Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

United States and Israel Collaborative Research: Safe Recycle of Aquaponics and Hydroponics Water

Scientists from the University of Illinois and Agricultural Research Organization, Israel are collaborating to reduce the use of water in aquaponics and hydroponics.

USA.- Scientists from the University of Illinois and Agricultural Research Organization, Israel are collaborating to reduce the use of water in aquaponics and hydroponics. To prevent plant pathogens from spreading in these soilless environments, water disinfection is required.

The researchers found that disinfection with ozone created lower toxic effects than with chlorine. They also found that lower concentration of disinfectants over a longer exposure time created lower toxicity in the recycled water. The results were presented to aquaponics and hydroponics producers in Illinois.

Tackling the Food Crisis with a Borderless Collaboration

At Omron, opportunities to engage with new challenges are abundant

After graduating from university in London, Kassim Okara joined the largest specialist distributor of control and automation products in the UK, where he worked on numerous large-scale projects. He decided to leave however, to join Omron Electronics as field sales engineer in 2015, as he had always felt that he wanted to contribute to society from a business development standpoint.

At Omron, opportunities to engage with new challenges are abundant; the varying projects involve not only control equipment but also healthcare and mobility as well as initiatives to actively employ disabled persons.

At that time, Intelligent Growth Solutions (IGS) had begun working on automated vertical farming to optimize crop production. Based at the James Hutton Institute in Scotland a leading crop science and research institute, the opportunity to collaborate was one of the key considerations in this location. To advance the efforts to practical application level, IGS needed an automation solutions provider.

In search of a suitable provider, IGS found Omron. In addition to its solutions, Omron's commitment to social responsibility attracted them into collaboration.

With the addition of Omron's automation technology to the expertise and knowledge of the two organizations, the first-ever UK project for automated vertical farming using IoT was initiated. Kassim was assigned as project leader on Omron's side. His passion for his work increased by the day as he deepened his understanding of his partners' enthusiasm toward the project.

In the beginning, developing an understanding of the project was particularly challenging, as it was unprecedented so that previous case studies could not be found. Despite this, Kassim took on the project, led by his determination to respond to social needs through business.

Publication date : 10/29/2018

Aquaponics – a Great Way to Increase Farmers’ Income

For those who don’t know, Aquaponics is a sustainable method of raising both fish as well as vegetables.

26 October, 2018 | By Pawan Kumar Sharma

Population wise India is the second largest country in the world hence the government is worried about how to control the increasing population level but at the same time it is a matter of pride that we have largest youth potential in the world. In the present era we have a challenge to create employment opportunity for the job seekers and to provide nutritious diet to the present as well as future generations.

Good agriculture production could have been a solution but due to rising population, agricultural land is diminishing. Growing wasteland is also a big problem in farming. In urban areas due to space problem people don’t think about agricultural production but always demand for fresh quality vegetables and protein sources.

For all these problems there is one solution - Aquaponics.

For those who don’t know, Aquaponics is a sustainable method of raising both fish as well as vegetables. Aquaponics is a great indoor farming method, which can be done anywhere. It provides fresh local food that is without any pesticides, herbicides and chemical fertilizers. Other benefits include:

It provides two crops in one place at a time and is very helpful in increasing the farmer’s income.

It gives more production than traditional farming method.

It provides vegetables from hydroponics and fishes from re-circulatory aquaculture system at the same time. We know that vegetables are the good source of vitamins and fish is a good source of protein with high amount of w -3 fatty acids that is helpful in maintaining good health.

Easy to operate.

It can be implanted in very small space like 10 m2, so the vegetables and fishes can be grown on site of restaurant, hotels, houses, and farms easily.

Aquaponics can be a good opportunity for the unemployed; they can start it as a startup business under START UP YOJANA.

HOW IT WORKS:

It combines Hydroponics and Re-circulatory aquaculture system and this is suitable for both as the nutrients requirements is fulfilled by the disposing of nutrient-rich fish waste from aquaculture unit thus there is no need for nutrient media. This fish waste provides a natural nutrient solution for plant growth and this nutrient-rich effluent is used to irrigate a connected hydroponic bed while fertilizing its plant crops at the same time. The filtration of water is done by the hydroponic unit as the plants absorb the nutrients and filter the water through the sand filter so this media based hydroponic system serves as an aerobic bio filter that is generally used in RAS, converting ammonia to nitrate. The ammonia is converted by denitrifying bacteria in the hydroponic grow bed into forms readily up taken by plants for energy and growth. Essentially, the hydroponic bed and its crops serve as a bio-filter for the fish waste water before it is returned, cleaned back into the fish tank. To utilize the nutrients more in amount from the waste water effluent of aquaculture unit, the Aquaponics unit should be dominated by the hydroponics system.

Preferable vegetables and fish species for Aquaponics:

Vegetables:

Lettuce, Basil, Coriander, Spring onion, Fruit vegetables such as tomato, cucumber, Beets, Okra, Blueberries, etc

Fish species

Nile Tilapia (the most preferable fish), Catfish, common carp, Asian Barramundi , Mullet, Perch, Largemouth bass, bester sturgeon, Grass carp, Ornamental fishes.

Potential of Aquaponics Production System (Fish and Vegetable):

The vegetables are produced around double in hydroponic and aquaponics systems as compared to more conventional horticulture system. Some researchers has demonstrated the total production from Fish and vegetable up to 160 kg/m2/yr. so the aquaponics is a great solution for food security and unemployment problem.

About the Author:

Pawan Kumar Sharma

Dr. J. Stephan Sampath Kumar

Centers for Sustainable Aquaculture, Thanjavur- 614904

Tamil Nadu Dr. J. Jayalalithaa Fisheries University Tamil Nadu.

pawan.sharma32224@gmail.com

Mobile- +91-9024974343

South Korean Road Tunnel Smart Farm No Rose-Coloured Pipe Dream

Behind a blue wall that seals a former highway tunnel stretches a massive indoor smart farm bathed in rose-tinted light.

AP | 30 August 2018

Behind a blue wall that seals a former highway tunnel stretches a massive indoor smart farm bathed in rose-tinted light.

Fruits and vegetables grow hydroponically — with no soil — in vertically stacked layers inside, illuminated by neon-pink LEDs instead of sunlight.

Operators of this high-tech facility in South Korea say it is the world’s first indoor vertical farm built in a tunnel.

It’s also the largest such farm in the country and one of the biggest in the world, with a floor area of 2300sqm, nearly half the size of an American football field.

Indoor vertical farming is seen as a potential solution to the havoc wreaked on crops by the extreme weather linked to climate change and to shortages of land and workers in countries with ageing populations.

The tunnel, about 190km south of Seoul, was built in 1970 for one of South Korea’s first major highways.

Once a symbol of the country’s industrialisation, it closed in 2002.

An indoor farming company rented the tunnel from the government last year and transformed it into a “smart farm”.

Instead of the chirrups of cicadas, Claude Debussy’s Clair de Lune resonates in the tunnel in hopes of stimulating the crops’ healthy growth.

“We are playing classical music because vegetables also love listening to music like we do,” said Choi Jae Bin, head of NextOn, the company that runs the vertical farm.

Head of NextOn Choi Jae Bin explains how his high-tech tunnel-based vertical indoor farm NextOn in Okcheon, South Korea, could be a potential solution to the havoc wreaked on crops by the extreme weather linked to climate change, and to shortages of land and workers as the country ages.Picture: AP

Sixty types of fruits and vegetables grow in optimised conditions using NextOn’s own growth and harvest systems.

Among them, 42 are certified as no-pesticide, no-herbicide and non-GMO products, said Dave Suh, NextOn’s chief technology officer.

He said the tunnel provided temperatures of 10 to 22 degrees celsius, enabling the company to optimise growing conditions.

High-tech smart farms, used also in places like Dubai and Israel where growing conditions are challenging, can be a key to developing sustainable agriculture, experts said.

“Society is ageing and urbanisation is intensifying as our agricultural workforce is shrinking,” said Son Jung Eek, a professor of plant science at Seoul National University.

