Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

2-Acre Vertical Farm Run By AI And Robots Out-Produces 720-Acre Flat Farm

A San Fransisco start-up is changing the vertical farming industry by utilizing robots to ensure optimal product quality

Plenty is an ag-tech startup in San Francisco, co-founded by Nate Storey, that is reinventing farms and farming. Storey, who is also the company’s chief science officer, says the future of farms is vertical and indoors because that way, the food can grow anywhere in the world, year-round; and the future of farms employ robots and AI to continually improve the quality of growth for fruits, vegetables, and herbs. Plenty does all these things and uses 95% less water and 99% less land because of it.

In recent years, farmers on flat farms have been using new tools for making farming better or easier. They’re using drones and robots to improve crop maintenance, while artificial intelligence is also on the rise, with over 1,600 startups and total investments reaching tens of billions of dollars. Plenty is one of those startups. However, flat farms still use a lot of water and land, while a Plenty vertical farm can produce the same quantity of fruits and vegetables as a 720-acre flat farm, but on only 2 acres!

Storey said:

“Vertical farming exists because we want to grow the world’s capacity for fresh fruits and vegetables, and we know it’s necessary.”

Plenty’s climate-controlled indoor farm has rows of plants growing vertically, hung from the ceiling. There are sun-mimicking LED lights shining on them, robots that move them around, and artificial intelligence (AI) managing all the variables of water, temperature, and light, and continually learning and optimizing how to grow bigger, faster, better crops. These futuristic features ensure every plant grows perfectly year-round. The conditions are so good that the farm produces 400 times more food per acre than an outdoor flat farm.

Storey said:

“400X greater yield per acre of ground is not just an incremental improvement, and using almost two orders of magnitude less water is also critical in a time of increasing environmental stress and climate uncertainty. All of these are truly game-changers, but they’re not the only goals.”

Another perk of vertical farming is locally produced food. The fruits and vegetables aren’t grown 1,000 miles away or more from a city; instead, at a warehouse nearby. Meaning, many transportation miles are eliminated, which is useful for reducing millions of tons of yearly CO2 emissions and prices for consumers. Imported fruits and vegetables are more expensive, so society’s most impoverished are at an extreme nutritional disadvantage. Vertical farms could solve this problem.

Storey said:

“Supply-chain breakdowns resulting from COVID-19 and natural disruptions like this year’s California wildfires demonstrate the need for a predictable and durable supply of products can only come from vertical farming.”

(Credit: Reuters)

Plenty’s farms grow non-GMO crops and don’t use herbicides or pesticides. They recycle all water used, even capturing the evaporated water in the air. The flagship farm in San Francisco is using 100% renewable energy too.

Furthermore, all the packaging is 100% recyclable, made of recycled plastic, and specially designed to keep the food fresh longer to reduce food waste.

Storey told Forbes:

“The future will be quite remarkable. And I think the size of the global fresh fruit and vegetable industry will be multiples of what it is today.”

Plenty has already received $400 million in investment capital from SoftBank, former Google chairman Eric Schmidt, and Amazon’s Jeff Bezos. It’s also struck a deal with Albertsons stores in California to supply 430 stores with fresh produce.

Ideally, the company will branch out, opening vertical farms across the country and beyond. There can never be too many places graced by better food growing with a less environmental cost.

Here’s a TechFirst podcast about the story behind Plenty:

Published by Dani Kliegerman for iGrow.News

Most Americans Have Roundup in Their Bodies. Researchers Say One Week of Eating Organic Can Help

Organic, pesticide-free eating is an important factor in health and is something consumers should remain conscious of when shopping.

Photo courtesy of Scott Warman, Unsplash.

One week of eating organic can dramatically reduce pesticide levels in the body, according to a recent study conducted by the Health Research Institute, Commonweal Institute, and Friends of the Earth.

The group of researchers tracked the pesticide levels of four families across the United States. They took measurements after six days on a non-organic diet and again after six days on an organic diet.

The study, and a companion study published last year, found 16 different kinds of pesticides and chemicals in every participant. But after six days of organic eating, these compounds decreased an average of 60.5 percent—and some as much as 95 percent. Glyphosate, the main ingredient in Roundup and the most used pesticide in the world, dropped an average of 70 percent.

A study by agricultural economist Charles Benbrook finds that the use of glyphosate has spiked 15-fold globally since genetically modified, “Roundup Ready” crops were introduced in 1996. The percentage of Americans with traceable levels of glyphosate in their bodies rose from 12 percent in 1972 to 70 percent by 2014, according to researchers at the University of California San Diego.

Glyphosate exposure has been associated with a wide range of health problems. Researchers have flagged glyphosate as a probable carcinogen, and the chemical has been linked to kidney disease, reproductive issues, DNA damage, hormone and digestion disruptions, fatty liver disease, and more.

The recent study poses organic eating as a straightforward way to avoid glyphosate. But the authors also recognize that organic food isn’t always accessible.

To improve the availability of organic foods in the United States, the team calls for top-down policy changes—like stricter regulations on pesticide use, more federal research into the effects of pesticides, and aid for farmers as they transition to organic farming.

“Our federal pesticide policy system is broken, and we need people shouting about that,” Dr. Kendra Klein, a co-author of the study and Senior Staff Scientist at Friends of the Earth, tells Food Tank. “Companies like Bayer, Syngenta, and Dow are spending millions lobbying, and they’re also spending tens of millions of dollars to shape the narrative and perpetuate myths, like the myth that we need pesticides to feed the world.”

Klein points out that just 1 percent of U.S. federal agricultural research dollars go towards ecological farming, and pesticide regulations are few and far between. In fact, the U.S. Environmental Protection Agency (EPA) has loosened some pesticide restrictions in recent years. Between 1993 and 2008, the EPA raised the threshold for glyphosate residues on oats from 0.1 ppm to 30 ppm.

Larry Bohlen, Chief Operating Officer at HRI Labs and another co-author of the study, also emphasizes a lack of resources for farmers who want to transition to organic farming. He explains that universities and government training programs have taught farmers how to use pesticides for decades. “If they placed models of successful organic farming side-by-side with the synthetic chemical models, farmers would have choices instead of just one option,” Bohlen tells Food Tank.

Stringent pesticide regulations might seem like a lofty goal in the U.S., says Klein, but change is already underway abroad. Earlier this year, the European Union announced plans to halve the use of “high risk” pesticides by 2030 and make at least 25 percent of farmland organic.

To spur change in the U.S., Bohlen urges consumers to vote with their wallets, if they’re able. “Each person’s purchase is a small vote that, when considered collectively, sends a signal back to the grocer and the farmer about what type of food is desired. It’s your purchase that has one of the biggest effects on land, farmer, and consumer health.”

Content like this article is only possible because of Food Tank members. Please join today and get exclusive member benefits at FoodTank.com/Join.

This Modular Hydroponics System Will Give You Fresh Vegetables Year-Round

If you want to enjoy fresh home-grown produce while also adding some greenery to your home, then consider the hydroponics system made by Rise Gardens

Rise Gardens Makes Growing Food

Easy With Its simple Setup And Handy App.

December 18, 2020

Hank Adams (Rise Gardens)

If you want to enjoy fresh home-grown produce while also adding some greenery to your home, then consider the hydroponics system made by Rise Gardens. This clever system grows more than 60 types of vegetables and herbs, including beets, eggplant, peas, green beans, celery, cucumbers, different variations of peppers and tomatoes, as well as rooted plants and microgreens. These can be grown anywhere in a home, thanks to built-in LED lights.

This is the only modular system on the market, which means you can buy whatever size you want and keep adding to it if you need more room to grow food. It can be built up to three tiers high, and those tiers can be set at different heights to accommodate plants of different sizes. A smaller countertop-sized Personal Garden is available for those who don't want to take up floor space with the Family Gardens.

Each of the levels holds a lot of plants. A company representative told Treehugger, "The single unit can hold up to 36 plants, and the largest unit can hold up to 108 (compared to competitors that can only hold a maximum of 30 plants). The Personal Garden can even hold up to 12 plants on its own."

