Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

40-foot Shipping Container Farm Can Grow 5 Acres of Food With 97% Less Water

The 40-foot containers house hydroponic farms that only draw on five to 20 gallons of water each day to grow produce like lettuce, strawberries, or kale

by Lacy Cooke

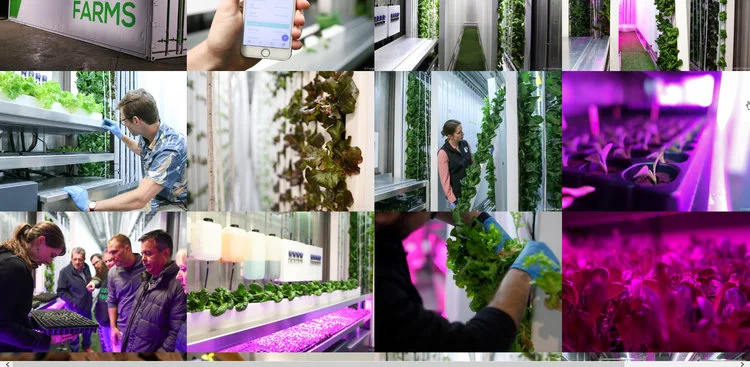

Communities that have to ship in fresh food from far away could start getting local produce right from their parking lots or warehouses thanks to Local Roots‘ shipping container farms. The 40-foot containers house hydroponic farms that only draw on five to 20 gallons of water each day to grow produce like lettuce, strawberries, or kale. Popping up all around the United States, these scalable farms “grow far more produce than any other indoor farming solution on the market” according to co-founder Dan Kuenzi. Local Roots is even talking with SpaceX about using their farms in space.

Local Roots’ 40-foot shipping container farms, called TerraFarms, grow produce twice as fast as a traditional farm, all while using 97 percent less water and zero pesticides or herbicides. They can grow as much food as could be grown on three to five acres. They’re able to do this thanks to LED lights tuned to specific wavelengths and intensities, and sensor systems monitoring water, nutrient, and atmospheric conditions.

Related: Pop-up shipping container farm puts a full acre of lettuce in your backyard

The process from setup to first harvest takes only around four weeks. TerraFarms can be stacked and connected to the local grid. CEO Eric Ellestad said in a video 30 million Americans live in food deserts, and their farms could be placed right in communities that most need the food.

Los Angeles is already home to a farm with several shipping containers, and a similar one will be coming to Maryland this year. It could offer local food like strawberries in January.

And Local Roots’ technology could one day allow astronauts to consume fresh produce in space. Their growing systems could offer a food source on long-term, deep space missions. Ellestad told The Washington Post, “The opportunities are global and intergalactic at the same time.”

Images via Local Roots Facebook

Agriculture, carousel showcase, Eat & Drink, Gardening and Plants, News

BREAKING NEWS: Keurig Dr Pepper Withdraws Peñafiel Bottled Water From US For High Arsenic Levels

Keurig Dr Pepper announced it was withdrawing Peñafiel spring water products from the U.S. market because sampling by an independent lab found they contained arsenic levels higher than the 10 parts per billion allowed by the FDA. The company did not say how high the levels were.

AUTHOR Cathy Siegner

June 24, 2019

Keurig Dr Pepper announced it was withdrawing Peñafiel spring water products from the U.S. market because sampling by an independent lab found they contained arsenic levels higher than the 10 parts per billion allowed by the FDA. The company did not say how high the levels were.

All unflavored Peñafiel mineral spring water products in PET bottles, which are imported from Mexico, are being pulled back. Keurig Dr Pepper said it had notified retailers, including Walmart, Target and others. Consumers can return products to retailers for a full refund.

The company noted arsenic is found in nature, including in aquifers where mineral water is sourced, and that levels can vary over time. It also said enhanced filtration systems had been installed at its facilities where Peñafiel is produced, and "the product now being produced is well within regulatory guidelines.":

Problematic arsenic levels in Peñafiel spring water became public several months ago. According to a recent Consumer Reports investigation, this brand and five others tested at 3 ppb or higher in a recent sampling of 130 bottled water brands. The report found that it was able to purchase Peñafiel products on Amazon and at retail stores in two states despite an existing FDA import alert issued in 2015 because the product contained arsenic levels above 10 ppb.

After the report came out, Keurig Dr Pepper told the group it had conducted new tests and found average arsenic levels of 17 ppb in Peñafiel samples. The company then suspended production at its bottling plant in Mexico for two weeks and said it was improving filtration. However, it did not issue either a voluntary withdrawal or a recall at that time.

Although arsenic occurs naturally, consumption over time has been linked to cardiovascular problems, lower IQ scores in children and certain cancers, according to the World Health Organization. On June 3, a California man filed a lawsuit in federal court alleging the company "acted irresponsibly and unlawfully" by selling bottled water containing unsafe levels of arsenic. More lawsuits could be coming since it took the company this long to withdraw the product from market. The complaint referenced the Consumer Reports investigation and stated the company had to have known there were high levels of arsenic in Peñafiel products before the report came out.

It's likely the ongoing controversy — and possibly higher arsenic levels in more recent testing — prompted Keurig Dr Pepper to issue the withdrawal. While Keurig Dr Pepper's core businesses include soft drinks, specialty coffee, tea, water and juice drinks, it's taking the time and money to withdraw the "very limited" Mexican products and invest in enhanced filtration systems, so Peñafiel's sales must be worth the effort.

This episode raises troubling questions about Peñafiel and could cause consumers to wonder whether it's safe to drink. Consumer Reports asserted in April that records it obtained through a Freedom of Information Act request show FDA has known about high arsenic levels in the brand's products "since at least 2013." The group is continuing to press the company and the FDA for more action about the problem and is advocating for reducing the federal arsenic level from 10 ppb to 3 ppb.

Meanwhile, Keurig Dr Pepper is working on its consumer-facing image by recently issuing a new corporate responsibility strategy and commitments document. Among pledges involving the environment, supply and communities, the company said it would "partner with leading organizations to accelerate portfolio innovation and transparency for health and wellbeing."

Other manufacturers have faced similar challenges, including Walgreens with acrylamide in cookies and General Mills, Kellogg and Post with acrylamide in cereal. Glyphosate has been found in most wine and beer, Tropicana and Safeway Signature Farms orange juice, Quaker Old Fashioned Oats, General Mills' Nature Valley granola bars and Ben & Jerry's ice cream. These incidents can lead to lawsuits, reformulations, new labeling and tightening up on production processes. But this latest case could also mean bad news for all the bottled water companies named in Consumer Reports' investigation, which may want to increase testing around their products.

Companies typically defend products by noting they meet state and federal standards for chemical residues, which is why Consumer Reports and other groups want to see permissible levels revised downward. Still, continuing negative news and withdrawals tend to leave a bad taste for consumers wanting healthier, untainted products.

Recommended Reading:

Program Provides A Low-Cost Way For Businesses To Obtain The Advanced GrowPod Cultivation System

CORONA, Calif.

June 18, 2019 /PRNewswire/

GP Solutions (GWPD), a leading developer of automated micro-farms, announced it is now offering financing to provide businesses with a quick, low-cost pathway to begin growing profitable herbs and vegetables with the advanced "GrowPod" system.

