Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Roto-Gro Set To Blast Into Space With Food Production System

Roto-Gro is capitalizing on the space exploration boom, as it applies to a NASA challenge developing novel food production technologies to feed astronauts on long-term missions

Advanced Agritech Company Roto-Gro International (ASX: RGI) Is Aiming To Feed The World’s Astronauts.

August 9, 2021

Roto-Gro is capitalizing on the space exploration boom, as it applies to a NASA challenge developing novel food production technologies to feed astronauts on long-term missions.

Advanced agritech company Roto-Gro International (ASX:RGI) is aiming to feed the world’s astronauts as it capitalizes on innovations in food production systems and a boom in space exploration.

Roto-Gro World Wide (Canada), a wholly-owned subsidiary of Roto-Gro International, has applied to the Deep Space Food Challenge as part of its first step into the space agriculture sector.

Administered under an international collaboration between National Aeronautics and the Space Administration (NASA) and the Canadian Space Agency (CSA), the international competition aims to incentivize the development of novel food production technologies needed for long-development space missions and terrestrial applications.

Roto-Gro’s application highlight’s the technological diversification and adaptability of its patented proprietary indoor vertical farming technology.

Astronauts’ food needs changing as missions evolve

Astronauts currently receive food from spacecrafts regularly launching from Earth, for example to the International Space Station.

However, NASA and the CSA recognize that as the distance and duration of space exploration missions increase, the current method of feeding astronauts will no longer be sustainable.

Future astronauts will be required to use food production systems on their voyages and be self-sustaining. The challenge aims to inspire the agricultural industry to help bring innovative food production technologies to space, reducing the need for resupply from earth and ensuring astronauts have continuous safe and nutritious food supplies.

The ability to develop sustainable food production is considered the crucial next step for longer-term human presence on the lunar surface and the future missions to Mars.

The challenge is not only about space exploration but also missions in extreme arid and resource-scarce environments on Earth. Like space, input efficiency will be key, including the efficient use of water and electricity to reduce resources needed for food production here on Earth.

Adapting Roto-Gro’s existing models key to space success

A new Roto-Gro rotational garden system — branded Roto-Gro Beyond Earth — will be designed with engineering adapted-off components from its existing Model 420 and Model 710 rotational garden systems.

Roto-Gro Beyond Earth will be a smaller, more portable version of the Model 420 but feature the injection feed system from the Model 710, significantly reducing the required resource inputs while maximizing nutritional outputs when compared to other indoor farming technologies.

Roto-Gro CEO Michael Di Tommaso said Roto-Gro Beyond Earth will enhance the already existing, unique benefits of its rotational garden systems, optimizing both the operational efficiencies and yield per m2, which is crucial to the development and prospective use of food production systems in space.

“The technology developed to form the application to the challenge is astoundingly demonstrating the vast applicability and sheer innovation of the company’s technology,” Di Tommaso said.

He said the company had developed several key relationships with organizations currently providing food system solutions for long-duration space voyages, along with others focused on using space to solve problems we are experiencing on earth.

“We look to develop and foster these relationships moving forward, further strengthening our position in the sector,” Di Tommaso said.

He said entering the space agricultural sector was a natural progression for Roto-Gro, supporting its vision to provide sustainable technological solutions for agricultural cultivation, critical to ensuring global food security.

“Food system innovation is crucial to our progression in space, and we are excited with the prospect of moving to the next phase of the Deep Space Food Challenge, while also generating other opportunities to develop and implement Roto-Gro’s technology in the industry,” Di Tommaso said.

Roto-Gro global forecasts international growth

Established in 2015, Roto-Gro is continuing to attract interest on a global scale.

The company recently partnered with agriculture company Verity Greens Inc. who has signed a binding $10M Technology License to purchase 624 RotoGro Model 710 rotational garden systems, with the first, flagship indoor vertical farming facility to be built in Canada.

The deal is expected to generate long-term, sustained recurring revenue with Di Tommaso hailing it as not only a “win-win” for both companies but a venture that works on a socially responsible level by helping tackle global food shortages.

“RotoGro will introduce our revolutionary technology into the booming indoor vertical farming space, while Verity Greens, utilizing the RotoGro Garden Systems and supporting technology, will operate with a viable and cost-effective competitive advantage,” he said.

“Verity Green’s first facility also serves to further its objectives – to roll out indoor vertical farming facilities globally utilizing RotoGro’s technology, not only to generate substantial revenue for both companies but also to provide a truly sustainable solution to address the issues caused by food insecurity.”

Lead photo: Pic: Giphy

This article was developed in collaboration with Roto-Gro International, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Growing Vegetables In Antarctica In the EDEN ISS Project

Scientific research studies to determine how to grow plants in extreme environments on Earth will help NASA understand how to grow plants in extreme conditions on the moon or Mars

Status Report From NASA Biological & Physical Science

July 1, 2021

Scientific research studies to determine how to grow plants in extreme environments on Earth will help NASA understand how to grow plants in extreme conditions on the moon or Mars. Growth of crop plants in lunar or Mars habitation systems will be essential for meeting astronaut nutritional needs and maintaining astronaut health during long-duration exploration missions. To facilitate these studies, an international agreement between NASA and DLR (German Space Agency) has been signed to enable research collaboration on the EDEN (Evolution and Design of Environmentally-Closed Nutrition-Sources) ISS project at the German Neumayer III Station in Antarctica.

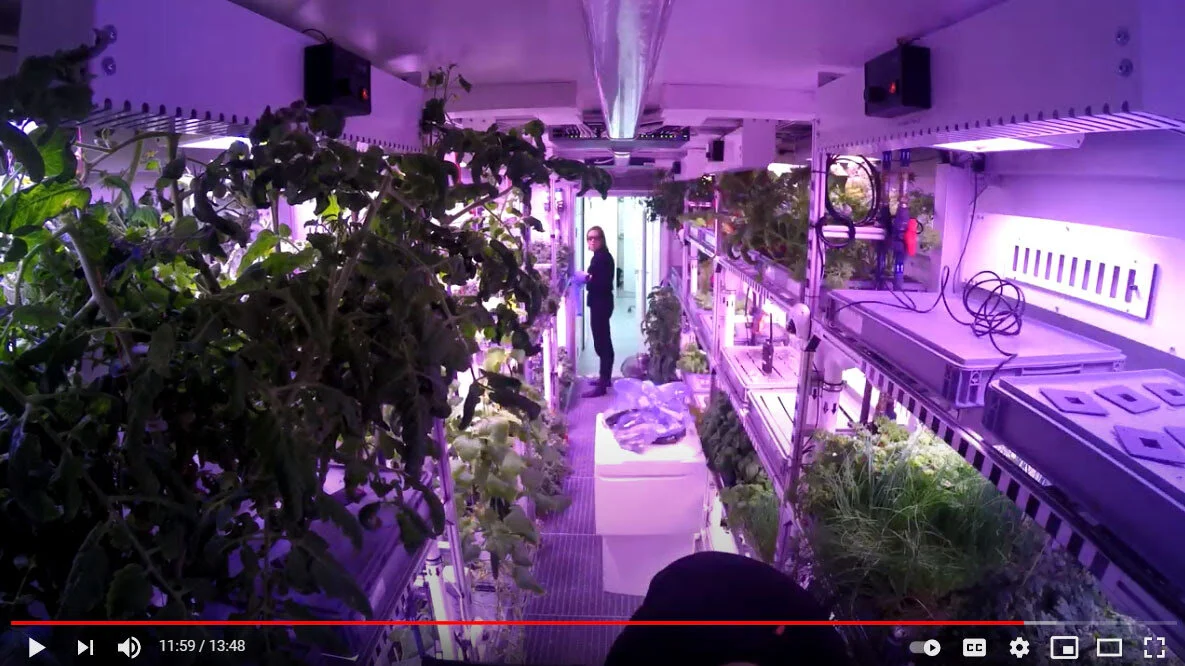

The EDEN module is designed to simulate a plant production system that might operate in a surface setting in space and is used to provide fresh food to the 10 “over-wintering” EDEN crew members. Biological and Physical Sciences research has been conducted at the EDEN site under the Space Biology grant titled “Spectral Imaging within the EDEN ISS Project - An Antarctic Analog for Enhancing Exploration Life Support.” For this Space Biology grant, PI Dr. Robert Ferl and Co-I Dr. Anna-Lisa Paul (both from the University of Florida) traveled to Antarctica to conduct their research.

