Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Start-Up Develops Hydroponic Garden For Your Living Room

20th November 2018, London

Home growing kit supposedly allows for crops to be grown faster, with greater yield and less water required than for a conventional garden

The Hope Eden Garden

Photo: Hope Innovations

A Canandian start-up is looking for donors so it can launch a “plug-and-play” indoor garden allowing consumers to grow their own fresh produce hydroponically at home all year round.

Designed by Hope Innovations in Edson, Canada, the Hope Eden Garden uses a simple hydroponics system and aims to make growing convenient, affordable and environmentally friendly for home gardeners.

The company, which is trying to raise CA$10,000 on Kickstarter to fund the project, claims that compared to conventional gardening methods, the system allows for crops to be grown 40 percent faster, with three times the yield and 20 times less water required.

Users place seeds in a ‘growth cup’, add water and nutrients, plug in the lighting strips provided (or rely on natural light), and watch their plants grow.

Hydoponic production (growing directly in water) uses less space than a conventional garden and is up to 40 per cent more efficient than growing in soil, according to the company, which claims the growing kit will pay for itself in less than a year through the money saved on buying groceries.

The company is also keen to stress the flexibility of its product, claiming that it works with any kind of nutrient and any type of seed.

According to Hope, a range of fresh produce grows faster than would be possible in a conventional garden, including kale, spinach, tomato, lettuce and basil.

Vertical Farming Robot Wins Design Challenge

The winners of the 2018 Valtra Design Challenge were announced at the EIMA Show in Bologna, Italy. The competition which started in April and ended on September 23rd was targeted globally to designers, academic design students, design studios and automotive suppliers. This year’s challenge was to design the multi-purpose vehicle of the future: a machine that can handle multiple tasks to meet future needs and that is more efficient than today’s highly specialized machines.

The first place of the competition was awarded to the work “VERTICAL” by Austrian design team Benjamin Miller, Jack Morris, and Alireza Saeedi. The jury praised the concept as being a very creative interpretation of the challenge theme. “At first glance it looks very specialized, but if you judge the complete system instead of only the tractor, a versatile and holistic concept for the future emerges. The concept takes care of everything from seeding to distribution of food”, comments member of the jury Hans Philip Zachau.

“Valtra has been widely recognized for ground-breaking and visionary industrial design. We started the Design Challenge in order to raise awareness of future challenges in the agricultural community and society at large. It is also a platform for designers to showcase their innovations.” comments head of the jury and industrial design & user experience manager at Valtra, Kimmo Wihinen. “The Valtra Design Challenge is the world´s largest design contest in agricultural machinery and one of the biggest in the off-road vehicle industry. The high number of innovative and high-class entries shows us that there is a demand for this type of competition, and we are already working on the theme for the next edition”, he adds.

The Valtra Design Challenge 2018 Jury members were Kimmo Wihinen from Valtra, Brandon Montgomery and Sam Freesmeyer from AGCO, Hans Philip Zachau from Lighthouse Industrial Design and Paolo Grazioli Frozen Design Tokyo.

The Valtra Design Challenge was organised for the second time in 2018. This year the competition has received 107 entries from 32 different countries and six continents. The first prize of the Valtra Design Challenge is a €10,000 cheque.

For more information:

www.valtra.com/designchallenge

Local Company's Indoor Growing System Could Be Solution To Safer Romaine And Other Lettuce

by Amanda Becker, FOX 11 News

Sunday, November 25th 2018

Local company's indoor growing system could be solution to safer Romaine and other lettuce. (WLUK/Amanda Becker)

FOX CROSSING (WLUK) -- The FDA and Center for Disease Control warned people this past week not to eat romaine lettuce due to a dangerous strain of E. Coli.

The CDC estimates that E.Coli, also referred to as STEC, causes 3,600 hospitalizations and 30 deaths in the US each year.

This past summer an outbreak caused 5 deaths.

The CDC has reported outbreaks of E. Coli, in various leafy green vegetables alone, 7 out of the last 12 years.

The latest scare came just before Thanksgiving and the busiest day of the year for many grocers.

While many businesses were clearing their shelves of romaine lettuce, it was the customers clearing the shelves here at the Free Market in Appleton.

“People snatched it all up. They've been saying this is the only place they can find it,” said Kyra Evers, a Free Market associate.

Sunday just one bag of mixed greens remained, but they don’t have far to go for more. The produce travels just two miles from the Fox Valley Hydro Farm to here. It's not your conventional farm, instead a vertical hydroponic system indoors.

“If we had an acre of these systems we could grow roughly 100 acres of conventional farming,” said Steve Main, the owner of Fox Valley Hydro Farm.

He grows and distributes, leafy greens to local businesses and at Farmers Markets- mainly lettuce.

Local company's indoor growing system could be solution to safer Romaine and other lettuce. (WLUK/ Amanda Becker){p}{/p}

Fork Farms is the Appleton tech company that designs and builds the system.

”We are able to control the environment here so not only can we control the growth rates and the success of the plant but we can also control the food safety really carefully,” said Alex Tyink president of Fork Farms.

Safety is what’s on the mind of shoppers when buying lettuce these days.

“The E. coli outbreak is really scary,” said Tyink.

Tyink says growing indoors, and locally, lowers the chances of bacterial growth.

“Those crops are coming from very large-scale farms usually in Arizona and California and it’s where we get majority of our produce right now in the United States,” said Tyink. “Farms like that they grow outdoors primarily.”

He lists things like human contact, travel time, well water and environmental conditions to all have negative effects on crops.

“That product being at such a large scale has to go through a lot of different steps in the supply chain in order to get here- and every one of those steps is an opportunity for pathogens to get into the food,” he said.

Steps that he says are eliminated with this hydroponic process.

“Some of those unknowns, we can really tightly control here,” he said.

From 'indoor farm' to table.

Walmart To Install Solar Panels On 19 Of Its Stores In Illinois

Walmart has reached an agreement with a California company to install solar systems at two distribution centers and 19 stores, including those in Belleville, O’Fallon, Sparta and Litchfield.

This Walmart video shows rooftop and ground-mounted solar panels at some of its stores and distribution centers in the United States. The company recently announced plans to expand its solar program to 21 sites in Illinois.By Teri Maddox

BY TERI MADDOX

November 16, 2018

The nation’s largest retailer is joining the solar boom in Illinois next year.

Walmart has reached an agreement with a California company to install solar systems at two distribution centers and 19 stores, including those in Belleville, O’Fallon, Sparta and Litchfield. It’s billed as a way to save money on electricity and help the environment by reducing carbon emissions.

The move was prompted by the state’s new Adjustable Block Program, which provides incentives for commercial and residential rooftop solar projects, as well as community solar farms.

“We can meet or beat our current cost of energy (under the agreement),” said Katherine Canoy, Walmart’s senior manager for renewable energy, speaking by phone from Bentonville, Arkansas. “From a business perspective, it makes sense for us on a lot of levels.”

The company already has solar systems at about 350 of its 5,000 sites in the United States, including Walmart and Sam’s Club stores. Canoy said installations don’t have a direct effect on prices, but the company’s increasing use of renewable wind and solar energy will help keep them low in the long run.

For Walmart’s first 21 solar projects in Illinois, the retailer is partnering with SunPower, a company based in San Jose, California. It designs, installs and maintains commercial solar systems all over the country, often combining rooftop and ground-mounted solar panels.

