Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

[INTERVIEW] For Indoor Farming, Why Are Cargo Containers More Optimal Than Warehouses?

Indoor farming projects have been touted for their environmental benefits, but a lack of scalability and profitability have caused smart farm startups to fail all over the world. However, Seoul-based automatic indoor farming startup n.thing is betting on a modular approach for success. The company found that shipping containers are appealing as scalable indoor vertical farming units, especially in countries that are short of fertile land.

The key to its flagship Planty Cube farming facility is a cluster of multiple 12-meter cargo containers, Kim Hye-yeon, CEO and co-founder of n.thing, said in an interview with The Investor.

August 23, 2019

Indoor farming projects have been touted for their environmental benefits, but a lack of scalability and profitability have caused smart farm startups to fail all over the world.

However, Seoul-based automatic indoor farming startup n.thing is betting on a modular approach for success. The company found that shipping containers are appealing as scalable indoor vertical farming units, especially in countries that are short of fertile land.

The key to its flagship Planty Cube farming facility is a cluster of multiple 12-meter cargo containers, Kim Hye-yeon, CEO and co-founder of n.thing, said in an interview with The Investor.

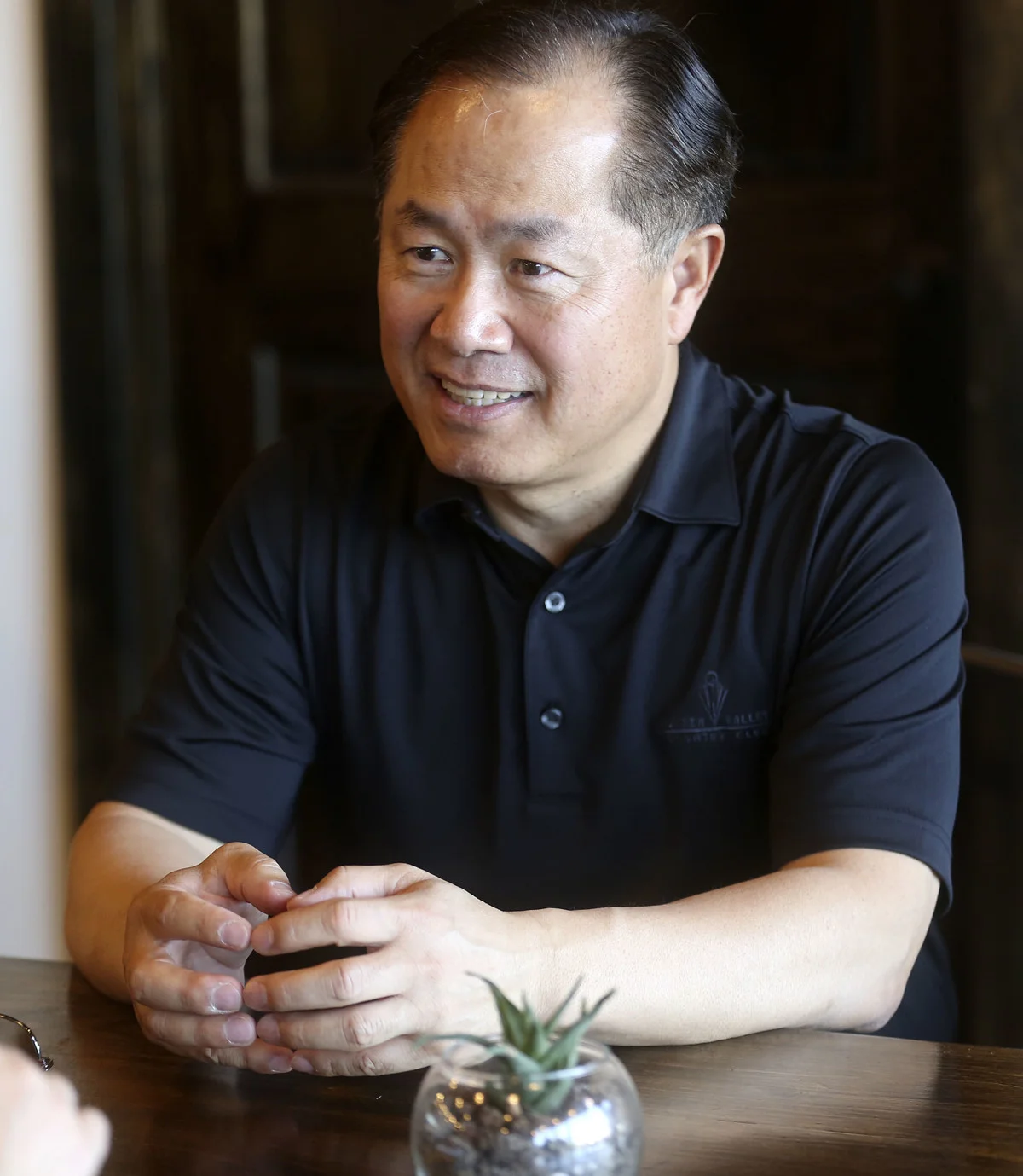

n.thing CEO and co-founder Kim Hye-yeon

Son Ji-hyoung / The Investor

“A stand-alone, single-unit shipping container is not suitable for farmers to do business,” the 34-year-old said. “The scheme to allow multiple shipping containers to be connected appealed to clients when they wanted to see how much space to use for indoor farming before their decision to buy.”

Farm owners may customize production volume and optimize green-growing environments simply by adding or removing cargo containers, making it easier to reflect the needs of farm owners with high flexibility.

Moreover, shipping containers are easy to find anywhere in the world, and they conform to international standards in size and quality, allowing the quality of produce to be consistent regardless of location.

“Such features make it much easier for us to export our indoor farming solution,” Kim said.

The startup’s effort may present a challenge to giant players, such as AeroFarms and Plenty. Their products -- indoor farms the size of a warehouse -- have limitations in exporting to foreign countries, Kim argued.

“Warehouses have higher ceilings, so there are differences in temperatures of warehouse indoor farms between higher places and lower ones. It can cause inefficiency in human effort for harvesting,” he said. “Also, a pest attack is likely to affect the whole of a warehouse farming area.”

A promotional image of modular indoor farm made up of cargo containers.

n.thing

In contrast, each Planty Cube unit is broken into 3-meter-high modules. Plants are sent to each module by stages of growth. Each module is assigned a role: loss control, seeding, sprouting, harvesting and pretreatment. The facility can grow leafy plants such as lettuce, as well as microgreens like herbs and sprouts. Each unit produces 300 kilograms of lettuce every four weeks at a default setting, except for the first seven weeks after the installation.

N.thing is inching closer to becoming the first indoor farming startup in Korea to win foreign customers. In Abu Dhabi, the United Arab Emirates, n.thing has embarked on a proof of concept with undisclosed partners in Korea and the UAE. It is considering expanding the smart horticulture business to other cities such as Dubai and Al Ain, as well as nations such as Singapore and Hong Kong.

“If we came up with warehouse-style indoor farming facilities, it wouldn’t have been attractive to clients in the Middle East,” he said.

Kim founded n.thing in January 2014. He was previously involved in a joint venture for an indoor agricultural facility in Uzbekistan. He studied electrical, electronic and communications engineering technology at Hanyang University.

The most crucial aspect to surviving in the automatic farming industry is a company’s ability to integrate diverse technologies into a solution -- from hardware like facilities and light-emitting diodes to software like internet-of-things sensors and farmer database.

“Technology companies with integrated farming solutions do not come overnight,” said Kim.

N.thing raised a combined 2.6 billion won ($2.1 million) in series A funding in December last year from investors including Naver-affiliated early-stage venture capital firm SpringCamp.

By Son Ji-hyoung (consnow@heraldcorp.com)

Bowery Adds Associates to Marketing and Sales Operations

Bowery, the modern farming company, has made two key executive hires to oversee the company’s marketing and sales operations. Katie Seawell (formerly of Starbucks) and Carmela Cugini (formerly of Walmart) have joined Bowery as the company’s Chief Marketing Officer and EVP of Sales, respectively

Bowery, the modern farming company, has made two key executive hires to oversee the company’s marketing and sales operations. Katie Seawell (formerly of Starbucks) and Carmela Cugini (formerly of Walmart) have joined Bowery as the company’s Chief Marketing Officer and EVP of Sales, respectively.