Kennedy Space Center (KSC) continues to support EDEN ISS. For this project, KSC contractor Jess Bunchek is in residence in Antarctica as one of the crew members at Neumayer III where she is operating and maintaining the plant chamber with the help of DLR colleagues at Bremen, Germany. She is growing crops that have been grown on ISS for BPS-funded experiments to compare growth in the two settings. She is tracking her time spent on horticultural activities, measuring the yields of the different crops, taking microbial samples for post-mission analysis, and helping administer surveys to the crew to obtain their opinions on having fresh food in their diet. Jess arrived in Antarctica in January 2021 and will be there until February 2022. Follow Jess as she journals her account of the journey to EDEN ISS.

Watch the video about the EDEN ISS project

Start of A New Series of Tests For Plant Cultivation on The Moon And Mars

The EDEN ISS greenhouse uses particularly robust varieties that were selected by the EDEN ISS Project team and from experiments at NASA’s Kennedy Space Center and as part of the VEGGIE project on the ISS

MAY 4, 2021

NASA Seeds Germinate in

DLR’s EDEN ISS Greenhouse

Start of a new series of tests for plant cultivation on the Moon and Mars

Nine weeks of darkness and temperatures down to minus 50 degrees Celsius. Under these harsh conditions of Antarctica, NASA and the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) have begun a joint series of experiments on vegetable cultivation techniques for use on the Moon and Mars. Until early 2022, NASA guest scientist Jess Bunchek will research how future astronauts could grow lettuce, cucumbers, tomatoes, peppers, and herbs, using as little time and energy as possible.

To this end, she will be working at DLR’s EDEN ISS Antarctic greenhouse, where she will put greenhouse technologies and plant varieties to the test. She is also recording any effects the greenhouse and its yield have on the isolated hibernation crew in the perpetual ice. Bunchek is part of the 10-person overwintering crew on Neumayer Station III, operated by the Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research (AWI).

First harvest – Lettuce, mustard greens, radishes and herbs

“The polar night will soon begin here on the Antarctic Ekström Ice Shelf. With the nine other members of the overwintering crew, it almost feels like we are alone on another planet,” says Bunchek. “In this hostile world it’s fascinating to see the greenery thrive without soil and under artificial light.” Bunchek is a botanist from the Kennedy Space Center, where she has primarily supported the VEGGIE project on the International Space Station (ISS) She was able to sow the first seeds in recent weeks, following a technical reconditioning of the EDEN ISS platform conducted by her and the DLR team. The first harvest, which included lettuce, mustard greens, radishes, and various herbs, followed a few days ago.

NASA seeds and new nutrient supply system

The EDEN ISS greenhouse uses particularly robust varieties that were selected by the EDEN ISS Project team and from experiments at NASA’s Kennedy Space Center and as part of the VEGGIE project on the ISS. The DLR/NASA mission also aims to record and compare the growth and yield of the crop varieties under the conditions of the Antarctic greenhouse. An additional focus will be studying which microbes thrive in the greenhouse alongside the cultivated plants.

NASA will also be testing a plant watering concept in the EDEN Module that can operate in u-gravity settings, like the ISS. The system contains the water and delivers it to the plants by a passive method. “This will provide a side-by-side comparison with the aeroponically grown plants of EDEN ISS” says Ray Wheeler, plant physiologist at NASA’s Kennedy Space Center. In aeroponic irrigation, the roots of the plants without soil are regularly sprayed with a nutrient solution.

Crew time – a precious commodity

Sowing, harvesting, tending, cleaning, maintaining, calibrating, repairing and conducting scientific activities. Bunchek records every second of her activities in the Antarctic greenhouse with a special time-recording eight-sided die, as crew time will be a precious commodity on future missions to the Moon and Mars. “In an initial test run of the greenhouse during the 2018 mission, we found that operations still took too much time,” explains EDEN ISS project leader Daniel Schubert from the DLR Institute of Space Systems in Bremen. “Now we are working on optimizing processes and procedures. We have learned a lot about operating a greenhouse under extreme conditions. We’re applying all this during the current joint DLR/NASA mission.” In addition to the crew’s time, the focus is on their well-being. The overwinterers regularly answer questions about their eating habits or how the plants affect their mood. “We hope to increase our understanding of having plants and fresh food for crews in remote, isolated settings like Neumayer III and ultimately for space” says Wheeler.

Eight months in isolation

On 19 January, Jess Bunchek reached the Antarctic continent on board the research vessel Polarstern. Since 19 March, the 10-person overwintering crew has been on their own at Neumayer Station III. “EDEN ISS is an asset for the crew in many ways,” says Tim Heitland, Medical Coordinator and Operations Manager at AWI. “I know from my own overwintering experience just how much you can begin to miss fresh produce. It’s not just about the taste, but also the smells, the colors, and the fascinating fact that something can grow in this inhospitable environment. That’s why there are always volunteers in the overwintering teams to help cultivate and harvest the plants.” The polar night at Neumayer Station III begins on 21 May, and the first rays of sunlight will not reach the station again until 23 July. Researchers for the summer season and new supplies will end the isolation of this year’s overwintering crew around the beginning of November.

The activities at the EDEN ISS Antarctic greenhouse can be followed on social media using the hashtag #MadeInAntarctica. The Antarctic greenhouse has Facebook and Instagram accounts, as well as a flicker image gallery. Jess Bunchek also writes about her personal experiences of the Antarctica mission in the dedicated DLR blog.

How The International Space Station Helps NASA Study Plant Growth In Space

Food for crews aboard the ISS is prepackaged, degrades, and requires resupply. But what if astronauts could grow some of their own food in microgravity?

As NASA plans long-duration missions to the Moon and Mars, a key factor is figuring out how to feed crews during their weeks, months, and even years in space.

Food for crews aboard the International Space Station is primarily prepackaged, requires regular resupply deliveries aboard cargo spacecraft, and degrades in quality and nutrition after about 18 months. But what if astronauts could grow some of their own food in microgravity? Researchers on Earth and crews aboard the International Space Station are exploring the idea by testing various crops and equipment to see if the plan could work.

NASA hopes to successfully grow fresh, pick-and-eat crops that are easy to produce and do not require a lot of extra equipment or precious electrical power. “Crews really seem to enjoy growing the food themselves,” said Howard Levine, chief scientist for NASA’s International Space Station Research Office at Kennedy Space Center in Florida. “It’s a nice reprieve from typical activities on the station, and astronauts often volunteer their free time to do it.”

To date, NASA has grown a variety of plants, including lettuces, mustard varieties, and radishes – and learned a lot about how to successfully do so in the process.

Here are seven aspects of plant growth they are studying aboard the space station:

1) Picking the right plants

What grows well on Earth may or may not do so well in space. Before sending a crop to space, scientists must identify which plants to test aboard the space station. To improve that process, NASA started a project in 2015 with the Fairchild Botanical Garden in Miami called “Growing Beyond Earth.” The program has recruited more than 230 middle and high school science classes across the U.S. to grow different seeds using special equipment. Seeds that grow well in the classrooms are then tested in a chamber at Kennedy that closely resembles the space station’s equipment. Selected seeds that do well at Kennedy are then sent to the station. How they grow in orbit can inform the selection of plants for long-duration missions only minimal crew attention.

2) Learning to garden in space

Plants need a place to grow, and NASA has tested out a number of facilities to host a microgravity garden. One way is by experimenting with the Vegetable Production System, or “Veggie,” which is a simple, low-power gardening chamber that can hold six crop plants. Seeds are grown in small fabric “pillows” placed in Veggie. Crews then look after and water the plants by hand, similar to caring for a window herb garden on Earth.

NASA is developing another system, called the Passive Orbital Nutrient Delivery System, or PONDS, to work with the Veggie platform. PONDS replaces the seed pillows with a new plant holder that automatically feeds and waters the produce, but still requires the crew to do some cultivation tasks. Research also uses a hands-off system called the Advanced Plant Habitat. This fully automated device is designed to study the physiology of how plants grow in space in ways that require only minimal crew attention.

