Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Spreading Hydroponic Farming Technologies Across India

AmHydro And Farms 2050

On April 9th, Farms 2050 of Bangalore and AmHydro of Arcata, CA celebrated the grand opening of what is the largest commercial hydroponic farm in India to date.

A rich agricultural heritage that has been challenged by a harsh climate, water scarcity and a rapidly growing population to feed has created an urgent need for newer, more sustainable farming methods in the region. In response to this need, Farms 2050 and AmHydro partnered to develop effective controlled environment agricultural (CEA) facility that provides local growers with the ability to produce large volumes of nutritious, high quality crops, all while using 95% less water than conventional farming techniques.

Construction nearly complete on state of the art greenhouse and packing house facilities

The first (of many) new hydroponic farms in Bangalore include a 45,000+ square foot climate controlled greenhouse, highly productive AmHydro hydroponic growing systems, and a 5,000 square foot packing house with processing, cooling, and shipping facilities. Each technology was carefully chosen to provide the highest level of performance while also remaining economically sustainable and providing growers with a fast return on investment. The initial farm features systems to produce both leaf crops (culinary herbs, lettuce, and greens), as well as vine crops (peppers, tomatoes, and cucumbers).

High performance AmHydro NFT leaf crop system, ready to plant

Prior to the grand opening event, AmHydro CEO Jenny Harris and VP Joe Swartz traveled from California, USA to Bangalore to fine tune and test the greenhouse and hydroponic growing system. When this was complete, they trained the local farming team in all aspects of high level hydroponic crop production; from proper seed selection, germination, crop production techniques to harvest, processing, storage and food safety. Professional film crews were on hand to assist in the production of instructional videos, providing present and future farmers with growing guidance and information.

Instructional videos of microgreens seeding techniques being filmed

In a lavish public ceremony, Farms 2050 and AmHydro then signed a mutual MoU with the support of Indian government officials to develop additional sustainable, high producing hydroponic farms across the region. Sharing the stage with the Minister of Water Resources, Minister of Revenue, and the Minister of Agriculture, Farms 2050 CEO Basan Patil and AmHydro CEO Jenny Harris signed a historic MoU to develop more hydroponic farms and controlled environment agricultural technologies in various locations within India. The primary goal of this venture is to dramatically improve the economic empowerment of local farmers as well as providing high quality vegetables, greens, and fruits to their communities.

Left: Indian Government Officials along with Farms 2050 and AmHydro Right: AmHydro CEO Jenny Harris

The signing event receiving national press attention

On the final day of the visit, local religious leaders stopped by to bless the new operation with good luck and success. Planting is now underway and plans for the next farm are already in development.

For more information:

AmHydro

amhydro.com

Future Farms: Agritech Innovations To Feed A Changing Planet

Hydroponic and vertical farming systems have long been touted as a solution to the problem of land use by agriculture, since much of the arable land is already taken and 31% of total global rice, wheat, and maize production in eastern Asia and northwest Europe has already plateaued.

April 3rd, 2019 by The Beam

The future of agriculture will be directly impacted by two of humanity’s biggest menaces on the horizon: population growth and climate change. With more mouths to feed and less planet to feed them on, and increasingly alarming predictions of environmental shifts, innovators working in crop agriculture have to figure out how to grow more food, faster, with fewer resources, by developing new technologies to scale up the planet’s food production mechanisms sustainably.

With 815 million people on the planet suffering from hunger and 1 in 3 malnourished already, the Food and Agriculture Organization of the United Nations has set sustainable development goals to eliminate world hunger by 2030. Adding at least 2 billion more people to feed by 2050, the FAO has estimated food production will have to increase by 70%.

To achieve these goals, agritech must overcome food production plateaus in areas that are being farmed to their maximum capacity, and ensure that these areas will continue to yield more food year over year without endangering future generations’ access to non-renewable resources. Balancing the need for technological innovation to increase food production at all costs to stop hunger in the next 12 years, while managing the conservation of the natural resources essential to modern agriculture is no small task: sustainable agriculture is already at odds with the status quo. New technologies must address the ways industrial agriculture currently uses land, water, fertilizers, pesticides, and energy resources.

On top of this challenge, the future is not yet evenly distributed. As high-tech innovations sweep Europe and North America, projects in China, India, and Africa are supporting the 500 million family farms that feed 80% of the planet. If all 570 million farms on the planet are able to operate at the efficiency levels demonstrated by these technological trends, agriculture in 2050 will look very different from today.

Growing trend: precision farming

Precision farming combines information science with agricultural engineering, harvesting massive amounts of data from the farming process. Utilizing technological advances like advanced sensors, machine learning, and artificial intelligence for data processing, precision farming helps monitor big picture environmental factors like weather patterns, water distribution, and soil chemistry, as well as tiny measurements like nutrient deficiencies in individual plants. Called the next “digital revolution” for agriculture, precision farming has already been shown to increase crop yields while reducing fertilizer and pesticide use, which decreases the pollution of groundwater and depletion of non-renewable resources like phosphorus.

GPS may not seem like a radical new technology, but its integration into John Deere tractors in 2001 allowed data to be collected on their location with precision down to a few centimeters. This innovation alone reduced fuel costs for tractors by as much as 40% in some cases by keeping them from covering redundant areas or missing a spot.

Using precision farming tech like driverless tractors tilling only specific land areas and quadcopters collecting data on soil chemistry, water content, nutrients, and growth, Dutch farmers, the world’s top exporters of potatoes and onions, and the second largest exporter of vegetables in overall value, are able to more than double the amount of potato yield per acre compared to the global average and reduce dependence on water by 90%.

For this trend to sweep the globe and be available to the 144 million farmers in Asia, basic digital literacy is the first step. While many of these populations now have access to smartphones, very few are using them for farming. Once these farmers are connected to digital infrastructures and can use these technologies to enable data-driven decision making, they too will be able to join the digital green revolution.

Precision farming agritech startups to watch:

Taranis, an aerial imaging company that provides farms in Argentina, Brazil, Russia, Ukraine and the United States with data to identify potential crop issues.

Tule Technologies, which focuses on irrigation and water use data.

Pynco, an agricultural data analytics platform available for over 160 countries that sends alerts directly to the farmers’ smartphones.

Hacking biology to feed the planet

Biotechnology that modifies the genetic code of crops to make them more nutritious, grow more quickly, and resist diseases and pests are the backbone of modern multinational industrial agriculture. Many anti-GMO lobbyists and farmers believe that tampering with the genetic code of food products is too risky to try at scale, but to grow food under the conditions that global warming will bring, scientists are hastening work on mutations that will help make crops more resistant to drought, heat, cold, and salt.

CRISPR, the gene-editing bacteria that has been making headlines for its potential use in the human genome, is one of the biotechnologies that scientists are using to make crops grow more plentifully by allowing more efficient photosynthesis, as in the C4 Rice Project, or to encourage nitrogen fixing in crops that don’t naturally pull nitrogen from the air, which would mean less fertilizer used, and less fertilizer runoff polluting groundwater.

Agritech is also turning to nature to find solutions to problems that are currently being solved synthetically with fertilizers and pesticides. As one example, Seattle’s Adaptive Symbiotic Technologies has created non-toxic and non-pathogenic microbes that grow alongside plants and help them be more nutrient efficient, tolerate environmental stress, and yield more produce. In high stress growing seasons field tested across the globe, these microbes have increased crop yields by 10–50%. Koppert Biological Systems, founded in the Netherlands, also uses solutions found in nature by providing the natural predators and micro-organisms that can eliminate pests and diseases. Farmers using Koppert’s bees instead of artificial pollination have reported a 20–30% increase in yields and fruit weight, another reason that saving the world’s bee populations is essential to sustainable agriculture.

Biotechnologies have reached the developing world in the form of innovations like Golden Rice, a genetically modified strain of rice that contains vitamin A. According to a paper by Dr. R. B. Singh, the Assistant Director-General and Regional Representative for the UN’s Food and Agriculture Organization in the Asia-Pacific region, 180 million children in developing countries suffer from deficiency in vitamin A, resulting in 2 million deaths annually. With the FAO behind the development and distribution of Golden Rice and the Bill and Melinda Gates Foundation supporting similar biotechnology projects like breeding bananas that provide higher levels of iron in sub-Saharan Africa, genetically modified crops will be a major technological trend in ending world hunger and providing for the population of 2050.

Three biotech startups to watch:

Trace Genomics, called the “23andMe for farms,” which does rapid microbiome testing for pathogens.

Symbiota, an open-source content management system for biodiversity data.

Clear Labs, a genetic sequencing startup built to look out for food-borne illnesses and pathogens on the molecular level.

