Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Vertical Farms In China Provide Food For 36,000 DAILY

Farmers in Zhejiang Province have designed 'smart' vertical farms which allow vegetables to be grown without much soil or sunlight. Plants are provided with nutrient solutions through an intelligent control system. A shorter growing season and a ban on pesticides also make smart farms more environmentally friendly.

Combining Geothermal Heat With Super-Fast Internet

The geothermal heat project Nature’s Heat in Kwintsheul is running at full speed to the satisfaction of the nine growers connected to the project. Not only heat pipes but also fiber optic cables were placed, so now they can even make use of high-speed internet. Nature’s Heat operator Paul van Schie: “More often than not, townships and cable companies don’t see the need to place fiber optic cables in the rural areas. We were able to hitch along with a cable that was placed from the town to a high-voltage tower close to here. Nature’s Heat is now the distribution station for fiber optic cable connections to a variety of connections.

Dennis Bos of CBizz tells us that the plans to put in fiber optic cables have been entertained for a while. “At the beginning of 2018, Paul came to us with the question if we could realize a collective fiber optic connection. In February we were ready to start when the needed number of clients was reached.” Dennis looks back on a fantastic project. “These types of projects are one in a million, they are quite unique. Worthy to be repeated, though a next project will need to be tailor-made again.”

100 percent uptime

Geothermic heating projects require a lot of stamina. Nature's Heat is an initiative of nine horticultural companies in Kwintsheul that, together, grow 51 hectares of tomatoes, bell peppers, eggplants, strelitzias, chrysanthemums, roses, and potted plants. On the 21st of March 2018, the project started. According to Paul, it was the well-executed preparations that resulted in a high-quality project. “We did have some teething problems here and there. In May the installation was turned off a few times for a software update, but we haven’t run into any big problems yet. Since May we've had a score of 100% uptime, not counting the planned pump changeover in July.”

Tailor-made

The software was developed specially for Nature’s Heat, says Paul. The company that designed and built the above-ground installations also wrote the software. And this is very convenient, because of this you have very short lines. This party does not only do the maintenance but also the management of the installation. Every day they monitor from a distance whether or not the installation is functioning accordingly.

“The above ground installation is made of stainless steel and the design of the filter units is different than usual. Also for the de-gassing, an entirely different installation is used. Where the de-gassing normally happens in big horizontal tanks, this installation accomplishes this by using cyclones. Underpressure is created, which separates the gas. You can compare it to the drain in your sink when you pull the plug.”

No free lunch

A heat roundabout in the province of South Holland is meant to connect all the heat projects so that the optimal amount can be saved on fossil energy. “It would be great if heat pipes would be placed from Rotterdam to the Westland, but there's no such thing as a free lunch. The horticulture industry has an important part to play in the supply of electricity. I think we ought to be careful to exclude CHP from the discussion involving the closing of the gas taps. If the demand to be able to flexibly switch to the use of electricity would arise, CHPs have preference over energy from power plants. Wiebes, the Dutch Minister of Economy and Climate, wants to get rid of the use of gas. But do we then need to close down sustainable CHPs and keep coal plants open? These are the questions that you as a grower need to consider.”

For more information:

Nature's Heat CBizz

info@naturesheat.nl

www.naturesheat.nl

CBizz

+31(0)88 002 0200

www.cbizz.nl

Veganism Boom Leads To $1.2 Million Seed Funding Growth For High-Tech Garden Startup

Natufia Labs, Estonian-born startup developing machine-learning technology that grows plants right in the kitchen, announced the closing of a $1.2-million seed round led by Butterfly Ventures, Techstars, and the Dubai-based family company Ginco Investments. The funds raised will be used to enable the company to expand into Europe and the US and will be on sale imminently.

"Natufia Labs” dynamic team has a groundbreaking impact on producing fresh food and changing the ways people consume it," shares Juho Risku, partner at Butterfly Ventures. "Natufia Labs is changing the traditional agriculture model, which has $10B+ in annual revenue in the United States alone."

Around 70% of the world's consumers have reduced or completely cut out meat consumption from their diets. With veganism rising by 600% in the US and 350% in the UK, the global appetite for meat-free and plant-based diets is driving the market to be worth $5.2 billion by 2020. The sales of vegetables alone is estimated to increase by 20% by 2021. However, consumers are struggling to keep this produce fresh and on average one third is thrown away. Estonian-born startup, Natufia Labs is bridging this gap by offering consumers sustainable agriculture at home.

The Natufia Kitchen Garden automatically grows fresh plants, vegetables, flowers and herbs in households and restaurant kitchens all year round. Using machine learning and real-time data analysis the connected garden will process environmental changes and adjust its settings accordingly. The automation increases the vitamin levels by 400%. Currently Natufia offers more than 30 types of fully organic and recycled seed capsules including popular herbs and plants such as basil and kale. The Natufia Kitchen Garden has been built using stainless steel, ceramics and integrating a built-in touch screen.

"Consumers are more aware than ever about what they are buying and they want to know what is on their plate, where it came from, who made it and if it was traded fairly. The Natufia Kitchen Garden empowers consumers to grow their own produce at home. The future depends on the decentralization of food production." says Gregory Lu, CEO of Natufia Labs.

For more information:

www.natufia.com

Publication date : 9/26/2018

Pure Flavor® Aims To Create Conversation At PMA Fresh Summit With 7 New Products

Leamington, ON (October 11th, 2018) – With the produce industry preparing to head to Orlando for PMA Fresh Summit, greenhouse vegetable grower Pure Flavor® is prepping for one of the biggest trade shows ever. In addition to creating conversation about the company’s recent expansion to Georgia, Pure Flavor® will be launching 7 new items at the trade show.

JAMIE MORACCI

CO-FOUNDER, PRESIDENT

“We are bringing new products to market that will help our retail & foodservice customers grow their business. New items not only create impact in the produce aisle but are also a vehicle to help increase fresh produce consumption”, commented Jamie Moracci, President. In addition to the new items being launched at PMA Fresh Summit, Pure Flavor®’s new greenhouse facility in Georgia will soon be growing tomatoes & cucumbers year-round under the Georgia Grown brand.

Pure Flavor®’s family of growers are producing more than ever before fueling the company’s positive momentum in the marketplace. This in turn is setting up opportunities to connect with retail & foodservice partners at the PMA Fresh Summit Trade Show in Orlando, FL October 19-20.

Pure Flavor® will be unveiling a host of new items at PMA Fresh Summit that include:

REDZILLA™ Monster Sized Sweet Red Peppers; The King of Peppers has arrived! Rich, sweet, stuffed or sliced. This larger than life pepper is versatile and ready to be your meal time hero.