Hydroponics may be a fancy-sounding word, but Rise Gardens has made the process incredibly simple. It takes only 45 minutes to assemble your garden (which is made of coated wood, not plastic, and makes for a much nicer aesthetic in the home), then you use the WiFi-enabled function to connect to an app on your smartphone that will tell you exactly what your plants need. (This step is optional.) Plant the seed pods provided by Rise Gardens by putting them into holes in the tray, then add water and plug in the system. Eventually, you'll add liquid nutrients, as well.

Hank Adams (Rise Gardens)

Rise Gardens assures that the plants will flourish in water. Through hydroponics, plants can grow larger than in soil because "they don’t have to work as hard to obtain nutrients. The plant doesn’t require an extensive root system, allowing more growth above ground." They also grow 25-30% faster, thanks to that direct contact with nutrients, and they require less water due to reduced evaporation and runoff.

While Rise Gardens does admit that soil-grown produce is more nutritious ("There is no way to compete with the power of sunlight and good soil, it's just the best"), keep in mind that the produce you buy at a store is usually picked unripe and transported from far away, which causes it to lose nutrients anyway. It could also be sprayed with pesticides, so you are still ahead by growing your own hydroponically. Plus, it's beautiful and convenient to have these vegetables flourishing in your own home.

Hank Adams (Rise Gardens)

The app is an interesting added feature, telling you exactly what your plants need at any given moment – whether they're low on water, how far along their growth is, if you should tweak their nutrient plan, etc. It also lets you set a schedule for the lights.

Rise Gardens is worth checking out for anyone interested in gardening. It's too late now for Christmas ordering, but units will deliver in early January – a little something to brighten a long, dark winter and add a satisfying crunch to your salad plate.

Nature Fresh Farms Has Expanded Operations With A New Distribution Center in Laredo, Texas

The new 61,000 square foot Distribution Center in Laredo, Texas, provides a new major hub of fresh produce

Leamington, ON (December 2, 2020) – Nature Fresh Farms has expanded operations with a new Distribution Center in Laredo, Texas, with future developments planned for next year.

The new 61,000 square foot Distribution Center in Laredo, Texas, provides a new major hub of fresh produce. Since the opening of the facility, they have employed over 30 team members with more positions available for hire. The center will help service Nature Fresh Farms Mexican winter program and allow for direct shipping of product, shortening their supply chain. With this fully operational facility, the company will be able to bring fresher produce to customers located in the Southern United States.

Laredo Division Manager, Sergio Restrepo, said the new Distribution Center is in response to Nature Fresh Farms continuous growth. “The acquirement of our new center is part of our plans to optimize our distribution network,” shared Sergio. “With this, we are able to further strengthen our logistics and operations, ensuring that we can better meet the needs and expectations of our consumers and customers.”

Nature Fresh Farms has had a streak of sustained operational growth with their newly completed Phase 7 and 8 greenhouses, and a large expansion planned for their Leamington location with more details to follow. The company also has future plans for expansion in Ohio with an extension of acreage, in addition to their current 45 acres of greenhouse, and the construction of a new Distribution Center.

“We are looking forward to further developing our Ohio location with many new initiatives planned,” said Vice President, John Ketler. “We see significant opportunities in the continued construction with these new facilities needed to support our growth.”

Nature Fresh Farms has experienced rapid growth over the last few years. Today the company has over 600 employees, 200 acres of greenhouses Tomato, Pepper, and Cucumber plants, with multiple facilities across North America.

-30-

About Nature Fresh Farms -

Continuously expanding, Nature Fresh Farms has become one of the largest independent, vertically integrated greenhouse vegetable farms in North America. As a year-round grower with farms in Leamington, ON, Delta, OH, and Mexico, Nature Fresh Farms prides itself on consistently delivering exceptional flavor and quality to key retailers throughout North America, while continuing to innovate and introduce more viable and sustainable growing and packaging solutions.

SOURCE: Nature Fresh Farms | info@naturefresh.ca T: 519 326 1111 | www.naturefresh.ca

Babylon Microfarms Bets On Automation For The Future of Vertical Farming

What started as a humble tabletop farm at the University of Virginia has since evolved into a major company to watch in the vertical farming space, particularly when it comes to the software piece of the process

What started as a humble tabletop farm at the University of Virginia has since evolved into a major company to watch in the vertical farming space, particularly when it comes to the software piece of the process. Babylon Microfarms has over the last few years garnered quite a bit of attention for its controlled-environment farms the company now licenses to hospitals, cafeterias, and other other foodservice operations.

Based in Charlottesville, Virginia (though soon moving HQ to Richmond, VA) Babylon makes a “plug-and-play” system for hydroponic farming that automates much of the grow process and makes controlled-environment farming more accessible. The company raised a $2.3 million seed round in January of this year and, its current product is a standalone farming unit that grows leafy greens.

Of late, however, the bulk of founders Alexander Olesen and Graham Smith’s focus is on software: namely, using it to automate the growing process, which removes the more complicated aspects of vertical farming that would be off-putting to the average user.

“Growing is a cumbersome experience for many,” Olesen explained to me over the phone this week. “Removing the friction of the user experience and combining that will some of the remote management [will make] smaller forms of vertical farming possible.”

Were the average person to try and build their own high-tech grow system, it would require significant expertise in horticulture, hardware infrastructure, and software development. To name just a few examples, that would include calculating one’s one LED light recipe (which takes the place of sunlight in controlled-environment ag), controlling the temperature of the farm, and understanding how much nutrient to feed each crop and when to do that. Everyday would require a certain amount of trial and error for every plant variety.

All of this makes for prohibitively high costs when it comes to commercial greenhouse production. Olesen noted that for controlled-environment farming to go mainstream, it has to be less technically complicated for the user.

Babylon’s software is one solution addressing those complications. The company’s “seed-to-sale” system automatically dispenses the right amount of nutrients, light, and water for each crop, simultaneously collecting data on the plants so that the system can make adjustments as needed. The entire system can be controlled remotely via a mobile app.

Up to now, the company has drawn comparisons to the likes of Farmshelf, Farm.One, and InFarm, all companies that license a hardware-software farming combination out to foodservice and hospitality operations.

But Babylon’s founders told me they aren’t necessarily interested in the hardware aspect going forward. Smith says they would prefer something like teaming up with a hardware manufacturer that wants to make vertical farms but perhaps needs more expertise in software to complement their hardware capabilities.

Such a scenario is actually on its way to becoming a reality. At CES this past year, hardware giant LG announced plans for a smart-farming appliance for the consumer kitchen. At the same time, GE Appliances showcased its Home Grown concept, which featured grow systems using hydroponics and soil-based methods. Prior to CES, Miele acquired Agrilution in another play for smart farms in the appliance space.

All of these hardware developments suggest great opportunity for the accompanying software. While many companies in the vertical farming space try to do both right now, Babylon’s future focus on being “an enabling company” that offers software and services may prove a wiser bid for the long term. Besides building out distribution of its own farms, Babylon is currently interested in working with other businesses, particularly those making hardware, that want to enter the vertical farming space.

There will be no one product that wins, Olesen said, adding that instead, it will be a combination of tools working together to make vertical farming more accessible to everyone.

FILED UNDER: AG TECH BUSINESS OF FOOD EDUCATION & DISCOVERY FEATURED FOODTECH

MODERN FARMER VERTICAL FARMING

Why Are British People Protesting U.S. Farm Imports?

10.28.2020

Cow costumes, tractor caravans, and Great British Bake Off support: U.K. farmers and their allies are registering opposition to a new agriculture bill.

This weekend, lawmakers in the U.K. were greeted with a strange sight. Costumed demonstrators—one dressed like President Trump carrying a syringe, others dressed like farm animals—gathered in London to protest the passage of a new agriculture bill.

At issue was the government’s failure to codify British food standards as the country exits the European Union. Activists fear this omission would crack open the door for an influx of food imports from the United States as part of a trade deal between the two nations. They argue that allowing imports of U.S. products like beef raised with hormones (hence the syringe) and chicken washed in chlorine would compromise food safety and animal welfare.

A similar battle is playing out across Europe: The EU recently issued a green farming plan that blocks these products and signals a shift away from chemical pesticides and fertilizers. U.S. trade representative Ted McKinney called the plan a “diss.” And the EU once faced fierce opposition over imports of hormone-raised beef and chlorine chicken from the U.S., leading to an eventual ban—which Britain may abandon.