Most customers are able to generate 40 to 75 percent of their electricity with solar, said Robert Rogan, SunPower’s senior director of strategy. Walmart generates 5 to 70 percent at its existing solar sites.

“It really varies from store to store, depending on how much of the roof space we can utilize and also how much energy that store is using,” Rogan said.

Some Walmart stores have skylights and air-conditioning units on their roofs, and climate can affect how much electricity is needed to heat and cool buildings.

This photo shows a commercial solar system installed by SunPower, a company based in San Jose, California. It’s designing systems for 19 Walmart stores and two distribution centers in Illinois.

Technology Distilled To Grow The Hydroponics Industry

By Chad Campbell

November 16, 2018

When Horticulture Assistant Professor Krishna Nemali joined Purdue in July 2016, he immediately began to develop a program as new to the school as he was. Nemali studied agriculture in India before earning his Ph.D. from the University of Georgia and spending nine years as a scientist in controlled environment crop physiology at Monsanto. All these experiences combined to provide him with the range of experience necessary in his current position coordinating research and Purdue Extension activities in Controlled Environment Agriculture (CEA).

CEA harnesses technology to grow plants like vegetables and ornamentals in conditions maximizing the efficient use of water, light, labor and space. Hydroponics, the method most commonly associated with CEA, minimizes water, nutrient and labor requirements to grow plants. It can also reduce other needs, such as pesticides. Researchers like Nemali work to discover the perfect combinations of water, light, nutrients, temperature and additional factors to make sure there is no wasted energy or potential. Nemali’s goal is to answer the question,

“How do you make that technology easily accessible to everybody?”

Nemali is working to harness the potential of smartphones, specifically new apps and add-on devices, to provide growers access to these processes. “There are companies and some apps already there that just take a picture and show some data. That’s not what we’re trying to get at. We have these expensive imaging stations and we are developing technologies that match that high-quality data.” A combination of research, calibration and algorithms takes place behind the scenes to provide farmers with valuable, yet easy-to-understand information, everything using their smartphones.

One app Nemali is creating will use background processing to measure plant growth. The plant’s size is calculated through pictures the user takes and algorithms designed by Nemali. With daily use, the app generates growth curves. “It’s like when you take your kids to a doctor, and they take a weight and height measurement.They put the numbers on a standard chart. 90th percentile height, 70th percentile weight. You can create standard curves for different species and plot this data under the standards.”

Nitrogen is essential in plant processes, including photosynthesis, yet the equipment needed to measure nitrogen levels in plants is cost-prohibitive. Nemali’s lab is currently creating a similar device for smartphones, available for less than $150. Nemali hopes to create widely adopted and applied technology to reach independent growers.

Through Purdue Extension, Nemali also works with Indiana farmers to capitalize on the untapped potential hydroponics provides. The industry is small, but rapidly growing at 3.5% annually in the US. For example, Nemali sees a wealth of opportunity in leaf lettuce production. The USDA estimates people eat about 11 pounds of leaf lettuce per year. With 6.7 million Hoosiers and a $1.00 wholesale valuation on each pound of lettuce, that’s over $70 million.

Indiana imports nearly all its leaf lettuce from places like Arizona and California. “We want that money to stay within Indiana," Nemali shared. We want our growers capitalizing on this. There is a demand there. Grow lettuce locally, sell lettuce locally, keep the money local. That money spread out among the 300 lettuce growers in Indiana, that’s going to improve their livelihood. That’s what sustainability, in my opinion, is.” He organizes workshops that provide both classroom style training and experiential learning to farmers.

The methods and technology Nemali creates produce a level of precision that can set hydroponic farmers apart. Even small adjustments to the levels of red, green and blue artificial light provided to grow plants can have significant effects on the growth, color and nutritional value of plants. Nemali tells his growers, “Don’t say simply that your lettuce is crisp and fresh. Everybody says that. How do you find a niche? Use technology to grow lettuce that has more nutritional value, antioxidants, and less nitrates. Show the value. Health. That’s what attracts millennials.” The results of this research are integrated into Nemali’s apps to bolster the intelligence of the technology.

Nemali also uses hydroponics and vertical farming techniques to address problems like childhood obesity. A few years ago, Nemali’s son participated in a multi-week summer camp where the children planted and harvested their own vegetables, making salads and soups.

“For the next couple of months,” says Nemali, “he was all about eating healthy. That told me something. Give kids that exposure to plants: how you seed them, sow them, you see them grow, you harvest them and clean them. That may change their attitudes and behaviors from a less favorable attitude towards eating healthy, and that’s what we’re trying to do.” He collaborates with schools to setup small indoor growing facilities for children using hydroponics.

As the benefits of hydroponics become increasingly apparent, nations around the world are studying, researching and building hydroponic facilities of their own. Scarcities of land and water are critical issues in many countries. Hydroponics are incredibly efficient in both respects. Vertical farming is a common practice in hydroponic facilities. Warehouses may accommodate 15 to 20 levels of plants. It is reasonable to expect five to ten times more production in such spaces.

Hydroponics brings researchers across the globe together to work toward a common goal. Nemali embraces the spirit of hydroponics by making the most of current resources and rapidly producing new resources to grow the industry.

Want to try hydroponics at home?

Create your own simple hobby garden.

Category: Agricultural & Biological Engineering, Agricultural Economics, Agronomy, Botany & Plant Pathology, Extension, Food Science, Forestry & Natural Resources, Giant Leaps, International Programs in Agriculture, Office of Multicultural Programs, Research, Teaching, Uncategorized

Aquaponics Farm Puts Fresh Fish And Greens On Plates Of Calgary Restaurants

Reid Henuset and Paul Shumlich of Deepwater Farms in Calgary's first commercial aquaponics farm on Tuesday, Nov. 20, 2018. Al Charest/Postmedia

AMANDA STEPHENSON, CALGARY HERALD

November 20, 2018

It looks like any non-descript industrial park warehouse, but the new Deepwater Farms facility in southeast Calgary produces fresh, local food daily using technology that some believe could be the future of agriculture.

It looks like any nondescript industrial park warehouse, but the new Deepwater Farms facility in southeast Calgary produces fresh, local food daily using technology that some believe could be the future of agriculture.

This urban farm, located in a 10,000-square-foot building, is the city’s first commercial-scale aquaponics facility — meaning it combines hydroponics and aquaculture to raise both leafy greens and fish. Giant tanks house as many as 10,000 fish of varying ages and sizes (currently, Deepwater is raising sea bass), and the waste from the fish is then broken down into nitrates that are used to fertilize the racks upon racks of lettuce, herbs and other greens growing under giant LED lights.

The unconventional technology has given Deepwater the capacity to harvest about 450 kilograms a week of organic, locally grown produce. The company expects to triple that output once it is fully ramped up in late 2019. It can also harvest about 900 kilograms of fish a month — fresh, sustainable seafood that can go straight to the plates of landlocked Calgarians.

“I literally just stumbled across the concept of aquaponics one day on the internet,” said company founder Paul Shumlich. “It was the closed-loop aspect that really spoke to me, because we could take a waste product and turn it into a valuable input in another process. It was a symbiotic system between the fish and the plants, and it was organic.”

