Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Element Farms Unveils New State-of-The-Art Greenhouse

New Facility Will 20x Company’s Current Capacity for Growing

Pesticide-Free, Local, and Sustainable Leafy Greens Year-Round

New York, NY -- October 31, 2019 -- Element Farms, one of the only companies capable of growing pesticide-free, local, and sustainable spinach year-round, has announced that it will begin operations at its new 70,000 square foot Lafayette, New Jersey, greenhouse facility in the coming weeks. The company will outfit its new site, once home to a horticulture company, with proprietary technology and supplemental lighting to produce a wider variety of leafy greens at a higher yield and lower cost than most competitors. At full capacity, Element Farms will produce over half a million pounds each year of pesticide-free baby spinach, arugula, baby lettuces, pea shoots, beet greens, and more.

The new facility is an evolution from Element Farms’ current home: the structure is made entirely of glass, which allows for more efficient transmission of sustainable natural sunlight, and the hilltop location moderates temperatures, bringing heating and cooling costs down during the company’s year-round production.

Most of the operation’s everyday tasks will be automated with Element Farms’ custom machinery, like seeders and harvesters, to increase yield per square foot. The new greenhouse is ideally situated on delivery routes for New York, New Jersey, and Pennsylvania’s population-dense and produce-hungry cities. As before, greens will be delivered directly to retailers within 24 hours of harvest for maximum shelf life.

“We couldn’t be more excited for our new greenhouse. We’re customizing every aspect for operational efficiencies, integrated pest management, and sustainability,” said company founder Serdar Mizrakci. “We’re also thrilled that we’ll be able to meet our ever-increasing demand and bring more pesticide-free, safe, and delicious greens to the retailers and customers who have been clamoring for it.”

The new greenhouse will have dedicated areas for research and development and fully climate-controlled space for both growing and packing. As the company grows, so will the facility: the rest of the property is similarly zoned for agriculture and can support more acres of greenhouse space. Element Farms expects to double its greenhouse team after launch and bring jobs to the surrounding area.

Mizrakci started Element Farms as an MBA student at Cornell University’s Johnson School of Management after learning that most leafy greens consumed on the east coast make a week-long trek from California and lose freshness and nutrients in transport. He envisioned and executed a better process based on his independent study work with co-founder Danny Janeczko at the College of Agriculture and Life Sciences at Cornell, his own expertise as an industrial engineer, and his passion for good food.

The Lafayette greenhouse is just the first part of Element Farms’ growth plan. The company is currently pursuing greenhouse projects in two other states where the markets for year-round local produce are ripe for disruption. Element Farms expects to announce these projects in the coming year.

About Element Farms

Element Farms launched in 2016 with a single goal: to grow the purest, best-tasting greens for the most people possible. Element Farms is one of the only indoor controlled-agriculture companies that can produce local, pesticide-free, hydroponic spinach at scale year-round.

Founder Serdar Mizrakci has solved the biggest issues in indoor agriculture--inconsistency, plant disease, and high operational costs--by bringing farming back to its most basic elements: the plant, light, nutrients, and water. The company uses proprietary technology and renewable energy to seed, grow, and harvest its produce and higher yields and lower costs than most competitors.

The Element Farms greenhouse is located in Lafayette, New Jersey. The brand’s current product line includes baby spinach, baby arugula, crispy lettuce, salad mixes, and more.

Learn more about the company at www.element-farms.com.

Images by Element Farms

365 Days of Lettuce Growing In Belton, Texas

A new 50,000 square feet greenhouse will be realized in Belton, Texas, by hydroponic lettuce producer TrueHarvest Farms. The greenhouse is equipped with growing automation technology from Green Automation

TrueHarvest Farms Goes For It

A new 50,000 square feet greenhouse will be realized in Belton, Texas, by hydroponic lettuce producer TrueHarvest Farms. The greenhouse is equipped with growing automation technology from Green Automation. Riding on the steadily increasing demand for locally grown produce, TrueHarvest Farms will grow fresh and pesticide-free head lettuce locally in the controlled environment of a greenhouse 365 days a year.

Family farm

Founded in 2017, TrueHarvest Farms is the evolution of a family hay and pecan farm now 40 years old. The company is strategically located in the “Texaplex Triangle”, which is formed between the cities Dallas-Fort Worth, Houston, San Antonio, and Austin. With a population of around 20 million people and having 80% of the state’s population growth since 2000 as well as generating up to 70% of the Texas economy, this area is the ideal location for new, innovative and sustainable production of leafy greens.

“The climate here in Texas makes year-round field growing of leafy greens impossible and the area has so far, as the rest of the USA, relied heavily on having lettuce trucked into the state from California and Arizona for a substantial part of the year”, says Marshall McDaniel, Managing Member at TrueHarvest Farms. “We will be distributing truly fresh, nutritious, safe and locally grown lettuce to stores within a 250-mile radius of our operations. The lettuce will be available to the customer in less than 24 hours of harvesting”.

TrueHarvest Farms, rooted in Belton, TX, is ready to supply fresh, nutritious and safe leafy greens to the Texaplex Triangle.

Increased interest in clean lettuce

Recent food safety scares in the lettuce industry have led to an increased interest in and call for safe and clean lettuce produced in a controlled environment. The greenhouse is a closed system, controlling what comes into the greenhouse, making it possible to not only keep the lettuce clean but also to grow them without using any chemical pesticides. The irrigation water, the air, and the growing medium are controlled, monitored and clean - keeping consumers safe and the environment protected.

“There is an enormous demand for locally grown and safe lettuce today”, confirms Jason Maks, Managing Member, and Grower at TrueHarvest Farms. “Our facility is in the final stage of obtaining PrimusGFS certification and we are dedicated to meeting the highest safety standards in the food industry. TrueHarvest Farms will be a reliable source for locally grown and safe produce for the Texas markets. We are ramping up our production right now and expect to reach full capacity in January 2020. At the moment we are growing Butterhead, Crisp and Romaine varieties”, explains Maks.

TrueHarvest Farms is using the automated growing system optimized for head lettuce production. “When growing leafy greens in tough climates it is imperative to operate the greenhouse with the highest efficiency and to generate the highest yields per square foot, therefore TrueHarvest Farms decided to use the automated growing system from Green Automation”, says Patrik Borenius, CEO, Green Automation Americas. “Throughout the entire growing process maximal space efficiency is achieved through automatic movement and adjustment of gutters, giving the plants as much space as needed, but as little as possible”.

Maximizing yield

In addition to maximizing yield through space efficiency, labor efficiency is an essential key component in a profitable operation. The system has a highly automated and versatile medium filling and seeding line arrangement using stackable trays and supporting both net pots as well as Ellepots. After seeding and germination, the plants are placed onto the automatic growing system, featuring adjustable and movable growing lines, where they will soak up the natural sunlight. As the plants grow, they are moved automatically through the greenhouse toward the harvesting station.

TrueHarvest Farms did multiple trips to reference operators in Europe, including to such remote locations as Joensuu, Finland, before making a decision. “It is a proven system and on par with our earth-conscious commitment. We are looking forward to growing and providing the Texas market with the highest quality lettuce”, says Marshall McDaniel. “This is only the beginning, we have room to grow and our head house as well as the irrigation system are designed for future expansions,” McDaniel explains.

Contact:

Patrik J. Borenius

Green Automation Americas LLC

13833 Wellington Trace, Suite #E4-203

Wellington, Florida 33414

www.greenautomation.com

Publication date: Thu 31 Oct 2019

Green Automation Is Bringing Automation And Efficiency To New Greenhouse Operation In Texas

Green Automation Group is proud to announce the latest project realization in the North American market – hydroponic lettuce producer TrueHarvest Farms in Belton, Texas. The 50,000 square feet greenhouse is equipped with growing automation technology from Green Automation

October 24, 2019, Wellington, FL, USA

Green Automation Group is proud to announce the latest project realization in the North American market – hydroponic lettuce producer TrueHarvest Farms in Belton, Texas. The 50,000 square feet greenhouse is equipped with growing automation technology from Green Automation. Riding on the steadily increasing demand for locally grown produce, TrueHarvest Farms will grow fresh and pesticide-free head lettuce locally in the controlled environment of a greenhouse 365 days a year. The farm is strategically located in the “Texaplex Triangle”, which is formed between the cities, Dallas-Fort Worth, Houston, San Antonio, and Austin. With a population of around 20 million people and having 80% of the state’s population growth since 2000 as well as generating up to 70% of the Texas economy, this area is the ideal location for new, innovative and sustainable production of leafy greens.

