Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Pure Flavor® Georgia Greenhouse Construction Project Coming to Life

Pure Flavor® Georgia Greenhouse Construction Project Coming to Life

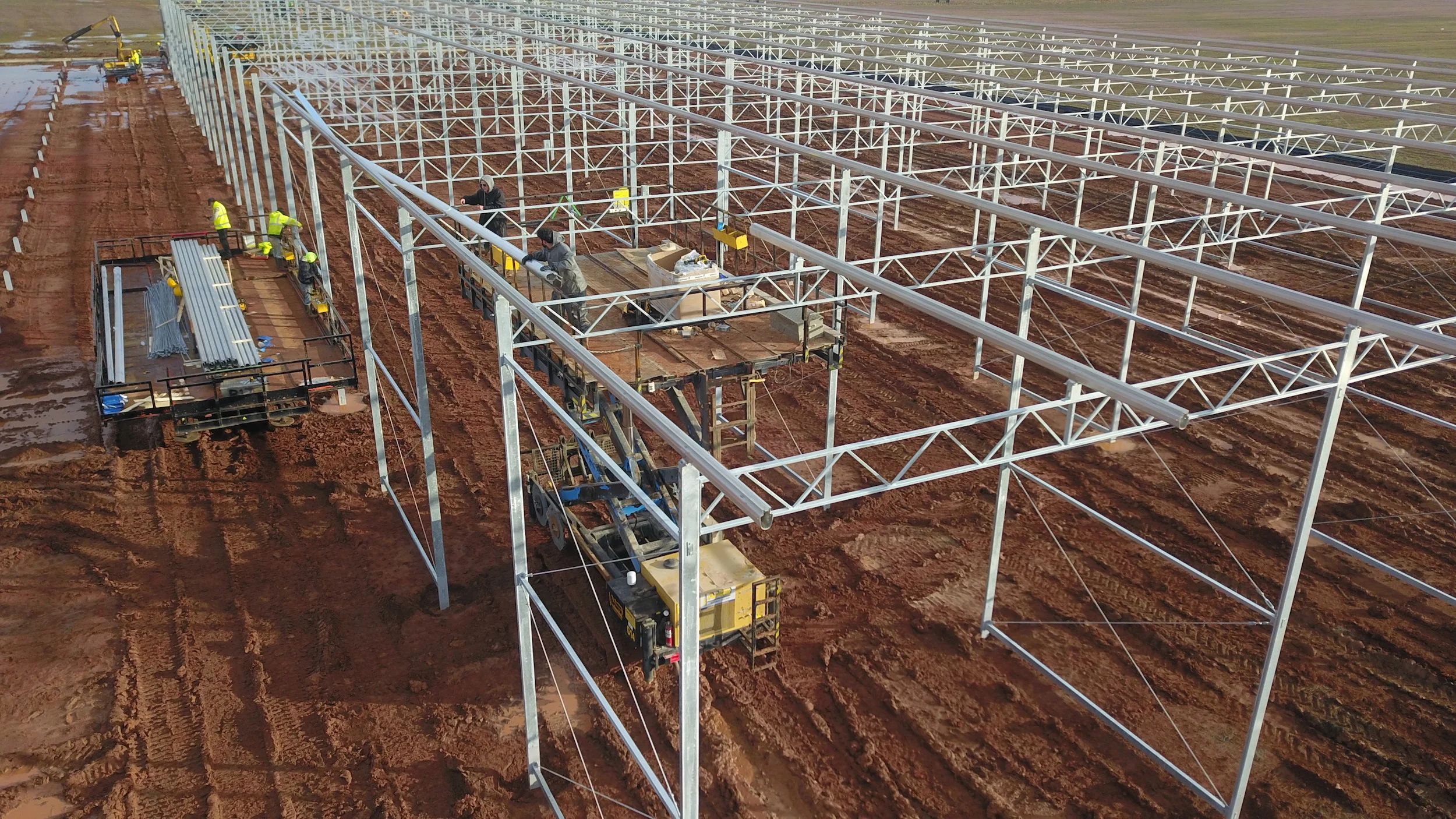

Fort Valley, GA (February 14th, 2018) – Cooperation with Mother Nature for good weather this winter has spurned a fury of activity at the site of Pure Flavor®’s greenhouse project in Georgia. Ground leveling completed in late fall lead to a smooth start of construction of the company’s new 75-acre high tech greenhouse facility in Peach County.

Over the course of the last few weeks once post holes were dug and backfilled, Dutch greenhouse builder Havecon began erecting the main structure with full-scale implementation now underway. From a timing standpoint, the project is on track for completion by late summer with the first crop of tomatoes & seedless cucumbers to be planted shortly thereafter.

“Building a high-tech greenhouse in Georgia was part of our growth strategy to extend our reach across North America. Being strategically located in Peach County allows us in some instances to have same day & next day deliveries in the southeast region”, stated Matt Mastronardi, Executive Vice-President. Pure Flavor® researched more than 400 sites throughout North America before settling on Peach County, GA. The 75-acre greenhouse project broke ground in September 2017 and will be built in 3 phases of 25 acres. Phase 1 is expected to be completed in late Summer 2018.

“Greenhouse tomatoes & seedless cucumbers grown in Georgia will help breathe new life in to the category. It will help our retail (& foodservice partners) in the region to have fresher product on store shelves while maintaining consistent quality and availability year-round. In the end, it is the consumer who will benefit from great product grown in the state of Georgia”, said Mastronardi.

Retail partners & consumers can follow the progress in photos of the Georgia greenhouse construction on a weekly basis by visiting the Pure Flavor® Georgia Photo Gallery: https://goo.gl/s5UCgc

“We are connecting our customers with the project in every way possible with frequent updates via social media, the photo gallery, and video stories shot by drone”, said Chris Veillon, Chief Marketing Officer. A custom website was built just before the groundbreaking in September 2017 to announce the project, the page now serves as the central resource for everything to do with the Georgia project. “A connected customer is an informed customer, we can’t wait to get our first plants in the greenhouse later this summer”, commented Veillon. Pure Flavor® expects the first crops to be picked in early Fall 2018.

Pure Flavor® will be exhibiting at the upcoming Southern Exposure Trade Show & Convention in Tampa, FL March 3rd. Visitors are encouraged to visit Booth #605 to learn more about the Georgia project.

To learn more about the Pure Flavor® Georgia greenhouse project, please visit GeorgiaGrownFlavor.com.

-30-

About Pure Flavor®

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise.

We are the next generation of vegetable growers, inspired to put quality, flavor, and customers first by providing greenhouse-grown vegetables from our farms that are strategically located throughout North America.

SOURCE: Chris Veillon | chris@pure-flavor.com

Chief Marketing Officer | Pure Flavor®

T: 519 326 8444

VIDEO: https://youtu.be/f6mXwHRuzMo

GALLERY: https://goo.gl/s5UCgc

A Lush Green Garden Without Soil On The Rooftop

You no longer need soil to grow a sustainable garden. A DIY tinkerer, D D Rajesvaran cultivates his plants by floating their roots on mineral enriched water on the terrace of his house. It is called hydroponics.

A Lush Green Garden Without Soil On The Rooftop

Soma Basu MADURAI | FEBRUARY 09, 2018

Fruit of labour and love: D D Rajesvaran and his wife Grace Rajesh spend much time inside their greenhouse named Southern Springs Hydroponics to check the progress of no-soil less-water plants. Photo: S. James

You no longer need soil to grow a sustainable garden. A DIY tinkerer, D D Rajesvaran cultivates his plants by floating their roots on mineral enriched water on the terrace of his house. It is called hydroponics.

As I stepped on to the roof of Rajesvaran’s house in Vishwanathapuram, I caught a glimpse of the future.

Inside a clean, perfect and healthy greenhouse with not a speck of dirt or soil, he has grown over a dozen varieties of fruits, herbs, and green leafy vegetables. The soft sound of gurgling water in the compact enclosed room and the sunlight filtering in through the green mesh over the fresh plants in contrasting colours was an instant feel-good and a sight to behold.

“These are the growing green walls of hydroponics,” he says with pride. Still visibly fascinated by the less water-based and no-soil planting system, he says initially he too did not believe but the yield he has got in just four months has made him chew his thoughts. He is the first Madurai resident to successfully grow a hydroponic garden at home.

The abundance of the very healthy looking green spinach, parsley, local keerais, mint, asparagus, celery, red and green lettuce, bok choy has magically revved up 400 sq.feet on his rooftop. “You can actually grow up to thousand plants in 500 sq feet,” he says, “and I have just begun.”