Reid Henuset and Paul Shumlich of Deepwater Farms in Calgary’s first commercial aquaponics farm. Al Charest/Postmedia

The 28-year-old Shumlich, who studied entrepreneurship at Mount Royal University, has been working on Deepwater Farms for close to five years, testing the technology in various garages and greenhouses, and building his customer base. Convinced there was a market for consistent, reliable produce that doesn’t need to be shipped from California or Mexico in the dead of winter, Shumlich started out by cold calling some of the city’s top restaurants.

He now has a 30-strong client list, and his produce appears in menu items at establishments including Model Milk, Ten Foot Henry, the Hyatt and the Teatro Group. Japanese restaurant Shokunin is the first restaurant to put Deepwater Farms’ fish on the menu, and the company, which now has 10 employees, expects more customers soon.

“In the city, we see the potential to grow 10 times our current size within the next three years,” Shumlich said.

While Deepwater is the largest farm of its type in commercial operation in Alberta, there is growing interest in aquaponics in the province. According to its website, Earthis Inc. is working on a design for a commercially viable vertical aquaponics greenhouse and already has a proof of concept up and running in Okotoks. And Current Prairie Fisherman Corp., which began farming tilapia and barramundi in Nobleford in 2008, recently built a large greenhouse to provide their restaurant clients with specialty vegetables as well, using fish waste as plant fertilizer.

Aquaponics is appealing from an environmental perspective and an economic perspective (plants grown through this type of system can grow three times as fast as conventionally grown produce), but it is more complex than other types of farming. Every part of the system must work in harmony and must be constantly monitored to ensure the health of both the plants and the fish. Still, Deepwater’s leaders say there is a future for aquaponics even in jurisdictions where indoor growing isn’t a necessity.

“Even though California and Florida have the weather to grow this stuff year-round, they still can’t control everything. They’re going to get rainy days, they’re going to get dry weather,” said acting president Reid Henuset. “If we can get our systems down to the point where we know how every little detail of it works, there’s no reason we couldn’t take it worldwide. Because, with this system, you can control everything.”

Deepwater has launched a crowdfunding campaign to raise money for expansion.

Shumlich said he believes aquaponics technology could have applications in cannabis production, greenhouses of all types and even industrial agriculture through the production of natural fertilizers.

“Vine crops I don’t think it makes sense to grow indoors, you’re not going to grow Prairie wheat and barley indoors,” Shumlich said. “But I think for things that are being transported out of southern California, like leafy greens, it’s definitely the future. And I think in general, smart agriculture is the future of all food production.”

Twitter.com/AmandaMsteph

EPA Case Study: Estimating The Environmental Effects of Green Roofs

Aramis Velazquez | November 2018

Photo: EPA

EPA Staff of Environmental Protection Agency writes:

Green roofs can contribute to environmental and livability goals—to mitigate the urban heat island effect, maintain clean air and water, and lower energy costs in buildings—while greening the urban landscape. As this methodology demonstrates, city planners, environmental regulators, and other practitioners can estimate the environmental and public health benefits of green roofs using free, credible, accessible tools. Because of the multiple benefits green roofs provide, they are gaining traction from a diverse set of stakeholders and businesses.

Interested parties nationwide can apply these methods and point to other evidence-based studies to estimate the value of green roofs and other green design practices in their areas. Using this methodology to quantitatively demonstrate the benefits of green roofs provides tangible data to decision-makers who have the power to implement green roofs as a strategy for achieving local environmental and public health goals.

The EPA-published case study, Estimating the Environmental Effects of Green Roofs, demonstrates the environmental and health benefits of green roofs for Kansas City, Missouri. The case study lays out a replicable analytical framework using free quantitative tools created by EPA and others that state and local decision-makers and practitioners can use to assess the multiple benefits of green roofs.

Aside from quantifying the benefits of green roofs, cities are pursuing ways to encourage green roof adoption, including voluntary incentives and regulatory mandates. Many cities have enacted policies that encourage green roof development through rebate programs, tax incentives, or fast-track permitting programs.

23 Cities that have implemented these policies—including Washington, D.C.; Toronto, Ontario; Philadelphia, Pennsylvania; Seattle, Washington; and Chicago, Illinois—also reported the largest square footage of green roof installations in 2016.

Find more information about Green Roofs in the EPA website.

Check out this video of the 909 Walnut Green Roof Project (from our Greenroofs.com Projects Database) in Kansas City, MO by Stott & Associates Architects, Jeffrey L. Bruce & Company, Soprema, Turf & Soil Diagnostics, and many more:

US (NM): Cannabis Provider Unveils 8.7 Million sq.ft. Facility

Ultra Health acquired 200 acres of farmland in Otero County, New Mexico to support the state’s growing medical cannabis program. At over 8.7 million square feet, the campus will be the largest cannabis cultivation facility in North America.

The new cultivation site also anticipates the legalization of cannabis for social use and large-scale hemp production in New Mexico. The facility will have the capacity to accommodate other New Mexico licensed producers and adjust to market and regulatory demands.

Ultra Health Tularosa will employ 100 local residents and house the nation’s most diverse cannabis cultivation operation. The new site will include 20 acres of indoor cultivation in 20 air-supported, wind-assisted style greenhouses, 80 acres of outdoor cannabis fields, 100 acres of outdoor hemp fields, and 120,000 square feet of production buildings.

"Two-hundred acres represents the largest cannabis grow in North America that I know of," said Hunter Wilson, Community Builder at Growers Network, a private community for cannabis professionals. "The next largest clocks in at 55 acres, not even close. From the looks of it, Ultra Health isn’t putting all their eggs in one basket. They're future-proofing their site for a diverse consumer base in New Mexico, and potentially the U.S."

The campus will blend modern agribusiness and green technologies including solar, wind and rainwater harvesting. In addition, the sustainable site will be supplemented with secured water rights of 1,000 acre-feet of water, or the equivalent of 325.9 million gallons of water per year. Addressing water requirements is a requisite to any long-term successful cultivation effort.

“Ultra Health Tularosa was conceived to solve a challenge and to seize an opportunity,” said Duke Rodriguez, CEO, and President of Ultra Health. “This new facility will ensure the commitment of continuing to produce and deliver the highest quality, most affordable and convenient cannabis in the State. The opportunity exists to have a ready solution to address the increasing need as we move forward to the social use of cannabis by adults and the commercial production of hemp.”

Residents and officials in Otero County highly anticipate and are supportive of the opening of Ultra Health Tularosa.

“Your company has thoughtfully considered the issues that we would be concerned about–security, water supply, the impact on neighboring properties,” The Board of County Commissions of Otero County wrote to Ultra Health in a signed letter. “Ultra Health appears to us to be a responsible, concerned corporate citizen. Your company will bring much-needed jobs and economic development to our county and we offer our support to your project.”

For more information:

Ultra Health

ultrahealth.com

2018

Infarm Expands Its ‘In-Store Farming’ To Paris

Steve O'Hear@sohear / November 8, 2018

Infarm, the Berlin-based startup that has developed vertical farming tech for grocery stores, restaurants and local distribution centres to bring fresh and artisan produce much closer to the consumer, is expanding to Paris.

