Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

New Opportunities For Agriculture Bloom in Cleanrooms

February 28, 2019

Some call it the future of farming and in some places it’s already here. It’s called indoor vertical farms, an alternative to conventional outdoor agriculture and it’s being tried in Europe, Asia and the U.S.

CGTN’s Hendrik Sybrandy reports.

“Why don’t we start on this one right here,” said Nathan Lorne, as he began a recent tour of his facility under a purplish glow.

Lorne is the Sales Manager at Infinite Harvest, an indoor hydroponic vertical farm in Lakewood, Colorado that grows four varieties of exactly one crop, lettuce. CGTN’s Hendrik Sybrandy takes us inside the facility.

“What you see here is a Bibb lettuce,” Lorne said. “The variety is Flandria.”

Inside a 500 square meter warehouse, under red and blue lights, because that’s what leafy green vegetables like, sit 52,000 heads of lettuce stacked from floor to ceiling. An automated system controls the variables that allow these crops to survive and thrive.

“Whether it be temperature, humidity, CO2, water temperature, light schedule, the list goes on and on,” Lorne said.

Welcome to at least a part of farming’s future, something that’s being tried in Europe and Asia, as well as other parts of the U.S.

“All of those problems that we see in agriculture as we know it are more or less solved by an operation like this,” Lorne added.

It solves problems like soil-borne contamination, labor costs and drought. It minimizes the need to truck food long distances, trips that often lead to food waste. It’s an answer to the age-old farmer’s dilemma.

“How do we optimize an environment to maximize the production of a crop,” said Josh Craver, an assistant professor of Controlled Environment Horticulture at Colorado State University.

The school dabbles in what’s called controlled environment agriculture. At a time when more and more people want locally produced, high-quality food, vertical farms are bringing that food to the dinner table. Of course man does not live on lettuce alone. This type of agriculture may not make sense for row crops like corn and wheat. While LED lighting has made indoor farming much more possible, it does use its share of power.

“It is relatively expensive to have these structures and to manage these structures year-round, but what you get in return is this premium high-quality crop that oftentimes can be sold for a premium,” Craver said.

Infinite Harvest is constantly tweaking its treatment of lettuce which can be a bit finicky.

“You can ask a plant to do something,” Lorne said. “You can’t tell it to do something.”

Unlike other lettuce farms, which harvest two or three times a year, Lorne says, “this company, whose produce is consumed in restaurants, hotels and hospitals, doesn’t take seasons off.”

Infinite Harvest says it will soon be profitable.

“I don’t think vertical farming or indoor farming will necessarily replace agriculture in the long run,” he said. “I think it will change it though.”

Now, Infinite Harvest is even looking to branch out and produce things like berries.

Video: Why Venture Capital Likes Modular Farming

Mar 07, 2019:

Wharton's Sherryl Kuhlman and Joey Hundert, CEO of Sustainitech, discuss why modular farming has become a hotbed of VC interest.

Modular farming, which is growing crops in self-contained, movable units so they can thrive in difficult climates, is becoming more than just a sustainability goal for social impact organizations. It is also becoming a big business that’s increasingly being backed by venture capitalists and private equity firms. New startups in this market are sometimes models for not only how to make profits while contributing to the social good, but also how such profits can lead to innovation that goes on to create additional social good.

In this podcast interview, Sherryl Kuhlman, managing director of Wharton Social Impact Initiative (WSII), interviews Joey Hundert, founder and CEO of Sustainitech, about these developments and where the whole movement is heading.

An edited transcript of the conversation follows.

Sherryl Kuhlman: Tell us about Sustainitech.

Joey Hundert: Sustainitech produces indoor agriculture facilities in spaces. We build modular indoor farms to produce crops in places where it’s very hard to grow crops. So, think really harsh winters. Dry, arid regions. Really hot places. We build indoor farms, typically inside of shipping containers that can be put anywhere to grow crops successfully where it can be hard to grow them.

Kuhlman: Who are the clients and consumers?

Hundert: In Canada, we grow lettuces and fresh herbs. And the clients are the everyday consumer. We’ve partnered with food companies – and we grow on their behalf. We package up the produce, ship it to them, and they ship it to the consumer. And then one of our customers is actually an ethnic group in Manhattan that requires produce a specific way. And so, we grow the produce and ship it to them. And they ship it to people who eat it.

Kuhlman: What are the latest trends in indoor container farming?

Hundert: What I’m seeing is trends in indoor farming writ large. It has attracted a lot of capital to the space. The idea is unfortunately sexy. The reason I say that is I think it has whipped up a bit of a frenzy of interest in international media and in the capital markets. And it has chased a lot of money into the space. Now, you might say, “well that sounds great.” And I am happy about that. That’s not the part I don’t like.

It’s that there are unrealistic expectations of the companies in this space. I think some of the money is coming in from Silicon Valley, where there’s a belief that industries can be cornered, and that a winner-take-all approach can be had. But when it comes to fresh food and agriculture, it is a hopelessly [fractured] and diverse space for a reason. And so, I think some of the trends that I’m concerned about with the arrival of so much money is companies are trying to scale into the hundreds of millions.

Kuhlman: So that they can drive out the others.

Hundert: Pretty much. Which looks silly. But beyond that, I see core flaws in their technology — in their whole approach. And I just worry what happens when you hit carbon copy 300 million times on something. And I worry about what the failure of some of these larger startups is going to mean for the rest of the market. And so, we’ve been building our company while keeping in mind that this is happening in the market. And we’ve been offered — like most of our competitors — a lot of cash. We’ve been very conservative about what we will receive and what we will do with it, trying to build a more durable company that’s going to last until the market economics are proven. And that’s the real critique.

“I worry about what the failure of some of these larger startups is going to mean for the rest of the market.” –Joey Hundert

Kuhlman: Even here in Philadelphia, there’s a lot of interest in urban farming to adjust the food deserts. And the fresh and healthy food is nice to get from your neighborhood container farm rather than shipped from California.

Hundert: Local food is probably what drove the initial interest in indoor farming. However, the further you get into farming — especially in the most developed nations — if you look past the first few hands into the food system, you find a massive industrial-scale mechanized complex of farms and processors whose unit economics are amazingly low. We’re talking pennies per pound. If you take a New York City — a Manhattan-based urban farm — they need $5 to $10 per pound just to turn the lights on. And so, I’m worried that those farms that need 10 times the amount per unit are going to have trouble.

The industry has chased a few ideas. Firstly, the vertical approach from Japan. We’ve built vertical farms. I’ve built non-vertical farms. The non-vertical farms are much more capital-efficient than the vertical ones. If we were building in Hong Kong, I would totally go vertical. But the places in the world where you need to go vertical are not many.

KNOWLEDGE@WHARTON HIGH SCHOOL

And then the other piece is, everybody chased lettuce because lettuce and leafy greens grow so fast. But it has also created a flood of product, and still competing with the produce from the field and from the greenhouses is incredibly hard. So, I think those two things — vertical growth and chasing greens — have steered indoor agriculture companies after some unattainable goals.

Kuhlman: You’re talking about the financing around this — venture capital chasing this, pushing it. How else can an entrepreneur get the funding to make these ideas happen? For farming and for other kinds of initiatives?

Hundert: Silicon Valley has created the well-paved, smooth-running highway of capital available to technology-based ventures — globally, but certainly in North America. And that is nothing to complain about. It has made it much more affordable for ventures like mine to go after capital. The agreements are standardized. The investment tools are standardized. The lawyers know what they’re doing, and there are many, many investment shops. And that is super cool. So, I think that we’ve benefited from that. We’ll continue to benefit from it, and I’m glad it’s there.

But I also built my company differently. Indoor farming is a very high-capital cost industry. If I was to have sold equity from day one, I would have 3% in the company left. I would have been diluted right out of it. And so, we’ve found other ways of financing the company. The first thing we did was sell an entire indoor farm on contract. We found a buyer of a very specific kind of indoor farm, and we sold that farm. And that injected cash into the company. The first two, two-and-a-half years of the company were built on just that contract. And it did let me get into the game and really see what was going on.

Then we scored a contract to ship produce to a company. And you can finance contracts if you know what your cost of production is — if you know you can make money at it. It may be hard to go find a buyer of this produce, but is it any less hard than going and chasing capital when you have no value? I found it easier to go find a customer for the produce that was willing to pay a really high price for the quality. And we grew for three years on that. And so, we didn’t even open up our cap table until year five. And then we started raising equity capital with a valuation I could stomach. And I want entrepreneurs out there to know there’s other types of capital out there. Sometimes countries will fund technology companies to make sales in other countries.

