Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Across China: Profits Grow Out of "Plant Factory"

The factory, with an area of over 10,000 square meters, is a project of Chinese e-commerce giant JD.com.

Source: Xinhua| 2019-03-30 | Editor: mingmei

BEIJING, March 30 (Xinhua) -- At 8 a.m., Qin Peng puts on a white coat and stands in front of a machine that blows dust off of him, preparing to start work.

Qin, 45, said the dust on the human body may contain pest eggs, so it has to be blown off.

Qin is a vegetable planter. Instead of toiling in fields, he works in a "plant factory" in the southeastern suburb of Beijing, where eight types of vegetables including lettuce and spinach are growing on planting beds.

The factory, with an area of over 10,000 square meters, is a project of Chinese e-commerce giant JD.com.

Last December, the company's fresh food brand JD Fresh partnered with Japanese chemical manufacturing giant Mitsubishi Chemical to open the factory featuring Japanese hydroponic technology.

To enhance livability, seeds are isolated in a sealed seedling box for around one week. The temperature, humidity and carbon dioxide concentration inside the box are adjustable to keep seeds growing in the best condition. LED lights are also equipped to accelerate the growth of vegetables.

After maturing, the seeds are taken out of the box and plugged into the holes on the plant beds, where their roots can be soaked in a nutrient solution.

The adoption of the recycled nutrient solution enables the factory to consume 90 percent less water than a traditional plantation, and the standard growing process is much more efficient, said Zhao Lei, head of the plant factory project.

"For instance, the growing season of spinach is only 19 days, which allows 19 harvests in one year, while the traditional cultivation of spinach on a farmland plot has only four harvests each year at most," he said.

Zhao said the factory-grown vegetables are sold both online and offline at four to five times the market price of ordinary vegetables, but still sell out every day.

The company aims to set up to 10 plant factories in China. The newly built facility is located in the Tongzhou District of Beijing and is expected to produce 300 tons of vegetable annually with its 11,040 square meter production area.

Zhou Wenjuan, a customer in Changping District, Beijing, has been ordering hydroponic vegetables online for more than a month.

"They are so clean that I don't even need to wash them. The vegetables are grown in a fully enclosed room without pests, and thus pesticide is not used," she said.

With rising incomes and a growing demand for a better life, an increasing number of Chinese consumers are willing to spend more on high-quality food that is nutritious and free of pesticides.

Besides the hydroponic plant factory in Beijing, similar soilless cultivation projects are seen in Shenzhen, Suzhou, Dalian, Changchun and other cities across the country.

Many enterprises, including China's largest food trade company COFCO, and scientific research institutions like the Chinese Academy of Sciences, have been engaged in the sector.

Zhao did not disclose the profits of the plant factory but said they are planning to expand.

"The factory does not need pesticides and can avoid soil pollution. Our 10,000-square-meter factory only needs eight workers. These advantages ensure the profitability prospect of the plant factory," he said.

“The JD Plant Factory in Tongzhou marks JD’s entry into the very beginning of the fresh food production chain, allowing us to guarantee that the fresh goods we sell have been treated with the care JD applies to everything we do. JD’s supply chain technology, logistics network and e-commerce expertise combined with Mitsubishi Chemical’s sophisticated growing technology puts us in an ideal position to create an entirely new model for agriculture, and cultivates a fresh and healthy lifestyle in China,” said Xiaosong Wang, president of JD FMCG and food businesses

Feeding Roots Via Nutritious Mist

First lettuce from French aeroponic greenhouse

The roots of the plants are hanging in the air. Nutricients, needed for the growth, are directly sprayed under the roots. This way a one hectare greenhouse equipped with the CombaSystem would be able to produce 750 tons of salad per year.

The recently installed pilot greenhouse is 5,000 sqm. From the location in Châteauneuf-sur-Loire, French retail and foodservice markets will be supplied with fresh salads and herbs.

The greenhouse is an initiative from CombaGroup and Les Crudettes . Les Crudettes is the French leader in bagged salads, CombaGroup is a Swiss agro-technology company active in aeroponic solutions.

Since 2013, CombaGroup has developed an innovative technological solution for growing healthy, pesticide-free salads and aromatic herbs. Its pilot greenhouse is installed in Molondin (Vaud, Switzerland). Since mid-February their first commercial greenhouse has been operational in Châteauneuf-sur-Loire (France). Comprising 5,000 sqm, it will supply French retail and foodservice markets.

To celebrate the launch of this first commercial project with Les Crudettes and to share further information about the partnership and the project, CombaGroup will host an event at Châteauneuf-sur-Loire (France) on 2 April. Over here the CombaGroup's Mobile Aeroponics will be presente.

"This solution of soilless agriculture in controlled-environment greenhouses reduces water consumption by 97 per cent and makes it possible to avoid any use of pesticides and phytosanitary treatment (including biological)", the team with CombaGroup explains. "Our farming system is committed to delivering the vegetables of the future with sustainably produced agriculture that benefits both the environment and consumers." To achieve this, nutrients necessary for the natural growth of plants are directly sprayed under the roots.

Mobile Aeroponics

"The CombaSystem™ contains two key innovative elements: mobile aeroponics, which is the automated spraying of a nutritive mist on roots hanging in the air, and space optimisation thanks to growing plates that move according to the stages of development of the product”, says Serge Gander, CEO of CombaGroup.

"As an innovation in innovation, this mobile and evolutionary system with additional faster harvest facilitation, immediately attracted the attention of French customer Les Crudettes, convincing them to implement the first CombaSystem™ greenhouse in France."

“The lettuce production and demonstration greenhouse located in Châteauneuf-sur-Loire is coupled to our bagging facilities, will allow us to deliver the freshest products possible to our customers”, says Thierry Dubois, General Manager of Les Crudettes.

Publication date : 3/27/2019

Author: Arlette Sijmonsma

© HortiDaily.com

The Future of Sustainable Food Is Fishy

Marketing manager Shawn Bonnough, Farm manager Jeff Smith and General Manager Barbara Bonnough are behind the new Aquaponics Training Institute. (Brieanna Charlebois - Morning Star)

Aquaponics Training Institute officially

launched last weekend in Vernon

April. 2, 2019

A new way to grow food has come to Vernon.

It’s called aquaponics and is the combination of aquaculture (breeding fish in captivity as a food source) and hydroponics (growing plants without soil).

Jeff Smith is the farm manager at the recently opened Aquaponics Training Institute in Vernon. He explained the process as a “match made in heaven.” In the symbiotic system, fish provide fertilizer for the plants, and the plants clean the water for the fish, eliminating water waste and making it the ultimate sustainable food source.

Link To Video

Marketing manager Shawn Bonnough said that his ultimate goal is to show people how to minimize their ecological footprint by growing food at home throughout the year.

“We’re really just a small training company with a small local footprint and our doors are open to the local traffic, but we have a global solution to a problem that we’re all going to be facing in 8.3 years and we’re going to hit a tipping point,” said Bonnough.

Smith explained that the system uses less than a tenth the amount of water in comparison to any other agricultural system. Very little waste is produced.

“There is no real waste to this system other than the evaporation. The fish are fed the appropriate ratio of food to produce the appropriate amount of food,” he said.

Bonnough said he hopes to be able to bring this science to small communities in northern Canada that don’t have food readily available based on distance to farmed food and weather conditions. Located at 4877 Haynes Road, the Institute is an indoor facility that will operate all year long.