Once again, the company is partnering with Metro in a move that will see Infarm’s “in-store farming” platform installed in the retailer’s flagship store in the French capital city later this month. The 80 metre square “vertical farm” will produce approximately 4 tonnes of premium quality herbs, leafy greens, and microgreens annually, and means that Metro will become completely self-sufficient in its herb production with its own in-store farm.

Founded in 2013 by Osnat Michaeli, and brothers Erez and Guy Galonska, Infarm has developed an “indoor vertical farming” system capable of growing anything from herbs, lettuce and other vegetables, and even fruit. It then places these modular farms in a variety of customer-facing city locations, such as grocery stores, restaurants, shopping malls, and schools, thus enabling the end-customer to actually pick the produce themselves.

The distributed system is designed to be infinitely scalable — you simply add more modules, space permitting — whilst the whole thing is cloud-based, meaning the farms can be monitored and controlled from Infarm’s central control centre. It’s data-driven: a combination of IoT, Big Data and cloud analytics akin to “Farming-as-a-Service”.

The idea isn’t just to produce fresher and better tasting produce and re-introduce forgotten or rare varieties, but to disrupt the supply chain as a whole, which remains inefficient and produces a lot of waste.

“Many before have tried to solve the deficiencies in the current supply chain, we wanted to redesign the entire chain from start to finish; Instead of building large-scale farms outside of the city, optimising on a specific yield and then distributing the produce, we decided it would be more effective to distribute the farms themselves and farm directly where people live and eat,” explains Erez Galonska, co-founder and CEO of Infarm, in a statement.

Meanwhile, the move into France follows $25 million in Series A funding raised by Infarm at the start of the year and is part of an expansion plan that has already seen one hundred farms powered by the Infarm platform launch. Other recent installations include Edeka locations in Düsseldorf, Frankfurt, Stuttgart, and Hannover. Further expansion into Zurich, Amsterdam, and London is said to be planned over the coming months.

“One thousand in-store farms are being rolled out in Germany alone,” adds Infarm’s Osnat Michaeli. “We are expanding to other European markets each and every day, partnering with leading supermarket chains and planning our North America expansion program for 2019. Recognising the requirements of our customers we have recently launched a new product; DC farm – a ‘Seed to Package’ production facility tailored to the needs of retail chains’ distribution centres. We’ve just installed our very first ‘DC farm’ in EDEKA’s distribution center”.

What's The Future of Food?

Scientists And Entrepreneurs Have Been Cooking Up Innovative Ways To Put Food On Our Tables.

What Are They Serving Up Next?

CALEB HARPER This computer will grow your food in the future

What if we could grow delicious, nutrient-dense food, indoors anywhere in the world? Caleb Harper, director of the Open Agriculture Initiative at the MIT Media Lab, wants to change the food system by connecting growers with technology. Get to know Harper's "food computers" and catch a glimpse of what the future of farming might look like.

SARA MENKERA global food crisis may be less than a decade away

Sara Menker quit a career in commodities trading to figure out how the global value chain of agriculture works. Her discoveries have led to some startling predictions: "We could have a tipping point in global food and agriculture if surging demand surpasses the agricultural system's structural capacity to produce food," she says. "People could starve and governments may fall." Menker's models predict that this scenario could happen in a decade — that the world could be short 214 trillion calories per year by 2027. She offers a vision of this impossible world as well as some steps we can take today to avoid it.

MATILDA HO The future of good food in China

Fresh food free of chemicals and pesticides is hard to come by in China: in 2016, the Chinese government revealed half a million food safety violations in just nine months. In the absence of safe, sustainable food sources, TED Fellow Matilda Ho launched China's first online farmers market, instituting a zero-tolerance test towards pesticides, antibiotics and hormones in food. She shares how she's growing her platform from the ground up and bringing local, organically grown food to the families that need it.

PIERRE THIAM A forgotten ancient grain that could help Africa prosper

Forget quinoa. Meet fonio, an ancient "miracle grain" native to Senegal that's versatile, nutritious and gluten-free. In this passionate talk, chef Pierre Thiam shares his obsession with the hardy crop and explains why he believes that its industrial-scale cultivation could transform societies in Africa.

PAMELA RONALD The case for engineering our food

Pamela Ronald studies the genes that make plants more resistant to disease and stress. In an eye-opening talk, she describes her decade-long quest to isolate a gene that allows rice to survive prolonged flooding. She shows how the genetic improvement of seeds saved the Hawaiian papaya crop in the 1990s — and makes the case that modern genetics is sometimes the most effective method to advance sustainable agriculture and enhance food security for our planet’s growing population.

An Interview With Saani Abdulai: Growing An Agripreneur In Ghana

"To help improve the farming activities of local farmers in Africa, and gradually making food insecurity a thing of the past". "That is my ambition"

What do you enjoy most about your job?

Being closer to the local farmers is the enjoyable part because through negotiation, I help farmers get fair prices for their produce. I am the bridge between local farmers and outside markets because I understand the needs of both. This collaboration with farmers has enabled me to understand their challenges they face such as poor market access and competitive prices for their produce. It is a win-win situation.

What attracted you to agriculture?

I became attracted to agriculture when I was a child. I used to follow my dad to the farm, helping him weed using the cutlass and the hoe, while guiding our cattle grazing. It was a natural feeling for me to go into agriculture and I enjoy the farmland.

Fertilizer use is fairly low in Ghana, how do you see your business helping farmers to understand the benefits and use of fertilizer?

Yes, fertilizer use is low in Ghana because our farmers who are the main source of farm products have little knowledge about the appropriate application of the fertilizer. Besides, many do not know about soil types and when or what type of fertilizers to use for what crops.

The local farmer also needs to travel to the town from his local community or village to access fertilizers in urban areas. So easy access to fertilizer and equipping farmers with the requisite knowledge on the applications are the main challenges confronting our farmers. As a result many are not motivated to use fertilizer on their farms.

I am looking at venturing into an agro dealership and thereby helping farmers access fertilizers and other inputs easily and affordably. In addition, I am exploring conducting training seminars/workshops in partnership with developmental organizations and private sector companies in the fertilizer industry to equip the farmer with the necessary information on the use of the fertilizer.

Once farmers see the benefits of using fertilizers in increased yields, I believe they will be motivated to use them. Increased yields are also a benefit for me as a trader because I will have more to sell and without doubt better quality too.

What challenges have you faced in running your agribusiness?

Many. My main challenges are getting in touch with the right networks that will help me expand my business through bigger markets. Finance is a setback. Easy credit is not available for me to be able to meet my customer’s orders and to expand the business. I still need to build a name as young business person to access credit from banks, for instance. Besides, I also have a challenge of assets, I need to build my own warehouse and secure my own truck to move my goods to market.

I think the biggest challenge for now is to find investors to help me set up the fertilizer side of my business.

Something has worked well to keep you in business, tell us about it?

Oh really, the big opportunity I had ever since I started this business is when I registered to attend the West African Fertilizer and Agribusiness conference organized by AFAP in 2017. After the conference I had better knowledge about agribusiness and fertilizers. It was an eye opener to me and an encouragement to pursue by dream of building a branded agribusiness that will create job opportunities for the youth and local farmers at the local community level. The conference ignited zeal in me to fight more for the local farmers to raise their production now and for the future.

I would love to dedicate this eye opening experience I had to Sandra Pires from AFAP who encouraged me to attend this conference where I met agribusiness and fertilizer industry players. I say thank you to Sandra for this opportunity.