Stingrays Hot Peppers; Spicy and ready to sting! Spicy and ready to sting, these multi-colored hot peppers are the secret ingredient to give a little heat to your next authentic creation.

Mini Munchies 4x4 Tomato Snack Packs; Our Mini Munchies Snack Sized Veggies aim to promote a healthy, active lifestyle to both children and their parents alike. The perfect healthy snack combination makes it easy for a grab and go snack! Exclusively on display at Booth 707 at PMA Fresh Summit, be on the lookout for the new 4x4 Tomato Snack Packs, a burst of sweet flavor in every bite!

SNACKERZ One Bite Nano Cucumbers; “Uh Oh, we shrunk the cukes!” We tried smaller but the technology would not allow it! Snackerz are here! Hydrate by the handful with the snack that will change recess & break time forever! Fresh, crunchy and full of healthy goodness!

SNACKERZ One Bite Nano Tomatoes; “Uh Oh, we shrunk the tomatoes!” We tried smaller but the technology would not allow it! Snackerz are here! Sweet treats by the handful with the snack that will change recess & break time forever! Nano sized, fresh, and full of healthy goodness!

Juno On The Vine; Vine Fresh Sweetness in Every Bite!” Nurtured on the vine and hand-picked at peak flavor, the new Juno on the Vine Sweet Red Grape Tomatoes are the perfect selection for a tomato connoisseur.

Azuca On The Vine; “Sweet Red Cherry Tomatoes on the Vine”. A premium tomato for the discerning tomato aficionado.

“By having a variety of fresh vegetable options from our family of growers, we remove the seasonality and provide a consistent, flavorful product 12 months a year. With new options and our Georgia facility getting ready for its first crop, we have a very exciting year ahead of us”, said Moracci.

“Our brand strategy is to always go beyond the package; when it comes to bringing new products to market, we want to ensure that our customers have all the information they need to make the right purchasing decision”, said Chris Veillon, Chief Marketing Officer. Pure Flavor® develops in-depth product descriptions, multi-product recipes, performs nutritional testing, and develops an extensive variety of promotional content to support all of its products. With a new website (pure-flavor.com) that was launched in July, Pure Flavor® employs a variety of digital strategies to connect with consumer in geo-specific regions throughout North America.

To learn more about Pure Flavor®, visit Booth 707 at PMA Fresh Summit in Orlando, FL October 19-20 or visit Pure-Flavor.com/PMA2018.

-30-

About Pure Flavor® -

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise

Education Matters: Students Grow Food Hydroponically

By: SUSANNE BRUNNER

September 24, 2018

CABOT, Ark. - Growing food without soil? It's happening at Cabot High School.

"It most definitely grabs their attention," says Griffin Prior, Cabot High Senior.

When you're walking down the halls, it's hard to miss these plant towers.

"It teaches us so much responsibility because if we don't take care of it, then it's just going to die," says Cora Hicks, Cabot High Senior.

Using a pH System, students in Plant Science Class are testing out their new hydroponic grow tower. The lettuce sprouts without soil. Instead, these teens use mineral nutrients in water and light.

"It's easier than to dig in dirt to show kids how the root system grows, how the plant itself grows, on what it uses to grow," says Prior.

Prior and his classmates are nurturing the leafy greens with a pH System. Periodically, students will test the pH in the water to see if the plant is getting the right amount of nutrients it needs. The process was a lot of trial and error.

Since July, students have harvested about 9 pounds of organic lettuce. With 6 of these plant towers on hand, there's enough lettuce for everyone.

"We kind of share it throughout the district. It is good! It tastes just like a salad," says Hicks.

From tower to table, Plant Science is growing with interest and this method is planting the seed to something bigger in agriculture education. Cabot High School received the towers during the summer and they hope to get more in the future.

To keep up with Susanne Brunner's Education Matters Reports, you can like her page here

US (MA): Horticultural Lighting On Show At Tech Festival

October 8-14 Boston

OSRAM will bring its technology to Boston’s City Hall Plaza in early October as the Gold Sponsor of HUBweek, a weeklong festival and civic initiative that explores the intersections of art, science and technology.

OSRAM will showcase smart horticulture lighting solutions, Human Centric Lighting (HCL) glasses and an HCL light ceiling in its shipping container; and will include pop-up experiences and exhibit participation with collaborative partners such as Workbar, Dan’s Power Plant, Corner Stalk Farm and FreshBox Farms. OSRAM technology experts also will take part in panel discussions and other events throughout the week. OSRAM will be centrally located at The HUB, across from the Hall of the Future, during HUBweek, held Oct. 8-14, 2018, on Boston’s City Hall Plaza.

“HUBweek has proven to be a hot spot for innovators. This year OSRAM is showing how some of its coolest technologies are at the heart of it all, including smart horticultural lighting for urban farms and human centric lighting glasses, which have been used by BMW M Motorsports race car drivers and the German ski team during the 2018 Winter Games,” said Lori Brock, OSRAM Head of Innovation, Americas Region. “Ten years ago, nobody could have predicted the impact of such technologies. Today, Urban Farming and HCL are increasingly making their way into the mainstream, providing a critical first step in fundamentally changing how we live our lives and build a healthier, more sustainable future.”

Brock will take part in a curated panel focusing on the impact of technology on health, along with other notable experts. The panel discussion will take place at Center Stage at The HUB at 2:30 p.m. Wednesday, Oct. 10, 2018.

Horticultural lighting solutions

Due to limited natural resources, indoor farming soon will become more prevalent, providing fresh produce closer to urban environments like Boston. Visitors of the OSRAM showcase at HUBweek will learn how growing plants indoors with smart LED-based lighting technology can save water and energy.

The horticultural lighting solutions also can help growers improve flavor and nutrition profiles, better manage the growth cycle, and increase yield – either on-site or remotely. LED technology and advanced sensors ensure plant growth 365 days a year and supports local food production while helping to significantly reduce the environmental footprint.

OSRAM will be located across from the Hall of the Future in The HUB during HUBweek, held Oct. 8-14, 2018, on Boston’s City Hall Plaza. For more information about OSRAM, visit www.osram.us, and for more information about HUBweek 2018 and to purchase one of three pass types to unlock all types of experiences during HUBweek, visit hubweek.org.

