Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

EDEN-ISS: Substantial Vegetable Harvest In Antarctica

“In just nine and a half months, we produced a total of 268 kilograms of food on just 12.5 square meters, including 67 kilograms of cucumbers, 117 kilograms of lettuce and 50 kilograms of tomatoes.”

EDEN-ISS ©Hanno Müller, AWI

Posted by Almut Otto | Aug 24, 2019 | Tags: Antarctic Neumayer III Station, Antarctica, DLR, greenhouses

No, luckily the climate in Antarctica is still inhospitable. And this is precisely why the German Aerospace Center (DLR) set up the EDEN-ISS greenhouse there in 2018. This is because food production of the future and future space missions are being researched in the immediate vicinity of the German Antarctic Neumayer III Station. In the meantime, the winter crew from the Alfred Wegener Institute (AWI), including DLR researcher Dr Paul Zabel, has spent a year surrounded by constant ice. The team presented the results on 23 August: There was an unexpectedly rich harvest. According to Zabel:

“In just nine and a half months, we produced a total of 268 kilograms of food on just 12.5 square meters, including 67 kilograms of cucumbers, 117 kilograms of lettuce and 50 kilograms of tomatoes.”

EDEN-ISS ©Hanno Müller, AWI

Before his trip, by the way, Zabel had been smart enough to look into artificial vegetable cultivation in Dutch greenhouses. Zabel adds:

“The taste of the fresh vegetables and their smell left a lasting impression on the winter crew and had a visibly positive effect on the team’s mood throughout the long period of isolation.

A correlation that is now also being researched from a psychological perspective.

Lower energy consumption than expected

Additionally, the scientists were surprised that they needed much less energy than they had initially expected. The average power consumption during the analog Antarctic mission was 0.8 kilowatts per square meter of cultivated area. It was consequently less than half as much as previously assumed for aerospace greenhouses, which were estimated at 2.1 kilowatts per square meter.

“This is an important aspect for a subsequent space venture and gives us confidence about the future of this idea”.

… says Project Manager Dr. Daniel Schubert from the DLR Institute of Space Systems. Aside from that, he stresses the potential and useful addition to space food that can be supplied by the earth:

“In one year in the Antarctic we have seen very clearly how enough food can be produced in a very small space in order to supplement the food of a crew of six by a third with freshly grown food.”

High workload should be reduced

Notwithstanding this, the researchers still see some potential for development. Because in order to save valuable astronaut time, the amount of work required for support and maintenance has to be significantly reduced in the future. Zabel needed an average of three to four hours a day in order to cultivate the plants:

” I spent about two thirds of my time operating and maintaining the greenhouse technology, another third on sowing, harvesting and maintenance. In the future, a space greenhouse needs to significantly reduce the amount of an astronaut’s valuable time.”

On top of that, the time required for experiments was about four to five hours per day. The aeroponic cultivation system, i.e. nutrient solution without soil, enabled the plants to flourish successfully. Some pumps caused problems in the intervening period and the biofilm in the nutrient tanks were unexpectedly high, yet these problems could be remedied.

New EDEN-ISS designed for the Falcon 9 rocket

Based on the results and experiences of the EDEN-ISS project, a new design concept for a space greenhouse has now been developed. This greenhouse is fairly compact in its design so that it can be launched aboard a Falcon 9 rocket. At the same time, it is expandable and large enough to provide sufficient food for the astronauts on the moon or on Mars. “The area used for cultivation is around 30 square meters, almost three times the size of the Antarctic greenhouse container. Using this system, around 90 kilograms of fresh food could be grown per month, which corresponds to half a kilogram of fresh vegetables per day and per astronaut if six astronauts are present,” Schubert explains.

The concept may also be combined with a biofilter system (C.R.O.P.). Its purpose is to produce a fertilizer solution for plant cultivation that is able to be utilized from biowaste and urine directly. This makes the greenhouse concept almost a fully bio-regenerative life support system for future habitats. Prof. Hansjörg Dittus, DLR Executive Board member responsible for space research and technology, elaborates further:

“The newly proposed concept for a space greenhouse is an invaluable foundation on which we intend to further expand our research work.”

EDEN-ISS is open to research teams worldwide

Following Paul Zabel’s return to Germany, the Antarctic greenhouse was initially in “sleep mode”. Previously, the DLR team had maintained all systems on site in January 2019 and completely overhauled the container. The Bremen researchers then woke the system up from its sleep at the beginning of May using a remote control system and powered it up again. A seed sown at an earlier stage began to flourish.

“This step served to test another space scenario. Because a provisional greenhouse is expected to arrive before the astronauts and ideally start its operation remotely.

… DLR researcher Schubert explains and he adds: “The test run was a complete success. Now the current AWI winter crew is continuing to operate the greenhouse with strong support from the Bremen Control Center, from where we monitor as much as we possibly can from a distance. The procedures developed last year are currently proving their worth in minimizing the crew’s workload and simplifying procedures as far as practicable”.

The greenhouse is also now available to various research groups worldwide who are interested in conducting plant cultivation experiments in the Antarctic.

“As one of the first new collaboration partners, the American space agency NASA has already sent us original NASA salad seeds, which are also cultivated on the International Space Station ISS and now thrive here in Antarctica,” Schubert adds.

Findings are interesting for global food production

The frozen continent of Antarctica is one of the most exciting research regions in the world. “It is primarily here that we gather data on global climate change and Antarctic biodiversity. However, the greenhouse is an excellent example of how we can conduct research at Neumayer Station III on other important questions for the future. After all, we have a lot in common with space travel when we travel to regions that are hostile to humans in order to gain new insights. At the same time, the permanent supply of fresh fruit and vegetables has a very positive side effect on our winter crew this year once again,” says Prof. Antje Boetius, Director of the Alfred Wegener Institute, who, during her stay at the station, was able to convince herself of the wonderful flavor of a juicy giant radish from the greenhouse. The cultivation of vegetables is consequently also interesting for future missions by the research icebreaker Polarstern.

Moreover, global food production is one of the central challenges facing society in the 21st century. An ever-increasing world population and the simultaneous upheavals caused by climate change call for new ways of cultivating crops even in climatically unfavorable regions. A self-contained greenhouse enables harvests that are independent of weather, sun and season, as well as lower water consumption and the elimination of pesticides and insecticides for deserts and regions with low temperatures, as well as for space missions to the moon and to Mars. In the EDEN-ISS project, such a model greenhouse for the future is undergoing long-term testing under extreme Antarctic conditions.

EDEN-ISS partners

EDEN-ISS is developed by DLR in cooperation with the Alfred Wegener Institute, Helmholtz Center for Polar and Marine Research (AWI) as part of a winter mission at the German Neumayer Station III in Antarctica. Numerous other international partners are working together as part of a research consortium under the leadership of DLR with the aim of ensuring that the Antarctic greenhouse functions properly. These include Wageningen University and Research (Netherlands), Airbus Defense and Space (Germany), LIQUIFER Systems Group (Austria), National Research Council (Italy), University of Guelph (Canada), Enginsoft (Italy), Thales Alenia Space Italia (Italy), AeroCosmo (Italy), Heliospectra (Sweden), Limerick Institute of Technology (Ireland), Telespazio (Italy) and the University of Florida (USA). The project is funded by the European Research Framework Program Horizon 2020 under project number 636501.

SUPPORT US!

Innovation Origins is an independent news platform, which has an unconventional revenue model. We are sponsored by companies that support our mission: spreading the story of innovation. Read more here.

On Innovation Origins you can always read articles for free. We want to keep it that way. Have you enjoyed this article so much that you want to contribute to independent journalism? Click here:

Share this article!

ABOUT THE AUTHOR

Almut Otto

Almut Otto is a writer and has over 30 years of know-how in the communications industry. She learned the trade of journalism from scratch in a daily newspaper and in a special interest magazine. After studying communication sciences in Munich, she worked as an international PR manager in the textile, shoe, outdoor and IT industries for a long time. For some years now, she has been concentrating more on her journalistic background. As a passionate outdoor and water sports enthusiast - her hobbies include windsurfing, kitesurfing, SUP boarding, sailing and snowboarding - she is particularly interested in keeping the oceans clean and shaping a sustainable future. In addition, she is always fascinated by the latest developments from the world's hardware and software laboratories.