He is very happy to get a head start on his dream project, the idea for which came from a friend. This was about two years ago when he had to take his bore well from 250 to 900 feet. “And when I got the water tested in the lab, it showed a lot of microbial elements and two dangerous elements – chlorine and sodium – much above the normal levels.”

The quality of keerais grown locally in the city already under the grip of water shortage struck him and he began reading about hydroponics on the net. “Israel and the US were full of success stories and it was very heartwarming to see how technology had automated soil-less growing methods, such as hydroponics, aquaponics, and aeroponics,” says Rajesvaran.

There are techniques like the Dutch bucket system or the single bucket deep water cultivation but Rajesvaran chose hydroponics based on Nutrient Film Technique (NFT) because mixing 16 types of water-soluble macro-and micronutrients and trace elements in different measures and practically directing the plants to grow brought out the chemistry student in the otherwise quintessential businessman.

In places where there is not enough fertile ground or enough water, hydroponics can provide a much-needed solution, wows the 68-year-old now who in the last 12 months -- through trial and error -- has also grown brinjals, lady’s finger, types of beans, cucumbers and watermelon.

But it is the rich harvest of cherry tomatoes and two exotic breeds of tomatoes – the Big Boy from UK (resemble our desi tomatoes but are bigger and bright red in colour with resistance to cracking and work well in salads and sandwiches) and the San Marzano, the famous plum tomatoes of Italy known for the elongated pointed shape, thick flesh, fewer seeds, sweeter and low acidity – that has put Rajesvaran on a high.

Experimenting with circulating water and soluble nutrients was challenging enough but growing plants of different climatic conditions and temperatures required regulated conditions and constant monitoring. It prompted Rajesvaran – whose family markets motor pump boosters, stabilizers, inverters and solar panels and run restaurants in the city besides a cosmetic manufacturing unit in Pondicherry -- to turn into an ardent urban farmer in no time.

“He grew up in verdant Kanyakumari before shifting to Madurai in 1963, so his passion for greenery was showing,’ says his wife, Grace, “it was like he was living his dream.”

For weeks together, both of them would check day and night the seeds they had sown, the progress of the plants from sapling to trees and anxiously awaited the first fruits. Just a fortnight back their greenhouse, which they have named ‘Southern Springs Hydroponics’, was a riot of red and greens. The tomato trees had grown 10 feet tall and with much joy, they went around distributing the fruit. “It has been a very rewarding experience,” beams Rajesvaran.

“Greens are the easiest to grow but once you understand the basic concept of hydroponics, you can grow anything,” he adds.

Hydroponics will save Madurai’s water, he makes a case, as a struggle for land, water and resources will increase. “Indoor or rooftop gardening will make our food more accessible to us. Hydroponics makes plants grow much faster because they neither have to search for nutrients like in soil nor fight the soil bugs. Safe from fungal attacks, they require no weeding and we can also regulate their growth to any height and increase the yield as well,” he further explains.

Rajesvaran spent Rs.Two lakhs to set up his greenhouse and put the NFT Hydroponics system in place. The greenhouse is designed to give complete control of the growing environment, including light, temperature, humidity, CO2, and nutrition. He has used the regular irrigation tubes through which the water circulates continuously and is mixed with the enriched solution so that the plants’ roots are bathed in the nutrients. Rajesh has connected his NFT to a 500 watts solar power plant which keeps a motor running for oxygenation in the tubes and four small fans that circulate the air inside the enclosure.

“Once the set up is established, you just have to learn to balance the water chemistry by getting the right mix of nutrients, with the right seeds, and at the right pH,” he says, adding, regular cleaning of the tubes after each harvest is equally important.

“Hydroponics is less wasteful farming future,” he says, “It gives you the real, delicious, fresh and also fast food that is not necessarily seasonal,” “The Babylonians used hydroponics at its most basic for their ancient hanging gardens and we have come full circle.”

QUOTE

Hydroponics uses up to 90 percent less water than soil farming and you can grow high-density, high-value, rich in taste organic food 365 days literally anywhere -- D D Rajesvaran

For the beginners

The hydroponic system is uncomplicated, easy to learn and maintain, says Rajesvaran who has devised a starter’s kit to make the system more accessible to all. It contains a 20 litres plastic basket with a cover tray and the pots to sow the saplings, different varieties of seeds, a small air pump to oxygenate the water, a TDS meter to check nutrient level and the water-soluble nutrients divided into four groups of master solutions. It costs Rs.3,800.

He is also in the process of developing a Junior kit that will be the miniature model of the water circulating system. Priced at Rs.10,000

Ways We Can Make The Food System More Sustainable

If you’ve been paying any attention to the changing food climate over the past several years, you’ve probably heard a certain buzzword repeated time and time again: sustainability.

Ways We Can Make The Food System More Sustainable

February 7, 2018

Written by Megan Ray Nichols

If you’ve been paying any attention to the changing food climate over the past several years, you’ve probably heard a certain buzzword repeated time and time again: sustainability.

But what does a sustainable food system refer to, exactly?

The answer is complex and composed of many moving parts, but at its heart, a sustainable model in the food system promotes the physical health of the public, the economic health of farmers and producers and the fair treatment of the earth, animals and people.

A sustainable food system also refers to an approach that makes the most of the earth’s resources for future generations. It guards against depleting these resources. Why, then, has sustainability not yet been achieved? Perhaps it’s because not enough folks know how to achieve it.

Here are 10 ways that consumers, food producers and legislators can work together to make the food system more sustainable.

1. Local eating

The cost of transporting food across the globe isn’t measured just in dollar signs, but in carbon emissions too. When you buy food from local farmers, you’re contributing to your community’s economy and also decreasing your impact on Mother Nature. Win-win.

Tip: If you really want to reduce your food miles, we recommend growing your own herb garden. It’s easy, economical and sustainable. Check out this post on growing herbs.

2. Encourage cooking

Since sustainability promotes better health among consumers, learning to cook at home more skilfully — and more frequently — is an essential component. When people have control over their own food, they can eliminate ingredients like added sugars and fats. This, in turn, creates a healthier public.

Tip: Check out the video below that we created to encourage people not only to cook vegan, but to grow their own food too!

3. Design menus to follow seasons

Eaters like to enjoy fruits and veggies year-round which is part of the reason foods are imported from all over the world: to gratify the appetites of consumers. This however is unsustainable. If you stick to seasonal produce, however, you’ll be able to buy almost everything locally — and make sure that you get more variety in your diet over the course of a year. This practice will help to reduce your carbon footprint and boost your health.

4. Rotate crop varieties regularly

When farmers plant the same crops again and again, they eventually suck the nutrients out of the soil, making it near useless and often necessitating chemical-laden fertilizers. There’s a simple, natural and time-tested trick to avoid this, though. Farmers can plant different crops every few years to keep the soil healthy. Consumers just have to get on board with mixing up their diet too.

5. Waste less

If you added up all the food to be produced from now until the year 2050, the sum would equal the same amount of food that’s been consumed over the past 8,000 years. Clearly, as the food industry grows, so will its impact on the earth. In order to offset this impact, consumers should strive to toss out less food at home and make the most of their groceries. Businesses, supermarkets and industry should stop throwing out food too and strive to donate to charity or other organisations.

Tip: It’s important that food isn’t sent to landfill as it adds to the carbon pollution problem as rotting food in landfills help to create methane, a greenhouse gas. So make sure to compost your food. To learn more about the food waste problem, we recommend reading this post which runs through the issue in great detail.

6. Support Fair Trade

Foods that bear the Fair Trade label have been produced in a way that ensures fair treatment of employees and the earth. So if you’re committed to the sustainable food movement, you should opt for Fair Trade foods whenever possible to support the right kinds of producers.

Tip: If you really want to support a sustainable food system, make sure to choose more plant-based foods, reduce your meat intake or try a vegetarian or vegan diet.

7. Consider food’s true cost

The “true cost” of food refers to the often unseen environmental and social impacts that mass food production creates. Although unsustainable foods may be cheaper at the supermarket, they ultimately have a higher “true cost” in their negative impact on people and planet. It’s important to keep this issue in mind when you buy food.

Tip: If it’s more sustainable to support local grocers, farmers and primary producers, why not quit the big supermarkets? This post offers some helpful advice.

8. Invest financially

The Netherlands is a small nation, but it exports the second-highest amount of food in terms of value, second only to the United States. How? The Dutch have invested in sustainable agriculture. They get innovative, using indoor farming techniques to make the most of every square inch of land. They also forego most chemical pesticides so they can keep their soil fertile.

