Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Technology Promises To Calculate "True" Shelf Life

One of the causes of food waste is produce that goes bad earlier than expected. Of course, shipping produce that is fresh is the goal of every grower. In what manner it arrives and how fresh it remains once in the store, however, is largely out of their control. Furthermore, it is also in the retailer's best interest for the produce to remain fresh and tasty for customer's enjoyment.

Zest Labs, a company based in San Jose, California, has come up with a solution called Zest Fresh that allows growers and shippers to know how long each pallet of their produce will remain fresh. Using IoT sensors placed in each pallet at the time of harvest and cloud-based analytics, Zest Fresh takes into consideration temperatures at time of harvest, cut-to-cool duration, as well as conditions at each point right up until the receiver, and based on this data, calculates what the "true" remaining shelf life is.

"IoT sensors in each pallet use predictive analytics, machine learning and other functions to calculate a freshness metric of the dynamic remaining shelf life for each pallet," said Kevin Payne of Zest Labs. "We have profiled produce from different regions to determine the maximum freshness duration. Consider us as a postharvest freshness management solution. The reason is that despite a batch of produce coming out of the same field on the same day, the conditions in which they were harvested and eventually placed in the cooler can vary significantly. A pallet of strawberries picked at 7:00am and placed in the cooler at 8:00am will have a different shelf life than the pallet picked at 2:00pm during the heat of the day and placed in the cooler at the end of the day. This causes the 'true' remaining shelf life to be different for each pallet."

Kevin Payne and Todd Clayton with Zest Labs

Sending the pallets to the optimal destinations

Data collection and analysis is great, but varying forms have been around for a long time. Zest Labs noted that the point of difference with their Zest Fresh technology is that something can be done about proactively solving the problem. "Many solutions out there tend to be reactive, meaning an action can only take place after the fact," Payne explained. "However, we believe we offer the only proactive solution, by using the predictions and allowing the shipper to make decisions based on insights and information."

Fundamentally, the idea is to utilize the information to send pallets to destinations most appropriate for the calculated freshness. Most obviously, the greater the shelf life remaining, the further the produce can be sent. "When the calculated shelf life of one pallet is, say, 3 days shorter than another, it can be sent to a receiver that is closer, in order to maximize the shelf life for the receiver," Payne added. "The data is collected continuously and is read at pre-determined waypoints, such as being placed in the cooler, in the truck, moving out of the warehouse, arrival at the receiver, etc. This produces a dynamic shelf life, updated at each interval to give the most accurate shelf life at any one time."

Payne further noted that growers can use the data to monitor their processes to ensure they're being adhered to, adjusting procedures accordingly. "Zest Fresh empowers workers to keep product on process with real-time tools that reflect each process step – such as received inventory, time and temperature of product staged for pre-cool, pre-cooling, and shipping," he said. "It also drives notifications when preset process parameters are exceeded, focusing workers on the most acute problems in real-time."

The ZIPR Code

To help with the monitoring process, Zest Fresh collects, stores and displays all the data in a unique, automatically-generated code, called the "ZIPR Code" which stands for Zest Intelligent Pallet Routing, the industry’s first freshness metric. The ZIPR Code references the dynamic remaining shelf-life of individual pallets and then users can view and manage that pallet's information.

"Once Zest Fresh combines the data and applies a score, it creates the ZIPR Code for each pallet," Payne explained. "This ZIPR Code is then matched to pending orders to ensure each pallet has sufficient remaining freshness to meet the retailer’s needs. The ZIPR Code ensures that customer shipments are loaded correctly, and that quality is tracked through actual delivery – providing the grower with visibility of delivered quality."

"The ZIPR Code can be integrated into a warehousing management solution, providing alerts and updates on whether the pallet is still in a suitable condition and routing," he added. "It is designed to be autonomous and wireless."

Practicalities

The company said the sensors themselves are small and easy to handle. They can be inserted into pallets at any time, depending on whether the grower wishes to monitor the entire supply chain, or just certain sections.

"The IoT sensors are about the same size as a deck of cards and are placed in the pallet in the field or at any point along the way," Payne described. "They are reusable and can also be used for certain segments. The software to view information is cloud-based, with the desktop and mobile tags operated by access points. A technician will install these and all that is required is power and a network connection."

The Zest Fresh "dashboard"

Zest Labs is aiming to be at the forefront of technology, so Payne shared that Zest Fresh has Blockchain capability for those that desire it. "Blockchain, which is basically a secure way to exchange and share information, is one of the aspects that I get asked about often," he said. "We do have the support for it although it is not required."

What types of produce and where?

According to Payne, the most common produce type that growers use Zest Fresh for are highly perishable fruits like berries. This is no surprise as these fruits are the ones that feel every effect of temperature changes and inadequate cooling times, for example. Currently, the company is working with growers in North America, and has also worked with suppliers in Central and South America.

"Zest Fresh can be used for any produce type, however most growers and retailers start by using them for the highly perishable produce items like berries, closely followed by leafy greens," Payne said. "We have also seen interest in grapes, cherries and stone fruit. Right now, our technology is used across North America, and we have also worked with growers in Central and South America, particularly in the northern winter. We are aiming to be at the forefront of technology and modernize the supply chain for the fresh produce industry."

For more information:

Kevin Payne

Zest Labs

Tel: +1 (408) 200-6527

Publication date: 7/10/2018

Author: Dennis M. Rettke

Copyright: www.freshplaza.com

Starting An Outdoor Hydroponic Garden

Indoor gardening can get expensive if you’re constantly running air conditioners and dehumidifiers. Why not take advantage of free sunlight and start an outdoor hydroponic garden?

Source: Pixbox77 / Dreamstime.com

Takeaway: Indoor gardening can get expensive if you’re constantly running air conditioners and dehumidifiers. Why not take advantage of free sunlight and start an outdoor hydroponic garden?

Indoor gardening can get expensive in the heat of the summer, especially if you’re constantly running air conditioners and dehumidifiers. Why not take advantage of all the free sunlight nature has to offer and start an outdoor hydroponic garden?

Outdoor hydroponics still provides the perfect balance of water and nutrients, and your plants will grow much faster than in soil. Plus, there’s no weeding!

Choose a Sunny Location for Your Hydroponic Garden

There is no substitute for full-spectrum summer sunlight, and best of all, it’s free! Even a 1,000W lamp, placed a foot from your plants, can’t compare with a sunny day in mid-July. So when setting up an outdoor hydroponic garden, pick a sheltered area with a good southern exposure if you can.

I’ve grown prolific amounts of basil in a nutrient film technique system in a parking lot, towers of aeroponic herbs and strawberries on my back porch, and a huge row of tomatoes in stonewool in front of my garage.

