Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Vertical Farming: Pick-Your-Own Fruit And Veg At Retail Parks?

Is there a business case for wide scale commercial vertical farming in the UK or will it remain a niche opportunity for high-end restaurants and retail? This is the challenge to be discussed by early adopters at the Agri-Tech East conference‘Bringing the outside in - Innovating for Controlled Environment Agriculture’ next month (19 March).

19/02/2019

Advances in technology, from more energy efficient LEDs to better sensors and advances in soilless cultivation, are enabling the expansion of novel farming methods, but how might controlled environment agriculture disrupt the value-chain? Agri-Tech East's 'Bringing the outside in' investigates.

Is there a business case for wide scale commercial vertical farming in the UK or will it remain a niche opportunity for high-end restaurants and retail?

This is the challenge to be discussed by early adopters at the Agri-Tech East conference‘Bringing the outside in - Innovating for Controlled Environment Agriculture’ next month (19 March). Advances in logistics and the falling cost of LED lighting may enable year-round growing of undercover produce in the UK, but will energy costs and technical issues delay scale-up and integration within the food supply chain?

“We do think there is the potential for indoor farming to be commercially viable and there are some immediate gains for growing crops such as leafy salads in high hygiene environments,” comments Lindsay Hargreaves, MD of Frederick Hiam, a farming and fresh produce business with farms in Suffolk and Cambridgeshire. “Growing indoors provides greater control of quality and quantity and fewer inputs of plant protection products.

“There is also the matter of growing crops closer to the point of consumption. Being able to grow more exotic crops in East Anglia close to distribution centres would reduce the food miles. Additionally, there are opportunities to grow crops for pharmaceuticals, cosmetics and vaccines within a controlled environment.”

There are many approaches to indoor cultivation, such as deep-water hydroponics, vertical soilless cultivation, and aeroponics, where exposed roots are sprayed with nutrients. All of these methods are to be discussed at the conference along with advances in monitoring and robotics.

However, despite the news that Sterling Suffolk, one of the UK’s most technically-advanced glasshouses, is set to produce millions of tomatoes starting in February 2019, the cost (£30M) and the technical challenges mean there are few commercial installations in the UK.

Also, it is proving difficult to demonstrate to retailers that controlled environment agriculture (CEA) can bring tangible benefits to their supply chain.

Kate Hofman, co-founder of GrowUp Urban Farms, which from 2015 to 2017 operated 'Unit 84', a commercial-scale aquaponic urban farm inside an industrial warehouse. The 8,200 square feet of growing space could produce enough for 200,000 salad bags and 4,000kg of fish each year. It sold directly into restaurants, through a New Covent Garden distributor and also through bricks and mortar supermarkets and Farmdrop, the online supermarket.

Kate comments: “A key learning over the last six years is that we can’t just focus on technology – we have to partner along the supply chain to create a business model that ultimately delivers commercial success for growers and retailers.

“One of the major challenges for CEA is to optimise operations to bring down the cost of production to match existing imported products. Our prototype urban farm showed that it was possible to use CEA commercially, and we were able to demonstrate the demand for the produce we could grow. This ranged from specialist micro-greens and cut herbs through to mixed baby leaf salad.

“We are now working on scaling up our business. This will involve relocating, so that our production is co-located with a renewable energy plant and working in partnership with more traditional farming businesses to integrate their experience and expertise.”

There are also technology challenges to be addressed when trying to meet the highly variable consumer demand for high quality, fresh produce.

G’s Fresh supplies baby leaf crops all year round, with much of the winter supply grown in Spain and Italy to ensure security of delivery. In summertime it produces a huge amount of outdoor salad crop, particularly lettuces and celery in the UK. Ben Barnes is investigating how controlled environment agriculture can increase the long-term viability and profitability of both of those parts of the business.

The organisation has a large standard greenhouse facility that is used to propagate seedlings for planting out into the field. It is running two projects: Smart Prop, which is looking at increasing the efficiency of the propagation facility to improve growth and make stronger plants so they transplant better back into the field. And Winter Grow, a pre-commercial trial, to see if it is feasible to produce baby leaf crops during the winter at an affordable price point.

Ben explains: “I'm going to be talking at the Agri-Tech East event about the commercial journey, in terms of the go and no-go decision-making process and what the key things are that we need to learn in order to be able to make those kind of investment decisions.

“One element of this is the development of ‘lighting recipes’ to enhance plant growth characteristics. We've got multi-spectrum LED lights, so we can turn up the different amounts of red, blue, green and white, and even far red light. These are fairly expensive, so once we have worked out what works best we can buy fixed spectrum lights, which are a tenth of the cost.

“You think LEDs are very efficient, but they still generate a heck of a lot of heat when you’ve got them turned up to full. It is more about keeping the space cool, and the plants obviously are transpirating so we've got dehumidifiers in there sucking the moisture out of the air.

“One of the biggest problems with the vertical farming concept is this interaction between moisture and temperature. You’ve got the two factors constantly fighting against each other and that ends up sucking up huge amounts of energy if you're not careful.”

Dr Belinda Clarke is director of Agri-Tech East, an independent membership organisation that is facilitating the growth of the agri-tech sector, comments that the commercial challenges need addressing along with the technical and agronomic aspects: “The promise of CEA is sustainable, intensive production but achieving that may require a different type of value chain.

“It could be that supermarkets of the future allow you to pick your own fruit and baby leaf instore, or we may see large-scale distribution of veg boxes, with produce grown indoors in optimum conditions or perhaps traditional growers would have more flexibility to grow a greater range of produce all year around with less waste.

“These ideas all have potential but also require significant capital investment and creative solutions for energy management. These are some of the themes we will discuss in the conference.”

'Bringing the outside In – Innovating for Controlled Environment Agriculture' taking place on 19 March from 10.00 – 16.00 at Rothamsted Research, Harpenden. It will look at the different growing systems, emerging technologies, the challenges of implementing a system and the logistics involved with integrating a controlled environment agriculture into the food value chain.

Agri-Tech East is an independent business-focused cluster organisation for the East of England. It is creating a global innovation hub, to improve the international competitiveness of plant and crop-based agriculture and catalyse economic growth.

80 Acres Farms Strikes 'Significant Investment' From San Francisco Private Equity Firm

15-Jan-2019 By Mary Ellen Shoup

Vertical indoor farming company, 80 Acres Farms, has received a "significant investment" from Virgo Investment Group, a San Francisco-based private equity firm, to help rapidly commercialize the company's specialized indoor farming technology.

For more information:

Technology Will Make The UAE One of The World's Most Food-Secure Countries By 2021

From vertical farms to artificial intelligence, the nation is embracing cutting-edge innovations to achieve this ambitious goal, says the UAE Minister of State for Food Security

Food security is without doubt one of humankind’s most pressing concerns and the issue is one that is felt particularly keenly in the UAE. Although considered food secure – primarily because it enjoys a high degree of economic and political stability – the UAE still faces significant challenges. These stem from its arid climate, its shrinking groundwater levels and the volatility of the wider region. Added to these geographic and geopolitical stressors is the country’s spectacular growth. As its population has expanded exponentially, increasing from about 300,000 in 1971 – the year the UAE was founded – to more than nine-and-a-half million today, the need to provide for its residents has increased correspondingly.