Elsewhere in the country, protestors have staged tractor parades down city streets and enlisted the support of celebrities including Jamie Oliver and Great British Bake Off judge Prue Leith in support of their cause. (Leith actually voted in favor of Brexit, so her tweets promoting British food standards were met with backlash from opponents who said she should have considered the consequences for farmers before voting to leave the European Union.)

“In this country, we’ve been through some major food crises with foot and mouth 20 years ago. We had the horsemeat scandal. We had the egg scandal in the 80s, with salmonella.” says Liz Webster, a self-described “farmer’s wife” and campaign organizer with Save British Farming, a group that advocates for British food standards. “We’ve got stricter standards about how many animals you can have in an area.”

Jamie Oliver put it another way in a video with the BBC: “Imagine being a British beef farmer and all of a sudden someone across the pond who uses hormones—those cows have never seen grass—they can sell you a product much cheaper.”

The messaging in these campaigns is a little muddled: They’re claiming that loosening import rules is bad for animal welfare, and also that it’s bad for farmers’ bottom lines, and, perhaps most alarmingly, that imported food threatens the health of the people who eat it. And it is true that the European Union has adopted food standards that ban some potentially harmful products used in animal production and food processing in the U.S., including bovine growth hormone. If the U.K. adopts its own agriculture policy without banning the same products, activists worry they’ll find their way into the food supply. It’s also true that Europe has adopted some stricter animal welfare laws, including rules that give chickens a bit more space than their American counterparts.

“They’re trying to imply that food imported from America isn’t safe somehow, or that it’ll poison them or something—they don’t spell it out because it’s not true.”

Yet the implication in many of these campaigns that U.S. food imports are less safe than homegrown beef is not backed up by acknowledgment from the U.S. or the World Trade Organization. “They’re trying to imply that food imported from America isn’t safe somehow, or that it’ll poison them or something—they don’t spell it out because it’s not true. What they’re really talking about is the way the food is produced,” said Sean Rickard, an economic analyst who advises clients on food and farming.

Of course, there’s a deeper set of issues at play here: This bill, which represents the government’s foray into post-Brexit agricultural policy, has been a wake-up call for farmers, half of whom voted in favor of leaving the EU, Rickard said. “What farmers realized as it was going through the Houses of Parliament was that it wasn’t actually the sort of milk and honey that they had been expecting,” he added. The bill removes direct payments to farmers and replaces them over the next several years, though the details are hazy. More concerning to some are the trade implications.

“Farmers suddenly woke up to the fact that one of the dangers was that if this bill didn’t protect them against imports of cheaper food, they were going to be completely screwed,” Rickard said. “They were not only going to lose their support systems, but they were also going to face imports from countries that can produce food more cheaply.”

Over time, the food service sector will slowly start purchasing imported meat, and Britons will start eating chicken grown in the U.S. at KFC.

Rickard is cynical about the potential inclusion of food standards language in the agriculture bill because such a move could jeopardize a trade deal with the U.S. “[Representatives] made abundantly clear there will be no trade deal with us if we are not prepared to accept American standards,” Rickard said. That puts politicians in a bind: Some of Prime Minister Boris Johnson’s key supporters are farmers, but a bilateral trade deal with the U.S. is not compatible with a policy that limited American farm imports.

U.K. legislators have promised not to allow imports of the two most incendiary products—beef raised with growth hormones and chicken washed with chlorine—but The Guardian notes that the proof will be in the pudding. Under pressure to sign a trade deal with the U.S., these assurances may fall by the wayside.

In the long run, Rickard envisions a slow, grudging acceptance of U.S. food imports. “I think in the short run, the supermarkets will say, ‘Oh, we’re going to put big labels up. None of our food will be produced in the way Americans do,’” he said. But over time, the foodservice sector will slowly start purchasing imported meat, and Britons will start eating chicken grown in the U.S. at KFC. Slowly, the grocery stores will follow suit. “The truth is that when it comes to buying food—and we have a lot of people, unemployed, single-parent families, in this country—cheaper food will find its way into the supermarkets,” he added.

Lead photo: AP Photo/Alberto Pezzali

Also tagged farmers, food imports, trade, trump administration, united kingdom

H. Claire Brown is a senior staff writer for The Counter.

SOUTH AFRICA: 'We See Hydroponics As The Future of Farming’

Getting children to learn how to grow vegetables at school is an idea that is growing in popularity across Mzansi

By Terry van der Walt

November 10, 2020

Getting children to learn how to grow vegetables at school is an idea that is growing in popularity across Mzansi.

The topic is close to the heart of Branden Gee and his business partner Cameron Blair, who also have a hydroponic set-up in Pinetown outside Durban, as well as an e-commerce business.

“Our major ambition is to get either a hydroponic system or a 100 percent organic and sustainable vegetable patch in every school in the country. That’s the reason we do it for free. We want everyone to learn how to grow their own food and self-sustain.

“Each project deals with a different aspect that contributes to a greater goal, and that goal is sustainable living,” said Gee.

This past Friday they visited Curro Hillcrest Independent School and taught learners the basic building blocks of permaculture, and introduced a worm farm to the school.

“Worms are arguably the most important organisms to life on our planet. They convert organic matter into valuable nutrients that your plants will thank you for later,” he said.

The worm farm makes use of vegetable scraps which the worms feed on, which creates a nutrient-rich liquid - worm wee - which helps build fertile soil, resulting in thriving crops.

On Saturday the duo hosted Thomas More College learners at their Geeshydro hydroponic farm and grow store.

“We use the farm as an educational tool to teach anyone and everyone who is wanting to learn more about hydroponics.

“We see hydroponics as the future of farming since it uses 90% less water than traditional farming, and it can grow a surplus of food in a smaller area using vertical grow towers,” he said.

Brenden Gee and Cameron Blair, in front, are getting learners to grow food. Picture: Supplied

Their e-commerce website called Our Local Market is free to vendors in the upper highway area and was set up to create and support opportunities for young entrepreneurs to thrive by offering them a platform to sell their products with no risk.

“We want the next generation to not only learn how the natural world works, but also how to use it to create a business.

“By using nature the kids can learn how to create a vegetable garden that can thrive. We teach them how to build soil, how to harvest worm wee, how to grow seedlings to sell, growing chickens and learning how to harvest the eggs, as well as selling their produce,” he said.

Learners from Thomas More College get the low-down on hydroponics. Picture: Supplied

Their business is structured around three major principles: Earth care, People care, Fair share.

Gee hopes to adopt more schools and relies on donations to make it happen.

If you want to help go to: https://gf.me/u/y6gtkm

“I know money has been harder to come by this year but I’ve been getting a little from all over, so any donation makes a huge difference, every little bit helps,” he said.

Lead photo: The hydroponic set-up uses a fraction of water and is used as an educational tool for visiting schools. Picture: Supplied

SINGAPORE: New Vertical Farm To Produce 500,000 kg of Greens Annually

&ever has been awarded funding under SFA’s ‘30x30 Express’ grant to ramp up local food production over the next six to 24 months

&ever Singapore Pte Ltd (previously Farmers Cut Pte Ltd), a fully-owned subsidiary of &ever GmbH from Germany, will grow and deliver leafy greens to consumers in Singapore with its first indoor farm in the region.

Amid the global food supply challenges posed by the COVID-19 pandemic, the Singapore Food Agency (SFA) launched a ‘30x30 Express’ Grant earlier this year. The grant will support the country’s agri-food industry and accelerate the ramp-up of local production, with the aim of meeting 30 percent of Singapore’s nutritional needs with food produced locally by 2030.

&ever has been awarded funding under SFA’s ‘30x30 Express’ grant to ramp up local food production over the next six to 24 months. The grant is awarded to companies who make use of highly productive farming systems that can be constructed and implemented quickly to achieve high production levels.

&ever will produce annually up to 500,000 kg of leafy greens for consumers in Singapore using their Dryponics method. Dryponics keeps the plants alive, with the roots intact, until they reach the consumer. Consumers will be able to harvest the plants only seconds before consumption, resulting in higher nutritional value and better-tasting greens.