GrowPods are portable, automated, perfectly-tuned cultivation environments that use significantly less space and water than conventional methods. The proprietary plug-and-play system allows a business to have a sustainable, efficient, and environmentally-friendly farm located virtually anywhere.

GP Solutions' new financing plans offer a variety of options for businesses to enter the highly profitable world of micro-farming.

GrowPods can be customized to provide the perfect environment for a wide variety of cash-crops, herbs and vegetables.

The system features a number of advanced technologies, including optimized photosynthesis, high level security, 24/7 remote control, video monitoring via a cloud-based platform, and precision environmental controls for temperature, humidity, and other vital factors.

Unlike other growing systems that use fixed greenhouses or require enormous capital for large indoor "warehouse farms," GrowPods are modular, scalable, indoor micro-farms that can be placed virtually anywhere. The pods have been shown to outperform other methods of cultivation, providing quicker harvest times with higher yields and greater consistency.

GrowPod farmers are provided with data, insights and other tools to further refine and improve their crops. As a sealed environment, GrowPods give farmers the ability to keep crops and strains separated, eliminating contaminants, pathogens, and pesticides.

For more information on GP Solutions' financing options or the GrowPod system, visit: www.growpodsolutions.com, or call (855) 247-8054.

ABOUT GP SOLUTIONS:

GP Solutions developed "GrowPods" – portable, modular, automated indoor micro-farms that provide optimum conditions for plant cultivation with total environmental control.

Forward-Looking Statements

This release includes predictions or information that might be considered "forward-looking" within securities laws. These statements represent Company's current judgments, but are subject to uncertainties that could cause results to differ. Readers are cautioned to not place undue reliance on these statements, which reflect management's opinions only as of the date of this release. The Company is not obligated to revise any statements in light of new information or events.

Connect:

Email: info@growpodsolutions.com

Website: www.growpodsolutions.com

Facebook: facebook.com/GrowPodTechnology

Twitter: @GrowPodSolution

Media:

hello@inov8.us

Urban Agriculture’ Leads Off A 26-Episode Weekly Video Series on Vegetable Production

Linked by Michael Levenston

Mitchell assembled a team of professors from California’s public universities with agricultural programs – UC Davis, Chico State, Fresno State and CalPoly San Luis Obispo – to pull together a series of videos designed to spark the interest and begin training future farmers and ag workers in sound agronomic, economic and environmental stewardship skills.

University of California

UC Agriculture and Natural Resources (UC ANR) YouTube

Each Monday morning from May 13 through Nov. 4, a new video will premiere in the playlist.

(Must see. Mike)

From Video:

Urban agriculture is proliferating across the state of California on both public and private lands, taking the form of school, community, church and backyard gardens, vertical and rooftop farms, for-profit and non-profit enterprises, as well as a whole suite of other food production methods.

These urban farms are transforming the landscape of food production, helping to address urban food insecurity, creating opportunities for micro-enterprise development, and educating our youth and the public about the value of growing and eating healthy foods. The value of urban farming is indisputable, as studies provide mounting evidence of the myriad social, economic, ecological, recreational, therapeutic, and nutritional benefits of urban agriculture.

Urban farming is emerging at a growing number of sites. It is very much in flux with respect to its many forms and implementation. It addresses a wide range of goals and it represents a very broad array of motivations. This video provides a general introductory overview of some of the variety of urban farms in California today. It highlights the work of thirteen urban farmers from Los Angeles through the Bay Area cities of Oakland, Berkeley, and Hayward.

This video captures the creativity, innovation and dedicated work that is underway on a wide range of urban agriculture fronts at this time in California. This is indeed a very exciting and challenging time for urban farmers. With an estimated 50% of our nation’s farmland projected to change hands in the coming ten years, new farmers and new farming models are going to be needed to meet the needs for food that we will have. Urban agriculture is likely to play a role in meeting these huge challenges.

SOLD - December, 2015 Freight Farm Premium - Computer Controlled Hydroponic Grow System - Southern Connecticut - $37,500

December, 2015 Freight Farm Premium Leafy Green Machine (LGM)

Manufacturer - Freight Farms

Location - Southern Connecticut

Price - $37,500

Description

Original owner well maintained December, 2015 LGM.

This LGM has been a reliable producer of healthy produce.

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

Intelligent Growth Solutions Attracts £5.4 million Series A Funding to Achieve Global Growth in Vertical Farming

Scottish agri-tech business to

deliver ground-breaking technology to burgeoning

indoor farming sector

Invergowrie, Scotland – 18 June 2019 - Intelligent Growth Solutions Ltd (IGS), the Scottish-based vertical farm technology business, announced today a £5.4 million Series A funding round led by US-based S2G Ventures, the world’s leading agri-foodtech investor.

IGS supplies highly sophisticated plug-and-play vertical farming technology to indoor farms to enable the efficient production of food in any location around the world.

To demonstrate the unique technology stack it has developed, IGS opened its first vertical farming demonstration facility in August 2018. Since that announcement the company has received significant interest from around the world with orders mounting for its ground-breaking, patented technologies.

IGS’ unique technology has been designed specifically to address some of vertical farming’s biggest challenges, including the cost of power and labour, as well as the inability to produce consistently high-quality produce at scale. These economic and operational barriers to growth have inhibited the sector’s expansion to date. IGS has designed all its products to be highly pragmatic, flexible, modular and scalable in-line with market requirements.

The £5.4 million investment will allow IGS to create jobs in areas such as software development, engineering, robotics and automation. It will also help IGS to increase its product development, including continued innovation in AI, big data and the Internet of Things. IGS will also be building global marketing, sales and customer support teams in three continents.

This growth is pivotal for IGS to meet significant demand from growers, retailers and governments aiming to address food security issues through alternative methods of production and new business models in their regions. In 2019, IGS will be deploying indoor farming systems for clients in every major territory globally.

With global market growth in vertical farming predicted at 24 percent per annum over the next three years, the opportunities for IGS are substantial, with over 95 percent of its sales expected to be exported either directly or through regional channel partners.

The Series A funding round was led by S2G (Chicago), the most active agri-foodtech investor globally in 2018, with online venture capital firm AgFunder (San Francisco), the second most active and Scottish Investment Bank (SIB).

“Indoor agriculture production is at a tipping point. Grocery and food service firms have never been more interested in adopting this in their future supply chain. Cost and quality of product will be critical to scale this adoption. IGS’s revolutionary technology has proven itself to reduce power consumption, improve ventilation and hence reduce the capital and human costs to deliver fresh and differentiated products to consumers,” commented Sanjeev Krishnan, Managing Director of S2G Ventures. “We are excited IGS will help enable this emerging movement”.

“We see IGS as the perfect foray for AgFunder into the indoor agriculture arena,” said Michael Dean, founding partner at AgFunder. “As a developer of highly sophisticated energy and control system technologies for third-party indoor farms, IGS satisfies our bias for investing in enabling technologies rather than technology-enabled production with the inherent risks associated with building and operating a large asset.”

Kerry Sharp, Director of the Scottish Investment Bank, said: “We are delighted to support the continued development of IGS as it looks to take its technology to the global marketplace. The company has been account managed by Scottish Enterprise since 2014 and has received both financial and non-financial assistance covering innovation and R&D as well as supply chain management and international market entry. The company has made significant progress over the last 12 months and has assembled an impressive team with a clear focus on taking the IGS offering to an international market.”