My responsibility as UAE Minister of State for Food Security is to ensure that the nation continues to enjoy an adequate food supply for its citizens as it develops and to elevate its current position of 31st on the global ranking for food security to the top 10 by 2021. In order to achieve this, we are championing trade facilitation and enabling technology-based production and supply of food. The initiatives to support strategic goals are anchored in diversification of supply, alternative supply sources, technology-enabled enhancement of local production and international trade links, among others. Thus, a major part of my mandate is involved in incorporating agricultural technology – also known as “AgTech” – into the country’s food security agenda. This agenda is enshrined in the UAE’s recent launch of its National Food Security Strategy.

Variously defined as “transforming the global food system through digital technology” and “smart farmers getting smarter using digital technology”, AgTech encompasses advanced agricultural methods that differ distinctly from the traditional ways of farming practised for millennia. Increasingly seen as a solution to the UAE’s food security issues, my office is now placing a strong focus on adopting AgTech in the country’s agricultural sector, as part of a concerted effort to considerably reduce the 90 per cent of food that the country currently imports.

The AgTech government accelerator project, with its two components, is one such initiative. The first component is the promotion of the use of “controlled-environment agriculture” (CEA), which is a technology-based approach toward food production that utilises highly efficient technologies to properly manage agriculture inputs and maximise output. It involves agricultural industry entrepreneurs working alongside government bodies to provide tangible solutions to promote CEA, primarily through implementing an enabling business environment that is conducive to innovation.

The second component of the project is aquaculture, which is farming in controlled conditions of fish, crustaceans, molluscs, aquatic plants, algae and other organisms in freshwater and saltwater. With agriculture in general being the world’s thirstiest industry, accounting for approximately 72 per cent of total freshwater consumption, aquaculture represents one of the best uses of what is the region’s most precious resource. To this end, the UAE has established a vibrant aquaculture sector with an investment of more than Dh100 million to develop hatcheries and fish farms.

Vertical farming is another AgTech component that my department is promoting and one that has been identified as offering a solution to the UAE’s food security issues. The concept involves plants being grown in vertically stacked layers in an indoor environment where environmental factors can be controlled. Vertical farms typically use artificial light, humidity regulation, temperature control and minimum use of pesticides, enabling the production of vegetables in large quantities all year round without the need for soil, sunlight and chemicals. The commercial applications of vertical farming are already being realised in the UAE, with the opening of the Gulf region’s first-of-its-kind facility in December 2017. Located in the Al Quoz industrial area of Dubai, the 8,500sq ft farm produces 18 varieties of micro-greens, including rocket, kale, radishes, red cabbage, basil and mustard.

Remote-controlled drones have become an accepted presence in the skies above the UAE, with the ubiquitous flying machines used by the authorities to – among other things – monitor traffic and deliver post. Now they are providing benefits for the country’s agricultural sector, with unmanned aerial vehicles (UAVs) being used to map farming areas across the country. Announced in June 2017, the pilot project sees UAVs being used to create a highly accurate agricultural database that supports decision-making and forward planning by enabling the best use of resources and determining the optimum areas for crop growth.

Perhaps the most prevalent form of AgTech being incorporated in the UAE’s agricultural sector is the use of sensors, with their adoption resulting in increased yields in both large-scale agricultural projects and smaller organic farms. Sensor-equipped gyroscopes, accelerators and GPS monitors are being employed to enhance crop production by making the most of land and water use – precision irrigation that is highly effective in reducing water waste. A good example is an organic farm in Sharjah that relies heavily on sensors to determine the salinity and mineral content of the soil to ensure optimum crop growth with minimal use of water. Another prime example is a household name Japanese electronics manufacturer that is creating a farm in Dubai to grow strawberries, with the facility incorporating light-emitting diodes for controlled lighting, air distillation technology and other appliances to check room temperature and humidity.

Aquaculture, vertical farming, drone use and sensors are just four of the technologies that are being utilised in the UAE to maximise crop production while ensuring good husbandry of resources. This is only the start of what will be an expanding role for AgTech in the country’s agricultural sector. The office of food security is currently evaluating how emerging areas of technology, such as robotics, can play a part. Automation combined with artificial intelligence is an exciting field that we are currently assessing. One company in the US has produced a robot that mimics what a fruit picker in the field does. It uses AI to determine which fruit is ripe and ready to be picked, leaving unripe fruit in place on the vine. We are closely following such developments as part of the National Food Security Strategy and will be assessing how rapid technological changes that form part of the Fourth Industrial Revolution can be best incorporated to ensure food security for all.

Mariam Al Mheiri is the UAE's Minister of State for Food Security

Updated: January 16, 2019 04:25 PM

LED Lighting for Indoor Agriculture

Now, plants can be commercially grown without any sun light. LED lighting is replacing the sun due to advanced technological innovations.

Len Calderone for | AgritechTomorrow

01/10/19, 08:14 AM

Since the beginning of time, plants have relied on the sun to feed and grow through the method known as photosynthesis—a process used by plants and other organisms to convert light energy into chemical energy. Now, plants can be commercially grown without any sun light. LED lighting is replacing the sun due to advanced technological innovations.

Light emitting diodes (LED) work by passing a current between semiconductors. Compared with other forms of electrical illumination, LEDs use less energy, give off little heat and can be controlled to optimize plant growth compared to other forms of electrical illumination, such as fluorescent lamps, which contain mercury, which is needed to make the inert gasses conductive at all temperatures and to make the lamp work properly and efficiently. Mercury is a heavy metal, which is hazardous to the environment.

Then, we have incandescent lamps that are considered the least energy efficient type of electric lighting commonly found in residential buildings. Because of their inefficiency and brief life spans, they are more expensive to operate than LED and fluorescent lights.

LEDs are tiny light bulbs that fit into an electrical circuit. Unlike incandescent bulbs, they don't have a filament that will burn out, and they don't get very hot. They are illuminated uniquely by the movement of electrons in a semiconductor material. The lifespan of an LED exceeds the short lifespan of an incandescent bulb by thousands of hours.

In LEDs, the conductor material is usually aluminum-gallium-arsenide. In pure aluminum-gallium-arsenide, all of the atoms adhere entirely to their neighbors, leaving no free electrons to conduct electric current. Additional atoms change the balance by adding free electrons or creating holes where electrons can go. Either of these variations make the material more conductive.

In agricultural applications, LED lights are used to change how plants grow, alter when they flower, transform how they taste and even modify their levels of vitamins and antioxidants. LED lights can extend a plant’s shelf life as well.

Growers can use LED light modifications to grow two types of basil from the same plant. For example, they can grow sweeter basil for the grocery store and more spicy versions for chefs.

These plants are grown indoors, utilizing a fraction of the land, water and fertilizers of greens raised outdoors with conventional farming. Since the plants are gown indoors, they can be grown close to urban centers. Growers don’t need varieties bred for disease resistance, or plants genetically modified to handle the stresses of growing outside. The harvest isn’t transported across the country in refrigerated trucks, and they are not susceptible to the effects of climate change, which is making growing much more difficult for a lot of farms around the country and around the world.

Indoor growing and LEDs allow fast, year-round crop cycles. This permits growers to produce 200,000 pounds of leafy greens, vine crops, herbs and microgreens annually in a 12,000-square-foot warehouse, which is the equivalent of 80 acres of farmland. Not dependent on the outside weather, plants can grow year-round, enabling a grower to produce 15 or more crops a year.