“The climate here in Texas makes year-round field growing of leafy greens impossible and the area has so far, as the rest of the USA, relied heavily on having lettuce trucked into the state from California and Arizona for a substantial part of the year”, says Marshall McDaniel, Managing Member at TrueHarvest Farms. “We will be distributing truly fresh, nutritious, safe and locally grown lettuce to stores within a 250 miles radius of our operations. The lettuce will be available to the customer in less than 24 hours of harvesting”.

TrueHarvest Farms, rooted in Belton, TX, is ready to supply fresh, nutritious and safe leafy greens to the Texaplex Triangle.

Recent food safety scares in the lettuce industry has led to an increased interest in and call for safe and clean lettuce produced in a controlled environment. The greenhouse is a closed system, controlling what comes into the greenhouse, making it possible to not only keep the lettuce clean but also to grow them without using any chemical pesticides. The irrigation water, the air, and the growing medium are controlled, monitored and clean - keeping consumers safe and the environment protected.

“There is an enormous demand for locally grown and safe lettuce today”, confirms Jason Maks, Managing Member, and Grower at TrueHarvest Farms. “Our facility is in the final stage of obtaining PrimusGFS certification and we are dedicated to meeting the highest safety standards in the food industry. TrueHarvest Farms will be a reliable source for locally grown and safe produce for the Texas markets. We are ramping up our production right now and expect to reach full capacity in January 2020. At the moment we are growing Butterhead, Crisp and Romaine varieties”, explains Maks.

TrueHarvest Farms is using the automated growing system optimized for head lettuce production. “When growing leafy greens in tough climates it is imperative to operate the greenhouse with the highest efficiency and to generate the highest yields per square foot, therefore TrueHarvest Farms decided to use the automated growing system from Green Automation”, says Patrik Borenius, CEO, Green Automation Americas. “Throughout the entire growing process maximal space efficiency is achieved through automatic movement and adjustment of gutters, giving the plants as much space as needed, but as little as possible”.

In addition to maximizing yield through space efficiency, labor efficiency is an essential key component in a profitable operation. The system has a highly automated and versatile medium filling and seeding line arrangement using stackable trays and supporting both net pots as well as Ellepots. After seeding and germination, the plants are placed onto the automatic growing system, featuring adjustable and movable growing lines, where they will soak up the natural sunlight. As the plants grow, they are moved automatically through the greenhouse toward the harvesting station.

TrueHarvest Farms did multiple trips to reference operators in Europe, including to such remote locations as Joensuu, Finland, before making a decision. “It is a proven system and on par with our earth-conscious commitment. We are looking forward to growing and providing the Texas market with the highest quality lettuce”, says Marshall McDaniel. “This is only the beginning, we have room to grow and our head house as well as the irrigation system are designed for future expansions,” McDaniel explains.

Contact:

Patrik J. Borenius

Green Automation Americas LLC

13833 Wellington Trace, Suite #E4-203

Wellington, Florida 33414

About Green Automation Group

Green Automation Group Ltd, headquartered in Finland, and it’s subsidiary Green Automation Americas LLC, based in Florida, develop, manufacture and market the most advanced greenhouse automation systems for lettuce and herb production. The systems are designed for commercial greenhouse operations with a growing area of 1 acre / 0.4 hectares and above. www.greenautomation.com

About TrueHarvest Farms

TrueHarvest Farms, LLC is a controlled environment hydroponic farm specializing in leafy greens. Founded in 2017, the company is focused on rapid growth through the production and distribution of high-quality lettuce and other leafy greens. TrueHarvest Farms is the evolution of a family hay and pecan farm now 40 years old. So, whether it is the “family roots” or the “plant roots,” we are truly “Rooted in Belton, Texas”.

https://www.facebook.com/trueharvestfarms

Greenhouses In Southern France Demolished By Extreme Weather

This week’s weather around the Mediterranean caused a lot of damage in the south of France; the French government declared a state of a natural disaster

This week’s weather around the Mediterranean caused a lot of damage in the south of France; the French government declared a state of natural disaster. In Béziers, 6 gallons per square feet fell in 24 hours. Other municipalities in France and in Spain were also severely affected. The episode inevitably has consequences for the fruit and vegetable sector.

“We have not drawn a report yet, but several crops have been affected in France and in Spain,” reports Charles Farran de Ritex, wholesaler based in Perpignan. “In France, it is the season of autumn and winter vegetables like artichokes and lettuce. For those products, water is not necessarily a bad thing, and we hope that there won’t be too much damage. The apple and pear orchards are probably also affected. Other products like the tomatoes are grown in greenhouses so they will not be directly impacted. However, several greenhouses have been destroyed by the storm in the region of Nîmes and Avignon.”

In Spain, the Mediterranean episode also had some impact. “Grapes were severely affected by the water,” explains Charles, who imports a lot of his products from Spain.

Nearly 108,000 square feet of greenhouses blown away

As he was about to pick his lettuce, Eric Vidal saw a small tornado, on the night of Tuesday to Wednesday, blow away 108,000 square feet of his farm located at the heart of the Jardins Saint Jacques. He reported to the newspaper L’Indépendent that “everything is ruined, both the facilities and all the lettuce of course, which is mostly produced for fast food restaurants. We were supposed to harvest in 10 days, it’s a dry loss. Luckily, I have insurance.”

The cause of the damage is a devastating blast limited to one corridor. More minor damage has been reported in the same area. “When I arrived at the greenhouses, I understood right away that something had happened. The greenhouses in the back were completely crushed. It was like a bull ran through, destroying everything. The surprising thing is that the other facilities, right next to them, were not affected at all,” explains Eric.

The farm had already suffered from a similar situation in January 2009 with storm Klaus. “After the expert’s report, we will have to disassemble, clean and rebuild everything. We won’t get any lettuce until next summer.” The farm is likely to lay off part of its staff temporarily.

Source: lindependant.fr

Publication date: Mon 28 Oct 2019

© HortiDaily.com / Contact

Can Altius Farms Convince Denverites To Pay More For Ultra-Local, Aeroponic Produce?

Sally Herbert's urban farm in Curtis Park uses less water and land to produce lettuce, arugula, and other greens for Denver's booming restaurant scene—and for your kitchen table

Towers of produce at Altius Farms. Photo by Rebecca Stumpf.

Sally Herbert's urban farm in Curtis Park uses less water and land to produce lettuce, arugula, and other greens for Denver's booming restaurant scene—and for your kitchen table.

BY CALLIE SUMLIN | NOVEMBER 2019

At the intersection of 25th and Lawrence streets in Curtis Park, on the second story of a building—high above the millennials zipping around on electric scooters and the yoga warriors exiting a nearby studio—sits Altius Farms, an 8,000-square-foot aeroponic greenhouse. Inside, small fans whoosh gently overhead and the temperature is always somewhere between 65 and 80 degrees. There’s a slight, almost pleasant humidity to the air and the fresh, clean mineral smell of lettuce. The clear polycarbonate roof diffuses and softens the Colorado sunlight, and glass walls make you feel like you’re surrounded by open sky.

Completing the urban Garden of Eden picture is Altius’ version of fields: 340 columns, each eight feet tall, from which sprout floppy green rosettes of butter lettuce, neon mustard frills, ruffles of baby red Russian kale, and lily-pad-like nasturtium leaves. The plants blanket the white, food-grade-plastic columns so thickly they look like edible topiaries.

Fifty-six-year-old Sally Herbert, co-founder, and CEO of Altius, walks through her fields, pausing often to pluck baby kale leaves or fronds of pink-tipped lollo rosso lettuce for sampling. The kale is mild and tender, the lettuce juicy and crisp. Nearby, a smiling intern snips baby arugula leaves into bins while farm manager Ethan Page and other staffers wash, dry, and package the day’s harvest. Assistant grower and account manager Brian Adams will soon deliver bags of the greens to Altius’ growing list of clients, which include Uchi (the farm’s downstairs neighbor), Il Posto, Butcher’s Bistro, and Marczyk Fine Foods.

There’s an efficiency to the way the staff moves that might make you think Altius has been honing its operations for many seasons. In truth, the farm’s been operating for a little over one year. In that time, the company has become a supplier for 40-some restaurants and luxury grocers, and it’s one of Denver’s largest hydroponic vegetable farms. It’s also the only aeroponic-specific facility producing food in Denver proper.

