Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

VIDEO: Investing 20 Minutes Per Week To Grow 200 Plants

In this video the founders of Caulys explain how the fully automated, modular greenhouses only need up to 20 minutes of maintenance per week to grow up to 200 plants, ranging from aromatics, microgreens, edible flowers to small fruits and vegetables

Students at the EPFL University of Lausanne can reap the harvest of the start-up of - amongst others - Tom and Grégoire.

At the campus, they were able to install the prototypes of their smart indoor greenhouses Caulys. In this video the founders of Caulys explain how the fully automated, modular greenhouses only need up to 20 minutes of maintenance per week to grow up to 200 plants, ranging from aromatics, microgreens, edible flowers to small fruits and vegetables.

In your living room, your cafeteria, next to the coffee machine or in your restaurant: the Caulys Farm is your urban greenhouse. It enables you to access quality products, wherever you are, without GMO, pesticides, from seeds selected for their flavor and nutritional value. Grow fruits, vegetables, greens or edible flowers right in front of your eyes.

The Caulys Farm is modular, and answers to your needs.

It also respects the planet and reduces the ecological footprint of your food, requiring less packaging, transportation, using up to 95% less water compared with traditional agriculture. It allows you to eat fresh and local products, all year long.

Your greenhouse is autonomous and optimally manages its light, irrigation and nutrients delivery. Temperature, humidity and air quality are adjusted in real time to provide the best growing conditions for your production.

Heliponix Capturing Innovation And Hearts In Indiana's Great Southwest

Heliponix is an Agriculture Technology company that sells the GroPod to consumers. The GroPod is a revolutionary smart appliance that grows fresh produce in your home any time of year with an organic seed-pod subscription without any preservatives or pesticides

See The First GroPod One In-Person At The Purdue University Graduate Student Plant Science Symposium on August 1 At The Beck Agricultural Center.

Heliponix is an Agriculture Technology company that sells the GroPod to consumers. The GroPod is a revolutionary smart appliance that grows fresh produce in your home any time of year with an organic seed-pod subscription without any preservatives or pesticides.

The business model is similar to the keurig k-cup model, but is also a practical solution to counter the environmental damage wreaked by conventional soil agriculture since it uses hydroponics which grows produce faster with 95% less water. This is important because the human population will reach 9.8 Billion in the year 2050 which will increase food demand by 70%. This will likely not be met with current agriculture practices in the US accounting for almost 80% of all freshwater consumption and 50% of land use.

Heliponix was co-founded by Southern Indiana natives, Scott Massey and Ivan Ball. Although they did not know each other before completing their respective engineering degrees at Purdue University, they met each other as co-working on a NASA funded research study at Purdue.

There, there research energy efficent LED lighting spectrum optimization to reduce the energy consumption of the hydroponic growing systems on the International Space Station. As undergraduate students, they had the idea to create an IoT (internet of things) appliance that would automate the complex process of hydroponics so every-day consumers would have the ability to grow their own produce at home. They then competed in business plan competitions at various universities and research institutions to raise several hundred thousand dollars in funding to commercialize their proprietary technology. Purdue University was among their first investors through their venture division focused on innovations within the agricultural and biological engineering domain.

Heliponix won first place in the Evansville Regional Pitch Competition after debuting considerable traction bringing the GroPod to market as well as the their first production model from their manufacturing facility that will have the capability to produce several thousand GroPods.

Scott Massey said: “We considered many other cities when deciding where to locate a high-tech appliance company such as Heliponix. Fortunately, the Ohio River Valley is fertile in engineering talent and manufacturing plants to produce our exact product. We will continue creating high-paying jobs as we define an entirely new frontier for agriculture. In the not so distant future, the majority of culinary herbs, microgreens, and leafy green vegetables will be grown indoors as consumers favor the flavor, health, and food safety benefits of fresher food. That’s why we are excited to advance to the state finals since our company truly has so much growth potential for our region.”

Automated Containers Make Organic Urban Farming Feasible

Commercial containers such as those from Seedo would expand the potential for urban farming to anywhere, anytime. Plants can be cultivated 24/7, regardless of location

The future of agriculture can be found in commercial containers, in which plants can be grown hydroponically.

Hydroponic farming has many benefits, including saving the resources involved in soil cultivation and avoiding the uncertainty of weather conditions, according to Seedo, an innovator in the field of commercial growth containers.

Approximately 40 percent of the costs of produce in large city supermarkets are used to cover logistics and shipping. Commercial containers such as those from Seedo would expand the potential for urban farming to anywhere, anytime. Plants can be cultivated 24/7, regardless of location.

For example, the automated urban farm is ideally suited to the growing market for medical cannabis and medical cannabis products. Seedo is the technology behind the world's first automated medical cannabis farm, which will yield significantly more plants than traditional controlled greenhouses.

Another opportunity for the Seedo technology is to improve the agriculture of at-risk countries, where global warming and other concerns threaten consistent farming and food production.

In some areas, farmers can use Seedo equipment and technology for growing not only medicinal herbs, but also greens such as lettuce, kale, and wheatgrass; herbs such as parsley, dill, and basil; and vegetables such as cherry tomatoes and bell peppers, and even strawberries. In the home, individuals can set up a small unit that grows plants easily and effectively without intervention.

Seedo, a pioneer in agriculture and technology with 20 years of experience, is now delivering indoor growth systems to homes and businesses across the country. Currently, Seedo has sold more than 3,000 home units through pre-orders.

The Seedo products use artificial intelligence software to control and monitor plant development from the moment the seed is planted. The software tracks each plant's development, and responds by taking action to optimize growth. The hermetically sealed systems are designed to yield consistent results regardless of the local climate.

Growers need only to plant seeds or seedlings and monitor the growth process via the Seedo app.

Other features of the Seedo system include a unique lighting system that self-adjusts based on an individual plant's stage of growth, and a smell-proof cover with built-in CO2 cartridges to prevent smell leaks.

Equally important to note is that all produce cultivated with Seedo's technology (both home and commercial) is pesticide-free, of high quality, and has a significantly extended shelf life.

Visit seedo.com for more information about investing in the growth industry of indoor gardening, and to learn more about the Seedo technology and products.

Seedo is a publicly traded company with the ticker symbol OTCQB:SEDO.

Verdeat Is Launching A Kickstarter For Its Hydroponic Garden System For The Home

Poznań, Poland-based company Verdeat announced this week it will launch a Kickstarter campaign in July for its modular vertical farm meant to fit inside apartments, offices, and other non-commercial spaces.

June 26, 2019

Image via Verdeat.

Poznań, Poland-based company Verdeat announced this week it will launch a Kickstarter campaign in July for its modular vertical farm meant to fit inside apartments, offices, and other non-commercial spaces.

Like other indoor hydroponic grow systems, Verdeat is able to cultivate most plants without the use of soil, though unlike a lot of systems, the 35 cm cylindrical device will still accommodate soil in certain configurations. The modular trays that come with the device can be switched out based on what you’re trying to grow, whether seeds and sprouts, which get planted in a substrate (like coconut fiber), or a potted basil plant you nabbed at the grocery store.

The entire system is controlled by a smartphone app that takes the majority of the guesswork out of the growing process, from knowing how much water to give each type of plant to how to adjust the LEDs to produce the right amount of sun-like light. The user simply fills the grow tray, adds some nutrients, and starts the app, which, according to an email from Verdeat, can run the farm more or less autonomously, only requiring the user to add nutrients every one to three weeks depending on the plants. The company also claims that plants in the Verdeat system grow faster and ripen 40 percent sooner than traditionally grown herbs and vegetables. At the moment, Verdeat’s system can grow the usual selection of herbs and leafy greens found in most vertical farms, as well as strawberries, peppers, blueberries, and other fruits.

Once the Kickstarter campaign launches, backers will be able to choose from a small, medium, or large device, depending on their individual space requirements. Remember earlier this year when The Spoon looked at vertical farms that would fit into closet-sized apartments? Verdeat definitely fits that criteria. It’s also reminiscent of the self-watering, hydroponic farm-in-a-pillar Zooey Deschanel is currently selling via her startup Lettuce Grow, and of Seedo, whose self-contained, airtight farm looks like a mini fridge.

In fact, with the vertical farming market expected to be worth $9.96 billion by 2025, we’ll see many more of these at-home versions of the vertical farm surfacing alongside more industrial-sized, hyper-automated counterparts.

