Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Five Indoor Farming Question With Paul Brentlinger of Cropking

Paul Brentlinger grew up aroundCropKing, a greenhouse service company founded by his parents Dan and Marilyn in the early 1980s. He grew his first hydroponic greenhouse crop before he was ten. Known for their personal service,

Five Indoor Farming Question With Paul Brentlinger of Cropking

Paul Brentlinger grew up around CropKing, a greenhouse service company founded by his parents Dan and Marilyn in the early 1980s. He grew his first hydroponic greenhouse crop before he was ten. Known for their personal service, CropKing now services nearly 700 commercial hydroponic growers throughout the country. Ahead of his presentation at Indoor Ag-Con in May, we asked Paul five questions about indoor farming.

1. CropKing is known for its longstanding relationships with family farms. How have your family farm customers’ needs changed over the years?

I don’t know if the needs have changed…if anything the needs have become amplified. A constant focus for CropKing is providing a complete option for a new grower to enter the hydroponic controlled environment ag market. A big component of that complete option is the ongoing technical support, understanding the systems, the environment, and how those things will work together in a greenhouse. CropKing has always offered it’s customers this training and technical support and in the past 5 to 7 years you are starting to see a few other companies in the space start to offer similar options, I think it was Albert Einstein who said “the only source for knowledge is experience”. At CropKing we have been conducting ongoing trials and testing in an effort to benefit our customers in our own greenhouses for over 30 years.

2. We see a number of new farmers entering the hydroponics growing space. How do you recommend that they learn about the industry?

Great questions, of course, we offer our monthly Grower Training Workshops usually at our facility here in Ohio. We realize as much as anybody that a two-day course is not enough time to completely prepare someone to become a qualified new, commercial, hydroponic food producer, but it does give a prospective hydroponic farmer a good overview of owning a hydroponic greenhouse. There are Universities across the country that are focusing on controlled environment agriculture and some that offer hydroponic training courses. We are currently working to develop and ideally this summer will start accepting interns for our 1-2 week long internship program taking interested participants much deeper into the day to day activities that are required to run a successful greenhouse operation. This will help to flatten out the learning curve that all new growers experience.

3. How long does a typical greenhouse build take? At what stage do you suggest that potential farmers contact you?

There is no such thing as a typical greenhouse build! Every build will have its challenges and unique issues to deal with. We do suggest that when conditions are optimum it generally requires about 6 weeks to 2 months to build a CropKing 2 bay (44′ x 128′ gutter connected greenhouse) on a prepared site. A prepared site would be defined as a graded pad with utilities available. So many things play into this answer like the weather and how many people are in your crew. CropKing starts talking to many growers years before they are ready to jump into this space, and that is what we want. This is a very long process to get everything in place especially for the family farms were this means taking out a mortgage on their home or against their retirement, we want people to spend the time researching and studying their local markets to ensure they have an outlet for the volume of produce they are about to grow. We want them to be completely comfortable with the process before putting down a deposit on their future.

4. Your parents started CropKing. How do you expect the indoor growing industry to change by the time your children are old enough to join the business?

I think hydroponics and CEA will become even more commonplace than it is today. As consumers continue to demand access to healthy, local, sustainable, fresh produce controlled environment agriculture and specifically hydroponics will continue to flourish.

5. What’s the coolest crop that anyone’s ever grown with your NFT system?

This is certainly a matter of opinion and we’ve seen everything from cannabis and peppers to carrots and corn being grown in NFT channels, but if I have to pick I think it’s carrots…when the root tip hits the bottom of the channel it fingers out and looks like a mutant hand when you harvest it. You have to open the channel and harvest from the bottom because you can’t pull it back through the hole in the top cover. (That’s right, CropKing’s channel has a removable top cover which also makes it easy to clean).

JOIN US AT THE 6TH ANNUAL INDOOR AG-CON ON MAY 2-3, 2018

REGISTER TODAY

This Hydroponic Farm Is Speeding Up NYC's Farm-To-Table Process

Hydroponic farming is becoming an increasingly popular option in cities with a high demand for fresh produce. Farm One is one such system that is providing their restaurant clientele with microgreens, herbs, and edible flowers grown right in Manhattan, Inhabitat reports.

This Hydroponic Farm Is Speeding Up NYC's Farm-To-Table Process

BY AIMEE LUTKIN

March 1, 2018

Hydroponic farming is becoming an increasingly popular option in cities with a high demand for fresh produce. Farm One is one such system that is providing their restaurant clientele with microgreens, herbs, and edible flowers grown right in Manhattan, Inhabitat reports. They claim they can reach 90 percent of their buyers by bike within 30 minutes. That's fresh.

Farm One is part of the Institute of Culinary Education, so it's a place for learning chefs as well—which is also a great way to build up a network of people who know about and support it. The hydroponic farm was built in April of 2016, with 150 different varieties of crops on rotation.

The space was developed by urban agriculture firm Agritecture, whose managing director Henry Gordon-Smith told Green Matters in an email that it's a really special place that is building a roadmap for future hydroponic growing technology.

"Farm One isn't like other vertical farms: for one, they grow the most unique and rare crops on demand for the most curious and sophisticated chefs. Additionally, each farm is optimized to match the urban site they set up an operation in, embracing the positive attributes of the space to the demands of their customers. Farm One is leading the way in the production of crops that have often never been grown in vertical farms to inspire chefs, cities, and customers to ignite their senses with the future of local agriculture," wrote Gordon-Smith.

The indoor farm is lit by LEDs, and the interior is monitored for conditions that are primed to grow greens. They use zero pesticides or herbicides, and the hydroponic system requires 95 percent less water than in a traditional garden. The main waste product from the enterprise is plant matter, which is composted.

Farm One is also committed to variety. They say on their website that they "scour the world" for "rare seeds" in an effort to promote biodiversity. It also doesn't hurt that the growers are themselves chefs, which means an interest in variety and flavor for its own sake. The farm is growing, but remains committed to staying local and minimizing travel time for their produce. If you can grow lettuce in the basement, you never need to eat a wilted leaf again.

Grow Pod Solutions Brings New Automation Technology To Indoor Farming

Grow Pod Solutions Brings New Automation Technology To Indoor Farming

Company partners with AR Systems to provide award-winning automation software

February 27, 2018

CORONA, Calif., Feb. 27, 2018, /PRNewswire/ -- Grow Pod Solutions, a leading AgTech company and the premier developer of portable indoor growing environments, has joined forces with AR Systems, to offer award-winning automation software and hardware to the indoor farming sector.

For the first time ever, growers will be able to use technology to automate virtually all cultivation processes and control the entire system from a computer or cell phone through the company's exclusive Online Communication Module.

Highly efficient, the "Grow Pod" from Grow Pod Solutions reduces water use to a minimum, increases growth rate, and speeds up harvests through energy-efficient LED lighting that is fine-tuned to individual plant requirements.

Grow Pod Solutions has made it possible to grow vegetables, fruits, and herbs anywhere in the world with its advanced technology, including humidity control, air conditioning, and the company's patented Bipolar Ionization, which provides an ideal environment for rapid and robust growth.

According to a recent article in Futurism Magazine, indoor farming represents the future of agriculture but noted that the process was difficult to master. "Vertical farmers need to know how to operate the technology, including systems that control elements such as soil contaminants and water availability," the publication reported.

However, Grow Pod Solutions' intuitive and easy-to-operate system can be set up in just a few hours, and then monitored and adjusted from anywhere in the world via the company's online portal.

Furthermore, the Grow Pod operates as a sealed system – eliminating the need for pesticides, herbicides, and additives that are commonly required on traditional indoor farms. The purified environment also eradicates any chance of cross-contamination or unwanted pollination.

George Natzic, President of Grow Pod Solutions, said the company's many recent developments represent not just staying ahead of the curve but inventing the very future of indoor farming.

"Our advanced, plug-and-go systems allow anyone to grow healthy, organic food and herbs anywhere in the world," he stated. "With our innovative, patented technologies, Grow Pod Solutions continues to advance the state-of-the-art in automated farms."