“With a background in education, we formed the Aquaponics Training Institute to be able to take food security to our planet’s most vulnerable population and that’s usually Indigenous communities worldwide,” said Bonnough. “We’ve got a scalable worldwide solution to a worldwide problem. When you look at the economic impact to a community who is shipping vegetables 50 to 100 kilometres on average to get to their community, we can turn that around and create jobs and opportunity for fresh, nutritious vegetables and fish, that are both healthy when they’re combined.”

The first information session took place Saturday, March 30 and hosted about a dozen local hobbyists. The next session is set to take place Saturday, April 6 from 9 a.m.-12 p.m. From there, people can sign up for workshops on how to build their own system.

Those who are travelling to Vernon for courses are also able to stay at the accommodations on site.

For more details, visit the Aquaponics Training Institute website.

Video: Underground Farming Could Transform The Way Your Coriander, Watercress And Rocket Is Grown

March 22, 2019

KEY POINTS

In London one farm is using LED technology and hydroponic systems to produce greens 33-meters below the surface.

Growing Underground has been collaborating with the University of Cambridge’s Energy Efficient Cities Initiative to analyze a range of data from its facility.

While we may associate farming with sunshine, fresh air and pretty patches of land, innovation and technology are beginning to change where food is grown.

In London, for instance, one farm is using LED technology and hydroponic systems to produce greens 33-meters below the surface. The company, aptly named Growing Underground, says its process uses 70 percent less water than a traditional, “open-field farming.”

Hydroponics, as the Royal Horticultural Society puts it, relates to “the science of growing plants without using soil, by feeding them on mineral nutrient salts dissolved in water.”

With a focus on reducing food miles, Growing Underground says its produce – which includes mustard leaves, pea shoots and coriander – can be delivered within four hours of picking and packaging.

For several years now, Growing Underground has been collaborating with the University of Cambridge’s Energy Efficient Cities Initiative to analyze a range of data.

“We automatically log temperature and humidity but also manually record crop growth,” Melanie Jans-Singh, a PhD student at Cambridge, told CNBC’s Sustainable Energy.

“We try to analyze all these relationships between energy, crop growth and environmental conditions in order to be able to grow plants as best as possible with a minimal amount of energy,” Jans-Singh added.

The utilization of underused areas of urban space – Growing Underground’s site is located in a former air raid shelter – is set to play an increasingly important role in the way people grow crops.

“The Growing Underground farm is a very good example where a derelict space has been put to good use,” Ruchi Choudhary, reader in architectural engineering at Cambridge, told CNBC.

This idea, Choudhary explained, could be pushed further by tapping into environments that were rich in waste heat and carbon dioxide, such as hospitals and school buildings.

Seedo Promises First Automated, Containerized Cannabis Farm In Israel

Seedo, the high-tech firm known for its fully-automated grow device for medical cannabis, has announced a plan to develop “the first fully automated, commercial-scale, pesticide-free containerized cannabis farm in Israel,” saying it will be partnering with Kibbutz Dan in northern Israel to do so.

The agro-tech firm from Israel last month began supplying its intelligent automated hydroponic system technology in home-grow units to customers in California.

Now, the company says its AI-powered, turnkey systems enable anyone -from average consumers to large-scale producers – to grow without prior experience or ample space.

“We are entering a new era of growing where demand for pesticide-free products will only continue to increase,” Seedo CEO Zohar Levy said in a statement this week.

“We’re thrilled to partner with Kibbutz Dan to provide a business model with governments that the world can look to. We’ve built our commercial-scale system to reflect our philosophy that technology can provide precise and reliable results without sacrificing yield,” Levy said.

The need for clean growing environments is growing, especially as legal cannabis markets around the world expand. A prevalence of pesticides, solvents, and bacteria present in the current supply chain pose a threat to consumer safety, especially for patients that are increasingly dependent on medical cannabis for treatment of a variety of illnesses.

Seedo says its revolutionary technology can control the purity of the crop to meet strict standards set by pharmaceutical and beverage companies looking to supply clean and consistent products to the market.

Its proven technology, originally developed for home-grow devices, is now being applied towards containers for commercial scale.

Each container features maximum daylight illumination, built-in carbon filters, automated air conditioning, and a smart post-harvest drying system that allows farmers to minimize cultivation costs and provide high-quality food with extended shelf life, according to a company statement.

Seedo. Via Seedo’s website

Levy tells NoCamels that Seedo’s team of experts have more than “15 years of experience in container farming in the vegetables and herbs sector.”

By taking the guesswork out of the cultivation process, communities will be able to grow both native and non-native products with less labor, energy and water than before. The airtight, stackable containers will allow cultivators to optimize land-use and reduce the environmental footprint of their farming operations.

Within 36 months of operation, the Seedo project is estimated to produce a minimum of 14 tons of dry cannabis bud, generating an estimated revenue of $24 million dollars, according to a press statement.

Of course, Seedo is not the only company to offer containerized cannabis farming. There are at least a dozen indoor container farming systems globally, offering growers climate-controlled temperature, precise airflow, water, light, and nutrients.

Medical cannabis. Photo by Eyal Basson,/The Israeli Health Ministry

One such company is BH Synergy Group. The company has 15 container systems already up and running in Canada and the US, and is planning on bringing the system to Israel.

BH Synergy Group mixes automation with manual labor.

“I believe in both systems (manual and automated). However, the higher quality tending of plants is always going to be, in my opinion, from manual labor,” Adam Shuster, CEO BH Synergy Israel and USA, tells NoCamels.

“The automatic systems are for heavy lifting, the robot is lifting pots that weigh 25-50 pounds, so for that you definitely want a robotic system. When it comes to tending the plants and the bud and making sure that you get maximum quality THC and CBD levels consistently month after month, you need qualified manual labor.”

Shuster likens the proper gardening care needed for marijuana plants to bonsai trees or orchid flowers.

“People take care of bonsai trees and orchid plants very meticulously. In return, they get a meditative pleasure from this care and ensure a quality bonsai tree or orchid plant. It gives beauty and value. With the cannabis, you want the medical value of CBD and THC levels on the same specific strain. For that you need human touch,” says Shuster.

A screenshot from Seedo’s promotional video announcing a containerized cannabis farm in northern Israel, March 2019.

But Levy tells NoCamels that his firm’s automatic system “can ensure high-quality yields and no [ill] effect on the plants because [Seedo] can provide the plant with the ultimate conditions it needs to grow healthily without being affected by the environment or by workers.”

With Israel’s recent approval of medical cannabis exports, the world’s requests for blue-and-white cannabis bud are expected to rise.

Levy tells NoCamels that Israel’s tech prowess is accepted in the canna field as well.

“Seedo’s headquarters are based in Israel because we believe the Israeli employees are very innovative and creative, the Israeli mind is known to think out of the box. This availability gives us the advantage on the market,” says Levy. “The Seedo team has the availability to create new standardization in the agro-tech sector.”

Viva Sarah Press is a journalist and speaker. She writes and talks about the creativity and innovation taking place in Israel and beyond. www.vivaspress.com

Watch: This Futuristic Vertical Farm Would Farm Fish, Bugs And Plants in The Middle of The City

March 25, 2019

Futuristic vertical farm would grow food in the middle of the city

French design company Studio NAB has come up with the idea of creating a large vertical farm called the Superfarm to promote sustainable living.