Smart farming can help address that challenge, he said, as well as make it easier to raise high-value crops that are sensitive to temperature and other conditions.

Only slightly more than 16 percent of South Korea’s land was devoted to farming in 2016, according to government statistics.

The rural population has fallen by almost half over the past four decades, even as the overall population has grown nearly 40 per cent.

The Agriculture Ministry announced earlier this year it would invest in smart farm development nationwide, expanding their total area to 7000ha from the current 4010ha.

Turning a profit can be challenging for indoor vertical farms given the high cost of construction and infrastructure.

NextOn cut construction costs in half by using the abandoned tunnel and developing its own LED lights and other technologies.

Sesame leaves grow on a vertically stacked styrofoam layer.Picture: AP

The proprietary technologies reduce water and energy use and the need for workers, cutting operation costs, Suh said.

Sensors in each vertical layer measure variables such as temperature, humidity, light, carbon dioxide and micro-dust levels to maintain an optimised environment for each crop.

The crops will cost less than conventionally grown organic vegetables, Suh said.

The farm will begin supplying vegetables to a major food retailer and a leading bakery chain beginning in late August, NextOn said.

Suh said the medicinal plant market was currently dominated by a few countries and regions.

“Our goal is to achieve disruptive innovation of this market by realising stable mass production of such premium crops,” he said.

First GLASE Meeting Is November 5th

September 19, 2018

GLASE gears up for their first meeting:

Guidelines for new Controlled Environment Agriculture energy-efficient technology adoption

November 5, 2018

8 a.m. to 5 p.m.

Statler Hotel, Cornell University, Ithaca, N.Y.

Lighting control is the last frontier in controlled environment agriculture. Well-designed horticultural lighting systems can reduce energy use and increase profits for greenhouses and indoor farms. GLASE is bringing together New York Controlled Environment Agriculture (CEA) growers with local utility companies, USDA officials and service providers to provide CEA growers with all the resources available for energy-efficient lighting and control systems technology adoption.

CEA growers attending the conference will have the opportunity to learn about all the opportunities available on the market to support new technology adoption:

• Financial opportunities

• State rebate programs

• Federal incentive programs

• Utility energy rebate programs

Speakers

• Gary Pereira – USDA Rural Development

• Dale Gates – USDA National Resources Conservation Service

• Robert Muller – National Grid

• Dustin Broderick – NYSEG

• Damon Bosetti – DesignLights Consortium

• Owen Raymond – Farm Credit East

• Neil Mattson – Cornell University

• Tessa Pocock – Rensselaer Polytechnic Institute

• A.J. Both – Rutgers University

• Erico Mattos – GLASE consortium

For more information and to register: https://glase.org/conference/

Freight Farmer Q&A: Bee's Greens Company

8 Questions with Lizzy Porter of Bee's Greens Company!

We caught up with Lizzy of Bee's Greens Co. to learn more about her island farm in Waipahu, Hawaii!

One of the best things of being part of the Freight Farms team is talking to our farmers and hearing about their successes, customers, and challenges as they pursue a variety of container farming ventures. They are a wealth of information, so we're sharing some of their stories with you!

“As an island in the middle of the Pacific, importing comes at great environmental and food quality cost.” — Lizzy Porter

Freight Farms: What’s the story behind your Freight Farms project?

Lizzy Porter: My Freight Farms project was born from an interest in the future and emerging exponential technologies, and developed into what it is today after learning about contemporary food issues in Hawaii. I learned about Freight Farms while on a path of learning about how existing big industries could be decentralized and democratized. I began to understand more about current food insecurity issues in Hawaii - where more than 80% of food is imported; where arable land can be hard to come by; where tropical weather can surprisingly and significantly impact a growing season.

As an island in the middle of the Pacific, importing comes at great environmental and food quality cost. With the Freight Farms technology in mind, I found there was an opportunity to participate in a futuristic pursuit while helping with contemporary issues. Not to mention, I was pretty ready for an excuse to move to a beautiful tropic island. Thus, Bee’s Greens Company, operating in Hawaii for Hawaii, came to be.

FF: What, if any, was your experience with farming before becoming a Freight Farmer?

LP: Not much! I had a personal vertical hydroponic gardening system before becoming a Freight Farmer, but would not say I had experience with farming, let alone on a commercial scale. However, I grew up very comfortable with life sciences and technology so was ready for the challenge. I also believe that success often comes from delegating to others whose strengths complement your own - so was confident that if I was struggling, I could always find someone or a team with different skills and experiences to make the project thrive.

Lizzy with her brother and dad, who help her out at the farm!

“The support of my family, the Freight Farms team, and the Freight Farms community has been absolutely instrumental in helping me overcome challenges of getting started and finding my footing.”

— Lizzy Porter

FF: What reaction do you typically get from people when you tell them what you do for a living?

LP: Surprise and genuine interest! I love that my answer is not traditional, whether I’m talking to someone on a corporate path, in the agricultural field, or pretty much any other avenue. It usually makes for a fun conversation about the future, unconventional passions, and potential solutions to contemporary issues - and inevitably ends up with looking us looking a dates to schedule a tour of the farm.

FF: How did you find customers to buy your produce?

Just one fun farmers market sign!

Photo: Bees Greens Co. on Instagram

LP: We’ve found our customers through farmers markets! We sell the majority of our greens to both patrons of the markets as well as other vendors at the markets. Other customers have come through by looking for like-minded companies.

FF: What’s your favorite crop to grow and why?

LP: My favorite crop is probably the Butterhead Rex. It is well loved here but doesn’t normally grow year-round, so the communities I serve are familiar with it and excited to see it when they hadn’t expected to. It’s also just the right amount of tender and beautiful.

“With the global culture and awesome technology that we have in 2018, it is unrealistic and uncreative to just decide that a society can only have the food that grows well traditionally in that location.”

— Lizzy Porter

Photo: Bees Greens Co. on Instagram

FF: What’s the most pressing issue in food and agriculture that you’d like to see solved?

LP: On a personal and local level, I think a very pressing issue is food security in Hawaii. 80% or more of food is imported to the islands from 3000 miles away, which means quality loss, environmental costs, and an economic loop that is not benefiting the local community as it could. The challenge is that, because the imported produce is produced in very large commercial scales, it can remain cheaper than fresh, low impact, local food.

With the global culture and awesome technology that we have in 2018, it is unrealistic and uncreative to just decide that a society can only have the food that grows well traditionally in that location. Things like the Freight Farms’ LGM provides a great opportunity for global selections of locally produced, consistent, high-efficiency, low impact goods.

We completely agree with Lizzy! Check out our blog, Freight Farming Over Freight Shipping: Bringing Local Back to the Island for more insights into the problems island communities face today.

Lizzy working in her farm–you'd never know she didn't have any previous growing experience!

FF: What was the most challenging part of becoming a Freight Farmer and how were you able to overcome it?

LP: The most challenging part of this project was moving into a field that was relatively new to me, having never been involved in commercial farming before. The support of my family, the Freight Farms team, and the Freight Farms community has been absolutely instrumental in helping me overcome challenges of getting started and finding my footing. Now that we’ve been operational for a while, that support has been epically supplemented by the help and knowledge of great employees, and getting to share our stoke and passion with our customers and community.

“Passion is contagious, and I’ve found the best way to keep the stoke is to share it! ”

— Lizzy Porter

FF: What’s the best piece of advice you can give to people interested in becoming Freight Farmers?

LP: Passion is contagious, and I’ve found the best way to keep the stoke is to share it! A new business venture can at times be a grind, but if you can find the pieces of being a Freight Farmer that are most interesting to you – i.e. the parts that blow your mind - those are what you want to hang onto and share with others to blow their minds in turn. A significant amount of my sales and new connections have come from when I get on a roll, talking about how cool the system is, and why it’s important for now and for the future. Sharing my excitement and having it reflected back to me has been endlessly inspiring and motivating.

How Do We Feed 7 Billion People?

We're looking at the technological advancements that allow us to feed our ever-growing population.

