Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Cultivatd Launches As A New Vertical Farming Technology Brokerage

Co-founded by two former executives at ZipGrow Inc, Cultivatd will represent over 30 different vertical farming and greenhouse growing technologies to better help people select which tools and tech are best suited for their project needs

JANUARY 1st, 2021: Cultivatd Inc, a startup based in Canada, is announcing it has begun operations and launched an indoor farming technology brokerage.

Co-founded by two former executives at ZipGrow Inc, Cultivatd will represent over 30 different vertical farming and greenhouse growing technologies to better help people select which tools and tech are best suited for their project needs.

“We were seeing a lot of people come to us in the past, asking for solutions that required more than one technology, so we decided to launch Cultivatd to fill that gap in the marketplace,” says Eric Bergeron, a serial entrepreneur who is now on his fourth AgTech startup. “We use our expertise as growers, manufacturers, and consultants to make recommendations on the proper setup and agtech solutions.”

Added co-founder Eric Levesque, the former VP of Business Development at ZipGrow, “We work with manufacturers and technology providers to help sell their products to customers that are best suited to their needs. Our brokerage services are free to the end-user as we work on behalf of our partners”.

At current, Cultivatd works with several known AgTech partners including long-time industry companies such as ZipGrow, Cubic Farms, Moleaer, AutoGrow, Ceres Greenhouses, Nelson & Pade Aquaponics, Modular Farms Australia, Growfilm, Iluminar, Hydrogreen, and Intravision Group as well as new technology providers such as GroStack, AmplifiedAg, GROV, Canobi Technologies, Auto Greenhouse, Just Vertical, Grobo and ATOM Controllers,.

Cultivated is also announcing two new service offerings;

Farming As A Service and Cultivatd Consultants.

Farming As A Service (FAAS) is a program where Cultivatd will send a farm manager to operate your indoor farm, removing the difficulties in getting a farm up-and-running and eliminating the barrier-to-entry for most new farmers. The service is contract-based and meant to get your farm to full operational efficiency with an experienced grower by your side. Once the team is trained and using the SOPs put in place, the farmer will move on or remain on as a consultant.

The Cultivatd Consultants service will be a brokerage of experienced master growers looking to share knowledge with indoor farm operators. Cultivatd currently has 6 consultants with expertise in cannabis, vertical farming, greenhouse production, operations, and sales & marketing for vertical farming. “We are always looking to expand our network of consultants as demand for this service is already outweighing our ability to connect experts to projects in need of support..” added Levesque.

“We continue to add new partnerships every day and want to work with the world’s best agtech technology solutions so we can offer our clients a true, unbiased, assessment of the right solution to solve their need”. added Bergeron.

Visit cultivatd.com for more details and to see the growing list of partnerships.

FOR MORE INFORMATION

Eric Levesque

Managing Partner, Cultivatd Inc.

+1 (613) 360-5195

Understanding The Key Tech Required In Vertical Farming

Staff Reporter Jan 25, 2021

Vertical farming involves; growing crops indoors under artificial temperature and lighting conditions. This technology focuses on increasing productivity in small places. It utilizes soil-free methods like aeroponics, aquaponics, and hydroponics. Read on to understand the main tech you need for your vertical farm.

(Photo : Valcenteu Wikimedia Commons)

Lighting systems

Covered agriculture, which is the traditional method of farming uses HPS (High-Pressure Sodium) vapor lamps. These units generate a warm light, which appears as an orange-yellow glow in areas with many glasshouses. LED technologies have evolved, becoming more energy-efficient and cheaper.

LED vertical farming lighting dictates the next generation controlled environment agriculture (CEA). While HPS lamps generate orangey-yellow light, LEDs can be designed to generate light in any color or combination of choice. Today, more LED lights are specially designed for the CEA industry.

Researchers are working with manufacturers to manufacture crop-specific lights to enhance photosynthesis, guarantee crop quality, and boost yield production. When growing crops in an indoor environment without a natural or external light source, the quality and quantity of artificial vertical farming lighting for your crops is critical.

Heating, Ventilation and Air Conditioning (HVAC)

Controlling the heating, ventilation, and air conditioning is crucial in managing a vertical farm. Remember, the HVAC can influence the yield, health, and quality of your crops. Smart regulating systems are crucial for the management and maintenance of ventilation, temperature, and humidity. Installing smart enabled HVAC systems that can be incorporated into a general control system is critical.

Nutrients

Controlled environment agriculture allows farmers to regulate the frequency, levels, and nutrients they use on the crops. Commercial nutrient mixes are not only readily available but are also easy to use for your vertical farm. However, you can improve the quality of your crops and increase production with a crop-specific nutrient mix. Research and knowledge help you produce efficient nutrient mixtures for your vertical farm.

Control Systems

Control systems audit, and manage all elements of a controlled environment. Doing so allows the farmer to make proper decisions for crop-specific growing conditions. Advanced control systems give farmers crucial data on crop health, development, and the environment.

With this data, the farmer can develop different features of the growing conditions. Further, control systems facilitate the implementation of nutrient mixes and light that can change throughout growing, light intensity, and delivery of supplementary C02 (carbon dioxide).

Future vertical farms should come with integrated control systems and inline crop monitoring systems to facilitate disease management. These components will help boost conditions, enhance energy-efficiency, and increase yield.

Growing Systems

Vertical farming involves various hydroponic systems, making soil and other growing media unnecessary. Farmers can use different substrates, as seen below.

NTF (Nutrient Film Technique)

The NTF comprises narrow troughs or channels where flowing small amounts of nutrient and water solution drains to the bottom of the troughs. This process creates a thin film. Plants are hanged over the trough in net containers. They receive small amounts of the nutrient solution often per day.

The fine nutrient film solution facilitates watering of the rear of the roots without getting soaked. The top part of the roots stays dry and consumes oxygen. The nutrient film technique is ideal for baby greens, salads, leaves, strawberries, and herbs.

Flood and Ebb System

The flood and ebb system is also known as drain and flood. It involves the use of trays filled with a nutrient solution for a few minutes before the water drains. The plant roots are swayed around the nutrient solution. Using flood like circumstances allows the plants to consume nutrients and oxygen, making them healthy and strong. The flood and ebb system is ideal for producing microgreens.

Finally

Vertical farming allows farmers to grow crops throughout the year, and this facilitates maximum crop production. This technology does not rely on the weather. You can grow your crops with the help of LED lighting. Apart from being eco-friendly, vertical farming allows you to farm within limited spaces, as is the case in cities.

What Are The Emerging Trends Affecting Indoor Farming? State of Indoor Farming Survey

Artemis Ag has opened its third annual State of Indoor Farming Survey, and is looking for your input

By Artemis Ag

January 9, 2021

Photo: Kalera

Artemis Ag has opened its third annual State of Indoor Farming Survey, and is looking for your input. The survey will provide insights on emerging trends and challenges in the greenhouse and vertical farming industries.

“We’re looking forward to learning how growers are facing new challenges such as COVID-19,” says Allison Kopf, CEO of Artemis Ag. “In the past, expansion was one of the prime goals for growers, and we’ve asked some new questions around the topic. We will be sharing even more information related to technology usage, the evolution of the industry, and how growers are working with lenders.”

In the past few years, more than 500 growers have participated in Artemis’ annual State of Indoor Farming Surveys. Past reports have been downloaded more than 2 million times and are one of the most widely circulated and respected sources of industry data.

More and better data collected means more insights for growers. Growers can participate in the 2020 State of Indoor Farming survey here.

The survey will be open for a few weeks and Artemis expects to launch the 2020 report immediately following.

Learn more here.

Nature Fresh Farms Advances In Sustainable Transportation Through The SmartWay Program

Nature Fresh Farms pledges to reduce freight transportation-related emissions by becoming a member of SmartWay

Leamington, ON (January 15, 2020) – Nature Fresh Farms pledges to reduce freight transportation-related emissions by becoming a member of SmartWay.

