Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Scientists Develop ‘Probiotics’ To Help Plants Fight Disease Without Pesticides

With concern about the impacts of pesticides on human health and the natural world growing, and disease resistance leading farmers to increase their use, the team is hoping to find a chemical-free solution

Enhancing a plant’s immune system with ‘probiotics’ could help it to fight off pests and diseases without the need for pesticides, according to scientists at the University of Sheffield. At the university's Institute for Sustainable Food, a study was launched, funded by a £1.5 million grant from the Biotechnology and Biological Sciences Research Council, into how beneficial bacteria protect plants’ health – in a similar way to gut bacteria in humans.

With concern about the impacts of pesticides on human health and the natural world growing, and disease resistance leading farmers to increase their use, the team is hoping to find a chemical-free solution.

Today, many fruits and vegetables – particularly tomatoes and soft fruits like strawberries – are grown hydroponically (without soil) in vast greenhouses and polytunnels covering 948 hectares in the UK. This enables farmers to grow high-value produce out of season – but because the plants are grown in sterile conditions, any diseases that do find their way inside can devastate entire crops.

By introducing beneficial bacteria to these greenhouse environments, the University of Sheffield scientists hope to prevent these outbreaks – helping to improve productivity and avoid food waste.

Looking at tomato plants, the team will use a combination of genetics and biochemistry to gain a thorough understanding of how roots interact with beneficial microbes in the soil. This knowledge will then be applied to develop plant versions of probiotics – methods of adding good bacteria to growing systems that will support the tomatoes to fight off pests and diseases using their own enhanced immune systems.

Scientists at the Institute for Sustainable Food have already developed synthetic foam ‘soils’, which can grow two to 10 times more produce than natural soil, relieving pressure on agricultural land and increasing the potential for urban farming. By injecting these probiotics into the foam, they hope to create ideal growing conditions for a whole range of herbs, fruits, and vegetables to be grown year-round.

"Scientists have learned a lot in recent years about how beneficial bacteria in our guts keep us healthy – and we believe the same is true for plants.

By investigating how tomato plants interact with good bacteria in the soil through their roots, we hope to be able to develop plant probiotics to boost their immune systems and help them fight diseases without the need for harmful pesticides.

Coupled with our synthetic foam soils, this completely new approach could help farmers to grow healthy and sustainable fruits and vegetables out of season and in the urban areas where most people live," says Professor Duncan Cameron.

Source: The University of Sheffield.

Publication date: Wed 3 Jun 2020

The FarmTech Society (FTS) Held Its Second Constitutional Annual General Meeting (Virtually) on June 24th, 2020

Newly elected Chairman Ian Kanski commented “Thanks to the excellent work of FarmTech Society’s founding board and members, the organization is well-positioned for growth and impact in 2020

The Farm Tech Society (FTS) is an international non-profit industry association that unites and supports the Controlled Environment Agriculture (CEA) industry, seeking to strengthen the sector through the development and implementation of resilient and future proof methods and technologies for indoor growing.

The FarmTech Society is enlisted in the EU Transparency Register with #469686733585-87

The FarmTech Society (FTS) held its second constitutional annual general meeting (virtually) on June 24th, 2020. FTS members elected a new board of directors, who in turn appointed the new advisory board. The new boards are elected for a period of two years. The board of directors also appointed the daily management team. The election was held electronically and independently third-party verified.

Newly elected Chairman Ian Kanski commented “Thanks to the excellent work of FarmTech Society’s founding board and members, the organization is well-positioned for growth and impact in 2020. This is an important time for all regions to be investing in sustainable localized food and circular agriculture. Our new leadership team is committed to supporting the quality, safety, and education initiatives that will drive the adoption of Controlled Environment Agriculture globally.”

The election results were as follows:

New Board of Directors

Chairman: Ian Kanski Harrisburg University

INTAG Systems

Vice-chair: Nicole Thorpe Cultinova

Vice-chair: Tisha Livingston Infinite Acres

Director: Marinus Luiten Priva Group

Director: Alina Zolotareva Aerofarms

Director: Nico Domurath Frauenhofer Institute

Director: Andrew Blume Symphony Agtech

Director: Wythe Marschall Ph.D. candidate,

Harvard University

Director: Stefan Frey FREYconsult

Honorary: Gus Van der Feltz (founding member)

The appointments by the Board of Directors were as follows:

New Advisory board:

Edwin Vanlaerhoven Certhon

Maren Schoormanns Viscon Group

Chante Van der Walt Candidate Full Stack

Developer Udemy

Marvin Boell TüVSüd

Enrico Costanzo Cerial Docks

Stefanie Linzer. Valoya

Pierre Grootscholten Grootscholten

Consultancy

Kyle Barnett HortAmericas

Franc Bogovic Finance.Brussels

Yanni Garcia (founding member)

Penny McBride (founding member)

Adam Rosenbaum (founding member)

Daily management:

Secretary-General: Thomas Zoellner (founding member)

Treasurer: Stefan Frey FREYconsult

Communication: Mark Horler Soya Project / UKUAT

Legal counsel Stanislas Demeestere European Future Forum

Future Farm Technology Expo Announces That The UK Urban Vertical Farm Association Urban Agritech UK (UKUAT) Has Joined Future Farm Technology Expo As An Official Supporter of The Event

Mark Horler, Chairman, and Founder of UKUAT commented “We are very excited to announce UKUAT’s partnership with FFT Expo and to have the opportunity to promote urban agriculture and the related technologies at such a leading and exciting event

Future Farm Technology Expo is delighted to announce that the Uk urban vertical farm association Urban Agritech UK (UKUAT) has joined Future Farm Technology Expo as an Official Supporter of the event as an Official Association. UKUAT will be working with the team at FFT Expo to help promote, educate and support UKUAT exhibiting members and connecting the UK urban vertical farming industry to suppliers, farmers, and those who are researching the industry. FFT Expo will run from 11th & 12th of November 2020, at the NEC Birmingham.

Statement from Mark Horler here:

Mark Horler, Chairman, and Founder of UKUAT commented “We are very excited to announce UKUAT’s partnership with FFT Expo and to have the opportunity to promote urban agriculture and the related technologies at such a leading and exciting event. Urban farming is an integral and rapidly growing part of farming. UKUAT is proud to represent and promote our members who are creating new technologies, sharing knowledge, and ultimately producing food in urban and peri-urban areas. It’s a truly exciting time to be involved with UKUAT, as we have networked with different internationally recognized institutions to promote the fantastic new technology that is arising from the sector. We seek always to create new strategic links with experts, organizations, institutions, and to share knowledge. This partnership with FFT Expo will enable us to expand and promote these activities, utilizing this event, online webinars, whitepapers, and networking events in the future.”

Mike Enser, Marketing Manager for the show said ‘the launch edition in 2019 attracted motivated and engaged visitors from across the farming community, with 96% of attendees having buying power. We are delighted that UKUAT is working with us. The knowledge they have of the UK sector is second to none and we at FFT Expo are looking forward to working with Mark and his team to ensure the UK urban vertical farm market is showcased through its exhibiting members, through the associations thought leadership and through its vision ‘To utilize Urban Agritech as a tool to achieve greater sustainability & resilience in the UK food system. Expanding the horizons of Urban Agritech to better inform communities across the UK.’

Future Farm Technology Expo is run by Farmers Weekly and Reed Exhibitions. The event hosts demonstrations of new technologies and the multitude of capabilities that data provides as well as bringing together innovators in agricultural technologies with farmers looking to improve their productivity and yields.

Editors notes:

The UK Urban AgriTech collective, or UKUAT, brings together the UK’s key players in modern agricultural technologies. We’re a cross-industry group devoted to promoting urban agtech as a solution for food and environmental crises. We influence policy by sharing information, educating, and communicating practitioner needs as one. We promote the uptake of agtech in urban and peri-urban settings by uniting to attract funding and customers.

Future Farm Technology Expo is one of the only UK events dedicated to solving the challenges faced by farmers through agricultural technology solutions.

Whether you are looking to optimise your production or reduce waste, here you have direct access to the experts and technological solutions that will benefit you long-term and plant those seeds for positive change.