Tip: Vertical farming is a great example of indoor farming. Not sure what it is? This beginner’s guide will bring you up to speed.

9. Avoid additives, pesticides and go organic

Synthetic pesticides, fertilizers and antibiotics take a toll on the earth and on animals, but are used frequently by primary producers and livestock farmers in conventional farming to ensure produce and animals grow – and turnover profit – as quickly as possible. When you have the option, try to buy organically grown and additive-free produce and grass-fed meats where possible This should be clearly marked on the packaging but if it isn’t, make sure to ask an assistant.

10. Be willing to forgo convenience

Supporting a sustainable food system isn’t easy. When you commit to buying locally-produced foods and Fair Trade foods and adhering to other tenants of sustainable living, these conscious choices may cost you time and money. But ultimately, you’re working toward a greater cause that will ensure you pass on a healthy earth to future generations.

Contributing to a sustainable food system may require a personal investment on your part, but when you weigh the benefits, it’s well worth the effort. With just a few minor tweaks to your daily life, you could have a huge impact on the way the food system develops in the coming decades. So pick one or two of these steps that you can take to do your part in living (and eating) more sustainably.

Urban Farming Platform Infarm Gets $25M Funding Endorsement

Berlin-based urban farming startup Infarm has received a rousing endorsement for its vertical, indoor farms in the form of cash. Like, lots of cash.

Urban Farming Platform Infarm Gets $25M Funding Endorsement

Photo Credit: Infarm

Berlin-based urban farming startup Infarm has received a rousing endorsement for its vertical, indoor farms in the form of cash. Like, lots of cash.

Balderton Capital was the leading investor in a Series A funding round, with other names such as Mons Investments, Cherry Ventures, and LocalGlobe claiming their stake in the promising indoor farming company. The round brings Infarm’s total funding to date to $35 million, and they plan on using the new capital to expand their international footprint in Paris, Copenhagen, London, and other German cities while improving upon their Berlin-based R&D headquarters.

The goal: 1,000 Infarm vertical farms in operation globally by 2019’s end.

Here’s how Infarm works. They conceived and control the glass-walled ‘vertical indoor farms’, allowing clients such as grocery stores and restaurants to place the Infarm incubator in their business. From there customer can pick their own herbs, lettuce, or other vegetables out for themselves, much like they would with any other fruit or vegetable. The difference is that they know Infarm produce is guaranteed fresh because they are picking the produce or herb from the incubator in which it’s grown.

Infarm’s techs and agricultural experts can manage their modules remotely, taking maintenance issues out of the hands of clients while using A.I. and a mass of analytical data to ensure that the produce is being grown as near to perfect as possible.

We collect 50,000 data points throughout a plant’s lifetime, Erez Galonska, cofounder and CTO explained, each farm acts as a data pipeline, sending information on plant growth to our platform 24/7 allowing it to learn, adjust, and optimize.

Each module can be controlled to establish the perfect amount of light, pH levels, temperature, and nutrients depending on what is being grown. The Infarm modules have been likened to their own contained, highly-controlled ecosystems, and Galonska has said that he hopes to create a world where seasonal changes and drought are irrelevant to one’s ability to produce food.

Infarm’s model makes too much sense for grocery stores, restaurants, and other establishments that waste countless funds throwing out over-ripe produce daily to overlook. It’s no wonder so many investors are willing to put their big bucks behind Galonska and his partners, brother Guy and Osnat Michaeli, and their one-of-a-kind urban farming platform.

The challenge [now] is in finding the right partners. Our initial focus is on supermarket chains, online food retailers, wholesalers, hotels, and other food-related businesses, for whom the superior quality and range of produce — with no fluctuation in costs — makes Infarm an attractive partner, Michaeli explains. In return, we can reintroduce the joy of growing to the urban population.

Spread The Love With Valentine’s Strawberries

Spread The Love With Valentine’s Strawberries

Valentine’s Day is a perfect opportunity for Driscoll’s to reach out to consumers by offering the best quality strawberries, large in size, light red in color and with exceptional flavor in a premium packaging. Berries are an emotional category driven by impulse. The valentine’s punnet is the perfect way to tap into this. The company believes that celebrating the special moments in the lives of consumers can contribute to building the berry category even further.

Driscoll’s is the world’s true expert in the breeding, production, and sales of strawberries, raspberries, blackberries, and blueberries. With over 100 year experience in the farming of berries, Driscoll’s is the true berry expert of the world.

The development of unique varieties is one of Driscoll’s top priorities. A nice intense color, exceptional flavor, and a long-lasting shelf life differentiate Driscoll’s berries from other varieties. Driscoll’s is working with independent growers from all around the world and by choosing the regions with the best-growing conditions Driscoll’s can deliver berries all year round.

Publication date: 2/14/2018

Under The Lights: $15M Makeover Means Greenhouse Strawberries In Time For Valentine's Day

Under The Lights: $15M Makeover Means Greenhouse Strawberries In Time For Valentine's Day

SHARON HILL, WINDSOR STAR

February 5, 2018

Strawberry plants replaced cucumbers in a Leamington greenhouse this summer when DelFrescoPure made a $15-million switch to grow and sell fresh strawberries through the winter.

It costs 30 to 40 per cent more to grow strawberries because of the extra expenses such as added lighting that tricks the everbearing strawberry plants to grow like it’s a long summer day.

“We took a big chance putting these lights in,” Carl Mastronardi, president and one of the owners of the Kingsville-based Del Fresco Produce, said Monday. “It’s working.”

The immediate payoff could be Valentine’s Day sales but in the long run for the greenhouse industry and for consumers, the move a couple of Leamington and Kingsville growers have made to greenhouse berries could be a game-changer.

“This could be a lot bigger than we think,” Mastronardi said of having fresh, local berries that are grown using less chemicals because of the beneficial insects greenhouses use to kill pests.

“This opens up a realm of trying a whole bunch of new things.”

Next on the list are raspberries, he said.

The strawberries are marketed as YES!Berries Your Every Day Snack! and are sold for $3.99 to $5.99 for a 12-ounce container. They can be found in local grocery stores including Metro, Sobeys, Walmart and Remark Farms.

“It’s a taste of summer all year round,” said marketing manager Fiona McLean. “Once you start you can’t stop.”

YES!Berries are picked almost 100 per cent ripe, are sweet and consistent, and can be in grocery stores sometimes as fast as the next morning, Mastronardi said. Florida and California berries are not picked ripe and take days for them to reach Ontario stores.

Strawberries are packaged at the Del Fresco Produce Ltd. strawberry greenhouse, Monday, February 5, 2018. DAX MELMER / WINDSOR STAR

Other local greenhouses have tried strawberries. Orangeline Farms in Leamington won a 2016 Premier’s Award for Agri-Food Innovation Excellence for its strawberries.

In October, Mucci Farms in Kingsville announced it was spending $12 million in addition to its $24-million greenhouses built just for strawberries to become the largest strawberry grower in North America under glass. It will have 36 acres.

Mastronardi doesn’t have the most indoor strawberry acres here but figures, for now, his 10 acres are likely the most under grow lights.

The electricity costs would have been too expensive so the greenhouse uses two natural gas generators to produce electricity and then heat, as a byproduct, which is distributed to the greenhouses through pipes as hot water, Mastronardi said.

Lights are used at the Del Fresco Produce Ltd. strawberry greenhouse, Monday, February 5, 2018.DAX MELMER / WINDSOR STAR

DelFrescoPure grows about 100 acres of tomatoes, peppers, cucumbers, beans and eggplant in its greenhouses. Strawberries could be harvested year-round but the season will run from late October to July because Mastronardi expects his berries grown with beneficial insects to kill pests can compete with field-grown berries.

He expects to have the most greenhouse strawberries available in local grocery stores this Valentine’s Day. Each acre has 43,000 strawberry plants with berries ripening daily.

There will be opportunities to try YES!Berries this weekend in some Sobeys stores in Ontario including the Amherstburg store and then the demos will be in some Metro stores in Windsor, London, and Sarnia Feb. 15 to 18.

The Promise of Indoor, Hurricane-Proof ‘Vertical’ Farms

A worker rides a lift past stacks of vertical farming beds with LED lights

A worker at an indoor vertical farm in Newark, New JerseyMike Segar / Reuters

The Promise of Indoor, Hurricane-Proof ‘Vertical’ Farms

They might be an efficient way to produce food in a world withmore extreme weather—but only if growers can figure out a successful business model.

