Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

How D.C.'s Oldest Hardware Store Ended Up Housing Two Cutting-Edge Urban Farms

You can now buy a bucket of paint and a carton of beet greens at D.C.'s oldest hardware store. W. S. Jenks & Son, which opened in 1866, is home to not one but two urban farms. Urban agriculture is gaining so much traction locally that the government is working to establish a specialized department to oversee key land use programs under the Department of Energy and the Environment

September 4, 2019

You can now buy a bucket of paint and a carton of beet greens at D.C.'s oldest hardware store. W. S. Jenks & Son, which opened in 1866, is home to not one but two urban farms. Urban agriculture is gaining so much traction locally that the government is working to establish a specialized department to oversee key land use programs under the Department of Energy and the Environment.

In the meantime, urban farm operators are getting creative looking for underutilized spaces to grow. For Cultivate The City and Little Wild Things, that means taking up residence inside Jenks at 910 Bladensburg Road NE in Trinidad. The former is on the roof. The latter repurposed a storage space that had previously been used as a parking garage.

Jenk's President Jerry Siegel says leasing space to both outfits is part of a strategy to get new and increased foot traffic into the shop, especially in today's retail climate where physical stores are Amazon's punching bags.

"A store like us, or any retail store, provides the opportunity for someone to come in to pick up merchandise and take it home and be happy with it," Jenks says. "I think there’s still a need for retail stores." It helps that Jenks does a good bit of business with the federal government, according to Siegel. "We’re trying to monetize using a garage now as a farm for Mary," he adds, naming Little Wild Things founder Mary Ackley. "She's been an incredible addition to what we do."

Finding a permanent home to grow her microgreens business has been a near all-consuming pursuit for Ackley over the past three years. Little Wild Things has bounced around growing flavor- and nutrient-packed baby greens and shoots everywhere from The Pub & The People's basement to a pair of vacant wholesaler buildings that hug Union Market. One after the next asked Little Wild Things to move out when it came time to develop the spaces. At one point she thought her greens would land in Ivy City, but Ackley ended up walking away from the deal.

Little Wild Things founder Mary Ackley

"Thank god I found this place," she says while showing City Paper the new Little Wild Things headquarters. She moved in early this summer. "We systematically went through every property available in the entire beltway and there were only five properties that met our requirements."

All they needed was between 3,000 and 5,000 square feet and the ability to heat and cool the space. Throughout this process, Little Wild Things didn't let business slip save for one incident where one of the Union Market-area spaces got too warm, preventing plants from producing. It meant they couldn't fulfill orders at two of their biggest clients: Chaia and Jaleo.

Little Wild Things sells an array of itty bitty greens such as nasturtium, beet, fennel, broccoli, cilantro, endive, mustard greens, amaranth, wheatgrass, and celery to a number of D.C. area restaurants. They include Beefsteak, Big Bear Cafe, Homestead, Espita, ANXO, Iron Gate, The Occidental, Coconut Club, RASA, and Jaco Juice & Taco Bar. A new partnership with Coastal Sunbelt Produce will allow Little Wild Things to expand its reach.

"Smaller restaurants are the bread and butter for us," Ackley says. "We've had some high profile, really cool restaurants but what they do is buy a tiny bit and say they're working with us. There are a lot of other restaurants that put their money where their mouth is, like DC Harvest."

Individuals can also purchase microgreens and edible flowers online for same-day delivery or for pick-up at the farm. They sell cocktail kits, for example, which party-goers can use to decorate their drinks. The flowers are grown in a different location—Little Wild Things outdoor farm at Carmelite Friars Monastery in Edgewood.

Little Wild Things new farm inside W.S. Jenks & Son

Ackley hopes to continue to diversify her business using the new space inside Jenks, which has its own separate entrance at 906 Bladensburg Road NE. Look for everything from happy hours, classes, and movie screenings to a retail shop where you can buy microgreens or build-your-own bouquets.

Cultivate The City founder Niraj Ray was delighted to have another green-thumb business join him at Jenks. In fact, he connected Ackley with the hardware store's owners. "Originally when I started the garden center, my vision was to have multiple urban farms there," he says. That's why he called his farm at Jenks "H Street Farms" instead of "H Street Farm."

Ray founded Cultivate The City in 2015. In addition to operating H Street Farms at Jenks, Ray manages the rooftop farm at Nationals Park, the campus farm at Gallaudet University, garden programming at Idea Public Charter School, and the garden at Miner Elementary School. He involves other schools in urban agriculture through field trips and on-site classes.

The Jenks partnership began when H Street Main Street sought Ray's help beautifying Starburst Plaza that sits where H Street NE curves into Benning Road NE. The director of the neighborhood nonprofit group tipped Ray off that Jenks was looking to make use of its rooftop.

"At first they wanted to do a restaurant, which didn't really make sense to me in terms of economic opportunity," Ray says. He estimated the build out would cost at least a half a million dollars. "On top of that, I didn't think it was as supplemental to their business as what we could offer." There's a Lowe's and Home Depot not too far away and both sell plants. "I made a pitch to them: You're leaving a lot on the table by not selling plants. We could function as your garden center. It was a match made in heaven."

In addition to selling unique plants to Jenks customers, like strawberries with extra long growing seasons, Cultivate The City's H Street Farms brings foot traffic to the hardware store through various events and classes. On Sept. 20, Ray will teach attendees how to care for a bonsai chili pepper tree. "I've been practicing for a year or two," he says. "Imagine having a Scotch bonnet pepper tree that always has a few peppers." His regularly recurring class on making hot sauce is also popular.

Little Wild Things is currently open to the public weekdays from 9 a.m. to 3 p.m. and Cultivate The City's H Street Farms is open Wednesdays and Fridays from 3 to 7 p.m.; Saturdays from 9 a.m. to 5 p.m.; and Sundays from 10:30 a.m. to 4:30 p.m.

ALL PHOTOS LAURA HAYES

Lead Photo: Little Wild Things just joined Cultivate The City inside W.S. Jenks & Son in Trinidad.

Five Bold Questions For Artemis CEO: Allison Kopf

I knew that technology could be a catalyst to move the industry forward. This was the spark that inspired me to venture into entrepreneurship and start Artemis

Warren Bobrow Contributor

Vices I work with cannabis and have done some wild things in life. cocktailwhisperer.com

Allison Kopf, CEO of Artemis | RICKEY PEETE

WB's Note: I grew up on a Biodynamic/Organic farm in northern New Jersey. Part of the difficulty of growing crops outside is the mostly inclement weather. There are just too many variables at work to make farming anything less than controllable. Lack of sunshine, oft inclement weather- hail, snow, rain, insects, all contribute to short growing seasons and lack of a good investment harvest. To the commercial grower, outdoor growing can be rewarding, or it can be a loss of an entire grow, and you should pick which one is more enticing. I would pick the one with the most comfort for the investors. Which means, don't mess it up or they are coming for their investment, as in right now! One of my fascinations in commercial growing is something that I saw in Arizona. It was a vast greenhouse, originally manufactured in Holland for growing tomatoes and tulips. What was being grown in this "Dutch" greenhouse was far from tomatoes and flowers. It was nearly three hundred thousand square feet of ultra-high-end cannabis and with the nearly 350 days per year of natural sunshine, this vast greenhouse earned it's keep in short measure.

Allison Kopf is also intrigued by greenhouses and farming. If you read on, you'll discover her passion for growing facilities and why we should embrace the sun.

Warren Bobrow=WB: Where are you from? What was your path to farming? Schooling? What did you originally want to be? (when you were a kid)?

Allison Kopf=AK: I was born and raised in New York. Not New York City; not upstate New York – but smack dab in the middle of the two. Spending as much time as I did in the black dirt region, I’ve always had a deep respect for our state’s farmers and farm workers, though I had no clue I’d end up working in the industry. As a kid, I was always interested in science and technology and originally wanted to be an engineer in Silicon Valley when I grew up. While getting my degree in physics from Santa Clara University, I started my professional career in the solar industry. I was the Project Manager for the California entry into the Solar Decathlon, which is a design and engineering competition for students at over twenty universities worldwide. We raised over $1.2M and over a period of two years, designed and built a solar-powered, efficient, fully functional home.