Aeroponics—which was popularized in the 1980s at Epcot’s Land pavilion in Walt Disney World—takes the principles of hydroponic gardening literally to the next level. As with hydroponics, there is no soil involved. In aeroponics, however, plants commonly grow out from vertical columns, not up from pots or beds. The plants’ root systems are housed in ports of spongy, inorganic growing mediums, which are popped into little openings in the columns. A gravity-fed, automated irrigation system pushes a pH-balanced, nutrient-fortified mist through the columns for three minutes at a time in 15-minute intervals, keeping the plants’ air-suspended roots moist.

Aeroponic towers produce lettuce in less space than traditional farming. Photo by Rebecca Stumpf.

The concept has become trendy around the world because these farms can produce food using up to 90 percent less land and water than traditional crops require and can be grown within miles—or even feet—of consumers. In 2018, GV (formerly known as Google Ventures) invested $90 million into Bowery Farming Inc., a New York-based brand that bills itself as “the modern farming company.” Everyone from IKEA executives to the sheik of Dubai has thrown money at AeroFarms, a similarly ambitious outfit in New Jersey. All provide answers to American consumers’ ever-louder demands for local and sustainable food. But the question remains: Can Herbert convince Denverites to join the movement and pay more for greens raised without soil?

Five years ago, Herbert had exactly zero farming experience when a friend recommended she check out Veterans to Farmers, a local nonprofit that trains former service members in traditional and hydroponic agricultural systems. Herbert, who served in the Air Force for 13 years (active duty and reserve), liked the group’s mission to provide veterans with fulfilling civilian careers and joined the board.

While helping a Veterans to Farmer’s trainee at his hydroponic operation in Lakewood in 2014, Herbert learned about controlled-environment agriculture and was fascinated. The timing was apt: Herbert, who typically dresses in plain T-shirts and the sort of breathable pants one might wear hiking, was burnt out as CEO of GS1, a global logistics company. She started researching farming trends and realized that Denver’s short growing season and proliferation of consumers who care about sustainability made it the perfect place for an innovative aeroponic operation.

Finding a location for Altius in the city proved challenging. “I needed a developer who believed in the cause and saw food production as an amenity to their site,” she says. When she connected with Westfield Company Inc. (the developer behind the S*Park complex of luxury townhomes and condos that encompasses Uchi and Altius) in 2015, things clicked.

As it turned out, the plot of land in Curtis Park had been a farm site before. (Elaine Granata, Denver’s grandmother of urban farming, had long coaxed peas and tomatoes from the ground there.) When the Denver Housing Authority sold the property to Westfield, it did so under the condition that the development includes a farming or green space component. Enter Altius. Where other new condominiums tout pools, S*Park’s tenants would have access to fresh vegetable subscriptions and events in the outdoor farm-to-table dinner space, making their “#gardengoals become a reality,” as the S*Park website promises.

With her location secured, Herbert needed funding to bring her vision to fruition. Despite the global interest in vertical farming and her business connections, she had no luck courting local investors. “There’s a lot of money floating around this town for tech startups,” Herbert says. “But trying to get someone to invest in an agriculture company? Forget it.”

It’s not surprising that some investors would be scared off by food production: Slim margins can mean a slow return on capital, and in a city where an acre of land can sell for upward of a million dollars, high-revenue businesses or development projects are preferable to farming’s modest profits. So, to get off the ground, Herbert financed the business herself.

In the midst of Denver’s brutal mid-July heatwave, Herbert’s plants are comfortable in their climate-controlled environment. Herbert, though, is outside, working in Altius Farms’ brand-new garden and event area. Just weeks ago, this ground-level space was a fenced-in rectangle of dirt. Now, it is fully built out with raised beds and long communal tables, ready for ticketed farm-to-table dinner events.

Herbert, her shiny, dark hair pulled into a low ponytail, hunches over one of the 15 soil-filled beds to carefully prune a tomato plant. Nine months in, things are going well at Altius: Through trial and error, Herbert’s team has figured out which varieties of seeds work best in the indoor tower environment. High-end restaurants all over town have begun to name-drop Altius’ greens, herbs, and edible flowers on their menus. And the farm has donated hundreds of pounds of produce to nonprofits We Don’t Waste and SAME Café.

Herbert hopes to expand her aeroponic business beyond Denver. Photo by Rebecca Stumpf.

But it is not enough to turn a profit—yet. It’s still difficult to convince a grocery shopper to pay $4.99 for a clamshell of salad mix when they can get a head of lettuce for less than $2 at King Soopers. “Farming is the hardest thing I’ve ever done,” Herbert says. And that’s even with Altius’ automated irrigation and temperature control systems, the polycarbonate roof that prevented a June hailstorm from shredding her crops, and a strong customer base.

Because, at the end of the day, it’s still farming. It’s still waking up in the middle of the night panicking about the crops. It’s still having to convince folks to buy a premium local product and coaxing nature into a business model. The aeroponic system has drawbacks, too: The towers aren’t suitable for growing root vegetables, and proponents of organic produce tend to frown upon the aeroponic method, which requires plants to be fed liquid nutrients.

Another challenge, which Herbert has grappled with since the beginning, is that the arrival of Altius in Curtis Park meant the displacement of other farmers; Granata now grows at a small space abutting a parking lot at the UCHealth University of Colorado Hospital. Herbert is conscious of the fact that to some, her aeroponic farm is just another sign of a gentrifying neighborhood. As such, she seeks ways to better serve the surrounding area (donating produce to Comal Heritage Food Incubator) and to support other farmers (continuing to serve on the Veterans to Farmers board).

While Herbert is surprised at just how many setbacks have arisen, she’s still confident in Altius. Just as she trusts her seeds will sprout, she says that the farm is on track to profitability. Her lofty goal—to potentially put locations in Denver and cities across the country—feels distant but possible. In the meantime, she pauses to wipe sweat from her brow and survey her work, just for a moment, before heading back to the greenhouse above.

CALLIE SUMLIN, CONTRIBUTOR

Callie Sumlin is a writer living in Westminster and has been covering food and sustainability in the Centennial State for more than five years.

"The Time Is Now For A Shift To Indoor Cultivation In India", Srishti Mandaar, Red Otter Farms

Indoor growing is at a very nascent stage in India. While there are significant policy changes being adopted by the government, there is still a severe lack of trained personnel in indoor environment management

Indoor growing is at a very nascent stage in India. While there are significant policy changes being adopted by the government, there is still a severe lack of trained personnel in indoor environment management. "It is only when this gap is addressed that the true potential of indoor growing will be leveraged", according to Srishti Mandaar, co-founder of Red Otter Farms.

Srishti points to the need for a concerted effort to bring the various stakeholders – infrastructure developers, produce based experts and professionals linking production to market – to come together and enhance the indoor growing community.

Non-linear trends

First things first though: the consumer, because consumer demand can be a catalyst for growth in the indoor ag market. Identifying singular trends in food can be quite difficult when it comes to India. With nearly five different geographical diversities, a multitude of cultures as well as social status, the consumption patterns vary vastly. From the coast to the high mountains and the deserts, climatic conditions have dictated the food patterns for centuries.

Interestingly, however, over the past two decades, with increased ‘globalization’, urban centers are now witnessing the first wave of food democratization. Food from different cultures are being adopted and adapted to local communities’ preferences. "As an example, the momo is a standard fare in the northeastern mountain regions – usually stuffed with meats and eaten with a spicy chili sauce", Srishti says. "Today, the momo has gained a place as an integral street food with mobile carts being set up but with a twist… it's even served with cream sauce."

So when it comes to the Indian consumer, trends are clearly non-linear. "In the metros, where we will typically find the primary consumers for indoor growing due to their paying capacities, the requirements have shifted. Supermarket shelves have gone international – they stock standard staple produce for a variety of cuisines. Yet, the awareness of the consumer is still limited.

While they now understand that there are at least three or four different types of pasta, their understanding of varieties within product classes is low. The Indian kitchen still buys tomatoes or cherry tomatoes and it will take time before they understand the difference between curry, soup and salad tomatoes."

Connecting with local partners

There is potential for growth in the Indian indoor ag market - but how to tap into that growth? According to Srishti, suppliers can do more to cater to Indian growers. "One of the issues we faced and still often face is technology, seeds, etc. that are offered have no research/data backing their use/trial in the Indian environment. For any of the seed or tech companies to make inroads, they need to believe in a longer-term strategy. They will initially need to invest in finding local partners who can help them demonstrate results over a few months. Agricultural production in that sense is driven by local success."

Opportunities for controlled environment agriculture

Given the very low monetary return from crops, Indian farmers need to improve their production, Srishti says. "Given the weather patterns across the country, CEA has immense potential. It not only mitigates crop losses due to weather but effectively will also enhance farm incomes.