For information on Grow Pod Solutions, visit www.growpodsolutions.com or call (855) 247-8054.

Connect:

Email: info@growpodsolutions.com

Website: www.growpodsolutions.com

Facebook: facebook.com/GrowPodTechnology

Twitter: @GrowPodSolution

Local Produce

February 19, 2018 | by LAUREN TOLAN

Do you know where your “local” fruits and vegetables come from? Co-owner of Buckingham Farms, TJ Cannamela, talks about the importance of knowing when and where your crops are coming from, and also how they were treated. He strives to grow fresh vegetables, year round, without the use of pesticides or other chemicals. One way to do this is through the use of hydroponics, which cuts water usage down by 80%, results in quicker plant growth, and eliminates the need for pesticides.

Cannamela advises people to be cautious and ask questions when buying from local markets. He acknowledges a few businesses in the area that stay true to the way many of us perceive the terms “local” and “fresh”. Which to many of us, means having been picked this morning. The state recognizes the term “local” to be in reference to a 250 mile radius around your business. How would you define it?

This Musk — Elon's brother — Looks To Revolutionize Urban Farming

This Musk — Elon's brother — Looks To Revolutionize Urban Farming

Zlati Meyer, USA TODAY February 18, 2018

Square Roots urban farming has the equivalent of acres of land packed inside a few storage containers in a Brooklyn parking lot. USA TODAY

(Photo: Jennifer S. Altman, for USA TODAY)

NEW YORK – In sunny California, Elon Musk is upending America's auto and space industries. And here, in a cold, gritty section of Brooklyn, his brother Kimbal has embarked on a project that's just as significant in its own way: Trying to reboot the food system.

The younger Musk is the co-founder of Square Roots, an urban farming incubator with the goal of teaching young people how to farm in cities while preaching the importance of locally sourced, non-processed food.

Having shown its potential during the past two years in the parking lot of a shuttered factory near public housing projects of Brooklyn's Bedford-Stuyvesant, Square Roots is ready to branch out. It is looking to set up plots — each the equivalent of 2 acres of farmland — in cities across the U.S. They're hydroponic, which means the crops grow in a nutrient-laced water solution, not soil.

The sites in contention, all of which had to pledge support from local governments and businesses, are in Chicago, Denver, Memphis, Indianapolis, Pittsburgh, Boston, Detroit, Los Angeles, Tampa, Atlanta, Dallas, Cincinnati, St. Louis, Washington, D.C., and a second site in New York. Musk and Square Roots CEO Tobias Peggs will narrow the list down to 10 later this year.

In Brooklyn, budding agricultural entrepreneurs set up year-round farms inside 10 retired metal ocean shipping containers and grow crops like microgreens, herbs and strawberries.

"I want them to get to know entrepreneurship through food," said Musk in a phone interview, who counts both growing business and food as big passions.

Kimbal Musk is a co-founder of Square Roots. (Photo: Neilson Barnard, Getty Images for New York Times)

In 2004, Musk co-founded The Kitchen Restaurant Group, which opened eateries in Colorado, Tennessee, Illinois and Indiana. Musk, who sits on the board of directors of his brother's electric car and solar power provider maker Tesla, also co-founded Big Green, an organization that installs gardens in underserved schools and teaches children about the importance of eating natural food.

With so much on his plate, Musk leaves the day-to-day running of Square Roots to Peggs. They usually talk twice a day, Peggs said. The two met while working at OneRiot, a social media target-advertising company in Colorado, which Walmart acquired in 2011. Peggs has a doctorate from Cardiff University in Wales in artificial intelligence but can just as easily switch to extolling the virtues of freshly-picked peppery arugula.

"By 2050, there’ll be 9.6 billion people on the planet and 70% of them in urban areas. That’s driving a lot of investment and interest in urban farming. Our thinking was if we start in New York and we can figure out solutions ... then we’ll be able to roll out those solutions to the world," he said.

To initially get set up in Brooklyn back in 2016, Square Roots raised $5 million in — no pun intended — seed money, Peggs explained. For each of the 10 new locations around the country, slightly more than $1 million is needed.

Peggs said the farmers find buyers for their produce, like stores, restaurants, and individuals, though they also inherit the client's list from previous Square Roots participants. Some of Square Roots' staff of 14 help generate leads, too. Thirty percent of what they earn goes to Square Roots, and expenses are another $30,000. That leaves them with an annual profit of $30,000 to $40,000.

A single 40-foot container provides 320 square feet of growing space. It is outfitted with long, narrow towers studded with crops that are hung on tracks from the ceiling in rows, like vertical blinds. The plants get their water and nutrients from irrigation pipes running along the tops of the towers and their sunlight from dangling narrow strips of LED lights. Besides arugula, crops include kale, radicchio, and pak choi.

More: Urban farmers grow veggies in freight containers

More: Farm on wheels will deliver fresh produce to food deserts

"What we’ve proven in the first phase is we can take young people with no experience in farming and get them very, very quickly to grow really high-quality food that people want to buy," he said.

Over the year-long program, the young, mostly 20-something farmers learn about not only agricultural science and farm management but also marketing, community outreach, leadership, and business, according to Peggs. During a typical week, they spend about 15 to 20 hours doing farm work, 10 hours handling the business side and 10 hours getting coached by Square Roots' in-house agriculture expert and the team of mentors the company has assembled.

Last year's group was comprised of 10 people, and this year has six. More than 1,500 individuals have applied to Square Roots, the company said.

The program has attracted participants like Hannah Sharaf, who sells her weekly yield of 25 to 30 pounds of microgreens to office workers for $7 per 2.25-ounce bag. Sharaf, 27, said she is fascinated by "how food affects the body," prompting her to give up a career in international marketing. "I really want to be a farmer. I'm exploring both urban and soil."

"High-profile, really cool projects are important because they draw attention to urban agriculture. They fascinate people. They attract capital, and that helps to grow the sector," said Nevin Cohen, research director of the City University of New York's Urban Food Policy Institute.

Part of the draw is the bold-faced name attached to it: Musk. That could make urban farming a bigger topic in the national conversation about local and fresh food, which also is driven by thousands of small activists, some of whom have been advocating for decades.

"I don’t enjoy the industrial food system. It's definitely not good for America or the world," Musk said, citing high obesity rates, the thousands of miles food has to be shipped and the lackluster taste. "We're very excited to teach America about real food."

But Musk acknowledged that not everyone can afford that — including some of Square Roots' neighbors. At least, not right now.

"It's not something restricted to the urban elite," he said. "Our mission is real food for everyone. We need food to be delicious and young entrepreneurs to be empowered."

Vertical Farming: Lettuce From The Skyscraper Next Door

Vertical Farming: Lettuce From The Skyscraper Next Door

09.02.2018

Graz (TU GRAZ) - Vertical farms are greenhouses - only the cultivated areas are not laid out next, but rather stacked up on top of each other. A Graz-Viennese concept combines structure with urban architecture.

Urban farming, in other words carrying out agricultural projects in urban surroundings, has been a thing for years. Vertical farming goes one step further - a step upward, to be precise. Use is made of building façades to grow fruit and vegetables and to yield a proper return, on the one hand, and to create added benefits for the building in terms of energy technology, on the other. Many existing projects involving vertical cultivation resemble classic greenhouses - only laid out vertically, not horizontally. In Graz and at the Vertical Farm Institute in Vienna, the aspiration is to integrate cultivated areas into the architecture of buildings, thus using synergies and saving energy. "Our goal is to maximize cultivation area while at the same time minimizing the necessary surface area - currently we can create up to 50 times more cultivation area on traditional farming surface areas.

At the same time, we would like to design energy use as efficiently as possible and integrate the farm into the building symbiotically," explains Sebastian Sautter of the Vertical Farm Institute in Vienna and staff member of TU Graz's Institute of Building and Energy. Having dealt with the concepts for many years, he has now, together with colleagues in the exploratory project "Vertical Farming", simulated a prototype farm in Vienna's Urban Lakeside Aspern, and is about to launch a pilot experiment at the Tabakfabrik (former tobacco factory) in Linz.