February 12, 2018, The Atlantic Daily | MEAGAN FLYNN

Federico Marques feared the worst for his farm as he watched live coverage of Hurricane Harvey ravaging fields across the Gulf Coast and inundating every pocket of Houston.

Marques was trapped at home during Harvey and could only monitor his crops from his couch, anxiously viewing footage from the farm’s single working indoor camera. “We couldn’t get in here for four days,” Marques said as he showed me around on an unseasonably warm afternoon this November. “I’m looking at all these aerial photos and thinking, ‘Oh my God, everything is underwater.’ When we finally got back, we had 10 inches of water on the floor—but we only lost maybe 5 percent of the product. The rest was perfectly fine.”

In a way, Harvey was a test for Moonflower Farms. Founded by Marques in December 2015, it was one of the state’s very first indoor “vertical” farms—where plants are stacked in trays on shelves, instead of laid out horizontally across larger plots of land. In these high-tech structures, plants don’t rely on sunlight or soil, rainwater or pesticides, but LED lights and minerals instead. The goal of vertical farms isn’t just to save space; it’s also to find a more economical way of producing food for the growing population—and to reduce the costs and consequences of getting that food to where people actually live.

Moonflower is in an industrial area about 15 miles south of downtown Houston, tucked away inside a relatively small, unassuming white shack. The small farm is housed in a 900-square-foot room with a 14-foot ceiling. There are hot-pink lights and a small irrigation system quietly feeding 20 varieties of micro-greens, which sprout up from a mineral-based substitute for soil called vermiculite. In Marques’s growing room, everything from the temperature to the lighting to the watering schedule has been engineered to replicate conventional outdoor farming, but without all the interruptions that plague it: seasonal changes, droughts, bitter cold, fires, and, of course, floods.

A Moonflower Farms employee checks on produce in the 900-square-foot growing room in southeast Houston. (Meagan Flynn / The Atlantic)

Houston has developed other vertical-farm concepts in the past two years. There’s Space City Farms, a backyard aeroponic vertical garden; Dream Harvest, a hydroponic system similar to Moonflower; and Acre in a Box, a literal take on the operation housed in a shipping container.

Acre in a Box’s founders—Andrew Abendshein, who works for an oil and gas trading firm in Houston, and Ana Buckman, a Rice University languages and creative-writing instructor—had no background in agriculture when they invested $80,000 in their first shipping-container farm. Abendshein said he has long had an interest in getting fresh produce to urban food deserts and hopes to one day start moving shipping-container vertical farms into those neighborhoods. For now, though, Acre in a Box’s two farms are hidden in the parking lot of an abandoned drill-bit factory at the end of a dead-end street in Houston’s East Downtown, a few blocks from where Houston’s two largest bayous intersect.

Harvey, and the deluge it brought, are exactly the kind of scenario that vertical farms are designed to withstand. Catastrophic flooding events like Harvey are only expected to become more frequent, and threats of food and water scarcity are projected to worsen in the years to come—all as the population grows. The United Nations projects that the world’s population will be 9.8 billion by 2050, with roughly two-thirds of those people living in urban areas, which aren’t exactly conducive to large-scale farming.

To meet the growing demand for food, the UN’s Food and Agriculture Organization estimates that there needs to be a 50 percent increase in global agriculture production—a distinct challenge, the UN warns, in the face of climate change and the growing need for water conservation. Vertical farms present a potential solution: There is no fertilizer runoff into the groundwater, fewer CO2 emissions from delivery trucks’ long journeys, and no land to till. They require only a fraction of the acreage and use only a fraction of the water—anywhere from 90 to 97 percent less—that traditional farms do.

“We are kind of at the beginning of a revolution,” Per Pinstrup-Andersen, a graduate-school professor at Cornell University’s College of Human Ecology, told me. “We’re at the beginning of a very rapid development in the use of indoor controlled facilities for producing vegetables and some fruits,” he said. “No matter what happens with climate change, you still have your controlled environment.”

The technology used for these farms has been around for decades. In fact, Marques began studying it in the 1990s after learning that NASA used it to grow plants in space. But only in the last several years has interest in using the technology for urban, commercial-scale agriculture picked up. Indoor farms have recently sprouted up in old warehouses, shipping containers, and small skyscrapers in New Jersey, South Korea, Germany, India, and Dubai—places where traditional farming is either difficult or impossible due to climate, population density, or the land itself. In Houston, sprawling commercial and residential developments were built on top of a swamp, making large-scale outdoor farming virtually impossible.

Marques and I hopped in his minivan and headed about a mile away from his garden to the site of the Moonflower Farms expansion, where men in hard hats were surveying the land. The new facility doesn’t look like much yet—just a large elevated mound of dirt with metal poles sticking out of it. But by the time it’s operational, Marques plans to have a 20,000-square-foot greenhouse that he expects will churn out 1,000 pounds of produce per day—compared with the 20 pounds that his tiny facility produces now. He currently sells to a couple dozen restaurants but plans to expand to regional and national distributors and local grocers once the new facility is up and running.

The elimination of long, cross-country transports to get the produce to grocery stores means consumers wind up with fresher food. Right now, Marques said, the time from harvest to table is sometimes only a matter of hours, which means that produce arrives in better shape and then lasts longer both in the store and in people’s homes. “If we can make this work in the city of Houston and produce 1,000 pounds a day or more of product—high-quality product that has three times the shelf life—then we have a good model that we can pretty much [take] to any city in the world and replicate,” Marques said.

The new greenhouse will operate like a research-and-development facility, helping Marques perfect a prototype that interested farmers around the world can use as a template. He already knows that he’ll need to make some changes. For starters, he’s not going to rely exclusively on LED lighting as he does now; instead he will mostly use sunlight, plugging in energy-efficient lighting as a supplement—a measure that will cut costs significantly. Marques said he has already had inquiries about this model from a food distributor in Cairo, where the arid climate and heavy reliance on imported crops make the food supply unpredictable. Marques says he has also talked to strawberry growers in Norway, where thousands of metric tons of strawberries are imported every year due to the short growing season. And he has heard from cattle farmers in Brazil, where the shrinking availability of pastureland and prohibitions on razing rainforests mean that some farmers may need to import grass to feed their cows.

Ana Buckman, Acre in a Box’s CFO, shows off kale that was later sent off to local businesses in Houston. (Meagan Flynn / The Atlantic)

Cutting the costs of building and maintaining the systems themselves will be crucial as vertical farms continue to evolve, according to Henry Gordon-Smith, the co-founder of the International Association for Vertical Farming and a consultant at the New York-based firm Agritecture. As a result of high costs, Gordon-Smith said, several vertical farms in North America have failed in recent years. That’s what happened at LocalGarden, a rooftop vertical farm in Vancouver that went bankrupt in 2014, and at PodPonics, a shipping-container vertical farm in Atlanta, where high labor and technology costs were consistently undermining return on investment.

Mike Nasseri, who was the harvest supervisor at LocalGarden, said that design flaws had inflated the endeavor’s operational and energy costs to the point that the farm couldn’t make enough money. Even though the farm had started small, Nasser said the crew decided to scale up too quickly to a commercial operation. To make matters worse, Nasseri said, the costs of the real estate in the middle of downtown Vancouver—a central location he said he would not recommend for new vertical farmers —were way too high. “That placement [in the middle of downtown] is basically the first way you can screw up,” Nasseri said.

Still, he’s a major proponent of vertical farming, primarily because of its environmental benefits. He’s now working at a startup called Ava Technologies, developing indoor “smart gardens,” essentially mini vertical farms that can fit on kitchen counters.

Gordon-Smith said the industry-wide goal going forward has to be to minimize the risk of failure, financial or otherwise, as much as possible in order to make vertical farming more accessible to the younger generation of produce growers, who have been moving steadily away from rural areas and toward cities over the past few decades. Still, he said, the failures serve as lessons for new investors as they continue to develop various types of vertical farms.

Like Marques, Abendshein, the founder of Acre in a Box, was stuck at home monitoring his produce from the couch during Harvey. But he knew he could rest assured that, as the waters raged, his produce was safe. Without land that could be ruined for an entire season, the worst that could happen, he thought, was that his farms would float away.

How Urban Farmers Are learning To Grow Food Without Soil Or Natural Light

Growing food in cities became popular in Europe and North America during and immediately after World War II.