I loved seeing the innovation and creativity at the Solar Decathlon and I fell in love with solving problems within complex supply chains. This led me back to New York to join BrightFarms, which is one of the largest venture-backed indoor agriculture companies in the country. I was one of their first employees and helped scale up projects across the country as well as focusing on how we could improve operational performance at each individual site. I became frustrated at an over-reliance in the industry on spreadsheets and pen-and-paper to track critical operational data.

I knew that technology could be a catalyst to move the industry forward. This was the spark that inspired me to venture into entrepreneurship and start Artemis.

(FKA Agrilyst).

WB: Why cannabis? How does cannabis fulfill your passion? What is your passion? Outdoor or indoor grown?

AK: Cannabis is an exciting industry and something we started really scaling into this year, and now accounts for about half of our customer base. There’s so much going on today around regulatory compliance and consumer safety, and it seems every day there’s something in the news about a large public cannabis company going through some kind of compliance or product recall issue. It’s a bit of a roller coaster, but it’s exciting to be in the midst of such a fast-growing sector with lots of opportunity ahead for businesses that approach compliance the right way.

The Artemis platform | COURTESY: ARTEMIS

For us, the cannabis industry fits right into our passion for helping specialty crop growers minimize risk, increase profit margins, and scale their businesses in what’s becoming a highly competitive and consolidated industry, with many companies even starting to go public on the U.S. stock market. Whether cultivated indoor or outdoor, cannabis, like any crop, is subject to risk. Furthermore, as an emerging industry with a controversial product (still illegal federally in the U.S.), cannabis is subject to increased levels of scrutiny. This translates into a maze of regulations which are constantly changing. Our goal is to help growers safeguard their business from these fast-changing regulations and compliance laws. With the recent news of the CannTrust debacle, cannabis growers, now more than ever, need to make regulatory compliance a core component of their company culture. This includes conducting regular internal audits and digitizing their regulatory compliance paperwork.

It also goes beyond just compliance. Cannabis cultivators are scaling across multiple states and countries, opening up locations faster than ever before. This is hard to do without proper systems in place. One of the easiest things a cultivator can do is implement technology to help plan production and workflow. It adds a layer of accountability, even across multiple locations. The companies that will be at the top in a few years will be the companies who invest in technology and systems for growth.

I’m currently obsessed with outdoor operations. We’ve spent a lot of time in the indoor space (it’s how we got our start), but as the hemp space begins to scale in the U.S., it’s brought me to more and more outdoor operations. The opportunity for cannabis and hemp to play a major part in regenerative agriculture, sustainability, and economic re-birth of the agriculture industry is completely fascinating. Indoor will always be my first love and it’s always exciting to see a really clean, well-run greenhouse or indoor operation.

Artemis - Laptop + Phone (1) | PHOTO COURTESY: ARTEMIS

WB: Tell me about your company? What do you do? What is your six month plan? One year?

AK: Our mission is to solve a problem I’ve personally been obsessed with for a while — creating a more efficient, traceable, and compliant agricultural economy. As part of our mission, we developed the industry’s first real Cultivation Management Platform (CMP) to help global enterprise farmers growing fruits, vegetables, cannabis, hemp, flowers, and other specialty crops to manage all of their people, plants, process and compliance with a single solution. Many growers today aren’t protecting themselves from risk without technology implementation across their full operation. Existing technologies available for the industry weren’t designed for growers with business expansion in mind. Enterprise operations deploy expensive, bulky, ERP systems and/or use regulatory software mandated by states. There hasn’t been a good solution for the enterprise operation to manage cultivation designed for them as the operator. This leaves them at a disadvantage in what is already a low-margin, high-risk business.

We developed our platform as the solution to close this gap. Providing growers with a CMP to add to their technology stack (CMP + ERP or Seed-to-Sale) sets them up for true long-term success. Since launching in 2015, we’ve seen strong customer growth with companies worth a collective $5 billion using the platform daily. Over 1 billion pounds have been harvested using our system in just the past year and a half. Our core customers are enterprise specialty crop farmers interested in security, compliance, profitability, and potential to expand their operations. We also have partnered with many others in the agtech ecosystem, enabling users to further reduce risk across all areas of their business. Over the next 6 - 12 months, we have aggressive growth plans. This year, we entered into the fast-growing cannabis and hemp industries, and we plan to expand our work in this sector. We are also working hard to carve out an industry leadership role and platform in regulatory compliance — helping customers stay ahead of the curve of regulatory compliance in food and cannabis to not only improve product outcomes and satisfy regulations, but to protect the integrity of the trust between producer and consumer.

Artemis - Laptop + Phone (1) | PHOTO COURTESY: ARTEMIS

WB: Is there anything that you eat or drink *or smoke* that brings a tear to your eye when you eat, drink, or smoke it? Do you cook? What is your favorite thing to eat? Favorite restaurant? Where? What kind of food?

AK: My grandmother’s chicken and rice. This has become somewhat of a family joke over the years. My grandmother makes the most incredible chicken and rice dish – the secret is in the butter and the old baking pan. All of the grandparents and cousins have tried to duplicate the recipe to no avail. Nothing is as good as the original. At my wedding shower, my grandmother gifted me the recipe and I definitely let a tear out.

I do love to cook. I’m currently into making comfort food recipes with fresh and local ingredients. The other day, I made biscuits and a summer stew that was pretty stellar. I’ve also been known to dip into Bavarian recipes. My family is German and it’s my favorite food region.

WB: If you can be anywhere in the world right now, where would that be? Doing what? With whom, even *Dead or Alive!* Why?

AK: Easy; playing tennis with Serena Williams. Not only has she set the bar for women who excel in their field, she’s the greatest athlete of her time and it would be incredible to play a game or two against her. I love playing tennis and it would be fun to see if I could return her serve. Perhaps a speaker showdown at Forbes Under 30 in Detroit?

Follow me on Twitter or LinkedIn.Check out my website or some of my other work here.

Warren Bobrow, the Cocktail Whisperer, is the multi-published author of six books. Apothecary Cocktails: Restorative Drinks from Yesterday and Today, Whiskey Cocktails:

AgTech Insight, Agritecture Announce Strategic Partnership

AgTech Insight will advise and provide services to Agritecture clients in the large scale outdoor agriculture industry while Agritecture will advise and provide services to AgTech Insight clients in the urban agriculture space

September 6, 2019

The Deal Will Allow Both Companies To Offer

Clients A Broader Collection of Services

AgTech Insight, based in Salinas, California, and Agritecture, based in Brooklyn, New York, have announced the formation of a strategic alliance between the two firms. AgTech Insight will advise and provide services to Agritecture clients in the large scale outdoor agriculture industry while Agritecture will advise and provide services to AgTech Insight clients in the urban agriculture space. The focus of the mutually beneficial effort is aimed at improving both firms capabilities across a broader array of services for clients in the ag sector globally.

"The urban and indoor agriculture space is rapidly growing around the world and collaborating with Agritecture, given their leadership in their industry sector and global vision using innovation and best practices to help a growing population is a natural fit," Aaron Magenheim, founder of AgTech Insight, said, per a press release. “Over the past year, it has been great to work with David Ceaser and the Agritecture team sharing our expertise and working on projects together. There is a unique resource we have been developing together which we will be sharing with the world soon and are excited to be working together to bridge the urban and large scale agriculture sectors.”

"Agritecture is very excited about our collaboration with AgTech Insight," David Ceaser, Agritecture's horticultural specialist said, per the release. “ Urban and peri-urban farming is generally smaller scale agriculture and focuses on smaller more niche consumer markets. But, as far as the farming goes, there is no reason to re-invent the wheel. There is a ton that we can learn from large scale outdoor ag. The vast amount of experience and knowledge that Aaron and his team bring to the table is invaluable for us.”

