Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

AeroFarms and Nokia Bell Labs Partner to Further AI-Plant Technology

AeroFarms and Nokia Bell Labs have unveiled a multi-year partnership. The goal is to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels

By Johnny Eppich

August 11, 2021

AeroFarms and Nokia Bell Labs have unveiled a multi-year partnership. The goal is to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels.

As part of this partnership, AeroFarms, a global leader in indoor vertical farming, contributes its commercial growing expertise, comprehensive environmental controls, an agriculture-focused data platform, and machine vision core foundation.

Nokia Bell Labs, the industrial research arm of Nokia, contributes its autonomous drone control and orchestration systems, private wireless networks, robust image and sensor data pipelines, and innovative artificial intelligence (AI) enabled mobile sensor technologies.

AeroFarms and Nokia Bell Labs have been working together since 2020. They have reached a milestone of achieving a proof of concept for this state-of-the-art integrated system and testing the technologies with AeroFarms’ current commercial crop varieties.

Together, they plan to scale this system to all of AeroFarms’ crops and future indoor vertical farms, including the next ones in Danville, VA, and Abu Dhabi.

The integration of Nokia Bell Labs’ AI-enabled drone-based sensors and advanced machine learning, computer vision, and data analytics technologies with AeroFarms’ existing machine vision tools enhances and elevates AeroFarms’ position as an agriculture platform and capabilities organization dedicated to solving food and agriculture supply chain challenges.

“With Nokia Bell Labs, we have developed the next-generation system that can image every plant every day in a cost-effective way at scale,” says David Rosenberg, CEO at AeroFarms. “This level of detailed imaging and insights helps us be better farmers by monitoring our plant biology dynamically and allowing us to course-correct as needed to ensure the highest level of quality all year round.”

Nokia Bell Labs’ machine vision technology has enabled the most precise data capture yet, down to the level of individual plants, using leaf size segmentation, quantification, and pixel-based scanning to identify consistency and variation.

Going beyond what even the human eye can perceive, this state-of-the-art imaging technology enables the gathering of immense insights about a plant, including its leaf size, stem length, coloration, curvature, spotting, and tearing.

The end-to-end system is flexible and robust, built to take advantage of Nokia’s 5G private wireless network with cloud processing technology. The network is designed for low latency and high privacy in an on-premises network. It also provides intelligent industrial analytics capabilities as an integrated service that can be deployed quickly and efficiently anywhere.

“Nokia Bell Labs is driven to solve hard and impactful problems, and together with AeroFarms, we are building the ability to see and identify plant interactions at unprecedented levels,” says Thierry Klein, Vice President of Integrated Solutions and Experiences Research Lab at Nokia. “The fundamental technologies of this partnership are our strength, and vertical farming is just the beginning. With the AeroFarms platform, we are exploring the power of network-driven intelligence for industrial outcomes. These capabilities can expand into a multitude of indoor industrial operations, including logistics, warehousing, distribution hubs, and manufacturing.”

Geoponica Greens, Indoor Vertical Farm, To Open Facility In Hamilton Twp.

Geoponica Greens, an indoor hydroponics vertical farm business based in Chesilhurst, is expanding its existing operations to the historic Mill One warehouse in Hamilton Township this fall, the company announced.

August 4, 2021

Geoponica Greens, an indoor hydroponics vertical farm business based in Chesilhurst, is expanding its existing operations to the historic Mill One warehouse in Hamilton Township this fall, the company announced.

Desmond Hayes, founder and owner of Geoponica Greens, said the company utilizes hydroponics, an agricultural practice of growing plants without soil, using only water and nutrients — while avoiding the use of pesticides or insecticides.

By delivering the nutrients straight to the plants’ roots, this grow method is also able to shorten crop cycles, produce the best flavors and level of nutrition and increase the lifespan of the crop, he said.

“Geoponica Greens is dedicated to changing the way food is both grown and realized through our low-waste model and our hyperlocal interaction within nearby areas,” Hayes said.

“New Jersey is strategically located between New York City and Philadelphia, making it the perfect place to reimagine farming. We are especially excited to reach minority communities, Opportunity Zones and food deserts, and introduce our sustainable methods of agriculture to new areas.”

The new warehouse space will support Geoponica Greens’ efforts to provide fresh microgreens, leafy greens and herbs to the local communities, with plans to hire three to five employees and interns in the first year.

Because the produce will be grown in an indoor farm, it is not subjected to the effects of climate seasonality, so the facility will be able to harvest 2-3 tons of greens per year at full capacity, Hayes said.

Geoponica Greens also plans to create a local Community Supported Agriculture program aimed at bringing a subscription-based model to customers.

A minority business owner, Hayes founded Geoponica Greens in 2014.

Choose New Jersey provided Geoponica Greens with state resources information, economic development connections and site selection assistance and will continue to support the company’s success in New Jersey.

Choose New Jersey CEO Jose Lozano said his group was happy to keep such an innovative company within the state.

“True to our nickname as the Garden State and the most densely populated state in the country, it is no surprise that New Jersey is on the forefront of the urban farm movement,” he said.

“Geoponica Greens is an integral part of that movement, and Choose New Jersey is proud to support their continued growth in our state as they bring agricultural innovation to Hamilton and its surrounding communities.”

Geoponica Greens, an indoor hydroponics vertical farm business based in Chesilhurst, is expanding its existing operations to the historic Mill One warehouse in Hamilton Township this fall, the company announced.

Desmond Hayes, founder and owner of Geoponica Greens, said the company utilizes hydroponics, an agricultural practice of growing plants without soil, using only water and nutrients — while avoiding the use of pesticides or insecticides.

By delivering the nutrients straight to the plants’ roots, this grow method is also able to shorten crop cycles, produce the best flavors and level of nutrition and increase the lifespan of the crop, he said.

“Geoponica Greens is dedicated to changing the way food is both grown and realized through our low-waste model and our hyperlocal interaction within nearby areas,” Hayes said.

“New Jersey is strategically located between New York City and Philadelphia, making it the perfect place to reimagine farming. We are especially excited to reach minority communities, Opportunity Zones and food deserts, and introduce our sustainable methods of agriculture to new areas.”

The new warehouse space will support Geoponica Greens’ efforts to provide fresh microgreens, leafy greens and herbs to the local communities, with plans to hire three to five employees and interns in the first year.

Because the produce will be grown in an indoor farm, it is not subjected to the effects of climate seasonality, so the facility will be able to harvest 2-3 tons of greens per year at full capacity, Hayes said.

Geoponica Greens also plans to create a local Community Supported Agriculture program aimed at bringing a subscription-based model to customers.

About Mill One and Geoponica Greens

The historic Mill One warehouse was once home to notable Atlantic Products Corp. during the World War II era in the Trenton area. The 2,000-square-foot warehouse was selected because of its important features that will support Geoponica Greens’ hydroponics operations. With high ceilings, skylights and exposed brick walls, the impressive existing warehouse is being renovated to become a modern, sustainable space.

A minority business owner, Hayes founded Geoponica Greens in 2014.

Choose New Jersey provided Geoponica Greens with state resources information, economic development connections and site selection assistance and will continue to support the company’s success in New Jersey.

Choose New Jersey CEO Jose Lozano said his group was happy to keep such an innovative company within the state.

“True to our nickname as the Garden State and the most densely populated state in the country, it is no surprise that New Jersey is on the forefront of the urban farm movement,” he said.

“Geoponica Greens is an integral part of that movement, and Choose New Jersey is proud to support their continued growth in our state as they bring agricultural innovation to Hamilton and its surrounding communities.”