Farms in the city

The CEO of Iron Ox, a hydroponic farm that is managed by precision farming techniques and automation, argues that “If farms are to survive, we need to think about them as tech companies.” What makes Iron Ox unique from other hydroponic operations is the amount of automation it uses, having developed a 1,000-lb robot arm that is finely tuned to harvest the 26,000 leafy green plants and herbs in its California facility. The robot, nicknamed Angus, also has an array of Lidar sensors that allow it to identify diseases, pests, and abnormalities plant by plant, and picks them up by grasping specially designed pots that don’t damage the veg. Through all of these innovations, Iron Ox has managed to boast production of 30% more produce than traditional farms.

Hydroponic and vertical farming systems have long been touted as a solution to the problem of land use by agriculture, since much of the arable land is already taken and 31% of total global rice, wheat, and maize production in eastern Asia and northwest Europe has already plateaued. While these extant farms are nudged by other technologies to increase yield and use less resources, indoor farms in urban areas are expanding the potential area that can be used to grow crops.

Since hydroponic systems are soil-less, isolated from environmental stress, pests, and diseases, and commonly use drip irrigation techniques, they avoid a lot of the problems faced by outdoor farms in conserving resources, but their many obstacle is energy. Running LED lights for indoor farms 24 hours per day is not sustainable, even for Iron Ox: it plans to expand into traditional greenhouses supplemented by LEDs. Some indoor and vertical farmers are already looking to solve the energy and light problem: Growing Underground, a UK operation set up in World War II bomb shelters, uses LED lights that only emit at spectrum ranges optimal for photosynthesis, and there are several companies including Valoya, Heliospectra, and even Philips, that are specifically developing longer-lasting and more energy-efficient LEDs for indoor agriculture. Another solution, pioneered by the Sky Greens vertical farming system in Singapore, uses a hydraulic system that consumes the equivalent of one lightbulb’s energy to rotate troughs of produce up and down 9-meter tall towers to take turns basking in sunlight.

Today, 54% of the world’s population lives in urban areas, and this number is predicted to rise to 66% by 2050. With the potential effects that global warming will have on the efforts of traditional agriculture, it’s a safe bet for vertical farms to develop in urban areas alongside advances in agritech for outdoor farms. Vertical farms can integrate many of technological innovations developed for traditional farms to produce as much food as possible, while isolating crops from pests and diseases, conserving non-renewable resources by closely controlling inputs and outputs, and minimizing transportation costs to put food on the table for booming urban populations.

Urban farming startups could be coming to a city near you:

Freight Farms, creators of the Leafy Green Machine™, a complete hydroponic system built into a 40-ft. shipping container.

AeroFarms, which has converted a 69,000-foot former steel mill into a facility to breed 1.5 million pounds of produce annually.

Edenworks, which has developed an aquaponic ecosystem for New York City’s rooftops.

If the predictions of experts on the climate and population for the next 10–25 years are correct, technological innovators in industrial agriculture have their work cut out for them. These future trends of farms moving into cities, biotechnology making food more nutritious and faster-growing, and precision farming incorporating big data with agricultural science will help tackle one of humanity’s greatest challenges yet, eliminating hunger while conserving the natural resources of the planet for future generations.

Key stats:

815 million: the number of people on the planet who suffer from hunger, 1 in 3 from malnourishment

70%: the amount global food production must increase to meet population growth demands by 2050

2/3: the fraction of the world population estimated to live in water-stressed countries by 2025

By Jonny Tiernan

This series of articles has been prepared with the support of our partner Viessmann, which has celebrated 100 years of its company in 2017 and is actively involved in positively shaping the next 100 years.

Starbuck's Is Anchoring New Food And Tech Fund Valor Siren Ventures With $100M Investment

March 22, 2019

Starbucks announced it is making a $100 million investment in Valor Siren Ventures Fund (VSV), a newly launched venture fund that will back the next generation of food and retail technology startups.

In the coming months, VSV said that it is aiming to raise another $300 million from other outside investors.

“We believe that innovative ideas are fuel for the future, and we continue to build on this heritage inside our company across beverage, experiential retail, and our digital flywheel,” said Kevin Johnson, president and CEO, Starbucks.

Managed by Chicago-based Valor Equity Partners, a leading growth private equity investment firm that is a backer of Tesla and a long-time investor in food tech, this new fund will identify and invest in innovative companies that are developing new technologies, products, and solutions for the food and retail sectors.

Founded in 1995 by managing partner and CIO Antonio J. Gracias, Valor Equity is a previous investor in SpaceX, Tesla, Eatsa, Fooda, and Wow Bao, among others. And in July of last year, raised $1.05 billion for its Fund IV, bringing the total funds raised by the company, at the time, to more than $2 billion.

The fund also will act as an incubator for startups with which Starbucks can partner, and gives the company first-hand access to innovations that it can leverage to advance its own technology and retail platforms.

“At the same time, and with an eye toward accelerating our innovation agenda, we are inspired by, and want to support the creative, entrepreneurial businesses of tomorrow with whom we may explore commercial relationships down the road,” said Johnson. “This new partnership with Valor presents exciting opportunities, not only for these startups, but also for Starbucks, as we build an enduring company for decades to come.”

I Think We’ll Need a Bigger Wagon…

In recent years there has been a flurry of accelerators and venture capital arms launched by large CPG companies. This reflects the continued truth that there is a shift occurring within the food sector that is creating a scenario in which Big Food needs the rapid-response innovation generated by startups as much as startups need the capital available from Big Food.

The move to launch venture capital arms and accelerator programs or incubators has become a widely used method by some of the world’s largest and most conventional companies to achieve diversification, and to gain a foothold and to establish relevance in a swiftly changing consumer market. CPG companies also use these programs as a means to stay a step ahead of their competition while realizing the growth potential in disruptive food innovation.

Others that have come before include:

General Mills, which launched 301 Inc., in October 2015 – a venture capital arm that has gone on to outrank the likes of Time Warner and Merck for investment activity.

Campbell’s Soup, which launched its $125 million venture capital fund, Acre Venture Partners, in February 2016.

Anheuser-Busch, which partnered with Techstars to launch an accelerator in April 2016.

Danone, whose venture capital fund Danone Manifesto Ventures made its first investment in June 2016 in France’s Michel et Augustin, a producer of premium biscuits, dairy products, fresh desserts, and beverages.

Tyson, which launched its $150 million venture fund, Tyson New Ventures, in December 2016.

Kellogg’s, which launched its venture capital unit, eighteen94, in January 2017, making its first investment in Kui Kuli, a manufacturer and distributor of moringa-based bars, powders, and energy shots.

Barilla, which launched Blu1877, a hybrid venture capital fund and innovation hub, in November 2017.

Pepsi, whose PepsiCo HIVE made its first investment in Health Warrior, a producer of plant-based and superfood snacks and protein powders in October 2018.

And Mars, which announced the launch of Seeds of Change™, an early stage, food-focused accelerator, in March of this year.

At this point, an initial investment for the Valor Siren Ventures Fund has not been disclosed, however a company statement noted that Starbucks is “embracing new ideas and innovations that are relevant to Starbucks customers, inspiring to its partners, and meaningful to its business.”

Valor Equity CIO Antonio J. Gracias said, “as experienced investors in food and retail technology, we are thrilled to partner with Starbucks, one of the most iconic and forward-thinking global brands. Under our partner Jon Shulkin’s leadership, we are incredibly excited to partner with Starbucks to drive innovation in the food and retail industries.”

~ Lynda Kiernan

Lynda Kiernan is Editor with GAI Media and daily contributor to GAI News. If you would like to submit a contribution for consideration, please contact Ms. Kiernan at lkiernan@globalaginvesting.com.

Opportunities For Evolving Horticulture

Greenhouse Technology Village

Macfrut (8th-10th May 2019) introduces the Greenhouse Technology Village, showcasing the producers of technologies, materials and technical means, seed producers and specialized nursery gardeners with the aim of increasing protected crops to extend the supply calendars and defend them against extreme events.

The brains behind the Greenhouse Technology Village is Luciano Trentini, who explained that "the area will showcase opportunities for an increasingly evolved agriculture. Everything focuses on competitiveness. Horticulture is evolving in Italy and it will grow over the next few years as well: we need to keep up to date with what the others are doing and with the latest technologies. We need to increase productivity while diminishing inputs, saving water and limiting treatments."

The exhibition will be accompanied by the "Il futuro della serricoltura e la serricoltura del futuro" convention (The future of greenhouse production and greenhouse production of the future - 9th May). Organized with the scientific collaboration of Cecilia Stanghellini from the Wageningen University & Research Greenhouse Horticulture Unit. The meeting will discuss production trends for the European and global fresh produce market and new technological trends.

Speakers from the Netherlands (Cindy van Rijswick, Fresh Produce Analist, Rabobank), Spain (Roberto García Torrente, Director Innovación Agroalimentaria Cajamar, Almeria), Morocco and Eastern Europe (Paolo Battistel, Ceres) will attend.

These countries believed in the new soil-less production techniques (substrate, NFT systems, Floating System, greenhouse air conditioning and artificial lighting) and are now the protagonists of the international vegetable market.

