Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

VIDEO: Five Tips On Hydroponic Substrates

This video is part of the series called “Five Tips for Horticulture” featured on the Greenhouse Training Online channel (https://tinyurl.com/ufgto). The series highlights technical topics from university and industry experts

Dr. Paul Fisher from the University of Florida IFAS Extension interviews Shawn Mallen from A.M.A. Horticulture in a new YouTube video where they discuss the different commercial substrates most commonly used in hydroponic production, the importance of air porosity, and compaction of substrates.

This video is part of the series called “Five Tips for Horticulture” featured on the Greenhouse Training Online channel (https://tinyurl.com/ufgto). The series highlights technical topics from university and industry experts. Subscribe to receive upcoming videos on topics such as growing media, vermicompost, and running successful trials. The channel is sponsored by the Floriculture Research Alliance (floriculturealliance.org).

For more information on hydroponics, take the UF IFAS Extension online course for growers on Hydroponic Vegetable Production beginning on November 9 (https://hort.ifas.ufl.edu/training/) in English and Spanish.

For more information:

UF/IFAS

www.ifas.ufl.edu

2 Nov 2020

An Urban's Rural View - Vertical Farming Is Looking Up

It looks like some of the big boys in agriculture are finally taking vertical farming seriously

11/2/2020

By Urban C Lehner , Editor Emeritus

Connect with Urban: @urbanize

It looks like some of the big boys in agriculture are finally taking vertical farming seriously.

Last month one of the biggest, the berry behemoth Driscoll's, became an investor in and joint venture partner of Plenty Unlimited, an indoor vertical-farming startup. (https://www.businesswire.com/…) (https://agfundernews.com/…) From Driscoll's and Japanese tech investor SoftBank, Plenty is getting $140 million, bringing its total funding to $500 million. More importantly, it's getting to work with Driscoll's on growing strawberries indoors.

Entrepreneurs have been trying to make a go of indoor vertical farming since 1999 when Columbia University professor Dickson Despommier and his students developed the concept. It seemed like a no-brainer to grow food close to where it would be consumed, with high yields on minimal acreage, with less water and fewer if any chemicals, without soil in some iterations, and without fear of droughts, fires, floods, frost or high winds.

The disadvantages were less obvious -- but debilitating. For conventional farms, the sun provides free photosynthesis. For farms inside buildings, the cost of artificial lighting is horrific, and the cost of climate control makes matters worse. An Irish researcher contends that in the United Kingdom, indoor farms require more than ten times the energy of heated greenhouses. He recommends rooftops for those who want to grow food in cities. (https://theconversation.com/…)

Other disadvantages include high costs for labor, rent, and capital-equipment depreciation. "Despite the advances that have been made in controlled environment agriculture, it isn't quite ready for prime time and many opportunities for innovation remain," a Cambridge Consultants paper concluded. (https://www.cambridgeconsultants.com/…)

Vertical farmers, venture capitalists, consultants, academics, and others are doing cartwheels trying to solve these problems. Plenty Unlimited uses wind power and solar cells to generate its electricity and has developed special forms of plastic LED lights. A University of Florida researcher is working on pulsing light -- five seconds on, 10 or 20 seconds off -- and seeing signs that it cuts lighting costs substantially without hindering plant growth. (https://theconversation.com/…)

While depreciation costs are high, capital is available; fearless investors are hurling money at the sector. Rent costs could start coming down, too. With the pandemic encouraging more work from home, there will be surplus space in office buildings. (On the other hand, some vertical farms sell directly to restaurants, which the pandemic has been hard on.)

Though making progress, vertical farming remains a tiny corner of the multi-trillion-dollar agriculture and food business. A market research firm estimated it at $212 million in 2019 and predicted it would hit $1.4 billion by 2027. (https://www.prnewswire.com/…) When I last covered this subject in 2015, many vertical farms were still losing money. It's likely many lose money today. (https://www.dtnpf.com/…)

All that said, vertical farming has come a long way in the last few years. Hundreds of operations have germinated and sprouted in countries around the world. There have been innovations in lighting and climate control.

After years of growing mostly leafy greens and herbs, vertical farms are preparing to add crops like potatoes, tomatoes, and blueberries. As vertical-farm pioneer Despommier wrote in the Wall Street Journal recently, "Vertical farms are no longer some futuristic fantasy." (https://www.wsj.com/…)

As an example, Despommier cited Infarm, a company that was started in Israel, is now headquartered in Berlin and employs 400 people in 40 countries, mostly European. According to Despommier, who serves as an unpaid adviser to Infarm, the company provides grocery stores with automated, hydroponic systems that allow them to grow food in their produce aisles.

"Each store selects its own mix of greens and herbs, and consumers are encouraged to choose, taste and harvest from a menu growing right in front of them," he wrote. You can't cut transportation costs much more or provide much greater freshness.

And now, to move the sector further forward, comes Driscoll's and Plenty.

You can see the benefits to Plenty in this deal. They go beyond the $140 million and the expansion into a new and promising product, strawberries. They're hitching their wagon to a company that controls about a third of the $6 billion U.S. berry market. It has proprietary genetics and a team of geneticists developing new products. It has a recognized brand name and marketing muscle; the "clamshell" berry package was its idea. (https://www.newyorker.com/…)

What does Driscoll's get out of the arrangement? Plenty, too, has plenty to offer a partner. It says its Laramie, Wyoming, farm -- where Driscoll's berries will be grown -- is "the largest privately-owned vertical farm research and development center in the world." Plenty says it's "currently building the world's highest-output, vertical, indoor farm in Compton, California." https://www.businesswire.com/…)

But why vertical farming in the first place? Bloomberg emphasized Driscoll's desire to learn robotics from Plenty, whose farms are highly automated. Labor is a big part of Driscoll's cost structure and immigrant labor is becoming scarcer in the U.S. (https://www.bloomberg.com/…)

The Financial Times pointed to the fires in Driscoll's home state of California. A Driscoll's executive told the FT that instead of moving a whole farm farther up the mountain to get away from them, it can move to vertical farms. (https://www.ft.com/…)

The FT also mentioned "deglobalization," by which it apparently meant that in the future there may be less cross-border trade in food. That would encourage big players like Driscoll's to produce locally. The FT noted that two of Driscoll's biggest markets are in Hong Kong and the Arab world. It won't grow berries outside in either place but could grow them vertically indoors.

Whatever the reasons, what Driscoll's has done is big. Of all the progress vertical farming has made over the last several years, getting the big boys in ag to take it seriously is arguably the most important.

Urban Lehner can be reached at urbanize@gmail.com

Small Urban Farms, An Oasis For Underserved U.S. Neighbourhoods

Thus the children and their families get a sense that food comes from the soil. This is not so obvious a connection in Ward 8. In this corner of the capital of the US, there is one full-service grocery store for 80,000 people, and access to something as basic as fresh vegetables is limited

October 30, 2020

Adrian Higgins

THE WASHINGTON POST – I ate the last of the season’s potatoes the other day, and it’s not a bad harvest achievement when you consider I dug the lot in July from a bed no more than 15 feet long. I’ve eaten many meals over the summer where the bulk of my plate has come straight from my small community garden plot in the city.

It is amazing how much you can grow in a small space if the soil is good and you stay on top of tasks such as watering and weeding. But even in a pandemic-driven planting year full of homegrown potatoes, beans and carrots, you have to face reality. If you relied on most urban veggie plots alone to feed yourself, never mind a large family, you’d be forever tightening your belt.

This is why I’ve had my doubts about whether urban agriculture can meet the challenge where it is most needed – in poorer, food-insecure neighbourhoods. Rosie Williams is in charge of such a garden, in an expansive side lot of the National Children’s Center, an early-learning and educational development provider in Southeast Washington, in the United States (US).

The garden packs a lot in. There are almost 70 raised planter beds, each four by eight feet and filled with deep, rich soil. That’s a lot of growing area; the beds generate bushels of edible plants for most of the year.

A shed houses tools, a single beehive is active, a few fruit trees ring the area, and one side is devoted to little benches for little people. The centre, which normally houses classes for 188 children up to age five, has been closed because of the pandemic, though a limited re-opening is in the works.

Teacher and garden coordinator Williams showed me cool-season veggies growing in the fall, young plants of kale, collards, cauliflower, broccoli and red cabbage. In other planters, mature plants are seeing out the season in robust vigour. The most obvious is a single pepper plant – now taller than Williams – whose leaves hide unripe green chillies that hang like ornaments. This is a mighty hot pepper from Trinidad named Scorpion, she said, and I have no doubt that it has a sting in its tail.