Publication date : 10/1/2018

Humans And Food Are Part of Our Water Cycle

Water is the basis of all life on Earth. Treating and managing water in a sustainable and integrated way helps maintain water quantity and quality for a variety of uses, including agriculture

Water is the basis of all life on Earth. Treating and managing water in a sustainable and integrated way helps maintain water quantity and quality for a variety of uses, including agriculture. This new animation is on YouTube from the CONSERVE Water for Agriculture CAP project at the University of Maryland School of Public Health and regional partners, supported by NIFA, Grant number 20166800725064.

How Do You Grow Vegetables In The Desert?

A Syrian farmer in the UAE is producing a variety of salad vegetables and herbs in the inhospitable climate and terrain of the region.

Amjad Alkhal, who works as an agricultural engineer at Emirates Hydroponics Farms , uses a hydroponic farming system - an innovative method of growing plants without soil - but instead using a liquid nutrient solution. Amjad Alkhal grows produce in the desert using a hydroponic farming system Chilled water passes through insulating tubes to nourish plants like lettuce, which are planted in a fibrous material called rockwool. Rockwool is made of crushed rocks and holds water like a sponge.

Once the water has completed a cycle, it is drained back out to be filtered and reused. In this process crops are planted in rockwool, a fibrous material made of crushed rock Using alternative farming systems has saved Alkhal around 90 percent of the water that he would have used by deploying traditional farming methods. The farmer also uses a vertical farming rotatory field - a stackable, revolving farm bed with 18 rows.

This set-up has also saved Alkhal space, allowing him to be located closer to the city centre and deliver produce to stores faster, which in turn has reduced the farm’s environmental footprint. “That rotatory greenhouse, which we applied in 2005, is the first rotatory greenhouse in the Middle East,” says Alkhal, “Due to the system, if you were going to plant in the same area for traditional agriculture it would need around six times [the space of] this one.”

Alkhal’s rotatory greenhouses use six times less space than traditional agriculture Emirates Hydroponics Farms is approximately two hectares large, equivalent to the size of two rugby fields. Alkhal is able to produce around 500,000 lettuce plants - including nine varieties - and two million herbs each year. Like Alkhal, many UAE-based farmers grow their crops on 'marginal land' - meaning that it has low agricultural worth due to factors like poor soil, little freshwater and harsh temperatures.

The International Center for Biosaline Agriculture is also working to find homegrown solutions in the UAE, exploring ways to get the most out of scarce resources like freshwater. The centre uses salty seawater to farm certain crops that are both salt and heat tolerant, such as quinoa and mustard plants. Other than using salt water for agriculture, the ICBA has an ‘integrated aquaculture’ that desalinates naturally salty groundwater to produce freshwater for farming.

It also produces brine – a highly concentrated salt water - to farm fish. The ICBA enriches the water with fish waste products to fertilise crops In a separate operation, this brine water is enriched with fish waste products, and used to fertilise a sea-bean-like vegetable called salicornia. Yet another growing trend in regional agriculture is so-called precision farming, which gives plants the exact amount of what they need to flourish.

“Date palms require about 50 litres [of water] a day in the winter and about 150 litres in the summertime. Whereas if you talk to any farmer, they provide more than 300 liters a day per tree,” explains ICBA’s Director Ismane Elouafi, “With precision agriculture, you give the information to the farmers that they don’t need to use more than 50 litres, and sensors can also make the irrigation stop at a certain time.”

Drones are used to measure plants hydration, allowing for a precise irrigation system that saves water This type of ‘smart farming’ uses drones with sensors to measure a plant's hydration. It is currently being applied in a variety of ways in the UAE, which is investing in new food technologies .

The country is planning to build in Dubai the world’s largest vertical farm later this year. Construction is set to being in November.

In addition, Masdar - a sustainable city in the desert of Abu Dhabi set up with an original investment of $15 billion - plans to test smart home farms, whilst looking at ways to better conserve energy and water nationwide. / Euronews

Will America's Future Farmers Be Robots?

Iron Ox Start-Up

Angus possibly will be America’s farmer of the future. He's heavyset, weighing in at nearly 1,000 pounds, and he is a bit slow. But he's strong enough to hoist 800-pound pallets of maturing vegetables and can move them from place to place on his own. Angus is a robot.

To Brandon Alexander, Angus and other robots are key to a new wave of local agriculture that aims to raise lettuce, basil and other produce in metropolitan areas while conserving water and sidestepping the high costs of human labor. It's a big challenge, and some earlier efforts have flopped.

After raising $6 million and tinkering with autonomous robots for two years, Alexander's startup Iron Ox says it's ready to start delivering crops of its robotically grown vegetables to people's salad bowls.

As reported by cbsnews.com, Iron Ox planted its first robot farm in an 8,000-square-foot warehouse in San Carlos, California, a suburb located 25 miles south of San Francisco. Although no deals have been struck yet, Alexander says Iron Ox has been talking to San Francisco Bay area restaurants interested in buying its leafy vegetables and expects to begin selling to supermarkets next year.

Publication date : 10/4/2018

Does It Make Economic Sense For You To Install Grow Lights?

Posted on 09/27/2018

Written by David Kuack, HortAmericas.com

The Lighting Approaches to Maximize Profits (LAMP) project aims to determine how growers can maximize their return on investment when considering installing grow lights.

As light emitting diodes (LEDs) become more efficient and more affordable, an increasing number of greenhouse and plant factory growers will consider installing LED luminaires to light their crops. In the case of greenhouse growers, these luminaires would provide light to supplement natural sunlight. For plant factory growers, production depends entirely on the light provided by an artificial light source including LEDs, high pressure sodium or metal halide luminaires.

According to University of Georgia horticulture professor Marc van Iersel, the electricity for supplemental lighting in a greenhouse accounts for 20-30 percent of variable costs. In the case of plant factories which rely solely on artificial light, the electricity cost accounts for 50-60 percent of the variable costs.

van Iersel is heading up a $5 million, four-year research project that will focus on enabling growers to maximize the return on their lighting investment. Funding for the Lighting Approaches to Maximize Profits (LAMP) project is being provided by the USDA National Institute for Food and Agriculture Specialty Crop Research Initiative. The team that has been assembled to work on the project includes 15 university researchers, an advisory panel of greenhouse and plant factory growers and industry consultants.

“The job of the advisory grower panel is to make sure that the research that we do is actually what they need,” van Iersel said. “These are growers who will directly benefit from the research. We are also working with consultants who represent a big section of the industry. We are looking to them to help disseminate the information generated by the research to the industry.

“The research is looking to determine how growers can maximize their return on investment. There has been a lot of research done on how to grow plants with LED lights. We know growers can produce plants with lights. But what we don’t really know is how can growers make the most money doing it.”