What motivates you?

Nothing motivates me in my work more than seeing a local farmer wipe sweat from their brow while doing what they are good at: farming. Sealing a deal and delivering the right commodities to my customers motives me too because I know I am able to get more business from satisfied customers.

Getting more youths into agribusiness is also a source of motivation because I believe the young hold the food future for our continent.

Where do you see yourself in five years?

I see myself running a reputable branded agribusiness company that is into mainstream supply of farm produce to organizations in the country and beyond its borders. I can see myself being a major distributor of quality fertilizers in the country.

What advice would you give to youths seeking a career in agribusiness?

Keep working on your dreams in the agribusiness. First play by the rules and register your business and keep working on it daily. The registration of my business happened sometime after I thought of trading farm produce. I was born and raised by a local farmer and knew from scratch the essence of farming which provides food and income. Without farming there is no food.

State Grant Program Offers Money, And Legitimacy, For Urban Agriculture

By Taryn Phaneuf | 10/09/2018

MinnPost file photo by Ibrahim Hirsi

Michael Chaney, a long-time advocate from north Minneapolis who founded Project Sweetie Pie, a grant recipient, said he approached lawmakers with the idea about four years ago.

Urban farming in Minnesota reached a milestone this summer, when the state announced the first round of grants for agriculture education and development projects in cities.

It’s the first time the state has allocated money specifically for urban agriculture, and it took several tries to get the legislation passed. Michael Chaney, a long-time advocate from north Minneapolis who founded Project Sweetie Pie, a grant recipient, said he approached lawmakers with the idea about four years ago. At the time, he saw plenty of interest in urban agriculture — but not the kind of financial support that exists for rural farmers. “I was disenchanted and discouraged,” Chaney said.

Advocates said state investment is crucial because it lends credibility to what Chaney calls the “changing face of agriculture.” Such state funding, even a small amount, can usher in a shift toward seeing urban areas as potential farms and their residents as fellow food producers.

That shift can also bring education and economic opportunities that are often more associated with rural areas. “Agriculture has been deemed corporate ag with rural roots and conventional farming techniques,” Chaney said. “What we’re proposing with urban farming is a whole reconfiguring. … What’s the role of urban communities in growing food?”

Rep. Karen Clark, DFL-Minneapolis, authored the bill, which called for $10 million annually to fund urban ag projects in cities throughout the state. The legislation prioritizes poor communities of color and Native American communities. Clark kept the idea alive at the state level for years, and finally made headway when legislators commissioned a study of urban agriculture that defined its scope and the purpose and identified policy recommendations.

The study cost $250,000, the same amount the Legislature eventually earmarked for urban ag grants for each year in the current budget. It’s far less than program advocates wanted, but it maintained the original intent, said Erin Connell, who administers the grants for the Minnesota Department of Agriculture. Eligible groups include for-profit businesses, local governments, tribal communities, nonprofits, or schools in cities of more than 10,000 people. Cities with between 5,000 and 10,000 people are also eligible if 10 percent of residents live at or below 200 percent of the poverty line, or where 10 percent of residents are people of color or Native American.

“It’s exciting for me so see the acceptance of urban ag as a new standard for ag production,” said Connell, who grew up in the Twin Cities metro area and didn’t discover her interest in ag until she started studying food systems at the University of Minnesota.

Urban agriculture’s impact

Growing food in the city is partly about improving residents’ diets and food security, but it also extends to building wealth, culture, and independence. “Community members were very vocal about wanting to bring the benefits of ag into various urban areas,” Connell said.

Jolene Jones, president and interim CEO of the Little Earth Residents Association, said the community received a grant for nearly $45,000, which they’ll use to teach more children to help in their gardens by creating a storybook that shows them how indigenous people farm in the city.

This fall, they’re learning to construct a hoop house that will extend their growing season, and learn how to grow the four medicines – sage, cedar, sweetgrass, and tobacco. “To actually be able to grow them, it will be awesome for them,” Jones said. “Culture is very sustainable. … the way to put culture in agriculture is to teach children the traditional value of their plants.”

A local food system – which includes everything from growing food to processing it to buying and consuming it – also creates jobs, income, and infrastructure. That’s the mindset used to justify public spending on agriculture development in Greater Minnesota, like one that helps farmers modernize their livestock operations by, say, expanding their facilities to hold more animals. That has visible impact, Peterson said, by providing more work for veterinarians and feed companies.

That’s exactly the kind of ripple effect local food advocates imagine in places like north Minneapolis. Project Sweetie Pie, for example, will put its grant toward establishing a greenhouse that will belong to a broad coalition of groups, who will use it to operate year-round, Chaney said. It’s another step forward in their vision to grow their local food economy.

The fight for funding

Urban agriculture joins a suite of initiatives funded through the Agricultural Growth, Research, and Innovation program (known as AGRI), which supports the state’s agricultural and renewable energy industries through various grants and loans.

AGRI was an important win for Minnesota agriculture when it was established in 2009. At the time, the state subsidized ethanol production. “When those payments were going to end, we got concerned we were going to lose investment into agriculture,” said Thom Peterson, who lobbies the state government with the Minnesota Farmers Union.

Advocates convinced the state to establish AGRI, and the program will allocate a little more than $13 million a year for fiscal years 2018 and 2019, according to the most recent report.

The Farmers Union backed the bill to add grants for urban ag to the AGRI program, Peterson said. And he sees its addition as a chance to expand public support for state ag funding as a whole. “There’s agriculture all over the state, including in the metro areas,” he said.

He credits Clark, who is leaving the Legislature at the end of her term, with pushing the matter forward for years, until Rep. Rod Hamilton, a Republican from Southwest Minnesota who heads the House Agriculture Finance Committee, got on board. “Urban ag is going to need a new champion at the legislature now that Karen Clark is gone,” Peterson said.

Connell repeated the concern, saying the top question facing the urban ag grant program is whether funding will continue past 2019. She said communities that benefit from urban farming, especially from the grants handed out these two years, will need to show up when 2020-2021 budget talks begin.

“Getting the funding this first time is very difficult,” Connell said. “I also feel like after you get that first round of funding, some people who may have been very passionate may get less interested. They might get comfortable in a sense. Every two years, we’re going to get a new budget. Every two years you’re going to have to fight to continue that funding until it’s been there long enough that it’s assumed it goes in the budget.”