Countries love export revenue. It’s awesome for GDP. And a lot of countries in the advanced world have a terrible imbalance in imports and exports. And so, there are funds available to assist in export of technology and crops. What I would have done differently — and what I encourage entrepreneurs to do — is to have gone to the major trade shows sooner to find out how specialized a lot of these buyers are and that you can get forward contracts on a lot of this stuff. It’s a different way of going about it, but I would rather build value and ultimately build more equity before approaching a VC, especially in a high-capital expenditure business.

“I would rather build value and ultimately build more equity before approaching VC, especially in a high-capital expenditure business.”–Joey Hundert

Kuhlman: A lot of the student entrepreneurs we’re seeing — and even ones we’re reading about — they’re going after the venture capital right away. They’re thinking it’s a long shot, but if you get that quick hit, you’re set.

Hundert: One of our competitors raised $128 million a month and a half ago in a Series B. There was a competitor last year that raised $200 million in a Series D. What life was like before that round and after that kind of a round — that is a way-different existence. And again, if the unit economics were there, great. But I think entrepreneurs have to ask themselves, what are they in it for? When you become instantly corporate, you’ll have a board filled with very serious people and specific goals and KPIs, that if you don’t hit, you won’t have much time to mess around when there’s a couple hundred million at play.

Whereas, at $20 million to $60 million at play, I think there’s more flexibility to go after more profitable ends and niches in the market. It’s a global market: Agriculture — fresh produce is a massive [market]. And you can even process the produce — making it into essential oil, a tea, a dried herb or a nutraceutical. It opens up global markets. And so, the further I’ve gone, the more happy I am with the choice not to play in the commodities of these farms.

Kuhlman: You’ve been visiting us as the Nazarian Social Innovator in Residence. This year it’s official, but you’ve been with us for seven times, right? … We’ve seen your development along the way. You like to make improvements. I could see why you would say, “I’d rather have the freedom to continue to change, explore and develop rather than get the money that forces me to scale in ways that I’m not comfortable with,” right?

Hundert: Exactly right. If I had an opportunity a year ago to take on lots of capital and scale massively — if I had scaled with those ideas, I’m sure we could have pulled out the win, of some kind. What we broke through to, technically, in the last nine months — even the last six months — is amazing. And I can head after those opportunities now.

We’re already writing contracts on them. The margins eclipse that which we were doing before. It also embeds more of a purpose piece in what we were doing. It has continued to change the nature of the company. And we’re in the millions. It’s not like there are small opportunities. It’s that if I, like some of my competitors, had just scaled what I was doing a year ago, I wouldn’t be anywhere near as confident as I am today that the profitability is really there.

Kuhlman: And that gives you a great deal of flexibility in thinking about what you’re going to do next, who you’re going to approach, and how you’re going to structure your next rounds.

Hundert: Absolutely right. And it changes the type of investors that we’re approaching and making sure that we’re as exciting to those investors as we’ve ever been. But if anything, our investors are feeding back that they get confident the more clarity with which we’re seeing the global market.

Kuhlman: What kinds of trends are you seeing in investors? I know you’ve funded your first initiative — the Sustainival, the carnival — through more traditional nonprofit grants and sponsorships. How are you seeing that transition going? Is there more blended capital? More venture capital?

Hundert: I would say that venture capital is incredibly mature at this point. It’s also a great time to be raising money. A lot of these funds are flush. Sure, there’s concern about a coming recession. However, there are funds that have just closed their rounds. They have three and four and five years of dry powder to spend. So, I’m seeing lots of capital. I’m seeing new private equity shops pop up every day that I didn’t know about. A lot of them are getting even more purpose-built — for food, for robotics, for tech, for pharmaceuticals. Or even the venture arms of big corporations. They’re going at a purpose. And they’ve got these sidecar funds of $50 million or $100 million to go after a purpose.

“I’m seeing new private equity shops pop up every day that I didn’t know about.” –Joey Hundert

The ecosystem is so differentiated and flush. But beyond that, I think that some investors are wary of the companies that say, “we’re going to lose money for 15 years, and you’re going to need to pour in $10 billion, but then, we are going to boil the ocean.” I am seeing some skepticism about that now. There’s no question that some of these unicorns have blitz-scaled to the $50 billion mark. And everybody looks at Uber and looks at Airbnb and looks at Amazon, and says, “See?”

Kuhlman: You can do it.

Hundert: Right. But what about the 30,000 ventures that didn’t get anywhere close to that? What’s wrong with a 10x or a 30x? Why does it have to be a 700x? I’m seeing some skepticism in the capital markets about companies that say, “what we’re tackling is so huge and fundamental for society, someday we’re going to make money. Just bet on us and keep betting on us.” I’m seeing the preference for some investors to see some business savvy along the way. Can you cash-flow the venture? Is it profitable? When are you going to reach profitability? Can you do it a bit sooner? Can you access traditional bank financing? These are questions that we are being asked, and something that I’ve been seriously considering.

Because for a high-capital cost business, if I can get bank financing, that’s the cheapest non-dilutive capital that I could ever hope for. So, I’ve been working with banks to start to line that up because every dollar I borrow for our systems is a dollar I didn’t have to raise through equity capital. So, I think that the height of “We’ll make money someday” is actually behind us. And I’m seeing more value consciousness among certain institutional VC shops.

Kuhlman: I like the point you made about purpose, and more entrepreneurs and investments going towards that. We have a radio show on SiriusXM — Dollars and Change — and we’ve been doing it for about five years. And one of the things that we continue to see — our hypothesis is that the more funding that can go towards these purpose companies, the more likely entrepreneurs are to think about that as an opportunity. It proves the concept that you can have a business that has a purpose — makes a positive social impact — and still make money. And if you show that that’s possible, I think that inspires more entrepreneurs to think about how to make that happen.

Hundert: I would agree.

Kuhlman: It’s more fun to solve problems like that, right?

Hundert: It is. I think it’s in the heart of people. When I come to Wharton, I always like to take to pulse on what I’m hearing around here. What’s clear is that the concept of impact investing itself has matured here. People are looking at Wharton and looking at WSII — they’re coming here for that. I’ve talked with a couple of dozen students that came here because of WSII. I didn’t used to hear that. And they came here to learn about impact investing. I’ve even heard students saying, “I’m going into X big firm — big banking, big consulting firm — and I want to take these methodologies with me. I want to promulgate these ideas inside of large global firms.” That’s exciting. Wharton is one of those schools where that can actually come from. And students can carry it into those industries.

I’m also hearing a lot about the desire to blend purpose into venture – but it’s more sophisticated than in the past. It’s more concrete. In our company, we’ve had purpose on our minds the entire time. And there’s that terrible tension between making the company work and float and staying with the purpose. And one needs the other. Sometimes, you prioritize one or the other. I admit, much of the last six years was just making this thing technically work so that I could, again, point back more directly at [the company’s] purpose — when we could afford it, but most importantly, when the purpose made money to focus more on it. And to me, that’s the most virtuous blend.

If you can get the purpose to make money and actually be inspiring from a profitability standpoint, that’s maximum, when one isn’t taking away from the other [but] I admit, that is very hard. And we’ve done things just for profitability while I’ve had some purpose on my mind. And this year, we’ve begun to redevelop those programs — and they’re global in nature. They’re big. It’s a big lift. But we’ve restarted those programs that have purpose and profitability baked right into them.

Kuhlman: What advice would you give to an entrepreneur in this exciting, innovative, flush time for them to think about how to be most successful?

Hundert: I would actually report on something I’ve seen here at Wharton which I’m inspired by. I’ve been coming for eight years. This year, I’m [finding more people who would] most likely be candidates for success in venture than I’ve heard in years past. Somewhere, somehow, feedback came back to the cohort of students here to “get more specific. Niche out. Pick a niche and pick a product that is specifically built for something.”

I used to come in here [and hear startup pitches like] “It’s the Uber for this,” “it’s the Airbnb for that.” While there was lots of passion and energy, that [lack of focus] would concern me because you cannot boil the ocean and make your way. This year, I’m hearing about B2B plays on the most obscure things: switches and SaaS services for categories I didn’t even know existed. How students are finding this within weeks and months — it tells me something has trained them to look at the problem more carefully, and to look deeper into the market to find real problems instead of reading Fast Companyand being like, “I want to be like that.” I’m heartened to see this shift towards more specific, niche high-growth opportunities.

That’s my advice back to entrepreneurs that might listen to this. Pick a niche. Pick it carefully. You’re not expected to know [it’s the right one for you] right away. Go deeper into the field. Deeper into the market. Meet players at trade shows. Stay curious. Ask tons of questions. Eventually, those apertures of real peer opportunity are going to open up. And they may not have been visible to you in the beginning. They may even be totally uninteresting to the general population. But they could be super profitable — and easier to build a moat around, and easier to capitalize. I like that movement. I like the movement towards specificity — niche-based, high-profit opportunities — instead of trying to boil the ocean.