3) The right light

The composition of light that shines on plants can affect their size, nutritional content, microbial growth, and taste. Plants particularly rely on red and blue light to grow. Researchers ran experiments aboard the space station to see how different ratios of red and blue light influenced plant development in space. The experiments showed that plants in space grow well under the same light conditions preferred by plants on Earth. While green lights are not necessary for plant growth, they are included in plant growth systems so the plants also appear similar to those grown on Earth.

4) The influence of gravity

Changes in gravity can affect how plants grow and how many crops they yield. Plants can sense gravity using a mechanism that involves changes to calcium within their cells. Astronauts recently ran experiments aboard the space station to measure how microgravity affects these calcium levels, which could offer clues for designing improved ways of growing crops for food in space.

In the PESTO experiment, crews grew wheat plants to see how microgravity may change some of their key features. They found that microgravity alters leaf development, plant cells, and the chloroplasts used in photosynthesis, but did not harm the plants overall -- in fact, wheat plants grew 10% taller compared to those on Earth.

Station crews also successfully grew two generations of mustard plants using the Advanced Astroculture chamber for an experiment that showed the change in gravity caused seeds to be smaller and secondary branches and seed pods to grow differently. Additionally, the experiment grew soybeans from seed-to-seed in space, which produced larger plants and seeds.

5) Water delivery

One significant challenge to growing plants in microgravity is providing enough water to their roots to keep them healthy without drowning the plants in too much water. Numerous experiments have tested a variety of methods to achieve this, including the new PONDS facility mentioned above and the Plant Water Management experiment. The water management study demonstrated a hydroponic method for providing water and air to the root zone to help them grow. Researchers are growing plants both aboard the space station and on Earth to compare how well they develop.

6) How old is too old?

Future space missions could go on for years, which means the seeds that astronauts bring along could be far from fresh by the time they need to plant them. On Earth, seeds have a decrease in viability and germination over time. But how do the age of seeds and long-term exposure to the spaceflight environment affect their ability to germinate and grow? To find out, in January 2021 NASA grew lettuce and seeds from the cabbage family (kale, mustard, and bok choi) that had been aboard the station for nearly three years. The results showed that while the lettuce seeds did not grow well compared to seeds that had been in space less time, the mustard seeds responded better than expected to the storage time in space.

7) The human effect

Gardens need tending, of course, which means astronauts or robots have to look after the plants that are growing. NASA studied how gardening in space could contribute to the behavior and well-being of astronauts. Many astronauts reported they found caring for the plants a fun and relaxing activity.

“Taking care of plants can also help astronauts stay in touch with the life cycles on Earth,” said Gioia Massa, a life sciences project scientist at Kennedy. Massa’s research focuses on growing plants aboard the space station.

What’s more, astronauts say the time spent gardening makes them excited to eat the fresh produce once it’s ready. The excitement motivates astronauts to creatively use the produce as ingredients in their meals, increasing their quality of life in space and boosting their morale.

For more information:

NASA

www.nasa.gov

8 Apr 2021

AUSTRALIA: NSW Architect’s Idea For Sustaining Life on Mars is a Winner

Calabrese’s submission outlined how rockets would send robotic self-building farms a year prior to the first human landing. Using Artificial Intelligence and 3D printing, these buildings, preloaded with seeds, would then assemble autonomously and begin growing enough fruits and vegetables to sustain nine astronauts for up to two years

7/12/2020

Architecture news & editorial desk

A proposal conceptualized by an NSW architect for an international design competition that sought ideas for sustaining life on Mars has won the top prize.

Giuseppe Calabrese, the senior architect at Council Approval Group – a small Australian town planning and architecture firm – was placed first at the international competition launched by the Californian smart city development company, Mars City Design, and backed by NASA. The primary objective of the competition was to source ideas to sustain human life on Mars for more than two years.

Calabrese’s submission outlined how rockets would send robotic self-building farms a year prior to the first human landing. Using Artificial Intelligence and 3D printing, these buildings, preloaded with seeds, would then assemble autonomously and begin growing enough fruits and vegetables to sustain nine astronauts for up to two years.

Last month, Calabrese was shortlisted in the top 10 designs, competing against international firms from the USA, Germany, United Arab Emirates, and Taiwan. On the live-streamed awards night recently, his submission was announced as the winner for ‘Mars City Design Urban Farming Challenge 2020’, which was presented by NASA astronaut, Col. Terry Virts.

Until less than a year ago, Calabrese spent his time designing granny flats, duplexes and boarding houses for investors. Following the COVID pandemic, he was able to keep his job thanks to the Job Keeper program. During this period, he was also able to use his surplus design time on a passion project – town planning on Mars. When the competition came up, he decided to apply his architectural skills to the challenge.

Competition founder Vera Mulyani was very impressed with the Australian submission, not only for the visually appealing designs but also for the fact that every detail was supported by hundreds of pages of research and scientific data.

“Our next step is to secure funding, so we can build a prototype of the winning designs, which include Calabrese's proposal, in the Californian desert,” Mulyani added.

Calabrese’s smart farm idea couldn’t have come at a more perfect time given that NASA’s latest high-tech Rover will be reaching Mars in February 2021 while Elon Musk is considering a mission to the red planet as early as 2024.

“Australia already leads the world in many farming practices. So why not in space? And when billionaire Elon Musk needs an architect to design his mansion on Mars, he now knows who to call,” Calabrese said with a smile.

Abu Dhabi’s AgTech Ecosystem Expands Across Land, Sea And Space

The Abu Dhabi Investment Office (ADIO) announced today individual partnerships with Pure Harvest Smart Farms (Pure Harvest), FreshToHome, and Nanoracks that will see the companies receive financial and non-financial incentives totaling AED 152 million (USD 41 million)

ADIO partners with Pure Harvest Smart Farms, FreshToHome, and Nanoracks

AED 152 million (USD 41 million) incentives for ‘land, sea and space’ projects to increase AgTech capabilities for food production in arid and desert environments

New partnerships part of ADIO’s AgTech Incentive Programme, established under Ghadan 21, Abu Dhabi’s accelerator program

Abu Dhabi, UAE – 10 November 2020: Three innovative agriculture companies will develop cutting-edge projects in Abu Dhabi to boost the emirate’s agriculture technology (AgTech) capabilities across land, sea, and space. The Abu Dhabi Investment Office (ADIO) announced today individual partnerships with Pure Harvest Smart Farms (Pure Harvest), FreshToHome, and Nanoracks that will see the companies receive financial and non-financial incentives totaling AED 152 million (USD 41 million). The research and technologies developed by these companies will expand existing capabilities in Abu Dhabi’s AgTech ecosystem and promote innovation in the sector to address global food security challenges.

The new partnerships are a continuation of ADIO’s efforts to accelerate the growth of Abu Dhabi’s AgTech ecosystem through the AgTech Incentive Programme, which was established under Ghadan 21, Abu Dhabi’s accelerator program. The Programme is open to both local and international AgTech companies. The partnerships follow ADIO’s AED 367 million (USD 100 million) investment earlier this year to bring four AgTech pioneers – AeroFarms, Madar Farms, RNZ, and Responsive Drip Irrigation (RDI) – to the emirate to develop next-generation agriculture solutions in arid and desert climates.

H.E. Dr. Tariq Bin Hendi, Director General of ADIO, said: “Abu Dhabi is pressing ahead at full steam with our mission to ‘turn the desert green’ and solve long-term global food security issues. We have created an environment where innovative ideas can flourish and this has enabled the rapid expansion of our AgTech sector. Innovations from the companies we partnered with earlier this year are already propelling the growth of Abu Dhabi’s 24,000 farms. Partnering with Pure Harvest, FreshToHome and Nanoracks adds a realm of new capabilities to the ecosystem across land, sea, and space.”

Bin Hendi continued: “We are driving innovation across the entire agriculture value chain and this is producing a compounding effect that is benefiting farmers, innovators, and companies in our region and beyond.”

Pure Harvest, FreshToHome, and Nanoracks have been awarded financial and non-financial incentives to expand operations in Abu Dhabi. The competitive incentive packages include rebates on innovation-linked high-skilled payroll, high-tech CAPEX, as well as land, utility, and intellectual property support.

Since the beginning of 2020, ADIO has attracted seven AgTech companies to Abu Dhabi, each bringing a complementary skill to expand the ecosystem. ADIO’s new partnerships with Pure Harvest, FreshToHome, and Nanoracks will build on the achievements made by AeroFarms, Madar Farms, RNZ, and RDI, the AgTech pioneers ADIO partnered with earlier this year to establish R&D and production facilities in Abu Dhabi.