Designers at Studio NAB have come up with the idea of creating a large vertical farm called the Superfarm to promote sustainable living.

The designer’s nifty solution is to focus on the production of super foods, or foods with a high nutritional value.

The six-storey building would incorporate renewable energy to farm fish, insects, and plants including aloes and seaweed.

French design company Studio NAB has come up with the idea of creating a large vertical farm called the Superfarm to promote sustainable living.

It forms part of their idea to combat future food shortages as the world’s population increases to 10 billion and brings food to where, by 2050, 80% of the world's population will be living: urban spaces.

Feeding the world would require new land the size of Brazil to be farmed in order to produce enough food, if farming practices continue as they are practiced today, according to the Food and Agriculture Organisation of the United Nations,

“Nowadays, the agri-food system and its production methods are poorly organised and unsustainable over the long term, we see its limits and misdeeds everyday,” the design company says.

The designer’s solution is to build indoor vertical farms which can produce sustainable food for the consumer in urban areas.

Far from the traditional urban farm producing salads or other fruits and vegetables, the Superfarm project, as its name suggests, focuses its production on the culture of foods with a high nutritional value.

The Superfarm would be six stories tall, with its topmost layer containing solar panels and wind turbines to produce renewable energy.

Level two would feature an open terrace with plants such as ginseng, spirulina and aloe vera cultures.

Levels three and four would be dedicated to insect breeding and algae cultures.

The fifth floor would farm aquatic creatures such as trout and tilapia and young plant cultures, while the sixth story would contain a greenhouse that would include plants such as acai berries and goji berries.

Each floor would have a specific purpose and would work in unison with other floors to create a viable ecosystem.

The project strives to recreate an ecosystem in an urban environment that incorporates seaweed, beekeeping, insect farming, aquaponics and also various greenhouse cultivations and outdoor cultures, allow each living being to serve the growth of the others.

Video: Australian Gardener Harvests Over 400 Kilos of Food From Her Gardens

The garden is maintained with approximately half a day each week, though this is unevenly distributed throughout the season. Surplus is preserved using bottling, drying, freezing and fermenting to supply the kitchen during the leaner months

Kat Lavers describes her approach to gardening, including vertical and biointensive growing, and how important it is – and possible! – for city dwellers to be food resilient in the face of natural, financial and social crises.

Happen Films

Feb 22, 2019

(Must see film. Mike)

Excerpt:

In response to space constraints, Kat trades homegrown persimmons for an annual supply of pumpkins, and buys a bag of potatoes every year. Almost all other herbs, veg and fruit are grown onsite. Gifting and swapping with family and friends adds extra variety to the diet. The garden emphasizes highly productive, resilient fruit trees and perennial vegetables like wild rocket, perennial leeks and bunching onions that thrive with minimal maintenance.

In 2018 the site recorded 428 kg of fresh produce, a figure which the household believes could ultimately grow to around 500kg when the full design is implemented. About half this produce is from the 20m² kitchen garden (30m² including paths).

The garden is maintained with approximately half a day each week, though this is unevenly distributed throughout the season. Surplus is preserved using bottling, drying, freezing and fermenting to supply the kitchen during the leaner months.

A covey of Japanese quails provides the household with eggs and occasional meat. The small aviary has trigger feeders and waterers for easy maintenance, as well as a deep litter floor of thick wood chips and autumn leaves that eventually breaks down into compost for the kitchen garden.

Read the complete article here.

Video: London Farm Experiments With Growing Underground

By CBS

March 19, 2019

LONDON (CBS) Farmers in London are taking their crops from tunnels to tables. The underground technique is changing the way city consumers get their greens.

One-hundred below London's busy streets there are rows of green farmland like you've never seen before.

''Leafy greens are possible, microgreens, heads of lettuce,' said Richard Ballard, the founder of Growing Underground.

The project relies on a World War II air raid shelter to hold its tasty harvest. The first of its kind, this farm provides an innovative alternative for urban agriculture by growing herbs like parsley, chives, and cilantro.

Unlike traditional farms, the sun is replaced with LED lighting. The temperature is also carefully controlled, allowing crops to grow year-round. Farms based in cities have a smaller carbon footprint.

'Here we can harvest, we can deliver to our customers. Some of them very, very close by, in just a few hours," said Eric Nynkson, a chef at the restaurant Esca. It's one stop on their delivery route -- located just above the farm.

Nynkson uses the herbs in his signature dishes. ''It makes it very good looking and presentable," he said.

The crop concept surprises custormers like Steven Watson.

Steven Watson: 'Really? I didn't know that. I mean it tastes amazing. It tastes really good.

Reporter Gwen Baumgardner: You can't tell the difference?

Steven Watson: No, no different, really good, really fresh.

Growing underground's success has encouraged other cities, like New York, to start planting similar farms.

''There's a vast amount of underground space all over the world," Ballard said.

Meaning, the next farm could soon be growing right under your feet.

Farmers hope to expand their underground crops from herbs to full sized vegetables. The founders of Growing Underground say they don't want to replace traditional farming, just provide more alternatives for cities.

Future of Food Is Fishy

Darren Handschuh - March 29, 2019

It's a marriage made in heaven.

One that produces food faster and uses far fewer resources than traditional growing methods – and it is happening right here in the Okanagan.

With the right equipment, aquaponics can be done just about anywhere.

“Aquaponics is the perfect marriage of hydroponics and aquaculture,” says Jeff Smith with the Aquaponics Training Institute in Vernon. “Aquaculture is the raising of aquatic species in a closed system, and hydroponics is a soilless growing of plants within a closed system.”

Put the two together, and you get a method of producing food that leaves almost no environmental footprint.

Smith will be hosting information sessions and workshops to teach people how to set up their own systems.

Information sessions will be held this Saturday, from 9 a.m. until noon, and then again on April 6.

From there, people can sign up for workshops on how to build their own system.

“That's a full hands on, face-to-face workshop here in our facility, so they will get to learn all about aquaponics,” said ATI's Barbara Bonnough.

“The workshops are geared toward people who want to run their own facility in their own home, up to someone who might want to do it in an outdoor greenhouse and set up an aquaponics facility that would feed a community.”

More information can be found at the Aquaponics Training Institute website.

Video: How Urban Farming is Helping to Feed Tokyo

Japan currently produces just over a third of the food consumed at home. But it's hoping to raise its food self-sufficiency rate to 45%. It’s a challenging task because the number of full-time farmers has been falling.

Japan currently produces just over a third of the food consumed at home. But it's hoping to raise its food self-sufficiency rate to 45%. It’s a challenging task because the number of full-time farmers has been falling.

As part of our Leading Cities series, Mariko Oi looks at how creative urban farming is helping to feed the city’s residents.

India: "The First Large-Scale Automated And Soilless Greenhouse In The Country"

The world is now waking up to agricultural practices which are environment-friendly and guarantee healthy produce. India is also channeling into this growing consciousness. We are witnessing an organic food revolution in the country. Taking this a step further, the D.S. Group has now brought hydroponic technology to India with its latest venture, Nature’s Miracle. The term hydroponics means “working water”. It is a soil-less technology for growing high-quality, tasty and healthy fruits and vegetables in a natural way.