10,000 years ago, our ancestors lived a completely different lifestyle. They were nomadic people living in small groups, constantly moving in migratory patterns and hunting and gathering their food. Today, the majority of the seven billion people living on the planet have permanent residences in, or near, major cities. Most of us have easy access to clothing, food, and home goods. While there have been thousands of developments over the past 10,000 years that have bridged the seemingly impenetrable gap between ancient hunters-gatherers and modern consumers, none has been more impactful than the advent of agriculture.

Today, we define agriculture as the practice of cultivating soil, producing crops, raising livestock, and (to some extent) the preparation and marketing of the resulting products. Agriculture represents 20% of the national economy, and is the one of the most compelling reasons that our global population has boomed.

While agriculture has a long history, the greatest leaps in technology were made in the 18th-21st centuries. We decided to look at five main categories of technological development that have made the greatest impact on the global population: animals, crops, soil, labor, and storage.

**Quick disclaimer: these categories focus on the history of agricultural technology in Western Europe and the United States. While we recognize and celebrate the diversity of historical and cultural differences that exist between the Western world and other regions, we’re focusing on these regions for the sake of making this (somewhat) brief and easily digestible!**

Before we get into the technology that changed agriculture, let’s quickly review just some of the major scientific discoveries that made much of this progress possible.

1855 | Theory of Mineral Nutrients

Research performed originally by scientist Carl Sprengel and popularized by Justus von Liebig identified that nitrogen (N), phosphosus (P), and potassium (K) are essential for plant nutrition. They also published findings that plants take carbon, hydrogen, and water out of the atmosphere. Additionally, Liebig popularize the Law of the Minimum, which stated that a plant’s growth is not determined by the total amount of resources available, but by the resource that is least available.

1859 | Darwin’s Theory of Evolution

Darwin proposed a theory of evolution by natural selection, where changes that allow an organism better adapt to its environment will help it survive and have more offspring, thus creating a lineage with altered and improved characteristics. This theory was made through observations only; Charles Darwin had no knowledge of genetics and the impact of genetic mutations.

1866 | Mendelian Inheritance

Mendelian inheritance is the longest standing theory of genetics that is still applicable today. It was developed by Gregor Mendel after he performed experiments with pea plants, which deduced that genes come in pairs and are inherited as distinct units, one from each parent. This became the basis of our understanding of human, plant, and animal genetics!

Here's a great overview of Mendel's theory!

Now that we know the basics, let’s look at the technology that paved the path to today’s agro-industrial complex. It’s important to understand that all of these advances needed each other to develop, as breakthrough technology in one category created opportunity for the others to expand.

Animals

Most agricultural progress seen in the meat and dairy industries had to do with increasing production. As a result, meat and dairy products became more affordable, and became more prevalent in Western diets.

c. 1760 | Selective Breeding

Robert Bakewell, one of the first agriculturists to breed cows and sheep for meat, was a pioneer of selective breeding methods. Selective breeding involved mating animals to reproduce favorable qualities in the offspring (such as bigger, more muscle, better wool production, etc). Although Bakewell lived before Darwin and Mendel, his practice of selective breeding aligned with both theories of genetic inheritance. Selective breeding later became a cornerstone for the factory meat industry as ways to create animals with higher meat, eggs, or milk outputs.

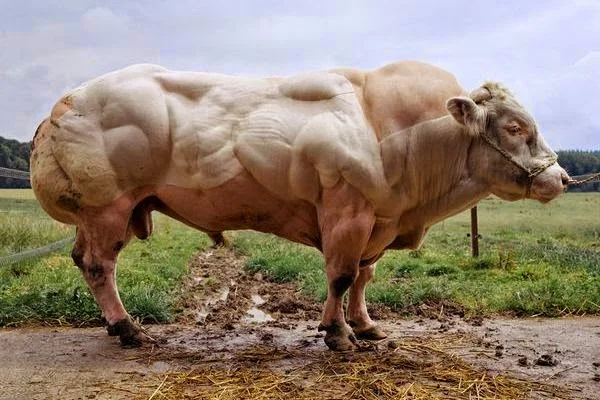

Example: the Belgian Blue Cow

The Belgian Blue cow's genetic make-up makes it more efficient at gaining muscle mass. This gene mutation was maintained through line breeding to make it a fixed property of the breed!

1865 | Pasteurization

Louis Pasteur’s research showed that microorganisms were the reason for food spoilage. He found that heating liquids like milk to between 60 and 100ºC killed most of the bacteria. This process became known as “pasteurization”, and it’s discovery made it possible to preserve and transport dairy goods much longer and further than ever before.

1926 | Penicillin

Alexander Fleming discovered penicillin, the world’s first antibiotic. It was successfully used to treat infection in 1930, and was mass-produced in the late 1940s. As factory animal farming became more prevalent, animals began receiving antibiotics to prevent viruses such as rotavirus, E. coli, pinkeye, and brucellosis. This allowed for animals to adapt to close and often unsanitary living conditions of feedlots that made meat abundant and affordable.

1994 | rBST

Patented by Monsanto, rBST is a synthetic cow hormone. When administered to dairy cows, the hormone increases milk production 14 percent, while consuming less grain and water. This allowed the dairy industry to expand and increase their output.

Crops

Similarly to the meat and dairy industries, advancements in crop production were mainly concerned with increasing crop yields. Thanks to the creation of more resilient breeds of corn and soy, along with long-standing government support for these commodity crops, most farmland moved towards single crop production (also known as monocultures). Furthermore, crop resilience helped create food reserves and drastically reduced famine around the world.

1908 | Hybridized corn produced

George Harrison Shull showed that a hybrid corn plant created from two inbred species would increase the plant’s yields significantly. In 1924, hybrid seeds were sold commercially and by the 1950s the majority of U.S. corn was hybrid. This development allowed corn to become a dependable commodity crop that would later be used as nutritionally dense animal feed (making animals fatter faster) and for producing penicillin (1940), high fructose corn syrup (1970s), ethanol (1970s), and more.

See how corn, watermelons, and peaches have changed thanks to selective hybrid breeding over the past 9,000 years.

1930 | Mutation breeding

A practice started in 1930 and still used today, mutation breeding uses radiation to create random mutations in seeds. Thanks to this practice, scientists have produced thousands of improved plant varieties (rice, wheat, barley, peas, cotton, peanuts, grapefruit, bananas, and cassava to name a few). This is not genetic modification, but a way of nudging species towards useful mutations that make them more productive and resilient.

1937 | Hydroponics

Although principles of hydroponics have been around for centuries, they were popularized by Dr. W.F. Gericke, who displayed enormous tomatoes that were grown without soil. By the 1960s, many hydroponic greenhouses and farms were operating around the U.S. as a first example of alternative farming methods.

1939 | Synthetic Pesticides

Paul Muller discovered DDT, a broad spectrum synthetic pesticide that had a widespread effect on insects, but a seeming low toxic effect on mammals. It was not water soluble and was easy and inexpensive to apply. While it was later proven that DDT was toxic to aquatic animals and had many indirect negative effects on the environment, this was the first widely adopted and inexpensive pesticide which greatly increased food supply and decreased plant disease.

1940s | The Green Revolution

In the 1940s, scientist Norman Borlaug began performing experiments in Mexico to develop disease resistant, high-yield wheat crop varieties in an effort to make Mexico more self-sustainable. He succeeded, and Mexico became a global exporter of wheat. Borlaug and the Ford Foundation replicated this success in India in the 1960s with high performance rice (IR8), which allowed India to become a global rice exporter. The IR8 rice strain was later adopted all over Asia.

1994 | Flavr Savr tomato

The Flavr Savr tomato was the first commercially produced genetically modified food to be deemed safe for human consumption. It was created by Calgene, a company later acquired by Monsanto. Since 1994, Monsanto has produced several genetically modified products like squash and soy in 1995, corn in 1996, sugar beets in 2006, potatoes in 2016, and, most recently, apples in 2017. Most genetic modifications are designed to make food insect and disease resistant, tolerant to herbicides, and more visually appealing.

Soil

Although soil-less methods like hydroponics and aquaponics have become increasingly popular over the past century, most global agriculture is still soil dependent. Historically, advancements in soil technology has been centered around replenishing and extracting as many nutrients as possible to improve plant yields.

