Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

South Korean Road Tunnel Smart Farm No Rose-Coloured Pipe Dream

Behind a blue wall that seals a former highway tunnel stretches a massive indoor smart farm bathed in rose-tinted light.

AP | 30 August 2018

Behind a blue wall that seals a former highway tunnel stretches a massive indoor smart farm bathed in rose-tinted light.

Fruits and vegetables grow hydroponically — with no soil — in vertically stacked layers inside, illuminated by neon-pink LEDs instead of sunlight.

Operators of this high-tech facility in South Korea say it is the world’s first indoor vertical farm built in a tunnel.

It’s also the largest such farm in the country and one of the biggest in the world, with a floor area of 2300sqm, nearly half the size of an American football field.

Indoor vertical farming is seen as a potential solution to the havoc wreaked on crops by the extreme weather linked to climate change and to shortages of land and workers in countries with ageing populations.

The tunnel, about 190km south of Seoul, was built in 1970 for one of South Korea’s first major highways.

Once a symbol of the country’s industrialisation, it closed in 2002.

An indoor farming company rented the tunnel from the government last year and transformed it into a “smart farm”.

Instead of the chirrups of cicadas, Claude Debussy’s Clair de Lune resonates in the tunnel in hopes of stimulating the crops’ healthy growth.

“We are playing classical music because vegetables also love listening to music like we do,” said Choi Jae Bin, head of NextOn, the company that runs the vertical farm.

Head of NextOn Choi Jae Bin explains how his high-tech tunnel-based vertical indoor farm NextOn in Okcheon, South Korea, could be a potential solution to the havoc wreaked on crops by the extreme weather linked to climate change, and to shortages of land and workers as the country ages.Picture: AP

Sixty types of fruits and vegetables grow in optimised conditions using NextOn’s own growth and harvest systems.

Among them, 42 are certified as no-pesticide, no-herbicide and non-GMO products, said Dave Suh, NextOn’s chief technology officer.

He said the tunnel provided temperatures of 10 to 22 degrees celsius, enabling the company to optimise growing conditions.

High-tech smart farms, used also in places like Dubai and Israel where growing conditions are challenging, can be a key to developing sustainable agriculture, experts said.

“Society is ageing and urbanisation is intensifying as our agricultural workforce is shrinking,” said Son Jung Eek, a professor of plant science at Seoul National University.

Smart farming can help address that challenge, he said, as well as make it easier to raise high-value crops that are sensitive to temperature and other conditions.

Only slightly more than 16 percent of South Korea’s land was devoted to farming in 2016, according to government statistics.

The rural population has fallen by almost half over the past four decades, even as the overall population has grown nearly 40 per cent.

The Agriculture Ministry announced earlier this year it would invest in smart farm development nationwide, expanding their total area to 7000ha from the current 4010ha.

Turning a profit can be challenging for indoor vertical farms given the high cost of construction and infrastructure.

NextOn cut construction costs in half by using the abandoned tunnel and developing its own LED lights and other technologies.

Sesame leaves grow on a vertically stacked styrofoam layer.Picture: AP

The proprietary technologies reduce water and energy use and the need for workers, cutting operation costs, Suh said.

Sensors in each vertical layer measure variables such as temperature, humidity, light, carbon dioxide and micro-dust levels to maintain an optimised environment for each crop.

The crops will cost less than conventionally grown organic vegetables, Suh said.

The farm will begin supplying vegetables to a major food retailer and a leading bakery chain beginning in late August, NextOn said.

Suh said the medicinal plant market was currently dominated by a few countries and regions.

“Our goal is to achieve disruptive innovation of this market by realising stable mass production of such premium crops,” he said.

"Producing More With Less Water And Nutrients"

Stefanie van Wienhoven, Grodan

The concept of 'Precision Growing' stipulates that optimal growing conditions can be achieved during an entire growing season. In precision cultivation the plants are supplied with the exact amount of water and fertilizers they need. Excess water and fertilizers can be collected efficiently and be reused. And while less resources are needed, the crop yield per square meter increases.

Water management

Precision cultivation literally translates into more growth with less input. In this context, Grodan focuses on water management in the root environment of the mat. By using water and nutrients more efficiently and in a more targeted manner, crop yield and fruit quality improves. This can be achieved by carefully aligning the water content (WG) of the substrate and the electrical conductivity (EC) in accordance with the current climatic conditions and generative/vegetative plant balance.

Extra attention for root environment

"By matching the needs of the plant in a smart way with the characteristics of the substrate mat, a strong and productive plant can be planted without waste of water and nutrients," says Stefanie Wienhoven of Grodan.

In greenhouse horticulture, much more efficient use is made of water than with (uncovered) open field crops. However, large amounts of water and fertilizers are lost in freely draining substrate systems. Water use efficiency can be improved by collecting the drain water and bringing it back to the crop. In this way glasshouse horticulturists can further improve their efficiency of water use and become more sustainable producers.

Careful management

Careful management of water and nutrients in combination with re-use of the drain water in the cultivation can have the following benefits according to Wienhoven:

Reducing total fertilizer use

Saving costs

Optimizing crop growth

Ensuring sufficient and clean irrigation water

Keeping a sufficiently wide range of crop protection products available

Protecting the environment

Complying with the legislation

Sustainable cultivation methods

According to the stone wool manufacturer, precision cultivation is an interesting concept for helping with current and future challenges in the area of water management. They continue to think about even better and smarter ways to grow crops in a sustainable way. They want to cooperate with growers, retailers and scientists for this.

The drought of this summer and the consequences of climate change motivate the company even more to think again about the best methods for efficient cultivation and the saving of even more water. This should be possible with newer, innovative techniques in water management.

Source: Glastuinbouw Waterproof

For more information:

Combining Geothermal Heat With Super-Fast Internet

The geothermal heat project Nature’s Heat in Kwintsheul is running at full speed to the satisfaction of the nine growers connected to the project. Not only heat pipes but also fiber optic cables were placed, so now they can even make use of high-speed internet. Nature’s Heat operator Paul van Schie: “More often than not, townships and cable companies don’t see the need to place fiber optic cables in the rural areas. We were able to hitch along with a cable that was placed from the town to a high-voltage tower close to here. Nature’s Heat is now the distribution station for fiber optic cable connections to a variety of connections.

Dennis Bos of CBizz tells us that the plans to put in fiber optic cables have been entertained for a while. “At the beginning of 2018, Paul came to us with the question if we could realize a collective fiber optic connection. In February we were ready to start when the needed number of clients was reached.” Dennis looks back on a fantastic project. “These types of projects are one in a million, they are quite unique. Worthy to be repeated, though a next project will need to be tailor-made again.”

100 percent uptime

Geothermic heating projects require a lot of stamina. Nature's Heat is an initiative of nine horticultural companies in Kwintsheul that, together, grow 51 hectares of tomatoes, bell peppers, eggplants, strelitzias, chrysanthemums, roses, and potted plants. On the 21st of March 2018, the project started. According to Paul, it was the well-executed preparations that resulted in a high-quality project. “We did have some teething problems here and there. In May the installation was turned off a few times for a software update, but we haven’t run into any big problems yet. Since May we've had a score of 100% uptime, not counting the planned pump changeover in July.”

Tailor-made

The software was developed specially for Nature’s Heat, says Paul. The company that designed and built the above-ground installations also wrote the software. And this is very convenient, because of this you have very short lines. This party does not only do the maintenance but also the management of the installation. Every day they monitor from a distance whether or not the installation is functioning accordingly.

“The above ground installation is made of stainless steel and the design of the filter units is different than usual. Also for the de-gassing, an entirely different installation is used. Where the de-gassing normally happens in big horizontal tanks, this installation accomplishes this by using cyclones. Underpressure is created, which separates the gas. You can compare it to the drain in your sink when you pull the plug.”