Over the past year, Nature Fresh Farms joined the SmartWay Transport Partnership to further its sustainable development and continue to lead in its environmental initiatives. SmartWay is administered in Canada by NRCan and is free to those interested in becoming members, aiming to help both shippers and carriers move goods efficiently, by maximizing load capacity and keeping fuel costs and environmental impact at a minimum.

SmartWay is an internationally recognized program that encourages its members to be more aware of their carbon footprint by helping them track fuel consumption and improve their overall performance. Through their membership, Nature Fresh Farms can use the program to measure the environmental impact of their freight supply and use recommendations from SmartWay to improve and modify their transportation and operation strategies. With Nature Fresh Farms’ commitment to reducing emissions, their goal is to have at least 80% of their carrier base SmartWay certified by 2023.

“It has always been important for Nature Fresh Farms to recognize and understand our carbon footprint in every area of our operations,” shared Leigh Ann Breault, Director of Logistics. “Making the necessary improvements to our freight supply chain, using the recommendations provided from SmartWay, will only help reinforce our position as an industry leader in sustainability.”

With environmental performance becoming increasingly important as a business metric, more companies are becoming aware of the benefits of being a part of programs such as this. Having over 3,600 North American companies signed on to the SmartWay partnership, Nature Fresh Farms membership demonstrates their continued environmental leadership and corporate responsibility.

-30-

Continuously expanding, Nature Fresh Farms has become one of the largest independent, vertically integrated greenhouse vegetable farms in North America. As a year-round grower with farms in Leamington, ON, Delta, OH, and Mexico, and with their Distribution Centers established in Leamington, Delta, and Laredo, TX, Nature Fresh Farms prides itself on consistently delivering exceptional flavor and quality to key retailers throughout North America, while continuing to innovate and introduce more viable and sustainable growing and packaging solutions.

SOURCE: Nature Fresh Farms | info@naturefresh.ca T: 519 326 1111 | www.naturefresh.ca

PUERTO RICO: Indoor Vertical Farming Jumpstarts Agribusiness

Francisco Santana founded Grupo Vesan in 2015 with a simple concept: farming differently and more effectively. He looked to indoor vertical farming and became the first company in Puerto Rico to adopt that model

Grupo Vesan Seeks To Provide Food Security

With Sustainable Practices

Unlike other lettuce produced in Puerto Rico, the ones grown via vertical farming are unaffected by saltpeter, a naturally occurring nitrate. Courtesy of Grupo Vesan

January 13, 2021

A small business in the southern region of Puerto Rico is seeking to revolutionize agribusinesses with sustainable practices while providing food security and reducing the need for imported produce.

Francisco Santana founded Grupo Vesan in 2015 with a simple concept: farming differently and more effectively. He looked to indoor vertical farming and became the first company in Puerto Rico to adopt that model. As previously reported by THE WEEKLY JOURNAL, indoor vertical farming allows farmers to generate fresh food items in a controlled environment with smaller required spaces.

“Everything is with artificial lights and it works with 62 degrees F of temperature. It is a completely different environment. We regulate the humidity and even the oxygen level is controlled. The concept of all these parameters is completely different from what one usually finds in the market,” Santana explained.

In its beginnings, Grupo Vesan started with a 40-foot wagon and is now producing a variety of fruits and vegetables in Canas Industrial Park in Ponce, working with a 20-foot ceiling and 14 different parameters that allow for a broader range of products. Even after Hurricane Maria devastated nearly 70 percent of the island’s hydroponics, the company stood strong.

As such, Santana hopes that more agribusinesses incorporate this system so that residents have access to fresh food in times of crisis. “One of the benefits of this system… is that it provides food security. What we project is that agriculture should move indoors,” he said.

“Agriculture in Puerto Rico is not where it should be. That is the main issue of food security tied to this subject of indoor vertical farming. On the other hand, at the technology level, we are the pioneers in this process. We promote the idea of impacting the agriculture of Puerto Rico for new generations. [The idea that] new generations are not going to go to traditional agriculture; that is not true. We have, for example, an alliance with the Catholic University of Ponce and they send students here. They are working in air conditioning, in a white coat, like a pharmacist. They are doing scientific research, but they are really doing agriculture,” he added.

Islandwide Agriculture

Another benefit of indoor vertical farming is that it can be employed virtually anywhere in Puerto Rico, regardless of the soil’s fertility or if the area is prone to flooding or droughts. In fact, Grupo Vesan was founded while the island was experiencing a drought that prompted the Aqueduct and Sewer Authority (Prasa) to ration water.

Indoor vertical farming is also tied to the concept of “urban farming,” which is gaining popularity in Europe. That is, residents in any corner of Puerto Rico, including the San Juan metropolitan area or beachy municipalities like Dorado, can start their own agribusiness.

Likewise, this type of farming can be applied in spaces labeled as “brownfields,” which are areas that are contaminated and, therefore, unsuitable for traditional farming practices. Grupo Vesan even sells wagons for these purposes because one of their aims is to popularize this technique.

Environmental Impact

According to Santana, if more agribusinesses emerge with this model, the island would drop its carbon dioxide (CO2) emissions because there wouldn’t be a need to transport fresh food via long distances. “It also provides fresher food to consumers and businesses like restaurants could apply the farm-to-table concept,” he said.

Moreover, Grupo Vesan packs its agricultural products with its roots in a pouch with water. This allows the product to have greater longevity, thus reducing food waste and allowing for financial savings by not having to purchase fresh fruits or vegetables as often. As an example, Santana stated that the lettuce produced by his company can last “two or even three weeks” without spoiling.

Apart from lettuce, Grupo Vesan also grows spinach, tomatoes, cilantro, peppers, broccoli, carrots and a variety of other agricultural products.

“Revenue, a sense of community, and environmental impact; those are the components of a sustainable company. In our case, we don’t use any insecticide or pesticide, none of that. Our products are practically organic,” he affirmed.

He added that the company is currently developing a project to grow strawberries, noting that indoor vertical farming could eventually minimize the need to import foods that can’t be grown in Puerto Rico via traditional farming.

Reporter for The Weekly Journal. She is a journalist with experience in social media management, translations, and digital marketing.

Follow Giovanna Garofalo, The Weekly Journal

Bowery Farming Brings Indoor Vertical Farm To Bethlehem, PA - On Every Main Street

New York-based Bowery Farming is set to build its fourth and largest facility on the nearly 9-acre Lehigh Valley Industrial Park VII site in south Bethlehem

By GREG CAPOGNA • JAN 5, 2021

Lead Photo: Bowery Farming transforms industrial spaces into smart farms where crops are stacked vertically to maximize space. The design and year-round operation can yield 100 times more produce in the same space as traditional outdoor farms. BOWERY FARMING

Host Greg Capogna, in a Lehigh Valley exclusive, sits down with Irving Fain, CEO, and Founder of Bowery Farming, and Dennis Davin, Secretary of Pennsylvania's Department of Community and Economic Development, to discuss Bowery coming to Bethlehem, vertical farming, sustainable agriculture, the environment and jobs for the Lehigh Valley.

Listen

OEMS 1/4/21 Bowery Farming

New York-based Bowery Farming is set to build its fourth and largest facility on the nearly 9-acre Lehigh Valley Industrial Park VII site in south Bethlehem. The move is expected to create 70 new full-time jobs within the next three years. Bowery is the largest vertical farming company in the U.S..

Tune in to On Every Main Street Mondays from 6:30 to 7:00 PM following Lehigh Valley Arts Salon.