Partnerships with Pure Harvest, FreshToHome, Nanoracks

Pure Harvest is a home-grown, tech-enabled farming venture that uses cutting-edge food production systems to grow fresh fruits and vegetables in a climate-controlled environment, enabling year-round production anywhere, while using seven times less water compared to traditional farming methods. Pure Harvest will invest in smart farming and infrastructure technologies at its new farms in Al Ain, Abu Dhabi, to optimize growing conditions through hardware design innovations, artificial intelligence, autonomous growing and robotics, plant science research, and desert-optimized machines. The company will also progress R&D and deployment of a commercial-scale algae bioreactor production facility that will grow higher quality, healthier Omega-3 fatty acids without the limitations and challenges of traditional animal sources.

Sky Kurtz, Co-Founder, and CEO of Pure Harvest, said: “We are delighted to have received the support of ADIO to further invest in our home-grown, innovative growing solutions. It also serves as a powerful endorsement of our business case and mission as we pursue innovation to address food security locally and internationally. As one of the pioneering champions in the region’s emerging AgTech sector, this commitment will give us the resources we need to drive and expand our R&D capabilities and will position us for international expansion from our strategic base in Abu Dhabi. This partnership further demonstrates how committed the government is in supporting and enabling innovative technology companies, providing them with the tools, resources, and support to thrive and make a large-scale impact in the region.”

FreshToHome is an e-grocery platform for fresh, chemical-free produce. The company maintains complete control over its supply chain, inventory, and logistics by obtaining produce directly from the source through an AI-powered auction process. ADIO’s partnership will aid the expansion of FreshToHome’s land and sea operational and processing capabilities in the UAE, bringing expertise in aquaculture, contract farming for marine and freshwater fish species, and precision agriculture to Abu Dhabi. It will also invest in innovative fish farming technologies and cold chain.

Shan Kadavil, CEO and Co-Founder of FreshToHome, said: “At FreshToHome we use cutting-edge research in AI and precision aquaculture for furthering food security in a sustainable manner while also giving better value to consumers, fishermen, and farmers. To this end, we intend to bring our US patent pending AI-powered Virtual Commodities Exchange technology, our e-grocery platform, and our nano farm aquaculture technology to Abu Dhabi, enhancing food production and distribution for the region. ADIO has been a terrific partner to us and we are thankful for their support in helping us be part of the vision.”

US-based Nanoracks, the single largest commercial user of the International Space Station, opened its first UAE office in Abu Dhabi’s global tech ecosystem, Hub71, in 2019. Nanoracks is building the first-ever commercial AgTech space research program, the ‘StarLab Space Farming Center’, in Abu Dhabi as a commercial space research facility focused on advancing knowledge and technology for organisms and food produced in space and in equally extreme climates on Earth. The space-based technology will be applied to desert agriculture to address pressing environmental and food security challenges and to benefit long-term human space exploration.

Allen Herbert, SVP of Business Development and Strategy, and Head of Nanoracks, UAE, said: “Much of today’s technology used for vertical, urban and closed environment agriculture initially came from space research from 30 years ago, and Nanoracks is ready to synergize these technologies back to in-space exploration. We firmly believe that space research holds the keys to solving major challenges on Earth from climate change to food security. And our StarLab Space Farming Center in Abu Dhabi is just the beginning. We’re building a global research and development team that will produce and commercialize organisms, technology, and innovative products that will not only revolutionize farming in Earth’s deserts and harsh environments but also change the way humans are able to explore deeper into our universe.”

How A Winnipeg Company Wants To Change Agriculture

Conviron has provided plant growth chambers and technology to the top government research agencies, universities and AgBiotech companies in over 90 countries around the world

Here are some other interesting tidbits about Conviron. Founded in 1964 by the Kroft family, CEL Group of Companies is headquartered in Winnipeg, MB. CEL comprises Conviron Canada, USA and Australasia. It also includes Argus Controls, a supplier of plant-centric environmental controls and automation systems used in greenhouse and indoor growing facilities.

Conviron has provided plant growth chambers and technology to the top government research agencies, universities and AgBiotech companies in over 90 countries around the world.

CEO Steve Kroft, often refers to his company’s solutions as 'weather in a box' because they mimic outside conditions and changing seasons over time through the automated control of temperature, light, humidity, irrigation and nutrients. In effect, it's a specialized type of high-tech greenhouse or indoor farm with environmental factors that can be precisely controlled.

The company has also delivered equipment to biotech companies like Medicago for the incubation and germination of tobacco plants critical for their research into plant-based vaccines for Ebola and SARs. Medicago recently announced it has produced a virus-like particle of the novel coronavirus, a first step towards producing a vaccine, which will now undergo preclinical testing.

Chambers range in size from six sq. ft. to over 2,000 sq. ft. depending on the application and includes lighting, temperature and humidity systems as well as a user-friendly control system to create and manipulate any kind of climate regime.

Argus Controls makes controlled environments for plant growth. It provides systems that automate the monitoring and controlling of all horticulture operations through on-site, remote and mobile interfaces.

Dating back to the early 1990s, Conviron has provided NASA with several chambers to support its research related to growing plants in outer space. The University of Guelph uses Conviron chambers and Argus controls systems in their high-tech facility in their research aligned with the Canadian Space Agency and International Space programs.

Since 2005, the National Science Foundation's Amundsen-Scott South Pole Station in Antarctica has been using an Argus control system to operate its food growth chamber that provides fresh vegetables and some much needed light, humidity and green space for the staff and scientists who winter at the station. The system operates the lighting, temperature control, and hydroponic nutrient feeding systems in the chamber, which is programmed and managed remotely from the University of Arizona.

Researchers at University College Dublin in Ireland can reconstruct prehistoric atmospheres using Conviron chambers and investigate plant evolution throughout Earth's history.

When canola was first developed in the 1970s, part of the research was done in Conviron chambers. Canola is the world’s only “Made in Canada” crop. In response to the ban of trans-fatty acids in food products, canola was developed by researchers from Agriculture and Agri-Food Canada and the University of Manitoba in the 1970s, using traditional plant-breeding techniques.

Some of the turf used around the greens at Augusta National Golf Club was also developed in Conviron equipment.

Source: Economic Development Winnipeg.

Publication date: Fri 22 May 2020

The Indoor Farm Revolution

Coronavirus chaos has spurred a grow-your-own food movement — and space-age hydroponic technology is rising to meet it.

Coronavirus chaos has spurred a grow-your-own food movement — and space-age hydroponic technology is rising to meet it.

NOTE FOR 2020 READERS: This is the eleventh in a series of open letters to the next century, now just 80 years away. The series asks: What will the world look like at the other end of our kids' lives?

Dear 22nd Century,

For all the pain, grief and economic hardship the 2020 coronavirus pandemic has sown, a handful of green shoots seem to have taken root in its blighted soil.

Green being the operative word, because many of these developments could be a net positive for the planet. In lockdown, many of us are seeing what our cities look like without smog. Office workers are experiencing office life without the office; just last week, Twitter announced that most of its employees could work from home forever, while much of Manhattan is reportedly freaking out about what could happen to commercial real estate. Thousands of companies just discovered they can still function, and maybe even function better, when they don’t chain employees to desks or force them to make a soul-crushing, carbon-spewing commute 10 times a week.

And what do more people do when they’re spending more time at home? Well, if you’re like my wife, you start literally planting green shoots. Our house is filling up with them as I write this: lettuce, chard, tomatoes, basil, strawberries, to name the first five shoots poking out of dozens of mason jars now taking up residence on every windowsill. She’s hardly alone; garden centers and seed delivery services are reporting as much as 10 times more sales since the pandemic began. Even the mighty Wal-Mart has sold out of seeds. If viral Facebook posts and Instagram hashtags are any guide, pandemic hipsters have moved on from once-fashionable sourdough starters to growing fresh fruit and veg.

Another one of our cyclical “back to the land” movements seems to be underway, just like during the 1960s and the Great Depression before that. Only this time, we don’t need land. We don’t need soil. We don’t need pesticide of any kind. We don’t even need natural light. Thanks to giant leaps forward in the science of hydroponics and LED lighting, even people in windowless, gardenless apartments can participate in the revolution. With a number of high-tech consumer products on the way, the process can be automated for those of us without green thumbs.