The hires are in support of broadening consumer awareness for the brand and increasing retail distribution.

Katie Seawell spent more than a decade at Starbucks Coffee Company, where she held a variety of leadership roles within the marketing and product organizations including driving brand campaigns, developing go-to-market strategies & integrated marketing campaigns and product innovation. Most recently, Katie was SVP of Siren Retail Operations, leading the launches of the Starbucks Reserve Global Roasteries including Starbucks market entry into Italy.

In her new role as Chief Marketing Officer, Katie will lead the company’s marketing team, spearheading initiatives to build Bowery’s brand and consumer reach in existing and new markets. Katie will also partner with the agriculture science team to lead Bowery’s innovation strategy, providing insights on consumer produce trends to make sure the company is fulfilling the wants and needs of its consumers.

Carmela Cugini joins Bowery with experience across e-commerce retail, consumer packaged goods, financial planning and sales with organizations including Walmart, Jet.com, PepsiCo and Merrill Lynch. Over the last three years, Carmela was Vice President and General Manager of Walmart’s US e-commerce team, leading online grocery and focusing on accelerating growth strategies across Walmart’s e-commerce and Jet.com.

Prior, Carmela spent 13+ years at PepsiCo and four years at Merrill Lynch, holding key leadership positions across various functions including sales management, sales operations, key account sales, business development, revenue management strategy, marketing and brand development. As EVP of Sales at Bowery, Carmela will take the lead on growing its network of retail partners and distribution channels as Bowery expands into new markets, while educating grocers on the benefits of indoor-grown, pesticide-free produce.

Bowery is the modern farming company growing food for a better future by revolutionizing agriculture. By combining the benefits of the best local farms with advances made possible by technology, Bowery’s indoor farms create the ideal conditions to grow the purest produce imaginable. BoweryOS, the company’s proprietary software system, uses vision systems, automation technology, and machine learning to monitor plants and all the variables that drive their growth 24/7.

Bowery controls the entire process from seed to store, and Bowery farms use zero pesticides, 95% less water, and are 100+ times more productive on the same footprint of land than traditional agriculture. Bowery produce is currently available at select Whole Foods and Stop & Shop stores in the Tri-state area; Brooklyn Fare, Westside Market and Foragers Market in NYC; and online through Peapod, AmazonFresh and Jet.com. Additionally, Bowery is featured at sweetgreen, and on the menus of Tom Colicchio’s New York restaurants Craft and Temple Court.

In December 2018, Bowery announced a Series B fundaise of $95 million led by GV (formerly Google Ventures), bringing Bowery’s total funding to $122.5 million. Notable investors in this round include Temasek (the global investment company backing companies leading change for the future of agriculture), Dara Khosrowshahi (CEO of Uber), Almanac (the fund of David Barber, co-founder of Blue Hill), Jeff Wilke (CEO of Amazon Worldwide Consumer), Henry Kravis (Co-founder of Kohlberg Kravis Roberts & Co.), First Round Capital, GGV Capital and General Catalyst.

Atlanta Suburb Working With Organizations, Government To Build Up Urban Agriculture

Atlanta nonprofit Food Well Alliance is a collaborative network of local food leaders heading up a new program it believes will be a game-changer for urban agriculture in cities across metro Atlanta

City of East Point Mayor Deana Holiday Ingraham signs the City Agriculture Plan MOU with Allison Duncan, Atlanta Regional Commission Principal Planner (left) and Food Well Alliance’s Kim Karris, Executive Director; Will Sellers, Deputy Director and Sarah Benedict, Operations Coordinator.

Photo © Caleb Jones

The City of East Point has been selected to pilot a new City Agriculture Plan in partnership with the Atlanta Regional Commission

August 28, 2019

Posted by Patrick Williams

Atlanta, GA — Atlanta nonprofit Food Well Alliance is a collaborative network of local food leaders heading up a new program it believes will be a game-changer for urban agriculture in cities across metro Atlanta. According to a press release, the City Agriculture Plan will do exactly what its name says: bring growers, community leaders, and city officials together — guided by the planning expertise of the Atlanta Regional Commission (ARC) — to develop city-wide plans that prioritize urban agriculture. The end goal? Thriving community gardens and urban farms providing greater access to locally grown food across the metro Atlanta region, which translates to healthier people, environments, and communities.

After a thorough exploration process with seven metro cities earlier this year, Food Well Alliance has announced the City of East Point has been selected to pilot the new City Agriculture Plan. The plan will begin with a community engagement and asset-mapping phase led by Food Well Alliance, followed by a six-month planning process undertaken with support from ARC. Once the plan is developed, Food Well Alliance will guide the implementation of the plan and provide a minimum of $75,000 in funding to help the community bring it to life.

“We are thrilled the City of East Point will be joining us in this exciting new endeavor,” said Food Well Alliance Executive Director Kim Karris. “We believe that East Point is uniquely poised to take bold steps and become a national model for urban agriculture. The work begins today, and it couldn’t come at a more crucial time. Metro Atlanta is one of the fastest growing regions in the country, and our cities are rapidly becoming more developed. This threatens the long-term viability of community gardens and farms. The City Agriculture Plan paves a way for city officials to work directly with growers and community leaders to determine the policies, ordinances, and programs that will move the needle most effectively.”

As the City Agriculture Planning process gets underway in East Point, six other metro Atlanta cities that rallied to pilot the program will receive funding support to catalyze their own urban agriculture initiatives: Alpharetta, Clarkston, Hapeville, Lawrenceville, Lovejoy, and Pine Lake. “The level of enthusiasm demonstrated in all seven cities shows us that we are onto something - that people want community spaces to reconnect to where their food comes from - so we are going to keep building on the momentum,” Karris said.

Nearly 500 people attended Community Food Forums held in the seven cities this February and March to learn more about City Agriculture Planning and share their ideas. Over time, Food Well Alliance aims to help develop City Agriculture Plans in all 54 cities in its five-county region serving Clayton, Cobb, DeKalb, Fulton, and Gwinnett counties.

Funding for the City Agriculture Plan pilot has been made possible by The Zeist Foundation and Food Well Alliance founding benefactor, the James M. Cox Foundation.

“We are truly humbled and honored by being selected to create and implement the first City Agriculture Plan in the region,” said City of East Point Mayor Deana Holiday Ingraham. “This amazing partnership with Food Well Alliance and the Atlanta Regional Commission will be impactful and transform our City. The intense focus on community engagement and leadership throughout our City Agriculture Planning process will help ensure sustainability of the projects implemented to systemically address our food access challenges.”

“The City of East Point is extremely excited about its partnership with Food Well Alliance,” said Maceo Rogers, CEcD, director, Department of Economic Development for the City of East Point.

“It marks the beginning of a new collaboration between the City, residents, businesses and metro area organizations all uniting together to take a holistic approach to transforming the overall health of the community through access to local food production, community gardens, and farms.”

“Local agriculture is a key part of developing healthy communities,” said Sam Shenbaga, manager of ARC’s Community Development Group. “ARC is proud to support community agriculture and put our resources behind initiatives that improve our region starting at the local level."

Australia: This Car Park Turned Urban Farm Has Grown 300 kg of Produce For People In Need

Forget the assumption that cities have a lack of space available to grow fresh produce. This experimental urban farm proves that it's possible to grow masses of vegetables in a space as small as a car park

Produce grown in the urban farm in Port Melbourne. (William Hamilton-Coates)

28 August 2019

Forget the assumption that cities have a lack of space available to grow fresh produce. This experimental urban farm proves that it's possible to grow masses of vegetables in a space as small as a car park.

By Yasmin Noone

An urban farm project in Melbourne, powered by coffee compost and food waste that would otherwise go to the landfill, has successfully reached its target and grown around 300 kilograms of vegetables and herbs for people in need.

The farm, spread across two empty car spaces in Port Melbourne industrial parking lot, was originally intended to be a 12-month experimental project run by Cirrus Fine Coffee, Biofilta and Australian Ecosystems.

But having already generated 360 kilograms of produce in under eight months and donated more than 90 per cent of food grown to OzHarvest, the farm will now remain functioning on-site indefinitely.

"So an urban farm like this aims to tackle the existence of food deserts in cities like Melbourne, and improve the nutrition of people in need.”

“In our cities, we have food deserts – areas where there are high concentrations of fast food outlets,” says Brendan Condon, director of the three sustainability companies involved in the collaboration.