(Original air-date: 1/4/2020)

How COVID-19 Has Impacted Indoor Farming

Yahoo Finance’s Zack Guzman and Akiko Fujita discuss the indoor farming outlook and the plant-based fresh food categories with Viraj Puri, Gotham Greens Co-Founder, and CEO

January 11, 2021

Yahoo Finance’s Zack Guzman and Akiko Fujita discuss indoor farming outlook and the plant-based fresh food categories with Viraj Puri, Gotham Greens Co-Founder, and CEO.

To View The Video, Please Click Here.

ZACK GUZMAN: Welcome back to Yahoo Finance LIVE. Of course, 2020 was an interesting year for a lot of startups out there, particularly when it comes to being able to raise capital, as that quickly dried up when the pandemic first hit. But following that, a lot of companies were able to raise new capital to take on some pretty important goals here.

We're going to focus on two, one tied to the reopening of the economy as we continue to-- I don't want to say suffer through online events here, but one Zoom competitor, as well as our next guest here, focused on indoor farming-- a very interesting startup that is trying to challenge some traditional ways of doing things in farming. That would be Gotham Greens, which recently raised $87 million in new investment capital, and we're joined here by the co-founder and CEO of Gotham Greens. Viraj Puri joins us now.

And Viraj, I mean, we've talked about indoor farming for a few years here in the way that it's gained momentum to take on traditional agriculture in perhaps being a way that's more sustainable over the long term. But how have you seen maybe new capital getting put to work here recently as it catches on?

VIRAJ PURI: Absolutely. Well, I think to start with, this pandemic has really underscored the value proposition of more resilient supply chains. And indoor farming can really provide that because one can really farm anywhere, regardless of climate or availability of arable land, et cetera. So in our country, up to 50% of fresh produce is imported, and the balance majority comes from places like California and Arizona on the West Coast, which requires that fresh produce has to travel great distances to reach consumers throughout the country.

Conversely, indoor farming allows one to really grow anywhere, regardless of the climate, regardless of the soil conditions or land, et cetera. So I think when supply chains were really challenged early on this year with the pandemic, it has really revealed some of the benefits of indoor farming. And then, on top of that, sustainability is more of a topic that more consumers and companies care about.

And then on the third, sort of, point is food safety. We've seen more and more incidences of food safety and food safety recalls associated with that over the past decade or so, and indoor farming provides a compelling solution to reduce some of those risks. So as a result, we've seen a lot more capital rush into the space over the last 24 months.

AKIKO FUJITA: When you talk about the reliance that we saw exposed early on, in terms of where the food comes from, in particular states like California or Florida, how do you see the distribution shifting as a result? Indoor farming, of course, inherently means you can farm in any different region here. How have you seen that shift, the distribution channel shift as a result of that?

VIRAJ PURI: Yeah, similar to other sectors, we're seeing more last mile distribution centers, and we're seeing more just-in-time fulfillment, right? So with indoor farming, one can do that. The traditional supply chain is obviously dealing-- it's quite complex. A lot of middlemen, a lot of different actors along the way, and you're dealing with a highly perishable product when it comes to agricultural commodities-- many fresh agricultural commodities, particularly the ones that we grow and sell in market, including lettuce, leafy greens, herbs, things like that.

So this decentralized supply chain allows us to deliver much quicker to retailers. They don't have to place their purchase orders so far out in advance. And then it also allows us to fill those voids on the store shelves, depending on demand and supply with shoppers. So it really also reduces waste, which is a real ill that faces the food supply chain. Almost 50% of fresh produce in our country is thrown away between farm to fork, and we believe that indoor farming systems can really help create that equilibrium between demand and supply, which helps reduce that waste.

AKIKO FUJITA: Viraj, how have you seen your customer base shift? Is it-- is it restaurants that are getting in, that are expanding your base? Is it grocery stores?

VIRAJ PURI: Primarily grocery stores. I think pre-pandemic, it was really both. We did lose some food service business, restaurant business, at the onset of the pandemic, but that was more than made up for by increase in retail sales. Our revenue doubled in 2020, compared to the previous year, and a lot of that is a result of just the supermarkets wanting suppliers that can be more nimble with the supply chain.

And then increasingly, consumers are spending their dollars behind brands that speak to many of their values around ESG, around food safety, around supporting local economies. So those have been some of the factors that have really led to our doubling of our growth this last year, and we're very optimistic about the years ahead, for both our company and the broader indoor farming industry.

ZACK GUZMAN: Yeah, in the broader space discussion, too-- I mean, I know you guys have greenhouses across five states-- New York, Rhode Island, Maryland, Colorado, Illinois-- but when you think about the push here for more sustainability coming from the incoming administration, how much of that really throws fuels on the fire in terms of growth right now in expectations that there could be more friendly policy around indoor farming? Was that the impetus here to raise new capital, and if so, where do you look to put that to work in the short term?

VIRAJ PURI: I think there was a variety of factors that led to raising this capital, but primarily, it's less about the incoming administration and really more about capturing this opportunity in the marketplace to capture share from incumbents that are facing a lot of headwinds, whether it's climate issues, water issues out west, labor issues due to, sort of, you know, the reliance on migrant farmworkers to harvest and package and process product, along with food safety.

So we had actually put an expansion-- a pretty aggressive expansion plan into place prior to the pandemic, but post-pandemic, we're accelerating that change and using this capital to expand our network of greenhouse facilities across the country. As you pointed out, we currently operate-- we have manufacturing facilities in five states, and we service about 40 states. And our vision in the next few years is to really cover much of the country to truly become a national supply chain solution and consumer brand for consumers around the country.

ZACK GUZMAN: Yeah, it was interesting when you first saw indoor farming kind of taking hold here in the country and always interesting to see how fresh this stuff is in the store when I come across Gotham Greens. But Viraj Puri, I appreciate you coming on here. Co-founder and CEO at Gotham Greens. Thanks again.

Agri-Tech Startup Granted £566,000 To Develop Growth Chambers

Driven by the need to reduce the environmental impact of agriculture, and to improve the nutritional quality and availability of fresh produce, the vertical farming market is a very exciting place to be for an agri-tech startup-like Grobotic Systems

Innovate UK, the UK’s innovation agency has just awarded Grobotic Systems and their consortium partners a grant worth £566,000 to fund the development of their cutting-edge growth chamber and to support the UK Government’s Industrial Strategy to transform food production.

Agri-tech startup Grobotic Systems believes the best way to deliver this promise is with their latest invention, a new class of plant growth chamber loaded with high-tech sensors and plugged into the internet. This state-of-the-art growth chamber will help vertical farmers identify the best way to grow plants to produce the most nutritious and environmentally-friendly food possible.

Managing director, Dr. Moschopoulos says “Through collaborating with industry leaders in photonics, controlled environment agriculture, and plant physiology, this funding enables Grobotic Systems to recruit additional staff, accelerate product development, and access the rapidly growing global vertical farming market with our innovative growth chamber technologies.”

“Driven by the need to reduce the environmental impact of agriculture, and to improve the nutritional quality and availability of fresh produce, the vertical farming market is a very exciting place to be for an agri-tech startup-like Grobotic Systems. Our novel technologies will help farmers grow healthier food more efficiently - that is better for the environment, better for the farmer, and better for the consumer.”

This project builds on the patent-pending growth chamber technology developed by Grobotic Systems over the past year. Grobotic Systems will lead this project in collaboration with partners from the Fraunhofer Centre for Applied Photonics, Stockbridge Technology Centre, and the University of Sheffield.

Founded in 2018 by Dr Alexis Moschopoulos, a plant geneticist, and Richard Banks, an electronics engineer, Grobotic Systems is a Yorkshire-based startup engaged in the design and manufacture of innovative plant growth chambers for plant science research.

