Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Smart-Farming Startup Grow Computer Has Just Launched Their First Product - A Digital Growing Platform Called GrowStrip

BROOKLYN, NY, September 26, 2018

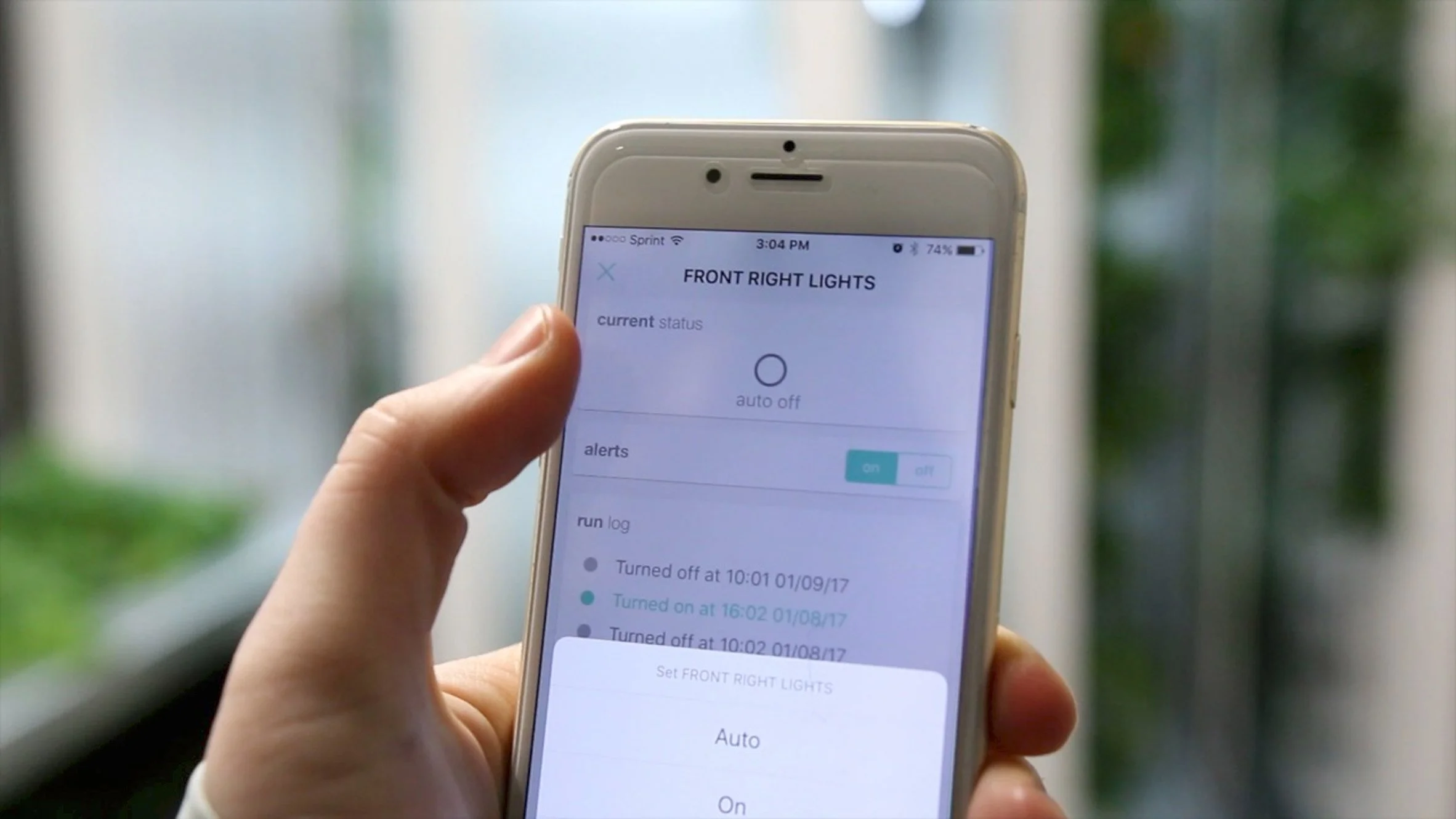

GrowStrip offers a user-friendly way for growers of all kinds to make their grows smarter through a simple hardware and software platform. GrowStrip gives any farmer, student, home grower, or researcher the ability to collect environmental and energy data, build automation, remotely monitor, and receive alerts.

The system was designed for usability and takes only minutes to setup, requires no tools, and is totally plug and play.

Indoor farming is an exciting global trend and is empowering anybody to grow almost any plant in their own homes. Hydroponics and other indoor systems conserve water, remove the need for pesticides, and allow a year-round growing cycle. Around the world, hydroponic systems are being used to build amazing indoor farms, empower entrepreneurs, and teach STEAM education in K–12 classrooms.

The company grew out of two communities of agtech startups, one in Brooklyn, NY, and the other in Sacramento, CA. Co-founders Dan Nelson (CEO) and Ian McEachern (CTO) met online through MIT’s Open Agriculture forums, and built out the rest of team at the urban farming co-working space AgTech X in Brooklyn.

McEachern is a medical device engineer with over fifteen years’ experience developing exciting products and, cutting-edge medical devices, including artificial hearts. Nelson is an experienced startup founder and has worked with dozens of companies as a for-hire virtual CFO.

Grow Computer’s vision is to empower people around the world to connect and share plant growing “recipes” and new ideas. They hope this will democratize critical technologies and techniques. In Nelson’s words, Grow Computer may unlock a new urban farming revolution by providing access to better hardware around the world. If we can get a distributed community of growers working together, the potential for scientific, educational, economic, phenotypical, genetic, or operational innovations becomes incredible.”

Grow Computer is proud to launch our crowdfunding campaign in conjunction with Agritecture Xchange, taking place in Brooklyn from September 24–29.

The Xchange conference is a week-long series of events in New York City that will explore agriculture’s role within the sustainable city movement.

GrowStrip will launch exclusively on Indiegogo starting on Wednesday, September 26.

GrowStrip retails for around $600 US and ships with a thermometer and camera, as well as the free, open-source software platform. Indiegogo buyers can purchase GrowStrips at a significant discount.

Why Indoor Growing is Important

Urban populations are growing, bringing with them a growing need for high-quality, sustainably produced food.

To meet global demand, the world needs more farmers, and farms that are more efficient than ever.

We believe that indoor agriculture is the answer. Hydroponics, rooftop greenhouses, and vertical farms are proliferating in major cities and in people’s homes around the world. But, the available technology is still either prohibitively expensive or stuck in the 1980s.

press@growcomputer.com

40 Bushwick Ave

C/O AgTech X

Brooklyn, NY 11206

###

Your Local Greens Lands $500,000 From 20 Investors

Sprouts at Your Local Greens

by Ryan Herron, North Carolina Business News Wire — September 7, 2018.

BURLINGTON — Your Local Greens Partners Inc. has raised $500,000 from 20 investors, according to a filing with the Securities and Exchange Commission.

The Burlington-based company filed a Form D to report the offering but declined to disclose what the funds would be used for.

The initial $600,000 offering by the organic farming company was comprised of a combination of debt and equity and has a duration of less than one year. It still hopes to raise an additional $100,000.

The company was founded by its current chief executive officer, Douglas Calaway, in 2015.

Your Local Greens establishes local indoor controlled environments to grow its crops. By doing so, it is able to increase the yield of its crops while using fewer natural resources to produce pesticide-free greens.

It is in the process of developing a hydroponic vertical farming building in the Raleigh-Durham area.

A hydroponic farm uses water to grow plants indoors, which allow it to grow crops at all times of the year. While a vertical farm grows plants in vertically stacked layers to maximize the use of space in an indoor farming facility.

“Live Better Than Organic”

Three Cyclist From Paris Bike 2000 Miles Visiting 60 Urban Farms

Linked by Michael Levenston

L'Equipe Agrovelocity Visit City Farmer from Michael Levenston on Vimeo.

Adèle, Audrey, and Mathilde from L’Equipe Agrovelocity Visit Urban Farms on the West Coast of North America from April to mid-August 2018

Aged of 22 years old, Audrey Rague, Adèle Maury and Mathilde Negri gather around a mutual interest for sustainable food supply, environment and the futures of agriculture. Inspired by the project Agrovélocités and Agrovelocity East Coast and in collaboration with their funders, they decided to continue AgroVeloCity together.