Pure Flavor®’s New Georgia Greenhouse Growing Results

Leamington, ON (March 6th, 2019) Now almost 3 months since their first picks of fresh greenhouse grown vegetables from their new Fort Valley, GA greenhouse facility, Pure Flavor® has started to change the landscape in the southeast.

“When we put the first shovel in the ground 18 months ago, we knew we had our work cut out for us as a project of this scope had never been built in in the Southeast”, said Jamie Moracci, President. To be built in 3 phases of 25 acres over 5 years, Phase 1 was completed in late Fall 2018 with the first crops of Cucumbers & Tomatoes picked in early December 2018. “We have a strong leadership team in place who have embraced the opportunity to create impact with a great product, the feedback from customers has been fantastic”, said Moracci.

The new greenhouse in Fort Valley, GA is growing the following items:

Tomatoes on The Vine

Sweet Red Cocktail Tomatoes

Long English Cucumbers

Mini Cucumbers

As a vertically integrated vegetable company with a family of growers throughout North America, the Georgia facility has opened new doors with a regionally grown product to service key retail & foodservice partners in the southeast. This has also allowed Pure Flavor® to open other markets with additional product as the company’s family of growers continues to expand season over season.

“Our team has done a great job in Fort Valley getting our first growing season under our belts. Learning how a crop will react to the environment has been a great experience to date and our Growers are adapting it to ensure the plants our producing in an optimal environment”, commented Matt Mastronardi, Executive Vice-President.

“When it comes to bringing new products to market like our new Georgia Tomatoes & Cucumbers, we have embraced the Georgia Grown brand to ensure that our customers know where the product is grown and who grew it”, said Chris Veillon, Chief Marketing Officer. The response to new products has been very positive on all fronts with feedback coming across all social channels and email. The new Tomatoes & Cucumbers were served recently at the Governor of Georgia’s Inaugural Luncheon when he took office.

Pure Flavor® will be exhibiting this weekend at SEPC’s Southern Exposure Trade Show in Orlando where the company’s focus will be on promoting the new Georgia greenhouse.

Construction of a new 60,000 sq. ft. Distribution Center will be wrapping up later this spring, located just off I-75, minutes from the greenhouse facility. The new Distribution Center will serve as a consolidation point which will provide an opportunity for a greater assortment of Pure Flavor® greenhouse grown vegetables to retailers & foodservice partners in the southeastern US region. Pure Flavor® operates distribution centers in Leamington, ON, Romulus, MI, and San Antonio, TX to support its vast network of growers throughout North America.

To learn more about Pure Flavor®, visit Booth 1120 at SEPC’s Southern Exposure in Orlando, FL March 9th or visit Pure-Flavor.com/SouthernExposure2019

-30

About Pure Flavor®

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise.

We are the next generation of vegetable growers, inspired to put quality, flavor, and customers first by providing greenhouse-grown vegetables from our farms that are strategically located throughout North America.

Vertical Farming Could Be About To Transform The Way Our Greens Are Grown

Vertical indoor farming is becoming popular, with an increasing number of businesses using the technique.

One such company is Crop One Holdings, which recently launched a $40 million joint venture with Emirates Flight Catering.

Published 02-22-19 CNBC.com

Vertical farming could be about to transform the way our greens are grown

We all know that a bowl of fresh green salad represents a healthy addition to any meal. And while the benefits of eating your greens are well-known, the way that they're grown is changing.

Vertical indoor farming is becoming popular, with an increasing number of businesses using the technique to grow produce such as salad leaves and micro herbs.

One such company is Crop One Holdings, which is headquartered in San Mateo, California. The business recently launched a $40 million joint venture with Emirates Flight Catering.

The aim is to build the planet's largest "vertical farming facility" in Dubai and produce herbicide and pesticide free greens. That farm, according to the business, will produce three tons of produce per day.

Crop One Holdings' production technique is advantageous for several reasons, according to its CEO.

"Most field grown produce is grown in soil and we don't use any soil, we only use water as our growth medium," Sonia Lo told CNBC's Sustainable Energy. "That means that we can have quite precise control on the nutrients," she added.

The company's chief scientific officer, Deane Falcone, echoed Lo's sentiment. "Being indoors you have the ability to control all the environmental variables, for example temperature, humidity (and) carbon dioxide levels that we feed to the plants."

Having control over those variables meant that producers could control the way plants grow, Falcone added. "The second thing is that you can grow at very high density and… that leads to a very high output for the same amount of growth area."

Indeed, the business says that just one of its 320 square foot "growing units" can act as a substitute for as much as 19 acres of farmland, using less water than "field-based growing."

CEO Sonia Lo added that in terms of productivity, Crop One Holdings' facilities can produce 32 harvests per year, on average, compared to a field-based farmer's "one or two" harvests.

For the University of Cambridge's Steve Evans, changes in the agriculture sector are set to play an important role going forward.

"In a world where there's a large number of people and they're becoming increasingly prosperous and they want to eat more and more rich diets, we have to learn how to grow the food with the land that's available," Evans, who is director of research in industrial sustainability at the university's Institute of Manufacturing, explained to CNBC.

"The world isn't expanding, so we're going to go vertical simply because of that need," he added.

Anmar Frangoul Freelance Digital Reporter, CNBC.com

Green Roofs Benefit People, Environment

A team at the University of the District of Columbia in the nation’s capital has created a garden on the top of one school building. The garden holds many kinds of plants to help absorb rainwater… and grow food at the same time.

February 17, 2019

by VOA

Water is a necessity of life. Rain, especially, helps plants grow and stay green. But too much rain -- especially in cities -- can lead to flooding. That can cause waste water systems, like sewers, to overflow and send pollutants into rivers and other waterways. To fight the problem, several cities in the United States are starting programs like rooftop gardens.

A labor of love

A team at the University of the District of Columbia in the nation’s capital has created a garden on the top of one school building. The garden holds many kinds of plants to help absorb rainwater… and grow food at the same time.

Architect David Bell has designed five “green roofs" for the university. He says he is excited about the project because “it meant doing something more than just dealing with storm water management.”

“It took advantage of a resource above the city that you see all over where you have these flat roofs that aren’t doing anything and it really made it something that was about urban agriculture.”

Rainwater is collected in large containers and sent through a system that waters the rooftop garden.

The roof is filled with green life that appeals to insects.

Urban agriculture

In cities, “you don't have that many spaces to choose from and so rooftops are just (unused) space,” says Caitlin Arlotta. She is a student in the school's Urban Agriculture program.

The project is part of a research program to see which plants do well on rooftops. The researchers are looking at plants including strawberries, tomatoes and sweet potatoes.

“We have the same experiment running with tomatoes as we do with strawberries, so we’re doing variety trials and we're trying just to see which variety grows the best in a green roof setting.”

Community involvement

The university also has other green spaces.

“We also have our own farm experiments,” Arlotta said. “Within each of those growing systems, we want to be able to tell people which sorts of these crops grow the best.”

One goal of the program is food justice; or in Arlotta’s words, “bringing fresh food into cities where you wouldn't necessarily have that access.”

And that includes produce that might be more recognizable to immigrant members of the community.

“In the U.S., it may not seem very common to use hibiscus leaves and sweet potato leaves as food, but in many places around the world it is.”

Surprisingly productive

Sandy Farber Bandier helps run UDC’s Master Gardener program. It seeks to improve cities and make them beautiful by training people to become Master Gardeners.

She says she’s been surprised by the garden’s output.

“My biggest surprise was that we produced 4,250 pounds of produce the first year and was able to disseminate that to people in need."

Spreading the wealth

She likes being able to show people who live in D.C. and others beyond the nation's capital what -- and how -- food can be grown on a rooftop.

“This is the future for food. What we have established here at this college is food hub concept of you grow it here, you prepare it in a commercial kitchen, you distributethrough farmers markets, food trucks, and then you recycle.”

I’m Susan Shand.

VOA’s Julie Taboh reported this story. Susan Shand adapted this story for Learning English. Caty Weaver was the editor.

Write to us in the Comments Section or on our Facebook page.

________________________________________________________________

Words in This Story

rooftop – n. the top of a building

absorb – v. to soak up liquid

management - n. the skill of organizing people and events

advantage - n. something (such as a good position or condition) that helps to make someone or something better or more likely to succeed than others

urban – adj. in a city area

access - v. a way of being able to use or get something

disseminate - v. to cause (something, such as information) to go to many people

distribute - v. to give away to people

VIDEO: The Future of Farming May Take Place Indoors

Vertical farms transform conventional agriculture with biotechnology, data science, and engineering. Here’s why the future of farming may be indoors.

