiana Business interview with Dr. K and Gerry Dick

Although we had been veryfortunate to secure some funding from business plan competitions for patents and prototype development, we had reached the ceiling of competition funding available in Indiana for an idea not yet generating revenue. My Co-Founder, Ivan Ball accepted a full-time, electrical controls engineering job offer upon graduation to pay off student loans at GPC (Grain Processing Corporation, an ethanol and grain alcohol processing plant in Washington, Indiana) after interning and co-oping as a student for several years prior. Together we worked exhausting hours for a full year to refine the GroPod design until we created a functional product able to generate revenue in Ivan’s garage.

One of many harvests from the fourth generation GroPod™. ALL RIGHTS RESERVED. HELIPONIX©

Ivan Ball at his electrical work station in an unheated garage assembling the fourth generation GroPod™. ALL RIGHTS RESERVED. HELIPONIX©

This marked a major turning point for the company after three generations of failed prototypes. When asked if we both worked on Heliponix full-time to this point, I would honestly say yes. Our individual hours spanned 50–70 hours weekly even though Ivan had a full-time day job that took 40–45 hours per week. At this time, we had spent almost all competition award winnings on patents, prototyping, travel for events, or other business expenses. We simply did not have the capital needed to cover materials to assemble the first GroPod betas. I then approached Eric Steele, my Entrepreneur in Residence with Elevate Ventures (Indiana’s state venture fund) seeking capital needed to fund inventory. Eric referred us to the ISBDC (Indiana Small Business Development Center) who advised the Vectren Foundation Grow Local loan program for small businesses. After working with Douglas Claybourn and Kim Howard, we sent an application to the Vectren Foundation board to build the first GroPods. After waiting patiently, we were approved for a loan needed to build these GroPods with very favorable terms for any company, let alone a startup with zero cash flow history. We used the loan to buy all the parts needed, and collected the remaining $1,500 left on each GroPod order with early adopters to sell out of the beta models assembled by hand. We 3D-printed all parts, wrote our own code, soldered our boards, assembled every aspect of the product Ivan and I had designed entirely by ourselves, and delivered each GroPod in person to the early adopters. There was so many GroPod parts laying around Ivan’s home, I had to deflate my air mattress to make more room, and slept on his couch for months.

Ivan Ball installing a camera on the fifth generation GroPod™. ALL RIGHTS RESERVED. HELIPONIX©

GroPod™ assemblies consuming every square foot of Ivan Ball’s home in Washington, Indiana. ALL RIGHTS RESERVED. HELIPONIX©

Ivan Ball (Left), Scott Massey (Right) with first functional GroPod. ALL RIGHTS RESERVED. HELIPONIX©

At this point Ivan quit his job at GPC, to work solely at Heliponix, and sold his house in Washington, Indiana to be fully committed to the company. Today, I am pleased to announce that the risk the Vectren Foundation took on us for funding the loan is being paid back in full plus interest. This market validation thrusted us into the long sought after post-revenue status, which did not go unnoticed by local and regional angel investors; however, this is a story for another day. Despite the undeniable fact that the largest investment funds are in major cities, very few early stage hardware companies receive those investments due to the amount of competitors who rarely manufacture products within these cities, let alone the state. It is much better to refine the product and user experience until a sizable MRR (monthly recurring revenue) is established before approaching these funds which are beginning to invest outside of their states to leverage the capital efficiency of a midwest startup.

Talent

Delivering the first GroPods was just the beginning of a long troubleshooting learning curve with paying customers… Internet connectivity with a connected, IoT (Internet of Things) device will come with many software bugs as well as faulty sensor failures when buying in low quantities from Chinese suppliers. The problems that you are both unaware of, and unable to solve are the hardest any startup will encounter. It is incredibly important to find these problems by getting your product in the hands of early adopters as soon as possible to identify and solve. The dilemma of an underfunded hardware startup company is that you will more than likely need to sell a product that doesn’t yet have all the features needed to make it “perfect” in order to stay cash flow positive. The reality is that no garage startup will be fully ready, and you will certainly find excuses to not be ready if you look for them. This is called the MVP (minimum viable product). Then something amazing happened, customers began to complain less each day as we solved problems one after another, until I began to hear feedback that their GroPods were growing more food than they could consume! This major milestone was met with interest from angel investors who provided the capital needed to hire a full-time software development lead. Unfortunately, there is not a plethora of software developers in Evansville at this time, so we needed to look for a remote employee. After interviewing several developers, Ivan and I decided to hire Bryan Lemon, a PhD computer scientist from West Virginia University living in South Carolina. Bryan’s experience with IoT device companies translated very well into solving problems, creating new features that kept customers happy, and attributed to our zero-percent churn rate. Despite never meeting Bryan in person, we were quickly able to determine his technical ability by first hiring him as an independent contractor for an agreed upon milestone. I strongly encourage that early stage technology companies consider remote software developers to save cost, expand your professional network, and reach a wider pool of candidates to only hire top talent. You do not need to go to the bay area or other major cities to find top talent, and the operational cost of your business will increase by multiples if you move to a larger city.

