Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Gene Editing – And What It Really Means to Rewrite The Code of Life

We now have a precise way to correct, replace or even delete faulty DNA. Ian Sample explains the science, the risks and what the future may hold.

We now have a precise way to correct, replace or even delete faulty DNA. Ian Sample explains the science, the risks and what the future may hold

Ian Sample Science editor @iansample

2018

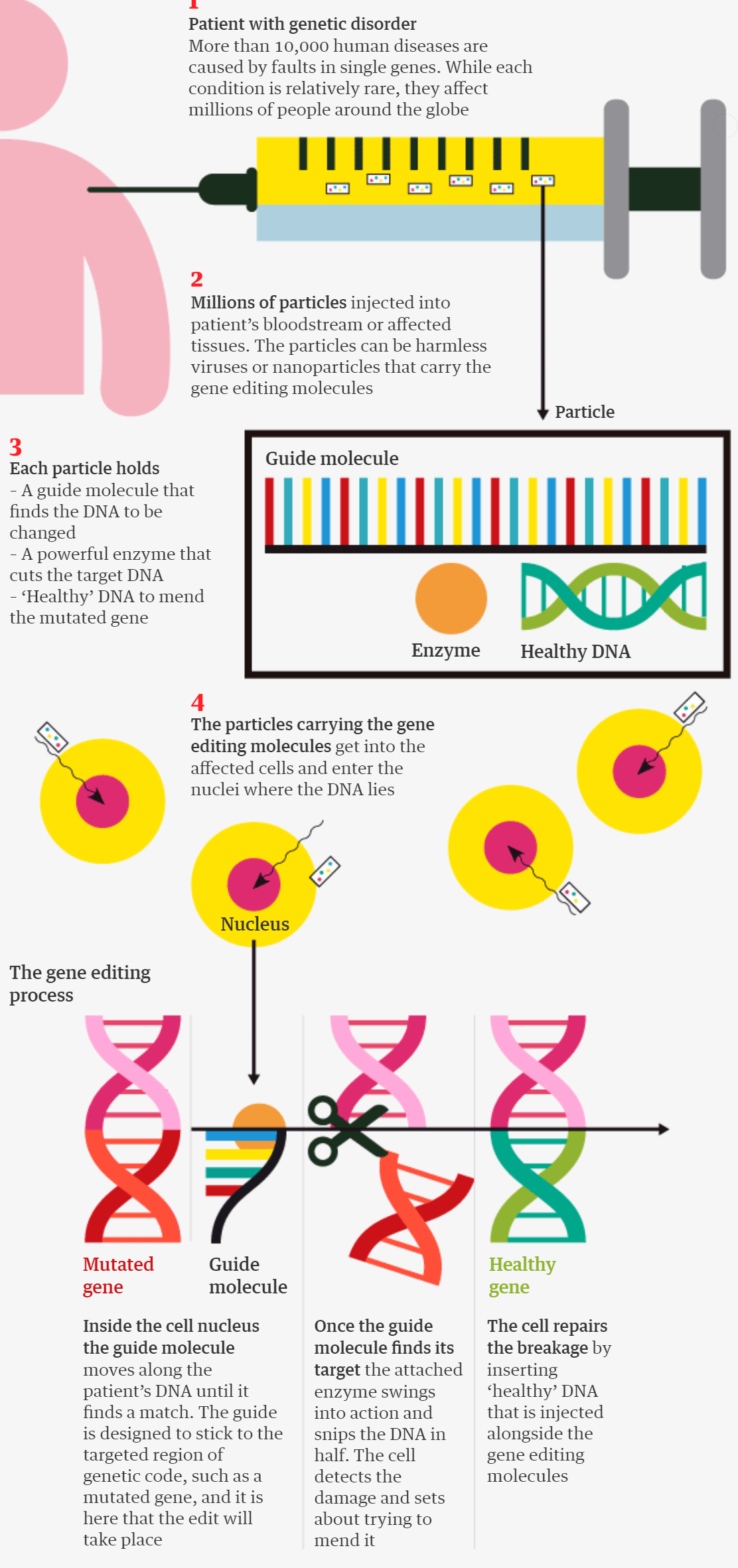

Gene editing has the potential to treat or prevent thousands of forms of human disease. Illustration: Guardian design team

So what is gene editing?

Scientists liken it to the find and replace feature used to correct misspellings in documents written on a computer. Instead of fixing words, gene editing rewrites DNA, the biological code that makes up the instruction manuals of living organisms. With gene editing, researchers can disable target genes, correct harmful mutations, and change the activity of specific genes in plants and animals, including humans.

What’s the point?

Much of the excitement around gene editing is fuelled by its potential to treat or prevent human diseases. There are thousands of genetic disorders that can be passed on from one generation to the next; many are serious and debilitating. They are not rare: one in 25 children is born with a genetic disease. Among the most common are cystic fibrosis, sickle cell anemia and muscular dystrophy. Gene editing holds the promise of treating these disorders by rewriting the corrupt DNA in patients’ cells. But it can do far more than mend faulty genes. Gene editing has already been used to modify people’s immune cells to fight cancer or be resistant to HIV infection. It could also be used to fix defective genes in human embryos and so prevent babies from inheriting serious diseases. This is controversial because the genetic changes would affect their sperm or egg cells, meaning the genetic edits and any bad side effects could be passed on to future generations.

What else is it good for?

The agricultural industry has leaped on gene editing for a host of reasons. The procedure is faster, cheaper and more precise than conventional genetic modification, but it also has the benefit of allowing producers to improve crops without adding genes from other organisms – something that has fuelled the backlash against GM crops in some regions. With gene editing, researchers have made seedless tomatoes, gluten-free wheat, and mushrooms that don’t turn brown when old. Other branches of medicine have also seized on its potential. Companies working on next-generation antibiotics have developed otherwise harmless viruses that find and attack specific strains of bacteria that cause dangerous infections. Meanwhile, researchers are using gene editing to make pig organs safe to transplant into humans. Gene editing has transformed fundamental research too, allowing scientists to understand precisely how specific genes operate.

So how does it work?

There are many ways to edit genes, but the breakthrough behind the greatest achievements in recent years is a molecular tool called Crispr-Cas9. It uses a guide molecule (the Crispr bit) to find a specific region in an organism’s genetic code – a mutated gene, for example – which is then cut by an enzyme (Cas9). When the cell tries to fix the damage, it often makes a hash of it, and effectively disables the gene. This in itself is useful for turning off harmful genes. But other kinds of repairs are possible. For example, to mend a faulty gene, scientists can cut the mutated DNA and replace it with a healthy strand that is injected alongside the Crispr-Cas9 molecules. Different enzymes can be used instead of Cas9, such as Cpf1, which may help edit DNA more effectively.

An illustrated example of Crispr in action

Guardian graphic

Remind me what genes are again?

Genes are the biological templates the body uses to make the structural proteins and enzymes needed to build and maintain tissues and organs. They are made up of strands of genetic code, denoted by the letters G, C, T and A. Humans have about 20,000 genes bundled into 23 pairs of chromosomes all coiled up in the nucleus of nearly every cell in the body. Only about 1.5% of our genetic code, or genome, is made up of genes. Another 10% regulates them, ensuring that genes turn on and off in the right cells at the right time, for example. The rest of our DNA is apparently useless. “The majority of our genome does nothing,” says Gerton Lunter, a geneticist at the University of Oxford. “It’s simply evolutionary detritus.”

What are all those Gs, Cs, Ts and As?

The letters of the genetic code refer to the molecules guanine (G), cytosine (C), thymine (T) and adenine (A). In DNA, these molecules pair up: G with C and T with A. These “base pairs” become the rungs of the familiar DNA double helix. It takes a lot of them to make a gene. The gene damaged in cystic fibrosis contains about 300,000 base pairs, while the one that is mutated in muscular dystrophy has about 2.5m base pairs, making it the largest gene in the human body. Each of us inherits about 60 new mutations from our parents, the majority coming from our father.

But how do you get to the right cells?

This is the big challenge. Most drugs are small molecules that can be ferried around the body in the bloodstream and delivered to organs and tissues on the way. The gene editing molecules are huge by comparison and have trouble getting into cells. But it can be done. One way is to pack the gene editing molecules into harmless viruses that infect particular types of cell. Millions of these are then injected into the bloodstream or directly into affected tissues. Once in the body, the viruses invade the target cells and release the gene editing molecules to do their work. In 2017, scientists in Texas used this approach to treat Duchenne muscular dystrophy in mice. The next step is a clinical trial in humans. Viruses are not the only way to do this, though. Researchers have used fatty nanoparticles to carry Crispr-Cas9 molecules to the liver, and tiny zaps of electricity to open pores in embryos through which gene editing molecules can enter.