Have You Seen 'Hydroponically Grown' On Your Produce? Here's What It Means

Have you been perusing the produce area at your store and noticed fruits or vegetables that say “hydroponically grown?” They just kind of popped up one day, and we noticed there wasn’t much explanation

By Dawn Jorgenson - Graham Media Group

August 21, 2019

Image by engin akyurt from Pixabay.

Have you been perusing the produce area at your store and noticed fruits or vegetables that say “hydroponically grown?” They just kind of popped up one day, and we noticed there wasn’t much explanation.

If you’re anything like us, you may have bypassed it just because you’re unsure about what a hydroponically grown product is.

As it turns out, unless you’re attempting to try this growing process yourself (spoiler alert: it can be tricky), the advantages seem to outweigh the disadvantages.

How it works

The fruits or vegetables are grown in a liquid solution that contains minerals they need to thrive. There is no soil used, and instead, the root system is supported by a medium such as perlite, rockwool, clay pellets, peat moss or vermiculite, according to Full Bloom Hydroponics. Doing so allows the plant roots to have direct contact with the nutrient solution, as well as access to oxygen.

The process allows the plant to not work as hard to obtain the nutrients, therefore allowing it to mature 25% faster and produce up to 30% more than the same plant growing in soil.

Growing plants hydroponically also uses less water than soil-based produce because the system is enclosed, preventing much evaporation.

Are hydroponically grown produce good for you?

Because hydroponic fruits and vegetables are not exposed to outdoor elements, they do not need the same level of pesticides to protect the plants from insects or pathogens, according to LiveStrong.com. This often allows organic farming methods.

This is good news, but there does seem to be a possible drawback to hydronic produce. Because of the high humidity of the greenhouses, the produce can be more susceptible to salmonella contamination. However, washing and cooking vegetables thoroughly should remove and help destroy any possible salmonella.

LiveStrong made a special note to remind consumers that even though hydroponic farming appeals to some because of environmental concerns, any diet high in vegetables can improve health, regardless of whether it was grown conventionally or hydroponically.

Have you tried hydroponically grown produce? What did you think about it? Let us know in the comment section below.

Modular Farms Australia Will Be The Training Partner For The Greenhouse Technical Management Course Hosted by Graeme Smith And Rick Donnan In Conjunction With Gotafe

Modular Farms Australia is pleased to announce that they will be the training partner for the Greenhouse Technical Management Course hosted by Graeme Smith and Rick Donnan in conjunction with gotafe

Modular Farms Australia is pleased to announce that they will be the training partner for the Greenhouse Technical Management Course hosted by Graeme Smith and Rick Donnan in conjunction with gotafe.

Whether you're considering becoming a modular farmer or already own a farm, this hydroponics course covers all you need to know about growing the most delicious hydroponic crops!

Email: LTaig@gotafe.vic.edu.au

Website: http://www.gotafe.vic.edu.au/

SIGN UP NOW

If you would like further information please contact the course coordinator Leigh Taig on the above details.

Email: LTaig@gotafe.vic.edu.au

Building A 2.76M Square Foot Sustainable Greenhouse In Job Starved Appalachia

The UN's Intergovernmental Panel on Climate Change just released a report highlighting the alarming effect climate change and the rise in global temperatures are having on fertile soil—and on the world's ability to produce enough food to feed the planet's growing population

Anne Field Contributor Entrepreneur

AppHarvest facility rendering | APPHARVEST

The UN's Intergovernmental Panel on Climate Change just released a report highlighting the alarming effect climate change and the rise in global temperatures are having on fertile soil—and on the world's ability to produce enough food to feed the planet's growing population. There’s also an increasing depletion of the global water supply.

Jonathan Webb, founder of two-year-old startup AppHarvest, thinks his company can help address those urgent crises. Specifically, he plans to produce more food with less water using massive controlled-environment, sustainable greenhouses. In the process, Webb, a native of Kentucky who also worked in renewable energy, also hopes to help revive the struggling Appalachian economy.

“There are technical solutions to many of these problems,” says Webb. “But much of it is a matter of execution at scale and at a rapid pace.”

His plan: build a 2.76 million-square-foot controlled-environment agricultural facility on 60-acres in Morehead, Kentucky, using hydroponic growing techniques, which rely on a nutrient solution, instead of the usual soil. As a result, according to Webb, it will be able to grow pesticide-free tomatoes and cucumbers year-round using 90% less water than traditional farming—and do so in the middle of coal country. Water will come from rainwater kept in a retention pool and there will be circular irrigation systems. The whole project takes its inspiration from the Netherlands, which is a top exporter of tomatoes, potatoes and onions, among other food, thanks to its pioneering work in climate-controlled agriculture.

The facility is also in a strategically-situated location that’s within a day’s drive of 70% of the U.S. population, according to the company. That should slash the amount of gas used in transportation compared to imports trucked across the country to the East Coast, while supplying markets with fresher produce. The company is working with distribution partner Mastronardi Produce.

In job-starved Appalachia, where one in four residents live in poverty, according to the U.S. Census Bureau, the facility also could provide a boost to the economy. While AppHarvest is buying components from the Netherlands, Webb estimates that the project will create 285 full-time positions, plus 100 construction jobs. The company will also work with local universities to add job training classes.

Webb recently closed an $82 million all-cash deal with Equilibrium Capital to build its greenhouse. Plus, it raised more money in a Series A round led by Value Act Spring Fund and joined by existing investor Revolution’s Rise of the Rest Seed Fund.

The mega-greenhouse is projected to be up and running by mid-2020. As for building similar facilities in other parts of the country, Webb says he wants to see that happen, but by different parties. “We’re in Appalachia,” he says. “But I hope other people will be building throughout the country.”

I'm an award-winning journalist with a particular interest in for-profit social enterprise, as well as entrepreneurship and small business in general. I've covered those areas for many many places, including The New York Times, Bloomberg Businessweek, Crain's New York Business, Inc. and Business Insider. As an entrepreneurial journalist--ie, a freelancer--I work from my home office in Pelham, NY.

Mucci Farms Acquires Orangeline Farms And Announces Expansion Plans

Mucci Farms announces that it has acquired controlling interest of Leamington, Ontario based Orangeline Farms, including its existing greenhouse and warehouse facilities, and additional land with plans for expansion. Subsequently, the company also announced additional expansion plans in Canada and the United States

August 21st, 2019 (Kingsville, Ontario)

Mucci Farms announces that it has acquired controlling interest of Leamington, Ontario based Orangeline Farms, including its existing greenhouse and warehouse facilities, and additional land with plans for expansion. Subsequently, the company also announced additional expansion plans in Canada and the United States.

Duffy Kniaziew

Bert Mucci

“It’s an exciting time for the company as we continue our aggressive expansion plans to increase our local and regional production,” says Bert Mucci, CEO. “The Orangeline acquisition comes with a 32-acre greenhouse and a warehouse with additional land totalling 100 acres. Consumers are demanding more local production, and we’re listening. We also have plans in place to build on the additional land that was received as part of the agreement.”

Founded in 2000 by the Kniaziew family, Orangeline Farms is an award-winning grower predominantly known for their unique pepper offerings grown under the Zing!TM Healthy Foods brand. “In searching for growth opportunities for both Orangeline’s staff and our ever loyal customers, the chance to partner with a world class organization like Mucci Farms was an easy decision to make,” said Duffy Kniaziew, Founder. Mucci Farms will continue to use the Zing!TM brand for the foreseeable future as it has quietly established itself among retailers and consumers. “Duffy and his team have done a great job with the brand and it’s familiar in our region, so we’re not looking to make any dramatic changes at the moment,” said Emily Murracas, Director of Marketing.

Originally a 60-acre project in Huron, Ohio, the company has also acquired additional land adjacent to the current property to increase the totality of the enterprise to 75-acres. “The first 24-acre phase is in its second season of harvesting, and we’ll be building two more identical ranges. Phase two construction is already underway,” remarked Bert Mucci. “The Ohio program has gotten off to a great start and we’re looking forward to growing our presence in the community and the regional market.”