No free lunch

A heat roundabout in the province of South Holland is meant to connect all the heat projects so that the optimal amount can be saved on fossil energy. “It would be great if heat pipes would be placed from Rotterdam to the Westland, but there's no such thing as a free lunch. The horticulture industry has an important part to play in the supply of electricity. I think we ought to be careful to exclude CHP from the discussion involving the closing of the gas taps. If the demand to be able to flexibly switch to the use of electricity would arise, CHPs have preference over energy from power plants. Wiebes, the Dutch Minister of Economy and Climate, wants to get rid of the use of gas. But do we then need to close down sustainable CHPs and keep coal plants open? These are the questions that you as a grower need to consider.”

For more information:

Nature's Heat CBizz

info@naturesheat.nl

www.naturesheat.nl

CBizz

+31(0)88 002 0200

www.cbizz.nl

Registration Is Now Open For EcoFarm 2019

EcoFarm Conference is the oldest and largest organic farming conference in the West - an essential networking and educational hub for farmers, ranchers, distributors, retailers, activists, researchers, and educators to nurture safe, healthy, just, and ecologically sustainable farms, food systems, and communities. Join us, January 23 - 26, 2019!

Save 7% with discount code: earlyreg when you register by Sun. Dec 9.

Urban Farm Offers Women A Place To Live & Work After Getting Out Of Prison

October 2, 2018

INDIANAPOLIS -- An urban farm opening in central Indiana will provide women coming out of the criminal justice system with a place to live and work so they can get their lives back on track.

While working at Bellfound Farm, the women will also receive mental health counseling, coaching and skill development training.

Alena Jones, co-founder and COO of Bellfound Farms, says they are getting started with a grant from the Women’s Fund of central Indiana.

“When we’re talking about how nine out of 10 women who have been incarcerated have experienced trauma, what we know about being in a green environment is that it calms your nervous system down and gives you a little bit more brain space to process what’s going on inside of you,” said Jones.

The first group of women are set to move in early next year, once the farm is ready and the buildings renovations are complete.

If you’d like to volunteer with Bellfound Farm you can visit their online website.

"The Emirates Are An Extremely Attractive Market"

First Harvest BayWa Greenhouse UAE:

Two months after planting the first 90,000 seedlings in Al Ain, United Arab Emirates, BayWa AG, Munich, and Al Dahra Holding, LLC, Abu Dhabi, have begun harvesting the first 1.5 tonnes of snack tomatoes. Starting from October, consumers will be able to find this premium vegetable, going by the brand name Mahalli (mahalli.ae), on local food retail shelves.

The snack tomatoes have ripened over an area of five hectares in a state-of-the-art climate-controlled glasshouse that BayWa and Al Dahra Holding constructed within the scope of their joint venture Al Dahra BayWa Agriculture LLC. The entire production facility comprises two five-hectare climate-controlled glasshouses. As the harvest was getting underway, the second climate-controlled glasshouse was being put into operation and planted.

The goal of the joint project between BayWa and Al Dahra is to efficiently cultivate vegetables and market them locally while conserving resources. The environmental conditions for agriculture are very challenging in the Emirates. At the same time, there is high demand for regional and sustainably produced fruit and vegetables. Even before production began, the complete first harvest had been marketed.

A view of the total of ten hectares of production facilities: as the harvest is getting underway in the first climate-controlled greenhouse, the second climate-controlled greenhouse is being planted.

“I'm delighted that we have built a state-of-the-art, climate-controlled greenhouse in record time with the support of our local and international partners and that we're already harvesting the first tomatoes,” says Klaus Josef Lutz, Chief Executive Officer of BayWa AG. “The project is part of our Group specialities strategy, where we're concentrating on special products for lucrative markets and long-term sales opportunities.”

“The Emirates are an extremely attractive market,” says Christiane Bell, Head of the BayWa Global Produce business unit. The Emirates must import 80 percent of all their goods. “This is why there is strong desire for self-sufficiency, especially when it comes to fruit and vegetables. At the same time, people are highly aware of the value of high-quality foodstuffs.”

Two months after planting in the first climate-controlled greenhouse, the first snack tomatoes are now ripe for harvesting.

The modern climate-controlled greenhouse in Al Ain allows production to be carried out all year round, irrespective of the conditions outside. Using up to 70 percent fewer resources, ten times more produce can be harvested than in outdoor production. By the end of October, the volume being harvested each week in Al Ain will have risen to 15 tonnes, with production and harvesting taking place according to European standards.

The specially trained pickers separate the red fruit from the vine by hand, while unripe tomatoes stay hanging on the vine. The aim is to offer consumers only the best, tastiest snack tomatoes. The harvested vegetables are then fully automatically weighed and packed in trays of different sizes.

The packaging, which was developed while taking sustainability factors into account, was conceptualised for marketing in the Emirates and has a film that can be resealed up to 22 times. A total of roughly 100 people work in the climate-controlled glass house in different roles.

Pure Flavor® Aims To Create Conversation At PMA Fresh Summit With 7 New Products

Leamington, ON (October 11th, 2018) – With the produce industry preparing to head to Orlando for PMA Fresh Summit, greenhouse vegetable grower Pure Flavor® is prepping for one of the biggest trade shows ever. In addition to creating conversation about the company’s recent expansion to Georgia, Pure Flavor® will be launching 7 new items at the trade show.

JAMIE MORACCI

CO-FOUNDER, PRESIDENT

“We are bringing new products to market that will help our retail & foodservice customers grow their business. New items not only create impact in the produce aisle but are also a vehicle to help increase fresh produce consumption”, commented Jamie Moracci, President. In addition to the new items being launched at PMA Fresh Summit, Pure Flavor®’s new greenhouse facility in Georgia will soon be growing tomatoes & cucumbers year-round under the Georgia Grown brand.

Pure Flavor®’s family of growers are producing more than ever before fueling the company’s positive momentum in the marketplace. This in turn is setting up opportunities to connect with retail & foodservice partners at the PMA Fresh Summit Trade Show in Orlando, FL October 19-20.

Pure Flavor® will be unveiling a host of new items at PMA Fresh Summit that include:

REDZILLA™ Monster Sized Sweet Red Peppers; The King of Peppers has arrived! Rich, sweet, stuffed or sliced. This larger than life pepper is versatile and ready to be your meal time hero.

Stingrays Hot Peppers; Spicy and ready to sting! Spicy and ready to sting, these multi-colored hot peppers are the secret ingredient to give a little heat to your next authentic creation.

Mini Munchies 4x4 Tomato Snack Packs; Our Mini Munchies Snack Sized Veggies aim to promote a healthy, active lifestyle to both children and their parents alike. The perfect healthy snack combination makes it easy for a grab and go snack! Exclusively on display at Booth 707 at PMA Fresh Summit, be on the lookout for the new 4x4 Tomato Snack Packs, a burst of sweet flavor in every bite!

SNACKERZ One Bite Nano Cucumbers; “Uh Oh, we shrunk the cukes!” We tried smaller but the technology would not allow it! Snackerz are here! Hydrate by the handful with the snack that will change recess & break time forever! Fresh, crunchy and full of healthy goodness!

SNACKERZ One Bite Nano Tomatoes; “Uh Oh, we shrunk the tomatoes!” We tried smaller but the technology would not allow it! Snackerz are here! Sweet treats by the handful with the snack that will change recess & break time forever! Nano sized, fresh, and full of healthy goodness!

Juno On The Vine; Vine Fresh Sweetness in Every Bite!” Nurtured on the vine and hand-picked at peak flavor, the new Juno on the Vine Sweet Red Grape Tomatoes are the perfect selection for a tomato connoisseur.

Azuca On The Vine; “Sweet Red Cherry Tomatoes on the Vine”. A premium tomato for the discerning tomato aficionado.

“By having a variety of fresh vegetable options from our family of growers, we remove the seasonality and provide a consistent, flavorful product 12 months a year. With new options and our Georgia facility getting ready for its first crop, we have a very exciting year ahead of us”, said Moracci.

“Our brand strategy is to always go beyond the package; when it comes to bringing new products to market, we want to ensure that our customers have all the information they need to make the right purchasing decision”, said Chris Veillon, Chief Marketing Officer. Pure Flavor® develops in-depth product descriptions, multi-product recipes, performs nutritional testing, and develops an extensive variety of promotional content to support all of its products. With a new website (pure-flavor.com) that was launched in July, Pure Flavor® employs a variety of digital strategies to connect with consumer in geo-specific regions throughout North America.

