Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

The Future of Food - AppHarvest Is Growing A Better Tomato

Gosnell said the technology is “very unique” for the United States, but it's been used elsewhere in the world where the need for sustainable, indoor agriculture is more pressing

By JEREMY D. WELLS Journal-Times

September 11, 2019

Dean Crockett, with AppHarvest, helps a participant put on a VR headset for a virtual greenhouse tour.

JEREMY D. WELLS | JOURNAL-TIMES

There is little that Appalachian foodies appreciate more than a good, garden fresh tomato in season. They may debate the best way to bread a fried green tomato, or the proper condiment for a juicy tomato sandwich (the correct answer is salt and pepper only, by the way, so there is no need to argue about what brand of mayonnaise), but one thing that is undeniable is the love for the savory fruit. Once summer is over, though, and garden fresh tomatoes are gone, the excitement pales.

Everyone who loves them has had the experience of picking up a gorgeous, plump, firm, red tomato in a grocery store, getting home and slicing into it with anticipation, only to find that it's dry and tasteless.

“Like the cardboard box it came in,” is a common description of these “hot house” tomatoes that you find in the winter.

But the problem, explained Matt Gosnell with AppHarvest, isn't necessarily that it was grown in a hot house. In fact, many of the so-called “hot house tomatoes” might have actually been grown outdoors.

The problem, he explained, is in the picking.

Because of the long transport time from California or Guatemala that these off-season fruits undertake, they aren't picked at the peak of ripeness. Instead they are picked early and allowed to ripen on the truck as they are moved to market.

AppHarvest expects to fix this problem. By growing fruit much closer to the markets where it will be sold, they can afford to leave their tomatoes on the vine longer, allowing them to ripen properly and for their flavors to develop.

If they have their way, next winter you might be able to pick up a grocery store tomato that is every bit as juicy and tasty as the ones from your own summer garden. This is all thanks to a growing technology that has already been thoroughly tested in other countries around the world.

“There are a couple of unique things about it,” said AppHarvest's VP of Development Matt Gosnell. “First we have to talk about our retention pond, which is ten acres and will hold a three-month supply of rain water we will use and recirculate through our facility and hydroponic system, so it will be a near net-zero water facility,” he said.

This means they won't need to purchase any outside water to grow their crops, and they won't be contributing to waste water disposal for the community.

But the other thing tomatoes need is light, and they plan to make use of those sunny days as much as possible.

“We're collecting rainwater; we're also using sunlight. That differentiates us from the vertical farms you might have read about where you retrofit a warehouse, stack trays (and use all artificial light),” he added.

That doesn't mean they won't be using any artificial light. They've got a state of the art LED system, and lights will be used to regulate the temperature in the environment, but the plants will get the full spectrum of the sun's rays to grow the plants as close to nature as possible.

“Our strategy is: we're here in Kentucky which gives us a lot of land, and we want to use what God gives us, which is the sun and the rainwater, so the warehouse model isn't exactly what we're going after. Our facility is 60 acres under glass, 2.7 million plus square feet. This is a monster. Three quarters of a mile from one end to the next. So, in terms of the controlled environment itself, it uses different technologies depending on what type of produce you're growing. In this case, tomatoes, which like high heat.

So we're using combination high pressure sodium lighting, which is traditional for tomatoes, as well as interspersed LEDs. It's actually going to be the largest LED lighting system in the world, under glass. That, at the same time, brings our energy costs down and also provides us with a heavier fruit, more dense fruit. So it's a win-win for us. We spend a little more money up front, and we get a great return on it, in terms of more volume, more product, as well as making us a more sustainable facility.”

Gosnell said the technology is “very unique” for the United States, but it's been used elsewhere in the world where the need for sustainable, indoor agriculture is more pressing.

“We're getting this technology from people who have been doing this very efficiently for decades. I'm talking about the Dutch, principally. The Israelis are also very good at this. These are people that had to do this. Post WWII the Netherlands was in heavy food need, so they developed this technology out of necessity and perfected it over the decades. So we're bringing that technology to Kentucky.”

Another advantage of this system over traditional agriculture is the efficiency of space.

“We can grow in one acre what would take ten acres (in traditional field based agriculture),” Gosnell said. “This is a result of controlling the environment, controlling the water, controlling the nutrients, pH, and giving a plant exactly what it needs. So, compared to open field agriculture, not only are you more efficient, but you take the guesswork out of the possibility of worsening storms, too much or not enough water, pests. These things, we take all the guesswork out of it.

So we've got a predictable four to five harvests a year. We can give you the date. We can give you the volume. Because we know exactly what we're growing and the quantity... We're really excited that this is going to be our first project, of what we hope is going to be many, here in the bluegrass.”

The other side of the product's value in being produced locally, once it's grown, is the shipping.

“If you look at a tomato market, specifically, six billion pounds of tomatoes are consumed each year in the United States. Almost four billion of that comes from Mexico,” Gosnell said. “So we've all had the experience of biting into what looks like a very ripe and tasty tomato, only to find it utterly tasteless. This is because it's picked when it's not yet ripe, it's sprayed, it's put on a truck.

Then it's five to six days north to a market. So we're saying, 'Hey, we're going to get you something grown in Kentucky. It's going to be fresher. It's going to taste a lot better. It's going to be healthier, with more nutrients. And we're going to get it to you in a quicker time at a decreased price than what you are paying now.' So it's a win-win-win for us all around, and it's been a really exciting thing to see come to fruition.”

Contact the writer at jwells@journal-times.com.

Indoor Vertical Farming Discovers A New Company That Is Not Sheepish About Its Wool Insulation

The company’s insulation is made using wool imported from sheep-farming operations in New Zealand. He says wool is used widely across the residential building sector both in that country and Australia

While fiberglass and mineral wool have been around for decades, a new generation of manufacturers is looking to new materials that might be less manufacturing-intensive. One of these, Havelock Wool, is drawing on what founder and CEO Andrew Legge sees as a more sustainable option.

The company’s insulation is made using wool imported from sheep-farming operations in New Zealand. He says wool is used widely across the residential building sector both in that country and Australia.

Legge explains that wool insulation offers multiple advantages for environmentally oriented homeowners. The material has evolved over millennia to be a natural insulator, he notes, and it incorporates a protein called keratin which doesn’t support mold growth. Additionally, he says, wool absorbs a number of airborne toxins, including formaldehyde.

Havelock Wool’s batts and blown-in insulation come at a premium; Legge says they’re priced similarly to closed-cell spray-foam products. However, he adds, wool is very easy to handle, requiring no extra experience for anyone familiar with fiberglass installation.

Sustainability is at the heart of the value proposition Legge puts forward as a wool-insulation advocate. The manufacturing process requires no heat and is centered around 60-year-old wool carding machines, as opposed to large-scale industrial plants. And when asked about the methane produced by the sheep supplying the company’s wool, Legge has a response quickly at hand.

“We’re a byproduct of a different industry—you’re raising those animals to eat them, so we’re very comfortable with the argument that the methane isn’t attributable to the insulation,” he says. “If people stop eating sheep and lamb, we won’t have a business.”

Vertical Farming Is The New Frontier In Delivering Freshness With Sustainability

GoodLeaf Farms is revolutionizing farming in Canada. A state-of-the-art, fully automated 45,000 sq. ft. vertical farm is now operational in Guelph, ON., promising Ontarians a safe and steady supply of local, pesticide-free greens year-round

NEWS PROVIDED BY GoodLeaf Farms

September 10, 2019

GoodLeaf Farms launches fresh and delicious vertically farmed, local, pesticide-free microgreens and baby greens throughout Ontario retail stores and restaurants.

GUELPH, ON, Sept. 10, 2019 /CNW/ - GoodLeaf Farms is revolutionizing farming in Canada. A state-of-the-art, fully automated 45,000 sq. ft. vertical farm is now operational in Guelph, ON., promising Ontarians a safe and steady supply of local, pesticide-free greens year-round.