"Proponents of CEA, as well as the infrastructure providers, need to adapt their deliverables based on geographical climate, power availability as well as for the produce being grown. At Red Otter Farms, we have had to go to the drawing board to develop a controlled facility that can address the needs year-round and are currently testing our second prototype. Our own example gives us a clear indication of the benefits of adopting CEA, yet the lack of trained resources and cost-effective technologies has led us to undertake a research route at present."

"Market size should not be a concern"

Srishti also notices a growing awareness amongst the consumer regarding the use of chemical fertilizers, insecticides, and pesticides in their food. "In addition, there is also a realization amongst them that there are options available such as organic and soilless cultivated. The potential for high quality, chemical-free produce is therefore high."

In addition to the growing interest in organic produce, research shows that the Indian plate has been seeing a rise in the use of vegetables as a source of nutrition over the past three decades. "With all these factors aligning themselves, the time is now for a shift to indoor cultivation", Srishti concludes. "And the market size should not really be a concern. India is a country with the largest population of millennials – aware, well-traveled and cares about the quality of the food they eat – and equally ready to pay the premium it may need."

For more information:

Red Otter Farms

www.redotterfarms.in

Publication date: Wed, 23 Oct 2019

Author: Jan Jacob Mekes

© HortiDaily.com

Start of Realization Horti Center In Shandong

Dutch horticultural manufacturers, system suppliers, training and education partners, the Chinese government and related investors have jointly attended the official announcement last week of the start of the realization of the first Chinese Multi-Functional Horti Center in Shandong (DHC)

For Structural Transformation of Horticulture In China

Dutch horticultural manufacturers, system suppliers, training and education partners, the Chinese government and related investors have jointly attended the official announcement last week of the start of the realization of the first Chinese Multi-Functional Horti Center in Shandong (DHC).

(from left to right: Perry van Adrichem (Hortitech), Marcel Schulte (Holland Netting International), Peet van Adrichem (Hortitech & DCA & member of strategy and designer team within DSG), Ruud Schenkels (De Gier Drives), Pim van Adrichem ( Hortitech), Pascal den Heijer (Holland Screening International), Fokke Kracht (Valk Horti Systems), Don Kester (Priva), Jörgen Kint (DSG & DGOG & DCA) and Frank Boers (BOAL), Oscar Niezen (representative for Lentiz C&C) is missing in the photo, as well as Theo Stolze (Stolze))

The purpose of this fully functional Horti Center is to be the co-creator and supporter of a modern horticultural industry in China with its base in Shandong, the vegetable province of China. Shandong has 300,000 ha of solar greenhouses and 675,000 ha of multi-span plastic greenhouses and tunnels. An active platform on the highest cooperation level for Chinese transformation to modern horticulture and cluster industry for horticulture. Gathering knowledge, engineering, manufacturing and innovation power for support to the structural turnaround of rural areas and create the consent modus for a Chinese standard.

This ambitious plan has been adopted recently by major big Chinese companies taking part in Shandong Dutch Standard Greenhouse Agricultural Technology Co., Ltd. (DSG). Comprising the Dutch partner Dutch Greenhouse Operation Group B.V. (DGOG), China National Minorities Economic Technology Development Company by Zhongmin Jingkai Technology Development Co., Ltd. (CNMED-T) and Capital Development Investment Fund Management (Beijing) Co., Ltd. (CDIFM) which is a collaboration of 11 Chinese banks and financial institutes.

Both national companies have started, by order of Government, to spearhead rural areas and improve living standards.

DSG is the operational partner for upcoming project investments and developments in the horticulture sector.

DSG announced to plan to construct more commercial greenhouse developments throughout China starting next year growing to 150 till 250 ha yearly by own funds and those for third-party projects. DSG’s vision stated that one can not exist without the other so growth from Horti Center output has to be in balance with the availability of proper build commercial greenhouses and right grow support solutions.

Producing food-safe vegetables is a topic for DSG and for third-party projects. For the guarantee there will be an autonomous Horti Quality Office for governance on constructing and the quality of total greenhouse production machines. As well as one that ensures that operations are carried out in accordance with food safety and production requirements. Within the implementation, protocols for distribution, tracking and origin apply. Supplementary DSG has a sophisticated market approach to get paid slightly more for premium products.

It seems DSG will become a major developer with close ties to the Horti Center in Shandong in which there is close cooperation among the Dutch companies and institutes who are members of the Dutch Chinese Association for the Promotion of Horticultural Cooperation (DCA)

(photo 1 – Official start of realization of the Horti Center; photo 2 - Official announcement of the Horti Center in the presence of governments, investors and the Dutch delegation; photo 3 - Earlier visit of AAB BM International to DSG in Dezhou from left to right Mr. Lei Xu Chairman of DSG, Anton Hanemaaijer architect, Jörgen Kint DSG; photo 4 - Impression Horti Center in Shandong)

In addition to the fact that several companies have already registered with DSG with the desire to participate and are currently deepening, DSG indicates that more companies are welcome. There is certainly a need for more disciplines, specialisms at all levels to arrive at a sector-wide interpretation that can grow with the desired expansion plans. In addition to the Dutch horticulture industry and sector, international companies operating at Dutch level are also welcome for DSG. According to DSG, there is sufficient work so localization, cost price reduction and capacity growth is more important than internal competition thoughts because market-conform prices are always on the agenda.

DSG will provide appropriate support, unburdening, co-investing and financing where necessary for the connecting companies. The position of the cluster of companies is paramount and DCA will represent the face for projects and the brands and products within the Horti Center. In addition, every effort is made to ensure that the Horti Center guarantees sufficient upscaling of high-quality people.

In short, DSG stated that first comes cooperation second localization, third upscale capacity and subsequently preserve the Dutch export position from out China.

The attraction to the cluster in Shandong, for projects throughout China directly connected to DSG’s investment partners and its huge companies structures, national and local investors, governments at local and provincial level looks very promising for both the Dutch and the Chinese sector. DSG is open to jointly investigating the possibilities for sector-wide collaborations and hope to succeed together to leave a footprint behind for next generations.

For more information:

DHC – DCA - DSG – DGOG

info@greenhouseoperation.nl

www.nl-dca.com

www.cn-dsg.com

www.greenhouseoperation.nl

Publication date: Tue, 22 Oct 2019

Research Into The Combination of Geothermal Heat, Lettuce Cultivation And Fish Farming Started

Under great interest, the project Geofood has been started. The aim of Geofood is to investigate whether geothermal heating can not only be used to heat greenhouses but also to breed fish

Under great interest, the project Geofood has been started. The aim of Geofood is to investigate whether geothermal heating can not only be used to heat greenhouses, but also to breed fish. As a symbol for opening the new aquaponic facilities, a floater with lettuce plants was placed on an aquarium with tilapia during the opening operation. Geofood is a collaboration between the Business Unit Greenhouse Horticulture of Wageningen University & Research and partners from Iceland, Slovenia, and the Netherlands.

A constant water temperature is required for fish farming all year round. Supply and demand are less constant in greenhouse horticulture: relatively much is heated in the winter and hardly ever in the summer. In addition, there are more and more cultivation companies with a geothermal source. This creates a surplus in the summer. Selling geothermal heat could be another revenue model for geothermal resources.

To this end, WUR developed an energy model for the combination of geothermal-greenhouse horticulture-aquaculture. To validate this model, an advanced fish farming system was installed at WUR in Bleiswijk in early 2019. It is a so-called recirculating aquaculture system (RAS). The largest tanks in this system contain around 10,000 liters of water containing thousands of fish. Data is collected from, among other things, the water quality, temperature, water consumption and CO2 produced by the fish.

WUR carries out this research in collaboration with partners from Iceland, Slovenia and the Netherlands. Algae production and food processing processes are also being investigated as potential applications for circular food systems that run on geothermal energy. Funding for the research comes from the European GEOTHERMICA - ERA NET Cofund Geothermal. Dutch participation in the project is supported by RVO and Top Sector Horticulture & Propagation Materials.