For immediate circulation:

To get in touch with UKUAT please email info@ukuat.org

If you would like to talk to the team behind FFT Expo, please email Mike Enser –michael.enser@reedexpo.co.uk

US (CA): Vertical Farm Launches Personalized Cultivation and Delivery Service

South Bay Area residents will be the first to experience Farming as a Service through Willo’s innovative cultivation technology. Residents within 20 miles of Santa Clara, Calif. can subscribe to an exclusive plot in Willo’s farm starting at $99 a month at willo.farm

Indoor vertical farming startup Willo debuted a brand new direct-to-consumer delivery program in San Jose to provide a custom produce experience in the Bay Area. Founded by brothers Samuel and John Bertram, Willo’s personalized cultivation and delivery service connects consumers directly to their own plot in Willo’s local vertical farm.

South Bay Area residents will be the first to experience Farming as a Service through Willo’s innovative cultivation technology. Residents within 20 miles of Santa Clara, Calif. can subscribe to an exclusive plot in Willo’s farm starting at $99 a month at willo.farm. The membership grants access to regular deliveries of customizable packaged salads starting in August. A single purchase option is also available for $49. The rapidly growing list of available crops currently includes Toscano Kale, Red Mizuna, Pea Shoots, Protein Crunch and Genovese Basil. Willo will add additional fruits and vegetables to its farming capabilities as it scales.

“Willo is unleashing the power of plants on human health,” said Samuel Bertram, co-founder and CEO of Willo. “For the first time, fresh food will be grown specifically for the person consuming it. Personalization exists everywhere except for the food industry; and we’re here to give the market what they are asking for. By letting people configure their own plot in Willo’s farm, we can grow the specific fruits and vegetables they desire, while making recommendations tailored to their health needs. Willo plans to build farms in every major city on Earth with the mission to eliminate diet-related disease through personalized plant-based nutrition.”

A strong proponent of Community Supported Agriculture (CSA), Willo also announced a partnership with HomeFirst Services of Santa Clara County to further extend the positive impacts of sustainable local indoor farming practices. Willo will deliver fresh produce from its farm to assemble 40 ready-made plant-based meals each month for homeless individuals and families in the San Jose area.

“This is a really important part of a well-balanced diet that is difficult to procure on a large scale for homeless shelters,” said Lori Smith, director of development and communications at HomeFirst. “Together with HomeFirst, Willo will bring tasty, nutrient-dense produce to shelter guests and the at-risk community served in Santa Clara County.”

Scalable and sustainable farming in cities

Willo’s technology is optimized for scaling into urban settings with the intent of making local farming a global reality. Willo currently delivers within 20 miles of its farm, and the consumer’s hands are the first to touch it. Willo’s highly automated farming techniques remove pesticides and contamination, and produce essentially zero water consumption by recycling the water supply.

Following the success of the Bay Area launch, Willo will continue expanding the Farming as a Service model to urban communities across the country with planned expansions to cities like Los Angeles, San Diego, New York and Washington D.C. in the next 24 months. Willo aims to scale its technology to every major city globally to make local and sustainable farming accessible to everyone.

For more information:

Willo

willo.farm

Publication date: Mon 15 Jun 2020

VIETNAM: Shipping Container Farm - Growing Strawberries Indoors in Vietnam

At the 88.17 hectare Agriculture High Tech Park in Ho Chi Minh City, Center for Business Incubation of Agricultural Hi-Tech (AHBI), a first batch is underway with 100% indoor cultivated strawberries. The first batch was planted earlier this year and harvest is expected within 3 months

At the 88.17 hectare Agriculture High Tech Park in Ho Chi Minh City, Center for Business Incubation of Agricultural Hi-Tech (AHBI), a first batch is underway with 100% indoor cultivated strawberries. The first batch was planted earlier this year and harvest is expected within 3 months. The AHBI serves as a testing lab as well as an educational centre to stimulate the development of advanced horticulture in the region.

Meeting the demand for fresh organic produce

Ph.D. Hoang Anh Tuan, Deputy Director of AHBI, talks about how the cultivation is doing and what the challenges and opportunities are. “The demand for fresh and affordable strawberries is increasing across Asia. Our aim is to grow strawberries all year round and near the city”, says Ph.D. Hoang. Until recently, growing strawberries in Ho Chi Minh is not possible due to the local climate. With improvements in climate control, many parameters could be controlled but the right lighting with easy controls was not available until HortiPower launched in Vietnam.

Upgrading yields and more investments

While Vietnam is already known as a significant agricultural producer, its farmers are increasingly looking to upgrade production capacity and increasing yields. PhD Hoang explains: “New generation growers are looking to maximize the yield per square meter with high-value cultivars, to lower the energy use per fruit and affordable solutions to help them start.” There is also a push from private investors, but they are looking to start with technologies and investments that can scale, rather than a large upfront investment with long payback term.

“To support private investors and help them move towards high-tech agriculture we introduced hydroponic container farms. It allows us to control the climate which enables us to grow a high value crop and to grow all year round”.

“The initial investment is reasonable and has only a 2-year payback. They allowed us to do a trial so we would have our own data about potential production results”.

Growing high quality strawberries and producing them year-round has remained a challenge when growing in the field. Growing strawberries in consistent size and quality will require the right lighting, so that the production process becomes more predictable and the yield increases. Consumers indicate that they are prepared to pay more for overseas strawberries that are larger, sweeter and have a softer, smooth skin compared to the local varieties grown normally in the region. Getting the right lighting is very important when growing fully indoor. “We’ve evaluated many different lighting fixtures from other companies. We had the best results with HortiPower since its lighting system allowed us to completely control lighting distribution, the intensity and spectrum. It can also run lighting algorithms without the need for a local onsite computer.”

“Since last year we have actively visited several growers onsite to understand their needs and challenges. We are working closely with a team of our own researchers and several universities to provide suitable lighting solution for many laboratories in the region”, says Katherine Tran - Sales Director of PTP Vietnam which represents HortiPower.

Starting in the spring

This spring, new LEDs from HortiPower were installed. Each shelf has 4 fixtures for an even distribution of light. And with a fully adjustable µmol intensity and spectrum, the strawberries can get exactly what they need at each stage of strawberry cultivation. Supporting plant growth, flowering, and fruiting may require different lighting which affects the nutrient production, quality, taste, and brix. The new lighting also gives better control of harvest times, which is commercially relevant to get ready just before the popular spring festivals and other dates with peak consumer demand.

“With HortiPower we are able to control the exact amount of light intensity, spectrum and ratio. We are now able to control the growing process in a much better way.”

Katherine Tran during A/B testing at AHBI

The right lighting

AHBI evaluated horticultural lighting and chose HortiPower with a spectrum of plant-centric red, green, blue, white, and far-red. This spectrum not only produces the desired stem elongation, but it also makes it possible to achieve a higher yield of strawberries with a low percentage of malformed fruit. The team evaluated various models and chose the linear 20W version with full control on intensity and ratio. “We’re excited and look forward to delivering delicious strawberries all year round”, says the Deputy Director with a smile on his face.

For more information:

HortiPower Asia

Katherine Tran - Sales Director

info@hortipower.com

HortiPower Research

Jille Kuipers – Innovation Manager

info@hortipower.com

www.hortipower.com

Publication date: Mon 8 Jun 2020

Infarm Looks to Raise $200m For Vertical Farm Expansion

Berlin-based Infarm has closed an initial $140m of a planned $200m Series C funding round, said people involved in the deal, at more than double the valuation at which it raised $100m a year ago

German Start-Up Grows Herbs and Salads

Inside Supermarkets and Restaurants

Infarm’s latest funding deal will value the company in the hundreds of millions of dollars © Simone M.Neumann - www.simone-m-neumann.de

June 28, 2020

by Tim Bradshaw in London

Infarm, a German start-up developing indoor farms, is closing in on a new $200m investment, hoping to capitalise on renewed investor appetite for companies that can address food supply problems that arose during the pandemic.

Berlin-based Infarm has closed an initial $140m of a planned $200m Series C funding round, said people involved in the deal, at more than double the valuation at which it raised $100m a year ago. The deal values the company in the hundreds of millions of dollars, these people said.

Unlike other vertical farming ventures that install crops in huge warehouses, Infarm’s smaller “modular” units sit on supermarket aisles and inside restaurants. These hydroponic farms can avoid the use of pesticides thanks to a tightly controlled environment, and reduce lengthy supply chains by offering produce that is fresh at the point of sale.

Hundreds of its small farms growing herbs and salads can be found on the shelves of supermarkets after it struck deals with Marks and Spencer in the UK and Kroger in the US, as well as European supermarkets including Metro, Casino, and Migros. Last month it signed up Aldi in Germany.