Focused on LEDs

van Iersel said most of the project’s research will focus on the use of LEDs with some economic comparison to high pressure sodium (HPS) lamps.

“LEDs are clearly the lights of choice for the future,” he said. “Where we are interested in comparing LEDs and HPS is in regards to the economics. LEDs are more efficient, but they are also more expensive. Is the extra cost of LEDs worth it or are some growers actually better off paying less in capital expense for HPS lamps and more for the electricity to operate them? That is not a simple question to answer.

“There really hasn’t been a big price drop in LEDs. What LED manufacturers have done is rather than lowering the price, they have focused on making the LEDs better. Newer LED lights have hundreds of individual diodes in them. That is one way to help make the lights more efficient. But obviously they are putting more hardware in the lights. In older LED lights there were fewer individual diodes that went into a single light. The diodes were expensive. Now that the diodes are relatively cheap the manufacturers are putting in more of them so that the lights are more efficient. There seems to be a race among manufacturers to try to make the most efficient LED light possible. Right now it seems like the focus is more on creating a more efficient light than on creating a cheaper light.”

van Iersel said LED light manufacturers can easily match the light intensity of HPS lamps.

“What the LED manufacturers typically do with more diodes is run the diodes at only a fraction of their full power,” he said. “That makes the diodes more efficient. If an LED operates at 50 percent of its maximum power, it is substantially more efficient than running it at full power.”

Using supplemental light efficiently

One area that van Iersel is particularly interested in studying is making sure that growers provide supplemental light when plants are best able to efficiently use the light.

“LEDs are fully dimmable and can be dimmed instantaneously,” he said. “LEDs can very easily be programmed to respond to ambient light levels. One of the things that we are working on is designing systems that dim automatically as the sunlight level increases.

“With LEDs it’s more than turning them off and on, it’s dimming them. We have a system where we are calculating every second how much light to provide and how much to dim or brighten the LEDs. That is not possible to do with HPS.”

van Iersel said most LEDs are already dimmable.

“Every LED light is dimmable, it’s just a matter of using the right driver, which provides the power to the LEDs,” he said. It is very easy to incorporate into the lights. What I would hope is going to ultimately happen is growers are going to demand this kind of technology when they look at LEDs and the manufacturers have no choice than to provide it.”

van Iersel said another area of interest with the research is using the light spectrum as a way to manipulate quality.

“This could be accomplished with either the red:blue ratio or the amount of far red that is incorporated into the spectrum,” he said. “We also want to look at how the light is actually delivered to the plants. Right now, at least with ornamentals, growers look at the daily light integral (DLI) that is required to grow a particular crop. There are some clear indications that if the DLI is spread out over a longer photoperiod, for example, 20 hours instead of 14 hours, with the same amount of light over the entire day that more growth occurs with the longer photoperiod. This would be a lower instantaneous light level, but the same amount of light over the course of the entire day. This would allow growers to purchase fewer lights.”

Simplifying growers’ choices

van Iersel said one of outcomes of the research project is to be able to provide growers with a simple to use calculator that allows them to figure out if supplemental lighting will actually pay back in their particular production situation.

“If we can prevent growers from buying lights if they are not going to realize a return on investment that is going to be a good thing,” he said. “If they do decide that they want to use supplemental light, what makes more sense? Is it better to purchase HPS or LEDs? Which lights are going to offer a better return on investment? We hope to develop spreadsheets and some of this information will be incorporated into the Virtual Grower software program that is available free to growers.”

Current, powered by GE, Arize Lynk LED grow lights are being used by mGardens in its vertical farm in Gorham, Kan.

van Iersel also said some of the information that has been incorporated into the proposed horticultural lighting label is going to be required for the calculations.

“The lighting companies typically provide this information already, specifically the efficacy of the lights. Every reputable lighting manufacturer will be able provide this information. After the LAMP research is completed, growers should be able to look at the label information from different lighting companies and run some scenarios to tell them which lights are the most cost effective for them. It is really difficult right now for growers to decide whether or not to light and what kind of lighting is cost effective. It depends on a number of factors including where they’re located, their electricity prices, the crops they’re producing and how well those crops respond to supplemental light. Unfortunately, currently there is a lot of information that needs to go into doing these calculations. This has hampered the adoption of LED lights because growers can’t determine if they can pay for them.

“Once the research is done, the only numbers growers should need to plug in are basically the profit margins on their crops. Hopefully we will be able to provide them with the rest of the information they need to determine whether installing lights makes sense financially.”

For more: Marc van Iersel, University of Georgia, Department of Horticulture, Athens, GA 30602; (706) 583-0284; mvanier@uga.edu; http://hortphys.uga.edu/personnel/van-iersel.html; https://www.facebook.com/HortLAMP.

This article is property of Hort Americas and was written by David Kuack, a freelance technical writer in Fort Worth, TX.

Posted in News

Tagged Ag Tech, Indoor Ag, LED, LED grow light research, LED Grow Lights

See How People Are Using FarmBot

Drag & Drop

Graphically design your farm by dragging and dropping plants into the map. The game-like interface is learned in just a few minutes so you’ll have the whole growing season planned in no time.

Growing Regimens

Build regimens for taking care of a plant throughout its entire life by scheduling sequences to run when the plant is a certain age. Regimens can be reused, making replanting a breeze.

Sequence Building

Quickly create custom sequences to take full advantage of your hardware – no coding is required. Simply drag and drop basic operations together, adjust the parameters, and save.

Real-Time Control

Move FarmBot and operate its tools in real-time with the manual controls. Scare birds away from work or next time friends are over, pull out your phone for a quick and impressive demo.

Below are three video stories that chronicle how a young family, a university professor, and a non-profit are all using FarmBot in unique ways. Each video is a little long (~8 minutes) so you might just want to watch the one that sounds most interesting to you.

Video 1: The Sudweeks Family

Garrett and Lexie Sudweeks are first generation FarmBot builders in Cedar City, Utah in the United States. Watch them put together their v1.2 FarmBot Genesis kit and hear what it means to them to grow their own food and be a part of the larger open-source FarmBot community.

Video 2: FarmBot in Education

John G. Wells, Ph.D. is an Associate Professor of Technology Education at Virginia Tech University. Learn how he is implementing FarmBot in a multi-generational, research-based fashion that engages undergraduate students, doc students, and faculty at the university and K-12 level.

Video 3: FarmBot as an Accessibility Technology

Thrive Upstate is a non-profit in Greenville, South Carolina that provides people with disabilities services, opportunities, and support, so they may thrive. See how they use FarmBot for horticultural therapy and to empower individuals who otherwise could not grow their own food.