Mucci Farms is a vertically integrated fruit and vegetable grower that owns and operates 250-acres of tomato, pepper, cucumber, lettuce and strawberry greenhouses in Canada and the United States, with a partner-grower network of 1500 acres across North America. Committed to maximizing efficiencies, the organization makes sizeable investments in automation and technology to provide consumers with the most flavourful fruits and vegetables in the market.

In addition to harvesting and packing equipment, these investments include a significant acreage of grow lights that allow the company to grow locally 365 days per year, with an end goal of equipping 100% of their hi-tech glass facilities with High Pressure Sodium and/or LED lights.

US, OHIO: Great Lakes Ag Tech Summit - September 23, 2019

Join Urban Ag News, Hort Americas and Current, powered by GE, for the inaugural Great Lakes Ag Tech Summit on September 23. The summit will be held at at the historic Nela Park campus in Cleveland, Ohio

By urbanagnews

August 14, 2019

Join Urban Ag News, Hort Americas and Current, powered by GE, for the inaugural Great Lakes Ag Tech Summit on September 23. The summit will be held at at the historic Nela Park campus in Cleveland, Ohio.

The one-day event features keynote presentations and panel discussions from leading researchers and innovative growers in the Great Lakes region. Attendees will be able to connect with growers, scientists, researchers and entrepreneurs as we shape the future of food and move controlled environment agriculture forward.

Keynotes

Optimizing Plant Production Under a Controlled Environment – Research and Education Programs at the Ohio State University

Dr. Chieri Kubota – The Ohio State University

Dr. Kubota’s research mission is to serve in the development of science and technology in the area of controlled environment agriculture (CEA). Her projects are in an interdisciplinary area that encompasses plant physiology and horticultural engineering to enhance understanding and efficiency of CEA plant production systems such as greenhouses, warehouses (vertical farms), and growth chambers.

Are Consumers and Growers Putting Dollars in the Local Food Industry? Insights on Technologies and Preferences

Dr. Ariana Torres – Purdue University

Dr. Torres’ background combines field experience in agriculture with theoretical and applied research on agricultural economics. She has worked on projects looking at the impact of marketing choices on technology adoption for fruit and vegetable growers; the economic implications of social capital on entrepreneurship; and the role of community support on the resilience of small business after disasters.

Dr. Torres uses economic analysis to support the economic viability of the horticulture industry. Her research focuses on the intersection between the horticulture industry and marketing decisions. Her goal is to conduct innovative outreach and applied research in specialty crops marketing, with the end of promoting economic sustainability for horticultural businesses.

Dr. Torres is currently working on a project evaluating the market, economics, and potential barriers to produce export-quality dried apricots from smallholders of southern Tajikistan. She is also working on evaluating the adoption of a solar dehydrator for selected dried specialty crops in Indiana and Georgia. Lastly, she is collecting foundational data and establishing long-term pricing reports for Indiana farmers markets.

Vertical Farm Production of Young Plants, From Hemp to Tomatoes

John Jackson – Sustainable Indoor Growing Systems, Inc.

John is the CEO of Sustainable Indoor Growing Systems, Inc. (SIGS) born from an USDA funded industry-academic partnership with Grafted Growers, the University of Arizona, and North Carolina State University. John is an award-winning entrepreneur and University of Arizona alum with an MBA from the Eller College of Management. John has successfully launched investor and grant funded businesses and operated tech based companies to early stage revenue. Born in Compton, California, John continues his grandfather’s legacy as a sharecropper of tomatoes in rural Texas.

SIGS gives plants what they need to express the features that the market wants.

Sustainable Indoor Growing Systems, Inc. (SIGS) is a clean agricultural technology company that uses controlled environment agriculture to induce young generic plants to express enhanced physiological traits customers want – while increasing the economics of propagation. This is made possible by scientific discovery and development of unique growing recipes which are learned and enabled only by the SIGS multi-layered growing platform and architecture.

Click Here to Register Now! Seats Are Limited!

Location

1975 Noble Rd. Cleveland, OH 44112

Date & Time

Monday, September 23, 2019

9 am to 4pm

Registration

Early bird admission price is $30 if registration occurs before Sept. 16.

Regular admission: $50

Hotel

Hyatt Legacy Village

24665 Cedar Rd

Lyndhurst, OH 44124

The rate is $129 for the night of 9/22/19.

• Call the toll-free number at 1-888-492-8847 for Hyatt Place Reservations and ask for the “Great Lakes Ag Tech Summit” or code G-GLGT

• OR use this link https://www.hyatt.com/en-US/hotel/ohio/hyatt-place-cleveland-lyndhurst-legacy-village/clezl?corp_id=G-GLGT

Click Here to Register Now!

About Urban Ag News

The mission of Urban Ag News is to be the leading science communicator for the commercial hydroponics, greenhouse vegetable, vertical farming and urban agriculture industries. Urban Ag News educates readers and provide an understanding of the industry’s latest technologies and luminaries.

About Current, powered by GE

Current, powered by GE, offers cutting-edge innovations in horticultural lighting. We’ve spent years perfecting our lighting technology and working with growers, systems integrators and plant scientists to establish the specific needs of the horticulture industry. The result? LED grow systems that maximize the potential of greenhouses and indoor farms by enabling efficient growth at an industrial scale.

TAGS Ariana Torres Chieri Kubota Conference GE Lighting Greenhouse Greenhouse Technology Hort Americas Indoor Ag Technology LED Grow Lights Ohio State University

Urban or Rural: Where To Build A Greenhouse

Drawing from experience, Lefsrud points out that governments across the world, not just in Quebec, have largely been slow to consider using urban greenhouses as a legitimate food generator

‘You need political will, and it takes time’ – urban greenhouses could benefit from more direct support from governments, experts say.

August 20, 2019

Written by Doug Johnson

Montreal’s Lufa Farms now has three locations and around 17,000 customers.IMAGES: Lufa Farms

The first two floors of 1400 Rue Antonio Barbeau in Montreal look like they belong on any other low-density commercial building – blocky, covered in mottled brown brick and windows gazing into a beige interior. Just over the lip of its roof, though, peeks long walls made of glass and metal, and inside them, rows of vegetables.

Around a decade ago, the building was a full floor shorter. That was before Lufa Farms – a Montreal-based urban farm and food delivery service – began. It touts itself as the world’s first commercial greenhouse located on a rooftop.

Now, Lufa Farms has three locations spread across Montreal – others are in the Laval and Anjou neighbourhoods – and around 17,000 customers that the company has dubbed ‘Lufavores.’

But back when it first started, urban agriculture, in- or outside of a greenhouse, was something new and untested. Even Lufa Farms – which is now often pointed to as a model of what urban agriculture could be – had a rough time finding a home and traversing the untested waters of starting a farm of its size in a city.

“The biggest thing [was], there was no proof of concept ... Everything from finding a suitable building – because it was something that hadn’t been done – to an open building owner to city and zoning. It was very out-of-the-box,” says Lauren Rathmell, Lufa Farms’ co-founder and greenhouse director.

Quebec’s agriculture department, Ministre de l’Agriculture, des Pêcheries et de l’Alimentation (MAPAQ), recently released a report on the state of greenhouse-grown produce in the province. The report noted that only 31 per cent of greenhouse vegetables consumed in Quebec were grown in the province – Rathmell, and other urban agriculture dignitaries, say there’s potential here. The report also notes that the increased demand for organic foods presents Quebec with another area due for growth, and that Ontario has not actively pursued it.

While many of Montreal’s neighbourhoods now vie for a Lufa Farms location, its growing pains are familiar to many sizeable urban agriculture efforts.

Mark Lefsrud has studied different ways of growing food for more than 20 years. He is an associate professor at McGill University’s Macdonald Campus where he is a leader of the Biomass Production Laboratory and worked on the design of the Advanced Plant Habitat on the International Space Station.

Drawing from experience, Lefsrud points out that governments across the world, not just in Quebec, have largely been slow to consider using urban greenhouses as a legitimate food generator.

“It was an unknown – that’s the best way to describe it. They’re used to external, outside-of-the-city food production systems and field conditions. The idea of [using] full, controlled environments wasn’t in their comfort [zone],” he says.

However, the idea of turning unused space in urban centres into something that could aid food security is not an old one. It’s been around for maybe a decade, and agricultural ministries around the world are increasingly eyeing it as a path to feed and employ people – particularly in food deserts.