How Verdeat fares amid all this competition will depend largely on some factors the company hasn’t yet released, including the cost of each device unit, how widely available it will be (it’s manufactured in the EU), and how long backers will have to wait before they can actually get their hands on the device and start growing. If they get their hands on it: As we’ve seen with other crowdfunded hardware projects, there is always the possibility that the product might not make it to market as promised. But perhaps manufacturing right there in the EU, will make it easier for Verdeat to keep tabs on the process and avoid those pitfalls.

The Kickstarter campaign will launch at the very beginning of July.

Singapore: High-Rise Building Features Vertical Sky Allotment Gardens

CapitaLand unveiled the design of One Pearl Bank perched atop the verdant Pearl’s Hill. The development comprises two gently curving 39-storey towers linked at the roof by sky bridges. Towering at 178 metres, One Pearl Bank will be the tallest residential development in the Outram-Chinatown district in Central Singapore.

One Pearl Bank will feature a series of sky allotment gardens arrayed vertically at one edge of each tower. With each tower featuring an allotment garden every four storeys and each garden housing 11 plots, One Pearl Bank will have a total of 18 sky allotment gardens with close to 200 plots where residents can grow their own herbs, fruits and vegetables. The allotment gardens not only support urban farming, they offer spaces to promote community bonding.

Mr Ronald Tay, CEO of CapitaLand Singapore, Malaysia and Indonesia, said: “As the one and only development atop Pearl’s Hill, One Pearl Bank offers residents an exclusive opportunity for city living amidst a lush garden setting. Given its unparalleled location, we wanted a design scheme that contributes meaningfully to Singapore’s cityscape and enhances its surroundings.

These include incorporating abundant greenery at different elevations and adding a landscaped path linking One Pearl Bank to the adjacent Pearl’s Hill City Park – a beautiful but hitherto largely underutilised public park. Residents can look forward to the rejuvenation of the City Park, which will be transformed into a playground and social space for the community and linked to Fort Canning Park through the scenic Singapore River, as part of the Urban Redevelopment Authority’s Draft Master Plan 2019.”

For more information:

www.capitaland.com

www.onepearlbank.com.sg

Publication date: 5/20/2019

Hydroponic Farming Systems: Try Before You Buy

NexTech AR Solutions has signed a deal with Just Vertical, a hydroponic farming technology company, to provide augmented reality solutions to enhance the online shopping experience. Just Vertical will utilize NexTech’s ARitize eCommerce platform to create true 3D AR models of its AEVA hydroponic farming system, enabling consumers to ‘place’ it in their home before purchase to assure correct sizing and aesthetic appeal.

“Traditional agriculture is in dire need of disruption, as the current solutions on the market are not cutting it for consumers. We believe we’re on the path to changing that – our AEVA system has already helped to save more than two million liters of water, grown more than 10,000 pounds of fresh local food, and eliminated more than 100 million miles of food transport,” said Kevin Jakiela, co-founder of Just Vertical. “We chose NexTech to ARitize our AEVA system because we know it will provide a better level of education for our product and empower the consumer’s path to purchase as they shop on our website. We’re excited to provide our consumers an AR shopping experience like no other in the agricultural industry.”

Just Vertical’s customers will be able to view the AEVA farming system in high fidelity 3D, with full 360-degree rotation, as if they were walking directly around the item themselves.

“For retailers selling larger-sized items, like Just Vertical’s AEVA farming system, utilizing AR technologies to showcase the product online provides an edge that can push consumers toward purchase. Many are hesitant to purchase a large item online without seeing it first in their living space. Our ARitize eCommerce platform enables them to do just that,” said Evan Gappelberg, CEO of NexTech.

For more information:

www.nextechar.com

www.justvertical.com

Publication date: 5/6/2019

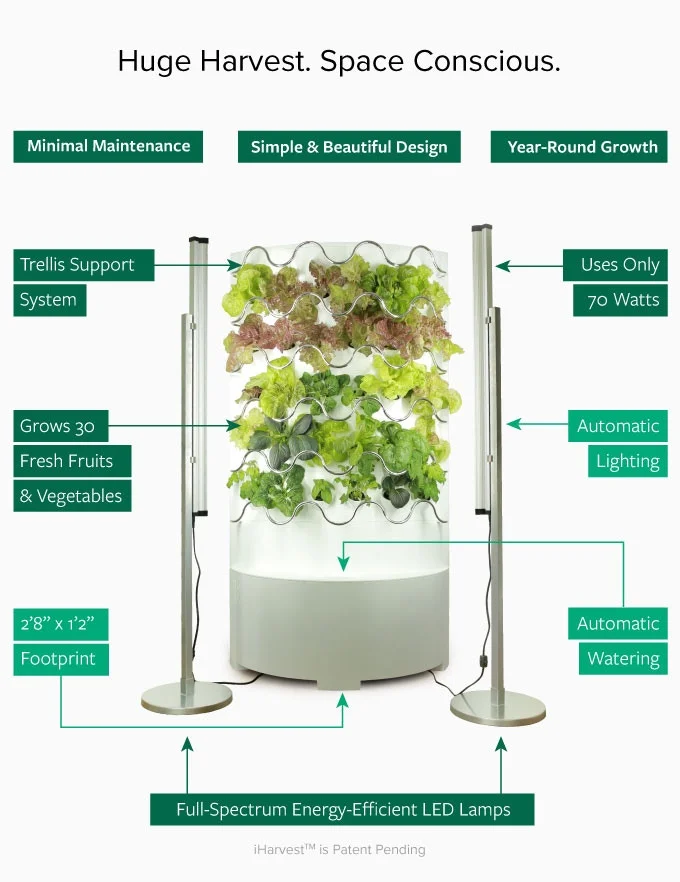

Indoor Garden Works’ (IGWorks™) iHarvest Kickstarter Introduces A Beautiful, Soilless Indoor Garden For Growing Big Fruits And Vegetables At Home

IGWorks™ announces the April 16th launch of their Kickstarter campaign for the patent pending iHarvest™: a beautiful hydroponic system that will reinvent vegetable gardening

April 14, 2019 | San Clemente, California

IGWorks™ announces the April 16th launch of their Kickstarter campaign for the patent pending iHarvest™: a beautiful hydroponic system that will reinvent vegetable gardening.

“All the existing systems were either too small to grow real food or too ugly to enjoy with your family and friends,” shared founder and CEO Dave Stevens. The solution was a hydroponic, automated and fully self-contained system that simultaneously grows up to 30 fruits and vegetables, all within 2.5 sq. feet of floor space.

The iHarvest™ makes it easy for the indoor home gardener to grow a wide variety of fruits and vegetables, including cucumbers, strawberries, beans and more, while saving up to $1,000 a year on groceries.

The Perfect Garden for Small Spaces

Smaller indoor and outdoor spaces, limited time, harsh seasons and unpredictable climates can make it increasingly challenging to grow healthy produce at home. “We knew that the answer lied in hydroponics; however, the existing systems were either unattractive, cumbersome, costly or challenging to use,“ said Stevens. “I wanted an attractive, indoor garden that could easily fit into the smallest apartment, while also providing enough produce to help feed a family year-round.”

Realizing that there was nothing on the market that met his needs, Stevens enlisted a team of individuals, including engineers and business advisors, to bring iHarvest™ and IGWorks™ to life. The result was an eye-catching self-contained growing wall that enhances spaces with a burst of greenery and light.

Experience how iHarvest™ will reinvent indoor gardening:

Faster Growing Time – Harvest your produce 30-50% faster than traditional vegetable gardens

Fresh, Healthy Produce –Grow your food precisely the way that you want it including zero pesticides, zero herbicides, and without GMO’s.

Automated LED Lights – High-efficiency, visually pleasing, full spectrum LED lights allow the user to predetermine when the sun rises and sets while using the same amount of energy (72W) of a standard lightbulb.

95% Less Water – Requires 20 X less water than traditional growing methods

Vertical Design – Fits in the smallest of spaces, while the included trellis easily accommodates hanging vegetation.

Easily Assembled - Simply add seeds to the medium, place into the pod, add water and grow.