“But many people can’t get access to nutrient-dense, high-quality food. So an urban farm like this aims to tackle the existence of food deserts in cities like Melbourne, and improve the nutrition of people in need.”

OzHarvest collects the produce grown at the urban farm in Port Melbourne. (Image: William Hamilton-Coates)

The small farm will now be used as a test case for a much bigger scale rooftop farm, Melbourne Skyfarm, to be built on a larger parking lot in the heart of the city in 2020.

“We tend to think that cities are congested places with no space, but in Melbourne, we have huge amounts of spare, under-utilised space to be growing food,” explains Condon.

“On top of that, we have huge streams of organic waste streams that come out of our cities, as well as massive amounts of water running off our rooftops. We could be using the water and organic waste and putting it back into urban farming.

“This small project proves that cities can be really food abundant and we can grow huge amounts of food in small spaces.”

How coffee compost and food waste is charging this urban farm

The farm's recipe for success is multifactorial. Firstly, it uses water-efficient wicking beds. But the real secret seems to lie in the soil, featuring composted coffee grounds and coffee chaff from the company’s roaster, as well as composted organic waste from South Melbourne Market.

Composted coffee grounds contain a large amount of minerals such as potassium, magnesium and phosphorus, calcium and iron, making them a good additive into compost. They are also a valuable source of nitrogen.

The organic waste from the markets includes fish residues. “That’s fish guts, heads, bones and innards,” he says. “Fish residues turbocharges your garden, as it’s high in nitrogen.”

Off-cuts from produce stalls at South Melbourne Market also make it into the farm’s compost heap.

“Fish residues turbocharges your garden, as it’s high in nitrogen.”

South Melbourne Market stall-holder, Alan Li from Fruits on Coventry, tells SBS he contributes masses fruit and vegetable waste to the farm.

“We sell around 45-50 tonnes of fresh food a week,” says Li. “So we fill around three green bins a day of green waste, plus two extra bins of green waste from the oranges we juice for our customers. In total, that’s about 5 big bins of green waste a day. That’s a lot of green waste that we produce, which doesn’t end up in landfill.”

Li explains leaves, off-cuts and leftover produce from the stall goes into green waste bins, before being hot composted and then donated to the urban farm for fertiliser.

“We are using our green waste to create a benefit for the community as most of the food grown at the urban farm goes towards feeding the homeless and people in need. I’m really happy with the outcome.”

Volunteers work on the urban farm, spread across two car spaces in the Cirrus Fine Coffee parking lot in Melbourne. (Image: William Hamilton-Coates)

Since the project started in January this year, the double car-park garden has grown heritage varieties of tomatoes, corn, zucchini, pumpkin, spring onion, beetroot, rainbow chard, spinach, silverbeet, flowers to attract beneficial insects and also a range of herbs like chives, basil, oregano and coriander.

Although winter has been slow, Condon believes that spring will reap a plentiful harvest.

“We can’t grow all of the diverse food plants that comprise the entire modern diet,” says Condon.

“But by volume, weight and value, we can punch a big hole in city food demands within city limits by using readily available organics that we currently treat as waste.”

How D.C.'s Oldest Hardware Store Ended Up Housing Two Cutting-Edge Urban Farms

You can now buy a bucket of paint and a carton of beet greens at D.C.'s oldest hardware store. W. S. Jenks & Son, which opened in 1866, is home to not one but two urban farms. Urban agriculture is gaining so much traction locally that the government is working to establish a specialized department to oversee key land use programs under the Department of Energy and the Environment

September 4, 2019

You can now buy a bucket of paint and a carton of beet greens at D.C.'s oldest hardware store. W. S. Jenks & Son, which opened in 1866, is home to not one but two urban farms. Urban agriculture is gaining so much traction locally that the government is working to establish a specialized department to oversee key land use programs under the Department of Energy and the Environment.

In the meantime, urban farm operators are getting creative looking for underutilized spaces to grow. For Cultivate The City and Little Wild Things, that means taking up residence inside Jenks at 910 Bladensburg Road NE in Trinidad. The former is on the roof. The latter repurposed a storage space that had previously been used as a parking garage.

Jenk's President Jerry Siegel says leasing space to both outfits is part of a strategy to get new and increased foot traffic into the shop, especially in today's retail climate where physical stores are Amazon's punching bags.

"A store like us, or any retail store, provides the opportunity for someone to come in to pick up merchandise and take it home and be happy with it," Jenks says. "I think there’s still a need for retail stores." It helps that Jenks does a good bit of business with the federal government, according to Siegel. "We’re trying to monetize using a garage now as a farm for Mary," he adds, naming Little Wild Things founder Mary Ackley. "She's been an incredible addition to what we do."

Finding a permanent home to grow her microgreens business has been a near all-consuming pursuit for Ackley over the past three years. Little Wild Things has bounced around growing flavor- and nutrient-packed baby greens and shoots everywhere from The Pub & The People's basement to a pair of vacant wholesaler buildings that hug Union Market. One after the next asked Little Wild Things to move out when it came time to develop the spaces. At one point she thought her greens would land in Ivy City, but Ackley ended up walking away from the deal.

Little Wild Things founder Mary Ackley

"Thank god I found this place," she says while showing City Paper the new Little Wild Things headquarters. She moved in early this summer. "We systematically went through every property available in the entire beltway and there were only five properties that met our requirements."

All they needed was between 3,000 and 5,000 square feet and the ability to heat and cool the space. Throughout this process, Little Wild Things didn't let business slip save for one incident where one of the Union Market-area spaces got too warm, preventing plants from producing. It meant they couldn't fulfill orders at two of their biggest clients: Chaia and Jaleo.

Little Wild Things sells an array of itty bitty greens such as nasturtium, beet, fennel, broccoli, cilantro, endive, mustard greens, amaranth, wheatgrass, and celery to a number of D.C. area restaurants. They include Beefsteak, Big Bear Cafe, Homestead, Espita, ANXO, Iron Gate, The Occidental, Coconut Club, RASA, and Jaco Juice & Taco Bar. A new partnership with Coastal Sunbelt Produce will allow Little Wild Things to expand its reach.

"Smaller restaurants are the bread and butter for us," Ackley says. "We've had some high profile, really cool restaurants but what they do is buy a tiny bit and say they're working with us. There are a lot of other restaurants that put their money where their mouth is, like DC Harvest."

Individuals can also purchase microgreens and edible flowers online for same-day delivery or for pick-up at the farm. They sell cocktail kits, for example, which party-goers can use to decorate their drinks. The flowers are grown in a different location—Little Wild Things outdoor farm at Carmelite Friars Monastery in Edgewood.

Little Wild Things new farm inside W.S. Jenks & Son

Ackley hopes to continue to diversify her business using the new space inside Jenks, which has its own separate entrance at 906 Bladensburg Road NE. Look for everything from happy hours, classes, and movie screenings to a retail shop where you can buy microgreens or build-your-own bouquets.

Cultivate The City founder Niraj Ray was delighted to have another green-thumb business join him at Jenks. In fact, he connected Ackley with the hardware store's owners. "Originally when I started the garden center, my vision was to have multiple urban farms there," he says. That's why he called his farm at Jenks "H Street Farms" instead of "H Street Farm."

Ray founded Cultivate The City in 2015. In addition to operating H Street Farms at Jenks, Ray manages the rooftop farm at Nationals Park, the campus farm at Gallaudet University, garden programming at Idea Public Charter School, and the garden at Miner Elementary School. He involves other schools in urban agriculture through field trips and on-site classes.

The Jenks partnership began when H Street Main Street sought Ray's help beautifying Starburst Plaza that sits where H Street NE curves into Benning Road NE. The director of the neighborhood nonprofit group tipped Ray off that Jenks was looking to make use of its rooftop.

"At first they wanted to do a restaurant, which didn't really make sense to me in terms of economic opportunity," Ray says. He estimated the build out would cost at least a half a million dollars. "On top of that, I didn't think it was as supplemental to their business as what we could offer." There's a Lowe's and Home Depot not too far away and both sell plants. "I made a pitch to them: You're leaving a lot on the table by not selling plants. We could function as your garden center. It was a match made in heaven."