“We are three French students from Paris Institute of Life Science, and we are doing a project to see urban farms all the way of the west coast of the U.S., and we will be in Vancouver between the 3rd of August to the 10th!

Voici une petite vidéo sur l’agriculture urbaine à Los Angeles et les merveilleuses rencontres que nous avons faites avec les acteurs de la ville !

We are in partnership with the team of researchers from our university in Paris and we are doing report, videos, and social media like Instagram, facebook. We already visit more than 60 urban farms and community gardens in San Diego, Los Angeles, Sacramento, in the Bay area, Portland, and Seattle. And we go everywhere by bike!

Share this post: on Twitter on Facebook on Google+ on LinkedIn

St. Cloud University Measures Eight-Fold Increase in CO2 Transfer To Plants Using CO2 GRO’s CO2 Foliar Spray Technology

TORONTO, ON – July 9, 2018 – CO2 GRO Inc. (“GROW” or the “Company”) (TSX-V: GROW) is pleased to announce further scientific proof validating its dissolved CO2 foliar spray technology accelerating plant growth. The second set of scientific trial results at St Cloud State University ("St. Cloud") measured over an eight-fold efficiency increase in the conductance (transfer availability) of CO2 from the dissolved CO2 enriched water sprayed on Romaine lettuce leaves over both unenriched water spray and no spray control plant treatments.

Conductance in plant leaf stomata (pores) is an estimate of the rate of CO2 gas entering and/or water vapor exiting a plant leaf. This further evidence was measured in three separate experiments using an SC-1 leaf porometer. With a series of previously announced scientific trials showing a fourfold sustained increase in Romaine leaf chlorophyll, GROW now has scientific proof why its dissolved CO2 Foliar Spray works better than indoor growers that gas with CO2 and outdoor growers that have no alternative to add CO2 outdoors to their plants.

According to Tridge Intelligence, the worldwide lettuce market of 26.8M tonnes/y is worth $30B/y wholesale with the US producing 15.2% or 4M tonnes/y, mostly in California. GROW believes that St Cloud's scientific CO2 gas transfer and chlorophyll experiments are confirming the potential of 1-2 more lettuce crops/year in California or $1-2B/y more wholesale California lettuce revenue with less water use per unit of lettuce yield.

St. Cloud's second plant science report for GROW excerpts: "This data continues to be encouraging and consistent with the hypothesis of significant plant growth enhancement with CO2 delivered via foliar spray" and that "NO significant difference existed between unenriched foliar spray and no spray plant treatments, strongly suggesting that CO2 availability was the factor increasing both chlorophyll A and CO2 gas conductance"

St Cloud State is now measuring: 1) CO2 foliar spraying plants versus gassing a control plant group at 1200 PPM, 2) a variety of bug, mould and mildew experiments to measure whether CO2 foliar spray has positive plant resistance impacts reducing the needs of herbicides, insecticides, pesticides and fungicides, 3) improved leaf stomata water vapor efficiency using dissolved CO2 reducing water needs per unit of plant yield and 4) completing ongoing grow trials started from lettuce and pepper seeds.

All patentable results from scientific discoveries at St Cloud are 100%-owned by GROW.

About CO2 GRO (GROW.TSXV) or "GROW"

GROW's mission is to accelerate all indoor and outdoor value plant growth naturally, safely, and economically using its patented advanced CO2 foliar technologies. GROW's global target plant markets are retail food at $8 trillion per year (Plunkett Mar 2017), retail non-food plants at an estimated $1 trillion per year and legal retail cannabis that may reach $50 billion per year by 2022 (Bay St Analyst estimates). GROW's sole focus is working with its plant grower and Agri-industrial partners in proving and adopting its CO2 technologies for specific growers’ plant yield needs.

The CO2 technologies work by transferring CO2 gas into water and foliar spraying across

the entire plant leaf surface area, which is a semi permeable membrane. The dissolved concentrated CO2 then penetrates a leaf's surface area naturally like nicotine naturally dissolves through human skin from a nicotine patch.

Foliar spraying natural nutrients and chemicals on plant leaves has been used for over 60 years by millions of indoor and outdoor plant growers. To date, outdoor growers have not had any way to enhance plant CO2-gas uptake for faster growth.

Indoor use of CO2 gassing has enhanced plant yields for over 60 years. However, over 50% of the CO2 gas is typically lost through ventilation. Current greenhouse CO2 gassing levels of up to 1500 PPM are also not ideal for worker health and safety. GROW's safer dissolved CO2 foliar spray can be used by indoor and outdoor plant growers with minimal CO2 gas lost.

GROW's CO2 technologies are commercially proven, scalable and easily adopted into existing irrigation systems. GROW's proven crop yield enhancements and revenue model is compelling for growers and Agri-industrial partners.

Forward-Looking Statements This news release may contain forward-looking statements that are based on GROW's expectations, estimates and projections regarding its business and the economic environment in which it operates. These statements are not guarantees of future performance and involve risks and uncertainties that are difficult to control or predict. Therefore, actual outcomes and results may differ materially from those expressed in these forward-looking statements and readers should not place undue reliance on such statements. Statements speak only as of the date on which they are made, and the Company undertakes no obligation to update them publicly to reflect new information or the occurrence of future events or circumstances, unless otherwise required to do so by law.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Scientific Proof of CO2 GRO's Dissolved CO2 Foliar Spray Plant Benefits On Lettuce

Scientific Proof of CO2 GRO's Dissolved CO2 Foliar Spray Plant Benefits On Lettuce

TORONTO, ON – June 20, 2018 – Toronto based CO2 GRO Inc. (“GROW” or the “Company”) (TSX-V: GROW) is pleased to announce more scientific proof validating its dissolved CO2 foliar spray technology on lettuce.

The first trials at St Cloud State University in Minnesota ("St. Cloud") measured a fourfold sustained increase of chlorophyll concentration in Romaine lettuce leaves with dissolved CO2 foliar spray pulsed in 15-minute intervals for four hours. More chlorophyll lets plants grow faster and larger.

According to Tridge Intelligence, the worldwide lettuce market is 26.8M tonnes/y with the US producing 15.2% or 4M tonnes/y.

Over 90% of US lettuce grown is in California.

At the current $1.17/kg global wholesale lettuce price, the global wholesale lettuce market is worth $30B/y.

GROW believes that these initial chlorophyll trials with further replication of previous lettuce grow trials using its CO2 foliar spray technology will confirm the potential of 1-2 more lettuce crops/year in California or $1-2B/y more wholesale California lettuce revenue with less water use per unit of lettuce yield.

St. Cloud's first weekly plant science report states " Notable in these initial experiments is the rapidity of physiological response seen in CO2 exposed plants. This data is encouraging and consistent with the hypothesis of significant plant growth enhancement with CO2 delivered via foliar spray:"

In April 2018, GROW signed an ongoing Collaboration Agreement with St Cloud for scientific plant cultivation research services. Regular scientific documentation of CO2 foliar spray impacts on plant leaf stomata and now started grow trials in lettuce and peppers will be ongoing.

The primary objective of the started St. Cloud Romaine lettuce trial is to duplicate the excellent 100% incremental biomass results from an earlier lettuce trial conducted by the University of Guelph. That dissolved CO2 foliar spray lettuce biomass result was measured against lettuce grown with 800 PPM of CO2 gassing.

All patentable results from scientific discoveries at St Cloud will be 100% owned by GROW.

About CO2GRO (GROW.TSXV) or "GROW"

GROW's mission is to accelerate all indoor and outdoor value plant growth naturally, safely, and economically using its patented advanced CO2 foliar technologies. CO2 GRO's global target plant markets are retail food at $8 trillion per year (Plunkett Mar 2017), retail non-food plants at an estimated $1 trillion per year and legal retail cannabis that may reach $50 billion per year by 2022 (Bay St Analyst estimates). GROW's sole focus is working with its plant grower and Agri-industrial partners in proving and adopting its CO2 technologies for specific growers’ plant yield needs.