US (NY): Farm Tours, Panels, Workshops And Networking Events During AgTech Week

The NYC Ag Collective - a consortium of 15+ commercial urban farms, tech companies, and non-profits - announces the 4th annual NYC AgTech Week, the only AgTech conference on the East Coast run by the leaders of the industry themselves

September 21-26, New York City

The NYC Ag Collective - a consortium of 15+ commercial urban farms, tech companies, and non-profits - announces the 4th annual NYC AgTech Week, the only AgTech conference on the East Coast run by the leaders of the industry themselves. This six-day conference features exclusive farm tours, panels, workshops, and networking events all focused on the innovative AgTech sector, promising unprecedented access to industry founders, investors, startups, and thought leaders.

Other events that are being held in conjunction with AgTech Week, such as the “Vineyard in the City Networking Finale”, “Chef x Farmer Mixer + Grazing Table”, as well as the “AgTech x UrbanTech Mixer”, will also provide a chance to network and mingle with these industry leaders.

Publication date: 8/26/2019

What Is The State of Indoor Farming? Your Help Is Needed

The survey is open to all specialty crop growers and operators of enterprise farms, including operators of greenhouses, high tunnel farms, indoor facilities, and field growers, and will close for responses on Oct. 15, 2019

Posted by Brian Sparks

August 24, 2019

Artemis, an enterprise Cultivation Management Platform (CMP), has launched its first Global Ag Report survey, which is designed to capture the latest trends, challenges, and opportunities for growers producing fruits, vegetables, ornamentals, cannabis, hemp, and other specialty crops. The survey will inform the newest iteration of the State of Indoor Farming Report, released in previous years by Artemis under the company’s former name, Agrilyst.

The survey is open to all specialty crop growers and operators of enterprise farms, including operators of greenhouses, high tunnel farms, indoor facilities, and field growers, and will close for responses on Oct. 15, 2019.

The purpose of the new and improved survey is to give specialty crop farmers an industry voice around the most significant issues they are facing today. Artemis plans to use the survey responses to inform its first Global Ag Report. The report will provide an overview of the global specialty crop industry, as well as a deep dive into key topics such as production and operations, technology, and market outlook.

“Today we work with large international specialty crop farms that face a different set of challenges and opportunities than smaller, local operations,” said Allison Kopf, CEO of Artemis. “This report will dig into their pain points and market potential, to produce a comprehensive look into the global specialty crop industry. That is our priority in constructing our new survey for the Artemis Global Ag Report.”

Data from the survey will be supplemented with additional research from Artemis, and growers can use these shared insights as a resource for industry awareness, strategic planning and implementation of best practices in the coming years.

Artemis is a partner to some of the world’s largest farming companies. Since launching in 2015, it has seen strong customer growth with companies worth a collective $5 billion using the platform daily. Artemis has attracted a wide range of users that are foremost interested in the security, compliance, profitability, and potential to expand their operations.

Global Ag Report Survey

Brian Sparks is a senior editor of Greenhouse Grower and editor of Greenhouse Grower Technology.

How To Determine If LED Grow Lights Are A Good Investment

As LED grow lights continue to become more affordable, an increasing number of greenhouse growers and vertical farmers are considering whether the lights would benefit their production systems

Based on the benefits controlled environment growers are experiencing with LED grow lights, a return on investment (ROI) analysis could help you decide how quickly the payback would be for your operation.

As LED grow lights continue to become more affordable, an increasing number of greenhouse growers and vertical farmers are considering whether the lights would benefit their production systems. Add to this the testimonials of growers who have installed LEDs and the positive results they’ve gotten with commercial horticultural crops has caused more growers to look at the efficiencies these lights have to offer.

Comparing investment options

“The information on return on investment (ROI) for LED grow lights would have application to any type of equipment growers would be looking to purchase,” said Nathan Farner, president and CEO at North Ridge Solutions Inc. in Dallas, Texas, who is an adviser to Hort Americas. “Growers would be using a business case modeling approach to determine full project costs of various solutions and to understand what it takes to implement those solutions.

“Comparing the savings or increased revenue related to these investments would enable growers to say which option or scenario makes the most sense for their operations. Growers would compare their options and determine how long it would take to recoup their investment. Whether it is installing LED lights or some other capital infrastructure for a greenhouse, this ROI analysis would apply.”

Farner said one of the advantages of determining the benefits of LED lights with a specific crop is growers should have an opportunity to see whether the lights provide the results desired.

“Growers who are seeking to prove the benefits of LED technology have the ability to do a portion of their operation to become comfortable with it and to validate the results before making a large capital expenditure,” he said. “Growers can conduct a trial in a fairly small area of their greenhouses to prove LEDs deliver the results they desire. After this testing it should be a relatively easy decision for most growers.”

Improved crops

Farner said when doing a business case analysis growers can look at the revenue side and the expense side.

“Looking at the revenue side for LED grow lights, this would include increased yields whether this is reducing the time to crop maturity of a crop like leafy greens or increasing the amount of produce from a long term crop like tomatoes and cucumbers,” he said. “There could also be increases in quality including size and/or number of fruit, taste and color. An example of this is red lettuce grown under LEDs, not only are there improvements in yields, but there is also an enhancement of the red pigment in the leaves. Growers who are able to increase crop yields and quality are able to continue to sell a consistent product at a consistent price year round.”

Nathan Farner at North Ridge Solutions Inc. said looking at the benefits of LED grow lights from the revenue side would include increased yields whether this is reducing the time to crop maturity or increasing the amount of produce. Photos by Jessie Wood, State Fair of Texas

Farner said growers need to be sure they have a market for the increased product they are going to be able to produce by installing LEDs.

“In general that has not been an issue, especially considering the increased interest and demand for locally-grown food products,” he said. “LEDs are going to help improve the quality of the product and most customers are going to welcome that.

“If growers choose to quadruple the size of their greenhouse space carries a lot higher capital expenditure. In that case, the growers better be sure they have the market for the increased amount of product they are going to produce. Installing or replacing grow lights, that is less of a challenge to sell the additional amount of product based on my experience.”

Improved energy efficiency

Looking at the benefits of LEDs on the expense side Farner said this comes primarily from LEDs being more energy efficient than alternative lighting sources.

“On the expense side primarily what growers are looking at with LED lights is reducing their operating costs,” he said. “Comparing the electrical costs of other grow lights that aren’t as efficient, there should be a significant drop in electrical expenses by installing LEDs.

“When talking about the lighting model from an electrical perspective, it is more than just buying and installing the fixtures. Depending on the fixtures that are being installed, they may exceed the current power infrastructure for the electrical supply to the greenhouses. If this is the case, more electricity would be needed and would require an investment to increase the electrical infrastructure as well. Once growers understand their lighting plan and the electrical requirements for their facilities, they can determine their annual operating expenses.”

Identifying the best ROI

Farner said growers would need to work with commercial horticulture lighting suppliers like Hort Americas to develop a light plan for their operations. This plan would be based on a number of factors including the crops that will be grown, the light spectrum required for the plants, the amount of production space that will be lit, and the expected number of hours the lights would be operating.

Comparing the electrical costs of less efficient grow lights to LEDs, there should be a significant drop in electrical expenses by installing LEDs.

“Once growers know the number of fixtures it becomes fairly straight math to figure the cost of the fixtures along with the installation costs to determine the capital investment required up front,” he said. “Other components that would have to be considered include maintenance requirements and parts replacement.”

Farner said regardless of the type of equipment purchased, growers should be able to earn back their investment in three to five years.

“The shorter that timeframe the decision becomes much easier,” he said. “Just like with other businesses, growers making capital investments should be looking at the ones that offer the best payback. Growers should always be looking for new equipment, systems or efficiencies that increase yield, drive revenue faster or lower costs so that margins are higher. Growers working to find different ways to build efficiencies and reduce costs for their overall operation should be looking for those that have the fastest payback. Based on my experiences of working with growers, LED lighting is one of those investments where they can get those types of returns more quickly.”

For more: Nathan Farner, North Ridge Solutions Inc., (214) 507-8594; nfarner@northridgesolutions.com.

This article is property of Hort Americas and was written by David Kuack, a freelance technical writer in Fort Worth, TX.