Early Kickstarter supporters will receive the iHarvest™ for a substantially reduced price, $449 versus the projected retail price of $850, a 47% savings. “This innovative system will reinvent the way that consumers look at indoor gardening, making it easy to grow fresh produce in every home,” said Stevens. “By supporting iHarvest™ on Kickstarter, supporters can help bring the future of gardening to market.”

Visit the iHarvest™ pre-release Kickstarter page, learn more about what inspired the product, and see how iHarvest™ will transform the way that we look at indoor produce gardening.

A Beginner’s Guide To Help You Grow Plants Indoors

In the last 5 to 10 years, a number of exciting technologies have come forward that may change the way people garden forever

Do you ever feel like your garden just won’t grow right, no matter how many nutrients, pesticides, or hours of care you throw at it?

If you answered yes, you are not alone! Growing up, many of us have seen our parents or teachers work magic with plants in their garden, dealing with cold weather, frost, bugs, animal invasions, and other tedious garden tasks. Many of us are left wondering how dealing with the elements and bugs can be worth it for anyone!

In the last 5 to 10 years, a number of exciting technologies have come forward that may change the way people garden forever. No longer do gardeners have to brave the elements and deal with cold winters where nothing grows. Indoor gardening has gained global attention, and there are countless innovators working on indoor growing solutions for the home and office.

Here are a few of these technologies. We hope these tips can empower you grow more food for more of the year!

LEDs

Horticultural LEDs have revolutionized indoor gardening in more ways than any other technology could. With access to controlled indoor light that isn’t too expensive to run, anyone can turn their soil or hydro container farm into an indoor set up, eliminating the need for sunlight and the risk of climate damage to crops. With the right LEDs giving your crops light, you can also expect way higher yields and fuller growth from your plants!

Hydroponics

This is the most popular of the indoor growing methods today. Hydroponics is the process of growing plants using no soil, suspending them in or over a nutrient rich solution for food and often using LEDs or artificial lighting to induce day/night cycles for plants and allow them the energy to photosynthesize. There are many kinds of hydroponic system designs and configuration, all of which carry out different approaches for different plants and outcomes.

Aquaponics

Similar to hydroponics, this growing method allows the user to grow plants without soil. Using slightly different irrigation and feeding methods, aquaponics takes fish waste from a fish tank and circulates it into the hydroponic root system, giving plants truly organic natural food. The plant roots then soak up the waste and clean the water, which can then be circulated back to the fish and the cycle repeats. This technology most closely mimics a natural energy cycle, and also has the added benefit of producing more than just plants, but seafood in your home too!

Container Gardening

Container gardens can be either indoor or outdoor, and are the lowest tech and oldest indoor gardening solution. Using a container with a water catching tray underneath, anyone can move their plants indoors, eliminating many of the pest and climate issues commonly associated with container gardening outdoors. Besides being the lowest cost indoor gardening solution, container gardens are a great way to transition from soil gardening outdoors to soilless gardening indoors using something like a hydroponic system. Whether using LEDs or natural light from a window, container gardening will keep you growing right through the winter months with a little less work and risk.

Smart Gardening

The newest of these options, smart gardening utilizes a plug and play growing appliance or device which controls lighting, feeding, watering, and monitoring your plants for you. This is the most effortless and failure free gardening option for homeowners anywhere. Whether you have a colder climate, a busy job, or a full social life, having a smart garden guarantees you the space and time to grow a garden without the hassle, time commitment, or pesticides. Smart gardens often utilize full climate control systems to guarantee your plants an optimal environment, and produce much less waste, toxins, and runoff than any other indoor gardening solution. Smart gardens come in all shapes and sizes, growing everything from herbs and greens to tomatoes and cannabis! If you are looking to up your gardening game for good, you can’t do better than a Smart Garden!

Many people we meet and talk to at Aeroasis agree on a few key things:

First, gardening is an incredibly rewarding experience, minus one or two very tedious and time consuming tasks. Second, limitations like seasonality make it hard to keep their garden up year after year, and this affects people’s willingness to garden over time. Third, everyone is looking for a better way to grow, spending more time and money on their plants directly and less on tertiary tasks like weeding, spraying, and watering their crops. With the option to garden inside, all of the more tedious aspects of growing become significantly less limiting, and seasonal plants are a thing of the past!

We at Aeroasis hope to keep empowering more people to grow their food indoors, and to spread the joy of controlled environment agriculture globally!

LEARN MORE ABOUT OASIS

Lettuce Grow’s Subscription Service Promises to Make Texas Gardening Much Simpler

Actress Zooey Deschanel at the Lettuce Grow launch party. Photo by: Julia Keim.

BY PAULA FORBES

March 13, 2019

Growing plants in Texas involves a steep learning curve. Even if you grew up seeding and weeding at the side of a knowledgable green thumb, there’s a lot of collective wisdom to internalize before you’re harvesting your own vegetables. Our warmer winters mean an entirely different planting schedule than is suggested on the backs of seed packets. Scorching hot summers require vigilant water management. Plus, the bugs more than live up to that old cliche that everything is bigger in our state.

Lettuce Grow, a startup from Emmy- and Grammy-nominated actor and singer Zooey Deschanel (known for New Girl, 500 Days of Summer, and the musical duo She & Him) and her husband, entrepreneur Jacob Pechenik, is an attempt to make that curve a little less steep. On March 10, 2019, at the South Congress Hotel, they hosted a launch party for the Austin-based company, which will begin shipping to its first subscribers soon.

The couple, who have two young children, split their time between Austin and Los Angeles and are familiar with the peculiar challenges of growing veggies here. “In a place like Texas, you have these [weather] extremes,” Pechenik says. With their backyard hydroponic system and accompanying subscription service, he claims, they want to enable people to “grow twenty percent of their food.” It’s an ambitious goal, but Lettuce Grow automates many aspects of gardening, effectively giving its customers a shortcut to homegrown produce. “You might not have a green thumb,” Deschanel says. “We want to do all the extra work that might stop people from growing a garden at their house.”

Here’s how it works: When you sign up, Lettuce Grow ships you one of their “farms.” Made from ocean-bound plastic (plastic that wouldn’t have been recycled otherwise), the farms are vertical hydroponic gardening systems. Hydroponics is a method of growing plants without soil. You set the grower in a sunlit area, fill it with nutrient-enriched water, plug it in, and then add the seedlings that Lettuce Grow ships you monthly. That’s it, more or less.

Deschanel and Pechenik in front of two of Lettuce Grow’s “farms” at the launch party on Sunday, March 10, 2019. Photo: Laura Hajar

The plant varieties have been selected to work well based on your geographic location, and the types of plants Texans can expect to receive through the subscription service will be tailored to the seasons and the weather. Lettuce Grow works with local farms to grow the seedlings. In Austin that farm is Agua Dulce, owned by Deschanel and Pechenik’s Farm Project. Varieties are tested and chosen for flavor, yield, insect resistance, climate compatibility, and more.

The goal is to get your Lettuce Grow farm to a point where it’s producing enough vegetables that you can harvest some every day. That way, says Pechenik, “you can start to build a lifestyle around eating at home, cooking at home.” The company has an accompanying app that advises when to harvest; advises when to clean, add nutrients, or add water to the Farm; and provides recipes and tips for eating your bounty. You can even send in photos of your plants if they seem to be struggling, and they’ll offer advice—or change the variety of plants in your subscription box to some better suited to your space.

All of this hand-holding comes at a price: Farms range from $399 to $469 depending on size, and the accompanying subscriptions cost between $49 and $69 monthly. But Lettuce Grow claims that, at peak season, the smallest farm produces $78 worth of produce a month—so if you stick with it, you’ll eventually save money. For those who want to garden and can afford the system, it removes plenty of hurdles to starting a garden. (Lettuce Grow also donates one farm and accompanying membership to “a school or community-based organization” for every ten subscriptions it sells.)

Pechenik discusses one of the company’s hydroponic growing systems.

Laura Hajar

“I am drinking the Kool-Aid,” says Stephanie Scherzer of Austin’s Rain Lily Farm, who has worked closely with Lettuce Grow in selecting varietals and growing seedlings. She admires the system for being accessible to children and the elderly as well as its performance. Scherzer says she’s been able to grow watermelon, eggplant, and peppers in her prototype farm and that the cooling properties of the hydroponics system extended the Texas growing season for crops like thyme, watercress, and kale. (For now, the service sends members mostly greens and herbs, but greater variety is planned.)