Source: Wageningen University & Research

Publication date: Wed, 23 Oct 2019

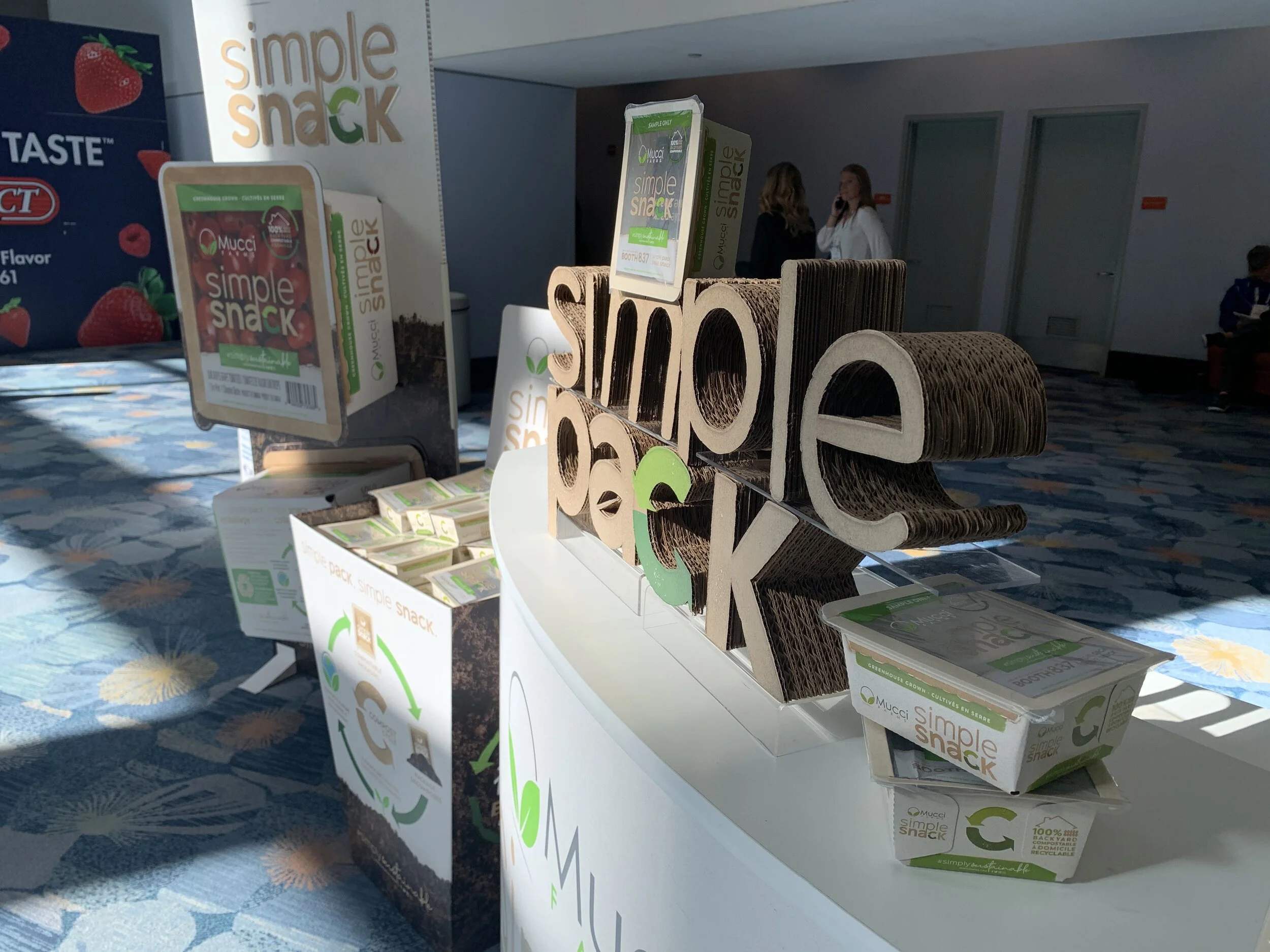

Mucci Farms Wins Best Sustainable Packaging Award At Fresh Summit 2019

“To win this category, in particular, is exciting because sustainability is by far the top of mind subject in the food industry today,” says Emily Murracas, Director of Marketing

October 21st, 2019 (Anaheim, California) – Mucci Farms announces that they have been awarded the top prize for Best Sustainable Packaging at the PMA’s Fresh Summit Conference and Expo for Simple Snack, a plastic-free, backyard compostable series of packaging. “To win this category, in particular, is exciting because sustainability is by far the top of mind subject in the food industry today,” says Emily Murracas, Director of Marketing.

“We’ve been recognized in the industry for flavour and innovation over the years, so we are ecstatic to be able to package those award-winning products in a package that helps to address a global concern. It’s also very special to win in a competitive category that included submissions from packaging suppliers and fellow marketers.”

A vertically integrated greenhouse grower extensively committed to sustainability at all ends of the business, Simple Snack adds to those commitments. The package is composed of a tray made from agricultural waste and the lidding film is made of sugar-cane and wood fibers using a process that emphasizes social and environmental responsibility.

“Consumer feedback over the last several months has been almost exclusively focused on the reduction of plastic, so we feel like we’ve addressed that concern by coming up with a truly plastic-free package,” said Fernanda Albuquerque, Packaging Development Manager. “We also saw the value of being able to add key messaging to the tray which gave our designers a larger canvas for branding, information, and education.”

A dedicated partner of the Produce Marketing Association, Mucci Farms also sponsored the annual Center for Growing Talent 5k race, which seamlessly fits with their company objectives to be a health and wellness conscious brand. Race participants were served refreshing smoothies made with the Award Winning SmucciesTM Sweet Strawberries. Additionally, the company had a sampling station at the show entrance where attendees could take home a sample of their very own Simple Snack package.

On the show floor, the Mucci Farms team welcomed buyers and attendees to their world of colours that included their entire lineup of offerings including their newest item, Zingers shishito peppers and the highly sought after CuteCumber Poppers. With chefs on hand putting together a variety of flavourful samples, the Mucci Farms booth has become a featured destination every year.

The Fresh Summit Conference & Expo took place from October 18-20 in Anaheim, California.

For Info:

Ajit Saxena

Public Relations & Digital Marketing Manager

519-326-8881 Ext 2253

asaxena@muccifarms.com

US: COLORADO - EPFL + Caulys --> Inauguration - October 21st & 23rd, 2019

We have installed 18 automated indoor greenhouses at EPFL (Coupole, CO building), to produce ultra-local and fresh food for the campus!

We are pleased to invite you to the Inauguration Days

of the EPFL + Caulys installation!

What is it?

We have installed 18 automated indoor greenhouses at EPFL (Coupole, CO building), to produce ultra-local and fresh food for the campus!

This will be the occasion for you to explore the details of this unique urban farming installation, and enjoy delicious greens grown there!

When?

21st and 23rd of October 2019 from 12h00 to 14h00: information stand and tasting of microgreens grown on-site,

22nd of October 2019 from 12h00 to 14h00: presentation and aperitif!

At EPFL, just there!

We look forward to seeing you there!

Caulis team

Indoor AgTech Landscape: 1,000+ Companies Innovating Inside

AgFunderNews created an image keeping track of the indoor growing landscape featuring 1000+ companies that take part in the industry, from greenhouse growers to suppliers of environmental controls

AgFunderNews created an image keeping track of the indoor growing landscape featuring 1000+ companies that take part in the industry, from greenhouse growers to suppliers of environmental controls.

The first thing to note is that they include greenhouses in the discussion as an indoor growing approach. At times, the conversation seems to be just limited to growing in buildings or containers with artificial lights, what we call “Sunless” or others broadly refer to as indoor, vertical, or urban farming.

Secondly, while there has been a great deal of activity around cannabis and alternative proteins such as insects, for the purpose of this landscape AgFunderNews kept to traditional food crop production.

The map focuses on the technology used in that production, from seeding to immediate post-harvest activities. We segment the landscape into the specific categories of component technologies, different types of growing systems and growers.

Read the full article, including the image of the landscape, at AFN (Louisa Burwood Taylor)

Pure Flavor® To Launch RedRoyals™ At PMA Fresh Summit

“We are excited to be bringing a new variety to market that we believe will be a game-changer”, said Jamie Moracci, President. After researching consumer trends, trialing dozens of varieties and conducting community sensory testing, the team selected a fantastic variety with a unique burst of sweet and unmistakable flavor

Leamington, ON (October 10th, 2019) While increasing its acreage of traditional greenhouse commodities of Tomatoes, Peppers, Cucumbers, and Eggplants season after season, Pure Flavor® continues to focus its strategic growth efforts on bringing new specialty items to market to meet retail, foodservice, and consumer demand. After years of research & development, the company will be unveiling its new RedRoyals™ Cherry Tomatoes on the Vine at the PMA Fresh Summit in Anaheim, CA October 18-19.

“We are excited to be bringing a new variety to market that we believe will be a game-changer”, said Jamie Moracci, President. After researching consumer trends, trialing dozens of varieties and conducting community sensory testing, the team selected a fantastic variety with a unique burst of sweet and unmistakable flavor.