For more information:

Grobotic Systems

Alexis Moschopoulos, managing director

alexis@groboticsystems.com

www.groboticsystems.com

Publication date: Fri 8 Jan 2021

JPFA Offering Online Training Course On Plant Factories

The Japan Plant Factory Association is starting a new online English-language training course on Plant Factories with Artificial Lighting (PFAL) in February and is receiving applications now

English Training Course on Artificial Lighting In February

The Japan Plant Factory Association is starting a new online English-language training course on Plant Factories with Artificial Lighting (PFAL) in February and is receiving applications now.

The JPFA 2021 online training course on PFALs scheduled for February 18 – March 11 comprises introductory classes and special content designed for participants to acquire practical knowledge and expertise. The learning event follows its first online English-language training course that was offered last year.

Click here to view the course brochure.

All interested parties in plant factories or vertical farms can seize this opportunity as the course is not only available for JPFA members but also for non-JPFA members. The JPFA is a nonprofit organization committed to advancing controlled-environment agriculture.

The lecturers include Toyoki Kozai, honorary president of the JPFA and former president and professor emeritus of Chiba University, who is known as the father of plant factories. Introductory classes will cover such topics as current PFALs and forthcoming technologies as well as environmental effects on plants. Special content will allow participants to learn practical methods.

The course will also provide participants with a virtual tour to a commercial, large-scale PFAL and exhibitions by companies in the PFAL and related businesses. Although participants cannot get together as in on-site courses, the course’s platform allows them to enjoy interacting with other attendees and representatives of exhibitors. Also, a live question-and-answer session is planned for participants to deepen their understanding.

“Thank you so much for the opportunity to look deeper into this ‘industry,’ which is likely to reshape our future soon,” a Romanian participant of the 2020 course said.

Because the course is online, it may be easier to attend it than an on-site one, especially for those who live outside Japan.

Click here to apply for the course.

Bowery Farming Expands With The Addition of A New Farm

“Adding our newest, most sophisticated, smart indoor farm in Bethlehem to our network is a critical next chapter in our growth,” said Founder and CEO Irving Fain

Jan. 6th, 2021

NEW BETHLEHEM, PA - If the new year has you thinking about all things bigger and better, you’re not alone. Bowery Farming announced its expansion with a new farm in Bethlehem, Pennsylvania, the company’s largest commercial farm yet.

Irving Fain, Founder and Chief Executive Officer, Bowery Farming“

Adding our newest, most sophisticated, smart indoor farm in Bethlehem to our network is a critical next chapter in our growth,” said Founder and CEO Irving Fain. “We’re proud to transform a former industrial site into productive, modern farmland, which will create year-round sustainable farming jobs for the community and expand access to a reliable source of traceable pesticide-free produce across the region.”

The farm, which is the most technologically advanced of Bowery’s farms, features industry-leading improvements like LED lighting that reduces energy consumption and a water transpiration system designed to recapture nearly all of the water from the plants, a press release revealed.

Bowery Farming announced its expansion with a new farm in Bethlehem, Pennsylvania, the company’s largest commercial farm yet

Bowery is working with the Commonwealth of Pennsylvania to transform the non-arable industrial site into useful, modern farmland. The grower is also partnering with the Pennsylvania Department of Community and Economic Development and Governor’s Action Team to bring the new farm to fruition. Because of its strategic location, the farm will bring local produce to the surrounding population of over 49 million consumers and provide year-round farming jobs.

Tom Wolf, Governor, Pennsylvania (Photo credit: National Governors Association)“

Pennsylvania welcomes Bowery Farming to our commonwealth’s rich and diverse agriculture industry and looks forward to supporting the company’s growth as it reimagines how farming can be more sustainable and impactful on our communities,” said Pennsylvania Governor Tom Wolf. “Bowery’s expansion will generate new opportunities by establishing this indoor vertical farm, and will create innovative farming practices, new jobs, and a chance to address food insecurity in the Bethlehem area.”

We at AndNowUKnow will keep our eye on the newswire as more and more growers continue to push for expansion in new markets.

Packaged Salads Value-Added Bowery Farming Expansion New Farm Farm Technology Water Transpiration System Lighting Sustainability New Jobs Facility Facilities Operation Growth Growing Expand Expanding Irving Fain Tom Wolf

COMPANIES IN THIS STORY

Bowery Farming

At Bowery, we're committed to growing the purest produce possible. To us, that means using zero pesticides and non-GMO...

Agtech Attracts Celebrities

Food and farming are attracting celebrity investment including from Meghan Markle, Oprah, and Katy Perry to name a few

January 3, 2021

Amy Wu Contributor

I report and write about food, farms, and farm tech.

Food and farming are attracting celebrity investment including from Meghan Markle, Oprah, and Katy Perry to name a few.

While food and farming are increasingly in the limelight in part driven by the pandemic. COVID-19 has catapulted food and farming to the forefront of the minds of ordinary folks who have had first-hand experiences related to food shortage, food supply, and food safety surfaced.

Now the sector has piqued the interest of investors too including celebrities.

In 2020 there was a steady stream of investments in a sector that has traditionally struggled to attract investors especially venture capitalists who seek fast returns.

Agtech has seen robust investment in recent years. Growers are increasingly seeking solutions for challenges including a severe labor shortage and water and land management issues, and open to adopting innovations that increase yield and efficiency.

A growing number of investors are also banking on companies that support sustainability and promote conservation. In 2020, venture capitalists invested $4 billion in startups in the agtech space, according to Crunchbase a research company. This is up significantly from the $2.8 billion that venture capital investors placed in agtech startups across the globe in 2019.

Little surprise that public figures are jumping on the bandwagon too.

“Celebrities have access to tech thought leaders and see what they are excited about and want to be in on the new trend,” says Jaleh Daie an entrepreneur and seed investor with a focus on agtech. Daie observes that the agrifood tech sector is climbing and has yet to see its peak.

Pam Marrone, the founder of Marrone Bio Innovations and investor in agtech start-ups, notes: “More than ever, consumers care about how their food is produced and processed. Celebrities are tuned into this trend and see that they can help shift us along to a more transparent and sustainable food system that reduces food waste and improves people’s health.”

Below are a few high profile investments by household personalities in 2020:

Meghan Markle invested in Clevr Brands a Santa Barbara, California-based company that specializes in instant oat milk latte. The company, led by CEO and founder Hannah Mendoza, asserts that its products are green-friendly and ethically sourced.

Meghan Markle (Photo by Max Mumby/Indigo/Getty Images)

Oprah Winfrey and Katy Perry invested in Apeel Sciences a California-based foodtech company that produces coasting for fruit that is edible. Among her various properties, Winfrey also owns and lives on a farm.

Perry, Serena Williams, and Jay-Z invested in Impossible Foods a company in Redwood City, California that develops plant-based substitutes in lieu of meat.

Finally, tech magnates Bill Gates the founder of Microsoft, and Eric Schmidt the former CEO of Google have been expanding their investment in agtech. In 2020 Microsoft announced that it had launched Azure, a suite of tch tools and resources to help agtech start-ups in India. The Schmidt Family Foundation made food and agriculture one of the four areas of investment.

A visitor takes a picture of vegetables growing under artificial light on a Grow Stack vertical farm at the 2019 RHS Chelsea Flower Show in London on May 20, 2019. (Photo by Daniel Leal-Olivas/AFP via Getty Images)

Coming in 2021

Marrone forecasts that agtech and food tech will continue gaining momentum in 2021 when it comes to interest and investment. Consumers are becoming more focused on eating healthier and interested in where their food comes from. On a global scale, there is a growing interest in food supply chain transparency through blockchain technology.

Vertical farms and indoor agriculture, plant-based protein substitutes, and companies tackling food waste attract significant attention.

“There is a burgeoning startup ecosystem of B2B agbio and agtech companies getting funded that are focusing on tackling the problems and inefficiencies of chemical fertilizers and pesticides,” Marrone says.