The CO2 technologies work by transferring CO2 gas into water and foliar spraying across the entire plant leaf surface area, which is a semi-permeable membrane. The dissolved concentrated CO2 then penetrates a leaf's surface area naturally like nicotine naturally dissolves through human skin from a nicotine patch.

Foliar spraying natural nutrients and chemicals on plant leaves have been used for over 60 years by millions of indoor and outdoor plant growers. To date, outdoor growers have not had any way to enhance plant CO2 gas uptake for faster growth.

Indoor use of CO2 gassing has enhanced plant yields for over 60 years. However, over 50% of the CO2 gas is typically lost through ventilation. Current greenhouse CO2 gassing levels of up to 1500 PPM are also not ideal for worker health and safety. GROW's safer dissolved CO2 foliar spray can be used by indoor and outdoor plant growers with minimal CO2 gas lost.

GROW's CO2 technologies are commercially proven, scalable and easily adapted into existing irrigation systems. GROW's proven crop yield enhancements and revenue model is compelling for growers and Agri-industrial partners.

Forward-Looking Statements This news release may contain forward-looking statements that are based on CO2GRO's expectations, estimates, and projections regarding its business and the economic environment in which it operates. These statements are not guarantees of future performance and involve risks and uncertainties that are difficult to control or predict. Therefore, actual outcomes and results may differ materially from those expressed in these forward-looking statements and readers should not place undue reliance on such statements. Statements speak only as of the date on which they are made, and the Company undertakes no obligation to update them publicly to reflect new information or the occurrence of future events or circumstances unless otherwise required to do so by law.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accept responsibility for the adequacy or accuracy of this release.

13 Vertical Farming Innovations That Could Revolutionize Agriculture

13 Vertical Farming Innovations That Could Revolutionize Agriculture

These revolutionary vertical farming innovations can soon replace the traditional agriculture techniques.

By Kashyap Vyas

July 4, 2018

Many have wondered for years if vertical farming is really the answer to the shortage of food in the world. However strange the concept of vertical farming might seem to many startups, it is an ingenious method to produce food in environments where arable land is unavailable or rare at the most.

This method is especially handy for challenging environments such as deserts, mountainside towns, and cities where many diverse types of vegetables and fruits are grown using precision agriculture methods and skyscraper-like designs.

Vertical farming is a revolutionary and more sustainable method of agriculture than its counterpart as it lowers the requirement of water to up to 70% and also saves considerable space and soil. This innovation in the field of agriculture with sustainability as its motto is making more and more heads turn today with its eco-friendly methods and making the possibility of farming real in difficult environs.

Let us check out the top 13 vertical farming innovations that could end up in your plate in the near future!

1. Hydroponics – Growing Plants Without Soil

Source: Oregon State University/Flickr

Hydroponics is a predominant system of growing that is used in vertical farming, and it is slowly but steadily, gaining importance. It involves around the growth of plants in solutions of nutrients that are essentially free of soil.

In this vertical farming innovation, the roots of the plants are submerged in a solution of nutrients. This is frequently circulated and monitored in order to ensure that there is the maintenance of the correct chemical composition in the nutrient solution.

2. Aeroponics – Growing Plants With No Soil and Very Little Water

Source: MyAeroponics/Wikimedia Commons

The innovation of Aeroponics in the field of vertical farming was made by The National Aeronautical and Space Administration (NASA). This sustainable growing technique was invented by NASA in the 1990s when it was looking for efficient techniques to grow plants in space.

This technique was then coined Aeroponics and was defined as "growing plants in an air/mist environment with no soil and very little water." However, these systems are yet to rise from an anomaly in the world of vertical farming even though they continue to create interest.

It is undoubtedly the most efficient way in vertical farming as it uses a staggering 90% less amount of water than the most efficient hydroponics systems too. It has also been observed that the plants that are grown with the aeroponics system uptake more vitamins and minerals, thus making the plants potentially healthier and more nutritious.

3. Aquaponics – An Ecosystem that Promotes Plants and Fish Farming Together

Source: Kate Field/Flickr

An Aquaponics System is much like the Hydroponics System but is only better. It aims to combine the fish and plants in the same ecosystem. In this system, fish grow in indoor ponds and produce a nutrient-rich waste that further acts as a food source for the plants grown in vertical farms.

The plants, doing their part, purify and filter the wastewater that gets recycled directly to the fish ponds. Aquaponics is definitely used at a smaller scale than most vertical farming innovations.

However, it is still used by many commercial vertical farms that wish to produce just a few fast-growing crops instead of including the component of aquaponics. As a result, the production and economics issues are simplified and it also maximizes efficiency.

That said, this closed-cycle system might become more popular with the popularity of new standardized aquaponic systems.

4. Lokal – Serving Fresh Food Right Where It’s Grown

Source: Space10

The Space10 innovation lab of IKEA came up with the idea of Lokal that uses a Hydroponic farming system. It also uses LEDs to have your kitchen garden in stackable trays.

According to the designers of Lokal, the greens grow three times faster in Lokal than traditional gardens. They are also testing another innovation wherein they will integrate sensors into the growing trays, which will help you check the status of the crops with the help of smartphones or Google Homes.

In the long run, they also want to use machine learning to collect and analyze data from the people using Lokal to assess the productivity. This innovation can really help people grow fresh food in their own local mini-farms.

5. AeroFarms – The Smart Vertical Farming Innovation

Source: AeroFarms

When it comes to indoor farming, AeroFarms are the commercial leaders in this field with their innovation of using the aeroponic system of farming that ensures predictable results of your harvest, less impact on the environment, faster harvesting period and superior quality of food. The technology helps growing greens without using any sun or soil.

Therefore, it is easier to control the results of the harvest. The vertical farming innovation makes use of smart light, smart aeroponics, smart nutrition, smart data, smart pest management, smart substrate and smart scaling.

AeroFarms aims to transform the whole system of agriculture by building and making farms that are environmentally responsible. They are building farms around the world to make sure there is a local production of food that is nutritious, safe, sustainable and delicious.

In short, they want to grow more crops in less space which can bring about a food revolution.

6. Plantscapers – A Building that Provides Food for its Occupants

Source: Plantagon

A Swedish food tech company called Plantagon is coming up with a creative solution that would allow office spaces and buildings to help feed a large number of people. In order to use the innovative methods of vertical farming, Plantagon has bought the rights to a vertical greenhouse from an organic farmer named Åke Olsson who believes in using technical innovation to find effective farming solutions.

Olsson developed a rack transport system that gradually moves the planting boxes from the floor to the ceiling of a vertical greenhouse, thus requiring no artificial light.

These vertical greenhouses or plantscapers are integrated directly into the office buildings with the functionality of hydroponic farming. The building would be named the World Food Building with the aim of producing at least 550 tons of vegetables every year and is planned to be constructed in Linköping, Sweden.

This is an estimated amount of vegetables that can provide food for almost 5000 people. High-level automation will be employed for the maintenance and harvest of plants in order to keep the costs very low.

Moreover, everything starting with sunlight, temperature, and nutrition, as well as air quality, will be measured through autonomous and controlled systems.

To sum up, it is a great innovation that keeps in mind sustainability and the requirements of people by keeping the costs of transportation very low and also by saving high amounts of energy, emissions, and water. If the concept becomes a success, more countries like Singapore, Hong Kong, United States and others have plans to adopt it too

7. VertiCrop – A Sustainable Farming Technique for Urban Areas

VertiCrop is a proprietary agriculture technique that has been deemed as one of the World’s Greatest Inventions by TIME Magazine in 2009. This patent-pending technology was designed and developed so that food could be grown naturally in the environment of bustling urban areas.

This proprietary method offers quite a paradigm shift in food production and sustainable farming methods. It provides up to twenty times the yield of your standard field crops and uses merely 8% of the water that is usually needed for soil farming.

The vertical farming innovation works on a suspended tray configuration that is unique in itself and moves on a conveyor system. VertiCrop offers optimal exposure to both artificial and natural light in addition to nutrients that are precisely measured for every plant.

It has been designed in a way that it can promote the healthy growth of crops in controlled and closed-loop environments. Furthermore, it entirely gets rid of the need for using harmful herbicides and pesticides and maximizes food value, nutrition and above all, taste.