IGS Chief Executive Officer David Farquhar said “We are thrilled to have the backing of the world’s leading agri-tech investors and the Scottish Investment Bank. We have recruited a world-class international management team, to be announced soon, to drive our plan forward with support from a board of senior international business people bringing industry expertise and best practice governance to the table.

“This industry is just at the starting line and we look forward to working with our customers, partners and colleagues at the James Hutton Institute to enable the highest quality produce to be grown at economically viable prices and help feed the burgeoning global population.”

The Scottish-led R&D team at IGS has developed, patented and productised a breakthrough, IoT-enabled power and communications platform consisting of patented electrical, electronic and mechanical technologies. All this is managed by a SaaS and data platform using AI to deliver economic and operational benefits to indoor growing environments across the globe. This technical solution enables the potential for reduction of energy usage by up to 50 per cent and labour costs by up to 80 per cent when compared with other indoor growing environments. It also can produce yields of 225 per cent compared to growing under glass.

Thorntons’ corporate and commercial team (led by Alistair Lang and with support from Victoria McLaren and wider team) acted for IGS throughout the Series A funding process.

A Shepherd and Wedderburn corporate team (led by Stephen Trombala with support from Christina Sinclair and Cath Macrae) acted for Chicago-based S2G Ventures - the lead investor in the first closing of the series A financing of Intelligent Growth Solutions Limited.

About IGS:

IGS was formed in 2013. Its purpose was to bring indoor horticulture to commercial reality by combining efficient internet-enabled smart lighting with automation and power management. The founders’ experience combined extensive knowledge of horticulture, industrial automation and big data.

IGS launched its first vertical demonstration facility in August 2018 and is now selling a revolutionary controlled-environment growth system. The location of IGS’ facility at the James Hutton Institute, a world leading crop research facility, was deliberately chosen to enhance collaboration opportunities for the benefit of customers. Scientists and researchers at the Institute are working with the team at IGS to better understand how growing indoors can impact different varieties of crop growth, as well as driving increased productivity.

For more information visit www.intelligentgrowthsolutions.com or connect with us on Twitter and LinkedIn.

About S2G Ventures:

S2G Ventures (Seed to Growth) is a multi-stage venture fund investing in food and agriculture. The fund’s mission is to catalyze innovation to meet consumer demands for healthy and sustainable food. S2G has identified sectors across the food system that are ripe for change, and is building a multi-stage portfolio including seed, venture and growth stage investments. Core areas of interest for S2G are agriculture, ingredients, infrastructure and logistics, IT and hardware, food safety and technology, retail and restaurants, and consumer brands. For more information about S2G, visit www.s2gventures.com or connect with us on Twitter and LinkedIn.

About AgFunder

AgFunder is an online Venture Capital Platform investing in the bold and exceptional entrepreneurs transforming our food and agriculture system. Our in-house technology enables us to invest globally and at scale, make better investment decisions, and support our portfolio companies. Through media and research, AgFunder has built a community of over 60,000 members and subscribers, giving us the largest and most powerful network in the industry.

Stay up-to-date with Food Tech and AgTech startup news, and other reports, by signing up to our newsletter here.

About Scottish Investment Bank:

The Scottish Investment Bank (SIB) is the investment arm of Scotland’s national economic development agency, Scottish Enterprise, operating Scotland-wide in partnership with Highlands and Islands Enterprise (HIE). SIB’s activities support Scotland’s SME funding market to ensure businesses with growth and export potential have adequate access to growth capital and loan funding.

SIB manages a suite of co-investment funds including the Scottish Co-investment Fund, the Scottish Venture Fund and the Energy Investment Fund on behalf of the Scottish Government. SIB is also an investor in Epidarex Capital’s Life Sciences Fund and is a participant in the Scottish-European Growth Co-Investment Programme with funding secured from the Scottish Government’s Scottish Growth Scheme alongside the European Investment Fund.

SIB also provides funding into LendingCrowd, Scotland’s marketplace lender providing loans to SMEs, and Maven's UK Regional Buy Out Fund (MBO) that offers financial support for management buyouts (MBOs) and helps existing management teams acquire their businesses from their owners so they can continue to flourish. SIB’s team of financial readiness specialists help companies to prepare for new investment and access appropriate finance.

Take a Tour of a Hema Supermarket And Experience "New Retail"

Chinese multinational conglomerate Alibaba has reiterated its plan to merge online and offline shopping experiences to better serve customers and improve efficiency, through among other measures, the rapid expansion of its grocery store Hema Supermarkets in China

Published on Jul 16, 2017

Alizila's Tom Brennan offers a tour of a Hema Supermarket, showing how online and offline shopping are merged into a seamless “New Retail” experience.

Winny Tang The Jakarta Post

Shanghai, China / Sun, November 11, 2018

Customers are pictured shopping at Hema Supermarket, part of Alibaba Group, in Shanghai, China. Hema is a digitized retail store that allows shoppers to buy food, eat in or order home delivery. (JP/Winny Tang)

Chinese multinational conglomerate Alibaba has reiterated its plan to merge online and offline shopping experiences to better serve customers and improve efficiency, through among other measures, the rapid expansion of its grocery store Hema Supermarkets in China.

Hema CEO Hou Yi said the group planned to open nine more stores by Dec. 12, from 91 stores it operates at present in 16 cities, including Shanghai, Beijing, Ningbo, Shenzhen, Hangzhou and Guiyang.

“By next month, we will have 100 Hema stores […] Hema is the first retail store where all products can be bought offline and online,” he told reporters during a media briefing in Shanghai on Saturday.

Hou Yi, said the company was currently focusing on expanding to Tier 1 and Tier 2 cities in China.

Hema is an example of a “new retail” model that Alibaba has incubated since 2015. The store provides a retail experience that uses a technology-driven concept for in-store purchases, online delivery and in-store consumption.

Shoppers can purchase products by using the Hema mobile app, which is linked to their Alipay account. Those living within a radius of 3 kilometers from the store can also use its home delivery services.

At Hema’s robotic restaurant in Shanghai, customers are served by robots that deliver dishes right to their table. (dwa)

Singapore’s Sky Farms Are Transforming The Agriculture Sector

Jun 06, 2019

Apollo Aquaculture Group CEO Eric Ng checks on his fish at his prototype vertical fish farm in Singapore May 17, 2019.(Photo: REUTERS/Edgar Su)

Singapore's cost-efficient sky farms are changing the way people in the city-state view farming and agriculture as a whole. Lab-grown and in-building products are being promoted to help achieve the ultimate goal of producing 30 percent of Singapore's total food by 2030.

According to Voice of America, the basic principle in sky farms is to grow fish, vegetables, and other crops and seafood on top of the city-state's skyscrapers. Singapore has an estimated 5.6 million citizens, but the local agriculture sector only produces 10 percent of food products for Singaporeans.

Among the challenges that the government is faced with are population growth and climate change. With more people moving to the city-state, the biggest dilemma is space for growing crops.

"Whenever I talk about food security in Singapore, I tell folks don't think land - think space. Because you can go upwards and sideways," agriculture professor at Nanyang Technological University, Paul Teng, noted.

The idea of growing seafood outside sea areas emerged after fish farmers complained of algae blooms gradually killing fish and other oceans produce. For Apollo Aquaculture Group, the new project could help propel production for Singaporeans who patronize seafood.