The vines grew so dramatically that strangers driving by would stop their cars, knock on my door and ask me how I was making the tomatoes grow so fast!

They were amazed when I showed them my hydroponic systems. By the end of the summer, the vines were growing up to the roof and I had a wall of gourmet-quality tomatoes.

Keep the Water Reservoir Cool

Plants will transpire a lot more water in the outdoor heat than when they are grown indoors, so make sure you top off the reservoir with cool water from your garden hose often. It’s also a good idea to keep the reservoir in the shade whenever possible.

In an ebb and flow system, it’s easy because the nutrient reservoir is underneath the flood table anyway. But if the reservoir is somewhat exposed, I like to at least partially bury it if I can. The earth acts as a natural heat sink to pull some of the excess heat out of the reservoir.

On the hottest days of the summer, adding a little ice to the reservoir can help. Keep a couple of two-liter bottles of water in the freezer, and drop one into the reservoir occasionally.

If you walk by later in the sweltering afternoon and you notice the ice has melted, put the bottle back in the freezer and drop in another. Luckily, the worst heat waves usually don’t last more than a few days, so such emergency measures are rarely needed.

Lower the Electrical Conductivity (EC)

In hot weather, it’s best to lower the electrical conductivity of the nutrient solution. For example, if I normally keep the EC for my lettuce-growing system at 1.2, I’ll lower it to 1 in the summer. Plants are thirstier in the summer, so doing everything possible to make it easier for them to take up water is a good thing.

Low-to-medium EC stimulates vegetative growth by making the nutrient solution less salty, while medium-to-high EC restricts vegetative growth. During the heavy fruiting and flowering stage, a little salt stress is good but watch your plants carefully. At the first sign of browning at the edges of the leaves, lower the EC a little more.

The worst thing that can happen to an outdoor hydroponic garden is to let the reservoir run dry. Plants won’t last long in the summer sun without water. It might be a good idea to add a float valve to your reservoir as an insurance policy.

If the water level gets too low, the float valve will open automatically and top off the tank with fresh water. Plants can go a few extra days without fertilizer, but they will only last a few hours without water. Plan ahead so you can enjoy a few days away at the beach when you want to.

Boost the Heat Tolerance of Plants

The best time to condition your plants against stressful situations is before the stress happens. In the earlier part of the summer, try adding a combination of humic acid and kelp extracts to your nutrient solution.

A 10-year study at Virginia Tech showed that humic acids combined with seaweed extracts work 50% better than either product alone. A 5:2 ratio of humic acid to kelp works best to greatly stimulate lateral root growth and improve overall root mass. When the summer heat comes, the more roots the better for taking up the extra water they need.

The humic acid/kelp combo also encourages the plant to make extra plant-protection agents. Under ideal conditions, plants have no trouble protecting themselves from cell damage, but when plants are under too much stress, they can’t keep up with the constant barrage of damaging free radicals.

Free radicals break down cell membranes such as chloroplast and mitochondrial membranes, which is why plants go from green to yellow to brown under excessive heat and UV light.

If you condition your plants against stress with a combination of humic acids and kelp, plants will produce 50% more of the protective molecules that sponge free radicals, and plants will stay green longer when the summer heat arrives.

Remember to condition the plants before it gets hot—if the plants are already suffering in the middle of the summer, the bio-stimulants won’t have enough time to help.

Ensure Air Movement

Air movement is important, especially in the summer. One of the advantages of outdoor hydroponics is the breeze. The air movement helps cool the plant and keep the stomata open.

Stomata are the pores in the leaves that take in carbon dioxide and transpire water vapor and oxygen. As the breeze takes away the water vapor from the leaves, it has a cooling effect on the plant.

Too much wind has the opposite effect—plants close their stomata to conserve water so they don’t dry out too fast. Outdoors, we don’t have much control over the wind, so try to grow in a spot that has good air movement but also provides a protective windbreak.

Planting along a fence row with southern exposure is a good choice. Also, think ahead about what you will do if a major storm approaches. I’ve learned the hard way how important it is to properly stake and trellis my plants and provide a little extra emergency protection.

Protect Against Pests

One downside to growing outdoors is that you often have to share your crops with animals and other pests. The simplest advice is to fence in your garden or grow a few extra plants and hope the critters don’t get too greedy.

If you’re not willing to share, there are other deterrents available at your hydro store such as wolf and coyote urine (I’m serious!) that help keep rabbits and other invaders away. There are also some good natural sprays such as neem oil and insecticidal soaps that help fight bugs and act as natural insect repellents.

But the best defense against pests, particularly sucking insects, is to grow healthy plants. Use full-spectrum, all-purpose fertilizers, and keep the potassium-to-nitrogen ratio high. Too much nitrate nitrogen produces large cells with thin cell walls, making them an easy target for sucking insects and fungi, so don’t over-fertilize.

For even healthier plants, try using a bio-hydroponic fertilizer that combines minerals with organic bio-stimulants. For example, amino acids stimulate the uptake of calcium.

Due to the extra calcium intake, plants grown with amino acids have thicker cell walls and a higher resistance to temperature extremes. The plants will also have a stronger vascular system, allowing them to take up water and minerals more efficiently. (Read more about pests in Maximum Yield's pest control article archives)

It all adds up to nutrient-dense, high-brix plants that have an increased resistance to pests and diseases. If all goes well, sucking insects won’t even recognize the plants as food.

Just wait until you taste what a well-managed outdoor hydroponic garden can produce. Healthier plants mean tasty, nutrient-dense food high in vitamins and minerals.

Colors and aromas are also much richer, and you can literally see the difference in growth from day to day. It’s hard to imagine just how productive an outdoor hydroponic garden can be until you try one for yourself!

Giant Indoor Vertical Farm Backed by Chinese Firm Launching Just East of Las Vegas Strip

- One of the country's largest indoor vertical farms was built about 6 miles east of the Las Vegas Strip on the site of a former mail-order prescription drug facility.

- Oasis Biotech plans to start deliveries next week and said it can produce about 9,500 servings of mixed salad per day for local restaurants and casinos

- The vertical farm requires 90 percent less water than a traditional farm and uses about 50 percent less energy than most other indoor ag facilities.

17 July 2018 CNBC.com

An indoor vertical farm that uses 90 percent less water than conventional growers is about to launch in Las Vegas and will be able to supply nearly 9,500 servings of leafy green salads per day to casinos and local restaurant chains.

"Las Vegas is the location that has the highest density of high-end restaurants, which can afford this premium specialty product," said Brock Leach, chief operating officer and general manager of Oasis Biotech. "We're going to be able to get our product from harvest to the customer in around 24 hours."