Deschanel says she’s enthusiastic about Lettuce Grow because “it’s really such an advantage to grow your own food.” She notes that freshly picked vegetables retain the most nutrients and that picking only as much food as you need to eat can reduce food waste. She adds that her daughter loves picking the vegetables, and the Lettuce Grow system provides a starting point to get kids involved in gardening. “It’s a great way to explore the food you’re eating and explore healthier options too.”

Lettuce Grow is taking preorders for its first round of subscriptions. Farms begin shipping in three to five weeks, and it’s available nationwide.

The House of The Future: Super-Sustainable With Room to Grow Your Food

The house and garden of the future is sustainable and produces its own food. Photo: supplied

MELISSA HEAGNEY SENIOR JOURNALIST

MAR 3, 2019

The phrase “house of the future” may, at first, provoke images of cartoon family The Jetsons with sky-high homes, flying cars and robot servants.

But according to the experts, the reality is much more sustainable and green. And it’s already here.

One display at the upcoming Melbourne International Flower and Garden Show will feature a range of sustainable builders’ ideas and products linked to the house and garden of the future.

Future homes are set to be highly sustainable, have minimal impact on the land and produce enough fresh food to feed several adults over a year, according to participant Brendan Condon.

Mr Condon is director of three sustainability companies including gardening outfit Biofilta, and part of an award-winning deep-green development The Cape at Cape Patterson in South Gippsland.

Homes can and will have minimal impact on the land around it. Photo: Supplied

“We’re showing people can harness design and breakthrough technology that is already being used on houses around the world,” Mr Condon said.

He said sustainability was a must for the future of big cities like Melbourne and Sydney, especially when it comes to living a healthy and comfortable life.

“Suburbia now needs to become the new nature,” he said.

“Cities have huge opportunities to combine rainwater or rooftop rainwater runoff, waste stream organics like composted food waste and surplus city spaces with clever urban farming systems to grow huge amounts of fresh produce.”

Mr Condon said a new gardening system would be launched at the show to demonstrate to people that they could grow food anywhere.

Biofilta recently partnered with a local coffee company to set up pop-up farms in two car spaces in Rocklea Drive, Port Melbourne.

The aim is to grow over 300 kilograms of fresh food in over a year using used coffee grounds and chaff. They have already produced 180 kilograms of food in four months.

Gardens can be grown anywhere – including rooftops and car parks. Photo: Supplied

Mr Condon said there were opportunities to turn urban areas and high-rise blocks into environments for not only food production but also other types of biodiversity.

That included setting up areas of wetlands which would encourage frogs and insects to find a home in urban areas. More plants offering shading would also help with the urban heat island effect.

As well as food production, the house and garden of the future will also use solar energy and solar batteries to produce more power than they need. This could power electric cars – even if not actual flying cars promised by The Jetsons.

Director of modular home group Ecoliv Building Ashley Beaumont agreed, saying sustainable home design was now at a point where heating and cooling appliances were minimally used.

Passive solar design – using the sun to heat and cool homes – meant power bills would be massively reduced.

Mr Condon said this could be by as much as $2500 every year where efficient, all-electric appliances were used.

“Climate-adapted, resilient, comfortable homes powered by renewable energy with super-low energy bills, coupled with productive urban farming, are definitely the future,” Mr Condon said.

The Founders of The Farm Project Announce Nationwide Launch of Lettuce Grow

Founded by Jacob Pechenik and Zooey Deschanel as an initiative of The Farm Project, Lettuce Grow is calling all front yards, backyards, patios and balconies to move fresh food production back into our communities

THE FOUNDERS OF THE FARM PROJECT ANNOUNCE NATIONWIDE LAUNCH OF LETTUCE GROW: A NEW MEMBERSHIP EXPERIENCE EMPOWERING AMERICANS TO GROW 20% OF THEIR FOOD AT HOME

Los Angeles, CA, and Austin, TX (March 13, 2019)

The Farm Project is proud to announce today the nationwide launch of Lettuce Grow, providing everyone the tools, encouragement and inspiration to grow 20% of their food at home while building an expanding community of passionate growers who connect deeply through food and sustainable living. Lettuce Grow is now available for pre-orders, with membership programs starting in April 2019.

Founded by Jacob Pechenik and Zooey Deschanel as an initiative of The Farm Project, Lettuce Grow is calling all front yards, backyards, patios and balconies to move fresh food production back into our communities. By building the world’s largest distributed farm, Lettuce Grow is on a mission to change our food system, closing the gap on food mileage and resource waste, all while re-establishing a deeper, lasting and experiential connection with the food we eat.

The company will donate one Farmstand and membership for every ten member sign-ups to a school or community-based organization via its Lettuce Give program, in order to advance fresh food access and help cultivate the next generation of sustainable farmers, chefs and consumers.

”We couldn’t be more excited to finally bring Lettuce Grow to homes across the country,” say Founders Jacob Pechenik and Zooey Deschanel. “It’s something we’re extremely passionate about – empowering people to grow a substantial portion of healthy, fresh food at home while also helping to reduce waste and create more sustainable communities. We hope to inspire people to develop a new, more healthy relationship with the food they eat.”

More and more people want to grow their own food, but the lack of space, time, dependability and expertise keeps many from making it a reality. With Lettuce Grow, members only need a power outlet and 9 square feet of sunny outdoor space – everything else required to become successful master growers is included with the membership.

Lettuce Grow Farmstands use self-watering hydroponic technology and are sustainably made from ocean plastic. They’re designed to save time and space, delivering about the same yield as 40 square feet farmed conventionally in raised beds, with only a few minutes needed for maintenance and harvesting each week.

Lettuce Grow sends members bi-weekly deliveries of living baby plants, so their Farmstands are always fully stocked. Growing plans are curated based on eating preferences and include over 75 varieties of leafy greens, vegetables, herbs and edible flowers – even watermelons! Lettuce Grow’s data-driven approach takes into account the member’s location, individual environment, weather data and seasonality to make sure members can successfully and reliably harvest meaningful quantities of fresh food at peak harvest.

Along the way, members have access to educational content and support from expert horticulturists as well as their own interactive farming dashboard, which always shows them what’s growing and what’s ready in their Farmstands. And because the goal is to help members meet their personal healthy eating goals, Lettuce Grow provides them a steady stream of exclusive recipes and how-to’s to accompany their harvests.

Lettuce Grow Farmstands start at $399, with a monthly membership at $49 per month. For more information about how to sign up for Lettuce Grow and to start growing at home, visit

lettucegrow.com. Follow Lettuce Grow on Instagram at @lettucegrow and Facebook at @LettuceGrow.

Continuously Growing Microgreens At Home

The perfect present for a food-loving tech nerd should be an innovation that can be labeled as smart, urban and sustainable. Well, the Mizzle microgreen cultivator ticks all the boxes.

The concept, which is not for sale yet, is a product of designers Gökhan Cetinkaya & Deniz Ibanoğlu and a winner of the iF Design Talent Award. The duo designed a smart aeroponic kitchen for consumers to grow microgreens at home.

The Mizzle is divided into three compartments: the first one is for germination in a dark, closed space. The seeds are placed in a tray and once ready they can be pushed to the next compartment, where the microgreens can grow under sunlight or LED light. Once the third compartment has been fully harvested, a new growing pad with seeds can be placed in the tray and can be slid into the germination cell. This way the system allows the consumer to produce microgreens continuously.

What is even more convenient is that the user can install a specially designed app to follow the growing cycles and to get notified when they have to add water.

Read this article from Designboom to get more information.

Publication date : 2/22/2019

Author: Jobke den Hertog

© HortiDaily.com

How to Have a Hydroponic Farm In A Closet-Sized Apartment

At one point vertical farming as a solution would have been an outlandish solution, but it’s a growing industry, and more than one company now offers setups that the average person can fit into their home and operate without any assistance from an agriculture expert

I’ve long wanted to grow my own produce, even if it’s just lettuce. But since I live in a third-floor walkup the size of a Macy’s fitting room (and that includes the fire escape), outdoor gardening is out of the question.