"Canadians are demanding better, safer, healthier food and are getting behind their local farmers," says Juanita Moore, Executive Director of Operations. "We know GoodLeaf's greens represent a bright light in a mostly imported produce aisle because Ontarians want fresh, tasty, local greens grown responsibly."

In addition to efficient land use, GoodLeaf employs numerous sustainable farming practices (e.g., cleaning and reusing about 95% of water; recycling the plant growing medium for second-life use in landscaping). "Our mission at GoodLeaf is to have a positive effect on the environment and human health," Ms. Moore says.

With food safety and security concerns at the forefront, effects of climate change stressing supply chains, and increasingly popular plant-based diets further promoted through Canada's Food Guide, vertical farming brings Canadians a local source of safe and reliable leafy greens.

Vertical farming is a method where growing levels are stacked in layers. Temperature and humidity conditions are controlled, and light provided by high-efficiency LEDs. Irrigation systems deliver water and nutrients as needed for optimal growth. Continuous grow cycles combined with a controlled environment allow for systematic testing and learning for rapid improvement in nutrient density, flavor, and other key attributes.

Growing UP: Beyond Organic

According to Jeff Huber, GoodLeaf's Master Grower and Visiting Researcher at University of Guelph, "Unlike organics farming, which allow organic and some synthetic pesticides, our design considerations and our attention to strict bio-security protocols allow for a pest-free environment eliminating the need for pesticides. We feed our plants the precise nutrients and optimal light to grow the most nutritious and delicious greens. Our QA Department's robust Positive Release Program tests samples of our greens ensuring they're safe to eat prior to release to our customers. In fact, with GoodLeaf's automated process the first person to touch a leaf is the consumer upon opening the package. We're truly passionate about safety, quality, and giving Ontario families local greens they can enjoy year-round."

About GoodLeaf

GoodLeaf's vision is to enable every community to grow the world's healthiest food locally and sustainably.

With passion for delicious, nutrient-rich greens, GoodLeaf was founded in 2011 in Halifax, Canada. GoodLeaf uses innovative technologies leveraging multi-level vertical farming to create a controlled and efficient indoor farm, which grows fresh produce anywhere in the world, 365 days a year. The system combines innovations in LED lighting with leading edge hydroponic techniques to produce sustainable, safe, pesticide free, nutrient-dense leafy greens. GoodLeaf has ongoing R&D programs in collaboration with the University of Guelph, Dalhousie University, and Acadia University.

Please visit us at www.goodleaffarms.com.

For media inquiries, please contact Juanita Moore at jmoore@goodleaffarms.com.

SOURCE GoodLeaf Farms

Solar Power Farms Continue To Spread Across The Globe

Sungrow, the global leading inverter solution supplier for renewables, announced that a 100.1 MWp solar plant utilizing the Company’s 1500Vdc central inverter solutions came online in Cafayate, Salta Province, Argentina, demonstrating the Company’s dedicated contribution to the largest solar plant in one of LATAM’s most booming solar energy region

By Ivy Heffernan on August 19, 2019

Sungrow, the global leading inverter solution supplier for renewables, announced that a 100.1 MWp solar plant utilizing the Company’s 1500Vdc central inverter solutions came online in Cafayate, Salta Province, Argentina, demonstrating the Company’s dedicated contribution to the largest solar plant in one of LATAM’s most booming solar energy regions.

(Not Argentinian solar farm. In place to express how large the solar power farming industry is becoming).

The project is located in Cafayate, a region optimized for solar energy due to a high-volume of sunny days, while frequented by sandstorms, putting solar project equipment susceptible to significant wear-and-tear. Embedded with a high protection level and smart forced air-cooling technology, the 6.25 MW turnkey solution with Sungrow central inverter SG3125HV for 1500Vdc system can perform efficiently and stably even in harsh environments, making it the ideal match for the plant.

Optimized for large-scale utility PV plant, the solution enables high yields with maximum inverter efficiency of 99% and DC/AC ratio up to 1.5 while at the same time ensures low transportation and installation cost due to standard container design. Early this May, Sungrow secured deal for 400 MW solar park in Chile, utilizing the solution as well.

The solar park was selected by Argentinean government in the second round (Ronda 1.5) of the country’s RenovAr auction program for large-scale renewable energy plants. It is expected to supply approximately 240 GWh of clean power to the Argentinean power system per year and bring hundreds of job creations for local communities, contributing to the national renewable ambition of the emerging solar hub.

“We are delighted to partner with Sungrow to build the landmark project in this country with vital solar resource and look forward to collaborating on more ventures in the near future in line with the extension of ‘the Belt and Road’ initiative,” said an executive from PowerChina, the EPC of the solar plant.

“We are very proud to be a part of this monumental 100.1 MWp project which will provide thousands of Argentinians with clean energy,” said James Wu, Vice President of Sungrow. “This will have positive effects on local economy–tap the potential of renewable energy further and diversify the energy mix,” he added.

Since entering the Latin American market in late 2010s, Sungrow team has been establishing itself as the comprehensive technical, service and sales platform. Currently, the Company’s shipment in the region approaches 1 GW. Furthermore, a wide range of product portfolio will be showcased in the upcoming solar function, Intersolar South America 2019 (27-29, August, Booth D36), representing its commitment to technical innovation and concerns for local demand.

About Sungrow

Sungrow Power Supply Co., Ltd (“Sungrow”) is a global leading inverter solution supplier for renewables with over 87 GW installed worldwide as of June 2019. Founded in 1997 by University Professor Cao Renxian, Sungrow is a leader in the research and development of solar inverters, with the largest dedicated R&D team in the industry and a broad product portfolio offering PV inverter solutions and energy storage systems for utility-scale, commercial, and residential applications, as well as internationally recognized floating PV plant solutions. With a strong 22-year track record in the PV space, Sungrow products power installations in over 60 countries, maintaining a worldwide market share of over 15%.

Argentina, farming, green energy, renewable energy, solar, solar power, Sungrow

Solar Power Farms Continue To Spread Across The Globe added by Ivy Heffernan on August 19, 2019

View all posts by Ivy Heffernan →

Ivy Heffernan, student of Economics at Buckingham University. Junior Analyst at HeffX and experienced marketing director.and experienced marketing director.

Growing Up: Inside Infarm’s Plans To Feed The World

It is projected that by 2050 two-thirds of humanity – or 6.5 billion people – will be living in urban spaces. The challenge will be building and managing urban spaces to sustain such a massive population. In theory, industrial agricultural produces enough food to feed the world as a whole, but the current model is unsustainable

September 3, 2019

Infarm founders Osnat Michaelli and Erez and Guy Galonska

Editor’s note: This is the first installment of a series focusing on social impact startups. Stay tuned for more.

It is projected that by 2050 two-thirds of humanity – or 6.5 billion people – will be living in urban spaces. The challenge will be building and managing urban spaces to sustain such a massive population. In theory, industrial agricultural produces enough food to feed the world as a whole, but the current model is unsustainable.

Large-scale agriculture has led to deforestation on a mass scale – as we are currently seeing in the Amazon – along with soil degradation, water waste, and plant diseases that require the use of pesticides (and are constantly mutating). Moreover, due to energy use and lengthy transportation routes, the CO2 footprint of food currently represents 17% of total global emissions. Climate change will, in turn, have an increasing impact on agriculture – with changes in rainfall, rising temperatures, an increase in pests, and extreme events such as heatwaves, droughts, storms, and floods affecting our ability to provide food for a growing global population.

These challenges have been the driving force behind the global agtech movement. For two straight years, agtech startups have received $2 billion in funding and 2019 is set to be another banner year for agtech.

Leading the pack in Europe is Berlin-based agtech startup Infarm, which recently closed an €88 million Series B investment led by Atomico.

From concept to reality

Founded in 2013 by Osnat Michaelli and brothers Erez and Guy Galonska, Infarm pioneered putting ‘indoor vertical farms’ in city locations such as supermarkets, shopping malls, restaurants, schools, hospitals and similar spaces where the produce can directly reach the end customer.