Lead Photo: Geoponica greens uses hydroponic techniques to grow produce. - Geoponica Greens

5 Ways Vertical Farming Is Improving Nutrition

Vertical farming has taken cities by storm, enabling urbanites to grow produce within their own homes and entrepreneurs to meet the growing demand for fresher and higher quantities of locally-grown produce

August 3, 2021

Vertical farming has taken cities by storm, enabling urbanites to grow produce within their own homes and entrepreneurs to meet the growing demand for fresher and higher quantities of locally-grown produce.

We often hear about vertical farms using water sustainably, 95% less than traditional open field harvesting, to provide superior tasting crops.

But, how is this soilless farming technique impacting human health?

#1: Harvesting On Demand At Peak Freshness

&ever’s Grow Tower; image sourced from &ever

With the power to farm vertically within one’s own home, consumers can now harvest their crops only moments before consumption, resulting in a higher nutritional value, better-tasting greens, and significantly less food waste.

&ever’s Grow Box is a one-stop-shop system for leafy greens and can even be operated by untrained staff, according to &ever. The proprietary technology of the climate cell creates a steady microenvironment to allow plants to grow independently of weather, seasons, and pests, plus the use of “dryponics” helps keep the plants alive until the consumer is ready to harvest.

The key here is the freshness of the crops. Produce no longer has to travel miles and miles through countries or states to get to your kitchen table. This time saved in travel is also nutritional value preserved in the crops. Another benefit is that no artificial preservatives, like wax coatings, are needed to keep the produce consumer-ready.

#2: Growing Under Perfect Conditions

Vertical farms generally use hydroponics or aeroponics to grow their plants in nutrient-enriched water that can be carefully monitored through digital sensors. This degree of control over plant nutrient supply means that the fertilization strategies are designed to match the plant needs for all 14 essential plant nutrients throughout the growth period.

Control mechanisms are also utilized to balance temperature, humidity, and carbon dioxide levels in the grow facility and deliver the optimal combination of these factors for the specific crop or crops being grown. With climatic conditions playing no part in the crop’s success, growers have reliable year-round production of greater quantity and the highest quality.

In this sense, vertical farms are able to spend more time enhancing nutritional value and less time worrying about the success of their harvest. The SKY HIGH program led by Dr. Leo Marcelis of Wageningen University in the Netherlands, is one such program exploring factors that increase crop nutrients.

#3: Tailoring The Development Of Genetic Varieties

Vindara argues that the difference is in the seeds.

By designing seeds specifically for indoor vertical farms - “entirely through analytics, not gene-editing or GMOs” - this company claims to amplify crop yield, appearance, nutrition, and flavor.

Their seed-design system takes a data-driven approach to deliver any kind of genetic variety, tailored to each customer’s needs. According to Vindara, each property is individually editable.

Today’s seeds are still being bred for resistance to disease and pests, designed for long storage and transportation that isn’t as relevant for indoor vertical farming operations. This results in genetic tradeoffs that reduce nutritional value. Vindara removes these limitations that traditional seeds impose by delivering nutrient-dense seeds to growers.

#4: Growing Foods Adapted To Dietary Needs

Alongside fresh and flavorful food, there has been a growing demand and need for foods adapted to specific dietary needs.

Prime Delica, for example, has conducted research with Tamagawa University, CCS, and Signify to determine the optimal light recipe to increase the vitamin levels and nutritional value of lettuce. Dr. Céline Nicole from the Philips Lighting Research team has similarly studied the effects of the daily light integral (DLI) and light quality on the nitrate levels of arugula and spinach, alongside the vitamin C levels of arugula and tomatoes.

Through vertical farming, the Korea Institute of Science and Technology (KIST) has also successfully produced low potassium kale with increased glucosinolate content as a novel dietary option for renal dysfunction patients.

Growing foods with adapted dietary needs could thus make a world of difference in ensuring that we receive greater control over our diets, and allow us to design food-as-medicine alternatives to conventional produce.

#5: Food Safety

In using controlled growing environments, vertical farms are intrinsically free of harmful pesticides. Because of implementing biological controls, there is no need to contaminate crops with potentially toxic chemicals.

According to the CEA Food Safety Coalition, “traditional food safety risk profiles associated with conventional farming include examining the physical hazards and microbial hazards from water use, herbicide, and pesticide use, and impact from animals and animal byproducts. These do not impact CEA growers in the same way, if at all.” Even though the risk of contamination isn’t zero within CEA facilities (as seen in this recent news), CEA-grown produce has a reduced risk of such occurrences.

Compared to traditional field-grown crops, we find that the EPA regulates pesticides individually and not collectively, meaning that the pesticides can have a cumulative toxic loading effect on human health.

Studies have shown that pesticides most impact farmworkers and pesticide applicators with symptoms like nausea, abdominal cramps, diarrhea, dizziness, anxiety, and confusion. This long list of side effects tells us that pesticides are not to be taken lightly. As a result, it’s best to avoid them at all costs. Fortunately, vertical farms help us do precisely this.

Click here for more information.

Source and Photo Courtesy of Agritecture

Indoor Ag Sci Cafe Talks About Propagation And Transplants

This presentation ‘Precision Indoor Propagation for High Quality Transplants’ was given by Dr. Ricardo Hernandez (North Carolina State University) during our 32nd cafe forum on August 3rd, 2021

August 5, 2021

This presentation ‘Precision Indoor Propagation for High Quality Transplants’ was given by Dr. Ricardo Hernandez (North Carolina State University) during our 32nd cafe forum on August 3rd, 2021.

Upcoming Cafes:

September 21st (Tuesday), 11AM Eastern – ‘Introduction to Aquaponics‘ by Dr. Paul Brown and Dr. Cary Mitchell (Purdue University)

October 26th (Tuesday), 11AM Eastern – ‘Vertical Farming – Past, Present and Future‘ by Robert Colangelo (Green Sense Farms)

November TBA

December 7th (Tuesday), 11AM Eastern – ‘Plant-Made Pharmaceuticals under Controlled Environment‘ by Dr. Nobuyuki Matoba (University of Louisville)

Interested in giving a talk to share your thoughts and experiences? Please contact Chieri Kubota

AeroFarms and Nokia Unveil Partnership for Next Generation AI-Enabled Plant Vision Technology

AeroFarms and Nokia Bell Labs today unveiled a groundbreaking multi-year partnership to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels.

August 5, 2021

NEWARK, N.J.--(BUSINESS WIRE)--AeroFarms and Nokia Bell Labs today unveiled a groundbreaking multi-year partnership to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels.

As part of this partnership, AeroFarms, a Certified B Corporation and global leader in indoor vertical farming, contributes its commercial growing expertise, comprehensive environmental controls, an agriculture-focused data platform, and machine vision core foundation. Nokia Bell Labs, the world-renowned industrial research arm of Nokia, contributes its groundbreaking autonomous drone control and orchestration systems, private wireless networks, robust image and sensor data pipelines, and innovative artificial intelligence (AI) enabled mobile sensor technologies. This combination of innovative technologies allows AeroFarms to reach the next level of imaging insights that further enhance its capabilities as an industry leading operator of world-class, fully-connected smart vertical farms that grow the highest quality plants all year round.

AeroFarms and Nokia Bell Labs have been working together since 2020 and have reached an important milestone of achieving a proof of concept for this state-of-the-art integrated system and testing the technologies with AeroFarms’ current commercial crop varieties. Together, they are now ready to scale this system to all of AeroFarms’ crops and future indoor vertical farms, including the next ones in Danville, Virginia and Abu Dhabi, UAE.

The integration of Nokia Bell Labs’ AI-enabled drone-based sensors and advanced machine learning, computer vision and data analytics technologies with AeroFarms’ existing machine vision tools enhances and elevates AeroFarms’ position as an agriculture platform and capabilities organization dedicated to solving food and agriculture supply chain challenges.