Growing Food in Space,

on the Moon, and Mars

In July of 2017, the FarmBot core team and other open-source food groups were invited to the NASA Kennedy Space Center in Florida to participate in a 2-day event to brainstorm innovative open-source approaches to food production. Watch the video to see how FarmBot technology and our community of open-source contributors from around the world are helping humanity to one day grow food in deep space, on the Moon, and Mars.

Ready to get a FarmBot?

Order Here

Iowa Family-Owned Restaurant Embraces Hydroponics

When you think of a family-oriented eatery with a focus on home cooking, you probably don’t imagine a menu that includes hydroponically-grown lettuce, tomatoes and cucumbers. Junction 21 restaurant in Centralia, Iowa, however, provides the kind of farm-to-table experience that few people would expect in a place that serves up pizza, burgers and fries.

When co-owner Tim McAndrew’s son became vegan, he realized their eating options were limited. There weren’t many restaurants around them that offered plant-based foods and this realization helped spur the inspiration to create Junction 21. McAndrew and staff began growing their produce at GrowSpan’s Iowa campus using HydroCycle NFT channels. Having year-round access to fresh produce that can be grown without additives or chemicals was a big selling point for the owners.

McAndrew said the farm-to-table aspect of dining meant a lot to him, but it was also important to have a fun, casual atmosphere. Junction 21 attracts a wide variety of patrons, from farmers who have just finished working the field, to professionals holding business meetings. Along with traditional American fare, Junction 21 offers salads containing seven different kinds of hydroponic lettuce, which are mixed together and served in the salad bar daily. They also use whole tomatoes on sandwiches and pizzas and incorporate fresh basil into McAndrew’s homemade spaghetti sauce.

The HydroCycle Growing Systems featured in the video have served a wide array of customers, from large-scale growers like Junction 21, to hobbyists that just want to learn the basics of hydroponics from the comfort of their home. GrowSpan offers a variety of hydroponic equipment, including but not limited to Dutch buckets, NFT channels and ebb and flow systems.

For more information:

GrowSpan Greenhouse Structures

1395 John Fitch Blvd

South Windsor, Connecticut 06074

Toll-free USA: (800) 476 9715

International: +1 860 528 9550

info@growspan.com

www.growspan.com

Publication date : 9/28/2018

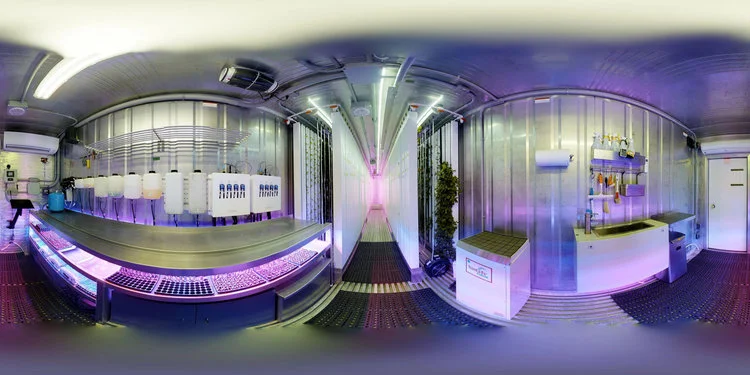

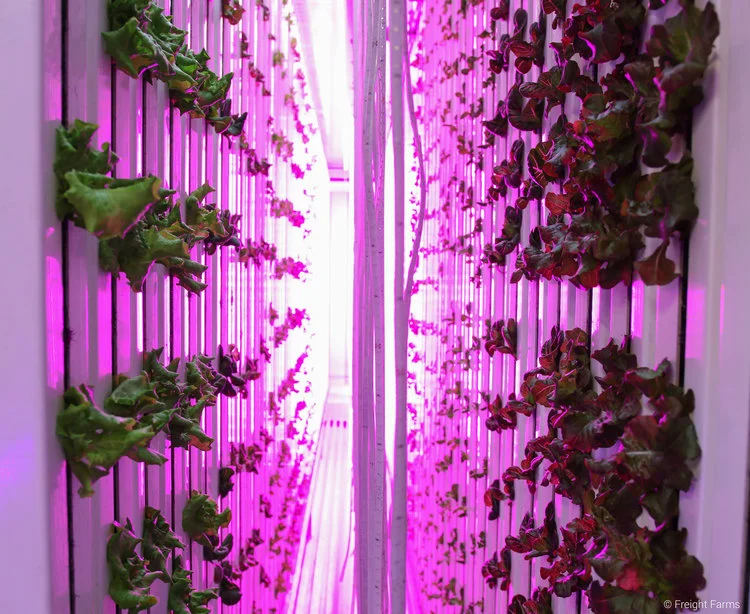

FOR SALE - November, 2016 Freight Farm - Computer Controlled Hydroponic Grow System - Colorado

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Make & Model - November, 2016 Leafy Green Machine (LGM)

Manufacturer - Freight Farms

Location - Colorado

Price - $60,000

Description

Well maintained late 2016 LGM purchased from Freight Farms.

This LGM has been a reliable producer of healthy produce.

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

1. ALL-WEATHER CONSTRUCTION

Steel frame with stainless interior, 40' x 8' x 9.6' overall footprint.

2. AUTOMATIC DOSING

Programmable nutrient & pH dosing for perfect growing conditions.

3. CUSTOM WORKBENCH

TIG-welded stainless workbench with integrated seedling growth stage.

4. COMMERCIAL VOLUME

Thousands of growing sites across 256 irrigated vertical towers.

5. HIGH-EFFICIENCY LED ARRAY

5:1 red / blue LED lighting optimized for green leafy growth.

6. INSULATED ENTRY

Padlock-proof safety door with controlled-environment insulation.

Product Booklet

All information is from sources deemed reliable but is subject to errors, omissions, changes in price, prior sale or withdrawal without notice.

No representation is made as to the accuracy of any description.

All measurements, yields and square footages are approximate and all information should be confirmed by the customer.

Disclaimer of Warranty - The 2016 Freight Farms LGM hydroponic farming container is being sold “as is” and the Seller disclaims all warranties of quality, whether express or implied, including the warranties of merchantability and fitness for a particular purpose.

Lef Farms Introduces Fusion, A Fresh New Take On Standard Spring Mixes

(LOUDON, NH) – How do you satisfy those who love baby greens but possess an unpretentious yet discriminating palette? Those who have been searching for a straightforward mix with a bit more punch than a…excuse us as we yawn…Spring Mix? Well, those are exactly the lettuce lovers lef Farms (pronounced “leaf”) is looking to attract with its newest blend of baby red and green leaf lettuce called Fusion.