Video: Learn How To Use The Bluelab Pulse Meter To Measure Moisture on A 10 x 20 Tray of Microgreens.

Pulse connects directly to your smartphone via the Pulse app for automated data collection, measurement comparison, storage and exporting

Quickly and consistently measure moisture, nutrient (measured in conductivity) and temperature directly in the root zone without the need for pour-throughs, slurries or extractions.

Pulse connects directly to your smartphone via the Pulse app for automated data collection, measurement comparison, storage and exporting

THE NICK GREENS GROW TEAM CAN HELP YOU

ANSWER THESE TOUGH QUESTIONS:

Do you have an efficient and dependable grow room and system?

Are your crops food safe?

Do you have a sustainable farm and a proven business model?

Can you determine crop yield, cost $/lb, and labor costs on a daily basis?

Is your crop mix optimized for production and profitability?

Have You Seen 'Hydroponically Grown' On Your Produce? Here's What It Means

Have you been perusing the produce area at your store and noticed fruits or vegetables that say “hydroponically grown?” They just kind of popped up one day, and we noticed there wasn’t much explanation

By Dawn Jorgenson - Graham Media Group

August 21, 2019

Image by engin akyurt from Pixabay.

Have you been perusing the produce area at your store and noticed fruits or vegetables that say “hydroponically grown?” They just kind of popped up one day, and we noticed there wasn’t much explanation.

If you’re anything like us, you may have bypassed it just because you’re unsure about what a hydroponically grown product is.

As it turns out, unless you’re attempting to try this growing process yourself (spoiler alert: it can be tricky), the advantages seem to outweigh the disadvantages.

How it works

The fruits or vegetables are grown in a liquid solution that contains minerals they need to thrive. There is no soil used, and instead, the root system is supported by a medium such as perlite, rockwool, clay pellets, peat moss or vermiculite, according to Full Bloom Hydroponics. Doing so allows the plant roots to have direct contact with the nutrient solution, as well as access to oxygen.

The process allows the plant to not work as hard to obtain the nutrients, therefore allowing it to mature 25% faster and produce up to 30% more than the same plant growing in soil.

Growing plants hydroponically also uses less water than soil-based produce because the system is enclosed, preventing much evaporation.

Are hydroponically grown produce good for you?

Because hydroponic fruits and vegetables are not exposed to outdoor elements, they do not need the same level of pesticides to protect the plants from insects or pathogens, according to LiveStrong.com. This often allows organic farming methods.

This is good news, but there does seem to be a possible drawback to hydronic produce. Because of the high humidity of the greenhouses, the produce can be more susceptible to salmonella contamination. However, washing and cooking vegetables thoroughly should remove and help destroy any possible salmonella.

LiveStrong made a special note to remind consumers that even though hydroponic farming appeals to some because of environmental concerns, any diet high in vegetables can improve health, regardless of whether it was grown conventionally or hydroponically.

Have you tried hydroponically grown produce? What did you think about it? Let us know in the comment section below.

CombaGroup Awarded Solar Impulse Efficient Solutions Label August 2019

To achieve this recognition, CombaGroup underwent a rigorous assessment process performed by external independent experts, based on a verified methodology and against several criteria that included technological feasibility, environmental and socio-economic benefits, and economic profitability

CombaGroup is proud to receive the Solar Impulse Efficient Solutions label awarded by Dr. Bertrand Piccard’s Solar Impulse Foundation.

Following the success of the famous solar powered flight around the world, the Solar Impulse Foundation decided to award the "Solar Impulse Efficient Solutions" label to 1000 products or services that meet high standards of both sustainability and profitability. A portfolio of these solutions, that includes CombaGroup, will be brought to decision-makers to encourage them to adopt more ambitious environmental targets and energy policies.

Swiss-based CombaGroup is honoured to have received this label in appreciation for its achievements in efficiency, sustainability, and profitability. For CombaGroup, the label serves as a new and credible symbol that is applied to products, processes and services in order to bridge the gap between ecology and economy while proving that protection of the environment is profitable.

To achieve this recognition, CombaGroup underwent a rigorous assessment process performed by external independent experts, based on a verified methodology and against several criteria that included technological feasibility, environmental and socio-economic benefits, and economic profitability.

CombaGroup contributed to 4 of the sustainable development goals (SDG):

SDG 6: Clean Water and Sanitation

SDG 9: Industry Innovation and Infrastructure

SDG 11 – Sustainable Cities and Communities

SDG 12: Responsible Production and Consumption

“Imagine the impact that this will have on the world! 1000 clean and efficient solutions with a label proving their profitability. They have the potential to create jobs and boost clean economic growth, while also reducing CO2 emissions and preserving natural resources. This is much more than ecological, it is logical!” says Bertrand Piccard, Initiator and Chairman of the Solar Impulse Foundation.

Serge Gander, CEO of CombaGroup said: “We are honoured to have been distinguished with the Solar Impulse Efficient Solutions label because the vision that is behind Bertrand Piccard’s drive to efficiently, sustainably, and profitably impact the planet resonates fittingly with CombaGroup’s mission to innovate for an efficient, sustainable, and profitable agriculture—that is clean, green, locally-grown, and pesticide-free all year round.”

NOTES TO EDITORS

About CombaGroup

CombaGroup is a Swiss agro-technology company that provides farmers and industrialists with innovative mobile aeroponic farming solutions for growing fresh, environmentally-friendly, nutrient- rich vegetables. CombaGroup’s patented technology significantly reduces water consumption and contamination risks while offering maximum productivity per square meter and minimising environmental impact. Mechanised irrigation and spacing systems produce clean, quality, pesticide-free salads, cabbages, and aromatic plants all year round, thus providing consumers with healthy, responsible products.

For more information

contact@combagroup.com

+41 21 545 99 25

Media information online

Media information and images can be downloaded directly from combagroup.com

Journalists can subscribe to our media mailings to receive information on CombaGroup’s aeroponic solutions and technology.

For the latest updates on CombaGroup, visit combagroup.com or follow on sur Instagram, Twitter, Pinterest, and LinkedIn

About Solar Impulse Foundation Efficient Solutions

https://solarimpulse.com/efficient-solutions/mobile-aeroponics-farming

Building A 2.76M Square Foot Sustainable Greenhouse In Job Starved Appalachia

The UN's Intergovernmental Panel on Climate Change just released a report highlighting the alarming effect climate change and the rise in global temperatures are having on fertile soil—and on the world's ability to produce enough food to feed the planet's growing population

Anne Field Contributor Entrepreneur

AppHarvest facility rendering | APPHARVEST

The UN's Intergovernmental Panel on Climate Change just released a report highlighting the alarming effect climate change and the rise in global temperatures are having on fertile soil—and on the world's ability to produce enough food to feed the planet's growing population. There’s also an increasing depletion of the global water supply.

Jonathan Webb, founder of two-year-old startup AppHarvest, thinks his company can help address those urgent crises. Specifically, he plans to produce more food with less water using massive controlled-environment, sustainable greenhouses. In the process, Webb, a native of Kentucky who also worked in renewable energy, also hopes to help revive the struggling Appalachian economy.

“There are technical solutions to many of these problems,” says Webb. “But much of it is a matter of execution at scale and at a rapid pace.”

His plan: build a 2.76 million-square-foot controlled-environment agricultural facility on 60-acres in Morehead, Kentucky, using hydroponic growing techniques, which rely on a nutrient solution, instead of the usual soil. As a result, according to Webb, it will be able to grow pesticide-free tomatoes and cucumbers year-round using 90% less water than traditional farming—and do so in the middle of coal country. Water will come from rainwater kept in a retention pool and there will be circular irrigation systems. The whole project takes its inspiration from the Netherlands, which is a top exporter of tomatoes, potatoes and onions, among other food, thanks to its pioneering work in climate-controlled agriculture.

The facility is also in a strategically-situated location that’s within a day’s drive of 70% of the U.S. population, according to the company. That should slash the amount of gas used in transportation compared to imports trucked across the country to the East Coast, while supplying markets with fresher produce. The company is working with distribution partner Mastronardi Produce.