OGarden Smart: Grow An Indoor Garden of 90 Fruits & Veggies

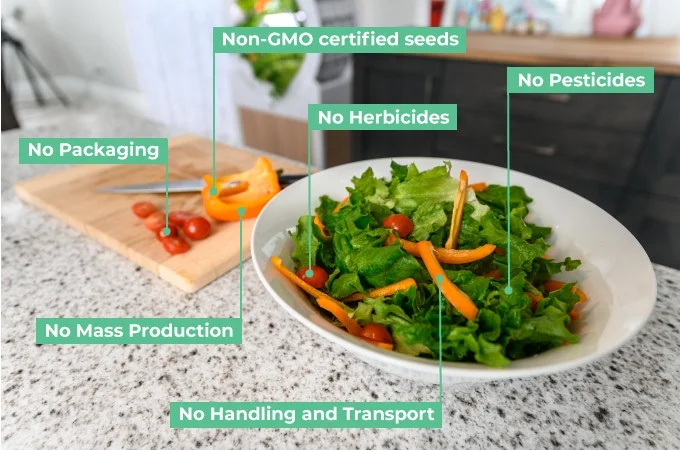

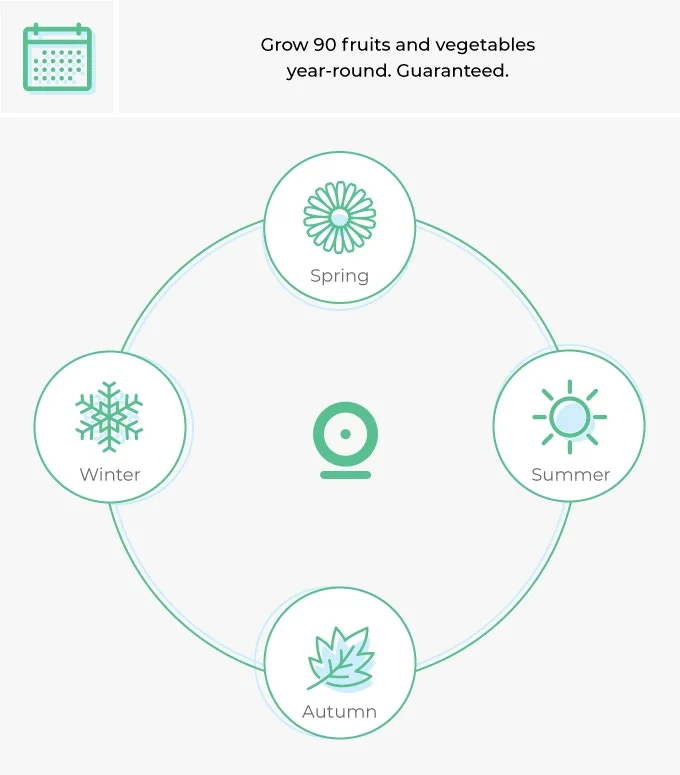

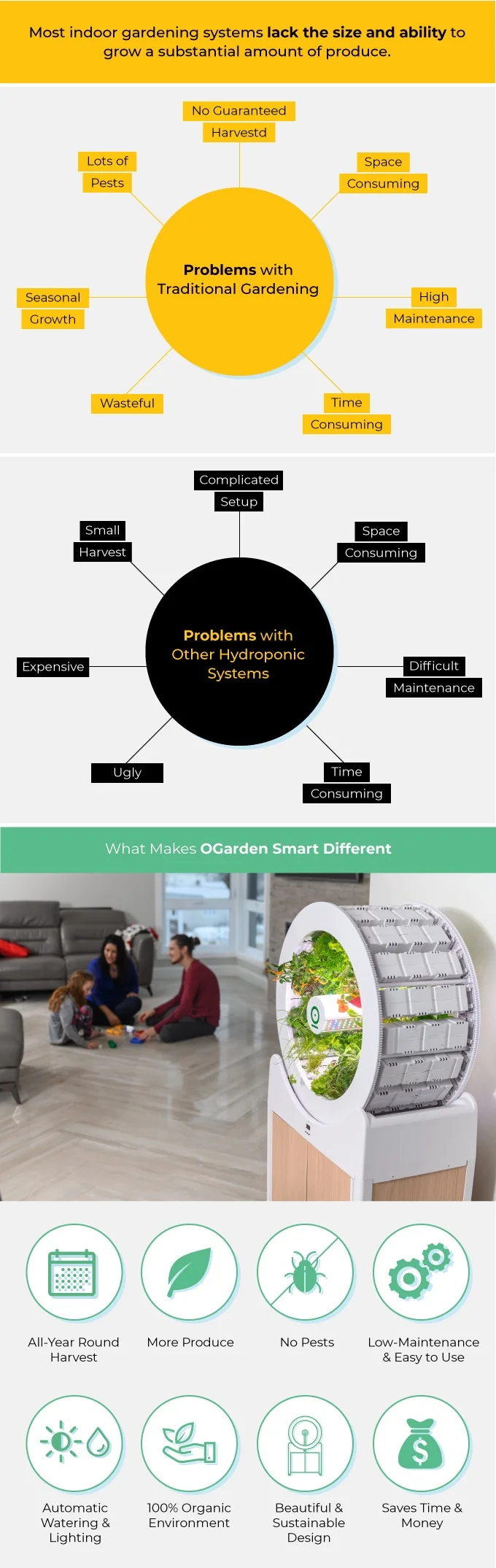

The OGarden Smart can grow up to 90 fruits, veggies and delicious aromatic herbs at once, so you can enjoy an abundance of super fresh food.

Automatic watering makes using OGarden Smart virtually effortless, and the automatic low energy consumption LEDs simulate the perfect amount of sunlight, offering optimal year round growth (and will automatically turn on and off for convenience and energy conservation)

All you need to do is plant a seed, make sure there is enough water in the tank (only once a week), and you can harvest your produce 30 to 40 days later, that’s it! And don’t forget to send the roots to the compost bin and start the life cycle again.

There are 90 available spots, so with a good rotation, you can have 2-4 large vegetables a day, every day.

Why is OGarden’s growth so efficient? And why is it so easy?

The key is in the cup of seeds. Made with organic soil and fed with all the organic fertilizer it needs, our seed cups create the perfect environment for the plant to grow. they’re also super clean! No spilled dirt or fuss. With a 100% biodegradable membrane, the seed cups stay in place without any mess.

OGarden Smart’s LEDs simulate the perfect amount of sunlight that your produce needs to thrive. No more worrying about which seasons to grow your produce in. No matter the conditions outside, OGarden Smart will grow up to 90 fruits and veggies at once, with 20 different varieties to choose from.

Is your favorite vegetable or fruit not on the list? No problem! With the Empty seed cup, you can sprout your own seeds. Have fun and grow your own original plants. We'd love to see what you grow! Take photos of your harvest and share them with the Ogarden Smart community.

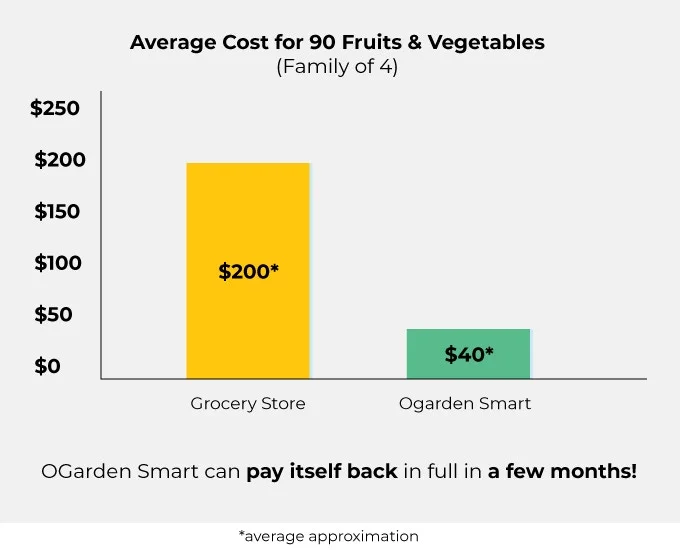

According to the U.S. Department of Agriculture, it costs a family of four an average of $850 per month for groceries*. OGarden Smart can save you up to 80% on your veggie expenses - allowing you to cut down your grocery bill.

*Official USDA Food Plans: U.S. Average, November 2017

With OGarden, you can get fully grown, pesticide-free veggies for as low as $0.45 cents!

By producing your vegetables, fruits, and herbs directly at home, you know the quality of the air, the water and environment they grow in. Have peace of mind knowing that all of your fresh produce is grown in a 100% organic environment.

WHAT COMES IN THE BOX:

● The Ogarden Smart (disassembled) ;

● 30 Empty seed cups;

● 3 packs of seeds (Basil, Chinese cabbage Tat-soi, Lettuce Green Oak Leaf)

Additional Empty cups and multiple varieties of seeds are available on the online shop.