RedRoyals™ Cherry on the Vine are flavor-rich with a vibrant sweet crunch, these royal wonders are the perfect accent to any eating occasion. Hand-picked with the utmost care, their majestic sweet flavor is nurtured on the vine by our family of growers who carefully select the perfect tomatoes for your delight. As the king of the tomato crop, RedRoyals™ deserves a crown.

Read more about RedRoyals™: https://www.pure-flavor.com/redroyals/

Watch the RedRoyals™ Promotional Video: https://youtu.be/OubFFSCOKi4

Pure Flavor® has been busy developing additional products to strengthen the brand’s product offering in the marketplace this year. The company has been working with their growers, seed companies, and retail partners to bring new items to market. The following items will be on display at Fresh Summit:

“It’s been a great year for launching new products & brands, we look forward to showcasing them all at Fresh Summit in Anaheim at Booth 4451 and in the New Product Showcases”, said Chris Veillon, Chief Marketing Officer.

To learn more about Pure Flavor® and what the company is promoting at the upcoming PMA Fresh Summit Trade Show (Booth 4451), please visit Pure-Flavor.com/PMA2019

-30-

About Pure Flavor® -

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise.

We are the next generation of vegetable growers, inspired to put quality, flavor, and customers first by providing greenhouse-grown vegetables from our farms that are strategically located throughout North America.

SOURCE: Chris Veillon | chris@pure-flavor.com

Chief Marketing Officer | Pure Flavor®

T: 519 326 8444 | Twitter: @PureFlavor

WEBSITE: https://www.pure-flavor.com/redroyals/

VIDEO: https://youtu.be/OubFFSCOKi4

Photo Credit: Pure Flavor® © 2019

UK: 29 Hectares of New Tomato Greenhouses To Use Waste Heat

A £120m project to construct two of the UK’s largest greenhouses at two farmland sites near Norwich and Bury St Edmunds has been announced. The advanced greenhouses will be warmed by residual heat from nearby water recycling centres owned by Anglian Water

A £120m project to construct two of the UK’s largest greenhouses at two farmland sites near Norwich and Bury St Edmunds has been announced. The advanced greenhouses will be warmed by residual heat from nearby water recycling centers owned by Anglian Water. The construction phase of the project will begin immediately, with completion expected in autumn 2020. Commercial-scale growers from the UK and the Netherlands have already committed to leasing the space.

Closed-loop heat pumps

Closed-loop heat pumps will be used to transfer the heat from the water recycling centers to the greenhouses, and will have the additional benefit of cooling the facility’s treated water outflow before it is returned to the environment.

Electricity for the greenhouse’s heat pumps will be provided by a Combined Heat and Power plant, with waste heat from the CHP providing further warmth for the greenhouses. The gas-fired CHP plant’s carbon emissions will be transferred into the greenhouses, raising the CO2 levels and further accelerating the growth of the plants, and capturing the majority of the carbon.

"The greenhouses will provide growing conditions for a range of plants and vegetables requiring a high-heat, and relatively low-light environments such as tomatoes, cucumbers, and peppers. Once operational, the greenhouses will be capable of producing more than 1 in 10 of the country’s tomatoes, and will create 360 permanent new jobs", the initiators say.

Greenhouses

The complete facility will be realized by Bom Group greenhouses are among the largest ever constructed in the UK with each covering more than 13 hectares. Standing around 7m tall the large glass structures allow crops to grow vertically along guidewires, and do not require any soil, instead of being grown hydroponically from nutrient-rich water solutions. Once in full production, they will be capable of growing more than 20 tonnes of tomatoes every day – 12% of the tomatoes grown in the UK.

Renewable heat

"In Europe, solar radiation alone cannot provide sufficient energy to reach optimal growing temperatures throughout the day, even in the summer. Most commercial greenhouses overcome this problem by using another heat source to increase temperature", they say.

The majority of greenhouses use gas-fired boilers for this additional energy. Greencoat Capital’s approach largely displaces these fossil fuel emissions by using waste heat from Anglian Water’s nearby water recycling centers.

Jobs

Once operating, the two greenhouses will create 360 permanent jobs in the local area, rising to 480 during high season.

James Samworth, Partner at Greencoat Capital, said: “We’re very pleased to have achieved another innovative first in the UK renewable energy sector. Technology and cross-sector co-operation is continuing to unlock some amazing possibilities in energy and agriculture. We see considerable opportunity to invest in renewable heat in the UK, providing pensions investors with the predictable returns they require to pay beneficiaries, meanwhile reducing our carbon emissions as an economy.”

Duncan Hale, Portfolio Manager at Willis Towers Watson said: “We are delighted to be partnering with Greencoat Capital on this project, particularly as we are making best efforts to invest in the low carbon economy while still delivering the strong risk-adjusted cashflows our investors are after. This marks a step-change in the decarbonization of agri-business and heating, and we are proud to be supporting UK infrastructure with the assets we manage.”

Dr. Lu Gilfoyle, Head of Environmental Quality at Anglian Water said: “It has been great to be involved in such an innovative project, helping to solve a number of challenges for Anglian. Removing excess heat from the river systems is a priority for DEFRA and ourselves, and it is fantastic to be able to put that heat energy to good use.”

Andy Allen, Director at Oasthouse Ventures, said: “Delivering a world-first low carbon greenhouse system is hugely exciting for the small team who took this from conception, design and planning, to contracting and now construction. The environmental, social and political benefits of these systems are significant, and we look forward to further disrupting the traditional carbon heavy models of agriculture.”

Pension investment

The capital for the project comes from a number of public and private pension funds in the UK, reflecting the growing trend of pensions managers seeking returns through direct investment into renewable infrastructure. Greencoat Capital now manages almost £2bn of private market pension fund capital through its various renewable infrastructure funds.

For more information:

Greencoat Capital

www.greencoat-capital.com

For more information:

Martin van Zeijl

Bom Group

Kulkweg 60

3151 XE Hoek van Holland

Tel: +31(0)174 725 160

www.bomgroup.nl

Publication date: Thu, 03 Oct 2019

Lighting Control Platform Enables Dimming on Demand

Based on research conducted at the University of Georgia, Candidus has developed an adaptive lighting control system that assures that supplemental light is provided when the crop can best use that light and only in the amount that can be effectively used by the crop

Candidus is a startup company in Athens, GA, USA, that focuses on smart lighting control systems for the greenhouse industry. Their mission is to reduce the cost of supplemental lighting for greenhouse growers by implementing an adaptive lighting control system.

Candidus was co-founded by Drs. Erico Mattos and Marc van Iersel in 2017. Dr. Mattos studied photosynthesis optimization using LED lighting at the University of Georgia and previously founded a LED lighting company. Dr. van Iersel is a professor of horticulture at the University of Georgia, with a background in plant physiology and environmental measurement and control. His research focus is the optimization of the cost-effectiveness of LED lighting in horticulture.

Integration with third-party lighting

Candidus was awarded a US Department of Agriculture grant to develop an innovative adaptive lighting control system. Based on research conducted at the University of Georgia, Candidus has developed an adaptive lighting control system that assures that supplemental light is provided when the crop can best use that light and only in the amount that can be effectively used by the crop. The system will not change the basic lighting settings. "Because growers, not us, should decide how to grow their crop", Marc van Iersel clarifies. "But growers can very easily change the photoperiod and daily light integral, after which the controller will implement it."

Using instantaneous light measurements and a proprietary algorithm, Candidus’ control system determines exactly how much supplemental light to provide and when. Using an industrial microcomputer, the control system monitors the ambient sunlight and sends a dimming signal to third-party lights. Candidus’ supplemental lighting control system technology is particularly well-suited for use with dimmable LED fixtures, but can also be used with non-dimmable LED or HPS lights.

The Candidus controller

Candidus does not make light fixtures. Instead, the focus is on the development of optimal control systems for third party lights. The company is already working with several light manufacturers. "So far we have worked with Fluence BioEngineering and our first round of grower trials used their VYPRx Plus lights. We are also working with Illumitex and Osram", Marc says. "Most dimmable LED fixtures take a 0 – 10 VDC signal to control light output and our technology is fully compatible with such lights, regardless of brand. Osram uses a proprietary protocol for dimming, so that requires coordination between Osram and Candidus. But our hardware is fully capable of dimming those lights as well."

