Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

"You’re Never Too Young to Make a Difference"

Rikalize Reinecke goes to school, just like the average kid in their late teens. But unlike them, she has an unusual side business. In January 2014, when she was just 12 years old, she started her own aquaculture and aquaponics farm just outside Pretoria, South Africa. And the inspiration came from the movie Dolphin Tale.

The movie inspired her to start her own fish farm, but there was more to it: "At more or less the same time that I watched the movie Dolphin Tale, we learned at school about all the natural resources that are being depleted, and that in a few years’ time, there will not be any fish left in the sea", she tells us. "When I saw the dedication of the people at the oceanarium, working with the dolphins, and helping them, that changed my life forever.

"I realised two things: I would like to have a similar experience one day, and that I had to do everything I can to prevent fish from becoming extinct."

From aquaculture to aquaponics

Rikalize started with a pure aquaculture farm. However, she found that ammonia and harmful impurities in the water grew to such an extent that the fish started to die. This and the fact that her capital input was very limited, meant that aquaponics was her only option.

"Aquaponics quickly solved the problem of reducing the high and dangerous water impurities and also provided me with a small constant income." Although her passion is fish, and she would choose aquaculture any time, aquaponics "opened doors for me as an inland resident, with a very limited water supply, to farm with fish in a sustainable way", she says. "Aquaculture would be my first choice, but I realize the value of aquaponics especially in the DAPS application that I developed."

From lettuce to leek, and strawberries to spring onion

Rikalize and her team grow a wide variety of crops in the aquaponic systems: "About 22 varieties, from various lettuces, spring onion, leek, celery, cucumber, rock melon, peppadews, green peppers, tomatoes, strawberries, baby marrows to various herbs, etc."

Most of that produce ends up at the shop she opened late last year, and is sold directly to the public. "I also sell fish to wholesale distributors and chef schools. Previously we would deliver to restaurants and lodges and mini supermarkets, but now all of them can buy and collect from my shop."

And she's constantly looking to expand that range, with a section where they do research and feasibility studies and grow produce to determine if it can be grown successfully in the aquaponics set-up.

With two and a half years of school still left, schoolwork comes first for Rikalize, but she is engaged in high level discussions on expanding production and acreage. "Offtake agreements are one of the ways we are looking at currently and that is the short term expansion. I can say that I am in the process of constructing a new Catfish Hatchery based on a brand new mobile and modular principle to be rolled out over Africa, the first POC will be ready end of July."

Spreading the word on aquaponics

Rikalize tells us that the aquaponics industry in South Africa has grown a lot since she took up farming three years ago. "One of my aims is to put a lot of effort into creating public awareness and hence grow the industry." And it hasn't gone unnoticed. "Aquaponics is now like the next best thing," she says.

One of the ways Rikalize is spreading the word is through the development of an app, which is now in the final testing phase before being rolled out on public platforms. "The team that worked on the design did a great job. The roll out date will be announced soon." She also provides training courses. "Training is the base of knowledge and education. As long as I need to build systems there will be training."

Her ultimate vision is to roll out the modular aquaponics system in Africa and all around the world, to equip people with the opportunity to have a job and provide food to their families. "Aquaponics is the most sustainable farming method of the new century," she says. "This system gives you the opportunity to process food in your backyard and generate a small income. One system can feed a family of 4-6 people sustainably."

And for all the young growers out there, Rikalize has a special message: "You’re never too young to make a difference."

For more information:

La Pieus Aqua

Publication date: 7/12/2018

Author: Jan Jacob Mekes

Copyright: www.hortidaily.com

Rep. Goyke Commends UW School For Urban Agriculture Initiative

Federal USDA grant follows on urban farming legislation introduced by Rep. Goyke calling for a School of Urban Agriculture in Wisconsin

By State Rep. Evan Goyke - July 12, 2018

MADISON – The University of Wisconsin – Madison recently received a three year federal grant from the USDA National Institute of Food and Agriculture to initiate the creation of a School for Urban Agriculture. The new school, as part of the University’s Farming the City Project, will target students, farmers, and non-profit staff.

This legislative session Rep. Goyke introduced the “The Wisconsin Urban Farming Futures” Initiative that focused on promoting urban agriculture in Wisconsin, including funding and siting for a future urban agriculture school (Assembly Bills 671, 672, 673, 674).

According to the grant description the new school and program will “…create curricula that meets the needs of students seeking short, intense training in specific aspects of urban agriculture (workshop and short course instruction) and the needs of four-year baccalaureate students who are interested in enhancing their education in this emerging content area.

…Importantly, the project will also target secondary students in an existing pipeline for college-level agricultural training in Wisconsin. In doing so, the project envisions a future workforce of urban farmers reflecting the social composition of the communities where many urban farms are being established.”

In response to the grant announcement and in support of its goals, Rep. Goyke stated:

“The fields of urban farmers look very different than the dairy farm my grandfather owned. Urban Agriculture offers a modern expansion of one of Wisconsin’s strongest traditions and can transform urban communities. In Milwaukee, we’ve seen new life spring from the ashes of old industry. Growing fresh healthy food in and near cities offers positive economic activity, job skills training, brings diverse communities together, and offers access to quality healthy food. Wisconsin’s agricultural future rests in the hands of future farmers, including those in this emerging sector of our agricultural economy. This new initiative and school will provide the tools and skills necessary for Wisconsin’s urban farmers to be successful.”

Emirates Is Creating a Massive New Farm for Fresh Airplane Food

Dubai is certainly well-known for being an over-the-top travel destination. But soon, it may become more famous for its farming.

Courtesy of Emirates

JULY 18, 2018

Dubai is certainly well-known for being an over-the-top travel destination, and with some of the most luxurious hotels, designer clothing stores, and world-class restaurants, it’s more than earned that descriptor. But soon, it may become more famous for its farming.

Emirates Flight Catering, a subsidiary of Emirates Group, announced in June a new partnership with Crop One Holdings. The pair of companies, Gulf News reported, will co-invest $40 million to create an absolutely massive indoor farm in Dubai that will break the vertical farming world record.

Courtesy of Emirates

The farm, which is set to open next year, will produce the equivalent of 900 acres of fresh food, Gulf News reported. That means it will produce three tons of “high-quality, herbicide-free and pesticide-free leafy greens daily.”

However, it will produce all this food using far less water than traditional farming, and will also grow produce without soil, sunlight, and chemicals. It will indeed mark a massive step for the United Arab Emirates towards becoming more self-sustainable. As Gulf News explained, a massive amount of the food consumed in the UAE comes from foreign markets. According to 2015 data, 85 percent of the UAE’s food was imported.

Courtesy of Emirates

“This investment to build and operate the world’s largest vertical farming facility aligns with the UAE’s drive for more agricultural self-sufficiency, a vision which began with the late His Highness Shaikh Zayed bin Sultan Al Nahyan, the UAE’s founding father,” Shaikh Ahmed bin Saeed Al Maktoum, chairman and chief executive of Emirates Airline and Group said in an announcement. “The introduction of ground-breaking technology at the facility also enhances Dubai’s position as a global innovation hub.”

According to the announcement, the two companies expect to be delivering their first batch of produce to their customers (which include their 105 airlines and 25 airport lounges) by December of 2019.

Giant Indoor Vertical Farm Backed by Chinese Firm Launching Just East of Las Vegas Strip

- One of the country's largest indoor vertical farms was built about 6 miles east of the Las Vegas Strip on the site of a former mail-order prescription drug facility.

- Oasis Biotech plans to start deliveries next week and said it can produce about 9,500 servings of mixed salad per day for local restaurants and casinos

- The vertical farm requires 90 percent less water than a traditional farm and uses about 50 percent less energy than most other indoor ag facilities.

17 July 2018 CNBC.com

An indoor vertical farm that uses 90 percent less water than conventional growers is about to launch in Las Vegas and will be able to supply nearly 9,500 servings of leafy green salads per day to casinos and local restaurant chains.

"Las Vegas is the location that has the highest density of high-end restaurants, which can afford this premium specialty product," said Brock Leach, chief operating officer and general manager of Oasis Biotech. "We're going to be able to get our product from harvest to the customer in around 24 hours."

Oasis Biotech, a Chinese-backed farm that uses hydroponic watering and microclimate controls for crop cultivation, is scheduled to make its first delivery in Las Vegas on July 24. The 215,000-square-foot facility is expected to be one of the largest in the nation when fully built and will initially focus on growing baby greens, micro greens, and specialty herbs but plans to eventually expand into baby carrots as well as soft fruits, including strawberries.