In job-starved Appalachia, where one in four residents live in poverty, according to the U.S. Census Bureau, the facility also could provide a boost to the economy. While AppHarvest is buying components from the Netherlands, Webb estimates that the project will create 285 full-time positions, plus 100 construction jobs. The company will also work with local universities to add job training classes.

Webb recently closed an $82 million all-cash deal with Equilibrium Capital to build its greenhouse. Plus, it raised more money in a Series A round led by Value Act Spring Fund and joined by existing investor Revolution’s Rise of the Rest Seed Fund.

The mega-greenhouse is projected to be up and running by mid-2020. As for building similar facilities in other parts of the country, Webb says he wants to see that happen, but by different parties. “We’re in Appalachia,” he says. “But I hope other people will be building throughout the country.”

I'm an award-winning journalist with a particular interest in for-profit social enterprise, as well as entrepreneurship and small business in general. I've covered those areas for many many places, including The New York Times, Bloomberg Businessweek, Crain's New York Business, Inc. and Business Insider. As an entrepreneurial journalist--ie, a freelancer--I work from my home office in Pelham, NY.

Artemis, Publisher of State of Indoor Farming Report, Launches First Annual Global Ag Report Survey

Today we work with large international specialty crop farms that face a different set of challenges and opportunities than smaller, local operations. This report will dig into their pain points and market potential, to produce a comprehensive look into the global specialty crop industry

Data and insights on emerging trends, challenges, and opportunities for enterprise specialty crop farmers to be included in new generation of State of Indoor Farming Report, now Artemis Global Ag Report

Today we work with large international specialty crop farms that face a different set of challenges and opportunities than smaller, local operations. This report will dig into their pain points and market potential, to produce a comprehensive look into the global specialty crop industry.

NEW YORK (PRWEB) AUGUST 21, 2019

Artemis, the leading enterprise Cultivation Management Platform (CMP), today announced the launch of its first Global Ag Report survey to capture the latest trends, biggest challenges, and opportunities for global enterprise farmers growing fruits, vegetables, cannabis, hemp, and other specialty crops. The survey will inform the newest iteration of the State of Indoor Farming Report, released in previous years by Artemis under the company’s former name—Agrilyst.

The survey is open to all speciality crop growers and operators of enterprise farms, including operators of greenhouses, high tunnel farms, indoor facilities, and field growers, and will close for responses on October 15, 2019.

The purpose of the new and improved survey is to give enterprise specialty crop farmers an industry voice around the most significant issues they are facing today. Artemis plans to use the survey responses to inform its first Global Ag Report. The report will provide an overview of the global specialty crop industry, as well as a deep dive into key topics such as production & operations, technology, and market outlook.

“Today we work with large international specialty crop farms that face a different set of challenges and opportunities than smaller, local operations,” said Allison Kopf, CEO of Artemis. “This report will dig into their pain points and market potential, to produce a comprehensive look into the global specialty crop industry. That is our priority in constructing our new survey for the Artemis Global Ag Report.”

Data from the survey will be supplemented with additional research from Artemis, and growers can use these shared insights as a resource for industry awareness, strategic planning and implementation of best practices in coming years.

Artemis is a trusted partner to some of the world’s largest farming companies. Since launching in 2015, it has seen strong customer growth with companies worth a collective $5 billion using the platform daily. Artemis has attracted a wide range of users that are foremost interested in the security, compliance, profitability, and potential to expand their operations. The company has also partnered with others in the agtech ecosystem, enabling users to further reduce risk across all areas of their business.

About Artemis

Founded in 2015, Artemis provides a world-class Cultivation Management Platform that enables owners and managers of enterprise horticulture facilities to drive efficiency, profits, and growth while ensuring security and regulatory compliance. With Artemis, users can manage workflow and daily tasks, register crop batches, trace food safety issues, manage workers, and leverage data insights to increase workforce efficiency and crop productivity.

The platform integrates easily with other software for climate control, shipping/logistics, accounting, ERP/MRP, CRM, and Point of Sale Commerce.

The company is headquartered in Brooklyn, NY. For more information visit Artemis

'Groundbreaking' New Venture To Create 'World's Most Advanced Indoor Farming Project'

Mastronardi Produce and visionary John Paul DeJoria say they will develop 'the world's large and most advanced indoor farming project’. North American greenhouse grower Mastronardi said they've selected the Middle East as the first market for the new venture

August 19 , 2019

Mastronardi Produce and visionary John Paul DeJoria say they will develop 'the world's large and most advanced indoor farming project'.

North American greenhouse grower Mastronardi said they've selected the Middle East as the first market for the new venture.

The newly formed company, Green International Ventures LLC (GIVE), will use its proprietary Advanced High-Density Farming System.

This will be the first project for the "groundbreaking" venture, Mastronardi said.

The company said the project will reduce the Middle East’s dependence on imported food, create a sustainable source of local employment, and significantly increase the region’s non-petroleum-based exports.

Green International Ventures poised for international expansion

Paul Mastronardi, president, and CEO said the company is eager to increase access to local and sustainably-grown produce.

“Our first location in the Middle East will allow us to reach over half the world’s population in less than 8 hours, and this is just the start," he said.

"[We will] look for more global locations as we continue to scale to meet the growing need for food security, safety, and sustainability.”

GIVE will also support the integration of modern AgTech initiatives into the local farming community, the company said. In addition, it will expand knowledge of sustainable agricultural techniques by establishing a Research and Development facility in the region.

“It has long been my passion to help feed the world’s population,” says John Paul DeJoria. “The introduction of this revolutionary model in the Middle East is the first step of many towards increasing global access to sustainably grown fruits and vegetables.”

Furthermore, all GIVE projects use innovative Advanced High-Density Farming Systems that incorporate a multitude of cutting-edge growing systems. These include water-saving irrigation and energy-efficient lighting. It also takes advantage of advanced automation, AI processes for predictive analysis, and real-time crop and soil monitoring.

GIVE will market all produce it produces with the innovation systems under the SUNSET brand.

Mastronardi, DeJoria Launch GIVE Partnership In Middle East

Mastronardi Produce Ltd.®, North America's leading grower and distributor of greenhouse produce, and visionary John Paul DeJoria have selected the Middle East as the first market in which to develop the world's largest and most technologically advanced indoor farming project.

NEWS PROVIDED BY

Aug 19, 2019

KINGSVILLE, ON, Aug. 19, 2019 /PRNewswire/ - Mastronardi Produce Ltd.®, North America's leading grower and distributor of greenhouse produce, and visionary John Paul DeJoria have selected the Middle East as the first market in which to develop the world's largest and most technologically advanced indoor farming project.

Green International Ventures LLC (GIVE)'s Middle East location will be the world's largest and most technologically advanced indoor farming project. (CNW Group/Mastronardi Produce Ltd.)

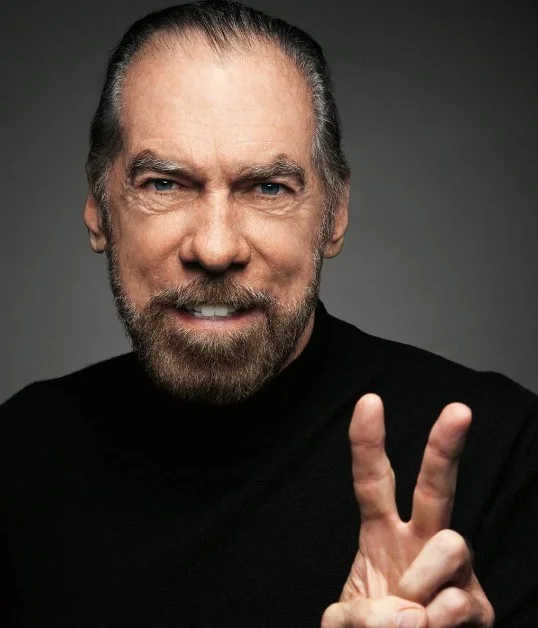

John Paul DeJoria (CNW Group/Mastronardi Produce Ltd.)