Does it have to be done in the body?

No. In some of the first gene editing trials, scientists collected cells from patients’ blood, made the necessary genetic edits, and then infused the modified cells back into the patients. It’s an approach that looks promising as a treatment for people with HIV. When the virus enters the body, it infects and kills immune cells. But to infect the cells in the first place, HIV must first latch on to specific proteins on the surface of the immune cells. Scientists have collected immune cells from patients’ blood and used gene editing to cut out the DNA that the cells need in order to make these surface proteins. Without the proteins, the HIV virus can no longer gain entry to the cells. A similar approach can be used to fight certain types of cancer: immune cells are collected from patients’ blood and edited so they produce surface proteins that bind to cancer cells and kill them. Having edited the cells to make them cancer-killers, scientists grow masses of them in the lab and infuse them back into the patient. The beauty of modifying cells outside the body is that they can be checked before they are put back to ensure the editing process has not gone awry.

What can go wrong?

Modern gene editing is quite precise but it is not perfect. The procedure can be a bit hit and miss, reaching some cells but not others. Even when Crispr gets where it is needed, the edits can differ from cell to cell, for example mending two copies of a mutated gene in one cell, but only one copy in another. For some genetic diseases, this may not matter, but it may if a single mutated gene causes the disorder. Another common problem happens when edits are made at the wrong place in the genome. There can be hundreds of these “off-target” edits that can be dangerous if they disrupt healthy genes or crucial regulatory DNA.

Will it lead to designer babies?

The overwhelming effort in medicine is aimed at mending faulty genes in children and adults. But a handful of studies have shown it should be possible to fix dangerous mutations in embryos too. In 2017, scientists convened by the US National Academy of Sciences and the National Academy of Medicine cautiously endorsed gene editing in human embryos to prevent the most serious diseases, but only once shown to be safe. Any edits made in embryos will affect all of the cells in the person and will be passed on to their children, so it is crucial to avoid harmful mistakes and side effects. Engineering human embryos also raises the uneasy prospect of designer babies, where embryos are altered for social rather than medical reasons; to make a person taller or more intelligent, for example. Traits like these can involve thousands of genes, most of them unknown. So for the time being, designer babies are a distant prospect.

How long before it’s ready for patients?

The race is on to get gene editing therapies into the clinic. A dozen or so Crispr-Cas9 trials are underway or planned, most led by Chinese researchers to combat various forms of cancer. One of the first launched in 2016 when doctors in Sichuan province gave edited immune cells to a patient with advanced lung cancer. More US and European trials are expected in the next few years.

What next?

Base editing

A gentler form a gene editing that doesn’t cut DNA into pieces, but instead uses chemical reactions to change the letters of the genetic code. It looks good so far. In 2017, researchers in China used base editing to mend mutations that cause a serious blood disorder called beta thalassemia in human embryos.

Gene drives

Engineered gene drives have the power to push particular genes through an entire population of organisms. For example, they could be used to make mosquitoes infertile and so reduce the burden of disease they spread. But the technology is highly controversial because it could have massive unintended ecological consequences.

Epigenome editing

Sometimes you don’t want to completely remove or replace a gene, but simply dampen down or ramp up its activity. Scientists are now working on Crispr tools to do this, giving them more control than ever before.

Further reading

A Crack in Creation: Gene Editing and the Unthinkable Power to Control Evolution by Jennifer Doudna and Samuel H. Sternberg

The Gene: An Intimate History by Siddhartha Mukherjee

The Epigenetics Revolution: How Modern Biology is Rewriting our Understanding of Genetics, Disease and Inheritance by Nessa Carey

Modern Prometheus: Editing the Human Genome with Crispr-Cas9 by Jim Kozubek

Weird New Fruits Could Hit Aisles Soon Thanks to Gene-Editing

Supermarkets stocked with peach-flavoured strawberries and seedless tomatoes on horizon, scientists say

Supermarkets stocked with peach-flavored strawberries and seedless tomatoes are on the horizon, scientists say

20 July 2018

A red-fleshed apple of the Redlove hybrid variety. Unusual fruits such as this could soon become more common thanks to use of technologies such as Crispr. Photograph: Bailey-Cooper Photography/Alamy Stock Photo

Smooth or hairy, pungent or tasteless, deep-hued or bright: new versions of old fruits could be hitting the produce aisles as plant experts embrace cutting-edge technology, scientists say.

While researchers have previously produced plants with specific traits through traditional breeding techniques, experts say new technologies such as the gene-editing tool Crispr-Cas9 could be used to bring about changes far more rapidly and efficiently.

It could, they say, potentially open the door to a new range of fruits and vegetables that look, taste and feel very different to those we are used to.

Gene-editing is already being used by scientists to change the characteristics of food. One such endeavor used Crispr to make mushrooms that don’t brown, while a team in Spain has been using the approach to try to produce wheat that can be eaten by people with coeliac disease. Still, others are looking at using gene-editing to give crops resistance to particular environmental problems or pathogens.

Earlier this year, biotech firm Monsanto invested $125m in a new gene-editing company called Pairwise that reportedly has goals such as sweeter-tasting strawberries, while scientists in Japan have used the technique to produce seedless tomatoes. Another team have been using Crispr to change the architecture of tomato plant branches and the spacing of fruit.

nside a lab in Norwich where researchers from a startup called Tropic Biosciences are using Crispr to create a better banana. Photograph: Tatum Reid/Tropic Biosciences

Among the genes flagged in the new study in the journal Trends in Plant Science are those behind the production of a family of substances known as MYBs, which are among the proteins that control whether other genes are switched on or off.

“MYBs are great targets because they are central to several consumer traits or features like colour, flavour [and] texture,” said Andrew Allan, a co-author of the review from the University of Auckland whose own projects include working on red-fleshed apples and changing the colour of kiwi fruits. “Russet skin in apple and pear [is linked to MYBs]. Hairs on peaches but not nectarines – another type of MYB.”

Dr Richard Harrison, head of genetics, genomics and breeding at the horticultural organisation NIAB EMR, who was not involved in the article, said tweaking MYB genes or the way such genes are themselves controlled was a fruitful approach.

“For fruits,” he said, “MYB genes have long been known to be associated with expression of molecules such as anthocyanin, a red-coloured compound that gives strawberries or blood-red oranges their colour. “Increasingly, MYBs are being implicated in the production of other important compounds, hence the interest in this family of genes that are conserved between many plant species.”

Gene-editing of MYB genes and other genes could bring a host of benefits, Harrison said, adding: “There is a large opportunity to improve the nutritional profile of fruits and vegetables in the future using gene-editing technology, as well as other techniques.” Such techniques, he said, introduce the same sort of DNA changes as plant breeders have introduced by artificially selecting traits that cropped up through spontaneous DNA mutation – but much faster.

Hybrid purple raspberries of the Glen Coe variety. Crispr may make such specimens more common. Photograph: PR/Suttons

“Red-fleshed apples developed through conventional breeding have taken decades to even come close to market acceptability,” he said, “due to the multiple rounds of breeding and selection that have had to occur to take the naturally occurring red-fleshed gene variant from a wild species of apple and introduce it into a commercially acceptable variety.

“In our normal breeding work, we often see seedlings produced purely from conventional breeding with a range of colour and flavour profiles that simply never make it to the market, such as peach-flavoured strawberries [and] super-dark purpleish strawberries.”

The review is timely: next week the European Court of Justice will announce if or how plants that have been gene-edited using techniques such as Crispr will be regulated, and whether they will be treated like genetically modified plants. The US has already ruled against serious restrictions, provided the changes could have been produced through traditional plant-breeding techniques.

“We are interested in making produce more healthy, sustainable and convenient so that people will eat more produce,” Dr Haven Baker, Pairwise’s chief business officer, said, noting that gene-editing could be used to increase levels of anthocyanins, improve taste, increase shelf life, improve yields, boost disease resistance or even lengthen the season of availability.

Such approaches, said Baker, could not only boost consumers’ nutrient intake, but could also reduce food waste and produce adaptations needed to weather climate change: “We are trying to solve problems that matter to both consumers and the agricultural systems.”