&ever’s fully automated technology allows for everything inside the farms to be controlled digitally- from the seeding to harvesting, CO2 levels, temperature, and airflow. IoT sensors and edge computing are collecting data throughout the farmhouses to produce and maintain the healthiest plants.

“To accelerate the ramp-up in local food production and meet our '30 by 30' goal, we will need to leverage productive farming technology. Technology can help farms achieve higher production levels, and be more resilient against the impacts of climate change. We are pleased to see our agri-food players, such as &ever Singapore adopting productive and innovative farming systems, and will continue to work with them to strengthen our food production capabilities. This in turn will enhance Singapore’s food security, and create good jobs for our people,” said Mr. Melvin Chow, Senior Director of SFA’s Food Supply Resilience division.

&ever has been present in the hyper-local agri-food scene since early 2019. With the successful launch of their first indoor farm in Kuwait earlier this year, they aim to bring their sustainable farming solution to other parts of the world with challenging climate conditions.

Dr. Henner Schwarz, CEO of &ever, said: “We are excited to continue our global roll-out and bring better tasting, highly nutritious salad to the people of Singapore.”

“At the same time we make a strong contribution to one of the world’s most exciting eco-systems for indoor vertical farming," added Mark Korzilius, founder and CISO of &ever.

For more information:

&ever

and-ever.com

27 Oct 2020

Biggest Swiss Fruit And Vegetables Cooperative Invests In Vertical Farming

A major Swiss domestic supplier, fenaco Landesprodukte, is working on a pilot facility for vertical farming. They're investing in YASAI, a spin-off of public university ETH Zurich. With an investment of CHF 500,000 in YASAI AG, the fenaco cooperative is participating in the construction of the pilot facility in Zurich

Fenaco Collaborates With YASAI

A major Swiss domestic supplier, fenaco Landesprodukte, is working on a pilot facility for vertical farming. They're investing in YASAI, a spin-off of public university ETH Zurich. With an investment of CHF 500,000 in YASAI AG, the fenaco cooperative is participating in the construction of the pilot facility in Zurich.

"Consumer demands for healthy, safe and sustainably produced food require innovative solutions from the agricultural and food industry. By participating in a pilot facility for the novel Vertical Farming production method, fenaco Landesprodukte wants to verify the advantages of this cultivation method", the company explains. "Thanks to its stacked installation, it increases productivity by a factor of 10 to 15 per square meter. Water consumption can be reduced by 90%."

"In the future, we do not want to produce ourselves, but rather use our experience in the field of vertical farming to open up a new, profitable business segment for growers," says Daniel Schwab, Head of the Vegetable Category at fenaco Landesprodukte. To this end, a sounding board was set up with vegetable producers from the Seeland region.

No chemical crop protection is used, or very small amounts only. In addition, year-round indoor production allows growth 24 hours a day, 365 days a year and it is possible to increase the proportion of Swiss vegetables and herbs. "The aim is also to demonstrate the economic efficiency for various product categories and to reduce energy consumption by exploiting synergies", they explain.

A strong signal for innovation in the agricultural and food industry

fenaco entering the field of vertical farming is a strong signal for innovation in the Swiss agricultural and food industry. The partnership with the ETH spin-off enables fenaco to better understand the potential for vertical farming and, if positive, to exploit economies of scale with larger plants. On the one hand, the product portfolio will be tested in cultivation and marketing and on the other hand, central agronomic questions will be addressed in a research project in cooperation with Agroscope.

"We are working on the farm of the future and regard this investment as a preliminary work and a basis for decision-making for future investments of our producers", says Markus Hämmerli, Head of fenaco products and research cooperations. This means the commitment is based on the goals of the fenaco cooperative: to support Swiss growers in the economic development of their companies.

Industry and technology know-how go hand in hand

The ETH spin-off YASAI under the leadership of CEO Mark Essam Zahran is the ideal partner for fenaco. The four founders and majority shareholders have excellent know-how in the field of software and hardware as well as a large international network. After several successful financing rounds, fenaco's financial commitment and the associated construction of the first pilot plant in Switzerland is an important milestone for the still young company.

"Thanks to the cooperation with fenaco, we now have a strong industrial partner with a lot of market and customer knowledge from the agricultural sector on our side. This is extremely valuable when scaling up the technology and entering the Swiss market," says Mark Zahran of YASAI. The partnership with fenaco also enables YASAI to distribute the vegetables and herbs it produces nationally in the retail trade and in the catering trade.

For more information:

www.fenaco.com

www.yasai.ch

29 Oct 2020

US: MAINE - Planning Board Signals Support For Vertical Greenhouse/Parking Garage In Downtown Westbrook

The $60 million project is a collaboration between the city and developers that would see the Mechanic Street parking lot downtown turned into a free parking garage, topped with over 50 apartments and a Vertical Harvest farm along the structure’s side

The Vertical Harvest Project Will Go

To The Planning Board For Approval In November

AMERICAN JOURNAL

BY CHANCE VILES

The Westbrook Planning Board will vote Nov. 3 on a proposed $60 million combination greenhouse, apartment complex and parking garage. Courtesy

WESTBROOK— Planning Board members spoke in favor of a multi-use parking garage and vertical greenhouse at a public hearing Oct. 20.

The $60 million project is a collaboration between the city and developers that would see the Mechanic Street parking lot downtown turned into a free parking garage, topped with over 50 apartments and a Vertical Harvest farm along the structure’s side.

A rendering of what the view would be looking southwest from Main Street. Courtesy

“I love this project,” Ward 2 member Jason Frazier said. “It has jobs, parking, housing. It’s the perfect project.”

RELATED

Read more about the Vertical Harvest

The greenhouse would produce about 1 million pounds of food per year and bring in 56 full-time jobs with a focus on providing careers for people with disabilities.

“This is the equivalent of 40 acres worth of food, using 90% less land and water,” developer Nona Yehia said. “We recirculate all of the water we use in the greenhouse. … We aim for our food to be sold and consumed within the state of Maine and from farm-to-fork in less than 24 hours.”

The Planning Board members, on the right, look at the first-floor ground plan at their public hearing Oct. 20. Courtesy photo

The garage will be maintained by the developers, while city residents will still have access to over 400 free parking spaces.

Advertisement

According to Economic Development Director Dan Stevenson, they are confident the greenhouse will be successful, though developers did say that if need be, it could be turned into some other workspace.

“In my career, this is one of the strongest business models I have seen,” Economic Development Director Daniel Stevenson said.

RELATED

Read more about the whole project

“I am thrilled,” Ward 4 member Robin Tannenbaum said. “We are touching a lot of exciting areas and contributing to densification. To set the bar high, where there is still room, I’d like to see more development of the design to let the building sing.”

“Coming from the other side of the river into Main Street and into the downtown, that building is going to tower over all of these other, so why not?” Board Chairperson Rene Daniels said. “It would make it pop, it would be outstanding,”

The city will be paying $15 million for the parking garage through an agreement using tax revenue generated from the project, Stevenson said, meaning there will be no direct impact on taxpayers. Developers will take on $40 million of the cost.

“It’s been a goal of ours for a while to start expanding vertically downtown, and this meets that,” Ward 5 member Ed Reidman said.

The Planning Board will vote on the project Nov. 3.

A rendering of the building. Some Board members called for a more lively facade for the apartments on the top floor. Courtesy

Developers say there will be space outdoors with vegetation for some outdoor opportunities, as well as common spaces within the building for residents. Courtesy

AppHarvest Breaks Ground On Third High-Tech Greenhouse, Expands From Tomatoes Into Leafy Greens

The indoor facility will grow non-GMO, chemical pesticide-free leafy greens to be distributed to U.S. grocers and restaurants

October 26, 2020

Source: AppHarvest

Creates Eastern US Source of Crop Grown Primarily In California, Arizona

BEREA, Kentucky, Oct. 26, 2020 (GLOBE NEWSWIRE) -- AppHarvest today announced it has started construction on a third high-tech controlled environment agriculture facility in Central Appalachia and is expanding into growing leafy greens. Located in Berea, KY, the farm, when complete, will be 15 acres.