Located in Greater Noida, the facility is India’s first large-scale fully automated hydroponic glass greenhouse. In this kind of farming, plants are grown without any soil and all the required minerals and nutrients are supplied through water. So how does this work? The roots of the plants are put in an absorbent inert medium, like coconut husk, a substitute for soil. At the Greater Noida facility, cocopeat is used as a seed base instead of soil. Completely pesticide-free, hydroponic farming is miles ahead of organic farming, as it nullifies the effects of harmful chemicals that might be present in the soil. Thus, consumers get the healthiest produce possible.

About bringing hydroponic farming to India, Ravi Kumar, co-founder of Nature’s Miracle, said, “We realised that hydroponics was the future and started exploring more about it. We wanted to bring this world-class agricultural technology to India. Initially we faced issues in terms of location, weather, consistency in taste etc. But now we are facing the bigger challenge of changing the mindset of consumers and making them try our produce.”

To this, Anchal Kumar, Partner at Nature’s Miracle, added, “These products are so healthy and fresh. The taste is consistent and they are a great option to snack on.”

The official launch of the brand was celebrated at the greenhouse over the course of three days, from 7-9 March. For the occasion, celebrity chefs Vicky Ratnani and Manish Mehrotra curated dishes using the fresh produce from the greenhouse.

Chef Vicky Ratnani talked to us about his views on this advanced agricultural technology and the importance of healthy produce. “Technology and innovation are there for the wellness of people. It should extend to the agricultural sector. You pay the farmer, and not the doctor. It’s a global cause. Knowing the traceability of products is important for us as chefs. But I think consumers should also know where the produce is coming from,” he said.

Video: CEO of CO2 GRO Explains How Their Patented CO2 Foliar Spray Technology Accelerates Plant Growth

CO2 GRO’s outlook is based on an expanding clientele and increased acceptance of their technology.

Alberta, Canada: Hydroponic Lettuce Revolution In Bruderheim

Arthur Green

More from Arthur Green

January 29, 2019

A look at the new addition to Thiel’s Greenhouses in Bruderheim, Alberta.Thiel’s Greenhouses has invested in this new technology from Dry Hydroponics to mass produce fresh lettuce. Arthur C Green/The Record

Growing green and growing clean, in lettuce Thiel’s Greenhouses trusts.

An Ontario-Alberta-Netherlands connection has led to the sky glowing pink over Thiel’s Greenhouses in Bruderheim, Alberta.

Since 1958, Thiel’s Greenhouses have been serving the Fort Saskatchewan, Bruderheim, Lamont and Vegreville areas. The company has been focused on creating superior product quality and with the recent upgrade they look to enter a new market.

Nadine Stielow grew up in the Bruderheim area and as a little girl, she frequented the business she now has made her own. Arthur C Green/Submitted Image

Owner Nadine Stielow grew up in the Bruderheim area and as a little girl, she frequented the business she now has made her own. Stielow is taking Thiel’s Greenhouses to the next level of plant cultivation with the installation of a hydroponic system to grow lettuce.

Stielow was thrilled to give Postmedia a tour of the brand-new equipment purchased from Dry Hydroponics in the Netherlands. Stielow made the decision to purchase after visiting with Dry Hydroponics in NL where they have demonstration/trial greenhouses showcasing their product.

“I was there last January to learn from them,” Stielow told The Record.

The state of the art system uses cultivation ponds built of cement. Nutrient-rich water is added to the ponds and the crops grow in crop holders placed on floats. Arthur C Green/The Record

The Dry Hydroponics system is suitable for short-cycle crops, like lettuce, herbs and flowers according to the company’s website. Thiel’s Greenhouses will be able to produce 1500-1900 heads of fresh lettuce a week with the new equipment.

“The state of the art system uses cultivation ponds built of cement. Nutrient-rich water is added to the ponds and the crops grow in crop holders placed on floats,” Stielow said.

The design has been patented by Dry Hydroponics and allows crops to acquire sufficient amounts of water, light, nutrients, CO2 and oxygen, Stielow told Postmedia.

The designs give an ideal microclimate and allow the crops to grow in a natural way.

A shot of Thiels Greenhouses in the night sky. Residents of Bruderheim will now see a glow of pink in the evenings. Arthur C Green/The Record

‘The Ontario-Alberta-Netherlands Connection’

Thiel’s Greenhouses, which is located in Bruderheim, Alberta uses a hydroponic supplier based in Ontario named AMA Horticulture.

“I also get some of my spring plant supplies from AMA Horticulture as well,” Stielow said. “Shawn Mallen who is a specialist with that company is here helping with the setup.

Capping an incredible wk with Fri goodbye/vaarwell to my ON-AB-NL #DreamTeam

For NOW! Time to GROW #epic #finalbuild #VeniVidiVici @amahort @Dry_Hydroponics @PhilipsHorti @BallHort @AFSC_AB @Bruderheim @ThreeSixtyAB @AsGr8AsHome @1BIOBEST #liveit12:08 AM - Jan 28, 2019

See Thiel's Greenhouses's other Tweets

Martin Naaborg is a specialist with Dry Hydroponics and has traveled nearly 7,000 kilometers to install the system for Thiel’s Greenhouses.

“Both Shawn and Martin were here for the week to consult in the final stages of the project,” Stielow said. “AMA Horticulture is the Canadian dealer for Dry Hydroponics. Both companies are stellar in the tech support and overall help they provide to customers.”

‘Growing clean and looking to enter new markets’

Thiel’s Greenhouses has invested in this new technology from Dry Hydroponics to mass produce fresh lettuce. They will in turn market this product to local consumers and the high-end restaurants.

“To be considered organic in Canada plants must be grown in soil,” Stielow said. “I am growing clean; no pesticides will be put on our plants. I do not use chemicals in our greenhouses.”

The water heaters that were installed at an additional cost. The system is state of the art. Arthur C Green/The Record

You can walk up to any plant and eat it without a worry about it affecting your health. But this type of growing is not considered organic, Stielow added.

“Everything is being started from seed,” Stielow said. “We obtained seeds that are specifically created for hydroponic growing.”

Stielow admits that although lettuce is her company’s main focus right now, she would like to add different products as time progresses.

“I would love to try growing some new products such as bok choi and lemongrass,” Stielow said. “There are others I would like to try but I won’t go too crazy yet.”

Arthur C Green/The record

If you would like to visit Thiel’s Greenhouses, they are located on 4916 45 Street in Bruderheim. Or they can be found on the web at www.thielsgreenhouse.ca

“Our mission is simple,” Stielow said. “To supply the highest quality plants, products and services for our customers”

Video: Vertical Farming: Growing Food In The Air And The Role of Big Data

Posted on 8 Mar 2019 by Nick Peters

The world’s food chain faces a growing crisis from climate change, population growth and the contamination of water and soil via intensive farming.

With insect populations, so vital to plant propagation and fertilisation, also under threat, the planet is heading for a crisis, one that cannot be solved by simply tweaking the existing, creaking system of agriculture. A new type of agriculture – vertical farming – has been developed that offers hope, and food, for the future. And it is all made possible by data and lean manufacturing.

Vertical farming is not a new concept. The theory that food can be grown in large quantities inside tall buildings has been around for decades. Only recently has it become possible at a price point that matches that of produce grown using traditional methods, and that is thanks to the same digital manufacturing technologies that are revolutionising our factories.

AeroFarms of Newark, New Jersey, is a pioneer of aeroponic farming with an ambition to set up vertical farms in towns and cities across the world to meet the growing ecological and human crisis of the next few decades. (Unlike hydroponics, where plant roots sit in a small container of water, aeroponics involves ‘misting’ roots with water and nutrients.)