Controlled-environment agriculture

The chemical-free facility uses hydroponics technology, so it grows plants without soil. It also uses high-end clean rooms similar to those found in computer manufacturing as well as special filters and ultraviolet lights to control air and water — all designed to keep the food safe.

"We are producing food that is the safest and securest food that you can possibly produce," said Leach.

Oasis Biotech

One of the nation’s largest indoor vertical farms is about to launch in Las Vegas and eventually span more than 200,000 square feet.

The recent scare over salads at McDonald's due to an intestinal parasite outbreak highlights how difficult it is to monitor fresh produce grown on traditional farms. The FDA is still investigating what the source of the outbreak is for the cyclospora illnesses.

"The fact that the McDonald's outbreak made news is a warning of sorts, because we've always had foodborne outbreaks from various infectious diseases," said Dickson Despommier, professor emeritus for environmental health sciences at Columbia University and leading expert on vertical farming. "This [indoor controlled farming] technology allows you to avoid that."

Despommier said indoor vertical farming in cities will continue to grow in the future due to demand from restaurants and stores that are looking for "growers that can promise healthy, fresh produce year-round right next door to where the store is. The model has been developed, and I think it's a viable one."

Most of the leafy greens and other fresh produce supplied to the Las Vegas market are grown in California and Arizona, so there are added shipping costs and product can sometimes take several days to reach southern Nevada customers. Las Vegas hosted more than 42 million visitors last year and southern Nevada is home to more than 2.1 million residents or about three out of every four residents in the Silver State.

Talking to casinos

"We will be meeting with a lot of the major casinos here in the next few weeks," said Leach. "But they won't be part of our initial distribution. We're focusing more on independent restaurants and small chains."

The major casinos declined to comment for this story.

Leach said the vertical farm plans to sell its leafy greens and other products through a large local produce distributor. "They touch over 80 percent of our target customer base," he said. "Many of the large casinos already buy from this distributor."

The vertical farm's parent company is Sananbio, which is owned by Chinese LED chip-making giant Sanan Group. Sananbio already operates one of the world's largest vertical farms in China's coastal city of Quanzhou. Oasis Biotech represents its first major foray into controlled agriculture in the United States and an opportunity to showcase its technology and sell equipment and lights to other indoor agriculture businesses.

'One of the largest players'

"We're going to be one of the largest players in the industry," said Leach. "I don't see anyone in this space as competition but a potential collaborator."

The LED lighting installed at Oasis Biotech uses 50 percent less energy compared with traditional indoor growing, according to the company.

The Chinese company spent about $30 million on the vertical farm, including the 215,000-square-foot industrial property located about 6 miles east of the Las Vegas Strip. The vertical farm is located on the site of a former mail-order prescription drug facility.

The first phase of the indoor farm consists of about 60,000 square feet of production or the equivalent of a 34-acre farm. A second phase, planned for early next year, is expected to add 50 percent more space.

According to Leach, Oasis Biotech expects to be profitable from an operating standpoint in 2019.

"We're the only large indoor controlled-environment ag operation right now that is corporate-backed" and not funded by venture capital, Leach said. "That means we can focus on scale without having to spend a huge amount of resources on capital raising."

Automating harvesting

The microgreens and baby greens are currently harvested by hand, but the company plans to go to a fully automated harvesting in the second phase. The harvest automation equipment is based on the technology that has been used for several months at Sananbio's China operations.

"It will be automated from seed to harvest," said Leach.

Oasis Biotech employs about 130 people. The growing supervisor for the vertical farm is a former potato farmer from Idaho.

"We've got over 70 farmhands with maybe three people who have done controlled-environment ag before. We're teaching them how to be hydroponic technicians. There's going to be a whole new generation of farmers that are going to grow up around controlled-environment ag."

Water efficiency

Water supplies are limited in southern Nevada, a region facing drought conditions and where most of its water comes from the Colorado River or groundwater. The Las Vegas indoor farm uses 90 percent less water than a traditional farm, or roughly 300 to 500 gallons per day — about as much as a family of four uses flushing their toilets and running their showers.

While the mercury soared into the triple digits in Las Vegas this week, Oasis Biotech relied on micro-climate controls to keep the temperature and humidity just right for growing plants in hydroponic systems.

"If you can pull this off in the middle of a desert and this extreme heat, you should be able to do it in other places," said Leach, who previously was CEO of Urban Till, an indoor farming company in Chicago. Prior to that, he worked for a logistics company that handled food distribution for McDonald's.

Many of the early indoor vertical farms built in the U.S. have been in abandoned factories or industrial locations. The indoor farms also offer a solution to countries that need to import most of their fresh produce due to limited arable land or where water scarcity is a constant challenge.

Indeed, a new low-water indoor vertical farm is going up in Dubai this fall and expected to produce upwards of 6,000 pounds of leafy greens daily. The $40 million high-tech farm's backers include Emirates Flight Catering, which supplies more than 200,000 meals daily.

Lettuce traditionally grows in 80 to 90 days outdoors, and producers tend to get up to three harvests out of the field during the season. The indoor vertical farm in Las Vegas can output lettuce in 18 to 24 days and farm 365 days a year, according to Leach.

"The days are longer because we leave the lights on for about 16- to 18-hour cycles," said Leach, and "there's never a cloudy day."

-Story updated to reflect changes in fact sheet provided by Oasis Biotech.

French Homeless Shelter Plans To Build Rooftop Greenhouse

An urban farm could be installed on the roof of a French shelter, in order to develop agriculture in the city and to supply the social restaurant of the shelter in particular. It’s located on the Island of Nantes. The association Les Eaux Vives will open this project in 2019, which will be called "5 Ponts (5 Bridges)".

Homeless people will be offered hour-based work contracts. Missions will be proposed within the urban farm, the Emmaus boutique, the restaurant, or the green spaces of the site.

Next, to the restaurant, Les Eaux Vives now offers a day stop and a night stop, and an emergency shelter on three different addresses in Nantes.

The 5 Bridges project is organized around a covered street to facilitate the meeting of different audiences. The project is supported by the City of Nantes, and the European Union as part of the UIA (urban innovative action) project.

Publication date: 8/14/2018

How Georgia O’Keeffe’s Garden Keeps Growing, Three Decades After Her Death

August 14, 2018, Casey Lesser

While traveling in rural New Mexico in the 1930s, Georgia O’Keeffe first set her sights on a forlorn property perched remotely on a plateau in Abiquiú, New Mexico. In 1940, she’d buy a home at Ghost Ranch, a short drive away, but it left something to be desired. “I was living and painting at Ghost Ranch, but I kept returning to Abiquiú to look around,” O’Keeffe told Architectural Digest in 1981. “The garden pleased me enormously.”

"Georgia O'Keeffe" at Tate Modern, London

Maria Chabot, Georgia O’Keeffe in the Abiquiú Garden, 1944. © Georgia O’Keeffe Museum.

O’Keeffe, who is known to have been an extremely healthy eater, had wanted a garden to grow her own produce. She’d expressed frustrations that, while living in Ghost Ranch, by the time she got home from the nearest market (either in Española or Santa Fe), her lettuces would be wilted. So, in 1945, when she purchased the Abiquiú property—a ruin that had belonged to the Catholic archdiocese of Santa Fe—she hired help to repair the buildings and turn them into a home and studio, but also to till the land and plant a garden. She’d later hire a gardener, a local named Estiben Suazo; under his supervision, it flourished. Over the next four decades (until O’Keeffe died in 1986), the garden would be a source of fresh produce and year-round preserves, but also joy and solace—and it still is today.

Abiquiú House Gardens Outside of Kitchen, 2010. Photo by Paul Hester and Lisa Hardaway. © Georgia O’Keeffe Museum.

Indeed, the garden is one of the highlights of a visit to the Abiquiú home and studio, which has been overseen by the Georgia O’Keeffe Museum since 2006, and is accessible to the public via guided tours. (Hers is among a long tradition of gardens created by artists for inspiration and enjoyment.) With its original layout and adobe irrigation ditch, the garden sits across a series of terraces over nearly an acre of land beside the house. It bears everything from lilacs and day lillies, to kale and chard, to the fruits of a small orchard of apricot, peach, pear, and apple trees. Though it’s not all the same as what grew in O’Keeffe’s time, her former gardener still has a presence: Suazo taught his grandchildren how to care for the Abiquiú garden and the grounds, which they continue to do.