"Adjusting the lighting is simple and there really are no big challenges on that end of things as long as lighting manufacturers use dimmable drivers", Marc continues. "Some companies, like Signify, use non-dimmable drivers and those lights can only be turned on and off. The bigger challenge is with lighting systems that may not be designed in a way that allows growers to actually achieve their goals. For example, the overall lighting capacity may not be enough to allow growers to actually achieve the daily light integral when needed."

Web-based interface

Greenhouse growers use the control system through a web-based interface, entering only a few simple settings: the daily light integral target value, the time the lights should come on, and when the light should go off. If needed, growers can also program in low-intensity night interruption lighting for control of flowering of photoperiodic crops.

A sample of the monthly report growers get. Click here for a bigger version.

While the crop growth isn't monitored directly, Marc says they can make recommendations for a wide range of crops. "If growers are willing to share information on crop growth, we can make refinements in the lighting strategy."

At the moment, the Candidus platform doesn't tie in with existing cultivation software, but the company is interested in doing this in the future. "Hopefully, our software can be an integral component of control systems made by companies like Priva and Hoogendoorn", Marc says.

For more information

Candidus

info@candidus.us

www.candidus.us

Publication date: 9/16/2019

Author: Jan Jacob Mekes

© HortiDaily.com

Revolution Farms Hires Head Grower

Tammam Serage to Lead Hydroponic Growing at Grand Rapids’ Sustainable Lettuce Farm

GRAND RAPIDS, Mich., October 9, 2019 – Revolution Farms, a leading indoor hydroponics farm in Caledonia, announced today that Tammam (Tam) Serage has taken over as head grower at the farm. Serage came to Revolution Farms from Shenandoah Growers in Harrisonburg, Va., where he most recently served as the farm’s corporate grower. Tam has more than 25 years of practical experience in the efficient and sustainable production of organic herbs, microgreens and decorative plants.

“As we continue to scale the farm, Tam’s experience and knowledge will ensure we can grow the very best salad greens possible, while simultaneously improving our sustainability initiatives,” said John Green, CEO of Revolution Farms. “His extensive hydroponics expertise will help us continue to make our product better and more nutritious, ensuring it’s the best salad option for Michigan and Midwest consumers.”

Serage previously worked as head grower at farms in Maryland and Delaware, as well as serving in multiple growing roles at farms in Alabama and Saudi Arabia. He holds Bachelor of Science and Master of Science degrees in Horticulture from Virginia Polytechnic Institute and State University, as well as an Associate of Science from Virginia Western Community College.

Revolution Farms’ 85,000 sq.ft. indoor farm, located on 76th St in Caledonia, has the capacity to produce more than 500,000 pounds of fresh lettuce and salad greens for Michigan and the Midwest region every year. Its leafy greens go from farm to store in as few as 1-2 days, less than half the time it takes for lettuce grown and shipped from California, Arizona and Mexico to make it to Michigan store shelves.

“Revolution Farms has the momentum and the people behind it to innovate hydroponic farming, and expand growing operations on a large scale for Michigan and beyond,” said Serage. “My passion is identifying and incorporating new technologies and sustainable growing techniques that will produce healthier greens at greater yields. I am thrilled to join John and the Revolution Farms team to be part of this fast-growing farm.”

Revolution Farms is built on a mission to disrupt the fresh produce industry by growing and harvesting hyper-local salad greens for consumers year-round, using advanced indoor farming methods and technologies. Its lettuce is currently available at more than 100 SpartanNash stores across Michigan – including Forest Hills Foods, D&W Fresh Market, VG’s and Family Fare stores, as well as through Doorganics for direct consumer delivery and VanEerden for use in restaurants and foodservice.

About Revolution Farms

Revolution Farms is leading the hydroponics revolution in Michigan with one of the largest and most advanced indoor hydroponic farms in the United States. Located in Caledonia, Mich., its 85,000 sq.ft. greenhouse produces fresh, local lettuce and salad greens for consumers across the Midwest. Revolution Farms was founded to leverage the social, economic, and environmental benefits of hydroponics in a state-of-the-art facility. More info at www.revolutionfarms.com.

# # #

Glase Provides Analysis of CEA Market Growth To Industry Members

Using the results of the USDA’s 2007, 2012 and 2017 censuses, Mattos discussed the national market growth of food crops produced under protection with detailed analyses of the top producing states

During GLASE’s Industry Talks series presentation, executive director Erico Mattos discussed changes to the CEA market based on USDA Census of Agriculture data.

By David Kuack

One of the benefits offered by the Greenhouse Lighting and Systems Engineering (GLASE) consortium to its industry members is its Industry Talks series. This series of informal conversations are presented by academics and field experts who focus on topics suggested by the consortium’s industry members.

During the consortium’s Industry Talks presentation in August, GLASE executive director Erico Mattos reviewed controlled environment production market growth based on the results of the USDA’s Census of Agriculture. Using the results of the USDA’s 2007, 2012 and 2017 censuses, Mattos discussed the national market growth of food crops produced under protection with detailed analyses of the top producing states. The full video can be accessed by GLASE members at the GLASE.org

Increasing value of protected food crops

Total market value for all protected food crops, including tomatoes, vegetables, berries, and fresh herbs, increased 17.9 percent from 2012 to 2017. Market growth for sales of all protected food crops increased 20 percent from $634 million in 2012 to $748 million in 2017. Greenhouse tomato sales increased 4.7 percent from $400 million in 2012 to $419 million in 2017. Other greenhouse vegetable sales increased 40.6 percent from $234 million in 2012 to $329 million in 2017. Fruit and berries sales decreased 13.5 percent from $29 million to $25.1 million even though production area for these crops rose from 7.9 million square feet to 11.7 million square feet.

Greenhouse tomato production area expanded from 55.1 million square feet in 2012 to 63.9 million square feet in 2017, a 16 percent increase. For other greenhouse vegetables, production area rose from 42.8 million square feet in 2012 to 48.6 million square feet in 2017, a 13.6 percent increase.

Only other greenhouse vegetables and fresh-cut herbs saw an increase in market share from 2012 to 2017, rising from 35 percent to 43 percent. Both greenhouse tomatoes and fruit and berries saw a decline in market share between 2012 and 2017. Tomatoes fell 6 percent from 60 percent in 2012 to 54 percent in 2017. The decrease for fruit and berries was only a 1 percent drop from 4 percent in 2012 to 3 percent in 2017.

Increase in protected food crop operations, production area

The number of protected growing operations increased for all crop categories between 2012 and 2017. The number of farms producing greenhouse tomatoes rose 26 percent, up from 6,323 operations in 2012 to 7,974 operations in 2017.

The number of farms producing other greenhouse vegetables rose 36.6 percent between 2102 with 5,268 operations to 7,198 operations in 2017.

Farms producing greenhouse fruit and berries also saw a double digit increase (25.7 percent), up from 673 operations in 2012 to 846 operations in 2017.

Number of small farms increasing

Mattos said the increase in the number of protected crop operations is driven by the establishment of smaller farms.

“There are a lot of smaller farms producing greenhouse vegetables, but they represent a very small part of the market share,’ he said. “In general, as the size of the farms increases the value of sales increases until the size of operations reaches 40,000 square feet or more where there is a dramatic jump in the value of sales.”

Small size farms from 1-999 square feet represent 31.6 percent of the number of farms in the United States. These small operations only cover 1.1 percent of the square foot production area for the total industry. These farms also only represent 1 percent of total sales. They are receiving a net rate of $5.74 per square foot for what they are selling.

Operations from 1,000 to 2,999 square feet account for 32.8 percent of U.S. farms. The net rate sales are the lowest for operations from 2,000 to 2,999 square feet at $4.42.

Those greenhouse vegetable operations with 20,000 to 39,999 square feet in size are earning the most money per square foot at $11.23 per square foot. Mattos said this size category might be a good mix of technology and greenhouse management and are definitely doing something right.

Mattos said there are fewer large farms producing greenhouse vegetables, but they dominate a big part of the market. The largest operations in the U.S. with 40,000 or more square feet represent 2.7 percent of the number of farms. However, they account for 67.6 percent of the square footage (76.1 million square feet) in the U.S. These large operations also have the highest value of sales per square foot at 67.8 percent. These farms are making $6.67 per square foot.

For greenhouse tomatoes, the largest operations are the most efficient, accounting for 74.5 percent of sales and having the largest return per square foot at $7.28.

Major protected-environment producing states

On a state-by-state basis for all greenhouse vegetable categories, the top state in regards to market share value was California with 46 percent, which had a market value increase of 26 percent from 2012 to 2017. Even though the number of farms decreased from 427 to 409, the amount of square footage grew 24 percent from 28.3 million to 35.2 million square feet.