1842 | Superphosphate

Patented by Sir John Bennet Lawes, superphosphate was a manure formed by treating phosphate with sulfuric acid, which gave rise to the synthetic fertilizer industry. Once it was adopted, the commercial fertilizer took the agricultural industry by storm: In less than 100 years, annual commercial fertilizer use has gone from 1.8 million tons in the 1890s, to 47.4 million tons in the 1980s.

1910 | Nitrogen fixation

As Liebig determined in his research, nitrogen is essential for plant health. Fritz Haber created a process for pulling N2 out of the atmosphere and turning it into ammonia (i.e. nitrogen fixation) to be used as fertilizer for industrial feedstocks. The process was perfected and scaled to meet industrial needs by Carl Bosch.

Labor

For centuries, agricultural development was limited by time: men and horses could only do so much in one season. The development of farming machinery unlocked huge potential, which technological animal, crop, soil advancements were able to fill.

1793 | Cotton gin

Invented by Eli Whitney, the cotton gin was one of the greatest contributors to the American Industrial Revolution. It greatly simplified the process of removing seeds from picked cotton–previously an extremely slow and tedious process. While the cotton gin inadvertently led to the rise of slavery in the South, it is still considered one of the most influential agricultural inventions of the 20th century.

1842 | Grain elevator

Developed by Joseph Dart and Robert Dunbar at the rise of the grain trade. The grain elevator was originally a steam-powered deposit for grain awaiting to be sold. Steam-powered conveyor belts brought the grain to a storage platform at the top of the elevator, where it was kept until offloading. Then, the grain would be brought down using gravity, and loaded onto trains or ships for distribution. Not only did the creation of elevators significantly reduce labor, but they also kept the grain “dry, cool, free from vermin, and safe from pilferage”.

1892 | First gasoline tractor

Invented by John Froelich, the tractor was able to harvest 1,000 bushels of grain using only 26 gallons of gasoline, which far exceeded the harvesting capacity of farmers–it took 40-50 labor hours to harvest just 100 bushels using wagons and horses. By 1954, tractors exceeded the use of horses, and by 1955 the labor needed to harvest 100 bushels was reduced to just 6.5 hours.

Storage

While decreased labor hours were able to bring an abundance of food to the market, it was pointless without refrigeration. Food cooling and freezing technology expanded food’s lifespan, made it easier to transport long distances, and allowed people to buy for the future.

1856 | First commercial refrigerator

The first refrigerator, built by James Harrison and patented in 1856, was a vapor compression system using ether, alcohol, or ammonia. He introduced the technology to breweries and meat packing houses, and had several systems in operation by 1861.

1867 | Refrigerated shipping

The first refrigerated railway car was patented by J.B. Sutherland. It used heavy insulation, roof hatches, floor drains, ice bunkers, and strategic airflow. As a result of this cold transport system, a huge network of icing stations were developed around the country, and the first transcontinentaltransport of cold goods from California to New York occurred in 1889.

1927 | Frozen foods

The birth of the frozen food industry is tied to Clarence Birdseye’s patent for a multi-plate freezing machine, which allowed for food to be quickly frozen without damage. By 1927, his frozen products included fish, meat, poultry, fruit, and vegetables. Birdseye later sold his patent to what eventually became the General Food Corporation to produce the Birdseye Frozen Food Company. By World War II, Americans were encouraged to buy frozen foods, with 800 million poundspurchased between 1945 and 1946. However, it was the invention of the TV dinner that made frozen food an American stable in 1954.

1930s | At-home fridge

Companies like Electrolux and General Electric began selling refrigerators and freezers for domestic purposes at a commercial scale. Unlike previous models, these units used Freon instead of toxic gases, making it a safer option. This coincided perfectly with the development of frozen foods (as we learned above!). By 1950, more than 90 percent of urban homes had a fridge.

So, where do all of these technological advancements leave us today?

For one, they have made it possible to feed over 7 billion people: From 1820 to 1975, agricultural production across the world doubled four times over and, while in 1940 one farmer could supply an estimated 10.7 people, by 1990, one farmer could supply 100 people. Today, one farmer can feed 155 people. As a result, we have seen a global decline famines and hunger, with a rate of undernourishment at 10.8 percent in 2015 (although this number has risen in recent years as a correlation to rising conflict and instability in many regions).

For most of its history, agricultural technology was focused on creating a more efficient and high-yielding system in order to better feed the world. As we can see, with reductions in labor and hunger worldwide, we were widely successful. Unfortunately, many of the methods used over the past 300 years have created negative effects that we are now only beginning to understand. Issues associated with Big Ag (the entire corn-soy-meat industry combined) include:

Soil nutrient degradation due to planting one type of crop over and over again, leading to a dependence on synthetic fertilizer.

Extreme water usage and waste.

The chemical contamination of groundwater (as a result of fertilizer usage).

The introduction of dangerous pesticides and herbicides into the ecosystem and their widespread repercussions on insect and animal populations.

Introduction of new bacteria and pathogens into the food supply–a result of factory farmed animals living in unsanitary conditions.

The development of antibiotic resistant bacteria as a result of antibiotic overuse in factory farmed animals.

Environmental pollution caused by machinery and animal excretions.

Rising rates of “western” diseases such as obesity, heart disease, cancer, and diabetes as a result of over consumption of readily available corn, soy, and meat products.

As a result, many of today’s newest technologies are focused on creating alternative methods of agriculture that will be more environmentally sustainable, as well as viable options in the face of climate change and increasingly irregular weather patterns.

2010s | Urban farming

While urban farming has existed throughout history, it has recently turned into a full-blown movement: Issues of local food access and healthy eating have made urban solutions necessary in the face of Big Ag. Hydroponic technology is a viable solution–companies like Freight Farms (2010) use repurposed shipping containers to create dense growing environments in small footprints. Similarly, many cities make use of of rooftops to set up greenhouses or even soil farms, like Gotham Greens (2009) or Brooklyn Grange (2010)

2010s | Data

Just as urban farming boomed starting in 2009, so did the agricultural data industry. Farm management software such as Spensa Technologies (2009), Mavrx (2012), farmhand (2013) Granular (2014), Trace Genomics (2015), and many others arrived on the market to give farmers more transparency into their farmland using satellite imaging, sensors and IoT technology, robotics, and more! The goal is to increase efficiency, and help farmers implement eco-friendly solutions easily on a large scale.

2013 | BountiGel

Company mOasis has created a hydrophilic gel (“hydro” = water, “phillic” = loving) that can be added to soil to absorb 250 times its weight in water. As a result, farms can use less water and improve their yields by 18 percent across the board. The gel is non-toxic and can break-down safely after several seasons. California approved mOasis’ first product for commercial use in November 2013.

2013 | Cultured Meat

This is perhaps the most extreme solution to many of the problems we see with factory farmed meat today, which requires huge amounts of water, pollutes the environment, and produces 14.5% of global human greenhouse-gas emissions. Lab-grown meat would help address the growing global demand for affordable meat while leaving a less damaging footprint. The world’s first lab-grown burger was introduced in August 2013.

2013 | Robotic Bees

The first robotic insect took flight in May, 2013 at Harvard University. It was based on the anatomy of a small fly, and inspired more projects in Japan which went on to create a robotic bee. The need to develop this technology is urgent: the U.S. alone has lost 44% of it’s honeybee population in 2016, leading experts to consider what a world without our most essential pollinators might be like. Even industry giants like Walmart are getting involved in developing this technology.

Government of Aruba Approves Vertical Farming Project Using Affinor Growers' Technology

The technology will allow VDA Vertical Designs Aruba VBA to produce crops year-round in Aruba's tropical climate while utilizing land that, previously, could not be utilized for farming

VANCOUVER, British Columbia, Aug. 10, 2018 -

Affinor Growers Inc. ("AFI" or the "Company") (CSE:AFI, OTC:RSSFF, Frankfurt:1AF) is pleased to announce that on Aug 9, 2018, the Government of Aruba held a press conference to announce they have approved VDA Vertical Designs Aruba VBA to build a vertical farming project in Aruba, using AFI's vertical farming technology.