Nearby, a Japanese eggplant is full of purple streaked fruit. Along another path, Williams stopped to lift a wayward cherry tomato vine and places it back in its bed. “I don’t like to step on my babies,” she said.

Elsewhere, wizened sunflowers have had their day. “We bring the kids out, we show them how to plant seeds, what the plants need,” she said. “It’s getting folks exposed to the garden.” Food from the garden is used in the centre’s kitchen.

Thus the children and their families get a sense that food comes from the soil. This is not so obvious a connection in Ward 8. In this corner of the capital of the US, there is one full-service grocery store for 80,000 people, and access to something as basic as fresh vegetables is limited.

“We have a lack of grocery stores,” said Jahni Threatt, the Community Supported Agriculture (CSA) programme Market Manager for the non-profit Building Bridges Across the River. “In Wards 7 and 8, we have three grocery stores.” Residents eat from fast-food chains or out of convenience stores. “The food that’s available isn’t necessarily healthy,” she said. Under the CSAs, growers provide direct weekly harvests to subscribers.

The Baby Bloomers Urban Farm that Williams coordinates at the National Children’s Center is one of seven in a network of city farms east of the Anacostia River, including a one-acre farm run by Threatt’s organisation at THEARC, the arts, education and social services campus at 1901 Mississippi Ave.

This one farm produced as much as 1,600 pounds of food this year, but to provision its CSA programme, the Building Bridges group turns to an additional 10 farms within 50 miles of the city, most of them Black-owned, said Scott Kratz, vice president.

The CSA runs three seasons of subscriptions, and bags are picked up on Saturdays at THEARC. The spring season was cancelled because of the pandemic, but the summer and fall ones have been heavily subscribed and will provide food for over 400 families this year. The season has also been extended, from the end of this month to the end of next. Lower-income subscribers get a reduced rate, and families on assistance get the food free, Kratz said.

This is heartening, because the pandemic has hit the city’s poorest wards the hardest. Many residents have underlying health issues related in part to their diet, and many are front-line workers or rely on the gig economy, putting them at greater risk of contracting the novel coronavirus, Kratz said.

Ward 8, which is 92 per cent Black, so far has the highest number of virus deaths in the district, with 127, according to city data. Ward 3, 81 per cent White, had 34 for the same period.

“We need to make sure that the programming we have is coming through the lens of equity and making sure the access people need is available to everybody in the community,” said Building Bridges Farm Director Dominic Hosack. I am rethinking my sense that mini-farms in the city are of limited value. They are, rather, a key portal into a larger infrastructure of food-security efforts. Beyond their utility, they are places of deep reconnection, to the soil, to food and to communities. In the food deserts of big-city America, they are the oases.

GARDENING TIP

Whiteflies are tenacious pests of certain houseplants and should be tackled, preferably before bringing plants indoors for the season. A vacuum cleaner is an effective way of dealing with them without using pesticides. Repeat as needed.

Lead photo: Garden coordinator Rosie Williams checks a pepper plant at the National Children’s Center urban farm in Washington. PHOTO: THE WASHINGTON POST

Vertical Farming Made Easy With Sarab From Ecotwigs

Sarab lives in Mumbai, India. In 2017, she completed an internship in Canada at the In.Genius Farms, a small-scale vertical farm in Laval, Quebec. Mentored by Khaled Majouji, aka The Plant Charmer, she learned about the potential of vertical farming. Once back home, she decided to be the change she wanted to see in her country

August 5, 2020

Sarab lives in Mumbai, India. In 2017, she completed an internship in Canada at the In.Genius Farms, a small-scale vertical farm in Laval, Quebec. Mentored by Khaled Majouji, aka The Plant Charmer, she learned about the potential of vertical farming. Once back home, she decided to be the change she wanted to see in her country.

Inspired by her experience in Canada, Sarab started her own startup: Ecotwigs. With the help of her father, Gurmukh Singh, an entrepreneur in computer numerical control (CNC) machinery, they designed and developed a ready-to-assemble vertical farming system.

It can be produced on an industrial scale, delivered wherever it is needed, and easily deployed upon reception.

Sarab at her vertical farm near Mumbai

As in many countries, the COVID-19 pandemic has disrupted the mobility of agricultural workers in India, adding pressure to food supply chains and compromising the food security of the most vulnerable populations. The situation raised awareness on the importance of local farming and shorter supply chains.

Sarab vertical farming solution comes at the right time. It aims to solve a few problems at once:

requires less land;

reduces the workload and dependence on seasonal foreign workers;

increases yields per square-foot;

improves food salubrity;

simplifies traceability;

and fosters profitability.

Given the current pandemic, such a farming system, which also requires limited interactions and manipulations while operated, would be more than handy.

How it all started

Sarab studied sciences in Junior college. “It was the rational choice”, she said. However, her real dream was to become a pastry chef. She had always been fascinated by big wedding cakes, but convincing her dad about this career choice was challenging.

Nonetheless, while in college she started a side gig as a freelance pastry chef. She liked it so much that after college, she did a bachelor’s degree in Hotel and Hospitality Administration. While studying, she spent a semester working as an intern at the Danat Jebel Dhanna Resort on the outskirts of Abu Dhabi in Ruwais city.

Before completing her bachelor’s degree, a research topic on lifestyle diseases based on our diets shed a different light on her passion. “I realized that what I was loving [baking cakes] was making people diabetic”, she said. “I thought I was giving people joy, but I was giving them diabetes”, she added.

Sarab explained that although she still enjoys baking and has nothing against eating pastries, it may not be the purpose she wanted in life. When she graduated, suddenly she felt like she didn’t want to follow this path anymore.

One day, while waiting for a friend near a market, she was watching how the food was handled. Among other things, she noticed bunches of cilantro unloaded directly on the dirty pavement of a street in Mumbai. Given that cilantro is a garnish in almost every Indian dish, she thought that she could do better. She started to crawl Youtube and looked at hours of videos on how to grow food. The first thing she tried was to grow kiwis from seeds. “I never stopped after that”, she said.

She made a rooftop garden, but without any background in agriculture, she admitted her results were suboptimal. Nevertheless, she was determined to pursue this new path. In 2017, she was following Khaled, aka The Plant Charmer, on Instagram. When she saw a post about an internship opportunity at his new vertical farm, she jumped on it.

The Instagram post that caught Sarab’s attention

Although it sounded like a crazy idea to her parents, generating some fuss in her family, they ended up being supportive of her choice. “Going to Khaled’s farm was the best decision in my life”, she said.

When I was at Khaled’s farm it struck me: this is the future of farming. – Sarab

Sarab wanted to see the full cycle, from seedling to harvesting, including everything in between. “I was supposed to do a one-month internship only”, she explained. “But I was so fascinated on how the system works, I asked to stay longer”, she added.

Sarab at the In.Genius Farm in Laval, QC, Canada

At the end of her internship, another big decision was awaiting Sarab. She had to decide whether to stay in Canada and apply for permanent residence, or to return to India. “The greatest accomplishment in our country is to leave”, Sarab said. “With everything I learned, I felt like the right thing to do was to bring back this knowledge and do something for my country”, she added.

When she returned home, she faced a few challenges. The same as any small-scale urban farming entrepreneurs would encounter in India and elsewhere: access to land, in or near the city, is difficult.

The real estate in Mumbai and other major Indian cities is as expensive as any major city in North America or Europe. It makes farming possible only in remote and often deficiently developed regions. Moreover, a lot of lands in or near the cities and suburbs are highly contaminated, making agriculture beyond gardening nearly impossible. Luckily, Sarab’s uncle provided her with the opportunity to develop her project on an 18,000 sq.-ft plot of land he owns, only 20 minutes away from Mumbai’s suburbs.

Why vertical farming

A new climate report from the United Nations has warned that the world might face a food crisis due to climate change and overexploitation of land and water resources. The vertical farming infrastructure proposed by Sarab aims to enable growing food wherever there is place while reducing pressure on farmlands and fostering soil regeneration.

Without farming the land itself, the annual yields are still calculated in metric tons on less than an acre. By growing above the ground, pest damage and diseases are drastically reduced without the need for any pesticides or harmful chemicals.

For Sarab, vertical farming as she learned it at the In.Genius Farms makes organic farming way easier. “It reduces operational costs, requires fewer resources [human and natural], while increasing yields and margins”, she explained.