NOW ON KICKSTARTER (Feb.12th)

"Fresh Lettuce Even With Snow On The Ground"

CubicFarms is growing again

CubicFarms has completed its latest CubicFarm System near Edmonton, Alberta. Located in Weslock, AB, Swiss Leaf Farms founder and CEO David Pfaeffli is now selling his CubicFarms produce under the Thriiv Local Garden brand to a variety of stores and restaurants. Swiss Leaf Farm’s 14 machine CubicFarm System is capable of growing over a million and a half heads of lettuce a year, along with microgreens, basil and more.

Even though snow is on the ground, and temperatures are dipping below -20 oC, fresh, crisp, local lettuce and microgreens are now available.

David and Alyssa Paeffli and family in front of one of their CubicFarm Machines

DelFresco Pure installation has begun

Ontario CubicFarm customer Del Fresco Pure has completed their building, and 14 CubicFarm growing machines have been delivered to one of Ontario’s largest greenhouse operators. Del Fresco and CubicFarms are partnering together on several exciting projects and were recently together at the CPMA in Orlando where they featured a fully functional “Demo CubicFarm” complete with live produce. Passers by were memorized by the lettuce, basil, and microgreens growing before their eyes. The booth featured Del Fresco’s wide range of greenhouse crops, including strawberries. The ice cream machine was a hit and we featured Del Fresco strawberries and Cubic’s “Microbasil” as toppings.

Del Fresco expects to bring their CubicFarms grown produce to the Ontario market in the next 2 months, including lettuces and microgreens.

The Del Fresco Pure and CubicFarm Systems teams at the Orlando PMA

CubicFarms is working on its public listing on the TSX V

CubicFarms was approximately 40% owned by Bevo Farms, but in late 2018 that ownership was spun out as a one-time special dividend to shareholders. CubicFarms expects to be listed as a publicly traded company in the next month or so, making it one of the first publicly traded vertical farming companies.

For more information:

CubicFarms

1-888-280-9076

info@cubicfarms.com

www.cubicfarms.com

Publication date : 2/1/2019

'It's A Blizzard Outside And We're Growing Lettuce': Busby Area Farmers Grow Vertical

A unique farm has opened near Busby growing leafy greens in fabricated shipping containers

Travis McEwan · CBC News · Feb 02, 2019

Greens are expected to grow at Swiss Leaf Farms out of 14 different shipping containers. (Trevor Wilson/CBC)

An indoor farm near Busby, Alta. is harvesting leafy greens in the middle of winter using a system called vertical farming and fabricated shipping containers.

David and Alyssa Pfaeffli of Swiss Leaf Farms have been growing lettuce, microgreens, and herbs in a 9,500-square-foot warehouse for the past couple of months. The system they are using will allow them to grow year-round.

The growing machines are developed by a company in Langley, B.C. and an irrigation system waters each tray as it rotates past a water spout. A single row of growing lights sit on the top of the container.

A heating and cooling system ensures the plants grow at the right temperatures.

CBC News Edmonton | A Busby, Alberta farmer uses a vertical farming system to grow leafy produce all year round.

Within the warehouse, there are 14 growing machines that grow different varieties of leafy greens. Each container holds 4,000 heads of lettuce, with each head of lettuce taking a month to grow. The microgreens are harvested every six days.

The farm just had their first harvest last week and have delivered greens to grocery stores in Westlock, Barrhead and Edmonton.

"We can provide the same produce that's fresher, tastes better, it's healthier and there's zero pesticides. It's better for the planet," said David Pfaeffli. "You're not driving a diesel rig all over North America to deliver lettuce."

Alyssa and David Pfaeffli of Swiss Leaf Farms started the vertical farm a few months ago. Their 14 shipping containers have the capacity to grow 4,000 heads of lettuce per container. (Trevor Wilson/CBC)

The couple say they're able to grow a lot within a small space, as a traditional garden will take up a lot more land. Within their building, they can also control the temperatures with a heating and cooling system.

"This system allows us to do that here now, whereas before in Alberta where would you be able to do that? It's a blizzard outside and we're growing lettuce." said Alyssa Pfaeffli.

The cost of vertical farming

Financing the vertical farm was the biggest challenge for the couple, said David Pfaeffi. Without large farming equipment, he didn't have a lot of collateral if things dried up.

"Agricultural lending outfits weren't too eager to lend a large sum of money on equipment like this because they'd have a hard time recouping their costs. It's not a combine," David said.

The Pfaeffli's are excited about their new farming venture, but at the moment they're trying to not get too ahead of themselves.

"We want to grow not only plants but we want to grow the business. We want to keep adding on phases of growing machines. I'd like to see 50 acres of growing containers eventually," David Pfaeffi said.

Their greens are sold in grocery stores like Freson Bros. in Stony Plain. The Swiss Leaf Farms product fills a void of locally-produced lettuce in the winter months.Their latest order sold within 24 hours.

"We try to have an Alberta item everywhere. As soon as we get something like this, there are [consumers] willing to pick it up and try it," said Dan Pazder, Freson Bros. produce director.

Busby is approximately 71 kilometres northwest of Edmonton.

With files from Trevor Wilson

First Wheelchair Accessible Farm At Local Bronx Public School

By urbanagnews

February 8, 2019

Empire BlueCross BlueShield and Green Bronx Machine to Launch First Wheelchair Accessible Farm at Local Bronx Public School

Press Release – NEW YORK – Green Bronx Machine (GBM), a nationally recognized non-profit organization dedicated to helping students live happier and healthier lives, is partnering with Empire BlueCross BlueShield (Empire) to launch the first wheelchair accessible farm and teaching kitchen in America at P.S. 721x, a District 75 school in the Bronx dedicated to educating students living with disabilities.

“Our students and faculty are so excited and so grateful to Empire and Green Bronx Machine for this classroom makeover that inspires healthy living, healthy learning, and creates 21st century career and college readiness.”~ Frank Degennaro, Principal, P.S. 721x

On Wednesday, February 13th, GBM and Empire will host a ribbon-cutting event at the school to unveil the new, in-school farm. In addition to the wheelchair accessible farm and teaching kitchen, P.S. 721x teachers and students will receive GBMs fully integrated health and wellness curriculum, a GBM Mobile Classroom Kitchen—a fully portable “indoor food truck” complete with sink, refrigerator, convection oven and food warmer and a media studio where students can participate in video conferences with other schools and organizations, post updates to social media, live stream educational programming and older students can record practice interview sessions.

“Thanks to this partnership, we’ve been able to develop the first fully accessible piece of hydroponic technology that will create opportunities for untold Americans and farmers around the world. Empire and Green Bronx Machine are growing something greater – for all!”~ Chris Higgins, Founder & CEO, Hort Americas

GBM founder Stephen Ritz has built his program on the belief that healthy students drive healthy schools, which in turn drives healthy communities. To help educate students on the importance of proper nutrition, Stephen developed a fully integrated core curriculum that teaches students how to grow, eat and love their vegetables while also learning about math, science, and English in a fresh and engaging way.

“To see these future chefs and farmers smiling with glee as they cook and farm, three stories up in the middle of winter, makes me proud and excited to be a New York City public school teacher with District 75.” ~ Jeremy Kottkamp, Teacher, P.S. 721x

In addition to forever changing their eating habits and health, these students will be more prepared to enter the workforce in emerging fields that provide living wage opportunities while enhancing quality of life for all.

“Beyond happy healthy students, this partnership proves that every classroom in America can have an affordable, portable, professional, mobile classroom teaching kitchen that is accessible for all.”~ John Stephenson, Founder of Port-Equip/Stephenson Custom Case

Having first launched GBM’s National Health, Wellness and Learning Center in an underutilized 100+ year-old library at C.S. 55 in Claremont Village, students who have participated in this program have experienced health improvements that lower the risk of childhood obesity, diabetes and heart disease while also increasing their performance in school.

“We’re proud to partner with Empire and NYC DOE to create the first wheelchair accessible classroom farm and kitchen in America. Every child deserves a safe, healthy, nurturing environment and we’re so proud – this is Bronx innovation at its best!” ~ Stephen Ritz, Founder, Green Bronx Machine

If you are interested in attending the event, details are included below and interviews are available.

WHO:

Stephen Ritz, Green Bronx Machine

Victor Pupo, Empire

Frank Degennaro, Principal, P.S. 721x

WHEN:

Wednesday, February 13th at 12:00 PM – 1:00 PM

WHERE:

P.S. 721x; Room 319

2697 Westchester Ave.

Bronx, NY 10461

Media Contacts:

James Freeman, Empire Communications

215.756.2495

James.freeman2@anthem.com

Stephen Ritz, Green Bronx Machine

917.873.6449

Stephen.ritz@greenbronxmachine.org

I’m Pretty Sure You Don’t Want To Miss This….

iGrow News Branding Sessions Go Live This Friday

iGrow News Branding Sessions are going LIVE this Friday at noon PST to show you How to turn your business into a strong brand

We all know that in today's world having a good product or service is not enough. How many of you working hard to offer great products and services but don't get the results you desire?