The convention will analyze the strengths and weaknesses of the sector, which can now benefit from the advantages determined by renewable energy, which can contribute to their development. Stefania de Pascale (University of Naples), Giorgio Prosdocimi Gianquinto (University of Bologna), Massimo Lucchini (Idromeccanica Lucchini) will the topic. There will also be a round table "Cosa serve per rendere la serricoltura italiana a prova di futuro?" (What do we need to make Italian greenhouse cultivation future-proof?).

Contacts:

Cesena Fiera

Via Dismano 3845

47522 Cesena (FC) - Italy

Tel.: +39 0547 317435

Fax: +39 0547 318431

Email: info@macfrut.com

Website: www.macfrut.com

Publication date : 3/18/2019

© FreshPlaza.com

Nebullam and LEAH Laboratories Selected Into Y Combinator

Photo courtesy of flickr.

Nebullam and LEAH Laboratories

Selected Into Y Combinator

Two Iowa-based companies, Nebullam and LEAH Laboratories, were selected into Y Combinator’s winter cohort accelerator program.

Their acceptance into the program comes with a seed investment of $150,000 along with mentorship throughout the 90-day program that culminates this week with a demo day in San Francisco.

“One of the biggest takeaways that we’ve had from YC is the fact that the community is just as open when talking about failure as they are with talking about success,” said Clayton Mooney, CEO and co-founder of Nebullam “That openness to sharing what doesn’t or didn’t work is healthy and required for growing a technology startup ecosystem. I believe Ames has the potential to become a powerful technology startup hub over the coming years, but only if the community reaches the point where it wants to optimize for the upside, while not sweating the downside.”

Prior to the winter cohort, Nebullam went through Y Combinator’s Startup School, a 10-week online program that provides mentorship and a startup network.

“Coming into the program, we had been developing this idea for about a year and really needed a ton of flam to light all the gas that we had and Y Combinator really provided that for us,” said Wesley Wierson, co-founder and CEO of LEAH Laboratories.

Out of approximately 12,000 applicants, 205 were selected for the YC winter cohort. This is the first time that two Iowa-based startups have been selected for Y Combinator.

“This was the lowest acceptance rate by YC to date,” said Joel Harris, co-director of Ag Startup Engine. “In spite of that, two Iowa built and based companies, both from the Ag Startup Engine portfolio and with ties to Iowa State University, were selected. Recognition from a leading program like Y Combinator is terrific for Nebullam and LEAH Laboratories, but also an inspiration for other entrepreneurs about the quality of technology businesses being started in the Heartland.”

Both companies will be pitching to investors later today as part of Y Combinator’s Demo Day.

Previous coverage

Leah Laboratories receives seed investment from Ag Startup Engine -Jan. 16, 2019

Middlebit: Nebullam one of six finalists for inaugural IFT Next Food Disruption Challenge -July 20, 2018

Nebullam: Indoor farming -April 17, 2018

Seeding The Right IoT Architecture To Build A Better Farm

AeroFarms is using data-driven insights from an IoT deployment to increase yields, conserve resources and improve the flavor of its produce.

Dell EMC

Enterprises around the world are working actively to capitalize on the opportunities brought by the convergence of high performance computing, data analytics and artificial intelligence. And we’re not talking about just the big, global players. Small and midsize businesses are very much in this game — in a big way.

That’s the case at AeroFarms, a U.S.-based company that is on a mission to build and operate environmentally responsible farms throughout the world by enabling local production at scale.

This young company is dedicated to nourishing communities with safe, nutritious and delicious food. To carry out its mission, AeroFarms runs the world’s largest indoor vertical farm, which yields up to 390 times more produce than a traditional field farm — all without sunlight, soil or pesticides, and all with 95 percent less water.

AeroFarms builds vertical farms in urban areas that aren’t known for agriculture — such as Newark, New Jersey, where the company has its global headquarters, as well as indoor farming operations. In these and other facilities, AeroFarms is proving that through a high-tech, data-driven method of misting nutrients directly on to the plant roots, as well as directing appropriate amounts and wavelengths of artificial light, leafy greens can thrive in an indoor farming environment.

All of this, of course, takes more than great ideas and great execution. It also takes a lot of great technology to harness the data that helps AeroFarms gain insights into operations and make informed decisions. This is where Dell Technologies enters the picture. Through its partnership with Dell Technologies, AeroFarms is well positioned to implement the right data-driven machinery into its industry-leading processes. Using data related to temperature, humidity, airflow, nutrients, light, water and food safety, AeroFarms automates and analyzes everything from seed to package.

The IoT journey

To begin its IoT journey, AeroFarms worked with Dell Technologies Consulting to determine its use cases, design a technical architecture that met its business requirements, and then to develop an implementation roadmap to achieve the company’s business goals.

From an IT architecture standpoint, AeroFarms faced several unique challenges and considerations. Here’s a look at some of these higher-level issues, and how Dell Technologies approached them.

Dell EMC

As part of the architecture, we recommended the use of Dell Edge Gateways for IoT to help the research and production farms accelerate the analysis of plant health instrumentation data. We also included a Dell EMC PowerEdge 740xd high-performance compute node to support artificial intelligence, deep learning and advanced, custom analytics. These capabilities can help AeroFarms improve growing conditions — for example, by automating image recognition and classification to adjust plant nutrients, light and other factors.

Key takeaways

Ultimately, AeroFarms is a technology company that is leveraging science and engineering to redefine what’s possible in agriculture. In this quest, the company is equally vested in harvesting not just its plants but also its data to gain a closer understanding of the symbiotic relationships among biology, environment and technology, and to drive better performance.

AeroFarms is a fascinating example of how technology advances human progress, and we’re proud to be part of the company’s story. In providing strategic and technical guidance, Dell Technologies Consulting has helped AeroFarms implement a scalable architecture that meets business requirements, including custom grow analytics, and that also works within the unique parameters of an emerging company.

To learn more about our consulting services and the work we did at AeroFarms, watch the video “Achieving Scale with Big Data and IoT.”

Laddie Suk leads a cross-functional Dell Technologies Consulting team focused on digital transformation and industry solutions.

\

Video: CEO of CO2 GRO Explains How Their Patented CO2 Foliar Spray Technology Accelerates Plant Growth

CO2 GRO’s outlook is based on an expanding clientele and increased acceptance of their technology.

"With Digital Agriculture, Some Improvements Are Automatic"

Jian Jin, Assistant Professor of Agricultural & Biological Engineering, knows to make progress, one must continuously move forward. The mindset is reflected in his life, and in the plants in his automated greenhouse.

Jin first found success in the phenotyping industry, designing imaging systems for plant screening. After finishing a milestone facility construction project in industry, he decided to switch to academia to continue the exploration of new phenotyping technologies. Jin joined Purdue, drawn by the opportunities to bring new ideas to life.

“We do higher risk, higher reward research as we explore frontiers,” says Jin. “Then, when we find something, we publish those findings. Many other people can adopt those new developments or technologies to be applied.”

In one of the greenhouses his lab oversees, Jin utilized conveyors for an advanced imaging system that enables researchers to perform automatic hyperspectral imaging of over 100 potted plants on an hourly basis. Stationary plants are affected by microclimates within a greenhouse. In a single room, factors like lighting, sunshine, temperature and air circulation can vary significantly.

Jin’s studies show that the conveyor system can eliminate 90% of plant variance. This assures the recorded differences between plants stem from genetics, not environmental factors.

Scanning the plants hourly provides a crucial advantage for Jin. Rarely are other plant images and manual measurements performed on a single plant more than once a day.

“Plants have a biological clock. It’s very different from time to time,” says Jin. “If, when I’m sleeping, you measure my heartbeat or blood pressure, those features are very low. Right now, I’m actively talking. If you measure my biological features now, everything is actually much higher. After jogging, you can imagine, it’s very different. It’s actually the same situation for plants.”

Precision is also the reason Jin uses hyperspectral imaging. While human eyes see visible light in three bands, hyperspectral imaging detects a broader spectrum and measures in narrower bands. The hyperspectral cameras can gather up to 10 terabytes of data each day. With such an influx of information, Jin places a high value on colleagues with the expertise to sift through vast sets of data.

“The image processing and data processing scientists behind the equipment are very important. For hyperspectral cameras, each pixel can have hundreds or thousands of values. How do you store and process that data? With better processing, you can see your imaging results in just a few hours or even immediately after the imaging.”

Digital agriculture innovations continue to stem from Jin’s lab. A second automatic high-throughput phenotyping greenhouse utilizes an overhead collection of cameras that travels to the plants. The greenhouse system simulates the remote sensing of a drone in the field and offers a combination of hyperspectral, thermal, and 3D imaging.

Purdue engineers developed a handheld hyperspectral imager with Jin’s lab as well. It compactly provides the benefits of a precise signal with a lower price than similar offerings.