Up high

But everything in the right order. Vertical farms are greenhouses which are arranged vertically rather than horizontally. Today, classic greenhouses no longer grow their crops in soil, instead, they use hydroponic systems with the plants being grown in so-called trays. The plant boxes are watered regularly with a blend of nutrients. "This also makes them very efficient regarding water consumption because the plants only absorb the water they need - the rest is recirculated," explains Sebastian Sautter.

In traditional greenhouses, the light the plants need to survive and thrive comes through a glass roof. "In vertical farming, the light cannot come from above because the plants are stacked on top of each other. Light can only come into the greenhouse through the façade. This means the plants' best exposure to light takes place directly via the façade. The idea is to transport the plants to daylight," explains Sautter. "Plants don't have to be exposed to light constantly. They can store light energy and you just have to supply the required daily ration of light. This makes them happy and they grow."

In the exploratory project Vertical Farming funded by the Austrian Research Promotion Agency (FFG), researchers at TU Graz's Institute of Building and Energy, the University of Natural Resources and Life Sciences, Vienna, (BOKU Wien) and Siemens are examining current findings in vertical farming and seeing where more research should be done. The project will be phased out in March of this year. The follow-up project is already in the planning stage: a pilot experiment at the Tabakfabrik in Linz.

Lift to the light

A kind of lift system has been developed at TU Graz which transports the plants to the light. The trays are hung and slowly vertically rotated. The plants thus receive the required light in a uniform way. On top of this, they can also get artificial sunlight in the morning and evening or on bad weather days. "We're in the optimization phase at the moment, and we're investigating when the best time to turn the artificial lighting on and off is. At the moment we're planning to turn it on at 4 a.m. and turn it off at approx. 10 pm. The plants need a dark rest period for about six hours a day."

The purpose of the farms is not only to provide fruit and vegetables: optimizing energy consumption is also an important topic. The trays can also serve as thermal insulation next to external walls and are also able to use waste heat for better plant growth. They can also be positioned in areas facing south or west to provide shade and a good indoor climate. "We've got several ideas here, and we're working on optimizing them. Of course, it would be ideal to be involved in planning such a farm when constructing a new building. But they can also be integrated into existing buildings," says Sautter.

Prototype for Linz

The first machine will be installed in the listed former porter's lodge of the Tabakfabrik in Linz. "It's not absolutely ideal because it faces north. But it's wonderful and the windows look out onto a street - but it needs to be optimized for the users," explains Sautter. It is intended to build the vertical farm behind the window façade and to move the trays on a slow circular path. Another arm, which extends into the room, is intended to be used for maintenance and harvesting. You can imagine it as a horizontal T. The technology group Siemens was able to be won over as a partner. Siemens wants to equip the trays with sophisticated sensors to measure the supply of water and light to optimize growth.

This is how the prototype in the Tabaktrafik in Linz should work: In this YouTube-Video the people responsible are introducing their plan.

Transparency in foodstuff production

The concept has been precisely designed to achieve a rich yield of fruit and vegetables. "At the same time, we also want to reduce foodstuff waste. About a third of foodstuffs are currently thrown away due to transport waste. That wouldn't happen in our case, of course, because the head of salad which is eaten or sold would be harvested directly," explains Sautter. Transparency in foodstuff production is also an important topic. "At the moment I cannot at all say where my fruit and vegetables come from, even when it says on the package. We want to change this using visible growing areas and thus create trust among the customers."

Information

The Vertical Farming Institute is organizing the Skyberries Conference in Vienna which runs from 28th February to 2nd March and is part of the Urban Future Conference. You can pick up all the important information on the subject there, also from well-known speakers such as the mastermind of vertical farming, Dickson Despommier, and establish contacts in the scene. By the way, tickets are available at a discounted price for members of TU Graz - see contact box for details.

Contact: Sebastian David Sautter Dipl.-Ing. Institute of Building and Energy Rechbauerstraße 12/II | 8010 Graz Phone: +43 316 873 4756 sautter@tugraz.at

Vertical Farming, LEDs and The Flavor of Leafy Greens

Vertical Farming, LEDs and The Flavor of Leafy Greens

A large climate cell with endless racks of microgreens illuminated with soft pink or white light works 24/7 to bring delicious microgreens to the kitchens of some of Amsterdam’s top restaurants. GROWx is one of Europe’s most known vertical farms and its offering of more than 20 microgreen varieties has quickly earned its spot within Amsterdam’s top 10% restaurants. At the moment it is only microgreens and only for the city of Amsterdam but the ambitions of GROWx’s founders are to re-invent agriculture for urban areas. ‘This revolution can’t come fast enough’ says the CEO and Co-Founder, Mr.John Apesos.

This high tech, futuristic looking environment is what the farming of the future could look like. Nevertheless, when it comes to the end customers, restaurant chefs and their patrons in this case, it is primarily about flavor and freshness. These microgreens go from the farm to the dinner plate in a matter of hours and according Mr.Apesos this is what keeps the flavors intense. The varieties include everything from the common pea-shoots to the more exotic ones like the borage crest.

The GROWx vertical farm is fully equipped with Valoya’s LED grow lights. The primary spectrum used is the AP673L which has been optimized for the vegetative stage of plant development. This means that plants grown under this light will quickly develop biomass (stems and large, thick leaves) while flowering will be delayed or completely prevented making it ideal for microgreens and leafy greens in general. In a research conducted by Wageningen University and Democritus University, the AP673L spectrum boosts the development of chicoric, rosmarinic and caffeic acids and other phenolic compounds making the plants more flavorful and nutrient dense1. The other spectrum is NS1, a sunlight replica spectrum, good for the entire growth cycle. Both spectra are wide and patented with a high CRI (Color Rendering Index) value meaning that plants and other objects look natural under them i.e. their colors look as they would under natural sunlight.

1 F. Bantis et al.(2016) Artificial LED lighting enhances growth characteristics and total phenolic content of Ocimum basilicum, but variably affects transplant success, Scientia Horticulturae 198 (2016) 277–283

About Valoya Oy

Valoya is a provider of high end, energy efficient LED grow lights for use in crop science, vertical farming and medicinal plants cultivation. Valoya LED grow lights have been developed using Valoya's proprietary LED technology and extensive plant photobiology research. Valoya's customer base includes numerous vertical farms, greenhouses and research institutions all over the world (including 8 out of 10 world’s largest agricultural companies).