The technology will allow VDA Vertical Designs Aruba VBA to produce crops year-round in Aruba's tropical climate while utilizing land that, previously, could not be utilized for farming

The Company had previously announced, on February 21, 2018, that it had signed an exclusive license agreement with Vertical Designs Aruba Inc. Due to some legal obstacles during the incorporation process, VDA Vertical Designs Aruba VBA was incorporated in place of Vertical Designs Aruba Inc. The Company and VDA Vertical Designs Aruba VBA are in the process of finalizing a new amended licensing agreement. The licensing agreement is expected to be completed early next week.

Nick Brusatore, CEO, commented that "This is absolutely thrilling news for the Company, VDA Vertical Designs Aruba VBA and the country of Aruba. Not only will this project have a substantial, and lasting, economic impact on Aruba, but this will be the first step in revolutionizing the farming industry in the Caribbean. This is the perfect showcase for our vertical farming technology and we hope this will act as a catalyst for other vertical farming projects around the world."

About Affinor Growers

Affinor Growers is a publicly traded company on the Canadian Securities Exchange under the symbol ("AFI"). Affinor is focused on growing high quality crops such as romaine lettuce, spinach, strawberries using its vertical farming techniques. Affinor is committed to becoming a pre-eminent supplier and grower, using exclusive vertical farming techniques.

Neither Canadian Securities Exchange nor its Regulation Services Provider (as that term is defined in the policies of the Canadian Securities Exchange) accepts responsibility for the adequacy or accuracy of this release.

This news release may contain assumptions, estimates, and other forward-looking statements regarding future events. Such forward-looking statements involve inherent risks and uncertainties and are subject to factors, many of which are beyond the Company's control that may cause actual results or performance to differ materially from those currently anticipated in such statements.

For More Information, please contact:

AFFINOR GROWERS INC.

"Nicholas Brusatore"

CEO

"Greening" The Green Monster: Fenway Park Farms

The Boston Red Sox, Recover Green Roofs, and Green City Growers took “going green” to a whole new level

Image Credit: Green City Growers/https://greencitygrowers.com/fenway-farms/fenway-farms-faq/

The Boston Red Sox, Recover Green Roofs, and Green City Growers took “going green” to a whole new level when they transformed Fenway Park (the oldest ballpark in Major League Baseball history) into prime real estate for urban farming.

Fenway Farms, the result of their successful collaboration, serves as a benchmark for large-scale urban farming operations. The rooftop garden project started as an initiative sponsored by the Boston Red Sox, who felt compelled to give back to fans and members of the local community in the greenest way imaginable. By turning the rooftop of the Green Monster, a beloved section of the ballpark's seating area, into an urban farm, the team was able to repurpose an underutilized space into a creative way to give back to their community.

Fenway Farms is situated atop a 5,000 square foot roof right above the Red Sox front offices. Completed within a month, the farm installation process only cost $200,000, proving that "going green" doesn't always need to be a costly project.

The farm grows close to 6,000 lbs. of organic produce and herbs every year using a milk crate container growing system. While most of the produce collected from the gardens supplies Fenway Park's in-park restaurants, a significant portion of the fresh produce is donated to the local community through the non-profit food rescue organization Lovin’ Spoonfuls. Fenway Farms further promotes environmental stability by mitigating the effects of air pollution, conserving energy, lessening the impact of the “Urban Heat Island Effect,” and managing stormwater runoff.

Fenway Farms is a true team effort. Recover Green Roofs designed, built, and installed the rooftop farming system, while Green City Growers handles all aspects of farm management. The collaborative work of both companies has won them prestigious environmental awards. In 2017, Recover Green Roofs received the Intensive Institutional Award of Excellence and Green City Growers received the Walden Woods Project’s Environmental Challenge Award in recognition of their work on Fenway Farms.

'Green Monster' Is Taking On A Whole New Meaning At Fenway Park

The luscious green produce at Fenway Park

Stacy Buchanan

August 31, 2018

On a hot summer day at Fenway Park there’s a different kind of team, hard at work, on a very different type of field. High above Yawkey Way, along the 3rd Base side of the stadium, you’ll find Fenway Farms, a 5,000-square-foot working farm that's growing produce that is being served at Fenway and donated to a local food rescue. Instead of Wally or home runs, we’re talking about peas, kale, and scallions, to name just a few of the many varieties of produce growing here.

Jessie Banhazl, CEO & Founder of Green City Growers

Stacy Buchanan

The relatively lightweight milk crate farm was installed by Recover Green Roofs and is managed by Green City Growers (GCG), who also maintain the largest rooftop farm in New England atop the Whole Foods in Lynnfield. GCG was introduced to Linda Henry after winning an award through the Henry Foundation, which led to the Fenway Farms partnership. A spot had already been designated by Henry as a potential green roof, and a little bit of that magic that lives in Fenway must have been at work because the space happened to be furnished with perfect growing conditions for a rooftop farm.

The milk crate system at Fenway Farms

Stacy Buchanan

“The milk crate system was chosen because it is very mobile and modular, like Legos,” says Jessie Banhazl, CEO & Founder of Green City Growers. There are over 2,000 milk crates and the small boxes can be arranged to take up every available space, which is helpful given the unusual angles and shape of the roof. But there’s big return for such a relatively small farming space – the farm currently cultivates about 6,000 pounds of produce annually!

“I’m so spoiled now,” says Fenway’s Executive Chef, Ron Abell. “The care and nurturing [GCG] put into it, the organic nature, it’s incredible.” When asked his favorite part of having Fenway Farms in his operation, Abell says, “The food travels 100 feet and it’s in my kitchen. You don’t have to do much to it and it tastes amazing.”

“Luckily, baseball season happens to align perfectly with the growing season in New England,” Banhazl explains, so the farm operates primarily while the park is in full swing. That means fans can often see the farmers at work, harvesting produce or tending to the crops. It is also one of the most popular stops on the park tour, where approximately 10,000 people a week get to see “the best farm team in baseball” as the guide punned to the group who passed through during our visit.

Fenway’s Executive Chef Ron Abell picks peppers from the rooftop farm

Stacy Buchanan

The farm is split into two spaces. There’s an area of closely controlled farm rows that maintain the strict standards required by the park’s food production company, Aramark, and grows about 35% of the produce served in the EMC Club throughout the season. Then there’s the vineyard vines deck, which grows produce around its perimeter and between event spaces. This area hosts youth and community engagement programs, like the Fenway Rooftop Sessions, and 100% of the produce grown here is donated to Lovin’ Spoonfuls, the largest food rescue agency in New England.

Patrons of the ballpark tour admire the rooftop farm

Stacy Buchanan

Chef Abell, in his 12th season at Fenway Park, creates a new menu at the EMC Club for every home stand. “I like to experiment,” he says. “Being this close to the produce really gets your creative juices flowing and opens your mind to what you can do with it. Like kohlrabi – we use it in root vegetable hash, shaved on to salads, and even pickled – it’s great!”

The culinary team strives to be as zero-waste as possible, using as much of the produce grown as possible – carrot tops in pesto, beet greens in salads, and a variety of preserving techniques for whatever can’t be used fresh during the baseball season. Late-season tomatoes are roasted and frozen for stocks and braises, chilies are turned into hot sauce, and cucumbers and green tomatoes are pickled. “What we harvest here can make its way around to almost anywhere in the ballpark,” Chef Abell said. Look out for items, such as a kale Caesar wrap made with kale from the farm next time you’re at Fenway.

Fresh herbs growing in the vineyard vines club

Stacy Buchanan

The choice of what to grow on this small-scale farm is an annual collaboration between Green City Growers, Chef Abell, and his team. The variety is impressive, producing everything from hearty greens and root vegetables to French breakfast radishes, and of course, copious amounts of scallions for Chef Abell’s infamous scallion pancakes. There are even strawberries that grow twice a season, to the delight of the park’s pastry staff.