Jin’s next endeavor is an outdoor automatic imaging system at the Agronomy Center for Research and Education. Upon its completion this summer, a hyperspectral camera will automatically traverse a rail approximately 25 feet above the field, providing remote sensing in a fairly high frequency.

“My goal here is to keep developing ideas,” says Jin. “The best sensor system for the next generation… We have to take some risks. We have to do something people have never done before. With all those new ideas, many will fail. We’ve failed several times already, but sometimes we try some new ideas that work and improve the value for farmers and consumers.”

Jin continued, “This is a really exciting time at Purdue. Different modes of automatic phenotyping, different cameras. We’ve learned a lot from these facilities.”

Source: Purdue University (Chad Campbell

CEA Advisors Announces International Collaborations

March 20, 2019

CEA Advisors, Fospan Worldwide and Canna Pro, global players in Horticulture are pleased to announce that they have finalized their agreement to collaborate on cannabis related business opportunities. These industry heavyweights are joining forces to provide marketing, sales, consulting and technical support to the global Cannabis industry.

CEA Advisors is a major player in the global indoor farming industry. For the past 10 years, they have designed and built state of the art custom container farms for commercial clients such as growers, food manufacturers, pharma manufacturers, universities, government agencies, schools and non-profits worldwide. They are also the designer and manufacturer of Growracks®, an industry standard plug and play vertical production system in use worldwide. www.growtainers.com

Fospan Worldwide SL, headquartered in Barcelona, Spain is an experienced solution provider of Horticultural services to the medicinal and recreational cannabis industry. The registered Dutch- Spanish company also acts as a distributor for many of Europe’s top Horticultural products including their proprietary LED product, Magnus Lights by Parus. Fospan Worldwide’s management boasts of many years of industry experience and the successful completion of high-profile Cannabis projects in Denmark, Switzerland and throughout Europe. www.fospan.com

Canna Pro, a division of Pro Horticulture Inc has spent years designing and building premium indoor cannabis facilities & light deprivation greenhouses for growing high yielding healthy crops. They are a global cannabis entity with strategic partnerships in Canada, USA and Europe. Canna Pro has assembled a team of all-stars bringing tried and true cultivation methods mixed with the perfect dose of cutting-edge technology. They’ve built greenhouses and growrooms all over the globe and work closely with their team of HVAC engineers to provide the optimum indoor environments for rapid growth of healthy plants. www.cannapro.co

Tech Connection Boosts NY Vertical Farmers

By AFP

24 February 2019

A Bowery Farming employee inspects some of their greens grown at the hydroponic farming company in Kearny, New Jersey

Workers at Bowery Farming's warehouse near New York have swapped out a farmer's hoe for a computer tablet that takes real-time readings of light and water conditions.

Launched in 2015, Bowery is part of the fast-growing vertical farming movement, which employs technology in a controlled, man-made setting to grow fresh vegetables indoors all year long.

Champions of the practice see vertical farming as a key tool to meet the world's food needs at a time when the population is rising and the climate is changing.

Irving Fain, CEO and co-founder of Bowery Farming, talks about his hydroponic grown greens

The company's chief executive and co-founder, Irving Fain, said his company's Kearny, New Jersey site uses fewer resources than traditional farms and does not employ pesticides.

"I have been a big believer my entire life in technology as being able to solve not only hard problems, but also important problems," said Fain, who previously ran a company that provides data analysis for big companies on their loyalty programs.

Bowery employs more programmers than agricultural scientists. The company says its use of algorithms enables it to be 100 times more productive per area compared with a traditional farm and to use 95 percent less water.

- Lower electricity costs -

Greens are grown at Bowery Farming, a vertical farming site founded in 2015

Vertical farming has long been practiced in Japan and some other places but it did not take off in the United States until recent technological leaps made it viable.

A key component has been LED bulbs, which have enabled indoor farmers to drastically cut electricity costs.

But Bowery is also making heavy use of robotics and artificial intelligence to keep prices under control.

Bowery makes heavy use of robotics and artificial intelligence to keep prices under control

The combination of these newer tools "is how we really rethink what agriculture will look like in the next century and beyond," Fain said.

The company has also benefited from more than $120 million in funding from tech titans including Google Ventures and Uber Chief Executive Dara Khosrowshahi.

The Silicon Valley connection has also boosted San Francisco-based Plenty, another prominent vertical farming company, which has garnered more than $200 million from Amazon Chief Executive Jeff Bezos, Softbank and others.

US-based Crop One and Emirates Flight Catering have launched a $40 million joint venture to build a giant vertical farming facility in Dubai.

- Profitable? -

AeroFarms co-founder and chief marketing officer Marc Oshima looks at baby kale

The world's biggest vertical farm is in Newark, New Jersey and operated by AeroFarms.

The company, founded in 2004 and considered a pioneer in the sector, remains privately-held and does not disclose financial data. But the company says it is now profitable after a series of fumbles.

David Chang, founder of the noodle restaurant brand Momofuku, is an investor.

AeroFarms exclusively uses company-made technology that has now made its way to China, the Middle East and Europe, said its co-founder Marc Oshima.

AeroFarms's vertical grow towers in Newark, New Jersey

In a warehouse that was once a steel mill with 40-foot (12-meter) ceilings, the company is growing kale and arugula leaves set in rows of 12 metal racks each. The roots are suspended in the air as they are intermittently irrigated while the leaves bask under LED lights.

AeroFarms experiments regularly with lighting and nutrients with an eye towards finding the optimal recipe for each plant and developing the best algorithm.

The company produces watercress that reminded a reporter of her grandmother's soup, kale as tender as spinach and arugula with a hint of spice.

Basil from Bowery Farming was tinged with the flavor of lemon.

But it can take a while for vertical farms to find solutions that are viable.

"The big, big vertical farms are having a difficult time being profitable because they are so capital-intensive at the beginning," said Henry Gordon-Smith, founder of Agritecture, a consultancy.

Large farms typically need seven or eight years before they are profitable, with smaller farms requiring perhaps half as long.

But entrepreneurs in the business are confident in their prospects as more young people in cities express worry about climate change and pesticides.

Baby kale is grown at AeroFarms

"Vertical farming is not THE solution to food security," said Gordon-Smith. "It is one out of the possible solutions."

Critics of vertical farming say it has a large carbon footprint due to heavy use of lighting and ventilation.

But defenders say that this negative impact is more than offset from the benefits of lower water use, the location near population centers and the non-use of pesticides.

A bigger issue may be the limitations of the output itself, at least in terms of nutrition.

"You can't feed the world with salad alone," said Princeton University plant researcher Paul Gauthier, who says vertical farmers will need to develop more protein-rich offerings.

Gauthier -- who grew spicier peppers in his own lab by subtly increasing potassium levels -- said vertical farming could supply fresh food to so-called food "deserts" where it is absent and could in the long-term meet growing food demand as the climate changes.

US: New Solar Greenhouse Registered

Green Stream has registered its proprietary and unique design, solar greenhouse, with the cities of Los Angeles and New York.

"The Solar Greenhouse design is the result of a collaboration among architects Anthony Morali and Richard Hofmeister, in conjunction with plans and concept development provided by Green Stream and its staff. The concept of the Solar Greenhouse is to plant, to grow, and to harvest vegetables on rooftops that are currently unused and non-functioning areas of real estate on top of a building.", the team with the company explains.

"Large food suppliers, such as large market chains and food processors, will be able to grow up to 100,000 pounds of vegetables, such as lettuce (depending on roof space available), on an unused rooftop. The immediate benefit is that the vegetables are able to grow in longer cycles, and need not be picked before thoroughly ripe, thus making them fresher for consumers as well as less expensive as savings are passed on to the end users."

"In addition to those clients of Green Stream, the designs, having been registered with the building departments, will be available for others to use with the payment of a licensing and royalty fee to be determined.", the company concludes.