Other leading states with market share included Texas (14 percent), Ohio (10 percent), New York (9 percent), Maine (8 percent), Virginia (7 percent) and Minnesota (6 percent). Ohio had the largest rise in sales, increasing from $10.5 million in 2012 to $43.8 million in 2017, accounting for an increase of 317 percent in just five years. Virginia also experienced a large sales increase (270 percent), going from $8.5 million in 2012 to $31.5 million in 2017.

While California still had the largest market share (33 percent) for greenhouse tomatoes, it wasn’t as dominant as it was for total greenhouse production. Other states which accounted for greenhouse tomato market share included Texas (21 percent), Ohio (13 percent), New York (12 percent), Minnesota (10 percent), Arizona (6 percent) and Illinois (4 percent).

States with the largest increase in tomato share included Ohio (908 percent increase), going from $3.2 million in 2012 to $32.1 million in 2017. Illinois also saw a major rise in greenhouse tomato sales going from $1.7 million in 2012 to $10.7 million in 2017, a 517 percent increase.

For other greenhouse vegetables and fresh-cut herbs, California dominates sales ($126. 2 million) with 60 percent of the market. Virginia followed with 11 percent of the market and Illinois had a 7 percent market share. These two states had the largest growth in this crop category with sales in Illinois rising 565.8 percent from $2.2 million in 2012 to $14.3 million in 2017. Virginia saw sales grow 245 percent from $6.7 million in 2012 to $23 million in 2017.

For more: Erico Mattos, Greenhouse Lighting and Systems Engineering (GLASE), (302) 290-1560; em796@cornell.edu; https://glase.org.

David Kuack is a freelance technical writer in Fort Worth, Texas; dkuack@gmail.com.

Posted in News

Founders Brewing Executive Named CEO of West Michigan Hydroponics Farm

John Green, who for more than a decade served as executive chairman of Founders Brewing Co., has been named CEO of Revolution Farms, an indoor hydroponic farm based in Caledonia that grows lettuce and salad greens

September 17, 2019

John Green has been named CEO of Revolution Farms. (Courtesy photo)

By Brian McVicar | bmcvicar@mlive.com

CALEDONIA, MI — John Green, who for more than a decade served as executive chairman of Founders Brewing Co., has been named CEO of Revolution Farms, an indoor hydroponic farm based in Caledonia that grows lettuce and salad greens.

Green is a founding investor in the farm and has served as acting CEO for the past three months, according to a news release. He is also chairman of its board of directors.

“We launched Revolution Farms to change the world by changing the way we grow food," he said in a statement. “Our revolution begins at home, by growing closer to where we live, more sustainably, with less water and land, and figuring out how to accomplish this in Michigan all year long.”

Revolution Farms has the capacity to produce more than 500,000 pounds of lettuce and salad greens on a yearly basis at its 85,000-square-foot indoor farm on 76th Street in Caledonia, the company says. Its products are sold at Family Fare, D&W Fresh Market and VG’s Grocery stores across Michigan.

West Michigan company's innovative salad greens now on store shelves

Revolution Farms is selling its product in 16 SpartanNash stores in Michigan.

The farm grows its products using 95 percent fewer acres and 90 percent less water than traditional farming methods, Green said. Its salad greens can be shipped to stores in one or two days, “less than half the time it takes for lettuce grown and shipped from California, Arizona, and Mexico to make it to Michigan store shelves.”

Green has worked at Founders since 2006. He will remain at the brewery while its majority ownership transitions to Spanish brewing conglomerate Mahou San Miguel. Founders announced late last month it was selling a 59 percent ownership stake in the company to Mahou.

The deal is expected to close next year and was valued at $198.8 million, according to documents filed with the Michigan Liquor Control Commission. Once completed, the deal will boost Mahou’s ownership of Founders to 90 percent. Mahou purchased a 30 percent ownership stake in Founders in 2014.

Green is among a group of Founders shareholders selling their stake in the company to Mahou. Records submitted by Founders to the liquor control commission show Green owned an 8.03 percent stake in the company. In addition, members of his family-owned an 8.36 percent stake in Founders.

In addition to his position at Revolution Farms, Green will maintain roles with Odyssey Media Group and Cirkul.

He also serves as director of the Grand Valley State University Foundation and is a founding board member of Grand Rapids Whitewater. Green also sits on the board of directors for the Grand Rapids Downtown Market.

In addition to Family Fare and other SpartanNash grocery stores, Revolution Farms sells its products through Doorganics, an organic grocery delivery service based in Grand Rapids, and Van Eerden Food Service.

Colorado: Urban Farm, Restaurant And Market Coming To Englewood

Behind that glass window will reside a hydroponic system where plants will grow on indoor towers. Hydroponics is a method of growing plants year-round in sand, gravel or liquid with added nutrients without using soil. Farms that use the hydroponic method use up to 10 times less water than traditional farms, according to the National Park Service

Grow + Gather Will Occupy The Old Bill's Auto Service Building

Monday, September 16, 2019

Joseph Rios

jrios@coloradocommunitymedia.com

George Gastis sold his tech business four years ago — a year after he packed his bags and moved to Englewood from Platt Park. Contemplating what his next move would be, he knew he always had a green thumb and a love for food.

At first, he had planned to find a property to purchase or rent where he would grow food that would be sold to grocery stores and restaurants. In the process of planning his next steps, Gastis purchased the old Bill's Auto Service building, located at 900 E. Hampden Ave.

“The idea quickly became more than just a place to grow food. There seemed to be a great opportunity to create a place where not only can we grow food, but reconnect the neighborhood and surrounding communities,” said Gastis, referring to places like Littleton, south Denver, Greenwood Village and other areas near Englewood. “Our geographic location is sort of strangely unique in the sense that we sit on the edge of some of those communities.”

After planning and talking to people from his past, Gastis realized there was an opportunity to create a hub around food at the old Bill's Auto Service building. Gastis seized the opportunity, and depending on construction, Grow + Gather will open its doors in October. The development will be a casual restaurant and a market that'll sell coffee and freshly harvested produce and foods - all grown at Grow + Gather.

“When we moved to this neighborhood, I saw the potential in this area. There wasn't a ton to do,” said Gastis. “Combined with trying to figure out what I wanted to do and recognizing the opportunity here — Englewood seemed to be in the process of reviving itself with a lot of new businesses moving in, a lot of development, certainly (Swedish Medical Center) and their role they played in the community — it seemed really interesting.”

The restaurant will be operated by chefs like Caleb Phillips, a Tennessee native who plans to bring a Southern twist to some of Grow + Gather's dishes. Phillips says the menu will be simple, but it'll center around ingredients that will come from Grow + Gather's farm. Some of its dishes will include biscuits, salads, pies, egg dishes, and grits. Beer will also be available at the restaurant, brewed from the second level of the building.

“It's just the neatest idea. I get to walk 20 yards to get fresh vegetables,” said Phillips. “The community has already been super kind and receptive. I think it's going to be a lot of fun.”

When customers walk through Grow + Gather's community room, an area designated for guests to have coffee and for classes on gardening and cooking, they'll be able to see their food being grown behind a glass window. Behind that glass window will reside a hydroponic system where plants will grow on indoor towers. Hydroponics is a method of growing plants year-round in sand, gravel or liquid with added nutrients without using soil. Farms that use the hydroponic method use up to 10 times less water than traditional farms, according to the National Park Service.

Gastis says the rooftop of the building will serve as rooftop greenhouse, where he'll grow crops like tomatoes.

“It is exciting to see a new business concept like Grow + Gather here in Englewood as well as the repurposing of the property once occupied by Bill's Auto Service. It is sure to bring new life to that area,” said David Carroll, executive director of the Greater Englewood Chamber of Commerce. The chamber works to promote its business members while engaging with new businesses in the city.

PHOTOS: COURTESY OF GEORGE GASTIS

US: Indiana - High-Tech Aeroponic Farming Company Bringing Greenhouse To Electric Works

A northeast Indiana native and Purdue graduate, Clint Crowe, with an extensive background in health technology, is bringing his innovative and high-tech urban-farming concept to Electric Works

September 18, 2019

A northeast Indiana native and Purdue graduate, Clint Crowe, with an extensive background in health technology, is bringing his innovative and high-tech urban-farming concept to Electric Works.

Sweetwater Urban Farms, an Atlanta-based company founded in 2017 that uses aeroponic technology, helped by with proven Internet of Things — no human interaction to transfer data — to produce nutrient-rich greens and herbs, will open a greenhouse in the food hall at the planned Electric Works, according to a statement from a spokesman for the developer, RTM Ventures.