David Rosenberg, CEO at AeroFarms, said: “With Nokia Bell Labs, we have developed the next-generation system that can image every plant every day in a cost-effective way at scale. This level of detailed imaging and insights helps us be better farmers by monitoring our plant biology dynamically and allowing us to course correct as needed to ensure the highest level of quality all year round. When I watch the drones autonomously imaging our plants, I am blown away by how this truly represents the power of harnessing leading-edge technologies and bringing brilliant problem solvers together from diverse groups to grow the best plants possible.”

Roger Buelow, CTO at AeroFarms, said: “AeroFarms’ expert team of plant scientists and engineers have been working together for two years with Nokia Bell Labs’ top researchers and engineers to train these complex learning systems with a nuanced understanding of plant biology. We have created a cross-disciplinary understanding at an industrial scale to develop the latest imaging technology to help accelerate our ability to introduce new crops and ensure the highest quality for our commercial operations.”

Nokia Bell Labs’ machine vision technology has enabled the most precise data capture yet, down to the level of individual plants, using leaf size segmentation, quantification, and pixel-based scanning to identify consistency and variation. Going beyond what even the human eye can perceive, this state-of-the art imaging technology enables the gathering of immense insights about a plant including its leaf size, stem length, coloration, curvature, spotting, and tearing. The end-to-end system is flexible and robust, built to take advantage of Nokia’s industry-leading 5G private wireless network with cloud processing technology, designed for low latency and high privacy in an on-premises network. It also provides intelligent industrial analytics capabilities as an integrated service that can be deployed quickly and efficiently anywhere.

Thierry Klein, VP, Integrated Solutions and Experiences Research Lab at Nokia, said: “Nokia Bell Labs is driven to solve hard and impactful problems, and together with AeroFarms, we are building the ability to see and identify plant interactions at unprecedented levels. The fundamental technologies of this partnership are our strength, and vertical farming is just the beginning. With the AeroFarms platform, we are exploring the power of network driven intelligence for industrial outcomes. These capabilities can expand into a multitude of indoor industrial operations, including logistics, warehousing, distribution hubs, and manufacturing.”

The multi-year partnership between AeroFarms and Nokia is anchored on shared values as mission-driven companies with the vision to scale technologies for the greater good. AeroFarms’ vertical farming platform is more sustainable than traditional farming with up to 390 times greater productivity per square foot annually, while using up to 95% less water and zero pesticides. In addition, vertical farming provides local food options for communities, reducing the environmental impact of trucking and shipping produce long distances and helping combat food waste.

Additional resources

AeroFarms website

Nokia Bell Labs website

About Nokia

At Nokia, we create technology that helps the world act together. As a trusted partner for critical networks, we are committed to innovation and technology leadership across mobile, fixed and cloud networks. We create value with intellectual property and long-term research, led by the award-winning Nokia Bell Labs. Adhering to the highest standards of integrity and security, we help build the capabilities needed for a more productive, sustainable and inclusive world.

About AeroFarms

Since 2004, AeroFarms has been leading the way for indoor vertical farming and championing transformational innovation for agriculture. On a mission to grow the best plants possible for the betterment of humanity, AeroFarms is a Certified B Corporation with global headquarters in Newark, New Jersey. Named one of the World’s Most Innovative Companies by Fast Company two years in a row and one of TIME’s Best Inventions in Food, AeroFarms patented, award-winning indoor vertical farming technology provides the perfect conditions for healthy plants to thrive, taking agriculture to a new level of precision, food safety, and productivity while using up to 95% less water and no pesticides ever versus traditional field farming. AeroFarms enables local production to safely grow all year round, using vertical farming for elevated flavor. In addition, through its proprietary growing technology platform, AeroFarms has grown over 550 varieties and has developed multi-year strategic partnerships ranging from government to major Fortune 500 companies to help uniquely solve agriculture supply chain needs. For additional information, visit: https://aerofarms.com/.

On March 26, 2021, AeroFarms announced a definitive business combination agreement with Spring Valley Acquisition Corp. (Nasdaq: SV). Upon the closing of the business combination, AeroFarms will become publicly traded on Nasdaq under the new ticker symbol "ARFM". Additional information about the transaction can be viewed here: https://aerofarms.com/investors/.

No Offer or Solicitation

This press release does not constitute an offer to sell or a solicitation of an offer to buy, or the solicitation of any vote or approval in any jurisdiction in connection with a proposed potential business combination among Spring Valley and AeroFarms or any related transactions, nor shall there be any sale, issuance or transfer of securities in any jurisdiction where, or to any person to whom, such offer, solicitation or sale may be unlawful. Any offering of securities or solicitation of votes regarding the proposed transaction will be made only by means of a proxy statement/prospectus that complies with applicable rules and regulations promulgated under the Securities Act of 1933, as amended (the “Securities Act”), and Securities Exchange Act of 1934, as amended, or pursuant to an exemption from the Securities Act or in a transaction not subject to the registration requirements of the Securities Act.

Forward Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “might,” “will,” “estimate,” “continue,” “contemplate,” “anticipate,” “intend,” “expect,” “should,” “would,” “could,” “plan,” “predict,” “project,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this press release, including those regarding the expected benefits of the partnership, improvement of plant yields and quality and Spring Valley’s proposed acquisition of AeroFarms are forward-looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of the respective management of AeroFarms and Spring Valley and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AeroFarms and Spring Valley. These forward-looking statements are subject to a number of risks and uncertainties, including changes in domestic and foreign business, market, financial, political, and legal conditions; the inability of the parties to successfully or timely consummate the proposed transaction, including the risk that any regulatory approvals are not obtained, are delayed or are subject to unanticipated conditions that could adversely affect the combined company or the expected benefits of the proposed transaction or that the approval of the stockholders of Spring Valley or AeroFarms is not obtained; failure to realize the anticipated benefits of the proposed transaction; risks related to the expansion of AeroFarms’ business and the timing of expected business milestones; the effects of competition on AeroFarms’ business; the ability of Spring Valley or AeroFarms to issue equity or equity-linked securities or obtain debt financing in connection with the proposed transaction or in the future, and those factors discussed in Spring Valley’s Annual Report on Form 10-K, Quarterly Report on Form 10-Q, final prospectus dated November 25, 2020 and definitive proxy statement/prospectus dated July 26, 2021 under the heading “Risk Factors,” and other documents Spring Valley has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. There may be additional risks that neither Spring Valley nor AeroFarms presently know, or that Spring Valley nor AeroFarms currently believe are immaterial, that could also cause actual results to differ from those contained in the forward-looking statements. In addition, forward-looking statements reflect Spring Valley’s and AeroFarms’ expectations, plans, or forecasts of future events and views as of the date of this press release. Spring Valley and AeroFarms anticipate that subsequent events and developments will cause Spring Valley’s and AeroFarms’ assessments to change. However, while Spring Valley and AeroFarms may elect to update these forward-looking statements at some point in the future, Spring Valley and AeroFarms specifically disclaim any obligation to do so. These forward-looking statements should not be relied upon as representing Spring Valley’s and AeroFarms’ assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Contacts

AeroFarms Contacts

Investor Relations:

Jeff Sonnek

ICR

Jeff.Sonnek@icrinc.com

1-646-277-1263

Media Relations:

Marc Oshima

AeroFarms

MarcOshima@AeroFarms.com

1-917-673-4602

BASF Venture Capital Invests In Indian Startup UrbanKisaan

With the investment from BASF, UrbanKisaan plans to further expand its market presence in India, deploy its farming technology to work with thousands of farmers, and bring fresh, local, sustainable produce to urban dwellers

Startup optimizes sustainable agriculture without soil in tropical climates

■ BASF Venture Capital’s first investment in this early stage Indian business strengthens AgTech activities in Asia

Hyderabad, India, and Ludwigshafen, Germany, July 13, 2021 – BASF Venture Capital GmbH (BVC) is investing in the Indian startup UrbanKisaan, which specializes in hydroponic cultivation of various types of vegetables, greens and herbs in tropical urban environments. This is BVC’s first investment in an early stage business focusing on India. Conceptualized in 2017, UrbanKisaan operates several suburban greenhouses and vertical indoor farms in Hyderabad and Bangalore. The company sells the fresh produce, some of which is grown directly in the shops, in its franchise-owned brick-and-mortar stores and via an app and website. Both parties agreed not to disclose financial details of the investment.