“My two co-founders and I came together around the idea that being close to the land and particularly its produce is vital to our health and creativity as a society. And from the beginning we began to explore – through travel, growing and experimentation – ways to bring natural vitality of the local farm into the city and the freshness and flavour back into our lives,” explained Infarm CEO and co-founder Erez Galonska.

“We also realised that our current food system’s biggest deficiency is that it is too far removed from the people it is trying to feed. At infarm, rather than asking ourselves how to fix these deficiencies in the current supply chain, we looked to redefining the entire chain from start to finish; Instead of building large-scale farms outside of the city, optimising on a specific yield, and then distributing the produce, we decided it would be more effective to distribute the farms themselves throughout the city.

“In 2013 we converted a 1955 Airstream trailer into our first vertical farm in one of Berlin’s most well-known urban farm spaces, ‘Prinzessinengarten’. This trailer became a hub for our early experimentation, where visitors could harvest herbs and microgreens and we could welcome a vibrant community of urban planners, designers, food activists, bio-dynamic farmers, architects, chefs, biologists, and hackers to explore the diverse challenges behind making urban farming a reality. This research station and lab would form the beginnings of what we today call Infarm.”

Today, ‘infarms’ can be stacked to fit any space and size, and are designed to easily plug into the city’s existing infrastructure. Infarm controls the farms remotely using sensors and a centralised, cloud-based platform that adjusts and improves itself continuously, so each plant grows better than the one before – providing plant seedlings with an ideal combination of light spectrums, temperature, pH, and nutrients for optimal growth.

The concept was further refined with inputs from biologists and cooks. The startup’s farms use no pesticides, 95% less water than traditional farms, and reduce transportation by 90%. Infarm’s largest module can grow up to 680,000 plants each year on only 25 square metres, making it 420x more efficient than soil-based agriculture.

In 2016, Infarm received a grant of €2 million from Horizon 2020, Europe’s biggest research and innovation programme. The grant was awarded on the basis of Infarm providing sustainable agriculture using hydroponics, proprietary lighting algorithms combined with indoor vertical farming, along with its patented modular ‘growth trays’ to create an incredibly efficient growing environment. The same year Infarm partnered with Metro Group, one of Europe’s biggest wholesalers, and in 2017, the startup received an early VC investment of €4 million.

2018 was a banner year for Infarm – both in terms of increased presence and funding. It secured a partnership with supermarket chains EDEKA and REWE in addition to partnering with several restaurants including Tim Raue and Good Bank. It also raised a Series A funding round of €20 million led by Balderton Capital. By mid-2018, Infarm was present in more than 50 customer-facing locations and launched its first Infarm in France via Metro Nanterre in November 2018.

Infarm has been rapidly growing and scaling since, and with its impressive €88 million round. Today, Infarm has over 200 in-store farms, over 150 farms in distribution centres and harvests more than 150,000 plants every month. In addition to its early partners Metro and Edeka, Infarm has partnered with major food retailers including Migros, Casino, Intermarche, Auchan, Selgros, and Amazon Fresh in Germany, Switzerland, and France.

Infarm’s team has grown from 40 people in 2016, to 150 in 2018, and the startup now employs over 250 people in several locations across Germany, as well as in Denmark, France, Switzerland, UK, and the US.

Today the total market for fruit and vegetables is €2.2 trillion worldwide, with an average of 10 kilos of salad per year, per person. This market is expected to grow to €5 trillion by 2030 as people’s diets are shifting to healthier and fresher food.

With this growing market size, Infarm sees a great opportunity for expansion while filling a societal need. The startup is planning to land in the UK this month, and is setting its sights on foreign markets; the startup is already in advanced discussions with retailers in the US and Japan. Its ultimate vision is to feed the 10 billion people living in urban centers by 2050.

Agriculture-as-a-Service

What makes Infarm attractive to supermarkets and other similar establishments is its ‘Agriculture-as-a-Service’ business model. The modular ‘farms’ themselves remain the property of Infarm, which receives income per harvested plant. Infarm coordinates with retailers and takes care of the farm including installation, cultivation, harvesting, and maintenance. Its farm unit becomes part of the retailer’s vegetable department. Aside from the regular visits by a service personnel to plant new plants, the farms are controlled remotely. This modular, data-driven and distributed approach — a combination of big data, IoT, and cloud analytics — sets Infarm apart from competitors.

From a price point, Infarm is attractive for supermarkets, which get a better product at the same price. In addition, the plants, especially herbs, are harvested fresh; preserving color, smell, flavour, and nutrients.

Sustainable cities with responsible production

Before there was agtech and its cousin foodtech, it was all under one banner: agrifood tech. This vertical is now split in two: upstream or agtech is closer to the farmer, while downstream is foodtech, closer to the consumer. Infarm sits perfectly at the intersection, innovating in farming while at the same time drastically reducing or even eliminating the farm to market supply chain and bringing its produce directly to consumers. In effect, Infarm addresses two United Nations sustainable development goals: impacting both building sustainable cities (SDG #11) and communities and responsible production (SDG #12).

Infarm is redesigning the entire food supply chain from start to finish by distributing the ‘farms’; farming directly where people live and eat. It claims to be 400x more efficient than traditional agriculture.

The impact of its instore farms is best illustrated by the following numbers:

2 square metres of instore farms is equivalent to 400 square metres of traditional farmland

Only 0.5% space usage for each instore farm

95% less water than traditional agriculture

90% less transportation

75% less fertilizers, 0 pesticides

150,000+ plants per month harvested

The future of farming

Infarm’s goal for the future is to gain an even deeper understanding of the optimal conditions for plants, and for supermarkets to source all their needs for herbs from Infarm alone. With its data collected from sensors that measure and control plant growth, Infarm possess a unique plant database and may well be on track to achieving this goal.

Although experts agree that feeding a rapidly burgeoning urban population cannot be solved by vertical urban farming alone, Infarm and similar agtech startups are hailed as trailblazers. They form part of the solution, while appealing to people who care about what they eat and where it comes from.

The signs are clear that in the near future, Infarm and similar companies will become the norm and not a novelty.

Maricel Sanchez has over 10 years of experience in various fields including trading, supply chain management, logistics and manufacturing. As well as helping startups to raise funds, she is an award-winning public speaker and the current President of Toastmasters Nice, a bilingual club that promotes public speaking and leadership.

CombaGroup Awarded Solar Impulse Efficient Solutions Label August 2019

To achieve this recognition, CombaGroup underwent a rigorous assessment process performed by external independent experts, based on a verified methodology and against several criteria that included technological feasibility, environmental and socio-economic benefits, and economic profitability

CombaGroup is proud to receive the Solar Impulse Efficient Solutions label awarded by Dr. Bertrand Piccard’s Solar Impulse Foundation.

Following the success of the famous solar powered flight around the world, the Solar Impulse Foundation decided to award the "Solar Impulse Efficient Solutions" label to 1000 products or services that meet high standards of both sustainability and profitability. A portfolio of these solutions, that includes CombaGroup, will be brought to decision-makers to encourage them to adopt more ambitious environmental targets and energy policies.

Swiss-based CombaGroup is honoured to have received this label in appreciation for its achievements in efficiency, sustainability, and profitability. For CombaGroup, the label serves as a new and credible symbol that is applied to products, processes and services in order to bridge the gap between ecology and economy while proving that protection of the environment is profitable.

To achieve this recognition, CombaGroup underwent a rigorous assessment process performed by external independent experts, based on a verified methodology and against several criteria that included technological feasibility, environmental and socio-economic benefits, and economic profitability.

CombaGroup contributed to 4 of the sustainable development goals (SDG):

SDG 6: Clean Water and Sanitation

SDG 9: Industry Innovation and Infrastructure

SDG 11 – Sustainable Cities and Communities

SDG 12: Responsible Production and Consumption

“Imagine the impact that this will have on the world! 1000 clean and efficient solutions with a label proving their profitability. They have the potential to create jobs and boost clean economic growth, while also reducing CO2 emissions and preserving natural resources. This is much more than ecological, it is logical!” says Bertrand Piccard, Initiator and Chairman of the Solar Impulse Foundation.