Nick Peters, Editorial Director of The Manufacturer, discussed the project with CEO David Rosenberg:

The technologies that enabled David Rosenberg and AeroFarms to create the food chain of the future inside urban factories were provided by Dell EMC.

Nick Peters spoke to Nigel Moulton, Global CTO at Dell EMC, about AeroFarms and how successful businesses navigate their way on the digital journey:

This story appears in the March edition of The Manufacturer. Be sure to get your copy every month. Subscribe here!

Learn more about AeroFarms here and more about what Dell Technologies did for Aerofarms here

VIDEO: New York Restaurant Basement Farm to Table

Underneath two-star Michelin restaurant Atera in Lower Manhattan is an actual working farm. Using LED lighting and hydroponics, Farm.One grows rare herbs and greens for some of New York City’s top restaurants. We talk to the founder Rob Laing about his venture and get a taste of what he’s growing.

FRI, MAR 15 2019 • 1:02 PM EDT

Brandon Gottsacker, Superior Fresh: US (WI): “Science Runs This Facility”

Leafy greens and fresh Atlantic salmon. Add a little lemon wedge and it will be the perfect meal at a picnic. Those two elements also make the biggest aquaponics system in the world, which is located in Hixton, Wisconsin.

At a 123,000 square feet greenhouse they annually grow 1.8 million pounds of leafy greens in the dead of winter. The fish production yields 16,000 pounds a year. In this video Brandon Gottsacker, president of the company explains how it all works and he also tells that they are currently finishing their phase 2 greenhouse which will double the annual yield of leafy greens.

For more information:

Superior Fresh

W15506 Superior Fresh Drive

Hixton, WI 54635

info@superiorfresh.com

www.superiorfresh.com

Growing Up: How Vertical Farming Works

FOR thousands of years, human populations have farmed the land for food. But with a sharp rise in the number of people on our planet over recent centuries – as a result of the industrial revolution, increased living standards and falling mortality rates – the pressure on traditional farming has continually increased.

Fred Mills

6 March 2019

With the global population set to exceed 10 billion people by 2050, the challenge of providing enough food for everyone in a sustainable, efficient and cost-effective way is rising in significance. Shedding the restrictions of seasonal weather patterns, overcoming transportation challenges and significantly enhancing yields, the growing trend of “vertical farming” could herald the future of food production.

FOR thousands of years, human populations have farmed the land for food. But with a sharp rise in the number of people on our planet over recent centuries – as a result of the industrial revolution, increased living standards and falling mortality rates – the pressure on traditional farming has continually increased.

While modern techniques have enabled enhanced production rates, more than 11% of the world’s total land area is now used for crop production - creating environmental challenges that range from habitat clearing to soil degradation - and placing immense pressure on our planet’s resources.

Furthermore, as our cities expand, the distances between suitable farming land and the large populations who consume their produce are growing, raising the impact of transportation.

Added to these challenges is a changing climate that is disrupting seasonal weather patterns and the lack of suitable soils in close proximity to rapidly expanding areas.

One potential solution is the quite literally growing trend of "vertical farming" - a concept that sees the sprawling crop farms of old condensed into much smaller factory-like sites where conditions can be optimised and yields significantly increased.

Vertical farms use multi-layered controlled environments to deliver significantly greater yields (image courtesy fo AeroFarms).

Facilities like Aerofarms’ in New Jersey see crops produced in an enclosed environment where almost everything from the lighting and ambient temperature to soil conditions and nutrients are carefully controlled.

The facility uses extensive vertical racking to optimise space as compared to a conventional crop farm, enabling it to be located on a far smaller site and much closer to an established urban area.

Such a location reduces the extent of haulage or “food miles” required to transport produce to consumers, cutting CO2 emissions.

Geography aside, the creation of controlled conditions delivers many benefits.

Firstly, the process of crop production is insulated from seasonal weather patterns that are highly susceptible to disruption as a result of our changing climate.

On a vertical farm, lighting, water and temperature can all be optimised to remove climatic risks and enhance production rates. As a result, sites like MIRAI’s facility near Tokyo – the world’s largest city – are able to generate yields 50 to 100 times greater than that of a traditional crop farm.

The use of a controlled environment also eliminates the losses from birds and insects that must be factored on conventional farms, cutting the need for harmful pesticides to be used and improving the quality of produce.

By removing external factors, like weather and insect damage, vertical farms can produce more nutritious food with fewer pesticides.

Vertical farms also optimise the level of nutrients that crops receive, solving the challenge of finding a sufficient extent of suitable farming land in close proximity to a major urban area.

In many instances, soil is removed altogether and crops are grown on membranes where they are sprayed with nutrient-rich solutions.

Of course, vertical farms do have their limitations and critics have pointed to the level of energy required to maintain such refined environments.

While these concerns are valid, several vertical farms are powered by renewable technologies and recycle many of their resources.

The use of energy efficient LED lighting reduces power consumption, while the blue and red shades of light are even more economical to run.

Using blue and red LED lighting makes vertical farms more economical to run (image courtesy of AeroFarms).

The optimised crop production process also allows vertical farmers to reduce the amount of water used, and many vertical farms are served by rainwater harvesting systems. Some even collect and recycle the water that condenses within the controlled environment itself.

This closed-cycle approach has the added benefit of preventing nutrients and fertilizers from damaging the land or being washed in rivers and streams.

Though the cost and availability of land for vertical farms in urban areas can prove challenging, many facilities are finding home in re-purposed shipping containers, former factories and disused warehouses.

Above: Adapting disused structures reduces the initial cost of vertical farms. (image courtesy of GrowUp Urban Farms).

More sophisticated schemes, like the proposal by Studio NAB below, could even see the vertical farming concept broadened to include the production of fish and honey while re-connecting consumers with the food production process and establishing sustainable jobs for the surrounding community.

Above and Below: Studio NAB's vertical farm proposal (images courtesy of Studio NAB).

While the vertical concept still represents a small part of the global food production industry, the benefits it offers to our ever-expanding population could come to tilt the farming landscape by 90 degrees.

Images courtesy of Kyodo Via, Ilimelgo Architects, AeroFarms, David Williams, Mandy Zammit, Priva, GreeOx, Grow to Green, GrowUp Urban Farms, Heather Aitken and Studio NAB.

We welcome you sharing our content to inspire others, but please be nice and play by our rules.

The Investment Company The World Needs

March 9, 2019

Kyle Baldock

Setting a Higher Standard in AgriTech Investment

Neon Bloom is a venture capital firm that focuses on acquiring innovative agriculture and ancillary technology products and services across the globe. With a suite of flagship investments in Holland and one in South Korea, Neon Bloom has made a strong start for a company that only began in January of this year. Of central importance to their investment strategy is a keen understanding of the holistic nature of the industry: they invest in complimentary companies in order to bring various parts of the value chain under a single umbrella. I interviewed Company Director Werner Huisman about this “Seed to Sale,” approach to investing. He told me:

“The big advantage is bringing knowledge together from many different parts of the world. Having the opportunity to bring so many talented individuals under one brand with the same mission and vision empowers each company within the portfolio.”

Read on to learn more about Neon Bloom’s mission to advance the industry for the betterment of mankind.

Getting to know: Neon Bloom

When did Neon Bloom start operating and why is it focused on AgriTech?