Singapore state investor Temasek has been helping fund agriculture companies interested in sky farms. Among the firms that Temasek assisted is Sustenir Agriculture, a farming company that raised around $16 million in 2018 for expansion purposes.

Sustenir Agriculture utilizes artificial lighting within skyscrapers to grow various crops such as strawberries and kale. The government has been promoting the farming process to other agri-businesses in Singapore as a means of reducing costs and overcrowding in the small city-state.

Founder and CEO of Metabolic, Eva Gladek, said last week that the current food system that many countries around the world have adopted is further pushing the planet to deteriorate. According to TNW, Gladek noted that around 25-30 percent of greenhouse gas emissions have been linked to the world's food habits.

Gladek mentioned Singapore's sky farms in her speech at the TNW Conference, noting that low carbon hydraulic farming systems like the one Singapore Sky Greens utilizes can help reduce the levels of energy that tech-assisted farming demands.

Singapore stepped up its game in food security earlier this year when the government announced that malls are now welcoming various forms of agriculture. The city-state's Orchard Road features a mall where a Comcrop farm measuring 600 square meters is being tended to by expert farmers.

Since agriculture is not among the key sectors in the city-state, the government is hoping that farmers will indulge in vertical farming to reduce supply disruptions that come with excessive importing of food.

Infarm Gets $100 Million Financial Boost

Urban farming platform Infarm has announced a $100M Series B investment led by Atomico, with participation from existing investors Balderton and Cherry Ventures.

The new funding will be used to scale Infarm’s growth in Europe to the US and beyond, and grow the R&D, operational, and commercial teams.

"Infarm was founded with an ambitious vision to feed the cities of tomorrow by bringing farms closer to the consumer, and with this round of funding we aim to grow our presence further", said Erez Galonska, co-founder and CEO of Infarm.

Infarm has developed easily scalable and rapidly deployable modular farms to grow fresh produce in any retail space or restaurant right in the heart of cities where people live in. Infarm’s technology is specifically designed and built to work anywhere in any available space. There is no need for a centralized warehouse or farm, and no need for special infrastructure or set-up.

infarm was founded in Berlin in 2013 by Osnat Michaeli, Erez Galonska and Guy Galonska.

Since Balderton led Infarm's Series A, it has grown to 250 employees and is on track to book over $100m in contract value this year.

Infarm has partnered with 25 major food retailers including Edeka, Metro, Migros, Casino, Intermarche, Auchan, Selgros, and Amazon fresh in Germany, Switzerland, and France and deployed more than 200 in-store farms, 150 farms in distribution centres, harvesting 150,000+ plants monthly and growing.

Infarm is launching in the U.K. this September with some of the country’s largest online and brick-and-mortar supermarkets and are in advanced discussions with retailers in the U.S. and Japan.

As part of the investment round, Atomico Partner Hiro Tamura will join the company’s board.

For more information:

infarm.com

www.atomico.com

www.balderton.com

www.cherry.vc

Timelapse: Scottish Strawberries In A Vertical Farm

Scotland is famous for its strawberries grown mainly in the summer months, but now there is the potential that it could be famous for them all year round. Following the first successful propagation trials which took place in February 2019, Intelligent Growth Solutions have grown a small crop of strawberries in their vertical farm.

David, the CEO, commented: “This is an exciting advance for us, showing that increasingly broad range of produce such as strawberries can be grown economically, right here, all year round. Growing in this controlled indoor environment means that we are better able to guarantee consistency of quality, appearance and flavour.

“Soft fruits are now perennial items on supermarket shelves, but this does mean considerable shipping costs and environmentally damaging food miles. And frankly the imported product is often tasteless and lacks juiciness. We are just on the cusp, but this trial shows that there is the potential to produce delicious, fresh produce all year round much closer to home which is very exciting for growers, retailers and consumers alike.”

For more information:

Intelligent Growth Solutions

c/o The James Hutton Institute

Invergowrie

Dundee

DD2 5DA

T: 0131 202 1050

info@intelligentgrowthsolutions.com

www.intelligentgrowthsolutions.com

Publication date: 5/20/2019

BREAKING NEWS: Infarm Raises $100 Million To Expand Its Urban Farming Platform To The U.S. And Beyond

JUNE 11, 2019

Infarm @ Auchan, Luxembourg

Infarm, a Germany-based startup that distributes “modular farms” to grocery stores and other urban locations, has raised $100 million in a series B round of equity and debt funding led by Atomico, with participation from existing investors including Balderton Capital, Cherry Ventures, Astanor Ventures, and TriplePoint Capital.

The CO2 emissions produced by growing, farming, and transporting food around the world is significant, with some estimates pegging the food footprint(“foodprint”) at around one-quarter of the total global greenhouse gas emissions. By creating a system of vertical micro-farms in cities, which entails producing food indoors within a stack of glass cases in a controlled environment, Infarm is pushing to reduce the environmental burden that food production has on the planet.

Founded out of Berlin in 2013 by Osnat Michaeli alongside brothers Erez and Guy Galonska, Infarm has partnered with a number of food retailers across Europe, including Amazon Fresh, Metro, Edeka, Migros, Casino, Auchan, and Intermarche to install vertical indoor farms inside their outlets.

Infarm @ Metro in France

Infarm said that its technology is designed to be built and distributed in any available space, and there is no need for a centralized warehouse or other infrastructure setup costs. The farms can be found in restaurant kitchens, supermarket aisles, and warehouses, and are designed to scale and make cities self-sufficient in producing their own plant-based food.

Each farm is “connected,” with sensors collecting and recording growth data, while they can be controlled remotely by the Infarm platform that “learns, adjusts and improves itself continuously,” according to the company.

Infarm

Prior to now, Infarm had raised nearly $34 million, and with another $100 million in the bank, it’s now gearing up to add additional markets to its roster, including the U.K., where it’s launching in September. The company said that it’s also in “advanced discussions” with retailers in the U.S. and Japan, while it plans to invest in various R&D, commercial, and operational initiatives.

“Infarm was founded with an ambitious vision to feed the cities of tomorrow by bringing farms closer to the consumer, and with this round of funding we aim to grow our presence further — sowing the seeds for a delicious and sustainable food system in urban centers across North America, Asia, and Europe,” noted Erez Galonska, Infarm cofounder and CEO.

Vertical

Infarm isn’t alone in its quest to introduce indoor farming to market. U.K. supermarket giant Ocado yesterday announced it was investing $22 million and joining a vertical farming joint venture, while back in December Alphabet’s VC arm GV led a $90 million investment in New York-based Bowery, taking its total funding to nearly $120 million. And San Francisco-based Plenty has raised north of $200 million for a similar proposition.

For Atomico, Infarm represents the latest in a line of “sustainable”-focused investments. Just yesterday, the London-based VC firm announced it had led a $25 million investment in Norway’s Spacemaker, which is working toward optimizing urban development projects with AI-powered simulation software, to cater to the expected population surge over the next few decades.

“The consumption of fresh produce is a huge environmental burden on our planet, one that will only increase as urban populations increase,” added Atomico partner Hiro Tamura, who now joins Infarm’s board of directors. “This is not sustainable long-term. Infarm has perfected the holy trinity when it comes to solving this massive global problem; their unique technology makes fresh food production sustainable, their solution has a global audience which means they have operated internationally from day one; and this has resulted in the company being a commercially attractive proposition for all stakeholders in the supply chain.”