Serge Gander, CEO of CombaGroup said: “We are honoured to have been distinguished with the Solar Impulse Efficient Solutions label because the vision that is behind Bertrand Piccard’s drive to efficiently, sustainably, and profitably impact the planet resonates fittingly with CombaGroup’s mission to innovate for an efficient, sustainable, and profitable agriculture—that is clean, green, locally-grown, and pesticide-free all year round.”

NOTES TO EDITORS

About CombaGroup

CombaGroup is a Swiss agro-technology company that provides farmers and industrialists with innovative mobile aeroponic farming solutions for growing fresh, environmentally-friendly, nutrient- rich vegetables. CombaGroup’s patented technology significantly reduces water consumption and contamination risks while offering maximum productivity per square meter and minimising environmental impact. Mechanised irrigation and spacing systems produce clean, quality, pesticide-free salads, cabbages, and aromatic plants all year round, thus providing consumers with healthy, responsible products.

For more information

contact@combagroup.com

+41 21 545 99 25

Media information online

Media information and images can be downloaded directly from combagroup.com

Journalists can subscribe to our media mailings to receive information on CombaGroup’s aeroponic solutions and technology.

For the latest updates on CombaGroup, visit combagroup.com or follow on sur Instagram, Twitter, Pinterest, and LinkedIn

About Solar Impulse Foundation Efficient Solutions

https://solarimpulse.com/efficient-solutions/mobile-aeroponics-farming

Fifty Percent of Consumers Would Buy 'Vertical Agriculture' Products

Rising populations and worsening weather conditions due to climate change make it difficult to produce enough healthy and fresh food. A contribution to solving this problem could be provided by so-called vertical agriculture

Georg-August-University Göttingen observes:

Rising populations and worsening weather conditions due to climate change make it difficult to produce enough healthy and fresh food. A contribution to solving this problem could be provided by so-called vertical agriculture. Here, the vegetables and fruits are grown on floors one above the other. This system requires neither direct sunlight nor farmland, as the plants grow in nutrient solutions under artificial light or daylight. A team of scientists from the University of Göttingen has investigated the acceptance of vertical cultivation systems. The results have been published in the journal Sustainability.

Researchers from the Department of Marketing for Food and Agricultural Products surveyed around 500 consumers from Germany on various vertical farming systems. The rating was for a refrigerator-sized appliance for home use, a medium-sized greenhouse in supermarkets, and a vertical farm that can be built into former industrial buildings. For 81 percent of consumers, environmental friendliness is an important issue.

Only seven percent had already heard of vertical agriculture. Interestingly enough, half of the participants would buy fresh products from vertical farming systems. It also shows that the larger the system, the higher the likelihood that it will be considered sustainable. The small systems for household use were rated worse overall.

Focus on sustainability

"Our results show that the development of vertical farming systems should focus in particular on sustainability. Only systems that are truly environmentally friendly will convince consumers," says Kristin Jürkenbeck, PhD student and lead author of the study. "The topic of sustainability is becoming increasingly important for consumers in all areas of life, as illustrated by the public discussions. This must not be ignored by the big companies," says Prof. Dr. med. Achim Spiller, Head of the Marketing Group for Food and Agricultural Products.

Publication date: 8/12/2019

We Need To Change Our Farming & Eating Habits Or Face 'Catastrophic' Global Warming Says UN

When it comes to global warming, it's not just logging and pollution that's making things worse. It's also that our everyday lifestyles are wasteful. Now the UN says if we don't get it together and change our diets, we could be in for catastrophic levels of global warming

Gwyn D'Mello Aug 08, 2019

When it comes to global warming, it's not just logging and pollution that's making things worse. It's also that our everyday lifestyles are wasteful.

Now the UN says if we don't get it together and change our diets, we could be in for catastrophic levels of global warming.

IMAGES COURTESY: REUTERS

This is the organisation's first comprehensive on the link between climate change and human land usage. It suggests that we need to change our diets to avoid food waste, and also adopt more sustainable means of farming, in order to tackle climate change.

The UN's Intergovernmental Panel on Climate Change (IPCC) says that human activity has caused significant land degradation, deforestation and destruction of natural habitats. All of these effects together have resulted in a significant amount of carbon dioxide being released from the soil and into the atmosphere.

The report says that we need to adopt diets with more plant-based foods such as grains, nuts, fruit, and beans, as well as animal-based food produced with low greenhouse gas emissions.

Until now, the land has been responsible for absorbing a lot of carbon dioxide, thanks to photosynthesis in plants and the like. Cutting down all those trees, plus other climate-change effects like wildfires and desertification has resulted in all that land now releasing at least a third of all greenhouse gases into the air.

"This is a perfect storm. Limited land, an expanding human population, and all wrapped in a suffocating blanket of climate emergency," said Professor David Reay from the University of Edinburgh. "Crop yields are already being hit hard by climate change, staples like wheat, maize and rice are all at risk. The global web that is our food system means that impacts on farms thousands of miles away ripple right back to our own dinner plates."

"Earth has never felt smaller, its natural ecosystems never under such direct threat."

The report indicates that the Earth's soil now holds only about one percent of the planet's total carbon, as opposed to the seven percent they earlier held. The solution to this problem, the UN says, is to immediately stop deforestation, and stop degrading the soil with exploitative farming methods.

We also need to diversify our farming to avoid leaching the soil of its nutrients. Farmers need to instead start relying on a mix of farming a mix of crop, as well as raising livestock, in order to allow the land to be more resilient to the effects of climate change.

For instance, that could mean mixing banana plantations with coffee. The former provides shade to the latter, and the mix of crops allows the farmer to be less reliant on a single crop. And the key to promoting this experts say is to first and foremost end subsidies on big single crops like corn and sugarcane.

Can Vertical Farming Feed The World And Change The Agriculture Industry?

Can Vertical Farming Feed The World And Change The Agriculture Industry?

Year after year, cities expand and pristine natural habitats are turned into farms and pastures to support the world’s growing population. But despite our encroachment into the environment, we still struggle to feed everyone. Vertical farms could offer a solution by producing higher crop yields year-round in less space than conventional agriculture.

What Is Vertical Farming?

With land for crops and pastures growing scarce — plus the threat of pesticides and herbicides taking a toll on our health and the environment — people are exploring new ways to grow food, such as urban agriculture. In general, this is the process of growing food within city limits – whether on rooftops, in backyards or on balconies. The goal is to provide families with fresh, healthy food that isn’t laced with chemicals — and when you grow your own crops, you can control these elements.

Vertical farming is a type of urban agriculture – but vertical farms are often constructed indoors in extremely controlled environments. Crops are grown on shelves that extend upward instead of outward, and the environment is carefully monitored, so crops grow year-round.

In addition to growing crops, some vertical farmers have developed ways to grow fish in a self-sustaining system. Water from the plants is recycled into fish tanks, and the waste from the fish becomes fertilizer for the plants. Then, both the plants and fish can be harvested for food.

The benefits of vertical farming

The benefits of vertical farming are numerous. Farmers can control the crops’ environment in vertical farms, so the plants aren’t subjected to nasty weather conditions or droughts. Humidity, nutrients and water are administered to growing plants to achieve optimum growing conditions. Because of the controlled environment, crops can be harvested more than once a year, resulting in higher yields than traditional farming.

Related: The GCC’s first commercial vertical farm launches in Dubai

Vertical farms are more sustainable than conventional farms because they use less water (which is often recycled through the system), they take up less space and they use less fossil fuels because they don’t rely on heavy machinery such as tractors and harvesters.

Technology helps vertical farmers get the best output from the farm. Tailored lamps help plants get more light exposure, which encourages them to grow faster than crops that rely on the sun. Vertical farms also provide greater protection from insects, thus decreasing the need for harmful chemical products.