WH: Neon Bloom started the operation beginning this year. We are focused on the three pillars of water, power and food. We believe in “the zero hunger” mission and want to be a part of this mission. After learning about the importance of technology to improve sustainability and reduce the cost of goods we realised the importance of innovation to help with “The Zero Hunger” mission.

What technologies and trends are you most interested in for the coming decade?

WH: I believe in technologies based on natural and sustainable solutions. By the year 2050 the world population is expected to grow to 10 Billion people. This is over a 56% increase of food needed compared to 2010. It is going to take innovative technologies and a group effort to meet the demand. Looking at the solutions we bring in from Holland, they are all natural and sustainable.

Within HollandPlug we produce 100% organic substrates based on jute and PLA. This should replace the environmentally-unfriendly stonewool substrates.

Within Holland Pulse Light we are able to extend the expiration date for food by generating an enormous amount of energy through our pulse light technology- the pulse light flash has a power of 1850 Joule. With the electronic magnetic field and the enormous number of photons we are able to generate we are able to flash the food with the light and eliminate bacteria, fungi and viruses with all-natural products. Our machine utilises mainly UV-A which is able to rupture the cell membranes; whereas UV-C light impacts the DNA which changes the texture and taste of the food.

Within Holland2O we sell water machines which are able to produce HOCl water with a very low ppm value! (<30 ppm). This water has a redox value of around 1000 Orp(V) and an pH of 6.6 which is able to remain stable for a long period of time. With this water, we are able to kill all sorts of bacteria, fungi and viruses using only natural substances.

Where in the world are you seeing the most innovation in your three pillars of power, water and food?

WH: In principle, all around the world. In each part of the world there is a shortage of water; in each part of the world they grow fruit and vegetables and in each part of the world there are problems with fungi, viruses and bacteria. We believe that it will take a global effort to help meet the needs of the world over the next several decades.

Which volume are you in the market for- what is a normal project volume?

WH: Depends on which product you are talking about, but talking about % in the substrate market, we think we can take over 30% in 3 years’ time. We also believe our other technologies will have the capabilities to capture a significant amount of the market share. It is important to us that sustainable technologies lead the way in vertical farming.

What does Neon Bloom look for in potential acquisitions/investments?

WH: The requirements are in general as follows:

Product should have a relation to power, water or food;

The product should have a sustainable character;

It should have international potential;

The company must share our core values and vision

Does your company do VC or corporate finance? Debt or equity financing? Does Neon Bloom invest its own money?

WH: Neon Bloom is a VC with a focus on sustainable companies operating in power, water or the food industries. Our firm will provide debt or equity financing depending on our clients need. Yes, Neon Bloom invests its own money and is always searching for innovative companies to help us meet the “Zero Hunger” mission.

What advice would you give to AgTech companies that are looking to attract capital?

WH: You can attract capital from anywhere, so I would advise them to take a substantial amount of time defining their mission and vision statements. If your company’s core values and mission don’t align with an investment partner; then I would recommend finding a better fit. Secondly, see how their network and skill set can help grow your company’s footprint as well as impact in the world.

Why did Neon Bloom choose to become a member of the National Cannabis Industry Association?

WH: We decided to become a member of the National Cannabis Industry Association because of our first-hand experience of seeing the medical benefits the plant provides. This can help veterans dealing with PTSD or individuals with serious diseases. Cannabis is grown naturally and we believe it is a much better medicine than the drugs provided from pharmaceutical companies. It also has had a huge impact on slowing down the opioid crisis.

Why is there no visible investment in any cannabis related tech or producer?

WH: Our substrate technology can be utilised directly when growing cannabis along with our water. Both of these innovative technologies will allow for a product that is free of pesticides. It is the company’s goal to begin working with hemp producers this year. This will help provide food to the world as well as numerous other benefits to other industries.

Why did Neon Bloom join AVF?

WH: We don’t define success based on how much money a company is able to generate. Our firm determines success based on the impact and legacy we can leave on the world. It is crucial for humanity that we begin to implement many of the policies and beliefs of the AVF if we plan on having a sustainable future and to be able to meet the food demand for the ever-growing world population.

Want to find out more?

Visit Neon Bloom on the web: neonbloominc.com

KYLE BALDOCK

Urban Agriculture May Uproot Traditional Farms in World of Food Ethics

Even though urban farms are more sustainable, they may encourage gentrification

Photo by Gabriella Holm | The State Press

"Gentrification in cities is changing farming as we know it." Illustration published on Wednesday, Feb. 27, 2019.

By Katelyn Reinhart | 02/28/19

Family-owned farms are decreasing as community gardens and urban agriculture find their footing in a world of food ethics.

In Arizona, it is not atypical to see farmland sold for urban development. Arcadia, a neighborhood located 10 miles from ASU's downtown Phoenix campus, was originally known for its citrus groves before the land was sold for development.

Similarly, the ASU Polytechnic campus hosts the Morrison School of Agribusiness, which was given its name to honor ASU alumni Marvin and June Morrison, who donated farmland to the school in 1998.

David King, an assistant professor in the School of Geographical Science and Urban Planning, said larger farms may be suffering from a shifting economy that relies less on citrus and more on housing.

“Agriculture is very resource intensive to grow here,” King said. “A lot of the agriculture that supported the economy in earlier stages just isn’t as critical to the economy now.”

He said that there are people in urban planning who see a future in urban agriculture, which is popular due to its sustainable appeal.

Kristen Osgood, a program manager for the Rob and Melani Walton Sustainability Solutions Service, said supporting local farmers could save travel time and quality in the foods people eat. She also said protecting farmers is extremely important as farmland is sold for housing development.

“We saw this happen in Mesa, where people were buying land next to a well-established feed-lot and then complained about the smell and tried to have it shut down — farmland isn’t something that grows back, once it’s gone, it’s gone, and that’s something we need to protect,” she said.

UN highlights role of farming in closing emissions gap http://bbc.in/174DJT8 #climate #agriculture

@ClimateNow As organic becomes more mainstream, the need for BigAgri, MonoCulture farms will decrease.

The priority must be the family farm

Osgood said that while farmers should be protected, growing food in a community garden setting could be valuable sustainably, physically and mentally as well.

Greg Peterson, owner of the Urban Farm in Phoenix, said his urban farm takes up a third of an acre and offers free webinar classes and other tools for users to educate themselves on sustainability topics.

“Something we think is important is growing food where we live,” Peterson said. “We have classes, tours and everything we grow here is grown organically.”

Peterson said that while there has been an increase in younger visitors, the most common visitors are baby boomers who want to know more about the way their food is grown.

Even though urban agriculture offers a more sustainable, local option for produce, it may bring gentrification.

Daoqin Tong, an associate professor in the School of Geographical Sciences and Urban Planning who has studied community gardens and urban agriculture said that in her work, said she saw that it was more difficult for community gardens to be successful in low-income areas.

“For a lot of community gardens, people will pay fees to keep it around,” Tong said. "A problem with that is, in the summer, it’s very hard to grow anything, so that money goes to an empty garden. For wealthier families, the pay just doesn’t seem like that much.”

She said lower income families often cannot dedicate the time to maintaining a garden if they are working multiple jobs to support themselves.

Danielle Vermeer, a junior majoring in sustainability and urban planning, said that community gardens and urban agriculture have unreached potential in providing for communities.