“Vertical farming with my infrastructure can be done by anybody because the hard work factors of conventional farming were removed”, she said. “There’s no kneeling, no bending, and no weeding”, she added. From her experience at In.Genius farms, Sarab thinks that 1 worker for every 100 units is more than enough (100 units cover about 10,000 sq.-ft.).

Business model

Once back from her internship at In.Genius Farms, Sarab realized something: she didn’t want to start a farm, she wanted to become the vertical farming infrastructure provider.

I want to be the person who set [up] vertical farms for others because that’s the future. – Sarab

Sarab explains that going through the process of figuring out vertical farming by yourself can be daunting. “Of course some could do it by themselves, but it would turn out to be expensive and time-consuming”, she said. “I want to make things simple and affordable to those wishing to start a vertical farm”, she added.

Her business model is to provide customers with a turnkey vertical agricultural infrastructure and technical assistance to ensure they reach the full yield potential. Therefore, land use and the time, effort, and money spent would be optimized.

As what IKEA does to home furniture, Ecotwigs does to farms by designing and selling ready-to-assemble vertical farms. – Sarab

Sarab’s main market for her vertical farming infrastructure will be existing farmers, but also a new generation of food entrepreneurs who own small plots of land and wish to start small-scale farming businesses. For Sarab, too many farmers in India (and elsewhere) are not treating their farm as a business, and when they do, it is often not managed efficiently. Thus, she wants to provide them with proper customer support to create lasting prosperity.

Vertical Farming Systems

As Sarab’s father noticed her enthusiasm for vertical farming, he decided to help her in her venture. He helped her design and engineer a new system following her experience in Canada.

This A-frame is made of inert material. Suitable for outdoor and indoor farming, it is lighter than wood and easier to assemble (or disassemble if needed). Moreover, it is made to last a minimum of 10 years.

A 100 units farm can be assembled within a week by 2 people. – Sarab

One unit can be assembled by 2 people in 30 minutes. Each A-frame unit includes 10 rammers that are 12 feet long (or 3.90 meters). There are 5 rammers on each side. Working 7.5 hours per day, it would take two people about 7 days to set up a 100 unit vertical farm on 10,000 sq.-ft.

Depending on the crop and location, each unit can generate from $400 to over $1000 in revenue per season. The price to buy a unit is not yet settled. Nevertheless, the price range will be established to allow clients to get a great return on investment (ROI).

Our challenge was to design the most profitable, eco-friendly, food-safe, sturdy, and long-lasting farming system. – Sarab

The rain gutters, as used on the In.Genius Farms’ A-frame, are replaced by a custom made rammers. For marketing purposes, Sarab and her father decided to change the name of this component, which is the channel used to grow food. “In India, when you say gutters, it is associated to a filthy place”, she explained. “It is not the place where people would want their food to grow”, she added.

The rammers’ length, width, and depth were increased to allow higher yields per unit and the growth of a wider variety of crops. The angle of the rammers was set to get a maximum sun or LED light exposure. The system can be deployed either as a few units in a backyard, on rooftops, or at scale on acres.

The next steps

Sarab currently operates a 30 unit vertical farm. It serves as a research and development lab. “That is where data are validated”, she said. Sarab is growing varieties of lettuce and spinach, arugula, peanuts, sweet bell peppers, edible flowers, and eggplants. She will also experiment with growing strawberries, which is unusual for Mumbai’s climate.

As the rammers are longer, deeper, and wider than the model she experienced at the In.Genius farms, bigger crops like cauliflower, celery, and zucchinis will be tested as well. The food harvested at her farm will be for friends and family. With 30 vertical farming units, Sarab already knows that she will not have the volume necessary to consistently supply clients like chefs or grocery stores.

Her focus is on supplying the infrastructure and acting as a vertical farming consultant to her clients. Thus, operating the farm to gather data is the priority. The system will be continuously tested to make sure it can perform well, and that yield expectations are accurate.

Sarab explained that “when a client is looking to invest in infrastructure like this, we need to give them the proper numbers. And I know that at one point, the numbers will speak for themselves”.

Sarab is well aware of the Canadian winter. “Made of inert material, these A-frames do not react much to temperature fluctuations”, she explained. She also knows how robust the system needs to be to endure the cold temperature of northern countries, as well as snow and ice accumulation.

Takeaways on vertical farming

The approach of the farmers should change, and the status quo should be disrupted. Sarab explained that Indian farmers are treated as the bottom of the supply chain. If they could be provided with the proper tools and means to grow, market, and distribute food efficiently, she believes it could make them the leaders of the supply chain. The main issue Sarab stressed is to make sure you have enough customers for those high yields.

“The best part, since all labor-intensive tasks of conventional farming have been stripped out, it could be done by anybody”, Sarab proudly said. Adding some fun, fashion, and style to the business concept is also part of her branding.

I genuinely enjoy working at my farm and the message I want to spread is: this is cool! I can be fashionable and still be a farmer. -Sarab

Do you have an inspiring urban agriculture story to tell or innovative ideas to share? Contact us or leave a comment below!

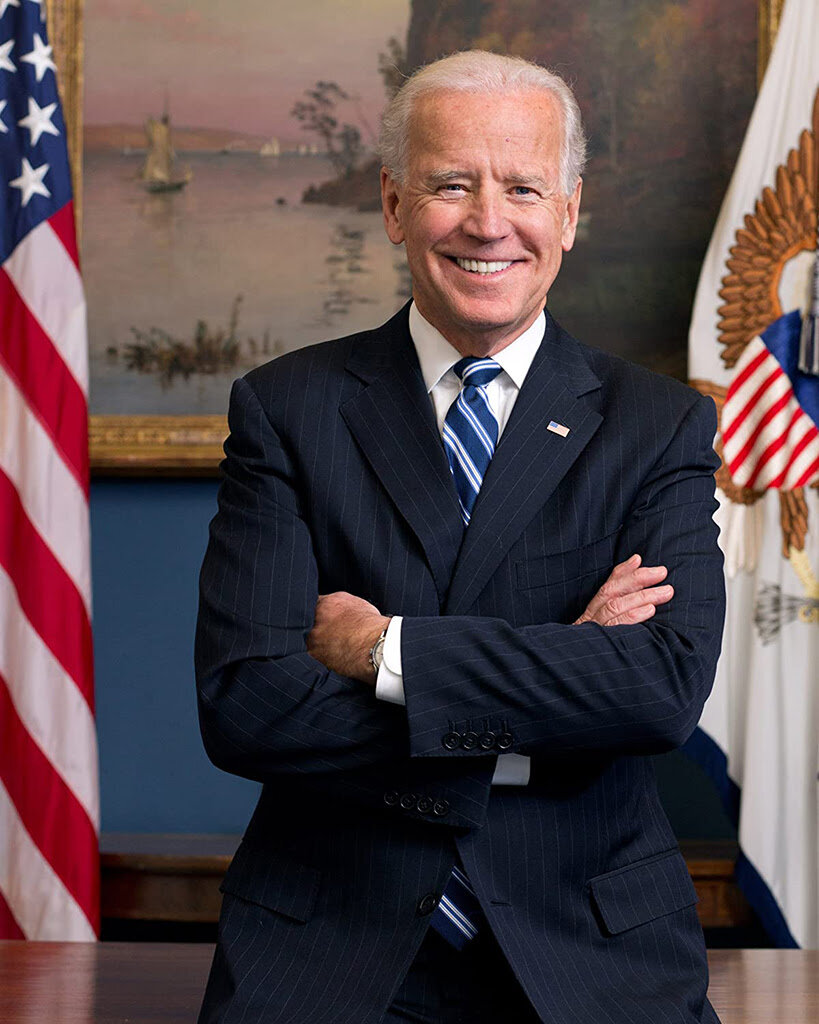

Joe Biden - President Elect #46

President-elect of the United States

Assuming office January 20, 2021 - Vice President Kamala Harris (elect) - Succeeding Donald Trump 47th Vice President of the United States

President-elect of the United States

Assuming office January 20, 2021

Vice President Kamala Harris (elect)

Succeeding Donald Trump 47th Vice President of the United States

In office

January 20, 2009 – January 20, 2017

President Barack Obama

Preceded by Dick Cheney

Succeeded by Mike Pence United States Senator

In office

January 3, 1973 – January 15, 2009

Preceded by J. Caleb Boggs

Succeeded by Ted Kaufman

Chair of the Senate Foreign Relations Committee

In office

January 3, 2007 – January 3, 2009

Preceded by Richard Lugar

Succeeded by John Kerry

In office

June 6, 2001 – January 3, 2003

Preceded by Jesse Helms

Succeeded by Richard Lugar

In office

January 3, 2001 – January 20, 2001

Preceded by Jesse Helms

Succeeded by Jesse Helms

Chair of the International Narcotics Control Caucus

In office

January 3, 2007 – January 3, 2009

Preceded by Chuck Grassley

Succeeded by Dianne Feinstein

Chair of the Senate Judiciary Committee

In office

January 3, 1987 – January 3, 1995

Preceded by Strom Thurmond

Succeeded by Orrin Hatch

Member of the New Castle County Council from the 4th district

In office

November 4, 1970 – November 8, 1972

Preceded by Henry Folsom

Succeeded by Francis Swift

Personal details

Born Joseph Robinette Biden Jr. November 20, 1942 (age 77)

Scranton, Pennsylvania, U.S.Political party Democratic

Spouse(s) Neilia Hunter (m. 1966; died 1972)

Jill Jacobs (m. 1977)

Children

Parents

Joseph R. Biden Sr.