For more information:

GreenStream Finance

8335 Sunset Boulevard

info@greenstreamfinance.com

greenstreamfinance.com

Publication date : 2/22/2019

Freight Farms Announces Next-Generation Container Farm, Advancing Production Limits of Hydroponic Vertical Farming

Agtech innovator's new technology adds 70% more growing space, drives yield, efficiency, automation

NEWS PROVIDED BY Freight Farms

Feb 26, 2019

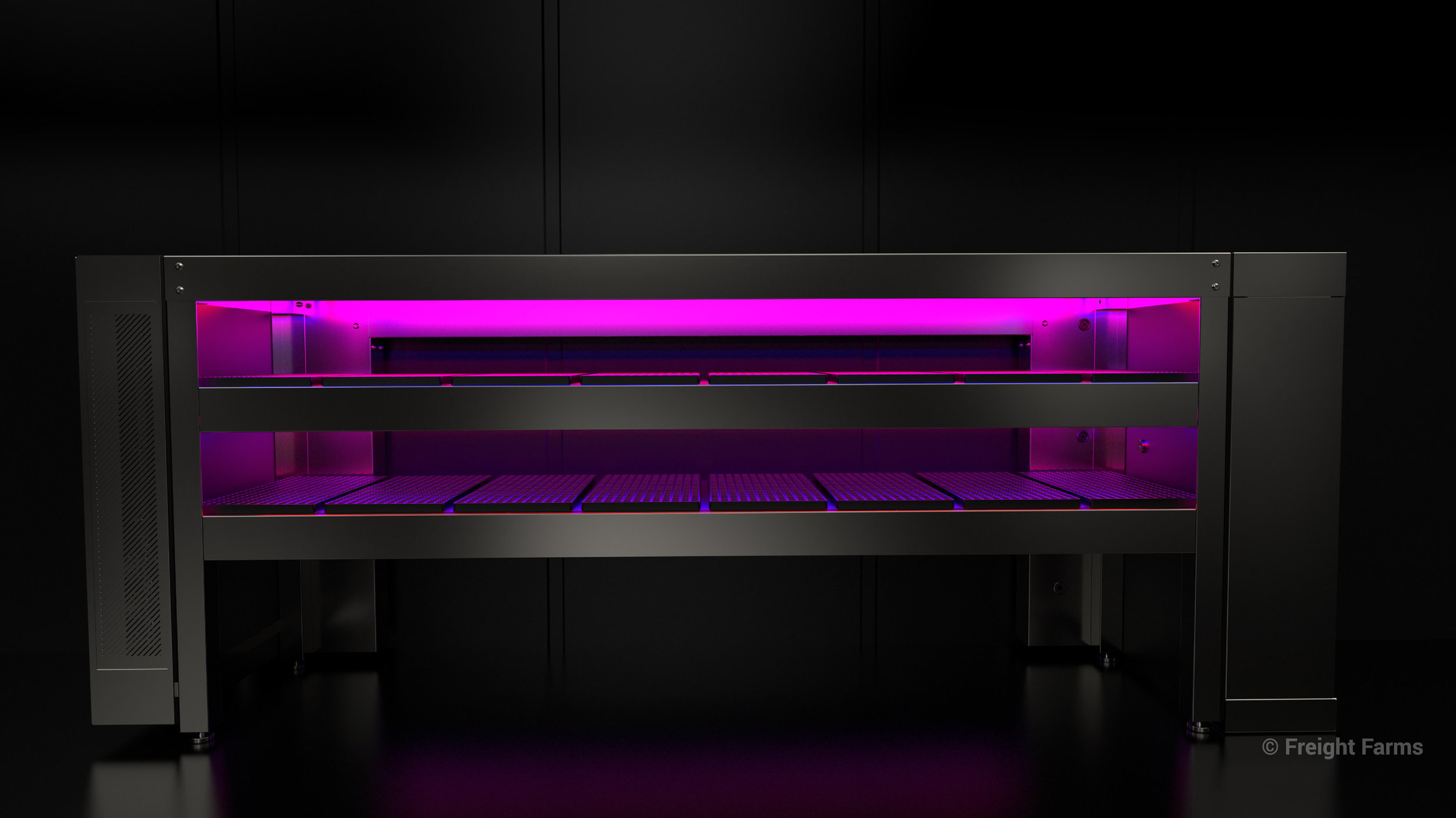

BOSTON, Feb. 26, 2019 /PRNewswire/ -- Freight Farms is proud to announce the Greenery™, successor to the Leafy Green Machine™ (LGM), and the first generational product leap since Freight Farms pioneered the containerized agriculture industry in 2010. Within the same standard 320 sq. ft. footprint, the Greenery offers farmers 70% more growing space, with unprecedented versatility, efficiency, and automation control – advancing the limits of production, and making farming more accessible than ever before.

Performance-Driven Container Farming

The Greenery combines dynamic aisles with new plant panels and LED technology to boost yields and create streamlined operations for the farmer. Simplified Workflows: Moveable rows provide easy access to plants for convenient harvesting, pruning, cleaning, and maintenance. This drastically reduces labor and increases productivity. Customization & Versatility: With the sliding rack system, farmers can arrange the Greenery based on their needs, allowing them to grow larger plants without experiencing spacing or airflow problems.

Exterior of Freight Farms' Greenery: now made from purpose-built freight containers with all-weather paint, premium metalwork, and superior manufacturing.

The Greenery’s main growing area features 88 plant panels and 112 LED panels. The LED panels are hyper-directionally focused on the plant canopy to prevent light waste and yield fuller, heavier crops in shorter time-frames.

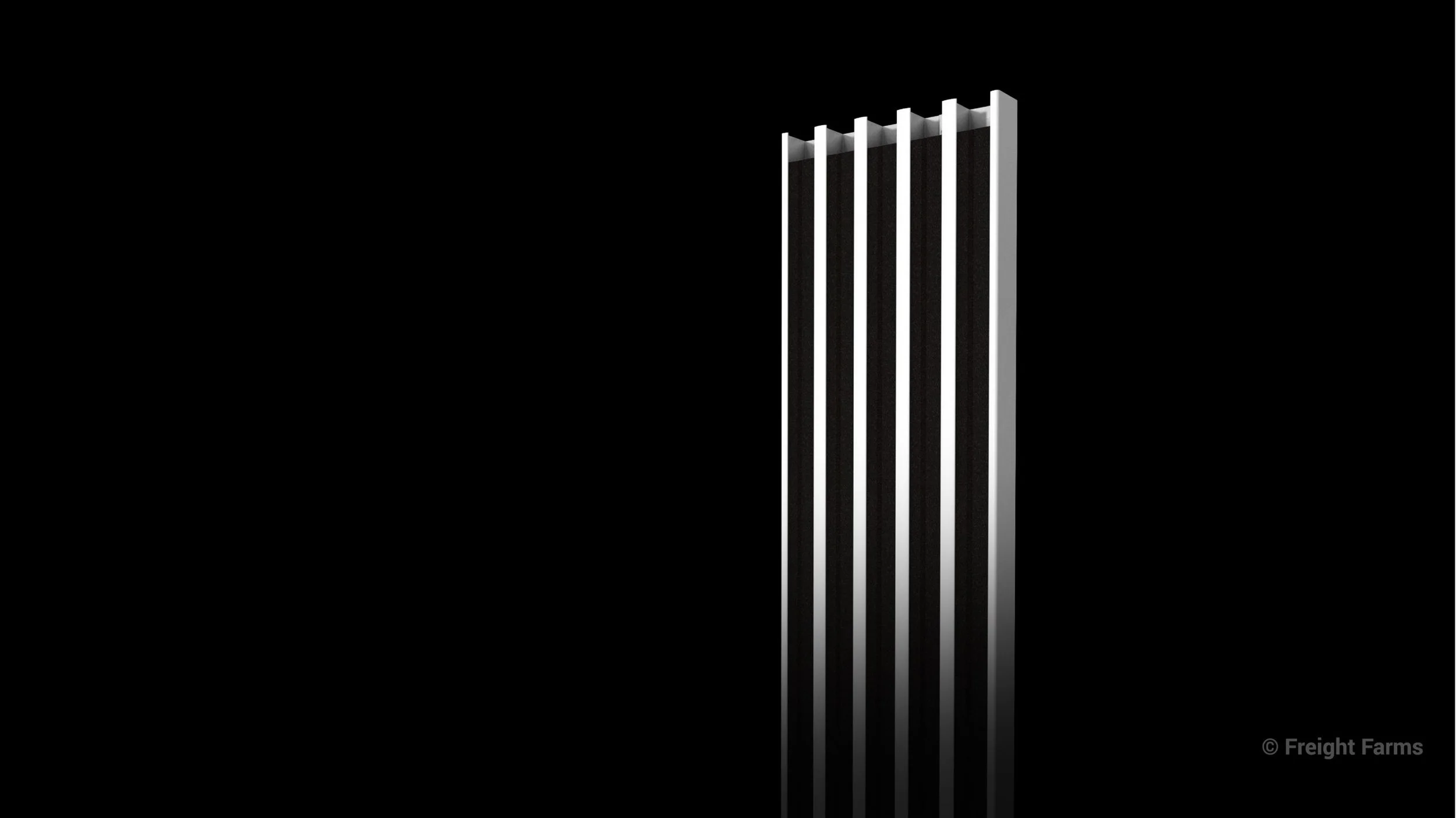

Freight Farms' new vertically hanging 5-channel plant panels replace previous single-channel crop columns, capturing previously unproductive space to unlock 70% more growing space within the Greenery’s 320 sq.ft. footprint.

The Greenery’s nursery station holds 4,608 plant sites. Seedlings grow up toward 3:1 red-to-blue LED light panels that focus directly onto the canopy, with minimal light fall-off or wasted energy.

After years of data collection and development based on the experience of hundreds of farmers in its global network, Freight Farms has again raised the industry bar with a fundamental container farm redesign. Instead of reorganizing existing technology into a refreshed layout, the company saw the potential to blueprint entirely new farm components previously unavailable to the industry. In doing so, Freight Farms keeps the ergonomics of both farmers and plants as the central priority to improve yield, efficiency, and workflow. Today Freight Farms reveals three pillars of the Greenery's design.