UrbanKisaan has optimized hydroponics technology for use in tropical climates such as India. With only one tenth of the costs, the proprietary technology is significantly more efficient than conventional global standards in hydroponics cultivation. The company is also capitalizing on the trend of online food retailing, which is booming on the subcontinent. “Our approach in hydroponics enables us to produce our food cost-effectively and with relatively little effort,” said Vihari Kanukollu, co-founder and CEO at UrbanKisaan. “Our produce also contributes towards sustainability as it is grown in clean, hygienic farms in and around the city, thus minimizing the total carbon footprint. Use of IoT (Internet-of-Things)-enabled technology for monitoring the farms ensures pesticide-free produce. The growing demand from our customers shows that our idea is well-received,” he added.

UrbanKisaan’s farms are managed through their proprietary technology. Nutrient content, pH levels, atmospheric humidity, CO2 concentration, light concentration and other important parameters are controlled and adapted to the needs of the particular plants with an app.

“UrbanKisaan, as a pioneer in the hydroponics space, has developed a unique growing method and combines this with a compelling business model for sales,” commented Markus Solibieda, Managing Director of BASF Venture Capital GmbH. He added: “AgTech is one of our key investment focus areas worldwide. This includes, in particular, our goal of supporting innovative agricultural and food-related businesses in Asia. We look forward to learning more about hydroponic farming and exploring its potential through a close collaboration between UrbanKisaan and BASF’s agriculture experts.”

With the investment from BASF, UrbanKisaan plans to further expand its market presence in India, deploy its farming technology to work with thousands of farmers, and bring fresh, local, sustainable produce to urban dwellers.

Hydroponic farming – an efficient way to use limited resources

The world’s population is expected to reach 10 billion by 2050 1 while the area available for farming and freshwater reserves are becoming increasingly scarce. Hydroponics offers a sustainable way to grow crops without soil and using vertically stacked layers while reducing water usage by about 90 percent 2. Especially in densely populated urban areas, this presents a more efficient way to use limited resources like water, space and manpower. Water that is not absorbed by the plants is captured, purified and fed back into the farm’s water circulation system, minimizing wastage significantly.

India is the second-largest producer of fruits and vegetables in the world, with a production value of about $64 billion3. It is also a large consumer of fruits and vegetables, and while much of this is through unorganized channels (local vegetable markets, hand-pulled carts and neighborhood stores), organized channels (modern trade and online retail) account for a little over 20 percent of the market4. Thus, hydroponics is a fast growing and efficient alternative to traditional supply chains in the organized fresh produce market.

About UrbanKisaan

UrbanKisaan was conceptualized in 2017 in Hyderabad, India. The company began as a farming enterprise but wanted to grow more than just fresh and nutritious food. They wanted to create a sustainable future for farming and feed the world in a way that is good for both people and planet. Today, with its hyper-local urban farms the company is creating a transparent supply chain with a low carbon footprint, leveraging on proprietary growing technology that helps save 90% of water yet grow 30 times more crops compared to traditional farms of similar area. Further information at www.urbankisaan.com.

About BASF Venture Capital

At BASF, we create chemistry for a sustainable future. BASF Venture Capital GmbH (BVC) also contributes to this corporate purpose. Founded in 2001, BVC has offices in Europe, the U.S., China, India, Brazil, and Israel. BVC’s goal is to generate new growth potential for current and future business areas of BASF by investing in young companies and funds. The focus of investment is on new materials, AgTech, Digitization and new, disruptive business models. Further information at www.basf-vc.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. More than 110,000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €59 billion in 2020. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S. Further information at www.basf.com.

3 Fruits & Vegetables Production value at Current Prices for 2015-16, Horticultural Statistics at a Glance 2018, Government of India, Ministry of Agriculture and Farmers Welfare

4 Avalon Consulting - http://www.fruitnet.com/asiafruit/article/178572/india-on-the-move

Farmers At Growing Underground Launch Fresh Branding As They Announce B Corp Status And Growth Plans

Since 2015, Growing Underground crops have been generating proprietary data, improving technology and methods to increase yields and reduce resources to create a net carbon negative growing system

Growing Underground announces its status as a B Corp brand, making it the first B Corp salad brand available in mainstream UK supermarkets. Meanwhile, owner Zero Carbon Farms (ZCF) is the first certified B Corp vertical or controlled environment farm in the UK and Europe. B Corporations are businesses that meet the highest standards of verified social and environmental performance, public transparency, and legal accountability to balance profit and purpose. Growing Underground boasts a fully net carbon negative growing system, meaning that it off- sets more carbon than it emits.

Target-busting investment shows industry and individual support for the vertical farming movement

Since 2015, Growing Underground crops have been generating proprietary data, improving technology and methods to increase yields and reduce resources to create a net carbon negative growing system. Now the AgTech brand has formed a strategic partnership with one of the leading fresh fruit and veg suppliers to the UK, Reynolds, allowing the brand to distribute nationally.

To scale up its innovative farming mode even further, ZCF is currently undertaking a share offering. The financing has met with strong industry interest and investor endorsement and included a deliberately targeted crowdfunding campaign that hit its target in less than 24 hours. The offering has been over-subscribed and in total over £4 million has been raised, which will be used to expand into a second site in North London this summer.

“Growing Underground continues to grow in every sense,” comments Richard Ballard, Co-Founder & Farmer-in-Chief, Growing Underground. “We’re looking forward to translating our carefully crafted model and sustainability credentials into an industrial-scale distribution network, accelerating the world’s transition to carbon negative farming and continuing to transform the future of sustainable food production in the UK.”

Read the complete article at: Fresh Plaza

For more information:

Growing Underground

www.growing-underground.com

9 July 2021

The Future of Agritech: Inside Singapore’s Vision For Food Security

Local farms are turning to tech to increase food production. Melvin Chow, Senior Director, Food Infrastructure Development & Management Division at Singapore Food Agency (SFA), shares how that’s bolstering the city-state’s food security

Melvin Chow, Senior Director, Food Infrastructure

Development & Management Division,

Singapore Food Agency Discusses The

Role of High-Tech Urban Farms.

By Justin Tan

9 JULY 2021

Early last year, Covid-19 restrictions led to hordes storming supermarkets. Eggs, butter, and even toilet paper were flying off the shelves.

As a small city-state with limited resources, Singapore is especially vulnerable to such disruptions. It imports over 90 percent of its food from other countries, and only one percent of its land is set aside for agricultural use. How can it ensure its food supply remains stable amid today’s volatile world?

Local farms are turning to tech to increase food production. Melvin Chow, Senior Director, Food Infrastructure Development & Management Division at Singapore Food Agency (SFA), shares how that’s bolstering the city-state’s food security.

Stacking production

Singapore aims to produce 30 percent of local nutritional needs by 2030. To reach the goal, the country will increase local production of commonly consumed food such as fish, eggs and vegetables. These are also more perishable and vulnerable to supply disruptions, Chow says.

With limited land spaces and resources, the nation needs to optimize the limited land resources they have through “intensifying each unit area”, he adds.

A local farm, Sustenir Agriculture is using tech to optimize farming spaces. It uses LED lighting to grow vegetables indoors across multiple floors. Their system is designed to fit into existing multi-story buildings such as industrial areas, eliminating the need for specialized new compounds to be built.

Sustenir Agriculture is a high-tech indoor farm that taps on hydroponics and a controlled environment agricultural system to grow crops such as kale and lettuce.