Pure Flavor® Georgia Greenhouse Construction Project Coming to Life

Pure Flavor® Georgia Greenhouse Construction Project Coming to Life

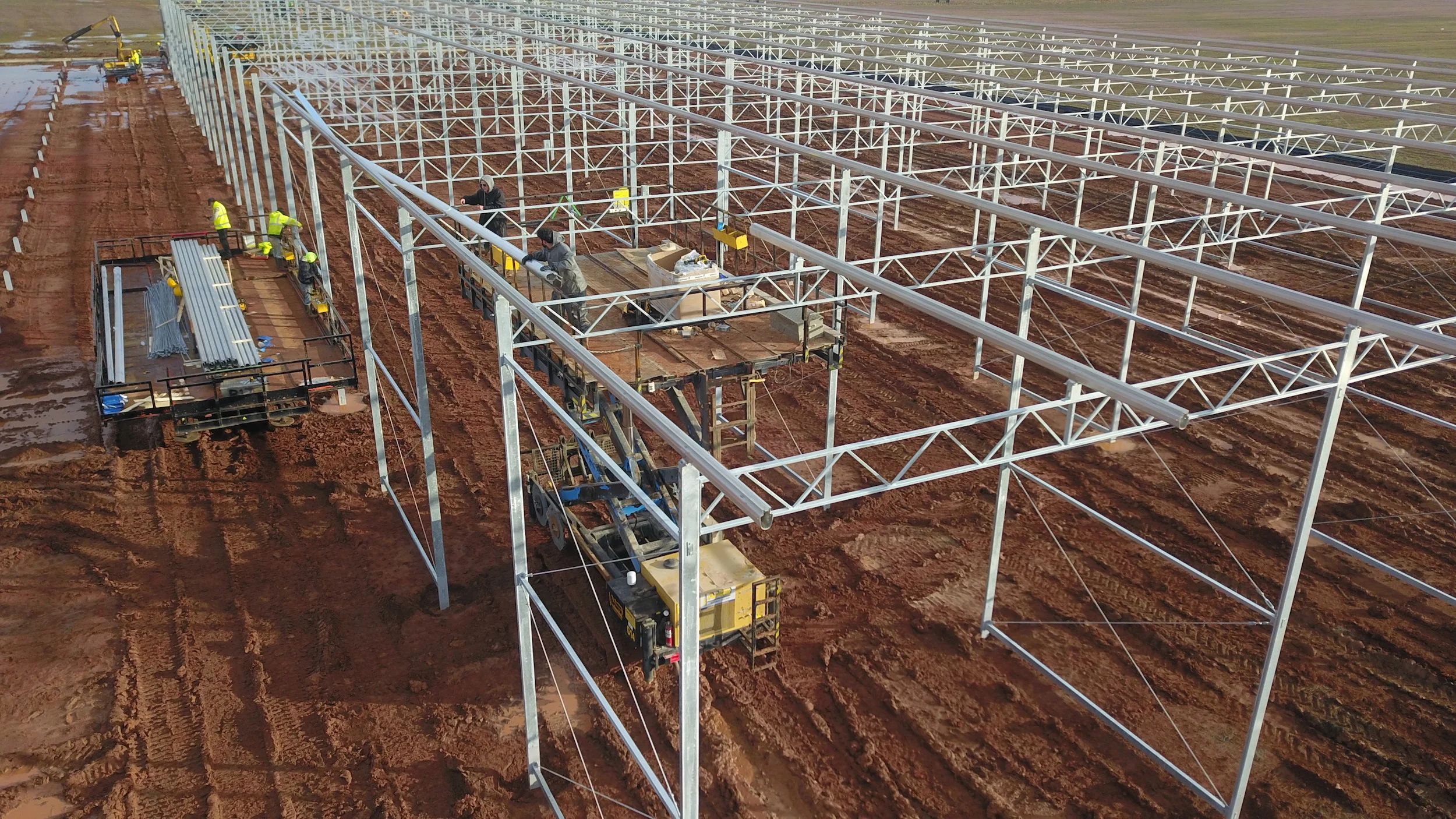

Fort Valley, GA (February 14th, 2018) – Cooperation with Mother Nature for good weather this winter has spurned a fury of activity at the site of Pure Flavor®’s greenhouse project in Georgia. Ground leveling completed in late fall lead to a smooth start of construction of the company’s new 75-acre high tech greenhouse facility in Peach County.

Over the course of the last few weeks once post holes were dug and backfilled, Dutch greenhouse builder Havecon began erecting the main structure with full-scale implementation now underway. From a timing standpoint, the project is on track for completion by late summer with the first crop of tomatoes & seedless cucumbers to be planted shortly thereafter.

“Building a high-tech greenhouse in Georgia was part of our growth strategy to extend our reach across North America. Being strategically located in Peach County allows us in some instances to have same day & next day deliveries in the southeast region”, stated Matt Mastronardi, Executive Vice-President. Pure Flavor® researched more than 400 sites throughout North America before settling on Peach County, GA. The 75-acre greenhouse project broke ground in September 2017 and will be built in 3 phases of 25 acres. Phase 1 is expected to be completed in late Summer 2018.

“Greenhouse tomatoes & seedless cucumbers grown in Georgia will help breathe new life in to the category. It will help our retail (& foodservice partners) in the region to have fresher product on store shelves while maintaining consistent quality and availability year-round. In the end, it is the consumer who will benefit from great product grown in the state of Georgia”, said Mastronardi.

Retail partners & consumers can follow the progress in photos of the Georgia greenhouse construction on a weekly basis by visiting the Pure Flavor® Georgia Photo Gallery: https://goo.gl/s5UCgc

“We are connecting our customers with the project in every way possible with frequent updates via social media, the photo gallery, and video stories shot by drone”, said Chris Veillon, Chief Marketing Officer. A custom website was built just before the groundbreaking in September 2017 to announce the project, the page now serves as the central resource for everything to do with the Georgia project. “A connected customer is an informed customer, we can’t wait to get our first plants in the greenhouse later this summer”, commented Veillon. Pure Flavor® expects the first crops to be picked in early Fall 2018.

Pure Flavor® will be exhibiting at the upcoming Southern Exposure Trade Show & Convention in Tampa, FL March 3rd. Visitors are encouraged to visit Booth #605 to learn more about the Georgia project.

To learn more about the Pure Flavor® Georgia greenhouse project, please visit GeorgiaGrownFlavor.com.

-30-

About Pure Flavor®

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise.

We are the next generation of vegetable growers, inspired to put quality, flavor, and customers first by providing greenhouse-grown vegetables from our farms that are strategically located throughout North America.

SOURCE: Chris Veillon | chris@pure-flavor.com

Chief Marketing Officer | Pure Flavor®

T: 519 326 8444

VIDEO: https://youtu.be/f6mXwHRuzMo

GALLERY: https://goo.gl/s5UCgc

What If We Could Grow Delicious, Nutrient-Dense Food, Indoors Anywhere In The World?

This Computer Will Grow Your Food In The Future

What if we could grow delicious, nutrient-dense food, indoors anywhere in the world? Caleb Harper, director of the Open Agriculture Initiative at the MIT Media Lab, wants to change the food system by connecting growers with technology. Get to know Harper's "food computers" and catch a glimpse of what the future of farming might look like.

Vertical Planting Establishes Roots In Laramie

An example of vertical gardens in downtown Laramie. (Photo taken by Seth Haack)

Vertical planting established more permanent roots in Laramie when the company Plenty, formerly Bright Agrotech, began construction on their new headquarters; providing jobs as well as fresh herbs in the community.

Rising from the ground in upright containers under controlled lighting and water systems, the latest trend in agriculture is featured just past the entrance of Washakie dining center and according to University of Wyoming researchers, vertical farming is here to stay.

“Plenty’s farms will be located near communities around the world, delivering industry-leading yields of delicious, locally-grown, backyard-fresh produce,” a Plenty spokesperson, Senior Communications Manager Patrick Mahoney stated in an email. “By shaving thousands of miles and weeks off the journey from farm to table, Plenty will transition agriculture to a reliable, predictable and resource-efficient model.”

The company was founded by Dr. Nate Storey, a UW alumnus.

“Nate Storey was a student of mine,” Extension Horticulture Specialist Karen Panter said. “He got all three of his degrees here in our department of plant sciences. The company includes engineers and computer experts and plant growth people and researchers and [Plenty’s] got some plant breeders now, there’s a lot of people working here in Laramie.”

Vertical farming allows for an increase in production per square foot, Panter said.

“So, there’s a limited amount of land that we can grow food on, limited resources, we have what growing people often refer to as ‘food deserts’ which are centers of urban settings with limited access to fresh produce,” Associate Professor of Agroecology Urszula Norton said. “And the fact that you can actually produce fresh green vegetables that don’t really take too many days and a way shorter period of time under optimum growth conditions.”

Indoor controlled conditions don’t experience drought, hail or other afflictions, resulting in a quicker growth turn around. The crops that are most compatible with vertical farming conditions tend to be leafy greens and some herbs, like lettuce and spinach.

“Plenty’s vertical towers can achieve industry-leading yields of fresh fruits and vegetables,” Mahoney stated in an email. “Up to 350 times greater per square foot than the field. Plants that get too big like tomatoes or that kind of thing just don’t work. The plants’ architecture is just completely wrong. It’s really hard to grow larger, longer, vining type plants.”

Norton, along with Liping Wang and other plant scientists, are in the midst of submitting a proposal to the National Science Foundation to better understand and improve on efficiency of water and energy using vertical farming settings.