To learn more about Pure Flavor®, visit Booth 707 at PMA Fresh Summit in Orlando, FL October 19-20 or visit Pure-Flavor.com/PMA2018.

-30-

About Pure Flavor® -

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise

Education Matters: Students Grow Food Hydroponically

By: SUSANNE BRUNNER

September 24, 2018

CABOT, Ark. - Growing food without soil? It's happening at Cabot High School.

"It most definitely grabs their attention," says Griffin Prior, Cabot High Senior.

When you're walking down the halls, it's hard to miss these plant towers.

"It teaches us so much responsibility because if we don't take care of it, then it's just going to die," says Cora Hicks, Cabot High Senior.

Using a pH System, students in Plant Science Class are testing out their new hydroponic grow tower. The lettuce sprouts without soil. Instead, these teens use mineral nutrients in water and light.

"It's easier than to dig in dirt to show kids how the root system grows, how the plant itself grows, on what it uses to grow," says Prior.

Prior and his classmates are nurturing the leafy greens with a pH System. Periodically, students will test the pH in the water to see if the plant is getting the right amount of nutrients it needs. The process was a lot of trial and error.

Since July, students have harvested about 9 pounds of organic lettuce. With 6 of these plant towers on hand, there's enough lettuce for everyone.

"We kind of share it throughout the district. It is good! It tastes just like a salad," says Hicks.

From tower to table, Plant Science is growing with interest and this method is planting the seed to something bigger in agriculture education. Cabot High School received the towers during the summer and they hope to get more in the future.

To keep up with Susanne Brunner's Education Matters Reports, you can like her page here

The Future of Farming is Moving Indoors – The Opportunity For Geothermal?

Technological advances have allowed farming to be more precise, with large amounts of fresh produce being now produced in urban environments with minimal space and smaller amounts of water than on a traditional farm

Alexander Richter 22 September 2018

With technological advances, farming is changing and more and more moving indoors. With either small-scale urban greenhouse operations or larger-scale greenhouses, their operation is rather energy intensive, both for electricity and light, but also for heating - a big opportunity for geothermal energy.

With an increase in population and demand for localised food production, a recent article published by the World Economic Forum describes “indoor farming as the next big thing”.

Technological advances have allowed farming to be more precise, with large amounts of fresh produce being now produced in urban environments with minimal space and smaller amounts of water than on a traditional farm. But these indoor “farms”, be it on smaller or larger scale need both light and heating to be productive.

With the energy intensiveness of indoor farming in greenhouses, it is not surprising that operators are actually looking at different, clean and cost effective sources of energy – both for light and heating. And there are plenty examples on how geothermal energy is increasingly receiving attention or is already used.

In Kenya, one of the largest flower producers Oserien is utilising geothermal energy both for heating, but also producing power with small-scale geothermal power generation. In the Netherlands, due to the increasing cost for energy, greenhouse operators are teaming up on drilling geothermal wells to tap that resource for heating. Iceland utilises geothermally heated greenhouses to produce vegetables year round.

In Germany, in conjunction with geothermal power projects, greenhouse operators are looking into the use of the resource for heating.

An article by BBC (linked below) describes efforts made in Colorado in the United States. At Pagoda Springs, geothermal energy is used not only to produce vegetables but also use the resource for wider economic development.

How far geothermal energy will be a common form of energy used in greenhouse operations will have to be seen. In what form geothermal energy can be utilised or compete with other sources depends on the location and on where resources can be found. But the examples mentioned above show that there are opportunities being seized and actually could expand beyond the countries/ regions mentioned.

Source: World Economic Forum, BBC

TotalGrow Turns Greenhouse Into Year-Round Operation

During the cold, dark months of January and February, the greenhouses of Mud Lake Farm were formerly dormant. Most of the staff was on temporary layoff awaiting a return to work when the longer daylight of spring made the farm bounce back to life.

TotalGrow Lighting

Thanks to an unexpected opportunity to test the TotalGrow light emitting diode (LED), the green houses now grow produce all year long and the staff is never without work. It’s an interesting story that is founded upon energy efficient lighting.

The Kent Garden Club recently heard the fascinating story of Mud Lake Farm in a presentation highlighting hydroponic gardening. The speaker was Kris Van Haitsma and I followed up with her to hear the rest of the story.

Kris is co-owner of Mud Lake Farm along with her husband Steve. The title of Kris’s presentation to the garden club was “Playing with Mud” and detailed the evolution of the farm from a muddy cow pasture to a highly productive hydroponic greenhouse operation.

The property on which the farm was built has been in Steve’s family for generations. It is primarily low lands and difficult to grow crops on. Kris wanted to do something different with the land which led her to purchase a used greenhouse. After many false starts Kris and Steve settled upon a hydroponic farming operation as the focal point of the farm.

At the point where Kris and Steve had four greenhouses operating during the usual short growing season they were asked to test TotalGrow LED lighting in one of their greenhouses. The goal was to extend the growing season and increase their productivity.

Hydroponics

With hydroponics no soil is needed and the plants float on nutrient rich water 4 to 12 inches deep. During the winter many types of lettuce thrive in a hydroponic garden if they can be kept from freezing and if supplemental light is provided.

In the past the Van Haitsmas had considered high pressure sodium lighting but could not justify the inefficiency of what is considered a typical greenhouse light. The bulb is expensive, uses lots of electricity, needs to be replaced fairly frequently and does not produce the optimum spectrum of light for good plant growth. Not a good combination when your goal is profitability.

An attempt at supplemental lighting with fluorescent bulbs led to less than desirable plant growth so when the test offer was presented, the Van Haitsma’s agreed to install the LED based TotalGrow system in one of their greenhouses.

Kris and Steve were amazed when they realized that the one greenhouse, using TotalGrow lights, was producing more than the other three greenhouses combined. That made adding TotalGrow lights to a second green house an easy decision. Ultimately they have plans to light the remaining houses with total grow as demand for their products rises.

Using a geothermal heating system to keep the air temperature above freezing, the Van Haitsmas expanded the variety of plants they could grow at the same time they developed new outlets for selling their fresh produce. Mud Lake Farms is now a vibrant year round operation!

According to Kris:

“We grow around 40 different varieties of lettuce, including red and green romaine, butterhead, batavia, and leaf lettuces. Since we grow lettuce year-round, we can provide produce to our customers even in winter.”

Kris’s customers include 80 – 100 families living in West Michigan that are enrolled in a type of buyers club. During the Farmer’s Market season they have a booth offering fresh picked products including custom made cordials (flavored syrups) that are made from ingredients grown on the farm.

Mud Lake Farm Cordials

Many local chef owned restaurants prefer the premium quality of Mud Lake Farm’s freshly picked produce. Relationships with those chefs are most often made by word of mouth and one came from a web search of LocalHarvest.org. Sadly, most chain restaurants do not seek out local growers, a situation that the restaurant chain Chipotle is making great strides at correcting.

Kris noted that a lot more infrastructure is in place for connecting locally grown products with local outlets. The sustainability and farm to table movements are helping drive those connections.

When a product like the energy efficient LED TotalGrow can improve the cost efficiency and productivity of a local grow operation, everyone wins as more products are brought to market and enjoyed by customers in many venues. The Van Haitsma’s Mud Lake Farm is a “shining” example of using energy efficiency to drive productivity as well as profitability!

The Energy Alliance Group of Michigan is a leader in clean energy PACE project development and financing.

Neighbourhood Watch: Farming Grows Sense of Community At Dubai's Sustainable City

Biodomes and allotment spaces are helping to build a thriving neighbourhood, where sustainability really matters

Nick Webster

September 5, 2018

A look inside the gates of Dubai’s Sustainable City offers a glimpse into how more of us could live our lives in the future.

The growing eco-development, surrounded by desert on the outskirts of Dubai near Emirates Road, is fast becoming famous for its harnessing of the environment to power modern life.

In just two years, the 465,000 square metre mini city has grown to become a thriving community of like-minded inhabitants, all with a keen eye on energy efficiency.

And the successes of its ecological ideology are all too clear – with villa occupancy rates at around 98 per cent and a waiting list for new residents.