These indoor farms will be more “resilient to some of the impacts of climate change”, Chow says. Urban farmers can incorporate sensors that will help to ensure factors like air quality, light, and water are optimally balanced.

Apollo Aquaculture Group is another local innovator that is maximizing production with eight floors of vertical fish farms.

Apollo Aquaculture Group’s indoor multi-story fish farm utilizes Recirculating Aquaculture System which treats and recycles water to reduce waste.

Each floor will be equipped with a tank system that will purify, monitor, and recirculate water within the farm. Only five percent of the water will need to be replaced when contaminated by fish waste. That reduces water wastage compared to traditional farms that regularly clean out whole tanks, reported Smithsonian Magazine.

Such innovative farms help to produce up to 10 to 15 times more food product per hectare as compared to traditional farms, Chow says.

To overcome land constraints, SFA is also looking to use alternative spaces for farming. The rooftops of multi-story car parks have been used to grow vegetables. Citiponics, one such farm in the Ang Mo Kio neighborhood, sells pesticide-free vegetables and provides job and training opportunities for senior residents.

These community farms will help to raise public awareness and support for local produce, Chow told CNA.

Sustainable farming

To encourage more sustainable farming methods, the SFA recently launched a new agricultural standard for local farms. This will ensure farms are using resources efficiently and recycling waste. Non-edible crop waste, for instance, can be used for composting before it is disposed of.

Singapore currently incinerates up to 95 percent of food waste, which is a “waste of resource”, Dr. Per Christer Lund, Science and Technology Counsellor at Innovation Norway told GovInsider.

Food waste can be converted into animal feed – recycling nutrients back into the food production loop, Chow says. SFA is looking to improve the efficiency of tech that can convert food waste into animal feed, Chow says.

The National Environment Agency is moving to support this, as large restaurants and food factories will have to segregate their food waste for treatment from 2024.

Singapore is also hoping to encourage “green citizenry” that consumes and wastes less, Chow says. Singapore’s Green Plan 2030 – a nationwide agenda to advance sustainable development – plans to educate youths on sustainable living habits, reported CNA.

Support for the industry

SFA is providing funding for the adoption of innovative tech. Last year, the organization launched a “30×30 Express” grant which offered SG$39.4 million (US$29.1 million) to nine high-tech farms to boost local food production.

One of the farms, I.F.F.I, will set up an indoor vegetable farm that uses AI to monitor the growth of produce. It will also set up a water treatment system that reduces the amount of bacteria and extends the shelf life of crops, reported by The Straits Times.

SFA’s SG$60 million (US$44.4 million) Agri-Food Cluster Transformation fund also encourages farms to adopt tech-enabled and sustainable farming practices, Chow says.

As the farming industry transforms, the workforce will need to be trained. Young people must also be attracted to join the industry. “By 2030, we expect about 4,700 jobs to be created and upskilled in the agri and aqua-tech food industry,” Chow says.

On this, the agency is working with local farms and institutes of higher learning to roll out internship programs and diploma courses. 20 students studying aquaculture at local polytechnics have been placed in internships at ten local fish farms, SFA reports.

Existing workers in the sector or workers looking to make a switch can take the SkillsFuture Continuing Education and Training courses, Chow says. The courses include part-time diplomas in aquaculture and agriculture technology.

The turbulence of the past year has underscored the need for governments to bolster food security. Innovative and sustainable farms will help Singapore reduce its reliance on food imports.

Images by the Singapore Food Agency

BrightBox Farms’ Gideon Saunders Sees Alaska’s Future For Agriculture In Hydroponics

Nestled next to an otherwise ordinary house on Kodiak is a shipping container. It looks out of place, but the garden in it is even more noticeable

July 8, 2021

Nestled next to an otherwise ordinary house on Kodiak is a shipping container. It looks out of place, but the garden in it is even more noticeable. The growing area of the BrightBox Farm looks like a prop from a movie about space exploration – the vertically oriented hydroponic farm has its own perfect microclimate.

The use of this shipping box has enabled Gideon Saunders to conquer the seasons that otherwise rule Kodiak Gardens.

“There we worked with Freight Farms, who build 40-foot containers, high cubes, 2.50 m high, 2.40 m wide, standard containers, only slightly higher, very insulated, highly insulated R-28. So we agreed with them and picked out a unit and then delivered it to us, ”Saunders said.

Freight Farms made the interior of the shipping container. Inside, there are shelves with lettuce and other greens, interspersed with panels of blindingly bright ultraviolet light. A panel filled with nutrients feeds into a water tank on the back, which in turn feeds drips into the hydroponic system. The air is supplemented by a carbon dioxide tank, which ensures that the plants do not lack for anything.

The container is completely controlled by an app. And it even comes with built-in bluetooth speakers. But for the container, function is more than form – Saunders boasts that he could grow 1,000 heads of lettuce a week in less than 30 hours.

It doesn’t just look futuristic. Saunders believes systems like this will revolutionize agriculture.

“I think it’s the future. I mean, we can get into the politics of agriculture and water rights and freshwater use worldwide, and global warming and all these hot topics – 8 billion, 9 billion, 10 billion people, how do you feed them? The population is growing – how do you become more efficient with your food? Well, when it comes to vegetables and leafy greens and what we do, we use 95% less water than traditional farming. We do not use herbicides, pesticides or insecticides. So no glyphosate, no Miracle Grow. Chemically nothing bad. You can control it. So it’s the future of agriculture, ”Saunders said.

This type of production is not cheap. Saunders says the device costs around $ 100,000 with shipping and handling. But as technological advances inevitably push prices down, it becomes more cost-effective for smallholders to invest in such equipment.

And Saunders says it’s already inexpensive, although its container is complemented by a small homemade addition in its garage. He sells microgreens as a subscription service, in which he provides his subscribers with bags of greens for a monthly fee, and through sales at the local farmers’ market. Even on an island known for its horticultural and merchant shipping challenges, herbivores can enjoy fresh, locally grown produce year round.

USA - MIAMI, FLORIDA: Three Local Men Hope To See Their Work On ISS

“We have been involved in this program with NASA for years, after conversations about the challenge of growing plants in space,” Lewis said. “Year One was about how to make the best use of limited growing volume on a spacecraft

July 7, 2021

Three South Florida men with diverse backgrounds — and all volunteers at Fairchild Tropical Botanic Garden — have teamed together in a unique collaboration to design a plant-growing method that they hope will someday be found on the International Space Station (ISS).

It’s all part of the nationwide Growing Beyond Earth Maker Challenge that calls for contestants in three team categories — High School, College and Professional — to submit designs for growing plants in space. Six finalists remain out of the 60 original submissions in year two of the three-year contest.

Jack Hahn, a photographer, heard about the program while working as a volunteer in the Fairchild Imaging Lab, was intrigued and submitted a proposal to grow “veggies in space that do well in microgravity.” His proposal impressed the judges — Dr. Gioia Massa, NASA Plant Research; Trent Smith, NASA Procurement, and Ralph Fritsche, NASA Veggie Project Manager — and he became one of the six finalists in the Professional (non-collegiate) category.

According to Dr. Carl E. Lewis, Fairchild Tropical Botanic Garden director, each year of the competition is intentionally getting more challenging.

“We have been involved in this program with NASA for years, after conversations about the challenge of growing plants in space,” Lewis said. “Year One was about how to make the best use of limited growing volume on a space craft. This year is about automation. Can you set it and forget it? Next year will be about robotic planting and harvesting. We’re looking forward to seeing what you [contestants] come up with.”

After Hahn was selected for phase two of the competition, the Kendall resident realized he needed more assistance.

“I was very excited to hear that I was a finalist,” said Hahn, husband of Marjorie Hahn, executive and music director of the South Florida Youth Symphony. “But I realized that I needed to put together a team with various skill-sets and talents to go further.”