At one point vertical farming as a solution would have been an outlandish solution, but it’s a growing industry, and more than one company now offers setups that the average person can fit into their home and operate without any assistance from an agriculture expert. Armed with that encouragement, I’ve been shopping for an indoor farm that will a) fit into my tiny apartment and b) compensate for the fact that I’m such a bad gardener that I once killed a cactus.

Here’s what I found:

CityCrop

CityCrop‘s farm has automated much of the science behind plant care, so that a user just buys the device and downloads an app, drops seeds into the farm’s base, then lets the system do the rest. Via notifications to the app, the software will tell you how to adjust the temperature so it’s ideal for your crops and when to water, and will even give plant care tips based on snapshots of your plants.

The farm is also small, which means it easily fits into tiny living spaces. Predictably, leafy greens are the most common crops, though the UK-based company also says you can grow things like edible flowers and strawberries. If the point is access to fresh greens even when you’re a city dweller with no time to grow, this makes sense as a solution — though it doesn’t come cheap. CityCrop is shipping in Q1 of 2019, for £999 (about $1300 USD) excluding shipping and VAT fees. As with any product that has yet to ship, proceed with a grain of caution as there’s no guarantee as to when it’ll actually hit the market.

Ponix Systems

Ponix promises on its website that “you neither need a balcony nor water to grow your vertical farm at home.” The company’s hydroponic farm, named Herbert, is a wall-like slab with shelves mounted to it where the plants grow accompanied by overhead LEDs.

To use Herbert, you place seeds into the pods, which then fit into the shelves. Add water every one to two weeks, and fertilizer every three to four weeks. The system does the rest of the work in terms of helping you maintain healthy plants, adjust light settings, and perform other maintenance tasks. Herbert can grow up to 15 plants at a time.

Because it lives on a wall-mounted panel, Herbert definitely takes up the least amount of space of any farm on this list. Right now it’s selling for €490.00 (~$553 USD) not including shipping. From a cost-point and a space perspective, I’d say Herbert is probably most appropriate for a dressing-room-sized apartment.

SproutsIO

Smart Kitchen Summit alum SproutsIO has a smart microgarden lets you grow up about 36 servings of leafy greens in the span of one month, and on your coffee table. The actual “farm” is basically a smart device in a potted plant, and at a mere 12 inches wide, is a self-contained farm that would fit on your coffee table with no problems.

The microgarden uses a proprietary combination of wavelength-tuned LEDs, sensors (for light, temperature, etc.), and an onboard camera, and connects to your smartphone via the SproutsIO app. The base of the device, meanwhile, can includes and electronic mister, to circulate water, and can expand as plant roots get larger. And it’s dishwasher safe.

The product is expected to ship in Q3 of 2019, for $799. As of right now, SproutsIO is for U.S. orders only.

Ava Byte

Ava Byte also uses a combination of hardware, software, AI, sensors, and a smartphone app to bring intelligent gardening to your tabletop. One thing about this grow system that’s different from others is that Ava Technologies developed lights that adapt to different types of plants, rather than the standard “on/off” timer used with most systems. A time-lapse camera lets you monitor plant growth remotely, and Ava claims its plants can grow three times faster than those farmed with traditional methods.

Ava Technologies, who raised a $2.6 million seed round last year, is another SKS alumni, and you can see company Valerie Song pitch the product in this video to get a good idea of how it works. Byte is by far the cheapest on this list, at $299. Throw in an extra $99 for a year’s worth of seeds.

Opcom

Opcom’s farm is a little bit bigger but will still fit in larger houses. The five-foot GrowWall2 grows up to 80 plants at once, which means you could supply the family with fresh greens every day and still have enough to moonlight as a farmer’s market retailer if you wanted. Opcom also makes a smaller GrowFrame, which fits on a wall. Its smallest, most affordable offering is the GrowBox.

GrowBox is a tabletop, automated hydroponic system that manages its own lighting and water circulation. Each GrowBox is shipped with seeds, and the device itself is super portable, despite its 50-plant capacity. It’s $599, though Opcom sells a ton of different products, and there are even smaller, cheaper options. But if you’re looking to get familiar with vertical farming or just want better greens in your life, this is a good route to travel.

As of this writing, I’m leaning towards Ponix Systems’ Herbert as the best option for indoor farming in a tiny space, as it only requires a wall, not floor or table space. However, this is not an exhaustive list of at-home vertical farms, so if there are others that merit mention, drop ’em in the comments. And stay tuned for further adventures in urban farming.

Related

Meet Farmlab.One, The Latest Indoor Farming Experiment From Germany's Largest RetailerAugust 14, 2017In "Future of Grocery"

Why Vertical Farming Won't Grow Without More DataJanuary 3, 2019In "Data Insights"

What Bowery's Latest Funding Round Says About Indoor FarmingDecember 13, 2018In "Ag Tech"

TAGS

Jennifer (Jenn) is a writer, editor, and ghostwriter based in NYC. At The Spoon she covers agtech, sustainable food issues, and restaurant tech. She is obsessed with IKEA.

Masdar City Unveils Sustainable Smart Home Farming

Exhibition at Eco-Villa highlights Masdar’s support of the UAE’s National Food Security

Published: January 17, 2019 Staff Report

Abu Dhabi: Masdar City in Abu Dhabi has unveiled a Smart Home Farming Showcase called ‘Bustani’ at its Eco-Villa prototype to demonstrate emerging farming solutions that will help UAE residents produce their own food at home.

The exhibition, which will be open to the public throughout 2019, will demonstrate more than 15 innovative home solutions, around food production, water and waste recycling, said a press release issued on Thursday. These solutions, which Masdar sourced from local and international suppliers before being installed at the Masdar City Eco-Villa earlier this month, will be tested throughout the year.

The showcase is a collaboration between Masdar and the UAE-based agri-tech specialists Madar Farms, and is one of the outcomes of a partnership between the UAE Office for Food Security and Masdar.

The objective of the showcase is to highlight how progress in technology has allowed the emergence of solutions to increase food security at the home level, as well as raise awareness of the broader global challenges of sustainably and nutritiously feeding a growing population.

Mariam Al Muhairi, Minister of State for Food Security, officially opened the showcase in the presence of Mohammad Jameel Al Ramahi, CEO of Masdar; Yousuf Baselaib, Executive Director, Sustainable Real Estate at Masdar; and Abdul Aziz Al Mulla, CEO and Founder from Madar Farms.

Mariam commented that Smart Home Farming as showcased in Masdar City encourages self-sufficiency and reduces the burden on commercial food producers and suppliers by enabling villa-dwellers to produce food from facilities on their own premises. Smart Home Farming turns consumers into ‘prosumers’ and if initiated on a wide enough scale, could result in a new paradigm of food security for the nation, she said.

Al Ramahi, Masdar CEO, said: “Global food systems are faced with the challenge of sustainably feeding more than nine billion people by 2050. Today’s food systems are falling short of these objectives and remain both unsustainable for the environment and unable to adequately nourish a major part of the global population.” He said the smart home farming showcase demonstrates Masdar’s commitment to exploring innovative and sustainable approaches to farming.

Masdar is supporting start-up companies and entrepreneurs to develop an innovation ecosystem focused on improving food and water security for the region. One of Masdar City’s key themes for 2019 is sustainable agriculture.

Al Mulla, founder Madar Farms, said: “By showcasing innovative smart farming solutions from all over the world, we hope to raise awareness of the exciting change that is currently taking place in the ag-tech landscape.”

Launched during Abu Dhabi Sustainability Week 2017, the Eco-Villa pilot project at Masdar City incorporates various water and energy saving technologies. The 405 square-metre residential property is the first villa to achieve a 4-Pearl rating under the Estidama Pearl Building Rating System (PBRS), introduced by Abu Dhabi’s Department of Urban Planning and Municipalities.

It uses around 72 percent less energy and 35 per cent less water than a typical Abu Dhabi property of the same size, while displacing an estimated 63 tonnes of carbon dioxide annually, said the press release.

Grow Strong: African Farmers, Entrepreneurs Revamp Agriculture Norms Through Purdue Partnership

Scott Massey, a Purdue University graduate and founder of Heliponix, a company that makes an appliance that fits under a kitchen counter and grows produce year-round, is hoping to change that by bringing sustainable agriculture methods in Cameroon.