How Urban Farmers Are learning To Grow Food Without Soil Or Natural Light

February 13, 2018

Mandy Zammit/Grow Up, Author provided

Author

- Silvio Caputo

Senior Lecturer, University of Portsmouth

Disclosure statement

Silvio Caputo does not work for, consult, own shares in or receive funding from any company or organization that would benefit from this article, and has disclosed no relevant affiliations beyond their academic appointment.

Partners

University of Portsmouth provides funding as a member of The Conversation UK.

Growing food in cities became popular in Europe and North America during and immediately after World War II. Urban farming provided citizens with food, at a time when resources were desperately scarce. In the decades that followed, parcels of land which had been given over to allotments and city farms were gradually taken up for urban development. But recently, there has been a renewed interest in urban farming – albeit for very different reasons than before.

As part of a recent research project investigating how urban farming is evolving across Europe, I found that in countries where growing food was embedded in the national culture, many people have started new food production projects. There was less uptake in countries such as Greece and Slovenia, where there was no tradition of urban farming. Yet a few community projects had recently been started in those places too.

Today’s urban farmers don’t just grow food to eat; they also see urban agriculture as a way of increasing the diversity of plants and animals in the city, bringing people from different backgrounds and age groups together, improving mental and physical health and regenerating derelict neighbourhoods.

Many new urban farming projects still struggle to find suitable green spaces. But people are finding inventive solutions; growing food in skips or on rooftops, on sites that are only temporarily free, or on raised beds in abandoned industrial yards. Growers are even using technologies such as hydroponics, aquaculture and aquaponics to make the most of unoccupied spaces.

Something fishy

Hydroponic systems were engineered as a highly space and resource efficient form of farming. Today, they represent a considerable source of industrially grown produce; one estimate suggests that, in 2016, the hydroponic vegetable market was worth about US$6.9 billion worldwide.

Hydroponics enable people to grow food without soil and natural light, using blocks of porous material where the plants’ roots grow, and artificial lighting such as low-energy LED. A study on lettuce production found that although hydroponic crops require significantly more energy than conventionally grown food, they also use less water and have considerably higher yields.

Growing hydroponic crops usually requires sophisticated technology, specialist skills and expensive equipment. But simplified versions can be affordable and easy to use.

They grow up so fast. Mandy Zammit/Grow Up, Author provided

Hemmaodlat is an organisation based in Malmö, in a neighbourhood primarily occupied by low-income groups and immigrants. The area is densely built, and there’s no green space available to grow food locally. Plus, the Swedish summer is short and not always ideal for growing crops. Instead, the organisation aims to promote hydroponic systems among local communities, as a way to grow fresh food using low-cost equipment.

The Bristol Fish Project is a community-supported aquaponics farm, which breeds fish and uses the organic waste they produce to fertilise plants grown hydroponically. GrowUp is another aquaponics venture located in an East London warehouse – they grow food and farm fish using only artificial light. Similarly, Growing Underground is an enterprise that produces crops in tunnels, which were originally built as air raid shelters during World War II in London.

The next big thing?

The potential to grow food in small spaces, under any environmental conditions, are certainly big advantages in an urban context. But these technologies also mean that the time spent outdoors, weathering the natural cycles of the seasons, is lost. Also, hydroponic systems require nutrients that are often synthesised chemically – although organic nutrients are now becoming available. Many urban farmers grow their food following organic principles, partly because the excessive use of chemical fertilisers is damaging soil fertilityand polluting groundwater.

To see whether these drawbacks would put urban growers off using hydroponic systems, my colleagues and I conducted a pilot study in Portsmouth. We installed small hydroponic units in two local community gardens, and interviewed volunteers and visitors to the gardens. Many of the people we spoke to were well informed about hydroponic technology, and knew that some of the vegetables sold in supermarkets today are produced with this system.

A simplified hydroponic frame in Portsmouth. Silvio Caputo/University of Portsmouth, Author provided

Many were fascinated by the idea of growing food without soil within their community projects, but at the same time reluctant to consume the produce because of the chemical nutrients used. A few interviewees were also uncomfortable with the idea that the food was not grown naturally. We intend to repeat this experiment in the near future, to see how public opinion changes over time.

And while we don’t think hydroponic systems can replace the enjoyment that growing food in soil can offer, they can save water and produce safe food, either indoors or outdoors, in a world with increasingly scarce resources. Learning to use these new technologies, and integrating them into existing projects, can only help to grow even more sustainable food.

As with many technological advancements, it could be that a period of slow acceptance will be followed by rapid, widespread uptake. Perhaps the fact that IKEA is selling portable hydroponic units, while hydroponic cabinets are on the market as components of kitchen systems, is a sign that this technology is primed to enter mainstream use.

Vertical Planting Establishes Roots In Laramie

An example of vertical gardens in downtown Laramie. (Photo taken by Seth Haack)

Vertical planting established more permanent roots in Laramie when the company Plenty, formerly Bright Agrotech, began construction on their new headquarters; providing jobs as well as fresh herbs in the community.

Rising from the ground in upright containers under controlled lighting and water systems, the latest trend in agriculture is featured just past the entrance of Washakie dining center and according to University of Wyoming researchers, vertical farming is here to stay.

“Plenty’s farms will be located near communities around the world, delivering industry-leading yields of delicious, locally-grown, backyard-fresh produce,” a Plenty spokesperson, Senior Communications Manager Patrick Mahoney stated in an email. “By shaving thousands of miles and weeks off the journey from farm to table, Plenty will transition agriculture to a reliable, predictable and resource-efficient model.”

The company was founded by Dr. Nate Storey, a UW alumnus.

“Nate Storey was a student of mine,” Extension Horticulture Specialist Karen Panter said. “He got all three of his degrees here in our department of plant sciences. The company includes engineers and computer experts and plant growth people and researchers and [Plenty’s] got some plant breeders now, there’s a lot of people working here in Laramie.”

Vertical farming allows for an increase in production per square foot, Panter said.

“So, there’s a limited amount of land that we can grow food on, limited resources, we have what growing people often refer to as ‘food deserts’ which are centers of urban settings with limited access to fresh produce,” Associate Professor of Agroecology Urszula Norton said. “And the fact that you can actually produce fresh green vegetables that don’t really take too many days and a way shorter period of time under optimum growth conditions.”

Indoor controlled conditions don’t experience drought, hail or other afflictions, resulting in a quicker growth turn around. The crops that are most compatible with vertical farming conditions tend to be leafy greens and some herbs, like lettuce and spinach.

“Plenty’s vertical towers can achieve industry-leading yields of fresh fruits and vegetables,” Mahoney stated in an email. “Up to 350 times greater per square foot than the field. Plants that get too big like tomatoes or that kind of thing just don’t work. The plants’ architecture is just completely wrong. It’s really hard to grow larger, longer, vining type plants.”

Norton, along with Liping Wang and other plant scientists, are in the midst of submitting a proposal to the National Science Foundation to better understand and improve on efficiency of water and energy using vertical farming settings.

“It is generally a proposal about learning more about where are we standing in terms of efficiency of vertical farming and how can we move it toward increasing effectiveness, efficiency, water use and energy,” Norton said. “My role would be pretty much to assess the growth yield and the quality of the produce.”

While the research and growth of vertical farming programs are certainly hot topics in the ag community, horizontal farming is not becoming obsolete by any means.

“[Vertical Farming is] not going to supplant traditional farming because there’s so many crops that can’t be grown in this type of system,” Panter said. “It’s not likely that we’ll be growing wheat or anything like that in this kind of a system, but for niche crops, it’s another tool to use.”

Evergreen Farm Wins Best Indoor Farming Innovation Award

Evergreen Farm Wins Best Indoor Farming Innovation Award

EverGreen Farm Oy participated in the Global Forum for Innovations in Agriculture (GFIA) at Abu Dhabi during the 5th and 6th of February, 2018, where it was presented with the Best Indoor Farming Innovation Award by the Minister of State, Her Excellency Mariam Bint Mohammed Saeed Hareb Al Mehairi, from the Abu Dhabi Food Control Authority.

During the conference H.E Mariam Bint Mohammed Saeed Hareb Al Mehairi stated “The Food Security Innovation Sessions are an ideal platform for joint action, aimed at putting the government and relevant sectors in a row to explore the future of food security and finding solutions to increase the contribution of the private sector in the food equation of the UAE. We cannot consider the issue of food security as an independent issue and separate from society, we must activate the role of all entities in addressing the challenges we face, taking into consideration that innovation is the key tool for improving food and agricultural production and essential for food security.”