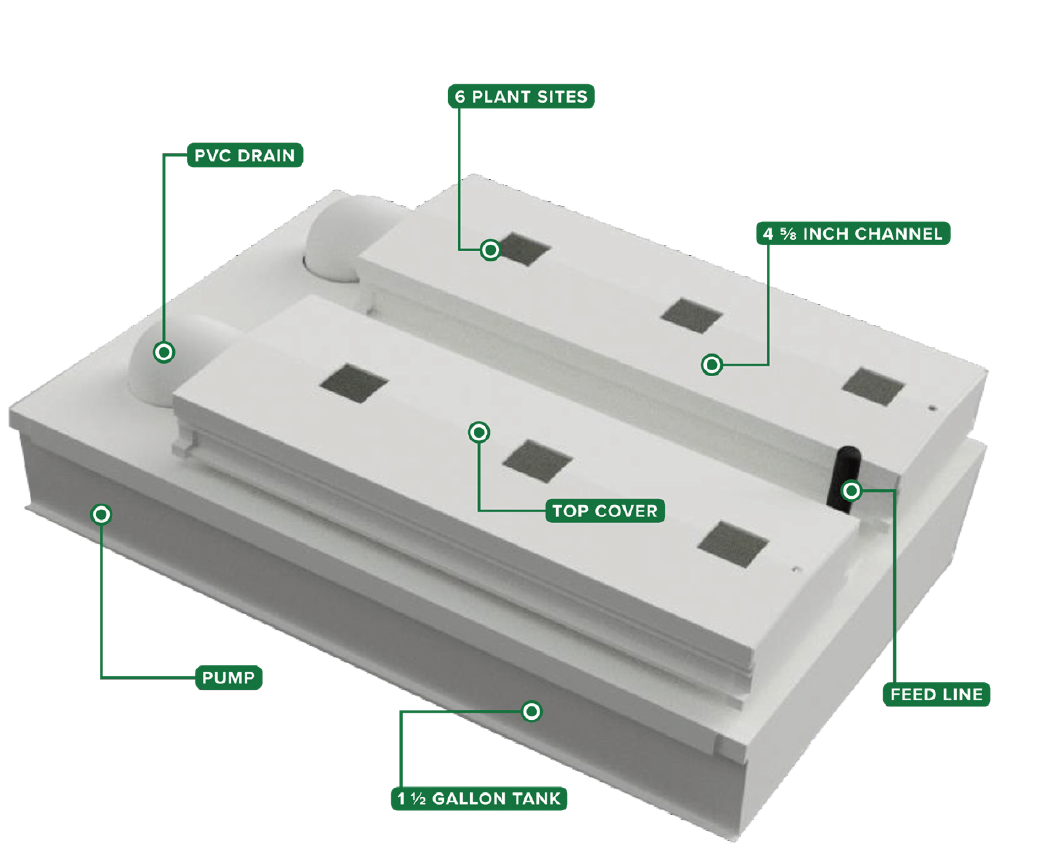

Desktop NFT System

Grow fresh, high-quality leafy greens on your desktop or kitchen counter.

Our unique hydroponic desktop NFT system has all the capabilities of a traditional sized NFT system allowing you to grow fresh, high-quality leafy greens on your desktop or kitchen counter. Perfect for schools, hobby growers and anyone looking for fresh produce year-round!

This system features:

• A removable top cap (lid) makes the channels easy to use and easy to clean.

• End caps on both ends of the channel, keeping light out & preventing algae growth.

• Constructed of non-toxic, food grade, UV-stabilized plastic.

• A standard electric plug – no additional power source required.

• Square top cap holes that are made for 1" seedling cubes.

Specs:

• Measures 16'L x 11'W x 4'H

• Weighs 3.5 lbs when the tank is empty & 12 lbs when it’s full.

System Includes:

• (2) 1' x 4 ⅝' grow channels

• 6 plant sites

• Pump

• Feed line

• 1 ½ gal tank

• Fertilizer & Rockwool cubes

$49.95

Get yours today by calling 330-302-4203!

*volume and educational discounts available

CropKing.com

Growing Microgreens With LED Grow Lights In Sonora, Mexico

Written by, admin

Urban grower Karla Garcia is proud to announce the creation of her new company, Microgreens FLN based in Sonora, Mexico. Karla is a recent graduate with honors and a master's degree in plant science from the University of Arizona. She is proud of her company's commitment to specializing in microgreens production using an indoor vertical farming strategy. Microgreens are an emerging class of specialty leafy greens and herbs. The crops are harvested when the cotyledons are fully developed and in some cases when the young plants have one true leaf.

Studies have shown that microgreens are an excellent source of vitamins (Sun et al., 2013; Xiao et al., 2012) that offer a variety of flavors, textures and colors. For this reason they are quickly gaining in popularity among foodies, salad lovers and top chefs around the world. Karla and Microgreens FLN are currently focused on producing a wide variety of microgreens, including broccoli, mustard, coriander, beetroot and radish.

Creating the proper growing environment

Climate management is key in allowing Karla and her team to grow consistently and year round. Their specifically designed grow room enables them to maintain production throughout the year regardless of the outside temperature. The room is conditioned with fans and a cooling system to maintain seedlings at an average temperature of 21 ° C (70 ° F). Growracks are used to stack the crops and maximize the square foot production area.

Microgreens FLN is also working with Hort Americas to create the proper light intensity and light spectrum with ARIZE LED grow lights from GE in combination with white fluorescent lamps . This combination enables the company to provide at least one daily light integral DLI of 12 mol / m / d in order to maintain quality, predict growth and reduce energy costs.

How-to tips

For growers interested in trying to grow microgreens, Karla offers the following tips.

1. Ensure a clean area by disinfecting trays, seeds (in case they need it) and shelves.

2. Germinate seed by keeping trays in dark and humid conditions for the first three days.

3. After germination, place seedlings under grow lights for about two weeks and then harvest.

Harvesting techniques

Microgreens FLN has two different harvesting techniques. Some customers request that their microgreens be delivered live, still growing in trays filled with substrate which provides a longer shelf life. Other customers prefer that the crop be harvested with sterilized scissors and packaged in a plastic clam shell. The delivered product is protected ready to be washed and served.

Microgreens FLN's goal is simple: offer a fresh, healthy, environmentally-friendly product that is nutritious and flavorful.

"Take care of your body, take care of the planet, eat microgreens!" Said Karla.

Urban farmer Karla Garcia is proud to announce the creation of her new company, Microgreens FLN in Sonora, Mexico. Karla (recently graduated with honors and a Masters in Plant Sciences from the University of Arizona) is proud of her company which is committed to specializing in the production of shoots using vertical farms as a strategy. For those who do not know the term buds. The shoots are a new class of vegetable product, which consists of edible seedlings grown from vegetable seeds or herbs, which are harvested at the end of the development of tender leaves called cotyledons.

Studies have shown that shoots are an excellent source of vitamins (Sun et al., 2013; Xiao et al., 2012), also offering a range of colors, flavors and textures. Reason why this product has quickly gained interest in consumers of vegetable products, salad lovers and top chefs around the world. Karla and Microgreens FLN are currently focused on the production of different types of shoots such as: Mustard, broccoli, radish, beet and cilantro.

Creating the right environment to grow

The control of the environment is the cornerstone that allows Karla and her team to grow shoots throughout the year. This team has been dedicated to design a quarter of growth to maintain its production during the year regardless of the outside temperature. The room is conditioned with fans and cooling system to maintain seedlings around 21 ° C on average. They use a shelf system to maximize production per area. Microgreens FLN also collaborates with Hort Americas to create the right lighting environment using GE "Arize LED" lights for plant growth with a combination of fluorescent bulbs. This combination allows Karla and her team to maintain quality, predict growth (Managing at least one DLI of 12 mol m -2 d -1 ) and in turn to reduce energy costs.

Tips to grow

For those wondering how they can do shoots at home, Karla gives the following tips:

The first step for the production of shoots is to ensure a clean area, by disinfection of trays, seeds (if necessary) and shelves. Second, induce germination by keeping the trays in a dark and humid place. After germination, the seedlings are placed under the growth lights for two weeks and then harvested.