In addition to selling unique plants to Jenks customers, like strawberries with extra long growing seasons, Cultivate The City's H Street Farms brings foot traffic to the hardware store through various events and classes. On Sept. 20, Ray will teach attendees how to care for a bonsai chili pepper tree. "I've been practicing for a year or two," he says. "Imagine having a Scotch bonnet pepper tree that always has a few peppers." His regularly recurring class on making hot sauce is also popular.

Little Wild Things is currently open to the public weekdays from 9 a.m. to 3 p.m. and Cultivate The City's H Street Farms is open Wednesdays and Fridays from 3 to 7 p.m.; Saturdays from 9 a.m. to 5 p.m.; and Sundays from 10:30 a.m. to 4:30 p.m.

ALL PHOTOS LAURA HAYES

Lead Photo: Little Wild Things just joined Cultivate The City inside W.S. Jenks & Son in Trinidad.

This Brilliant Hydroponic System Puts A Whole Garden On Your Countertop

Growing your own food is one of life’s great pleasures—plus it’s good for you and for the environment. But in increasingly tight, urban homes, we don’t all have room for gardens

08.19.19

It’s Not Just A Garden—It’s A Work of Art

[Photos: courtesy Bace]

Growing your own food is one of life’s great pleasures—plus it’s good for you and for the environment. But in increasingly tight, urban homes, we don’t all have room for gardens. And hydroponic systems, as appealing as they may be, often appear to be a whole lot of hardware for only a bit of actual green. Some fresh arugula would be nice for dinner, but who wants giant plastic box taking up half their kitchen to get a few leaves?

[Photo: courtesy Bace]

The Rotofarm, by an Australian company called Bace (which appears to have produced skincare products in a past life), is a space-friendly hydroponic system, and it doubles as a beautiful sculpture in your home. With a circular design, which rotates plants like a Ferris wheel through the day, the Rotofarm is able to fit nearly five feet of growing area inside a countertop footprint of just 11 inches. Water is dispersed through the nutrient and water reservoir in the stainless steel base, and a bright LED grow light lives in the middle like a tiny sun. Then to harvest, you can tilt the farm 180-degrees and pull off its clear cover. You take what you want (kale, mint, lettuce, spinach, or, yes, marijuana), and close it back up.

Of course, you might be wondering, will it work? Can you grow plants upside down? In fact, you can. NASA has discovered that root systems understand how to grow just fine in zero gravity. Meanwhile, existing rotary systems like the Omega Garden contend that moments of flipped gravity can actually help plants grow and flower, but you wouldn’t want the Omega Garden’s giant drums in your apartment. “The rotary design has been around in agriculture for a while, but these are things that take up a whole room with giant troughs of water underneath,” says Bace’s founder Toby Farmer (yes, his name is “farmer”). “Rotofarm is the first concept that really belongs inside the home.”

[Photo: courtesy Bace]

The Rotofarm is supposed to debut on Kickstarter next month. Despite connecting with Farmer on email, we’re left with all sorts of questions about its true feasibility. Will you need to buy the special, potentially expensive fertilizer packets for the machine seen in the teaser video? What’s the monthly power usage like? How will some teased automation features—from misting to overgrowth sensors—actually work? And of course, what will the whole thing cost?

As a prototype, the Rotofarm is intriguing. As a product, it has all sorts of everyday execution details that need to be just right for the system to be a productive joy rather than a big, annoying, green lamp. That said, so far, so good. Rotofarm offers a convincing thesis on the future of urban gardening. Now we’ll see if the Bace product team can deliver it.

ABOUT THE AUTHOR

Mark Wilson is a senior writer at Fast Company who has written about design, technology, and culture for almost 15 years. His work has appeared at Gizmodo, Kotaku, PopMech, PopSci, Esquire, American Photo and Lucky Peach

What Is Vertical Farming?

Vertical Farming or vertical agriculture facilitates viable agricultural production inside buildings, in the metropolitan areas of our cities. Vertical Farming is therefore a form of urban agriculture.

Vertical Farming or vertical agriculture facilitates viable agricultural production inside buildings, in the metropolitan areas of our cities. Vertical Farming is therefore a form of urban agriculture.

Newest findings are used to facilitate sustainable agriculture and the mass production of vegetable products inside of buildings. Because we are able to stack plantings, we are building vertically. Every square meter of floor space of vertical farming produces approximately the same amount of vegetable crops as 50 square meters of conventionally worked farm land. A vertical farm is able to use 95% less water, because it is recycled. Because our production is indoors, we need virtually no herbicides and pesticides. Vertical Farming makes the year-round cultivation of food possible and adaptable to a variety of crops. The primary focus of all functions in and around vertical farming is on optimal plant growth while maximizing the use of natural resources, such as the sunlight. This is why a vertical farm production is no longer dependent on using fossil resources.

Buildings are the central element of the city and thus the urban ecosystem. It is therefore especially important that each building is embedded into the social, architectural and economic city environment. We design vertical farms as multi-functional buildings today, creating a space of relaxation for the city dwellers, a work and meeting place, a market and dining area, as well as a place to grow food – right there where they live. Food production becomes a part of the urban everyday life again.

A VERTICAL FARM…

…drastically reduces agricultural land use.

…saves up to 95% water.

…makes cultivation possible, independent of weather conditions & season.

…delivers each harvest with continuous quality.

…brings maximum freshness into the city.

…saves on transport to the consumer.

…limits CO2 and puts less strain on the climate.

…brings agriculture back into urban everyday life.

GLOBAL CHALLENGES

The human race is growing

An omnivorous (eating everything) person requires an average of approximately 2300 m2 of cultivation area for his/her nutritional needs. Austria imports more than half of its consumed food stuffs from other countries. Above all, the Asian and African population is growing at an accelerated rate. One thing is going to be very important in the years to come: To ensure the food supply for rapidly growing world populations. How are we to provide for nine billion people in the year 2050?

Resources are getting scarce

The basic resources for plant cultivation are light, water and nutrients. A lack of precipitation often leads to sourcing the needed water from groundwater, lakes or rivers, resulting in the lowering of groundwater levels and the drying up of natural water resources. The increased demand for agricultural space has led to clearing rain forests by fire all over the world, which then leads to significantly higher production of CO2. Crude oil is still the central energy source for the food sector, fertilizer and transport and thus contributes significantly to climate change.

Supply security is threatened

Post-Fukushima Japan has already built 150 plant factories. Because last, but not least, we need to ask ourselves how we are going to produce healthy food in a heavily polluted world. Reinsurance and insurance companies providing guarantees in case of hail have complained about greater storm damages of hundreds of millions of euros, and that in Austria alone. Hail, storms and torrential rains can destroy crops in a matter of minutes. The real sufferers are the producing farmer and the consumers. So how can we secure our food production, regardless of ever increasing extreme weather events, and what is the best way to produce year around?

CULTIVATION AREAS FOR OUR FOOD

An omnivorous human needs approximately 2.300 m2 of land for his/her own food production.

OUR VISION

We secure the future of food

Vertical farms preserve our ecosystem in a variety of ways. Because the space is utilized vertically instead of on the ground level, only a fraction of the ground surface is needed compared to what is required for conventional farming. Innovative irrigation systems and lighting methods make food production possible year around – regardless of weather conditions. We are thinking along the lines of circulation systems for materials and resources: Wastewater is to be reused as irrigation water, plant residues are used for heat in the form of biogas. The protection of the building’s shell and new lighting methods make food production possible year around – regardless of weather conditions. This contributes to food security for cities in a significant way.

We are rethinking regional focus

For more than 11,000 years we have produced our food in the same places we consumed them. We want to restore this practice again. Biological, fresh and local products are produced by consumers directly in their cities. Furthermore, vertical farm products can be prioritized at the site, processed further, packaged, sold and consumed close by. Our relationship to this locally produced and consumed food is holistically regional again at last.

New occupational fields are created

A vertical farm is not only versatile in its use, but also creates new occupational groups and jobs in all of its core areas: In its cultivation, plant supply and technology, during harvest and processing, as well as in sales and catering or the restaurant business. Today’s practical applications already manage inclusive projects successfully. In addition, there is no limit to the imagination: Public spaces can be rethought and revived for relaxation and collaboration, social interaction takes on a new meaning, and local economic interdependence will be established.

VERTICAL FARMING AND FOOD SECURITY

A vertical farm operation increases the output per cultivated area and saves valuable resources like water and soil in closed energy cycles.