Greater Yield, Productivity, and Usability: A fully-reimagined farm interior combines customizable grow rows with innovative plant panel and LED technology to boost yields and create streamlined operations for the farmer.

Mobile rack system: Farmers can now shift grow rows and LED panels to create custom layouts to support the growth of a new variety of crops (larger, vined, rooted, etc.) while drastically improving workflow.

Increased production: Capturing previously unproductive space, a unique 5-channel plant panel design replaces traditional crop columns to unlock 70% more growing space within the same small footprint. The Greenery also hosts 30% more nursery plant sites.

Industry-leading LEDs: Unique, rigid LED panel arrays replace previous rope lighting, tripling the crops' access to light energy to result in fuller, heavier plants within a faster growth period.

Superior Resource Efficiency: Newly designed systems throughout the Greenery, including lighting and climate control, use and reclaim resources with unrivaled efficiency.

Best brightness-to-power ratio: Because the LED arrays are focused directionally, light energy waste is prevented, and despite triple the intensity, there is no 3x corresponding electricity draw.

Intelligent moisture reclamation: The farm's powerful new climate control system condenses and recycles ambient moisture so efficiently that in certain humid regions it is capable of capturing upwards of 1.5 gallons of water per hour, rendering some Greenery operations water-positive.

Time savings: The mobile rack system gives farmers direct access to all plants for more convenient harvesting, pruning, cleaning and maintenance. This reduces farm work time by 25–50%.

Climate Automation and Connectivity: The Greenery pairs exceptional design with complete connectivity. Each farm component is built from the ground up with farmhand® IoT integration, bringing unparalleled control and transparency to farming.

Smart farm: Using IoT-connected sensors, the Greenery continuously relays all climate, component, and camera data directly to farmhand®. With this information at their fingertips – via smartphone, tablet, or desktop – farmers can confidently operate and monitor their farm remotely.

Tailored climate control: With Freight Farms' catalogue of real-world growing data, farmers can replicate ideal environmental conditions, or "recipes," for consistent crop quality. They can even make non-native produce varieties available in their local market by creating environments otherwise impossible in their region.

Combined, the Greenery's features signal a major shift in containerized agriculture. "The Greenery's forward leap in data and sensor technology represent a fundamental improvement to farmers' workflow and production versatility," said Brad McNamara, Freight Farms Co-Founder and CEO. "It also allows for total, real-time transparency for consumers. A single romaine head can be traced back through every growing stage back to the seed it came from, even down to the hour. That standard was previously considered impossible, and one we hope the entire industry will now adopt."

Versatile Design For the Future

With size and resource conservation central to its design, the Greenery is deployable by a single individual, yet powerful enough to meet the needs of regional distributors. This turnkey system can grow a higher capacity of hyper-local food directly onsite for communities, without resorting to time-consuming and capital-intensive indoor farming installations that are often located remotely.

"The Greenery is the most powerful standalone hydroponic farm available, with a fully-connected technology platform you can't achieve from any combination of products elsewhere in the industry," added Jon Friedman, Co-Founder and COO. "By revolutionizing a farm that can be operated by anyone, in any climate, and can successfully support a diverse range of business goals, our team is helping support a higher standard for society's food system than previously possible."

Establishing Containerized Farming

In 2012, Freight Farms debuted the first vertical hydroponic farm built inside an intermodal shipping container—the Leafy Green Machine—with the mission of democratizing and decentralizing the production of fresh, healthy food. With its technology system and integral IoT data platform, farmhand®, Freight Farms now has the largest network of connected farms in the world.

In 15 countries and most U.S states, farmers use Freight Farms technology to grow food in environments ranging from urban neighborhoods to extreme climates. These farms are the cornerstones of hundreds of independent small businesses and non-profit initiatives that localize and improve food access geographically and socio-economically. Leafy Green Machines have also been added to numerous educational infrastructures, as well as corporate and wellness programs by customers like Google, Ford Motor Company, Everlane, and Kimbal Musk's Square Roots.

The Greenery, available for pre-sale starting today, retails for $104,000, with general availability this Spring. For purchasing information, please visit freightfarms.com, or inquire at 1-877-687-4326 ext. 1. Freight Farms can also be visited on Instagram, Twitter, or Facebook.

Affinor Growers Inc. - Corporate Update

February 27, 2019 | Source: Affinor Growers Inc.

VANCOUVER, British Columbia, Feb. 27, 2019 (GLOBE NEWSWIRE)

Affinor Growers Inc. (“AFI” or the “Company”) (CSE:AFI, OTC:RSSFF, Frankfurt:1AF) is pleased to provide an update on its operations.

Over the past four months, the Company has been working on several fronts in order to broaden the Company’s operations and build a strong foundation for future success. In doing so, the Company is extremely pleased to announce the development of three new tower designs, two significant agreements, as well as an invitation to the BC Tech Summit 2019 from the BC Ministry of Agriculture in order to showcase our new towers.

Technology Development

Since October 2018, the Company has been working aggressively with our manufacturing partner, Cobotix Manufacturing Inc. (“Cobotix”), to develop new tower designs and new technologies. The result of this work is three new tower designs. We have a newly designed vertical farming tower for soiled-based growing, a new hydroponic version of the vertical farming tower and a newly designed vertical farming tower that is a hybrid of hydroponic and aeroponic growing.

The new designs allow the Company to increase its footprint in the vertical farming space and gives the Company a product line that, we feel, can compete with other hydroponic and aeroponic growing systems on the market. In addition, the new designs also open up the home and light-duty commercial markets for the Company, markets in which we see great potential for growth.

Randy Minhas, President and CEO commented, “This is a significant step forward for the Company. As a technology company, it is absolutely crucial that we continue to innovate and develop in order to remain competitive. I am extremely pleased with the new tower designs and look forward to introducing the towers to the market.”

Agreement with Fundamental Lighting Solutions Corp. (“Fundamental Lighting”)

The Company is pleased to announce that it has reached a four-year, worldwide exclusive, distribution agreement with Fundamental Lighting. Fundamental Lighting is a corporation out of Monroe, Washington and they have developed high-efficiency, white LED lights and coloured LED growing lights to be used for indoor growing operations, including greenhouses. The Company will have the exclusive right to distribute the lights for Agricultural projects and earn a commission on the sale of the lights.

In addition, the Company is helping Fundamental Lighting develop cannabis specific growing lights (“Cannabis Lights”) to compete with the widely used high-pressure sodium lights. The design work and the research for the Cannabis Lights has been completed and the process is moving to the prototype phase. We expect to have eight Cannabis Lights manufactured and ready for testing in the next 6-8 weeks.

The design team behind the LED lights and the Cannabis Lights is led by Mr. Wayne Bliesner. Mr. Bliesner is the CEO and Head Scientist at Fundamental Lighting. Mr. Bliesner is in charge of the company direction, choosing executives, scientific research, managing the lab team, and new production R&D. He earned a Master’s Degree from the University of Washington in Aeronautical Engineering and spent 20 years at Boeing as a lead engineer, where he has multiple patents there in several technologies.

He also spent 16 years as an independent scientist developing ground breaking technologies. He has raised over $10 million for R&D as an independent scientist and is attached to over 100 patents in the U.S., Canada, Europe, and Australia.

Mr. Minhas commented “This is a very significant agreement for the Company. We are looking forward to working with Mr. Bliesner and his team. The LED growing lights will be a great complement to our new towers. In addition, the development of the Cannabis Lights will be a game changer. Currently, the cannabis market is dominated by high-pressure sodium lights, which emit a significant amount of heat and use a significant amount of electricity. The LED Cannabis Lights will significantly reduce the electricity usage, lower the heat emissions within a grow facility and last considerably longer than the high-pressure sodium lights. We’re very excited to get these lights manufactured and tested in the coming months.”

Agreement with the University of Fraser Valley (“UFV”)

The Company is pleased to announce that we have entered into a two-year agreement with the UFV to complete strawberry grow trials in the newly designed soil-based, vertical growing tower with the use of the LED lights from Fundamental Lighting.

The Company will install a total eight towers at the two Surrey Biopod greenhouses, replacing the two larger, first generation, towers from several years ago. The Surrey Biopod facility is a partnership between the University of the Fraser Valley, the John Volken Academy (“Volken Academy”), and the City of Surrey. The Volken Academy provides life and job skills to addicted youth, and the Biopods offer Volken students the opportunity to learn growing and research skills in an urban greenhouse environment.

The grow trial will consist of four towers in each Biopod greenhouse with half of the towers being used to grow strawberries using conventional substrate and the other half growing in organic substrate. In addition, the Company will install white LED lights in one greenhouse and coloured growing LED lights in the second greenhouse.