Catherine Eugenia Finnegan

Relatives

Edward Francis Blewitt

(great-grandfather)Education University of Delaware (BA)

Syracuse University (JD)

Occupation

Politician

lawyer

author

Awards

Presidential Medal of Freedom with distinction (2017)

SignatureWebsite Campaign website Transition website

Jump to navigationJump to search"Biden" redirects here. For other uses, see Biden (disambiguation). "Joseph Biden" redirects here. For his son Joseph Biden III, see Beau Biden.

This article is about a person involved in a current event. Information may change rapidly as the event progresses, and initial news reports may be unreliable. The last updates to this article may not reflect the most current information. Please feel free to improve this article (but note that updates without valid and reliable references will be removed) or discuss changes on the talk page. (November 2020)

From Wikipedia, the free encyclopedia

November Webinars - Latest In Aquaponics, Seeds of The Future

Cities face increasing pressure to attract innovative solutions and guarantee the food security of their residents

UPCOMING NOVEMBER CONVERSATIONS:

Take A Deep Dive Into Aquaponics, Grow Your

Knowledge With Seeds Of The Future

Presented by the Aquaponics Association

Panelists:

Regina Gruell Cook, Co-Founder and Vice President of Marketing & Operations, Symbiotic Aquaponic

Claudia Andracki, owner, Desert Bloom Eco Farm and Aftaz Growing Systems

Carlos Leon, Biotechnologist Engineer, Aquaponia – BoFish

Charlie Shultz, Lead Faculty, Controlled Environment Agriculture Program, Santa Fe Community College

Tawnya Sawyer, Co-Owner, The Aquaponic Source and Colorado Aquaponics

LEARN MORE & REGISTER

Presented by The American Seed Trade Association (ASTA)

Moderator:

Andy LaVigne, President & CEO, American Seed Trade Association

Panelists

Dr Aaron Crawford, Lead, Technical Product Commercialization, Pairwise

Tracy Lee, Head, Controlled Environment Agriculture Department, Sakata Seed

Kees Roenburg, Hydroponic Sales Manager, Enza Zaden North America

LEARN MORE & REGISTER

And, look for details coming soon for other upcoming programs from the Hemp Industries Association and more!

INDOOR AG-CON IS A PROUD MEDIA PARTNER OF AGRITECTURE XCHANGE

Cities face increasing pressure to attract innovative solutions and guarantee the food security of their residents. We’re proud to be a media partner of Agritecture XChange, a virtual conference connecting key innovations in the field of AgTech to the future health of our cities. Learn more and save 10% off the ticket price with our special Indoor Ag-Con promo code IAC10

SPECIAL THANKS TO OUR INDOOR AG-CON 2020

EXHIBITORS, SPONSORS,

MEDIA ALLIES & INDUSTRY PARTNERS

AUSTRALIA: Food In The Capital

Canberra’s first ever sustainable food event is here. Starting on 17 November 2020, Canberra will play host to Food in the Capital, a first of its kind, sustainable food conference program

Shayna Siakimotu 17 November 2020

Where:

Online and Kambri ANU

When:

17 November 2020, 9:00 am to 5:00 pm

18 May 2021, 9:00 am to 5:00 pm

16 November 2021, 9:00 am to 5:00 pm

Canberra’s First Ever Sustainable Food Event Is Here

Starting on 17 November 2020, Canberra will play host to Food in the Capital, a first-of-its kind, sustainable food conference program.

The 3-event series, scheduled across 12 months, set out to connect people from across the industry including farmers, food businesses and manufacturers, community groups, thought leaders and policy makers.The focus will be on food production, consumption and technology and is the first of its kind in the region.

Tickets starting $297 and are for all 3 events.

17 Nov '20 | 18 May '21 | 16-17 Nov '21

The three events set out to connect people from across the industry including farmers, food businesses and manufacturers, community groups, thought leaders and policy makers.

Improvements to our Food System envisaged at FIC could conservatively:

Generate up to 3,000 jobs for the local economy.

Reduce Canberran’s grocery costs by $200 million.

View the program and speakers online and get your tickets today!

Join Canberra’s first ever sustainable food event, starting 17 November 2020. Photo: Supplied.

The Details

What: Food in the Capital – Sustainable food event

When: 17 November 2020, 18 May 2021, 16 November 2021

Where: Online and Kambri Centre ANU, Acton ACT 2601

Cost: Tickets start from $297 (+ booking fee) and covers entry to all 3 events. Single event tickets are not available

For more information, visit Food in the Capital.

LATVIA: Safety of Food Grown In Urban Vertical Gardens

The project, called G(U)ARDEN, is a vertical garden experience set in Latvia aimed at exploring the safety of growing food in urban gardens.

26-10-2020 | Inhabitat

Interior architecture firm Annvil has brought together a team of urban planners, designers, environmentalists, and natural scientists to study the interaction between the urban environment and horticulture. The project, called G(U)ARDEN, is a vertical garden experience set in Latvia aimed at exploring the safety of growing food in urban gardens.

Urban agriculture has already been proven to reduce air pollution, collect and use runoff, increase productivity of space, and aid in urban cooling, but it is still lacking in substantial scientific research in the safety of these plants being used for food. The G(U)ARDEN project will measure the biochemical composition of vegetables and fruits grown in urban environments, especially in places with intense traffic and air pollution.

The primary urban vertical garden of this project is located in Riga, Latvia and is made up of local plants from the city’s horticulture centers and nurseries. Researchers chose to use endemic plants to inspire residents to grow and conserve locally as well as to encourage sustainable and effective urban environmental development discussions.

“Today we live in a digital world where everything is instantaneous. In answer to that, we want to stimulate people’s interest in real-life — interest in the physical world and in being close to nature,” said Anna Butele, author of project G(U)ARDEN and the founder of Annvil. “We can do that by creating even more green environments in the city — meeting places that bring together different groups of society. This way we can also bring attention to neglected environments in the city.”

The pilot program has started with the team studying the garden’s vegetable and fruit harvest in a scientific laboratory. Crops are measured for the presence of heavy metals, while the air and water is measured for the microbiological composition to help identify all possible risk factors associated with the impact of the urban environment on edible plants. The data obtained from the experiment will aid in continued projects to help create a series of urban gardens in Latvia’s largest cities next year.

Photography by Ingus Bajārs via Annvil

Source: Inhabitat

Research And Indoor Farming University Network

The Indoor Farming University Network (IFUN) aims to create a space for strategic communication in the indoor farming industry between research departments and universities across the world

OCTOBER 29, 2020

When the pioneering vertical farms were established around the world, comparatively basic first-generation technology used created relatively inefficient systems compared with today. Although these operations only enabled the most basic functions to occur, they demonstrated how feasible it was to grow plants in vertical structures and thus, for the first time in history, opened doors to the vast number of opportunities associated with space-optimised and controlled-environment food production in urban environments.

Notably, this had the potential to bridge the gap between the food source and consumer-created by the second agricultural revolution of the 17th century, which led to the industrial revolution and mass urbanisation.