“Our goal was to introduce a new mix that captures the hearts and taste buds of those looking for something simple but something that still carries a unique flavor and texture profile they can’t find in an everyday mix”, affirms lef’s President and CEO, Henry Huntington.

Similar to the approach lef took in the creation of its flagship Smooth and Spice mixes, lef performed an extensive analysis of the lettuce market. And what it uncovered was a sizable base that’s looking for a more straightforward lettuce option. But, true to form, lef added its own flair by melding soft, red buttery Bibb lettuce with a crisper and more substantial Romaine variety, resulting in the distinctive combination found in lef’s new Fusion.

“Each bite gives our customers a wonderfully tasty and crunchy experience,” smiles lef’s Sales & Marketing Manager, Donald Grandmaison. “Whether they’re enjoying a Fusion salad or topping off their favorite sandwich with some fresh Fusion greens, our new blend is as versatile as you can get.”

With Fusion the possibilities are endless, which isn’t too dissimilar to its shelf life. Like all of its baby blends, lef's Fusion is harvested in a cooler at 35°F. This quickly removes heat created during the growing process in order to lock in fresh taste, increase post-harvest performance, and extend shelf life. And, like its other blends, Fusion greens are delivered to shelves and kitchens across the Northeast within just 24 hours of harvest. So, they arrive to you just as crisp and fresh as when they left lef’s greenhouse.

Available in 4 oz. fuchsia-labeled clamshells, Fusion can be found, along with lef’s Smooth and Spice blends, at grocers all across the Northeast. For retailers, Fusion comes in an 8-pack case containing 32 oz. of lef-y goodness. And for food service, our 2 x 1.5 lb.-pack case amasses 3 lbs. of fresh Fusion in clear bags.

lef Farms is a 75,000-sq. ft. greenhouse growing facility, expected to produce nearly 1.5 million pounds annually of the freshest and healthiest baby greens for New England. www.lef-farms.com

Second Greenhouse Heated By Cryptocurrency Mining

Miami-based United American Corp announces the completion of its second BlockchainDome and the full commissioning of 1,500 additional miners for a total of 2,500 miners (3.8 megawatts) now in service in two BlockchainDomes. Pre-installation of 1.5 megawatts of electrical service for adjacent greenhouses heated by the BlockchainDomes is now also complete.

The latest BlockchainDome incorporates a number of improvements in construction and deployment from the first dome which includes mass pre-fabrication of a number of dome components and in-house CNC manufacturing of the mining rig docking stations. Construction logistics have also been refined to include pre-installation of foundations and utilities for future domes resulting in overall lower construction costs and shorter construction timelines.

"We have taken everything we have learned from the construction of the first BlockchainDome and used this knowledge to make the implementation of this subsequent BlockchainDomes faster, cheaper and of better quality," stated UnitedCorp CEO Benoit Laliberte. "Along with the generation of heat from the BlockchainDomes for agricultural purposes, our goal remains to be the low cost and environmentally sustainable standard for the industry."

UnitedCorp's technology uses the heat from cryptocurrency mining to support greenhouse agricultural operations through the BlockchainDome Heat Station system which keeps greenhouses at 20oC year-round. This represents a simple design solution compared to various alternatives whereby the cost of generating this heat from a single source is shared between multiple use cases.

Commercial greenhouses in cooler climates like in the Province of Quebec typically require a significant amount of thermal energy to supplement daytime solar energy, particularly during the period of September to May, and many older greenhouses utilize inefficient heating systems for this purpose. The dry heat produced by the BlockchainDome Heat Station is also used in the summer to reduce greenhouse mold and fungus caused by condensation thereby reducing or eliminating the need for chemicals to treat this problem and creating a more organic growth environment.

UnitedCorp believes this "Heat Campus" approach for heat generation and utilization is the future for agriculture and any other industry that can make use of low-cost heat with the ultimate goal being to get as close zero waste as possible. This is not only good economically but allows businesses to "green" their operations by significantly reducing the amount of electricity the combined operations require from the grid.

For more information:

UnitedCorp

5201 Blue Lagoon Drive, 8th floor,

Miami FL 33126

www.unitedcorp.com

Publication date : 9/25/2018

Record Harvest At Antarctic Greenhouse

77 kilograms fresh lettuce, 51 kilograms cucumbers, 29 kilograms tomatoes

The Antarctic greenhouse EDEN ISS has weathered the polar night – as well as Antarctic storms and temperatures below minus 40 degrees Celsius – in its practical test under the direction of the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR). It has been yielding herbs, lettuce and freshly harvested vegetables to the 10-member overwintering crew in the Alfred Wegener Institute’s Neumayer Station III for the first time since the beginning of 2018.

After more than half a year of operation in Antarctica, the self-sufficient greenhouse concept appears to be effective for climatically demanding regions on Earth, as well as for future manned missions to the Moon and Mars.

DLR researcher Paul Zabel is overcoming challenges, as well as acquiring knowledge from cultivating plants under such harsh conditions. To the overwintering team, the fresh greens are a welcome change during their long-term isolation. Zabel reported on his experiences in a live transmission from Antarctica on 13 September 2018.

Plenty of lettuce and tomatoes, few peppers, and no strawberries yet

“The harvests are now so plentiful that some of it does not always make it straight to the table, and we now have the luxury of spreading out our consumption of some refrigerated lettuce and herbs over several days,” Zabel says. “The overwintering team members are always looking forward to their next fresh meal.” Indeed, the lettuce, tomatoes, cucumbers and herbs thrive especially well under the conditions of 21 degrees Celsius and 65 percent relative humidity in the greenhouse. Seventy-seven kilograms of lettuce, 51 kilograms of cucumbers, 29 kilograms of tomatoes, 12 kilograms of kohlrabi, five kilograms of radishes and nine kilograms of herbs have been grown and harvested on a cultivation area of about 13 square metres.

“What astonished us was the failed harvest for peppers and strawberries,” Zabel says. The pepper and strawberry plants grow quickly in Antarctica as well, but the artificial pollination causes some problems, whereby only a few fruits or – in the case of strawberries – none at all have been produced. EDEN ISS Project Manager Daniel Schubert adds: “The pepper plants bore ample fruit during the greenhouse trial run in Bremen last year. This shows how important and instructive the greenhouse’s extreme test under Antarctic conditions is.”