Chef Abell garners a lot of creative inspiration and culinary satisfaction from the rooftop farm

Stacy Buchanan

We were lucky enough to visit Fenway on one of the biweekly days when the folks from Green City Growers work on the farm. A few farmers picked the day’s impressive haul, which included 30 pounds of kale, 20 pounds of Swiss chard, and 20 pounds of scallions, as well as heirloom tomatoes, Italian and Oriental eggplant, chives, thyme, mint, sorrel, and parsley.

Heirloom tomatoes growing in milk crates

Stacy Buchanan

They were also planting new mid-season crops of carrots and radishes. One of the farmers is Production Site Specialist Carissa Unger, who talked about the particularly good soil used here. “It’s the best soil I’ve ever worked with. It’s wet and fluffy.” The proprietary organic blend from the Vermont Compost Company was specifically chosen for its light weight, yet superior nutrient and moisture retention. The quality of the soil is one important reason why the farm can successfully grow large plants, such as heirloom tomatoes, in tiny 12x12-inch milk crates.

Production Site Specialist Carissa Unger turns the soil

Stacy Buchanan

This isn’t just another trendy undertaking by a high-profile organization. It’s real food that’s grown and served right at Fenway Park. That’s not to say that the posh location has no bearing on the success of the project. It’s obvious that the budget is plentiful and the maintenance top-notch. Not many projects of this scale go from concept to fruition in about 8 months, but that kind of dedication is exactly what’s making Fenway Park a leader in sustainability initiatives.

The drip irrigation system is the most efficient and sustainable style, distributing the water directly to the roots of the plants, avoiding waste through evaporation. The system also has weather sensors that deactivate the irrigation when it rains. Other sustainability benefits include improved building insulation, help with storm water runoff, and reduced pest-management needs. While the farm still has to contend with some flying pests, not a single four-legged digging creature has made its way up onto the roof, making it a bit easier for the farmers to protect and maintain the crops.

The drip irrigation system at the rooftop farm

Stacy Buchanan

The only unfulfilled wish the team has is even more space to grow a larger percentage of the produce consumed at the park. The obvious success of the project means some form of expansion isn’t out of the question. But for now, partnerships with local farms, such as Ward’s Berry Farm in Sharon, provide larger quantities and produce that can’t grow in milk crates.

And make no mistake, the term 'Green Monster' will continue to take on a whole new meaning in this unique corner of 'America’s Most Beloved Ballpark'. We encourage you to take a hike up to farm to see what’s on deck during your next Fenway visit.

The rooftop farm at Fenway

Stacy Buchanan

The Rise Of The Urban Rooftop

With space at a premium, cities are exploring new ways to make better use of their rooftops.

The rooftops of our cities are wowefully under-utilised, despite the constant-battle for land (Image credit: Shutterstock)

With space at a premium, cities are exploring new ways to make better use of their rooftops.

Our cities have never been denser, taller, or busier than they are now, and with that, comes the constant battle for land. Whether you’re a city dweller, developer, transport planner, or farmer, you’re forced to compete for dwindling amounts of available space. And with two-thirds of the world’s population predicted to live in cities by 2050, the stress on urban infrastructure looks set to outpace even the most carefully-laid plans. But if we look at aerial images of any city center, we can quickly spot plenty of unused space – the rooftops. Speaking to Scientific American, Steven Peck from a non-profit called Green Roofs for Healthy Cities, describes the roofscapes of our cities as “the last urban frontier – (representing) 15 to 35 % of the total land area.”

So what can we use this precious resource for? In a growing number of high-density cities, some of it is dedicated to recreation – everything from bars and pools, to soccer pitches and running tracks can now be found atop skyscrapers. Others host smog-eating roof tiles or questionable wind turbines, while in China, a large shopping mall has 25 villas on its roof. But when a rooftop offers access to sunlight, there are two more obvious candidates for its use – agriculture and solar power.

Green Cities

Green roofs have been growing in popularity for more than a decade, and in some cases, growing in scale too – atop a convention center in Manhattan sits the city’s largest, covering an area of 89,000 m2. Usually comprised of planted beds, or carpet-like tiles that encouraged the growth of low profile vegetation, green roofs can provide a habitat for birds and insects in an otherwise hostile environment. They also act as thermal insulation for the building, and reduce storm water runoff that can otherwise cause havoc in urban sewers.

Green roofs come with the added benefit of mitigating the dreaded urban heat island effect, whereby, as a result of heat-absorbing materials like asphalt and concrete, cities can be several degrees warmer than the surrounding countryside. In contrast, trees and green spaces can absorb shortwave radiation, and use it to evaporate water from their leaves – a kind of ‘double cooling’ effect. There are countless studies that back up this idea. One of the most interesting came from researchers at the University of Georgia. In 2015, they showed not only that ‘green’ cities are cool cities, but that networks of small urban green spaces, such as parks, gardens and green roofs, were more effective at reducing a city’s temperature than a singular park of the equivalent size.

In some European and US cities, councils now offer significant financial incentives to developers who install a green roof – in Hamburg, building owners can receive subsidies of 30–60% of its installation costs. And from 2020, green roofs will be considered compulsory for all new, large-scale builds in the city. (CONTINUED...)

uilding-intergrated PVs are growing in popularity. But are they always the best option? (Photo by Thomas Imo/Photothek via Getty Images)

As food security and urban nutrition creep ever-higher on the agenda for the United Nations, there’s also a worldwide movement of using green roofs for hyper-local food production. In regions with suitable climates, hundreds of different vegetables, fruits, herbs and salad leaves can be grown on rooftops. Beehives and chicken coops are also becoming commonplace amongst the high-rises. But not all rooftop farms are equal, as we’ll discuss.

Power Up

But first, what about solar power? With so many cities now divesting from fossil fuels, and the costs of solar panels dropping dramatically, photovoltaic (PV) systems have become the ‘go to’ option for generating distributed power in built-up areas. And, even with standard commercial panels, the energy gains are dramatic. The US National Renewable Energy Laboratory (NREL) have estimated that rooftop PV systems could generate almost 40% of electricity demands nationwide. NREL also developed a very cool visualization tool called PVWatts to help people discover if solar panels would work for them. In 2012, Dutch researchers calculated that building-integrated photovoltaics could deliver 840 TWh of electricity – that’s more than a fifth of the total annual demand for all of the EU-27 countries.

In 2011, a fascinating map was published by the City University of New York. Assembled from images taken by a LIDAR-enabled (Light Detection and Ranging) aircraft, it showed that at the time, 66.4% of New York’s buildingshad roof space suitable for commercial photovoltaic systems. Furthermore, they estimated that, even with NYC’s changeable weather, rooftop installations could meet close to 14% of the city’s annual electricity consumption.

And cities have certainly taken note of this data – in many cases, making such installations compulsory, as in Sao Paulo, where Brazil’s Ministry of Cities announced that future low-income housing developments should include rooftop photovoltaics.

Which one to choose?

There’s no doubt that in both cases, a network of ‘productive rooftops’ could benefit the local community by supplying a portion of a necessary resource – either food or electricity – while also reducing their environmental burden. But is one better than the other? (CONTINUED...)

This was the question posed by researchers from MIT and the University of Lisbon in a recent paper in the journal Cities. Focusing on the rooftops of a mixed-use neighborhood in Lisbon, they carried out a Cost-Benefit Analysis for four scenarios – 1. Open-air rooftop farming, 2. Rooftop farming in low-tech greenhouses, 3. ‘Controlled environment agriculture’ (farming in high-tech greenhouses) or 4. Solar PV energy generation. Starting with existing data on everything from installation costs and resources used, to carbon footprint and yield, they modelled the impact that each installation would have on the local community over a period of 50 years.

The researchers took a footprint of one square meter of roofing, considered a population of 17,500 residents, and for the farms, looked only at a single crop – tomatoes. The fruit is not only incredibly popular in the Portuguese diet – with an average of 10.4 kg eaten per year, per person – there’s also a large body of data available on their growing requirements and yields. For solar power, they considered standard single-crystalline silicon PV modules, arranged on flat or pitched roofs. They also assumed that the PVs installation would act as part of the grid – in other words, though generated locally, the electricity would be distributed via existing infrastructure.