The project will be overseen and managed by Dr. Laila Benkrima. Dr. Benkrima is currently a Horticulture Instructor with the UFV and runs the Surrey Biopod program. Dr. Laila Benkrima holds a Ph.D. in Plant Biology and MSc in Plant Physiology from the University of Paris (France). She has over 25 years of experience in research and development within the horticulture and plant biotechnology industries. She has been responsible for the planning, development and creative problem solving of various projects from plant micropropagation and functional/medicinal crop cultivation to hydroponics and laboratory design.

Mr. Minhas commented “We’re very please to be working with the University of Fraser Valley and Dr. Benkrima. This agreement gives us access to fully operational greenhouses and the ability to test our newly designed soil tower with the LED white lights and coloured growing lights. The data received from these grow trials will greatly enhance our ability to market and sell these towers.

This is also a great opportunity for the students at the Volken Academy and at-risk youth to gain hands on experience with vertical farming technology. We are certainly thrilled to be able to participate in the Surrey Biopod project for the next two years and we are pleased to say, we will be donating all eight towers to the Surrey Biopod project at the conclusion of the agreement.”

BC Tech Summit 2019

The Company is excited to announce that we have been invited to the BC Tech Summit, March 12-13, 2019, at the Vancouver Convention Center by the BC Ministry of Agriculture. The Company will use the BC Tech Summit to launch its new hydroponic growing tower and our hybrid hydroponic/aeroponic tower. In addition, we will also be showcasing the LED white lights and the coloured growing lights as part of our exhibit. The Company’s exhibit will be part of the BC Ministry of Agricultures showcase.

Mr. Minhas commented “We are thrilled to be attending the BC Tech Summit with the BC Ministry of Agriculture and very grateful to have been given this opportunity. It is a great honour to be invited to this event. This will be a great platform to launch our new towers and showcase Fundamental Lighting’s LED lights.”

Randy Minhas

President and CEO

About Affinor Growers

Affinor Growers is a publicly traded company on the Canadian Securities Exchange under the symbol ("AFI"). Affinor is focused on developing vertical farming technologies and using those technologies to grow fruits and vegetables in a sustainable manner.

Neither Canadian Securities Exchange nor its Regulation Services Provider (as that term is defined in the policies of the Canadian Securities Exchange) accepts responsibility for the adequacy or accuracy of this release.

This news release may contain assumptions, estimates, and other forward-looking statements regarding future events. Such forward-looking statements involve inherent risks and uncertainties and are subject to factors, many of which are beyond the Company's control that may cause actual results or performance to differ materially from those currently anticipated in such statements.

AFFINOR GROWERS INC.

www.affinorgrowers.com

Republic Polytechnic Launches Course to Groom High-Tech Farmers

A new course here aims to train the next generation of high-tech farmers so that Singapore can produce more of its own food.

PUBLISHED

JAN 11, 2019, 5:00 AM SGT

A new course here aims to train the next generation of high-tech farmers so that Singapore can produce more of its own food.

The Diploma in Applied Science in Urban Agricultural Technology, launched by Republic Polytechnic (RP) on Wednesday, is the first full-qualification diploma course in agricultural technology in Singapore.

The course was developed by RP, in consultation with the Agri-Food and Veterinary Authority of Singapore, to develop a local core agriculture workforce with modern agricultural knowledge and techniques to drive the sector's growth and transformation.

Senior Minister of State for Trade and Industry Koh Poh Koon spoke at the launch of the diploma, which was held together with the opening of the polytechnic's Agriculture Technology Laboratory.

Dr Koh highlighted the need for a new generation of talent in agricultural technologies, to turn Singapore into a leading Asia hub for urban agriculture and aquaculture technologies.

The growth of the Republic's urban agriculture and aquaculture sector is also an essential pillar in upholding Singapore's food supply resilience, he added.

"As a small country where land is a scarce resource, Singapore has always had limited land space for domestic food production," said Dr Koh, adding that Singapore might be affected by global food supply developments and disruptions.

He added that Singapore's local farms produce just 10 per cent of food fish, 13 per cent of vegetables and 27 per cent of eggs consumed here. But he is confident that these percentages will continue to grow, with technological developments and more young farmers joining the industry through avenues such as RP's urban agriculture diploma.

The first batch of 25 students will start the part-time diploma course in June. These students will be taught five modules, with a focus on agricultural technologies for food production, farming process and management, urban farming technology and systems, agribusiness, and sustainable farming.

The programme's first run also involves eight local farms: Citizen Farm, ComCrop, Farm 85 Trading, Koh Fah Technology Farm, Liteleaf, Nippon Koi Farm, Sustenir Agriculture, and Vegeponics.

The farms will give students in the course on-the-job training opportunities and internships.

The course comes in two formats - one for fresh Institute of Technical Education graduates to build on what they have learnt in school, and the other for adult learners who want to switch to, or further their careers in, the agro-technology and agri-business sector.

RP's new Agriculture Technology Laboratory will give students in the diploma course in-house, hands-on training. The laboratory will also be used as a platform for workshops, industry-relevant projects and research in agriculture technology to incubate solutions to enhance productivity in farms.

It features technologies used in the farming industry today, including vertical farming towers irrigated by a nutrient tank and a horizontal hydroponic system irrigated by shallow tubes.

The laboratory also displays the hydroponic deep water culture system, where the roots of plants are submerged in a nutrient solution, and an energy-efficient substrate growing system.

A version of this article appeared in the print edition of The Straits Times on January 11, 2019, with the headline 'Republic Poly launches course to groom high-tech farmers'. Print Edition | Subscribe

Do Plants Have Senses?

Yes, kind of. To make things interesting let us invoke the five traditional senses we normally think about when talking about people: Sight, hearing, taste, smell, and touch. How do plants compare?

The Bowery Source

A destination dedicated to educating and connecting with our community.

Feb 2019

Do plants have senses?

Yes, kind of. To make things interesting let us invoke the five traditional senses we normally think about when talking about people: Sight, hearing, taste, smell, and touch. How do plants compare?

While plants can sense their environment, it is still quite different than how people and animals perceive the world. According to the American Psychology Association, sensation is defined as “The process by which stimulation of a sensory receptor gives rise to neural impulses that result in an experience, or awareness of, conditions inside or outside the body.” Plants do not have neurons and therefore do not experience the world as we and other animals do. Instead, plants have evolved rudimentary sensing mechanisms that in some ways are similar to how animals sense the environment. Here, we will explore some of those similarities.

Sight

We see light in the form of a small portion of the electromagnetic spectrum (image below) as a result of radiation from the sun and space coming in contact to the surface of the earth. The visible spectrum, one tiny portion of the electromagnetic spectrum that our eyes can see, is composed of wavelengths that range from about 400-700 nm (Figure 1). Wavelengths in the visible spectrum range from about 400-700 nm. As it turns out, plants use light in the visible spectrum for photosynthesis and can detect slightly higher wavelengths in the 710-740 nm range.

Humans and other animals can see because of an organ that is sensitive to light. In our case, the eye is incredibly complex and can perceive a multitude of colors. The lens in our eyes focuses light to the back of the eye where the wavelengths of light in the visible spectrum are perceived by specialized cells called rods and cones. These rods and cones contain protein pigments which absorb certain wavelengths (colors) and eventually transmit this information to the brain.

Obviously plants don’t have eyes. However, they are able to “sense” and physiologically respond specifically to the ratio of red light and far-red light, and blue light. Plants can sense these colors because they themselves have protein pigments, called photoreceptors, that are sensitive to the wavelengths that correspond to those colors. These photoreceptors transmit information about the light quality of the environment surrounding the plant and elicit a change in growth habit or development.

Plants can “see” their neighbors because light reflected or transmitted from nearby plants has a lower ratio of red light to far-red light. The ability of plants to detect red light, far-red light, and their changing closeness to their surroundings is probably one of the most important ways in which plants can sense.

Plant can also sense blue light. One of the most commonly studied blue light responses of plants is the directional growth that is seen in response to the direction of a light source.

There are other important blue light responses of plants. For example, circadian rhythms requires both phytochromes and blue light receptors. This means plants can sense day and night cycles. Another critical role of photoreceptors is in the flowering of plants which exhibit photoperiodism. Plants that exhibit photoperiodism are sensitive to the duration of night length and begin flowering when the nighttime is short or when the nighttime is long depending on the species.

Hearing

Have plants evolved tiny ears that allow them to hear you? It was often said that plants grow “better” if you talk or sing to them. Does this mean plants are listening? Should we be concerned they know all our secrets? Well, carbon dioxide is the carbon source plants use to form sugars via photosynthesis. When we talk or sing to plants we are doubling or tripling the concentration of carbon dioxide around the leaves of a plant so in some cases they can grow “better.” Don’t worry, they do not have tiny ears or any sort of auditory sensory mechanism and therefore cannot hear us.

Smell

Nope.

Taste

They cannot.

Feel

Some plants can actually detect when they are being touched. This might be most obvious in the Venus’ flytrap. Hairs on the trap lobes can detect the movement of an insect. When an insect moves within a window of time and activates the trigger hairs, the trap rapidly closes ensnaring the insect.