January 28, 2019

Scott Massey, founder of hydroponics startup Heliponix, discusses agricultural innovations with Togonese students as a part of his first Mandela Washington Fellowship. In 2019, Massey will workshop at Cameroonian universities, empowering students interested in agricultural innovation and entrepreneurship. (Photo provided) Download image

WEST LAFAYETTE, Ind. – Many farmers in the Republic of Cameroon usually grow just enough food to feed their families due to limited fertilizer and high-yield seeds, coupled with poor soil quality and lack of irrigation.

Scott Massey, a Purdue University graduate and founder of Heliponix, a company that makes an appliance that fits under a kitchen counter and grows produce year-round, is hoping to change that by bringing sustainable agriculture methods in Cameroon.

Massey has been selected for a second Mandela Washington Fellowship to lead educational workshops at Cameroonian universities this month. Approximately 200 million hectares of suitable land remains unfarmed across Africa, causing many observers to wonder how African nations can unlock their full agricultural potential.

The Mandela Washington Fellowship seeks to promote agricultural development through the academic and entrepreneurial empowerment of African peoples.

“African entrepreneurs have immeasurable economic opportunities to market solutions using new agricultural technologies,” Massey said. “Our overall goal is to provide these resilient people the means to their own production and permanently break the cycle of dependency on foreign aid.”

Massey has used his extensive knowledge in hydroponic systems and agricultural engineering to develop GroPod, an in-home appliance that grows produce year-round. His background also gives him the unique expertise to teach innovative and sustainable farming techniques in Cameroon.

“In these workshops, we are implementing a new vertical farming technique that utilizes an adaption of the proprietary vertical farming technology also used in GroPod,” Massey said. “Not only will we be teaching the students about these advanced technologies that they can use to start their own businesses, but we will also be building model farms that they can incorporate into their curriculums to grow clean food.”

On this trip, Massey will travel with Daliwa Joseph Bainamndi, another Mandela Washington fellow, to give Cameroonian farmers vital information on developing and incorporating innovative farming practices into their work. The pair will lead lectures on hydroponic farming, entrepreneurship, 3D printing and computer-assisted design at the University of Ngaoundéré, University of Ngoa-ékélé and the agriculture school of Institut Superieur des Sciences et Techniques de Yaounde.

In general, African farmers struggle against nonexistent agricultural infrastructure and poor farming conditions, making subsistence farming the most advantageous practice. However, Massey and Bainamndi’s work could empower Cameroonian students and farmers to expand operations sustainably and successfully through entrepreneurship and innovation.

Massey’s work aligns with Purdue's Giant Leaps celebration of the university’s global advancements made in health, space, artificial intelligence and sustainability as part of Purdue’s 150th anniversary. Those are the four themes of the yearlong celebration’s Ideas Festival, designed to showcase Purdue as an intellectual center solving real-world issues.

Massey received his first Mandela Washington Fellowship in 2018 when he traveled to Togo, Africa, to teach farmers there about the farming usages of hydroponics systems. Read more about his first trip here.

“This diplomatic humanitarian mission will fight the war against hunger on its front line and expand the addressable technology market to maximize global impact,” he said. “I look forward to the day that Africa becomes an environmentally and economically sustainable farming model.”

About Purdue Foundry

The Purdue Foundry is an entrepreneurship and commercialization accelerator in Discovery Park's Burton D. Morgan Center for Entrepreneurship whose professionals help Purdue innovators create startups. Managed by the Purdue Research Foundation, the Purdue Foundry was co-named a top recipient at the 2016 Innovation and Economic Prosperity Universities Designation and Awards Program by the Association of Public and Land-grant Universities for its work in entrepreneurship. For more information about funding and investment opportunities in startups based on a Purdue innovation, contact the Purdue Foundry at foundry@prf.org.

Writer: Kelsey Henry, 765-588-3342, kehenry@prf.org

Purdue Research Foundation Contact: Tom Coyne, 765-558-1044, tjcoyne@prf.org

Source: Scott Massey, scott@heliponix.com

Evansville, A Home For Business

Back text: “E — Scenic View of Ohio River, V — Reitz Memorial High School, A — Vandenburgh County Courthouse, N — Adm. Bldg., Evansville College, S — Evansville National Guard Armory, V — Dade Park Race Track, I — Electric Fountain, Garvin Park, L — Greyhound Bus Station, L — Lions Den, Mesker Park Zoo, E — Dress Plaza”

After graduating from Purdue University in May 2017, I continued to rent co-work space on campus in West Lafayette working for Heliponix full-time until my apartment lease ended at August 2017. At the time, I was hyper focused on the engineering design tasks at hand for Heliponix to debut a new prototype GroPod™ at the Forbes AgTech Summit. After the summit ended, I brought all of my possessions back to Evansville. It occurred to me I was once again living in Evansville only after I had moved back home. Upon moving back, I was asked to speak at Evansville’s Tech on Tap weekly entrepreneurial meetup where I was asked why I came back. I answered, “Evansville is home, and I can continue working on my company without paying myself by living with my parents.” This seemingly obvious answer spurred a new found sense of urgency that if I were to scale a technology company, than I must leave southern Indiana for greener pastures. I then began to look for every possible reason why I should move away from Evansville for the benefit of Heliponix. I identified the following four reasons why I could not headquarter Heliponix in Evansville, Indiana.

Early adopter customers for new technologies do not live in the midwest.

Tech companies need investors. Evansville did not have venture funds.

Tech companies need top tier software engineering talent. Evansville did not have individuals with this skill set on hand.

Hardware companies such as Heliponix need to manufacture overseas to be cost competitive in the marketplace.

Customers

Heliponix (formerly Hydro Grow) team picture after winning first place at the Schurz Innovation Prize at Purdue University. Left to Right: Scott Massey (CEO), Jimmy Carlson (Software Engineering Intern), Ivan Ball (CTO)

Starting a company without experience or the money needed is comparable to charging into a battle unarmed and unaware of the terrain with dangers ahead. I was acutely aware of my limitations, and spent my senior year at Purdue University delivering newspapers at night for about $9/hour, and competing in business plan competitions between classes for cash awards. Although we were very lucky to have successfully secured over $80k over the course my senior year and a little under $100k from competitions post graduation, the money was the second most valuable aspect of winning these pitch competitions. For every competition we won, at least two or three articles from local media publications would cover the story with our name on the front title. We jumped at every opportunity to showcase our prototypes at schools, STEM career fairs, and also leveraged my position as the lowly delivery boy to publish articles in the Exponent to grasp as much publicity as possible for an early stage company.

Scott Massey giving a STEAM (Science, technology, engineering, agriculture, and math) career talk about indoor agriculture to middle and high school students Our Lady of Providence School in New Albany, Indiana.

For every article and interview that was published, I received an email from random Indiana residents interested in purchasing a GroPod when it became available for purchase. I kept a running list of these potential customers, and reached out to collect a $500 pre-order deposit when we had finally landed on a GroPod design that worked reliably. We had definitively proven that a pre-revenue startup company could launch an expensive product in Indiana if they are able to achieve enough publicity to convert impressions into executed sales. Although there are many more wealthy individuals in major cities who could buy an early stage product; we did not yet have the production capabilities to meet this demand, and still had product development to refine before we would be ready for a massive user base.

Funding

Inside Indiana Business interview with Dr. K and Gerry Dick

Although we had been veryfortunate to secure some funding from business plan competitions for patents and prototype development, we had reached the ceiling of competition funding available in Indiana for an idea not yet generating revenue. My Co-Founder, Ivan Ball accepted a full-time, electrical controls engineering job offer upon graduation to pay off student loans at GPC (Grain Processing Corporation, an ethanol and grain alcohol processing plant in Washington, Indiana) after interning and co-oping as a student for several years prior. Together we worked exhausting hours for a full year to refine the GroPod design until we created a functional product able to generate revenue in Ivan’s garage.