8. Modular Farms – Produce Fresh Plants Virtually Anywhere in the World

The very exclusive and sustainable Modular Farm System is another great innovation in the world of vertical farming from the company called ModularFarms. It is an entirely indoor system of vertical farming that has the ability to produce healthy and fresh plants virtually in any climate and anywhere in the world.

If that doesn’t intrigue you enough, it is a custom-built design that is based on an urban farm idea. This modular farm scales according to need and has additional modules that are available for diverse purposes.

The Modular Farm System concentrates solely on farmer ROI and plant health. This system is the perfect pairing of container farms, and the tried & tested technology of vertical farming.

This balance between the two promotes an endless growth of fresh and locally produced plants. A highlight of this vertical farming innovation is that you can customize your system and extend its functionality according to your agriculture needs to accommodate any sized operation.

9. Cubic Farming Systems – The Next-Gen Sustainable Farming System

Cubic Farms, as its CEO Dave Dinesen points out in his TEDx Abbotsford speech, is the next generation of consistent, predictable and profitable farm productions. It works on the conveyor rotation method, automated nutrient delivery system and LED lighting.

The machines used for growing crops create an optimal environment for the greens. It also uses 1/26th the amount of water that is utilized in traditional agriculture, thus making it sustainable.

One would usually not associate these words with agriculture or growing. However, the patented Dutch Cubic Farming system entirely eliminates risks of common farming to standardize the outputs by controlling the inputs.

This, in turn, means a steady and more predictable income in addition to more consistency in the size, taste, and color of the produce. It also promises a longer shelf life and higher nutritional content for your greens.

10. ZipGrow – Vertical Farming for the Modern Farmers

The motto of ZipGrow is to ‘EDUCATE. EQUIP. EMPOWER.’ The ZipGrow team has come up with innovative farming solutions for the modern farmers who do not have the required tools and experience to scale or start a hydroponic farming business.

ZipGrow understands the challenges that are faced by the average farmers today in terms of suboptimal growing equipment, poor farming or poor understanding of what the market really wants. As a result, ZipGrow has built a multitude of services and products so that the deck can be stacked in their favor.

They have basically revolutionized the industry of vertical farming with system controls, vertical plane growing technology and high-tech workflow designs to help countless farmers globally.

11. Bowery – The Most Technologically-sophisticated Commercial Indoor Farm in the World

Source: boweryfarming/Instagram

The indoor farming company, Bowery is developing a technologically advanced farming system that will be capable to yield 30 times more produce and grow more than 100 kinds of herbs and leafy greens. The system according to the company will control the entire growing process indoors without using pesticides through their technology system BoweryOS.

The technology will automatically generate ideal conditions for the plants while collecting the data as they grow. The data will help in providing the plants with the exact amount of light, nutrients or purified water.

In addition, the sophisticated analysis will further allow harvesting the crops at the right time when its flavor is at its best. The produce cultivated through Bowery’s system utilizes 95% less water compared to the traditional farming.

12. Skyfarm – A Wind-Powered Vertical Farming Tower

Source: Rogers Stirk Harbour + Partners

An architectural firm, Rogers Stirk Harbour + Partners from London demonstrated a concept called Skyfarmduring the World Architectural Festival in 2014. The idea is to build a hyperboloid tower that makes use of different farming techniques including aquaponics and traditional soil-based planting methods to produce crops within high-density urban areas or at places where land availability is less.

The multi-story building uses bamboo to create a rigid circular frame while maximizes the sun exposure onto the farm. The tower supports both the growth of crops and fish together through a re-circulating system where the nutrients from fish water are fed to the crops while the plants provide filters for the fish to thrive.

The bottom of the tower is designed to have a large transparent tank consisting of freshwater for the farming of fishes like bass, tilapia, and barramundi. In the middle of the tower, the plants are grown through hydroponics using water.

Above this, the plants are grown through aeroponics using only water mists and no soil. The top of the tower consists of water tanks and turbines.

The tower is an example of a sustainable solution for growing produce with a short shelf life around the year with easy accessibility for the urban population.

13. Sky Greens – The World’s First Hydraulic Driven Vertical Farm

Source: Sky Greens

The Singapore-based company Sky Greens has developed a revolutionary vertical farming system which is also the world’s first low carbon, hydraulic driven farm. The vegetables are planted on shelves that keep on rotating throughout the day.

The plants at the bottom receive water, while the ones at the top get sunlight and the process continues. This approach minimizes the use of water, land, and energy over the conventional farming techniques.

In addition, the Sky Urban Vertical Farming System is capable of producing 10 times more yield compared to traditional farms. While the system is currently used to grow Asian vegetables, it can also be used to grow all kinds of fruits and veggies.

Vertical farming is definitely an attractive option for farmers these days as more and more industry experts embrace it and for a good reason. It promises a much more sustainable way of farming in addition to not just producing quality produce but also cutting down on costs and making agriculture more eco-friendly.

These innovations are bound to rise in popularity and revolutionize the face of vertical farming in the future!

Urban Agriculture Starting To Grow In London, Ontario

Urban Agriculture Starting To Grow In London, Ontario

Urban agriculture, as defined by the city, is “the process of growing, processing, sharing and distributing food within the city.”

June 22, 2018

After about a year of discussing it, London is finally implementing its urban agriculture strategy which, by the looks of it, is flourishing.

Urban agriculture, as defined by the city, is “the process of growing, processing, sharing and distributing food within the city.”

The strategy is intended to guide people who are growing and harvesting food in the city for themselves, for social enterprises such as community kitchens or food banks, and for sale.

Urban Roots is a local volunteer-run not-for-profit urban farm that began its operations last summer on a hectare of land in the city that was a former horse pasture.

At the time, the fledgling enterprise was in farming limbo as it waited for an urban agriculture policy from the city to help guide them.

Urban Roots volunteer Mariam Waliji weeds the zucchini and squash rows at their garden plot located off of Hamilton Road near Highbury Avenue in London. (Mike Hensen/The London Free Press)

Now, one of the Urban Roots founders, Richie Bloomfield, said the city strategy has enabled his group to expand from planting one tenth of a hectare last season to more than 0.4 hectares this spring.

“Truthfully, it doesn’t feel like a lot has changed and that’s a good thing,” Bloomfield said.

City planner Leif Maitland said the city is making sure it is aware of urban agriculture needs and is trying to reduce barriers for those wanting to grow food. To do so, the city has established a steering committee to help implement the strategy, which was written in November.

“It’s about education and connection,” Maitland said.

Urban Roots already has connected with community partners and has made it part of the organization’s mandate to do so, said Bloomfield.

Bloomfield said they have adopted a three-tier model in which one third of what is grown at Urban Roots is sold to local restaurants in the city such as The Root Cellar or Locomotive Espresso. Money raised helps fund the farming operation.

Another third will be sold at cost at the farm gate to community members once a week as well as to social enterprises such as Edgar and Joe’s cafe at Goodwill Industries.

The final third will be donated to places such as the London Food Bank and the Crouch Neighbourhood Resource Centre on Hamilton Road.

“Last year we barely got in the ground and scrambled to do something,” Bloomfield said. “This year is more of a trial (of) … what can we do with this model and see if its sustainable.”

Bloomfield said when it comes to testing soil quality, the farm is still relying on guidelines for Toronto, because the city has not implemented guidelines yet for urban agriculture soil quality.

Maitland said while community gardens have soil quality guidelines, he thinks the way to make sure farms are being placed on the right plot of land is by looking at its environmental history.

“What we’ve looked at is helping people find spaces that don’t have an issue,” Maitland said.

Bloomfield said Urban Roots is “humbled” by the volunteer support they’ve received.

The organization has been able to plant a variety of crops including carrots, beets and lettuce and will be holding a summer solstice launch on Saturday to show off what it has done and what it plans to do with its community partners.

While Bloomfield said the founders of Urban Roots didn’t have green thumbs before, he said they’ve grown into it now.

“We have done a lot of learning ourselves, but that has truly been a community supportive effort,” Bloomfield said. “So many people have the knowledge we don’t and they’ve shared it with us.”