It's all about marketing and brand awareness.

That is why In this free webinar, Chief Strategist & Owner of D Branding, Dino H Carter, will teach you how to use branding to grow sales and brand awareness.

The webinar will be live on YouTube. Subscribers will get a link to the webinar before the webinar will start.

>>> 1-CLICK REGISTER HERE! <<<

If you want to learn what big brands use, so you can get more high-quality customers to buy your product or service, this free training is for you.

Here’s what you’ll learn:

The 3 elements for a successful brand that will save you money

How to develop an authentic brand personality that fits your customer

How to sell without selling and why is it so important

Ten-Year Anniversary of The Neumayer Station III

The scientific and political community alike stress the importance of German Antarctic research

The Antarctic is a frigid continent south of the Antarctic Circle, where researchers are the only inhabitants. Despite the hostile conditions, here the Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research (AWI) operates a research station where researchers live and work year round. Since 2009 the Neumayer Station III, located on the Ekström Ice Shelf on the eastern coast of the Weddell Sea, has served as the primary base of operations for German Antarctic research activities. The station crew, together with a delegation from the research and political communities, are now celebrating its ten-year anniversary.

Extreme cold, raging storms, and the seemingly never-ending Polar Night: the Antarctic is one of the most fascinating habitats on our planet. At the same time, it has a major influence on our climate. For the past ten years, the Neumayer Station III has provided vital support for German and international research projects in the Antarctic. Just a few kilometres from its two predecessors, the station was erected in the course of two consecutive Antarctic summers, and completed in early 2009. In a region that is sparsely populated, even by Antarctic standards, the station’s observatories are continuing unique time series that date as far back as the 1980s. At the same time, new research questions to investigate crop up year after year. In this regard, the station offers an essential ‘base camp’ for expeditions to the Antarctic hinterland, where e.g. the AWI’s snowcats and polar research aircraft come into play.

“The Antarctic continent is home to the Earth’s largest ice masses, and the Antarctic Ocean absorbs tremendous amounts of CO2 and heat, which is why conducting research in this region is of fundamental importance. In order to better grasp global changes, at the Neumayer Station III we gather data over extended time frames – from minute-to-minute weather observations to exploring the planet’s climatic history on the basis of ice cores. In addition, we provide support for observations of Antarctica’s diversity, from penguin colonies to the cold-water corals below the massive ice shelves,” explains AWI Director Antje Boetius.

For example, at the station’s meteorology observatory, radiosondes attached to weather balloons are launched on a regular basis to measure the temperature, humidity, barometric pressure, wind and the distribution of ozone in the atmosphere. Further focus areas include research on atmospheric chemistry, the Earth’s magnetic field, sea ice, and a colony of emperor penguins. Since 2017, under the auspices of the German Aerospace Center (DLR), the EDEN-ISS greenhouse has been tested at the Neumayer Station III. The goal: to pave the way for cultivating crops in space and in regions with challenging climatic conditions. As a result, this year’s overwintering team was the first that could look forward to fresh lettuce on a regular basis. In addition, here Germany’s Federal Institute for Geosciences and Natural Resources (BGR) operates one of 60 infrasound stations deployed around the globe, which serve to monitor adherence to the Comprehensive Nuclear-Test-Ban Treaty (CTBT). The German Meteorological Service (DWD) is also represented at the station, and provides essential forecasts that help ensure researchers know when it is safe to work outside. In the region of the Antarctic known as Dronning Maud Land, the DWD also supports international partners from e.g. Russia, Norway and South Africa by providing aviation weather forecasts.

Currently, a fourteen-person delegation led by the Parliamentary State Secretary at Germany’s Federal Ministry of Education and Research (BMBF), Dr Michael Meister, is taking an inspection tour of the Neumayer Station III.

“These past few days have given us the chance to see for ourselves just how necessary and relevant polar research is for everyone. We need in-depth information on polar processes in order to understand the global climate and its on-going changes, and in order to devise policy recommendations on that basis. This scientific information is an essential prerequisite for making sustainable political decisions. I’d like to thank all of the experts among the research, technical and logistics staff for the valuable work they do under these harsh conditions,” stresses Parliamentary State Secretary Meister.

“With its interdisciplinary centres and its impressive research infrastructures, Helmholtz is making an important contribution to addressing the great challenges of our time,” says Otmar D. Wiestler, President of the Helmholtz Association. “The long-term research being conducted at the Neumayer Station III in the Antarctic is a prime example. Various scientific disciplines profit from the station’s unparalleled resources, including meteorological and climate research, space research, biology, geology and many more. Ultimately, all of these fields help to preserve or enhance our natural resources. I’m grateful to have now had the opportunity to experience the work being done at this extraordinary research station first-hand.”

The Neumayer Station III: Background

For more than three-and-a-half decades, the AWI has maintained a research station staffed year-round in the Antarctic. Named in honour of the German polar researcher Georg von Neumayer, the Georg-von-Neumayer Station commenced operations in 1981. In 1992 it was replaced by the Neumayer Station, which, like its predecessor, was essentially a tubular structure. The current Neumayer Station III represents the largest and most comfortable station in the history of German Antarctic research. During the summer months, it offers accommodation for 50; as a rule, the overwintering team only consists of nine people. Unlike the majority of research stations in the Antarctic, virtually all workspaces, common rooms and supply rooms are centrally located under the same roof. In addition, both the station’s design and operation reflect the highest environmental protection standards. The energy it produces is recirculated in a closed system to the maximum extent possible, ensuring its optimal utilisation. Moreover, at the end of its service life, the entire station can be dismantled down to the last screw, so that the tracks left behind in this invaluable region are kept to a minimum.

That being said, its geographic position alone subjects the station to harsh conditions: every day, the ice shelf creeps roughly 40 centimetres toward the coast, which means there is a natural “expiry date” for the station. In addition, the very ground the station was built upon will one day calve as an iceberg – though, if the ice continues to flow at its current speed, that won’t happen for at least another 100 years. Buildings in the Antarctic also have to withstand virtually never-ending snowfall. In this regard, the Neumayer Station III is optimally adapted to its environment. Unlike its two predecessors, there’s no risk of it eventually being crushed by accumulating snow, since the entire station stands on 16 hydraulic struts, which technicians adjust at regular intervals to keep the building out of the snow. This allows it to rise in keeping with the snow cover, ensuring the platform remains at a constant height of ca. six metres above the surface. Thanks to this system, the station is bound to enjoy a far longer service life than the two stations before it – tentatively, at least until 2035.

Notes for Editors:

Your contact person is Dr Folke Mehrtens, Dept. of Communications, Alfred Wegener Institute, phone +49 (0)471 4831-2007 (e-mail: media(at)awi.de).

Printable images and a video are available in the online version of this Press Release: https://www.awi.de/en/about-us/service/press.html

The Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research (AWI) conducts research in the Arctic, Antarctic and oceans of the high and mid-latitudes. It coordinates polar research in Germany and provides major infrastructure to the international scientific community, such as the research icebreaker Polarstern and stations in the Arctic and Antarctica. The Alfred Wegener Institute is one of the 19 research centres of the Helmholtz Association, the largest scientific organisation in Germany.

Westland Promofilm 2019

Pioneering solutions to meet global challenges.

Westland is a dynamic municipality. In this relatively small area of just 9 000 hectares, we come up with pioneering solutions to global challenges. We produce high quality food products, flowers and plants, sustainably and innovatively, to improve the well-being and welfare of people all over the world.

The Westland area is the world’s main greenhouse horticulture cluster. Over the last 120 years, Westland has become the international hotspot when it comes to growing indoor crops. As early as 1918, Westland growers started planting indoors to extend the growing season of their tomato crop. The development and exchange of knowledge make innovation possible.

An unparalleled cluster of greenhouse horticulture companies and related industries. Importers, exporters, packaging and repackaging companies, growers, breeders, R&D, suppliers, transporters and warehouses, and many more. A cluster like this concentrated in such a small area is found nowhere else in the world. With the opening of the World Horti Center, the region now has a campus where the business community, education and government can come together.

The international innovation hub is also the main innovation centre of the international greenhouse horticulture sector, where business, research, demonstration, teaching and education converge. It is also where local and international greenhouse companies innovate and do business. Westland’s geographical location is unique. Situated close to Schiphol and the Port of Rotterdam, our logistics hub can reach 500 million European customers within 24 hours.