One of many harvests from the fourth generation GroPod™. ALL RIGHTS RESERVED. HELIPONIX©

Ivan Ball at his electrical work station in an unheated garage assembling the fourth generation GroPod™. ALL RIGHTS RESERVED. HELIPONIX©

This marked a major turning point for the company after three generations of failed prototypes. When asked if we both worked on Heliponix full-time to this point, I would honestly say yes. Our individual hours spanned 50–70 hours weekly even though Ivan had a full-time day job that took 40–45 hours per week. At this time, we had spent almost all competition award winnings on patents, prototyping, travel for events, or other business expenses. We simply did not have the capital needed to cover materials to assemble the first GroPod betas. I then approached Eric Steele, my Entrepreneur in Residence with Elevate Ventures (Indiana’s state venture fund) seeking capital needed to fund inventory. Eric referred us to the ISBDC (Indiana Small Business Development Center) who advised the Vectren Foundation Grow Local loan program for small businesses. After working with Douglas Claybourn and Kim Howard, we sent an application to the Vectren Foundation board to build the first GroPods. After waiting patiently, we were approved for a loan needed to build these GroPods with very favorable terms for any company, let alone a startup with zero cash flow history. We used the loan to buy all the parts needed, and collected the remaining $1,500 left on each GroPod order with early adopters to sell out of the beta models assembled by hand. We 3D-printed all parts, wrote our own code, soldered our boards, assembled every aspect of the product Ivan and I had designed entirely by ourselves, and delivered each GroPod in person to the early adopters. There was so many GroPod parts laying around Ivan’s home, I had to deflate my air mattress to make more room, and slept on his couch for months.

Ivan Ball installing a camera on the fifth generation GroPod™. ALL RIGHTS RESERVED. HELIPONIX©

GroPod™ assemblies consuming every square foot of Ivan Ball’s home in Washington, Indiana. ALL RIGHTS RESERVED. HELIPONIX©

Ivan Ball (Left), Scott Massey (Right) with first functional GroPod. ALL RIGHTS RESERVED. HELIPONIX©

At this point Ivan quit his job at GPC, to work solely at Heliponix, and sold his house in Washington, Indiana to be fully committed to the company. Today, I am pleased to announce that the risk the Vectren Foundation took on us for funding the loan is being paid back in full plus interest. This market validation thrusted us into the long sought after post-revenue status, which did not go unnoticed by local and regional angel investors; however, this is a story for another day. Despite the undeniable fact that the largest investment funds are in major cities, very few early stage hardware companies receive those investments due to the amount of competitors who rarely manufacture products within these cities, let alone the state. It is much better to refine the product and user experience until a sizable MRR (monthly recurring revenue) is established before approaching these funds which are beginning to invest outside of their states to leverage the capital efficiency of a midwest startup.

Talent

Delivering the first GroPods was just the beginning of a long troubleshooting learning curve with paying customers… Internet connectivity with a connected, IoT (Internet of Things) device will come with many software bugs as well as faulty sensor failures when buying in low quantities from Chinese suppliers. The problems that you are both unaware of, and unable to solve are the hardest any startup will encounter. It is incredibly important to find these problems by getting your product in the hands of early adopters as soon as possible to identify and solve. The dilemma of an underfunded hardware startup company is that you will more than likely need to sell a product that doesn’t yet have all the features needed to make it “perfect” in order to stay cash flow positive. The reality is that no garage startup will be fully ready, and you will certainly find excuses to not be ready if you look for them. This is called the MVP (minimum viable product). Then something amazing happened, customers began to complain less each day as we solved problems one after another, until I began to hear feedback that their GroPods were growing more food than they could consume! This major milestone was met with interest from angel investors who provided the capital needed to hire a full-time software development lead. Unfortunately, there is not a plethora of software developers in Evansville at this time, so we needed to look for a remote employee. After interviewing several developers, Ivan and I decided to hire Bryan Lemon, a PhD computer scientist from West Virginia University living in South Carolina. Bryan’s experience with IoT device companies translated very well into solving problems, creating new features that kept customers happy, and attributed to our zero-percent churn rate. Despite never meeting Bryan in person, we were quickly able to determine his technical ability by first hiring him as an independent contractor for an agreed upon milestone. I strongly encourage that early stage technology companies consider remote software developers to save cost, expand your professional network, and reach a wider pool of candidates to only hire top talent. You do not need to go to the bay area or other major cities to find top talent, and the operational cost of your business will increase by multiples if you move to a larger city.

Manufacturing

Whirlpool Refrigeration Plant on Highway 41. Source: Courier and Press

I remember all too well the day that the Whirlpool plant in Evansville shut down for the last time, a major manufacturing hub for appliances that employed several thousand people. At a very young age, this instilled the idea that hardware manufacturing companies must leave the United States in order to find competitive manufacturing prices. That is why I took a flight to Shenzhen, China to tour contract manufacturing plants. This massive manufacturing city is often called the hardware capital of the world based upon its speed, competitive labor, and material rates. After returning and considering the cost of manufacturing overseas, I began to factor in the not-so-obvious costs of building products outside of Evansville. The language barriers requires a translator to be present, and often leads to misunderstandings that can be very costly mistakes. The logistical challenges, uncertain trade relationship, and intellectual property theft quickly amounted to a cost that far exceeded that of domestic contract manufacturers. Most startup companies fail by aimlessly pursuing random goals without strategy as capital dwindles.

I have discovered that the resources I need to prototype and manufacture are widely available within the Midwest ecosystem. We then began to look locally for contract manufacturers within the Evansville-Cincinnati-Louisville trifecta that had worked at GE and Whirlpool appliance manufacturing plants and engineering design centers. Without disclosing trade secrets, we can confirm that the midwest has manufacturing capabilities that are very competitive with international rates. In our case, we were able to source almost all parts needed in manufacturing from Indiana, Illinois, and Kentucky. In addition to Evansville and Louisville being the former appliance manufacturing capitals of the world; we have been able to find top tier talent and industry partners with relative ease. Eventually, most hardware companies manufacture overseas when they exceed 1,000–10,000 units per year, but automation is the equalizer in a world where labor can be bought for a few dollars per hour, or be subsidized by a country in the process of industrialization. Indiana is uniquely positioned to be an entrepreneurial hotbed with several investment groups, and countless angel investors in one of the top manufacturing states in total manufacturing GDP (Gross Domestic Product).

Conclusion

After speaking to countless successful and not-so-successful entrepreneurs; I believe that starting a company requires two things.

The drive to achieve your goals

The means to achieve your goals

This has led to a new revelation about Evansville; it is not a good place to start a company… it’s a great place to start a company. It is uniquely large enough to have the means to fund a startup company, but not so large that the means become unobtainable to newer companies. The cost of living combined with these resources will triple to quintuple how far your dollar will go as opposed to a startup in a major city.

I now proudly say that Heliponix is based in Evansville, and we intend to stay here for the foreseeable future. We will continue to directly and indirectly create new jobs as operations expand. This only leaves one question from me to you, “Why not stay in Evansville?”.

Indiana entrepreneurial resource map, courtesy of Drew Peyronnin.

Indiana entrepreneurial resource map, courtesy of Drew Peyronnin.

The infographic above shows just some of the many resources available for startups in Indiana that has helped Heliponix many times in the past, present, and future. Purdue Foundry, Elevate Ventures, Purdue Polytechnic Institute, Blue Sky Capital, CoWork Evansville, APPCOM/BIZCOM, SVBIG, Certificate Entrepreneurship and Innovation — Purdue University, Burton D Morgan Business Plan Competition, Foundry@WestGate, GAGE, Agrinovus, Centric, IU IP Clinic, E is for Everyone, SouthWest Indiana Chamber of Commerce, Innovation Connector, TedxWabashCollege, Schurz Innovation Prize, Center for Entrepreneurship — PNW, Vectren Foundation, iGrow.news, and prospectively the MakerStation which conveniently holds many of these resources in one building; Innovation Pointe.

Scott Massey

Founder and CEO of Heliponix™. Purdue University, class of 2017. Mandela Washington Fellowship Alumni.

Start-Up Develops Hydroponic Garden For Your Living Room

20th November 2018, London

Home growing kit supposedly allows for crops to be grown faster, with greater yield and less water required than for a conventional garden

The Hope Eden Garden

Photo: Hope Innovations

A Canandian start-up is looking for donors so it can launch a “plug-and-play” indoor garden allowing consumers to grow their own fresh produce hydroponically at home all year round.

Designed by Hope Innovations in Edson, Canada, the Hope Eden Garden uses a simple hydroponics system and aims to make growing convenient, affordable and environmentally friendly for home gardeners.

The company, which is trying to raise CA$10,000 on Kickstarter to fund the project, claims that compared to conventional gardening methods, the system allows for crops to be grown 40 percent faster, with three times the yield and 20 times less water required.