“I volunteered at the Tiger Mountain Foundation through ASU," Vermeer said. "What we did was work on an urban farm for people who were incarcerated and are trying to integrate back into the community. As much as I think it would be nice for people to use gardens as a food source, at the moment I do see gardening as more of a privilege.”

Reach the reporter at kreinha3@asu.edu and follow @ReinhartKatelyn on Twitter.

Like The State Press on Facebook and follow @statepress on Twitter.

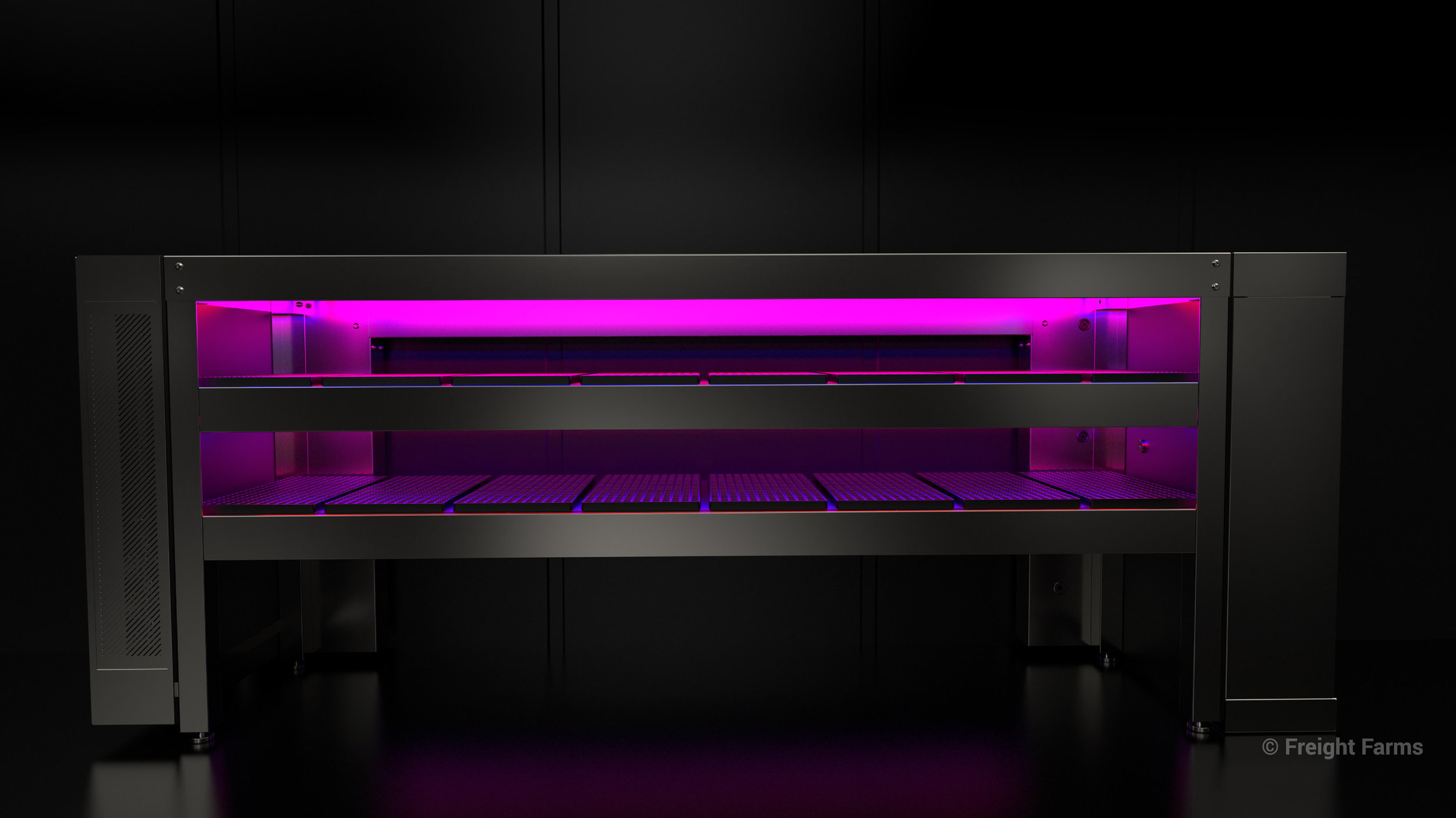

Freight Farms Announces Next-Generation Container Farm, Advancing Production Limits of Hydroponic Vertical Farming

Agtech innovator's new technology adds 70% more growing space, drives yield, efficiency, automation

NEWS PROVIDED BY Freight Farms

Feb 26, 2019

BOSTON, Feb. 26, 2019 /PRNewswire/ -- Freight Farms is proud to announce the Greenery™, successor to the Leafy Green Machine™ (LGM), and the first generational product leap since Freight Farms pioneered the containerized agriculture industry in 2010. Within the same standard 320 sq. ft. footprint, the Greenery offers farmers 70% more growing space, with unprecedented versatility, efficiency, and automation control – advancing the limits of production, and making farming more accessible than ever before.

Performance-Driven Container Farming

The Greenery combines dynamic aisles with new plant panels and LED technology to boost yields and create streamlined operations for the farmer. Simplified Workflows: Moveable rows provide easy access to plants for convenient harvesting, pruning, cleaning, and maintenance. This drastically reduces labor and increases productivity. Customization & Versatility: With the sliding rack system, farmers can arrange the Greenery based on their needs, allowing them to grow larger plants without experiencing spacing or airflow problems.

Exterior of Freight Farms' Greenery: now made from purpose-built freight containers with all-weather paint, premium metalwork, and superior manufacturing.

The Greenery’s main growing area features 88 plant panels and 112 LED panels. The LED panels are hyper-directionally focused on the plant canopy to prevent light waste and yield fuller, heavier crops in shorter time-frames.