Greenhouse technology in extreme conditions

Quite often, a storm prevents Zabel from making the 400-metre outdoor trip from the Neumayer Station III to the greenhouse. Under these circumstances, the control centre in Bremen takes complete responsibility for monitoring the plants and supervising the greenhouse. However, this has been necessary on no more than three consecutive days so far, so Zabel has been able to do a good job of ensuring that the plants receive continuous care. The importance of his presence on site has been demonstrated repeatedly at times when the greenhouse technology has run into difficulties under the extreme conditions and urgent assistance has been needed. “On one occasion, for example, I had to go to the greenhouse quickly because a screw had come loose in the thermal system, and the lamp cooling was no longer sufficiently ensured.” Small repairs like these are hardly foreseeable and teach the researchers about the greenhouse concept and how to make its design more robust in future.

“It is important for us to be able to react when there are complications with the existing tools and resources on site. After all, the sound operation of a greenhouse on the Moon and Mars would be essential for survival,” says Schubert, the Project Manager. Forty different experiments are currently running in the greenhouse. This means a lot of work for Zabel, as he extensively analyses the cultivation of vegetables. His tasks include taking regular microbiological samples, examining the precise quality of the harvest, and periodically checking all systems, such as light, temperature regulation, and the nutrient- and carbon dioxide-enriched air supply. He also documents how fresh food is affecting the health of the overwintering team members.

Sharing the fun live with strawberries and peppers, and providing tips

Gaining insights into Antarctic plant cultivation has so far been reserved for the international researchers on the project, but everyone will have this opportunity in the future. “Until now, we in the control centre have received daily images of the individual plants through 32 cameras in the greenhouse. The researchers involved have access to these images and can provide the relevant tips,” Schubert says. “Now, we are opening these plant images to the public via an online tool on the EDEN ISS project website. Anyone who is interested can take part live in our vegetable cultivation in the Antarctic.” Every day, photos of the individual plant cultivation boxes are automatically taken at a specific time and under special lighting conditions. These images are then transmitted to the mission control centre in Bremen and made available online. The plant growth can be followed via an interactive timeline. In this way, people can interactively participate in a technology that will become more important in the future.

Positive effect is noticeable

Eberhard Kohlberg from the Alfred Wegener Institute, who is the logistics manager for the Neumayer Station III and has been a member of the overwintering crew on several occasions, says how pleasant it is to have a garden with lettuce and herbs just around the corner: “Otherwise, the menu just consists of long-life products from the freezer and storage room.” Only at the end of October 2018 will the first supply aircraft be able to provide the overwintering team with fresh food items from the outside world once again. Neumayer III station manager Bernhard Gropp adds: “We greatly value and enjoy the fact that regularly fresh salad, herbs and vegetables from the greenhouse enrich our diet. The positive effect is noticeable.” The last part of the winter is particularly challenging for the crew, as they gradually have to switch back to normal operation with many people at the station.

For more information:

EDEN ISS

Hydroponic Farms Become Produce Alternative For Local Businesses

By Desiree Montilla | September 20, 2018

CHARLOTTESVILLE, Va. (CBS19 NEWS) -- A couple of places around the city will soon be farming indoors when their hydroponic gardens from Babylon Micro-Farms are installed.

Babylon Micro-Farms is a company that focuses on bringing fresh produce to the table using hydroponic control technology.

The company said it will be installing hydroponic gardens at a couple of University of Virginia dining halls and the Trout House at Boar's Head Resort.

Three Notch'd Brewery already installed a hydroponic farm and has been using it for a month to help produce spices and herbs for dishes.

Patrick Carroll, executive chef at Three Notch'd Brewery, said the company reached out to them and offered this alternative indoor method to grow their produce.

"We use a lot of different microgreens for garnishing and also for soups," said Carroll.

Carroll said a representative from Babylon Micro-Farms approached him with the idea to bring their farming indoors.

"The great thing about hydroponic is that you can grow pretty much the same thing with no soil and 50 times faster than with soil," he said.

He also said the hydroponic farm is an important feature to show their guests the way they handle their food.

"It's a huge wild factor for guests because you don't see this anywhere. I think that it really draws people to the restaurant," Carroll said. "They see that we're really doing craft things here growing our own food and harvesting our own food."

The hydroponic farm also challenged Carroll to use new herbs in recipes.

"It kind of challenged me a little bit more to learn about what it tastes like and what would go well with it and then we would put that in our menu," he said. "Since we change our menu every week here at Three Notch'd, it's actually easier for us to do because we have new micro-greens and greens coming out for us."

Babylon Micro-Farms said it'll be installing hydroponic gardens at Newcomb and O-Hill Dining Halls at UVA on Friday.

The Trout House renovation is expected to be completed in late October.

South Korean ‘Smart Farm’ Built Inside Former Road Tunnel

A South Korean company is operating the country’s largest indoor “smart farm” inside a former road tunnel.

In this Aug. 9, 2018, photo, head of NextOn Choi Jae Bin explains how his farm's crop cultivation system works. (AP Photo/Han Myung Oh)

September 05, 2018 by VOA

A South Korean company is operating the country’s largest indoor “smart farm” inside a former road tunnel.

The farm produces fruits and vegetables hydroponically, which means the plants do not grow in the ground. Instead, they grow on vertical equipment that provides a continuous flow of water. Indoor farms use artificial light instead of sunlight.

There are other vertical smart farms in South Korea. But this one – built by the company NextOn about 200 kilometers south of Seoul - is the nation’s biggest. It is also one of the largest indoor vertical farms in the world, with a total area of 2,300 square meters.

But what makes the farm even more unusual is the fact that it sits inside a huge tunnel. The tunnel was built in 1970 for one of South Korea’s first major highways, but it closed down in 2002. NextOn signed an agreement with the government last year to take over the tunnel and turn it into a high-tech farm.

NextOn officials say the tunnel environment permits ideal conditions for an indoor farm. It keeps a steady temperature of between 10 and 22 degrees Celsius. The tunnel is also completely dark, making it easier to provide exactly the right amount of artificial light.

A set of bright blue doors covers the entrance of the tunnel that holds the farm NextOn in Okcheon, South Korea.(AP Photo/Han Myung Oh)

The farming system can produce more than 60 different kinds of fruits and vegetables. The company said foods produced in the indoor farm are also healthier since harmful chemicals are not necessary to prevent large insect invasions.

In South Korea, indoor vertical farming is seen as a possible solution to crop damage related to extreme weather that could get worse due to climate change. The country’s farming industry has also been hurt by shortages of land and workers.

South Korea’s Agriculture Ministry announced earlier this year it plans to invest in smart farm development nationwide. Those plans call for nearly doubling the current area for such farms.