Oasis Biotech, a Chinese-backed farm that uses hydroponic watering and microclimate controls for crop cultivation, is scheduled to make its first delivery in Las Vegas on July 24. The 215,000-square-foot facility is expected to be one of the largest in the nation when fully built and will initially focus on growing baby greens, micro greens, and specialty herbs but plans to eventually expand into baby carrots as well as soft fruits, including strawberries.

Controlled-environment agriculture

The chemical-free facility uses hydroponics technology, so it grows plants without soil. It also uses high-end clean rooms similar to those found in computer manufacturing as well as special filters and ultraviolet lights to control air and water — all designed to keep the food safe.

"We are producing food that is the safest and securest food that you can possibly produce," said Leach.

Oasis Biotech

One of the nation’s largest indoor vertical farms is about to launch in Las Vegas and eventually span more than 200,000 square feet.

The recent scare over salads at McDonald's due to an intestinal parasite outbreak highlights how difficult it is to monitor fresh produce grown on traditional farms. The FDA is still investigating what the source of the outbreak is for the cyclospora illnesses.

"The fact that the McDonald's outbreak made news is a warning of sorts, because we've always had foodborne outbreaks from various infectious diseases," said Dickson Despommier, professor emeritus for environmental health sciences at Columbia University and leading expert on vertical farming. "This [indoor controlled farming] technology allows you to avoid that."

Despommier said indoor vertical farming in cities will continue to grow in the future due to demand from restaurants and stores that are looking for "growers that can promise healthy, fresh produce year-round right next door to where the store is. The model has been developed, and I think it's a viable one."

Most of the leafy greens and other fresh produce supplied to the Las Vegas market are grown in California and Arizona, so there are added shipping costs and product can sometimes take several days to reach southern Nevada customers. Las Vegas hosted more than 42 million visitors last year and southern Nevada is home to more than 2.1 million residents or about three out of every four residents in the Silver State.

Talking to casinos

"We will be meeting with a lot of the major casinos here in the next few weeks," said Leach. "But they won't be part of our initial distribution. We're focusing more on independent restaurants and small chains."

The major casinos declined to comment for this story.

Leach said the vertical farm plans to sell its leafy greens and other products through a large local produce distributor. "They touch over 80 percent of our target customer base," he said. "Many of the large casinos already buy from this distributor."

The vertical farm's parent company is Sananbio, which is owned by Chinese LED chip-making giant Sanan Group. Sananbio already operates one of the world's largest vertical farms in China's coastal city of Quanzhou. Oasis Biotech represents its first major foray into controlled agriculture in the United States and an opportunity to showcase its technology and sell equipment and lights to other indoor agriculture businesses.

'One of the largest players'

"We're going to be one of the largest players in the industry," said Leach. "I don't see anyone in this space as competition but a potential collaborator."

The LED lighting installed at Oasis Biotech uses 50 percent less energy compared with traditional indoor growing, according to the company.

The Chinese company spent about $30 million on the vertical farm, including the 215,000-square-foot industrial property located about 6 miles east of the Las Vegas Strip. The vertical farm is located on the site of a former mail-order prescription drug facility.

The first phase of the indoor farm consists of about 60,000 square feet of production or the equivalent of a 34-acre farm. A second phase, planned for early next year, is expected to add 50 percent more space.

According to Leach, Oasis Biotech expects to be profitable from an operating standpoint in 2019.

"We're the only large indoor controlled-environment ag operation right now that is corporate-backed" and not funded by venture capital, Leach said. "That means we can focus on scale without having to spend a huge amount of resources on capital raising."

Automating harvesting

The microgreens and baby greens are currently harvested by hand, but the company plans to go to a fully automated harvesting in the second phase. The harvest automation equipment is based on the technology that has been used for several months at Sananbio's China operations.

"It will be automated from seed to harvest," said Leach.

Oasis Biotech employs about 130 people. The growing supervisor for the vertical farm is a former potato farmer from Idaho.

"We've got over 70 farmhands with maybe three people who have done controlled-environment ag before. We're teaching them how to be hydroponic technicians. There's going to be a whole new generation of farmers that are going to grow up around controlled-environment ag."

Water efficiency

Water supplies are limited in southern Nevada, a region facing drought conditions and where most of its water comes from the Colorado River or groundwater. The Las Vegas indoor farm uses 90 percent less water than a traditional farm, or roughly 300 to 500 gallons per day — about as much as a family of four uses flushing their toilets and running their showers.

While the mercury soared into the triple digits in Las Vegas this week, Oasis Biotech relied on micro-climate controls to keep the temperature and humidity just right for growing plants in hydroponic systems.

"If you can pull this off in the middle of a desert and this extreme heat, you should be able to do it in other places," said Leach, who previously was CEO of Urban Till, an indoor farming company in Chicago. Prior to that, he worked for a logistics company that handled food distribution for McDonald's.

Many of the early indoor vertical farms built in the U.S. have been in abandoned factories or industrial locations. The indoor farms also offer a solution to countries that need to import most of their fresh produce due to limited arable land or where water scarcity is a constant challenge.

Indeed, a new low-water indoor vertical farm is going up in Dubai this fall and expected to produce upwards of 6,000 pounds of leafy greens daily. The $40 million high-tech farm's backers include Emirates Flight Catering, which supplies more than 200,000 meals daily.

Lettuce traditionally grows in 80 to 90 days outdoors, and producers tend to get up to three harvests out of the field during the season. The indoor vertical farm in Las Vegas can output lettuce in 18 to 24 days and farm 365 days a year, according to Leach.

"The days are longer because we leave the lights on for about 16- to 18-hour cycles," said Leach, and "there's never a cloudy day."

-Story updated to reflect changes in fact sheet provided by Oasis Biotech.

Gene Editing – And What It Really Means to Rewrite The Code of Life

We now have a precise way to correct, replace or even delete faulty DNA. Ian Sample explains the science, the risks and what the future may hold.

We now have a precise way to correct, replace or even delete faulty DNA. Ian Sample explains the science, the risks and what the future may hold

Ian Sample Science editor @iansample

2018

Gene editing has the potential to treat or prevent thousands of forms of human disease. Illustration: Guardian design team

So what is gene editing?

Scientists liken it to the find and replace feature used to correct misspellings in documents written on a computer. Instead of fixing words, gene editing rewrites DNA, the biological code that makes up the instruction manuals of living organisms. With gene editing, researchers can disable target genes, correct harmful mutations, and change the activity of specific genes in plants and animals, including humans.