Conventional greenhouses have depended on on high-pressure sodium lamps (HPS) to complement sunlight, but HPS lights don’t work as well as LED because they consume much more power to produce the same light levels. They also generate too much heat to place near young greens. Greenhouses are moving to a combination of HPS and LED lighting for supplemental lighting, though growers see a time when they will use LEDs alone. Lately, LED lighting costs have been cut in half, and their effectiveness has more than doubled.

Scientists have acknowledged that photosynthesis is improved within the red band, but plants also need blue light waves to prevent stretching and enhance leaf color. A visible range beyond red, known as far red, encourages larger leaves, branching and flowering. With advances in LED technology, light recipes can be finely tweaked to each crop and even to each phase in a crop’s life.

Sunlight is inefficient when it comes to improving small-scale, urban agriculture. The heat produced by the sun can damage plants. The sunlight’s heat effect is further amplified when the plants are packed close together, which they are in urban farming.

In contrast to sunlight, LED lights are known for shifting nearly undetectable amounts of heat onto plants, and the light bulbs are cool to the touch. When using LED lighting, urban farms can closely pack plants for maximum efficiency. This would not be achievable in ordinary agricultural environments without conceding the health of the plants.

There is normally a higher upfront cost using LED lighting. The best way to acknowledge the cost-savings of LED lighting is to look at it in terms of a long-term investment. Over time, LED lighting has a much higher energy productivity over time as compared to other urban farming lighting technologies.

LED's use much less electricity than pressure sodium lights or fluorescent, as much as 40% - 50%. For indoor growing, proper ventilation is required. Ventilation for indoor growing helps prevent excess moisture, the propagation of pests and the weakening of plant stems. LEDs produce much less heat than other types of grow lights, resulting in the need for less ventilation.

LED's grow lights have an extreme life length. They typically have 50,000 hours of usable life, which is approximately 6 years of continuous use. So, if you are utilizing the lights on a 50% on 50% off schedule, the life of LED grow lights is over 11 years.

Since LED's have much lower heat output, they can be located nearer to the plants. This allows the grower to stack more plants in the same vertical space. Therefore, the benefit of using LEDs is to double or triple the production output without changing the area of the growing space. Of course, this depends on the height of the growing space.

As used in commercial indoor growing, LED lighting technologies have been around less than ten years. LED lights are less understood than other types of grow lights, which have been studied for several decades. So, what does this mean? The support for and the knowledge of LED grow lights is far more limited than other types of grow lights. Most importantly, because of the knowledge gap, there are great opportunities.

UAE Leads In Vertical Agriculture In Region

The National Food Security Strategy in the UAE aims to develop a comprehensive system, which aims to achieve sustainable food production.

Sumaira FH 1 month ago Mon 10th December 2018 | 07:00 PM

ABU DHABI, (UrduPoint / Pakistan Point News / WAM - 10th Dec, 2018) The National Food Security Strategy in the UAE aims to develop a comprehensive system, which aims to achieve sustainable food production.

The system will involve 38 short and long-term initiatives, as per the "2051 Vision" and "2021 Work Agenda."

Many specialist newspapers highlighted the UAE’s plans and projects that aim to attract major investment in vertical or horizontal agriculture, in line with related growth forecasts for the Gulf region, which amounts to US$1.21 billion by 2021, a compound annual growth rate of 26.4 percent.

The Business Standard stated that the UAE leads in this type of investment, and has launched many recent leading projects.

Mariam Hareb Almheiri, Minister of State for Food Security, announced, during the UAE government’s annual meetings in November, the "National Food Security Strategy," which includes many related objectives, such as achieving sustainable local production through the use of technology and smart applications.

The Ministry of Climate Change and Environment approved the launch of 12 vertical farms while Emirates Airline is planning to launch the largest vertical agriculture farm in the world, in partnership with Crop One Holdings.

Food import rates amounting to 90 percent and the issues associated with the scarcity of water and arable land in the region strongly support this trend.

In August, Xinhua signed an agreement with China's Chongqing University related to the use of modern technology, to utilise sand as arable soil, and relevant field tests will be conducted in cooperation with Mawared.

Almheiri raised the idea of establishing a "Food Valley" or a technology centre dedicated to developing food products and automated agriculture, to attract a new generation of farmers who can help achieve future sustainability.

The UAE hosts many specialist forums and exhibitions, which aim to promote the latest technologies and showcase them in the region’s agricultural and business markets.

Henry Gordon Smith, Founder and Managing Director of AgriDetriti, said that the middle East has the ability to reshape its vital infrastructure, which will support modern life.

It also has the potential to transform a relatively small and conventional agricultural industry into the world's most technologically advanced agriculture industry, he added.

Bob Honch, Sales Manager in Van Der Hoven Company, said that the UAE has already started this industry, revealing the completion of the largest glass houses project in the UAE (11 hectares), using advanced technologies allowing climate control and stressed that the project could produce around 3000 tonnes of tomatoes throughout the year.

$1.2bn GCC Vertical Farming Boom Seen by 2021

The UAE is leading the vertical farming change and has upcoming projects facilitated by the government as well as private players to help increase food security in the region.

Image by: Crop One Holdings

A growing importance is being given to vertical farming across the GCC and is generating interest and increased investments from regional and overseas players, according to a new report.

Orbis Research said the region's vertical farming market is expected to reach $1.21 billion by 2021 at a compound average growth rate (CAGR) of 26.4 percent from only $380 million in 2016.

It said the UAE is leading this change and has upcoming projects facilitated by the government as well as private players to help increase food security in the region.

These include the UAE Ministry of Climate Change and Environment allotting space for 12 vertical farms to be built by Shalimar Biotech Industries, and the world’s largest vertical farm for Emirates Airlines by Crop One Holdings Inc.

Image by: Crop One Holdings

With around 90 percent of food being imported in the UAE, territorial problems of water scarcity and small percentages of arable land, vertical farming is becoming increasingly vital to ensure food security within the region, the report added.

Mariam Al Mehiri, Minister of Future Food Security, also plans to create a "Food Valley" or a technology hub, dedicated to the development of food and farming automation.

The report comes ahead of AgraME 2019, a platform for the latest technology to be showcased to the regional agribusiness market.

Henry Gordon-Smith, founder and managing director of Agritecture who will be speaking at AgraME 2019, said: “The potential is certainly there to transform what has historically been a relatively small traditional farming industry into perhaps the most technologically advanced agriculture industry in the world.

"This means economic development, increased production of nutritious local produce, and lowered food costs, all with minimal water consumption and increased resilience to climate change and foreign markets.”

Samantha Bleasby, exhibition director of AgraME added that the show, which takes place in Dubai from March 5-7, is attracting key players in the industry such as Certhon, Agrotonomy, Veggitech, Wuxi, iGrowths Technology Co Ltd, Ozorganic Urban Farming and Van der Hoeven.

New York Vertical Farm Aims To Instill Consumer Trust With Transparency

Starting today, consumers can just point their camera app at the QR code, or type in the lot number, found on all Square Roots food packaging to trace their food’s path from seed to sale.

By Laura Drotleff| December 19, 2018

Consumers can simply scan the QR code with the camera on their phones to get the full story on when, where, and how Square Roots’ herbs are produced in Brooklyn, NY.

In the wake of the romaine lettuce recall, Square Roots, a Brooklyn, NY-based vertical farm with famous co-founders, has launched new labeling that will allow consumers to access the full backstory for when, where, how, and by whom their food was grown with a simple scan.