Farming experts say high-tech farms, also used in Dubai and Israel, could be a good way to deal with problems many countries are facing with weather, decreasing farmland and fewer agricultural workers.

In this Aug. 9, 2018, photo, rows of illuminated grow spaces fill the tunnel-based vertical indoor farm NextOn in Okcheon, South Korea. (AP Photo/Han Myung Oh)

It can be difficult, though, for smart farmers to make a profit because of the high cost of building and operating. But NextOn said it cut its building costs in half by using the former tunnel and developing its own lighting and water systems.

These technologies reduced water and energy use and the need for workers. Sensors also measure things such as temperature, humidity, light and air quality. NextOn says the crops will cost less than other organic vegetables grown today.

Operators of the farm say they even provide music for the plants, since the tunnel blocks out any real sounds of nature. “We are playing classical music because vegetables also love listening to music like we do,” said the NextOn’s chief, Choi Jae Bin.

The company says it plans to expand its farm inside the tunnel in the near future to begin growing even more kinds of fruits, as well as plants used for medicinal purposes.

I’m Bryan Lynn.

Bryan Lynn wrote this story for VOA Learning English, based on a report by the Associated Press. Hai Do was the editor.

New Forum With CEA Scientists

By urbanagnews

September 21, 2018

Join three CEA scientists (Chieri Kubota, Erik Runkle and Cary Mitchell) who are organizing an online monthly forum series, called ‘Indoor Ag Science Café’. This online forum has been designed to discuss the science and technologies that can contribute to indoor controlled environment agriculture (AKA vertical farms). According to Chieri, “we wish to make the forum develop as a non-competitive, informal communication platform among indoor agriculture industries”.

Please contact Chieri Kubota (kubota.10@osu.edu) if you would like to join the Café.

The most recent topic presented by Erik Runkle at the Café is now available:

Grow Your Veggies At Home, Without Soil

Koay (left) and co-founder Johanson Chew turned a hobby into a career. (Photos by Low Yen Yeing/EdgeProp.my)

Growing your own vegetables could be fun and help you get the freshest greens to your dining table, but not everyone has the luxury of space to have their own vegetable plot at home.

However, with the hydroponic system, city dwellers could enjoy harvesting their own vegetables even with limited space.

With rising concerns over food safety and security, planting your own vegetables makes perfect sense and City Farm co-founder Jayden Koay believes that growing your own food at home will be the trend of the future for urbanites.

“The best way to keep your vegetables fresh is to keep them alive. The best is to pluck the vegetable, cook and serve it straight away,” he tells EdgeProp.my.

The two-year-old City Farm was initially established to offer fresh vegetables to the public but has evolved into a solutions provider to urbanites who want to become “city farmers”.

The outfit was formed by three electrical engineering graduates from the Malaysia Multimedia University including Koay. Growing their own food was first a hobby but quickly turned into a business. They believe that with the right knowledge and equipment, everyone can be urban farmers.

Unlike conventional planting, hydroponics is a soilless cultivation method of growing plants in a water-based and nutrient-rich solution as well as other inert medium such as rockwool, clay pellets and peat moss as a support to the roots.

Koay notes that the traditional way of using soil could cause soil contamination in the long run, due to the use of pesticides and chemical fertilisers. A polluted plot of land could take around 20 years to undergo natural soil treatment.

Part of the vegetables in City Farm are grown using Nutrient Film Technique.

“As the population grows and new agricultural land becomes scarce, fresh produce will be less and the quality of the produce will degrade. We will then be heavily exposed to preserved vegetables and processed food but all these can be avoided if we could self-supply,” he says.

Challenges

The challenge in maintaining a vertical farm is in ensuring the quality of the water; hygiene management; and pest control.

The hydroponic method may be cleaner and easier to manage than soil planting but it could still attract pests such as mosquitoes and spider mites, hence discipline is required to manage the vertical farm.

The seedling transplantation is another tough process as the seedlings are vulnerable to environmental changes and water quality. The ideal environment is a cold yet well-ventilated environment.

“Those using the balcony to grow their vegetables could choose the wicking system and opt to grow local vegetables which could stand our hot weather. The balcony is suitable for hydroponics as it has good ventilation,” Koay offers.

As for indoor hydroponic systems, air-conditioning and lighting are essential to create a controlled environment. Consumers could choose to plant highland vegetables or micro greens.

For commercial usage, hydroponic vegetables take about four weeks to harvest, but for self-consumption, the vegetables could be harvested in the second or third week.

Micro greens (left) and Ice Plant (right) grown in the hydrotrays

Don’t start planting your favourite veggie

The common mistake among beginners is the tendency to grow their favourite vegetable from the get-go which are often difficult to care for, rather than easier options.

“They will then feel disappointed and give up after a few tries, hence the best way is to start with easy-to-grow vegetables such as Choy Sum, kangkung and Bok Choy as well as herbs such as basil.

“They could move on to the more difficult plants such as tomatoes and chili padi or highland plants such as butterhead and chamomile once they are more equipped with experience and knowledge.

“So far, butterhead lettuce is one of the most challenging vegetables on my list as it requires extra care and grows slowly. The leaves will easily turn yellow or have burnt tips without proper care, hence the price is higher than other lettuces,” Koay says.

According to him, the average cost of hydroponic vegetable planting is around RM40 per pot, including the seeds, nutrients and the reusable equipment.

To encourage the concept of “farm to table”, City Farm has collaborated with 12 café operators in providing hydroponic solutions at their eateries, enabling patrons to purchase the fresh vegetables or pick the vegetables for the restaurant to cook on the spot.

The freshest way of eating vegetables: from farm to table.

“Currently, we have completed two vertical farms in two cafes. One is in Petaling Jaya, the other is in Seri Kembangan,” he says.

The vertical farm comprises multi-tier shelves of hydro trays with planting pots and LED lighting. It enables the café operators to grow at least 28 pots of vegetables, depending on the type of vegetables. Leafy salad greens such as butterhead, Arugula and Green Coral are the most popular vegetables that consumers will purchase off the rack, says Koay.

The vertical farm could also serve as a green wall in the cafe, creating a green and natural indoor environment, he adds.

Besides helping restaurants set up vertical farms, City Farm also organises monthly classes teaching city folk to grow their own vegetables.

Growing your own vegetables provides the pleasure of reaping the fruit from your labour. It can be fun and you do not have to worry about it being unsafe for your health.

This story first appeared in the EdgeProp.my pullout on Sept 7, 2018. You can access back issues here.

VEGETABLES DINING SPACE HYDROPONIC CITY FARM MALAYSIA MULTIMEDIA UNIVERSITY