“[Suazo’s] work in the garden was meticulous.…He knew exactly what Ms. O’Keeffe wanted, and what she liked or disliked,” explained Agapita Lopez, Suazo’s granddaughter who was a private aid and secretary for O’Keeffe beginning in 1974, and is now the Georgia O’Keeffe Museum’s director of historic properties. “But Ms. O’Keeffe herself would say that they sometimes would get into a battle when it came to planting the garden,” she added with a laugh.

“She would say he had a mind of his own, and he wanted to do things his way,” Lopez continued. “Whatever they did, they must’ve compromised, because the gardens were always lush and fertile, and yielded a lot of produce.” Harvests from the garden would become O’Keeffe’s vegetable-rich salads, soups, and other dishes. “She was, I would say, into organic gardening before it was the norm,” Lopez offered, adding that the artist was not, however, a vegetarian.

Abiquiú Garden Ditch from the Room Looking South and West, 2010. Photo by Paul Hester and Lisa Hardaway. © Georgia O’Keeffe Museum.

Beginning in the early 1970s, O’Keeffe began hiring Lopez’s brothers to help Suazo with the garden; later, they’d be hired full-time and taught how to care for the garden to the artist’s liking. Decades later, in 2006, when the Georgia O’Keeffe Museum took over the Abiquiú property and decided to bring the garden back to its former glory, the Lopez family was essential to the process.

“They had the knowledge,” Lopez explained, referring to her brothers Margarito, who is now the gardener, and Belarmino, who is the construction and maintenance specialist. “Of course there’s always new ways of doing things, but we also want to maintain some of the old history of how things were done when Georgia O’Keeffe was at her house, to maintain the authenticity and her aesthetic. It’s a very contemplative place.” That history includes watering the plants through the original flood irrigation system, where the area is flooded “almost like a rice paddy,” Lopez explained, so that even the deepest soil absorbs the moisture.

“Ms. O’Keeffe herself would start her vegetable garden as early as February, planting her peas,” Lopez explained, “and we follow basically the same procedure she did, but the things that are grown in the garden today may not necessarily have been around at the time that she was still here with us.” Among the crops there today are tomatoes, squash, corn, beans, kale, eggplant, berries, and herbs. But the growing season starts later, to coincide with a dynamic summer internship program—a collaboration between the museum and the Santa Fe Botanical Garden—that brings students from local high schools to the garden to help with planting and harvesting the produce. (The two institutions also teamed up with two local high schools to create a livestream of the garden online.)

This summer, a dozen students worked with Margarito to learn the ins-and-outs of organic gardening, and about O’Keeffe herself. “She didn’t like to use pesticides, and that’s exactly what the students are learning now,” Lopez offered; they’re working on natural repellents to keep critters from eating the tomatoes, squash, and zucchini. At the end of the season, the students harvest the garden and take home their share; the rest is delivered to a local food bank.

Abiquiú Garden Project Interns, 2016. Photo by Micaela Butts. © Georgia O’Keeffe Museum.

Lopez suggested that the artist’s interest in the garden traces back to her upbringing on a farm in Wisconsin, as well as the summers she spent in Lake George with her partner Alfred Stieglitz (there are photographs of her there, pruning fruit trees). Though she did get her hands dirty from time to time (as photographs verify), O’Keeffe was enamored with the way the garden nourished her. Later in life, as she lost her vision due to macular degeneration, she had a small path built into the center of the garden so that she wouldn’t accidentally tread on the plants, and could walk out and enjoy it alone.

“She liked seeing things grow and coming out of the ground,” Lopez explained. “She liked to bring the outdoors in.”

Inside the Abiquiú house today, various potted plants are the ones that belonged to O’Keeffe—including a geranium and an aloe plant in the kitchen, a fern in the dining room, and an iron plant in the sitting room. “Those were here when she was still alive,” Lopez reflected. “They’re part of her and part of her history. They’re as important as everything else.”

Casey Lesser is Artsy’s Creativity Editor.

Real Organic Project Seeks Add-On Label To USDA Organic Seal

July 17, 2018

For some growers, organic certification alone just isn’t good enough anymore.

The East Thetford, Vt.-based Real Organic Project wants an “add-on” label to the U.S. Department of Agriculture organic certification.

The project, a coalition of organic farmers and advocates, objects to USDA’s National Organic Program rules that permit hydroponics and concentrated animal feeding operations to be certified as organic, according to a news release.

The group said its proposed add-on label, which requires adherence to standards above and beyond USDA organic certification, would only be available to agricultural products that have already been certified organic by the USDA.

The Real Organic Project in July announced the launch of its pilot farm inspection program.

The release said the program aims to implement new standards that will provide consumer transparency by “distinguishing organic farms that grow their crops in the ground, foster soil fertility and adequately pasture livestock according to foundational organic standards and principles.”

The Real Organic Project add-on label to USDA organic certification, expected by spring 2019, will increase transparency under the organic seal by allowing consumers to trace retail products back to the farm, according to the release.

The inspection process includes a video interview of the farmers on their land explaining their organic production practices, the group said.

Real Organic Project associate director and Colorado farmer Linley Dixon is leading the pilot project effort, according to the release. For the past five years, she has been the senior scientist at the Cornucopia Institute.

Taking control

Controversy on the question of whether soil is essential to grow organic produce has been bubbling for years.

By a vote of 8 to 7, the USDA National Organic Standards Board on Nov. 1 rejected proposals to make hydroponic and aquaponic production methods prohibited under the U.S. Department of Agriculture’s National Organic Program.

“Clearly the industrial egg operations became so powerful that they had significant political influence,” Dixon said in the release.

“We tried to keep the same thing from happening in other sectors of organic, especially tomato and berry production, but we lost that battle at the USDA last fall,” she said.

“Now we are taking matters into our own hands because we know it is what the consumer wants and expects when they choose organic.”

The add-on label will give farmers a way of communicating practices to “consumers who care,” the group said.

Sharing information with consumers and the trade in a positive manner is fair, said Lee Frankel, executive director for the Coalition for Sustainable Organics, a group that has defended USDA certification of hydroponic operations.

“The fear is that people resort to disparaging their competition and claiming that somehow they don’t meet the USDA organic standard,” he said.

“At this point, it looks like the Real Organic Project is trying to tell what they perceive as positive aspects about how they how they grow and how they operate.”

The release said the Real Organic Project will be managing a pilot program this year certifying a limited number of farms.

Real Organic board member Lisa Stokke, executive director of Next7.org, said July 16 that 41 farms from California to the Northeast have signed up for the pilot project so far this year.

The group said the “vast majority” of certified organic farms in the U.S. will easily meet these new “standards,” and the release said the provisional standards will be open for public comment this fall.

Stokke said that the movement is farmer-led, and there hasn’t been a lot of interaction with retailers yet. However, she believes the add-on label will appeal to retailers if consumers want it.

“I think it’s going to be about consumer demand,” she said. “As consumers begin to request this I would imagine retailers would also be on board.”

The pilot program will test the certification process in preparation for the label going public in 2019, according to the release.

In May, the group released what they called their provisional standards for the add-on label.

The standards are available at the group’s website.

Weird New Fruits Could Hit Aisles Soon Thanks to Gene-Editing

Supermarkets stocked with peach-flavoured strawberries and seedless tomatoes on horizon, scientists say

Supermarkets stocked with peach-flavored strawberries and seedless tomatoes are on the horizon, scientists say

20 July 2018

A red-fleshed apple of the Redlove hybrid variety. Unusual fruits such as this could soon become more common thanks to use of technologies such as Crispr. Photograph: Bailey-Cooper Photography/Alamy Stock Photo

Smooth or hairy, pungent or tasteless, deep-hued or bright: new versions of old fruits could be hitting the produce aisles as plant experts embrace cutting-edge technology, scientists say.

While researchers have previously produced plants with specific traits through traditional breeding techniques, experts say new technologies such as the gene-editing tool Crispr-Cas9 could be used to bring about changes far more rapidly and efficiently.

It could, they say, potentially open the door to a new range of fruits and vegetables that look, taste and feel very different to those we are used to.

Gene-editing is already being used by scientists to change the characteristics of food. One such endeavor used Crispr to make mushrooms that don’t brown, while a team in Spain has been using the approach to try to produce wheat that can be eaten by people with coeliac disease. Still, others are looking at using gene-editing to give crops resistance to particular environmental problems or pathogens.