Starting today, consumers can just point their camera app at the QR code, or type in the lot number, found on all Square Roots food packaging to trace their food’s path from seed to sale, with the aim of bringing a “whole new level of transparency” to the food chain.

Co-founded by Tobias Peggs and Kimbal Musk (yes, Elon’s brother), Square Roots is a seed-to-sale indoor urban farm that produces a variety of fresh, pesticide-free herbs that are hand-harvested, self-packaged, and same-day-delivered to retail stores in New York City. The company was built on the premise of reconnecting city dwellers with the “comfort, nourishment, and taste of food and the people who grow it.” In addition to growing and selling herbs, Square Roots has taken it upon itself to groom next-generation farmers and future leaders in urban farming through its training platform that requires a one-year commitment to the company.

The Why Behind Square Roots’ Transparency Timeline

Musk wrote in a blog-post revealing Square Roots’ reason for launching its new scan-able label is that the operation wants to provide consumers with the transparency they’re demanding about where and how their food is grown.

Following the E. coli outbreak that resulted in the recall of all romaine lettuce grown in the U.S., consumers were put at risk, and the complexities and lack of traceability in the agricultural supply chain resulted in it taking weeks for federal agencies to track down the source of the bacteria.

Meanwhile, by growing in controlled environments, indoor food producers can provide advantages to minimizing the occurrence of outbreaks. Musk says by promoting this, Square Roots’ customers can enjoy the operation’s locally grown products “with the comfort and confidence of being able to see exactly how and where your food was grown and who grew it.”

Grown hydroponically inside climate-controlled, refurbished shipping containers, Square Roots’ end-to-end system monitors and controls every aspect of the production process, Musk says. The operation’s technology stack surrounds its farmers with data, tools, and insights to make smart decisions in real time, allowing them to sustainably produce food year-round.

Musk says while there’s a lot of excitement around the possibilities that blockchain offers for food traceability that could improve the current supply chain, consumers are turning to locally grown produce because there are fewer steps and less time involved from farm to fork.

“We, like many local farmers, don’t need to utilize blockchain architecture to give the consumer what they want today – total transparency, without the buzzword BS.”

Read Musk’s full article on the Square Roots blog, and learn about the company on its website. Stay tuned for more stories on how indoor producers are promoting food safety and transparency on GreenhouseGrower.com.

Indoor Farming with Bowery Farming

Were reappropriating previously unusable industrial space to grow crops indoors, closer to the point of consumption, at a rate that is 100+ times more productive per square foot of land than that of traditional agriculture.

Tell us about Bowery Farming and what you do.

Bowery is growing food for a better future by revolutionizing agriculture. Our modern farming company combines the benefits of the best local farms with advances made possible by technology to grow produce you can feel good about eating. BoweryOS, our proprietary software system, uses vision systems, automation technology, and machine learning to monitor plants and all the variables that drive their growth 24/7. Bowery produce is currently available at select Whole Foods and Foragers stores in the Tristate area, at select sweetgreen and Dig Inn locations in New York, and featured on the menus of Tom Colicchio’s New York restaurants Craft and Temple Court.

What got you started in the search to improve your energy monitoring and consumption?

While Bowery farms offer vast improvements compared to traditional agriculture - using zero pesticides, 95% less water, and are 100+ times more productive on the same footprint of land - we knew there was an opportunity to make our farms even more efficient and sustainable. We began our search to improve energy monitoring and consumption so that we could reduce our Co2 emissions, which make up a meaningful majority of our energy usage.

Tell us about the microgrid system you will be installing at Bowery Farming.

Bowery’s microgrid system will use distributed energy resources (DER), including a rooftop solar array, a natural gas generator equipped with advanced emissions control technologies and Schneider Electric’s lithium-ion battery energy storage system (BESS) interconnected in a behind-the-meter configuration. The system will greatly reduce Co2 emissions by using sustainable energy to offset the electric grid, reducing the power load we put on the grid, and offsetting our power load during periods of peak demand.

The main drawback currently for Indoor Farming is energy expense from lighting, what are your expectations for overall energy savings you will see with this system?

While Bowery farms require energy to power LED lighting systems, LEDs are effective and have more than doubled in efficiency in the last five years, making them an energy efficient solution. The offerings provided by Schneider Electric and Scale Microgrid will help cover a meaningful amount of our energy consumption needs and set us up with the knowledge and experience to install significantly more sustainable solutions in future farms.

Bowery Farming is at the forefront of the indoor farming industry. Why is it important for you to continue to innovate and lead the industry?

We’re continuing to innovate and lead the industry because we believe technology applied at scale can solve difficult and important, global problems. Agriculture sits at the epicenter of many global issues; over 70% of our global water supply goes to agriculture, we use over 700 million pounds of pesticides each year in the U.S. alone, and industrial farming practices have caused a loss of over 30% of the arable farmland in the last 40 years. At the same time, our global population is growing to 9-10Bn people by 2050 and we will need 70% more food in order to feed a population of that size. The result is a world in which the current food system must support the needs of an expanded population with a rapidly dwindling set of resources.

At Bowery, we’re re-thinking the current agricultural system to address the needs of an ever-increasing population by growing produce in large scale indoor farms. We’re reappropriating previously unusable industrial space to grow crops indoors, closer to the point of consumption, at a rate that is 100+ times more productive per square foot of land than that of traditional agriculture. In addition, our proprietary software and work management system BoweryOS organizes and directs the entire workflow inside the farm, driving efficiency, collecting data and creating a highly scalable framework for our farms.

Where do you see the indoor farming and Bowery Farming 5 years down the road?

We believe that indoor farming will continue to be a great contributor to solving difficult and important global problems. Our goal is to build a Bowery farm in every major city of the world to address major global challenges around food supply, environmental degradation and food waste.

Urban Farm In Brooklyn Looking To Attract Young Farmers

Located in a former Pfizer factory in the Williamsburg district, the company said one of its main aims is to offer young people careers in agriculture.

So-called 'urban', or 'vertical', farms have been making their way into some US cities over the past few years. With limited land in major metropolitan areas, indoor urban farms offer the chance for city stores and restaurants to get their hands on locally-grown produce. Square Roots in Brooklyn, New York, is one of these next generation indoor farms. Located in a former Pfizer factory in the Williamsburg district, the company said one of its main aims is to offer young people careers in agriculture.

"The average age of the American farmer is 58," noted Karsten Ch'ien of Square Roots. "With more young people living in cities, we bought shipping containers into the city because that is where many of them live. Young people are very technology literate, and with the rise in demand for healthy, locally-grown foods, this is the perfect combination for them to get involved in the produce industry. As a result, the average age of our farmers is just 24."

Ch'ien said that Square Roots offers training and skill building as part of helping young farmers establish a firm foundation in the industry. "At the heart of Square Roots is the Next-Gen farmer training program, which creates opportunities for more people to become farmers—and future leaders in urban farming—through a year-long commitment on the Square Roots team."

Produce is grown in modified shipping containers. Ch'ien is on the far right.

Growing in shipping containers

Produce at Square Roots is grown in shipping containers, which have been climate controlled and fitted with the latest in vertical farming gadgetry. All the operations are controlled in the company's offices overlooking the parking lot where the ten containers lie. The shipping container model gives the company great flexibility.