Downsides to vertical farming

While vertical farms can help with local hunger issues and sustainability, there are some barriers that may keep them from gaining worldwide traction. The cost of setting up a vertical farm can be prohibitive. Conservative estimates put the initial start-up cost at around $110,000, but there are estimates upward of millions of dollars.

Finding an abandoned warehouse or building in an urban setting for a reasonable price might be difficult. Since vertical farms rely on electricity for growing lamps and strict environmental controls, the location has to have reliable power — not just any old abandoned building will do. Vertical farms also depend heavily on technology, which can be costly. Keeping the lights on and the environmental controls running will impact energy use — and your budget.

Not every crop that is grown traditionally can be raised successfully in a vertical farm. Leafy greens and herbs do the best in an indoor environment, while staple crops like wheat and potatoes are difficult to grow indoors, as are some fruits and vegetables. The crops that can be harvested from a vertical garden are limited.

Growing food to feed the hungry is a noble gesture, but it also has to be profitable, especially when the initial cost to set up a vertical farm is so high. If there isn’t a market in your area, it’s a waste of time to grow large amounts of food that you won’t be able to sell.

The Verdict

Despite the downsides, the positives are plentiful. In addition to embracing sustainability and helping combat hunger, vertical farms can also encourage support for local economies. These farms can create jobs, turn a profit and provide a healthy source of food for locals.

As technology continues to advance, new approaches will improve the efficiency and productivity of vertical farms. If nothing else, the idea sparks the conversation about changing the agricultural industry and gives us a place to start for finding better, more sustainable ways to grow food.

Images via Depositphotos, Aqua Mechanical and Mike Chino for Inhabitat

under Agriculture, Features, Innovation, Sustainable Food, Urban Farming

The Future of Food: Why Farming Is Moving Indoors

A car park opposite the infamous New York City housing estate where rapper Jay-Z grew up seems an unlikely place for an agricultural revolution. Ten shipping containers dominate a corner of the Brooklyn parking area, each full of climate control tech, growing herbs that are distributed to local stores on bicycles. This is urban farming at its most literal

By Russell Hotten BBC News, New York

August 22, 2019

Tobias Peggs says the fledgling industry is still developing the right business models. SQUARE ROOTS

A car park opposite the infamous New York City housing estate where rapper Jay-Z grew up seems an unlikely place for an agricultural revolution.

Ten shipping containers dominate a corner of the Brooklyn parking area, each full of climate control tech, growing herbs that are distributed to local stores on bicycles. This is urban farming at its most literal.

The containers are owned by Square Roots, part of America's fast-expanding vertical farming industry, a sector run by many tech entrepreneurs who believe food production is ripe for disruption.

The world's best basil reputedly comes from Genoa, Italy. Square Roots grows Genovese seeds in a container that recreates the city's daylight hours, humidity, Co2 levels - and all fed hydroponically in nutrient-rich water.

"Rather than ship food across the world, we ship the climate data and feed it into our operating system," says co-founder Tobias Peggs.

High costs

An artificial intelligence expert, Mr Peggs founded Square Roots with investor Kimball Musk (Elon's brother) two years ago. They've signed a deal with one of America's big distribution companies, Gordon Food Service, to locate herb-growing containers at some its 200 warehouses.

He says the deal represents everything about indoor farming's potential: locally grown, quick-to-market, fresh produce that can be harvested year-round and is free of pesticides and harsh weather.

Bowery is set to open its third industrial-sized indoor farm. BOWERY FARMING

"Indoor farming can answer many of the questions being asked by today's consumers about the provenance, sustainability and health of the food they eat," he says.

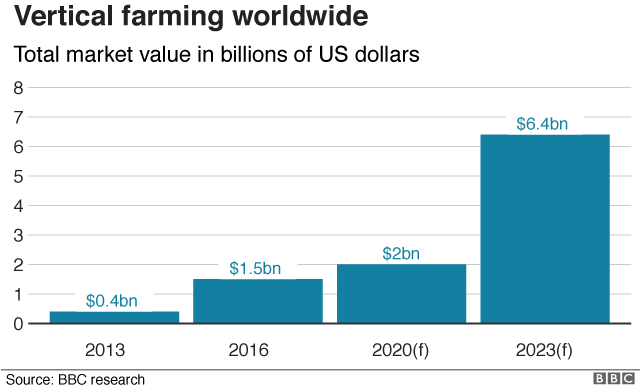

Jeffery Landau, director of business development at Agritecture Consulting estimates the global value of the vertical farming market will rise to about $6.4bn by 2023, from $403m in 2013, with almost half that attributed to growth in the US.

Despite the sector's high costs and limited food range, the potential is not lost on investors. Recently, AeroFarms, a producer of lettuce and other leafy greens, raised $100m, including from Ingka Group, Ikea's parent company. Bowery Farming raised $90m in a funding round backed by Google Ventures and Uber boss Dara Khosrowshahi.

Plenty, another major US player, raised funds from Softbank chief executive Masayoshi Son and former Google head Eric Schmidt. The company has ambitions to build hundreds of vertical farms in China. In the UK, food delivery and robotics company Ocado is investing in indoor farming.

But there have also been failures. "Vertical farms are a highly intensive capital expenditure," says Mr Landau. "Your lighting system will be one of your highest capital costs." And then there's ventilation, air conditioning, irrigation and harvesting. "Make a mistake and you will have one costly upgrade on the horizon," he adds.

Mr Peggs chose a modular system based around shipping containers because he says it is quickly scalable according to demand. "We can put a herb farm in new city for less than $500,000 and be growing within two months. We just press the 'basil button' - or mint, or tarragon - and the box configures itself to grow in optimum climate conditions."

In neighbouring New Jersey, however, Bowery Farming, takes a different approach. The five-year-old company runs industrial-sized farms. Outside one huge, grey windowless warehouse a heat haze shimmers off the concrete. It's a sharp contrast to the chilly interior where an aroma of fresh farm produce hits you immediately.

Robots

Produce is grown on trays stacked ceiling-high to maximise acreage. Everything from the automatic seeding machine to harvesting is run by Bowery's proprietary operating system (OS) which controls light, adjusts water nutrients and takes camera images of each plant to monitor its health.

"The OS is our central nervous system. There are millions of data points," says founder Irving Fain. "The artificial intelligence is constantly learning and predicting how to produce the best quality product."

Irving Fain hopes to soon start producing radishes and turnips commercially. Michael BACA Image

Running the farm manually would be difficult, he says. Staff operate things from computer screens and iPads. In the cavernous farm room itself, the only sound is robots moving the shelves.

Growing food indoors has been around for decades, but the industry got a kick-start from advances in the performance of lower cost LED lighting. Combine that with robotics, innovations and AI, and you have an industry that Mr Fain says is both viable and scalable.

"The big question was, how can we grow in large volumes at a consistently high quality? Suddenly, the economics changed," he says. "We can grow 365 days a year - a major departure from thousands of years of agriculture. Unlike outdoor farming, our yield is virtually 100% guaranteed."

Vertical farmers talk with a zeal you'd expect of entrepreneurs with tech world backgrounds. With population growth and climate change putting pressure on food production, they think they may have answers.

Square Roots' herbs are delivered to customers by bike. SQUARE ROOTS

But this highlights one of the industry's limitations. You can't feed the world on leafy greens. That said, for Mr Fain, if Bowery only ever grew lettuce or kale, "it's still a win". But his ambitions are greater. Bowery is growing radishes and turnips that he expects to come to market with two years.

Square Roots hopes to soon start commercial production of beetroots and strawberries, and is experimenting with so-called heirloom produce from rare and long-forgotten seeds.

Carbon footprint

Mr Peggs says: "It makes sense to grow perishable produce in the same neighbourhood as the consumer - stuff that doesn't travel well. A lot of produce - tomatoes, strawberries - are grown for travel, not for taste. It doesn't make sense to vertically farm food with a long shelf life."

But different produce presents different challenges, says Mr Landau. Where plants are concerned, not all light is created equal. Fruiting and flowering crops such as tomatoes, strawberries and peppers have different needs.