“It is generally a proposal about learning more about where are we standing in terms of efficiency of vertical farming and how can we move it toward increasing effectiveness, efficiency, water use and energy,” Norton said. “My role would be pretty much to assess the growth yield and the quality of the produce.”

While the research and growth of vertical farming programs are certainly hot topics in the ag community, horizontal farming is not becoming obsolete by any means.

“[Vertical Farming is] not going to supplant traditional farming because there’s so many crops that can’t be grown in this type of system,” Panter said. “It’s not likely that we’ll be growing wheat or anything like that in this kind of a system, but for niche crops, it’s another tool to use.”

Farmers for America - New Documentary Screening in Fairfield, Iowa 2/17 and 2/18

Farmers for America - New Documentary Screening in Fairfield, Iowa 2/17 and 2/18

A Documentary to Celebrate, Inspire, and Support Young Farmers

Saturday, February 17 at 7:30 pm

Sunday, February 18 at 2:00 pm

Orpheum Theatre, Fairfield, IA (NOTE LOCATION CHANGE)

Saturday evening features a panel discussion with director Graham Meriwether and area farmers

Farmers for America, a new documentary from director Graham Meriwether (American Meat), traces the extraordinary changes coming to Americas food system as more and more consumers flock to farmers markets, embrace farm-to-table lifestyles and insist on knowing where their food is coming from. At the center of the film are the farmers, young and old, who provide the spirit and energy to bring urban and rural America together over what both share in common: our food. These farmers reflect nothing less than the face of America.

With the average age of todays farmer at 60, and rural America losing population as the cost of land and equipment soars, this film reveals the people waiting to take their place, the practices theyre championing and the obstacles they must overcome.

After the film on Saturday evening, Meriwether will be present to facilitate a conversation with a panel of local farmers of all backgrounds- from small-scale niche production to large-scale commodity farmers. Meriwethers goal is to bring these two perspectives together and forge a shared path towards our next agriculture.

Admission by donation.

Click here for more information on the film.

To be added to the JFAN email list, type SUBSCRIBE in the Subject Line and hit return. To unsubscribe from the JFAN email list, hit reply, type REMOVE in the Subject Line and hit return. JFAN never sells or shares its email list. Thank you!

Jefferson County Farmers & Neighbors, Inc.

PO Box 811

Fairfield, IA 52556

Follow us on Facebook: https://www.facebook.com/JFANIowa

Now on Twitter! https://twitter.com/JFANIowa

JFAN is funded by grassroots support and gratefully welcomes your donations. https://www.jfaniowa.org/donate-today

A Startup Is About To Build 300 Vertical Farms In China, Thanks In Part To Jeff Bezos

A Startup Is About To Build 300 Vertical Farms In China, Thanks In Part To Jeff Bezos

A Silicon Valley vertical farming startup sees a future in China. (AP Photo/Martha Irvine)

WRITTEN BY Chase Purdy

January 26, 2018

A Silicon Valley agriculture startup is preparing to build 300 vertical farms across China, propelled by investments from funds created by Amazon chief executive Jeff Bezos and Alphabet executive chairman Eric Schmidt.

By entering the Chinese market, the startup, Plenty, hopes to tap into the country’s growing demand for organic foods. Chinese citizens have become all too familiar with food safety scandals in recent years. Perhaps the most dramatic was in 2008 when six babies perished and at least 54,000 were made sick when tainted baby formula created a kidney disease outbreak. Now that the country is experiencing a swelling middle class with more buying power, more people are willing to spend a premium to purchase organic foods, which are perceived as safer to eat (something that isn’t always true).

Plenty plans to build and fill warehouses with 20-foot-tall, plant-growing towers that sparkle with LED lights. Herbs, kale, mustard greens, and more will grow horizontally from the poles, fed by water disseminated from the top of the structures via gravity—and won’t need soil or pesticides. Plenty can’t yet grow root vegetables or fruits this way, so it’s focusing its attention next on strawberries and cucumbers.

The company is able to make the move into China in part because of a massive $200 million investment round led by the Japanese telecom company SoftBank Group in July 2017, and which included money from Bezos Expeditions and Eric Schmidt’s Innovation Endeavors.

Plenty’s business proposition is these sorts of agricultural operations can help an increasingly urbanized global population cut back on amount of water and land used in a conventional farming. Because they can be built in cities, the vertical farms can reduce and even eliminate the financial and environmental costs of transporting food long distances. Plenty is building one such farm in spring 2018 outside Seattle, Washington. It’s expected to produce about 4.5 million pounds of greens per year, enough to feed more than 183,000 people.

The type of operation Plenty wants to bring to China could fit in well with steps the government there is taking to revamp how it feeds its people. Earlier this month (Jan. 16) at a meeting about creating green zones for growing food in major cities, Chinese agricultural minister Han Changfu said in a statement (in Chinese) that he wants to change the way China approaches agriculture. “It is necessary to speed up the transformation of agriculture from yield-oriented to quality-oriented, raise the overall quality of agricultural products, promote the transformation and upgrading of agriculture,” he said in the statement.

Read this next: You next head of lettuce, grown by a robot

Electrical Experiments With Plants That Count And Communicate

Electrical Experiments With Plants That Count And Communicate

Neuroscientist Greg Gage takes sophisticated equipment used to study the brain out of graduate-level labs and brings them to middle- and high-school classrooms (and, sometimes, to the TED stage.) Prepare to be amazed as he hooks up the Mimosa pudica, a plant whose leaves close when touched, and the Venus flytrap to an EKG to show us how plants use electrical signals to convey information, prompt movement and even count.

This talk was presented at an official TED conference, and was featured by our editors on the home page.

Green in the Desert: Local Farmer Captures Carbon to Grow Food, Feed Community

Green in the Desert: Local Farmer Captures Carbon to Grow Food, Feed Community

Shahid Mustafa, Taylor Hood Farms founder, picks lemon cucumbers at his farm near Old Mesilla.

Guest Columnist October 7, 2017

Shahid Mustafa is the first to admit his farm might not look as orderly as those you see while driving down the highway.

At Taylor Hood Farms, you won’t find manicured rows or flood-irrigated fields. Nor will you notice bed after bed of a single crop like alfalfa, commodity cotton or chile peppers.

To hear Mustafa say it, there’s a little bit of chaos in nature. Some of that chaos reflects in the appearance of his farm, where red amaranth grows tall and sweet carrots fill beds near lemon cucumbers and artichokes. But embracing nature’s way, according to Mustafa, could offer key solutions to some of the region’s most urgent environmental and health difficulties—even if some chaos is part of the package.

“The regenerative way is to work with nature, instead of against it,” he said. “Our philosophy is that the best food comes from the best soil, so most of our focus and attention is on enriching or enhancing the soil that we have.”

In the Paso del Norte region, Mustafa is pioneering an innovative approach to farming called regenerative agriculture. The practice could help restore topsoils degraded by conventional farming techniques, to say nothing of its implications for ensuring residents have consistent access to healthy foods.

The Regenerative Way

A tractor sits before a container with a mural on it at Taylor Hood Farms.

Mustafa runs two farms in the area—one in La Mesa, near Old Mesilla, and the other in Socorro. His mission is twofold: to make fresh produce available to all families in the region and to demonstrate the power and promise of regenerative farming.

In most respects, Mustafa said, the two are mutually inclusive: it’s hard to care for the community if one deprives the land on which it relies.

Regenerative agriculture refers to farming and grazing techniques that rebuild organic materials in soil, a ground-up approach that pays dividends in terms of clean, nutrient-dense produce, water-retention rate, native-species habitat, ecosystem health, soil fertility, biodiversity and even climate change.

The practice walks hand-in-hand with carbon farming, which harnesses the power of photosynthesizing plants to actually capture carbon dioxide and sink it into the nutrient-rich soil.

Stored safely in the earth, Mustafa said, the carbon becomes a proactive part of the crops’ life-cycle, rather than trapping heat in the atmosphere as a greenhouse gas—the primary driver of global warming.