"Growing in shipping containers requires less upfront capital to establish and maintain," Ch'ien explained. "They are easy to retrofit and move if we need to. Additionally, it's very simple to expand the farm. Instead of remodeling or building an extension, we simply add another shipping container and fit it out in the same manner. Here in the parking lot, we have plenty of room to grow horizontally. At this stage, it's not practical for us to stack containers due to the need for climbing up and down ladders with produce."

According to the company, each shipping container yields between 50 and 70 pounds of produce each week. The containers have been engineered to be environmentally friendly and food safe. "The mineral nutrient system cycles and recycles, so each container only requires eight to ten gallons of water per day. Any kind of food safety issue can be contained in each farm," Ch'ien said.

Culinary herbs the focus

Vertical farms still have a way to go to become a mainstream source of produce. Currently, they are typically restricted to leafy greens and other plants that have minimal energy requirements. Square Roots focuses on culinary herbs. The herbs are grown and packed inside the container and then delivered to local independent retailers on one of the company's tricycles.

"Leafy greens are the easiest to grow vertically," Ch'ien observed. "We can also grow things like grape tomatoes and other small vegetables. It really depends on the energy requirements of each plant. Here at Square Roots, we focus on culinary herbs, with each container specializing in a herb. Typically, the timeframe of maturity to harvest is four to six weeks, depending on the herb. We grow in sections and harvest each container twice per week, so that there is always produce that is ready to be picked."

Square Roots uses these tricycles to deliver their produce direct to customers in the NYC area.

Ch'ien notes that growing more energy-intensive commodities such as tomatoes and small root vegetables is not economical at this stage but said that this may soon become viable as technology continues to improve. "Outside of leafy greens and herbs, it's very challenging to grow other crops economically right now. However, technology is improving each year, providing us with increased opportunities to scale and moderate costs. Additionally, we want to ensure we balance sellable yields with quality."

As to the question of whether vertical farming is a threat to traditional farming, Ch'ien believes the two are not mutually exclusive, but rather the whole system can work side by side. "We don't see it as a competition between traditional land-based farming and urban, vertical farming. All growers have the same goal which is to deliver the freshest, best quality produce to customers. We believe vertical farming can work in tandem with traditional farming, each serving a useful purpose in the industry."

For more information:

Karsten Ch'ien

Square Roots

Ph: +1 (740) 337-6687

karsten@squarerootsgrow.com

www.squarerootsgrow.com

Publication date : 12/18/2018

Author: Dennis Rettke

© FreshPlaza.com

Belgian Supermarket to Introduce In-Store Vertical Farms

The retail group sees multilayer cultivation as part of its wider aim of pursuing more sustainable products, shortened chains and innovation.

Colruyt Group is testing a system developed in-house for 'vertical farming' or multilayer cultivation in climate-controlled conditions. The retail group sees multilayer cultivation as part of its wider aim of pursuing more sustainable products, shortened chains and innovation. Colruyt Group aims to start stocking the shelves of its retail formula Bio-Planet with the first herbs from its vertical farm from the autumn of 2019, under its own label Boni Selection, which is strongly committed to a sustainable product range.

Ambition: herbs with a very small ecological footprint

Consumers are making increasing demands regarding responsible consumption. Colruyt Group wants to offer a possible solution using vertical farming. "Our multilayer cultivation creates the perfect conditions for plants", explains Stefan Goethaert, Director at Colruyt Group and responsible for product sustainability. "Air, light, water and nutrients are dosed in the ideal quantities. As a result, we only use the amount of energy and raw materials that is strictly necessary, whilst still allowing the plant to achieve optimum growth. And it's no longer necessary to use pesticides. The plants are therefore 100% natural. Moreover, they reach maturity twice as fast than when conventionally cultivated. And the quality remains high throughout the year, regardless of the weather conditions."

The first results after a year of testing confirm the story, says Stefan Goethaert. "We are already using 90% less water and 50% less nutrients than in conventional cultivation. We reuse all of the nutrients that the plant doesn't use. Moreover, we only work with filtered rainwater. Our LED lighting is twice as efficient as the current standard on the market. And the system runs on green electricity from our own wind turbines and solar panels." It is Colruyt Group's ambition to sell herbs that have a very small ecological footprint. That's why the entire lifecycle of the plants is looked at, from seed to consumer's home. The retailer is therefore also working on recyclable packaging and a long shelf life, and will minimise the number of kilometres driven by integrating the vertical farm in a distribution centre in the future.

Home-grown innovative technology

Colruyt Group is the first retailer in Belgium to test a vertical farm that was developed in-house. The technology used has been fully developed within its own R&D department. In the current test set-up, biotechnologists and engineers continue to work on optimising growing conditions.

For Colruyt Group, this project isn't a leap into the unknown: recent innovation projects around water purification, LED lighting, renewable energy, automation, eco-design and refrigeration have formed the basis. In addition, the R&D department works together with a number of knowledge institutions. "We are also in talks with potential partners", adds Stefan Goethaert. "We also want to make some of the plants available to innovative entrepreneurs who work on food trends. Together we can explore the possibilities for using our products."

First trial at Bio-planet in 2019

"We are still in the testing phase, but the goal is to sell the first herbs at Bio-planet within a year", says Jo Ghilain, business unit manager of Bio-planet. "Vertical farming fits perfectly with our brand positioning. Bio-Planet stands for healthy, natural and local products. Furthermore, our customers are early adopters and are looking for added value. They are the people demanding products with a sustainable story." The herbs are currently grown using certified organic seed and substrate. "That was a decisive argument, in addition to the sustainability score of the plants", says Jo Ghilain.

Meanwhile, Bio-Planet customers were the first to taste test basil plants in three stores: on 27 November in Uccle, on 28 November in Grimbergen and Jambes. Jo Ghilain emphasises the added value of this co-creation: "The people of Uccle, Grimbergen and Jambes will help us determine the eventual flavour of the plants. Based on their opinions, we will adjust the cultivation process and the taste. This means that our customers actually choose the end result themselves."

For more information:

Colruyt Group

www.colruytgroup.com

Publication date : 12/5/2018

Playing "Happy Families" To Understand Urban Agriculture In France

We hear a lot about urban agriculture, but what is it exactly? How is it different from traditional agriculture? What is the difference between rural farms and urban farms?

11 December 2018

Agnès Lelièvre, lecturer in agronomy at AgroParisTech, Baptiste Grard, postdoctoral researcher at the Laboratory of Functional Ecology and Ecotoxicology of Agroecosystems (AgroParisTech/INRA), Christine Aubry, head of the Urban Agriculture research team at AgroParisTech, and Véronique Saint-Ges, economist at INRA, tell us about the different forms of urban agriculture.

We hear a lot about urban agriculture, but what is it exactly? How is it different from traditional agriculture? What is the difference between rural farms and urban farms?

New definitions of that concept have emerged in the past few years—including that of Canadian expert Luc J.A. Mougeot (2000) and French experts Paula Nahmias et Yvon Le Caro (2012)—, along with new typologies such as those of Cerema, Exp’AU and IAU. In the present case we will use Mougeot’s definition of urban agriculture:

“A production unit located within a city or metropolis (urban) or in its direct vicinity (peri-urban) that produces, raises, processes and distributes a diversity of food or non-food products by massively (re)using human and material resources, products and services from that urban area and its surroundings, and providing human and material resources, products and services to that same area.”