Using the basic principle of hydroponics, Evergreen Farm Oy has developed an innovative vertical indoor farming technology that produces high-quality fruits and vegetables in a state-of-the-art, environmentally controlled, the multi-level indoor facility called the Direct Feed Vertical Hydroponics (DFVH) system.

"Best Indoor Farming Innovation" Award

Evergreen Farm Oy Wins "Best Indoor Farming Innovation" Award During the Global Forum for Innovations in Agriculture (GFIA)

The GFIA was founded in 2014 and it is the world’s largest series of events dedicated to showcasing innovations in sustainable agriculture across all types of food production. “The Global Forum for Innovations in Agriculture is based on the notion that the ongoing drive for innovation in the agriculture sector is the only way to feed 9 billion people sustainably by 2050,” said Nicolas Davison, Director of the Global Forum for Innovation in Agriculture.

Evergreen Farm Oy’s mission is to fundamentally transform agriculture by implementing the technologically advanced and easy-to-use DFVH system throughout the world. Thus, improving crop production while encouraging responsible, innovative farming methods that protect the environment and educate the community.

“We are extremely proud and thankful for the "Best Indoor Farming Innovation" award. We have now launched the first production-ready product portfolio, including both industrial and home units. After years of product development, we have got one step closer to our objective to make fresh, healthy, delicious, non-GMO, chemical and pesticide-free food accessible to everyone. While doing so, we also aim to improve the quality of life of local communities by providing job opportunities and a platform for growth and education, “ said Ali Amirlatifi, CEO of Evergreen Farm Oy.

Evergreen Farm is not only focusing on the technology for crop growth but also developing artificial intelligence (AI) based services to optimize production and accelerate our customers’ fruit and vegetable business entry into the markets. “With AI driven operations we can automate almost everything but also analyse global vegetable and fruit market automatically for our customer, “ thought Ali Amirlatifi.

For any inquiry to EverGreen Farm Oy please contact:

Ali Amirlatifi CEO, EverGreen Farm Oy

ali.amirlatifi@evergreenfarm.fi

Mobile: +358 50 390 3333

Website: www.evergreenfarm.eu

Evergreen Farm Oy is a Finnish company, located in Tampere. Evergreen Farm Oy is a technology company focused on providing clean sustainable food through agricultural innovation.

By offering the World highest yield per square meter as well as cubic meter, indoor protection from the elements, a variety of crops that go beyond leafy green, and the benefits of existing technology in robotics artificial intelligence and engineering, Evergreen Farm is sure to provide a solution to the food crisis and its associated environmental impacts.

Introduce Vertical Farming by Hydroponics and Aquaponics in Dry Arid Regions of India

It is known for everyone in India that the farming communities of the dry and arid regions of Central India mostly in the regions of Bundelkhand, Vidarbha and Marathwada have been struggling for a long time.

Introduce Vertical Farming by Hydroponics and Aquaponics in Dry Arid Regions of India

Independent started this petition to pmoindia and 4 others

It is known for everyone in India that the farming communities of the dry and arid regions of Central India mostly in the regions of Bundelkhand, Vidarbha and Marathwada have been struggling for a long time. Droughts and Farmer Suicides are rampant in Vidarbha and Marathwada. There were times when people have to eat even grass to kill their hunger in Bundelkhand. Unfortunately even though new technologies have been developed around the world to develop crops and food in most difficult situation, still these technologies have not reached these farmers who are in dire need of hope.

Hence I appeal to the Govt of India and the Ministry of Agriculture to introduce Vertical Farming by Hydroponics (and Aquaponics) to the farmers of these regions. Hydroponics is the method of growing plants without soil, using mineral nutrient solutions in a water solvent. This method can be used to grow plants in Vertical Towers and Stands without any need for soil.

Advantages of Vertical Farming using Hydroponics:

- No need for soil so can be set up in dry and arid regions.

- No effect of drought or storms or unseasonal rains.

- 80-90% less usage of water due to water recycling.

- Crops grow quickly hence improved productivity of 10-12 crops per year instead of 2-3 crops per year.

- Scope of Installing Solar Panels for Generation of Solar Electricity on top of Warehouse.

- Vertical Farms give more crops per acre. No limit of vertical expansion of farm.

Today, the advanced countries have been using these technologies for mass production of food for the people of their countries. Vertical Farming in Temperature Controlled Warehouses are now a proven and standard system for food production. Combined with installing Solar Panels on top of the roofs, these system can become a food production industry in itself and can bring the farming communities of Bundelkhand, Vidarbha and Marathwada out of Poverty. Since the plants being raised using Hydroponics are not dependent on soil, these can be setup in the dry and arid regions easily (and also anywhere in the country).

I am sure the ministry of agriculture must be aware of these technologies. I request the ministry and the Govt of India to urgently look at introducing Vertical Farming by Hydroponics in India. Not only it has the potential to eliminate poverty of the farming communities but also it can bring enough food for all the needy and the poor.

Hope the farmers of India can be benefitted and they come out of poverty quickly.

Regards

Souvik Jana

Farmers for America - New Documentary Screening in Fairfield, Iowa 2/17 and 2/18

Farmers for America - New Documentary Screening in Fairfield, Iowa 2/17 and 2/18

A Documentary to Celebrate, Inspire, and Support Young Farmers

Saturday, February 17 at 7:30 pm

Sunday, February 18 at 2:00 pm

Orpheum Theatre, Fairfield, IA (NOTE LOCATION CHANGE)

Saturday evening features a panel discussion with director Graham Meriwether and area farmers

Farmers for America, a new documentary from director Graham Meriwether (American Meat), traces the extraordinary changes coming to Americas food system as more and more consumers flock to farmers markets, embrace farm-to-table lifestyles and insist on knowing where their food is coming from. At the center of the film are the farmers, young and old, who provide the spirit and energy to bring urban and rural America together over what both share in common: our food. These farmers reflect nothing less than the face of America.

With the average age of todays farmer at 60, and rural America losing population as the cost of land and equipment soars, this film reveals the people waiting to take their place, the practices theyre championing and the obstacles they must overcome.

After the film on Saturday evening, Meriwether will be present to facilitate a conversation with a panel of local farmers of all backgrounds- from small-scale niche production to large-scale commodity farmers. Meriwethers goal is to bring these two perspectives together and forge a shared path towards our next agriculture.

Admission by donation.

Click here for more information on the film.

To be added to the JFAN email list, type SUBSCRIBE in the Subject Line and hit return. To unsubscribe from the JFAN email list, hit reply, type REMOVE in the Subject Line and hit return. JFAN never sells or shares its email list. Thank you!

Jefferson County Farmers & Neighbors, Inc.

PO Box 811

Fairfield, IA 52556

Follow us on Facebook: https://www.facebook.com/JFANIowa

Now on Twitter! https://twitter.com/JFANIowa

JFAN is funded by grassroots support and gratefully welcomes your donations. https://www.jfaniowa.org/donate-today

Beginners Guide To Plant Nutrition

The reason for releasing the beginners guide to plant nutrition is to help you from making wrong decisions in your indoor grow room.

The reason for releasing the beginner's guide to plant nutrition is to help you from making wrong decisions in your indoor grow room. Visualize... by the end of this blog, you will be able to understand plant nutrition.

Introduction

Plants are able to take in essential plant nutrients through leaves, a fact known for years. Foliar fertilization has been used for years mainly with high value crops such as vegetables and fruits. Early uses of foliar fertilization were mainly used to balance micronutrient deficiencies such as iron deficiency with blueberries or to boost the appearance and shelf life of foliage plants and cut flowers. Foliar applications of nutrients can balance nutrient deficiencies caused by diseases, insect damage and help plant recover from other stress conditions. Both quantity and quality of yield can be increased by foliar application of deficient nutrients regardless of cause.

Nutrient Mobility and Foliar Fertilization

Foliar fertilization is especially important for nutrients that are poorly mobile in the plant. An endless supply of these nutrients is needed to provide that plant has sufficient nutrition for acceptable growth and yield. If the supply of these nutrients from the water or growing media is unable to keep up with demand, then new growth will suffer from nutrient deficiency. The application for moderately mobile or very mobile nutrients is also important when the crop cannot take and deliver adequate nutrients to the growing points of the plant, but mobile nutrients have the benefit of being able to taken for older plant tissue and translocated to the new growing points. Foliar application of mobile nutrients will help prevent the depletion by older tissue by these mobile nutrients. One frustration in using foliar sprays to supply nutrients to plants is that intake and translocation of the applied element may not be rapid enough for growing crop yields if foliar application is the major source of a nutrient. This problem is greater for macronutrients. Foliar application of plant nutrients continues to gain increasing widespread acceptance. The mobility of nutrients generally is classified into three categories of mobility: very mobile, moderately mobile and poor or slightly mobile.