So, in May, Hahn met with the other two Fairchild volunteers who responded to an email he sent — Coconut Grove’s Nic Brunk, a molecular biologist (and crew coach for the Miami Beach Rowing Club), and Shenandoah’s Allen Diehl, a photographer with a degree in mechanical engineering.

Their goal is to grow high-density vegetables (with a high Vitamin K benefit) in a limited amount of space (a 50 cm cubic growing environment) using an autonomous system that won’t require any further human interaction (after initial seed planting) over a 30-day period.

Together, the three South Florida “scientists” have come up with an eye-catching design (with the limited constraints on size per NASA’s specs) that, well, looks like something from outer space. It has three levels (heights) for the difference phases of growth of the red romaine lettuce most competitors are using.

And, in a bold move they hope will impress the judges — and be used in future growth models in space — the threesome is growing their plants hydroponically.

“Even though you think of ‘weightlessness’ in space, weight is everything, including in the space shuttle bringing supplies to the ISS,” Brunk said. “Soil is weight and messy to deal with, especially in space.”

Diehl said, “Hydroponics is definitely the way to go. It eliminates the soil factor, and you can recycle or repurpose the water.”

Basically, the automation model the threesome has developed works by small computer, which turns the growing lights on/off, and activates fans and pumps. Additional automation to replenish the nutrient solution levels will follow.

But all three agree that the small monetary prize which awaits the winner of the NASA/Fairchild collaboration, which will be announced in July/August of this year, is not the reason for the countless hours of sometimes tedious work.

“This competition will provide NASA with valuable input and data, which will someday enable those on the International Space Station as well as Moon and Mars missions with a means of complimenting their diet while giving them something live and green to look at in a sterile environment,” Hahn said. “It will be great to know that our team had something to do with that.”

Lead photo: Jack Hahn (left) has joined with Nic Brunk (center) and Allen Diehl in the Growing Beyond Earth Maker Challenge to find effective ways to grow plants in space.

How AppHarvest Is Investing In The First Generation of High-Tech Farmers

Agriculture may have been slower to digitize than other parts of the food sector, but these days a lot of folks would agree artificial intelligence, automation, and other technologies have a role to play in the future of farming

By Jennifer Marston

July 6, 2021

Agriculture may have been slower to digitize than other parts of the food sector, but these days a lot of folks would agree artificial intelligence, automation, and other technologies have a role to play in the future of farming. The presence of such things means farming will soon require lots of new skills, which in turn means training a whole new generation on a whole new set of tools. It means, in the words of AppHarvest’s founder and CEO Jonathan Webb (pictured above), “getting young people to really visualize what agriculture is” in a way they haven’t before.

Standing under a tent in the middle of a downpour outside Elliott County High School in Sandy Hook, Kentucky recently, Webb explained to me how his company is training the next generation of farmers while simultaneously investing in the company’s own future as a high-tech agricultural powerhouse.

We, along with with students, parents, teachers, and Kentucky governor Andy Beshear, were at the launch for the latest unit of AppHarvest’s high-tech educational container farm program, which teaches high-tech farming to Eastern Kentucky high-school students. Launched back in 2018, the program retrofits old shipping containers to house controlled-environment vertical farms that grow leafy greens. Farms at each school serve as hands-on agricultural classrooms where students can learn not just horticulture but also how to use the technologies powering the next wave of farming innovations around automation, connectivity, and data.

“What we’re doing here is trying to plant the seeds of what it means to be in an exciting industry and get that groundswell early,” Webb told me.

He was talking specifically about the container farm program but might as well have been referring to the entire company’s MO. AppHarvest, itself a product of Eastern Kentucky, is both a Public Benefit Corporation and a Certified B Corporation, which means the company has to strike a balance between profit and less measurable purposes like environmental impact, transparency, and social good.

The company’s main business is headquartered about an hour away from Elliott County High School, in Morehead, Kentucky, where AppHarvest operates a 60-acre high-tech greenhouse that grows different varieties of tomatoes. Two additional farms, one for leafy greens and another for tomatoes, are under construction, and the company just broke ground on a couple more last month. All of these farms provide or will provide produce for restaurants and grocery retailers within a day’s drive. They will also provide jobs for a local community that’s seen unemployment rise as the coal industry declines.

The high school container farms are altogether smaller and somewhat different in terms setup and technical specs, but the idea is the same: grow crops in a controlled environment and use technology to improve plant yield, quality, and nutrition profile. In doing so, people from the community get an opportunity to learn the kinds of skills that will be relevant as agriculture gets more and more digitized.

“We’ve tried to say at AppHarvest we’re not building facilities, we’re building an ecosystem,” said Webb. “Obviously our large production facility is the core critical centerpiece of that, but us investing in a high school education, we’re truly trying to create an ecosystem that includes facilities and the brainpower to be able to operate the facilities.”

This isn’t just feel-good talk, either. Technologies like artificial intelligence, robotics, sensors, and analytics are coming to agriculture in response to multiple problems looming in the near future for the global food system. As McKinsey notes, “Demand for food is growing at the same time the supply side faces constraints in land and farming inputs.” With a population expected to grow to 9.7 billion by 2050, the planet needs to produce around 70 percent more available calories. At the same time, inputs like water supply and arable land are shrinking, raising costs for farming and negatively impacting an already burdened planet.

Part of the promise of controlled environment agriculture formats like high-tech greenhouses and container vertical farms is that they can grow more food faster, at a higher quality, and closer to the buying public. Many of these facilities operate via hydroponics systems that recirculate water, saving on that resource. (AppHarvest’s greenhouse runs off rainwater collected from the facility’s roof.) In the case of vertical farming, less land is required because plants are stacked. AppHarvest’s container farms, for example, can pack three to five acres of leafy greens into a forty-foot-long shipping container. Other large-scale vertical farms a la Kalera or Plenty are growing pounds of greens that number in the millions and also exploring additional crops such as berries.

Most individuals in this industry I’ve spoken to agree that indoor farming isn’t “the savior” that will wholly replace traditional agriculture. Nor was it never meant to be. Rather, greenhouse growers, vertical farm companies, and those operating container farms believe we need all of these formats working together and alongside traditional agriculture practices to try and resolve the above issues.

One of the many things needed to make that a reality is a new generation of young people interested in farming as a career and able to navigate the technical as well as horticultural aspects of agriculture.

Right now, that’s a challenge. “We don’t have our brightest young people inspired to go into agriculture,” said Webb, adding that the issue is, “How do we inspire them early to get into agriculture and the technology sphere of agriculture?”

AppHarvest started investing in its education program before its main facility was ever complete, spending $200,000 of its initial $1 million investment on the program. “I’m not sure if there’s ever been a venture-backed company that’s taken 20 percent of their raised proceeds early and invested in education,” said Webb.

In 2021, AppHarvest has five different container farm programs operating at Eastern Kentucky high schools, all of them operating independently but also networked together, just as AppHarvest’s larger farms will eventually be networked.

Students learn a huge range of skills working on these farms, from horticultural-related ones like seeding and harvesting to technology management across multiple farms to food safety, data entry, marketing, packaging, and creating a budget. Via a screen inside the farm, students can learn to track the pH levels of plants, carbon dioxide levels, temperature, humidity, and all the other variables present in a farm. And since farms from every high school are networked together, students can view one another’s activity. Elliott County High can see data from Shelby Valley High School in Pike County and vice versa, for example.

Webb says the farms are also an opportunity for schools and students to collaborate using different skillsets, whether technological, horticultural, or otherwise. “Some students might have more of a background or interest in horticulture. Some students might have more of a background or interest in craftsmanship. All we’re trying to do now is say, ‘Here, it’s your thing, bring it to life, and openly share information.’”