LGT Lightstone, the “impact investing” arm of the Princely House of Liechtenstein, is said to be among Infarm’s new investors, joining venture capitalists including Atomico, Balderton, TriplePoint, Cherry Ventures, and LocalGlobe. LGT Lightstone is also an investor in Lilium, the German air-taxi developer.

Infarm’s modular units sit on supermarket aisles and inside restaurants © Simone M.Neumann - www.simone-m-neumann.de

“Vertical farming is a pandemic-proof business,” said one investor.

Infarm declined to comment. LGT Lightstone did not immediately respond to a request for comment.

But while the Covid-19 pandemic’s pressures on food supply chains have opened opportunities for new producers such as Infarm, it has also hit demand from restaurants, which make up a smaller portion of the company’s business.

While tech investing has continued during the pandemic, lockdowns make it harder for potential investors to perform due diligence on hardware-based companies such as Infarm.

The company was founded in 2013 by Osnat Michaeli and brothers Erez and Guy Galonska. It competes with several other venture-backed indoor farming start-ups including Plenty, Bowery Farming and AeroFarms.

The group was founded in 2013 by Osnat Michaeli, pictured, along with brothers Erez and Guy Galonska © Simone M.Neumann - www.simone-m-neumann.de

Bowery has raised more than $140m from investors including Alphabet’s GV, according to Crunchbase, while SoftBank-backed Plenty has a $400m war chest.

Infarm’s latest fundraising, when complete, would allow it to close the gap with Plenty, which also counts Amazon founder Jeff Bezos and former Google chief Eric Schmidt among its investors. In late March, Bloomberg reported that Plenty was looking to raise at least $100m in new financing.

However, Infarm’s expansion has outpaced Plenty, which remains largely focused on building facilities in its native California.

While larger warehouses such as Plenty’s have high upfront costs and are expensive to provide with lighting and air conditioning, Infarm argues its modular farms are easier to scale and prove appealing to retailers looking for differentiation. Investors hope that it can also build a brand of its own, unlike most agricultural suppliers.

Additional reporting by Emiko Terazono

Space Peppers to Spice Up Astronauts' Diets

Astronauts and cosmonauts spend a lot of time aboard space stations - sometimes more than a year at a time. When you're up there that long, it would be nice to bite into some freshly grown vegetables

Astronauts and cosmonauts spend a lot of time aboard space stations - sometimes more than a year at a time. When you're up there that long, it would be nice to bite into some freshly grown vegetables. Particularly if humans will return to the Moon or even go to Mars, it's essential to be able to grow fresh food there. Researchers are looking into the unique challenges of growing space veggies, learning a thing or two about cultivation on Earth in the process. One of them is Jacob Torres, who works at the Space Crop Production Lab at NASA’s Kennedy Space Center. In a recent webinar, he shared his experiences conducting space agriculture research.

Jeff Kohler, who supports the Technology Transfer Program at NASA and hosted the webinar, said he met Jacob Torres about a year ago, when the latter submitted a proposal for a new plant nutrition system. Jacob was raised in a traditional farming community in New Mexico, so it's not entirely surprising that he ended up working in agriculture, albeit controlled environment agriculture.

Tap to pollinate

Kicking off the webinar with a video shot in one of his plant growth chambers, Jacob explained why (chile) peppers are particularly suitable to grow in space. First of all, there are no pollinators in space - you can't just open up a box of bees inside a space station. "With peppers", Jacob explains, "you can tap on one of the flowers, then a pepper starts to grow." This makes peppers more suitable than crops like cucumbers, which do require pollination. Another advantage is the high nutrient content of peppers, making them a welcome addition to the astronaut diet. And last but not least, peppers are both fresh and spicy, adding extra flavor to space food, which can sometimes taste bland due to the way taste buds behave in space.

Moon and Mars missions

The research Jacob and his team carry out at the Kennedy Space Center, serves astronauts on the International Space Station (where they use systems like Veggie and the Advanced Plant Habitat), but they're also looking at the bigger picture. With the Artemis program, NASA is looking to put people on the Moon again, and they also have their sights set on Mars. On those longer missions, astronauts will spend a lot of time in deep space such as on Gateway space stations, and later on the red planet itself, where they will appreciate having fresh grown food and fresh food will supplement the packaged diet. The main idea behind this is to add more vitamin C, K and B to space traveller's diet, which will be the team's mission for the next 10 to 15 years.

Spare parts

No matter how advanced NASA's technology may be, it's only a matter of time before a part starts to fail. "When this happens on the Moon, you can't just go to a shop to get spare parts, or order them through Amazon Prime - not yet at least", Jacob jokes. So what do you do then? When an acid addition pump in one of Jacob's NFT channels disintegrated, he found out it took two weeks to have a new one shipped. "Hand mixing the pH or stopping the experiment was not an option." Instead he had the disintegrated part 3D printed, and the system was back up and running in no time.

A bit of New Mexico on Mars

With the technical details sorted out, the next step is to figure out what variety of pepper to use. "So we hit up the literature to see what work had already been done and demonstrated. In New Mexico, chile peppers are a big part of the culture, so graduate students and professors have been writing research on that for over a century." Gathering pepper seeds from all over the world, it was found that one particular New Mexico pepper performed really well: Española Improved, a hybrid between Big Jim and Española peppers. Española also happens to be Jacob's hometown - "I'm really stoked about that", he commented.

Red Robin tomatoes growing in the water delivery test bed (DAP 88)

Light recipes

The Advanced Plant Habitat, one of the NASA-developed plant growth systems that Jacob works with, features LED light banks with all frequencies, provided by OSRAM. With the system, colors in LEDs can be adjusted, even the UV, to create recipes for specific crops (leafy green, peppers, and so on). Technology like this is absolutely vital in astrobiology, Jacob explains. "Growing crops won't be a primary thing that astronauts have time to do." In addition to the light recipe system, hyperspectral imaging to monitor crop health will also help them with that, and it may even work better than the human eye, according to Jacob.

Irrigation without gravity

Another issue when growing without gravity is irrigation. When you wring a towel in space, the water just sticks around the towel, as demonstrated in the video below by Canadian astronaut Chris Hadfield. "The same thing happens with roots", Jacob explains. "Existing hydroponic systems are largely inoperable in microgravity." (The current system uses time-released fertilizers, but they would like to use a hydroponic system at some point.)

To find a solution to this problem, several candidate microgravity systems were tested against a control system. "Irrigation systems for microgravity should be sustainable, ideally even with reusable plant medium you don't have to throw away, featuring low heat production and energy use, minimal failure mode (without a pump, that would be awesome), reduced crew interaction, and it should be scalable. You should be able to do science on it, then scale it up to do crop production and grow a lot."

PPTNDS

The Passive Porous Tube Nutrient Delivery System (PPTNDS) was the solution to the irrigation problem, using the capillary force of water to force water up. "You can wick water up, the water evaporates from the tube, and water from the bag then replenishes it."

Jacob and his team used water bags like the ones used on the International Space Station, which they connected in a loop to the hoses. They put seeds on top of the tubes, wrapped them up with wrap, added water, air, light - and the crops started to grow, much to the team's delight.

Jacob grows lettuce, peppers, and tomatoes in the PPTNDS. The Red Robin tomatoes (top left) were still going strong 111 days after planting. The peppers (top right) didn't fare so well, but given that Jacob had forgotten about them for weeks, if not months, it's quite impressive that they still bore fruit.

When compared with the NFT control system, the PPTNDS uses much less water (about 25% of the standard amount of water). With only six plants grown on each system, the PPTNDS crops also used up only 25% of the space used in the control system, and the number of crew interactions is also a lot lower, which is a must in space. And as an added bonus, the PPTNDS also scored better in taste tests.

Back on Earth

So, what does this all mean for the non-astronauts among us? Well, in industrial cultivation, the PPTNDS could see use in the top layers of vertical farms, which can't be visited that often by growers. In education, teachers can use it to teach students about agriculture in a system that basically grows itself, and it could even be marketed as a novelty item to consumers, Jacob believes, using the slogan "Developed by NASA". NASA’s expertise in space and scientific exploration contributes to essential services provided to the American people by other federal agencies, such as weather forecasting and natural resource management. The agency freely shares this unique knowledge and works with institutions around the world.

If you're looking to get involved in the agricultural space race, you can participate in the Space Chile Challenge, to grow the hottest possible space pepper. Later this year, NASA will also open up the Lunar Nutrition Challenge, asking the public, academia and industry to develop and demonstrate food production systems suitable for future space exploration. Registration for that is expected to open in late 2020.