As the industry’s capital expenditure tends to remain high, increasing the financial viability of vertical farming businesses by cutting down the operating costs is crucial for securing a successful future and has thus become a key focus of research. The transition from first-generation to second-generation technology is critical. Second-generation technology enables automation and continual optimisation of the growing process, resulting in immensely higher yields and more appealing and feasible investment opportunities.

In the indoor farming industry’s short history, advancements in automation have been made in a range of areas including watering and hydroponics, and monitoring of water parameters. More modern practices integrate robotics and even allow plants to be moved. The automation of light quality and intensity plus the incorporation of LEDs has also been key to creating big energy savings and higher quality produce, and there are emerging examples of systems with LEDs that respond and automatically adjust their intensity according to real time data output from the plants.

Check Out UPLIFT, a Fully Automated Vertical Farm by SANANBIO

An example of interdisciplinary research projects

PB ‘Horticultural Systems of the Future’ (HORTSYS) innovates for the future of indoor (and outdoor) horticulture using the latest sensor technology and model-based decision support systems (DSS). The research group, HORTSYS.2, is developing resource-optimised production systems in controlled growing environments including vertical farms. It is a cooperative effort between Wageningen University, the Leibniz Institute for Vegetable and Ornamental Plant Production (IGZ), Danish Technological Institute, Aarhus University, Humboldt University Berlin, and many more.

Laura Cammarisano at AVF Indoor Learning Lab and Demo Center, Munich, Germany

Laura Cammarisano (a scientist at the IGZ and AVF member), describes her work:

“I collaborate to create solutions that combine plant mathematical models and sensors for the automation of plant cultivation in closed environments.”

HORTSYS.2 uses knowledge of important parameters affecting plant behaviour, such as light quality or nutrient uptake. They combine understanding from addressing key research questions related to mathematical modelling and sensor technology as well as plant physiology.

There is a call for and a growing need for such collaborative efforts because high tech farming systems, such as vertical farming, combine knowledge and data from a range of different research areas.

Laura Cammarisano added: “One very important aspect at the moment, at least to me, is the need for data as it would help a lot in the automation process.”

The Importance of Building Networks and Consortia

Communication and working together is vital to help the industry move forward as this facilitates more rapid advancements in the automation process and produce quality, increasing the economic viability of VF technology. This helps to secure investment, in turn paving the way for the integration of VF technology and its innumerable benefits into our daily lives.

The Indoor Farming University Network (IFUN) aims to create a space for strategic communication in the indoor farming industry between research departments and universities across the world. With the main priority being to emphasise the importance of research and collaboration during the climate crisis, IFUN will initiate and support interdisciplinary partnerships to create a network offering a range of benefits to its members from consortium building for grant applications and identifying knowledge gaps to education for future researchers, decision-makers, and the general public.

You can find out more about IFUN and how to join here.

Author: Laura Nelson

Tech Startup iFarm Raises U.S. $4 Million to Expand Do-It-Yourself Urban Farms

Most urban farming companies do one of two things: grow and sell their own food or manufacture technology to assist experienced farmers, such as LED lights and robots that can monitor and harvest produce

The Finnish technology startup iFarm recently raised US$4 million to build vertical farms for more customers across Europe and the Middle East. Using these funds, iFarm aims to help more entrepreneurs and businesses set up their own urban farms—at any time, in any place.

iFarm, founded in 2017, develops autonomous farming systems to grow greens, berries, and edible flowers indoors. It sells smaller, individual growing modules, as well as vertical farms for larger-scale production.

Most urban farming companies do one of two things: grow and sell their own food or manufacture technology to assist experienced farmers, such as LED lights and robots that can monitor and harvest produce.

iFarm falls into a third, less common category. Rather than standalone technology, the company sells entire urban farming systems with built-in robotics. These systems enable customers to start farms with little to no knowledge of agriculture.

iFarm’s growing module, iFarm Cropper, is designed for grocery stores, restaurants, or homes. Their vertical farms are intended for larger spaces, like warehouses. These systems are equipped with drones and artificial intelligence that spot diseases and track plant growth. They can also be controlled by an app, iFarm Growtune, that automatically plants seeds and adjusts lighting and humidity.

Kirill Zelenski, the Managing Director of Europe at iFarm, tells Food Tank that the company’s name is reminiscent of the iPhone. With an iPhone, he says, “you don’t need to know anything… You just need to know what you want to do, and it will do it itself. Same with our farms.” He explains that a customer simply has to push a button to grow arugula, and the system knows what to do.

Urban farming companies boast several ecological, economic, and health benefits. iFarm’s technology, for instance, uses 90 percent less water and 75 percent less fertilizer compared to conventional farms, and no pesticides.

Controlled climates inside urban farms reduce the risk of air and water pollution, while allowing for more reliable yields. iFarm reports that 100 percent of their seeds sprout.

Indoor farms can also exist anywhere. The urban farming company Square Roots, for example, grows greens in the heart of Brooklyn. This flexibility cuts down on land use—which is increasingly sparse—and improves access to fresh food in urban areas.

iFarm’s founder, Alex Lyskovsky, decided to start the company for exactly that reason: his hometown in Siberia lacked access to fresh food. Now, thanks to iFarm, says Zelenski, “Even sitting in Finland, I can grow—for example—tomatoes like they would be grown in Sicily.”

Zelenski imagines a world where proximity to farmland no longer dictates where people reside. “Our idea is that it will change the world and how people are living. Because of the possibility to build farms in every house, you can live wherever,” Zelenski tells Food Tank.

Zelinski believes that autonomous farming companies—particularly those that sell already-programmed systems—have the potential to radically reshape the industry. “Modern farmers,” as he calls them, won’t necessarily need to know how to farm.

However, there are downsides. Zelenski notes that iFarm’s drones reduce the need for labor by 800 hours per month, which boosts efficiency and saves farm owners money—but could also threaten job security for farm workers.

iFarm isn’t the only company selling urban farms. Manhattan-based Farm.One offers everything from single-plant hydroponic units to entire vertical farming setups. InFarm, based in Berlin, installs its modular setups in grocery stores. And companies like Agrilution, Rise Gardens, and Aspara sell in-home hydroponic systems.

As for iFarm, the company plans to put half of its recent funding towards scaling up in Europe and the Middle East, 30 percent into research and development, and the remaining 20 percent into internal management and hiring.

The company plans to leave a big mark on the agriculture industry. “We think our technology will change not just [farmers’] work, it will change the world totally,” Zelenski tells Food Tank. “Our idea totally disrupts the industry.”

October 30, 2020

NEW ZEALAND: Southland Lawyer-Turned Lettuce Farmer Expanding Hydroponics Business

Aviation lawyer Angela Beazer, who has been working for the Civil Aviation Authority part-time, was a recent recipient of a $2.5 million Provincial Growth Fund loan

1 November 2020

Otago Daily Times

By: Mary-Jo Tohill

A Southland lawyer-turned lettuce farmer is looking forward to devoting all her time to expanding her hydroponics business.

Aviation lawyer Angela Beazer, who has been working for the Civil Aviation Authority part-time, was a recent recipient of a $2.5 million Provincial Growth Fund loan.

While flying high, the 45-year-old has her feet firmly on the ground. With plans afoot to triple the lettuce farm's production, it had become clear to her she could no longer do both jobs and would have to quit one.

"But now I'm ready for change. I've been trying to juggle both, but they're not complimentary.

"I have a life many people would envy. I can work on my own schedule. I can be there to pick up my daughter from school, but as I say, they (lawyer/lettuce growing) are not complementary. I could not give 100 percent to both. If I do something I like to do it properly.

"I'm quite looking forward to focusing just on the lettuces."

If someone had told the former career professional eight years ago that she was destined to become a lettuce farmer, she would have laughed.

"I pictured lettuces sown out in the middle of the muddy paddock. Not my cup of tea at all."

She and her partner, Craig Macalister, had already taken a big leap of faith when they moved from Wellington to Invercargill so that he could take up a new position with financial advisory and accountancy firm Findex.

However, it was their frustration at not being able to find a suitable rural lifestyle block that led them to a property in Myross Bush.

Shoulder-tapped by a real estate agent, they went out and looked at a place that happened to have a hydroponics setup — Drysdale Hydroponics.

"I knew nothing about growing lettuces. We'd been down here about a year. I had a plot where I grew some veggies — a bit of broccoli, some cauliflower, a few potatoes. Actually, the potatoes were already there. That was about the extent of my horticultural experience."

Fast forward eight years and now she grows lettuce by the hundreds at her farm Southern Hydroponics, still trading as Drysdale Hydroponics, near Invercargill.