Earlier this year, biotech firm Monsanto invested $125m in a new gene-editing company called Pairwise that reportedly has goals such as sweeter-tasting strawberries, while scientists in Japan have used the technique to produce seedless tomatoes. Another team have been using Crispr to change the architecture of tomato plant branches and the spacing of fruit.

nside a lab in Norwich where researchers from a startup called Tropic Biosciences are using Crispr to create a better banana. Photograph: Tatum Reid/Tropic Biosciences

Among the genes flagged in the new study in the journal Trends in Plant Science are those behind the production of a family of substances known as MYBs, which are among the proteins that control whether other genes are switched on or off.

“MYBs are great targets because they are central to several consumer traits or features like colour, flavour [and] texture,” said Andrew Allan, a co-author of the review from the University of Auckland whose own projects include working on red-fleshed apples and changing the colour of kiwi fruits. “Russet skin in apple and pear [is linked to MYBs]. Hairs on peaches but not nectarines – another type of MYB.”

Dr Richard Harrison, head of genetics, genomics and breeding at the horticultural organisation NIAB EMR, who was not involved in the article, said tweaking MYB genes or the way such genes are themselves controlled was a fruitful approach.

“For fruits,” he said, “MYB genes have long been known to be associated with expression of molecules such as anthocyanin, a red-coloured compound that gives strawberries or blood-red oranges their colour. “Increasingly, MYBs are being implicated in the production of other important compounds, hence the interest in this family of genes that are conserved between many plant species.”

Gene-editing of MYB genes and other genes could bring a host of benefits, Harrison said, adding: “There is a large opportunity to improve the nutritional profile of fruits and vegetables in the future using gene-editing technology, as well as other techniques.” Such techniques, he said, introduce the same sort of DNA changes as plant breeders have introduced by artificially selecting traits that cropped up through spontaneous DNA mutation – but much faster.

Hybrid purple raspberries of the Glen Coe variety. Crispr may make such specimens more common. Photograph: PR/Suttons

“Red-fleshed apples developed through conventional breeding have taken decades to even come close to market acceptability,” he said, “due to the multiple rounds of breeding and selection that have had to occur to take the naturally occurring red-fleshed gene variant from a wild species of apple and introduce it into a commercially acceptable variety.

“In our normal breeding work, we often see seedlings produced purely from conventional breeding with a range of colour and flavour profiles that simply never make it to the market, such as peach-flavoured strawberries [and] super-dark purpleish strawberries.”

The review is timely: next week the European Court of Justice will announce if or how plants that have been gene-edited using techniques such as Crispr will be regulated, and whether they will be treated like genetically modified plants. The US has already ruled against serious restrictions, provided the changes could have been produced through traditional plant-breeding techniques.

“We are interested in making produce more healthy, sustainable and convenient so that people will eat more produce,” Dr Haven Baker, Pairwise’s chief business officer, said, noting that gene-editing could be used to increase levels of anthocyanins, improve taste, increase shelf life, improve yields, boost disease resistance or even lengthen the season of availability.

Such approaches, said Baker, could not only boost consumers’ nutrient intake, but could also reduce food waste and produce adaptations needed to weather climate change: “We are trying to solve problems that matter to both consumers and the agricultural systems.”

No, Vertical Farms Won’t Feed the World

While they are well-intentioned, new indoor “farms” won’t help feed the world or reduce the environmental impacts of agriculture. We would be better to focus our efforts elsewhere.

Lettuce grown in my garden. Photograph © 2016 Jonathan Foley

August 1, 2018

While they are well-intentioned, new indoor “farms” won’t help feed the world or reduce the environmental impacts of agriculture. We would be better to focus our efforts elsewhere.

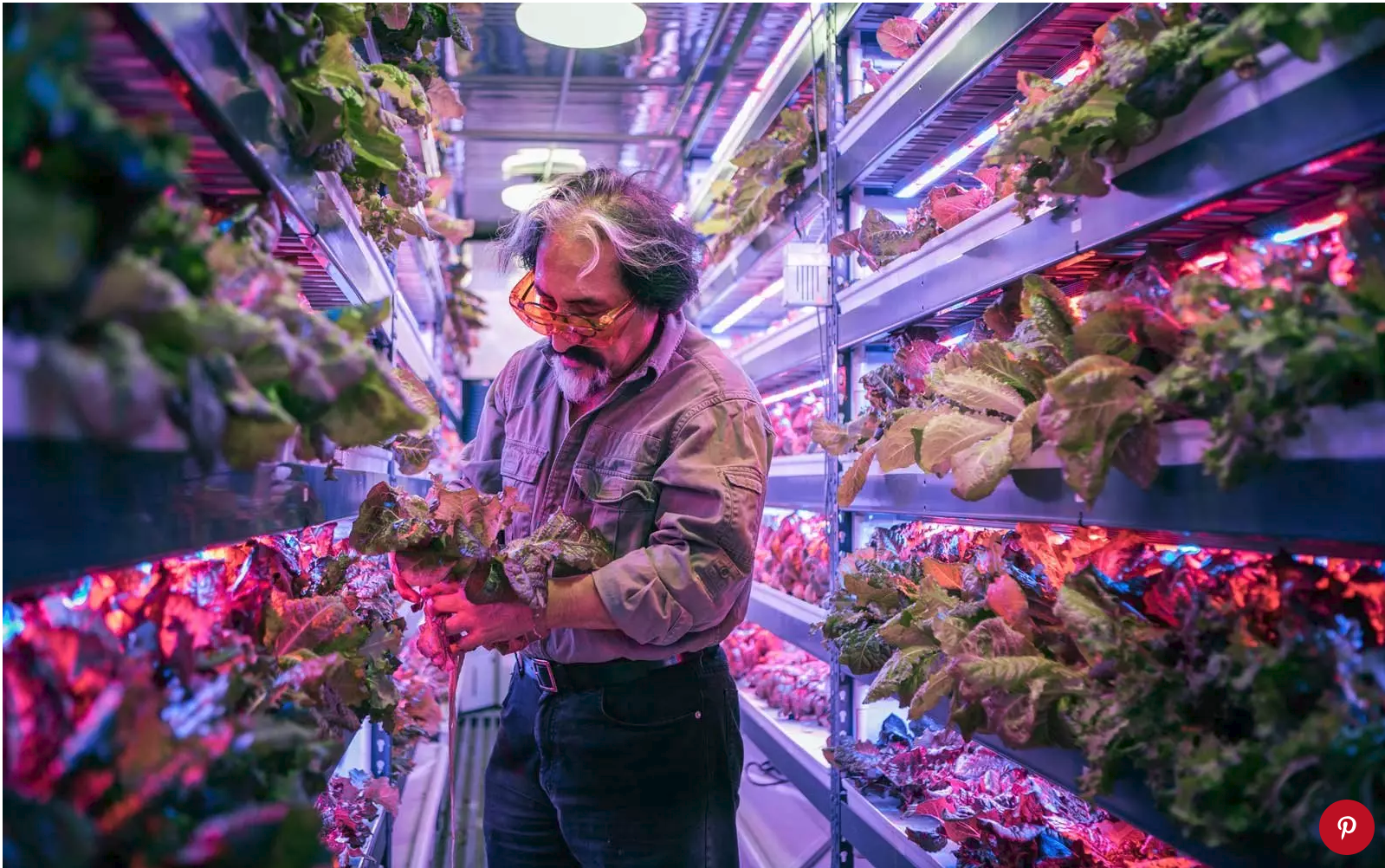

We’re beginning to see a new fad in agriculture — so-called “vertical farms” that grow food indoors with energy-intensive, artificial life support systems.

In the last few years, a number of tech companies have designed “farms” that utilize artificial lights, heaters, water pumps, and computer controls to grow crops inside. These systems glow with a fantastic magenta light — from LEDs that are specially tuned to provide optimal light for photosynthesis — often with stacked trays of plants, one on top of the other. Some of this technology is new, especially the LEDs, although pot growers have used tools like this for years.

Some of the more notable efforts to build indoor “farms” include Freight Farms in Boston. And there is a group at MIT that is trying to create new high-tech platforms for growing food inside, including “food computers”. These folks are very smart and have done a lot to perfect the technology.

At first blush, these “farms” sound great. Why not completely eliminate food miles, and grow food right next to restaurants, cafeterias, or supermarkets? And why not grow crops inside closed systems, where water can be recycled, and pests can (in theory) be managed without chemicals.