When Mustafa goes about farming, his mind is on setting the stage for nature to take its course, then gently aiding the production along the way.

“We do that through composting, crop rotation and reduced tillage,” he said. “That means we’re not cultivating every year; every year, we’re not creating new beds. In fact, we like to keep the same beds and keep building on those beds, because that lets the soil generate natural beneficials.”

Those beneficials, as he describes them, are microbiotic life forms that feed on the decomposition of organic material, passing nutrients into the growing food. In this way, even the nutrients in the food itself are reliant on soils.

“In terms of the value of the food,” Mustafa said, “that, to me, is the most logical answer. If the food is not feeding from a source [the soil] that’s rich in nutrients, then where else is it going to get the nutrients?”

Childhood Food Insecurity

Local farms such as Mustafa’s play a pivotal role in providing nutritious foods to the community, and their importance—given the demographical statistics—can hardly be overstated.

In El Paso County, nearly one in four children is listed as food-insecure, meaning they lack reliable access to nutritious foods.

Shahid Mustafa, Taylor Hood Farms founder, cleans produce at his farm near Old Mesilla.

Surrounding counties—many of which are mostly rural—rank even worse in child-food-insecurity ratings.

For example, Hudspeth County’s child-food-insecurity rate is about 32 percent. Luna County’s is 33.6 percent. Poverty and unemployment frequently precipitate food insecurity in the U.S., according to Feeding America, a hunger-relief organization.

Additionally, food insecurity is associated with chronic health problems like diabetes, heart disease, obesity and depression. But local farms can help assuage these problems simply by providing healthy, inexpensive produce, said Leah Whigham, executive director of the Institute for Healthy Living, an organization dedicated to fostering healthier communities in the Paso del Norte region.

While some nutrients remain in certain foods for long after they’re picked, other crucial nutrients found in fruits and vegetables tend to reduce as they move through the long industrial-shipping process.

“Really what you want to emphasize is, as often as you can, buy the local produce,” Whigham said, “because some of the kinds of nutrients that you can only get from the fresh fruits and vegetables do dissipate if they’re shipped on a truck.”

Additionally, buying local can help take the guesswork out of whether the food is healthy, organic and ethically sourced.

Most of Mustafa’s food, for example, is available in El Paso True Foods boxes, a community-supported agriculture (CSA) venture. The True Foods program aggregates food from numerous different farmers in the region and packs it into boxes.

Each week, customers who sign up for the program can pick up their boxes at various locations throughout the city.

Farmer Shahid Mustafa delivers El Paso True Foods boxes to city offices in downtown El Paso. The boxes contain food grown from various farmers in the region.

True Foods Co-founder Adriana Clowe said the program supports both local farmers and community health. On the one hand, local farmers get a consistent market from residents who buy the weekly boxes. On the other, customers get healthy food right from the region—food that hasn’t degraded during the course of long-haul shipping.

“As consumers, we vote with our dollars,” Clowe said. “Wherever we decide to put our money—that’s what we’re supporting. With True Foods, we hope that the social interaction with farms and farmers…can open people up to that larger world of making mindful choices.” Giving the people the tools Mustafa has hopes for his efforts as well.

By farming here in the Chihuahuan Desert, he thinks he can help address issues of food insecurity and land deprivation, not only by offering nutritional produce straight from the farm, but by re-connecting people to the inherent value in the land and the food it produces.

“One of the answers to food deserts and food inequality is really to show people how to do it themselves, to become self-reliant,” he said. “If I had my way, I’d set this [farm] up as a perfect demonstration site and always be out showing somebody else how to replicate what we do.”

“Empowerment comes from the community,” he added. “Once they know how and are given the tools, they can do it themselves.”

***

Editor’s Note: Green in the Desert is a new column exploring sustainability and conservation efforts in the El Paso/Juarez area. Previous Columns can be read HERE.

Writer Chilton Tippin is project manager and communications coordinator for Wondor Eco:Nomics. He likes to write, bike, ski, climb and explore. In 2015, he walked across America.

There’s An Indoor Farm Growing From 2,000 Solar Panels On A South Philly Roof

The farm is the product of Metropolis Farms, a technology company that specializes in creating both indoor and outdoor vertical farming systems. The idea is to give farmers the chance to grow produce year-round, regardless of weather, while also making the technology affordable for any community.

USER @CLIMATEGROUP/TWITTER

Solar energy prices have dropped significantly as the technology figures to assume a key role in the global energy mix of the future.

OCTOBER 04, 2017

There’s An Indoor Farm Growing From 2,000 Solar Panels On A South Philly Roof

It's the only solar-powered indoor farm the world has ever known

SOLAR URBAN FARMING PHILADELPHIA EQUITY TECHNOLOGY FARMING SOUTH PHILADELPHIAURBAN GARDENING

BY MARIELLE MONDON

PhillyVoice Staff

Not far from the South Philly Target, more than 2,000 solar panels cover about 100,000 square feet of roof – creating the only solar-powered indoor farm the world has ever known.

The farm is the product of Metropolis Farms, a technology company that specializes in creating both indoor and outdoor vertical farming systems. The idea is to give farmers the chance to grow produce year-round, regardless of weather, while also making the technology affordable for any community.

According to a post on the company’s blog, the roof’s solar panels will capture enough sunlight to supply more than half a megawatt of energy, allowing the indoor vertical farm just below on the fourth floor to grow what’s equivalent to 660 acres’ worth of crops.

“Before starting this project, the fourth floor of this building was only growing pigeons,” the company’s blog post reads.

“But now, using our innovative technology that can uniquely grow everything, this solar-powered indoor farm will be growing fresh tomatoes, strawberries, lettuce, herbs, broccoli, and other crops for local Philadelphians.”

Metropolis Farms says there are currently about eight acres of urban farmland in Philadelphia, and that's not unique to many other large cities. If more cities have the opportunity to farm locally, the company posits, it will improve the quality of food across all communities, offer fresher meals and help boost local economies.

Metropolis Farms President Jack Griffin is an ex-banker originally from Philly who launched the company early last year, seeing the project as a method of civic engagement for the city.

“Instead of being a customer, we have to become our own supplier,” Griffin told the Philadelphia Citizen in 2016. “That way, we can keep our money moving within our own city.”

In less than two weeks, Philly will host its first-ever Indoor Ag-Con on Oct. 16, a daylong event scheduled to be held at the Pennsylvania Academy of the Fine Arts that will feature presentations from various indoor agricultural professionals, including Griffin.

Solar energy prices have dropped significantly as the technology figures to assume a key role in the global energy mix of the future.

Life On Mars A Possibility With New Indoor-Farming Technology

They say their technology will also benefit the earth as it uses less water than traditional farming techniques.

Life On Mars A Possibility With New Indoor-Farming Technology

A US-based company has developed technology that can replicate any kind of climate inside a shipping container, bringing sustenance on a mission on Mars one step closer to reality.

The company, Local Roots Farms, has joined forces with Space X, a company that's trying to get people to Mars. (File photo/ Reuters)

A company in California says it could be the first to grow food on Mars.

Local Roots Farms has developed an indoor farm that could feed astronauts on longer-term space missions.

They say their technology will also benefit the earth as it uses less water than traditional farming techniques.

TRT World’s Frances Read reports from Los Angeles.

Indoor Farm Thrives In North York Industrial Unit

Indoor Farm Thrives In North York Industrial Unit

Jonah Krochmalnek's crops require less water than traditional farming methods, and taste delicious all year-round.

By ALEX MCKEEN | Staff Reporter

Tues., Sept. 5, 2017

Jonah Krochmalnek is a 26-year-old farmer. He pulls up to work every day ready to plant, tend and harvest a variety of organic greens and herbs.

He produces loads, too. In a given year — he doesn’t have to worry about seasons on his farm — Krochmalnek estimates he could grow 16,000 kilograms of pea shoots, if they were his only crop.

Living Earth Farms, the company Krochmalnek started four years ago is no ordinary farm.