I am award-winning writer and documentary filmmaker for the women’s ag and agtech movement, and previously covered agriculture for The Californian in Salinas, Calif. I am also the founder of From Farms to Incubators, an online platform that profiles minority women entrepreneurs in agtech and includes an award-winning documentary that has screened at SXSW and Techonomy. I have over 24 years of experience working as an investigative journalist including at Time magazine, the USA Today Network, and The Deal. I earned my master’s degree in journalism from Columbia University.

Lead photo: FUJI CITY, JAPAN - A worker inspects lettuce plants at the hi-tech Innovatus farm. Sensors collect information on all the factors that affect the development of plants. (Photo by Jonas Gratzer/LightRocket via Getty Images)

VIDEO: IRELAND: Could Vertical Farming Help Avoid Brexit Supply Issues?

Ireland's network of disused mushroom houses could be the ideal infrastructure to develop a hydroponic farm system which could in turn reduce our dependence on imports of herbs, salads and small greens

11 Dec 2020

Agriculture & Consumer Affairs Correspondent

Ireland's network of disused mushroom houses could be the ideal infrastructure to develop a hydroponic farm system which could, in turn, reduce our dependence on imports of herbs, salads, and small greens.

Hydroponic farming uses water rather than soil to grow plants.

It uses much less water than conventional growing, a tiny amount of space, and is immune from adverse weather conditions because it is indoors.

One farm in Tipperary has started the transition. Near Ballyporeen, one of eight mushroom tunnels is now converted into a vertical farm.

Brian O’Reilly had been growing mushrooms for almost two decades, but tight margins and anxiety over the potential impact of Brexit made him change course.

"The risks were too high so we decided to step back. Tighter margins were number one and Brexit was the number two reason, and labour was a problem too," he said.

Now, he has turned to basil. His first crop will be harvested in the coming days and will be sold into the catering industry.

Mr. O'Reilly said the process of growing herbs and small greens is similar to mushrooms. There is a cycle and within 32 days from planting a seed, the basil is finished.

It is grown in tiny pods on shelves with the roots stretching down to nutrient-rich water. Bright LED lights encourage the growth, as does hot air blowing into the tunnel.

A wind turbine nearby generates the electricity and a hot humid house means the plant thrives. But the lights are also powered down for hours in order to let the plants sleep.

It looks a million miles from any conventional farm. The tunnel is filled with rows of white plastic shelves, with tiny holes through which the plants appear. Water is circulating under the shelves and overhead there are strips of lighting; white, red, and blue.

It is bright and humid with the constant hum of air being pumped in and there is a gentle trickle of water flowing through the system.

Farmony, an Irish technology company, has developed the technology being used in Ballyporeen.

It has built farms in several countries and said the system could make Ireland self-sufficient in herbs and small greens within a few years.

Farmony's John Paul Prior said the range of plants that can be grown is vast and goes way beyond herbs.

He said: "In Ireland, we grow between May and September/October. Imagine if you could recreate that perfect summer's day all-year-round.

"That is what we are doing with controlled environment farming, so we could come close to self-sufficient with all your leafy greens, all your microgreens, and all your herbs."

Ireland imports the vast bulk of those products and the development offers a huge opportunity to expand the horticulture sector in Ireland.

It is environmentally positive too. If mushroom houses are used, it is utilizing something that has limited suitability for anything else. Farmony claims that the system uses 90% less water than conventional farming methods and is pesticide-free too.

The tunnel in Ballyporeen is part-funded by the Department of Agriculture as a pilot project and Mr O'Reilly is already testing crops other than basil.

"We are growing microgreens, peashoots and coriander at the moment. We are experimenting with them, we can change our model at any time and grow to what the customer wants," he said.

"When you think of it, this basil which we are growing would normally be imported, sometimes from thousands of miles away, from Morocco, Kenya, Israel, Spain or the UK. We are replacing that. The food miles are being dramatically reduced and we can do it without worrying about the weather outside."

Abandoned mushroom farms are dotted all over the country. There were more than 400 growers at one point, now there are just a few dozen. It is a tight margin business, which is dominated by a few companies and is almost entirely export-dependent.

Last year, Ireland exported €102m worth of mushrooms. Up to September this year, we exported more than €82m worth of mushrooms.

Any delays at ports after Brexit could have a huge impact on delivering fresh product to supermarkets in the UK. The possible imposition of tariffs is also an issue.

The Government wants to expand Ireland's horticultural offering. It is lower-emitting than sectors such as beef and dairy and there is huge scope for expansion.

Often, our climate is an issue. We have a shorter growing season than other countries and they can also offer scale and a cheaper cost base.

There are some areas of Ireland that grow high-quality vegetables, but it is a sector in decline over recent years.

The dominance of the big multiples as the primary buyers has tightened margins and many growers complain that the sector is controlled by too few buyers. Up to September this year, Ireland imported €146m worth of vegetables alone.

Its dependence on UK imports of potatoes and other vegetables could be a problem after Brexit, but it is something which the sector is aware of.

Farmony hopes that developing a network of vertical farms could dramatically reduce our food miles, reduce reliance on imports, and also create jobs and revitalize a declining sector.

Lead photo: Hydroponic farming uses water rather than soil to grow plants

The Salad Days of AI

Many courses in computer science are heavy on theory, so having a course grounded by growing plants makes it more interesting and relatable, he said

Nidhi Jain has never had much luck growing plants. "I've tried to work with plants, but they didn't want to work with me," said the senior computer science major from California. "So I've stuck to succulents."

Green thumb or no, Jain and her classmates in the School of Computer Science's "Autonomous Agents" course this fall-applied their knowledge of artificial intelligence, including machine learning and computer vision, to grow lettuces and radishes in small, automated greenhouses. Without ever seeing or touching their plants in person, they worked in groups of three to nurture their sprouts, writing programs that made all of the decisions on adjusting light, humidity, and soil moisture based on sensor data.

Reid Simmons, who teaches the course with Stephanie Rosenthal, said using AI to grow vegetables is a good way for students to put the knowledge of AI-based autonomous agents that they learned in class into practice. Agents have applications in many areas, such as self-driving cars, intelligent factories and smart homes. Another — automated greenhouses — proved a good match to the need for a course exercise.

The autonomous farm

"We wanted something that was physical, that would have to interact with the environment," explained Simmons, a research professor in the Robotics Institute and Computer Science Department (CSD) who directs SCS's undergraduate AI degree program. And they wanted these agents to run for two weeks at a time. "Most of the alternatives were robots and the likelihood that a robot would work for two weeks was very low."

Plants grow — and die — slowly, so they don't provide the immediate, dramatic feedback of, say, a robot running into a wall. But students said they nevertheless learned a lot about the pitfalls of autonomous agents during the two growing periods during the semester.

"Deployment isn't as easy as you think," said Vicky Zeng, a senior artificial intelligence major from Singapore. The autonomous agents receive input from temperature, humidity, soil moisture, and light sensors, which they interpret to make adjustments on light, watering, and fan operation. Faulty soil moisture sensors, however, plagued all of the teams, resulting in plants going without needed water. "Even if your agent is running fine, it can end up making poor decisions if it's getting bad sensor data," she said.

"Some of what they're learning is that relying only on your sensor values can be problematic," said Rosenthal, an assistant teaching professor in CSD. During the second growing period, she noted, moisture sensors showed there was plenty of water in the soil despite most teams never having watered, "but after a week we know the plants probably need water." In that case, the students were allowed to make a one-time adjustment to prevent all their plants from dying.

Autonomous agents thus must be designed to cope with errors, Zeng said. More than that, "we can't be waiting to see errors; we have to have methods for predicting errors. Sometimes things are out of your control but you try to prevent them from getting into that state." One solution: setting a maximum number of days that the plants can go without watering.

The harvest

Arthur Dzieniszewski, a senior computer science major from New Jersey, comes from a family of gardeners and was immediately intrigued by the "Autonomous Agents" course when he heard about it. Many courses in computer science are heavy on theory, so having a course grounded by growing plants makes it more interesting and relatable, he said.