And with the expansion that will employ another 30 people, she's set to grow more, and other vegetable crops, including capsicums and tomatoes.

"We're been producing a fairly fixed amount of product. The business does need to expand because there's more competition. The minimum wage's gone up, so you either shut down or you expand and make it worthwhile."

Increasing production and lowering costs made for better economies of scale. Beazer liked the concept of hydroponics as an efficient way of growing food on a large scale.

However, while it had been a great move, it was also a huge lifestyle change,

"I think sometimes, 'why am I doing it?' But you're working at waist height — you're not having to bend and I quite like working undercover, but still feeling like you're working outdoors.

"On the other hand, this is a 24/7, 365-day operation. Someone has to be here watching all the time. There's a lot that goes on behind the scenes."

It was sometimes hard to close the greenhouse door and walk away when you had to be constantly checking things like nutrients and temperature, she said.

"One thing I'm really looking forward to is being able to move to a heat pump from the boiler, with the expansion."

There might also be time to take up some interests again — like Zumba.

"I was doing it, but since lockdown and everything I haven't got back into it and I've been a bit of a lazy bum and not been doing it."

Lead photo: Angela Beazer surveys her hydroponic lettuces. Photo / Supplied

INDIA: Farm To Fork, The Hi-Tech Way

The lockdown has created a new food chain for both the urban farming community growing produce on home terraces and agriculturists on conventional farms

Hyderabad-based Simply Fresh has commissioned India’s largest high-tech ‘plant factory’, spread across 140 acres.

November 1, 2020

Lead photo: Greens from Simply_Fresh

The lockdown has created a new food chain for both the urban farming community growing produce on home terraces and agriculturists on conventional farms. Artificial Intelligence and new machinery are making it efficient and progressive. For example, an IIT Madras app offers a seed-to-plate supply chain. NeerX Technolabs’s low-cost sensors are even used by ISRO and IARI to replace expensive imported remote sensors.

Cloud cues

From red tape bureaucracy to ignorance, prevents data across categories. Cloud Cues, a project led by IIT Mandi, brings data on a single platform to be distributed according to need. “Small-scale farmers benefit by sharing resources such as weather prediction, irrigation, soil nutrition, seed selection, disease and pest control, surveillance and market access and credit.

Crop protocols being explained to a

farmer by AB InBev

Water saver

Bengaluru-based Gourmet Garden focuses on improving water and nutrient use in sustainable farming sensor-based technology. It automatically assesses nutrition delicacy and auto-fertilises soil thereby reducing water use by over 90 percent. It can be controlled through a mobile phone or computer. “All plants will get uniform nutrition,” says Arjun Balaji and Vishal Narayanswamy, Co-founders, Gourmet Garden, a company that deals with hydroponics.

Artificial intelligence

Hyderabad-based Simply Fresh has commissioned India’s largest high-tech ‘plant factory’, spread across 140 acres. “We use AI-based precision farming, climate e-engineering, and hydroponics. From growing to processing, it’s cheaper than expensive US operations,” says Sachin Darbarwar, CEO. The company has developed proprietary software for farm management.

Supply chain solution

Smart Barley: AB InBev, the world’s leading brewer, works with KisanHub, an agri-food supply chain company, to empower farmers to manage their supply chain, identify and resolve risks, make large-scale supply planning decisions and improve sustainability.

Machine learning

Agrojay platform: The horticulture app implemented in Nashik, Maharashra, is used by more than 22,500 people for online consultation for predictions, crop patterns, and sales to highly rated traders via AI and Machine Learning.

Andaz Dubai The Palm Launches Hydroponic Container Farm

Andaz Dubai The Palm has partnered with Green Container Advanced Farming to grow its own fresh produce on site

It will grow produce including lettuce, herbs, and microgreens

November 04, 2020

Andaz Dubai The Palm has partnered with Green Container Advanced Farming to grow its own fresh produce on site.

The boutique lifestyle hotel will host a 400 sq ft hydroponic organic container farm on its Palm Jumeirah terrace, allowing them to harvest fresh produce such as lettuce, herbs, and microgreens.

Kifah Bin Hussein, general manager of Andaz Dubai The Palm, said: “At Andaz we strive to be more sustainable in everything that we do, using resources responsibly to help address today’s most pressing environmental issues.

With this partnership our goal is to bring the freshest and finest ingredients from their natural environment straight to our guests’ tables. We have a dedicated grower who visits the farm daily.

They work within sterile conditions and get to know every single crop within the unit. Once the crop is ready to consume it is delivered straight to our kitchens where our dedicated chefs prepare it ready to be served to our guests. It really take the farm to table concept to the next level.”

The hydroponic container system uses 90% less water than traditional farming methods, while the short distance from farm to fork ensures a large reduction in carbon footprint caused by typical distribution methods.

Guests visiting Andaz’s dining venues, including The Locale and Hanami, will be able to enjoy dishes made with ingredients sourced daily from the farm.

Tags: ANDAZ FARMING SUSTAINABILITY

CombaGroup SA Reveals Rebrand With New Name, Logo, and Products

The new name, CleanGreens, is synonymous with powering clean, sustainable solutions in the agrotech space. It also reflects the company's mission to represent more directly what they are bringing to the table: fresh, healthy, premium quality yields of their customers’ favorite crops

Molondin, Switzerland – 5 November 2020: On the 21st October 2020, CombaGroup SA has announced the company's complete rebranding and launch of its new website.

Last year, the company realized it was time to leverage its unique position in the field of mobile aeroponic growing solutions. This year, they've rebranded to solidify their stance, offering, and direction within the industry.

The new name, CleanGreens, is synonymous with powering clean, sustainable solutions in the agrotech space. It also reflects the company's mission to represent more directly what they are bringing to the table: fresh, healthy, premium quality yields of their customers’ favorite crops.

The rebranding is a response to accelerated company growth and a renewal of its corporate vision, subtly captured by its new

With six years of R&D and technology breakthroughs in mobile irrigation and agronomy expertise, CleanGreens is proud to offer CleanGreens Pro, a system designed to be as simple as A-B-C, with immediate support and maintenance as well as a technical hotline available in addition to the built-in resources.

As a platform, CleanGreens is expanding to welcome new communities of users and has gone even further in solidifying its global position going forward. It has released new product packages and features that allow its clients to build, manage, and deploy custom applications quickly with its own intuitive, integrated, cloud-based operating application, GURU by CleanGreens. The platform gives clients the ability to grow exactly what they want with the support they require whenever they need it.

Based on the experiences and feedback from CleanGreens’ agronomist team and customers, this new app assists in key tasks like sowing, harvesting, and preventive maintenance and also features built-in reminders, alerts, and real-time records. It’s like having your own personal CleanGreens agro-expert assistant at your fingertips.

Currently, there are seven cultivation lines in operation in three locations: Molondin and Geneva in Switzerland, and Châteauneuf-sur-Loire in France. More are in the pipeline for the future. The new improvements have allowed CleanGreens to meet elevated customer demands for more of its innovative products and technologies.

"Our complete solution is different from any system in the market and our re-branding is largely driven by our effort to reflect this for our products, mission, vision, and of course, our customers and consumers,” says Serge Gander, CEO.

He adds: ”We've taken a clean, modern approach to the name, the website's design and the user experience in our new look and rebrand. We purposefully set out to challenge the status quo in all aspects of our business and this redesign reflects that." logo with the notion of interaction and connectedness. These are core to the capabilities of scalable mobile aeroponic technology platforms that are a priority for both CleanGreens and its clients and partners.

Please visit the revamped website www.cleangreens.ch to explore the new website and learn more about the products and services offered.

About CleanGreens

CleanGreens is a Swiss agro-technology company that provides farmers and industrialists with innovative mobile aeroponic farming solutions for growing fresh, environmentally-friendly, nutrient-rich vegetables. A certified B Corp company CleanGreens’ patented technology significantly reduces water consumption and contamination risks while offering maximum productivity per square meter and minimizing environmental impact. Automated irrigation and mechanized spacing system produce clean, quality, pesticide-free salads, aromatic herbs, and medicinal plants all year round, thus providing consumers with healthy, responsible products.

For more information

info@cleangreens.ch +41 21 545 99 25 www.cleangreens.ch

Media information online

Media information and images can be downloaded directly from cleangreens.ch Journalists can subscribe to our media mailings to receive information on CleanGreens’ aeroponic solutions and technology.