IF YOU GO

What: Urban Roots Summer Solstice Launch Party

Where: 21 Norlan Ave., London

When: 9 a.m. to noon

Swedish Supermarket Grows Microgreens in Basement

Swedish Supermarket Grows Microgreens in Basement

Supermarket ICA Kvantum Liljeholmen introduced, with assistance from Urban Oasis, a subterranean nursery that doesn’t require any soil.

In a basement space below the supermarket, large amounts of fruit and vegetables are cultivated. And that in an underground cultivation space, without soil. However, that does not affect the taste. The products are just as tasty, fresh and healthy as crops that are simply grown in Mother Nature. In addition, underground cultivation has great environmental benefits.

With the underground cultivation, a significant step is taken into the future. It does away with over-fertilization, climate-unfriendly transportation or unnecessary import. At the moment, 70 percent of all vegetables in Sweden come from abroad. That figure can soon be lowered considerably. In Liljeholmen, the production of the 50 m2 goes straight to the supermarket salad bar, a distance of 500 meters.

"We can use this technique to cultivate anything we want. We have the motto ‘Break the seasons’. We are just a small step away from sun-ripened tomatoes and ripe strawberries for Christmas," says sales manager Joakim Haraldsson of ICA Kvantum Liljeholm.

The efficient urban cultivation method of Urban Oasis is the result of a pilot project of an inventive foursome: two students from the Technical University, an architect and a financial expert, who set a goal to establish a company for sustainable food production.

"With a so-called hydroponic system, you can grow crops in water, without soil. So locally we can cultivate nutritious products in a special environment where horticulture and technology meet. And also in Sweden, we can produce fresh, local vegetables all year round," says Albert Pajaro, general manager and one of the initiators of Urban Oasis.

Ica Kvantum Liljeholmen had already made great strides in the search for environmentally friendly cultivation methods earlier. Now that the underground cultivation company of Urban Oasis will soon be working even more efficiently, the intention is that more than five tons of vegetables will be produced daily. That must be sufficient to satisfy the hunger of thousands of salad enthusiasts among ICA customers every day.

"ICA is an innovative company. So it is great to work together with other special companies and help them to conquer the market," Joakim Haraldson of ICA concludes.

Entrepreneur prize

ICA has established an Entrepreneur Prize that will be awarded to persons who have distinguished themselves in one of these two categories: Local Hero of the Year and Startup of the Year. A cash prize of 10,000 euros is available for both categories. In addition, from 2020 ICA aims to provide 200 new small local entrepreneurs with the opportunity to deliver their products directly to ICA branches.

Source: www.di.se/

Publication date: 5/10/2018

The Vertical Farming Panel at GreenTech

The Vertical Farming Panel at GreenTech

The LEDs & Innovators Conference 2018 is set to be one of the highlights of GreenTech this year. A full day conference will gather some of Europe’s leading vertical farmers, crop science researchers and cannabis cultivation specialists in one room.

The vertical farming panel will be held from 12.00 till 13.30 (Wednesday, June 13th) and the speaker's line-up consists of:

- Mr. Richard Ballard (Co-Founder, Growing Underground, London)

- Mr. John Apesos (CEO & Co-Founder, GROWx, Amsterdam)

- Mr. Thomas Zöllner (Vice Chair, Association for Vertical Farming) and

- Mr. Lars Aikala (CEO, Valoya).

Farmers Cut, a Hamburg based vertical farm has just been added to the speaker's line-up and will be represented by Mr. Mark Korzilius, its Co-Founder & CEO. In addition to having some of Europe’s leading figures in the vertical farming industry on stage, this event will be an opportunity for the audience members to network and source business partners.

To learn more about the conference and sign-up click here. Seats are on a first-come-first-served basis and the number is limited.

In the video below you can learn more about Farmers Cut and Valoya, its lighting supplier and the organizer of the LEDs & Innovators Conference 2018 at GreenTech.

About Valoya Oy

Valoya is a provider of high end, energy efficient LED grow lights for use in crop science, vertical farming, and medicinal plants cultivation. Valoya LED grow lights have been developed using Valoya's proprietary LED technology and extensive plant photobiology research. Valoya's customer base includes numerous vertical farms, greenhouses and research institutions all over the world (including 8 out of 10 world’s largest agricultural companies).

Additional information:

Valoya Oy, Finland

Tel: +358 10 2350300

Email: sales@valoya.com

Web: www.valoya.com

Facebook: https://www.facebook.com/valoyafi/

Twitter: https://twitter.com/valoya

Click Here

Heavenly Good From The Underworld

Heavenly Good From The Underworld

April 17, 2018, 16:25

Forget about organic farming. Now it is about urban urban cultivation. ICA Kvantum Liljeholmen peered in the crystal ball and was helped by Urban Oasis to introduce the country's first underground crops - completely without the help of soil.

In a mountain room under ICA Kvantum Liljeholmen, fruit grows, greens and green so it's cracking. No wonder, if you do not think that Urban Oasis's cultivation area is not only underground but because the frog beds also lack soil. However, the taste can not be mistaken; The products are just as tasty, crisp and healthy as they were grown with native Mother Nature. But in the long run, the difference can be huge for our planet.

Underground crops are, in short, a giant cliff straight into the future. For here, there is no talk of either eutrophication, climate impact or unnecessary imports. Today, 70 percent of all vegetables in Sweden are purchased from abroad. Soon that number can be a memory only. In Liljeholmen it moves on 50 square meters of small production of freshly harvested only 500 meters, straight into ICA Kvantum's fresh salad bar.

"We can grow almost anything here. With the technology in place, it is only the imagination that sets limits. "Break the seasons" we are talking about. Maybe we're just a small step from sun-dried tomatoes and crispy strawberries at Christmas, says ICA Kvantum Liljeholm's sales manager Joakim Haraldsson.

Urban Oasis's resource-efficient urban cultivation is the result of a quartet pilot project - consisting of two KTH students, an architect and a finance man - with the goal of forming a foodtech company for sustainable food production.

- By so-called hydroponic cultivation, cultivating in water without soil, we can produce nutritious and nutritious food in an exciting environment where agriculture and technology meet. We will be able to offer fresh, roasted vegetables all year round even in Sweden, "said Albert Payaro, CEO and one of the initiators behind Urban Oasis.

Ica Kvantum Liljeholmen has already taken great steps in pursuit of environmentally friendly farming practices. When the Urban Oasis underground plant will soon be utilized even more efficiently, the ambition is to produce nearly 5 tonnes of vegetables - a day.

It is enough to calm the hunger of thousands of salmon-hot ICA customers in Liljeholmen every day.

"ICA is basically an entrepreneurial company and it is therefore fun that we can support and collaborate with other exciting entrepreneurial companies and help them to market," concludes Joakim Haraldsson at ICA.

• Growing in water without soil gives great harvest on a small surface - year round. Nutrition reaches the roots via an aqueous solution under the boxes. As an air gap is left between the plant and water, oxygen is added all the time, which causes the crops to grow rapidly above the surface.

• What can I grow? Almost whatever for green. Spices like basil, coriander and parsley, lettuce and other leafy vegetables, of course, but also tomatoes, chili, eggplant.

• If you do not have daylight, the crops can get energy using small LED lights.

• Farming without soil is nothing new. It already did the ancient Egyptians 600 BC. in one of the world's seven wonders: Babylon's famous hanging gardens.

ICA's Entrepreneur Prize is awarded for the first time in 2018 and goes to people outside the ICA organization. The prize goes to two categories: the local hero of the year and the new star of the year, and a scholarship of 100,000 kronor each. The winner is appointed by a jumbo jury and an online poll that weighs as heavily as one of the jury's voices.

In addition to ICA's Entrepreneurial Award, Ica aims to provide 200 new, small local suppliers with the opportunity to sell their products directly to ICA stores by 2020.

published: April 17, 2018

Every Essential Nutrient Buffered To The Exact pH

Every Essential Nutrient Buffered To The Exact pH

New liquid fertilizer Gold Leaf

A complete liquid fertilizer that contains every essential plant nutrient has been the ‘holy grail’ of liquid fertilizers for many decades. Many have tried to create such a product, all have failed. That is why the developers of “Gold Leaf” by Plater Bio claim to have reached a major achievement with the launch of Gold Leaf.