13 Vertical Farming Innovations That Could Revolutionize Agriculture

13 Vertical Farming Innovations That Could Revolutionize Agriculture

These revolutionary vertical farming innovations can soon replace the traditional agriculture techniques.

By Kashyap Vyas

July 4, 2018

Many have wondered for years if vertical farming is really the answer to the shortage of food in the world. However strange the concept of vertical farming might seem to many startups, it is an ingenious method to produce food in environments where arable land is unavailable or rare at the most.

This method is especially handy for challenging environments such as deserts, mountainside towns, and cities where many diverse types of vegetables and fruits are grown using precision agriculture methods and skyscraper-like designs.

Vertical farming is a revolutionary and more sustainable method of agriculture than its counterpart as it lowers the requirement of water to up to 70% and also saves considerable space and soil. This innovation in the field of agriculture with sustainability as its motto is making more and more heads turn today with its eco-friendly methods and making the possibility of farming real in difficult environs.

Let us check out the top 13 vertical farming innovations that could end up in your plate in the near future!

1. Hydroponics – Growing Plants Without Soil

Source: Oregon State University/Flickr

Hydroponics is a predominant system of growing that is used in vertical farming, and it is slowly but steadily, gaining importance. It involves around the growth of plants in solutions of nutrients that are essentially free of soil.

In this vertical farming innovation, the roots of the plants are submerged in a solution of nutrients. This is frequently circulated and monitored in order to ensure that there is the maintenance of the correct chemical composition in the nutrient solution.

2. Aeroponics – Growing Plants With No Soil and Very Little Water

Source: MyAeroponics/Wikimedia Commons

The innovation of Aeroponics in the field of vertical farming was made by The National Aeronautical and Space Administration (NASA). This sustainable growing technique was invented by NASA in the 1990s when it was looking for efficient techniques to grow plants in space.

This technique was then coined Aeroponics and was defined as "growing plants in an air/mist environment with no soil and very little water." However, these systems are yet to rise from an anomaly in the world of vertical farming even though they continue to create interest.

It is undoubtedly the most efficient way in vertical farming as it uses a staggering 90% less amount of water than the most efficient hydroponics systems too. It has also been observed that the plants that are grown with the aeroponics system uptake more vitamins and minerals, thus making the plants potentially healthier and more nutritious.

3. Aquaponics – An Ecosystem that Promotes Plants and Fish Farming Together

Source: Kate Field/Flickr

An Aquaponics System is much like the Hydroponics System but is only better. It aims to combine the fish and plants in the same ecosystem. In this system, fish grow in indoor ponds and produce a nutrient-rich waste that further acts as a food source for the plants grown in vertical farms.

The plants, doing their part, purify and filter the wastewater that gets recycled directly to the fish ponds. Aquaponics is definitely used at a smaller scale than most vertical farming innovations.

However, it is still used by many commercial vertical farms that wish to produce just a few fast-growing crops instead of including the component of aquaponics. As a result, the production and economics issues are simplified and it also maximizes efficiency.

That said, this closed-cycle system might become more popular with the popularity of new standardized aquaponic systems.

4. Lokal – Serving Fresh Food Right Where It’s Grown

Source: Space10

The Space10 innovation lab of IKEA came up with the idea of Lokal that uses a Hydroponic farming system. It also uses LEDs to have your kitchen garden in stackable trays.

According to the designers of Lokal, the greens grow three times faster in Lokal than traditional gardens. They are also testing another innovation wherein they will integrate sensors into the growing trays, which will help you check the status of the crops with the help of smartphones or Google Homes.

In the long run, they also want to use machine learning to collect and analyze data from the people using Lokal to assess the productivity. This innovation can really help people grow fresh food in their own local mini-farms.

5. AeroFarms – The Smart Vertical Farming Innovation

Source: AeroFarms

When it comes to indoor farming, AeroFarms are the commercial leaders in this field with their innovation of using the aeroponic system of farming that ensures predictable results of your harvest, less impact on the environment, faster harvesting period and superior quality of food. The technology helps growing greens without using any sun or soil.

Therefore, it is easier to control the results of the harvest. The vertical farming innovation makes use of smart light, smart aeroponics, smart nutrition, smart data, smart pest management, smart substrate and smart scaling.

AeroFarms aims to transform the whole system of agriculture by building and making farms that are environmentally responsible. They are building farms around the world to make sure there is a local production of food that is nutritious, safe, sustainable and delicious.

In short, they want to grow more crops in less space which can bring about a food revolution.

6. Plantscapers – A Building that Provides Food for its Occupants

Source: Plantagon

A Swedish food tech company called Plantagon is coming up with a creative solution that would allow office spaces and buildings to help feed a large number of people. In order to use the innovative methods of vertical farming, Plantagon has bought the rights to a vertical greenhouse from an organic farmer named Åke Olsson who believes in using technical innovation to find effective farming solutions.

Olsson developed a rack transport system that gradually moves the planting boxes from the floor to the ceiling of a vertical greenhouse, thus requiring no artificial light.

These vertical greenhouses or plantscapers are integrated directly into the office buildings with the functionality of hydroponic farming. The building would be named the World Food Building with the aim of producing at least 550 tons of vegetables every year and is planned to be constructed in Linköping, Sweden.

This is an estimated amount of vegetables that can provide food for almost 5000 people. High-level automation will be employed for the maintenance and harvest of plants in order to keep the costs very low.

Moreover, everything starting with sunlight, temperature, and nutrition, as well as air quality, will be measured through autonomous and controlled systems.

To sum up, it is a great innovation that keeps in mind sustainability and the requirements of people by keeping the costs of transportation very low and also by saving high amounts of energy, emissions, and water. If the concept becomes a success, more countries like Singapore, Hong Kong, United States and others have plans to adopt it too

7. VertiCrop – A Sustainable Farming Technique for Urban Areas

VertiCrop is a proprietary agriculture technique that has been deemed as one of the World’s Greatest Inventions by TIME Magazine in 2009. This patent-pending technology was designed and developed so that food could be grown naturally in the environment of bustling urban areas.

This proprietary method offers quite a paradigm shift in food production and sustainable farming methods. It provides up to twenty times the yield of your standard field crops and uses merely 8% of the water that is usually needed for soil farming.

The vertical farming innovation works on a suspended tray configuration that is unique in itself and moves on a conveyor system. VertiCrop offers optimal exposure to both artificial and natural light in addition to nutrients that are precisely measured for every plant.

It has been designed in a way that it can promote the healthy growth of crops in controlled and closed-loop environments. Furthermore, it entirely gets rid of the need for using harmful herbicides and pesticides and maximizes food value, nutrition and above all, taste.

8. Modular Farms – Produce Fresh Plants Virtually Anywhere in the World

The very exclusive and sustainable Modular Farm System is another great innovation in the world of vertical farming from the company called ModularFarms. It is an entirely indoor system of vertical farming that has the ability to produce healthy and fresh plants virtually in any climate and anywhere in the world.

If that doesn’t intrigue you enough, it is a custom-built design that is based on an urban farm idea. This modular farm scales according to need and has additional modules that are available for diverse purposes.

The Modular Farm System concentrates solely on farmer ROI and plant health. This system is the perfect pairing of container farms, and the tried & tested technology of vertical farming.

This balance between the two promotes an endless growth of fresh and locally produced plants. A highlight of this vertical farming innovation is that you can customize your system and extend its functionality according to your agriculture needs to accommodate any sized operation.

9. Cubic Farming Systems – The Next-Gen Sustainable Farming System

Cubic Farms, as its CEO Dave Dinesen points out in his TEDx Abbotsford speech, is the next generation of consistent, predictable and profitable farm productions. It works on the conveyor rotation method, automated nutrient delivery system and LED lighting.

The machines used for growing crops create an optimal environment for the greens. It also uses 1/26th the amount of water that is utilized in traditional agriculture, thus making it sustainable.

One would usually not associate these words with agriculture or growing. However, the patented Dutch Cubic Farming system entirely eliminates risks of common farming to standardize the outputs by controlling the inputs.

This, in turn, means a steady and more predictable income in addition to more consistency in the size, taste, and color of the produce. It also promises a longer shelf life and higher nutritional content for your greens.