The indoor facility will grow non-GMO, chemical pesticide-free leafy greens to be distributed to U.S. grocers and restaurants. Because of the company’s strategic location in Appalachia, AppHarvest can reach nearly 70% of Americans in just a day’s drive, reducing transportation costs by up to 80% compared to existing growers. American production is concentrated in Arizona and California, which combine to grow 90% of US-grown leafy greens.

These states are in the midst of a decades-long drought and are consuming precious water resources. By contrast, Central Appalachia, where AppHarvest is investing in building controlled environment agriculture facilities, has an abundance of rain. The facility in Berea, like AppHarvest’s other controlled environment agriculture facilities, will be designed to have its water needs met entirely by recycled rainwater using a closed-loop irrigation system where all water not absorbed by the plants is cleaned using sand and UV and then reused.

The facility will continue to expand AppHarvest's growing space in Central Appalachia. AppHarvest opened its flagship farm — a 2.76-million-square-foot facility growing tomatoes — last week in nearby Morehead, KY, and also broke ground for a second facility of similar size in Madison County outside Richmond, KY.

“With this facility, we will expand beyond vine crops to leafy greens, which face many of the same challenges in today’s broken food systems,” said AppHarvest Founder & CEO Jonathan Webb. “Leafy greens are grown almost exclusively in states with little water and then travel thousands of miles to most Americans. We’re working to create a more resilient American food system, and water usage is at the heart of the issue.”

Added Berea Mayor Bruce Fraley, “The city of Berea is thrilled to welcome AppHarvest to our community. Throughout the site selection process, it has become clear to me that Berea is a perfect fit for AppHarvest, and AppHarvest is a perfect fit for our city. We are very glad to be part of a truly revolutionary movement in AgTech.”

How is AppHarvest different from traditional agriculture companies?

The company’s greenhouses are designed to reduce water usage by 90% compared to traditional open-field agriculture due to unique irrigation systems connected with large-scale rainwater retention ponds. The system is designed to eliminate harmful agricultural runoff, which contributes to toxic algae blooms.

AppHarvest farms are located in water-rich Central Appalachia in contrast to much of America’s vegetable production that is concentrated in Arizona and California, states that continue to confront water scarcity and climate disruptions.

Strong relationships with leading AgTech universities and companies in the Netherlands position AppHarvest as a leading applied technology agriculture company. The Netherlands has developed a significant high-tech greenhouse industry, becoming the world’s second-largest agricultural exporter despite having a landmass roughly equal in size to Eastern Kentucky. Earlier this year, AppHarvest led a landmark 17-organization agreement uniting Dutch and Kentucky governments, universities, and private companies, with all committing to building America's AgTech capital from within Appalachia. Among the signatories is Berea College, which is based in Berea, KY.

“AppHarvest is such a forward-looking business organization, and we think it surely belongs in one of the most forward-looking towns in Kentucky,” said Berea College President Lyle Roelofs. “We look forward to many learning and participation opportunities for the Berea College faculty and students who are involved in our great programs in agriculture, sustainability, business, and computer science.”

In just over two years, AppHarvest has attracted more than $150 million in investment into Central Appalachia and announced on September 29 a definitive agreement for a business combination with publicly-traded special purpose acquisition company Novus Capital Corporation (Nasdaq: NOVS). The combination, which is expected to close late in the fourth quarter of 2020 or early in the first quarter of 2021, will provide $475 million of gross proceeds to the company, including $375 million fully committed common stock PIPE at $10.00 per share anchored by existing and new investors – including Fidelity Management & Research Company, LLC, Inclusive Capital, and Novus Capital Corporation. Upon closing of the transaction, the combined company will be named AppHarvest and is expected to remain listed on Nasdaq under the ticker symbol APPH.

AppHarvest’s investors include Revolution’s Rise of the Rest Seed Fund, Inclusive Capital Partners, Equilibrium, Narya Capital, Lupa Systems, Breyer Capital, and Endeavor Catalyst. Endeavor selected AppHarvest Founder & CEO Jonathan Webb as an Endeavor Entrepreneur in 2019.

Board members include food icon Martha Stewart, Narya Capital Co-Founder, and Partner JD Vance, Impossible Foods Chief Financial Officer David Lee, and impact investor Jeff Ubben.

About AppHarvest

AppHarvest is an applied technology company building some of the world’s largest indoor farms in Appalachia. The Company combines conventional agricultural techniques with cutting-edge technology and is addressing key issues including improving access for all to nutritious food, farming more sustainably, building a home-grown food supply, and increasing investment in Appalachia. The Company’s 60-acre Morehead, KY facility is among the largest indoor farms in the U.S.

For more information, visit https://www.appharvest.com/.

Forward-Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “will,” “estimate,” “continue,” “anticipate,” “intend,” “expect,” “should,” “would,” “plan,” “predict,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this press release, regarding Novus Capital’s proposed acquisition of AppHarvest, Novus Capital’s ability to consummate the transaction, the benefits of the transaction, and the combined company’s future financial performance, as well as the combined company’s growth plans and strategy, future operations, estimated financial position, estimated revenues and losses, projected costs, prospects, plans and objectives of management are forward-looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of AppHarvest’s management and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AppHarvest. These forward-looking statements are subject to a number of risks and uncertainties, including those discussed in Novus Capital’s registration statement on Form S-4, filed with the SEC on October 9, 2020 (the “Registration Statement”), under the heading “Risk Factors,” and other documents Novus Capital has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. In addition, forward-looking statements reflect AppHarvest’s expectations, plans, or forecasts of future events and views as of the date of this press release. AppHarvest anticipates that subsequent events and developments will cause its assessments to change. However, while AppHarvest may elect to update these forward-looking statements at some point in the future, AppHarvest specifically disclaims any obligation to do so. These forward-looking statements should not be relied upon as representing AppHarvest’s assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Important Information for Investors and Stockholders

In connection with the proposed transaction, Novus Capital has filed the Registration Statement with the SEC, which includes a preliminary proxy statement to be distributed to holders of Novus Capital’s common stock in connection with Novus Capital’s solicitation of proxies for the vote by Novus Capital’s stockholders with respect to the proposed transaction and other matters as described in the Registration Statement, as well as the prospectus relating to the offer of securities to be issued to AppHarvest’s stockholders in connection with the proposed transaction. After the Registration Statement has been declared effective, Novus Capital will mail a definitive proxy statement, when available, to its stockholders. Investors and security holders and other interested parties are urged to read the proxy statement/prospectus, any amendments thereto and any other documents filed with the SEC carefully and in their entirety when they become available because they will contain important information about Novus Capital, AppHarvest and the proposed transaction. Investors and security holders may obtain free copies of the preliminary proxy statement/prospectus and definitive proxy statement/prospectus (when available) and other documents filed with the SEC by Novus Capital through the website maintained by the SEC at http://www.sec.gov, or by directing a request to: Novus Capital Corporation, 8556 Oakmont Lane, Indianapolis, IN 46260. The information contained on, or that may be accessed through, the websites referenced in this press release is not incorporated by reference into, and is not a part of, this press release.

Participants in the Solicitation

Novus Capital and its directors and officers may be deemed participants in the solicitation of proxies of Novus Capital’s shareholders in connection with the proposed business combination. Security holders may obtain more detailed information regarding the names, affiliations and interests of certain of Novus Capital’s executive officers and directors in the solicitation by reading the Registration Statement and other relevant materials filed with the SEC in connection with the business combination when they become available. Information concerning the interests of Novus Capital’s participants in the solicitation, which may, in some cases, be different than those of their stockholders generally, is set forth in the Registration Statement.

1 https://lgma.ca.gov/about-us#overview

MEDIA CONTACT: press@appharvest.com

IMAGE/VIDEO GALLERY: Available here

Indoor Farming Start-Up BrightFarms Raises $100m In Funding

The start-up has raised over $200 million in funding to date, and BrightFarms claims that it will use these latest funds to invest in its current farms and retail programs and expand its network of regional indoor farms across the US

By Martin White

21 October 2020

Indoor hydroponic farming start-up BrightFarms has secured $100 million in a Series E funding round led by Cox Enterprises, which now owns a majority stake in the company, and a further investment from Catalyst Investors.