.Paul Mastronardi (CNW Group/Mastronardi Produce Ltd.)

The newly formed company, Green International Ventures LLC (GIVE), will make locally grown fresh produce more widely available around the globe via its proprietary Advanced High-Density Farming System. This will be the first project for the groundbreaking GIVE venture, and it will reduce the Middle East's dependence on imported food, create a sustainable source of local employment, and significantly increase the region's non-petroleum-based exports.

"As pioneers in the greenhouse industry, we are passionate about increasing access to local, sustainably grown fruits and vegetables," says Paul Mastronardi, President and CEO, and the fourth-generation family member to lead Mastronardi Produce. "Our first location in the Middle East will allow us to reach over half the world's population in less than 8 hours, and this is just the start. Look for more global locations as we continue to scale to meet the growing need for food security, safety, and sustainability."

GIVE will also support the integration of modern AgTech initiatives into the local farming community and expand knowledge of sustainable agricultural techniques by establishing a permanent Research and Development facility in the region.

"It has long been my passion to help feed the world's population," says John Paul DeJoria. "The introduction of this revolutionary model in the Middle East is the first step of many towards increasing global access to sustainably grown fruits and vegetables."

All GIVE projects use innovative Advanced High-Density Farming Systems that incorporate a multitude of cutting-edge growing systems, such as water-saving irrigation and energy-efficient lighting, and they take advantage of advanced automation and robotic devices, AI processes for predictive analysis, and real-time crop and soil monitoring.

Produce grown in these innovative AgTech systems will be marketed under the SUNSET® brand. Known for award-winning flavor, innovation, and packaging, SUNSET's many exclusive labels include Campari®, the world's first branded tomato, and the uniquely colorful Aloha™ pepper.

SUNSET of Holland® will be the first distributor for the GIVE partnership.

About Paul Mastronardi and Mastronardi Produce Limited

Paul Mastronardi is the President and CEO of Mastronardi Produce, which recently received the prestigious honor of being named one of "Canada's Best Managed Companies" for the 10th consecutive year. In 2016, Paul was named Produce Person of the Year at the United Fresh Convention & Exposition in Chicago, USA, and in 2013, he was named Ernst & Young's "Entrepreneur of the Year" for Ontario.

Mastronardi Produce, the leading greenhouse company in North America, grows and sells flavorful, world-class tomatoes, peppers, cucumbers, and berries under the Sunset® brand. As pioneers in revolutionary greenhouse technology, they focus on sustainable non-GMO growing practices, recognizing that what is good for the environment, is good for business.

About John Paul DeJoria

John Paul DeJoria is a serial entrepreneur, philanthropist, business leader, and mentor with a true rags-to-riches story. Once homeless, he overcame adversity, and went on to build two billion-dollar brands—leading professional hair care manufacturer, John Paul Mitchell Systems, and Patrón Spirits—and several global enterprises. He started his first company, John Paul Mitchell Systems, with partner Paul Mitchell and a borrowed $700. He remains true to his motto, "success unshared is failure," and dedicates himself to numerous charitable causes through his philanthropy hub, JP's Peace, Love & Happiness Foundation, and he has committed to donate more than half of his wealth to philanthropy through his signing of Bill Gates and Warren Buffet's "The Giving Pledge."

SOURCE Mastronardi Produce Ltd.

Related Links

BrightFarms Names New CEO To Lead Expansion

BrightFarms has hired Steve Platt has as its new CEO, according to a company press release. Company founder Paul Lightfoot will stay on as the packaged salad brand's president. Both men will sit on the company's board of directors

(Credit: BrightFarms )

AUTHOR: Jennifer Sweeney

Aug. 15, 2019

Dive Brief:

BrightFarms has hired Steve Platt has as its new CEO, according to a company press release. Company founder Paul Lightfoot will stay on as the packaged salad brand's president. Both men will sit on the company's board of directors.

Platt has spent his career working with CPG companies, most recently as CEO of yogurt brand Icelandic Provisions. Before that, he led Danone brands including Dannon, Oikos and YoCrunch.

Platt said in a statement that this is an exciting time to join the company as continues to expand nationally, and Lightfoot acknowledged Platt's "know-how" as a leader of CPG brands and his ability to take BrightFarms to the next level.

Dive Insight:

BrightFarms, which currently operates greenhouses in Illinois, Ohio, Pennsylvania and Virginia, recently announced plans to open three additional farms in Massachusetts, New York and North Carolina next year. The additional greenhouses are expected to break ground at the end of this year, with production kicking off in early 2020. The expansion shows that the company is ready for aggressive, national growth, and along with that comes the need for a new CEO with expertise to help the company scale.

During his career with national brands, Platt has had particular success with helping brands grow quickly. According to BrightFarms' press release, Platt was at Icelandic Provisions he grew the company to more than 6,500 retail stores and turned it into "the fastest-growing brand in dairy yogurt."

Platt's hire follows two other notable additions this year, both of which position BrightFarms for ongoing growth. In February, Steve Campione joined the company as Chief Financial Officer. Campione brought a background in finance and investment banking and spent a decade raising capital for companies looking to expand. BrightFarms added Brian Jenny as vice president of sales in May, filling a key role to lead business development.

The company is expanding its retail partnerships in areas where its greenhouses operate. As of January, BrightFarms' produce is available at Jungle Jim’s International Marketplace in Ohio, select Food Lion stores in Virginia, Dierbergs in St. Louis and more than 140 Tops Friendly Markets in New York, Pennsylvania and Vermont. BrightFarms also works with Misfits Market, a delivery service that ships imperfect produce to subscribers in Pennsylvania, New Jersey and Delaware.

Demand for products from companies like BrightFarms continues to grow as Americans prioritize locally grown food. Indoor farming startup Square Roots has partnered with food distributor Gordon Food Service to provide produce to Gordon customers, and vertical farming company AeroFarms recently raised $100 million in funding for expansion.

Recommended Reading:

GROCERY DIVE BrightFarms plans three new greenhouses

GROCERY DIVE BrightFarms expands its retail footprint

HAREDI HYDROPONICS: Technology And Sustainability Meet At The Diaspora Yeshiva

“Probably many of these guys have never had kale before,” comments Robin Katz, founder and CEO of Start-Up Roots, the nonprofit that runs hydroponic gardens here and at two haredi (ultra-Orthodox) schools in Jerusalem

JACOB SCHONZEIT checks the roots of greens growing in the hothouse. (Photos: Jordana Benami)

• JORDANA BENAMI

AUGUST 16, 2019

In the courtyard of a 2,000-year-old stone building on Mount Zion, a sign taped to a tiny black door announces the unlikely scene found within: The Diaspora Yeshiva Hydroponic Garden.

Inside, two agronomists in white shirts and black kippot tend tiers of vibrant kale, basil and romaine lettuce. The strings of their tzitzit gently sway as they climb up and down, adjusting nutrient and pH levels, preparing new seedlings and checking lights and filters.

The hyper-local and hyper-fresh greens, grown in a soil-less medium bathed in nutrient-enriched water, will be harvested and carried across the courtyard to the yeshiva’s kitchen to find their way into a variety of dishes.

“Probably many of these guys have never had kale before,” comments Robin Katz, founder and CEO of Start-Up Roots, the nonprofit that runs hydroponic gardens here and at two haredi (ultra-Orthodox) schools in Jerusalem. “I’ve had some kids look at let- tuce and say, ‘Are you sure this is kosher? I’ve never seen it in my house.’”

Katz, a Chicago émigré, is a lawyer and teacher by profession. Since 2015, her organization has been installing hydroponic systems in schools and providing a multidisciplinary curriculum that teaches how to care for the produce, how to incorporate it into nutri- tious meals and how to monetize the bounty. A photo-journalism element allows the students to create visual documentation of the growth process.

The Diaspora Yeshiva setup was donated by Irving Backman of Massachusetts, an international benefac tor of sustainability and advanced technology initiatives through his DATT (Developers of Advanced Technology Today) group. Backman’s grandson, Rabbi Yaakov Kent, is the son-in-law of the Rosh Yeshiva of the Diaspora Yeshiva and the study partner of Katz’s son, Rabbi Zechariah Kaplan, at the nearby Yeshivas Bircas HaTorah.