Plater Bio, founded in 2016 in Glossop (Derbyshire, UK) and have been developing Gold Leaf for the last two years. Plater Bio founder Dr Russell Sharp says “the aim when creating Gold Leaf was not only to produce a product that contained every essential nutrient, but which was also buffered to the exact pH that plants need for optimal growth and with all the micronutrients in a chelated form in order to keep them available to the plant”.

They have done so now and the immediate, and most obvious use for Gold Leaf is as a hydroponic fertilizer. "Currently hydroponic systems rely on two or three-part products that all need to be kept in separate tanks, blended, dosed, pH controlled, and monitored for electrical conductivity (EC). All these tasks need to be completed before fertilizer can be applied to the crop. In contrast, Gold Leaf is simply mixed with water at the desired rate and is then ready for use."

While Gold Leaf was initially designed for hydroponics, it is now being trialed in other agricultural systems, such as field crops. Plater Bio founder Dr. Russell Sharp adds “we are finding there is a lot of interest in Gold Leaf from conventional farming. This is because, as a complete nutrient solution, Gold Leaf reduces the number of products that need to be applied to a crop, thus saving farmers time, money, and water.”

He continues: "While there are suspension products already available that contain lots of plant nutrients, they contain solid material suspended in liquid. The problem with suspension fertilizers is that the solid part (calcium phosphate and calcium sulfate) are completely insoluble, even when diluted down and left for days. This is not surprising as calcium phosphate is the principal component that makes animal bones! This means the calcium and phosphate are not available to the plant, plus the solid particles can block applicator filters."

"The lack of calcium in conventional compound fertilizers has limited crop yields globally as calcium is essential for many metabolic processes in plants. This has meant crops regularly suffer from physiological disorders caused by calcium deficiency, such as Blossom End Rot in tomatoes, or Bitter Pit in apples. In addition, it is now widely accepted that modern fruit and vegetables contain far less mineral nutrients (such as calcium) which are essential for meeting human nutritional demands." As such the team at Plater Bio believe that Gold Leaf is set to become a major new tool employed by farmers in all sectors in the near future.

Gold Leaf is now being tested by potential distribution partners globally and Plater Bio are happy to speak with organizations looking to partner on realizing the full potential of Gold Leaf.

Plater Bio is to exhibit at the GreenTech exhibition June 12-13-14 in Amsterdam. Find them in hall 10, stand 111.

For more information on the GreenTech exhibition and the GreenTech Summit, check out www.greentech.nl.

For more information:

Plater Bio

Publication date: 5/10/2018

FarmBot Wants to Cultivate An Open-Source Future For Remote Farming

FarmBot Wants to Cultivate An Open-Source Future For Remote Farming

January 3, 2018

“Farm from anywhere” is a phrase we’re likely to hear more and more of as technology enables easier access to fresh, locally grown food. We just wrote about Babylon Micro-Farms, a remote, hydroponic farm you can keep inside your living room. There’s also a healthy urban farming market: thanks to companies like Farmshelf and Smallhold, restaurants, schools, and the average consumer get better access to fresh food and more involved in the food production itself.

But no one’s tackled the reinvention of farming quite like the folks at FarmBot.

FarmBot is basically precision agriculture for the people. When he launched the FarmBot project in 2011, founder Rory Aronson wanted to find a way to bring the benefits of remote farming to the everyman without the hefty price tag.

Precision agriculture normally involves technology like self-steering tractors and aerial drones that can make better use of resources. Because the method uses real-time data to understand weather, air quality, labor costs, and other factors, growers can make smarter decisions about how much and how often to employ resources. As its name suggests, precision agriculture provides meticulous records of every single step of the growing process.

Historically, it’s been the territory of industrial farmers. But thanks to Aronson, anyone with a little space and (considerably less) cash can get involved in food production.

Both FarmBot products, made up of cartesean coordinate robots along with software and documentation, can work on rooftops, in backyards, and can accommodate both small- and large-scale farming operations. It’s unclear whether the company means “farm from anywhere” literally, as it says on its website. But considering the highly customizable nature of the product, anyone with some tech know-how could theoretically hack the bot and make it work in any given climate.

A visual interface lets you “plan your garden like a videogame,” according to the company’s website. So the fact that the interface looks a bit like FarmVille is no coincidence. You can drag and drop plants into the virtual plot of land (below), build care regiments, and even scare away birds.

After the garden is planned, the machine plants seeds, measures soil moisture content and water, and can detect and destroy weeds. Email alerts tell a user when the crops are ready for harvest.

It’s also open source, including the hardware, software, and documentation. That means all design files, source code, and hardware specs are available for free on the company’s website, so anyone can customize their farm without having to fork over a bunch of extra money.

Right now, the FarmBot Genesis goes for $2,595 via the company’s website. The FarmBot Genesis XL, which is available for preorder, costs $3,295 and covers “421 percent the area of for just 38% more cost.” Shipments of both machines are expected to go out in May of this year.

Aronson would eventually like to get the price point down to $1,000. It’s unclear whether that will happen soon or if it’s some ways off. Meanwhile, FarmBot is making its way into universities and non-profits, and the company is working with NASA to develop open-source food production on Mars, the Moon, and deep space. Remote farming indeed.

All images courtesy of FarmBot.

Meet Farmlab.One, The Latest Indoor Farming Experiment From Germany’s Largest Retailer

Meet Farmlab.One, The Latest Indoor Farming Experiment From Germany’s Largest Retailer

By Michael Wolf | August 14, 2017

While we haven’t arrived at a future where every corner grocery has an in-store farming system with rows and rows of produce, it isn’t for lack of trying.

This is especially true for METRO Group, Germany’s largest retailer, who has been experimenting with in-store farming since early 2016.

The First InStore Farm in Europe**** The first of its kind farm in the METRO Supermarket in Berlin. Delicious greens grow 365 days a year InStore In full transparency and by demand.

That’s when the retailer launched Kräuter Garten (herb garden), the first retail in-store farming installation in Europe. The technology for METRO’s first foray into vertical farming was provided by INFARM, a vertical farming startup based in Germany. Since the launch of Kräuter Garten in Berlin, other retailers such as EDEKA (Germany’s largest grocery store chain) have since taken an interest in in-store growing.

Now METRO is at it again, launching another vertical farming experiment with Farmlab.one, a joint project between the retail giant and Schmiede.ONE, a German innovation lab focused on future business models that intermingle agriculture and cutting edge technologies such as artificial intelligence.

The project will be managed by James Lindsay of Schmiede.ONE in an indoor lab in Düsseldorf. METRO has provided resources in the form of indoor farming racks from TowerGarden, the indoor farming division of Juice+. The project is starting with three crops to start, which you can watch here via Periscope.

While the project is a modest one, it’s a sign of continued interest in vertical, in-building farming by a large food retailer. In the US, we’ve seen growing interest in solutions from companies like Farmshelf, and just last month we saw one of the biggest investments ever in a vertical farming startup when Jeff Bezos, among others, invested $200 million in stealthy startup Plenty.

A comparison of yields and resource consumption of indoor vs. soil-based farming. Source: Schmiede One

While it’s unlikely that in-store vertical farms could produce at the scale to meet the total demand for fresh produce purchased at a high-volume urban retail storefront, it’s clear that soilless vertical farms produce at a much high rate of productivity compared to soil based farming, which means much less overall space is needed to produce the same amount of produce. With such high yields, one can envision a future where a mix of in-store grown produce combined with other warehouse grown urban farmed food could be enough to meet a large percentage of overall demand for fresh produce.

While we haven’t arrived at a future where every corner grocery has an in-store farming system with rows and rows of produce, it isn’t for lack of trying.

This is especially true for METRO Group, Germany’s largest retailer, who has been experimenting with in-store farming since early 2016.

The First InStore Farm in Europe**** The first of its kind farm in the METRO Supermarket in Berlin. Delicious greens grow 365 days a year InStore In full transparency and by demand.