For more information:

NASA Technology Transfer Program

technology.nasa.gov

Publication date: Fri 26 Jun 2020

Author: Jan Jacob Mekes

© HortiDaily.com

TODAY AT 4 pm EST - Join Indoor Ag-Conversations - United Fresh - Webinar Panel

Verlage Joins Top Execs from United Fresh, DNO Produce, BrightFarms For Virtual Panel On Produce Trends, Business Growth Opportunities For Indoor Growers Emerging From Covid-19 Pandemic

LAS VEGAS (May 27, 2020) – Victor Verlage, Senior Director of Agriculture Strategy Development, Walmart, will join the panel line-up for the debut session of the new Indoor Ag-Conversations webinar series announced last week.

Scheduled for Wednesday, June 3 at 4 pm EST, the program, “United Fresh Produce Association Panel: Produce Trends & Business Opportunities For Indoor Growers Emerging From Covid-19 Pandemic, ” will be moderated by United Fresh President & CEO Tom Stenzel, and also include panelists Alex DiNovo, President and COO, DNO Produce and Paul Lightfoot, President and Founder, BrightFarms.

Leading Strategic Food Sourcing at Walmart Inc, Verlage joined the company in 2010. In 2014 he relocated to Bentonville, Arkansas to spearhead the development of next-generation products and is responsible for securing the long term food supply for Walmart’s growth demand plans.

Indoor Ag-Con LLC, producers of the premier event for the indoor|vertical farming industry, created the new Indoor Ag-Conversations series to share content originally planned for its May 2020 in-person annual conference that has been postponed due to the Covid-19 pandemic.

During the 60-minute webinar, Verlage and the other members of the executive panel will explore the unprecedented challenges and opportunities industry members face today. Participants will learn: key produce trends to watch; tips for building mutually beneficial relationships with produce distributors; how Covid-19 is accelerating demand for locally grown food; what indoor growers are doing now to adjust to a changing market and more.

Attendees will also get a sneak preview of United Fresh 2020 Live, the Association’s new virtual event coming the week of June 15.

Indoor Ag-Conversation webinars are free to industry members. To register for the upcoming June 3, 2020 session, visit www.indoor.ag/webinar

In addition to Verlage, the June 3, 2020, Indoor Ag-Conversations | United Fresh program will share insights from:

Moderator Tom Stenzel, the President, and CEO of the United Fresh Produce Association is a frequent speaker on industry issues and has been recognized for his leadership frequently throughout his career. Tom has testified numerous times before Congress and works closely with leaders at the White House, USDA, FDA, and other U.S. regulatory agencies.

Paul Lightfoot, President, and Founder of BrightFarms, is creating the first national brand of locally grown produce. In four years, Lightfoot has led the company from a proof-of-concept to operating four greenhouses in key markets like Washington, D.C., Chicago, Cincinnati, and Philadelphia.

Alex DiNovo is President and COO of DNO Produce Group of Companies, a rapidly growing family-owned group of businesses located in Columbus, Ohio. DNO is a fresh fruit and vegetable processor, as well as a distributor, with a distribution network throughout the Midwest, Great Lakes, and the southeastern United States.

ABOUT INDOOR AG-CON LLC

Founded in 2013, Indoor Ag-Con touches all sectors of the business, covering produce, legal cannabis, hemp, alternate protein, and non-food crops. In December 2018, three event industry professionals – Nancy Hallberg, Kris Sieradzki, and Brian Sullivan – purchased Indoor Ag-Con LLC, setting the stage for further expansion of the events globally.

For more information, visit: https://indoor.ag

ABOUT UNITED FRESH PRODUCE ASSOCIATION

United Fresh brings together members across every segment of the supply chain to build relationships that are as solid with a handshake as with a contract. We empower industry leaders to join forces to shape sound government policy. We deliver the resources and expertise companies need to succeed in managing complex business and technical issues.

For more information, visit: https://www.unitedfresh.org and to learn more about United Fresh LIVE! Visit www.unitedfreshlive.org

Indoor Ag-Con, 950 Scales Road, Building #200, Suwanee, GA 30024, United States

Digital Image Processing And Analysis For Plant Phenotyping

LemnaTec, based in Aachen, Germany, has been developing hardware and software for plant phenotyping since 1998

LemnaTec, based in Aachen, Germany, has been developing hardware and software for plant phenotyping since 1998. These systems use digital image processing for applications in research and development, which are used in breeding, science, agro- and biotechnology, as well as in the seed industry.

"Digital tools are the key to modern phenotyping", says Fred Corbett with LemnaTec. "Mendel's visual inspection of pea crosses has enabled groundbreaking discoveries in genetics and, even in the 21st century, phenotypic data is essential for plant research and breeding. Today, computer-aided analysis and machine learning are used for solution-oriented phenotyping."

In addition to tailor-made solutions for complex research questions - e.g. large installations for greenhouses and open field systems - LemnaTec supplies a range of products for routine applications in phenotyping and for seed testing.

"The classical "workhorses" for digital phenotyping are imaging sensors, in particular, high-resolution industrial cameras as known from other areas of image processing. These provide data on the size, shape, and color of the test objects", Fred explains.

"For the analysis of physiological properties, more complex sensor systems are also gaining in importance, such as fluorescence cameras that, in combination with special lighting and filters, provide data on the performance of the photosynthesis system of plants. Application-oriented analysis systems also include methods for evaluating plant diseases and pests."

Digital seed test

The digital seed test developed by LemnaTec is an application derived from phenotyping, which provides valuable services in the seed industry and for gene banks in determining germination capacity, germination quality, and seed quality.

"The experience gained from numerous large-scale installations and laboratory systems has been incorporated into a new product line that provides image recognition solutions for reliable documentation, analysis, and evaluation of data", Fred shows.

SeedaixpertThe Seedaixpert belongs to the new Aixpert product series and is suitable for paper-based germination and seedling emergence tests. "Unified imaging and analysis make data reproducible and standardizable. Modern image processing algorithms including machine learning provide reliable and comprehensive data, the quality and information content of which exceeds the classical visual assessment. In addition, the digital image data can be retrieved at any time so that complete documentation of the samples is guaranteed."

The Seedaixpert offers extensive accessories.

For more information:

Fred Corbett

LemnaTec GmbH

Nerscheider Weg 170

52076 Aachen, Germany

Phone: +49 2408 9818514

E-Mail: fred.corbett@lemnatec.de

Internet: http://www.lemnatec.com

Publication date: Tue 19 May 2020

VIDEO: Growing Healthy Food Indoors

How many of us live in apartments or townhomes and long for a big backyard to start a garden?

How Many of us Live in Apartments or

Townhomes And long For a Big Backyard to Start a Garden?

Well with new technology, indoor herb growers give anyone the chance to grow their own food. You don't even need a backyard anymore to grow healthy foods.

Now, you can do it all from the comfort of your home. In this article, we're going to talk about our favorite indoor herb grower right now and why you should try it for yourself!

Read more

Nature Fresh Farms is Working With BMO to Make Banking Accessible For Employees

The new ATM has been very well received, with employees happy to have a more convenient means of completing financial transactions

Leamington, ON (May 25, 2020) – To make banking more accessible for its employees, Nature Fresh Farms is working with BMO to bring them on-site access to an ATM to access cash or to complete simple, everyday banking transactions.

With current social distancing and business restrictions still in place, individuals are primarily leaving their residences for essential errands only. Nature Fresh Farms collaboration with BMO allows employees access to an on-site ATM at their farm location helping to reduce or eliminate employees’ essential trips to the bank. The new ATM has been very well received, with employees happy to have a more convenient means of completing financial transactions.

“Throughout this pandemic, we have been looking for ways to make things more convenient for our workers – to give them the option to avoid travel to town for necessities,” shared Vice President, John Ketler. “This has included bringing vendors on-site, some of whom, due to the rapid onset of restrictions, are not set up for debit transactions. We are providing a means for our employees to support these vendors.”

The installation of an ATM is just one of many measures taken by the company to make essential services more accessible to their employees and minimize any additional risks from off-site traveling. In addition, they have made groceries and prepared food easily accessible by bringing approved vendors on-site and allowing representatives from financial institutions to come to the facilities to help workers complete money transfers home.