Overall, the teams had great success in the two growing periods. Though they were graded based on the first two weeks of growth, Simmons and Rosenthal allowed the plants to grow an extra two weeks so they had a chance to grow big enough for harvesting.

The vegetable-growing exercise proved popular with the students, Rosenthal said, and several chose to take the course, in part, because of it. Dzieniszewski has even created his own automated greenhouse that is functionally equivalent to what the class used. Though he doesn't have any plants growing yet, he can control the greenhouse remotely and use an autonomous agent to run it.

After each growing period, the teams would make presentations to the class, summarizing their experiences and lessons learned. Jain said this was one of her favorite parts of the class. Another highlight, she said, was when Simmons harvested some of the vegetables from the first growing period and ate the radishes during class.

"This was really exciting because I was finally able to have some success at growing some plants," Jain added.

For more information:

Carnegie Mellon University

www.cmu.edu

21 Dec 2020

Things To Think About Before Purchasing A Freight Farm

In this article, I will detail all the steps, hurdles, and bureaucracy I endured trying to start and bring a Freight Farm into my local community in Canada

Connor McGoran

In this article, I will detail all the steps, hurdles, and bureaucracy I endured trying to start and bring a Freight Farm into my local community in Canada. While this may not be the same experience for everybody, I will share what I learned and how I failed at starting a Freight Farming business. This process took me approximately three months to go through. The goal of this article is not to dissuade anyone from trying to start a Freight Farm business but to learn from my shortcomings so that the next individual who embarks on this journey will succeed and know what to expect.

Background

I had just finished my degree in Technology Management from NAIT and the early phase of COVID-19 hit which caused community lockdowns across Canada. During the lockdown, I stumbled upon an article from the MIT Technology Review about a unique way to grow roughly 1.5 acres of food in a retrofitted sea-can using LEDs, hydroponics, and specialized HVAC. My curiosity got the best of me and I asked myself if there was a feasible business case for this type of innovation in my home town. This to me seemed like a well-timed idea due to the broken food supply chain across North America due to COVID-19. With further research, I even found that Elon Musk’s younger brother Kimbal used multiple Freight Farm’s to grow his produce for his restaurants. This led me to read more to see if this magic box would be feasible from an economics and business perspective.

Step 1 : Research

The first thing I did was reach out to Freight Farms in Boston where I had a wonderful experience dealing with the Freight Farm Team. They gave me all the documentation I would need to get started detailing the cost of a brand new unit to be 115,000 USD. I also reached out to another company called FarmBoxFoods to see how their technology differed and what their price was set at 125,000 USD. Due to the high cost and the poor CAD-USD currency conversion (1.4), I looked at purchasing a used Freight Farm from the iGrow Group which re-sells used units online.

LGM Freight Farm Operating Costs

Step 2: Business Spreadsheet

I then created my own spreadsheet-based upon the numbers provided to me by the Freight Farm team and my own research to see if it would be feasible from a business perspective. There are some numbers included in this spreadsheet which I will talk about later in the article.

LGM Calculator Tab 1

LGM Calculator Tab 2

LGM Calculator Tab 3

After building my spreadsheet, I determined that the only way for me to make money and pay off any debt in Canada with the CAD-USD conversion rate was to purchase a used unit through the iGrow Group. Different brands of hydroponic growing sea-cans and units ranged from 55,000 USD to 150,000 USD depending on the model and year.

Step 3: Business Plan

After creating my spreadsheet I called other Freight Farmers within Canada to ask about their experience running a company. The expertise of people who already operated their own Freight Farms was extremely insightful because they were able to share their difficulties, what they learned, and what I should anticipate. This helped me write a modified version of the business plan below. I decided to call my company KLC Greens.

KLC Greens Business Plan

KLC Greens is a hydronic farming company that would provide the highest quality local produce to the local industry in Canada 365 days a year! It has the capability to turn around over 1000 heads of lettuce or other leafy greens after a 6-week initial phase.

Demand for local produce is booming and KLC Greens would be perfectly positioned to increase the availability of “hyper local” foods for our customers. By utilizing the very best hydroponic farming technology, Freight Farms’ Leafy Green Machine would grow high value cash crops year-round with consistent high quality that is not possible with outdoor farming in the local community.

Marketing Strategy:

KLC Greens marketing strategy would focus on selling their produce to wholesale grocery stores, a retail CSA program, and local restaurants that want the best produce available year-round. KLC Greens has been in contact with different local grocery stores that have shown interest to our product.

Company Description

KLC Greens is a hydroponic farming company that would provide fresh produce to the local vegetable industry in Canada. We will grow different lettuce varieties for restaurants, wholesalers, and retail through CSA that would aim to support the growing local food movement in Canada.

Our world is changing. More people than ever are now living in tightly populated, urban areas, and there’s an increasing demand for locally grown and sustainably produced food. People want to know the story behind the meal on their plates. And even city dwellers want their food to be fresh and full of nutrients, not pre-packaged and shipped from thousands of miles away.

Our climate is also continuing to evolve. Extreme weather conditions are becoming more common, and land and water are becoming scarcer. Large-scale food production and distribution has had a significant impact on the earth’s ecosystem, and it’s continuing to affect our water levels and biodiversity.

Transparency is key to understanding where and how food is produced and KLC Greens is committed to improving transparency in the produce industry by growing ‘hyper-local’ produce in one of the most innovative hydroponic system available, Freight Farms’ Leafy Green Machine. Growing in the Leafy Green Machine enables us to provide unparalleled transparency in all operations from seed to harvest and provides our customers with the certainty that they are eating, receiving, buying Okanagan produce grown via the best agricultural practices available.

Our Product

We will initially grow different lettuce varieties and sell it to wholesalers and restaurants at an expected price of 2$ per head of lettuce. This type of cash crop takes 6 weeks to reach maturity and we estimate harvesting 4044 heads per month. For details on harvest volumes, see Appendix A for revenue calculation data and assumptions.

Our lettuce is hyper-local, meaning that our lettuce is grown in the community where it will be consumed, and is thus considered a premium and differentiated product by the market, commanding a higher price point than even organic foods. This differentiation is what enables us to command the higher price of 2$ as opposed to the general wholesale price of 1.50–1.75$.

Market Breakdown

KLC Greens will specifically target high-end restaurants in the Canada area. Our target customers are chefs and restaurant owners in the farm-to-table movement who already provide information to customers about their sourcing policies and chefs and restaurant

owners in the ethnic cuisine space who require specific fresh greens for their dishes that are not available year-round through traditional farming.

Our competitors in the restaurant industry include direct competition from other local farmers, and wholesalers who source exclusively from local farms but are constrained by seasonality, and indirect competition from larger wholesalers who bring in low cost produce from around the world and in all seasons. KLC Greens will compete by providing “hyper local” produce to the restaurant industry regardless of season.

KLC Greens plans to sell its lettuce into the wholesale market in Canada. We will target smaller wholesale companies who specialize in local produce as opposed to working with the larger, national companies where we will struggle to meet sufficient volumes to be a relevant partner.

Our competitors for local wholesale are other local farmers growing vegetables and different varieties of vegetables (traditionally or hydroponically). During the summer months, traditional farmers will be KLC Greens greatest competition as the supply of local Lettuce is significantly increased and the price is driven down. During the non-summer months, regional, large-scale hydroponics producers are the greatest competitors for KLC Greens. In both instances, KLC Greens will rely on its freshness and consistent availability to appeal to our wholesale partners.

KLC Greens will sell its produce in farmers markets in the Canada area. We will target markets in middle to upper-middle class areas in order to gain access to consumers who are dedicated to eating fresh, local produce and have the disposable income to purchase our premium Lettuce.