“Most people don’t come to the community for the social side of life here, but it’s something they very quickly discover once they arrive,” said Karim Al Jisr, executive director of the development’s innovation centre.

“The sense of community is not something that’s easy to pitch without coming here, but once people live here it becomes the number one attraction and the driver to get people to stay.

“Utility bills are low and service charges are zero, so there are lots of attractive factors.

“People have access to farming, they can grow their own food and that also attracts a certain mindset.”

Plants growing inside the urban farming area at Sustainable City. Pawan Singh / The National

Dubai’s Sustainable City sits on the southern outskirts of the rapidly expanding metropolis.

Residential areas within the complex are car-free zones and instead the community has access to a fleet of 124 shared electric buggies.

Last year, the vehicles were used to drive a total of 216,735 kilometres. A driverless shuttle system that can carry 11 passengers is also being trialled.

There is also a Dh10,000 incentive to switch to an electric vehicle for use outside of the community, with multiple charging points available in the parking zone near the city's entrance.

On Wednesday, developers said they hoped the community would become the region’s first net zero energy residential zone through its use of solar energy.

Villas generate electricity from photovoltaic panels and return the surplus to the national grid, with the excess taken off monthly household bills.

Sustainable Plaza at the Sustainable City on Alqudrah Street in Dubai, a mini city that could offer a glimpse of the future. Pawan Singh / The National

Phil Dunn, 46, a landscape architect from Canada lives in the city with his wife and two children.

“Urban farming has really connected people,” he said. “There’s no better way of growing a community than physically growing in the community.

“We are growing food and becoming friends with our neighbours and it has created a real sense of stewardship.

"It attracts a wide range of different people, from housemaids, to kids, stay at home mums and working dads at the weekend.

“We mostly grow vegetables, but also fruit trees, like lemon, lime, mango and pomegranate, and we’ve harvested nearly 60,000 tonnes of dates that the community have either shared or sold off commercially to invest back into the community."

A donkey shills at the Sustainable City animal sanctuary. Pawan Singh / The National

Mr Al Jisr said the farm uses aquaponics, an integration of aquaculture with hydroponics, to farm fish and plants together.

“The reason that aquaponics is such a unique solution is that the fish waste provides a food source for the plants, while the plants filter the water for the fish," he said.

“Residents are also offered vouchers every month where they can pick up their own herbs from the farming operation.”

Sustainable City's success could now be used as a benchmark for how to build similar communities in the future.

Read more:

UAE minister outlines new drive to create 'Silicon Valley' of food production technology

Forward-thinking plan served up to protect UAE's future food supply

Save the bees before it's too late

In July, the Sustainable City became the first gated community in the UAE to release its greenhouse gas inventory to give an indication of the emissions produced there.

During 2017, 563 villas and apartments were occupied by about 1,900 people. Results showed the average greenhouse gasses were almost half that of a conventional UAE home.

“These results confirm the Sustainable City is continually working to fight climate change and proactively reducing our carbon emissions,” said Faris Saeed, CEO of Diamond Developers, the company behind the city.

“Moving forward, we will be taking steps to further reduce our emissions through the addition of more solar energy, biodiesel for construction activities, and various awareness campaigns for residents.”

Mr Dunn added: “It’s a very diverse community in the urban farming areas. The kids have taken a big interest and we have four special gardens set aside for the children to grown what they want.

“It has been so successful we’ve extended it into summer, and we’ve been able to grow crops in the summer that is very impressive.

“We have common compost bins set up around the community to use our waste and we don’t use any pesticides. Six bee hives are in the community to help with pollination.”

‘Nagarkrishi’ Spreads Urban Farming in Dhaka

September 20, 2018

Recognising the need for more vegetation and green spaces in urban areas, Nagarkrishi, a start-up, began its journey two years ago with an aim to spread urban farming practices on rooftops and balconies of buildings and adjacent open spaces in the city.

A group of friends launched the start-up while they were studying in Sher-e-Bangla Agricultural University in the capital.

“We felt the need to do something so that greenery can be developed and accommodated conveniently in urban areas. Our Nagarkrishi aims to provide support and encourage those who love gardening even if it is on a small patch,” Kamrul, who joined the start-up as its chief executive officer (CEO) said.

Besides teaching and training on gardening practices, another operation of ‘Nagarkrishi’ is its ‘Little farmer’ project.

In this project, school-children are given hands-on training on how to plant trees and caring for them.

“We aim to produce urban farmers. Therefore, we want to spread our love for plants to the future generation,” the Nagarkrishi CEO added.

To know more about Nagarkrishi’s story, watch the Star Live video, and also don’t forget to subscribe to our channel.

Related Topics

Agbotic Expands With Five New Robotic Greenhouses

SEPTEMBER 30, 2018

SYDNEY SCHAEFER / WATERTOWN DAILY TIMES

Construction is underway on Thursday on a major expansion to the robotic produce grower Agbotic in Sackets Harbor.

SACKETS HARBOR, NEW YORK — John P. Gaus plans to grow his automation-driven farm Agbotic Inc. fivefold with larger, more advanced greenhouses all in operation by early 2019.

Workers began building Mr. Gaus’s five new 18,000-square-foot greenhouses in July and have already constructed three of them at its County Route 75 farm where the company grows organic root vegetables and hemp. The foundation has also been laid for the other two, he said.

“Actually, the project is going very well. We’re on schedule,” said Mark W. Manns, president and COO of Agbotic.

The greenhouses will include the company’s signature robotic gantries, or self-navigating tilling, watering and harvesting machines, but will also feature more advanced automated technology to help gather and use more data, Mr. Gaus said.

Mr. Manns said acquiring more data with the upgraded technology will allow Agbotic to implement more optimal climate settings for produce growth, which the team can control in the greenhouses.

The expansion also includes a food washing and packing building, a cogeneration facility to power the greenhouses and plans to retrofit the first greenhouse with new technology.

“To the extent you think about an automated greenhouse as a machine, we’ll be driving that machine to machine learning and artificial intelligence,” Mr. Gaus said.

Mr. Gaus launched Agbotic in 2014 with his first 15,000-square-foot robotic greenhouse equipped with the gantry, climate controls and organic soil.

The prototype greenhouse has produced 40,000 to 60,000 pounds of food annually, but adding five larger facilities could increase the company’s annual yield to 240,000 or 320,000 pounds of food, if not more. Mr. Manns said the company could ship more product to its existing service markets in New York City, Watertown, Alexandria Bay, Syracuse, Utica, Rochester and Buffalo.

“The current greenhouse has the capability of growing year round. However, the new greenhouses will be more capable of doing it through better control measures,” Mr. Manns said.

The growth at Agbotic also comes with a growth in staff, with Mr. Gaus saying he wants to hire 10 or 11 more full-time workers.

“We’re particularly focusing on veterans leaving the military,” he said about hiring.

Despite multiplying the footprint of his operation, Mr. Gaus considers the advancement only the beginning of what he aims to accomplish with Agbotic.

The engineer and entrepreneur said he wants to replicate the success experienced by producers in the Netherlands, who also use controlled environmental agriculture. The European country generates $15 billion from agricultural product sales, Mr. Gaus said, while New York, which is about three times larger, brings in $5 billion from agriculture.

“The first greenhouse was very much a prototype to prove out the concept, and the next six greenhouses are just a small step in where we want to be,” Mr. Gaus said. “New York State is our initial focus area, but our investors are very interested in building a very big company with clusters (of greenhouses) throughout the United States.”

Agbotic also recently bolstered its operation by adding hemp to its product line. The state welcomed the company into the Industrial Hemp Agricultural Research Pilot Program, which permits farmers, businesses and institutions to research large-scale hemp production, in November. After initial testing, the firm dedicated an entire 300-foot soil bed in its greenhouse to growing hemp.

Announcing “Food Talk With Dani Nierenberg” And 23 Great Food Podcasts

Food Tank is excited to introduce the podcast “Food Talk with Dani Nierenberg.”