BrightFarms builds and operates indoor farms near major metropolitan areas in the US, providing supermarkets and retailers with a consistent supply of locally grown produce. It currently operates indoor farms in Illinois, Ohio, Pennsylvania, and Virginia, with three new farms currently under development in North Carolina, Massachusetts, and Texas.

The start-up has raised over $200 million in funding to date, and BrightFarms claims that it will use these latest funds to invest in its current farms and retail programs and expand its network of regional indoor farms across the US.

BrightFarms claims that its growing methods “use 80% less water, 90% less land and 95% less shipping fuel than traditional agriculture”. The company claims that its indoor growing methods can provide pesticide-free packaged greens to supermarkets in as little as 24 hours after harvest.

The start-up has formed partnerships with major retailers including Ahold Delhaize, Kroger, and Walmart, distributing produce to over 2,000 stores in the US. The firm anticipates that it will expand its distribution to more than 15,000 stores by 2025.

Steve Platt, CEO of BrightFarms, said: “Our goal over the next five years is to make quality, locally-grown greens a staple on grocery shelves and in refrigerators nationwide.

“We are thrilled to have the strong financial backing of Cox Enterprises, an organization that closely aligns with our mission to build a healthier and more sustainable future and to have the additional support of our long-term partners at Catalyst Investors. Together we are ready to scale our model for local indoor farming in every major market in the US”

"We Have Barely Scratched The Surface In The MENA AgTech Sector"

"Badia Farms is the first commercial vertical farm to launch in the GCC. We officially started operations in the heart of Dubai in 2016, but the seeds were planted further back

"Badia Farms is the first commercial vertical farm to launch in the GCC. We officially started operations in the heart of Dubai in 2016, but the seeds were planted further back. My background is in engineering and banking. I first took the entrepreneurial leap in Saudi Arabia in the hospitality sector by opening multiple unique restaurant concepts." That's how Omar Al Jundi, Founder & CEO of Badia Farms, introduces himself.

Mesmerized by hydroponics

When he decided to enter his next venture, he says "I knew it had to be both challenging and able to add value and make a difference to our society and communities. When I was introduced to the concept of hydroponics, I was mesmerized with this new technique of growing where we don’t require any soil, we can recycle 90% of the water, and it can be grown in a fully closed environment, without even sunlight! Years before we launched I learned as much from experts, conferences, courses, and by working in a high-tech greenhouse facility in Holland."

Sustainability

Food security is one of the main issues in the MENA region, and the development of sustainable farming is crucial. "We have seen this first hand during the early days of the Covid pandemic," Omar says. "Produce supply chains were halted, and many countries (especially in MENA) had to reassess their long-term plans and fast-track their commitment to AgTech models such as vertical farming."

The choice to go vertical

Vertical farming and AgTech is needed in the GCC. Why? Omar explains: "Over-dependence on imported produce and the simple fact that traditional framing does not work in our arid desert climate. I want to tackle an issue that will make a difference to society while preserving our natural resources such as water. Badia products are pesticide and herbicide-free. Since our crops are grown naturally in sterile, soil-free mediums, along with the controlled environment, it removes the need for harmful additives. We can also harvest fresh produce all year round. Our harvest yields 4-8 times the amount of crops in the same space compared to conventional soil farming. As a former restaurateur, it has been amazing to be able to work with the top chefs and restaurants in the UAE and be able to supply them with fresh, better than organic flavourful products that wouldn't be available to them otherwise. The journey from food to table is much shorter."

Optimal growth conditions

In this vertical farming environment, Badia Farms is able to control every aspect of the ecosystem to ensure optimal growth conditions are provided for each crop. "For example, our facilities utilize LEDs, artificial lighting to replace the sunlight, we control and monitor all environmental inputs (humidity, temperature, CO2), and we use computer linked dosing units to schedule the irrigation and feed formulas," Omar points out. "Lastly, our hydroponic growing methods use 90% less water compared to open field growing, and since we recirculate our water there’s no wastage."

Support needed

There were also some challenges along the way to achieving this, as AgTech and modern farming are still very new to the region. "The biggest challenge is there aren’t off the shelf solutions that we can purchase and implement immediately," Omar says. "In the case of vertical farming, which is still at an infancy stage globally, we had to design our own grow system to form our IP and ensure we have a commercial operation that will yield high-quality products and profits to ensure we stay in business.

We surely need a lot more support from the government and private sectors for this industry to see the light. For example, the government can support the industry by introducing cost-effective initiatives that reduce the operational cost that will ensure the viability of the projects. Educating the public and consumers on the benefits of modern farming and vertical farming is very important to ensure the continuity of this new industry. We are seeing more regional and global VC's and investment funds interested in the AgTech sector in our region, but they haven’t made the big investments yet!"

Opportunities in the Middle East

Asked what advice Omar would give to people looking into breaking into the UAE food/ag market, he says: "What's great right now is that we have barely scratched the surface in the MENA AgTech sector, so there are so many opportunities, which has been propelled by the pandemic. The UAE is an open economy, I suggest whoever is interested to enter the market to come and meet with the different governmental entities, to meet with distributors, understand the market dynamics, pricing, etc. Come and do the work themselves vs hiring a consultant to do the job. The journey won't be easy. But even with the advent of technology farming is still what it was hundreds of years ago: to grow something needs constant attention, passion, and patience."

E-commerce platform

Badia Farms has a lot in store for the future, like increasing their product offering, expanding their facility in the UAE, and growing their team. "We are also excited about the launch of our own e-commerce platform! The crop will be harvested only once a customer places an order and will reach them within a couple of hours. We are also raising our next round of funding. So a lot is going on", Omar concludes.

Omar Al Jundi will be one of the speakers during the upcoming Agritecture Xchange. When registering, you can use the code 'HDaily10' to get 10% off tickets.

For more information:

Badia Farms

www.badiafarms.com

Publication date: Fri 23 Oct 2020

Author: Jan Jacob Mekes

© HortiDaily.com

Living Lettuce, Vertical Gardening: This Startup Is Using AI For Organic Farming

Analytics India Magazine got in touch with Shivendra Singh, founder and CEO of Barton Breeze, who believes that in the future the vegetable greens will likely come from the building next to you

13/10/2020

Srishti currently works as Associate Editor at Analytics India Magazine.…

The interest and popularity of organic and sustainable farming are increasing drastically. While the consumers are often skeptical about the food products that they consume, Dubai and New Delhi-based Barton Breeze is growing safe, delicious, and healthy food while relying on analytics and AI. It offers top-quality products that are grown locally in nutrient-rich water without pesticides. The crops are harvested weekly and delivered to sales outlets within a couple of hours.

Following the principle of ‘living lettuce’, it follows a method where roots are left intact, which makes it last longer. The startup also follows vertical gardening where it uses vertically stacked growing beds, up to five levels high using less than 1% of the space required by the conventional growing, a precious commodity in densely populated urban areas.

Analytics India Magazine got in touch with Shivendra Singh, founder and CEO of Barton Breeze, who believes that in the future the vegetable greens will likely come from the building next to you.

The Journey

After graduating from IIM Ahmedabad, Singh started working on a pilot project around hydroponics and set up two container farms in Dubai. “During this time I thought, a country like India with profound climate changes needs this technology more than anyone else,” he says.

Soon after, Barton Breeze was established in 2015 in Dubai, UAE, with a mission for technology innovation in agriculture. As Singh recalls, the journey initially was challenging and well expected, but with the right vision, it became unstoppable. In addition to the lack of proper information, availability of funds, market volatility, the task to create consumer confidence was critical. Another challenge was that hydroponics was a new technology to adapt, and the existing unprofessional quality and high prices made it difficult to find the right customer in the market.

Overcoming these challenges, Barton Breeze is now the market leader in the sector and has expanded operations to India.

Data Science And AI Is At The Core

Barton Breeze team includes experts from deep data science to engineering, and from marketing to producing. “When we started, people had no idea about this new technology. And whatever talent was available, they had to unlearn. Training and building our staff from the ground up, we are now a team of six core members, supported by 25 field farms,” added Singh.