THE OPPORTUNITY

The food industry of tomorrow

A vertical farm can be built anywhere and at any time. First examples of successful vertical city farms are now available (Singapore, Sweden, the Netherlands, USA, Japan). These agricultural technologies will be redefining the food industry in the years to come. The vertical farm market is estimated to reach 5.8 billion USD by 2022, with an annual growth rate of 24.8% (2016-2022).

PLANNING THE FUTURE TODAY

In the coming years the food industry will dwarf all other industries. Vertical farming will be able to secure the food supply for the cities of tomorrow.

Our Solution

We specialize in the development of vertical farm operations with transparent facades to maximize utilization of the sunlight. Instead of black boxes, we rely on the power of readily available natural forces. There is another good reason for our building being transparent: We want to restore the trust in industrial food production. People are able to see for themselves how their food is grown, right in their city: Transparent, regional and with the highest of quality.

Your opportunity

The vertical farm institute meets these and other challenges head on with courage, drive and innovation. This is where you find our offers. Join us!

Become part of a movement that brings more freshness into the cities and reclaims urban spaces for food production. Meet up with us at our events, engage in discussions with us on Facebook or put in an application with us – you can become part of the future of food!

Resetting The Table: An Aquaponic Farm Rooted In Community

The sun is beating down on Oko Farms, and goldfish the size of sandals swim lazy circles through a tank of water shaded by a tarp-covered tent. Sunflowers sway in the wind, a light breeze rustles through planter beds, and bees hum as they move between clusters of bright little flowers

Elazar and the camera crew head to Bushwick, New York to meet the woman behind New York City's largest outdoor aquaponic farm

August 27, 2019

To View The Video, Please Click Here

[Photographs: Vicky Wasik. Video: Serious Eats Video.]

Editor's note: Resetting the Table is a monthly Serious Eats video series celebrating the diverse foodways that inform the way we eat in America. In each segment, Elazar Sontag cooks and talks with someone whose work in food, farming, or social justice is making a difference.

The sun is beating down on Oko Farms, and goldfish the size of sandals swim lazy circles through a tank of water shaded by a tarp-covered tent. Sunflowers sway in the wind, a light breeze rustles through planter beds, and bees hum as they move between clusters of bright little flowers. It’s not the kind of scene you expect to find in noisy, traffic-jammed Brooklyn, squeezed between a pizza shop and a banner promising "Fast & Professional!!" tax preparation services. But on this plot of land in Bushwick, Yemi Amu has transformed an abandoned concrete lot into New York City’s largest outdoor aquaponic farm.

Yemi utilizes the space on her farm to grow many of the vegetables she ate growing up in the coastal city of Lagos, Nigeria. Alongside onions and kale, she also grows gburé (water leaf), clove basil, several varieties of rice, sorghum, and other hard-to-find vegetables and herbs for Nigerian chef friends to incorporate into their cooking.

[Photograph: Vicky Wasik]

Aquaponic farming is a sustainable method of growing plants and raising fish simultaneously, perfect for areas like this one, where a fire hydrant is the most accessible source of water. In aquaponics, water from a large freshwater fish tank is filtered to remove solid waste, then it's pumped through pipes into plant beds, providing the plants with nutrient-dense fertilizer. The plants filter out any toxic waste from the water, so that it’s clean when it returns to the fish tank, and the cycle repeats. This method of farming uses just a fraction of the water that conventional methods use.

Other farmers turned the Bushwick lot down, since without a water source it wasn’t farmable land. But Yemi saw the empty lot’s potential for aquaponic farming, and got to work.

Oko Farms before and during the building process. [Photographs: Courtesy of Yemi Amu.]

The 2,500-square-foot farm she has created acts as a community space of sorts. Students regularly visit Oko Farms to learn about aquaponic farming, and Yemi welcomes anyone in the community to wander through and learn more about what she’s doing. When she's not tending to her own farm, Yemi helps build aquaponic farms throughout New York.

Early one morning, I headed to Oko with the Serious Eats camera crew to meet Yemi, learn about aquaponic farming and the incredible work she’s doing in her community, and to cook lunch on the beautiful farm.

This post may contain links to Amazon or other partners; your purchases via these links can benefit Serious Eats. Read more about our affiliate linking policy.

ELAZAR SONTAG ASSISTANT EDITOR

Elazar Sontag is a writer from Oakland, California, living in Brooklyn. He’s the author of Flavors of Oakland: A Cookbook in 20 Stories, a book about home cooks and their food cultures. He's written for the Washington Post, New York Magazine, Vice, and this excellent website. Find him on Instagram: e_zar

Central Illinois Fresh Hydroponic Greens Bring New Life To Geier Florist Shop

Something is flourishing inside the old Geier Florist building. Sam Hendricks and Brandon Neuzil are partners in a new business growing microgreens in an urban agriculture environment. Their business is called Central Illinois Fresh

By Brady Johnson / of the Journal Star

August 18, 2019

WEST PEORIA — Something is flourishing inside the old Geier Florist building.

Sam Hendricks and Brandon Neuzil are partners in a new business growing microgreens in an urban agriculture environment. Their business is called Central Illinois Fresh.

The 28-year-old Neuzil had been looking for space last year to try out his idea and had been in contact with Geier Florist. When that longtime West Peoria business at 2002 W. Heading Ave., shut down earlier this year, Neuzil bought out the first floor of the building.

In February, he and Hendricks got into contact and their business began to come to fruition in April. The duo have been selling microgreens and leafy greens since the beginning of June, including at the Riverfront Farmers Market in Peoria each Saturday — selling out their stock there during many weeks.

“We wanted to get involved in the food movement in Peoria,” Neuzil said.

It’s a business he’s completely new to, with no experience running a greenhouse or using commercial hydroponics, though Hendricks has farmers’ market experience.

“Hydroponics we do for all of our lettuce,” Neuzil said. “NFT system, which means Nutrient Film Technique, is our process. We get our equipment from a manufacturer in Ohio. We purchase from them and then set it up to fit our greenhouse layout.”

The system works as produce is placed into pipes where their roots interact with a small line of nutrient-mineral water. The process doesn’t need potting soil because all of the nutrients needed are mixed into the water system. Neuzil and Hendricks just have to replenish the tank of mineral water every week.

“Hydroponics is still relatively new to agricultural,” Neuzil said. “Currently we are producing 870 heads of lettuce. We have 870 holes to work with.”

The method allows for consistent production throughout the year.

“I think a way that will separate ourselves from other farmers is that come winter time urban agricultural will be able to produce year round,” Hendricks said. “There are a lot of limitations with the seasons and weather. We are trying to produce strong quality products year round.”

Microgreens do not require a lot of time to produce, with an average growth rate of two weeks compared to produce that can take 45 to 90 days, Neuzil said.

The result comes in trays filled with cabbage, radishes and red Russian kale.

“Microgreens can be produced in almost any building as long as it is climate controlled and you have good water. You can do it in your garage or below ground,” Neuzil said. “There is a hydroponics company that produces lettuce hundreds of feet underground in a mine shaft. As long as you have water and power and some air flow you can make your own microgreens.”

The produce has even started to appear on local restaurant plates.

They’re growing a great product,” says Dustin Allen, who operates Edge in Peoria Heights. His usual order is 10 to 12 pounds of leafy greens and several pounds of microgreens.

He and Hugh Higgins at Hearth up the street in the Heights are two restaurant owners using Central Illinois Fresh’s produce.

“For us and our business model, we have no national suppliers at all in our restaurant,” Allen said. “It takes us over 60 family farms to run this restaurant on a yearly basis. To me, they are just another part of that, part of our system.”

The prospect of a year-round supply has made Allen a very happy restaurant owner.

“What we are excited about is that they have the ability to provide yearly to us.,” Allen said. “That opens up a segment to our menu that in years past has been very small.”

Neuzil, meanwhile, hopes to educate youth in the area about sustainable farming like microgreens. He sees the idea of urban agriculture as an important one to the next generation.

“You don’t have to use much,” Neuzil said. “You just sprinkle some on your salads and flatbreads and you can also eat it plain on crackers. We have people who come to us and tell us about their microgreen experiments in cooking. We are wanting to get feedback from everyone.”

For now, both men run the business on the side, with Neuzil working for Cazenovia Salt and Hendricks at Kaufman Wellness Center. But they’d like to add in a storefront to allow for more business, and they’re laying plans for an open house and concert at their venue sometime next month.