Contributing Author: Katherine Walla

Food Tank is excited to introduce the podcast “Food Talk with Dani Nierenberg.” On the podcast, Nierenberg invites chefs, experts, and activists to outline their ideal food system—and how their projects are making a better food system more attainable. This week we launched two brand new episodes with New Orleans legend, restauranteur Dickie Brennan, and activist Karen Washington, the owner of Rise and Root Farm. We hope you’ll listen, subscribe, rate, review, and let us know who you would like to see interviewed. You can listen to “Food Talk with Dani Nierenberg” on Apple iTunes, Stitcher, or wherever you consume your podcasts.

Food Tank is also highlighting 23 podcasts we admire—podcasts that explore issues relating to food politics, environment, history, access and affordability, and women’s equality. Listen, enjoy, learn, and of course, let us know which podcasts are your favorites.

A Taste of the Past, a Heritage Radio Network podcast, connects food cultures of the past to the present, reaching back as far as ancient Mesopotamia and Rome. Host Linda Pelaccio, a culinary historian, invites authors, scholars, and culinary experts to discuss food history. The podcast not only covers single ingredients, such as noodles, but also trends in recipes, dining, and employment in the food system.

2. Agro Africa

Channel Africa’s podcast Agro Africa discusses agriculture and its role in Africa’s development. The podcast brings together entrepreneurs, farmers, and researchers searching for solutions to industrial agricultural practices or practices threatened by climate change. Agro Africa not only discovers ways Africa’s agriculture must change in the future, but also discovers agricultural changes it has made in the past that contribute to the continent’s preparations for climate change.

3. Bite

Bite is “a podcast for people who think hard about food.” Hosted by Mother Jones Magazine Writers Tom Philpott, Kiera Butler, and Maddie Oatman, the podcast invites farmers, chefs, scientists, and writers to explore food. Together, they uncover the politics, history, and science behind food choices today. Bite also breaks down news from the food world for listeners of all backgrounds.

On Farmer to Farmer, host Chris Blanchard introduces listeners to successful farmers and growers. The podcast, made by farmers for farmers, explores what it takes to make a farm successful. Listeners can hear about a range of issues including employment in the farm sector, soil fertility, farming challenges, and even the secrets to cultivating carrots.

Food Heaven Podcast co-hosts Jessica Jones and Wendy Lopez share tips for using diet and health choices to commit to sustainable, healthy living. The podcast invites experts in topics like food, health, and nutrition to share advice on ways listeners can work toward their desired healthy lives. Jones and Lopez’s focus on health goes beyond food, covering topics such as mental health and body kindness.

6. Gastropod

Co-hosts Cynthia Graber and Nicola Twilley discover more about food on Gastropod. The podcast brings together experts at research labs, farms, and archaeological sites in order to use food as a tool to understand the world and its history. Gastropod also tries to identify the role that food plays in shaping cultures, history, and current trends.

7. Good Food

Good Food presents the latest news about what’s happening in food and restaurant culture throughout America. Host Evan Keliman discusses the latest water and agricultural issues, food politics, and cultural movements relating to the food system. Kleiman’s take on life, culture, and the human species explores trends in southern California, ranging from avocados, tacos, and the best L.A. pie.

8. Gravy

Gravy spotlights Southern foodways, highlighting the way Southern traditions and food innovations intertwine in the region. Host John T. Edge uses the food we eat to explore the American South as it evolves with new dynamics, movements, stereotypes, and voices. Gravy’s episodes also show how the South accommodates new immigrants and their traditions, coming from around the globe.

Part of the United Nations World Food Programme’s Storytellers project, Hacking Hungershares stories about hunger and nutrition in current events. Host M.J. Altman shares the stories of those not only living with hunger, but fighting it: Altman talks to aid workers, journalists, lawmakers, community leaders, and survivors to encourage listeners to find their own place in fighting hunger.

10. Homesteady

Homesteady finds ways for listeners to lead a self-sufficient and sustainable life, growing and raising food on their own. Host Aust—a farmer and father—lives off the land with his family, trying to create a steady life on the farm. The podcast realistically portrays the obligations of homesteading, from foraging and hunting, to farming and harvesting.

Plate of the Union brings together chefs, farmers, and policymakers with passions for advocacy. Sponsored by Food Policy Action, the podcast aims to promote safe, healthy, and affordable food for all. Host Spike Mendelsohn—celebrity chef and Chairman of the D.C. Food Policy Council—joins Food Policy Action’s Executive Director, Monica Mills, to discuss guests’ dreams for a better food system and their initiatives bringing these dreams into reality.

12. Real Food Reads

Founder and Director of Real Food Media, Anna Lappé believes books have the power to expose reasons why the food system is broken and solutions to fix it. On Real Food Reads, Lappé brings listeners together to discuss top books in food. The podcast also brings prominent authors into the discussion, considering questions big and small, for the future of the food system.

13. Sound Bites

Sound Bites brings together researchers, academics, dietitians, and more to talk about strategies to find good food and maintain healthy nutrition. Host Melissa Joy Dobbins tackles topics including healthy diets, weight management, diabetes, agriculture, farming, and more. Sound Bites aims to provide listeners with credible information on the latest food news and events, like recent episodes on pesticides, pop culture’s psychological effects, and school food.

Small Farm Nation seeks to show listeners the benefits and obligations of having a successful sustainable farm. Host Tim Young gives tips on how to attain success by treating the farm as a business, with marketing strategies and branding tools. The podcast addresses topics like business growth, finding customers, community involvement, and social media engagement to help listeners in any stage of the process of building a farm.

On Sustainable World Radio, host Jill Cloutier interviews sustainability experts about possible solutions to environmental challenges. The podcast focuses on the environment and natural world, exploring ecology, soil, herbal medicine, organic growing, regenerative agriculture, and more. Cloutier also explores the link between psychology and ecology, hoping to find solutions to climate change.

The Beginning Farmer Show follows host Ethan Book—farmer, blogger, and founder of Crooked Gap Farm—as he starts his farm from scratch. Book shares both the easy and difficult lessons he learned along the way growing crops and raising livestock, including listeners in his hard decisions such as downsizing his herds.

On The Doctor’s Kitchen, United Kingdom National Health Service Doctor Rupy Aujla seeks to show listeners that food is medicine. Aujla sits down with experts and researchers to discuss how nutrition and lifestyle are dependent on one another. The podcast outlines the smartest diets for specific illnesses and diseases while avoiding fad-diets and trends.

18. The Eater Upsell

The Eater Upsell is Eater’s flagship podcast hosted by Eater Editor-in-Chief Amanda Kludt and Audience Development and Special Projects Producer Daniel Geneen. The podcast covers food news, restaurant culture, and industry trends, with a deep look into the newest food innovations. The Eater Upsell also presents the “10 Best Food Stories” each month.

The Female Farmer podcast is part of the Female Farmer Project, which seeks to document the rise of women in agriculture and their roles in the food system. The podcast serves as a platform for women to share their stories, discussing all aspects of being a female farmer. Co-hosts Audra Mulkern and Kate Doughty dive deep, bringing up discussions not only about feminism, but also motherhood, disability, and veteran support.

20. The Food Chain

The Food Chain, a BBC podcast series, examines the business, science, and cultural significance of food. On the podcast’s special segment, “My Life in Five Dishes,” top chefs and food writers tell stories about their lives remembering five dishes that influenced them. Host Emily Thomas also composes stories of what it really takes to put food on the table.

The Secret Ingredient dives deep into one food system ingredient each episode focusing on anything from tomatoes, to school food, and even to democracy. Co-hosts Raj Patel, Tom Philpott, and Rebecca McInroy explore food history to tell listeners why they’re eating the food they eat, and why the food system appears as it does today.

The Splendid Table explores the intersection of food and life with conversations about culinary arts, culture, and lifestyles. New host Francis Lam, an award-winning food writer, gives a glimpse into the food world, discussing ideas about cooking, sustainability, and food culture. Known as “the radio program for people who love to eat,” The Splendid Table received numerous accolades since its start in 1995, including James Beard Foundation Awards for Best National Radio Show on Food and more.