Infarm also fits into a broader sustainability investment trend that has seen startups across urban mobility and waste reduction rake in investor cash. And in the food realm, meat substitute company Beyond Meat raised $122 million in funding ahead of its IPO last month — the company’s shares are currently red hot.

Aquaponics Is Coming To France

Widely used in Africa or the United States, aquaponics is now arriving in France. It is a form of market gardening that consists of growing vegetables in water that comes from fish farm tanks

Widely used in Africa or the United States, aquaponics is now arriving in France. It is a form of market gardening that consists of growing vegetables in water that comes from fish farm tanks.

It should not be confused with hydroponics, since in aquaponics, there are no inputs used but only natural products. "It is by feeding the fish that we will indirectly feed the plants," explains Matthieu Geyelin, a market gardener at the Terr'eau farm in Noth en Creuse.

After staying in the middle of trout and carp in fish farming basins, the water loaded with fish effluent is filtered and then assimilated by the plants.

"We will sow directly into the substrate where there is a stream of water passing through," explains Elise Geyelin maraichère, Terr'eau farm. The young plants are then transplanted, not into the soil, but directly into the water enriched by the fish. There is therefore no need for soil or weeding. And apart from root vegetables, everything grows whether it is salads, aromatic plants, tomatoes or strawberries.

Once filtered by the roots, the water flows back to the fish. "It is a significant saving, we will use 85% less water compared to open field market gardening. A technique that is almost unknown in France but which works," concludes the farmers' couple.

Source: france3-regions.francetvinfo.fr

Publication date: 5/28/2019

Urban Farming In The US: Breaching The Urban-Rural Divide

Farming is one of the oldest professions there is. But as society has urbanized, we have gradually lost our connection with the industry that puts food on our plates

Tuesday, June 04, 2019

Farming is one of the oldest professions there is. But as society has urbanized, we have gradually lost our connection with the industry that puts food on our plates. One jarring survey in the U.K. found that nearly 1 in 10 elementary school children think that tomatoes grow under the ground.

In parallel with urbanization has come the severing of our relationship with the people and land that grows our food. But now we are hearing that a new urban revolution in food is apparently sweeping through our city centers… so, can urban farming change our relationship with food? And can it be part of our reimagining of urban land uses?

Cutting down the food miles

Politically, agriculture tends to be treated as a "rural" issue — remote from the concerns of urbanites and left for farmers to battle over, as long as the food arrives on our supermarket shelves safe and sound.

So why bother bringing food production back into our cities? Surely we don’t have enough space left as it is.

When our societies were far less urbanized than they are today, food growing was woven into communities — indeed, the extraordinary and complex way we have developed to eat and source our food is a relatively new phenomenon.

Well before the advent of the Brooklyn urban-homesteading-hipster, the first settlers in the U.S. were growing their own, as were abandoned inner-city neighborhoods in the 1960s. Globally, small farmers still control the largest share of the world’s agricultural land.

One of the major benefits of farming within the city is that it brings the grower much closer to where it is eaten, cutting down dramatically on food miles. It can act as green infrastructure — absorbing storm water, combatting the urban heat island and filtering the air — and has a key role in injecting fresh produce into the nation’s "food deserts."

Finally, urban farms can transform the fractured relationship between farm and city into something more symbiotic. At Chicago’s City Farm, growers make use of one resource that is all too plentiful in American cities — food waste — to enrich the poor urban soil for producing vegetables. The strategy harks right back to that used by market traders in 19th century Paris, where the mess left behind by the horses of the market traders would be used to nourish local urban gardens.

Finding fertile ground

With a growing population, space within our cities is at a premium as never before. We also have more mouths to feed. But that doesn’t mean there is no fertile ground for growing.

The pressure on cities like Tokyo and New York have also been forcing agriculture onto rooftops.

But there are some obvious benefits to rooftop farms once you give it some thought. There are not quite so many rats on rooftops, and certainly fewer deer to nibble at your wares, even if dealing with high winds can take a bit of ingenuity.

In contrast, in some post-industrial cities like Detroit, urban agriculture has sprouted up in disused lots left over as the inner city was deserted as manufacturing declined. Indeed it was in such urban areas where the roots of the modern community gardening movement began in the 1970s.

The Michigan Urban Farming Initiative in Detroit has been described — only slightly wincingly — as one piece in the nation’s first urban "agrihood." Taking it up a level is the Hantz Group, who are controversially attempting to build the world’s largest urban farm, on land they snapped up in 2008 when land prices plummeted.

Scaling up urban farming

For many of us, our vision of urban farming is the rustic urban allotment or volunteer-led community garden. While those ventures are empowering and provide huge dividends in social capital and physical and mental health, urban farming is attracting the attention of commercial growers, too. They are trying to prove that urban farms can not only be environmentally beneficial but can turn a profit as well.

For many, this means embracing new technologies — and this is where we depart from the nostalgic vision of the urban homestead. Tokyo, one of the cities with famously intense pressures on land use, has been one of the cities experimenting with vertical urban farming — where crops are stacked up in warehouses and lit with UV lights.

Many of these crops use hydroponic technologies, which are a method of growing plants without soil. Instead of being embedded in the soil, nutrient-rich water or very moist air (known sometimes as “liquid soil”) is trickled or misted over their roots. New York-based Gotham Greens grow bok choy, basil and lettuce like this.

Others, including celebrated Milwaukee-based urban farm Growing Power have gone a step further by experimenting with aquaponic solutions — which throw fish into the mix.

NASA has been testing hydroponics out with a view to feeding colonies on the Moon. But, at the other end of the spectrum, hydroponics also made an appearance this year at the staunchly traditional Chelsea Flower Show in London.

Despite some teething problems (not least around energy use), the benefits of this "controlled-environment agriculture" (CEA) are considerable. The sun can always shine, and conditions can be controlled to an extent impossible on traditional farms.

As a consequence, the yields tend to be much higher and plants grow faster. The burden on water resources is also much lower compared to traditional methods and — handily for deindustrializing cities — the systems pack well into disused carpet factories.

We might recoil from this vision of vertically stacked lettuces, so distant is this futuristic image from the rural agricultural idyll we grew up with. But the precision that these technologies allow enable these growers to grow pesticide-free, which is more than can be said for most traditional farms.

Whether or not it makes you feel warm and fuzzy about the source of your food, we are likely to see a lot more of technologies like this.

Planning cities for a food revolution

Like many of the best ideas, urban farming is not a new idea but the revival of a tried and tested one. But despite the immediacy of the food crisis, one of the most exciting things about the supposed urban farming "revolution" are its co-benefits.

Urban growing projects are not only a response to the environmental and nutritional crisis posed by a growing population and a hungry planet, but it is also a response to the breakdown of community.

As advocates of "food sovereignty" tell us, the act of urban farming also answers a deep need in the modern world to take back control, and gardening has long been a reaction to periods of economic instability. The Victory Gardens encouraged during the Second World War are the most well-known example, and Cuba’s self-sufficiency experiment a more recent one.

Urban planners and city authorities have to lend a hand. Planners until recently have seen urban farms as too "low value" of an activity to afford urban space, but that is starting to change.

This might mean tweaking zoning laws to allow these uses to creep back into the city. In 2013, Detroit’s urban agriculture ordinance finally made the city’s hundreds of gardening plots legal, which is at least somewhere to start.