To depict the different forms of urban farming, we have chosen to use the analogy of “Happy Families”, where each category of urban agriculture is a family. For each family, we will relate the story of its ancestors and parents (the ancient forms) as well as that of its children (the current forms).

Without further ado, let’s get to know all these happy families.

1. The “Feet in the soil” family

This family has historically lived in an urban environment, while staying deeply connected to the soil. In today’s context, this category suffers from two recurring issues: access to land and pollution.

The ancestors of that category were the vegetable gardens of aristocrats, such as the well-known “King’s garden”, established in Versailles during the 17th century to provide fruit and vegetables to Louis XIV’s court.

In this family, the parents are a popular and commercial version of their ancestors. They are, for example, the marais ("swamps") at the heart of Paris, which have led to the French word maraîchage (“market gardening”). These farmers were great initiators and inventors of agricultural techniques that are still being used today. They practiced intensive agriculture on small areas using frames or glass domes to cultivate earlier in the season. Horse manure (which at that time was abundant in the city) and urban mud were some of the resources commonly used. This shows how helpful market gardeners were to city dwellers.

They have a large, varied descent that includes peri-urban farms, often pushed outside of the cities due to urban densification and hygienization. These farmers continue to sell their products to city dwellers, i.e. mainly vegetable produce and small animals (chickens, eggs, etc.). Over the past fifteen years, these farms have become increasingly popular through the development of short, local distribution networks such as AMAPs. These farms usually cover a few hectares each. In 2010, almost half of French farms producing vegetables and honey sold their produce through short distribution networks.

However, some farmers have managed to establish themselves within cities—or to maintain ancestral farms, although this is less common—by diversifying their activities. Some of them do community work, for instance for individuals that have been disconnected from the job market (such as the gardens of association Aurore), others do educational work (Veni Verdi for vegetable production, Bergers urbains for urban pastoralism) or organize cultural events (La ferme du bonheur).

The closest descendants of market gardeners work in production farms (such as Perma G’Rennes), located on former agricultural plots, or in schools or parks with plots from a few hundred m2 to 1 or 2 hectares.

The garden of the Pierre Mendès France college in Paris, overseen by the Veni Verdi association. (Michèle Foin/Vimeo, 2016).

2. The “Rooftop” family

This family has been around for centuries, as plants were already found on rooftop terraces in ancient Egypt, as shown in certain images of the book Palais et Maisons du Caire ("Palaces and houses of Cairo"), on the architecture of the 13th-16th centuries. Today urban honey is harvested from beehives installed on the roof of many public and private buildings.

There has been a growing interest in "green roofs" (i.e. not producing food) since the 1980s. Now the “agricultural descent” of this family includes farm that are community-oriented—to foster social interactions (Culticimes), for educational or experimental purposes (AgroParisTech‘s rooftop) or for event planning (Jardins suspendus). Some roofs also host farms for productive purposes (Aéromate, AgriPolis).

Interview of Louise Doulliet, co-founder of startup Aéromate. (Supbiotech/YouTube, 2017).

These “rooftop farms” have specific requirements as they have limited space compared to regular land farms. Today, rooftop vegetable gardens can be seen as a solution to issues related to land access and soil pollution, to the point that in a growing number of cities, new constructions anticipate their presence. Yet many questions remain unanswered, including about their design and the growing medium used.

3. The “Vertical” family

Growing produce on walls may seem risky... Yet Montreuil’s peach walls were renowned worldwide during the 19th century for the quality of their production: the fruits were exported as far as the Russian Tsar’s court. Vines have also been climbing on small walls and all kinds of arbors since antiquity.

Whether in museums, hospitals or malls, living walls designed for decorative purposes have become increasingly popular since the 90’s and 2000’s. Today living walls producing vegetables or hop are also found next to urban microbreweries. Farms specializing in event planning also use walls on rooftops. This family is less common than the two previous ones.

Paris hops will grow on the walls https://t.co/6XSGvftnTJ — Le Parisien | Paris (@LeParisien_75) 18 février 2018

4. The “Greenhouse” family

Greenhouse farming extends the production period of fruit and vegetables. The aristocracy was the first to reap its benefits through orangeries and winter gardens. During the 19th century, greenhouses were built in Auteuil and Paris’s Jardin des plantes to ensure the conservation of varieties and species constituting plant collections.

Today, greenhouses are extensively used in agriculture—including in the well-known Dutch production units—but also in cities for productive purposes (Skygreen) or on rooftops (Les Fermes Lufa, The New Farm). They can also be used to educate or experiment on social reinsertion and food therapy (such as in the Cité maraîchère in Romainville).

Greenhouse kale crops in Montreal’s Loufa farms. Les Fermes Lufa Facebook page

Aquaponics is another form of greenhouse farming that combines raising fish and growing vegetables. Although this type of production can be done in tanks based on a living substrate (with fertilizing power for the plants), it is usually based on a neutral substrate in hydroponic systems where the necessary elements for plants—and fish, if any—are provided through water. This type of production is currently being studied as part of a national research project.

5. The “Shade” family

The ancestors of this family developed underground, in mushroom and endive farms. They are known as produits de cave (“basement products”) and are commonly found in the greater Paris area. The parents haven’t diversified their products, yet they have developed new production systems. The children took over the family business by diversifying the offer, through micro-sprouts in particular, and by reusing new types of waste generated by the city, such as coffee grounds. It is mostly production-oriented (Boîte à champignons, La Caverne).

The Boîte à champignons (mushroom box). Agnès Lelièvre

A high tech “parent” has appeared in the last few years with growth in a controlled environment (light, atmosphere, etc.) thanks to recent progress in spatial research. Its children are using existing buildings or recycled containers (Agricool, Farmbox). This family is strongly developing in some countries with high population density or facing intense climatic stress. In France, it has been used as an opportunity to reuse areas such as abandoned parking lots, and in certain cases, to establish mobile farms.

6. The “Sunday gardening” family

The ancestor of the individual garden has led to private gardens, but also to group gardening with allotment gardens, which emerged at the end of the 19th century.

The children of this family continue to maintain private gardens on balconies, terraces and actual gardens, which can be produce high yields. They also practice collective gardening which covers shared gardens, family gardens and multiple hybrid experiments. While private gardening is aimed at growing vegetables, collective gardening also has a social and educational purpose.

This family has grown a lot since the 20th century and it has become increasingly popular, especially in the case of collective gardening. There are over 1,000 collective gardens in Île-de-France, covering at least 900 hectares, in a context where professional vegetable production covers 5,000 hectares. It is a great success, even though obtaining a plot to cultivate in the city or its surroundings remains difficult, as evidenced by the long waiting lists to access a family or collective garden.

Family gardens in the Lilas public park in Vitry-sur-Seine (94). Agnès Lelièvre.

7. The “Self-service” family

Inspired my movements such as Guerrilla gardening, which, in the 70s, started reclaiming land that had been built and abandoned, this is a family of creative, conquering activists.

It has given birth to active offspring seeking to establish plant production in public spaces for everyone to enjoy. It includes international initiatives such as the Incredible edibles, as well as initiatives launched by cities themselves such as permis de végétaliser ("license to plant") and the reintroduction of fruit trees in public parks. Although still discreet, this family has a bright future, as it is an inspiration to local communities.

The original version of this article was published on The Conversation.