Our competitors fall into two categories, direct competitors from the farmers market community and indirect competitors from outside the farmers market. To date, KLC Greens does not know of another hydroponic farmer participating in farmers markers in the Canada area, meaning that our primary direct competitors will be local farmers growing Lettuce in the traditional way. Outside of the farmers market, our competitors are traditional food retailers who may or may not stock local Lettuce. In both instances, KLC Greens has an advantage as we can differentiate on freshness and availability all year.

KLC Greens will also target middle to upper-middle class customers who already participate in CSA programs and demonstrate a commitment to eating local produce.

While most of KLC Greens competitors are not “hyper local” producers, it is worth briefly discussing the different methods of urban farming that may eventually enter the market as direct competitors. The four main competitors to KLC Greens Leafy Green Machine growing method in the urban farming space are indoor warehouses farms, urban greenhouses, rooftop farms, and small plots of land transformed into farms. Each have their benefits, however KLC Greens firmly believes that the Leafy Green Machine provides the best combination of protection from natural elements, cost effective production, and reliable crop yields that will make urban farming a profitable venture now and into the future.

Competitive Advantage

KLC Greens main competitive advantages are the farming technology we will use to produce our lettuce and the support of a network of small business hydroponic farmers.

We are in the process of purchasing a Leafy Green Machine from Freight Farms to use as our primary farming tool. A Leafy Green Machine is a turnkey hydroponic farm built inside of an insulated shipping container, enabling it to produce fresh vegetables in any climate for a full 365 days per year. To help ensure success, the Leafy Green Machine is equipped with sophisticated environmental controls which allow KLC Greens to easily grow consistently high-quality lettuce while simultaneously eliminating the guesswork inherent in traditional farming. The Leafy Green Machine only requires 20 hours a week to operate.

In addition to the benefits of the Leafy Green Machine itself, our purchase of a Leafy Green Machine provides us with access to the many resources Freight Farms offers to its extensive and ever-growing network of small business farmers. Freight Farms’ commitment to KLC Greens success includes:

· Comprehensive in-farm and online training

· A resident plant expert who is available to all beginning farmers

· Monthly shipments of customized nutrients and seeds

· Software designed to optimize harvest yields and allow remote monitoring of crops and control of the Greenery

· And most importantly, access to Freight Farms’ very active network of small business farmers who are available for assistance and advice

The strength of the Freight Farms network cannot be overstated. Each small business farmer has faced similar business challenges to those that KLC Greens will inevitably face. By leveraging the solutions of fellow Greenery farmers, KLC Greens can significantly reduce the risk associated with a new venture and move through challenges quickly and successfully.

Marketing and Sales Plan

KLC Greens sales plan is to target Restaurants, Retail (CSA) and wholesalers. Our company will target chefs and owners of high-end farm-to-table restaurants who have already demonstrated a desire to provide customers with transparency in food sourcing. Our Retail CSA program will target middle to upper-middle class customers who already participate in CSA programs and demonstrate a commitment to eating local produce. KLC Greens will also target wholesalers who are looking for consistent quality produce that can be supplied year-round.

KLC Greens has discussed our hyper-local lettuce with Natures Fare, Sysco, and Valley Green Foods and they are very excited about the possibility of buying year-round, local lettuce.

In order to obtain customers KLC Greens will implement the following marketing strategies of utilizing digital marketing tools, word of mouth, social media campaigns, and attending local regional industry events. KLC Greens will use a combination of digital marketing, via add words and a company website, and networking at industry events to identify and network with farm to-table restauranteurs, grocery chains and wholesalers. We will operate a booth at local conferences to better spread the word about our hyper-local lettuce, give potential customers the opportunity to try the lettuce for themselves, and direct further inquiries to our website for more information about the benefits of hydroponic produce.

KLC Greens will have a variety of different packaging for products depending on industry or consumer needs. If wholesalers require clam shell or hard plastic containers for packaging, our business will source that out. KLC Greens will package its lettuce in grams or kg in either rectangular clamshell packages or hard plastic containers for it’s wholesale partners.

Management Team

Key Partners:

· Accounting/Tax Partner: TBD

· Legal Advisor: TBD

· Insurance Provider: TBD

Use of Funds

KLC Greens is requesting $150,000 CAD for the purchase, transportation, and installation of a Greenery and for the cash flow necessary to get started. In addition to the requested loan amount, Farm Credit Canada has granted KLC Greens 80% of the funds to purchase the Leafy Green Machine. The 80% of the funds provided by Farm Credit Canada would be paid back to the loan.

A detailed breakdown of our planned use of funds is below:

· Greenery Purchase: $88,000

· Greenery Transportation: $9000

· Customs Tax (5%): $4375

· Greenery Installation: $3000

o Leveling: $1000

o Electric: $1000

o Plumbing: $1000

· Training: $4000

o Cost of training: $2500

o (if applicable) Cost of flight to Boston: $1000

o (if applicable) Cost of hotel in Boston: $500

· Business Materials Purchase: $1000

Financial Projections

KLC Greens financial projections are derived from the proven operations and profit models of fellow Leafy Green Machine small business farmers. Based on their experiences, collected, and consolidated by Freight Farms, we have constructed the following financial projections forecasting our first five years of operations.

Key Assumptions of Projected Financial Statements

· One month is 31 days (the Leafy Green Machine operates every day) or four weeks

· Year 1 begins on the day of Leafy Green Machine purchase

· Tax payments are not included in our calculations

· KLC Greens is a cash-based business so we will not offer terms to our customers and pay our bills upon receipt, therefore we have not calculated for Accounts Receivable or Accounts Payable

· We have elected to exclude inventory from our asset calculations however, there will be a nominal amount of work-in-progress and materials inventory at any given time

Step 5: Finding a Freight Farm

After creating my business plan I was ready to try and find a used unit that would fit within my budget through the iGrow Group. The team at iGrow was also super helpful and narrowed down the best unit that was close to where I lived to reduce shipping costs and help pair me with another business owner. I had to WhatsApp call the seller multiple times to ask questions and to inspect the unit due to COVID-19 as I was unable to cross the border. I was able to put a down payment on the unit until I secured further funding.

Step 6: Finding Capital (Funding)

In order to fund my business venture, I had to try and find different avenues for funding which led me on a rabbit trail for approximately two months. At the time of trying to obtain funding I was 22 and had no assets in my name but actually had little difficulty in getting approved funding. The only problem that occurred was that no bank in Canada would give me a bridge loan to bring the used Freight Farm into Canada. I called every single bank over the span of two months that I could possibly think of and tried to brainstorm creative ways to bypass the process. My seller was growing impatient so this led the seller to agree to send the unit across the border on the condition I would pay the remaining 90% and provide letters from the different financial institutions that I was approved for funding. I was able to obtain funding three different financial institutions called Farm Credit Canada, Community Futures, and RBC. Farm Credit Canada is a farm lender that is subsidized by the government which has a special young farmers loan for ages under 40 that can approve loans of up to a million dollars. Community Futures is a community-based organization that helps aspiring entrepreneurs within the Okanagan and RBC is a bank within Canada.

I reached an agreement with Farm Credit Canada after dealing with their business analyst’s and scrutinizing my business plan they would grant me 80% funding for the Freight Farm once it crossed the border, Community Futures would provide the operating expenses and other equity, and RBC would provide me a business account with an operating line of credit. Once I obtained the letters from all three financial institutions I was able to bring the Freight Farm across Canada.

Step 7: Logistics, Logistics, Logistics

Growing up in the Okanagan Valley in Canada which has an abundance of agriculture land and plenty of farming, I did not think I would have such a difficult time finding a place to put the Freight Farm. I reached out to numerous farmers, tried my contacts, and tried door knocking to try and find some land. What I found was that majority of old farmers did not want the hassle of having this on their property, did not understand the technology or it was not worth their time for the money. Being on a budget and knowing where I wanted my profit margins it was proving to be quite difficult. The Leafy Green Machine I was purchasing also required a certain power supply, access to water and it has to be leveled. If the land did not have these pre-requisites I would have to pay to have a sub-meter installed, the piping for water, and a contractor to have the unit leveled.