In previous letters I’ve discussed the inevitable rise of alternative meat, a process that has been accelerated by the pandemic. I talked about the smaller, more nutritious plant-based meals we're going to need for life extension; I assumed such meals would be delivered by drone. But now I see a future with no food deserts, in which every home is filled with rotating space-station-like hydroponics run by artificial intelligence — a cornucopia of push-button farming providing the side salad to your plant-based meat.

Even if you don’t grow your own, robot-run vertical farms and community “agrihoods,” now springing up everywhere, will make amazing-tasting produce abundant and cheap. The “locavores” of our era like to boast about their 100-mile diet. Yours will look more like a 100-yard diet.

Green, not soylent

It’s worth remembering that it wasn’t supposed to be this way. The 2020s, in fact, is when we were slated for starvation, food riots, and big business quietly processing our corpses into food.

That’s the plot of the 1973 movie Soylent Green, set in the year 2022. Fruit and veg have all but vanished. In one scene, Charlton Heston's detective hero smuggles home a single tomato and a wilted stick of celery, enough to reduce his roommate Sol (Edward G. Robinson) to tears. On the other end of the future, in a lighter but equally depressing vein, the 2006 comedy Idiocracy showed the Americans of 2500 running out of crops because they couldn’t figure out that water, not "Brawndo" (a spoof on colorful sports drinks), is “what plants crave.”

But these dismal future visions are receding thanks to the science of hydroponics — which dates back to the 19th century, no matter its present-day association with growing marijuana. By the 1930s, we’d figured out that what plants crave is surprisingly minimal: nitrogen, a handful of minerals, something to anchor the roots like rock wool or coconut husks, and H2O. Early hydroponic farms helped feed U.S. soldiers as they hopped through the Pacific during World War II.

Minimalist methods multiplied, and are still multiplying. We’re tweaking the spectrum of LED lights for maximum growth, and figuring out ways to use progressively less water and nutrients. My wife’s mason jar seedlings use something called the Kratky method, where you don't even need to change the water. It turns out this method was invented by a Hawaiian scientist as recently as 2009. And it’s the closest science has yet given us to a free lunch.

Reinventing the wheel

I’m nowhere near as excited by hydroponics as my wife is. But during our quarantine time, even my head has been turned — by the Rotofarm, which I’ve come to think of as the iPhone of gardening. It’s a beautiful device inspired by NASA research on growing plants in space. It uses anti-gravity — literally, when the wheel rotates around its LED light source and the plants are hanging upside down — to grow plants faster. A magnetic cover reduces the glare and increases the internal humidity. You manage it via an app.

Humankind’s oldest technology turns out to be the most efficient use of space for growing plants; even in this 15-inch-wide wheel, you can really pack them in. At the bottom of the wheel, plants dip their roots into the water and nutrient tanks. An owner’s only job is to refill the tanks every week or so, and to snip off their dinner with scissors a few weeks after germination. Some leafy greens, like my favorite salad base arugula, can be regrown without replanting.

Still, to be fully self-sufficient, a future apartment is going to need to have multiple Rotofarm-style devices on the go at once — but they’re designed to live anywhere you can plug in, on coffee tables, on desks, on walls, as eye-catching as artwork.

The main problem with the Rotofarm: It isn’t actually on sale yet. “It feels like we’ve done everything in reverse,” Rotofarm creator Toby Farmer said when I reached him via video chat from his home in Melbourne. “We’ve got the patents, we’ve got the design awards, we’ve got the customers. Now we need to finish the prototypes.” (One key tweak: reducing Rotofarm’s energy requirements, which as it stands could double many users’ household electricity bills.)

Still, orders have come from as far afield as Japan and the Netherlands, from retailers and regular users alike. Farmer’s biggest regret: When Ron Howard’s production company called, hoping to use eight Rotofarms in an upcoming Nickelodeon show set in space, Farmer didn’t have enough to spare.

Rotofarm has been in the works for a few years, but a crowdfunded Indiegogo campaign that closed last month exceeded its $15,000 goal by a third of a million dollars. Farmer, despite his name, had no experience in this area; just 23 years old, he had been a web designer since the age of 12. But he’s scaling up fast, hiring teams in LA and Singapore, soaking up their knowledge (he was keen to assure me he’d hired a lot of 40-somethings for this very reason).

After a projected 2021 release date, Rotofarm’s business model involves making money on proprietary seed pods — though Farmer admits that “there’s a DIY aspect” where customers can make their own. His hope is that official Rotofarm pods will be competitive because they’ll have fewer germination failures, but he'd rather see a world where more people own the device itself. In that spirit, he’s making it modular — the LED light bar can be upgraded separately, for example, rather than making customers buy a whole new device. (As for cost, Farmer says he can't comment yet — though Indiegogo backers were able to secure one for $900 a pop.)

Might the Rotofarm fail? Of course, just like any other crowdfunded project. Much depends on its price point, as yet unannounced. But it’s far from the only next-level, set-it-and-forget-it hydroponic station taking aim at your kitchen. There’s a Canadian Kickstarter called OGarden that also grows food on a wheel, albeit a much larger wheel. The OGarden was funded in its first six minutes online and is set to cost around $1,000 per unit. There’s Farmshelf, a $4,900 pre-order hydroponic device that looks like a see-through refrigerator, backed by celebrity chef Jose Andres. Users will pay a $35 monthly subscription to get all the seeds they need.

One of these models is the future; maybe all of them are. Right now, these are high-end devices aimed at early adopters (and restaurants, which get a lot of benefit out of showing off how fresh their produce is as customers walk-in). But with scale, with time, and with the growing desire for grow-your-own food that Rotofarm and its brethren have revealed, they will get cheaper and more widespread.

After all, the first Motorola cellphone, in 1983, cost $4,000. It looked like a brick and had 30 minutes of talk time. Now sleek, supercomputer-driven smartphones are accessible to pretty much everyone. The same process will happen in-home hydroponics.

Rise of the vertical farm

Give it 80 years, and I can see apartments with built-in hydroponic farms provided as a standard utility, much as a fridge is seen as a standard feature today. As more humans move to urban environments — two out of every three people will be in cities by 2050, according to the latest UN estimate — the need for such devices will only grow.

“We strongly believe the future of gardening is indoor gardening and more individual gardens,” OGarden CEO Pierre Nibart told us last year. “Stopping mass agriculture and starting to produce their own little stuff at home.” He said this while demonstrating his family's daily OGarden routine: His kids harvest most of what they need for dinner from the spinning wheel.

Mass agriculture hasn’t exactly covered itself in glory where produce is concerned. And in the post-coronavirus age, we are surely going to become less tolerant of the disease its intensive farming methods have caused.

Food poisoning caused by romaine lettuce, which makes up a quarter of all leafy greens sold in the U.S., has become depressingly familiar. The 2018 E Coli outbreak was the worst — it sickened 240 people in 37 states, hospitalized almost half of them, and killed five. But the CDC has logged 46 E Coli outbreaks since 2006 and says that every reported case of infection is likely matched by 26 unreported ones. And they’re only just starting to figure out the most likely cause: groundwater contaminated by nearby cattle manure. There could also be an infection from passing birds, another major vector of bacteria.

Never mind the wet markets of Wuhan that likely caused the coronavirus pandemic. We’re already sickening ourselves on the regular with a problem that is baked directly into our food system — and it’s affecting vegans as much as meat-eaters.

I have no doubt you’ll look at our barbaric farming methods and shake your heads. Why did they use so much water? Why did they transport produce an average of 1,500 miles? Why did they grow it outdoors, where it’s vulnerable to pests, and then use pesticides that had to be washed off? Why did they think “triple washing” did anything to remove bacteria (it doesn’t)? Why did they bother using soil, for goodness’ sake? Didn’t they know what plants crave?

The force of legacy agriculture is strong, but an increasing number of companies are figuring out a better way: the vertical farm, so named because they can stack hydroponic produce in shelves or towers. As I write this, there are more than 20 vertical farm operations being constructed and tested around the country. They use around 90 percent less water than regular soil farms, can grow roughly 10 times more food per acre than regular soil farms, and using precision software they can harvest their produce 30 percent faster than regular soil farms.