QR codes on the food packaging can tell customers the history of the produce. SQUARE ROOTS

"Lights for these types of crops will generally be more expensive, require more electricity, and produce more heat, meaning additional cooling," says Mr Landau. "Harvesting these crops can be a significant operational cost."

But it is being done. In the US, Oishii vertically farms the much-prized Japanese Omakase strawberry year-round. And Farm One produces more than 200 products, including 34 edible flowers. Plenty is experimenting with watermelons. As technology costs fall and R&D intensifies, the crop variety will expand.

That may also ease criticism of the industry's carbon footprint. In the artificial light versus sunlight debate, the latter often has the upper hand. But, then, indoor farmers point to the transportation costs and waste in traditional agriculture.

For the moment, Mr Landau says, the carbon footprint concerns are valid, although he expects indoor farms to increasingly draw on renewable energy.

"And when you look at markets located in extreme climate environments or island nations where they import a majority of food, indoor farming could be a viable option," he says.

Mr Peggs stresses that industry is still young are trying to work out the right business models and direction. The entrepreneurs don't agree on everything, though they certainly agree on this: vertical farming has the potential to transform global food production as we know it.

'Groundbreaking' New Venture To Create 'World's Most Advanced Indoor Farming Project'

Mastronardi Produce and visionary John Paul DeJoria say they will develop 'the world's large and most advanced indoor farming project’. North American greenhouse grower Mastronardi said they've selected the Middle East as the first market for the new venture

August 19 , 2019

Mastronardi Produce and visionary John Paul DeJoria say they will develop 'the world's large and most advanced indoor farming project'.

North American greenhouse grower Mastronardi said they've selected the Middle East as the first market for the new venture.

The newly formed company, Green International Ventures LLC (GIVE), will use its proprietary Advanced High-Density Farming System.

This will be the first project for the "groundbreaking" venture, Mastronardi said.

The company said the project will reduce the Middle East’s dependence on imported food, create a sustainable source of local employment, and significantly increase the region’s non-petroleum-based exports.

Green International Ventures poised for international expansion

Paul Mastronardi, president, and CEO said the company is eager to increase access to local and sustainably-grown produce.

“Our first location in the Middle East will allow us to reach over half the world’s population in less than 8 hours, and this is just the start," he said.

"[We will] look for more global locations as we continue to scale to meet the growing need for food security, safety, and sustainability.”

GIVE will also support the integration of modern AgTech initiatives into the local farming community, the company said. In addition, it will expand knowledge of sustainable agricultural techniques by establishing a Research and Development facility in the region.

“It has long been my passion to help feed the world’s population,” says John Paul DeJoria. “The introduction of this revolutionary model in the Middle East is the first step of many towards increasing global access to sustainably grown fruits and vegetables.”

Furthermore, all GIVE projects use innovative Advanced High-Density Farming Systems that incorporate a multitude of cutting-edge growing systems. These include water-saving irrigation and energy-efficient lighting. It also takes advantage of advanced automation, AI processes for predictive analysis, and real-time crop and soil monitoring.

GIVE will market all produce it produces with the innovation systems under the SUNSET brand.

National Geographic Features UVI Aquaponics Program

The University of the Virgin Islands Agriculture Experiment Station is featured in the August issue of National Geographic, one of the leading magazines on science, geography, history, and world culture

By Source staff | . August 18, 2019

A raft of lettuce grows in a pond, with the shaded tilapia tanks in the background. (UVI photo)

Aquaponically grown lettuce is harvested at UVI. (UVI photo)

The University of the Virgin Islands Agriculture Experiment Station is featured in the August issue of National Geographic, one of the leading magazines on science, geography, history, and world culture.

The ag station, which features an aquaculture program, is spotlighted in the magazine’s Explore Decoder section. Accompanying graphics illustrate the principles of aquaponic design and operation, according to a news release issued by the university.

The online component of the publication includes a video demonstrating how vegetables can be grown through aquaponics.

UVI, a land grant institution, has been a leading public university researching aquaponics and has a great depth of knowledge and experience in the field. The program, which began in 1979, boasts a facility spanning 1.95 acres on UVI’s St. Croix campus.

Donald Bailey, research specialist in the aquaculture program, began assisting National Geographic journalists with the story in April, providing them with information and illustration for the home-scale system that is included in the issue.

“Throughout the collaboration, I realized from the lead writer, illustrator and editor that they needed accurate and precise information, clearly stated, so that magazine readers would not be misinformed or misled,” Bailey said. “I’m happy with the final product, including the drawing of the UVI Aquaponic System in the upper right corner of the illustration.”

Research Specialist Donald Bailey (UVI photo)

Among the illustrations included is a drawing of the UVI Commercial Aquaponic System. The main illustration shows a home-scale system that includes the main components of a well-designed aquaponic system: a separate fish rearing tank, solid waste removal, deep water channel hydroponics with floating rafts, continuous aeration and water flow.

Six detailed steps lead the reader through the system processes with illustration focus points highlighting nitrification, the natural process of water purification and seedling/vegetable production.

Vegetable production is the primary benefit of aquaponics, as it contributes to cleaning the water for reuse in fish production and provides valuable revenue for the operation, according to the UVI news release.

“Through its research, the AES Aquaculture Program developed a sustainable design with reliable operating procedures that can be scaled for home and hobby use or commercial production,” Bailey said. “The magazine illustrates a home-scale system with the necessary components for continuous operation and production of fish and vegetables. We hope that the home-scale system can be adopted by more Virgin Islanders.”

The university saw the expansion of the aquaculture program with the development of research and demonstration systems in aquaponic and biofloc systems and cage culture in watershed ponds in 1979 when James Rakocy joined the university. It also hosted annual workshops drawing budding agriculturists from all over the world to learn how to set up systems for home or commercial use.

The August 2019 issue of National Geographic is available in both St. Croix and St. Thomas campus libraries.

Mastronardi, DeJoria Launch GIVE Partnership In Middle East

Mastronardi Produce Ltd.®, North America's leading grower and distributor of greenhouse produce, and visionary John Paul DeJoria have selected the Middle East as the first market in which to develop the world's largest and most technologically advanced indoor farming project.

NEWS PROVIDED BY

Aug 19, 2019

KINGSVILLE, ON, Aug. 19, 2019 /PRNewswire/ - Mastronardi Produce Ltd.®, North America's leading grower and distributor of greenhouse produce, and visionary John Paul DeJoria have selected the Middle East as the first market in which to develop the world's largest and most technologically advanced indoor farming project.

Green International Ventures LLC (GIVE)'s Middle East location will be the world's largest and most technologically advanced indoor farming project. (CNW Group/Mastronardi Produce Ltd.)

John Paul DeJoria (CNW Group/Mastronardi Produce Ltd.)

.Paul Mastronardi (CNW Group/Mastronardi Produce Ltd.)

The newly formed company, Green International Ventures LLC (GIVE), will make locally grown fresh produce more widely available around the globe via its proprietary Advanced High-Density Farming System. This will be the first project for the groundbreaking GIVE venture, and it will reduce the Middle East's dependence on imported food, create a sustainable source of local employment, and significantly increase the region's non-petroleum-based exports.

"As pioneers in the greenhouse industry, we are passionate about increasing access to local, sustainably grown fruits and vegetables," says Paul Mastronardi, President and CEO, and the fourth-generation family member to lead Mastronardi Produce. "Our first location in the Middle East will allow us to reach over half the world's population in less than 8 hours, and this is just the start. Look for more global locations as we continue to scale to meet the growing need for food security, safety, and sustainability."

GIVE will also support the integration of modern AgTech initiatives into the local farming community and expand knowledge of sustainable agricultural techniques by establishing a permanent Research and Development facility in the region.

"It has long been my passion to help feed the world's population," says John Paul DeJoria. "The introduction of this revolutionary model in the Middle East is the first step of many towards increasing global access to sustainably grown fruits and vegetables."