10. ZipGrow – Vertical Farming for the Modern Farmers

The motto of ZipGrow is to ‘EDUCATE. EQUIP. EMPOWER.’ The ZipGrow team has come up with innovative farming solutions for the modern farmers who do not have the required tools and experience to scale or start a hydroponic farming business.

ZipGrow understands the challenges that are faced by the average farmers today in terms of suboptimal growing equipment, poor farming or poor understanding of what the market really wants. As a result, ZipGrow has built a multitude of services and products so that the deck can be stacked in their favor.

They have basically revolutionized the industry of vertical farming with system controls, vertical plane growing technology and high-tech workflow designs to help countless farmers globally.

11. Bowery – The Most Technologically-sophisticated Commercial Indoor Farm in the World

Source: boweryfarming/Instagram

The indoor farming company, Bowery is developing a technologically advanced farming system that will be capable to yield 30 times more produce and grow more than 100 kinds of herbs and leafy greens. The system according to the company will control the entire growing process indoors without using pesticides through their technology system BoweryOS.

The technology will automatically generate ideal conditions for the plants while collecting the data as they grow. The data will help in providing the plants with the exact amount of light, nutrients or purified water.

In addition, the sophisticated analysis will further allow harvesting the crops at the right time when its flavor is at its best. The produce cultivated through Bowery’s system utilizes 95% less water compared to the traditional farming.

12. Skyfarm – A Wind-Powered Vertical Farming Tower

Source: Rogers Stirk Harbour + Partners

An architectural firm, Rogers Stirk Harbour + Partners from London demonstrated a concept called Skyfarmduring the World Architectural Festival in 2014. The idea is to build a hyperboloid tower that makes use of different farming techniques including aquaponics and traditional soil-based planting methods to produce crops within high-density urban areas or at places where land availability is less.

The multi-story building uses bamboo to create a rigid circular frame while maximizes the sun exposure onto the farm. The tower supports both the growth of crops and fish together through a re-circulating system where the nutrients from fish water are fed to the crops while the plants provide filters for the fish to thrive.

The bottom of the tower is designed to have a large transparent tank consisting of freshwater for the farming of fishes like bass, tilapia, and barramundi. In the middle of the tower, the plants are grown through hydroponics using water.

Above this, the plants are grown through aeroponics using only water mists and no soil. The top of the tower consists of water tanks and turbines.

The tower is an example of a sustainable solution for growing produce with a short shelf life around the year with easy accessibility for the urban population.

13. Sky Greens – The World’s First Hydraulic Driven Vertical Farm

Source: Sky Greens

The Singapore-based company Sky Greens has developed a revolutionary vertical farming system which is also the world’s first low carbon, hydraulic driven farm. The vegetables are planted on shelves that keep on rotating throughout the day.

The plants at the bottom receive water, while the ones at the top get sunlight and the process continues. This approach minimizes the use of water, land, and energy over the conventional farming techniques.

In addition, the Sky Urban Vertical Farming System is capable of producing 10 times more yield compared to traditional farms. While the system is currently used to grow Asian vegetables, it can also be used to grow all kinds of fruits and veggies.

Vertical farming is definitely an attractive option for farmers these days as more and more industry experts embrace it and for a good reason. It promises a much more sustainable way of farming in addition to not just producing quality produce but also cutting down on costs and making agriculture more eco-friendly.

These innovations are bound to rise in popularity and revolutionize the face of vertical farming in the future!

Smithers-Oasis Company Announces Partnership With Agrilyst

Smithers-Oasis Company Announces Partnership With Agrilyst

Smithers-Oasis Company, a worldwide leader in providing solutions throughout the plant and flower supply chain from propagation to consumer, announces its partnership with Agrilyst, leading provider of a software as a service (SaaS) product for greenhouses and vertical farms that allows growers to track crops, labor, inventory and other metrics.

Oasis Grower Solutions products will be included in Agrilyst and offered to growers that subscribe to the software, which helps them manage their crops and provides data-driven insights to make more profitable production decisions.

“With Agrilyst, we bring to the industry an understanding of how to leverage data, making it easier for growers to manage and scale their businesses,” said Allison Kopf, CEO of Agrilyst. “Including Oasis® Grower Solutions products in our platform will enable indoor growers to know when and what to order so they can perform optimally.”

The Agrilyst platform puts the power of precision agriculture in the hands of any grower, no matter what its size. The cloud-based platform leverages knowledge from other growers and offers a mobile app for ease of use. Indoor growers are able to extract data that helps them take control of their operations and improves their supply chain management.

“Using Agrilyst, growers can spend their time and expertise focused on their flowers and vegetables, rather than trying to maintain their supply chain,” said Bill Riffey, general manager, grower operations, Americas, Europe and Africa. “As the industry moves more and more towards indoor growing because of climate changes, it is important for Smithers-Oasis to be involved in the latest technologies that innovative growers are using to help grow their businesses.”

Oasis® Grower Solutions horticulture products provide for the strong, healthy, clean start and post-harvest care and handling of plants and flowers throughout their lifecycle to ensure the best user experience. The entire plant journey includes the breeder, propagator, growers, retailers, distributors and finally, the end consumer.

For more information

Agrilyst

www.agrilyst.com

Smithers-Oasis

www.smithersoasis.com

Publication date: 5/3/2018

Evergreen Farm Wins Best Indoor Farming Innovation Award

Evergreen Farm Wins Best Indoor Farming Innovation Award

EverGreen Farm Oy participated in the Global Forum for Innovations in Agriculture (GFIA) at Abu Dhabi during the 5th and 6th of February, 2018, where it was presented with the Best Indoor Farming Innovation Award by the Minister of State, Her Excellency Mariam Bint Mohammed Saeed Hareb Al Mehairi, from the Abu Dhabi Food Control Authority.

During the conference H.E Mariam Bint Mohammed Saeed Hareb Al Mehairi stated “The Food Security Innovation Sessions are an ideal platform for joint action, aimed at putting the government and relevant sectors in a row to explore the future of food security and finding solutions to increase the contribution of the private sector in the food equation of the UAE. We cannot consider the issue of food security as an independent issue and separate from society, we must activate the role of all entities in addressing the challenges we face, taking into consideration that innovation is the key tool for improving food and agricultural production and essential for food security.”

Using the basic principle of hydroponics, Evergreen Farm Oy has developed an innovative vertical indoor farming technology that produces high-quality fruits and vegetables in a state-of-the-art, environmentally controlled, the multi-level indoor facility called the Direct Feed Vertical Hydroponics (DFVH) system.

"Best Indoor Farming Innovation" Award

Evergreen Farm Oy Wins "Best Indoor Farming Innovation" Award During the Global Forum for Innovations in Agriculture (GFIA)

The GFIA was founded in 2014 and it is the world’s largest series of events dedicated to showcasing innovations in sustainable agriculture across all types of food production. “The Global Forum for Innovations in Agriculture is based on the notion that the ongoing drive for innovation in the agriculture sector is the only way to feed 9 billion people sustainably by 2050,” said Nicolas Davison, Director of the Global Forum for Innovation in Agriculture.

Evergreen Farm Oy’s mission is to fundamentally transform agriculture by implementing the technologically advanced and easy-to-use DFVH system throughout the world. Thus, improving crop production while encouraging responsible, innovative farming methods that protect the environment and educate the community.

“We are extremely proud and thankful for the "Best Indoor Farming Innovation" award. We have now launched the first production-ready product portfolio, including both industrial and home units. After years of product development, we have got one step closer to our objective to make fresh, healthy, delicious, non-GMO, chemical and pesticide-free food accessible to everyone. While doing so, we also aim to improve the quality of life of local communities by providing job opportunities and a platform for growth and education, “ said Ali Amirlatifi, CEO of Evergreen Farm Oy.

Evergreen Farm is not only focusing on the technology for crop growth but also developing artificial intelligence (AI) based services to optimize production and accelerate our customers’ fruit and vegetable business entry into the markets. “With AI driven operations we can automate almost everything but also analyse global vegetable and fruit market automatically for our customer, “ thought Ali Amirlatifi.

For any inquiry to EverGreen Farm Oy please contact:

Ali Amirlatifi CEO, EverGreen Farm Oy

ali.amirlatifi@evergreenfarm.fi

Mobile: +358 50 390 3333

Website: www.evergreenfarm.eu

Evergreen Farm Oy is a Finnish company, located in Tampere. Evergreen Farm Oy is a technology company focused on providing clean sustainable food through agricultural innovation.