That’s because it isn’t on a remote country road where plants have space to stretch out and soak up sunlight, but in an unassuming, 2,300-square-foot industrial unit in North York, the same area where Krochmalnek grew up and lives still.

Living Earth is an indoor, vertical farm where crops grow in stacked rows seven layers high with special red and blue LED lights designed for optimal growing conditions shining down on them. It’s the first of its kind to be organic certified in Ontario.

“It took a long time to figure all this out because there’s no book on this type of thing,” Krochmalnek said.

Jonah Krochmalnek is on the owner and operator of Living Earth Farm, an indoor vertical farm in Toronto. (ANNE-MARIE JACKSON / TORONTO STAR) | ORDER THIS PHOTO

His farm is closed to the public because Krochmalnek works there alone and doesn’t have the means to run an educational component yet.

Indoor farming is a new industry, especially in Canada where Krochmalnek runs one of the first such businesses to get off the ground. He sells wholesale to distributors all year — a pot of living basil goes for $2.40 ($4-$5 retail) and a 100-gram clamshell of a variety of microgreens sells for $10 (restaurants buy them for around $15).

Since he grows indoors, he has to automate as much of the growing process as possible, and ensure that it’s efficient enough to make money.

In fact, most of what makes up Living Earth Farms was put together by Krochmalnek himself, from the giant fans that control humidity, to the sub-irrigation system that keeps plants watered without risking contamination.

His choice of red and blue LED lights was informed by NASA research aimed at figuring out how to grow food in space.

“This is probably somewhat of a model that will be used if we go to Mars,” he said. Since the lights he uses are energy efficient, his hydro bill has never exceeded $1,600 (usually it’s closer to $1,000-$1,200).

By growing indoors, Krochmalnek is able to produce food year-round. It’s kind of like having a greenhouse — only it requires a seventh of the space to produce the same yield and uses about 95 per cent less water than traditional farms for crops like lettuce.

“In the winter something like basil takes me 16 days to grow. In a greenhouse, almost double that,” Krochmalnek said.

The quality, he said, is “not even close.”

“My basil tastes like summer. Basil in the winter grown in a greenhouse tastes like water.”

The reason for the difference is simply that the space Krochmalnek has designed is ripe for growing. It’s, as Krochmalnek describes it, the “perfect plant environment.”

“Let’s say you want to be in a tropical sunny place to go on vacation generally. This is like plant vacation. The plants have it easy here,” he said.

Well before he ever imagined making a living by designing and operating a plant paradise (he studied business, not agriculture), Krochmalnek cherished a love of gardening.

His dad showed him how to keep a garden at age 14 and he was instantly hooked.

“Whenever I had a summer job I would bring my cherry tomatoes to people at the office, and their face would light up, and that’s the best feeling,” he said.

Krochmalnek began to see agriculture as a career possibility only after he took part in Downsview Park’s urban farming initiative, Fresh City Farms, and loved it.

He chose indoor farming in an attempt to make farming within the city viable, and now he can’t imagine doing anything else.

“It’s 100 per cent certain that this will be part of the future. It won’t be the whole future for agriculture, but it’ll be a big part for leafy greens and perishable crops,” he said.

Rhonda Teitel-Payne, co-coordinator of Toronto Urban Growers, said that, while urban farms like Krochmalnek’s are unlikely to be sufficient to feed cities, they play an important role in food security, and connecting people to the food system.

“We are going to see more and more farmers, more rooftop growers, more vertical systems because people are running out of options in terms of access to land,” she said. Though land is scarce, interest is growing.

Vertical farming is “very new but there are a lot of people who are thinking about it, talking about it,” Teitel-Payne said.

Looking forward, Krochmalnek has imminent plans to hire his first employee, and longer-term ideas about possible expansion.

In the meantime, he hasn’t stopped gardening for joy, in addition to business. Three potted eucalyptus plants sat under his LED lights last month, not for selling “just for fun.”

Krochmalnek marvelled at the genetic differences that caused them to come out looking like a motley trio.

“These are all from the same batch of seeds,” he said. “And they all grew differently.”

Kimbal Musk: Food Is the Next Big Thing

Kimbal Musk: Food Is the Next Big Thing

Elliot Volkman

- Aug 10, 2017

Twenty years ago an internet pioneer made a fortune for being on the cutting edge of a booming industry, and today he is suggesting food will be the next big thing. Kimbal Musk, entrepreneur, venture capitalist, and environmentalist, and yes, sibling to Elon Musk, took the stage at last year’s Life is Beautiful to discuss the reality of food today and how the changing market can lead to large opportunities.

“We produce 30 percent more than we need to eat, in fact measured by the cheeseburger index, we are growing more than two-and-a-half cheeseburgers per person than we need. And the result is massive: obesity around the world 800 million in 1980 had obesity, today 2.1 billion people in the world are obese. And it’s a tragedy for those people and an economic disaster for the world,” said Musk.

According to Musk, the problem is not the food output overall, but industrial or processed foods. These foods are high in calories, lead to obesity, but at the same time lead to malnutrition for those who consume it. However, thanks to the internet, the world is becoming more informed about what Musk refers to as real food.

The Changing Supply and Demand of Real Food

Fast food chains are closing, and sales on microwavable and frozen foods are dropping. According to Musk, 45 percent of Americans want organic foods, but less than one percent of farms in the US are supply it. With information readily available, demand for organic food is rising, but there is still a separation based on age groups. More and more millennials want to see healthier local foods, are curious about where their food comes from, and want natural food. On the other hand, Musk says that baby boomers still see healthier food as slim shakes, fat-free, low-sugar, etc., which certainly has nothing to do with the mass amounts of marketing designed to convince people of such.

“The global software industry, which is where I started, is about a $400 billion industry. And while that sounds very big, it’s the size of the seafood market. When you look at food as a whole, it’s 10 percent of the global GDP and almost $5 trillion ($4.8T) in size. Think about all those friends you know of that mad a lot of money in software, multiply that by 10, that’s the opportunity in food,” said Musk.

In addition to the increase in demand, supply will see a change as well. In Iowa, 25 percent of the farmland is owned by a woman over the age of 75, and 26 percent is owned by a man over the age of 75. This means over the next 5-10 years there will be an avalanche of supply for farm land. Musk also highlights how 25 million acres of land are also used for ethanol, something the EPA has been looking into.

Although the EPA does not regular farm lands, Musk suggests this may change due to the increasing pollutants entering the global water supply as a result of nitrogen based fertilizers. If these changes to occur, and if ethanol producing farms are reduced, there will once again be a large supply of fertile farm lands.

Future Farming

The future of farming consists of as much technology as it does understanding the earth. From engineers building automated machines to do an otherwise unscalable skilled trade, to data scientists analyzing data from satellites regarding soil fertility, moisture, and crop harvest times, technologists will have an opportunity to take a piece of a booming industry. Musk ends his talk with a simple statement. For those who feel they missed out on the internet and .com boom of the past, real food is the opportunity they should pursue.

Life is Beautiful takes place in late September in downtown Las Vegas. Tickets are available now. More information, including the set times to expect each panel or activity, will be available on the website in the near future, but right now, you can browse all the events in the Life Is Beautiful lineup, from music, art, and food to ideas and comedy.

Tags: artisan foodsBusinessFoodKimbal MuskLIBLife Is BeautifulLife is Beautiful Festivalorganic foodStartupVideo

Metropolis Farms: Vertical Farming Designed to Grow Out, Not Up

Jack Griffin of Metropolis Farms. Credit: Tricia Burrough

Metropolis Farms: Vertical Farming Designed to Grow Out, Not Up

The Philadelphia-based startup is looking to change the thinking around the green-collar economy, building a sustainable, modular design around optimized indoor farming technologies.

By Matt Skoufalos | April 27, 2017

Photos by Tricia Burrough

Griffin holds a tray of microgreens grown at Metropolis Farms. Credit: Tricia Burrough.