Sure, they’re spending more on electricity, but they’re also spending nothing on pesticide. The economics seem irresistible.

Last year, less than 20 miles from where I write this, in highly urbanized South San Francisco, a company called Plenty unveiled its flagship operation, a vast vertical farm named Tigris. Its sheer scale invites the correct usage of California’s favorite word, “awesome.” Tigris can grow a million plants at once, harvesting 200 of them every minute. With $226 million in funding, Plenty says it has already farmed 700 varieties of produce. Right now, the cost to consumers is comparable to non-hydroponic products (I can get their baby arugula at my nearest Safeway for a dollar an ounce); in the long run, it should be cheaper.

And they are far from the only success story. A Chinese startup, Alesca Life, is turning disused parking lots into vertical farms as well as selling plug-and-play shipping container farms. Back in Silicon Valley, a company called Iron Ox is developing robot arms for indoor farmwork. The future looks green and bountiful, and mostly automated (which is yet another reason you’re going to need Universal Basic Income).

Fresh future: Inside Plenty's vast vertical farm in South San Francisco.PLENTY

Which is not to say that outdoor agriculture is going away completely; it’s just going to shrink to the size of a community garden. That’s the basis of new urban developments called “agrihoods,” or multi-home communities centered around a professionally managed farm; a just-published book called Welcome to the Agrihood represents their first directory.

Rooftop organic farms, urban allotments: These are places where city dwellers can connect to the land and feel the satisfaction of nurturing their seeds from scratch. Soil may not be necessary to feed us, but sometimes it’s good to feel the dirt in your fingers. Similarly, farmer's markets are unlikely to go away. In a world where grocery stores are increasingly becoming delivery centers for services like Instacart, there will still be value in meeting and buying direct from the growers of high-end produce.

With big agribusiness heading indoors, with our apartments growing much of what we need and vertical farms providing backup in every city, we’ll also be able to let most of our present-day farmland go fallow. That in itself should take care of a chunk of climate change, considering the amount of carbon-soaking vegetation that springs up on fallow land. Lab-grown and plant-made meat will remove the need for those disease-ridden feedlots. Aquaponics, another discipline where the science is expanding by leaps and bounds, may even let us grow our own fish for food, reducing the strain on our overfished oceans.

No doubt it won’t be all smooth sailing. No doubt we, as humans, will stumble upon fresh ways to mess up the planet and make life worse. But from where I’m sitting, surrounded by soilless germinating jars, the future looks very green and nutritious indeed.

Yours in leafy goodness,

2020

TOPICS: Tech, Tech, Food, Health & Fitness, dear 22nd century, Internet Of Yum, Indoor-gardening

The Best Growing Mediums For Microgreens

Growing microgreens is an easy and sustainable process that you can do from the comfort of your home. You can grow all kinds of nutritious microgreens that will enhance the flavor of your foods

Growing microgreens is an easy and sustainable process that you can do from the comfort of your home. You can grow all kinds of nutritious microgreens that will enhance the flavor of your foods. These special vegetable-like plants grow from 1-3 inches and are vibrant additions to your foods. They are also jam-packed with vitamins and antioxidants. We're going to discuss the different growing mediums you can use for your microgreens.

Soil

Using soil as your growing medium is a popular and effective choice. Soil will provide you with the best yields over any other medium. We believe the Sunshine #4 by Sunshine Aggregate is the best, and the Black Gold Potting Mix is a close second. Each of these soils are extremely sterile, which is ideal for indoor growing. While these soils can cost more (about $1 per 10x20 tray), they provide the best results. But, don't worry. You can compost and sterilize your soil to re-use it for future grows.

Burlap

Burlap is another popular growing medium because it's cheap. For .25 cents a tray, you can't beat the price. It is made from the jute plant, which is used to make nets and ropes. But burlap is an incredibly difficult growing medium to use. The perfect growing conditions for burlap include 72 degrees Fahrenheit, 65% humidity, and a good micro-dose fertigation plan (fertilizer + irrigation). If you can populate these results, then you can achieve yields and results that match soil mixes.

But be mindful that this takes a lot of practice and time, which is why using burlap is better for expert growers. If you don't get the growing conditions right, then your yields will suffer. We recommend using larger seeds like Pea Shoots and Wheatgrass when using burlap. These seeds will thrive with a burlap growing medium, and you will get bountiful results.

Coco Coir

This growing medium comes from coconut fiber. It's perfect for holding in moisture and is difficult to over-water. It is cheaper than soil (about .60 cents a tray), but it's just as messy. Coco coir has a better yield average than burlap, about a 25% to 30% better average. You will find this growing medium in dehydrated blocks. When you add water, they will expand way past their original size. You can use coco coir with an ebb and flow hydroponic method.

Jute Pads

This growing medium is derived from jute fiber. It's able to transport water evenly through your microgreens and maintain a near-perfect water/air ratio. It holds in water very well, which means you'll have to feed your microgreens less. Kale and broccoli grow especially well in jute pads.

What's the Best Growing Medium?

This entirely depends on your growing intentions. What are you planning to grow and how much effort are you willing to put in? We're going to cover the main questions you should ask yourself that will help you make this decision.

Feeding Your Plants: If you want to water your plants by hand, then we recommend soil and coco coir. But if you're able to feed your plants on a timer, then go for burlap or jute pads. It can be a better option because it's cost-effective and can still get the job done.

Choosing Your Seeds: What kind of microgreens do you plan to grow? If you're growing broccoli or kale, then we recommend buying jute pads. Do you want to grow a wide variety of seeds? Then choose soil or coco coir as your growing medium.

Messy Vs. Clean: Do you hate cleaning up messes? Then it's best to steer clear of soil and coco coir. Go with jute pads since they're easy to handle and clean.

Choosing your growing medium ultimately boils down to what you're planning on growing and how much effort you want to exert. We hope this list helped you understand what kinds of growing mediums there are and how they can help you yield the best results.

We are the microgreen growing experts. We're even working with NASA to help figure out how to get microgreens safely into space for astronauts to use! We meet once a month to discuss a variety of topics about microgreens. So, keep reading our blogs and watching our informative YouTube videos. There will always be exciting news coming your way.

#growing #medium #growingmedium #growingmedia #microgreeneducation #microgreensfarmer #microgreens #microgreen #bestmediatogrow #SmartNaturals #growmedia #growmedium #growingmicrogreens

Purdue University Mechanical Engineering Technology Grad Developing Food Technology For NASA’s Mars Missions

A graduate student who gained experience growing plants for a Purdue Polytechnic research project is now helping NASA develop microgravity food production technology to sustain astronauts during long missions to Mars

August 19, 2019

NASA Technical and Horticultural Scientist Jacob Torres works in the water for microgravity test bed at the Kennedy Space Center’s Space Station Processing Facility in Merritt Island, Fla. Thanks to Torres’ suggestion, the Española chile pepper will be the first fruiting plant to be grown in space this November on the International Space Station. (Photo courtesy Jacob Torres)

A graduate student who gained experience growing plants for a Purdue Polytechnic research project is now helping NASA develop microgravity food production technology to sustain astronauts during long missions to Mars.

Jacob Torres graduated from Purdue in May 2018 with a master’s degree in mechanical engineering technology. During his studies, he worked on the Biowall, an eco-friendly air filtration system that can be used in residential buildings to improve air quality. That experience proved beneficial when he applied for an internship at Kennedy Space Center in Merritt Island, Florida.

“I did the application and never thought I’d hear anything back from them, straight up,” said Torres. “On the application, there just happened to be one line that said, ‘plant growth for food production in microgravity.’ I thought that was pretty cool and in my research at Purdue, I made a biowall, and it uses plants to filter indoor air.”

After that 10-week internship, NASA (the National Aeronautics and Space Administration) invited Torres to continue his work for an additional four months. In December 2018, his position as a technical and horticultural scientist became permanent.

Torres’ path to becoming a research scientist at NASA has been anything but traditional. He moved from New Mexico to Las Vegas immediately after graduating from high school, found a job at a restaurant and worked his way into a management position. A chance encounter with actors Bill Murray and Billy Crystal led to several years as manager of three of Murray’s restaurants in South Carolina and Florida.

“It was such a rough ride,” said Torres. “I told myself I couldn’t run restaurants for the rest of my life. I was like, ‘Is this all I have to do, is this as far as I could go?’ No way.”