Harvesting techniques

Microgreens FLN has two different harvesting methods. Some consumers demand to keep their buds alive, growing on the substrate, which generates a longer shelf life. Other consumers prefer that Microgreens FLN harvest the product, by cutting with sterile scissors, being packed in plastic containers. The delivered product is then ready to be washed and consumed.

The goal of Karla and Microgreens FLN is simple, to offer a product full of nutrients and flavor that is fresh, healthy and friendly to the environment. Quoting Karla: "Take care of your body, take care of your planet, consume Microgreens FLN!"

Tagged

Forbes' At The 2018 AgTech Indiana Summit

Forbes' Maggie McGrath moderates a discussion between Robert Colangelo of Green Sense Farms, Sam Schatz of AeroFarms, Chaz Shelton of Merchant’s Garden ArgoTech, and Mark White of Prairie at the 2018 AgTech Indiana Summit.

From Roof to Table, This Farm is Bringing Organic Vegetables to Brooklyn Residents

Part of the Food Policy Community Spotlight Series

Name: Eagle Street Rooftop Farm

What they do: Eagle Street Rooftop Farm is a 6,000-square-foot organic vegetable farm located on a warehouse rooftop in Greenpoint, Brooklyn. The Farm is a product of the collaborative effort between the green roof design and installation firm Goode Green and the Brooklyn-based sound stage company Broadway Stages, which financed the installation of the Farm.

The Farm realizes the economic, ecological and societal benefits of green roofing while also bringing local produce to the North Brooklyn community. According to Michigan State University, green roofs can “improve stormwater management by reducing runoff and improving water quality.” In addition, they help to “conserve energy, reduce noise and air pollution, sequester carbon, increase urban biodiversity by creating a habitat for wildlife, increase the space available for urban agriculture, provide a more aesthetically pleasing and healthy environment for surrounding residents, and improve return on investment compared to traditional roofs.”

Eagle Street Rooftop Farm operates a weekly farm market and caters to area restaurants. Between 2010-2011, it became the first rooftop farm to host its own site-based Community Supported Agriculture (CSA) program. In 2010, the Farm also launched an Apprenticeship Program, which instructs seasonal apprentices (spring, summer, fall) in organic farming based on the Farm’s planting and growing practices. Additionally, with support from Growing Chefs, a nonprofit field-to-fork education program that is also under the aegis of Annie Novak (the co-founder and farmer of Eagle Street Rooftop Farms), the rooftop farm’s education staff operates a range of other educational programs.

How they do it:

In its first season, the Eagle Street Rooftop Farm grew over thirty types of produce, from watermelon to cabbage, in order to see which would thrive in a green roof growing environment. The most botanically successful crops for health and high yield included hot peppers, cherry tomatoes, and sage.

Since the 2012 growing season, the Farm has focused on a selection of hot peppers to begin development of a Brooklyn-based hot sauce. Currently you can find their hot sauce – “Awesome Sauce” – at Archestratus Books + Food as well as at Littleneck Outpost, both located in Greenpoint.

The Farm sells its harvest through its site-based Sunday farm market and delivers fresh produce by bicycle to local restaurants including Williamsburg’s Marlow & Sons and Greenpoint’s Paulie Gee’s, Brooklyn Brine, Eastern District, Anella’s, Spritzenhaus, Ovenly, Sea Bean Soups, and Champion Coffee.

On Sundays in the growing season, the Farm is open to the public and welcomes volunteers of all skill levels during its market hours, which are listed on the events calendar. Growing Chefs curates the farm’s Free Lecture series, which are held at two o’clock on Sundays and have covered topics ranging from urban chicken-keeping to pickle making.

Mission: to provide fresh, organic, locally produced fruits and vegetables to Brooklyn residents and restaurants

Latest project/campaign: The publication of their book, The Rooftop Growing Guide: How to Transform Your Roof into a Garden or Farm, in February 2016.

Major Funding: Broadway Stages, Gina Argento & family

Profit/nonprofit: Profit

Interesting fact about how it is working to positively affect the food system: The Eagle Street Rooftop Farm’s education staff, working with Growing Chefs’ curriculum, hosts a range of workshops for children and adults. Topics include growing food in New York City, seed-saving, the art of cooking locally, city composting, the benefits of green roofs, beekeeping, and guest lecturers.

FACT SHEET:

Location:

44 Eagle Street

Brooklyn NY 11222

Core Programs:

-Community Supported Agriculture program (CSA)

-Community Outreach/Education (urban farming education, Growing Chefs workshops)

-Farmers’ Markets

-Apprenticeship Program

Number of staff: 4

Areas served: Brooklyn

Year Started: 2009

Director, Manager or CEO: Annie Novak

Contact Information: info@Rooftopfarms.org

Owned by Broadway Stages and built by Goode Green, the farm was made possible by the generous support of Gina Argento and family. Learn more about Broadway Stages’ green work in Greenpoint here!

Tags: Eagle Street Rooftop Farm Farmers markets Garden Education Organic Farming Rooftop Farm Urban agriculture

Gabrielle Khalife

AI Does Food - TEDx Talk by Joel Cuello:

AI will help realize Cuello’s Law, which is the projected industry goal that crop productivity per unit resource use in a tech-dense vertical farm must double every 4-5 years.

The Global Marshall Plan for AI-based Food Production is introduced to provide capacity building so that no nation is left behind in AI-based food production, making sure that AI will be used to produce food sustainably, not only for some, but for all of us on the planet.

Joel Cuello is a Professor of Biosystems Engineering and Director of the Global Initiative for Strategic Agriculture in Dry Lands (GISAD) at The University of Arizona. A globally recognized expert in the engineering of sustainable biological and agricultural systems, Joel has designed various engineered systems, including those applied in bioregenerative space life support, industrial mass production of algae cultures, and vertical farming. This talk was given at a TEDx event using the TED conference format but independently organized by a local community.

Cities Can And Must Work To End Food Deserts Within Their Communities

By Mayor Debra March - - Wednesday, October 10, 2018

Limited access to healthy food continues to affect urban communities across the U.S., including the City of Henderson, Nevada, where I am privileged to serve as mayor.

Nearly all of the food consumed by the 2.1 million residents and 42 million annual visitors to the Las Vegas Valley, where Henderson is located, comes from somewhere else. This is a necessity given the environment of our drought-burdened Mojave Desert home, which makes growing fruits and vegetables for residents and visitors challenging.

In addition, many economically challenged areas across the nation, including our own, lack access to supermarkets with affordable fresh vegetables, fruits and other nourishing foods, so residents rely on neighborhood corner stores and fast-food chains that offer few fresh food options. As a result, despite being a vibrant community with a robust economy, safe neighborhoods and high student achievement, Henderson is not immune to the development of food deserts or food insecurity.

But hope is on the horizon. Among the strategies we are implementing to increase access to healthy food in economically challenged neighborhoods is the incorporation of urban vertical farming. This is an innovative process that sustainably produces exponentially greater numbers of crops while using significantly fewer land and water resources, making it a viable option for our desert home.

Even under normal conditions, our hot and arid climate — which averages less than 4 inches of rain a year — make it very challenging to grow produce. But through hydroponic watering and microclimate controls for crop cultivation, vertical farming can use up to 90 percent less water than traditional farming methods. This is a critically important benefit for a region that finds itself in the 18th year of a serious drought, with no relief in sight.