Lufa Farms’ earlier struggles were largely logistical ones, and the Gouvernement du Québec hasn’t particularly helped or hindered the business’ growth, Rathmell says. While the situation has improved in recent years, there are still challenges that face the industry as a whole.

Cost is a big issue – perhaps more so than other more traditional businesses. Besides the normal run of fees paid by every business, urban agricultural operations above a certain size need to pay to construct a specialized facility. However Rathmell notes that it has become cheaper as acceptance has grown.

Rooftop greenhouses are a bit of a different beast. There’s also the added difficulty of physically moving the building materials onto the roof. And, as much as they encourage people to give a useful purpose to a previously unused space, they come with a dossier of regulations. Functionally, they’re treated like an entirely new floor of a building.

The facility on this new floor needs a sprinkler system, and it needs to be sturdy enough to bear a lot of snow during the winter – [all] in all, it’s a hefty structure, Rathmell says.

Many places are not zoned for greenhouses or other agricultural activities like aquaponics, according to Rathmell. Historically, most urban planning in cities rarely took urban agriculture into consideration.

The land itself is also more expensive in urban areas than it is in rural ones. Lefsrud has a rough calculation for this. In rural operations, a plant usually costs between $0.05 and $0.10 to grow, compared to urban greenhouses, where the cost per plant can be as high as $0.45, depending on the season.

Vertical farming somewhat offsets this. Though there is a larger initial price tag to get started, after a while the density of plants – three dimensions as opposed to two – pays for the added costs. Traditionally, the companies that lend credit to agriculture ventures, like Farm Credit Canada and more recently Desjardins, have been wary of providing credit to urban agriculture efforts, but according to Lefsrud they are beginning to catch on.

Some costs can be offset in a city, though. It’s easier to find labour in high population centres, and the ambient warmth lowers the price of heating somewhat – either from the urban heat island effect or, more directly and in the case of rooftop greenhouses, the floors in the building below.

Regionally-based energy company Énergir – formerly Gaz Métro – offers grants for natural gas boilers, something which Lufa has taken advantage of to generate further warmth for its operations.

MAPAQ notes that Hydro Québec offers an incentive for growers with supplemental lighting. Designed for greenhouse operators who use all or part of their electricity supplied by Hydro Québec for photosynthetic lighting, this rate option is ideal for customers who can adjust their production to help manage their electricity consumption. According to the report, around 40 per cent of the greenhouse vegetable area in Quebec uses supplemental lighting, a tool that can help extend the growing season and, in turn, help growers take advantage of better market prices.

According to MAPAQ, the department has also established a network to aid urban agriculture across Quebec. As the province only obtains 31 per cent of its greenhouse produce from local sources, the remaining 69 per cent that is imported could potentially be met by local production.

However, according to Olivier Demers-Dubé, founder and CEO of Écosystèmes Alimentaires Urbains (ÉAU), around 80 per cent of greenhouses in Quebec grow for only three out of four seasons every year, limiting the sector’s potential.

“I think we’re producing a very low percentage of what we’re actually eating, even more so in [the] winter. These numbers ... that’s year-round,” he says of the information provided by MAPAQ.

Since it began five years ago, ÉAU has helped 10 communities in Quebec design aquaponic systems. This includes an Indigenous community in the north of the province, Whapmagoostui. ÉAU also works with private investors and pre-established food producers looking to attach a fish farm to their greenhouse or vice versa.

“We have this goal to bring back food production to where humans live, and humans live mainly in cities,” Demers-Dubé says.” We have this strong belief that food production need[s] to be close to where we live. We need to have contact, we need to interact with it. Eating is what we do most in our lives, minus breathing.”

According to Demers-Dubé, there are facets of starting an urban greenhouse that are becoming easier, but at a basic level, it’s still more difficult to set up a sizeable facility in the city than it is elsewhere. Further, he says, though many governments offer programs and funding that coincide with urban agriculture, there are still precious few initiatives that specifically seek to aid those operations.

“You need political will, and it takes time,” he says.

Going forward, one of the biggest challenges to urban agriculture comes in a fairly innocuous form. Now that Canada has legalized recreational cannabis, most of the thought and attention paid to greenhouses in general, by both businesses and governments, is dedicated to this relatively new industry.

“Right now, one of our biggest challenges is cannabis taking all the air out of the room,” Lefsrud says.

'Groundbreaking' New Venture To Create 'World's Most Advanced Indoor Farming Project'

Mastronardi Produce and visionary John Paul DeJoria say they will develop 'the world's large and most advanced indoor farming project’. North American greenhouse grower Mastronardi said they've selected the Middle East as the first market for the new venture

August 19 , 2019

Mastronardi Produce and visionary John Paul DeJoria say they will develop 'the world's large and most advanced indoor farming project'.

North American greenhouse grower Mastronardi said they've selected the Middle East as the first market for the new venture.

The newly formed company, Green International Ventures LLC (GIVE), will use its proprietary Advanced High-Density Farming System.

This will be the first project for the "groundbreaking" venture, Mastronardi said.

The company said the project will reduce the Middle East’s dependence on imported food, create a sustainable source of local employment, and significantly increase the region’s non-petroleum-based exports.

Green International Ventures poised for international expansion

Paul Mastronardi, president, and CEO said the company is eager to increase access to local and sustainably-grown produce.

“Our first location in the Middle East will allow us to reach over half the world’s population in less than 8 hours, and this is just the start," he said.

"[We will] look for more global locations as we continue to scale to meet the growing need for food security, safety, and sustainability.”

GIVE will also support the integration of modern AgTech initiatives into the local farming community, the company said. In addition, it will expand knowledge of sustainable agricultural techniques by establishing a Research and Development facility in the region.

“It has long been my passion to help feed the world’s population,” says John Paul DeJoria. “The introduction of this revolutionary model in the Middle East is the first step of many towards increasing global access to sustainably grown fruits and vegetables.”

Furthermore, all GIVE projects use innovative Advanced High-Density Farming Systems that incorporate a multitude of cutting-edge growing systems. These include water-saving irrigation and energy-efficient lighting. It also takes advantage of advanced automation, AI processes for predictive analysis, and real-time crop and soil monitoring.

GIVE will market all produce it produces with the innovation systems under the SUNSET brand.

Mastronardi, DeJoria Launch GIVE Partnership In Middle East

Mastronardi Produce Ltd.®, North America's leading grower and distributor of greenhouse produce, and visionary John Paul DeJoria have selected the Middle East as the first market in which to develop the world's largest and most technologically advanced indoor farming project.

NEWS PROVIDED BY

Aug 19, 2019

KINGSVILLE, ON, Aug. 19, 2019 /PRNewswire/ - Mastronardi Produce Ltd.®, North America's leading grower and distributor of greenhouse produce, and visionary John Paul DeJoria have selected the Middle East as the first market in which to develop the world's largest and most technologically advanced indoor farming project.

Green International Ventures LLC (GIVE)'s Middle East location will be the world's largest and most technologically advanced indoor farming project. (CNW Group/Mastronardi Produce Ltd.)

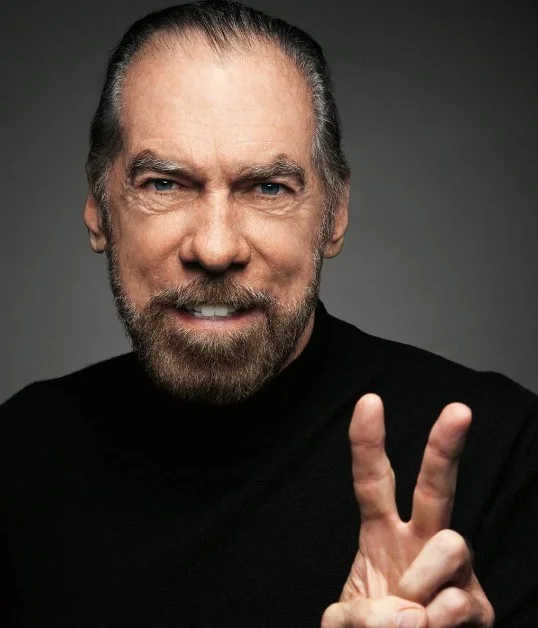

John Paul DeJoria (CNW Group/Mastronardi Produce Ltd.)