By offering the World highest yield per square meter as well as cubic meter, indoor protection from the elements, a variety of crops that go beyond leafy green, and the benefits of existing technology in robotics artificial intelligence and engineering, Evergreen Farm is sure to provide a solution to the food crisis and its associated environmental impacts.

Over 32 Trillion Data Points Give Growers Solid Environmental Intelligence

Over 32 Trillion Data Points Give Growers Solid Environmental Intelligence

17 January 2018 (PST): Autogrow, a leading global ag tech company, has announced their strategy to use trillions of available growing data points to help their growers’ crop production.

“Due to the unique nature of our architecture, over 32 trillion data points flow through our systems each year which would be one of the most substantial collections for indoor agriculture to date. Data is king when it comes to innovation but what you do with it is the key,” says CEO Darryn Keiller.

Darryn Keiller at head office

“The tricky part is, like most systems, a lot of the data generated contains noise. To date, our processing algorithm has filtered and stored over six billion data points which are then ingested by our state-of-the-art data pipeline, and analyzed by our scientists for our customers.”

“Our strategy is to orchestrate the data to make it meaningful for our growers, giving them deeper insight into their crop environments’, revealing critical factors of crop cycle and seasonality, to enable smarter decisions and better outcomes.”

Data is currently sourced from Autogrow’s MultiGrowTM, AphaeaTM, IntelliDoseTM and IntelliClimateTM control systems and, depending on the system being run, collates microclimate data every 3-5 seconds including air temperature, humidity, light levels, CO2, pH and nutrient levels as well as local macroclimate data.

The richness of the data is enormous spanning a vast array of produce, floriculture and arboreal plant nurseries in greenhouses, urban farms and protected cropping systems in over 40 countries.

Each grower can access their own data via the cloud or the controller at any time with enterprise level security in place, but the biggest challenge for the grower is seeing past the large quantity of data to the quality insight.

Autogrow’s Director of Crop Science and Agronomy, Dr Tharindu Weeraratne notes that information gathered gives a true reflection of how the plants are responding to their environment and what the optimum levels are for increased yields with high quality and consistency.

“All the factors involved including external and internal climate, plant biology, nutrient requirements, technology usage and how everything interacts together is vital. Add in the effects of consumer needs, geopolitical factors and climate change, and those leafy greens or tomatoes are more complex than most consumers realize.”

“There are a few factors that can’t be controlled with crop production but by gaining knowledge and understanding of those factors you do have control over, it’s really the first step to true innovation and business growth.”

Motorleaf's Agronomist.ai Software Cuts SunSelect's Yield Prediction Error Rates In Half

Motorleaf has come out of private BETA with a commercially available yield prediction service for commercial greenhouses, after working closely with SunSelect (150 acres in California & B.C.) with results that disrupt how commercial greenhouse farms worldwide can now operate their business, adding significant dollars to their client’s bottom line.

Motorleaf's Agronomist.ai Software Cuts SunSelect's Yield Prediction Error Rates In Half

Motorleaf, Montreal, Canada

Motorleaf has come out of private BETA with a commercially available yield prediction service for commercial greenhouses, after working closely with SunSelect (150 acres in California & B.C.) with results that disrupt how commercial greenhouse farms worldwide can now operate their business, adding significant dollars to their client’s bottom line.

Motorleaf has launched it’s Agronomist.ai platform with a world first for greenhouse owners/operators, allowing for accurate Yield Prediction.

“After 8+ months of private BETA testing with one of North America’s premier greenhouse operators SunSelect, our latest algorithm has cut the accuracy error rates of SunSelect by half. For such a high tech greenhouse- they’ve tried every method that’s out there,” – Alastair Monk, Motorleaf CEO/Co-Founder.

SunSelect’s co-owner Victor Krahn agrees, saying: “For us (and any commercial size operation) knowing/predicting exactly what quantity of product we'll have each week is one of the top metrics we obsessively track. This data feeds into all critical areas of our operation, from labour management to price negotiation, to buyer relationships and even trickling through to in-store marketing budgets. Like most commercial greenhouses, our ability to predict something so dynamic as yield is almost impossible to get right. Our error rates bounce between 5% to over 35% in some weeks. Motorleaf is now our new standard for predicting yield.”

With the emergence of so many AgTech companies in the past couple of years, Motorleaf has been building its suite of hardware and software to leverage the data it collects via its own hardware, but can also leverage data already been collected by greenhouse clients, which in most cases is not being leveraged to its potential by the greenhouse.

Mr Krahn continues: “Working with our team of growers and VP of Operations we were impressed at the level of accuracy Motorleaf’s team provided through both touching the plants in the greenhouse and reaching through the cloud for the data our state of the art greenhouses provides every day! The integration was easy, non-invasive and I think shows amazing promise to become the new industry standard.”

Both companies are looking to expand their relationship, with Mr. Krahn adding: “I'm proud to say SunSelect is not only a client, but we will be helping Motorleaf roll out an increasing number of solutions to the benefit of every Motorleaf client worldwide. Their latest algorithm cut our yield prediction error rates in half, and goes without saying is a game changer that no one saw coming!"

Mr Monk adds: “You know your team is delivering exceptional work when the head growers at a client’s location literally don’t believe the results can be so much better than what’s normal in the industry. We have to thank the very long hours our team has put into making this a reality, especially Scott Dickson-Dagondon and Ramen Dutta (AI Director and CTO/Co-founder) – this is a very exciting time for our company and we feel for greenhouse producers worldwide.”

Find out how Motorleaf's Ai-powered yield predictions can help your business:

CONTACT US

About Motorleaf: Motorleaf is developing Agronomist.ai – a virtual agronomist for every greenhouse and indoor farmer in the world. With a varied mix of monitoring, control and predictive capabilities, Motorleaf is leveraging AI & Machine learning to deliver predictable, repeatable, improved crop production worldwide.

Greenhouse Technology Could Be The Future of Food

Greenhouse Technology Could Be The Future of Food

Published: Jan. 17, 2018 • By Trent Knoss

Professor Ronggui Yang (left) and Assistant Professor Xiaobo Yin. Photo by Glenn J. Asakawa / University of Colorado Boulder

CU Boulder engineers have received a $2.45 million grant from the U.S. Department of Agriculture (USDA) to develop a scalable, cost-effective greenhouse material that splits sunlight into the photosynthetically efficient light and repurposes inefficient infrared light to aid in water purification. The material can also split the light streaming into greenhouses into rays that plants can use more efficiently.

The four-year research program could yield next-gen technology capable of solving food, energy and water security challenges posed by global population growth and climate change.

The study, administered under the USDA and National Science Foundation’s Innovations at the Nexus of Food, Energy and Water Systems (INFEWS) program, will be led by researchers from CU Boulder’s Department of Mechanical Engineering in collaboration with Michigan State University’s Department of Horticulture and Department of Mechanical Engineering.

“We are excited to work on a project that addresses one of the most important global challenges with our multidisciplinary colleagues at CU and MSU,” said Ronggui Yang, a professor of mechanical engineering who will lead the team.

Greenhouses have been used since the 1960s and remain the standard for effective plant productivity compared to open-field agriculture. But the structures carry high energy costs, requiring tremendous amounts of energy for heating, ventilation, electrical lighting and water for evaporative cooling. By the year 2050, current greenhouse capabilities will likely be unable to keep up with worldwide human consumption, making an increase in productivity an urgent mandate.

Under normal conditions, plants only use around 50 percent of incoming sunlight for photosynthesis while the remaining half goes unused.

“The new CU Boulder technology will take the form of a semi-translucent film that splits incoming light and converts the rays from less-desired green wavelengths into more desirable red wavelengths, thus increasing the amount of photosynthetically efficient light for the plant with no additional electricity consumption,” said Xiaobo Yin, an assistant professor of Mechanical Engineering and Materials Science and Engineering at CU Boulder.

The thin engineered material can be applied directly to the surface of greenhouse panels. The technology also makes use of the photosynthetically ineffective light by redirecting it to aid in solar-driven water purification.

“The near-infrared wavelengths can help clean brackish wastewater, allowing it to be recirculated in an advanced humidification-dehumidification interface and further reducing the greenhouse’s energy footprint,” said Yang, an American Society of Mechanical Engineers Fellow.