And while there’s no pressure, the hope is that some of these students eventually bring their skillsets to AppHarvest’s main operations and help improve them, along with indoor ag, over the coming years. “Hopefully in four years we have students that might end up at MIT. And then they’re telling us what to do,” said Webb, adding that the ROI here isn’t quick. The true impacts of the company’s investment in school programs probably won’t be seen for another five of six years, which is a few lifetimes when we’re talking about tech.

“We get judged on quarterly earning calls, [but] that’s not the way I think,” he said. “I want us to think, first decade, second decade, third decade, and these are very long-term investments.”

He hopes to see more tech companies investing in high schools, and AppHarvest isn’t quite the lone wolf when it comes to this. Freight Farms, which deals exclusively in container farms, has a partnership with Sodexo to bring its units to K-12 schools and universities in the U.S. AeroFarms, also a Certified B Corp., has partnerships with various schools and community centers, too.

For AppHarvest, the educational program is is an integral part of the operation, and one tied to the company’s long-term success. “It’s not a ‘nice to have,'” Webb told me. “It’s something we truly believe is going to give our company a competitive advantage medium to long term.”

VIDEO: Signify Expands LED Installation At Walters Gardens With Philips GreenPower LED Toplighting Compact

“It was a really easy decision to go with the Philips LED toplighting compact”, says Aren Philips, finishing lead grower at Walters Gardens. “The tops are fuller, the roots are more active, we are able to finish our hostas product 1 to 2 weeks ahead of schedule.”

July 6, 2021

Eindhoven, the Netherlands – Signify (Euronext: LIGHT), the world leader in lighting, is supplying Walters Gardens with the Philips GreenPower LED toplighting compact to expand their existing lighting installation. Walters Gardens is a market leader in the ornamental industry from Zeeland, Michigan, in the United States.

They first trialed Philips GreenPower LED toplighting in 2014 - one of the first growers in North America to install Philips horticulture LED grow lights over ornamental crops, with the aim to jump-start their spring perennial production.

As a result of the trial’s success, Walter’s Gardens partnered with Signify again, when expanding their lighted growing areas in 2019 - 2020, with the Philips GreenPower toplighting compact.

“It was a really easy decision to go with the Philips LED toplighting compact”, says Aren Philips, finishing lead grower at Walters Gardens. “The tops are fuller, the roots are more active, we are able to finish our hostas product 1 to 2 weeks ahead of schedule.”

Together with the high efficacy of the toplighting compact, and the easy 1:1 replacement of the HPS, leading to a great ROI, Walters Gardens knew the expansion would pay off.

Learn more about the Philips LED grow lights for floriculture here.

--- END ---

For more information:

Global Marcom Manager Horticulture at Signify

Daniela Damoiseaux

Tel: +31 6 31 65 29 69

Email: daniela.damoiseaux@signify.com

About Signify

Signify (Euronext: LIGHT) is the world leader in lighting for professionals and consumers and lighting for the Internet of Things. Our Philips products, Interact connected lighting systems and data-enabled services, deliver business value and transform life in homes, buildings, and public spaces. With 2020 sales of EUR 6.5 billion, we have approximately 37,000 employees and are present in over 70 countries. We unlock the extraordinary potential of light for brighter lives and a better world. We achieved carbon neutrality in 2020, have been in the Dow Jones Sustainability World Index since our IPO for four consecutive years and were named Industry Leader in 2017, 2018 and 2019. News from Signify is located at the Newsroom, Twitter, LinkedIn, and Instagram. Information for investors can be found on the Investor Relations page.

Contain Inc Announces Finance Arrangement With Edible Beats For FarmBox Foods Container Farm

The container farm is being built and customized for Edible Beats, and will produce ingredients for all of the EB concepts, Linger, Root Down, Vital Root, El Five, and Ophelais

NEWS PROVIDED BY

July 07, 2021

Contain Inc announces a financing agreement arranged between Edible Beats Restaurant Group & a prominent lender for a FarmBox Foods container farm.

Image courtesy of FarmBox Foods

With the FarmBox Food container, we can grow hyper-local, organic, year-round produce that will be featured at all of our restaurants. We feel this is just the beginning of what we can grow”— Justin Cucci of Edible Beats Restaurant Group

RENO, NV, UNITED STATES, July 7, 2021 /EINPresswire.com/ -- Contain Inc is pleased to announce a financing agreement arranged between Edible Beats Restaurant Group and a prominent lender for a controlled-environment container farm, FarmBox Foods. Edible Beats is a locally owned Denver-based restaurant group known for its diverse menus and healthy, plant-based dishes that highlight local and seasonal ingredients. Edible Beats will be able to grow herbs, leafy greens, salad greens, and various produce organically and year-round with the container farm that will be attached to their Vital Root location.

“We have always sought opportunities to be more responsible to the sourcing, growing, and handling of the incredible ingredients that we get,” said Justin Cucci of Edible Beats Restaurant Group. “With the FarmBox Food container, we can grow hyper-local, organic, year-round produce that will be featured at all of our restaurants. We feel this is just the beginning of what we can grow, and we are eager to add the mushroom grow operation in the future”

Image courtesy of Unsplash

Edible Beats purchased the container from FarmBox Foods, a Colorado-based company that builds automated farms that grow gourmet mushrooms, leafy greens, and culinary herbs. To FarmBox, controlled-environment agriculture is the future, and this deal is one of many leading us towards a more decentralized and eco-friendly food system.

“I think we’re going to see a lot more of these types of programs going forward,” said Chris Michlewicz, Chief Public Relations Officer at FarmBox. “Restaurants are realizing that their produce is fresher and has a longer shelf life when they have a container farm on site. It’s a reliable and sustainable source of food, and it’s more eco-friendly because you no longer have to transport food in from elsewhere.”

Image courtesy of Unsplash

Likewise, Contain Inc is thrilled to support Edible Beats as it ventures into indoor ag. “We're delighted to have assisted SemiMojo and FarmBox Foods in this innovative initiative. Contain is always excited to see more fresh food made available to consumers. Customers appreciate freshness and quality produce, year round. Restaurants and container farms make this possible”, said Doug Harding, Head of Leasing & Vendor Relations at Contain Inc. “We are thrilled to have collaborated with Edible Beets and Farm Box Foods on this project. It aligns perfectly with Contain's mission of supporting the controlled environment agriculture industry in its financing needs”.

The container farm is being built and customized for Edible Beats, and will produce ingredients for all of the EB concepts, Linger, Root Down, Vital Root, El Five, and Ophelais.

About Contain Inc

Contain is out to empower the indoor ag industry of tomorrow. Our first and key mission is bringing easier and faster financing to controlled environment agriculture, but we aren't stopping there. We create platforms to move the industry forward, and most importantly, find ways to make indoor ag more accessible to farmers of all stripes.

Contact Contain:

Doug Harding, Leasing & Vendor Relations

doug@contain.ag | 760-330-1199

About Edible Beats

Edible Beats is a locally owned independent restaurant group that operates such diverse concepts as Linger, Root Down, El Five, Ophelais, and Vital Root. “Walking the walk” is important to us and the various aspects of sustainable & local food sourcing, up-cycled design, and authentic Hospitality.

About FarmBox Foods

FarmBox Foods was founded to help provide a sustainable, eco-friendly food source to places where there is a lack of access to farm-fresh produce. The company’s mission is to use container farms to decentralize the food supply chain and empower local communities.

Doug Harding

Contain Inc

doug@contain.ag

Visit us on social media:

Twitter

LinkedIn

Vertical Farming World To Meet In September

With the theme of ‘Raising Expectations’, the 2nd Vertical Farming World Congress will host industry members, from global leaders to new start-ups, on 20-22 September at a hybrid event online as well as in-person

With the theme of ‘Raising Expectations’, the 2nd Vertical Farming World Congress will host industry members, from global leaders to new start-ups, on 20-22 September at a hybrid event online as well as in person.