“Irving Backman & Associates sent over the equipment for a hydroponic garden at the Diaspora Yeshiva, and Mr. Backman’s assistant, Ameth Alzate, asked me to help shepherd it through customs,” says Katz, who had worked with him previously.

With Backman’s blessing, she took the project under the wing of Start-Up Roots, and the garden was inaugurated on her birthday, June 12.

The site is professionally managed by Ari Waldman, chief operating officer of Start-Up Roots, with daily assistance from Jacob Schonzeit, another study partner of Katz’s son at Bircas HaTorah. “Jacob had a background in permaculture, so we trained him in hydroponics,” says Katz.

Diaspora Yeshiva students, who range in age from 17 to 70-plus, may choose to spend an hour or two every day helping to tend the system.

Daniel Levin, 36, found out about the garden when he saw Katz carrying supplies in the courtyard and offered to help. Now he volunteers regularly.

“When Robin showed me what was happening here, I thought it was cool because in South Africa I lived on a farm where we tried growing different plants and trees. It also combines other experiences I’ve had working with electricity and water pumps and salts and nutrients. We’re looking at what works well and could be most viable to grow efficiently and that would most benefit the yeshiva menu,” says Levin.

SEEDLINGS ARE started in a growing medium called rock wool, and incubated before being planted in the trays.

RABBI YOSEF GOLDSTEIN: Spending time in the hydroponic garden ‘helps our students get close to God.’

KATZ SEES all the Start-Up Roots projects as a strategy toward ensuring a healthier future.

“Chemical pesticides are killing us,” she says. “Israel has the highest chemical pesticide usage in the OECD.

We also have a high poverty rate and a high malnutrition rate, and we’re right behind America with a rising obesity rate. I really believe that schools can be a great agent for change.”

Katz discovered hydroponics several years ago and realized it could solve multiple problems at once: The veggies provide vitamins, minerals and fiber often missing in impoverished families’ diets; the plants don’t leave carbon footprints since they are grown on premises and aren’t trucked in; and the students work- ing in the enterprise gain valuable skills they could use to earn a living.

Moreover, during the shmita (agricultural sabbatical) year, when most haredi Israelis buy only imported pro- duce, the greens raised in the school gardens can be cultivated, harvested and consumed without worry because they don’t grow in the ground. The absence of soil and the indoor environment adds another benefit year-round in keeping the plants largely insect-free.

START-UP ROOTS CEO Robin Katz with the greens growing in the hydroponic garden at the Diaspora Yeshiva.

“You don’t need chemical pesticides. The idea is to control the environment so that insects aren’t such a problem,” says Katz. Before entering the growing area, all visitors cover their shoes with paper booties so as not to track in bugs or other contaminants.

She also explains that in a water-stressed region, growing in water actually makes good ecological sense.

“Hydroponics saves 90% of the water of regular agriculture because the water goes directly to the roots and not into the ground,” explains Katz.

Speaking of roots, the word in the name of the organization has more than one layer of meaning. “Many children think that lettuce comes from the grocery store. They have no concept of the chain behind it. So we try to connect kids with the source of their food,” says Katz.

Beyond that are the roots of Torah teachings involving agriculture. Religious schoolchildren learn the laws of tithing, for example, but rarely or never have the opportunity to pick fresh produce and perform the ceremony. It’s all been done at a distant packing house.

And on a more spiritual level, Katz adds, “By watching how the tiny seeds develop, kids learn that the universe is more complicated and bigger and more awesome than they ordinarily take time to stop and think about. They learn that if they don’t put in the effort nothing will grow, but there are also aspects that are beyond their control.”

Rabbi Yosef Goldstein, spiritual adviser at the Diaspora Yeshiva and son of its founder, says spending time in the hydroponic garden “helps our students get close to God.

It’s a way to clean their minds and to be surrounded by nature. Even learning next to the plants for an hour in the morning helps them grow spiritually. I love to come in here and see what’s growing and breathe in all the oxygen. And afterward, we get to eat this healthy nutritious food.”

GOLDSTEIN, WHO is also a practitioner of Chinese medicine, hopes the garden will raise herbs in the future. In only a few months, the site has produced vegetables including cucumbers, radishes, green beans and chard.

“We have 200 students from all over the world from many different backgrounds, and I believe this project can also be a way to build a future source of parnassa [income] especially in the shmita year,” adds Goldstein. “It will be nice for religious people to go into agriculture.”

Levin says that volunteering in the garden “gives me a new dimension of looking at what I am learning in the Torah.”

The connection between faith and farming is entrenched in Judaic sources. The 13th century Tosafist Talmudic commentators expressed it like this: “The farmer who sows seeds places his faith in the life-giver of all the worlds, for he trusts that God will provide all that is needed for his crops to grow.”

The Torah also admonishes against waste, Levin points out. “When you know where food comes from and how much goes into growing something that takes five minutes to eat, you are motivated not to waste anything.”

Katz extracts additional lessons from the hydroponic growing experience.

“In an indoor controlled environment, we’re putting nutrients directly into the water exactly what the plant needs – and we measure it every day along with the pH of the water because that affects how the plants absorb the nutrients,” she says.

“We use that as a metaphor for absorbing information in the learning environment. We encourage kids to think how they can optimize their own ‘pH level.’ They see that if you take care of something it thrives, and they can apply the same principle to themselves.”

Aside from the project at the Diaspora Yeshiva, Start-Up Roots has established hydroponic gardens at two haredi girls’ schools in Jerusalem. The schools’ science teachers present the science part of the curriculum, while a Start-Up Roots dietitian presents hands- on sessions to enable students to discover the impact of the food choices they can make.

“The students enjoy the nutritious food that they are growing, which enables them to incorporate the greens into their own diets in tasty ways,” says Katz.

Shiran Iluz, vice chairman of the IDC Entrepreneurship Club, came to one of these schools to help the students develop a viable business plan around the veggies.

“One girl thought of selling a green drink. Initially, the others thought it sounded awful but when they tried making it with our nutritionist, they discovered that they loved it. Then they named it and learned how to pitch it and sell it to their classmates. They had to learn how to network with kids outside their social circles, and this project totally changed the social dynamics of the school.”

In the fall, Start-Up Roots will implement a hydroponic garden at a pluralistic school in the Sharon region.

“Food is a great unifier and our environment is a great unifier,” says Katz. “I’m very happy that every segment of Israeli society is embracing our initiative and our curriculum.”

SINGAPORE: Largest FairPrice Store Opens In VivoCity

The new store includes a small indoor hydroponic farm - where vegetables are grown and harvested - by local urban farming firm ComCrop. Said ComCrop chairman Allan Lim: "When FairPrice approached us and asked if they could have an indoor farm, we thought it was a great idea because we want to educate Singaporeans about hydroponics."

Above: Besides an ice cream truck and a play castle for children, the FairPrice Xtra outlet in VivoCity has an in-house vegetable farm. A special corner has also been set aside for local enterprises to promote their goods.ST PHOTO: MARK CHEONG

August 5, 2019

90,000 sq ft Hypermarket - The Size of Two Football Fields

Carries Over 35,000 Products

FairPrice's newest store is also its largest, with features such as an in-house vegetable farm, an ice cream truck, a play castle for children and spaces to repair baggage as well as bicycles.

The 90,000 sq ft FairPrice Xtra hypermarket and Unity Pharmacy officially opened its doors yesterday. The size of two football fields, it spans two floors of VivoCity mall.

Singapore's largest retailer said the store was designed to better meet customers' changing lifestyles and needs, and provide a unique brick-and-mortar shopping experience amid stiff competition from online grocers.

Above: There is also a section selling and repairing luggage. ST PHOTO: MARK CHEONG

Shoppers at the VivoCity outlet can have their food prepared for them - from cut vegetables to marinated meat and grilled seafood - for them to take home and cook without fuss. There are also dining areas for those who want to eat at the store while grocery shopping.