About the Author

Lucy is a UK-based urban and environmental planner, with a background in Open Data policy and energy policy. She is fascinated by how we grow our cities and towns, and how we can learn from place, as well as how apparently dull policy details can transform the experience of our everyday built and natural environment. She writes here about urban spaces in the U.S. and beyond from all kinds of perspective — from the busker to the policy maker.

Homegrown Hydroponics Project Spreads Around The World

May 14, 2019 - Mike Enright '88 (CLAS), University Communications

Christian Heiden ’20 (ENG), center, started a non-profit organization Levo International to bring hydroponics to those in need in Haiti.

The idea began when UConn junior Christian Heiden ’20 (ENG) was working on his Eagle Scout project in high school. It has developed into a non-profit organization that is helping the poor of Haiti and inspiring the curiosity of students in the UConn Child Development Labs.

Through his scout work, Heiden, of Bloomfield, Connecticut, first built a hydroponic greenhouse for his high school, Northwest Catholic in West Hartford. Then, Heiden and his father, Bill, and brother, Nathaniel, traveled to Haiti and built a demonstration hydroponic greenhouse for a community in that nation.

Hydroponics is a method of growing plants without the use of soil and instead relying solely on mineral nutrient solvents in water. While it has been used on a large-scale basis for growing vegetables like tomatoes and lettuce, Heiden says, he has broken it down for the most simplified use yet.

“We wanted something that would only cost a few dollars a day to operate, so we designed our Babylon System which is a 5-by-2 foot system and grows 16 plants at a time,” said Heiden. “It allows people not just to grow produce for their family, but also at market. So they are gaining a way not to just eat but gain money for their family.”

Heiden started the non-profit organization Levo International in his freshman year at UConn to bring hydroponics to those in need in both Haiti and in Connecticut. He soon reached out to Jonathan Moore, an instructor at the operations and information management department (OPIM) in the School of Business.

“Through our emerging tech initiative OPIM Innovate, we have worked on a number of projects,” said Moore. “Christian reached out to me looking for advice on how we could incorporate technology into this work and what the cost would be. He also brought up the path of wanting to develop the for-profit side of the business in order to fund the non-profit side.

“I thought it would be a great idea for him to donate a prototype right here on campus and the Child Development Labs was a natural choice.”

The Child Development Labs are run by the Department of Human Development and Family Sciences and provide care for children up to five years old. Much of its staffing includes UConn students in the early childhood development and education program.

Anne Bladen, director of the Child Development Labs, said she liked the idea of situating a hydroponics greenhouse there for several reasons, including that the student-teachers would be able to see what happen when you increase nature experiences in your young students.

“We have a big commitment to having our children being outside in nature and being active,” said Bladen. “Having the hydroponic greenhouse at the Child Lab helps us get the children invested in learning where their food comes at a young age. It also gives us the opportunity to talk about Haiti and those less fortunate.”

UConn senior Eli Udler ’19 (CLAS) has been assisting Heiden and his company in the use of 3D printing in hydroponics as part of his work as a member of the team at OPIM Innovate.

“The goal is to make hydroponics more accessible in terms of cost and how easy the greenhouses are to build from ready made components,” said Udler. “I am interested in exploring this with the use of biodegradable material.”

Heiden sees a great future for the hydroponic greenhouses all over the world.

“Our goal is to bring sustainability into the agriculture system on a global scale,” said Heiden. “We think we have a really unique product that will allow us to leverage and accomplish that both here in the United States and the worldwide market.”

June 12, 2019 - LED Conference During GreenTech

The application of the LED technology can propel a cultivation business or a plant research project forward but can also pose challenges. Firstly, the LED offer on the market is vast, complex and confusing and secondly, LED is only one of the available lighting technologies.

The best way to understand how to advance properly onto LEDs is by hearing the stories of those who have done it before. Experts from the fields of crop science, vertical farming and medical plants cultivation will gather in the LEDs & Innovators Conference 2019 to discuss the application of the LED technology and more. The conference will be held during GreenTech at the RAI premises and is free of charge for the GreenTech participants but with a very limited number of seats available.

The 3-part event consists of a Crop Science and Light session, a Hard Science Talk on Cannabis session and a Vertical Farming Innovators Panel. Participants can choose which one to participate in and thus hear first-hand experiences from those who have ventured into the world of LEDs already. The scope will expand beyond just lighting and additionally participants will have a chance to ask their own questions.

In the Crop Science and Light session, we will try to show what kind of light is most useful for researchers and how to successfully transition from trialed and tested protocols made with fluorescent and other, more traditional technologies onto LEDs. In the Hard Science Talk on Cannabis, Dr. Grassi, one of Europe’s most prominent Cannabis sativa researchers, with two decades in the field will discuss terpenes.

The scent molecules of the cannabis plant are sought after almost as much as the cannabinoid compounds and our understanding of their value is still scarce. Finally, the Vertical Farming Innovators Panel will gather vertical farmers as well as industry specialists who will discuss not only lighting for vertical farming, but the ins and outs of this field which is on the exponential rise. You have a chance to propose a topic you wish to be discussed by the panelists. You will have an opportunity to do so in the registration form for the event.

The participation in the event is FREE of charge, however the number of seats is very limited so it is best to register right away.

To learn more about the event and register, please click here.

Conference Program

10:15 – 11:15 Crop Science and Light

Stefanie Linzer, Biologist, Valoya

High Quality White LED Light for Crop Science Applications

11:30 – 12:30 Hard Science Talk on Cannabis

Dr. Gianpaolo Grassi, Head Researcher, CREA-CI, Italy

How Does the Light Spectrum Affect the Terpene Profile of Cannabis?

13:00 – 14:30 Vertical Farming Innovators Panel

Mark Korzilius, Co-Founder & CEO, Farmers Cut, Germany

Rasmus Jakobsen, Manager, Greenlandic Greenhouse

Gus van der Feltz, Chairman, Farm Tech Society

Henry Gordon-Smith, Managing Director, Agritecture

Lars Aikala, CEO, Valoya

About Valoya

Valoya is a provider of high end, energy efficient LED grow lights for use in crop science, vertical farming and medical plants cultivation. Valoya LED grow lights have been developed using Valoya's proprietary LED technology and extensive plant photobiology research. Valoya's customer base includes numerous vertical farms, greenhouses and research institutions all over the world (including 8 out of 10 world’s largest agricultural companies).

Additional information:

Valoya Oy, Finland

Tel: +358 10 2350300

Email: sales@valoya.com

Web: www.valoya.com

Facebook: https://www.facebook.com/valoyafi/

Twitter: https://twitter.com/valoya

CAN (ON): Video Tour of An Ontario Based Cannabis Operation

James E. Wagner Cultivation Corporation President and CEO Nathan Woodworth gave a tour of the company’s new facility located in Kitchener, Ontario. Woodworth also talks about the company’s GrowthSTORM system and stresses that its high density, low-cost system is the most effective way to control the plant’s growth cycle. GrowthSTORM is a multi-part system that uses aeroponic and hydroponic techniques to optimize yield and plant growth.

“The degree of standardization that we can achieve with this system is proof that we have discovered a way to control the total plant growth cycle,” said Woodworth. “We’ve created a high-density, low-cost growth system which results in a 98 percent success rate after 11 to 14 days.”