The innovation could help improve U.S. agricultural competitiveness and lead to new best practices for greenhouse systems in different climates, especially in arid regions with limited freshwater availability where crops cannot be grown profitably.

The technology expands on the researchers’ previous successful efforts to develop a suite of scalable engineered materials that can cool structures and improve solar panel efficiency, among other applications.

The researchers plan to create a pilot greenhouse facility to test the material’s properties over the course of multiple tomato production cycles and, later, expand the test to leafy greens such as lettuce and herbs.

FFAR Awards $2.7 Million to Create Fellowship Program to Foster the Next Generation of Food and Agriculture Scientists

FFAR Awards $2.7 Million to Create Fellowship Program to Foster the Next Generation of Food and Agriculture Scientists

FFAR Will Collaborate With Industry Leaders and Universities to Provide Interdisciplinary Training for Graduate Students

WASHINGTON, January 17, 2017- The Foundation for Food and Agriculture Research (FFAR), a nonprofit established through bipartisan congressional support in the 2014 Farm Bill, today announced a $2.7 million grant to launch the FFAR Fellowship Program. A team at North Carolina State University led by John Dole, Ph.D., will manage the program. The grant will be matched by a consortium of industry leaders dedicated to preparing the agricultural workforce to optimize impact on the future of the industry.

The goal of the program is to combine cutting-edge food and agriculture science research with professional development training to better prepare graduate students for the workforce. The program will address the "STEM Paradox," or the observation that science, technology, engineering, and math students have strong scientific skills but sometimes lack other professional skills that make them successful in the workplace. Unlike other programs, the FFAR Fellowship focuses exclusively on food and agriculture sciences.

"At the Foundation for Food and Agriculture Research, we understand that the future of agriculture lies in training the next generation of scientists," said FFAR Executive Director Sally Rockey, Ph.D. "Students must be prepared to not only make the scientific breakthroughs that will sustain us but also have the professional skills to succeed in their careers across the agricultural sector."

The FFAR Fellowship Program will fund 48 graduate students over three years using an interdisciplinary approach to career readiness. Students will pursue research projects in an area of food or agriculture research related to FFAR's Challenge Areas and strategic initiatives, such as soil health, plant phenomics, precision agriculture, breeding technology, digital agriculture, and sustainable livestock production. In addition to academic advisors, students will be matched with industry mentors who will provide additional career guidance.

The flagship component of the FFAR Fellowship Program is the annual professional development workshop. Fellows will convene with industry peers to participate in training for professional and interpersonal skills, such as team building, project and time management, and science communication. These trainings will be complemented by a personalized development plan to help students obtain the professional skills they need to excel in the workforce.

"Industry and academia will be working together in this program to provide an unparalleled educational opportunity for graduate students studying in food and agriculture," said John Dole, Ph.D., North Carolina State University College of Agriculture and Life Sciences associate dean and director of academic programs. "The FFAR Fellows will be conducting innovative research, while learning what it takes to succeed from leading industry scientists."

Interested students should visit www.ffarfellows.org for details on eligibility, application requirements, and fellowship expectations.

###

About the Foundation for Food and Agriculture Research

The Foundation for Food and Agriculture Research, a 501 (c) (3) nonprofit organization, builds unique partnerships to support innovative and actionable science addressing today's food and agriculture challenges. Leveraging public and private resources, FFAR will increase the scientific and technological research, innovation, and partnerships critical to enhancing sustainable production of nutritious food for a growing global population. Established by the 2014 Farm Bill, FFAR is governed by a Board of Directors with ex officio representation from the U.S. Department of Agriculture and National Science Foundation.

Learn more: www.foundationfar.org | Newsletter Sign-Up

Connect: @FoundationFAR | @RockTalking

Philips Lighting’s New GrowWise Control System Gives Growers and Researchers More Flexibility and Control For LED Cultivation

Philips Lighting’s New GrowWise Control System Gives Growers and Researchers More Flexibility and Control For LED Cultivation

January 22, 2018

Eindhoven, The Netherlands – Philips Lighting (Euronext: LIGHT), the world leader in lighting, today announced the introduction of the GrowWise Control System which allows growers and researchers to easily create and run custom LED light recipes to meet the needs of specific crops to improve quality, productivity, and efficiency. The control system has been developed to work with the GreenPower LED production module “Dynamic”. It can be used as a standalone system or integrated into a climate or logistic computer system.

Custom light recipes to meet specific needs

“This is our first step towards digitization of Horti LED lighting systems,” said Udo van Slooten, Business Leader Horticulture at Philips Lighting. “The GrowWise Control System is the hardware platform that will allow us to build digital lighting control in the future. This will replace our current analog research systems.”

More control over every plant

A Philips Lighting light recipe provides the settings for the light spectrum, intensity, illumination moment, uniformity and positioning. The GrowWise Control System allows growers to create their own time-based recipes. Using a recipe, a grower can steer specific plant characteristics, from compactness, color intensity and branch development to flowering and more to improve results. With the GrowWise Control System, growers can give all the plants in their facility exactly what they need when they need it with just one LED system to enhance cultivation.

The GrowWise Control System controls 4 LED color spectra: Deep Red, Blue, White, and Far Red as well as the light duration and intensity. The system is easily updatable and has a maintainable digital system, making it future proof. The GrowWise Control System will be initially launched in Western Europe to work with the production module dynamic.

Philips Lighting will show its new products during IPM Essen, which takes place from January 23 to 26.

For further information, please contact:

Philips Lighting Horticulture LED Solutions

Daniela Damoiseaux, Global Marcom Manager Horticulture at Philips Lighting

Tel: +31 6 31 65 29 69

E-mail: daniela.damoiseaux@philips.com

www.philips.com/horti

About Philips Lighting

Philips Lighting (Euronext: LIGHT), the world leader in lighting products, systems and services, delivers innovations that unlock business value, providing rich user experiences that help improve lives. Serving professional and consumer markets, we lead the industry in leveraging the Internet of Things to transform homes, buildings and urban spaces. With 2016 sales of EUR 7.1 billion, we have approximately 34,000 employees in over 70 countries. News from Philips Lighting is located at the Newsroom, Twitter and LinkedIn. Information for investors can be found on the Investor Relations page.

Over 32 trillion Data Points Give Growers Solid Environmental Intelligence

Over 32 trillion Data Points Give Growers Solid Environmental Intelligence

17 January 2018

Darryn Keiller at head office

Autogrow, a leading global ag tech company, has announced their strategy to use trillions of available growing data points to help their growers’ crop production.

“Due to the unique nature of our architecture, over 32 trillion data points flow through our systems each year which would be one of the most substantial collections for indoor agriculture to date. Data is king when it comes to innovation but what you do with it is the key,” says CEO Darryn Keiller.

“The tricky part is, like most systems, a lot of the data generated contains noise. To date, our processing algorithm has filtered and stored over six billion data points which are then ingested by our state-of-the-art data pipeline, and analyzed by our scientists for our customers.”

Innovative. Exciting. Every aspect of your environment under your control.

Light and humidity, air flow, air and root temperature, nutrient delivery, pH balance and EC - with our systems every variable is under your direct control, so you can maximise growth and efficiency.

Optimise your environment for the best crop yield both in terms of quality and quantity.

Our systems let you directly manage your resources and productivity, offering 365 day availability, labour cost savings and the ease of controlling crop growth cycles.

“Our strategy is to orchestrate the data to make it meaningful for our growers, giving them deeper insight into their crop environments’, revealing critical factors of crop cycle and seasonality, to enable smarter decisions and better outcomes.”

Data is currently sourced from Autogrow’s MultiGrowTM, AphaeaTM, IntelliDoseTM and IntelliClimateTM control systems and, depending on the system being run, collates microclimate data every 3-5 seconds including air temperature, humidity, light levels, CO2, pH and nutrient levels as well as local macroclimate data.

The richness of the data is enormous spanning a vast array of produce, floriculture and arboreal plant nurseries in greenhouses, urban farms and protected cropping systems in over 40 countries.

Each grower can access their own data via the cloud or the controller at any time with enterprise-level security in place, but the biggest challenge for the grower is seeing past the large quantity of data to the quality insight.

Autogrow’s Director of Crop Science and Agronomy, Dr. Tharindu Weeraratne notes that information gathered gives a true reflection of how the plants are responding to their environment and what the optimum levels are for increased yields with high quality and consistency.