.Paul Mastronardi (CNW Group/Mastronardi Produce Ltd.)

The newly formed company, Green International Ventures LLC (GIVE), will make locally grown fresh produce more widely available around the globe via its proprietary Advanced High-Density Farming System. This will be the first project for the groundbreaking GIVE venture, and it will reduce the Middle East's dependence on imported food, create a sustainable source of local employment, and significantly increase the region's non-petroleum-based exports.

"As pioneers in the greenhouse industry, we are passionate about increasing access to local, sustainably grown fruits and vegetables," says Paul Mastronardi, President and CEO, and the fourth-generation family member to lead Mastronardi Produce. "Our first location in the Middle East will allow us to reach over half the world's population in less than 8 hours, and this is just the start. Look for more global locations as we continue to scale to meet the growing need for food security, safety, and sustainability."

GIVE will also support the integration of modern AgTech initiatives into the local farming community and expand knowledge of sustainable agricultural techniques by establishing a permanent Research and Development facility in the region.

"It has long been my passion to help feed the world's population," says John Paul DeJoria. "The introduction of this revolutionary model in the Middle East is the first step of many towards increasing global access to sustainably grown fruits and vegetables."

All GIVE projects use innovative Advanced High-Density Farming Systems that incorporate a multitude of cutting-edge growing systems, such as water-saving irrigation and energy-efficient lighting, and they take advantage of advanced automation and robotic devices, AI processes for predictive analysis, and real-time crop and soil monitoring.

Produce grown in these innovative AgTech systems will be marketed under the SUNSET® brand. Known for award-winning flavor, innovation, and packaging, SUNSET's many exclusive labels include Campari®, the world's first branded tomato, and the uniquely colorful Aloha™ pepper.

SUNSET of Holland® will be the first distributor for the GIVE partnership.

About Paul Mastronardi and Mastronardi Produce Limited

Paul Mastronardi is the President and CEO of Mastronardi Produce, which recently received the prestigious honor of being named one of "Canada's Best Managed Companies" for the 10th consecutive year. In 2016, Paul was named Produce Person of the Year at the United Fresh Convention & Exposition in Chicago, USA, and in 2013, he was named Ernst & Young's "Entrepreneur of the Year" for Ontario.

Mastronardi Produce, the leading greenhouse company in North America, grows and sells flavorful, world-class tomatoes, peppers, cucumbers, and berries under the Sunset® brand. As pioneers in revolutionary greenhouse technology, they focus on sustainable non-GMO growing practices, recognizing that what is good for the environment, is good for business.

About John Paul DeJoria

John Paul DeJoria is a serial entrepreneur, philanthropist, business leader, and mentor with a true rags-to-riches story. Once homeless, he overcame adversity, and went on to build two billion-dollar brands—leading professional hair care manufacturer, John Paul Mitchell Systems, and Patrón Spirits—and several global enterprises. He started his first company, John Paul Mitchell Systems, with partner Paul Mitchell and a borrowed $700. He remains true to his motto, "success unshared is failure," and dedicates himself to numerous charitable causes through his philanthropy hub, JP's Peace, Love & Happiness Foundation, and he has committed to donate more than half of his wealth to philanthropy through his signing of Bill Gates and Warren Buffet's "The Giving Pledge."

SOURCE Mastronardi Produce Ltd.

Related Links

Hydroponic Farms Use Less Land, Water To Grow Vegetables

Growing lettuce and other leafy greens indoors is gaining traction nationwide, as such big players as New Jersey-based Aero Farms and Bowery, are producing huge quantities in giant warehouses fueled by millions of dollars in investment

By Susan Salisbury For The Palm Beach Post

August 12, 2019

Green Life Farms’ hydroponic greenhouse occupies nearly 3 acres. It expects to yield 750,000 pounds of premium leaf green produce throughout the year, said Mike Ferree, vice president. The greens are grown, harvested and packaged onsite. [CONTRIBUTED BY HYDRONOV}

Greenhouses Allow Year-Round Growing

And Protection From Freezes And Extreme Rainfall.

Growing lettuce and other leafy greens indoors is gaining traction nationwide, as such big players as New Jersey-based Aero Farms and Bowery, are producing huge quantities in giant warehouses fueled by millions of dollars in investment.

The push comes as farmland becomes increasingly expensive and in short supply, and consumers demand locally grown produce that’s fresher because it hasn’t been transported hundreds of miles.

In Palm Beach County two new hydroponic farms—Green Life Farms and Patagonia Green Leaf— are being launched in greenhouses off U.S. 441 west of the Lake Worth Beach/Boynton Beach area. Hydroponic farming uses no soil. Instead, crops are grown in perlite, coconut fiber or nutrient-rich water in a controlled and enclosed environment.

Art Kirstein, agricultural economic development coordinator with the Palm Beach County Cooperative Extension Service, said that hydroponic farming offers advantages such as year-round growing, increased capacity on a smaller amount of land and protection from freezes and weather events such as extreme rainfall.

Green Life Farms harvested its first crop of baby arugula, baby romaine and baby spinach in mid-July. Its greenhouse occupies nearly 3 acres and will yield approximately 750,000 pounds of premium leaf green produce throughout the year, said Mike Ferree, vice president.

Baby romaine lettuce grows in the Green Life Farms hydroponic greenhouse off U.S. 441 west of Lake Worth Beach. The company has spent $15 million on the facility.

The greens are grown, harvested and packaged onsite, then picked up or shipped directly from the farm. They are also GMO and pesticide-free.

Green Life’s head grower, Greg Graft, said the produce is mechanically harvested using an automated system.

The first crop is not available for sale. Once Green Life begins official commercial production, products will be available at local grocery stores, restaurants and other locations, Graft said.

Green Life chose Palm Beach County for its large consumer market, proximity to sales partners and an agriculture-friendly environment, Graft said. It has invested $15 million so far.

Green Life uses a deep-water floating raft technology from Hydronov, an Ashley, Ind.-based leader in the hydroponic industry with more than 30 years of experience.

The floating raft system helps to conserve water, using the oxygenated clean water in which the plants grow as a conveyor system. Green Life will be able to produce 18 harvests each year and use 90 percent less water than conventional farming.

Patagonia Green Leaf, about a mile south of Green Life, is a hydroponic farm on a former plant nursery. It’s owned by the Canosa family. They’ve farmed in the traditional way in Argentina for 10 years.

The first phase of 10 greenhouses totaling 30,000 square feet is completed. The initial crop of baby greens will be planted soon, with harvesting expected by late September.

“The idea is to harvest and deliver the product within 24 hours,” said Juan Ignacio Canosa, who lives in Boca Raton.

After visiting Miami and Fort Lauderdale on vacations, the family started coming to Boca Raton. Last year they bought 5 acres from Boynton Botanicals, whose owner was retiring.

Plants will be grown pesticide-free using a system known as NFT, (nutrient film technique) from Arcata, Calif.-based AmHydro. A pump delivers fertilized water to the growing trays, flows over the plants’ roots, then drains back into the reservoir and is recycled.

Robert Hochmuth, regional extension agent with the University of Florida’s North Florida Research and Education Center, said since the early 2000s, the number of acres of produce grown in greenhouses and other structures in Florida has increased five-fold to more than 500 acres.

Producing in protected structures extends the season and reduces insects and diseases, Hochmuth said.

“You can be a consistent supplier in the marketplace over a long period of time,” Hochmuth said.

Most of the hydroponic farms in Florida are less than an acre and tend to cater to local markets.

Hochmuth said hydroponic growing is attracting people who are new to farming.

“Because they are going with high-value specialty crops, the likelihood of profitability makes sense,” Hochmuth said.

Of course, greenhouses and other facilities are at risk of being destroyed during hurricanes or high winds. Hochmuth advises removing the plastic from the structures prior to storms because it acts as a sail.

Hydroponic farming isn’t new to Palm Beach County. Walter Ross founded Farmhouse Tomatoes west of Lake Worth in 1996 and grows heirloom tomatoes in 160,000-square-feet of greenhouses from Nov. 1 through June 30.