What’s the point?

Much of the excitement around gene editing is fuelled by its potential to treat or prevent human diseases. There are thousands of genetic disorders that can be passed on from one generation to the next; many are serious and debilitating. They are not rare: one in 25 children is born with a genetic disease. Among the most common are cystic fibrosis, sickle cell anemia and muscular dystrophy. Gene editing holds the promise of treating these disorders by rewriting the corrupt DNA in patients’ cells. But it can do far more than mend faulty genes. Gene editing has already been used to modify people’s immune cells to fight cancer or be resistant to HIV infection. It could also be used to fix defective genes in human embryos and so prevent babies from inheriting serious diseases. This is controversial because the genetic changes would affect their sperm or egg cells, meaning the genetic edits and any bad side effects could be passed on to future generations.

What else is it good for?

The agricultural industry has leaped on gene editing for a host of reasons. The procedure is faster, cheaper and more precise than conventional genetic modification, but it also has the benefit of allowing producers to improve crops without adding genes from other organisms – something that has fuelled the backlash against GM crops in some regions. With gene editing, researchers have made seedless tomatoes, gluten-free wheat, and mushrooms that don’t turn brown when old. Other branches of medicine have also seized on its potential. Companies working on next-generation antibiotics have developed otherwise harmless viruses that find and attack specific strains of bacteria that cause dangerous infections. Meanwhile, researchers are using gene editing to make pig organs safe to transplant into humans. Gene editing has transformed fundamental research too, allowing scientists to understand precisely how specific genes operate.

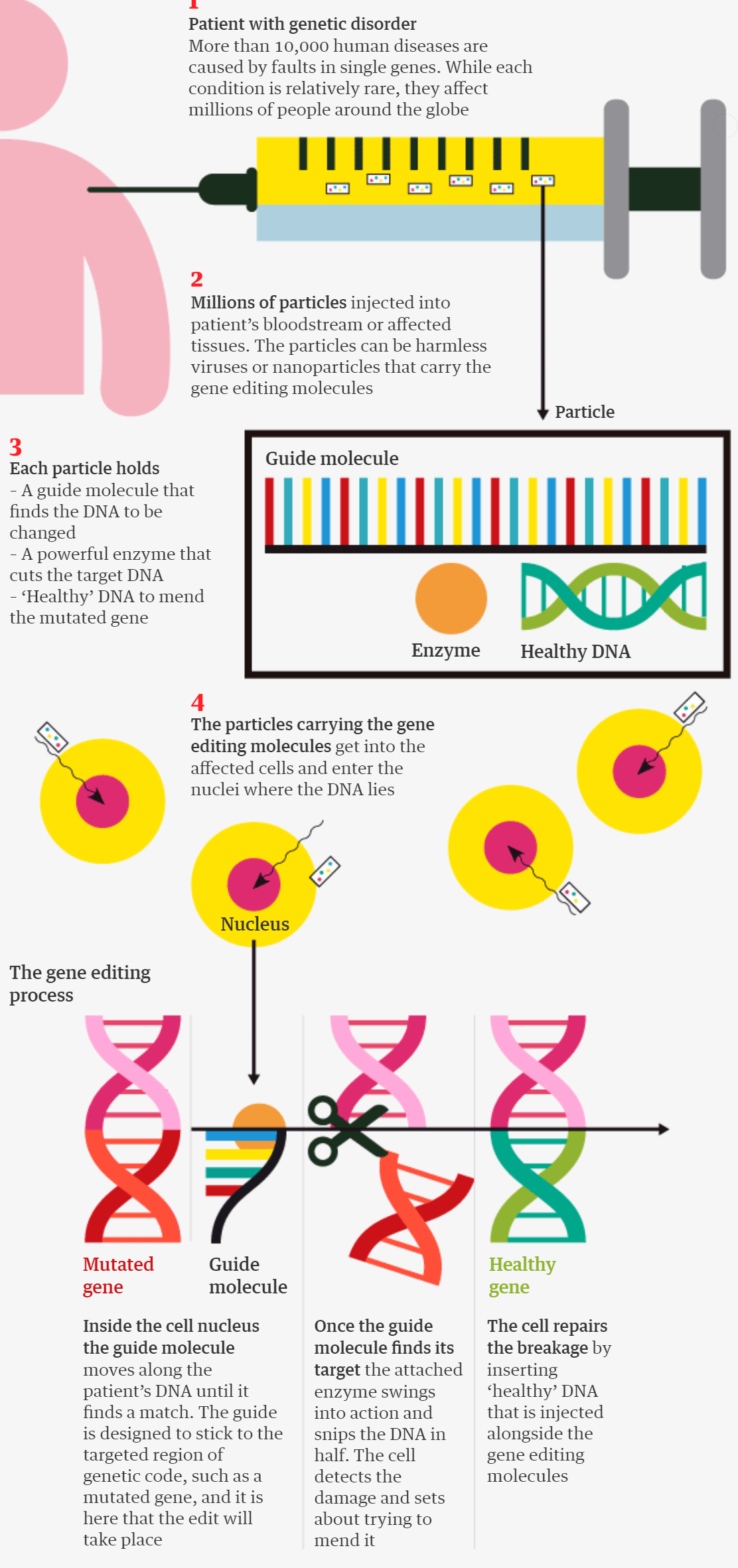

So how does it work?

There are many ways to edit genes, but the breakthrough behind the greatest achievements in recent years is a molecular tool called Crispr-Cas9. It uses a guide molecule (the Crispr bit) to find a specific region in an organism’s genetic code – a mutated gene, for example – which is then cut by an enzyme (Cas9). When the cell tries to fix the damage, it often makes a hash of it, and effectively disables the gene. This in itself is useful for turning off harmful genes. But other kinds of repairs are possible. For example, to mend a faulty gene, scientists can cut the mutated DNA and replace it with a healthy strand that is injected alongside the Crispr-Cas9 molecules. Different enzymes can be used instead of Cas9, such as Cpf1, which may help edit DNA more effectively.

An illustrated example of Crispr in action

Guardian graphic

Remind me what genes are again?

Genes are the biological templates the body uses to make the structural proteins and enzymes needed to build and maintain tissues and organs. They are made up of strands of genetic code, denoted by the letters G, C, T and A. Humans have about 20,000 genes bundled into 23 pairs of chromosomes all coiled up in the nucleus of nearly every cell in the body. Only about 1.5% of our genetic code, or genome, is made up of genes. Another 10% regulates them, ensuring that genes turn on and off in the right cells at the right time, for example. The rest of our DNA is apparently useless. “The majority of our genome does nothing,” says Gerton Lunter, a geneticist at the University of Oxford. “It’s simply evolutionary detritus.”