It sounds great, doesn’t it? But there are many challenges.

First, Vertical Farms Cost a Fortune

But there are costs to these farms. Huge costs.

First, these systems are really expensive to build. The shipping container systems developed by Freight Farms, for example, cost between $82,000 and $85,000 per container — an astonishing sum for a box that just grows greens and herbs. Just one container costs as much as 10 entire acres of prime American farmland — which is a far better investment, both in terms of food production and future economic value. Just remember: farmland has the benefit of generally appreciating in value over time, whereas a big metal box is likely to only decrease in value.

Second, food produced this way is very expensive. For example, the Wall Street Journal reports that mini-lettuces grown by Green Line Growers costs more than twice as much as organic lettuce available in most stores. And this is typical for other indoor growers around the country: it’s very, very expensive, even compared to organic food. Instead of making food more available, especially to poorer families on limited budgets, these indoor crops are only available to the affluent. It might be fine for gourmet lettuce, or fancy greens for expensive restaurants, but regular folks may find it out of reach.

Finally, indoor farms use a lot of energy and materials to operate. The container farms from Freight Farms, for example, use about 80 kilowatt-hours of electricity a day to power the lights and pumps. That’s nearly 2–3 times as much electricity as a typical (and still very inefficient) American home, or about 8 times the electricity used by an average San Francisco apartment. And on the average American electrical grid, this translates to emitting 44,000 pounds of CO2 per container per year, from electricity alone, not counting any additional heating costs. This is vastly more than the emissions it would take to ship the food from someplace else.

And none of it is necessary.

But, Wait, Can’t Indoor Farms Use Renewable Energy?

Proponents of indoor techno-farms often say that they can offset the enormous sums of electricity they use, by powering them with renewable energy —, especially solar panels — to make the whole thing carbon neutral.

But just stop and think about this for a second.

These indoor “farms” would use solar panels to harvest naturally occurring sunlight, and convert it into electricity so that they can power…artificial sunlight? In other words, they’re trying to use the sun to replace the sun.

But we don’t need to replace the sun. Of all of the things we should worry about in agriculture, the availability of free sunlight is not one of them. Any system that seeks to replace the sun to grow food is probably a bad idea.

Besides, “Food Miles” Aren’t a Big Climate Problem

Sometimes we hear that vertical farms help the environment by reducing “food miles” — the distance food items travel from farm to table — and thereby reduce fuel consumption and greenhouse gas emissions.

This sounds logical, but it turns out to be a red herring.

Strange as it might seem, local food typically uses about the same amount of energy — per pound — to transport as food grown far away. Why? Short answer: volume and method of transport. A larger food operator can ship food more efficiently — even if it travels longer distances — because of the gigantic volumes they work in. Plus, ships, trains, and even large trucks driving on Interstate highways use less fuel, per pound per mile, than small trucks driving around town.

Plus it turns out that “food miles” aren’t a very big source of CO2 emissions anyway, whether they’re local or not. In fact, they pale in comparison to emissions from deforestation, methane from cattle and rice fields, and nitrous oxide from over-fertilized fields. And local food systems — especially organic farms that use fewer fertilizers, and grass-fed beef that sequesters carbon in the soil — can reduce these more critical emissions. At the end of the day, local food systems are generally better for the environment, including greenhouse gas emissions. Just don’t worry about emissions from food miles too much.

And These Vertical “Farms” Can’t Grow Much

A further problem with indoor farms is that a lot of crops could never develop properly in these artificial conditions. While LED lights provide the light needed for photosynthesis to occur, they don’t provide the proper mix of light and heat to trigger plant development stages — like those that tell plants when to put on fruit or seed. Moreover, a lot of crops need a bit of wind to develop tall, strong stalks, needed later when they are carrying heavy loads before harvest. As a result, indoor farms are severely limited and have a hard time growing things besides simple greens.

Indoor farms might be able to provide some garnish and salads to the world but forget about them as a means of growing much other food.

A Better Way?

I’m not the only critic of indoor, high-tech, energy-intensive agriculture. Other authors are starting to point out the problems with these systems too (read very good critiques here, here, here, and here).

While I appreciate the enthusiasm and innovation put into developing indoor farms, I think these efforts are, at the end of the day, counterproductive.

Instead, I think we should use the same investment of dollars, incredible technology, and amazing brains to solve other agricultural problems — like developing new methods for drip irrigation, better grazing systems that lock up soil carbon, and ways of recycling on-farm nutrients. Organic farming and high-precision agriculture are doing promising things, and need more help. We also need innovation and capital to help other parts of the food system, especially in tackling food waste and getting people to shift their diets towards more sustainable directions.

An interconnected network of good farms —real farms that provide nutritious food, with social and environmental benefits to their communities — is the kind of innovation we really need.

Dr. Jonathan Foley (@GlobalEcoGuy) is a global environmental scientist, sustainability advisor, author, and public speaker. These views are his own.

© 2018 by Jonathan Foley. All rights reserved.

NOTE: parts of this piece were adapted from an earlier blog article of mine called “Local Food is Great, But Can It Go Too Far?”

Foreign Beef Can Legally be Labeled “Product of U.S.A.” It’s Killing America’s Grass-Fed Industry.

How rampant mislabeling puts America's grass-based cattle producers out of business.

How rampant mislabeling puts America's grass-based cattle producers out of business.

July 16th, 2018

by Joe Fassler

CULTURE ENVIRONMENT FARM POLICY SYSTEMS

Last month, in a petition formally filed with the United States Department of Agriculture (USDA), two advocacy groups made a stunning claim: Your American grass-fed beef might actually come from overseas, even if it’s labeled “Product of U.S.A.”

Those two groups—the American Grassfed Association (AGA), which offers the country’s leading “grass-fed” certification, and the Organization for Competitive Markets, a watchdog group that fights corporate consolidation in the food industry—point out that a massive regulatory loophole allows companies to falsely, and yet legally, claim their imported beef comes from our pastures.

The trouble began in 2015, when the Obama administration’s USDA rolled back Country of Origin Labeling (COOL) for beef and pork products, allowing meat to be sold without disclosing its home country on the label. But that decision, which angered many American ranchers, has further muddied the waters in a way no one quite anticipated. Under the current rules, beef and pork products that are shipped to the United States and processed further here, can be labeled “product of U.S.A.,” even if the animal was raised a continent away. That means a steer slaughtered in Uruguay and broken down into steaks at a meatpacking plant in Colorado is technically American meat—even if it isn’t.

Photograph by simarik (iStock), graphic by NFE

That’s a huge issue for American grass-fed producers, who are now finding themselves undercut by foreign competition. Allen Williams, a 6th-generation rancher and founding partner of Grass Fed Insights, a leading consulting group on grass-fed beef, says U.S. producers owned more than 60 percent of the domestic grass-fed market in 2014. Then came COOL repeal. By 2017, American ranchers’ share had plunged to just 20 to 25 percent, according to an industry analysis by the Stone Barns Center for Agriculture. Today, Williams, who consulted on the Stone Barns report, says American producers claim only about 15 percent of the grass-fed market—and that share is rapidly shrinking.

Ranchers attribute the decline directly to COOL repeal. The fact that foreign companies can pass their imported beef off as American, they say, has made fair competition impossible.

“The very idea of labeling beef in a grocery store ‘product of U.S.A.,’ when the animal never drew a breath of air on this continent, is just horrible,” says Will Harris, owner of White Oak Pastures, which produces its branded line of grass-fed beef in Bluffton, Georgia. (Harris is also on AGA’s board of directors.) “I don’t begrudge importers or producers from other countries selling to knowing consumers that want to buy that imported product. But I’m appalled at what the deception has done to the economies of our membership. It has moved the needle from grass-fed beef producers being profitable, to being a very break-even—or, if you’re not careful, a losing—proposition.”

But though pastured beef often isn’t as American as it looks, a question remains: How much does it actually matter? I found myself wondering how much we mean to prioritize domestic purchasing when we spend a little more to buy grass-fed, and whether the product’s country of origin makes a meaningful difference. Are grass-fed steaks from Australia all that different from those raised on a ranch outside Austin, Texas? I wanted to know whether we we should stop handwringing about geography—or if misleading labels somehow betray the grass-fed ethos, and amount to a profound abuse of consumer trust.