Manufacturing

Whirlpool Refrigeration Plant on Highway 41. Source: Courier and Press

I remember all too well the day that the Whirlpool plant in Evansville shut down for the last time, a major manufacturing hub for appliances that employed several thousand people. At a very young age, this instilled the idea that hardware manufacturing companies must leave the United States in order to find competitive manufacturing prices. That is why I took a flight to Shenzhen, China to tour contract manufacturing plants. This massive manufacturing city is often called the hardware capital of the world based upon its speed, competitive labor, and material rates. After returning and considering the cost of manufacturing overseas, I began to factor in the not-so-obvious costs of building products outside of Evansville. The language barriers requires a translator to be present, and often leads to misunderstandings that can be very costly mistakes. The logistical challenges, uncertain trade relationship, and intellectual property theft quickly amounted to a cost that far exceeded that of domestic contract manufacturers. Most startup companies fail by aimlessly pursuing random goals without strategy as capital dwindles.

I have discovered that the resources I need to prototype and manufacture are widely available within the Midwest ecosystem. We then began to look locally for contract manufacturers within the Evansville-Cincinnati-Louisville trifecta that had worked at GE and Whirlpool appliance manufacturing plants and engineering design centers. Without disclosing trade secrets, we can confirm that the midwest has manufacturing capabilities that are very competitive with international rates. In our case, we were able to source almost all parts needed in manufacturing from Indiana, Illinois, and Kentucky. In addition to Evansville and Louisville being the former appliance manufacturing capitals of the world; we have been able to find top tier talent and industry partners with relative ease. Eventually, most hardware companies manufacture overseas when they exceed 1,000–10,000 units per year, but automation is the equalizer in a world where labor can be bought for a few dollars per hour, or be subsidized by a country in the process of industrialization. Indiana is uniquely positioned to be an entrepreneurial hotbed with several investment groups, and countless angel investors in one of the top manufacturing states in total manufacturing GDP (Gross Domestic Product).

Conclusion

After speaking to countless successful and not-so-successful entrepreneurs; I believe that starting a company requires two things.

The drive to achieve your goals

The means to achieve your goals

This has led to a new revelation about Evansville; it is not a good place to start a company… it’s a great place to start a company. It is uniquely large enough to have the means to fund a startup company, but not so large that the means become unobtainable to newer companies. The cost of living combined with these resources will triple to quintuple how far your dollar will go as opposed to a startup in a major city.

I now proudly say that Heliponix is based in Evansville, and we intend to stay here for the foreseeable future. We will continue to directly and indirectly create new jobs as operations expand. This only leaves one question from me to you, “Why not stay in Evansville?”.

Indiana entrepreneurial resource map, courtesy of Drew Peyronnin.

Indiana entrepreneurial resource map, courtesy of Drew Peyronnin.

The infographic above shows just some of the many resources available for startups in Indiana that has helped Heliponix many times in the past, present, and future. Purdue Foundry, Elevate Ventures, Purdue Polytechnic Institute, Blue Sky Capital, CoWork Evansville, APPCOM/BIZCOM, SVBIG, Certificate Entrepreneurship and Innovation — Purdue University, Burton D Morgan Business Plan Competition, Foundry@WestGate, GAGE, Agrinovus, Centric, IU IP Clinic, E is for Everyone, SouthWest Indiana Chamber of Commerce, Innovation Connector, TedxWabashCollege, Schurz Innovation Prize, Center for Entrepreneurship — PNW, Vectren Foundation, iGrow.news, and prospectively the MakerStation which conveniently holds many of these resources in one building; Innovation Pointe.

Scott Massey

Founder and CEO of Heliponix™. Purdue University, class of 2017. Mandela Washington Fellowship Alumni.

BREAKING NEWS: Heliponix Wins Second Stage Investment From Purdue University Venture Ag-Celerator Fund. Midwest AgTech Investments On The Rise.

Midwest indoor agriculture startup, Heliponix (Evansville, IN) has won a second stage investment of $50k from the Purdue Ventures Ag-Celerator fund in West Lafayette, IN