What are all those Gs, Cs, Ts and As?

The letters of the genetic code refer to the molecules guanine (G), cytosine (C), thymine (T) and adenine (A). In DNA, these molecules pair up: G with C and T with A. These “base pairs” become the rungs of the familiar DNA double helix. It takes a lot of them to make a gene. The gene damaged in cystic fibrosis contains about 300,000 base pairs, while the one that is mutated in muscular dystrophy has about 2.5m base pairs, making it the largest gene in the human body. Each of us inherits about 60 new mutations from our parents, the majority coming from our father.

But how do you get to the right cells?

This is the big challenge. Most drugs are small molecules that can be ferried around the body in the bloodstream and delivered to organs and tissues on the way. The gene editing molecules are huge by comparison and have trouble getting into cells. But it can be done. One way is to pack the gene editing molecules into harmless viruses that infect particular types of cell. Millions of these are then injected into the bloodstream or directly into affected tissues. Once in the body, the viruses invade the target cells and release the gene editing molecules to do their work. In 2017, scientists in Texas used this approach to treat Duchenne muscular dystrophy in mice. The next step is a clinical trial in humans. Viruses are not the only way to do this, though. Researchers have used fatty nanoparticles to carry Crispr-Cas9 molecules to the liver, and tiny zaps of electricity to open pores in embryos through which gene editing molecules can enter.

Does it have to be done in the body?

No. In some of the first gene editing trials, scientists collected cells from patients’ blood, made the necessary genetic edits, and then infused the modified cells back into the patients. It’s an approach that looks promising as a treatment for people with HIV. When the virus enters the body, it infects and kills immune cells. But to infect the cells in the first place, HIV must first latch on to specific proteins on the surface of the immune cells. Scientists have collected immune cells from patients’ blood and used gene editing to cut out the DNA that the cells need in order to make these surface proteins. Without the proteins, the HIV virus can no longer gain entry to the cells. A similar approach can be used to fight certain types of cancer: immune cells are collected from patients’ blood and edited so they produce surface proteins that bind to cancer cells and kill them. Having edited the cells to make them cancer-killers, scientists grow masses of them in the lab and infuse them back into the patient. The beauty of modifying cells outside the body is that they can be checked before they are put back to ensure the editing process has not gone awry.

What can go wrong?

Modern gene editing is quite precise but it is not perfect. The procedure can be a bit hit and miss, reaching some cells but not others. Even when Crispr gets where it is needed, the edits can differ from cell to cell, for example mending two copies of a mutated gene in one cell, but only one copy in another. For some genetic diseases, this may not matter, but it may if a single mutated gene causes the disorder. Another common problem happens when edits are made at the wrong place in the genome. There can be hundreds of these “off-target” edits that can be dangerous if they disrupt healthy genes or crucial regulatory DNA.

Will it lead to designer babies?

The overwhelming effort in medicine is aimed at mending faulty genes in children and adults. But a handful of studies have shown it should be possible to fix dangerous mutations in embryos too. In 2017, scientists convened by the US National Academy of Sciences and the National Academy of Medicine cautiously endorsed gene editing in human embryos to prevent the most serious diseases, but only once shown to be safe. Any edits made in embryos will affect all of the cells in the person and will be passed on to their children, so it is crucial to avoid harmful mistakes and side effects. Engineering human embryos also raises the uneasy prospect of designer babies, where embryos are altered for social rather than medical reasons; to make a person taller or more intelligent, for example. Traits like these can involve thousands of genes, most of them unknown. So for the time being, designer babies are a distant prospect.

How long before it’s ready for patients?

The race is on to get gene editing therapies into the clinic. A dozen or so Crispr-Cas9 trials are underway or planned, most led by Chinese researchers to combat various forms of cancer. One of the first launched in 2016 when doctors in Sichuan province gave edited immune cells to a patient with advanced lung cancer. More US and European trials are expected in the next few years.

What next?

Base editing

A gentler form a gene editing that doesn’t cut DNA into pieces, but instead uses chemical reactions to change the letters of the genetic code. It looks good so far. In 2017, researchers in China used base editing to mend mutations that cause a serious blood disorder called beta thalassemia in human embryos.

Gene drives

Engineered gene drives have the power to push particular genes through an entire population of organisms. For example, they could be used to make mosquitoes infertile and so reduce the burden of disease they spread. But the technology is highly controversial because it could have massive unintended ecological consequences.

Epigenome editing

Sometimes you don’t want to completely remove or replace a gene, but simply dampen down or ramp up its activity. Scientists are now working on Crispr tools to do this, giving them more control than ever before.

Further reading

A Crack in Creation: Gene Editing and the Unthinkable Power to Control Evolution by Jennifer Doudna and Samuel H. Sternberg

The Gene: An Intimate History by Siddhartha Mukherjee

The Epigenetics Revolution: How Modern Biology is Rewriting our Understanding of Genetics, Disease and Inheritance by Nessa Carey

Modern Prometheus: Editing the Human Genome with Crispr-Cas9 by Jim Kozubek

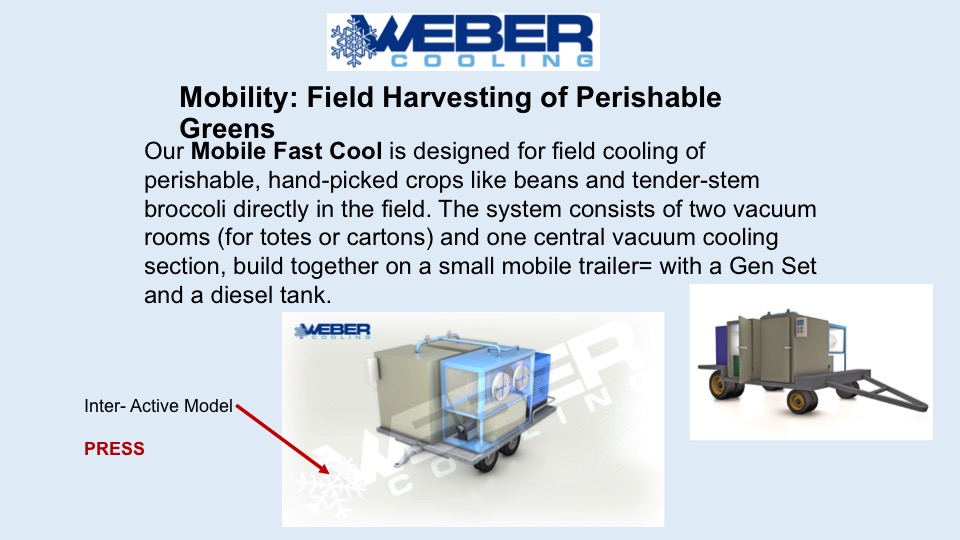

Weber Cooling Vacuum Chamber Systems

The process of VACUUM COOLING explained

Vacuum cooling is a pre-cooling method where the produce is cooled down by vaporizing moisture from inside the product itself. This vaporizing takes away energy in the form of heat from the product, and this ensures rapid cooling down, normally within 15 – 30 minutes for most products.