The Urban Farm Podcast assembles special guests to discuss urban gardening and growing. Host Greg Peterson aims to motivate every listener to grow some of their own food with podcasts covering topics like urban beekeeping, chicken farming, composting, and more. The Urban Farm Podcast also explores tools and resources to help listeners make better choices in their local food systems.

Antarctica Greenhouse Produces Cucumbers, Tomatoes And More in Mars-Like Test

By Elizabeth Howell, Space.com Contributor | September 24, 2018

DLR researcher Paul Zabel poses with kohlrabi harvested from the EDEN ISS Antarctic greenhouse. Credit: DLR

Fresh vegetables on Mars, anyone?

An Antarctic greenhouse known as EDEN ISS not only survived the polar night but emerged from it with a harvest for local researchers, thus providing hope that future Mars colonists could also enjoy fresh food during their time on the Red Planet, German Aerospace Center (DLR) officials said in a statement.

Regularly withstanding temperatures below minus 40 degrees Fahrenheit (minus 40 degrees Celsius), the greenhouse provided herbs, lettuce and other vegetables to 10 people who were riding out the winter in the remote station, called the Alfred Wegener Institute's Neumayer Station III. It's the first time the greenhouse operated through the winter. [How Living on Mars Could Challenge Colonists (Infographic)]

"After more than half a year of operation in Antarctica, the self-sufficient greenhouse concept appears to be effective for climatically demanding regions on Earth, as well as for future manned missions to the moon and Mars," DLR officials said in the statement.

"The harvests are now so plentiful that some of it does not always make it straight to the table, and we now have the luxury of spreading out our consumption of some refrigerated lettuce and herbs over several days," Paul Zabel, a DLR researcher who works with EDEN ISS, said in the statement. "The overwintering team members are always looking forward to their next fresh meal."

A thermotransport box sits in front of the Antarctic greenhouse EDEN ISS, which tests the ability to grow food in Mars-like conditions. Credit: DLR

The haul included 170 lbs. (77 kilograms) of lettuce, 112 lbs. (51 kg) of cucumbers, 64 lbs. (29 kg) of tomatoes, 26 lbs. (12 kg) of kohlrabi, 20 lbs. (9 kg) of herbs and 11 lbs. (5 kg) of radishes.

All of the crops were produced in a cultivated area measuring just 140 square feet (13 square meters). However, the peppers and strawberries failed to produce a harvest, likely due to pollination issues, according to the statement.

While Zabel tended to the planets when possible, stormy conditions in Antarctica often prevented him from walking the quarter mile or so (about 400 m) outdoors to the greenhouse. In those cases, a control center in Bremen, Germany, took over for as long as three consecutive days.

When conditions allowed, Zabel could perform urgent repairs, such as fixing a screw that came loose in the thermal system.

The path to EDEN ISS in the Antarctic. Credit: DLR

Other tasks for Zabel included looking at the quality of the harvest, picking up microbiological samples and checking on the systems (light, temperature regulation, and air supply enriched by nutrients and carbon dioxide). His responsibilities even included reporting on how the fresh food improved the health of his team members.

"We greatly value and enjoy the fact that regularly fresh salad, herbs and vegetables from the greenhouse enrich our diet. The positive effect is noticeable," Bernhard Gropp, Neumayer Station III manager, said in the same statement. Without the fresh produce, the crew would have to live on freeze-dried supplies until the next flight to Antarctica in October, DLR officials noted.

The EDEN ISS project website also provides regular updates to the public, including photos of the individual boxes that are taken every day. You can follow the project at DLR.de/EDEN-ISS or by using the hashtag #MadeInAntarctica on Twitter.

Follow us @Spacedotcom, Facebook and Google+. Original article on Space.com.

See How People Are Using FarmBot

Drag & Drop

Graphically design your farm by dragging and dropping plants into the map. The game-like interface is learned in just a few minutes so you’ll have the whole growing season planned in no time.

Growing Regimens

Build regimens for taking care of a plant throughout its entire life by scheduling sequences to run when the plant is a certain age. Regimens can be reused, making replanting a breeze.

Sequence Building

Quickly create custom sequences to take full advantage of your hardware – no coding is required. Simply drag and drop basic operations together, adjust the parameters, and save.

Real-Time Control

Move FarmBot and operate its tools in real-time with the manual controls. Scare birds away from work or next time friends are over, pull out your phone for a quick and impressive demo.

Below are three video stories that chronicle how a young family, a university professor, and a non-profit are all using FarmBot in unique ways. Each video is a little long (~8 minutes) so you might just want to watch the one that sounds most interesting to you.

Video 1: The Sudweeks Family

Garrett and Lexie Sudweeks are first generation FarmBot builders in Cedar City, Utah in the United States. Watch them put together their v1.2 FarmBot Genesis kit and hear what it means to them to grow their own food and be a part of the larger open-source FarmBot community.

Video 2: FarmBot in Education

John G. Wells, Ph.D. is an Associate Professor of Technology Education at Virginia Tech University. Learn how he is implementing FarmBot in a multi-generational, research-based fashion that engages undergraduate students, doc students, and faculty at the university and K-12 level.

Video 3: FarmBot as an Accessibility Technology

Thrive Upstate is a non-profit in Greenville, South Carolina that provides people with disabilities services, opportunities, and support, so they may thrive. See how they use FarmBot for horticultural therapy and to empower individuals who otherwise could not grow their own food.

Growing Food in Space,

on the Moon, and Mars

In July of 2017, the FarmBot core team and other open-source food groups were invited to the NASA Kennedy Space Center in Florida to participate in a 2-day event to brainstorm innovative open-source approaches to food production. Watch the video to see how FarmBot technology and our community of open-source contributors from around the world are helping humanity to one day grow food in deep space, on the Moon, and Mars.

Ready to get a FarmBot?

Order Here

Iowa Family-Owned Restaurant Embraces Hydroponics

When you think of a family-oriented eatery with a focus on home cooking, you probably don’t imagine a menu that includes hydroponically-grown lettuce, tomatoes and cucumbers. Junction 21 restaurant in Centralia, Iowa, however, provides the kind of farm-to-table experience that few people would expect in a place that serves up pizza, burgers and fries.

When co-owner Tim McAndrew’s son became vegan, he realized their eating options were limited. There weren’t many restaurants around them that offered plant-based foods and this realization helped spur the inspiration to create Junction 21. McAndrew and staff began growing their produce at GrowSpan’s Iowa campus using HydroCycle NFT channels. Having year-round access to fresh produce that can be grown without additives or chemicals was a big selling point for the owners.

McAndrew said the farm-to-table aspect of dining meant a lot to him, but it was also important to have a fun, casual atmosphere. Junction 21 attracts a wide variety of patrons, from farmers who have just finished working the field, to professionals holding business meetings. Along with traditional American fare, Junction 21 offers salads containing seven different kinds of hydroponic lettuce, which are mixed together and served in the salad bar daily. They also use whole tomatoes on sandwiches and pizzas and incorporate fresh basil into McAndrew’s homemade spaghetti sauce.

The HydroCycle Growing Systems featured in the video have served a wide array of customers, from large-scale growers like Junction 21, to hobbyists that just want to learn the basics of hydroponics from the comfort of their home. GrowSpan offers a variety of hydroponic equipment, including but not limited to Dutch buckets, NFT channels and ebb and flow systems.

For more information:

GrowSpan Greenhouse Structures

1395 John Fitch Blvd

South Windsor, Connecticut 06074

Toll-free USA: (800) 476 9715

International: +1 860 528 9550

info@growspan.com

www.growspan.com

Publication date : 9/28/2018

How Do We Feed 7 Billion People?

We're looking at the technological advancements that allow us to feed our ever-growing population.

10,000 years ago, our ancestors lived a completely different lifestyle. They were nomadic people living in small groups, constantly moving in migratory patterns and hunting and gathering their food. Today, the majority of the seven billion people living on the planet have permanent residences in, or near, major cities. Most of us have easy access to clothing, food, and home goods. While there have been thousands of developments over the past 10,000 years that have bridged the seemingly impenetrable gap between ancient hunters-gatherers and modern consumers, none has been more impactful than the advent of agriculture.