Urban farming might add value to a neighbourhood far beyond what had been previously assumed (Photo by John S Lander/LightRocket via Getty Images)

Here are a few highlights from their study:

The benefits of food production varied according to the supply chain, except for high-tech rooftop farms, which were predicted to be profitable regardless. Open-air and low-tech greenhouses were found to only profit when the crops are sold directly to consumers.

If the demand for tomatoes in Lisbon was to be met through rooftop farming, you’d require 1.89 square meters for organic field cultivation (#1), 0.37 m2 for soil-less cultivation in unconditioned greenhouses (#2), or 0.15 m2 for controlled-environment agriculture (#3)

A rooftops farm could potentially create five times as many local jobs as a rooftop PV system, but would involve much higher operation and maintenance costs

The electricity yield for PVs installed on south-oriented unshaded rooftops was calculated to be approximately 300 kWh/m2/year.

So, both options seem pretty good. But it’s when we look at the bigger picture that the differences start to show. I’ve written about the questionable profitability of urban farming in the past, but that was only ever as measured on individual farmers, which – I say, with the benefit of hindsight – doesn’t make all that much sense in the context of a city.

This study, however, takes a broader, and much more sensible view – it looks at rooftop installations as part of an interconnected network. And it’s which measures the overall value – in terms of economics and the environment – to both the building owner, and the community around it. And by looking at it that way, they concluded that for Lisbon, the use of rooftops for food production could yield significantly higher local value than solar PV energy generation or standard green roofs. Of course, this is very site-specific – in another city, you might come to exactly the opposite conclusion, but that’s kind of the point. There is no one-size-fits-all solution to make cities more sustainable, and anyone who tells you otherwise is massively over-simplifying a complex issue.

There are lots of things that will help anywhere – e.g. moving from private cars to mass transit, making renewable energy the default option, being smarter with how we use water, reducing our reliance on concrete, minimizing our waste footprint, and reserving single-use plastics for very, very specific applications. But when it comes to ‘other’ questions, like should we use our rooftops for energy generation or farming, the answers are a lot less black-and-white. By adopting research like the study I’ve featured here, we can get much closer to making the right decision for our specific circumstances. The authors said that their study “…aims to provide decision-makers with a basis for systematic and integrated comparison of these productive uses of rooftops.” Now, all I hope is that some of those decision makers start using it.

Imagining The Impossible: The Futuristic Designs of Vincent Callebaut

New Atlas takes a look at Vincent Callebaut's most interesting architectural designs.

July 24th, 2018

New Atlas takes a look at Vincent Callebaut's most interesting architectural designs (Credit: Vincent Callebaut Architectures)

Sometimes outlandish, often fantastical, but always compelling, Vincent Callebaut's projects range from realizable ideas like towers covered in greenery to conceptual works depicting a near-future in which architecture, technology, and nature are blended to make cities a more pleasant – and sustainable – place to live.

The Belgian architect heads his firm Vincent Callebaut Architectures in Paris, France. Over the years he has developed a recognizable design language that draws inspiration from nature and makes liberal use of honeycomb patterns and complex geometry. He seems poised for greater prominence now though, as at least two of his projects are due to be built in the next few years.

Let's take a look at some of his most interesting designs.

5 Farming Bridges

Now that the so-called Islamic State has been expelled from Mosul, Iraq, the reconstruction of the city can begin. The 5 Farming Bridges proposal involves rebuilding a like number of bridges destroyed during the fighting and using them as residential units and urban farms. Existing rubble would be used as building material, with flying drones and spider-like robots doing the actual construction.

Manta Ray

The Manta Ray proposal envisions a manta ray-shaped ferry terminal in Seoul, South Korea. The remarkable-looking building would float in place to deal with seasonal flooding and sport a huge roof covered with a solar power array, along with a wind turbine farm. Biodegradable waste and high-tech water turbines would transform the river's kinetic energy into power too – all of which would allow the ferry terminal to power itself and send a surplus to Seoul.

2050 Paris Smart City

Created for a competition seeking ideas to turn the City of Light into a City of Green in the coming decades, 2050 Paris Smart City calls for 15 new sustainable towers to be built on the rooftops of existing buildings on the city's famous Rue De Rivoli. The towers would feature residential units and sport dragonfly-shaped solar panels on their facade, providing all required electricity for the project.

Nautilus Eco-Resort

The Nautilus Eco-Resort is a paradise imagined for the Philippines that would allow well-heeled tourists to vacation without polluting the planet (excepting on the flight there, presumably). The whole thing would be arranged into a shape inspired by the Fibonacci sequence and include a dozen spiral hotel towers that rotate to follow the sun. Nearby, a like number of sea snail-shaped buildings would include exhibition spaces and hotels, while at its center would be a large timber building covered with vegetable gardens and orchards.

Tour & Taxis

Callebaut's Tour & Taxis sees the Belgian architect propose a return to his home country to transform a former industrial area in Brussels into a vibrant sustainable community. The area would comprise three ski jump-shaped high-rises that would be topped by solar panels and covered in greenery. Other notable elements include wind turbines, rainwater harvesting, and the production of fruit and vegetables.

Hyperions

Hyperions consists of a cluster of connected timber towers in New Delhi, India, that are named after, and take design cues from, the world's tallest living tree. It will boast extensive greenery and enable occupants to grow their own vegetables on balconies, as well as the facades, the rooftops, and in specialized greenhouses. The interior is taken up by apartments, student housing, and office space, and it will all be powered by solar panels. According to Callebaut, this one is going to be built and is due to be completed by 2022.

Agora Garden Tower

It can be difficult to imagine how exactly all these renders would translate into brick and mortar buildings, but Taipei's Agora Garden Tower shows the way. Sporting a twisting form inspired by DNA's double helix shape, the building twists 4.5 degrees each floor, turning a total of 90 degrees in all. Once completed, it'll feature 23,000 trees, as well as a rainwater capture system and solar power.

Meriden Aquaponics Firm Scores $500K Investment For New Haven Expansion

PHOTO | TRIFECTA ECOSYSTEMS

JULY 16, 2018

Meriden-based Trifecta Ecosystems, an aquaponics technology company and indoor farm, has received a $500,000 investment to grow its aquatic systems in the New Haven region.

New Haven-based water provider South Central Connecticut Regional Water Authority (RWA) announced Monday its investment will allow Trifecta Ecosystems to build a custom-controlled aquaponics system, an urban farming technology platform, and workforce training programs in the Greater New Haven region.

RWA, a nonprofit that provides water to 430,000 people in 15 municipalities throughout Greater New Haven, said the funds are aimed at creating sustainable agriculture and fish-farming practices in the area.

With board approval, RWA says it could invest another $1.5 million into the project.

Spencer Curry, CEO and co-founder of Trifecta, says the initial investment will allow his firm to grow a new aquaponics system in the New Haven region "that will combine food production, aggregation, processing, research, and workforce training at integrated locations, helping pave the way for statewide adoption."

"This investment will allow our company to continue towards our mission of creating the City that Feeds Itself, by providing communities the tools they need to grow their own food, cost-effectively, scalable, and repeatedly."

Under aquaponics farming, produce can grow naturally without chemical fertilizers in a system that uses less water because it is recycled. Aquaponic farms, which have a smaller physical footprint, reduce carbon emissions by using up to 95 percent less water vs. traditional growing methods.

Building a new aquaculture, which raises aquatic animals such as fish with hydroponics, in the region will help sustain farming and kick-start economic growth, RWA said.

"We believe the science of aquaponics holds real potential for Connecticut in addressing land management issues and overcoming resource challenges facing traditional agriculture," RWA CEO and President Larry Bingaman said.

Engineers Change The Future of Farming

In all honesty we have experienced issues of power failures which has caused our plants to die. My engineering mind said we need to find a way to fix this.

BY KARABO LEDWABA - 17 July 2018

Engineers Mogale Maleka and Tumelo Pule have come up with hydroponic farming system that will change the future of agriculture in SA. Image: Mduduzi Ndzingi

Two mechanical engineers have used their technical expertise to make soil-less farming more efficient by building a system that relies on 20 hours less of electricity than what is currently being sold on the market.