Weber Cooling

For products with a “high surface to weight” ratio like leafy salads, spinach, mushrooms, sprouts and flowers, vacuum pre-cooling is perfectly suited. But also other (more compact) produce like beans, broccoli, celery and sweetcorn, and perishable products like (straw)berries can quickly and efficiently be pre-cooled by using vacuum.

Mobile Chill Technology Ready For Its Moment

Fighting for dollars to invest in agricultural practices technology can be a challenge. But one product developer believes his technology will move with the trends already being seen in the agriculture business.

The most pressing trend is the emergence of the ‘New Fresh Paradigm’ (NFP) which is the push towards purchasing food via the Internet and offering same-day delivery. It’s a marked difference from the way consumers have long shopped—think weekly, more lengthy, experiences. “This is a growing trend that will gradually become a past time as millennial buyers overtake baby boomers as the largest purchasing group,” says Gregory Smith of ColdPICK International LLC in Bellevue, Wa. ColdPICK’s mobile cooling technology is looking to find its place in the NFP.

A change in offering groceries

In turn, retailers are responding. In June of 2017, e-commerce giant Amazon purchased Whole Foods Market Inc. Urban growers are emerging, including Vertical and Modular farms popping up nearby Walmart distribution centers in Cleburne, Tex. and Los Angeles. This will lead to commercial greenhouses exponentially increasing their participation in produce supply. The recent Digitally Engaged Food Shopper report from the Food Marketing Institute (FMI) and Nielsen notes that in five to seven years, 70 percent of consumers will grocery shop online and in June, Kroger’s began testing driverless cars for grocery deliveries.

With all of those trends coming closer and closer together, what does it mean for companies such as ColdPICK? It’s developing its role in the NFP by using its technology to extend the shelf life of produce, as well as reduce costs aimed at the Urban Grower and their need for a scaled cold chain.

ColdPICK’s technology works well with medium to high-respiration items such as berries, squash, peppers and peas requiring immediate forced air cooling and loose-leaf, broccoli and herbs using vacuum cooling. Both pre-cooling methods will need to be compact with a small footprint to fit the urban grower’s need for maintaining the cold chain. Meanwhile, material handling of pre-cooling may vary, but all retail-ready cartons will be discharged into an area for sorting by order for delivery to the end user.

Changing ways

And with technology ready for adoption, the challenge for Smith is convincing users to maximize their spending now for savings and product improvement later.

“Agriculture can be a traditional industry, from family businesses to large corporations,” he says. “In all cases the challenge is to understand that the methods of material handling in the cold chain must change and cannot mirror methods used over the past decades. The expectations of the consumer are greater than in the past relative to quality and shelf life. And the New Fresh Paradigm consumer also expects fresh, local produce to be delivered on the same day.”

For more information:

Gregory Smith

ColdPICK International LLC

Tel: +1 (863) 581-7279

glcgregory@gmail.com

www.coldpick.com

Publication date: 8/10/2018

Author: Astrid van den Broek

Copyright: www.freshplaza.com

Weird New Fruits Could Hit Aisles Soon Thanks to Gene-Editing

Supermarkets stocked with peach-flavoured strawberries and seedless tomatoes on horizon, scientists say

Supermarkets stocked with peach-flavored strawberries and seedless tomatoes are on the horizon, scientists say

20 July 2018

A red-fleshed apple of the Redlove hybrid variety. Unusual fruits such as this could soon become more common thanks to use of technologies such as Crispr. Photograph: Bailey-Cooper Photography/Alamy Stock Photo

Smooth or hairy, pungent or tasteless, deep-hued or bright: new versions of old fruits could be hitting the produce aisles as plant experts embrace cutting-edge technology, scientists say.

While researchers have previously produced plants with specific traits through traditional breeding techniques, experts say new technologies such as the gene-editing tool Crispr-Cas9 could be used to bring about changes far more rapidly and efficiently.

It could, they say, potentially open the door to a new range of fruits and vegetables that look, taste and feel very different to those we are used to.

Gene-editing is already being used by scientists to change the characteristics of food. One such endeavor used Crispr to make mushrooms that don’t brown, while a team in Spain has been using the approach to try to produce wheat that can be eaten by people with coeliac disease. Still, others are looking at using gene-editing to give crops resistance to particular environmental problems or pathogens.

Earlier this year, biotech firm Monsanto invested $125m in a new gene-editing company called Pairwise that reportedly has goals such as sweeter-tasting strawberries, while scientists in Japan have used the technique to produce seedless tomatoes. Another team have been using Crispr to change the architecture of tomato plant branches and the spacing of fruit.

nside a lab in Norwich where researchers from a startup called Tropic Biosciences are using Crispr to create a better banana. Photograph: Tatum Reid/Tropic Biosciences

Among the genes flagged in the new study in the journal Trends in Plant Science are those behind the production of a family of substances known as MYBs, which are among the proteins that control whether other genes are switched on or off.

“MYBs are great targets because they are central to several consumer traits or features like colour, flavour [and] texture,” said Andrew Allan, a co-author of the review from the University of Auckland whose own projects include working on red-fleshed apples and changing the colour of kiwi fruits. “Russet skin in apple and pear [is linked to MYBs]. Hairs on peaches but not nectarines – another type of MYB.”

Dr Richard Harrison, head of genetics, genomics and breeding at the horticultural organisation NIAB EMR, who was not involved in the article, said tweaking MYB genes or the way such genes are themselves controlled was a fruitful approach.

“For fruits,” he said, “MYB genes have long been known to be associated with expression of molecules such as anthocyanin, a red-coloured compound that gives strawberries or blood-red oranges their colour. “Increasingly, MYBs are being implicated in the production of other important compounds, hence the interest in this family of genes that are conserved between many plant species.”

Gene-editing of MYB genes and other genes could bring a host of benefits, Harrison said, adding: “There is a large opportunity to improve the nutritional profile of fruits and vegetables in the future using gene-editing technology, as well as other techniques.” Such techniques, he said, introduce the same sort of DNA changes as plant breeders have introduced by artificially selecting traits that cropped up through spontaneous DNA mutation – but much faster.