BrightFarms Names New CEO To Lead Expansion

BrightFarms has hired Steve Platt has as its new CEO, according to a company press release. Company founder Paul Lightfoot will stay on as the packaged salad brand's president. Both men will sit on the company's board of directors

(Credit: BrightFarms )

AUTHOR: Jennifer Sweeney

Aug. 15, 2019

Dive Brief:

BrightFarms has hired Steve Platt has as its new CEO, according to a company press release. Company founder Paul Lightfoot will stay on as the packaged salad brand's president. Both men will sit on the company's board of directors.

Platt has spent his career working with CPG companies, most recently as CEO of yogurt brand Icelandic Provisions. Before that, he led Danone brands including Dannon, Oikos and YoCrunch.

Platt said in a statement that this is an exciting time to join the company as continues to expand nationally, and Lightfoot acknowledged Platt's "know-how" as a leader of CPG brands and his ability to take BrightFarms to the next level.

Dive Insight:

BrightFarms, which currently operates greenhouses in Illinois, Ohio, Pennsylvania and Virginia, recently announced plans to open three additional farms in Massachusetts, New York and North Carolina next year. The additional greenhouses are expected to break ground at the end of this year, with production kicking off in early 2020. The expansion shows that the company is ready for aggressive, national growth, and along with that comes the need for a new CEO with expertise to help the company scale.

During his career with national brands, Platt has had particular success with helping brands grow quickly. According to BrightFarms' press release, Platt was at Icelandic Provisions he grew the company to more than 6,500 retail stores and turned it into "the fastest-growing brand in dairy yogurt."

Platt's hire follows two other notable additions this year, both of which position BrightFarms for ongoing growth. In February, Steve Campione joined the company as Chief Financial Officer. Campione brought a background in finance and investment banking and spent a decade raising capital for companies looking to expand. BrightFarms added Brian Jenny as vice president of sales in May, filling a key role to lead business development.

The company is expanding its retail partnerships in areas where its greenhouses operate. As of January, BrightFarms' produce is available at Jungle Jim’s International Marketplace in Ohio, select Food Lion stores in Virginia, Dierbergs in St. Louis and more than 140 Tops Friendly Markets in New York, Pennsylvania and Vermont. BrightFarms also works with Misfits Market, a delivery service that ships imperfect produce to subscribers in Pennsylvania, New Jersey and Delaware.

Demand for products from companies like BrightFarms continues to grow as Americans prioritize locally grown food. Indoor farming startup Square Roots has partnered with food distributor Gordon Food Service to provide produce to Gordon customers, and vertical farming company AeroFarms recently raised $100 million in funding for expansion.

Recommended Reading:

GROCERY DIVE BrightFarms plans three new greenhouses

GROCERY DIVE BrightFarms expands its retail footprint

Superior Fresh Leading The Way In Aquaponics

Nestled in the Coulee region of Wisconsin is one of the largest aquaponics facilities in the world. It sits on a 720-acre native restoration property and raises leafy greens as well as Atlantic salmon and Steelhead

BY ADAM CAMPBELL | AUGUST 19, 2019

Nestled in the Coulee region of Wisconsin is one of the largest aquaponics facilities in the world. It sits on a 720-acre native restoration property and raises leafy greens as well as Atlantic salmon and Steelhead.

Superior Fresh, located in Hixton, WI, is taking sustainability to the next level. “The restoration property has been converted from conventional, monocrop agriculture into natural, native prairies and oak savannas,” said Nate Hefti, regional sales manager for Superior Fresh. “The fish-house and greenhouses are using state-of-the-art technology to efficiently raise fish and vegetables, giving us the opportunity to return the land back to its native state. All waste products from the facilities are composted onsite and used to enrich the poor soils that exist throughout the land.”

The water used to raise the salmon is cycled through to then fertilize the aquaponics facility, then cycled back again to the salmon tanks, meaning zero discharge of production water.

“By weight, for every one pound of salmon we produce we feed the fish 1.1 pounds of food. This equals nearly a one-to-one feed conversion ratio (FCR) but does not include the additional 10 pounds of produce we grow per one pound of fish food,” said Hefti. “Therefore, we have a FCR that is one-to-10, equaling one pound of fish food into the system and 10 pounds salmon and vegetables out.” For perspective, cattle has a food conversion ratio of approximately 10 to one, meaning every one pound of beef requires 10 pounds of cattle feed.

Currently the company is shipping up to 4,000 pounds of baby greens 1,000 pounds of head lettuce every day and is always looking at opportunities to expand into other markets to allow more people the opportunity to buy organic, safe, local fresh food. With nearly zero water discharge, the company believes facilities could be located anywhere on the planet, making it a readily available and safe local food source.

Signify Helps AppHarvest To Increase Yields In 25-Hectare Greenhouse

Eindhoven has partnered with AppHarvest to help the company increase efficiency and boost yields using significantly fewer resources in their 25 hectare greenhouse in Morehead, Ky., USA

AppHarvest Improves

Efficiency Through Combining LED And Conventional Lighting

Eindhoven has partnered with AppHarvest to help the company increase efficiency and boost yields using significantly fewer resources in their 25 hectare greenhouse in Morehead, Ky., USA. The greenhouse will be fitted with a hybrid LED lighting system, utilizing Signify’s Philips GreenPower LED toplighting compact and Agrolux high pressure sodium lighting. AppHarvest will grow tomatoes and cucumbers in its facility, which will be completed in the second half of 2020.

“This LED installation reinforces how we use proven technology to grow more fresh food with fewer resources,” said Jonathan Webb, Founder and CEO of AppHarvest. “With this cutting-edge hybrid system, we will dramatically reduce energy usage in the greenhouse. Working with Signify has given us the benefit of leveraging on a decade of growing knowledge and expertise.”

The facility uses a unique LED and High-pressure sodium (HPS) hybrid lighting system, to significantly reduce energy while increasing yield over the year. The LED lighting system is 40 percent more energy efficient than traditional greenhouse lighting, while it disseminates less radiant heat. During fall and spring, LED lighting will be used to grow more produce. HPS lamps will be used during colder months, in addition to the LED system. The heat from the HPS system will help warm the greenhouse and reduce natural gas usage.

AppHarvest is partnering with Equilibrium, a leading greenhouse investment firm. The LEDs will be installed by Dalsem Complete Greenhouse Projects, which is overseeing construction of the greenhouse.

“We’re very excited about our collaboration with AppHarvest and Equilibrium,” said Bill Bien, CEO of Signify Agriculture Lighting. “It’s great to work with partners just as committed to sustainable horticulture as we are, and we’re looking forward to helping them increase growth predictability, crop quality and yields, while improving their energy efficiency.”

The LED toplighting compact delivers high light output of 1,800 µmol/s and an efficacy of up to 3.0 µmol/J and helps growers effectively optimize crop growth, enhance crop quality and cut operational costs. Compared to a 1,000 W HPS fixture, the Philips GreenPower LED toplighting compact produces the same amount of light, has a similar light distribution, while consuming 40% less power and emitting considerably less radiant heat. By separating heat and light, this product gives growers independent control over their greenhouse climate.

Nature Inspires Some of The Coolest Things

Unlike many other vertical farms, which are located in artificially lit warehouses and cut off from the outside world, Vertical Harvest makes use of natural sunlight and ventilation

By Chip Giller on August 3, 2019

Hey there,

I know what you’re thinking. Reading a nature-themed climate change newsletter from a guy who shows up to business meetings looking like he’s just finished up a hike is a little on-the-nose.

But hear me out. Nature’s got a lot more to offer us than a great place to eat trail mix.

Very Smart People everywhere are learning that natural processes and ecosystems offer great models for the world that we create: Think a biodegradable Michelin tire based on coral growth, Adidas shoes meant to one day be recycled into a new pair, even a flood-friendly courtyard tile dreamt up by a group of middle schoolers and inspired by … potatoes. (Weirdos like me sometimes call the concept biomimicry.)

Read on to learn more about nature-inspired design — how can you resist the allure of a kelp-based tank top or a seed-inspired monocopter you can make yourself?! You don’t need a pair of hiking boots to find inspiration in what already works.