“All the factors involved including external and internal climate, plant biology, nutrient requirements, technology usage and how everything interacts together is vital. Add in the effects of consumer needs, geopolitical factors, and climate change, and those leafy greens or tomatoes are more complex than most consumers realize.”

“There are a few factors that can’t be controlled with crop production but by gaining knowledge and understanding of those factors you do have control over, it’s really the first step to true innovation and business growth.”

Green thumbs, helping hands.

Autogrow was born in the greenhouses of New Zealand. With more than 20 years experience working with growers around the world, we want to work with you to help you make the most of your growing space.

Scale at your own speed.

Autogrow lets you choose what variables you want to control. No unnecessary extra bells and whistles, just good, clean growing at a price point you can afford.

We're not a walled garden.

Our open systems approach means that wherever possible you can re-use your existing investment in equipment.

How This Greenhouse And Fish Farm Operation Is Fuelled

How This Greenhouse And Fish Farm Operation Is Fuelled By Bitcoin Mining

Local company using waste heat from bitcoin miners to operate new business in St. Francois Xavier

By Samantha Samson, CBC News Posted: Jan 04, 2018 5:00 AM CT Last Updated: Jan 04, 2018 6:34 PM CT

Myera Group uses waste heat from bitcoin miners to keep their building warm enough to grow plants like lettuce. (Lyzaville Sale/CBC News)

- Where to invest: Bitcoin or Canadian Tire money?

- Beyond bitcoin: How cryptocurrencies are changing the world

- Bitcoin's dirty secret: it wastes an incredible amount of energy

More than 30 computers sit on the second floor of a former car museum west of Winnipeg, quietly working to mine bitcoin.

The heat generated by those computers, which are verifying bitcoin transactions by solving cryptographic puzzles, helps warm nearby plants in a makeshift greenhouse.

To water, the trays filled with lettuce, basil and sprouted barley fodder, Bruce Hardy, the owner of this 20,000-square-foot building in the Rural Municipality of St. Francois Xavier, clicks a button.

A pump waters the plants with wastewater from tanks located on the first floor in which around 800 Arctic Char swim and breed. The wastewater from the tanks is rich in nitrates, a great fertilizer for the plants upstairs.

It's a complex operation but that's the beauty of it, according to the owner.

"It's all connected, much like Earth," said Hardy, president of Myera Group.

'A popular move'

His company's goal is to use technology to create sustainable food systems.

Hardy runs his own software company and has been in the bitcoin mining business for two years. He used to pay for air conditioning to cool off the computers but quickly realized there was a better use for the heat.

"When bitcoin came, they were an excellent proxy for what a server could do in terms of emulating heat, and whether we could use that heat for agricultural purposes," he said.

About a year ago, he opened his operation in the old Tin Lizzie Auto Museum and the former Grey Nuns convent located on Highway 26 just west of Winnipeg

The greenhouse operation is small right now, but Hardy says he hopes to create several greenhouses in St. Francois Xavier that are fuelled by waste heat from bitcoin mining. (Lyzaville Sale/CBC News)

"From what we've seen so far, it looks like a popular move for the community," says Dwayne Clark, the Reeve of the RM of St. Francois Xavier. "It's already cleaned up what used to be an eyesore for a number of years."

The company is still experimenting with using the heat from bitcoin mining in different ways. Right now, about one-quarter of the second floor is filled with computers and plants, but Hardy hopes to eventually fill the space.

Starting the operation would have been a lot more difficult without the bitcoin cash, said Hardy. The price of a bitcoin is hovering around $19,000 Cdn.

"The revenue from those bitcoins has helped me to keep staff on, it's helped me create these displays so we can show people what we're doing in agriculture innovation," said Hardy.

Hundreds of Arctic Char swim in these tanks at Myera Group's operation in St. Francois Xavier. (Lyzaville Sale/CBC News)

Ways to use 'Manitoba's gifts'

Hardy hopes his operation becomes a place where people can research and develop sustainable food systems while programmers work with bitcoin technology.

Australian researchers and Chinese investors have expressed interest in his operation, he said.

Manitoba is a prime location for electricity-intensive operations like this, said Hardy.

"Hydro is one of our best assets in the province," said Hardy.

Manitoba has the cheapest commercial hydro electricity rates in the country and among the lowest temperatures of major North American cities, making it attractive to bitcoin miners.

"If we can take our energy and use it here in Manitoba, we value-add that energy, and we can do all sorts of great things," he said.

Bruce Hardy, president of Myera Group, hopes to create a global campus in St. Francois Xavier for food sustainability. (Lyzaville Sale/CBC News)

Local Skills Showcased At Arab Innovation Academy

Local Skills Showcased At Arab Innovation Academy

16 Jan 2018 - 1:05

Dr Maher Hakim, Executive Director, QSTP, with other experts and officials during the Grand Pitching Session held at the end of Arab Innovation Academy. RIGHT: Sinan Al Obaidi, CEO of AG Automation, doing a presentation during the Grand Pitching Session of Arab Innovation Academy. PICs: Baher Amin / The Peninsula

By Fazeena Saleem / The Peninsula

Doha: The innovation skills of young entrepreneurs have been recently showcased at the first Arab Innovation Academy (AIA). The unique 10-day startup boot-camp was organised by Qatar Science & Technology Park (QSTP) in collaboration with the European Innovation Academy (EIA).

The programme provided more than 100 talented students and young entrepreneurs from across the Arab world with an opportunity to work under the guidance of leading Silicon Valley mentors and establish a start-up.

Under the guidance of leading global tech startup mentors, teams whose members had never met before were challenged to take an idea to a viable startup after just two intensive weeks of working together.

“The young tech entrepreneurs who have participated in the first Arab Innovation Academy care about our region. They are passionate about, and committed to, helping solve the challenges it faces, and they are now global ambassadors both for Qatar and for the Arab world - building bridges among communities and cultures, through innovation,” said Dr. Maher Hakim, Executive Director of QSTP.

“What we have achieved through AIA is to help young people build their confidence, not only in their ability to do things other people cannot do but to demonstrate that they can make a positive contribution to our world,” he added.

In a Grand Pitching Session at the end of the AIA, held on Thursday at the QSTP, participants live-pitched the startup ideas they had developed from scratch during the programme to investors and experts from around the world. Ten teams presented innovative projects.

The winner was AG Automation, a startup that aims to use technology to transform indoor farming.

“Arab Innovation Academy has been a great experience for me. I was able to learn many things as an innovator and entrepreneur. It helped me to become a global citizen as well as an innovator and entrepreneur. It is a great opportunity and Qatar is doing a great job by giving us this opportunity,” Sinan Al Obaidi, CEO of AG Automation told The Peninsula. He is from Iraq and perusing his Ph.D in the United States under the sponsorship of Qatar Leadership Program.

Al Obaidi also said that AG Automation aims at shifting conventional farming to a complete industrial process.

Through the AIA, participating students from universities in Algeria, Lebanon, Oman, Tunisia, Morocco, Jordan, and Qatar had the opportunity to leverage an extensive global network of leading tech entrepreneurship experts, who introduced them to innovation tools and methods developed by leading universities and companies including University of California, Berkeley; Stanford University; Google; Amadeus IT Group; and QSTP, part of Qatar Foundation Research and Development (QF R&D). During the Grand Pitching Session, a group of five students from different countries studying in Qatar and Lebanon presented their project ‘Carryon’ which uses the free space in travellers luggage to send packages worldwide.

The team included Pierre Wehbe and Hussein El Hajj from American University of Beirut; Ahmed Abdilmalik of Qatar University; Mohammad Jawad from Virginia Commonwealth University School of the Arts in Qatar and Hafis Bello from Hamad bin Khalifa University. “The Arab Innovation Academy gave us the right guidance on how to change an idea into an actual business. It was an mind-opening ten days for us; the whole programme was more practical than theoretical,” they said.

FarmBot Wants to Cultivate An Open-Source Future For Remote Farming

FarmBot Wants to Cultivate An Open-Source Future For Remote Farming

January 3, 2018

“Farm from anywhere” is a phrase we’re likely to hear more and more of as technology enables easier access to fresh, locally grown food. We just wrote about Babylon Micro-Farms, a remote, hydroponic farm you can keep inside your living room. There’s also a healthy urban farming market: thanks to companies like Farmshelf and Smallhold, restaurants, schools, and the average consumer get better access to fresh food and more involved in the food production itself.

But no one’s tackled the reinvention of farming quite like the folks at FarmBot.