In addition, shoppers can buy loose quantities of grain, nuts, spices and pasta - instead of those prepacked in larger amounts.

NTUC FairPrice deputy CEO and head of channels Elaine Heng said a customer-centric approach was taken in developing the store: "We first look at our customers, what are their needs, their wants and how they are changing over time.

"Sustainability is a big agenda for us. All these initiatives are part of a wider whole-of-FairPrice push to minimise food waste and be more sustainable in our practices."

The hypermarket's shelves carry more than 35,000 products from around the world, including over 350 local brands. A special corner has also been set aside for local enterprises to promote their goods.

Minister for Trade and Industry Chan Chun Sing, who opened the store, welcomed the innovations and partnership with local firms.

"This is one of the best locations besides Changi Airport for us to promote our local brands and give them a chance to succeed," he said.

Above: Shoppers can buy loose quantities of grain and nuts, instead of those prepacked in larger amounts. They can also make their own nut butter. ST PHOTO: MARK CHEONG

VivoCity is close to Sentosa, as well as the Singapore Cruise Centre at HarbourFront, and the store has a special tourist section selling local delights, souvenirs and luggage.

Mr Chan added that the extensive array of products from around the world available on FairPrice supermarket aisles across the island is part of Singapore's plan to ensure a resilient food supply chain. "This will ensure that if anything happens in any part of the world, our supplies will not be disrupted."

He noted that FairPrice's range of products has also changed to keep pace with Singaporeans' needs and aspirations, enabling the social enterprise started by the labour movement in 1973 to maintain its position as a leading retailer.

The new store includes a small indoor hydroponic farm - where vegetables are grown and harvested - by local urban farming firm ComCrop. Said ComCrop chairman Allan Lim: "When FairPrice approached us and asked if they could have an indoor farm, we thought it was a great idea because we want to educate Singaporeans about hydroponics."

From next month, shoppers can use FairPrice's new "scan and go" mobile app to pay for items through their smartphones. It will also launch a pilot later this year where customers can buy products that are not on its shelves and have them delivered to their home.

Said Ms Heng: "In a fast-evolving retail landscape, FairPrice will continue to strengthen our core while leveraging on our capabilities to adapt and transform in serving our customers' needs."

Hexagro Urban Farming Biomimicry Insight

Following the biomimicry guiding principles, our Living Farming Tree is the first modular indoor garden that is completely developed for providing everyone their own customized solution for growing what they want, how much they want

When we first started to develop our products we asked ourselves how could we design a system that was not just another farming machine. We didn't want an ugly but functional PVC hydroponic system. One of those that are very complex to install, require above-average DIY skills but produce large quantities of produce. However, we didn't want one of those very beautiful small and unproductive gadgets that we now see in many homes either.

We did want to develop a system that could have the best of both products and then go even beyond.

Nature came to help and we started learning more and more about a new design approach called biomimicry. Through the study of natural patterns and existing well performing structures created by different billions of living creatures on Earth, we were able to get the right inspiration for the development of a product that was as compact as possible, had the right technical requirement for growing healthy and high-quality herbs and, at the same time, was modular and scalable.

B

eing able to leverage this knowledge of space optimization and adaptability, we then adopted different cutting-edge technologies for manufacturing and IoT to create a system that was not only able to adapt to any indoor environment, in terms of space and products farmed. But that could also start sensing what's around it and react and adjust cultivation cycles depending on the different environmental conditions where it was installed.

Following the biomimicry guiding principles, our Living Farming Tree is the first modular indoor garden that is completely developed for providing everyone their own customized solution for growing what they want, how much they want. Thanks to the different modules indeed, you can upgrade and downgrade your production based on your own taste and will. Different modules will be also available depending on the type of crop you want to produce. What basil needs for growing efficiently, is very different from what arugula does, and our agronomists know it. This is why for each type of crop, you will be able to set up different lighting conditions, irrigation cycles, and nutrient contents. And no worries! Everything will be fully automated and easy to monitor through our App and guiding tools!

If you want to know even more about the Living Farming Tree, you can also visit our FAQ page where we keep posting detailed techs&specs about our products.

Hexagro Team

One more time!

If you share our vision and you want to help us spread the voice around even further, here are some quick links to tell your friends online what we are doing.

They might like it as well!

And remember! Thousands of single voices are way more powerful than just a big one!

Tell a Friend!

Scottish Innovation Provides Vision of Future Farming

The young researchers were exposed to innovation from research facilities and growers using a range of crop systems

BY FRED SEARLE

31st July 2019, London

AHDB PhD students visit range of fresh produce firms in Scotland to inspire research projects

The students visited Angus Soft Fruits' East Seaton Farm in Arbroath

Students from AHDB’s £1.4 million PhD programme witnessed how the farming sector is tackling challenges such as labour and pest management on a recent visit to Scotland.

The young researchers were exposed to innovation from research facilities and growers using a range of crop systems.

There were six stops on the trip, including Scotland’s first vertical indoor farm at the James Hutton Institute; major vegetable producer Kettle Produce; one of Scotland’s leading soft fruit growers, East Seaton Farm; and Britain’s largest potato breeder, Cygnet PB.

PhD student Aaron Hoyle said: “The visit was like stepping into the future. The science in Scotland has massive economic potential for British farming and agriculture, with the added benefits of energy, water, and nutrient use efficiency; it’s going to be a very exciting time for the industry.

“The trip has motivated me to continue pursuing my passion for the industry and contribute to a revolution in crop science.”

AHDB senior crop scientist Joe Martin, who manages the studentship programme, added: “Industry depends on innovation by the best and brightest minds advancing crop science and its applications

“This annual event, taking place in different regions of the UK each year, allows students to see the impact scientific innovation has on advancing the industry, and inspire and motivate them to continue their valued research”

To continue to develop expertise, AHDB has committed £750,000 funding for academic institutions to support up to 10 new PhD studentships. Starting in 2020 these studentships will deliver new experts and science with practical benefits across agriculture and horticulture.

Click here for more information on AHDB’s PhD studentships.

Seedo Issues Letter to Shareholders

Together, we are delivering the future of automated plant growing technologies, from seed to harvest, for both consumer and commercial use

TEL AVIV, Israel, July 29, 2019 /PRNewswire/ -- Seedo Corp. - "Seedo" (OTCQB: SEDO) - an agritech company providing the world's first fully automated and controlled indoor growing technologies for the "at-home" and commercial agriculture markets, today issued a letter to shareholders.

Dear Fellow Shareholders,

Zohar Levy, CEO & Chairman Seedo Corp.

Together, we are delivering the future of automated plant growing technologies, from seed to harvest, for both consumer and commercial use. By integrating artificial intelligence (AI), big data, robotics, and remote grow technologies, we are delivering on our vision and mission to improve agriculture for a growing world population. We thank our shareholders for being our partners in this mission.

Consumer side of the business:

We are continuing to deliver the Seedo fully automated home grow device to customers in North America and Europe. We are satisfied to share that consumer response has been overwhelmingly positive, with customers sharing their satisfaction on social media platforms, further driving consumer enthusiasm and demand. Seedo has also recently garnered highly favorable coverage in key media outlets including Forbes, Vice, Maxim, Herb, Green Entrepreneur, Business Insider, Bloomberg, and The Guardian.

In addition to selling the Seedo direct-to-consumer through our website, we are currently ramping up our marketing and distribution efforts in North America and Europe in order to further increase device sales. Specialty retailers are very interested in selling the Seedo both through their physical and online stores that serve the medical cannabis grow market. Additionally, we are progressing with a number of strategic big-box retailers in North America for more meaningful sales exposure.

We are currently evaluating the option to offer a leasing model for our future customers with a third-party who will provide a credit line. We believe that providing customers the choice to own or lease the product will significantly increase future sales. In order to meet higher sales volume, we have begun to ramp up monthly manufacturing of the device.

Commercial side of the business:

We have begun to manufacture our B2B Seedo Farm containers. We have developed two lines of containers, one specialized for medical cannabis and a new line uniquely designed for vegetables and herbs.