Vertical farming is an emerging industry, and the private sector is eager to encourage its development as evidenced by an increasing number of vertical farms being built across the country. And just recently, Oasis Biotech opened its doors in Las Vegas, joining Urban Seed Inc., which opened in 2016.

Oasis Biotech, located near Henderson, is producing 9,500 servings of green salads per day from its 200,000 square-foot facility that houses the equivalent of a 34-acre traditional farm. The healthy food produced there supports local resorts, casinos and a national supermarket chain. Before this development, all local produce was usually supplied by distant farms in California and Arizona. In addition to added cost, produce shipped to Southern Nevada often loses vital nutrients and freshness during transport.

Being able to access locally produced and vertically farmed leafy greens and fruits for their restaurant salads allow these resorts to decrease reliance on produce shipped by truck or train. This change helps reduce air pollution and cuts carbon emissions while also promoting increased water conservation and sustainable farming techniques.

In addition, vertical farms like Oasis Biotech and Urban Seed Inc., will be able to tailor their produce to the specific need of its resort and supermarket partners and go from farm to table in 24 hours, which will create more nutritious, better tasting and diverse options for their clientele.

Henderson is taking a multifaceted approach to resolving issues that contribute to the lack of fresh produce experienced by our residents — an issue that can often lead to major health concerns including diabetes, hypertension and low student performance.

We recognized the importance of working with community stakeholders to effectively meet the challenge of providing all residents with access to healthy food. We incorporated this goal into the City’s “Henderson Strong” comprehensive plan and made this healthy food strategy a key component of the revitalization plan for Pittman, one of the City’s oldest underserved neighborhoods.

Part of this approach also includes working to attract new supermarkets and expanding existing stores. We’re also supporting school and community gardens and mobile farmers markets. The City Council also will consider an urban agriculture ordinance to support and facilitate larger scale and more sustainable food production — like vertical farming — in our city.

We have an exciting opportunity that will allow us to address the challenge of food deserts and food insecurity in our urban centers with vertical farming that takes place 365 days a year and produces food closer to where it’s consumed. But we must keep in mind that continued growth of this industry will not be possible without the assistance of public and private funding to support the infrastructure needed to develop it.

While there is no quick and easy panacea for the lack of healthy food options that residents across the nation face on a daily basis, forward-thinking municipalities like Henderson are actively implementing community-supported programs and exploring new technologies like vertical farming that will provide our most vulnerable families with healthier options.

• Henderson Mayor Debra March, a former councilwoman, was elected to Nevada’s second largest city in 2017. Please follow @debra_march and @cityofhenderson.

Dachnik Aquaponics Completes Vertical Aquaponics Renovation of Commercial Facility in Copperton, Utah

Dachnik Aquaponics, an Aquaponics Technology company founded in Utah, spent the entire summer renovating their Vertical Growing Commercial Aquaponics Facility located in Copperton, Utah.

Their previous design, consisting of Bamboo vertical growing towers, created a lot of attention and buzz in the community; including videos by top YouTube Organic Food channel “Growing Your Greens” which has currently received over 273,000 views explaining the system and its unique design in detail.

Video Link

Dachnik Aquaponics was barely able to keep up with email inquiries and phone calls for months when the system went live and was revealed to the world.

However, the bamboo towers while looked gorgeous; were not viable for a large-scale commercial operation. They did not have the durability needed to last long-term and were extremely high maintenance.

With every new system Dachnik Aquaponics builds, new ideas come along that help solve potential problems and how to make it better. Their goal is to never idlily standby any design, but to always keep improving it for maximum efficiency in order to keep raising the bar in Aquaponics.

“Most of the media attention, buzz and money is currently flowing towards Hydroponics. However, we feel like Aquaponics provides the full spectrum needed for sustainable agriculture but has remained quite stagnant over the years without any substantial, disruptive developments in order to solve the problems all commercial Aquaponics farms face that make it unattractive to farmers and investors and hinder profitability. Our next generation design solves the issues plaguing Aquaponics by creating a one-of-a-kind biofilter, massively increased plant yield per SqFt, and effectively eliminating most labor requirements.”

Sean Burrows, Co-Founder, Dachnik Aquaponics

Fast forward to where we are now. We have built a complete proof of concept and working farm about a 1/6th scale of the commercial farms we envision our next projects to be. Our automated vertical Aquaponics systems are simpler to operate and provide the most grow holes per square foot of any other Aquaponics system to date. Thanks to our new patented vertical growing tower consisting of 48 grow holes per tower as well as our “stackable” float bed design.

We can produce as many plants in 10,000 square feet as 36 acres in California. Based on 15,000 plants per acre and 4 harvests per year. Attached to the Aquaponics greenhouse is the fish and production/storage building where we expect the five 18,000-gallon fish tanks to produce up to 100,000lbs of fish per year, as well as Australian Redclaw and other Crayfish. We are forming alliances with state-of-the-art greenhouse designs and solar to create completely off grid systems with a very attractive return on investment.

Our Aquaponics growing system is quite simply the ultimate bio filter. We set out to create a system that works in harmony with nature and yes, we kept the media and worms.

Looking five years down the road, Dachnik Aquaponics sees itself as the leader in Aquaponics technology with large fully automated commercial systems built worldwide. We want to be adding billions of dollars into the economies where our systems are built. Dachnik Aquaponics is also planning on selling smaller “residential” sized systems as well based off their commercial designs.

Here’s the latest video update from Dachnik Aquaponics showing their new and improved design after the renovation of their previous one:

Video Link

Their current model is now selling fresh produce within Salt Lake County to restaurants, markets, caterers along with a monthly membership direct to consumer model.

Dachnik Aquaponics is currently taking orders for commercial sized farms.

Here’s a link to their website to learn more

Ellepot And TTA Enter Strategic Alliance

Danish supplier of the world-leading paper pot system, Ellepot and the world-leading Dutch young plant handling and selection experts, TTA form key partnership targeting forestry sector worldwide.

Global suppliers to the horticulture industry, Ellepot and TTA, have formed a partnership to better serve professional forest nurseries. The partnership is a formalization of many projects which already have been executed in good cooperation. The announcement comes at a time when both companies are realizing the benefits of strategic partnering to achieve enhanced customer service and company growth.

Ellepot developed the unique Ellepot Propagation System – an integrated eco-friendly growing method for healthier roots and high-quality plants that eliminates the need for plastic. Known for their game-changing innovations, within advanced machines for sorting, grading and transplanting, TTA became a market leader and continuously invests in R&D to deliver the best in production equipment for the handling and selection of young plants.

GREATER CONTROL THROUGH THE ENTIRE CHAIN

The two industry pioneers will offer a fully automated system to forestry customers worldwide, where every process is designed to optimize efficiency and production.

“Teaming up with TTA means that we can offer customers an even broader automated package, giving them the opportunity to influence the handling of young tree plants completely,” says Ellepot CEO, Lars Steen Pedersen.

“It is an honour joining forces with such an exceptional global industry player as TTA. Ellepot and TTA can learn from each other and use this synergy to help forestry customers all over the world benefit from improved production processes and quality throughout the entire value chain. We both have a strong focus on creating customer value through increased control in production, and this is the ultimate goal to bring to customers in the future.”