Read the full Rio Grande Sun article.

NASA: First Fruit Grown In Space To Spice-Up Astronauts' Menu

Researchers at NASA are planning on sending a version of chile peppers in space to be grown and harvested at the International Space Station

Researchers at NASA are planning on sending a version of chile peppers in space to be grown and harvested at the International Space Station. The peppers, from Española in New Mexico, would be the first fruiting plant to be grown in space once it is sent to the ISS for testing in March 2020. The tests are a part of NASA's major plan to produce food outside Earth's atmosphere.

NASA researcher Jacob Torres, has stated that the point of the mission is to see if NASA's Advanced Plant Habitat-a bioscience research facility at ISS that recreates a plant's environmental needs (CO2, humidity, etc.) can grow fruiting crops. NASA has already successfully grown leafy crops at ISS.

Why a pepper?

The obvious question is, if you're sending a fruiting plant, why not send something more appetizing than a pepper? The answer is that not every crop can successfully grow in space and the Española Chile Pepper could just help pave the way for interstellar farming. The plant has already met NASA's needs for easily pollination and the ability to survive in high CO2 environments.

The Farms of The Future Were Built For Outer Space. Will They Work On Earth?

It will be years until NASA is ready for a journey to the red planet, but if Earth continues to suffer from climate change, Mars could come to us.

It will be years until NASA is ready for a journey to the red planet, but if Earth continues to suffer from climate change, Mars could come to us.

August 13, 2019

Visitors look at vegetables growing under artificial light on a vertical farm, in the IKEA: Gardening Will Save the World garden, in London on May 20th, 2019. (Photo: Daniel Leal-Olivas/AFP/Getty Images)

On Mars, we'll all farm underground. Our crops will grow in a greenhouse, where large, parabolic mirrors focus the sun's weak rays and transmit them through fiber optic cables. We'll harvest vegetables to eat—but also the purified water that evaporates from their leaves. We'll all be vegan, because raising animals for food will be too expensive. And, most importantly, the plants will give us oxygen.

"That's the starting point to a whole civilization right there," says Utah State University researcher Bruce Bugbee. This is Bugbee's vision, one he's been dreaming of and testing and revising for years as a plant engineer with NASA.

Astronauts going to Mars can eat all the freeze-dried food they're able to ship, but if humans are going to survive on the planet they'll need to plants to produce oxygen. Not just any photosynthesizer will do: Mars is a difficult environment, with many challenges for farmers. Crops will need to be able to thrive in a small area, retain their nutrient content, and still taste good. Structures where they grow on the surface will need to withstand basketball-sized meteorites. The technology used to grow the plants will take massive amounts of energy. Mars also presents the ultimate recycling challenge, since astronauts can't pack all the water and nutrients they need on a two-and-a-half-year space flight.

Bugbee and his colleagues have been working on all these problems for decades, in a sometimes fantastical bid to support life on Mars (and, in the meantime, on space shuttles). Decades ago, NASA researchers ruled out some of the easiest plants to grow indoors, like algae: not enough sustenance, Bugbee says. Very tall crops like corn and sugarcane were also nixed because they wouldn't fit easily into the plant habitats.

What the astronauts really wanted was something green. "They say that having the texture and flavor and color and aromas of fresh foods apparently—and I believe it—really does add to the experience of eating," says NASA plant physiologist Raymond Wheeler.

Scientists started looking at traditional field crops like lettuce, tomatoes, and broccoli. Right now, astronauts are growing mixed greens 250 miles above Earth on the International Space Station, using two small, sealed greenhouse units called Veggie. NASA researchers have planned and adjusted and measured for everything—including which types of lettuce tastes best in space. Astronauts' clogged sinuses already make it so they "can't taste much of anything," according to Canadian astronaut Chris Hadfield, but the researchers are also curious to see whether the space environment affects a plant's flavor compounds and nutrient levels. Panels of specialists at NASA's Johnson Space Center in Houston typically conduct formal taste tests, but sometimes the researchers sample a leaf or two themselves.

What Bugbee and his team didn't expect is that the technology they created for this grandiose, futuristic mission would become somewhat eclipsed by those using it to farm on more familiar terrain.

In 2017, NASA commissioned a space farming project to figure out how to grow food on Mars, but they were also hoping to make some discoveries that could improve crop yields overall. The problems that space farmers of the future will face are similar to those already plaguing earthbound agriculture as climate change grows worse, including a dwindling water supply and poor soil. Now, researchers in Utah and three California universities—NASA's partners with the Center for the Utilization of Biological Engineering in Space—are working on projects that can sustain life not just on Mars, but on Earth.

"I think the reason NASA funds us is a powerful human fascination with being able to go inside a closed system and grow your own food," Bugbee says. "What if the atmosphere went bad and we had to build a big dome ... and go inside and live in it?"

In 1988, Wheeler built the first working vertical farm—growing plants on shelves, typically in a warehouse or storage container—at the agency's Kennedy Space Center. Wheeler's farm was 25 feet high and equipped with a hydroponic system for growing plants in water and high-pressure sodium lamps, the type commonly used for street lighting. All together, it was 20 square meters of growing space—almost 90,000 times less than the size of the average outdoor United States farm. According to Wheeler's calculations, it would take 50 square meters of plants to provide enough food and oxygen—and remove enough carbon dioxide—for one human in space. (Astronauts won't be using sodium lamps, though: A few years after Wheeler's innovation, a different group of NASA-funded researchers patented another significant piece of technology to indoor farmers: LEDs, which require much less electricity than sodium lights and are now used to power most greenhouses.)

Wheeler was focused on optimizing the area inside a chamber aboard a NASA space shuttle—and up seemed like the best way to go. "One of the things you have to think about in space is volume efficiency," he says. "You're vertically and dimensionally constrained." The team had to pick shorter crops: wheat, soybeans, potatoes, lettuce, and tomatoes.

In space, resources are limited: NASA scientists have to extract and reuse the nutrients from excess plant material and human waste; they collect water from the condensation that collects in the closed chambers. Here on Earth, water is also growing increasingly precious—climate change will make droughts more frequent and severe, devastating crop yields and making some staple crops like corn and soybeans obsolete. Every day, Earth looks a little more desolate, a little more like Mars.

When Wheeler started, the term "vertical farming" didn't exist yet. Today it's a $10 billion industry attracting interest from Silicon Valley and start-ups all over the world. Its acolytes believe the technology will one day completely replace conventional field agriculture, allowing businesses to grow crops year-round and indoors, insulated from the next drought or flood and the effects of climate change. "People imagine that we'll grow everything indoors, in skyscrapers in the middle of Manhattan," Bugbee says. "It's a wildly popular idea."

Sonio Lo, the chief executive officer of the biggest vertical farming company in the world, Crop One Holdings, says she believes vertical farming can "liberate agriculture from climate change and geography."

Crop One broke ground on the world's largest vertical farm last November in Dubai: a five-story, 130,000-square-feet warehouse, capable of producing three tons of leafy greens a day. The company is also growing chard, arugula, and other greens in large, sealed rooms—year-round. "I made my whole management team stand in the supermarket and give out samples of what we were growing in the middle of the Boston winter," Lo says.

Soon people across the U.S. can try it too. Crop One is building new farms in the northeast, southwest, and California, where it will grow food to sell through its FreshBox Farms brand.

While researchers have been quick to condemn vertical farming's promises as over-hyped, even the industry's greatest critics acknowledge that this approach eliminates some of the challenges with conventional agriculture: Since vertical farms are located in compact warehouses, they're often located much closer to their markets than, say, the corn belt is to a city, allowing producers to cut down on food waste and save on transportation costs—a major contributor to U.S. greenhouse gas emissions.

The lettuce grows in a controlled environment, free of pests and pathogens, meaning farmers can grow food without pesticides or herbicides, which have a massive environmental and human-health cost. Vertical farmers can also recycle their nutrients—like astronauts do in space—preventing phosphorus or nitrogen from flooding into the world's waterways and wreaking havoc with algal blooms. And indoor growth systems can be very productive: When all the conditions are right, researchers have surpassed record crop yields in the field by as much as six times.