Woodworth explained the process behind the system and its advantages. According to Woodworth, the plants are moved into GrowthSTORM baskets once they are fully rooted. The baskets allow the plant to form complex root systems throughout its life. Once the plants have reached full production size, they are moved to a low-density array until the flowering cycle is complete. Woodworth also talked about JWC’s latest innovation, the Dual Droplet system, which distributes a large and a small nutrient droplet. These droplets help KWC optimize the delivery and uptake of nutrients. The cannabis plants are then flat trained, ensuring standardization of yield per square foot and maximizing the quality of the finished product.

JWC’s facility has eight grow rooms that are capable of producing up to 50 kilograms per growth cycle with less than one percent crop loss. The company’s 29 strains, which feature four unique phenotypes, are all being grown using the GrowthSTORM system.

For more information:

JWC

1-888-594-4272

info@jwc.ca

jwc.ca

Publication date: 5/15/2019

How Urban Agriculture Can Meet Its Potential

New York City’s urban agriculture has not been found to provide benefits to either hungry people or the environment. How could city farms work better?

Eagle Street Rooftop Farm, Brooklyn, NY

By: James MacDonald

May 27, 2019

Interest in urban agriculture on both personal and commercial scales has grown in recent years. With land in short supply, and transportation carbon-intensive, why not place more farms in cities? It’s a way to improve land use, the environment, and food security all in one blow. But can it actually help?

According to a recent article in Anthropocene magazine, urban agriculture in New York City has provided few benefits to either hungry people or the environment. The main products are leafy greens for high-end restaurants. Moreover, a glut of indoor farms consume vast amounts of energy. New York, however, is not the only center of urban agriculture.

While the stereotypical city farmer might be a Brooklyn hipster tending to backyard kale, urban agriculture is not a new concept. Sustainability expert Milica Koscica writes in The Journal of International Affairs that cities have been incorporating farms almost as long as there have been cities. Ancient urbanites, from the Maya to the Byzantine Empire, maintained farms in urban centers as a backup in case of supply disruptions. During the world wars, the United States, United Kingdom, Canada, Australia, and Germany encouraged citizens to keep Victory Gardens in order to supplement a food supply that was drained by the war effort.

Today, urban farming is widely practiced in the developing world, mostly by low income, food insecure urban residents. In some places, up to 70% of urban residents supplement their food supply with some form of agricultural. In parts of Africa, for example, a small urban plot can provide up to 60% of a family’s food supply. Urban plots produce everything from eggs to mushrooms, using space-saving methods such as hydroponics. Given the poor transportation in many developing countries, an agricultural side hustle allows access to fresh, nutritious foods that low-income urban residents could otherwise never afford. Surplus can be sold, providing critical income.

But this is difficult to scale up beyond subsistence level. Despite various ingenious workarounds, space is at a premium in urban areas, and vertical farms are mostly experimental. According to horticulturists Leigh J. Whittinghill and D. Bradley Rowe, the use of green roof technology might be the answer. Many areas are trying to encourage so-called green roofs to improve energy efficiency and wildlife habitat. Potentially, roofs could be adapted for urban farming, preventing the energy use problems of indoor farming and the contamination risks of marginal soil. Some analysis is required to make sure that the benefits of green roofs would carry over to a green farm roof.

So while urban agriculture may be off to a rocky start in New York City, it may meet its full potential yet.

Freight Farms Webinar - Enlightened Crops

WEBINAR | ENLIGHTENED CROPS

SKIP TO YOUR FAVORITE PART!

2m35s Introduction to Freight Farms

5m47s Steve’s Freight Farms Discovery

10m09s Business Planning

15m16s Finding Customers

22m10s Crops, Yields & Pricing

26m34s Marketing

28m49s Site & Operations

40m08s Community & Farming Lifestyle

47m11s Live Q&A

INTERVIEW WITH STEVE HUNTLEY

After 18 years in a successful career, Steve decided it was time to pursue something new. His new career? Hydroponic farmer!

Our 1 hour live webinar with Steve talked all about how he discovered his passion for farming, how he finds customers, and what he grows. Don’t have time for the full recording?

Check out our complete summary (under 10 minute read!).

Update On Glyphosate And Organic Certification

The debate on the failing integrity of the National Organic Program has become international, as heard on last night's program on BBC World. Click here to hear Dave Chapman, farmers from Holland and India, and General Mills discuss the controversies in organic

The debate on the failing integrity of the National Organic Program has become international, as heard on last night's program on BBC World. Click here to hear Dave Chapman, farmers from Holland and India, and General Mills discuss the controversies in organic.

I was honored to be a part of this show. It is clear that we are ALL affected by the failures of the USDA organic program, from California to Singapore.

A certified hydroponic organic blueberry "farm."

In my last letter, I quoted NOP director Jenny Tucker as saying that there is no transition period for hydroponics. After reading my letter, some withheld judgment until the Seattle meeting of the National Organic Standards Board. Jenny promised she would address the issue of hydroponics and glyphosate at that meeting. No transition period means that a hydroponic producer could use ANY chemical on their land or greenhouse that is allowed in conventional agriculture. They could do this the week before bringing in new substrate and still qualify for immediate organic certification.

A Driscoll's certified organic blueberry "farm" of coco coir pots.

Substrate is the fancy word for the growing medium in the pot. Hydroponic producers choose materials to grow in like shredded coconut husks (called coir) because they don’t rot. They also don’t provide any nutrition to the plants. The coir holds the roots and the water. All the nutrition is provided as a near-constant liquid feed in the irrigation water. Hydroponics can happen in a container on the ground or on a table. For some crops, it even happens without any container at all. At its most extreme form, called aeroponics, the roots are suspended in the air and sprayed with the nutrient solution. There is no nutritional difference between spraying the roots in the air or watering them in a container of coir or a bucket of water. The difference is in the time the plant can survive if the electricity goes off. With an “aeroponic” system, it is a matter of minutes. With a container system, it is a matter of hours. It is the same nutrition.

Jenny’s comment created quite a stir as the implications became clear. In the new USDA interpretation, “certified organic” no longer defines how the land is farmed. It now only defines how a pot of coco coir is “farmed.”

How twisted will the USDA "new organic" standards become? Will they look something like the political machinations we see in this district map of Maryland?

The new USDA definition of organic is becoming a form of gerrymandering. Gerrymandering is the process by which a group of political officials manipulates the drawing of an election map in a way that benefits them. The result is a complex, illogical map that makes sense only to those who will profit. This principle is applied to many areas of government. When the allowable levels of glyphosate were being crossed in conventional farm products, the EPA simply increased the “safe” level. In the case of "organic" hydroponics, we are ending up with a convoluted set of regulations that look like the latest Congressional district designed to keep one party in power.

Or we are left with no regulations at all, with every certifier making up their own? That is the case until the USDA answers our questions.

Wasn't preventing such a "Wild West" scenario the justification for the NOP in the first place?

Real organic blueberry production. Soil-grown blueberries must be free of prohibited substances for 3 years before being eligible for organic certification. This is referred to as a "3 year transition period."

The reason for this is because hydroponics CAN’T fit into the real meaning of organic. Organic farming is based on the principle of stewarding the life in the soil in order to provide superior nutrition for plants, animals, and humans. I would now add climate to that list of benefits. It is, in fact, the opposite way of farming from “conventional.” This foundation of soil stewardship is well understood in the rest of the world, as clearly defined by IFOAM (The International Federation of Organic Agriculture Movements). The United Arab Emirates has just joined the rest of the world in prohibiting hydroponic from being certified as organic. It is also well understood in our own law, the Organic Food Production Act. And yet, the USDA continues to be the rogue nation embracing hydroponic as organic.