Nitrogen (N)

Nitrogen is a very mobile element within the plant, and foliar sprays using urea, nitrate salt, and ammonium have been used to supplement the nitrogen levels in plants.

Urea

Urea is the most effective form of foliar nitrogen followed next by ammonium ion and then by nitrate ion. Urea is easiest to traverse the cutin layer to enter the plant and is considered the most suitable form of N for foliar application because of its non polarity, rapid intake, low phytotoxicity and high solubility.

Ammonium

Ammonium application effectively boosts growth and yield for many crops through foliar application. Like urea, the plant assimilates most of the ammonium within 48 hours after application. Ammonium, once inside the plant cell has a similar effect on plant nitrogen, as does urea.

Nitrate

Nitrate, through adsorbed by the plant effectively, is less effective as a foliar source of nitrogen than urea or ammonium because it must first be converted into ammonium through nitrate reduction.

Phosphorus (P)

Phosphorus is a very mobile element within a plant and its application through foliar application is an effective means of supplying phosphorus. Phosphorus foliar application can increase the concentration of phosphorus in the foliage and is a more effective method of delivering phosphorus to the plant via water.

Potassium (K)

Potassium is a very mobile element, and applications as foliar sprays utilize potassium polyphosphate, potassium sulfate, potassium nitrate, potassium thiosulfate, or potassium hydroxide. Many of these sources have low salt index, are highly soluble, and can provide potassium to plants in situations where a deficiency of this element will reduce yield or is needed for foliar plants going to market.

If you enjoyed this, you might also enjoy these post:

"Understanding water pH in hydroponics"

"How to grow microgreens from seed"

Tags: hydroponic nutrients plant nutrition beginners guide NPK nitrogen phosphorus potassium

Agrilyst Adds Horizons Ventures to New Round with Eyes on China

Agrilyst Adds Horizons Ventures to New Round with Eyes on China

FEBRUARY 2, 2018 EMMA COSGROVE

Indoor farming software startup Agrilyst has raised an undisclosed strategic round, bringing in new investors with the aim of expanding the scope of its product offering and entering the Chinese market.

Agrilyst offers a software-as-a-service platform to help indoor agriculture operations maximize their efficiency. The platform offers workflow management tools, inventory tracking, and pest and nutrient management. The company analyzes data about these metrics to provide growers with recommendations on the best way to fine-tune their growing plans and increase profitability.

New investors in the round include iSelect Fund, Argonautic Ventures, Horizons Lab and Onlan Capital Ventures, with existing investors Compound and New York State Innovation Venture Capital Fund joining also participating.

Horizons Lab is the seed fund of Hong Kong-based Horizon Ventures, the VC fund belonging to billionaire Li-Ka Shing.

The firm is invested in major tech startups like Slack, Facebook, and Skype, but also several agrifood tech startups such as algae-based food company Algama, as well as alternative protein startups Impossible Foods, Modern Meadow, Hampton Creek, and Perfect Day Foods.

“We see a world where computation cost is driven to zero and we now have the resources to monitor the growth, health, and biology of every single seed,” says Phil Chen, Advisor at Horizons Lab. “I see Allison and her team at Agrilyst as the interpreters of this data to secure future food sources.”

Agrilyst CEO Allison Kopf told AgFunderNews that the company currently has customers in Singapore, but is looking to expand into the Chinese market.

Kopf said that iSelect Fund is also a strategic investor to her company’s growth as the St. Louis firm’s other agtech portfolio companies could be ideal partners. iSelect is also invested in Agrible and Benson Hill Biosystems among others.

This year Agrilyst will ad an app to its web-based suite of tools, which will allow growers to use traceability tools in their growing environments without ideal connectivity.

The company will also release a new inventory management module in the coming months that will eventually help growers to get better pricing on inventory items.

Kopf says the ultimate goal is for Agrilyst to be a central platform aggregating other data and services that indoor farmers might need.

“Our API has been open from day one. We are definitely trying to build an ecosystem with our growers and with our partners on the technology side. The more people we bring in, the more profit we can push back to the farmers,” said Kopf.

Agrilyst added more than 100 new customers in 2017 and has seen 500% growth in terms of both revenue and customers since 2016. The platform is currently available in 10 countries and its customers grow 800 different crop varieties, including cannabis, flowers, and insects, which are relatively new additions to the platform.

The company raised $1 million in seed funding in 2016 led by New York seed stage investors Brooklyn Bridge Ventures with participation from NYC early-stage tech investors Metamorphic Ventures as well as a group of angel investors.

Tregren's IoT Kitchen Garden Is Boosting The Strong Urban Gardening Trend

Tregren's IoT Kitchen Garden Is Boosting The Strong Urban Gardening Trend

NEWS PROVIDED BY Tregen

HELSINKI, February 8, 2018, PRNewswire

The ever growing urban gardening trend is hitting cities across the globe with an increasing intensity. We see this trend bringing green buildings, urban farms and now even automated gardens into our kitchens. The latest technologies in lighting and IoT have enabled the development of affordable kitchen gardens to be used in everyone's home. Tregren is the first company to bring these fully automated gardens to the consumers. Tregren's T-series kitchen gardens have been an instant success in Europe and North America.

"We could sense the potential already last year when we introduced our new T-series Kitchen Garden concept to our B2B customers at Ambiente-fair in Frankfurt. The first time we knew that we were on to something big was when our Kickstarter campaign was successfully overfunded. The strong demand continued when we recently announced the start of shipments and we immediately received orders from more than 15 countries across Europe. We are happy to see years of hard work is bearing fruit," says Tregren's CEO Jyri Timonen.

The success of T-series kitchen gardens is based on IoT combined with the innovative use of hydroponic cultivation. The state of the art technology in the T-series provide many benefits as it produces three times faster growth, big stable yields and the possibility to grow more than 100 different species of plants. The best thing is that this can be achieved without any previous knowledge of gardening.

The three times faster growth pace is the result of Active Growing TechnologyTM, a combination of hydroponic cultivation, the latest in growing light technology and growth nutrients. With T-series, Tregren also launched the Smart GardenerTM application. The Smart GardenerTM controls the Active Growing TechnologyTM that creates the right growing condition for the different plant species.

"Like human beings, every plant has its own special needs. Some plants need a lot of water when others don't. Some plants need more light than others and some need to grow in a nutrient-rich environment to flourish, whereas for others this can be harmful. This is something that many of us experience as challenging, even to the extent that we don't consider gardening as an option. With the T-series, we wanted to omit this hurdle and provide an easy and effective solution to indoor gardening for everyone. We believe that the T-series will do the same for urban gardening that iPhone did to mobile phones," says Tregren's CVO and founder Markus Nilsson.

The T-series isn't only about good yields and intuitive usability, but it is also about design. The T-series consists of three products, the T3, T6, and T12. The T3 is the perfect product for small households. The T6 is the family-friendly kitchen garden, where your family can have all of their favorite herbs growing in your kitchen all year round. The T12 is designed for high yield households and public places where continuous harvest is needed. The recommended price 89€ for T3, 139€ for T6 and 179€ for T12. The Smart GardenerTM works with both Android and iOS devices.

Tregren T-series takes a new approach to indoor gardening, incorporating innovative technologies, effortless usability, and contemporary design into a unified product. Easy to set up, easy to take care of and guaranteed success enabled by Active Growing TechnologyTM and the Smart GardenerTM application make T-series a unique product of the future.

Tregren develops and manufactures consumer products intended for cultivation in urban areas, particularly indoors. The products are examples of a new kind of Nordic design where functionality and form support each other. Tregren's product philosophy is based on consumer-friendly functional design. Tregren operates in more than fifteen countries and more than one hundred thousand products developed by Tregren have been sold since the company was established in 2010. The products are developed and manufactured in Finland. For more information, visit http://tregren.com

SOURCE Tregen

Agrilyst Raises Another $1.5M For Its Intelligent Indoor Farming Platform

Agrilyst Raises Another $1.5M For Its Intelligent Indoor Farming Platform

February 7, 2018 | Frederic Lardinois (@fredericl)

Agrilyst, a platform that makes it easier for indoor farmers to manage their crops based on sensor data, today announced that it has raised a $1.5 million funding round from iSelect Fund, Argonautic Ventures, Horizons Lab (Horizons Venture’s seed fund) and Onlan Capital Fund. The new investors were joined by existing investors Compound and the New York State Innovation Capital Fund. That’s on top of the $1 million round Agrilyst announced in 2016.