Sense of Balance

We don’t often think of balance as a sense, but we actually have an entire organ called the vestibular system in the inner ear that helps us stay balanced. Plants don’t necessarily need to balance themselves because they are anchored to the ground by their root system. But how do roots “know” to grow downward into the soil and not up? The tip of roots contains specialized cells with a gravity-sensing mechanism. Amyloplasts, parts of those specialized cells, are organelles which function to synthesize and store starch. When a root is oriented horizontally, the amyloplasts in these cells settle to the bottom of the cells by gravity. A hormonal signal is sent to the growing points of the root where the hormone is asymmetrically distributed causing differential growth resulting in a downward bend.

So while plants aren’t listening in on our private conversations, they are certainly more perceptive beings than previously considered.

This piece was written by Pablo Rosas-Anderson, an agricultural scientist at Bowery Farming.

Sources:

Ballare, C.L., Scopel, A.L. and Sanchez, R.A., 1990. Far-red radiation reflected from adjacent leaves: an early signal of competition in plant canopies. Science, 247(4940), p.329.

Glossary of psychological terms. Retrieved from http://www.apa.org/research/action/glossary.aspx

Kasperbauer, M.J., 1971. Spectral distribution of light in a tobacco canopy and effects of end-of-day light quality on growth and development. Plant physiology, 47(6), pp.775-778.

Simons, P.J., 1981. The role of electricity in plant movements. New Phytologist, 87(1), pp.11-37.

Swarup, R., Kramer, E.M., Perry, P., Knox, K., Leyser, H.O., Haseloff, J., Beemster, G.T., Bhalerao, R. and Bennett, M.J., 2005. Root gravitropism requires lateral root cap and epidermal cells for transport and response to a mobile auxin signal. Nature cell biology, 7(11), pp.1057-1065.

Indoor Ag-Con Las Vegas 2019

February 25, 2019

7th Annual Las Vegas Edition Heads To Red Rock Resort With Expanded Educational Conference And Exhibit Floor Offerings

LAS VEGAS, NV (February 24, 2019) – Indoor Ag-Con, the premier event covering the technology of growing crops in indoor systems using hydroponic, aeroponic and aquaponic techniques, heads to Red Rock Resort from May 22-24, 2019 for its 7th annual Las Vegas edition. Themed “Growing the Future,” this year’s event moves to a new location and welcomes a number of new features, including a special hemp spotlight, exclusive white paper release, expanded exhibition floor and conference schedule.

“Our ‘Growing the Future’ theme celebrates the tremendous growth potential we see for indoor agriculture,” says Nancy Hallberg who, along with other event industry veterans Brian Sullivan and Kris Sieradzki, acquired Indoor Ag-Con LLC from founder Newbean Capital in December 2018. “From timely conference tracks to the top names and emerging leaders joining our show floor, this will be the place to get a first-hand look at the industry’s breaking trends and innovations.”

Show highlights for Indoor Ag-Con Las Vegas include:

HEMP SPOTLIGHT JOINS CROP AGNOSTIC, TECH-FOCUSED OFFERINGS – New for 2019, Indoor Ag-Con will put a special spotlight on the hemp sector – from grower through manufacturer – on the show floor and in conference programming. What’s more, Indoor Ag-Con provides a venue for those working with any crop — from leafy greens and mushrooms, to alternate proteins, to medicinal crops — to meet and exchange ideas. At a time of rapid technology-led progress in indoor growing, the event will also showcase the latest innovations in artificial intelligence, LED lighting and control systems.

WHITE PAPER RELEASE: AUTOMATION, AI & THE NEXT GENERATION OF INDOOR AGRICULTURE –Indoor Ag-Con began releasing white papers at its events in 2015, and has provided participants with an exclusive hard copy of the newest white paper every year since. A culmination of months of research by Contain, Inc. and other Indoor Ag-Con team partners, the 2019 white paper, Automation, AI & The Next Generation of Indoor Agriculture, will be released in hard copy to all attendees during the Las Vegas event. To contribute or to receive more information, send a message to hello@indoor.ag

NEW LOCATION: RED ROCK RESORT – As a great trade show city, Las Vegas is hard to beat with its easy access, world class dining, top name entertainment and more. Previously held at the Las Vegas Convention Center, Indoor Ag-Con heads to Red Rock Resort for 2019. Nestled in the amber glow of the beautiful Red Rock Canyon, the new location provides the perfect backdrop for this year’s event and Indoor Ag-Con attendees and exhibitors can take advantage of discounted rates when they book through the event hotel block. Visit the show website for details – www.indoor.ag

FIVE TRACKS, 40+ INDUSTRY LEADING SPEAKERS – The Indoor Ag-Con conference agenda will bring together 40+ industry-leading speakers offering a deep dive into five key tracks: Grow Equipment, Crop Selection, Customers & The Supply Chain; Business; Policy and Societal Impact.

The full conference schedule will be posted on the event website soon – www.indoor.ag

EXPANDED EXHIBIT FLOOR & NETWORKING OPPORTUNITIES – Attendees will have the chance to meet face-to-face with some of the biggest names in the business as well as emerging innovators. From equipment and accessories to vertical farming and greenhouse solutions to technology providers, lighting and climate control systems, the industry gathers here. Indoor Ag-Con also offers a wide range of networking opportunities, including evening drinks receptions on May 22 and 23, continental breakfast and lunch gatherings, as well as extended networking breaks between conference sessions.

QUICK FACTS:

WHEN: Wednesday, May 22 – Friday, May 24, 2019 (Exhibits Open May 22-23)

WHERE: Red Rock Resort, 11011 W. Charleston Blvd, Las Vegas, NV 89132

INFO: For information on exhibiting or attending visit www.indoor.ag or email hello@indoor.ag

ABOUT INDOOR AG-CON LLC

Founded in 2013, Indoor Ag-Con has grown into the premier event in indoor agriculture, the practice of growing crops, raising fish and insects in indoor systems, using hydroponic, aquaponic and aeroponic techniques. Its events are tech-focused and crop-agnostic, covering produce, legal cannabis, alternate protein and non-food crops. It hosts events in Las Vegas, Singapore and the US East coast. In December 2018, three event industry professionals – Nancy Hallberg, Kris Sieradzki and Brian Sullivan – purchased Indoor Ag-Con LLC from Newbean Capital, so setting the stage for further expansion of the events globally. More information: https://indoor.ag

Does AI Hold the Key To A New And Improved “Green Revolution” In Agriculture?

Producing enough healthy food to feed the world—on a changing planet—is going to be a steep challenge. These researchers are giving farmers AI-driven techniques and tools to find solutions

Producing enough healthy food to feed the world—on a changing planet—is going to be a steep challenge. These researchers are giving farmers AI-driven techniques and tools to find solutions.

BY JACKIE SNOW | FEBRUARY 19, 2019 | NOVA NEXT

Automation in agriculture may soon make robots as common in greenhouses as they are on factory floors. Photo credit: Shutterstock

On a stretch of highway in the Netherlands not far outside of Amsterdam, a row of greenhouses at Wageningen University & Research (WUR) poke up like knuckles along the flat landscape. The Dutch university is known for its cutting-edge agricultural research, but some of these greenhouses recently ran an experiment that’s novel even for them: autonomous growing.

Stepping into a humid box from a brisk autumn day, you hear the noises of machines adjusting themselves mixing with the sounds of leaves rustling. The amount of light, water, fertilizers, and carbon dioxide—along with the temperature of the greenhouse—are all set by deep learning algorithms and executed by machines. Humans are still responsible for moving vines up the lattices as they grow, as well as pruning and harvesting.

But it’s pretty clear who—or rather, what—is calling the shots.

The Future of Farming?

By 2050, we’ll need to feed nine billion people with about a third less arable land than we had in the 1970s, experts estimate. Farmers will need all the help they can get, including insights gleaned from artificial intelligence, or AI. Developed carefully—and with the people who will be using it taken into account—AI can be part of the solution to feeding a growing world, according to the Refresh report, a document put together by researchers from Google, university professors, nonprofits, and farmers. And as an added bonus, some of the unsustainable practices developed over the past 70 years could be reversed with more efficient, AI-driven technology.

The Green Revolution was a set of advances that started in the 1950s in areas like high-yield crops, synthetic fertilizers, and irrigation technology that greatly increased food production, especially in developing countries—saving an estimated one billion people from starvation. But it left in its wake a culture of pesticides, reduced agricultural biodiversity, and overuse of chemical fertilizers that deplete the soil and poison waterways.

“It was never meant to be used in the long term,” says Danielle Nierenberg, the president of Food Tank, a non-profit working to build a better food system that also worked on the Refresh document. Farmers were supposed to transition back to organic, Nierenberg adds: It just never happened because increased yields generated by industrial-scale farming put pressure on smaller farms to follow suit.