While the first harvests of spring herald the upcoming farmers market season in South Jersey, across the river in South Philadelphia, Jack Griffin has been hauling in crops all winter long.

On the second floor of a warehouse in the 2400 block of Water Street, he’s just a few blocks away from the other shipping and receiving terminals that supply many area supermarket chains with fresh produce.

But in a fraction of the physical space—and at a fraction of the costs of growing and shipping those fruits and vegetables there from across the corners of the country—Griffin’s Metropolis Farms is quietly growing their organic, non-GMO, vegan-certified competition.

More to the point, Griffin is growing a business that he believes can close gaps in food insecurity, social justice, and sustainability.

“The transactional nature of food means that we have a lever to change the world,” he said. “Everybody eats. The conversations around food are so ingrained in our society [that] in between those transactions is an opportunity.”

Seedlings at the Metropolis Farms headquarters in Philadelphia. Credit: Tricia Burrough

Indoor vertical farming has been touted as “the next big thing” in the green-collar economy for about the past half-decade.

In September 2016, AeroFarms of Newark drew national headlines for the massive scale of its 69,000-square-foot, $30-million operation.

The company converted a shuttered steel factory into a indoor greenhouse the company says is the largest indoor farm in the world, capable of producing 2 million pounds of crops per year, according to CNN.

But Griffin said the thinking that produced it is grandiose and wrongheaded: in his opinion, the key to vertical farming is actually horizontal growth.

“If I’m ever the world’s largest vertical farm any way other than by accident, shoot me,” he said. “We don’t need the world’s largest farm, we need a dense network of independent, smart farms.

“Everybody’s got the same idea; ‘I’m going to build 60 farms,’” Griffin said. “Who’s going to buy 60 farms at $26 million a farm? We can make a profitable farm with our stuff for $600,000.”

Griffin claims the technology behind Metropolis Farms is capable of growing 2 million pounds of produce in just 14,000 square-feet of real estate, and by using one-tenth the energy of a system like AeroFarm’s. Powered by a rooftop solar array on Swanson Street in Philadelphia—where Griffin says he also can recapture 2 million gallons of water annually—Metropolis Farms is made to be energy-independent and disaster-resistant.

It also doesn’t need prime real estate to operate, or even much of it at all. By licensing the technology behind his work, which includes the growing equipment and seedling optimization schedule, Griffin is optimistic that he’ll be able to create a distributed indoor farming culture, not just a farming network. His licensing agreements will include labor clauses about paid time off, living wages, and possibly an degree correspondence program to give inmates the chance of a stable career upon release.

“I think that social responsibility should be part of this,” Griffin said. “Equal pay for equal work, and no discrimination. Our goal is to get as many people as possible farming.”

Lee Weingrad, VP of Metropolis Farms. Credit: Tricia Burrough

“It’s the evolution of technology,” said Metropolis Farms vice-president Lee Weingrad, a U.S. Air Force veteran who co-developed the technology at the heart of the system with Griffin.

“Everything’s on a schedule,” Weingrad said. “We made it simple on purpose. Anyone with a high-school diploma can work here.”

The Metropolis Farms infrastructure is modular and able to be built from equipment available at a hardware store, which Griffin said cuts out the construction costs of retaining a design firm to build custom architecture.

It’s able to be dismantled for cleaning with quick-connect PVC systems, and features optimization algorithms that are designed to help crops flourish without the use of genetic modification.

The first-generation lights were based on a design of Nikola Tesla’s, but the ballast atop them retained too much heat and showed too much infrared light, Griffin said. Their replacements are high-intensity discharge (HID) lamps with a proprietary core, shielded with lightweight, reflective, and refractive German aluminum. They’re suspended from a motorized track, which carries the light across the plants on a timed sequence to simulate cloud cover.

At $25,000 per unit, each tower can produce 20,000 pounds of produce annually, Griffin said. He expects farms will consist of 15- to 50-tower implementations; each can yield 19 harvests per year versus two-and-a-half on conventional real estate.

Insectivorous plants keep the produce free of pests without chemical sprays. Credit: Tricia Burrough

Nearby carnivorous plants secrete nectar and resin, attracting and eliminating pests without chemical sprays.

The entire system can pivot from fruits and vegetables to things like pharmaceutical herbs, stevia leaf, or biodiesel jet fuel, all grown at a consistent grade and domestically.

“A lot of what we’ve done is fourth-grade math and freshman geometry,” Griffin said.

“We’re selling ubiquity: a simple system with architecture.”

Griffin isn’t lacking for interest in his model; as of a few months ago, he was sitting on more than $20 million in letters of intent from cities across the United States and Canada to bring his model there. He wants to start in the Philadelphia metro area first.

The challenge when you’re growing 2 million pounds of produce per year is generating enough institutional purchases—from hospitals, universities, prisons, and other governmental agencies—to generate local “velocity of capital” that creates sustainable economic change.

“How many schools do you have?” Griffin said. “They’ll buy locally if you can produce at scale. The key is to drive cities to understand that where they spend their money matters. If we spend that money on local food, we create velocity of capital; we create local jobs.

Sprouts are grown floating in an aqueous solution. Credit: Tricia Burrough

“When those people go and buy things because they’re making $18 an hour, they’re getting benefits, they’re having a life,” he said.

“If we can show them better food, and they buy it because it’s in their self-interest to buy the food, that’s enough.”

Griffin said his goal “is to have every city in the United States steal this idea” so that Metropolis Farms can manufacture the necessary equipment at its core in Philadelphia and ship it out to other markets, creating yet another level of employment. But he believes the model should take root locally first because it has the potential to be a key driver of regentrification and redevelopment with a critical difference: pushing out the poverty instead of the impoverished.

“In Fishtown, there’s 15,700 people,” Griffin said. “What if I could produce enough lettuce for the daily lettuce requirement of everyone in that community, enough tomatoes, and peppers, and so on? And surround that community with wings of prosperity?

“It’s a synergistic model instead of an exploitive one. It is the ultimate demand-based business.”

Philadelphia Aims To Become International Hub For Indoor Farming

April 28, 2016 By Stephanie Stahl

By Stephanie Stahl

PHILADELPHIA (CBS) — On the CBS3 health watch, its vertical farming. Philadelphia aims to become an international hub for indoor growing, according to a resolution passed today by city council.

When growing produce we usually think of acres of farmland. Some say the next generation of farming will be in urban centers like Philadelphia, and you won’t need soil or the sun, just an old warehouse.

Welcome to vertical farming, where produce is grown inside, in specialized shelves that are stacked up vertically.

“We’re able to grow more food in less space,” said Jack Griffen “ we fit 13 acres in 1600 square feet.”

Inside this nondescript warehouse in South Philly is the prototype farm of the future.

“It’s a cool thing, I mean you know think about how many empty warehouses are in the Philadelphia region that could be creating jobs, that could be creating food for our local population,” said Jack Griffin the president of Metropolis Farms.

Philadelphia city council recognized Metropolis with resolutions to make the city an international hub for vertical farming.

The idea is “to establish Philadelphia as a promenade training center for this type of farming,” said Al Taubenberger.

“Remember we don’t have the weather, when it snowed this April we were growing inside,” Jack said. “We were growing food in January.”

The year round inside farm works by using artificial light. The light and the plants are grown in nutrient rich water, that’s constantly recycled.

“It’s the same nutrients as soil just in a cleaner fashion,” Jack said. “We’re vegan certified which means we have no pesticides, and I mean zero, no herbicides, and no manure, manure being one of the number one causes of food poisoning.”

They can grow everything from lettuce, and basil, to peppers and carrots.

“That’s about as fresh as it’s ever going to get.”

Jack has plans to branch out into empty warehouses all over the city, with hopes of becoming a world leader in vertical farming.

He says he’s addressed a variety of criticisms about vertical farming, by creating systems that are cost effective and use less electricity. Jack sells the produce to local restaurants and places like Whole Foods.

For more information, visit http://www.metropolisfarmsusa.com

Stephanie Stahl

Filed Under: HealthWatch, Stephanie Stahl, vertical farming