“This will be the most substantial dedicated event of the year, featuring many of the world’s leading companies and technologies, offering unparalleled networking opportunities as well as training for new entrants,” commented Richard Hall, Chairman of event organiser Zenith Global.

“We’re hoping as many people as possible will attend in person, so we’ve selected a hotel within the London Heathrow airport complex. Many others will wish to join us online, using a platform that allows for full participation including networking and questions. One advantage for everyone is that all sessions will be recorded and available for review later,” he concluded.

Congress sessions and speakers include:

Industry leadership panel with InFarm, Kalera, Plenty and YesHealth

Market opportunity and strategy with HortAmericas, Rabobank, VeggiTech and Vertical Future

Crop and technology innovation with 80 Acres, Bowery, Fork Farms, Grow Group IFS, Swegreen

and Vertical Field

Science briefing from NASA on vegetable production at the International Space Station

Industry policy forum with industry associations from Africa, Japan, UK and US alongside

Association for Vertical Farming and Farm Tech Society

Regional pioneers AgroUrbana from Chile, UrbanKisaan from India and 808 Factory from Japan

Customer and investor panels.

Other highlights include:

Agritecture workshops on planning an urban farming business

Vertical Future farm visit and fresh produce tasting

Presentation of 2021 Vertical Farming World Awards

Welcome and networking receptions.

The event is supported by Platinum sponsors Vertical Future and Intelligent Growth Solutions, and Gold sponsor CubicFarms. The awards are supported by Headline sponsor Cutlivatd.

Full programme and booking details are available on www.zenithglobal.com/events/vfwc2021.

For further information, email events@zenithglobal.com

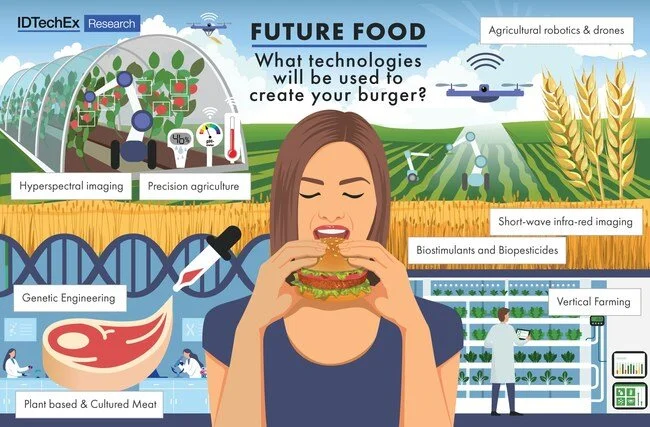

No Lives At Steak, IDTechEx Predicts How Food Will Be Made In The Future

A successful vertical farming future could see people buying their veggies at markets mere meters from where they were grown. Food miles could become a thing of the past

BOSTON, July 6, 2021

Syntheti bolognese

From free-range chicken to food miles on alfalfa, eating ethically is becoming more and more of a head-scratcher. Even for vegans, there are the questions of how sustainably agave was sourced, or whether environment-damaging pesticides were used to grow kale – and all that is without even considering how the food tastes.

Advances in the food and agriculture industry could answer every one of these questions, plus some of the regular consumers hadn't yet thought to ask.

For a slaughter-free spaghetti bolognese, a beef burger where no cows were harmed, and fresh produce growing from the walls of skyscrapers, food technology is turning science fiction into science fact one innovation at a time.

Plant-based burgers are on a roll

Meat alternatives are not new. Tofu and seitan have been around for over 1000 years and veggie burgers have been on supermarket shelves for decades. However, these have typically only appealed to vegans and vegetarians, a niche market perhaps prepared to compromise on how meat-like the product is for their own ethical reasons. With the advancement of new food technologies, that may no longer be a compromise that needs to be made; plant-based food is becoming increasingly convincing as meat. One example of plant-based food appealing to a more carnivorous palette is Impossible Foods, who used genetically modified yeast to make a vegetarian burger that bleeds.

But could the search for sustainable, guilt-free burgers go further? Cultured meat says yes.

Culture shock: meat the new burger on the block

A burger, made from 100% real beef, but no cows were harmed in its making? New technologies in cultured meat offer a potential solution for the burger-lover who feels bad about it.

Cultured meat involves directly culturing the same (or very similar) animal cells that make up conventional meat. Therefore, it is theoretically possible to create meat products completely indistinguishable from conventional meat, and without the need for slaughter.

Since the world's first cultured burger was produced in 2013, the industry has grown at a rapid pace, with start-ups around the globe competing to be the first company to commercialize a cultured meat product.

In December 2020, the industry received a major boost when Singapore became the first region in the world to grant regulatory approval for commercial sale of a cultured meat product, a hybrid product made from plant protein and cultured chicken cells produced by Eat Just. Many in the industry are hoping this will be the first of many approvals over the next few years, helping cultured meat transition from the prototype stage to consumer products.

For more information on how cultured meat is made, and promising companies in this area, see the IDTechEx report "Cultured Meat 2021-2041: Technologies, Markets, Forecasts".

Vertical farming takes agriculture to new heights

Let's not forget the lettuce and tomatoes! A successful vertical farming future could see people buying their veggies at markets mere meters from where they were grown. Food miles could become a thing of the past.

Vertical farming is a method of growing crops indoors under controlled environmental conditions, with crops grown in vertically stacked layers to save space. This could enable yields 20-30 times higher per acre than normal agriculture. By using advanced growing methods such as hydroponics and LED lighting tailored to the exact photosynthetic needs of the crops, vertical farming can achieve yields hundreds of times higher than the same space of conventional farmland.

Because it doesn't need large amounts of arable land to grow crops, it's possible to do vertical farming in urban areas, closer to population centers. This both frees up arable land and reduces the distance that food must travel to reach consumers.

Almost any location can be used for vertical farming, with companies operating out of old shipping containers (Freight Farms), disused warehouses (AeroFarms uses a warehouse in New Jersey for its indoor farming) and the walls of skyscrapers. The only limitations are being able to get resources in and harvested plants out.

Precision agriculture

Increasing agricultural yields in a sustainable manner will be crucial in feeding the world's growing population. Precision farming is a promising emerging approach, in which individual plants (or at least regions of a field) can receive targeted treatment. Furthermore, planting and harvesting can be tailored to ground conditions in a particular area and to the status of a particular fruit or plant.

Achieving this technological transition from the incumbent, broad-brush farming methodologies requires multiple new technologies, spanning robotics, imaging, machine vision and low-cost sensors. Indeed, this revolution in farming practices provides a substantial market opportunity for technologies perhaps more commonly associated with industrial automation.

Hyperspectral imaging

One technology that can monitor plant health and catch diseases early, minimizing the risk of wastage and lost crops, is hyperspectral imaging. Insight into plant health can be gained through hyperspectral imaging. Rather than expressing an image as red, green, and blue (RGB) values at each pixel location, hyperspectral imaging instead records a complete spectrum at each point, creating a full 3D data set. By obtaining a complete reflection spectrum for each pixel, far more information can be gained than from a standard image, enabling supervised machine learning to quantify chemical composition more precisely and hence determine ripeness or disease.

Extensive details of the wide range of competing technologies for SWIR and hyperspectral imaging, along with other emerging image sensor technologies and market forecasts for their adoption in different industries can be found in the IDTechEx report "Emerging Image Sensor Technologies 2021-2031: Applications and Markets".

Agricultural robotics and drones

Once agriculturally relevant data has been harvested and converted via AI into actionable insights, these need to be carried out. This will require agricultural robots, which can use this data to deliver precision-targeted planting, fertilizing, weedkilling and harvesting. Imagine varying planting densities across a field in response to soil conditions or targeting specific areas of a field with pesticides.

Short-wave infra-red imaging