Grazed and confused

If Williams is right that only 15 percent of the grass-fed beef is raised domestically, you wouldn’t necessarily know it just by strolling through the grocery store. On a recent trip to Trader Joe’s, I inspected a package of “100 percent grass-fed organic ground beef,” looking for clues about its origins. The casual observer could be forgiven for mistaking that product for American meat. The splashy consumer-facing label features a USDA organic seal, a USDA inspection sticker, and, in smaller print, the phrase “processed in USA” alongside Trader Joe’s corporate address in Monrovia, California. Of course, foreign beef can still be certified USDA organic and all imported meat goes through USDA inspection. But this product features not one but four allusions to the U.S. on its label. The average shopper wouldn’t be crazy to assume it’s coming from here.

Flip the package over, though—to the side few people read up close—and the label tells a different story. In small, no-frills font, below the freeze-by date and above the safe handling instructions, are the words “Product of USA, Australia, and Uruguay.” That phrasing would seem to suggest that Trader Joe’s ground beef is a blend of beef from American, Australian, and Uruguayan cows—an arrangement that might surprise some customers, given what the front of the package says. But even thatreasonable assumption may not be accurate. Trader Joe’s may only be buying Australian and Uruguayan meat that’s then ground at a facility in the U.S.—enough to qualify as American in the eyes of regulators. It isn’t really possible to tell.

Joe Fassler

If Trader Joe’s and other grocery brands were really selling meat from cows raised in this country, you’d think they’d make a bigger deal of it.

Trader Joe’s organic grass-fed ribeye steak also prominently features USDA’s organic and inspection seals on the front—as well as the phrase “Product of USA” in small font on the back, by the nutrition facts. But are the company’s grass-fed ribeyes really produced here? Or are they just processed here? It’s impossible to tell from the label alone, and Trader Joe’s had not responded to my requests for clarification by press time.

The Trader Joe’s scenario is a good example of how products can follow the letter of the labeling law and still be misleading. But other brands have done more to take advantage of this legal ambiguity—and some are downright deceptive.

Bubba Burger

Bubba Foods’ marketing would suggest that its beef is born and raised in the U.S. A look at its affidavit to the USDA suggest otherwise

Bubba Foods, a Jacksonville, Florida-based company whose products are sold by major retailers like Walmart, Kroger, and Wegman’s, puts its American-made claims front and center. The label on the company’s grass-fed ground beef displays a prominent “Product of USA” banner, complete with an American flag—and, if that wasn’t enough, the proud phrase “Born & Raised in the USA.” But paperwork filed with USDA, obtained by the American Grassfed Association and shared with me, suggests the product may not be American at all—at least, not in the conventional sense most shoppers would understand.

Any producer who wants to sell a commercial grass-fed beef product has to file an affidavit with USDA’s Food Standards Inspection Service (FSIS), laying out the agricultural practices it will use and submitting an example of their product label. Bubba’s affidavit includes several details that caught my attention, considering the aggressive nationalism of its label. A nutritional analysis describes the product as “import grass-fed” beef. It also includes an import record from Australia, noting that an “Australian National Vendor Declaration” will certify the product’s grass-feeding regime. The final 20 pages of the document lay out the specifics of Australia’s Pasture-Fed Cattle Assurance Standard, a program that isn’t available in other countries.

Bubba Foods initially assured me the company would answer my questions about the discrepancy, but did not provide more information after multiple follow-ups. At this point, the opacity only furthers my suspicion that the company is passing off its Australian grass-fed beef as a “born and raised” U.S. product—with the U.S. government’s blessing. (Bubba’s affidavit also contains a copy of its product label, which regulators presumably viewed in all its chest-thumping patriotism.) No wonder eaters are confused.

By now, it should be obvious that misleading—and, in some cases, overtly deceptive—labels are out there. But we still haven’t established whether any of this is a meaningful deception, materially speaking. Does anyone really care if their grass-fed beef comes from America or Australia—and, if not, should they?

Eating American

In his work as a consultant, Allen Williams and his clients have spent millions of dollars trying to pin down exactly what compels shoppers to buy grass-fed beef. His findings suggest that (relative) locality is a huge selling point: A desire to support America’s rural economies is one major reason people spend more to buy grass-fed. The preference is so clear that Williams believes virtually all of the products with fine-print “Product of USA” claims are really imported. If Trader Joe’s and other grocery brands were really making the effort to buy meat from cows raised in this country, you’d think they’d make a much bigger deal of it.

Charlie Bradbury runs Grass Run Farms, an American-raised, grass-fed beef brand owned by JBS, the world’s largest multinational meatpacker. He tells me that JBS—which has long sold grass-fed products from Australia and elsewhere, and marketed them as such—acquired Grass Run Farms because so many customers asked for specifically domestic grass-fed beef.

“The fact that the cattle are born and processed in the U.S. is an important reason people buy this product,” he says. “These cattle generally do come from smaller, family-farm operations. They [shoppers] believe the animal welfare is improved [in that context] and so, since our job is to sell beef, we’re trying to produce a system that fits in with those concepts.”

Will Harris offers some insight into why demand for American grass-fed is so strong. Over the years, he’s learned that customers buy White Oaks beef for three primary reasons: environmental sustainability, animal welfare, and to support rural economies, in that order. (Health considerations are a factor, too, but not in the top three.)

Each of these main drivers has a strong local emphasis, he tells me. If someone wants to help improve the environment, they’re likely to want to do so in their own backyard first. Those worried about animal welfare are more likely to feel assured by local products, with a farmer they know by name and a ranch they can visit, than by a product from a continent away. Finally, anyone buying grass-fed to support the local farm economy is certainly going to privilege domestic product. In Harris’s view, it couldn’t be any clearer—when buying grass-fed, Americans explicitly prefer that it be American.

But say you’re the kind of ethically minded meat eater who just wants to do what’s best for the planet in general. Does it really matter whether your burger comes from your local farmers’ market versus a ranch in Australia or Uruguay?

That’s harder to say.

Photograph by dustypixel (iStock), graphic by NFE

“If we are comfortable with the assumption that grass-fed beef is indeed more environmentally friendly than CAFO beef—and this depends quite a bit on your method for calculating environmental costs—then the real environmental impacts of grass-fed beef products have much more to do with how they are produced than where they are shipped from,” Caitlin Peterson, a PhD student in ecology at the University of California, Davis, told me by email. That’s because shipping beef across the ocean in a storage container is an incredibly cheap and efficient transportation method that doesn’t require much energy use or generate much pollution, even if it does rack up so-called “food miles.” Agricultural methods, she says, matter far more in general than transportation distances.

The trouble is that it’s very hard to get information about a given grass-fed producer’s practices. No government I could find legally defines a “grass-fed” standard. (The U.S. did, beginning in 2007—but ultimately revoked its standard in 2016, citing USDA’s inability to properly enforce it.) Though a few respected third-party certifications exist—the American Grassfed Association’s “Certified Grassfed” label is considered the gold standard by producers—ranchers can claim their product is grass-fed without independent verification. To use the term on products sold in the U.S., meat companies must only file an affidavit with USDA explaining how their grass-feeding program will operate. They can use an existing certification, or define their own protocols. As a result, practices vary widely, and quality control is difficult.

“Grass-fed is all over the map,” says Rick Machen, a professor and livestock specialist with Texas A&M University. “It could be a 700-pound calf right off the cow up to a 14-year-old cow that’s lived out its productive life. And within those there are all kinds—some are supplemented, some are 100-percent grass-finished. There’s a wide, wide, wide array of pre-harvest production systems, and technically they’re all within the bounds of what can technically qualify as grass-fed.”

Considering that, it’s hard to compare the environmental impact of domestic versus imported grass-fed beef in general. But if sustainability concerns are a wash, the domestic product really does fare better by one all-important metric: economics.

The price of grass

There’s a reason that imported grass-fed beef has come to dominate the American marketplace. It’s not because it’s a better product, necessarily. It’s simply cheaper.

Take Australia, for instance—the country that by far exports the most grass-fed beef to the U.S.—where virtually all beef production is pasture-based. Since cattle can graze year-round on the country’s naturally lush pastures, it makes far less sense to fatten them on grain. That makes the cost of bringing a steer to weight a much cheaper proposition—especially compares to many regions of the U.S., where grassland must be irrigated, or where cattle must be fed dried forage during the winter.

Though severe drought in Australia has complicated this picture in recent years, bringing the price of imported grass-fed beef closer to its domestic competition, the country has built-in advantages that have allowed it to undercut U.S. producers on price.