As Agrilyst co-founder and CEO Allison Kopf tells us, the company, which won our Disrupt San Francisco Startup Battlefield in 2015, has been on a bit of a roll lately. It added 100 new customers in 2017 and saw 500 percent growth in both revenue and customers since 2016. Its service is now available in 10 countries and its tools support more than 50 vegetables and 800 crops.

When the company launched, the team was very adamant that it didn’t want to be seen as a tool for indoor cannabis growers, but it recently added support for cannabis, as well as for floriculture and insect productions.

“We see a world where computation cost is driven to zero and we now have the resources to monitor the growth, health, and biology of every single seed,” says Phil Chen, advisor at Horizons Lab. “I see Allison and her team at Agrilyst as the interpreters of this data to secure future food sources.”

As for the team, it’s worth noting that the company recently brought on both a new CTO (to replace co-founder and CTO Jason Camp, who left the company last year) and a VP of Customer Success.

Unsurprisingly, Agrilyst plans to use the new funding to support its growth and expand into new markets and product lines. Having a number of new investors that focus on the large Chinese market (Horizons, Argonautic, and Onland) will surely help the company expand into this market, too.

Panasonic Vertical Farm in Full Operation

February.5, 2018 - 23:28 — Evangeline_H 311 pageviews

Panasonic Vertical Farm in Full Operation; Special Horticultural LED Lighting Deployed to Increase Vegetable Production

Multinational electronics company Panasonic will start growing and marketing high-value vegetables in China from March 2018 with its vertical farm in Suzhou. Those vegetables will be made into salads and sold to up to 30 shops in Suzhou and Shanghai.

(Image: Panasonic)

In China, food safety has become more and more important. Panasonic claims monitoring and management at each stage will be thoroughly executed in hope to increase the sales in the Chinese market.

Panasonic in 2016 started running a vertical farm in its electronic component manufacturing subsidiary in Suzhou. The vertical farm, taking a 1,000 square meter area, is now officially in full operation.

The company aims to raise the plant production by 3 times to a monthly production of 9 tons.

Prices of the vegetables will be 2-2.5 times higher, compared with prices local plant growers set for their production. Those vegetables grown in the vertical farm were sold to merely two channels in Suzhou—the AEON MALL and the Izumiya Supermarket. In the future, Panasonic plans to approach local shops as well, broadening the channel to market its plant production to the Chinese community.

Panasonic uses special LED lighting to provide and adjust the light in the vertical farm to ensure the temperature, humidity, and the density of carbon dioxide are maintained at a certain level. That turns the farm an environment suitable to grow β-carotene-rich plants anytime of the year.

The company says the salads it offers are nutrient-rich and safe to eat, and looks for collaborations with local restaurants. It will also be working with local e-commerce companies to develop strategies to market both high-value vegetables and the equipment in the vertical farm.

People in China have become more aware of food safety after being affected by overuse of pesticides. The awareness towards vertical farms thus increased. Plant factories have been built in several regions in China since 2010.

At the early stage, these facilities were simply regarded as the demonstration of advanced plant production technology by governments and big corporations. Later on, more companies established their vertical farms once the government released more subsidies.

Establishments across the nation eventually scaled up, with the largest facility (approximately 9,000 square meters) that is able to produce 45 tons of vegetables on a monthly basis.

Growing Their Own At Corner Cafe

Growing Their Own At Corner Cafe

Cooking students soon will have fresh herbs to harvest

Natovia Talbot, a junior at Princeton Township, IL, High School, places bok choy seedlings into the new tower garden at the Corner Cafe in the Area Career Center’s Dolan Building next to the La Salle-Peru Township High School. The 5-foot tower circulates water and nutrients under artificial light to grow lettuce and herbs, which culinary arts students will harvest and use. Tracey MacLeod

- Jeff Dankert | February 6, 2018

Indoor growing technology is putting fresh herbs into the hands of culinary arts students.

A 5-foot tower garden is starting to green up in the dining area of the Corner Cafe, which is in the Area Career Center’s Dolan Building on the La Salle-Peru Township High School campus.

A few students took a break from the kitchen a few days ago to transplant lettuce, onion, chard, arugula, bok choy and basil into the tower. The plants were started in trays where each plant was labeled with a plastic spoon.

The tower herbage should be ready in a few weeks, said Susan Stiker, culinary arts instructor.

The students use many greens and herbs in the kitchen.

“Actually quite a bit. Kale, basil for pesto,” said Abby Nord, a junior at Princeton Township High School. The Area Career Center teaches students from several area high schools.

“Aren’t we going to try Chinese and use the bok choy with it?” said Natovia Talbot, also a junior at Princeton High.

The new gadget and the growing plants get frequent checks by the students.

“Every day when they come in, they check this first,” Stiker said.

The growing tower looks like high-tech hydroponics but the maker calls it aero-ponics because the plants are not sitting in the water.

Seeds are started in a synthetic medium called rockwool inside grow trays. The clumps of rockwool, bearing tiny seedlings, are transplanted into slotted pods on the outside of the tower cylinder. A rack surrounding the tower glows with three florescent light tubes, oriented vertically, to provide energy for photosynthesis. The lights are on for 14 hours and off for 10, Stiker said.

At the bottom of the tower cylinder is a 20-gallon water reservoir that holds dissolved fertilizers and nutrients. A pump circulates water up and drips it down along the inside, watering and feeding the clumps of rockwool and plant roots growing within. The watering is set on a timer.

“It cycles on for 15 minutes and is off for 45 minutes,” Stiker said.

Deborah Aldana checks the progress of celery, avocado and potato roots growing inside jars of water. These plants won’t go into the tower garden but are a demonstration of how vegetable roots can be used to grow new plants.

This project integrates with the educational buzzword, STEM — science, technology, engineering, and math. Preparing and cooking food has many STEM opportunities, Stiker said.

“I’m doing all of that STEM stuff all the time. That’s what this is,” she said, pointing to the tower. “Students looking to do an independent study, this would be a great thing. I had the kids research how to harvest and how to check the pH.”

The $900 apparatus came with all the equipment and supplies to get started. It was funded by a grant from the La Salle-Peru Township High School Foundation for Educational Enrichment.

The Corner Cafe is a restaurant with a fully-equipped kitchen and dining area for the public. Students prepare food to sell and for events. Students recently made pies for a buffet, prepared food for a group of eighth graders, made chili for a fundraiser and prepared Super Bowl snacks for staff.

Indoor garden towers are a thing among urbanites. The vertical design uses less space, such as a corner of the dining area inside the Corner Cafe.

“I knew I had to do something smaller here,” Stiker said.

Stiker got the idea from a middle school in Texas that was growing plants in an indoor tower. School gardens, indoors and outdoors, have taken off, she said.

“There are schools that actually supply their cafeteria,” Stiker said.

Streator Township High School students constructed six indoor plant towers that are now growing lettuce, said agricultural educator, Riley Hintzsche.

Streator students have a vegetable garden two blocks away and grow sweet corn on one-fourth of an acre outside of town. Students harvest the vegetables and donate them to the food pantry, he said.

“We do have some of the food classes use the produce occasionally as they need them,” Hintzsche said.

Jeff Dankert can be reached at (815) 220-6977 or lasallereporter@newstrib.com. Follow him on Twitter @NT_LaSalle.

Infarm Reinventing Food Supply With Vertical Urban Farms

Infarm Reinventing Food Supply With Vertical Urban Farms

By Katy Askew

06-Feb-2018

Infarm founders Osnat Michaeli and the brothers Erez and Guy Galonska have big ambitions for their urban farm model

German urban farming group Infarm aims to expand its network of urban farms to 1,000 locations throughout Europe by 2019.

Infarm was founded in 2013 by Osnat Michaeli and the brothers Erez and Guy Galonska. The company distributes what it describes as “smart modular farms” targeting urban areas.

Fusing vertical farming techniques with the internet of things technology and data science, the group aims to develop an “alternative food system” that is “resilient, transparent, and affordable”.

“Rather than asking ourselves how to fix the deficiencies in the current supply chain, we wanted to redesign the entire chain from start to finish; Instead of building large-scale farms outside of the city, optimising on a specific yield, and then distributing the produce, we decided it would be more effective to distribute the farms themselves and farm directly where people live and eat,” explained Erez Galonska, co-founder and CEO.

How it works

A single two meter squared farm unit can deliver an output of 1,200 plants per month.