“Agriculture is a vital part of the Canadian economy, and part of our purpose as an organization is to drive positive change,” said Roy Dias, Head, Specialized Industries, BMO Bank of Montreal. “We saw an opportunity to help Nature Fresh Farms bring everyday banking services to their team members – helping both their employees and the community. We will always look for ways to help, as we navigate this environment together.”

-30-

About Nature Fresh Farms -

Continuously expanding, Nature Fresh Farms has become one of the largest independent, vertically integrated greenhouse vegetable farms in North America. As a year-round grower with farms in Leamington, ON, Delta, OH, and Mexico, Nature Fresh Farms prides itself on consistently delivering exceptional flavor and quality to key retailers throughout North America, while continuing to innovate and introduce more viable and sustainable growing and packaging solutions.

SOURCE: Nature Fresh Farms | info@naturefresh.ca T: 519 326 1111 | www.naturefresh.ca

Indoor Ag-Con Kicks Off New Webinar Series With United Fresh Produce Association Panel

Indoor Ag-Con LLC, producers of the premier event for the indoor|vertical farming industry, is launching a free monthly webinar series to share content originally planned for its May 2020 in-person annual conference that has been postponed due to the Covid-19 pandemic

INDOOR AG-CON KICKS OFF NEW FREE WEBINAR SERIES WITH UNITED FRESH PANEL DISCUSSION ON PRODUCE TRENDS, BUSINESS OPPORTUNITIES FOR INDOOR GROWERS

Free Monthly Virtual Events To Share Content Originally Planned For May 2020 Annual In-Person Conference Postponed Due to Covid-19 Pandemic

LAS VEGAS ( May 20, 2020) – Indoor Ag-Con LLC, producers of the premier event for the indoor|vertical farming industry, is launching a free monthly webinar series to share content originally planned for its May 2020 in-person annual conference that has been postponed due to the Covid-19 pandemic. Titled “Indoor Ag-Conversations,” the new virtual event series kicks off with the United Fresh Produce Association Panel: Produce Trends & Business Opportunities For Indoor Growers Emerging From Covid-19 Pandemic on Wednesday, June 3 at 4 pm EST.

Moderated by United Fresh President and CEO Tom Stenzel, the panel will include Alex DiNovo, President and COO, DNO Produce and Paul Lightfoot, President and Founder, BrightFarms.

“While Covid-19 has temporarily halted our opportunity to gather face-to-face for Indoor Ag-Con, it has not stopped us from sharing the incredible innovations and business-building opportunities our vibrant industry offers,” says Brian Sullivan, co-owner of Indoor Ag-Con. “We’re honored to have the United Fresh Produce Association kick off our first webinar with such a dynamic panel of industry leaders talking about the unprecedented challenges and opportunities we’re facing today.”

“Now more than ever it’s critical that we continue to find new ways to connect with industry peers to share industry ideas and experiences,” adds Tom Stenzel, President & CEO, United Fresh Produce Association. “Indoor growing is an important component of the fresh produce industry, and we’re excited to lead the first Indoor Ag-Con webinar on June 3 as we look ahead to our own new free virtual event, United Fresh Live!, coming the week of June 15.”

With plans to feature one to two sessions each month, the new Indoor Ag-Conversations webinar series will feature content originally planned for the now postponed Indoor Ag-Con 2020 Conference line-up, as well as new sessions designed to help industry members find new ways to grow their business.

Scheduled for June 3 at 4 pm EST, the Indoor Ag-Conversations United Fresh panel will share insights from (pictured clockwise from top left):

Moderator Tom Stenzel, the President and CEO of the United Fresh Produce Association, is a frequent speaker on industry issues and has been recognized for his leadership frequently throughout his career. Tom has testified numerous times before Congress, and works closely with leaders at the White House, USDA, FDA, and other U.S. regulatory agencies. He also leads the United Fresh Start Foundation, the association’s charitable foundation focused on increasing children’s access to fresh fruits and vegetables. The Foundation and its partners have donated more than 5,000 salad bars to schools in all 50 states.

Paul Lightfoot, President and Founder of BrightFarms, is creating the first national brand of locally grown produce. In four years, Lightfoot has led the company from a proof-of-concept to operating four greenhouses in key markets like Washington, D.C., Chicago, Cincinnati, and Philadelphia. BrightFarms was named 235th on the 2017 Inc. 500 list of fastest-growing private companies, ranking 10th among all food companies and the only produce company featured on the list.

Alex DiNovo is President and COO of DNO Produce Group of Companies, a rapidly growing family-owned group of businesses located in Columbus, Ohio. DNO is a fresh fruit and vegetable processor, as well as a distributor, with a distribution network throughout the Midwest, Great Lakes, and the southeastern United States. DNO distributes to customers both directly and indirectly through its network. Alex is a fourth-generation family member who has been involved in the produce business from a young age. He has knowledge and experience in many areas of the produce supply chain.

Indoor Ag-Conversation webinars are free to industry members. To register for the upcoming June 3, 2020 session, visit www.indoor.ag/webinar. In addition, the Indoor Ag-Con team is currently exploring dates and options for its postponed May 2020 in-person event and will be providing updates soon.

ABOUT INDOOR AG-CON LLC

Founded in 2013, Indoor Ag-Con touches all sectors of the business, covering produce, legal cannabis, hemp, alternate protein and non-food crops. In December 2018, three event industry professionals – Nancy Hallberg, Kris Sieradzki and Brian Sullivan – purchased Indoor Ag-Con LLC, setting the stage for further expansion of the events globally. For more information, visit: https://indoor.ag

ABOUT UNITED FRESH PRODUCE ASSOCIATION

United Fresh brings together members across every segment of the supply chain to build relationships that are as solid with a handshake as with a contract. We empower industry leaders to join forces to shape sound government policy. We deliver the resources and expertise companies need to succeed in managing complex business and technical issues. For more information, visit: https://www.unitedfresh.org and to learn more about United Fresh LIVE! Visit www.unitedfreshlive.org

SPECIAL THANKS TO INDOOR AG-CON 2020

SPONSORS, EXHIBITORS MEDIA ALLIES & INDUSTRY PARTNERS

In addition, Indoor Ag-Con is proud to be a member of the Hemp Industries Association.

Vertical Gardens Take The Hudson Valley’s Farm-to-Table Scene to New Heights

“Vertical Field offers a revolutionary way to eat the freshest greens and herbs by producing soil-based indoor vertical farms grown at the very location where food is consumed,” explains Vertical Field’s Chief Executive Officer Guy Elitzur

Sabrina Sucato

Photos by Vertical Field

Vertical Field Makes its Local Debut At a Leading Poughkeepsie Restaurant, With a Monsey Grocery Store Soon To Follow

In the Hudson Valley, farm-to-table is less of a foodie trend and more of a way of life. As an ideal, it’s woven into the threads of the community, crisscrossing its way between farms, artisans, restaurants, and the locals who support them all.

Even during the COVID-19 crisis, when so many in the region struggle to find their footing, the movement lives on through support for farm markets and restaurants, many of which are in new territory when it comes to delivery and takeout.

Yet it’s never gone quite this far. Or, ahem, this high.

Photo by Vertical Field

In a first for the Hudson Valley, farm-to-table takes a vertical turn. It’s all thanks to Vertical Field, an Israel-based agro-tech startup that crafts vertical agricultural solutions that make access to food easier and faster while reducing waste and cutting down on human handling – a major boon during a time of social distancing.

“Vertical Field offers a revolutionary way to eat the freshest greens and herbs by producing soil-based indoor vertical farms grown at the very location where food is consumed,” explains Vertical Field’s Chief Executive Officer Guy Elitzur. “Our urban farms give new meaning to the term ‘farm-to-table’ because one can virtually pick their own greens and herbs at supermarkets, restaurants, or other retail sites.”

While Vertical Field has installed gardens across the Middle East and Europe, it’s recently found a home at Poughkeepsie’s Farmers & Chefs, where chef and owner John Lekic uses it to take the hyperlocal experience at his restaurant even further.

“It’s making a full circle for a chef and restaurateur,” he says. “You get to serve the food you not only prepared or cooked, but you also grew from seed to plate.”

When Lekic first came across Vertical Field during an exhibition at the Culinary Institute of America in late 2019, he was hooked from the start. Knowing that the system would be a perfect fit for his concept, he ordered one for his Hudson River food truck-turned-eatery.

Lekic’s vertical garden arrived two days after Governor Cuomo mandated the closure of on-premise restaurant operations in New York State.