Hybrid purple raspberries of the Glen Coe variety. Crispr may make such specimens more common. Photograph: PR/Suttons

“Red-fleshed apples developed through conventional breeding have taken decades to even come close to market acceptability,” he said, “due to the multiple rounds of breeding and selection that have had to occur to take the naturally occurring red-fleshed gene variant from a wild species of apple and introduce it into a commercially acceptable variety.

“In our normal breeding work, we often see seedlings produced purely from conventional breeding with a range of colour and flavour profiles that simply never make it to the market, such as peach-flavoured strawberries [and] super-dark purpleish strawberries.”

The review is timely: next week the European Court of Justice will announce if or how plants that have been gene-edited using techniques such as Crispr will be regulated, and whether they will be treated like genetically modified plants. The US has already ruled against serious restrictions, provided the changes could have been produced through traditional plant-breeding techniques.

“We are interested in making produce more healthy, sustainable and convenient so that people will eat more produce,” Dr Haven Baker, Pairwise’s chief business officer, said, noting that gene-editing could be used to increase levels of anthocyanins, improve taste, increase shelf life, improve yields, boost disease resistance or even lengthen the season of availability.

Such approaches, said Baker, could not only boost consumers’ nutrient intake, but could also reduce food waste and produce adaptations needed to weather climate change: “We are trying to solve problems that matter to both consumers and the agricultural systems.”

From Farm to Fork: The Regulatory Status of Non-GMO Plant Innovations Under Current EU Law

A new article on the latest plant breeding methods will be published on the next issue of BIO-SCIENCE LAW REVIEW.

The existing EU regulatory framework, when considered holistically, provides efficient guarantees that every stage of the agri-food supply chain, from lab to fork, is subject to constraints and obligations dictated by harmonized legislation, each providing various degrees of scrutiny, risk management and control, sanctions and remedial action.

Comparisons between the existing non-GMO legal framework with the GMO legislation or with any other authorization regime based on a full pre-market risk assessment are, by definition, of little practical relevance, since such regimes aim to address potentially serious risks, which, as the SAM Note clarifies, have not been identified in the case of Non-GMO NBT Products.

In the absence of any such concrete, identifiable risk induced by (the use of NBTs for) Non-GMO NBT Products and in view of their non-distinguishability from CBT products, the protection of human/animal/plant health and the environment should thus be considered to be adequately ensured and Non-GMO NBT Products should not be treated differently from products resulting from CBT.

The opposite conclusion would not only raise serious concerns under the SPS Agreement but would essentially also mean that all non-GMO plant products on the market today must be considered inadequately regulated. Just as Advocate-General Bobek concluded in his Opinion in Case C–528/16,133 with regard to mutagenesis, that ‘one could hardly assume that a reasonable legislator could ever wish to state, en bloc and for the future, that something is safe to such a degree that it does not need regulating at all’, one can neither assume that all NBT-products should en bloc be considered to only yield products suspect of causing unacceptable risks.

Against that backdrop, it is submitted that both the precautionary principle and the specific safeguard clauses in horizontal and sectoral legislation can justify and sufficiently guarantee the adoption of stricter risk management measures if a previously unidentified risk arises.”

Future of Farming Is Rooting Itself In Central Oregon

A sustainable, shipping container 'vertical farm'

By: Lauren Melink

July 26, 2018

Around the Bend Farms

BEND, Ore. - There’s a new farm in Central Oregon, and it’s a bit different from your standard homestead.

It’s called Around the Bend Farms. And for now, you’ll find it in a laboratory at OSU-Cascades.

Around the Bend Farms CEO, Ben Marsh describes it like this: "It's definitely not your archetypal farmer who is in a field, sweating in 95-degree weather with a big combine. Our combine is a computer or a micro-controller."

Around the Bend, Farms is a non-profit organization that’s partnered with OSU-Cascades to create a personal food computer.

"What that means is that the computer can tell this thing, 'OK, I need you to turn on a light.' And this thing goes 'All right,' and turns on a light," Marsh said.

The farm is a sustainable "vertical farm" that after being programmed with the correct grow recipe, runs on its own.

"We’re controlling the heating, the cooling, the air movement, the lighting, temperature," Marsh said

The goal is to eventually build computer-run, sustainable, vertical farms inside shipping containers.

Lance Porter is an energy systems engineering graduate involved in the project. He thinks the computer farm will attract a different type of farmer.

"The newer generations really want to be more involved in where their food comes from and especially involved in how it’s made and how it’s produced," Porter said

Executive research associate Makena Whitaker said this unique kind of farming will hopefully keep people coming back.

"It’s more fun if you make farming fun and interesting. People will stick around," Whitaker said.

Around the Bend Farms also hopes to create a sense of community around growing food.

"Food was always a family endeavor and a community-based endeavor, and we want to kind of get back to that," Marsh said.

Around the Bend, Farms is in its early stages of development, but already they’ve tripled the size of their crop and hope to have a shipping container farm in Bend within two years.

For more information on the farm, you can visit the website at this link: https://www.aroundthebendfarms.org/

Palmerston North, New Zealand-Based Agri-Tech Biolumic Opens World-First Research Centre

Palmerston North, New Zealand-Based Agri-Tech Biolumic Opens World-First Research Centre

PAUL MITCHELL | May 25, 2018

MURRAY WILSON/STUFF

Biolumic founder and chief scientist Jason Wargent explains how the UV treatment works to Palmerston North mayor Grant Smith.

A bedroom experiment has budded into a pioneering agri-tech company with global reach in just six years.

Palmerston North agri-tech company Biolumic marked a new phase in its progress with the opening of a world-first ultraviolet photobiology research and development centre at Massey University on Friday.

Biolumic founder and chief scientist Jason Wargent said it was exciting, and mind-blowing, how fast the company had grown.

The Massey University associate professor's research focused on using UV light to boost plant growth and crop yields. Over the past six years he has developed it into a commercial product with business partner Biolumic chief executive Warren Bebb .

READ MORE:

* Palmerston North start-up Biolumic attracts significant overseas funding

* Top agricultural start-ups get a lift from Sprout business programme

* New entreprenuers visa to boost New Zealand's reputation for innovation

* Seed funding to give university-based ideas a boost to market

It all started as an LED array the size of a dinner plate, which Wargent kept in his bedroom over the weekends so he could keep an eye on his seedlings.

"Now we're going overseas and demonstrating our process to some of the biggest crop growers in the world – and it's all being done from [Palmerston North]."

The city's mayor Grant Smith said Biolumic was an impressive example of what Manawatū companies could accomplish.