US: Family of Entrepreneurs Looks To Pioneer Vertical Farming In Utah

A Utah family of Korean immigrants is hoping to tap into the vertical farming market, an endeavor where values in the United States are projected to reach $3 billion by 2024 according to recent market research

August 4, 2019

MURRAY — A Utah family of Korean immigrants is hoping to tap into the vertical farming market, an endeavor where values in the United States are projected to reach $3 billion by 2024 according to recent market research.

Since moving to Utah in 1987 to pursue a master's in bioengineering at the University of Utah, Chihan Kim and his family have headed up a string of local business ventures, from a gas station to glove manufacturing and a coffee shop.

Scott G Winterton, Deseret News

James Loomis, Green Team Farm director for Wasatch Community Gardens in Salt Lake City, shows off vertical growing tomato plants on Monday, July 22, 2019.

In February, Kim said he found a "good deal" on a warehouse near 150 East and 4500 South and purchased it. "Plan A was renting the building to somebody," he said, but "I looked into several different businesses" in case "I cannot find a tenant."

One of the options he looked at was indoor farming. Kim said, "When I started (researching) indoor farming business, I liked it, you know, so I changed (my) mind to do a business in the building instead (of leasing)."

According to Jack Wilbur, spokesman for the Utah Department of Agriculture and Food, there are currently three commercial vertical garden operations in Utah that supply to restaurants and farmers markets in the state.

Wasatch Community Gardens also runs a vertical farm operation, although not for commercial purposes. The community garden's Green Team initiative provides a farm-based job training program for women who are experiencing homelessness.

At the time Kim submitted his application, Murray had no land use code for a vertical farming operation.

"Mr. Kim came in and said, 'I want to start indoor farming,'" said Murray City Community Development manager Jared Hall. He said city representatives told Kim, "We don't actually have something specifically for that, we don't have anything specifically prohibiting it either."

Eugene Kim and his father, Chihan Kim, pose for a portrait at their coffee shop, The Bean Yard, in Sandy on Thursday, July 18, 2019. Chihan Kim initiated an ordinance to allow vertical farming in Murray, which the City Council passed.

Hall said the city was supportive of the initiative, noting "the planning commission was very positive about it from the get go."

He said the idea of zoning for indoor farming appealed to the commission and the council so much they took the initiative one step further. "We took Mr. Kim's application and broadened it basically to include other zones," he said.

He noted that the building Kim hopes to farm in is located in the city's commercial development zone. However, the commission felt other zones would also be appropriate for future projects.

The ordinance, recommended to the City Council by the planning commission, was passed by the council unanimously on June 18.

The measure amended text in both the city's standard land use code and municipal code to allow for indoor farming in the city's mixed use, manufacturing general, commercial development, transit-oriented development and business park zones.

"In an area like Murray, where things are built out, we don't have large agricultural areas anymore. It's nice to put food production close by," Hall said, noting that the commission and council "saw a lot of pluses and not a lot of detriments" to the ordinance.

It was precisely this type of flexibility and room to grow that Kim said inspired him upon arrival in the United States to move away from academics and into business investments.

"In Korea, I have to go to school, good engineering school, then I can get a good job, then I can live comfortably. That's why I studied," he said.

After obtaining an engineering degree in Korea, Kim said he came to Utah to earn a master's degree, followed by a Ph.D. in mechanical engineering from the University of Utah.

"I planned to go back to Korea and work as a professor, you know, that was my original goal," he said.

However, Kim said, when he began exploring the U.S. he saw it as a "large open land" and realized "study is not everything."

"There's so many other things to do in the United States of America," he said, recalling that while his fellow students and colleagues at the university seemed to enjoy academics, he said he studied only "to survive."

His first business operation was a gas station, which he said he expanded to include a car wash and a site for safety and emissions inspection. In the mean time, Kim said, he started two other businesses, one selling eyewear and another exporting medical equipment to South Korea.

"I still have a lot of inventory," he said, indicating his personal glasses on the table beside him and noting that the frame was his own design.

According to Kim, his most successful business thus far has been Advanced Gloves, a venture which he happened upon after a friend from Korea asked for his help marketing a new glove model he'd produced.

"I did not really mean to be in that business," he said, adding that he had meant to simply "find (a) buyer (in the U.S.) and connect him." However, after bringing samples to various buyers, he said he found the product to be quite successful.

"I don't know if you see a FedEx Express driver come to your office. If you see them, they wear our gloves," he explained.

As he spoke, Kim sat at a table in the Bean Yard, a coffee shop he owns and manages along with his wife, Haisoon Kim, and his son, Eugene Kim.

Kristin Murphy, Deseret News

Eugene Kim, co-owner of The Bean Yard, prepares a coffee at the Sandy shop on Thursday, July 18, 2019. Kim's father, Chihan Kim initiated an ordinance to allow vertical farming in Murray, which the City Council passed.

The coffee shop is located in Sandy, though Eugene Kim noted the family has plans to open another location in Salt Lake City this summer.

He said his father's latest business venture, indoor agriculture, was inspired by market research on the productivity of this type of agriculture.

"Growing outside is becoming more difficult, because seasons are changing, and people aren't able to predict the weather as well, as they had before," he said. "Hydroponic gardening in general is something that I think is good for people to start getting into now. And it's something that I think will ensure a more sustainable future."

Research for his venture in vertical farming has taken Chihan Kim as far as Korea and China to meet with suppliers for indoor agriculture equipment and research centers.

Eugene Kim noted that though his father had originally set his mind on lettuce, after some discussion and research the family had decided strawberries would be the best crop for their operation.

"The way that we see it is that lettuce, in general, does not make any money, and so (Chihan Kim) moved on to the next option of potentially doing strawberry farming", he said. Also, because strawberries tend to absorb a higher number of pesticides, he said, cultivating them indoors would be a good way of avoiding this.

Chihan Kim noted that his University of Utah studies will likely come in handy.

"Because I have an engineering background I can run this cultivation facility optimally," he said. His background and research will help him effectively test the efficiency of elements such as humidity levels, light and temperature.

To cover the start-up cost for the business, Kim plans to apply for federal agriculture loan programs, though he has also looked into and may apply for a state program that offers financing of up to $100,000 for high tunnel or indoor farming operations.

Wilbur said if Kim were to apply for and receive funding through the program, he'd be the first in the state to take advantage of it.

PHOTOS: Scott G Winterton, Deseret News

Eindhoven: ‘We Are Ahead In The Field of Urban Greening’.

Eindhoven is one of the three demonstration cities participating in the European climate research project that will be experimenting for five years with projects which make the city climate-adaptive using nature-based solution

Uitzicht over de binnenstad van Eindhoven

Posted by Lucette Mascini | Aug 24, 2019 | Tags: Brabant, demonstration cities, Eindhoven, EU, TU/e

Eindhoven is one of the three demonstration cities participating in the European climate research project that will be experimenting for five years with projects which make the city climate-adaptive using nature-based solutions. The aim is for other cities to be able to apply any successful results in their own municipalities. We asked Luuk Postmes, project leader from the municipality of Eindhoven, which of these projects are being implemented.

You are leading the project on behalf of the municipality of Eindhoven. What does your job involve precisely?

“As a civil servant working on urban water matters for the municipality of Eindhoven, I am both a project leader and an advisor. That covers the sewage system, the underground water and the surface water. As a result of the changing climate, we have to deal with drought, torrential rain and extreme heat stress. The question is: how do you deal with all of this? Greenery is a solution for many climate problems. Greenery can be used to cool the city. In turn, greenery is also dependent on water. Since this project is about climate adaptation, I have become the leader of this European project for the municipality of Eindhoven. The De Dommel WaterBoard and the province are also indirectly involved. But they are not a partners in the project. Eindhoven University of Technology is however.”

Project leader Luuk Postmes from the Eindhoven council

In what way is TU Eindhoven involved?

This is due to the participation of Lighthouse [a division of TU Eindhoven that specializes in sharing smart urban solutions, ed.], which is led by Rianne Valkenburg and Elke den Ouden. They are responsible for drawing up roadmaps for the process that should make the city more climate-proof. They also work together with the Following Cities as part of the EU project and are developing a vision for the future in this area.

Why is Eindhoven a demonstration city and other cities are called ‘Following Cities’?