Users place seeds in a ‘growth cup’, add water and nutrients, plug in the lighting strips provided (or rely on natural light), and watch their plants grow.

Hydoponic production (growing directly in water) uses less space than a conventional garden and is up to 40 per cent more efficient than growing in soil, according to the company, which claims the growing kit will pay for itself in less than a year through the money saved on buying groceries.

The company is also keen to stress the flexibility of its product, claiming that it works with any kind of nutrient and any type of seed.

According to Hope, a range of fresh produce grows faster than would be possible in a conventional garden, including kale, spinach, tomato, lettuce and basil.

Click & Grow Raises USD 11M And Gets Strategic Investors Ingka Group and SEB Alliance On Board

Palo Alto, November 1, 2018

Click & Grow, the leading producer of smart indoor gardens, closed its latest financing round led by Estonian-based United Angels VC alongside two strategic investors: Ingka Group, the world’s largest home furnishing retailer operating 367 IKEA stores, and SEB Alliance, the corporate venture arm of French Groupe SEB. This is the most significant round Click & Grow has raised so far. The aim of the round was to expand and accelerate Click & Grow’s worldwide presence and further popularize hyper-local gardening. Y Combinator and Yunqi VC also participated in the round.

Click & Grow’s breakthrough technology enables plants to be grown hyper-locally with zero effort, giving everyone a chance to grow fresh, GMO and pesticide-free greens at home or in any other space. Founded in 2009, Click and Grow has achieved a global presence and is now selling its third-generation smart gardens. The company’s largest market is in the US, followed by the EU and Singapore.

“Being one of the pioneers of hyperlocal gardening, we have been the drivers behind smart indoor gardens earning their rightful place among kitchen tools. Now we are working towards our next milestone to see how hyper-local farming can have a lasting impact on the sustainability of our food chain and reduce food waste. We couldn’t think of having better partners onboard to help us along the way than Ingka Group, with their commitment to a people and planet-positive future, and Groupe SEB, the world’s leader in small household equipment,” said Mattias Lepp, Founder, and CEO of Click & Grow.

The company’s strategy tackles one of the world’s major current issues, availability and affordability of the global food supply. According to the Food and Agriculture Organization of the United Nations (FAO), approximately one-third of all food produced in the world is lost or wasted, including about 45% of all fruits and vegetables. Hyper-local farming allows us to cut the supply chain to a minimum.

“This investment is part of Ingka Group’s broader commitment to support innovative companies contributing to a more sustainable and healthy food and we believe Click & Grow’s novel approach has great potential. We see this as another step forward in our journey to serve IKEA customers and our co-workers healthier and more nutritious food, and it opens up new opportunities for IKEA Retail markets to become more self-sufficient by growing fresh local produce,” explained Krister Mattsson, Head of Investments, Ingka Group

To accelerate the expansion of Click and Grow's global foothold and to strengthen the position in Europe, this July Groupe SEB (active in 150 countries with brands such as Krups, Rowenta and Tefal) became a co-branding and distributor partner of Click & Grow in the French and DACH markets.

“We see indoor gardening becoming a promising trend for home/office. We are convinced by the leading edge of Click and Grow products and technology in this domain. We strongly believe in our capacity to help the company in its future development on the base of co-branding with EMSA and leveraging our worldwide presence” said François-Xavier Meyer, Vice President SEB Alliance, Groupe SEB

About Click & Grow

Click & Grow was founded by Mattias Lepp in 2009 and has shipped its products to more than 450,000 customers around the world. Click & Grow is headquartered in Tallinn, Estonia. For more information, visit clickandgrow.com.

About the Ingka Group

Ingka Group (Ingka Holding B.V. and its controlled entities) is one of 11 different groups of companies that own and operate IKEA sales channels under franchise agreements with Inter IKEA Systems B.V. Ingka Group has three business areas: IKEA Retail, Ingka Investments and Ingka Centres. It is the world’s largest home furnishing retailer operating 367 IKEA stores in 30 markets. These IKEA stores had 838 million visits during FY18 and 2.35 billion visits to www.IKEA.com. Ingka Group operates business under the IKEA vision to create a better everyday life for many people by offering a wide range of well-designed, functional home furnishing products at prices so low that as many people as possible will be able to afford them.

About SEB Alliance

SEB Alliance is the corporate venture capital arm of Groupe SEB, the world leader in small domestic equipment. SEB Alliance prioritizes minority stake investments in innovative companies with high technological content operating in areas such as smart systems/connectivity & robotics, new forms of energy, aging population, preserving health, beauty and wellbeing, ecology and sustainable development. www.seballiance.com

About United Angels VC

United Angels VC is an early stage VC fund based in Estonia. It invests throughout the software stack and related areas. The fund and its partner’s portfolio include some of the fastest growing companies originating from Northern-Europe, such as Taxify, Monese, and Veriff. The fund’s food tech portfolio includes Click & Grow, Epic Foods, eAgronom, and FoodDocs. www.unitedangels.vc

Company Working To Bring Fresh Produce To U.Va. Dining Halls, Charlottesville Businesses And Homes

Babylon Micro-Farms has developed a system using hydroponic farming to make growing fresh produce more sustainable

By Rupa Nallamothu | 10/10/2018

In hydroponic farming, plants are grown in nutrient-rich, water solvent mineral solutions rather than in soil. Courtesy Babylon Micro-Farms

Babylon Micro-Farms, founded by University alumnus Alexander Olesen during his undergraduate years, has developed a system using hydroponic farming to make growing fresh produce sustainable for the urban consumer. The Babylon team has recently installed more apparatuses in the University dining halls, Charlottesville businesses and consumers’ homes.

Olesen developed Babylon Micro-Farms, a hydroponic farming system, to create an urban farming system easily accessible by consumers. During the spring semester of 2016, in the early stages of the company’s development, Olesen utilized several entrepreneurship resources available through the University.

“We started with the social entrepreneurship class, but then the founders went through the HackCville Alpha program, which was very helpful for them,” said Will Graham, the director of sales and marketing at Babylon. “From there, they went through the Darden iLab.”

In hydroponic farming, plants are grown in nutrient-rich, water solvent mineral solutions rather than in soil. This farming method removes environmental limitations to maximize respiration and absorption of nutrients in plants, which contribute to a greater harvest yield. Genetically modified organisms, pesticides or inorganic fertilizers cannot be used in a hydroponic culture.

Moreover, hydroponic farming can help reduce the distance between where a food item is grown and where it is sold by allowing plants to grow in normally inhospitable environments, such as inside urban buildings. This system could potentially allow restaurants and homes to grow plants inside their own spaces.

Since hydroponic systems are generally used in mass production due to their high cost, they are not readily available for urban consumers performing small-scale farming. Hydroponic systems also usually have restrictions on the types of plants that can grow in them.

However, Babylon Micro-Farms seeks to make hydroponics available for personal use and has developed technology that allows consumers to grow several different types of plants in their systems.

According to Graham, the Babylon team has several types of systems with varying degrees of technology. Some of the systems have two different reservoirs to allow different types of plants that require different types of nutrients or stratified sections of the same crop to grow on the same system.

The farming system has several versions which were developed throughout the growth of the company. Initially, the systems could not monitor the growth of the plants on each rack and were not stratified enough to grow multiple different types of produce on the same apparatus. Now, racks are divided based on the type of plant and can also be scanned into an app, which displays available information and data from the hydroponic system.

“You should able to scan a farm and tell it where you're putting plants, and it can adjust the lights and nutrients to grow something,” Graham said.

The Babylon team began testing prototypes around Grounds in 2017 after building an early model through HackCville, and received funding by winning $6,500 from the Green Initiatives Funding Tomorrow grant. After earning the GIFT grant, the company utilized the resources of Darden’s iLab, or the W.L. Lyons Brown III Innovation Laboratory — which supports the growth and development of business at an early stage by providing them resources, such as funding opportunities, legal services and faculty support.

According to Patrick Mahan, an electrical engineer at Babylon, the resources at the iLab helped the Babylon founders navigate the process of establishing a business.

After obtaining a financial basis for the project, the Babylon team installed their micro-farms in dining halls at the University. At Newcomb and O’Hill, these systems are utilized to grow produce used to prepare meals. On Sept. 12, the Babylon team installed two new systems in O’Hill and Runk.