All GIVE projects use innovative Advanced High-Density Farming Systems that incorporate a multitude of cutting-edge growing systems, such as water-saving irrigation and energy-efficient lighting, and they take advantage of advanced automation and robotic devices, AI processes for predictive analysis, and real-time crop and soil monitoring.

Produce grown in these innovative AgTech systems will be marketed under the SUNSET® brand. Known for award-winning flavor, innovation, and packaging, SUNSET's many exclusive labels include Campari®, the world's first branded tomato, and the uniquely colorful Aloha™ pepper.

SUNSET of Holland® will be the first distributor for the GIVE partnership.

About Paul Mastronardi and Mastronardi Produce Limited

Paul Mastronardi is the President and CEO of Mastronardi Produce, which recently received the prestigious honor of being named one of "Canada's Best Managed Companies" for the 10th consecutive year. In 2016, Paul was named Produce Person of the Year at the United Fresh Convention & Exposition in Chicago, USA, and in 2013, he was named Ernst & Young's "Entrepreneur of the Year" for Ontario.

Mastronardi Produce, the leading greenhouse company in North America, grows and sells flavorful, world-class tomatoes, peppers, cucumbers, and berries under the Sunset® brand. As pioneers in revolutionary greenhouse technology, they focus on sustainable non-GMO growing practices, recognizing that what is good for the environment, is good for business.

About John Paul DeJoria

John Paul DeJoria is a serial entrepreneur, philanthropist, business leader, and mentor with a true rags-to-riches story. Once homeless, he overcame adversity, and went on to build two billion-dollar brands—leading professional hair care manufacturer, John Paul Mitchell Systems, and Patrón Spirits—and several global enterprises. He started his first company, John Paul Mitchell Systems, with partner Paul Mitchell and a borrowed $700. He remains true to his motto, "success unshared is failure," and dedicates himself to numerous charitable causes through his philanthropy hub, JP's Peace, Love & Happiness Foundation, and he has committed to donate more than half of his wealth to philanthropy through his signing of Bill Gates and Warren Buffet's "The Giving Pledge."

SOURCE Mastronardi Produce Ltd.

Related Links

'Lettuce' Start A New Container Farming Venture

Essentially the company manufacturer purpose-built containers (sea containers don't work) housing a hydroponics system to vertically grow any number of products.

Ken Wilson 17 August 2019

Modular Farms Australia director James Pateras.

ON the surface you might think hydroponics farming is for somebody else to try.

But at last week's TECHSPO, Modular Farms Australia director James Pateras, laid out a tantalising case for the technology to be a niche business on any Australian farm.

A former Victorian dairy farmer and a Deakin University graduate majoring in economics and finance, Mr Pateras is now firmly ensconced in a vertical farming system, growing herbs, and making money.

He also is a director of Modular Farms Australia, which is linked to its Canadian parent in Ontario.

Essentially the company manufacturer purpose-built containers (sea containers don't work) housing a hydroponics system to vertically grow any number of products.

Being modular, additional modules are available for multiple uses.

"One of the secrets of producing quality product is lighting and our company has partnered with world-leading experts in LED lighting, plant health sciences, and indoor agriculture to re-think the container farm from scratch," Mr Pateras said.

"We focus entirely on plant health and farmer return on investment (ROI), which was one of the first questions Mr Pateras answered after his talk.

"The downside is we use a lot of energy in our enterprise but balancing the costs is the fact we are producing a high value product which we can supply virtually on demand year-round," he said.

"And to mitigate power costs it could be supplemented by on-farm energy, either solar or biomass.

His company also supplied cold storage units to maintain freshness until product was transported to clients.

"It's a closed loop system and we have a particular LED light recipe that enhances the quality of produce we market," he said.

Mr Pateras also reiterated the diminishing amount of arable land available throughout the world for farming practices.

"So, for example, we can grow 44,000 lettuce heads a year in a 36 square metre space," he said.

"The land needed to achieve that would be 1000 square metres.

"So vertical farming is making more efficient use of land with year-round supply and scalability.

"There already is work going on to produce rice by hydroponics so as technology improves there may be a way to grow our main line crops the same way.

"But at the moment opportunities exist to grow fresh produce and compete on quality and timing."

Another business opportunity for farmers existed with using biomass.

Department of Primary Industry and Regional Development (DPIRD) researcher Ron Masters said biomass was a realistic cash crop for farmers.

"Biomass on farms would mainly come from animal waste, crop residues or purpose-grown crops," he said.

"It's a renewable resource which reduces the carbon footprint and has the potential to be a substitutive product.

"For example, it could be used for carbon offsets or as a substitution for diesel and ethanol fuels.

"Biomass can be used to create steam for industrial uses or for a generator, bio-hydrogen, biochar and plastics.

"But I think the big winner for farmers will be using it for high value chemicals."

Though Mr Masters didn't expand on this subject, it is well known that sugar constitutes 75 per cent of all biomass, and it can be obtained from many different sources such as cane, beet and corn.

Even wood and straw can be processed into sugars that can be converted to chemicals.

Mr Masters also said renewable diesel would "probably" be the next big thing before renewable chemicals.

"The hidden gem is oil mallees," he said.

"Things have changed since the early days and we now have a commercial operator in Kochi Oil at Darkan which is processing the oil mallees.

"The resultant biomass is there to collect to power a greenhouse system, for example."

Have a commercial operator in the State makes such a proposition more viable."

Mr Masters said that overseas, biomass was a big business in making bio-hydrogen, nitrogenous fertilisers, plastics and used as a wood replacement.

When asked about the potential for canola oil, Mr Masters said there was "massive investment" internationally in canola as a first generation biofuel.

"WA has ignored this area for a long, long time but the opportunities are there," he said.

Meet Tigris, Our Largest Farm to Date

Plenty brought the farm indoors to create a better future for people and our planet. We need to triple the production of fruits and vegetables if we want to provide a healthy diet to everyone on the planet

August 2nd, 2019 By Plenty Farms

PLENTY - TIGRIS FARM

Plenty brought the farm indoors to create a better future for people and our planet. We need to triple the production of fruits and vegetables if we want to provide a healthy diet to everyone on the planet. This is an eye-opening statistic based on a Harvard study and data from the United Nations. Decades of research and development in outdoor farming have solved primarily for calories through yield gains while largely neglecting nutrients and flavor. This has led to the predominant global diet being low in nutrients and high in calories, driving the global pandemics of obesity and diabetes.

Farmers have relatively little control over the crops they grow. They select which seed, when to plant, and when to harvest. They can apply water, fertilizers, and chemicals to encourage growth and fend off pests. For crops to be profitable, they are typically chosen and grown to survive travel on trucks and for easy storage. Crops from different climates are shipped thousands of miles to customers. The end result is expensive, lower quality, and less delicious fruits and vegetables.

Plenty’s goal is to grow the best possible produce and to make it more accessible than ever before. We want to sustainably offer people the healthiest, happiest lives possible. Our new farm, code named Tigris, represents our largest and most ambitious leap forward. It demonstrates our ability to grow delicious produce using less than 5% of the water and less than 1% of the land compared to outdoor farms. By developing reliable, indoor, vertical farms that control everything our plants experience, we can reach people around the world with nutrient-rich fruits and vegetables that consumers will actually crave.

In order to change consumers expectations and to compete with flavorful processed foods, we grow the most delicious version of every crop that we sell. Can kale be decadent? Can mustard greens create the same binge response that we find in a bag of Doritos? Can we do this without genetic modification or pesticides? The short answer is a resounding yes. If you control the growing environment, you can find the world’s most delicious varieties and remove geography and seasonality as limitations.

Strawberries are more delicious in California because California is one of five Mediterranean climates in the world that has the ideal environment in which to grow produce. The Italian tomato isn’t the best because Italian farmers are magical, but because Italian tomatoes benefit from the most perfect tomato-growing environment in nature. Inside the walls of our indoor farms, Plenty is able to create the perfect environment for almost anyfruit or vegetable to create the perfect flavor. We can build local farms and replicate the ideal environment near any city in the world. By eliminating long-distance transportation, we can harvest and put these foods in consumer’s hands the same day.