FarmBot is basically precision agriculture for the people. When he launched the FarmBot project in 2011, founder Rory Aronson wanted to find a way to bring the benefits of remote farming to the everyman without the hefty price tag.

Precision agriculture normally involves technology like self-steering tractors and aerial drones that can make better use of resources. Because the method uses real-time data to understand weather, air quality, labor costs, and other factors, growers can make smarter decisions about how much and how often to employ resources. As its name suggests, precision agriculture provides meticulous records of every single step of the growing process.

Historically, it’s been the territory of industrial farmers. But thanks to Aronson, anyone with a little space and (considerably less) cash can get involved in food production.

Both FarmBot products, made up of cartesean coordinate robots along with software and documentation, can work on rooftops, in backyards, and can accommodate both small- and large-scale farming operations. It’s unclear whether the company means “farm from anywhere” literally, as it says on its website. But considering the highly customizable nature of the product, anyone with some tech know-how could theoretically hack the bot and make it work in any given climate.

A visual interface lets you “plan your garden like a videogame,” according to the company’s website. So the fact that the interface looks a bit like FarmVille is no coincidence. You can drag and drop plants into the virtual plot of land (below), build care regiments, and even scare away birds.

After the garden is planned, the machine plants seeds, measures soil moisture content and water, and can detect and destroy weeds. Email alerts tell a user when the crops are ready for harvest.

It’s also open source, including the hardware, software, and documentation. That means all design files, source code, and hardware specs are available for free on the company’s website, so anyone can customize their farm without having to fork over a bunch of extra money.

Right now, the FarmBot Genesis goes for $2,595 via the company’s website. The FarmBot Genesis XL, which is available for preorder, costs $3,295 and covers “421 percent the area of for just 38% more cost.” Shipments of both machines are expected to go out in May of this year.

Aronson would eventually like to get the price point down to $1,000. It’s unclear whether that will happen soon or if it’s some ways off. Meanwhile, FarmBot is making its way into universities and non-profits, and the company is working with NASA to develop open-source food production on Mars, the Moon, and deep space. Remote farming indeed.

All images courtesy of FarmBot.

China Will Grow Potatoes On The Dark Side of The Moon By The End of The Year

China Will Grow Potatoes On The Dark Side of The Moon By The End of The Year

JANUARY 5, 2017 TIBI PUIU

Credit: Pixabay / rkarkowski.

The moon has been neglected for far too long, and China seems keen on moving fast to cover all the lost lunar ground. The nation’s ambitious space program, among other things, is set on achieving several important milestones.

A trifecta, consisting of a lunar probe, lander, and rover, will be deployed to the moon’s orbit and surface respectively. This will be the first time a man-made contraption makes a soft landing on the far side of the moon, a site of renewed interest for many scientists. The mission will also carry insects and plants that will form a mini-ecosystem on the moon whose response will teach us valuable lessons in preparations for a manned outpost or even a colony.

Potatoes on the dark side of the moon

This remarkable mission is part of the Chinese Lunar Exploration Program (CLEP), otherwise known as the Chang’e Program, named so in honor of the Chinese goddess of the moon. Previously, the Chang’e program had already sent two orbiters and one lander to the moon.

In the first half of 2018, Chang’e 4 will initially launch a relay satellite aboard a Long March 5 rocket that will be positioned at the Earth-moon Lagrange point 2 (EM-L2).

Artist impression of the relay satellite slated for launch. Credit: CNSA.

This is where the satellite can essentially remain stationary relative to the bodies, since the Earth and Moon gravities cancel each other out. From this point, the communications satellite will relay data between controllers on Earth and the Chang’e 4 lander and rover slated to touch down on the moon’s far side — also known as the dark side of the moon since it faces away from Earth.

The lander and rover will be launched together six months after the relay satellite is deployed at EM-L2. The lander will be equipped with various instruments designed to study the lunar environment and geology in detail, but also a mini-habitat comprised of insects and plants.

“The container will send potatoes, arabidopsis seeds and silkworm eggs to the surface of the moon. The eggs will hatch into silkworms, which can produce carbon dioxide, while the potatoes and seeds emit oxygen through photosynthesis. Together, they can establish a simple ecosystem on the moon,” Zhang Yuanxun, chief designer of the lunar habitat, told theChongqing Morning Post.

Last year, researchers grew potatoes in Mars-like conditions. Pulling the same stunt completely outside of Earth will be a whole different challenge which will be very intriguing to follow.

The Chinese lunar rover which is supposed to land on the dark side of the moon by the end of the year. Credit: CASC/China Ministry of Defense

The lander and rover will be deployed in the huge South Pole-Aitken Basin. This is the single-largest impact basin on the moon, measuring a staggering 2,500 km (1,600 miles) in diameter and 13 kilometers (8.1 miles) deep. Previously, missions like the Lunar Reconnaissance Orbiter (LRO) and India’s Chandrayaan-1 orbiter confirmed that the basin contains water ice, likely sourced from meteors and asteroids.

This ice can survive in this form because the Aitken Basin is always shadowed. Once this finding was confirmed by NASA, the site has immediately been singled out as an important candidate for a possible lunar base. With this context in mind, the Chang’e 4 mission is valuable in the sense that it can help establish not only what the local terrain in the basin is like but also how the environment will influence organisms. For instance, gravity on the moon is just 16% that of Earth. Plants use gravity to decide the direction of their growth, and a strong or weak gravitational pull will also affect the height of plants.

If all of this sounds exciting, know that once the lunar habitat container is deployed at the end of this year, China plans to live stream the plants’ growth and development.

Your message can also be among the 20,000 that will be sent into space via the relay satellite. You can submit it to the WeChat account ‘slecbj’ from Dec. 19, 2017, to March 6, 2018.

webmaster@cnsa.gov.cn

Grow Pod Solutions Introduces Automated Farming to The Investor Community

Grow Pod Solutions Introduces Automated Farming to The Investor Community

NEWS PROVIDED BY Grow Pod Solutions

CORONA, Calif., Dec. 19, 2017 /PRNewswire/ -- Grow Pod Solutions, the developer of portable indoor growing environments, recently held a technology investor conference at its company's headquarters in California. The conference attracted some top investors and professional athletes.

Grow Pod Solutions has developed the world's most advanced growing pods. Their container farms are fully automated, and feature innovations such as greenhouse control software, Bipolar Ionization, automatic dosing, fertigation scheduling and full-time surveillance. The system conserves water, has minimal energy costs, and produces clean, pesticide-free crops.

Grow Pod president, George Natzic, spoke about the company's innovative technology and its ability to change the way food is grown and distributed in America.

"You can take charge of your food chain, and grow healthy, natural produce – without pesticides year round," he said.

Natzic said that Grow Pod Solutions allows individuals, businesses and organizations to grow anywhere, for profit or humanitarian efforts.

"No one needs to go to bed hungry," Natzic said. "Our automated farming technology can grow healthy food virtually anywhere on the planet."

Event key note speaker, Shannon Illingworth, Chief Innovation Officer at AR Systems, shared news about the strategic alliance between AR Systems and Grow Pod Solutions. AR Systems has developed advanced control systems for use in the automated farming industry, and has reached an agreement with Grow Pod Solutions as a technology provider.

"Our technology focuses on data acquisition, supervisory controls, sequencing actions, and the data logging aspects of automated farming," Illingworth commented.

Kyle Turley, former NFL All-Pro, also spoke at the event. Turley played with the New Orleans Saints, St. Louis Rams, and Kansas City Chiefs. He is a member of the advisory board at Grow Pod Solutions and spoke about his involvement with the company.

"I enjoy working with the team at Grow Pod Solutions and helping them extend their reach into sectors I deeply care about," Turley said. "The automation and technology we developed can empower people, communities, and organizations, by providing the tools they need to grow healthy foods and medicines anywhere in the world."

Turley said that Grow Pods are more than just fancy technology. "Our systems can dramatically improve lives."

For information on Grow Pod Solutions, visit: www.growpodsolutions.com or call (855) 247-8054.

Connect:

Email: info@growpodsolutions.com

Website: www.growpodsolutions.com

Facebook: facebook.com/GrowPodTechnology

Twitter: @GrowPodSolution

Media:

Innovation Agency

310-571-5592

www.inov8.us

info(at)inov8.us

3D Printing Saves Time and Money in Urban Farming Product Design and Prototyping