Shaping Smarter Cities: Urban Farming in Tokyo Japan

Shaping Smarter Cities: Urban Farming in Tokyo Japan

14 August 2017

With the next evolution of Mouser Electronics’ Empowering Innovative Together™ series, Mouser and Grant Imahara team up with the creative minds at WIRED Brand Lab to take a look at the modern city. Sponsored this year by our technology partners Analog Devices, Intel, Microchip a,nd Molex, we’re traveling the world to see and learn from the innovators and progressive companies creating a more livable future for our cities. We’re asking insightful questions: How can technology make our hectic lives better, and what solutions will it provide to the everyday problems today’s ever-growing cities face? Across the globe, there are many innovators hard at work already employing technology to create smarter cities that are more efficient, less polluted and more sustainable.

In the third episode of our 5-part video series, Grant heads to Tokyo, Japan to speak with engineers at a company called Mirai. Mirai is investigating how urban farming could enhance food production for ever growing populations in smart cities. Almost three-quarters of the landmass in Japan is mountainous. This leaves only a relatively small area for the entire population to live work and grow food. As the population increases, the strain on food production expands exponentially.

That is where Mirai comes in. They have converted a former Sony semiconductor factory into the world’s largest indoor farm. It ships out 10,000 heads of lettuce per day. By building these farms up instead of out Mirai has found one solution to the problem of space for farms in Japan.

Inside their indoor vertical farm, Mirai can control all the things that keep a farm awake with worry every night. In the controlled environment they have created rainfall can be precisely controlled, soil nutrients can be meticulously applied and damage from animals and insects ceases to be a concern. The yield per square meter is 50 to 100 times that of a normal farm.

The types of vertical farms that Mirai has created can be installed virtually anywhere they are needed. This means that the food miles (a measurement of the distance food has to travel from producer to consumer and the fuel required) for their products are greatly reduced.

The indoor nature of these farms also reduces water consumption. All drainage from the watering of crops is collected and recycled. Even the water lost to evaporation is trapped and then recycled.

These are just a few examples of how vertical farming will revolutionize the world of agriculture and enhance smart cities.

In the next episode Grant treks to Los Angeles, California to take a look at the future of city building.

Hydroponics – Future of Urban Food | CV Prakash | TEDxPESITBSC

Hydroponics – Future of Urban Food | CV Prakash | TEDxPESITBSC

Posted on August 16, 2017 by adminlfad

Simplified Hydroponics – Who Can Grow?

Where can you grow?

Why?

Grow Local, Eat Local.

Lt. Cdr CV Prakash is a former underwater weapons specialist of the elite Submarine arm of the Indian Navy.

Upon retirement CV learnt Hydroponics from the best of growers in Australia and is a pioneer in the field of Hydroponics in India. A hands-on Grower, Food Park designer, Auditor & Trainer in Hydroponics, CV’s “Pet Bharo Project” is credited for India’s first commercial hydroponically grown strawberries, spinach and herbs.

He is credited for building India’s first state-of-the-art Hydroponics Greenhouse and is one of the most widely read academic paper authors. His mission is clear- to bring simple yet sustainable technology that can help almost everybody grow clean, residue free, nutritious food. The best part about his technology being that it has very little entry barriers and reaches the poorest of the poor.

He believes that “it’s not enough to just have know how, but one must do how and show how”.

This talk was given at a TEDx event using the TED conference format but independently organized by a local community. Learn more at http://ted.com/tedx

Posted in Hydroponics · Tagged English, Food, Gardening, Global issues, Health, india, plants, TEDxTalks

Rooftop Farm Puts Ryerson In Good Stead

Rooftop Farm Puts Ryerson In Good Stead

The urban farm grows more than just produce for the Toronto university.

By ANQI SHEN | AUG 15 2017

Volunteers tend to kale crops at Ryerson University’s

rooftop farm. The initiative produces 4,500 kilograms of

food annually. Photo by Mark Blinch

On top of Ryerson University’s George Vari Engineering and Computing Centre, a bustle of students and staff harvest a farm field surrounded by a view of downtown Toronto. If “urban farming” once seemed like an oxymoron, it’s lately become less strange. “The reason isn’t just because we’re thinking about food security in a more serious way,” says Ryerson’s farm manager Arlene Throness, “but also I think people are enjoying being able to connect with food and how it’s grown.”

Ryerson is one of a handful of Canadian universities to have a rooftop farm. After a successful pilot project in 2013, students in the Centre for Studies in Food Security initiated the conversion of the building’s Andrew and Valerie Pringle Environmental Green Roof into a quarter-acre farm. “They worked with campus facilities to identify underutilized space that could be repurposed for food production and education,” said Ms. Throness, who gave a tour of the farm during a typical harvesting shift in late May.

The harvested produce is sold at a farmer’s market on campus and distributed among Ryerson food services and 30 Community Supported Agriculture members. “We grow 10,000 pounds [4,500 kilograms] of food annually, and we collect data to see how much food we’re actually producing. That way, we can share our techniques with other people who want to replicate the project,” said fourth-year food and nutrition student Terri-Lyn Zhou, who is one of the farm’s two data coordinators.

The farm is open to the public through short site tours, and offers a 10-week training program on food production, and workshops ranging from “probiotic dressings and dips” to “DIY mushroom cultivation.” The programs are another source of revenue for the farm, and private donors help to fill any gaps in the budget.

Recently, the farm became part of business services at Ryerson and now operates as an ancillary service. “There were a lot of options around the question of where to house it,” Ms. Throness said. “I like the idea that institutions and universities might include a farm in their ancillary services, along with parking and food services, and a bookstore.”

The farm has grossed about $20,000 annually the past two years, Ms. Throness said. The goal this year is to double that.

PIDO's Bike Share Farm Is A Community Garden That Can Be Pedalled From Place To Place

The hydroponic farm consists of a triangular steel framework supported by a pair of bikes. Pipes run across the metal base, with holes for pot plants to slot into. A set of solar panels are fastened onto the structure to power a pump that runs water through the entire system

PIDO's Bike Share Farm Is A Community Garden That Can Be Pedalled From Place To Place

Emma Tucker | 6 August 2017 Leave a comment

Beijing architecture firm People's Industrial Design Office has designed a mobile farm that lets the community share responsibility for crops' wellbeing.

Bike Share Farm – which was created and built by People's Industrial Design Office(PIDO) during a 72-hour hackathon in Seoul, South Korea – addresses the lack of space many major cities suffer from, particularly when it comes to room for growing produce.

The hydroponic farm consists of a triangular steel framework supported by a pair of bikes. Pipes run across the metal base, with holes for pot plants to slot into. A set of solar panels are fastened onto the structure to power a pump that runs water through the entire system.

The frame allows for bikes to be easily exchanged, so that a new cyclist can take responsibility for the farm at each stop. The system is designed to encourage a whole community to take part in farming, and offer more people the chance to get involved.

"Urban gardens are now common in many cities but few have access to them," PIDO co-founder James Shen told Dezeen. "The Bike Share Farm marries the bike share model with urban farming. A vertical and mobile farm addresses the land constraints found in dense cities like Seoul and Beijing."

According to Shen, the structure is light enough to be lifted by two people and is easy to control and steer.

"We imagine people would ride to a Bike Share Farm location, hook on their bikes and take it to a convenient location," he added. "This would allow large numbers of Bike Share Farms to spread throughout the city."

The studio is currently working on demonstrating the design with larger numbers of vehicles.

As cities with limited space continue to build upwards, new approaches to farming are being created by designers keen to introduce greenery. These include a vertical farm that would produce food amid Shanghai's skyscrapers and a floating "food forest" that would occupy a barge on New York's waterways.

Freight Farms Allows Crops To Be Grown Inside Shipping Containers

Freight Farms, a startup that has found a way to grow crops inside shipping containers, features in the latest video in our Dezeen x MINI Living series.

Calum Lindsay | Published 08-11-17

Freight Farms, a startup that has found a way to grow crops inside shipping containers, features in the latest video in our Dezeen x MINI Living series.

The organisation has developed a hydroponic farming system called The Leafy Green Machine. It uses this hi-tech growing technology to transform discarded freight vessels into mobile farm units.

Each farm occupies 320 square metres of space, but Freight Farms claims that each one can produce as much food as a two-acre plot of land.