“We [the three demonstration cities of Eindhoven, Tampere and Genoa, ed.] had been working for some time on making the city climate more adaptive, among other things by making it greener. The Following Cities of the EU project – Stavanger, Cannes, Prague, Castellon, Başakşehir – are a bit further along in this trajectory. They are keeping an eye on things with us.”

Why is Eindhoven participating in this experiment?

“The subject resonates very well with what we are doing in Eindhoven. If such a European project is of interest to us, we will apply for it and make a proposal. Then it remains to be seen whether it will be selected.

Which projects is Eindhoven currently carrying out?

“Some projects have already been concluded. We are still working on others. We have arranged green spaces in several streets because these were completely paved. This is how we tackled the Wagenstraat and the Bilderdijkstraat. By using less pavement, less water is channeled into the sewerage system. For instance, we are working on greening the Vestdijk. This involves looking at different types of vegetation. We are working on the design of a greener Clausplein, which is currently completely paved over. The Victoria Park is already located at the back of a former Philips building nicknamed the Witte Dame on Clausplein. The Gender river will come through there the back of there as well. The area will have a park-like layout where residents will be able to enjoy the peace and quiet and the greenery around them. We are also experimenting with greenery that can be mowed and which has a positive effect on biodiversity. Another method for increasing biodiversity is to mow the grass only once a year. This way you get tall grass that attracts insects and the subsoil is better able to absorb water. What you see is that if you mow less often, there will also be more and more different types of flowers and shrubs. You can see this happening on Parklaan, for example.”

But is that innovative?

“This is something that we, as a city, are pioneering. Other cities are following us. You can see in some foreign cities that they are often paved over an incredible amount. Everything is sealed with stones, concrete or asphalt. You can even see that when there is a tree on the pavement, the ground around it is completely covered in asphalt all the way up to the trunk. In Eindhoven we are looking for the best ways to make the city greener. What kind of plants should you choose? Should you choose plants that are better able to withstand drought? Or should we water plants when there is a prolonged drought? Are there any possible changes that can be made in their management that will help them cope with climate change and which will increase biodiversity? We try to answer these kinds of questions. We are also investigating how we could create more green space in places where there is limited space. One example is Eindhoven city center. It will be redeveloped in the next few years with more green space. We are trying in particular to encourage private-sector initiatives.”

What problems will these projects resolve?

“Initially, the disruption caused by heavy rain will be reduced. We will automatically be able to improve biodiversity by opting for a greener approach. That’ s a bonus for this project.”

How much money is the EU investing in it?

“The total budget is more than 10 million euros. Each of the three demonstration cities will receive approximately 1.7 million euros. The rest of the money will go to the other partners, including the Following Cities.”

The EU wants the results of the projects to be quantifiable. How are you going to measure them?

” It is still a struggle to figure it all out. But some results are fairly easy to measure. You are able to count how many species of bees and butterflies that have been added to a project site. Along with what the distance is between residents and green spaces and how many cool, green spaces have been added to the city. I have made a proposal to measure the heat stress sensitivity in the city using satellite images. In order to measure the effect on water management, we measure the soil infiltration capacity of areas with long grass. We compare the rates with those of areas where the grass is shorter. It turns out that the lawnmower compresses the subsoil. Consequently, water seeps into the ground less quickly if the grass is short, making it more difficult for it to soak into the soil.”

When will the project be finished?

“We have about three years for the implementation of the projects and two years for the monitoring. However, we won’t be able to achieve that for all of these projects. The main reason for this is that they conflict with the planning of other projects and processes. You can’t overhaul the entire city center all at once. The process may therefore take longer as a result.”

What are they doing in Tampere and Genua?

“In Tampere, Finland, they are focusing on two housing projects, one of which is on a former industrial estate. The most important focus point here is maintaining the water quality of the surrounding lakes. They have to take the shorter days and the lower temperatures in winter into account more. One experiment concerned the purification of water through the use of algae. The question was whether this would also work at those extremely low temperatures during winter. Which is what did transpire. The experiment was a success. In addition, they are also conducting experiments involving the construction of green roofs. In Genoa, Italy, they are converting an old barracks site into a park-like environment where you will be able to stay and enjoy leisure activities. In particular, they are looking at the use of greenery as a means of regulating water management.”

SUPPORT US!

Innovation Origins is an independent news platform, which has an unconventional revenue model. We are sponsored by companies that support our mission: spreading the story of innovation. Read more here.

On Innovation Origins you can always read articles for free. We want to keep it that way. Have you enjoyed this article so much that you want to contribute to independent journalism? Click here:

Share this article!

NEXTEDEN-ISS: Substantial vegetable harvest in Antarctica

ABOUT THE AUTHOR

Lucette Mascini

Looking For Urban Farming 'Silver Bullet' In China

After a successful first edition, the Urban Greenhouse Challenge is back.

After a successful first edition, the Urban Greenhouse Challenge is back. This time, student teams are developing an urban greenhouse in Dongguan, China. Fortunately, they're not left alone - partner companies, including main partners Rabobank and Country Garden Agriculture, are ready to help, and five top universities are involved: China Agricultural University, the University of São Paulo, Cornell, UC Davis, and of course Wageningen University & Research. We asked Marta Eggers, Project Officer WUR Student Challenges, to tell us a bit more about the upcoming challenge.

"Urban farming exists for a very long time already. Now there's a sort of revival of urban farming, and a lot of people are very excited about it. But we have a feeling that there's not a good model for how to do it. There's a lot of searching going on, but there's not a silver bullet solution yet."

The challenge is a way to come up with solutions that can inspire progress and boost innovation. "We want to make people enthusiastic about urban farming. We hope we can bring it to the next level", Marta says, referring to the challenge's slogan: 'Will you bring urban farming to the next level?'

Image: Spark Architects

Dongguan: Economic hub for China and the world

While the first Urban Greenhouse Challenge took place in the Netherlands, this edition is looking a bit further east. The choice for China seemed logical, given the relationship Wageningen University has with the country. "We have ongoing collaboration and very close links with China", Marta says, "and we also have a China office, so with this challenge, we're building on this collaboration."

The site itself is "one of the most fascinating areas in the world", she argues: the agropark of Dongguan is located in the Pearl River Delta Economic Zone. "It's like a special zone in China, a place where a lot of experiments take place. It's all very high tech and innovative. For instance, when paying, you don't use a credit card, but you pay with your face. It's an economic hub for China, but also for the world; it's a very fascinating place."

Part of that 'fascinating place' will be the Dongguan agropark. "It's going to be a very big project," Marta says, "with a mission to create a sort of clean island in a very urbanized area, and our project will be a part of it."

A rendering of the Dongguan agropark, with the challenge site in the foreground

Catalyst for change

Going beyond this particular project, the second Urban Greenhouse Challenge is really looking for a 'catalyst for change', Marta explains. "We really want to provide experiments for more innovation." Last year's challenge is evidence that this is indeed how it works - many of the participants have followed up, going further into the field of urban farming.

Another way in which the challenge seeks to be a source of inspiration is by bringing together disciplines that often don't work together, like architecture and agriculture. "Those are the groups that also don't really know each other. This will also spark new ideas and add value."

The winning design in the first Urban Greenhouse Challenge

Lessons learned

The UGC team's experience from the first edition of the challenge has geared them up for the second. "The first Urban Greenhouse Challenge was a big experiment. The idea of Wageningen organizing such a challenge came up in January 2017, and in June it was decided that the challenge would go through. So we didn't really have much time to prepare", Marta says, laughing. "When it started, we were still working out the details and running the challenge. It was crazy and very intensive, but we also learned a lot."

They used that experience for the second challenge. "We very much revised the format." The idea is the same: student teams developing a greenhouse in an urban environment and involving the local population, but a few things have been tweaked. "For instance, we have included milestones this time, we have very clear instructions for all the participating teams. We have also developed an online platform. We now have a website with a lot of functionalities to facilitate communication with teams."

Team GreenWURks, winners of the first UGC

Connecting student with companies

With the online platform that's been developed, participating students are able to get in touch with experts who can offer them advice. "We really hope that some interesting innovations will come out of this", Marta shares. "All our partners get access to the online platform, and the online platform is a meeting place. Via the online platform, you can initiate chat, which can be followed up by Skype calls or face-to-face meetings."

Getting in touch with companies isn't just beneficial for the students - there are mutual benefits. "We think this is a great HR opportunity for the companies. The people who join the challenge are really very eager students. They'd be the perfect employees because they are very ambitious, curious about the topic and very innovative."