Today, we define agriculture as the practice of cultivating soil, producing crops, raising livestock, and (to some extent) the preparation and marketing of the resulting products. Agriculture represents 20% of the national economy, and is the one of the most compelling reasons that our global population has boomed.

While agriculture has a long history, the greatest leaps in technology were made in the 18th-21st centuries. We decided to look at five main categories of technological development that have made the greatest impact on the global population: animals, crops, soil, labor, and storage.

**Quick disclaimer: these categories focus on the history of agricultural technology in Western Europe and the United States. While we recognize and celebrate the diversity of historical and cultural differences that exist between the Western world and other regions, we’re focusing on these regions for the sake of making this (somewhat) brief and easily digestible!**

Before we get into the technology that changed agriculture, let’s quickly review just some of the major scientific discoveries that made much of this progress possible.

1855 | Theory of Mineral Nutrients

Research performed originally by scientist Carl Sprengel and popularized by Justus von Liebig identified that nitrogen (N), phosphosus (P), and potassium (K) are essential for plant nutrition. They also published findings that plants take carbon, hydrogen, and water out of the atmosphere. Additionally, Liebig popularize the Law of the Minimum, which stated that a plant’s growth is not determined by the total amount of resources available, but by the resource that is least available.

1859 | Darwin’s Theory of Evolution

Darwin proposed a theory of evolution by natural selection, where changes that allow an organism better adapt to its environment will help it survive and have more offspring, thus creating a lineage with altered and improved characteristics. This theory was made through observations only; Charles Darwin had no knowledge of genetics and the impact of genetic mutations.

1866 | Mendelian Inheritance

Mendelian inheritance is the longest standing theory of genetics that is still applicable today. It was developed by Gregor Mendel after he performed experiments with pea plants, which deduced that genes come in pairs and are inherited as distinct units, one from each parent. This became the basis of our understanding of human, plant, and animal genetics!

Here's a great overview of Mendel's theory!

Now that we know the basics, let’s look at the technology that paved the path to today’s agro-industrial complex. It’s important to understand that all of these advances needed each other to develop, as breakthrough technology in one category created opportunity for the others to expand.

Animals

Most agricultural progress seen in the meat and dairy industries had to do with increasing production. As a result, meat and dairy products became more affordable, and became more prevalent in Western diets.

c. 1760 | Selective Breeding

Robert Bakewell, one of the first agriculturists to breed cows and sheep for meat, was a pioneer of selective breeding methods. Selective breeding involved mating animals to reproduce favorable qualities in the offspring (such as bigger, more muscle, better wool production, etc). Although Bakewell lived before Darwin and Mendel, his practice of selective breeding aligned with both theories of genetic inheritance. Selective breeding later became a cornerstone for the factory meat industry as ways to create animals with higher meat, eggs, or milk outputs.

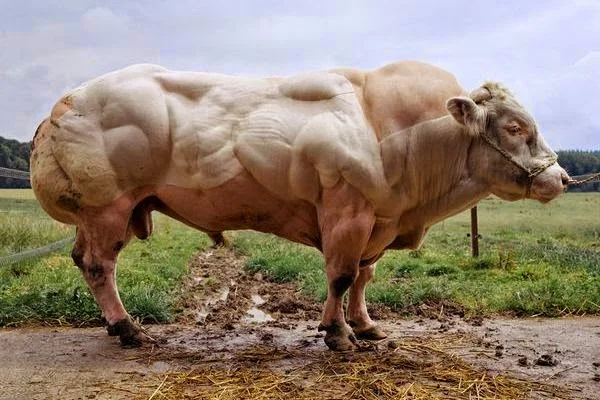

Example: the Belgian Blue Cow

The Belgian Blue cow's genetic make-up makes it more efficient at gaining muscle mass. This gene mutation was maintained through line breeding to make it a fixed property of the breed!

1865 | Pasteurization

Louis Pasteur’s research showed that microorganisms were the reason for food spoilage. He found that heating liquids like milk to between 60 and 100ºC killed most of the bacteria. This process became known as “pasteurization”, and it’s discovery made it possible to preserve and transport dairy goods much longer and further than ever before.

1926 | Penicillin

Alexander Fleming discovered penicillin, the world’s first antibiotic. It was successfully used to treat infection in 1930, and was mass-produced in the late 1940s. As factory animal farming became more prevalent, animals began receiving antibiotics to prevent viruses such as rotavirus, E. coli, pinkeye, and brucellosis. This allowed for animals to adapt to close and often unsanitary living conditions of feedlots that made meat abundant and affordable.

1994 | rBST

Patented by Monsanto, rBST is a synthetic cow hormone. When administered to dairy cows, the hormone increases milk production 14 percent, while consuming less grain and water. This allowed the dairy industry to expand and increase their output.

Crops

Similarly to the meat and dairy industries, advancements in crop production were mainly concerned with increasing crop yields. Thanks to the creation of more resilient breeds of corn and soy, along with long-standing government support for these commodity crops, most farmland moved towards single crop production (also known as monocultures). Furthermore, crop resilience helped create food reserves and drastically reduced famine around the world.

1908 | Hybridized corn produced

George Harrison Shull showed that a hybrid corn plant created from two inbred species would increase the plant’s yields significantly. In 1924, hybrid seeds were sold commercially and by the 1950s the majority of U.S. corn was hybrid. This development allowed corn to become a dependable commodity crop that would later be used as nutritionally dense animal feed (making animals fatter faster) and for producing penicillin (1940), high fructose corn syrup (1970s), ethanol (1970s), and more.

See how corn, watermelons, and peaches have changed thanks to selective hybrid breeding over the past 9,000 years.

1930 | Mutation breeding

A practice started in 1930 and still used today, mutation breeding uses radiation to create random mutations in seeds. Thanks to this practice, scientists have produced thousands of improved plant varieties (rice, wheat, barley, peas, cotton, peanuts, grapefruit, bananas, and cassava to name a few). This is not genetic modification, but a way of nudging species towards useful mutations that make them more productive and resilient.

1937 | Hydroponics

Although principles of hydroponics have been around for centuries, they were popularized by Dr. W.F. Gericke, who displayed enormous tomatoes that were grown without soil. By the 1960s, many hydroponic greenhouses and farms were operating around the U.S. as a first example of alternative farming methods.

1939 | Synthetic Pesticides

Paul Muller discovered DDT, a broad spectrum synthetic pesticide that had a widespread effect on insects, but a seeming low toxic effect on mammals. It was not water soluble and was easy and inexpensive to apply. While it was later proven that DDT was toxic to aquatic animals and had many indirect negative effects on the environment, this was the first widely adopted and inexpensive pesticide which greatly increased food supply and decreased plant disease.

1940s | The Green Revolution

In the 1940s, scientist Norman Borlaug began performing experiments in Mexico to develop disease resistant, high-yield wheat crop varieties in an effort to make Mexico more self-sustainable. He succeeded, and Mexico became a global exporter of wheat. Borlaug and the Ford Foundation replicated this success in India in the 1960s with high performance rice (IR8), which allowed India to become a global rice exporter. The IR8 rice strain was later adopted all over Asia.

1994 | Flavr Savr tomato

The Flavr Savr tomato was the first commercially produced genetically modified food to be deemed safe for human consumption. It was created by Calgene, a company later acquired by Monsanto. Since 1994, Monsanto has produced several genetically modified products like squash and soy in 1995, corn in 1996, sugar beets in 2006, potatoes in 2016, and, most recently, apples in 2017. Most genetic modifications are designed to make food insect and disease resistant, tolerant to herbicides, and more visually appealing.

Soil

Although soil-less methods like hydroponics and aquaponics have become increasingly popular over the past century, most global agriculture is still soil dependent. Historically, advancements in soil technology has been centered around replenishing and extracting as many nutrients as possible to improve plant yields.

1842 | Superphosphate

Patented by Sir John Bennet Lawes, superphosphate was a manure formed by treating phosphate with sulfuric acid, which gave rise to the synthetic fertilizer industry. Once it was adopted, the commercial fertilizer took the agricultural industry by storm: In less than 100 years, annual commercial fertilizer use has gone from 1.8 million tons in the 1890s, to 47.4 million tons in the 1980s.