Salmon Arm Business To Provide Fresh Greens Year Round

Wolf Wesle and Karen Dow show a tray of microgreens in front of a rack of lettuce, both of which are being grown by Living Leaf Growers located at the Westgate Public Market. (Jodi Brak/Salmon Arm Observer)

Area Residents Invited To Participate In Test Market To Help Develop Signature Salad Mix

December 15, 2018

Salad lovers will be able to access locally grown greens and microgreens, thanks to Living Leaf Growers.

Located at Westgate Public Market, co-owner Karen Dow says the company has been working on developing a commercial hydroponic system for two years under the direction of Wolf Wesle of Green Croft Gardens organic farm in Enderby.

While the produce will not be certified organic, Dow says it is as good as organic.

“It’s all done in water, no chemicals; it’s grown with just nutrients,” she says. “We are testing different types of nutrients as some are better than others.”

The produce will be grown in racks that go 24 feet high, consisting of seven rows, in four different sections. At the moment, Living Leaf is running about 25 per cent of the system but planning to be up to 50 per cent soon.

“We have eight different lettuce types that feed into a salad mix and we want to test different combinations of colours, types, textures and tastes,” she says. “We want to come up with their own best seller and we need help to do that.”

For the next two or three months while production ramps up, Living Leaf will prepare sample mixes of lettuce and invite a test group to buy a bag of salad or microgreens for $1 and provide feedback on how long it lasts in the fridge, texture and taste.

As well as lettuce and microgreens, Living Leaf is planning to grow strawberries and probably cherry tomatoes.

Microgreens are a vegetable green, harvested after sprouting as shoots, that are used as a component or ingredient to enhance the attractiveness and taste of dishes with their delicate textures and distinctive flavours.

“We have the capacity to grow 28,000 heads of lettuce a month and 700 strawberry plants and I don’t know what the numbers are, but we can grow a lot of microgreens year round,” says Dow. “Lettuce, mixed salad lettuce and strawberries will be available all year round, but the strawberries won’t be available until next spring.”

Dow says the first batch of lettuce will be harvested on Dec. 17, with lots more becoming available in January and February.

To join the test market and register for the lettuce and microgreen program, go online to www.westgatepublicmarket.com, click on the Living Leaf Growers page and fill out the registration form.

“When we have lettuce and/or microgreens available, we will notify you by email to come in and pick up your bag,” Dow says, noting people may only buy one bag at a time and will be required to fill out a questionnaire before they can buy more.

AVF Advertises Vertical Farming In Asia

You can catch a glimpse of AVF’s Asian activities through these photos:

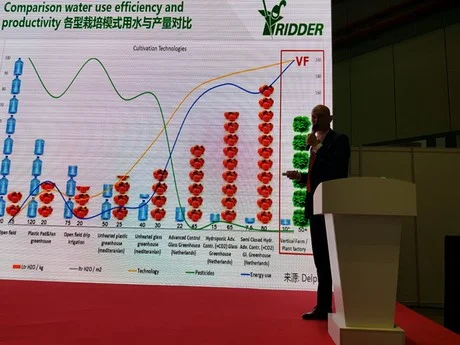

Horti China was the host to AVF's latest design thinking event in the search for a comprehensive roadmap for vertical farming. Prof. Jasper den Besten, Honorary Board Member, and Fulco Wijdooge, General Manager of Ridder Group in China talked about the science and scaling of vertical farming. The role of LED lighting in vertical farming was presented by member TüVSüd, and the Association's chairwoman met with Ms. Wei, the president of Agrigarden, one of the leading players in China's urban agriculture.

Before attending Horti China in Shanghai, AVF’s chairwoman Christine Zimmermann-Loessl visited Manila, Philippines to visit Urbangreens' project at the Science Museum in Manila, where visitors can learn about hydroponics, and she also attended the 25th Asian Seed Congress. She was invited to give a keynote speech in the Special Interest Group on Vertical Farming. According to the AVF, it was very well received and opened doors for more collaboration on future topics like "Nurturing Seeds of Tomorrow".

For more information:

Association for Vertical Farming

Marschnerstrasse,

81245 Munich,

Germany

info@vertical-farming.net

Danone Among Backers of French Urban Farming Start-Up Agricool

French urban agriculture start-up Agricool has secured $28 million in its latest funding round, including an investment from Danone’s investment arm, Danone Manifesto Ventures.

Posted By: Contributor on: December 07, 2018

French urban agriculture start-up Agricool has secured $28 million in its latest funding round, including an investment from Danone’s investment arm, Danone Manifesto Ventures.

In the past three years, Agricool has developed a technology to grow local fruits and vegetables more productively and within small and controlled spaces, known as ‘Cooltainers’ (recycled shipping containers transformed into urban farms).

The Paris-based business said it is responding to reports which suggest that by 2030 20% of products consumed worldwide will come from urban farming – compared to 5% today.

Other investors in the round – which adds to $13 million previously raised – include Bpifrance Large Venture Fund, Antoine Arnault via Marbeuf Capital, Solomon Hykes and a dozen other backers.

With the new funding, Agricool aims to position itself as a key player in the vertical farming sector. The start-up hopes to multiply its production by 100 by 2021, in Paris first, then internationally, starting in Dubai, where a container has already been installed in The Sustainable City.

Agricool said that its challenge, and that of urban farming, is to help develop the production of food for a growing urban population which wants to eat quality produce, while limiting the ecological impact of its consumption.

In a statement, the start-up said: “Agricool strawberries are harvested when perfectly ripe and contain on average 20% more sugar and 30% more vitamin C than supermarket strawberries.

“The production technique makes for strawberries which require 90% less water to grow compared to traditional agriculture, with zero pesticides, and a reduced transportation distance reduced to only a few kilometers between the place of production and point of sale.”

Agricool co-founder and CEO Guillaume Fourdinier said: “We are very excited about the idea of supporting urban farming towards massive development, and it will soon no longer be a luxury to eat exceptional fruits and vegetables in the city.”

Indoor Ag Sci Cafe Discusses How Industry and Academia Can Work Together

How Industry and Academia can Work Together’, Colangelo discussed the current status of indoor farming industries.

By

October 19, 201801337

This month’s ‘Indoor Ag Science Café’ featured Robert Colangelo, Founder of Green Sense Farms, as a speaker. In his presentation ‘Growing the Vertical Farming Industry – How Industry and Academia can Work Together’, Colangelo discussed the current status of indoor farming industries, gaps and cultural differences between businesses and academia, as well as possible strategies to work together on R&D for common critical technologies. Indoor Ag Science Café is a monthly online forum organized by three scientists (Chieri Kubota, Ohio State U; Erik Runkle, Michigan State U; and Cary Mitchell, Purdue U).

Please contact kubota.10@osu.edu to join the café.

Turn Africa’s Cities into Vertical Farms

African cities, according to a World Bank report, are home to 472-million people — almost half of Africa’s total population. This number is expected to double by 2050.

Esther Ngumbi 16 Nov 2018 00:00

Aerofarms in Newark, New Jersey, is the world’s largest high-tech vertical ‘farm’. It’s in a 9 144m2 warehouse, which has no sun or soil and uses less water

African cities, according to a World Bank report, are home to 472-million people — almost half of Africa’s total population. This number is expected to double by 2050.

One would expect these African cities to serve as hubs of productivity and hotspots of innovation where solutions to Africa’s problems, such as poverty, hunger and food insecurity, are born, incubated and implemented. One would also expect them to drive economic development and put the continent on a path towards achieving the United Nations’ sustainable development goals.