Business partners Mogale Maleka and Tumelo Pule, who are both 25 years old, ventured into hydroponic farming, also known as soil-less farming, after graduating with their honours degrees from the University of Johannesburg (UJ) in 2016. This type of farming does not require the use of soil but relies on water and fertilisers to hydrate and feed plants.

"In all honesty we have experienced issues of power failures which has caused our plants to die. My engineering mind said we need to find a way to fix this," said Pule. Hydroponic farming helps farmers avoid having their produce harmed by pests found in soil, diseases and weeds. It uses 90% less water than soil farming and allows for more plants to be grown in smaller spaces.

This type of farming is possible because plants such as spinach, lettuce, herbs and strawberries do not need to be submerged in the soil to grow. In these instances, soil is mainly used as an anchor for the plant and science allows for farmers to use other methods to keep the plants stable.

"Hydroponic systems need to feed the plant with water and nutrients continuously, which means that within an hour of electricity being gone, the plant will wilt and eventually die," said Maleka.

Their hydroponic planter is able to situate the water and fertilizer in a small reservoir without drowning the plant.

This means that water only needs to be pumped for four hours in a day, while traditional systems need water to pump for 24-hour periods to continuously feed and hydrate the plant.

The entrepreneurs said hydroponic systems are the future of farming.

"It is our belief that farming will need to rely on hydroponics because of issues such as urbanisation, climate change and an increasing population growth," said Pule.

Maleka said they had previously used the traditional hydroponic systems but found that they were not effective when combined with South Africa's load-shedding problem.

It took them seven months to finish their prototype, which cost them R28000.

"We were lucky enough that the University of Johannesburg believed in us and have given us a seed fund for our hydroponic planter," said Maleka.

The young innovators have plans to commercialise their product by selling it to farmers and eventually to households that want to grow their own produce.

Sipho Mahlangu from UJ's Process Energy and Environmental Technology Station (UJ PEETS) said the hydroponic planter was fascinating and innovative and that they would be assisting them in finding more funding to take it forward.

6 Places Where Soil-Less Farming Is Revolutionizing How We Grow Food

by Greg Beach

If it seems like “hydroponic systems” are everywhere, that’s because they are. Hydroponic farming is one efficient way to grow fruits and vegetables in small spaces without the use of soil. Instead of dirt, plants grow down into water, to which farmers have added the necessary nutrients for plant growth. These are then absorbed, along with water, through a plant’s roots. Light is provided either by the sun or specially designed grow lights, with many sustainable systems powered by renewable energy sources. Aquaponic farming incorporates fish into the soil-less system, using the closed-loop nutrient cycle from fish digestion to their advantage. Some systems even feed nutrients to plants through the air! From water-less deserts to the sun-less underground, soil-less farming is offering new possibilities to feed an increasingly urban, growing global population in a more Earth-friendly way.

1. Stores

Target has collaborated with MIT to create a hydroponics garden in several of its store, offering produce directly to customers.

With consumers increasingly conscious of their environmental impact, many stores have realized that going green is good for business. Big-box store Target began a series of trials in spring 2017 in which vertical, hydroponic gardens were installed in various Target locations to provide customers with the freshest possible produce. In collaboration with MIT Media Lab and Ideo, Target designed a system that is capable of growing leafy greens and herbs with minimal water usage. The company hopes to someday branch out into other crops, such as potatoes, zucchini and beets. MIT may even offer Target use of rare heirloom tomato seeds for its project. Meanwhile, IKEA has teamed up with Denmark-based SPACE10 to design high-tech hydroponics systems in-stores and in homes.

2. Deserts

Sundrop Farms uses solar energy to desalinize water that is then fed into its hydroponics system.

In preparation for a future dominated by climate change, in which oil becomes a lesser part of the world’s energy diet, Saudi Arabia has taken several major steps to build a more sustainable system in its challenging desert region. One such move is the rethinking of many traditional farming practices, especially focused on reducing water usage. A farm in the town of Jeddah uses neither water nor soil, rooting plants in mid-air while providing their nutrients through a mist. Designed by AeroFarms, the system is the first aeroponic farm in the Middle East and hopes to someday acquire all its water needs through capturing humidity in the air.

Related: The future of food: how dry farming could save the world

If a desert farm chooses to go hydroponic, there are ways to grow without draining freshwater supplies. In arid South Australia, SunDrops Farms grows 15% of the country’s tomato crop through a solar-powered hydroponic system. To eliminate the use of precious freshwater, SunDrops sources its water from the nearby saltwater gulf, which is then desalinated through the reflected heat of the sun.

In a very different kind of desert, soil-less farming helps growers from the Arctic to Antarctica make the most of a short growing season.

3. Cities

Farm 360 grows sustainable, local food in a hydroponic system that provides local jobs.

As the global population becomes more urban, cities are investing in more local food production systems that offer economic development opportunities and reduce a city’s carbon footprint. In a warehouse on the Near East Side of Indianapolis, Farm 360 are growing vegetables on a hydroponic system that is exclusively powered by renewable energy and uses 90 percent less water than traditional farming methods. The harvest is sold in local grocery stores while the farm supports dozens of living-wage jobs to residents of the neighborhood.

In even the most isolated urban areas, soil-less farming finds a home. With its ability to receive vital supplies and support a functioning economy severely restricted by the Israeli blockade, Gaza has stepped out onto the rooftops to grow its own food. Beginning in 2010, a United Nations-funded urban agriculture program equipped over 200 female-headed households with fish tanks, equipment, and supplies to build and maintain an aquaponics growing system. This initial spark has encouraged others to create their own and to teach others of this valuable skill.

4. The Underground

Tiny mushrooms sprouting at the underground farm La Caverne.

Farming without soil can often take place beneath the soil. In Paris, Cycloponics runs La Caverne, a unique urban farm that grows mushrooms and vegetables in an underground, formerly abandoned parking garage. The farm’s hydroponics system uses special grow lights to ensure the vegetables have what they need to survive. The mushrooms grow in a special medium and, through their respiration, provide valuable CO2 for the plants to thrive. La Caverne may have found inspiration from Growing Underground, London’s first underground farm. On 2.5 acres of unused World War II-era tunnels, Growing Underground produces pea shoots, several varieties of radish, mustard, cilantro, Red Amaranth, celery, parsley, and arugula.

Related: 7 agricultural innovations that could save the world

Honorable mention: shipping container farms. Although these may be mobilized on the surface, they may as well be underground due to the closed roof of most shipping containers. The solar-powered hydroponicsLA-based Local Roots can grow the same amount of vegetables, at cost parity, with 99 percent less water than traditional farming.

5. On the Water

GreenWave grows seaweed and shellfish in an innovative design system.

Some soil-less growing operations take it a step further, leaving the ground behind entirely and opting for a farm floating on water. Barcelona-based design group Forward Thinking Architecture has proposed a progressive solution to the decreasing availability of arable land by creating floating, solar-powered farms. Using modules that measure 200 meters by 350 meters, Forward Thinking’s design allows for expansion and custom configuration of farms. Each module has three levels: a desalinization and aquaculture level at the bottom, then a hydroponic farming level, topped off by a level of solar panels and rainwater collection. The company estimates that each module would produce 8,152 tons of vegetables a year and 1,703 tons of fish annually.

Related: NexLoop unveils water management system inspired by spiders, fungi, bees and plants

Greenwave takes an alternative approach to soil-less, floating farming by combining the cultivation of shellfish and seaweed, both profitable crops that also help to clean the aquatic environment and absorb greenhouse gases. The farm requires little external input, pulls carbon dioxide from the air and water, and consumes excess nitrogen that could otherwise result in algal blooms and dead zones.

6. Your Home

Urban Leaf offers a kit to turn glass bottles into miniature, soil-less gardens.

Yes, you too could get in on the soil-less action. Whether you prefer to DIY or you’d rather something more straightforward, there are options for every style.

Lead image via Depositphotos, others via MIT OpenAg, Sundrop Farms, Esther Boston, Cycloponics, GreenWave, and Urban Leaf

The World’s First “High-Tech Eco Village” Will Reinvent Suburbs