1910 | Nitrogen fixation

As Liebig determined in his research, nitrogen is essential for plant health. Fritz Haber created a process for pulling N2 out of the atmosphere and turning it into ammonia (i.e. nitrogen fixation) to be used as fertilizer for industrial feedstocks. The process was perfected and scaled to meet industrial needs by Carl Bosch.

Labor

For centuries, agricultural development was limited by time: men and horses could only do so much in one season. The development of farming machinery unlocked huge potential, which technological animal, crop, soil advancements were able to fill.

1793 | Cotton gin

Invented by Eli Whitney, the cotton gin was one of the greatest contributors to the American Industrial Revolution. It greatly simplified the process of removing seeds from picked cotton–previously an extremely slow and tedious process. While the cotton gin inadvertently led to the rise of slavery in the South, it is still considered one of the most influential agricultural inventions of the 20th century.

1842 | Grain elevator

Developed by Joseph Dart and Robert Dunbar at the rise of the grain trade. The grain elevator was originally a steam-powered deposit for grain awaiting to be sold. Steam-powered conveyor belts brought the grain to a storage platform at the top of the elevator, where it was kept until offloading. Then, the grain would be brought down using gravity, and loaded onto trains or ships for distribution. Not only did the creation of elevators significantly reduce labor, but they also kept the grain “dry, cool, free from vermin, and safe from pilferage”.

1892 | First gasoline tractor

Invented by John Froelich, the tractor was able to harvest 1,000 bushels of grain using only 26 gallons of gasoline, which far exceeded the harvesting capacity of farmers–it took 40-50 labor hours to harvest just 100 bushels using wagons and horses. By 1954, tractors exceeded the use of horses, and by 1955 the labor needed to harvest 100 bushels was reduced to just 6.5 hours.

Storage

While decreased labor hours were able to bring an abundance of food to the market, it was pointless without refrigeration. Food cooling and freezing technology expanded food’s lifespan, made it easier to transport long distances, and allowed people to buy for the future.

1856 | First commercial refrigerator

The first refrigerator, built by James Harrison and patented in 1856, was a vapor compression system using ether, alcohol, or ammonia. He introduced the technology to breweries and meat packing houses, and had several systems in operation by 1861.

1867 | Refrigerated shipping

The first refrigerated railway car was patented by J.B. Sutherland. It used heavy insulation, roof hatches, floor drains, ice bunkers, and strategic airflow. As a result of this cold transport system, a huge network of icing stations were developed around the country, and the first transcontinentaltransport of cold goods from California to New York occurred in 1889.

1927 | Frozen foods

The birth of the frozen food industry is tied to Clarence Birdseye’s patent for a multi-plate freezing machine, which allowed for food to be quickly frozen without damage. By 1927, his frozen products included fish, meat, poultry, fruit, and vegetables. Birdseye later sold his patent to what eventually became the General Food Corporation to produce the Birdseye Frozen Food Company. By World War II, Americans were encouraged to buy frozen foods, with 800 million poundspurchased between 1945 and 1946. However, it was the invention of the TV dinner that made frozen food an American stable in 1954.

1930s | At-home fridge

Companies like Electrolux and General Electric began selling refrigerators and freezers for domestic purposes at a commercial scale. Unlike previous models, these units used Freon instead of toxic gases, making it a safer option. This coincided perfectly with the development of frozen foods (as we learned above!). By 1950, more than 90 percent of urban homes had a fridge.

So, where do all of these technological advancements leave us today?

For one, they have made it possible to feed over 7 billion people: From 1820 to 1975, agricultural production across the world doubled four times over and, while in 1940 one farmer could supply an estimated 10.7 people, by 1990, one farmer could supply 100 people. Today, one farmer can feed 155 people. As a result, we have seen a global decline famines and hunger, with a rate of undernourishment at 10.8 percent in 2015 (although this number has risen in recent years as a correlation to rising conflict and instability in many regions).

For most of its history, agricultural technology was focused on creating a more efficient and high-yielding system in order to better feed the world. As we can see, with reductions in labor and hunger worldwide, we were widely successful. Unfortunately, many of the methods used over the past 300 years have created negative effects that we are now only beginning to understand. Issues associated with Big Ag (the entire corn-soy-meat industry combined) include:

Soil nutrient degradation due to planting one type of crop over and over again, leading to a dependence on synthetic fertilizer.

Extreme water usage and waste.

The chemical contamination of groundwater (as a result of fertilizer usage).

The introduction of dangerous pesticides and herbicides into the ecosystem and their widespread repercussions on insect and animal populations.

Introduction of new bacteria and pathogens into the food supply–a result of factory farmed animals living in unsanitary conditions.

The development of antibiotic resistant bacteria as a result of antibiotic overuse in factory farmed animals.

Environmental pollution caused by machinery and animal excretions.

Rising rates of “western” diseases such as obesity, heart disease, cancer, and diabetes as a result of over consumption of readily available corn, soy, and meat products.

As a result, many of today’s newest technologies are focused on creating alternative methods of agriculture that will be more environmentally sustainable, as well as viable options in the face of climate change and increasingly irregular weather patterns.

2010s | Urban farming

While urban farming has existed throughout history, it has recently turned into a full-blown movement: Issues of local food access and healthy eating have made urban solutions necessary in the face of Big Ag. Hydroponic technology is a viable solution–companies like Freight Farms (2010) use repurposed shipping containers to create dense growing environments in small footprints. Similarly, many cities make use of of rooftops to set up greenhouses or even soil farms, like Gotham Greens (2009) or Brooklyn Grange (2010)

2010s | Data

Just as urban farming boomed starting in 2009, so did the agricultural data industry. Farm management software such as Spensa Technologies (2009), Mavrx (2012), farmhand (2013) Granular (2014), Trace Genomics (2015), and many others arrived on the market to give farmers more transparency into their farmland using satellite imaging, sensors and IoT technology, robotics, and more! The goal is to increase efficiency, and help farmers implement eco-friendly solutions easily on a large scale.

2013 | BountiGel

Company mOasis has created a hydrophilic gel (“hydro” = water, “phillic” = loving) that can be added to soil to absorb 250 times its weight in water. As a result, farms can use less water and improve their yields by 18 percent across the board. The gel is non-toxic and can break-down safely after several seasons. California approved mOasis’ first product for commercial use in November 2013.

2013 | Cultured Meat

This is perhaps the most extreme solution to many of the problems we see with factory farmed meat today, which requires huge amounts of water, pollutes the environment, and produces 14.5% of global human greenhouse-gas emissions. Lab-grown meat would help address the growing global demand for affordable meat while leaving a less damaging footprint. The world’s first lab-grown burger was introduced in August 2013.

2013 | Robotic Bees

The first robotic insect took flight in May, 2013 at Harvard University. It was based on the anatomy of a small fly, and inspired more projects in Japan which went on to create a robotic bee. The need to develop this technology is urgent: the U.S. alone has lost 44% of it’s honeybee population in 2016, leading experts to consider what a world without our most essential pollinators might be like. Even industry giants like Walmart are getting involved in developing this technology.

Lef Farms Introduces Fusion, A Fresh New Take On Standard Spring Mixes

(LOUDON, NH) – How do you satisfy those who love baby greens but possess an unpretentious yet discriminating palette? Those who have been searching for a straightforward mix with a bit more punch than a…excuse us as we yawn…Spring Mix? Well, those are exactly the lettuce lovers lef Farms (pronounced “leaf”) is looking to attract with its newest blend of baby red and green leaf lettuce called Fusion.

“Our goal was to introduce a new mix that captures the hearts and taste buds of those looking for something simple but something that still carries a unique flavor and texture profile they can’t find in an everyday mix”, affirms lef’s President and CEO, Henry Huntington.

Similar to the approach lef took in the creation of its flagship Smooth and Spice mixes, lef performed an extensive analysis of the lettuce market. And what it uncovered was a sizable base that’s looking for a more straightforward lettuce option. But, true to form, lef added its own flair by melding soft, red buttery Bibb lettuce with a crisper and more substantial Romaine variety, resulting in the distinctive combination found in lef’s new Fusion.