But Australia has an additional, and perhaps more significant, advantage. Grass finishing has been the standard for so long that it’s big business, and has been for decades. Cargill and JBS, two of the biggest meatpackers in the world, process a combined 49 percent of the country’s grass-fed beef.

A company like Greeley, Colorado-based JBS, which owns farms, slaughterhouses, and transportation infrastructure on multiple continents, and has accounts with major retailers and foodservice providers, benefits from economies of scale unheard of in U.S. grass-fed beef production. In the U.S., where grass-fed claims just 1.5 percent of the overall market, it’s mostly small producers working with small, independent processors and marketing their products themselves. More than half of America’s grass-fed producers sell twenty or fewer cattle a year, according to the Stone Barns report, and most of them are too small to access the country’s hyperproductive slaughterhouses.

This distinction marks perhaps the fundamental difference between U.S. and imported grass-fed beef. In America, grass-based production is an alternative vision supported by individual innovators and rooted in local economies. In Australia, New Zealand, Uruguay, and other countries, it’s an established industry controlled by powerful global players.

“It’s a commodity product,” says Williams, speaking of imported grass-fed beef. “It’s produced off many different ranches, then harvested by the big packers. They’re the same guys that are the big packers over here in the U.S. It’s all aggregated together and shipped over here.”

If Americans are buying grass-fed as a way to support local foodways and bring dollars back to rural communities—and many of them seem to want to—that’s not happening when they’re fooled into buying imported beef.

For U.S. ranchers, switching to grass-fed can completely transform the economics of production. Williams says that the average American cattle rancher, someone who sells live animals to the big meatpackers churning out commodity beef, makes only about 14 cents of the retail dollar. “That way,” he tells me, “you’re working on razor-thin margins and any little economic hit can take you out of the game.”

Photo by gerenme (iStock), graphic by NFE

.But grass-fed producers selling directly via farmers’ markets can keep up to 85 percent of the retail dollar, according to Williams. And ranchers who run branded programs—paying a smaller, custom packer to process their animals, then selling that signature line of beef with the help of various retail partners—can reach thousands of customers while still keeping 25 to 50 percent of the retail dollar.

There are challenges, of course. Greenmarkets are a low-volume business—it’s hard to reach that many customers, even if the margins are significantly higher. And branded programs are a more expensive way to do business, with added costs related to marketing, distribution, and slaughter. Still, the margins improve enough to double or triple the income earned on every animal—giving ranchers a chance to make up for the increased costs of grass-fed production, mitigate their risk, and earn a sustainable living.

But now that the market’s been flooded with cheap imports, America’s grass-based ranchers aren’t thriving the way they’d hoped to. Though retail sales of grass-fed beef have soared—from $17 million in 2012 to more than 16 times that, $272 million, in 2016—American ranchers aren’t the ones reaping the benefit of all that increased demand. Harris and other ranchers attribute this directly to consumer confusion over labels. If we can’t tell the difference between Australian and American grass-fed beef—if both are labeled “Product of USA”—even a locally minded shopper is more likely to go with the cheaper product. The result, for ranchers who have spent heavily to transition or grow their herds, may be economic devastation.

Let’s go back to the petition that the American Grassfed Association filed with USDA for a moment. The organization believes that, if labeling law can be changed, ensuring that only truly American-raised beef is labeled that way, shoppers will start buying domestic grass-fed again, even if it costs more. If the choice between domestic and imported is made more apparent, grass-fed proponents like Carrie Balkcom and Will Harris think American grass-fed beef will have a fightning chance—that our rural communities will finally see the economic benefits of the standard they helped to build.

The fact that USDA is taking public comments on the issue suggests that the agency may be reconsidering things. And that could be a sign that significant change is on the horizon.

“As a U.S. grass-fed beef producer, I believe it is imperative that honest, transparent labeling is required for grass-fed beef sold in America,” writes Kay Allen, a Texas rancher, one of many producers who has commented publicly on the petition. “Not only does honest labeling protect American beef producers economically, it insures that WE, American citizens, control our own food supply.”

For those who want to see rural economies revitalized, the stakes are high. Labeled grass-fed beef is only about a $1 billion market in the U.S., tiny compared to the nation’s $105-billion conventional beef industry. But Williams points out that if the U.S. producers took back only 50 percent of the market—still down from more than 60 percent market share they enjoyed in 2014—it could send hundreds of millions of dollars into local communities each year. That would be a major departure from the current system, where profits from grain-finished domestic and grass-fed imported cattle flow primarily to large corporations.

“Instead of requiring just a handful of mega-feedlots to finish all this beef, we would need tens of thousands, even hundreds of thousands of smaller farmers and ranchers,” Williams says. “So instead of having one mega business, one major corporation, we’d be allowing thousands of small businesses, vibrant small businesses, to thrive. It would be a major boon not just to ranchers, but to local processors, and cold storage, and everyone who has a finger in this pie. Why would we not want to do that?”

The USDA is currently asking itself that same question. The agency will take public comments until August 17.

What's REALLY In Your Movie Theater Popcorn?

So just how bad for you is that tub of popcorn? (Spoiler alert: It is pretty bad.) We took a look at the nutrition information from both Cinemark and AMC, two of the nation’s biggest theater chains, spoke to nutrition experts and did a little of our own ingredient sleuthing. Keep reading to find out exactly what’s what in the buttery stuff.

BY SHANNAN ROUSS AUG. 02, 2018

Movie theaters without popcorn would be like baseball games without hot dogs or Christmas without eggnog. And while most of us probably wouldn’t think of mindlessly munching on the butter-soaked snack at home, we make an exception when we’re at the movies. Because it’s the movies! (Let’s just say that whatever marketing voodoo theaters use to make us crave the exploded kernels definitely works.)

So just how bad for you is that tub of popcorn? (Spoiler alert: It is pretty bad.) We took a look at the nutrition information from both Cinemark and AMC, two of the nation’s biggest theater chains, spoke to nutrition experts and did a little of our own ingredient sleuthing. Keep reading to find out exactly what’s what in the buttery stuff.

The Not-So-Bad News

It's not really plain: Even so-called “plain” popcorn at the movies is a far cry from the low-cal air-popped version you might get elsewhere. For starters, most theaters pop the kernels in either canola oil (at Cinemark locations) or coconut oil (at the majority of AMC and Regal Cinemas). While a three-cup serving of “naked” air-popped popcorn is fat-free and contains about 90 calories, Cinemark’s smallest popcorn option (the junior) has 200 calories and 11 grams of fat, and AMC’s smallest offering (the cameo) weighs in at 300 calories and 13 grams of fat, including nine grams of saturated fat.

We know what you’re thinking (we thought it too): 200 to 300 calories for a single bag doesn’t sound so terrible, right? Right, but that’s not all you get with your “plain” popcorn. Plus, the nutritional data may not be all that accurate (as will soon become apparent).

The Bad News

It**’**s loaded with salt: The secret ingredient that’s responsible for movie popcorn’s rich, buttery aroma and flavor? Flavacol (or its equivalent), a seasoning made mostly of very fine salt along with something cryptically referred to as “artificial butter flavor,” assorted yellow dyes (to give the popcorn its signature bright hue), and highly refined soy oil.

Flavacol adds 190 milligrams of sodium to Cinemark’s junior bag of popcorn — fairly reasonable if you can stick to this smallest of servings. As Maya Feller, RD, of Maya Feller Nutrition, points out, “Foods with 140 milligrams or less are considered low in sodium.” But go up to a true “small” bag from Cinemark and you get 450 milligrams, or 20 percent of the recommended daily value, says Feller, noting that it’s “definitely not low in sodium.” What’s more, “If you eat all your meals out or a lot of prepackaged items, 450 milligrams can definitely push you over the edge,” says Vanessa Rissetto, RD. “Not to mention the recommendation of sodium intake for someone with hypertension is 1,500 milligrams, which then means you’ve had about 30 percent of your daily intake in one little serving of popcorn.”

You won't believe how bad AMC’s smallest serving is in terms of sodium: It packs a whopping 740 milligrams. That’s more than you’d get in a McDonald’s cheeseburger.

Theaters may be underestimating their serving sizes: Although AMC says its small popcorn (popped in coconut oil) contains 300 calories and nine grams of saturated fat, those numbers aren’t necessarily accurate. According to a 2009 study from researchers at the Center for Science in the Public Interest, the AMC “small” they tested weighed about 50 percent more than the theater chain claimed and contained a total of 370 calories and 20 grams of saturated fat, the kind that can raise your bad cholesterol and increase your risk of heart disease. The American Heart Association recommends that no more than 5 to 6 percent of your calories come from saturated fat, which is equivalent to about 13 grams of saturated fat a day for most people — so 20 grams is way too much.