Explaining how Barton Breeze uses analytics and AI to increase the farm produce, Singh shares the areas as below:

Smart Farms: Each smart farm is backed with the expertise of the chief technology officer, a dedicated R&D team, plant scientists, microbiologists, mechanical engineers, and design engineers.

Cloud Architecture and Data Center: Barton Breeze collects hundreds of data points at each of its farms to its data center, which allows it to quickly alter its indoor precision control for taste, texture, color, and nutrition. It also helps in adjusting variables like temperature and humidity to optimize its crop yields. Barton also collects all yield and harvest data into the cloud to calculate sales projections and market trends.

Using Artificial Intelligence and IoT (Internet of things): Barton uses software with a device clipped on the stems and leaves of each plant. It informs the nutrients or mineral needs of the plants.

Highlighting other venues where AI is used, Singh shares that they have perfected their algorithm for optimal taste, texture, color, and nutrition so one can taste the science of flavor in every delicious bite of leafy greens. “We do this by leveraging plant science, engineering, and lighting to optimize our plants while also using 85% less water, 5x productivity, and zero pesticides,” he added.

He further shares that Barton Breeze carefully monitors the health and quality of plants daily to optimize taste, texture, color, nutrition, and yield to deliver a better product using AI. “Barton’s growing techniques can be highly customized,” he said.

The startup has also developed iFarm, a cloud-based data and farm output AI software. It allows the clients to get all their farm and production details on the cloud at home or office. “Our farm dashboard and IoT uses artificial intelligence and data analytics to measure important indicators that help in food/crop planning and hence help connect in the food security ecosystem,” he said.

Some areas where AI and IoT are used at Barton:

SMS alert system

Data logging facility

Online monitoring and control

Sensor-based control system

Environment management system

Water temperature management

Sunlight monitoring system

Crop management system

Farm system efficiency dashboard

Nutrition management system

Barton team includes members with deep expertise in science, engineering, technology, food safety, crop physiology, microbiology, and more to help deliver rapidly deployable and scalable solutions.

“Being first and one of a kind in the segment of agri-tech, we at Barton Breeze are trying to create and promote healthy lifestyle’ To achieve it, we are working into the whole ecosystem in the form of B-FRESH, B-FARM and B-HOME,” shares Singh.

Growth Story

With experienced and known names in the team, Barton Breeze has increased team members, post-COVID to increase the outreach. “Currently we are in 10 states, and Barton Breeze is planning to enter five more states in the next couple of months,” shared Singh. The startup takes pride in increased customer query by 200% and increased consumer awareness by 10X post COVID.

Singh further shares that there has been an increase in the interest level from angel investors and venture capitals for Barton Breeze with VC calls gone up by 150%. The startup is closing 1.5 million USD funding within this year.

“Our goal is to achieve 360-ton produce marketing per year by the end of March 2021 while adding 25 more clients. We are targeting 50 crores revenue @CAGR 800%. We would also be coming up with ten new commercialized farms apart from doing R&D on 50 crop varieties,” concluded Singh on an ambitious note.

Srishti currently works as Associate Editor at Analytics India Magazine. When not covering the analytics news, editing, and writing articles, she could be found reading or capturing thoughts into pictures.

Shorten Supply Chains With Urban Farming

While urban indoor agriculture may have seemed a far-fetched dream in the past, developments in city planning and technological innovation are making it into a reality

There are many reasons why a government or international organization may advocate the introduction of urban indoor farming. The association for vertical farming looks at some of the main motivations for bringing agriculture closer to the consumer. While urban indoor agriculture may have seemed a far-fetched dream in the past, developments in city planning and technological innovation are making it into a reality. These developments are helping to alleviate pressure on food supply chains and cultivate food security in a period of mass population expansion.

Urban indoor agriculture is seen as a viable solution to dramatic increases in population. Already fifty-five percent of the world’s population lives in urban areas and this figure is set to increase. Moreover, eighty percent of all food produced globally is destined for consumption in urban spaces to meet this increased demand. By bringing farming closer to the city, agricultural networks have a better chance of meeting this demand sustainably and efficiently by cutting out unnecessary segments of the supply chain. Farmers are also better able to attract young people into the workforce as they can offer new and innovative routes into agriculture which appeal to the urbanized workforce.

Agriculture in urbanized areas also presents an opportunity to establish a more circular economy. Farming can be integrated more holistically into the overall working of urban life by combining its production with other essential services like waste management. Rather than establishing a food network that operates on a ‘cradle-to-grave’ methodology, urbanized farming presents new opportunities to recycle and reuse resources in an integrated bio-economy. The decrease in transportation costs which comes from closer proximity between consumers and producers also helps to reduce emissions. The benefits of urban indoor farming can be seen to not only enhance economic efficiency but also maximize sustainability by cutting down the city’s overall carbon footprint.

Finally, urban indoor agriculture offers an exciting opportunity for communities to reconnect with the process of farming. Shorter supply chains not only increase accessibility to food but can also improve overall public engagement with the food production process. Supply chains can be seen not only as a means to an end but also as an opportunity for social engagement by integrating small producers, farms, and vulnerable groups along the supply chain. Educational opportunities for schools and society as a whole can be brought closer to the urban population which allows a reconnection with the cultivation of fresh produce.

While it is possible that cities never become solely reliant on urban agriculture, it is clear that the integration of agriculture into the urban zone offers several social, economic, and environmental benefits. Food supply chains should therefore actively cultivate urbanized agriculture to help reach increased standards of efficiency and sustainability at this time of rapid population expansion.

For more information:

Association for Vertical Farming

Marschnerstrasse,

81245 Munich,

Germany

info@vertical-farming.net

vertical-farming.net

Publication date: Mon 28 Sep 2020

Lef Farms Keeps The Fresh Coming With The Addition of Fresh New Production Manager

Mariana’s new position was created to provide more time for training, education, and coordination between different departments within the organization

(Loudon, NH) – Coming off a very eventful summer that resulted in expanding distribution by adding Stop & Shop stores throughout New England and supporting medical first-responders during the pandemic with donations of a quarter of a million dollars in baby greens, hydroponic lettuce grower, lef Farms continues its forward momentum by adding a new production manager to its mix.

“We’re so excited to add Mariana Robles to our management team”, smiles lef founder, Henry Huntington. “As a 2015 graduate from the University of Los Llanos Colombia, specializing in Agronomy, Mariana brings with her some fresh, out-of-the-box thinking that we can’t help but benefit from”, finishes Huntington.

lef Farms of Loudon, NH, welcomes its new production manager, Mariana Robles.

But Mariana isn’t a new face at lef Farms. With a passion for farming that brought her to the region in 2015, Mariana was eventually hired by lef in early 2018 to support its seeding line. Since then, Mariana developed into one of lef’s key team members, taking on additional responsibilities as food safety officer and cooler supervisor. As the company continued to grow, Mariana’s new position was created to provide more time for training, education, and coordination between different departments within the organization. As production manager, Mariana will be responsible for driving efficiencies, improving procedures and protocols, and increasing teamwork at Farm.

“With expansion in our near future, putting Mariana in the role of production manager allows the Farm to continue its maturation process prior to pulling that trigger”, concludes Huntington.

lēf Farms is a 1-acre hydroponic greenhouse growing facility located in Loudon, NH, producing nearly 1.5 million pounds annually of its Crisp, Smooth, Spice, and Fusion baby greens for New England.

The FarmTech Society (FTS) Held Its Second Constitutional Annual General Meeting (Virtually) on June 24th, 2020

Newly elected Chairman Ian Kanski commented “Thanks to the excellent work of FarmTech Society’s founding board and members, the organization is well-positioned for growth and impact in 2020

The Farm Tech Society (FTS) is an international non-profit industry association that unites and supports the Controlled Environment Agriculture (CEA) industry, seeking to strengthen the sector through the development and implementation of resilient and future proof methods and technologies for indoor growing.

The FarmTech Society is enlisted in the EU Transparency Register with #469686733585-87

The FarmTech Society (FTS) held its second constitutional annual general meeting (virtually) on June 24th, 2020. FTS members elected a new board of directors, who in turn appointed the new advisory board. The new boards are elected for a period of two years. The board of directors also appointed the daily management team. The election was held electronically and independently third-party verified.