For the latest updates on CleanGreens, visit www.cleangreens.ch, or follow on Instagram, Twitter @SmartLettuce, Pinterest, and LinkedIn.

CANADA: The Arrival of A Hydroponic Growing Container In Inukjuak

The Pirursiivik Project combines social art and on-the-land activities to improve the health of Inukjuammiut through a local greenhouse and the promotion of healthy practices around water and nutrition

NEWS PROVIDED BY

October 30, 2020

The Pirursiivik Project combines social art and on-the-land activities to improve the health of Inukjuammiut through a local greenhouse and the promotion of healthy practices around water and nutrition.

INUKJUAK, QC, Oct. 30, 2020 /CNW Telbec/ - The arrival of a hydroponic growing container in Inukjuak is a significant milestone in the Pirursiivik Project, and one of the first phases of a larger collaboration with the Pituvik Landholding Corporation (LHC) and Sirivik Food Centre to use a year-round greenhouse and container farm to grow, cook and share food and knowledge among the community. Over the past three years, the One Drop Foundation and Makivik Corporation have partnered with the RBC Foundation to implement the Pirursiivik Project in Inukjuak, Nunavik.

The Pirursiivik Project, meaning "a place to grow" in Inuktitut, is a 4-year initiative which aims to improve the community's health through the implementation of a greenhouse and a social art program to promote healthy habits around water and nutrition. This project represents a $2.7-million community investment between the RBC Foundation and the One Drop Foundation.

The arrival of the hydroponic container farm on October 11, 2020, is a significant milestone in this ambitious project yet is only the tip of the iceberg. The true success of this initiative lies under the waterline: the community mobilization and leadership at each step of the project. From day one, the community of Inukjuak stepped up to take concrete action towards improving access to fresh produce for Inukjuammiut. A Community Advisory Committee with representatives from over 15 local organizations was established, and this group of volunteers has continued to meet monthly to provide key input on project activities and planning.

The hydroponic container which uses water to grow instead of soil was purchased from The Growcer, a Canadian company established in Ottawa, and will be locally owned and operated. It will soon be installed and begin producing leafy greens this winter with the target to share the first harvest with the community. The fresh produce will be available to community members who, through social art activities, have learned fun new ways to use little-known vegetables such as kale and bok choy.

This growing initiative in Inukjuak was first piloted on a smaller scale, when the Pirursiivik Project supported the construction of and growing in seven community cold frames (outdoor garden boxes made of wood and polycarbonate). These were built using materials donated by the Kativik Ilisarniliriniq and constructed by the Environment Club at the Innalik School, and the Unaaq Men's Association.

With this new hydroponic container farm adapted for the Arctic, the community is now ready to take this next step towards increasing food security and access to fresh local produce grown by and for Inukjuammiut. This is the first phase in a larger collaboration with Pituvik Landholding Corporation and Sirivik Food Centre, a year-round greenhouse and Food Centre in which to grow, cook, and share food and knowledge among the community. The project team is currently identifying fundraising opportunities to secure the $6 million needed to advance this next phase. This innovative multifunctional infrastructure would be the first of its kind in the North and would set a precedent for future greenhouse initiatives in Nunavik and across the Arctic.

About the Pirursiivik Project

Over the past 3 years, almost 1,000 community members have participated in various social art and on-the-land activities, from drumming and cooking classes to a nature trip to identify and document knowledge related to local plant species. A circus show was created by Tupiq ACT, the first Inuit circus troupe from Nunavik, with the support of the project and technical assistance from One Drop (including advice and accompaniment throughout the process). These activities, inspired by Inuit culture and art, were not only fun and entertaining, but also created spaces for shared learning and exchange on traditional foods, nutrition, and the importance of clean water. Collective learning and sharing that will continue both in-person and online through the digital knowledge hub currently in development with the support of a grant from RBC Tech for Nature. Learn more about the project at www.onedrop.org/en/projects/canada

About One Drop

One DropTM is an international foundation created by Cirque du Soleil and Lune Rouge founder Guy Laliberté with the vision of a better world, where all have access to living conditions that allow empowerment and development. Together with its partners, One Drop deploys its unique artistic approach to promote the adoption of healthy water, sanitation, and hygiene-related behaviours and empower communities. For this to be possible, One Drop creates and produces novel fundraising initiatives supported by a visionary community of partners and donors. This year, One Drop is celebrating 13 years of turning water into action, with projects that will soon have improved the living conditions of over 2.1 million people around the world. In 2019, the Foundation was recognized for the second year in a row by Charity Intelligence, this time as one of the Top 10 International Impact Charities in Canada. To learn more about One Drop, visit www.onedrop.org Interact with One Drop on Facebook and Twitter @onedrop, or on Instagram @1dropwater

About Makivik Corporation

Makivik Corporation is the land claims organization mandated to manage the heritage funds of the Inuit of Nunavik provided for under the James Bay and Northern Québec Agreement. Makivik's role includes the administration and investment of these funds and the promotion of economic growth by providing assistance for the creation of Inuit-operated businesses in Nunavik. Makivik promotes the preservation of Inuit culture and language as well as the health, welfare, relief of poverty, and education of Inuit in the communities.

About Pituvik Landholding Corporation

Incorporated January 30, 1979, Pituvik holds title to 521 sq. km. on lands classified as Category I. These lands are held by Pituvik on behalf of the Inukjuaqmiut beneficiaries of the James Bay and Northern Québec Agreement. In this holding capacity, Pituvik has the right to allow people and organizations to use these lands and for that use is allowed to charge compensation. Pituvik also maintains a beneficiary list on behalf of all Inukjuakmiut. Pituvik is a not-for-profit corporation, however it can create and own for-profit subsidiaries to stimulate local economic growth and job creation.

About RBC Tech for Nature

RBC Tech for Nature is a global, multi-year commitment from the RBC Foundation to support new ideas, technologies, and partnerships to address our most complex environmental challenges. It is a core pillar of RBC's Climate Blueprint – its enterprise approach to accelerating clean economic growth and supporting clients in the transition to a low-carbon, sustainable economy. RBC Tech for Nature brings together charitable partners, technology experts, the public and private sector – as well as RBC's own unique capabilities – to build the multi-partner coalitions needed to work towards solving our shared environmental challenges. Learn more at: rbc.com/techfornature

About The Growcer

Growcer manufactures modular hydroponic systems that enable commercial food production in plug-and-play 40- foot modules. Its vertical farming technology enables customers to grow fresh vegetables in virtually any climate and has been deployed within the Arctic Circle at temperatures below -50°C. Growcer empowers conventional farmers, entrepreneurs, communities and institutions to grow food locally all year round. Growcer's work has been recognized with awards from Fast Company's World Changing Ideas, the Entrepreneurs' Organization, and was also featured on season 13 of CBC's hit show, Dragons' Den.

SOURCE One Drop Foundation

For further information: Media Resource Contact: One Drop Foundation, Marie-France Dos Santos, Marie-France.DosSantos@onedrop.org; Makivik Corporation, Carson Tagoona, CTagoona@makivik.org

Related Links

Pure Harvest Smart Farms, How To Grow Local In The Middle East ?

In the UAE where the climate is arid and very hot most of the time of the year, growing local and fresh vegetables can be a challenge or even impossible

03.11.20

Pure Harvest Smart Farms is a tech company that tries to disrupt the agricultural market in the UAE by tackling the problem of food security.

In the UAE where the climate is arid and very hot most of the time of the year, growing local and fresh vegetables can be a challenge or even impossible. There are imports from other countries to secure fresh vegetable supply year-round, but due to the air freight, the products aren’t fresh and are expensive. An issue that Pure Harvest farm tries to address by bringing the best of agriculture technology to develop fresh and locally grown tomatoes in the UAE. Today the company has raised $100 million to expand its production, and start growing in Saudi Arabia and Kuwait. We met Sky Kurtz, its CEO, and Co-Founder.

What is controlled environment agriculture and why is it so important in the UAE today?

Controlled environment agriculture (CEA) is the strategy taken by Pure Harvest to tackle the issue of food security. This means we engage in CEA with hybrid growing solutions that provide precise climate and environmental controls to deliver quality fresh produce. Pure Harvest’s CEA ensures increased productivity and reduced waste (including water, energy, time, and transport). The UAE is the perfect starting point for us to expand our agritech solutions into other import-reliant regions. There is a huge amount of sun energy waiting to be harnessed!