— Chip, Grist Founder

1. Your New Hero

Nona Yehia is CEO and co-founder of Vertical Harvest in Jackson, Wyoming. The company produces Bumble Bee tomatoes, rainbow chard, butterhead lettuce — as much bounty as a 10-acre traditional farm, all in a state-of-the-art, hydroponic greenhouse that takes up only one-tenth of an acre of land. And it does it with a lot of help and inspiration from nature.

Unlike many other vertical farms, which are located in artificially lit warehouses and cut off from the outside world, Vertical Harvest makes use of natural sunlight and ventilation. The company even uses “bug-on-bug warfare” to fend off insect pests, Yehia says.“We have parasitic wasps that are right now patrolling to take care of white flies and aphids.”

Vertical Harvest’s design and business model — many of the company’s employees are people with disabilities— have garnered attention from around the globe.

Check out our recent conversation with Yehia, a 2016 Grist 50 Fixer.

Superior Fresh Expanding Salmon Farm In Wisconsin, Looking At Additional Locations

U.S.A.-based aquaponics salmon and steelhead farmer Superior Fresh, which opened in 2015, is undergoing an expansion, with plans to boost its salmon production volume nearly tenfold over the next 24 months

By Erich Luening

August 5, 2019

Hixton, Wisconsin, U.S.A.-based aquaponics salmon and steelhead farmer Superior Fresh, which opened in 2015, is undergoing an expansion, with plans to boost its salmon production volume nearly tenfold over the next 24 months.

The project has an estimated USD 10 million (EUR 8.9 million) price-tag, which includes space to house fish tanks totaling 100,000 gallons in capacity, according to the Wisconsin State Journal.

“Over the past 12 months, we’ve raised 160,000 pounds of chemical-free Atlantic salmon rich in omega-3s,” the company stated in a LinkedIn post earlier this month. “Within 24 months, we’re set to bump that total up to 1.5 MILLION pounds per year!”

Superior Fresh is an aquaponics facility specializing in growing greens, Atlantic salmon, and steelhead. The facility is situated on a 720-acre native restoration property nestled in the Coulee region of the Midwestern state. It is owned by Todd Wanek, the CEO of Ashley Furniture, who has already invested an estimated USD 17 million (EUR 15.2 million) in the facility, according to the State Journal.

“Our harvests this year have continued without a hitch for both Atlantic salmon and steelhead, as we’ve consistently placed fish in the market every week at a mean size of about four [kilograms] and three [kilograms], respectively,” Superior Fresh Chief Science Officer Steven Summerfelt told SeafoodSource.

The company is currently producing approximately 200,000 pounds of Atlantic salmon and steelhead annually, Summerfelt said, noting that the expansion won’t mean additional staff hires.

“We have an excellent fish house team, which we have been slowly expanding and continuously train. This existing team can meet our fish house management requirements during our expansion to approximately 1.5 million pounds per year. We currently employ four to five in the fish house and expect to add another two technicians to help with the upcoming increase in fish harvest and processing requirements,” he said. “The majority of fish house staff time is spent on completing routine SOP’s plus weekly harvesting and processing tasks.”

Aquaponics is systems are a combination of fish and plant production using aquaculture and hydroponics systems, aquaponics is moving from the realm of experimental to commercial, according to the United States Department of Agriculture.

The growing popularity of aquaponics has prompted some analyses of the economics of these systems. The few studies developed to date show good potential for aquaponically produced vegetables to be profitable, with the fish portion possibly breaking even or incurring a net loss, according to a 2015 Southern Region Aquaculture Center (SRAC).

“Premium prices in high-end markets will be necessary for aquaponically produced vegetables and fish to be profitable,” University of Florida’s Carole Engle wrote in the SRAC paper. “Additional costs and risks associated with these complex systems must be analyzed carefully before investing in aquaponics.”

Superior Fresh lettuce is sold at Kwik Trip gas stations across Wisconsin. The farm’s living butterhead lettuce and baby spring mix is also available in more than 600 stores throughout Wisconsin and Minnesota, and the company’s washed leaf lettuce mixes are available at more than 30 stores throughout Wisconsin.

“In addition, our nearly six acres of greenhouses can produce up to two million pounds of leafy greens annually, depending on our production mix, e.g., baby greens versus head lettuce,” Summerfelt said. “Greenhouse production doubled in 2019 and – based on current construction activities – will more than double again in 2020. Thus, we continue to hire exceptional staff to expand our greenhouse team.”

In July 2018, De Pere, Wisconsin-based Festival Foods, which operates 28 stores, began selling Superior Fresh’s farmed salmon in all its stores in time for the Independence Day holiday (4 July). Superior is able to deliver salmon to stores within 48 hours post-harvest, according to the company’s website. Monterey Bay Aquarium’s Seafood Watch program rates Superior Fresh’s salmon a “Best Choice,” according to the supplier

“We are excited to offer such a fresh product to people right here in the Midwest,” Superior Fresh said on its Facebook page in 2018.

Summerfelt told the Wisconsin State Journal that Superior Fresh also begun initial plans to expand into even larger facilities on the U.S. East and West Coasts “that could each be more than twice the size of the operation in Wisconsin and bring locally grown salmon and greens within reach of millions more people.”

“We have great food, a great team and a production facility that can be (replicated) across the country,” Summerfelt told the State Journal. “We’ve developed technology to work within the regulatory framework. We have zero surface water discharge and that’s a very powerful statement.”

Photo courtesy of Superior Fresh

VIDEO: Investing 20 Minutes Per Week To Grow 200 Plants

In this video the founders of Caulys explain how the fully automated, modular greenhouses only need up to 20 minutes of maintenance per week to grow up to 200 plants, ranging from aromatics, microgreens, edible flowers to small fruits and vegetables

Students at the EPFL University of Lausanne can reap the harvest of the start-up of - amongst others - Tom and Grégoire.

At the campus, they were able to install the prototypes of their smart indoor greenhouses Caulys. In this video the founders of Caulys explain how the fully automated, modular greenhouses only need up to 20 minutes of maintenance per week to grow up to 200 plants, ranging from aromatics, microgreens, edible flowers to small fruits and vegetables.

In your living room, your cafeteria, next to the coffee machine or in your restaurant: the Caulys Farm is your urban greenhouse. It enables you to access quality products, wherever you are, without GMO, pesticides, from seeds selected for their flavor and nutritional value. Grow fruits, vegetables, greens or edible flowers right in front of your eyes.

The Caulys Farm is modular, and answers to your needs.

It also respects the planet and reduces the ecological footprint of your food, requiring less packaging, transportation, using up to 95% less water compared with traditional agriculture. It allows you to eat fresh and local products, all year long.

Your greenhouse is autonomous and optimally manages its light, irrigation and nutrients delivery. Temperature, humidity and air quality are adjusted in real time to provide the best growing conditions for your production.

CEA Food Safety Coalition Creates Board of Directors, Elects Officers And Seeks Members

The CEA Food Safety Coalition, comprised of leading controlled environment leafy greens producers, recently completed the formation of its governance structure and is taking steps to accept new members

By urbanagnews - August 13, 2019

Press Release – New York, NY – The CEA Food Safety Coalition, comprised of leading controlled environment leafy greens producers, recently completed the formation of its governance structure and is taking steps to accept new members. Controlled environment agriculture (“CEA”) is agricultural food production in environments that are indoors (such as in greenhouses and vertical farms) and controlled, providing crops with ideal growing conditions and protection from outdoor elements (such as weather and animals). The Coalition’s objective is to establish food safety standards, educate, and protect consumer health.

The Coalition, a tax exempt 501(c)(6), recently filed its articles of incorporation, adopted bylaws and elected the following individuals as the initial members of its board of directors: Michele Kubista (Revol Greens), Paul Lightfoot (BrightFarms), Christopher Livingston (Bowery Farming), Daniel Malech (Plenty), Marc Oshima (Aerofarms), Jack Seaver (Plenty), and Paul Sellew (Little Leaf Farms).

In addition, the Coalition elected the following officers:

Board Chairman – Paul Lightfoot (BrightFarms)

Acting Executive Director – Jack Seaver (Plenty)

Board Vice Chairman – Marc Oshima (AeroFarms)

Board Secretary – Christopher Livingston (Bowery Farming)

Board Treasurer – Paul Sellew (Little Leaf Farms)

Until the position is filled permanently, Jack Seaver of Plenty will serve as Acting Executive Director.