Lo says that a vertical farm using 100 percent renewables has one-tenth of the carbon impact of a conventional farm. But few companies have reached this goal; most are still moving toward a combination of renewable energy and non-renewables to power the electric lights used to grow the plants. It takes a lot of land to generate that much solar—about five acres of solar panels to supply the light for just one acre of indoor farm, Bugbee estimates. That's why many have resorted to fossil fuels, breaking one of vertical farming's great promises. "It takes massive amounts of fossil fuel energy, so, environmentally, it's really a disaster," Bugbee says. "Those people have used many of the principles that we've developed through NASA."

Bugbee's current project could help with that. His lab at Utah State is using LEDs and fiber optics to grow plants under different types of lights, with different ratios of colors—ultra violet, blue, green, red, far red (out of the limit of human vision)—to manipulate both photosynthesis and plant shape. The goal, he says, is to find "the most efficient system possible." Right now, the technology is too expensive: millions of dollars to light one building. But eventually, he believes fiber optics will replace electric lights for good.

But there are other qualms with vertical farming: Instead of helping to colonize space—the future that Mars researchers envision for their technology—vertical farms might take over city real estate, at a time when housing costs are extremely high. In some countries and some industries, it already has: Japan has had flourishing plant factories for the last 10 years. The fledgling cannabis industry has also started to ramp up its indoor production, poised to become even more profitable.

Lo says it won't be long until greens grown indoors cost the same as those in the field. "Field-grown food will continue to rise in cost, and course the climate is also changing," she says. "From a cost perspective, vertical farming will become competitive very quickly."

Others are more skeptical: "Economically, will they succeed? That question is still ongoing, because they always have to compete with field agriculture," Wheeler says. "What's their cost to pay for electric power? What are their labor costs? Are these operations sustainable? All of this is sort of a living experiment right now."

Technology for farming in climate change may be a by-product of NASA's research, but it has helped the agency ensure funding for its work in space. In response to the skeptic who doubts whether it's worth figuring out how to farm for a Mars mission we might never see, one only has to point to vertical farms in Boston or Seattle that already use some of NASA's innovations.

But Bugbee believes these earthly pursuits can be just as futuristic (or deluded) as those meant for space. "People that do it say they're going to save the planet ... but they have to have a lot of fossil fuels," he says. "It'll tell you all kinds of rosy pictures about it—that it saves water, it saves fertilizer."

He's not quite comfortable with his research being used to prop up this industry, now flooded with billions of dollars of venture capital. "I'm not doing it to make this more possible on Earth," he says. "We get asked all the time about the spinoffs: Could you do this, could you do that."

We may never make it to Mars. It will be years until NASA is ready for a journey to the red planet, and many more until Bugbee would be able to build his greenhouse underground, tucked away from meteorites. But if Earth continues on this collision course, Mars could come to us.

TAGS CLIMATE CHANGE VERTICAL FARMING NASA OUTER SPACE PLANTS AGRICULTURE

BY EMILY MOON

Emily Moon is a staff writer at Pacific Standard. Previously she worked at the Chicago Sun-Times and the Herald-Times in Bloomington, Indiana. She is a graduate of Northwestern University.

One Giant Leap: Space Programs Spin Off Vertical Farming, by Joel L. Cuello, Ph.D.

The author's NASA-sponsored project on design and demonstration of NASA’s first Hybrid Solar and Electric Lighting System for Bioregenerative Space Life Support for application in future long-duration manned missions to the Moon and Mars

The vertical farming industry will likely in

turn ultimately enable NASA

and other space programs

to realize their future food production

systems on the Moon, Mars and even beyond.

Original Content Written for The Association for Vertical Farming

NASA's Apollo 11 Lunar landing and moonwalk on 20 July 1962. (Photos courtesy of NASA)

As the 50th anniversary of Apollo 11's first Lunar landing and moonwalk on 20 July 1969 is observed this year, it is fitting to recall the myriad innovation spinoffs that NASA's space program had gifted mankind, ranging from the integrated circuit to computer microchips to satellite television to cordless tools to electric vehicles to freeze-dried food to memory foam, etc. -- and yes, still unbeknown to many, vertical farming.

The author's NASA-sponsored project on design and demonstration of NASA’s first Hybrid Solar and Electric Lighting System for Bioregenerative Space Life Support for application in future long-duration manned missions to the Moon and Mars.

While the Apollo program itself did not initiate or develop space farming, its unprecedented success directly led NASA to establish around 1978 the Controlled Ecological Life Support System (CELSS) division within its Advanced Life Support program with the aim in part of developing the technologies and strategies necessary to grow food and regenerate resources on the Lunar surface or on Mars for future long-duration manned missions and habitation.

Nearly two decades before NASA, however, the then Soviet Space program commenced activities beginning in 1961 toward developing its own bioregenerative space life support system. In 1968, the Soviets first realized growing crops in their completely sealed controlled-environment system Bios-2, located in the Siberian city of Krasnoyarsk, wherein they successfully cultivated wheat, carrots, cucumber, dill and other vegetable crops. (Bios-2 should not be confused with Biosphere 2 in Arizona which was constructed much later between 1987 and 1991.) An improved underground test facility, Bios-3, was subsequently built by the Soviets in 1972.

Fast forward to the 1980's and 1990's, NASA's CELSS program made significant advances in the cultivation of a whole range of crops in closed controlled-environment systems under optimized environmental conditions of lighting, temperature, relative humidity, air flow, nutrient compositions, etc.

The foregoing advances by both NASA and the Soviet Space program paved the way for the emergence of the first commercial vertical farms (or plant factories) in the United States and Japan. General Electric's Geniponics based in New York and Alaska as well as General Mills' Phytofarms of America in Illinois were established in the 1970's and operated through the 1980's, though eventually closing down owing to economic challenges.

It was in Japan in the 1980's, however, when the then fledgling vertical farming industry truly took root and flourished in part through their proactive adoption and incorporation of emerging technology innovations. For instance, TS Farm (Q.P. Corporation) was first in employing aeroponic systems, while Cosmo Plant Co. Ltd. in 2000 became the world's first commercial LED-based vertical farm and began producing up to 7,000 heads of lettuce per day, significantly exceeding the industry norm of 3,000 to 5,000 heads of lettuce per day in the 1990's.

Vertical farming today, of course, has gone global and, in parallel with advances in lighting technologies, climate control, data analytics, automation and other innovations, has correspondingly been setting new achievements in both yield and resource sustainability.

And just as the space program spun off the Vertical Farming industry, there is poetic symmetry in the very real prospects that it will be the vertical farming industry that will ultimately enable NASA, as well as other space programs, to develop and fully realize its bioregenerative space life support systems for future Lunar and Martian human habitats.

Just as Elon Musk's Space X, Jeff Bezos' Blue Origin and Richard Branson's Virgin Galactic have partnered with NASA to innovate on and advance space transportation, it is highly likely that partnerships with NASA for the design and operation of its future Lunar and Martian space farms will be brokered with the likes of AeroFarms, Plenty, Bowery Farming, CropOne Holdings, Gotham Greens, Infarm, AEssense and/or other vertical farming companies, some of which have yet to be formed.

In the future the vertical farming industry may indeed extend its prospects from the mere terrestrial to the extraterrestrial.

_________________________

Prof. Joel Cuello is Vice Chair of the Association for Vertical Farming (AVF) and Professor of Biosystems Engineering at The University of Arizona. He conducted his U.S. National Research Council postdoctoral research fellowship at NASA John F. Kennedy Space Center in Cape Canaveral, Florida in 1994.

Email cuelloj@email.arizona.edu

NASA Project Proves The New Mexico Chile Is Out of This World

A team of scientists at NASA is working to launch the Española chile pepper into space. This would be the first fruiting plant the United States has grown and harvested at the International Space Station

July 14, 2019

BY KAREN GRAHAM

A team of scientists at NASA is working to launch the Española chile pepper into space. This would be the first fruiting plant the United States has grown and harvested at the International Space Station.

New Mexico chili peppers were grown in 3-gallon pots in the Ghosh Grove, Rockledge, Florida, USA from seeds bought from the Chili Pepper Institute, New Mexico State University, Las Cruces, New Mexico,

Asit K. Ghosh Thaumaturgist (CC BY-SA 3.0)

One of the issues over long-term space missions is how to supply the needed food for the trip. Free-dried food can take up a lot of space and weight on an extended voyage and won't be that tasty. Back in the early 2000s,