Inside, seeds are planted in trays and exposed to LED grow lights until they sprout. The seedlings are then transplanted into vertical hydroponic planters, and fed nutrient-rich water from ceiling spigots that flow into artificial root systems.

In order to monitor and manage conditions inside the farm, Freight Farms has produced a smartphone app called Farmhand. Lighting, temperature, humidity and carbon dioxide levels inside the farm can be controlled remotely using this app.

This technology-based approach towards food production is known as controlled-environment agriculture (CEA). The benefit of this approach it that isn't affected by climatic and seasonal factors – one of the biggest limitations on traditional farming.

Freight Farms claims that its system enables food to be produced throughout the year in any location, as the outdoor climate has no impact on the conditions inside the shipping container.

The project taps into the growing trend for urban farming, which has seen an influx of investment and innovation in recent years, and is set to continue, as the proportion of people living in cities is growing exponentially.

According to Freight Farms, CEA systems could become commonplace in urban areas. City farmers would be able to expect plentiful harvests from a year-round growing-season, which would benefit urban communities lacking access to fresh local produce.

Freight Farms also claims that its fusion of technology with vertical farming has the ability to reduce the ecological footprint of food production, as its farms are able to produce food on a considerably smaller plot than is required by traditional crops.

Some restaurants, like B Good in Boston, have already installed Leafy Green Machines on-site, giving them immediate access to fresh and inexpensive produce.

Meanwhile, NASA has offered a grant to Freight Farms and Clemson University to develop off-the-grid farming systems using renewable energy, so that the space agency would eventually be able to adapt the technology to provide life support on Mars.

This movie is part of Dezeen x MINI Living Initiative, a year-long collaboration with MINI exploring how architecture and design can contribute to a brighter urban future through a series of videos and talks.

Read more

Wellspring Harvest Breaks Ground For Greenhouse In Springfield

By fall, between five and nine currently unemployed people will be working in a new hydroponic greenhouse growing salad greens for major local institutions like Baystate Medical Center, the public schools and Big Y supermarket.

Wellspring Harvest Breaks Ground For Greenhouse In Springfield

Updated on June 8, 2017 at 4:33 PMPosted on June 8, 2017 at 4:20 PM

Gallery: Wellspring Cooperative Corporation to build commercial greenhouse in Springfield

BY JIM KINNEY | jkinney@repub.com

SPRINGFIELD -- By fall, between five and nine currently unemployed people will be working in a new hydroponic greenhouse growing salad greens for major local institutions like Baystate Medical Center, the public schools and Big Y supermarket.

That's the plan from Wellspring Harvest, which broke ground Thursday at the former Chapman Valve site at 121 Pinevale St. in Indian Orchard.

"This will be a great place to go grow food. This will be a great place to grow people," said greenhouse manager and grower Stephen Hilyard.

Wellspring Harvest plans to grow at Indian Orchard greenhouse in Springfield by fall

The 2-acre project continues the process of putting the old factory property back to productive use, said Kevin Kennedy, city chief development officer.

Once one of the country's largest manufacturers of valves and fire hydrants, Chapman Valve had nearly 3,500 employees in the 1940s. The company supplied valves to the Manhattan Project, which built the first atomic bomb, and later machined uranium rods into slugs for reactor fuel at Brookhaven National Laboratory. In 1949, Chapman may have also conducted rolling operations on uranium metal.

Chapman Valve closed in 1986 when there were fewer than 100 employees.

An April 2005 federal study revealed that "significant" radioactive contamination remained at the plant at Pineville and Goodwin streets in Indian Orchard through the early 1990s.

Wellspring buying part of Chapman site for greenhouse

Wellspring is raising $900,000 for the project and has an event planned for investors Sept. 7.

Parts of the factory site, once 54 acres in size, were contaminated with radioactive waste that has since been cleaned up. Another part of the campus on Goodwin Street is the site of a 12-acre, 2.3-megawatt solar facility constructed by Western Massachusetts Electric Co., featuring 8,200 solar panels.

"I think it's amazing that we have been able to redevelop this site with 'green' uses," Kennedy said.

Jack Jack's Coffee House The 'Catalyst' For Urban Farming On Long Island

Jack Jack's Coffee House The 'Catalyst' For Urban Farming On Long Island

Jack Jack’s Coffee House in Babylon played a big role in helping bring the “Urban Farming” concept to Long Island, something that has caught the eye of local and NYC media alike.

Jim Adams of West Babylon was looking for a new way to benefit the community through the local and organic agriculture movement when he met the owners of Jack Jack’s, Mike Sparacino and Vanessa Viola.

As farmers themselves, Sparacino and Viola offered him tips to growing in the local area.

Signage that sits outside of Trimarco’s newly transformed lawn

They also helped him publicize his fledgling Long Island Farms effort and the need for volunteers.

Adams left a flier at Jack Jack’s asking people to “consider turning [their] lawn into a small local farm and at the same time eliminating landscaping expenses.”

“We are a place to share ideas that might be thinking out of the box,” said Sparacino.”So, when he put the poster up here we had a great response.”

Tilling The Lawn

Cassandra Trimarco, a physician assistant, who is a frequent customer at Jack Jack’s, was beyond excited to see the flier, being someone who was interested in growing her own food, but was restricted land-wise.

“I would grow little basil in cans, but that never worked out,” she said laughing.

After reading the ad she called immediately.

“[Jack Jack’s] was the catalyst and connection between [Lawn Island Farms] and myself,” she said.

Trimarco’s property was a perfect fit for a farm makeover.

Jim walking through his farmland at St. Peter’s Farm

And just this month, her little front-yard farm caught the attention of CBS News New York, with a Newsday report quickly following.

“On Long Island, there is now a ‘front yard to table’ effort and it’s turning heads,” CBS reported.

“We have plenty of land [on Long Island], we shouldn’t be flying in pesticide-filled [crops],” Adams told GreaterBabylon on Friday.

Trimarco moved into her Hyman Avenue house on May 1, and Lawn Island Farms immediately began the conversion process.

According to Lawn Island Farms, it took about two weeks of heavy pilling to get the initial seeds down, but now they are in harvest. Trimarco herself has no farming responsibilities, she just enjoys the view while getting $30 worth of crops per week.

“It’s great; I love it,” said Trimarco, “It’s attracting a lot of great things and it’s beautiful”

Jim Adams shows off a copy of The Urban Farmer

Lawn Island Farms takes the freshly grown produce and sells them to local businesses as well as at farmer markets in Bay Shore and Sayville.

The Movement

Jim became interested in urban farming after quitting his pool servicing job after 20 years in search of something more “meaningful.” He had read a book called The Urban Farmer, written by Curtis Stone, which gives guidelines to growing on small plots of land.

Jim and his wife, Rosette Basiima Adams, 34, soon started talking seriously about growing locally. For Rosette, who is from Uganda, she had found it odd to learn Americans didn’t grow their own food.

It wasn’t until she was 25 when she moved to the U.S. that she visited her first grocery store.

“When I first saw a supermarket I was excited and wowed,” she said. “Then I saw the food wasn’t fresh and was genetically modified.”

When Jim met with Sparacino and Viola, the first tip they were given was on a great location to start his farming.

“I recommended [Jim] to grow at St. Peter’s Farm,” said Saparcino.

St. Peter’s Farm is a small agricultural lot hidden behind by the St. Peter’s Episcopal Church in Bay Shore.

Both Jim and Rosette visited the church, where they agreed to take over 10,000 square feet of land and create their Lawn Island Farms.

Rosette Basiima Adams checking on her crops outside of Trimarco’s house

“We never even knew that land was back there,” said Jim. “Who knew?”

Now, Lawn Island Farms is trying to use their first urban farm’s success story to inspire others to grow locally.

“There are a lot of people who care about where there food comes from and seek it,” said Jim. “But if more of these small farms keep growing then even people who don’t care will be provided with [fresh food].

“They deserve better… we all deserve better.”

If you’d like to support Lawn Island Farms and learn more about their journey click here.

Rosette (left), Jim (middle), and Cassandra (right) in front of her house.

Fresh radishes grown by Lawn Island Farms.

Lawn Island Farms crops at St. Peter’s Farm.

Fresh lettuce growing outside of Trimarco’s household.