Biolumic has built a global reputation as a pioneer in its field, and employed scientists from all over the world, he said.

"It's like the UN of science ... and the fantastic thing is they're employing a lot of local graduates [as well]."

Biolumic has grown test crops of lettuce in Britain, Spain and Mexico, and has proven UV treatments can increase crop yields by up to 40 per cent in a variety of conditions.

Bebb said the new research and development centre would help develop tweaks to the treatment to tailor it for tomatoes, strawberries, cucumbers and other highly valuable crops – as well as other applications such as pest control.

MURRAY WILSON/STUFF

Biolumic researcher Lulu He, left, and chief executive Warren Bebb, centre, take Sprout summit attendees on a tour of the new research and development centre.

Bebb said Biolumic's success had attracted significant overseas investment, which had allowed it to expand the management team to include a few technical and business specialists.

"We've got this far as a two-man management team. [So] it's really exciting, and a really big step for us."

Building Clever Companies chief executive Dean Tilyard said the centre's opening and tour was the "jewel in the crown" of the annual Sprout summit.

He said the two-day event, which started on Thursday, highlighted Manawatū as an agri-tech startup powerhouse to 14 major agri-tech investors and senior members of agricultural, technology and engineering companies from around the world.

MotorLeaf: The Farming AI Which Helps Boost Modern Indoor Farms

MotorLeaf: The Farming AI Which Helps Boost Modern Indoor Farms

from RESET

Published on 23 May 2018

MotorLeaf introduces a green-fingered AI which can help indoor farms match the growing food demands of the future.

The Agronomist AI uses a range of wirelessly connected devices to monitor crops.

The recent expansion of agricultural tech, combined with emerging food security concerns, has led to the development of modern agricultural practices which seem a million miles away from the rolling green fields and romanticised ideas of farming yore.

For example, we recently reported on AeroFarms, a US-based company exploring the concept of urban vertical farming, while elsewhere, technological greenhouses can utilize new systems to greatly reduce water consumption without compromising on yield. Indeed, in many cases, the yield is drastically increased.

MotorLeaf is the latest company to find a role in this new market. The artificial intelligence developer has created a new AI which can help urban and indoor growers to monitor their crops, and predict issues in real time.

Their Agronomist AI uses data-driven machine-based learning to provide indoor farms with a comprehensive suite of insights, whether relating to potential yield or even predicting disease. Put all together, this data can help reduce waste and crop failure - something which will only become more important as more stress is put on the agricultural sector by population growth and climate change induced weather patterns.

Many of Agronomist’s services can be used individually or combined together with the MotorLeaf HEART system to operate as a larger AI manager of an indoor farm or greenhouse. Every four seconds, MotorLeaf’s AI collects data from a collection of wirelessly connected devices which can provide information on factors such as light spectrum, light intensity, CO2, humidity, air temperature, water usage and chemical makeup.

Recent trials conducted in California led to a fifty percent reduction in yield prediction errors of tomatoes, and with recently secured funding, they are seeking to expand the product to different crops and scales.

Can AI Be Environmental?

Currently, the system is mostly being used in hi-tech, comparatively low-yield indoor farms in developed nations - and is it likely to remain that way for some time. Furthermore, the current goal of MotorLeaf appears to be making these ventures more profitable and cost-effective, and less concerned with environmental protection - although the two are not mutually exclusive.

Despite this, technology such as the Agromost.ai or similar could also have major implications for farms and greenhouses in developing nations. Although the current expense and technical know-how required to operate such software may be beyond most farmers in the Global South, the ability to predict disaster and better monitor the conditions of your crops could become an invaluable tool in the fight against famines, crop failure, and poor weather conditions.

If AI is to become a tool of future, it should also be used broadly to help those most in need of its utility. AI that remains the sole possession of developed nations is likely only to exacerbate inequalities and economic gulfs between states. However, as AI becomes more widespread, and the tech it relies on cheaper and more available, it could be an important player in supporting an agricultural sector that can feed the entire world. Additionally, much else remains to be debated about AI from a social standpoint, including its potential impact on employment, not only in manufacturing but in a range of sectors and roles.

UAE Minister Reviews Smart Agricultural Technologies In The US

UAE Minister Reviews Smart Agricultural Technologies In The US

May 9, 2018

CALIFORNIA: During her visit to the United States, Mariam Hareb Almheiri, Minister of State for Food Security, reviewed the latest technological developments in indoor and smart agriculture, which are key future solutions to providing enough food for the whole of humanity.

She also participated in the Global Conference of the Milken Institute, a non-profit organization that aims to promote international prosperity, as one of the main speakers in a discussion about food security issues and the role of smart and vertical farming.

Almheiri stated that smart indoor agriculture is a promising area and is part of the efforts to increase food production and decrease consumption of resources while pointing out that recent technological developments have made it possible to produce large quantities of vegetables, fruits, and other fresh products in urban environments using minimal space and less water, compared to traditional farming.

She also highlighted the importance of this new type of agriculture, as the current era is witnessing greater pressure to produce food while posing many challenges, such as climate change, the lack of fresh water, deforestation and a greater demand for energy.

During her visit to “Windset Farms” in Santa Maria, California, Almheiri reviewed the latest advanced technologies of the company, which is a major supplier of sustainable natural products in North America. She also met with Steven Newell, CEO of Windset Farms, Tony Martin, CFO of Windset Farms, and John Hart, Executive Director of Windset Farms, while the farm’s team presented a detailed technical report about its production process.

She then visited the “Local Roots Farms” in Santa Monica, California, where she learned, from Eric Ellestad, CEO of Local Roots Farms, and Brandon Martin, Vice President for Business Development, the concept of indoor agriculture. She also met with officials from “TPG Rise,” which is an incubator for companies that assist in reducing hunger, increasing food security and encouraging sustainable agriculture, as well as representatives of Pontifex, which is an investment company in agricultural technology.

The Future Food Security Office is currently working on preparing the “National Strategy for Food Security,” with the aim of adopting a comprehensive national framework to guarantee the UAE’s short and long-term food security.

The plan is being developed in cooperation with relevant government authorities, decision-makers, academics and experts from the government and private sectors.

Inauguration Ceremony

Mariam Hareb Almheiri, Minister of State, and Mohammed Yusouf Al Awadi, UAE Ambassador to Peru and Non-Resident Ambassador to Costa Rica, attended the inauguration and swearing-in ceremony of Carlos Alvarado Quesada, the new President of Costa Rica. The ceremony, which was held on Tuesday at the capital, San Jose, was attended by a number of head of states, several states envoys, ministers, deputies, and representatives of international organizations.

WAM