“It was a lot of anxiety and uncertainty,” Lekic recalls. For the safety of his staff, he called for a break in operations to ensure no one was sick. During that time, he dedicated himself to setting up his vertical field. “It kept us busy. We installed our farm and planted about 10 days after. We already had our first crop.”

A rapid turnaround time is one of the pros of Vertical Field gardens, which take about three to four weeks per harvest. According to Lekic, he anticipates he’ll be able to grow about 400 pounds of produce per month. Much of it will be salad greens such as buttercrunch lettuce, kale, and arugula, although he also planted herbs like rosemary, sage, and basil.

While Lekic appreciates the convenience of the garden, which resides onsite at the restaurant for customers to see, he also loves that it’s a bug-free, pesticide-free operation with less need for human contact. With fewer intermediary steps (no transportation from producer to restaurant, for example) and up to 90 percent, less water required than in a traditional garden, Vertical Field urban landscapes are just about as eco-friendly as it gets.

“You can definitely taste that,” Lekic enthuses. “There are no chemicals. That’s a great experience.”

Just as Lekic values the freshness, so too do his customers. Farmers & Chefs is open for delivery and pickup during quarantine, so consumers are able to taste the metaphoric fruits of the garden’s labor for themselves. In fact, the garden has been such a hit that Lekic is brainstorming ways to incorporate the produce into more unique offerings.

“We make housemade ice cream with brown fennel and pistachio,” he says. “We’re playing around with some product that we aspire to take to market.”

Lekic may be the first to install a Vertical Field in the Hudson Valley, but he’s already paved the way for others. In Monsey, Evergreen Supermarket will soon have a sky-high garden of its own.

“I heard about [Vertical Field] through some people from Israel who showed me how some vertical farms are being set up in supermarkets,” explains supermarket representative Menachem Lubinsky. If not for the COVID-19 outbreak, he adds, Evergreen’s vertical garden would already be in place. As it stands now, the market expects the container will be delivered soon.

“I’m very excited about it,” says Lubinsky. “The technology allows it to have constantly changing light and heat. It eliminates the transfer from farm to supermarket and guarantees supplies.”

Lubinsky expects that Evergreen’s clientele, many of whom are already interested in more natural, organic products, will take to the Vertical Field produce immediately. Since Evergreen will set the container up in its parking lot, customers will be able to watch the garden grow during every shopping trip. If all goes well, the store may even purchase a second Vertical Field for its store in Lakewood, NJ.

“Almost everything you want to grow can grow,” Lubinsky enthuses. Fingers crossed, he hopes strawberries will soon be available for Vertical Field gardens, too.

Building Resilience Into The Vegetable Supply Chain Using Container Farming

Canada’s food supply chain is robust and reliable - even in times of the COVID-19 crisis - but there is an opportunity to become more self-sufficient. Container farming can provide your food supply with some autonomy and reduced reliance on external food supply chains

Canada’s food supply chain is robust and reliable - even in times of the COVID-19 crisis - but there is an opportunity to become more self-sufficient. Container farming can provide your food supply with some autonomy and reduced reliance on external food supply chains.

THE SUPPLY CHAIN DURING COVID-19

Empty shelves at the outbreak of the pandemic were a shock to many as grocery store retailers have experienced shortages, or delays, in their supply chain during this adjustment period.

The Food and Agriculture Organization of the United Nations (FAO) wrote in a special COVID-19 report that “supermarket shelves remain stocked for now [...] but a protracted pandemic crisis could quickly put a strain on the food supply chains, a complex web of interactions involving farmers, agricultural inputs, processing plants, shipping, retailers and more.” The FAO emphasizes that there is enough supply, but transportation is lacking to help get the crops where they are needed most.

FOOD PRICES ARE RISING

Even before COVID-19 struck, food prices in Canada were predicted to rise between 2 and 4 percent, especially vegetables and bakery items. Now, according to a new forecast by the University of Guelph and Dalhousie University, researchers say the factors contributing to the rise have changed but they still expect prices to rise nonetheless. Plus, grocery stores are now spending more to ensure the proper protection protocols are in place on top of paying their essential workers more. These costs won’t be changing soon, so what ways can more resilience be built into the grocery store model?

Students in Kugluktuk, Nunavut help run their Growcer system which provides produce to the school and community.

EVERYONE IS IMPACTED DIFFERENTLY

It is important to note that not every community’s food supply is going to be impacted the same way. In a Food Secure Canada webinar about Food Policy and COVID-19, the speakers spoke to how rural and Indigenous communities will be impacted differently than cities. One of the speakers, Jessica McLaughlin with the Indigenous Food Circle, said, “What has become very evident to us is the vulnerability of communities on that big industrial food supply chain and the lack of autonomy to self-determine their own food systems.” However, Mclaughlin added that despite this, communities are working together. “In this crisis, communities have been really resilient . . . you really see how communities pull together and they are taking this into their own hands,” McLaughlin said.

WHAT COULD A SOLUTION LOOK LIKE?

Each community has different needs, but one possible solution is container farming. With container farms, communities and grocery stores can grow a variety of produce year-round, no matter the weather, and even customize what’s being grown to match the demand of the community. You’re also not stuck to growing one crop. A grower can grow multiple types of produce at a time and switch out what’s being grown regularly. Having a local, year-round, consistent supply of produce allows the community not to rely solely on external sources and can provide a buffer when the supply chain experiences delays.

The Yellowknife Co-op's Growcer unit is operated by its existing employees who see it as an opportunity to serve their community.

Now, hydroponic growing might sound technical but operating one of Growcer’s systems is extremely simple. It only takes one week of on-site training to have employees comfortable with the system. Justin Nelson, general manager for The Yellowknife Co-op, shared that their employees love working in the Grower unit. “On a cold dark day in Yellowknife there’s no better place to be than inside the Growcer unit,” Nelson said. “When you’re actually harvesting the product that you’re selling it’s a great feeling.” You can read more about The Yellowknife Co-op’s story to see how they integrated a container farm with their store.

Food sovereignty and the ability for communities to decide how their food systems run has been brought to the forefront during COVID-19. It’s impossible to predict what lays ahead, but we do know that this could be a time for a reset for some of us.

April 27, 2020

What The Heck Is Farm Management Software?!

You can think of these platforms as “enterprise solutions” from Microsoft, IBM, Oracle, and SAP’s of the world...but for Ag.

By Aaron Magenheim, CEO & Co-Founder of AgTech Insight & Growers Insight

May 2020

Technology specifically built for Agriculture, (commonly known as AgTech or Precision Ag), has become an exciting space with Farm Management solutions leading digitalization. “Farm Management” has also turned into a buzzword many people use broadly and don’t really understand the importance of and details around – especially in our rapidly changing world.