If your company is looking to get in touch with those talented students, be sure to get in touch with the Urban Greenhouse Challenge team - they're still looking for expert partners.

For more information:

WUR Urban Greenhouse Challenge

studentchallenges@wur.nl

urbangreenhousechallenge.nl

Publication date: 8/29/2019

Author: Jan Jacob Mekes

© HortiDaily.com

AUDIO: Why A New Rooftop Farm In Paris Is A Glimpse Into The Future

The city of light may become the city of fruits and vegetables soon. French company Agripolis is slated to open a 150,000-square-foot rooftop farm in 2020, hosting 2,000 pounds of crop each day

By Tyler Kern

August 28, 2019

The City of Light May Become The City of Fruits And Vegetables Soon

French company Agripolis is slated to open a 150,000-square-foot rooftop farm in 2020, hosting 2,000 pounds of crop each day.

Urban farming and aeroponics have spread to America but this project is the most ambitious yet.

“In Europe they’ve really gone to another level with it,” Dave Schupmann, Senior Vice President of Sales and Marketing at Fortis Warranty, a roofing warranty provider, said.

Concerns about weeds and heaviness from rain and snow have traditionally been problems for rooftop farms, but advancements have made projects like this one more viable.

“Sustainability is great. The products that we’re using today, much more than ever are lasting longer. So, you’re able to put these giant farms on top of these systems without them breaking down every 10-15 years,” Schupmann said.

While green roofs are still relatively uncommon in the United States, the ability to turn a profit from them may spur more investment in the model, according to Schupmann.

“I think it’s fantastic what they’re able to do with the vegetative roofing, really making it more than just something nice to look at but making effective use of the land for the tenants around it,” he noted.

According to Curbed.com, the farm will host more than 30 different plant species. Parisians will also be able to occupy their own plots of land on the roof, creating a communal space for residents.

Tune in to Business Casual, MarketScale’s live radio broadcast, every Wednesday and Friday at 8 a.m. CST.

UK ‘Closing In’ On Large-Scale Vertical Lettuce Production

As investment increases and the cost of production comes down, vertical farming has the potential to replace imports in leafy salads

29th August 2019 London

BY FRED SEARLE

Vertical farm director says indoor production of salad heads in Britain has potential to replace imports from Spain as sector gathers steam

As investment increases and the cost of production comes down, vertical farming has the potential to replace imports in leafy salads.

This is the view of Vernon Mascarenhas, a director at the London-based vertical farming company GrowUp Farms, which has specialised in growing microgreens, salads and herbs for the restaurant sector and is now focused on applying its know-how to industrial-scale salad production.

Several companies in the UK and abroad are making good progress on the challenges of making vertical farming work at scale, said Mascarenhas, who believes we are no more than a few years away from produce grown in industrial-scale vertical farms becoming an established part of the UK supply chain.

Also a commercial director at New Covent Garden catering supplier Nature’s Choice, he stressed that if UK growers can start growing salad heads year-round in Britain, the implications of not having to import large volumes from Spain in the winter will be huge.

“If companies like G’s don’t invest multi millions, they will have a real problem,” he said. “As soon as we get up and running and can produce gem and cos in the UK in the winter, it’s going to replace supply from Murcia, and this will increase suppliers’ margins.

“The price of a two-pack of gem in a supermarket is around 75p, and to bring it over from Murcia costs around 28p. Instead of wasting this 28p per pack on long-distance haulage, we can use it to pay off the capital investment required to build vertical farms where we will soon be able to produce gems for around 12p.”

Mascarenhas also said UK supermarkets are on the verge of having vertical farms in store, on their rooftops or in their car parks that not only showcase food production, but also provide significant supply – in wholehead salads as well as herbs.

In Britain he thinks Ocado, Amazon or possibly Asda could be the first to invest in vertical production, predicting that Asda’s owner Walmart could soon be taken over by Amazon – “Amazon will invest whatever they need to in this kind of thing,” he said.

Indeed it has already been announced that Berlin-based start-up Infarm is set to launch its in-store vertical farms withsome of the UK’s largest online and brick-and-mortar supermarkets in September, adding to its network of over 200 in-store farms across Germany, Switzerland and France.

Although many are sceptical about the financial viability of growing vertically, Mascarenhas is confident the cost of production will come down quickly in the next few years as technology advances, operational knowhow improves, and large investments are made in the sector. For example, in June Ocado invested £17 million in two vertical farming businesses, with plans to grow herbs and leafy greens next to its distribution centres.

Up until now, only micro greens and herbs have proven financially viable for vertical production in the UK, but such developments will allow mainstream salad produce to be grown domestically for the retail sector – both in store and, more importantly, in big warehouses – starting with baby leaf and moving into gem and cos lettuce, lollo rossa, oakleaf and other salad leaves.

“These vertical farms will be completely automated," he said. "The salad seeds will be sown, grown, watered, harvested and packaged without a human hand and the products will be grown in controlled conditions, with no pests or chemicals.

“We have all that technology already and established horticultural companies are heavily involved in making this happen.”

Produced vertically, a gem lettuce will only take 28 days to grow from sowing to harvesting, according to Mascarenhas, and once this has been achieved, producers can move on to rocket and spinach, which he says will be possible to produce in just 18 days.

He added that as well as allowing for more consistent year-round production, vertical farming can deliver higher quality and safer products than are currently available since they are grown in a controlled environment.

“Leafy products are just the tip of the iceberg,” he said. “Trials are currently happening around Europe on fruiting crops such as strawberries, raspberries, tomatoes and cucumbers, although these are still very early stage and it will be a while before the know-how and technology gets to a place where it makes commercial sense to grow them in a vertical farm.

“Basically, anything that grows as a root crop doesn’t work, but anything that grow upwards might. There’s a possibility that products like courgettes, beans and peas could be grown vertically but we have no idea yet what the economics of that would look like.”

VIDEO: Can Vertical Farming Solve Asia’s Food Crisis?

The government is looking to curb this dependence on outside food sources under a programme titled ‘30 by 30,’ which aims to allow Singapore to grow 30% of its produce by the year 2030

Singapore Has Only 1% of Its Land Available For Agriculture, So It

imports 90% of Its Food Requirements.

The government is looking to curb this dependence on outside food sources under a programme titled ‘30 by 30,’ which aims to allow Singapore to grow 30% of its produce by the year 2030.

Local vertical farms like Sustenir are at the forefront of bringing about this change.

VICE visits the sustainable start-up to understand the future of food.

Bowery Farming Hires Execs From Starbucks And Walmart

In a move to broaden consumer awareness and increase retail distribution, Bowery Farming has made two key executive hires for the company’s marketing and sales operations.

Wednesday, Aug. 28th, 2019

NEW YORK CITY, NY - In a move to broaden consumer awareness and increase retail distribution, Bowery Farming has made two key executive hires for the company’s marketing and sales operations. The company appointed Katie Seawell (formerly of Starbucks Coffee Company) and Carmela Cugini(formerly of Walmart) as the company’s Chief Marketing Officer and EVP of Sales, respectively.

Irving Fain, CEO and Co-Founder, Bowery Farming

“We are thrilled to have Carmela and Katie join the Bowery team,” Irving Fain, CEO and Co-Founder, stated in the press release. “We are committed to building a smart and passionate team that is dedicated to our mission of growing food for a better future. Katie and Carmela will be tasked with sharing our mission—and the work we are doing to revolutionize agriculture—to retail partners and consumers, ultimately bringing Bowery’s safe, fresh, and delicious locally-grown produce to more homes."

Bowery Farming appointed Katie Seawell (formerly of Starbucks Coffee Company) and Carmela Cugini (formerly of Walmart) as the company’s Chief Marketing Officer and EVP of Sales, respectively

Both Seawell and Cugini come to Bowery with vast experience in the food retail industry and are set to play a vital role in expanding the company’s operations and supporting Bowery’s mission of growing safe, fresh produce for a better future as the company plans to expand its network of farms to new markets over the coming months.

Katie Seawell, Chief Marketing Officer, Bowery Farming

“I was immediately drawn to Bowery’s approach to re-thinking the agricultural system and offering sustainable, fresh produce that meets the needs of our growing population,” Seawell commented. “I look forward to helping grow the Bowery brand, uncovering ways to connect directly with customers who believe in our mission.