Most importantly, Plenty can grow produce that people want to eat. The human brain evolved to associate flavor with nutrients. Many processed foods are engineered to have the flavors our brains crave, but lack the nutrients that our bodies need. The intense artificial flavors don’t actually satisfy our bodies and our cravings drive us to eat more calories than we need. There are many communities around the world where there is enough food, but without balanced nutrition the result is excess consumption that leads to obesity and related diseases. Plenty is reestablishing the connection between flavor and nutrients to put an end to this cycle.

Building a new form of agriculture at a scale that can impact people around the world while using fewer resources and delivering mind-blowing flavor and nutrition is incredibly difficult. At Plenty, we have assembled an amazing team of the world’s leading Plant Scientists, Flavor Experts, Hardware and Software Engineers, Growers, Operations experts, and people from many related fields. We have built dozens of farm prototypes to attack this challenge from every angle. We have grown hundreds of varieties of plants to find the highest yielding plants with flavors that will change expectations. Tigris isn’t just a story about robots or climate control or LED lights or hydroponics. It is the first instance of a new way of feeding people that can deliver on the promise of each of these individual technologies when every detail is optimized.

Inside Tigris is the technological opportunity to revolutionize human health. We give plants the perfect environment to be the best and most craveable versions of themselves, so that we can all be the best, most nourished versions of ourselves. I hope people enjoy the photos and videos of Tigris, but I really can’t wait for people to taste our amazing produce.

Nick Kalayjian

SVP of Engineering, Plenty

Superior Fresh Leading The Way In Aquaponics

Nestled in the Coulee region of Wisconsin is one of the largest aquaponics facilities in the world. It sits on a 720-acre native restoration property and raises leafy greens as well as Atlantic salmon and Steelhead

BY ADAM CAMPBELL | AUGUST 19, 2019

Nestled in the Coulee region of Wisconsin is one of the largest aquaponics facilities in the world. It sits on a 720-acre native restoration property and raises leafy greens as well as Atlantic salmon and Steelhead.

Superior Fresh, located in Hixton, WI, is taking sustainability to the next level. “The restoration property has been converted from conventional, monocrop agriculture into natural, native prairies and oak savannas,” said Nate Hefti, regional sales manager for Superior Fresh. “The fish-house and greenhouses are using state-of-the-art technology to efficiently raise fish and vegetables, giving us the opportunity to return the land back to its native state. All waste products from the facilities are composted onsite and used to enrich the poor soils that exist throughout the land.”

The water used to raise the salmon is cycled through to then fertilize the aquaponics facility, then cycled back again to the salmon tanks, meaning zero discharge of production water.

“By weight, for every one pound of salmon we produce we feed the fish 1.1 pounds of food. This equals nearly a one-to-one feed conversion ratio (FCR) but does not include the additional 10 pounds of produce we grow per one pound of fish food,” said Hefti. “Therefore, we have a FCR that is one-to-10, equaling one pound of fish food into the system and 10 pounds salmon and vegetables out.” For perspective, cattle has a food conversion ratio of approximately 10 to one, meaning every one pound of beef requires 10 pounds of cattle feed.

Currently the company is shipping up to 4,000 pounds of baby greens 1,000 pounds of head lettuce every day and is always looking at opportunities to expand into other markets to allow more people the opportunity to buy organic, safe, local fresh food. With nearly zero water discharge, the company believes facilities could be located anywhere on the planet, making it a readily available and safe local food source.

Lawsuit Over Keurig Coffee Pod Recyclability Moves Forward

A federal judge in California recently ruled that a class action lawsuit against Keurig Green Mountain Inc. — one with interesting implications for recyclability claims about new product streams — can move forward

The Company Had Hoped A California Judge Would Dismiss A

Complaint Claiming its "Recyclable" Labels Are Misleading

AUTHOR Katie Pyzyk@_PyintheSky

July 15, 2019

A federal judge in California recently ruled that a class action lawsuit against Keurig Green Mountain Inc. — one with interesting implications for recyclability claims about new product streams — can move forward.

The lawsuit was proposed by a California consumer who says the company (now Keurig Dr Pepper) made false claims about its coffee pods' recyclability, namely that their size, composition and lack of an end market renders them unrecyclable. The suit points out that while the pods are made of polypropylene — a plastic (#5) accepted for recycling in about 61% of communities nationwide — most domestic MRFs aren't capable of capturing such small, light materials from the recycling stream.

According to the lawsuit, Keurig adds to the problem by telling consumers they need not remove the pods' paper filters before recycling. This creates a source of contamination, as it does for numerous other products made from multiple materials that are recyclable only when segregated, including paper envelopes lined with bubble wrap and aluminum cans with plastic shrink wrap sleeves.

Keurig had hoped the lawsuit would be dismissed on the grounds that advertising and labels for the coffee pods encourage consumers to "check locally" about whether the pods are recyclable. It claimed consumers would understand the items aren't recyclable in all markets, despite being labeled as recyclable. The judge, however, found this defense to be lacking because consumers allege the pods aren't recyclable through any MRF in the country, so telling them to "check locally" doesn't make Keurig's recyclability claims true.

"[C]ommon sense would not so clearly lead a person to believe that a package labeled 'recyclable' is not recyclable anywhere," U.S. District Judge Haywood Gilliam wrote in the ruling. "[A]lthough Keurig argues that its labeling is sufficient under the Green Guides... the complaint alleges facts that indicate the opposite."

The Green Guides are the Federal Trade Commission's advice on the types of marketing claims manufacturers can make about their products' recyclability. The goal is to prevent manufacturers from making deceptive or overtly false claims. A key part of the Green Guides is a section commonly referred to as the "60% access rule" – companies can make unqualified claims about a product's recyclability only when a substantial majority (60%) of customers or communities where the item is sold have access to recycling facilities accepting the material. In other words, while a product may technically be recyclable, it won't necessarily be considered as such in regions without adequate processing or sorting infrastructure.

Concerns over coffee pods' contribution to the waste stream have circulated for years following the product's growing mainstream popularity. Even the pods' inventor weighed in on the issue in 2015, saying he regretted inventing them due to their lack of recyclability.

But in the years since, manufacturers have made concerted efforts to create products that can be diverted from disposal. For example, Nespresso periodically expands its coffee pod mail-back recycling program. It partnered with Sims Municipal Recycling and New York's Department of Sanitation earlier this year to devise better strategies for recovering single-serve pods from the curbside recycling stream.

Two years ago, Keurig Green Mountain announced all of its Canada-made coffee pods would be recyclable by the end of 2018. The company released updated sustainability goals last month, including using 100% recyclable or compostable packaging and sending no waste to landfills by 2025. It also reiterated its previous goal of making all coffee pods recyclable by 2020.

Keurig Green Mountain was among the Association of Plastic Recyclers' (APR) initial group of Recycling Demand Champions, a campaign to expand market demand for recycled resins and improve plastic recycling in North America. According to APR, the two entities have "worked extensively" with one another to transition to a recyclable coffee pod container, and Keurig faced the same technological challenges as other companies that manufacture small, light, difficult-to-sort containers.

"Their efforts have led to the creation of technology and protocols that will be used by all brand owners that will allow more containers to be captured from the waste stream, thereby increasing the amount of material available for recycling while reducing contamination," APR President and CEO Steve Alexander told Waste Dive in a statement. "There have been few, if any, companies who have undertaken the vast array of efforts that Keurig has to address the sustainability of their products."

Keurig did not respond to a request for comment about the lawsuit prior to this story's publication.

In 2017, a company representative spoke at an event hosted by the Institute of Scrap Recycling Industries (ISRI) MRF Council about the company's strategy to make the pods recyclable by 2020. Some of ISRI's core work centers on creating products with end-of-life recycling principles in mind, and through its Design for Recycling program presents an annual award to a company that embodies these principles.