In which aspects is Pure Harvest disrupting the industry compared to other traditional greenhouses?

The UAE’s arid climate is the right laboratory for the conditions needed for this kind of project and as a result, Pure Harvest is now entering the world stage as a tech-agricultural business tackling the problem of food security. Some other vertical farming countries in the world such as the United States, Holland, France are looking at similar solutions but don’t have the right conditions or a laboratory. The gap between traditional greenhouse countries and import countries has been bridged, this is particularly relevant given the risk of long term import reliance exposed by the Covid-19 pandemic.

What kind of technologies do you use to grow fresh vegetables in the hostile climate of the UAE?

Pure Harvest integrates world-leading Dutch greenhouse growing technologies together with our proprietary climate management systems. Pure Harvest seeks to leverage innovative semi-closed growing technology (with overpressure climate control and mechanical cooling) in order to pioneer year-round production of affordable, premium quality fresh produce.

What kind of crops do you grow in your greenhouses today?

We are currently growing 26 varieties of tomatoes and 6 varieties of strawberries. We are creating new markets, not just displacing existing commercial import markets. There are over 400 commercial varieties of tomato, and Pure Harvest is proud to grow six that have never before been seen. We’re aiming to be able to produce anything which already grows under a Mediterranean climate in any variety.

Last April, you secured a multi-stage investment commitment valued at over USD 100 million with Wafra Investment company. Which kind of developments do you expect for the company?

This year, the company entered into a first-of-its-kind retailer-integration partnership with The Sultan Centre (TSC) in Kuwait, creating a ‘farm center’ that will include edutainment, a retail farmers’ market, and an integrated café. We are completely committed to supporting public initiatives focused on improved food security, water conservation, skilled job creation, and economic diversification. Through constant engagement with governments, schools, and research institutions, we believe that together, we can lead the Middle East into the next generation of sustainable agriculture.

SEE ALSO A French-Tunisian startup changes the future of sustainable agriculture with insect proteins

3 November 2020

80 Acres Farms Raises Funding Round Led by Barclays to Accelerate Growth in Automated Vertical Farming Technolog

80 Acres Farms addresses both sustainability and food security through growing food differently with vertical farming technology and reducing water usage by 97% on less than 1% of the land, with 300x the yield

HAMILTON, Ohio - November 2, 2020 Newswire.com

80 Acres Farms, the sustainable solution for fresh, pesticide-free food, announced that it added Barclays as a strategic investor in the business, joining Virgo Investments, Orange Wings Capital, QuietStar Capital, and other family office investors.

80 Acres Farms is a 2019 fellow from the Unreasonable Impact Americas program and award winner recognized for their work addressing the global pandemic's effects. 80 Acres Farms addresses both sustainability and food security through growing food differently with vertical farming technology and reducing water usage by 97% on less than 1% of the land, with 300x the yield.

Mike Zelkind, CEO of 80 Acres Farms, said: "There has been an explosion in demand for fresh, locally grown, nutritious food, and this investment round enables us to continue to meet that demand at the right unit economics. We look forward to developing our relationship with Barclays and their global network through our shared passion for enhancing sustainability in this industry."

Andrew Challis, Co-Head of Principal Investments at Barclays, said: "80 Acres Farms can shorten the vulnerable, carbon-intensive supply chain and secure retailers and consumers with consistent, safe, fresh, sustainably grown food. This is an exciting investment proposition for Barclays as it supports our clients' and consumers' transition to a low-carbon economy and underpins our ambition to take a leading role in tackling climate change."

80 Acres Farms operates eight indoor farms in the US, including a new state of the art facility in Hamilton, Ohio - built by an affiliated company, Infinite Acres - that will deliver 10 million servings in its first year. You can find 80 Acres' product of just-picked salads, tomatoes, cucumbers, herbs, and microgreens at Kroger, Whole Foods, The Fresh Market, Dorothy Lane Markets, Jungle Jim's Markets, and key National Foodservice Distributors including Sysco and US Foods.

About 80 Acres Farms

80 Acres Farms is a vertical farming leader providing customers with the freshest and most nutritious fruits and vegetables at affordable prices. Utilizing world-class technology and analytics, the Company offers customers a wide variety of pesticide-free food with a longer shelf life that exceeds the highest food safety standards

Lead photo: 80 Acres Farms'. Fully-Automated vertical farm located in Hamilton, OH.

For further information, please contact us at:

rebecca.haders@eafarms.com / +1 513-910-9089

About Barclays Sustainable Impact Capital initiative

As part of its broader commitments, Barclays will invest £175m of its own capital, led by the Principal Investments team, in fast-growing, innovative, environmentally-focused companies whose values are aligned with those of Barclays and which target the goals and timelines of the Paris Agreement. Investments will be strategic to Barclays, its clients, and the communities it serves, with clear scalable propositions that deliver both environmental benefits and economic returns.

For further information, please contact us at:

Investment Enquiries: PITeamInbox@barclays.com

Media Enquiries: emily.stead2@barclays.com / +44 (0) 7796 706166

Related Images

80-acres-farms-newest-location.jpg

80 Acres Farms Newest Location

80 Acres Farms'. Fully-Automated vertical farm located in Hamilton, OH

Related Links

Ground-Breaking Companies Join the 10th Unreasonable Impact Program

80 Acres adds Walmart, Dole execs to leadership team as it gears up for growth

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/67308

INDIA: Hydroponics: All You Need To Know About The Latest Farming Trend

Using soil-less methods to grow vegetables is no longer a fantasy as hydroponics takes centre- stage

November 1, 2020

Using soil-less methods to grow vegetables is no longer a fantasy as hydroponics takes centre- stage

Several celebrities like Bhumi Pednekar, Dia Mirza, Juhi Chawla, Shilpa Shetty, Mouni Roy took to gardening during the coronavirus-induced lockdown. Slowly and steadily it became trend of sorts. And in recent months, hydroponics took centre-stage. Let's find out more about this trend.

In 2017, a Mumbai based couple quit their jobs. Sakina Rajkotwala left her job at NGO Magic Bus and Joshua Lewis left ad company Directi as they were both missing a sense of purpose and wanted some time to reconnect with themselves. “We decided to pack our bags and go live in Auroville for three months and work on a farm as we wanted to get our hands dirty and also reconnect with nature,” says Sakina. They worked at Solitude Farm that also had a cafe where lunch was served using the ingredients harvested fresh off the farm the same morning.

“We ate our meals post work at the farm every day and food had never tasted better. It was always basic and simple food, but it changed everything for us in terms of our energy levels, our mood and in general our overall health. We felt happy and well,” adds Joshua. Eventually, this led them to co-found Herbivore Farms in Mumbai as a way for people to enjoy fresh healthy local produce.

Resource Crunch

Some of the key aspects that govern farming include soil, space, and water. Rapidly vanishing farmlands and extensive farming depleting the soil of its natural resources has led to hydroponics. Simply speaking this is a method of growing vegetables and flowers that requires no soil. Instead, the seeds are placed in an inert growing media with nutrient-rich solutions that also enables reuse of water while ensuring better control of nutrients and giving good yield.

Bengaluru-based Manikandan Pattabiraman, Founder & CEO, Hyperfarms Pvt Ltd. also known as Geekgardener in the gardening circles created 'geekgardener.in’ in 2008 as he could not find a vegetable gardening resources online for India. Today it is a trusted source for hydroponics farming in India. “Living the city, one is always on the lookout for space for gardening. I was looking for a way to grow veggies that use less water and uses very light growing medium such as cocopeat, peat moss instead of soil as it is very heavy. This led me to Hydroponics, a science of growing plants in water and other soilless growing media. I was hooked and was able to put together a system in place and started growing almost all plants. The results were very promising and to this day it continues to be,” says Pattabiraman.

Likewise, Arjun Balaji and Vishal Narayanswamy, Co-founders started Gourmet Garden in Bengaluru as an inspired attempt to bring back original tastes and ultra-freshness into our food and do so while ensuring it is fully sustainable and safe for consumption. “Given the unmet needs of consumers and the challenges with current farming approaches, we saw the answer in global innovations around controlled environment farming. These methods involve providing the most optimum clean environment for farming, where plants are grown without soil in water and other media. We invested all efforts into solving this problem and making the Naturoponic farming model viable for India. The end result of this inspiration is Gourmet Garden, the first full-range brand of high quality and safe produce in the country,” aver the duo.

Advantage Hydroponics