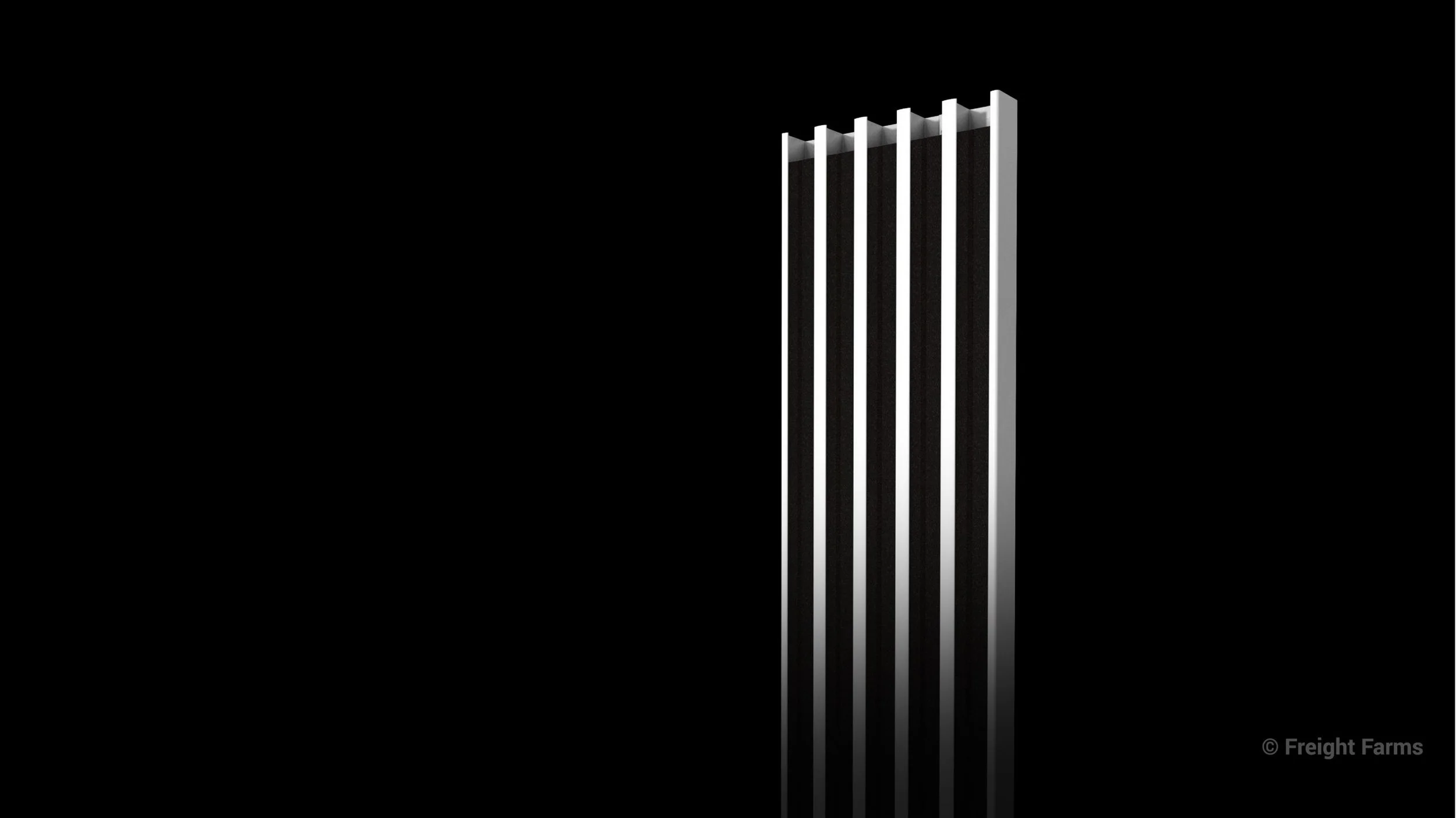

Freight Farms' new vertically hanging 5-channel plant panels replace previous single-channel crop columns, capturing previously unproductive space to unlock 70% more growing space within the Greenery’s 320 sq.ft. footprint.

The Greenery’s nursery station holds 4,608 plant sites. Seedlings grow up toward 3:1 red-to-blue LED light panels that focus directly onto the canopy, with minimal light fall-off or wasted energy.

After years of data collection and development based on the experience of hundreds of farmers in its global network, Freight Farms has again raised the industry bar with a fundamental container farm redesign. Instead of reorganizing existing technology into a refreshed layout, the company saw the potential to blueprint entirely new farm components previously unavailable to the industry. In doing so, Freight Farms keeps the ergonomics of both farmers and plants as the central priority to improve yield, efficiency, and workflow. Today Freight Farms reveals three pillars of the Greenery's design.

Greater Yield, Productivity, and Usability: A fully-reimagined farm interior combines customizable grow rows with innovative plant panel and LED technology to boost yields and create streamlined operations for the farmer.

Mobile rack system: Farmers can now shift grow rows and LED panels to create custom layouts to support the growth of a new variety of crops (larger, vined, rooted, etc.) while drastically improving workflow.

Increased production: Capturing previously unproductive space, a unique 5-channel plant panel design replaces traditional crop columns to unlock 70% more growing space within the same small footprint. The Greenery also hosts 30% more nursery plant sites.

Industry-leading LEDs: Unique, rigid LED panel arrays replace previous rope lighting, tripling the crops' access to light energy to result in fuller, heavier plants within a faster growth period.

Superior Resource Efficiency: Newly designed systems throughout the Greenery, including lighting and climate control, use and reclaim resources with unrivaled efficiency.

Best brightness-to-power ratio: Because the LED arrays are focused directionally, light energy waste is prevented, and despite triple the intensity, there is no 3x corresponding electricity draw.

Intelligent moisture reclamation: The farm's powerful new climate control system condenses and recycles ambient moisture so efficiently that in certain humid regions it is capable of capturing upwards of 1.5 gallons of water per hour, rendering some Greenery operations water-positive.

Time savings: The mobile rack system gives farmers direct access to all plants for more convenient harvesting, pruning, cleaning and maintenance. This reduces farm work time by 25–50%.

Climate Automation and Connectivity: The Greenery pairs exceptional design with complete connectivity. Each farm component is built from the ground up with farmhand® IoT integration, bringing unparalleled control and transparency to farming.

Smart farm: Using IoT-connected sensors, the Greenery continuously relays all climate, component, and camera data directly to farmhand®. With this information at their fingertips – via smartphone, tablet, or desktop – farmers can confidently operate and monitor their farm remotely.

Tailored climate control: With Freight Farms' catalogue of real-world growing data, farmers can replicate ideal environmental conditions, or "recipes," for consistent crop quality. They can even make non-native produce varieties available in their local market by creating environments otherwise impossible in their region.

Combined, the Greenery's features signal a major shift in containerized agriculture. "The Greenery's forward leap in data and sensor technology represent a fundamental improvement to farmers' workflow and production versatility," said Brad McNamara, Freight Farms Co-Founder and CEO. "It also allows for total, real-time transparency for consumers. A single romaine head can be traced back through every growing stage back to the seed it came from, even down to the hour. That standard was previously considered impossible, and one we hope the entire industry will now adopt."

Versatile Design For the Future

With size and resource conservation central to its design, the Greenery is deployable by a single individual, yet powerful enough to meet the needs of regional distributors. This turnkey system can grow a higher capacity of hyper-local food directly onsite for communities, without resorting to time-consuming and capital-intensive indoor farming installations that are often located remotely.

"The Greenery is the most powerful standalone hydroponic farm available, with a fully-connected technology platform you can't achieve from any combination of products elsewhere in the industry," added Jon Friedman, Co-Founder and COO. "By revolutionizing a farm that can be operated by anyone, in any climate, and can successfully support a diverse range of business goals, our team is helping support a higher standard for society's food system than previously possible."

Establishing Containerized Farming

In 2012, Freight Farms debuted the first vertical hydroponic farm built inside an intermodal shipping container—the Leafy Green Machine—with the mission of democratizing and decentralizing the production of fresh, healthy food. With its technology system and integral IoT data platform, farmhand®, Freight Farms now has the largest network of connected farms in the world.

In 15 countries and most U.S states, farmers use Freight Farms technology to grow food in environments ranging from urban neighborhoods to extreme climates. These farms are the cornerstones of hundreds of independent small businesses and non-profit initiatives that localize and improve food access geographically and socio-economically. Leafy Green Machines have also been added to numerous educational infrastructures, as well as corporate and wellness programs by customers like Google, Ford Motor Company, Everlane, and Kimbal Musk's Square Roots.

The Greenery, available for pre-sale starting today, retails for $104,000, with general availability this Spring. For purchasing information, please visit freightfarms.com, or inquire at 1-877-687-4326 ext. 1. Freight Farms can also be visited on Instagram, Twitter, or Facebook.