The Even Worse News

The “**buttery flavored” topping is all chemicals:** Here’s where things go from bad to worse. The viscous concoction you can drizzle on your popcorn contains soybean oil, beta carotene (for color), buttery flavoring (i.e., chemicals) and the preservatives tertiary butylhydroquinone and dimethylpolysiloxane (more chemicals).

Tertiary butylhydroquinone (or TBHQ for short) is a fairly common additive that was approved for use in 1972 by the FDA. The FDA says it is safe to consume at the concentrations allowed in food. But really? Although more research is still needed, preliminary studies from Michigan State University have suggested a link between TBHQ and the rise in food allergies. That’s not all. “According to the National Library of Medicine, cases of vision disturbances have been reported when humans consume TBHQ,” says Rissetto, adding that at higher levels the chemical has been shown to cause liver enlargement, convulsions and even paralysis in lab animals.

And what about that other impossible-to-pronounce ingredient in butter-flavored toppings? Dimethylpolysiloxane is a kind of silicon used both in Silly Putty (yum!) and food that acts as an anti-foaming agent and extends the shelf life of the oil. Again, the FDA puts the chemical in its “generally recognized as a safe category,” and we weren’t able to find any incriminating evidence that says otherwise. But still, it’s a chemical. Which, in general, you don’t want to eat too much of if you can help it.

The one silver lining (if we had to find one) is that in the past butter-flavored toppings were made with partially hydrogenated oils. Hello, trans fats! We know that the version that Cinemark uses today, Odell’s SupurKistNT, is trans-fat-free. While AMC didn’t respond to our request for more information about its buttery topping, by June of next year it won’t matter: That’s when the FDA’s ban on trans fat is supposed to take effect. (About time!)

Finally, Some Good News

Real butter is actually real: Repulsed by all the unpronounceable additives in the "buttery flavored topping" but still want that buttery taste? There may be a better way to get it: Many movie theaters (including AMC and Cinemark) offer real butter topping, which is officially called anhydrous butterfat. The term may sound suspicious, but it’s basically like ghee, says Feller. “It’s butter with the water and milk solids removed,” she explains. (The result is a topping that won’t make popcorn soggy like regular melted butter.) If you're going to indulge, the real butter is definitely better than the fake stuff.

You can make special requests: Cinemark says on its nutrition and allergen information page that you can ask the concession stand to make a special batch of Flavacol-free popcorn, which means you’ll get popcorn popped in canola oil, but otherwise truly plain. So with the theater’s “junior” bag, you’ll have a sodium-free snack that contains 200 calories and 11 grams of fat.

The Final Verdict

While Cinemark is the only theater we could find that advertises its custom-pop option (without the buttery salt), other theaters may provide the same if you ask. So if you can stick to the smallest bag of popcorn popped only in either coconut or canola oil, then it’s OK to indulge at the movies. Just remember not to tempt yourself with a larger container, even if you’re splitting it or planning to only have a little. “Sitting in a movie theater and eating is an act of mindless eating,” cautions Feller. “You’re actually there to watch a movie. Eating becomes passive. It’s really hard to say I’m going to eat half the bag and stick to it.”

What Do YOU Think?

Do you order popcorn at the movies? How worried are you about the chemicals contained in both Flavacol (the butter-flavored seasoning) and the butter topping? Would you ask the concession stand to make a special Flavacol-free batch for you? Let us know your thoughts in the comments!

From Farm to Fork: The Regulatory Status of Non-GMO Plant Innovations Under Current EU Law

A new article on the latest plant breeding methods will be published on the next issue of BIO-SCIENCE LAW REVIEW.

The existing EU regulatory framework, when considered holistically, provides efficient guarantees that every stage of the agri-food supply chain, from lab to fork, is subject to constraints and obligations dictated by harmonized legislation, each providing various degrees of scrutiny, risk management and control, sanctions and remedial action.

Comparisons between the existing non-GMO legal framework with the GMO legislation or with any other authorization regime based on a full pre-market risk assessment are, by definition, of little practical relevance, since such regimes aim to address potentially serious risks, which, as the SAM Note clarifies, have not been identified in the case of Non-GMO NBT Products.

In the absence of any such concrete, identifiable risk induced by (the use of NBTs for) Non-GMO NBT Products and in view of their non-distinguishability from CBT products, the protection of human/animal/plant health and the environment should thus be considered to be adequately ensured and Non-GMO NBT Products should not be treated differently from products resulting from CBT.

The opposite conclusion would not only raise serious concerns under the SPS Agreement but would essentially also mean that all non-GMO plant products on the market today must be considered inadequately regulated. Just as Advocate-General Bobek concluded in his Opinion in Case C–528/16,133 with regard to mutagenesis, that ‘one could hardly assume that a reasonable legislator could ever wish to state, en bloc and for the future, that something is safe to such a degree that it does not need regulating at all’, one can neither assume that all NBT-products should en bloc be considered to only yield products suspect of causing unacceptable risks.

Against that backdrop, it is submitted that both the precautionary principle and the specific safeguard clauses in horizontal and sectoral legislation can justify and sufficiently guarantee the adoption of stricter risk management measures if a previously unidentified risk arises.”

More Cyclospora Cases Reported In McDonald’s Salad Outbreak

The Food and Drug Administration reports 436 cases of cyclospora have been confirmed by labs in an outbreak linked to McDonald's salads.

August 9, 2018

The Food and Drug Administration reports 436 cases of cyclospora have been confirmed by labs in an outbreak linked to McDonald's salads. ( File photo )

The Food and Drug Administration continues to investigate infections caused by the parasite Cyclospora thought to have been transferred by McDonald’s salad, and the number of cases is still growing.

The FDA on Aug. 9 released another update on the outbreak. In the week since the last update on Aug. 2, the number of illnesses rose from 395 to 436 in 15 states.

The investigation centers on McDonald’s restaurants and a romaine-carrot blend supplied by a Fresh Express processing plant in Streamwood, Ill.

The FDA, Centers for Disease Control and Prevention, local and state health agencies and Fresh Express are aiding in the investigation.

“The investigation is ongoing and the FDA is currently reviewing distribution and supplier information for romaine and carrots,” according to the FDA update.

The last onset date was July 20, according to the FDA. It can be up to two weeks before someone exhibits symptoms associated with the parasite.

Emirates Flight Catering Seeks To Revolutionize Airplane Food Quality With US$40 Million Vertical Farming Venture

by Mark Lane marklanebusiness@gmail.com

Source: ©The Moodie Davitt Report

1 August 2018

UAE. Emirates Flight Catering (EKFC) and US firm Crop One Holdings have announced a US$40 million joint venture agreement to build the world’s largest vertical farming facility near Al Maktoum International Airport in Dubai.

EKFC said the venture was about securing its own supply chain of high quality and locally-sourced fresh vegetables, as it aims to “deliver a best-in-class product”.

Vertical farming involves growing produce in vertically stacked layers. When complete, the new hi-tech farm will cover 130,000sq ft. but have a production output equivalent to 900 acres of farmland.

Emirates Flight Catering Chief Executive Officer Saeed Mohammed and Crop One Holdings Chief Executive Officer Sonia Lo officially launch the joint venture.

Construction of the facility will begin in November this year and is expected to be completed towards the end of 2019. EKFC said that the first products would be delivered to its customers in December next year.

At full production, the facility will harvest 2,700kg of high-quality, herbicide-free and pesticide-free leafy greens daily, using 99% less water than outdoor fields, the partners said.

EKFC noted that the proximity of the farm to the point of consumption would also substantially reduce carbon emissions associated with transportation. A key advantage in the creation of onboard food is that the fresh products will reach customers within hours of harvest, maintaining high nutritional value.

Crop One says it has been in commercial production longer than any other major vertical farmer in the USA.

Joint venture partner and vertical farm operator Crop One Holdings is the company behind FreshBox Farms. The Massachusetts-based subsidiary has, since 2016, produced nine different leafy green retail products. It serves 38 different supermarkets and home delivery services in the Boston metropolitan area.

Crop One said it produced the highest crop yield per square foot, at 25% of the capital cost, of any vertical farm. This is because of what it describes as its “unique combination of proprietary technology platform and best-in-class plant science”.