“The growing methods in our industry are different as compared to field-grown produce,” said the Coalition’s Chairman Paul Lightfoot. “This coalition provides an opportunity for all brands in the space to collaborate to further protect consumers by establishing standards and sharing insights.” “This is a critically important step in maintaining consumer confidence and supporting the growth of our industry,” he added.

“We frequently get questions from growers and buyers as to what food safety means in a CEA environment” said Dr. Jennifer McEntire, vice president for food safety at United Fresh Produce Association. “We look forward to helping the coalition develop appropriate food safety standards for this growing segment”

The Coalition is developing an enrollment process for admitting new members. All leafy greens growers employing controlled environment methods (including hydroponics, aquaponics and aeroponics), and who are willing to submit to third party food safety auditing, are encouraged to join the Coalition.

Interested parties can contact membership@ceafoodsafety.org. In addition, the Coalition seeks great candidates for a permanent Executive Director, and welcomes applications at info@ceafoodsafety.org.

France: Greenhouses Fitted With Photovoltaic Films

Using the sun to its foremost, that's what three French horticultural partners are trying to do. That's why they've installed ASCA photovoltaic films at a commercial greenhouse nearby France

Using the sun to its foremost, that's what three French horticultural partners are trying to do. That's why they've installed ASCA photovoltaic films at a commercial greenhouse nearby France. Partners in the project are horticultural Eiffage Energie Systèmes, the French growers with Les Maraichers Nantais and Groupe Olivier.

Covering 43m² and incorporated in three different ways, the project aims to demonstrate the merits of the ASCA organic photovoltaic film and its ability to meet the specific needs of producers.

Solarizing agricultural greenhouses with OPV films: what are the benefits?

The desire to install photovoltaic technology on agricultural greenhouses is not a new idea. The experiment was already carried out a number of years ago with 1st and 2nd generation solar panels. Initial results proved inconsistent as growing cycles appeared to be lengthy with later harvesting and lower yields.

Unlike a classic solar panel, however, and due to its current transparency of up to 30%, the ASCA organic photovoltaic film offers the advantage of letting a proportion of the sunlight pass through, thereby enabling photosynthesis to take place.

Another advantage of the OPV technology is its low weight. In contrast to a photovoltaic panel which, once installed, remains fixed and cannot be easily removed, the ASCA film can be easily incorporated in a deployable and retractable system, adapting to the season or the weather conditions.

Solar greenhouses: how and why is the film installed?

With this demonstration, the growers and Eiffage Energie Systèmes are seeking to measure the contribution of organic photovoltaic film as both a low-carbon energy solution and as a regulator of luminosity and thermal conditions.

To meet this need, the ASCA Solutions Lab, dedicated to designing specific integrated applications for OPV film, produced three different modes of installation at the greenhouses of the Olivier Group.

2 horizontal shade sails. Installed inside two different large and plastic-covered greenhouses and one glass greenhouse, they offer the special feature of being easily deployed and retracted.

1 vertical curtain. Installed inside a glass greenhouse, it is also easily deployed and retracted.

Finally, 9 modules have been placed on the vertical exterior side of a glass greenhouse in its upper section. These “ready-to-attach” modules also illustrate their ability to activate all types of surfaces of existing buildings. These ultra-light BAPV (Building Applied Photovoltaics) systems are also currently undergoing certification.

Self-consumption mode

The entire system has been implemented by ARMOR, Groupe Olivier and Eiffage Energie Systèmes. The latter company also made the electrical connections for self-consumption mode.

What can this green electricity be used for?

The 79 ASCA photovoltaic modules installed as part of this demonstration cover a total surface area of 43m². The green electricity produced will be monitored over a period of one year and fed back into the grid, covering a proportion of the greenhouses’ energy costs: lighting, dehumidification, automatic irrigation system, etc.

The objective of the pilot project is therefore to demonstrate the merits of OPV technology and especially of the ASCA photovoltaic film for this type of application. If the test proves to be a success it will be deployed on a larger scale.

For more information:

ASCA

en.asca.com

Publication date: 8/6/2019

Evesham Vale Growers and R & L Holt Increase Marketable Yield By 25% Using Signify’s Hybrid Lighting System

Signify (Euronext: LIGHT), the world leader in lighting, today announced that Evesham Vale Growers and R & L Holt, premium tomato growers in the UK, have once again chosen Philips LED and HPS lighting for a new greenhouse, based on the 25% increase in crop production that was achieved with its Philips hybrid lighting set-up which was installed by Philips Horti LED partner Certhon in 2015

Hybrid lighting enables year-round production of consistent, high quality tomatoes for supermarkets

Hybrid LED plus HPS toplighting make it possible to precisely control growth throughout the year

R & L Holt and Signify extend their partnership to maximize crop results in new greenhouse

Eindhoven, the Netherlands – Signify (Euronext: LIGHT), the world leader in lighting, today announced that Evesham Vale Growers and R & L Holt, premium tomato growers in the UK, have once again chosen Philips LED and HPS lighting for a new greenhouse, based on the 25% increase in crop production that was achieved with its Philips hybrid lighting set-up which was installed by Philips Horti LED partner Certhon in 2015.

In the new greenhouse, the company will install Philips GreenPower LED toplighting compact and Philips GreenPower LED interlighting, together with HPS lighting installed by the Philips Horti LED partner Certhon. The compact, passively cooled LED toplighting can be easily installed with the HPS lighting on the same trellis. This combination allows the company to use LEDs to extend lighting in the spring when it’s warmer, instead of the HPS lighting which produces more heat.

“I’m delighted to see that our customers are returning to us for new projects”, said Udo van Slooten, Business Leader Horticulture at Signify. “Our long-term partnerships enable us to learn from the improvements they have achieved and help them further improve the consistency and predictability of their crops. This move also confirms that our customers recognize the value that the LED toplighting compact offers in terms of combining LED with HPS lighting on the same trellis construction.”

Evesham Vale Growers and R & L Holt grow cherry, cocktail and large tomatoes on the vine, as well as loose classic tomatoes. All crops are grown for flavor, as supermarket premium ranges. Since all of the crops are grown in heated glasshouses, the season can stretch from February until November, but the company is always looking to further extend its season.

“After our success with our first hybrid HPS and LED interlighting system, we knew we were on the right path,” says Roly Holt, co-owner of R & L Holt. “We did a trial in another greenhouse with LED toplighting, LED interlighting and HPS lighting, and that system allowed us to specifically target different parts of the canopy to control our products. That is why we’ve now chosen this three-component set-up. We think this will give us a really sustainable and consistent product.”

Introduced in June 2019, the Philips GreenPower LED toplighting compact delivers excellent performance. Its high light output of 1,800 µmol/s and efficacy of up to 3.0 µmol/J help growers effectively optimize crop growth, enhance crop quality and cut operational costs. Compared to a 1,000 W HPS fixture, the Philips GreenPower LED toplighting compact produces the same amount of light, has a similar light distribution, while consuming 40% less power and emitting considerably less radiant heat.

The Future of Arctic Farming – Infographic

Despite difficult growing conditions, the number of vegetable farms in Alaska, Norway, Canada and other Arctic regions appears to have increased

Green Iglus, solar retention greenhouses in Nunavut, aim at producing greenery and produce for the community. Photo: Mike Beauregard

Greenhouses and Hydroponic Systems are Becoming Ripe with Possibility

Despite difficult growing conditions, the number of vegetable farms in Alaska, Norway, Canada and other Arctic regions appears to have increased. The hope is that a better, more affordable supply of vegetables in Arctic communities will help battle public health issues, improve food security and decrease the economy’s dependence on oil and imports.

This infographic designed by Jennifer Cook illustrates the challenges of vegetable production in the Arctic as well as possible solutions offered by Arctic farming. Lower temperatures and permafrost result in short growing seasons and slow down the growing process.

A frequent solution, the import of vegetables, is often unreliable and expensive. Combined with other factors, this can affect the food security, health, well-being, and financial situation of communities. In recent years, the number of Arctic farming projects based on greenhouses, hydroponics, or other technologies has developed rapidly, offering the potential for a better, more affordable, and more sustainable supply of fresh vegetables.