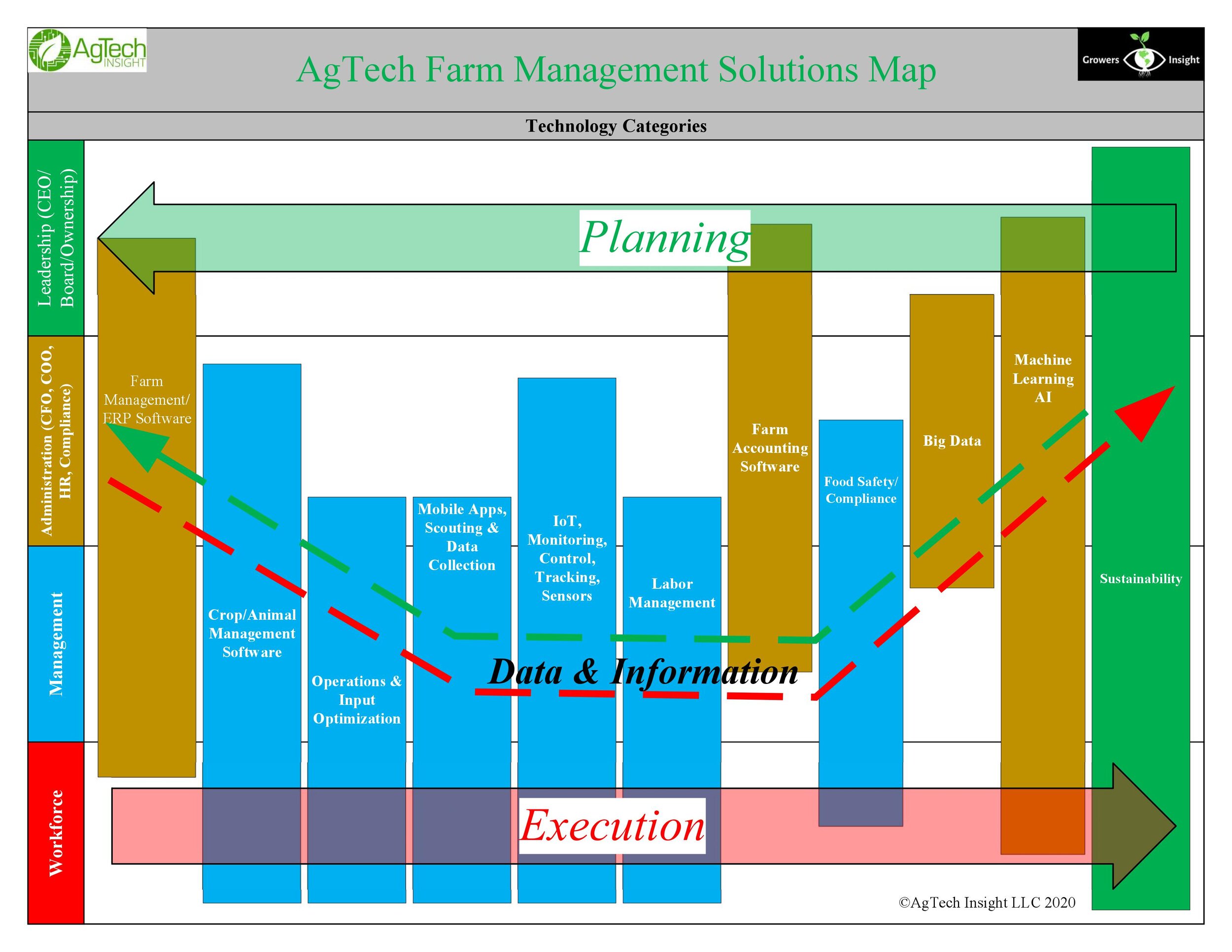

As CEO and co-founder of AgTech Insight, a global advisory and implementation firm specializing in AgTech, I have been monitoring the evolution of this industry for several years, evaluating both existing and new solutions and companies. In 2015 we launched our first AgTech Market Map leveraging our internal solutions database by providing a free, valuable resource for those wanting a better understanding of which companies are leading the market organized by category.

Over the past couple of years, our database of digital AgTech solution providers has grown to over 3,000 companies. Farm Management Software (FMS) has become the largest category, with over 500 listings. As we once again reviewed the details of each company to choose those we feel are leading their sector, it became clear we needed to further break down the FMS category based on core competency. This article explains the industry’s current state and how, as these AgTech solutions work in combination, they become extremely valuable for AgriFood businesses. We’ve also included an infographic illustrating how these technologies work together, who uses them, dataflow processes, and the value they bring throughout the organization.

Five years ago, lots of companies wanted to be the leading “FMS” platform. Today there is still no clear winner, so I think we can all agree it’s too big of a task with too many variables for one technology company. We must focus on user success, adoption, and RoI, therefore, our approach is to piece together many best-in-class solutions and then aggregate them — like they do in almost every other industry — to meet the needs of customers.

As the AgTech industry matures, there are companies who get really good at solving one specific problem becoming their “core technology.” This helps everyone understand where each company can provide the most value, as well as identifying the solution as complementary rather than competitive.

While the industry becomes more collaborative and standardized, each solution will continue to be a very important tool used day-to-day by some people on the farm while also feeding that data into larger farm management systems and platforms. These larger platforms are aggregating a variety of point source data being collected and provide a wider view of what’s happening on the farm for mid-level management. This data will be further shared to a business intelligence platform, which helps leadership make financial and business decisions but will not typically be used by a farm supervisor managing daily activities and production.

Leadership Level Solutions

Farm Management/ERP Software Platforms

You can think of these platforms as “enterprise solutions” from Microsoft, IBM, Oracle, and SAP’s of the world...but for Ag. They work with a variety of integrated software applications and systems to bring these dispersed datasets together and provide a variety of often custom analytic insights to company leadership. These platforms require an administrator and are primarily used to make financial and large business decisions rather than improving the day-to-day production of a specific crop.

Sustainability

Sustainability is an important topic across any organization and (along with agility) drives its future. Most companies and governments are integrating sustainability efforts across their business from soil and animal health through carbon farming and logistics. To meet the United Nation’s Sustainable Development Goals (SDG’s) by 2030, a huge effort needs to be put forth by every person, so this category spans the entire organization.

The following diagram shows the flow of decisions and data including each user group by category:

Upper-Level Management/Administration Solutions Farm Accounting Software

Tracking an Ag company’s financials is more important today than ever, thus feeding granular data from both revenue as well as ops/expenses to count pennies is of utmost importance – not only to keep the company in business, but to be able to calculate real RoI (Return on Investment) for innovation efforts and other expenditures. Many of the other systems being used across the operation will feed financial data into this system.

Big Data Providers

There is a plethora of data being collected from millions of sources, and while it may not always be extremely specific to your exact case/location (as in weather), leveraging Big Data across market pricing, asset values, consumer trends, and even imaging can be used to further support a farmer’s decision- making by finding anomalies, providing a larger data set, and more.

Machine Learning and Artificial Intelligence (AI) Tools

As Ag-focused tools to fill the needs of the sector have not yet emerged, great platforms and developer’s tools prominent in other industries are the solutions we can leverage in the near future. These tools can be used as a front end user interface like Power BI or Tableau, allowing the user to run data into the platform to analyze, build projections, prescriptions, and automate processes. They can also be used in the back end of other solutions, doing the heavy lifting and data crunching before sending the prescriptions and actions back to a software’s user interface or to be carried out autonomously.

Mid-Level Management and Workforce Solutions

Crop/Animal Management Software

This is still the largest bucket in the Ag software world, but we have narrowed it down significantly. These FMS are focused more on the operations side, helping to grow a better crop while reducing inputs. They are typically pureplay software and use API’s (Application Programming Interfaces) to collect and share data from a variety of applicable sources. These solutions are most often used by Ag operations directors through ranch managers to get a high-level view of what’s happening across their operations and highlight potential issues and opportunities for improvement. The workforce also uses these solutions by tracking their activities and receiving recommendations. It can also be a catch-all place to aggregate data and display important KPI’s (Key Performance Indicators) on a dashboard for easy and quick access to what is most important while allowing a deeper dive to further inspect as needed.

Mobile Apps, Scouting and Manual Data Collection

These important tools are typically used by advisors, agronomists, PCA’s (Pest Control Advisors), foremen, laborers, etc. to collect data and verify as tasks are being done. They also create an historic record that can be used in the future to compare and analyze events like pest infestations, animal health, or water usage.

IoT, Monitoring, Control, and Animal Tracking

There are a number of IoT platforms which focus on fixing a certain problem such as collecting soil moisture, irrigation data, and weather, or tracking a cow to alert when it’s becoming sick or ready to be bred. Their intention is to improve profitability and sustainability while also growing a better product. These hardware-centric approaches use real-time sensors (often from 3rd parties) to collect a variety of data on crops, animals, weather, equipment, people, and more before sending it to a database in the cloud. They produce real records and ground-truthing which can be used to trigger alerts, for analytics, modeling, to calibrate machine learning or AI models and more.

IoT Plus Analytics User Interface Similar to the above category, this is a large sector which also focuses on a specific problem. However, these companies have not only built the hardware portion, but they have also built a software user interface including more advanced analytics or modeling to provide actions around the conditions they are reporting. They typically will also pull in data from other sources to support the decision-making for the specific problem they are solving.

Input and Farm Operations Efficiency and Optimization

These solutions concentrate on helping improve the efficiencies around spray, variable rate applications, or energy/water usage. They can also help with logistics and optimization across a farm by having the right people, equipment and other resources at the right place, at the right time. This can reduce harvest costs by not having trucks and trailers waiting around and streamlining trucks arriving at a processing facility.

Labor Management

Ensuring you have the required workforce and staying connected with them has become a constant battle, as has ensuring they are performing the tasks planned at an acceptable level. These solutions can help mitigate labor shortages while collecting valuable insights to be fed into a FMS and enterprise solutions.

Food Safety/Compliance

This sector of solutions have mostly been built to mitigate risk but have a much larger role to play as they are integrated into larger platforms. Many will start using a backbone blockchain technology, allowing for easier data segregation and to provide invaluable insights into both cost and risk evaluation.