Our mentality is our defining feature: we work hard and efficiently, while always looking for ways to create synergy through partnerships. Many companies have chosen to establish their business in Westland. www.westlandhortibusiness.com

VIDEO: EPIC Urban Farming On Top of a Whole Foods | Gotham Greens Tour 🏙️🌿

A mythical urban farm on top of a Whole Foods in Brooklyn, NY, where they grow 13+ different types of greens and herbs.

It was called Gotham Greens, which is just about the best name for a hydroponic greenhouse you'll ever hear. They use nutrient film technique (NFT) channels to grow basil, arugula, leaf lettuce, and more. And better yet, it's all automated, down to CO2 monitoring, shade clothes, and more. They even make their own line of salad dressings, pestos, and other value-added products with the produce they grow!

Deep-Sea Drilling To Shed New Light on The Stability of The Antarctic Ice Sheet

AWI geoscientists lead international IODP expeditions to the Antarctic Ocean

Over the next few months, geophysicists and geologists from the Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research will gain unprecedented insights into the climatic history of the Antarctic Ice Sheet as part of the International Ocean Discovery Program (IODP). The experts will take part in three Antarctic expeditions on board the IODP drilling ship “JOIDES Resolution”, and will lead two of the three legs. By collecting the drilled cores, the researchers hope to find evidence of how the ice masses of the Antarctic have reacted to sudden temperature climbs in past interglacial periods – information that is urgently needed in order to more accurately predict future sea-level rise. In terms of modelling, the behaviour of the Antarctic Ice Sheet is still considered one of the greatest question marks.

How will Antarctic ice masses respond to climate change, and to what extent will they contribute to sea-level rise? Climate researchers still don’t have a satisfactory answer to that question, partly because they lack information on how ice sheets have behaved in previous interglacial periods. Geophysicists and geologists from the Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research (AWI) in Bremerhaven have now made it their goal to remedy the situation. Over the next seven months, they will join three international expeditions to the Antarctic Ocean on board the US-based drilling ship “JOIDES Resolution”, and will serve as the scientific directors for two of the three expedition legs. These journeys will be undertaken as part of the International Ocean Discovery Program (IODP), which is dedicated to investigating the history of our planet and its climate on the basis of deep-sea cores.

The first expedition (IODP 379) started in Punta Arenas (Chile) on 23 January 2019, and takes the 29-member team of international researchers, accompanied by technicians, drilling experts and ship’s crew (altogether 125 people) to the Amundsen Sea – and with it, to the region broadly considered to be the Achilles heel of the West Antarctic Ice Sheet. “Large sections of the West Antarctic Ice Sheet lie on land that is below sea level, which means these ice masses can easily be reached by warm ocean currents, and are therefore especially vulnerable to the effects of climate change,” explains Dr Karsten Gohl, an AWI geophysicist and one of the expedition’s two chief scientists.

Seeking signs of an eroding West Antarctic Ice Sheet

At the moment, those glaciers that empty into the Amundsen Sea are losing ice faster than all other ice streams in the Antarctic or in Greenland. Moreover, ice sheet simulations and sediment samples from the Ross Sea indicate that the ice masses of the West Antarctic retreated extensively during past interglacial periods – e.g., 3 million years ago in the Middle Pliocene, when the average global temperature was roughly 3 degrees higher than today. In other words, it was essentially the same temperature as that predicted for the year 2100 if greenhouse-gas emissions remain constant.

Back then, the researchers believe, the West Antarctic Ice Sheet suffered a near-total collapse. However, there’s still no evidence to back their hypothesis. The planned deep-sea drilling missions in the Amundsen Sea are intended to change all that. “By drilling down as far as 100 metres below the seafloor, we hope to find sediment deposits from the Pliocene and other warm epochs, where we should be able to see the remains of algae, foraminifera and other typical pelagic organisms. And these remains will prove that, in these warmer periods, there was little to no ice in West Antarctica,” says AWI geologist and expedition member Dr Johann Klages.

Finding these microfossils would also allow the researchers to reconstruct the past water temperatures, and to investigate which climate changes led to the retreat or decline of the West Antarctic Ice Sheet. For example, insights into how warm the deep-sea currents were back then are desperately needed. The researchers plan to subsequently compare these historical values with current observations of deep-sea currents in the Amundsen Sea, in order to determine whether or not they could be considered the harbingers of a potential future collapse.

In addition, the experts hope to find evidence of increased iceberg occurrence. “As they drift, icebergs lose sand, gravel and pebbles that were trapped in their ice,” explains Johann Klages. “If we encounter coarse sand and gravel deposits when we drill, it will tell us that large quantities of ice broke off from the ice sheet in past interglacial periods and drifted through the Antarctic Ocean.” Further, these stony deposits’ geochemical fingerprint would allow the researchers to identify the ice masses’ region of origin, and to reconstruct which glaciers lost the most ice in each respective interglacial period.

Drilling on a main route for icebergs

The participants in the second expedition (IODP 382), which will take them to the Scotia Sea from 20 March to 20 May, will rely on the same research principle. The waters between the Antarctic Peninsula and the Falkland Islands are considered both the main route for large icebergs and their graveyard. If the Antarctic did indeed lose substantial ice during the interglacial periods of the Pliocene and Pleistocene, there should be corresponding deposits in these waters – from West Antarctica and East Antarctica alike. But if they are there, they’re quite far down; as AWI geologist and expedition member Dr Thomas Ronge explains: “At the planned drilling sites, the water is roughly 4,000 metres deep. We’ll have to drill for several days before we reach our target depth of 600 metres below the seafloor. Another important consideration: while we’re drilling, we have to hope that we don’t cross paths with any icebergs.”

For any other research ship, the moment an iceberg drew near, the drilling site would have to be abandoned – but not for the “JOIDES Resolution”: in the event the 143-metre-long drilling ship has to evade an iceberg, the borehole on the seafloor will be sealed with a specially designed, funnel-shaped borehole plug. The plug can be relocated later, so that, once the ship has successfully avoided the iceberg, the team can easily resume drilling, right where they left off.

In the world’s largest ocean current

The third leg of the expedition (IODP 383), which will be co-led by AWI geologist Dr Frank Lamy and the German climate researcher Gisela Winckler from Columbia University (USA), will take the ship to waters west of the Drake Passage, starting in late May. Once they’ve arrived there, in the southeast Pacific region of the Antarctic Circumpolar Current, the most powerful ocean current in the world, the researchers will have to drill 500 metres down into the seafloor in order to gather sediment samples from the Pliocene and Pleistocene. “For our work, above all we’ll be considering the question of how wind and ocean currents in the Southern Hemisphere reacted to global warming trends in the past, and what major interactions there were between the atmosphere, the ocean, and the ice masses of the Antarctic,” relates Frank Lamy.

Once analysed and combined, the outcomes of the three expeditions are expected to allow the researchers to precisely reconstruct the ice masses’ behaviour during past interglacial periods. If all goes as planned, they will not only arrive at a much better grasp of one of the most central, yet poorly understood processes in the Earth’s climate system, but will also be able to more accurately predict the future development of the West and East Antarctic Ice Sheets. Taken together, the two sheets contain enough freshwater to raise the global sea level by roughly 58 metres.

The IODP is an international research programme in which the USA, Japan, China, South Korea, India, Brazil, New Zealand, Australia and 15 European countries, including Germany, are participating. The US-based IODP ship “JOIDES Resolution” can accommodate up to 50 researchers and 65 crewmembers. Its operations are financed by the National Science Foundation (USA), and by support organisations in all other IODP member states.

Notes for Editors

For further information on the International Ocean Discovery Program and the individual expeditions, please visit: http://iodp.tamu.edu/scienceops/expeditions.html

Printable images and graphics can be downloaded using the following link:

https://www.awi.de/en/about-us/service/press/press-release/deep-sea-drilling-to-shed-new-light-on-the-stability-of-the-antarctic-ice-sheet.html

Your academic contact partners at the Alfred Wegener Institute are:

IODP Expedition 379 to the Amundsen Sea:

∞ Chief Scientist Dr Karsten Gohl (tel.: +49(471)4831-1361; e-mail: Karsten.Gohl@awi.de)

∞ Dr Johann Klages (tel.: +49(471)4831-1574; e-mail: Johann.Klages@awi.de)

The expedition’s second chief scientist is the American Prof. Julia Wellner from the University of Houston (tel. +1(713)743-2887; e-mail: jwellner@uh.edu).

IODP Expedition 382 to the Scotia Sea

∞ Dr Thomas Ronge (tel.: +49(471)4831-2087; e-mail: Thomas.Ronge@awi.de)

IODP Expedition 383 to the Southeast Pacific / Circumpolar Current

• Chief Scientist Dr Frank Lamy (tel.: +49(471)4831-2124; e-mail: Frank.Lamy@awi.de)

The expedition’s second chief scientist is Prof. Gisela Winckler (tel.: +1(845)365-8756; e-mail: winckler@ldeo.columbia.edu).