Newly elected Chairman Ian Kanski commented “Thanks to the excellent work of FarmTech Society’s founding board and members, the organization is well-positioned for growth and impact in 2020. This is an important time for all regions to be investing in sustainable localized food and circular agriculture. Our new leadership team is committed to supporting the quality, safety, and education initiatives that will drive the adoption of Controlled Environment Agriculture globally.”

The election results were as follows:

New Board of Directors

Chairman: Ian Kanski Harrisburg University

INTAG Systems

Vice-chair: Nicole Thorpe Cultinova

Vice-chair: Tisha Livingston Infinite Acres

Director: Marinus Luiten Priva Group

Director: Alina Zolotareva Aerofarms

Director: Nico Domurath Frauenhofer Institute

Director: Andrew Blume Symphony Agtech

Director: Wythe Marschall Ph.D. candidate,

Harvard University

Director: Stefan Frey FREYconsult

Honorary: Gus Van der Feltz (founding member)

The appointments by the Board of Directors were as follows:

New Advisory board:

Edwin Vanlaerhoven Certhon

Maren Schoormanns Viscon Group

Chante Van der Walt Candidate Full Stack

Developer Udemy

Marvin Boell TüVSüd

Enrico Costanzo Cerial Docks

Stefanie Linzer. Valoya

Pierre Grootscholten Grootscholten

Consultancy

Kyle Barnett HortAmericas

Franc Bogovic Finance.Brussels

Yanni Garcia (founding member)

Penny McBride (founding member)

Adam Rosenbaum (founding member)

Daily management:

Secretary-General: Thomas Zoellner (founding member)

Treasurer: Stefan Frey FREYconsult

Communication: Mark Horler Soya Project / UKUAT

Legal counsel Stanislas Demeestere European Future Forum

What The Heck Is Farm Management Software?!

You can think of these platforms as “enterprise solutions” from Microsoft, IBM, Oracle, and SAP’s of the world...but for Ag.

By Aaron Magenheim, CEO & Co-Founder of AgTech Insight & Growers Insight

May 2020

Technology specifically built for Agriculture, (commonly known as AgTech or Precision Ag), has become an exciting space with Farm Management solutions leading digitalization. “Farm Management” has also turned into a buzzword many people use broadly and don’t really understand the importance of and details around – especially in our rapidly changing world.

As CEO and co-founder of AgTech Insight, a global advisory and implementation firm specializing in AgTech, I have been monitoring the evolution of this industry for several years, evaluating both existing and new solutions and companies. In 2015 we launched our first AgTech Market Map leveraging our internal solutions database by providing a free, valuable resource for those wanting a better understanding of which companies are leading the market organized by category.

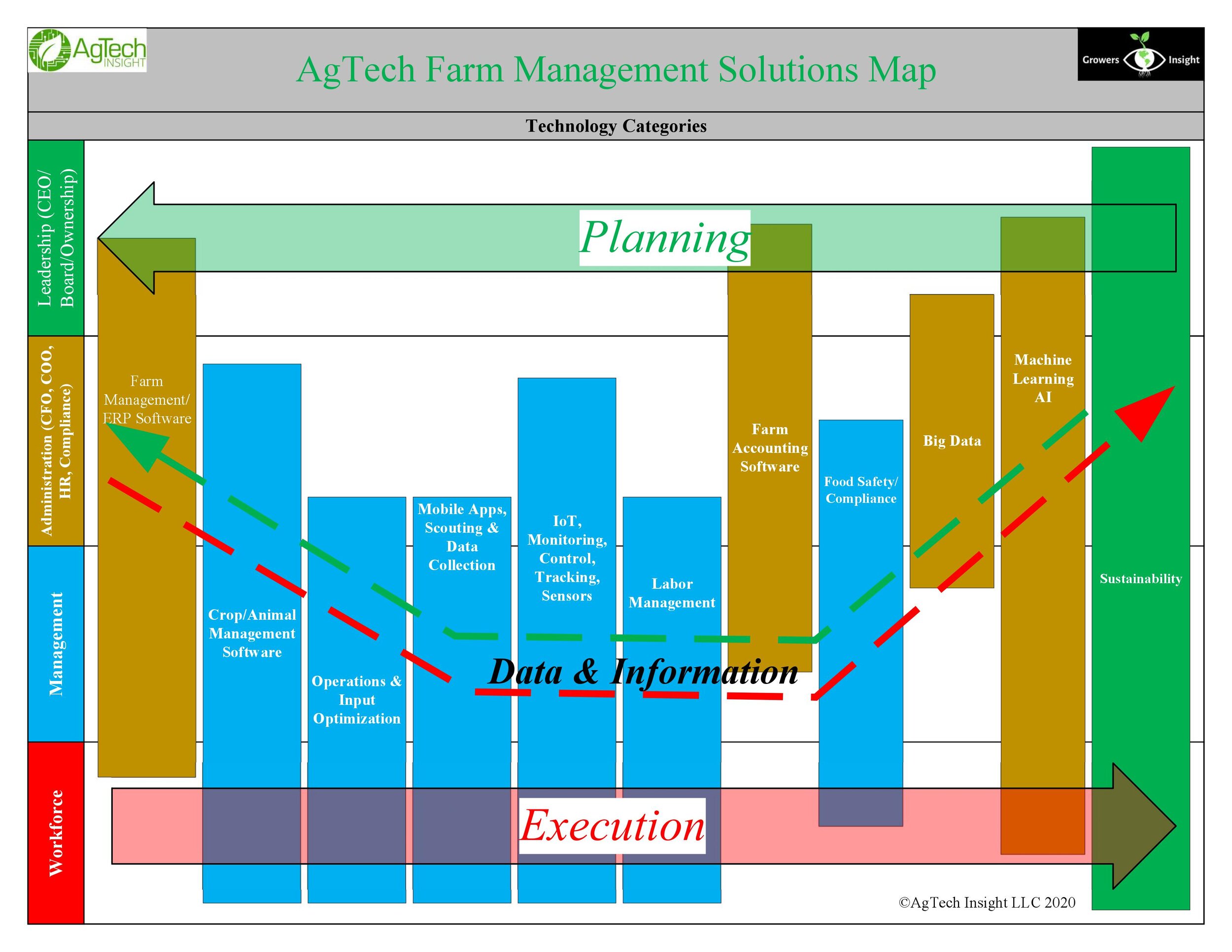

Over the past couple of years, our database of digital AgTech solution providers has grown to over 3,000 companies. Farm Management Software (FMS) has become the largest category, with over 500 listings. As we once again reviewed the details of each company to choose those we feel are leading their sector, it became clear we needed to further break down the FMS category based on core competency. This article explains the industry’s current state and how, as these AgTech solutions work in combination, they become extremely valuable for AgriFood businesses. We’ve also included an infographic illustrating how these technologies work together, who uses them, dataflow processes, and the value they bring throughout the organization.

Five years ago, lots of companies wanted to be the leading “FMS” platform. Today there is still no clear winner, so I think we can all agree it’s too big of a task with too many variables for one technology company. We must focus on user success, adoption, and RoI, therefore, our approach is to piece together many best-in-class solutions and then aggregate them — like they do in almost every other industry — to meet the needs of customers.

As the AgTech industry matures, there are companies who get really good at solving one specific problem becoming their “core technology.” This helps everyone understand where each company can provide the most value, as well as identifying the solution as complementary rather than competitive.

While the industry becomes more collaborative and standardized, each solution will continue to be a very important tool used day-to-day by some people on the farm while also feeding that data into larger farm management systems and platforms. These larger platforms are aggregating a variety of point source data being collected and provide a wider view of what’s happening on the farm for mid-level management. This data will be further shared to a business intelligence platform, which helps leadership make financial and business decisions but will not typically be used by a farm supervisor managing daily activities and production.

Leadership Level Solutions

Farm Management/ERP Software Platforms

You can think of these platforms as “enterprise solutions” from Microsoft, IBM, Oracle, and SAP’s of the world...but for Ag. They work with a variety of integrated software applications and systems to bring these dispersed datasets together and provide a variety of often custom analytic insights to company leadership. These platforms require an administrator and are primarily used to make financial and large business decisions rather than improving the day-to-day production of a specific crop.

Sustainability