Summary

With so many great technology solutions available today, deciding where to start and who to work with is important. The key to success comes through creating a cultural shift into modernization throughout a business organization. Our companies specialize in designing and implementing successful innovation plans for our clients.

Please Click Here to View: Growers Insight - Grower Overview Slides 3.0

For support through your AgTech journey, please contact:

Aaron Magenheim, CEO & Founder AgTech Insight & Growers Insight

AaronM@AgTechInsight.com

+1-831-595-6064 Mobile

+1-855-410-2030 Office

© AgTech Insight LLC 2020

Elevate Farms Executes Agreement to Bring Food Security to The Yukon and Other Isolated Northern Territories of Canada

Elevate and North Star have agreed to develop and construct a series of automated large-scale facilities (“CEF Facilities”) dedicated to the mass production of leafy green plants implementing, among other techniques, the use of patented LED lighting, moving grow boxes and controlled growth environments (“CEF Technologies”)

TORONTO, May 12, 2020

(GLOBE NEWSWIRE)

Elevate Farms Inc. (“Elevate” or “Elevate Farms”) is pleased to announce it has entered into an agreement (“Agreement”) for an initial build-out commitment of US $10,000,000 with North Star Agriculture Corp. (“North Star” or “North Star Agriculture”) to bring Elevate’s proprietary vertical farming, and cost-effective production of leafy green vegetables, to the Yukon and other isolated northern territories of Canada. Elevate and North Star have agreed to develop and construct a series of automated large-scale facilities (“CEF Facilities”) dedicated to the mass production of leafy green plants implementing, among other techniques, the use of patented LED lighting, moving to grow boxes and controlled growth environments (“CEF Technologies”).

The Agreement contemplates the development of CEF Facilities for the production and supply of leafy green plants employing financing, as well as operations and retail expertise, from North Star and industrial and technical support of the CEF Technologies from Elevate. Each element of the process of development of the CEF Facilities are conditional upon the completion of supporting documentation including the settlement of definitive agreements including, but not limited to, shareholders’ agreement, reverse vesting agreement, licensing agreement, and supply agreement. Each CEF Facility, once complete and operational, is expected to produce an estimated 10-tons (9,100 kilograms) of leafy green vegetables per week, which is the equivalent to in excess of 1,000,000 pounds (473,200 kilograms) of leafy green vegetables per year.

Amin Jadavji, Elevate Farm’s Founder and CEO, stated “We are extremely excited to partner with North Star to bring food security and nutrition to a particularly isolated and vulnerable region of Canada. This is Elevate Farms’ second Canadian million-pound facility for which Elevate has secured financing commitments - with significantly larger faculties already financed in New Jersey, USA and in Hamilton, New Zealand. Elevate is making excellent progress in executing our plan on creating a global brand in the area of food security and local sustainability.”

Sonny Gray, CEO of North Star, stated: “North Star Agriculture is committed to #FeedtheNorth by developing a variety of food security based projects and initiatives. Our partnership with Elevate perfectly unites with our goal of developing agriculture ‘north of 60’ with the aid of modern technology and sustainable farming practices.”

Travis Kanellos, Elevate Farm’s Chief Strategy Officer stated: “Food security, as defined by the United Nations' Committee on World Food Security, means that all people, at all times, have physical, social, and economic access to sufficient, safe, and nutritious food that meets their food preferences and dietary needs for an active and healthy life. As we have become aware, broken links in supply chains, at home and abroad, have become all-too-real as communities implement travel and supply restrictions to combat COVID-19. The underlying causes of food insecurity are not only drought and conflict in faraway lands but also distribution and access concerns in the end user’s locality.”

Amin continued, “Our vertical farming solution provides fresh and healthy leafy green vegetables - the only vegetables that cannot be frozen for later consumption - by securing availability, access, use, and utilization, as well as increased general stability with the potential for years-long self-sufficiency during uncertain times which may include events such as government-mandated quarantine and self-isolation. Elevate’s patented food production solution goes a long way to solve the issues facing the North, and other dependant environments affected as they may be difficult to reach regions or fragile ecosystems. ”

ABOUT ELEVATE FARMS

Elevate Farms Inc., previously operating corporately as Intravision Greens Inc., is a technology-driven vertically-stacked indoor farming enterprise focused on a mass scale and cost-effective operations with patent secured and patent-pending technology as well as over a decade of advanced photobiology research deployed.

Amin Jadavji

ajadavji@elevate.farm

Interview With Eddy Badrina, CEO of Eden Green Technology

One company that is looking to take on the commercial agricultural industry is Eden Green Technology, a company based out of Texas that focuses on sustainability in the food industry

Josiah Motley · April 27, 2020 · Short URL: https://vator.tv/n/5018

A look at the vertical farming platform that uses tech to grow a variety of healthy foods

When we talk about technology, it's easy to focus on things like computers, smartphones, apps, and the growing number of smart gadgets found in our homes.

But technology is far-reaching and can influence and change traditional sectors quickly. One sector that may seem immune to the growing use of technology is the farming industry, but a quick look at what farm equipment is becoming can prove that wrong quickly (even if the transition is proving difficult for some).

One company that is looking to take on the commercial agricultural industry is Eden Green Technology, a company based out of Texas that focuses on sustainability in the food industry.

I had the chance to interview Eddy Badrina, CEO of the company, to learn a bit more about what they are doing, how they use technology, and how they envision the future of the agricultural industry.

Check it out below.

Care to introduce yourself and your role with Eden Green?

Sure. I'm Eddy Badrina, and I’m the CEO of Eden Green Technology.

In just a few sentences, what is Eden Green?

Eden Green Technology is a vertical farming platform that grows large quantities of local produce safely, sustainably, and efficiently. We use less land, energy, and water than both traditional farming and other indoor solutions.

Our greenhouses are constructed on small footprints, in urban or suburban areas, to provide stable jobs and produce non-GMO, pesticide-free produce, which goes from farm to table in as little as 48 hours, compared to the 14 days it usually takes under the traditional model.

What inspired the creation of the company?

The founders of Eden Green are brothers Jacques and Eugene van Buuren. They witnessed firsthand the effects of hunger in their native South Africa and thereafter dedicated themselves to helping feed the world.

They came to the US to secure investment, source talent, and experiment with their technological solutions in our diverse climates. They started in Texas, with its own extreme range of environmental considerations, agricultural know-how, and business opportunities, and built from there.

What types of produce can your vertical farms grow?

Our greenhouses can grow 50+ varieties of produce, including herbs, leafy greens like spinach, kale, and arugula, and a sizable array of vegetables, plus other non-produce plants like hemp and research crops.

You call yourself a tech company, can you go into more detail on that?

Absolutely. So, our technical secret sauce consists of a few ingredients, including our patented vertical “vines,” where our produce grows, and the way we create microclimates for each individual plant with temperature-controlled air and nutrient-enriched water.

We also designed and built a proprietary mechanical, electrical, and plumbing solution specifically to automate and remotely monitor all our greenhouses. Because of that hardware and software combination, we like to think of ourselves as a technology company that happens to grow produce.

Eden Green seems extremely relevant right now with coronavirus, are you doing anything to help people and businesses affected by the virus?

We directed our R&D facility to start a unique partnership with a local business that had to pivot from supplying high-end restaurants to starting home deliveries of high-quality poultry, eggs, beef, and produce.

For every pound of our produce they deliver, we are giving one pound away to local food banks, homeless shelters, and other nonprofits. The creative problem-solving of combining how to sell our produce, help another small business grow, and feed the local underserved population all at the same time, was a really valuable experience.

More generally, the coronavirus crisis brings into focus the kinds of problems with traditional farming methods that we help directly address - easy access to local food sources, sustainability, and resiliency.

A more-widespread application of greenhouses like ours would also help defray the market effects of workforce shortages due to sickness, the personal effects of crowded, unsanitary, and otherwise-unsafe work environments, and the problems that come with relying on low-paid seasonal work.

What locations are you currently available in and do you plan on expanding?

We currently have our R&D facility in Texas and are prepping for facilities to be built in two other countries and a number of states.

Through our Texas facility alone, we’ve partnered with local food banks and nonprofit organizations, run pilot tests with two grocery companies, and a research university, with a lot more expansion planned in the coming years.

Do you believe this is the future of farming?

We absolutely believe that this is the future of farming. Not only does our solution make market sense - because global demand for year-round access to a variety of produce is growing, and costs to meet that demand are rising, having a locally-sourced, year-round solution solves for that - it’s also a sort of good on its own.