I ended up using a service called Young Agrarians which is a farmer educational resource network for new and young ecological, organic, and regenerative farmers in Canada. They had a local representative that assisted me with their land matching program and helped guide me through making a lease agreement. I ended up finding a landowner by door knocking who would allow me to put my Freight Farm on his land for a reasonable price and had the Young Agrarian Organization help build the lease agreement.

Step 8: Incorporation and Accounting

Due to my limited expertise and from the wisdom of other mentors I thought it would be best to get the advice from an accountant and lawyer to help me best set up my business. I know from other experiences that the CRA is not the most forgiving and can cause major headaches if you do not submit the proper paperwork. I consulted my local accountant where he advised me on the pros and cons of doing a sole proprietorship or incorporating and helped draft me a letter to my lawyer. I chose to incorporate and then sent the letter to my lawyer who set up the business to best suit my companies needs. A few weeks later KLC Greens was approved and incorporated.

Step 9: Website and Logos

While I was trying to find suitable land and was waiting for my business to be incorporated I decided to design my company logo and build a website. I utilized Fiverr as a platform to build my logo as it cost 60 CAD and was created within 48 hours. These were some of the designs created within 48 hours.

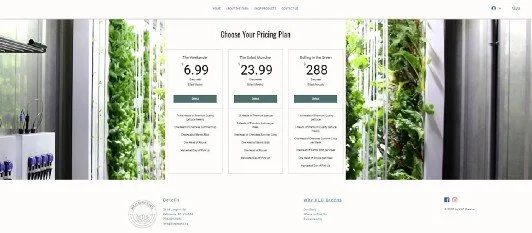

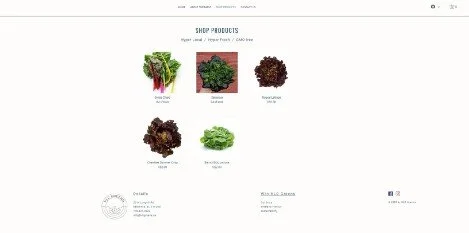

To build my website I decided to go through Wix. I used Wix because it was the most reasonably priced 25 USD and it had the best functionality for what I needed. I was able to create this website.

Step 10: Apply for a City Business License

Applying for a city license was an easy process as there was an online portal where I had to describe my business and what I was planning on selling. The estimated time to obtain a response was approximately 48 hours. I contacted my local city a few months prior to ask if there would be any concerns with having a Freight Farm within the city limits. So I expected my business license to be approved without any obstacles.

Step 11: Customs Broker/Shipping/Crane

While completing the last few steps I had to find a customs broker that would deal with the transaction so that the Freight Farm would come across the border without any difficulty. I also contacted numerous shipping companies with the IGrow Group to find the best deal. Once this was secured I could then schedule the crane companies in the seller's city and my home town. Now that everything was set, my Freight Farm was scheduled to come in three weeks' time.

Step 12: Bureaucracy

My assumption that obtaining a city business license was going to be easy proved to be wrong due to my city’s bylaws and bureaucracy. My application was forwarded to the agriculture department, the city planner, and the building inspector where I was met with the following response. I had numerous conversations about if there was any variance that could happen and how someone at the city three months ago told me they did not see anything wrong with my Freight Farming idea.

Hi Connor,

I was forwarded your email to help answer. The Planning Department and ALC both allow hydroponics to be grown on site (A1/ALR), however, the sea-can is not permitted. We only allow sea-cans/shipping containers on a permitted basis if they meet BC Building Code, which will require an engineer or an architect to make the sea-can structural sound. Sea-can’s are not permitted structures and won’t be given a Building Permit unless they are altered to meet the BC Building Code.

Please let me know if you have any other questions, I’m happy to help.

This was my response to the email above

To whom it may convern,

I talked with an associate at the city of Canada about three months ago about my business plan and any concerns I should foresee in the future, this associate saw no problems with my business and freight farm being in Canada. When I went to apply for a business license a week ago I ran into a few hurdles with the City about the freight farm meeting the BC Building Code and certain bylaws and obtaining a building permit. My understanding was that this container would be deemed a temporary unit on ALR land and should not need a building permit.I have reached an agreement with the business license team at the City and planners that this will be deemed a temporary structure for 6 months (as it can be moved readily at any time).

My container will be delivered in the next two weeks and I did not foresee these hurdles and I am looking for guidance on what to do next. I am a young entrepreneur and have taken a loan to start this business and would love to reach an agreement with the City and make the necessary legal changes to make my business work. I really appreciate how supportive the City has been and the amazing staff I have dealt with.

I have attached a pdf describing the leafy green machine, as well as the bylaw pdf on steel containers.

Here was the city’s reply;

Hi Connor,

I see from the web site link that you provided that this product comes from a USA based manufacturer. Do you have any support documentation from the supplier/manufacturer that references a Canadian standard for the electrical system, water system and building standard(s) that these are built to? We will require this information as part of a Building Permit & Plumbing Permit application along with a site plan showing where this container will be installed on the property

The bulletin that you have copied and referenced as allowable under exception, clearly identifies the exception for the use of the container as storage and not as an occupied/semi occupied building for the production of plants with a dedicated water system and electrical system. The British Columbia Building Code (2018 edition) is the Provincial standard that needs to be meet once the structure is being used as a building, which is what you are proposing. The A277 standard in BCBC 2018 is for factory built units, similar to modular homes that are factory inspected for compliance during construction and certified as compliant. The storage container can be stored on the site if approved by City of planning staff for 6 months, but would not be allowed connection to city water or electrical without meeting the minimum standard set by BC BC 2018. I would suggest that you reach out to the modular factory representatives to see if they can have a factory inspector come to do an on-site evaluation of the container unit to certify it or help provide information to cross reference Canadian to the USA based standards, so that you can apply for a building permit. https://www.kelowna.ca/homes-building/agricultural-land/dwellings is the link to the requirements for Building Permit application. A plumber will be required to apply for a plumbing permit if/when the building permit is issued and a proper back flow preventor will be required to protect the city water source.

This process may seem overwhelming but is no different than importing a USA built car into the Canadian market. The car would need to meet the standards set in Canada for the car to be registered and used in Canada. If the USA company has built these containers to meet or exceed Canadian standards and can prove this with valid documentation, the application process should be straight forward. An application for building permit can be made at 2nd floor city hall and the permit would be for an accessory building on farm land.

This response led me on another rabbit trail of trying to figure out if the Freight Farm I was purchasing would meet any of the building standards in Canada and so forth. At this point in time, my container was two weeks away, I had already purchased all my supplies for the Freight Farm and was going to sign my lease agreement. Freight Farm’s provided me with the following information below through an email and was able to confirm their shipping containers were ISO certified.

All LGMs are upcycled reefer containers. What this means is that they were previously used to ship produce to and from other countries. Once the refrigeration unit no longer worked, they were decommissioned. We would remove that unit, and retrofit our equipment. I bring this up, because the container itself will likely have some dents and marks from its usage as a freight container. This does not impact the structural integrity of the container at all. We have frequently had these container re-certified to be seaworthy, and safe for use from a structural standpoint. Additionally, the company that would have manufactured the farm has a number of certifications (CE, UL, etc.) that would apply to the actual assembly.

With this information, I called a few inspection agencies about what it would cost to bring the Freight Farm up to the BC Building Code or CSA standards where I got numerous replies saying it would cost thousands of dollars and be a very time-consuming process. On top of this, I would then have to be certified by the local building inspector and make sure the Freight Farm was conforming to any local bylaws.

Where it all went wrong