At the AWI’s Communications and Media Relations department, Folke Mehrtens (tel.: +49(471)4831-2007; e-mail: medien@awi.de) will be pleased to help you with any questions.

The Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research (AWI) conducts research in the Arctic, Antarctic and oceans of the high and mid-latitudes. It coordinates polar research in Germany and provides major infrastructure to the international scientific community, such as the research icebreaker Polarstern and stations in the Arctic and Antarctica. The Alfred Wegener Institute is one of the 19 research centres of the Helmholtz Association, the largest scientific organisation in Germany.

Florentaise Presents Its Vertical Farm On France 3

The company Florentaire recently invited the television channel France 3 in order to present its vertical farm.

The company Florentaire recently invited the television channel France 3 in order to present its vertical farm.

After the request for proposals won by the Parisculteurs, the company will install the facility at the Utopi’hall in Angers in March.

Transforming The Way Cannabis Is Grown

30% increase in yield and 8 week grow cycles

Pittsburgh, PA: New technology enables growers to significantly increase profit and yield, GrowQuick Systems patented technology will provide product 52 weeks a year. It is the fastest and most efficient system in the world. Proven to work it’s built with innovative features that will change the way cannabis, hemp and food are grown across the world.

Environmentally friendly while increasing profit due to lower energy use

30% Higher Yields

No Plant Loss Due To Mites or Bugs

The minimal maintenance required is a huge positive for growing in remote locations

7-8 Weeks From Clone to Crop

Less Than 24 Hour Turnaround From Crop to Clone

4-6 Inches Of Growth Per Day On Average

“This cutting edge technology will usher in a new age for cannabis grow systems similar to what the jet engine did for the airline industry”

-Ray Mays

Inventor/CEO

Each GrowQuick System is custom designed for each facility and customer. Featuring custom Full Spectrum LED lighting for fast growth and energy savings, with patented proprietary continuous disinfecting lighting. Allows remote monitoring of 120 control points with smart phone or tablet. Built to last with aluminum and powder coated racking.

GrowQuick Systems is technology for complete builds out of cannabis grow facilities. .

Video: Scientists Soup Up Photosynthesis

Oceanographer Penny Chisholm introduces us to an amazing little being: Prochlorococcus, the most abundant photosynthetic species on the planet. A marine microbe that has existed for millions of years, Prochlorococcus wasn't discovered until the mid-1980s -- but its ancient genetic code may hold clues to how we can reduce our dependence on fossil fuels.

Penny Chisholm · Microbial oceanographer, author

Penny Chisholm studies an extremely tiny microorganism that plays an enormous role in ocean ecosystems. Discovered only three decades ago, it has defined her career and inspired her to think differently about life on Earth.

Masdar City's Steel Urban Allotments Could Help Solve Food Security Crisis

Vertical farms and eco-villas to be profiled at Abu Dhabi Sustainability Week could help UAE grow more of its own crops

Abu Dhabi’s Masdar City is piloting a project that could see urban communities growing their own food in an allotment, but with a very modern day twist.

A pilot future farming facility built from recycled shipping containers could solve the region’s food production crisis by allowing communities to grow produce, despite the harsh desert climate.

Masdar City, which was built to be one of the world's most sustainable communities, is collaborating with Madar Farms, who try to find sustainable solutions to the GCC's food security issues, to develop vertical farming inside shipping containers. They are equipped with hydroponic systems that can operate using minimal water.

“With the world’s population expected to exceed 9 billion by 2050, efficient and sustainable production and distribution of food is becoming increasingly important,” said Yousef Baselaib, executive director of Masdar City.

“This is particularly true for countries with arid climates and harsh environmental conditions like ours.”

Hydroponics systems allow tonnes of greens to be grown in small spaces. Antonie Robertson / The National

The 1.5 acre plots inside each 12-metre container have the capability to grow crops using less than 40 litres of water a day.

The crops are constantly monitored by the latest technology within a sealed environment, shortening the growing cycle.

Temperature and carbon dioxide levels can be regulated via a mobile phone app, with an automated nutrient delivery system to produce the best possible results.

“We have begun investing in technologies and partnerships focused on sustainable agriculture with the aim of commercialising farming techniques,” said Mr Baselaib.

“These systems can be applied to urban areas to encourage people in the UAE to eat home grown produce.”

Read more:

Abu Dhabi Sustainability Week to place spotlight on real environmental change, says minister

Smart cities look well set to power global economy

Neighbourhood Watch: Farming grows sense of community at Dubai's Sustainable City

Food security and sustainable farming will be one of the key focuses of Abu Dhabi Sustainability Week (ADSW), which begins on Saturday.

The technology and methods used by Madar Farms use approximately 95 per cent less water and land than conventional farming, making the company one of the most efficient and sustainable growers in the GCC.

The initiative joins other similar schemes such as one run by Agricool in Sustainable City in Dubai, where they are growing fresh strawberries for the local community in hydroponic grow room inside shipping containers.

Masdar City first engineered ideas of productive landscapes in 2008 to address food security issues.

Since then, community gardening plots have been developed to allow for plant research, agricultural education and to encourage people to grow their own food.

Masdar’s agricultural strategy hopes to encourage traditional farming methods and the growth of indigenous plants.

An eco-villa has been built in the eco-friendly city to show how green living could be used in the home on a wider scale.

Kyle Wagner, head of operations at Madar Farms, checks the growth of crops grown in a retrofitted shipping container. Antonie Robertson / The National

“The villa is an example of Masdar’s commitment to sustainability and is a pilot project conceived as a template for affordable, energy- and water-efficient residential villas,” said Mr Baselaib.

By this month, they also hope to have implemented home farming technologies and they will be showcasing the project at ADSW.

The eco-villa uses about 72 per cent less power and 35 per cent less water than a typical villa in Abu Dhabi, displacing an estimated 63 tonnes of carbon dioxide annually.

During ADSW, Masdar will also show other projects focused on vegetable and livestock farming, water harvesting and recycling, waste recycling and how to use energy for cooking.

Less than 1 per cent of the region is arable and permanent crop land, and more than 40 per cent of the UAE’s food is imported.

Importing that volume of food will cost more than US$100 billion (Dh367b) by 2030.

The crops are grown inside shipping containers. Antonie Robertson / The National)

More than 40 per cent of natural water sources have been lost in the past 20 years through overuse and despite water scarcity, 84 per cent of water is used for agriculture and irrigation, which contributes less than 1 per cent to GDP.

That has left conventional farming unsustainable in the UAE, forcing the development of alternative models.

Masdar has paired up with the UAE Office for Future Food Security to rubber stamp its commitment to addressing the most important environmental issues likely to impact the nation.

Other sustainable farming methods are being developed in a Central Park project, using vertical farming techniques, solar-powered greenhouses, a self-contained farmers’ market and edible maze.

“Tackling the challenge of food security is a priority for Masdar and one that we are addressing in a holistic manner by looking at solutions in energy, food and water,” said Mr Baselaib.

The World Agri-Tech Innovation Summit Returns To San Francisco March 19-20, 2019.

Now in its 5th year, the summit will gather 1000+ global agri-food corporates, innovators and investors to uncover the most exciting innovations in the agri-food sector and to forge the right partnerships to take those solutions to market.

Turning Disruptive Technology into Business Strategy Through Partnership & Collaboration

Mission Statement:

Focussed on predictive agriculture, automation, robotics, AI backed genomics and biological discovery platforms, the World Agri-Tech Innovation Summit explores the business models and partnerships needed to scale new technologies and transform the food supply chain into a more sustainable, affordable and nutritious system for future generations.

Now in its 5th year, the summit will gather 1000+ global agri-food corporates, innovators and investors to uncover the most exciting innovations in the agri-food sector and to forge the right partnerships to take those solutions to market.

Each year the summit attracts important delegations from Europe, Israel, Asia and Australia and is where valuable business connections are made to accelerate the transition of technology from the laboratory to the field.

Venue:

Hilton San Francisco Union Square

333 O’Farrell Street

San Francisco

CA 94102

Registration:

https://worldagritechusa.com/register/

World Agri-Tech Innovation Summit:

Early Bird (until January 17, 2019) $1,895

Full Price $2,295

Two Summit Pass: World Agri-Tech and Future Food-Tech

Early Bird (until January 17, 2019) $2,995

Full Price $3,495

About the Summit

Focussed on predictive agriculture, automation, robotics, AI backed genomics and biological discovery platforms, the World Agri-Tech Innovation Summit 2019 explores the business models and partnerships needed to scale new technologies and transform the food supply chain into a more sustainable, affordable and nutritious system for future generations.