Hydroponic is the opposite way of farming from organic. Being a hydroponic organic producer is like being an illiterate book critic. They just don’t fit together.

Jenny Tucker speaking this winter at an event on organic integrity.

So people came to Seattle ready for answers. They got none. Jenny Tucker has given the seemingly contradictory statements that glyphosate would never be tolerated in organic AND that there was no transition time for hydroponics, thus allowing glyphosate (and hundreds of other pesticides) to be used immediately before certification. And there are no standards prohibiting hydro producers from going out of certification for a week during the crop changeover so they can spray whatever they want, and then being immediately recertified when they bring in new pots.

Laura Batcha of the OTA and Dave after speaking together on a panel in Washington this Spring. We often agree to disagree. Photo courtesy of Charles E. DeBourbon/The Hagstrom Report.

The Organic Trade Association (OTA) delivered a letter to the USDA signed by members, including the leading USDA organic hydroponic producers. It demanded that USDA make clear that glyphosate is not permitted in organic certification. Which of course, it is not. Dr. Tucker was happy to make that clear. The letter briefly mentions the question of whether glyphosate is allowed the week before organic certification. Which it is, in the absence of applying the three year transition period to hydroponic and container operations. Yet the three year transition period is a cornerstone of the Organic Foods Production Act.

Just to be clear, the OTA continues to strongly support certification for its hydroponic members such as Driscoll's and Wholesum Harvest. Although OTA has publicly opposed certifying “hydroponics,” their definition of hydroponics is a perfect example of “rebranding.” In the strange world of OTA, hydroponics is limited to plants growing with their roots in water or in the air. Clearly, this is not what the rest of the world means by that word. No wonder they are so confused. In their private world, “Hydroponic is what we say it is. Organic is what we say it is.”

CCOF President Phil LaRocca at the 2017 Jacksonville NOSB meeting.

Phil LaRocca, President of CCOF, testified in Seattle, where he clearly expressed his genuine outrage that this “no transition period” was being allowed. He said that he had been told by CCOF’s Executive Director that, indeed, no transition time was being required by some certifiers for hydroponics. As the largest certifier in the world, CCOF (California Certified Organic Farmers) would know. Phil asked that Jenny clarify the USDA National Organic Program position.

She would not.

Over and over people, including members of the National Organic Standards Board, pressed Dr. Tucker to respond and clarify the NOP position. Over and over Jenny responded that she would not respond to a question about “hypotheticals.”

It seems to me that when the NOSB and the President of CCOF ask what the USDA policy is on organic transition time, it is not a hypothetical.

I have wondered why Jenny refused to set the record straight and answer a simple question about policy? She did say that she misspoke in answering my question, but she would not disavow her statement! All she had to do was say, “I was wrong. A three year transition period is required for ALL organic production, and always has been.”

That answer would then lead to the decertification of those certified with no transition time. Probably that would lead to lawsuits. But if the USDA continues to allow this, that will also probably lead to lawsuits. It looks to me like the USDA is going to get sued (again), one way or the other.

The final testimony at the meeting came from Lee Frankel, the lobbyist for the misnamed Coalition For Sustainable Organics. They should be called the Coalition For Hydroponic Organics. They just don’t want you to know that. The desire to keep us in the dark seems to be the hallmark of the “hydroponic organic” producers. Lee asked what the logic was of requiring a three-year transition for hydroponics? It is interesting to note that Wholesum Harvest, the leader of the Coalition, is calling on the NOP to enforce a three-year transition in the OTA letter. On the same day, the Executive Director of the Coalition is questioning whether a three-year transition makes any sense.

Is there a logic in requiring a three year transition period for a pot of coco coir? The problem with this whole circus is that it doesn't make any sense certifying hydroponic as organic in the first place. Organic and hydro are opposite systems of growing. Let the hydro producers make their own label. Let them proudly offer their products to consumers.

But that transparency isn’t going to happen, is it? The large hydro growers run from honesty with their customers. The whole reason they want the organic label is to avoid being transparent.

Real Organic dairy at Radiance Dairy in Iowa.

People have said that real organic farmers are afraid of honest competition. I say bring it on. But let’s make sure it is HONEST. Let every hydroponic tomato and berry have an image above of plants growing in buckets of coco coir sitting on black plastic. Let every CAFO (concentrated animal feeding operation) produced container of milk or eggs have a picture of animals in confinement on the front. And real organic farmers will put pictures of our reality on our products, of plants growing in soil and animals eating fresh grass. Then we will see who wins the support of the customers.

Aurora Dairy in Colorado which, according to the Washington Post, is fake organic. For their investigation, the only cows found on pasture were "dry cows," not producing milk. Which milk would you buy? Photo courtesy of Washington Post.

Of course, this would be no contest. The HYDROs and CAFOs would go out of business. The farmers growing real organic would be unable to keep up with market demand. The stores would be falling over themselves to buy locally from real organic farmers. Real organic farmers would multiply.

The whole reason that we shouldn’t allow hydroponics to take over American organic vegetable production is that we want to be honest. We want to protect the customers from fraud. We want to protect the farms and farmers. We want to protect the land.

So I invite all in the organic community to come together.

If you are a consumer, demand that local real organic products are on the shelves of your grocery store.

If you are a member of CCOF, demand that your organization stops certifying hydroponics. Throw out CAFOs while you are at it.

If you are a member of OTA, demand that your organization publicly calls for an end to ALL hydroponic certification, including hydroponic containers. Throw out CAFOs while you are at it.

When that day comes, perhaps we can take back the organic seal in America. Oh, and we will need to elect a new President as well. I never said this was going to be easy.

In the meantime, please support the Real Organic Project.

Robot Farming Startup Iron Ox Sells First Produce In California

Robot farming startup Iron Ox has announced that it’s selling robot-reared leafy greens in a single location in California. The firm, which launched last October, is offering three varieties of greens at the San Carlos branch of Bianchini’s Market, a family-owned grocery store that specializes in local and organic produce.

Iron Ox is one of a number of companies trying to automate the human-intensive work of agriculture. It uses a combination of robotic picking arms, hydroponic vats, and self-driving porters to grow vegetables. But despite its repeated claims that its farming is “autonomous,” humans are still needed for a lot of the work. Laborers plant seedlings and package plants when they’re ready to eat: robots just tend them while they’re growing.

One benefit is that robot farms can be located nearer to customers because of their smaller physical footprint. Iron Ox says the greens it’s producing for Bianchini’s travel just 0.6 miles to get there, which is half the distance traveled by a typical head of lettuce. This means lower transportation costs and fewer food miles, a big factor when it comes to the environmental impact of what you put on your plate.

But the scale of Iron Ox’s operation is limited. It’s selling just three varieties of leafy greens and delivering them to Bianchini’s just once a week. The prices aren’t exorbitant, but they are on the expensive side. A two-ounce box of red-veined sorrel will go for $2.49, a two-ounce box of Genevieve basil will cost $2.99, and four heads of baby lettuce will be $4.99.

Source: www.theverge.com

Publication date: 5/3/2019