Yet residents of these rapidly urbanising cities face problems such as rising poverty, hunger, food insecurity and unemployment.

Such difficulties generate stress for people, but also political, economic and environmental upheavals. These cities are ticking time bombs.

Nigeria, for example, was recently reported to have overtaken India as the country with the largest number of people living in extreme poverty. In another report, two of Nigeria’s cities, Abuja and Port Harcourt, were ranked high on a list of fragile cities. In Kenya, the people most vulnerable to food insecurity live in the cities, specifically in the slums. And the country’s growing unemployment, especially in cities has been described as a national disaster.

Although the problems are enormous, cities can also offer unique opportunities to reduce poverty, deliver prosperity and economic development and tackle other issues that affect agriculture, including climate change. But African cities can be turned into agricultural hubs.

Agriculture is the source of livelihood for many Africans and contributes on average 15% of Africa’s total gross domestic product. It is regarded as the sector that offers the greatest potential for reducing poverty and inequality.

African cites should consider the value of vertical farming. Conventional agriculture has driven many energetic, creative and tech-savvy young people away from the rural areas.

From Aerofarms in New Jersey in the United States and Sky Greens in Singapore to Grow Up in the United Kingdom, vertical farms are becoming part of the fabric of some of the world’s cities. These farms epitomise what innovation can produce.

Vertical farms use sophisticated technology and climate-controlled buildings to grow crops. Because it is a closed system, vertical farms use 95% less water than farming on land. Vertical farming in cities can help to deal with the problems of rapid urbanisation. It also offers urban residents pesticide-free food. And they can provide employment.

Of course, vertical farming also has its own set of unique problems, especially in Africa. These include unreliable sources of energy and water and startup costs are high. But establishing partnerships that include the government, the private sector, universities, research institutions and civil society can counteract these obstacles.

Some African cities are uniquely positioned to establish vertical farming. Take the case of Nairobi, home to Konza Technology City. The government set aside 2 00 hectares of land 64km south of Nairobi to develop this technology hub. Now, what if the city of Nairobi fills this space with skyscrapers that are growing fresh food for urban dwellers? It would be a place where families can go to have intimate encounters with the food they eat and where Nairobi’s unemployed youth would find meaningful work.

Through these partnerships, Nairobi could unlock the power of the city to deliver economic development for its residents and the continent. The city could set the pace for other African cities and put the continent on the path towards achieving sustainable development and prosperity for all.

Esther Ngumbi is a postdoctoral researcher in the department of entomology at the University of Illinois

The Importance of Daily Light Integral (DLI) For Indoor Cannabis Cultivation

Daily light integral (DLI), represents the number of photosynthetically active photons that are delivered to a given space over the course of a day. Considering not all wavelengths of light can be utilized by plants, it’s important to distinguish between PAR light and visible light. PAR stands for photosynthetic active radiation and represents the area within the visible light spectrum that drives photosynthesis (400 – 700 nm).

This range in the visible light spectrum is also known as the quantum response area. PAR light is typically measured as PPFD, photosynthetic photon flux density. PPFD measures the precise number of photons that are delivered to one square meter in a given second. Quantum sensors are used to measure PAR light. They help growers calculate the daily light integral, the most accurate measurement for horticultural lighting.

Factors that can affect DLI are geographic location, weather and season. These variables cannot be controlled in an outdoor environment. Indoor horticulture allows for control of these metrics and consistency throughout a grow cycle. Light, temperature and carbon dioxide concentrations are the three factors that affect the rate of photosynthesis. An increased rate of photosynthesis promotes root development, plant growth and overall biomass production.

Many studies have shown that dialing in DLI values for specific crops can lead to increased flower number, larger biomass and decreased growth cycles. Various crop species require different DLI values for optimal growth. Plants also require different DLI values during various points in their life cycle. For instance, fruits and vegetables require DLIs ranging from 14-40 mol m-2d-2. Meanwhile, cannabis requires a much higher DLI. Large cannabis plants need about 65 mol m-2d-2 during their flower cycle. Sea of green grown cannabis requires about 48 mol m-2d-2 during flower. The sea of green growing method focuses on cultivating a large quantity of small plants, typically grown in vertical racking systems. Traditionally, growers cultivated a small number of large plants.

Read more at Smart Grow Systems

Publication date : 12/3/2018

Vertical Farming Robot Wins Design Challenge

The winners of the 2018 Valtra Design Challenge were announced at the EIMA Show in Bologna, Italy. The competition which started in April and ended on September 23rd was targeted globally to designers, academic design students, design studios and automotive suppliers. This year’s challenge was to design the multi-purpose vehicle of the future: a machine that can handle multiple tasks to meet future needs and that is more efficient than today’s highly specialized machines.

The first place of the competition was awarded to the work “VERTICAL” by Austrian design team Benjamin Miller, Jack Morris, and Alireza Saeedi. The jury praised the concept as being a very creative interpretation of the challenge theme. “At first glance it looks very specialized, but if you judge the complete system instead of only the tractor, a versatile and holistic concept for the future emerges. The concept takes care of everything from seeding to distribution of food”, comments member of the jury Hans Philip Zachau.

“Valtra has been widely recognized for ground-breaking and visionary industrial design. We started the Design Challenge in order to raise awareness of future challenges in the agricultural community and society at large. It is also a platform for designers to showcase their innovations.” comments head of the jury and industrial design & user experience manager at Valtra, Kimmo Wihinen. “The Valtra Design Challenge is the world´s largest design contest in agricultural machinery and one of the biggest in the off-road vehicle industry. The high number of innovative and high-class entries shows us that there is a demand for this type of competition, and we are already working on the theme for the next edition”, he adds.

The Valtra Design Challenge 2018 Jury members were Kimmo Wihinen from Valtra, Brandon Montgomery and Sam Freesmeyer from AGCO, Hans Philip Zachau from Lighthouse Industrial Design and Paolo Grazioli Frozen Design Tokyo.

The Valtra Design Challenge was organised for the second time in 2018. This year the competition has received 107 entries from 32 different countries and six continents. The first prize of the Valtra Design Challenge is a €10,000 cheque.

For more information:

www.valtra.com/designchallenge

Samsung Electronics Expands Horticulture LED Lineups To Advance Greenhouse And Vertical Farming

Samsung Newsroom 11.20.18

New horticulture LEDs are designed to promote healthier plant growth and enhance farming conditions for indoor growers

SEOUL, Korea – Nov. 21, 2018 – Samsung Electronics Co., Ltd., a world leader in advanced digital component solutions, today announced new horticulture LED lineups, including full-spectrum packages and modules as well as color (monochromatic) LEDs. Optimized for lighting in greenhouses and vertical farming*, the new LEDs provide a broader spectrum of light for healthier plant growth, enhanced farming environments and reduced lighting system costs.

Full-spectrum light encompasses a continuous range of wavelengths from blue and green to red, creating a light blend suitable for horticultural uses. Compared to narrow spectrum lighting, Samsung’s full-spectrum-based LEDs encourage healthier and more balanced plant growth by stimulating photosynthesis, enhancing plant immunity and increasing nutritional value. Additionally, the LEDs can help to improve the overall farming environment by enabling growers to observe plant conditions more easily and spot diseases, like damping-off, at an earlier stage under bright white lighting. As high-efficiency and cost-effective alternatives to higher-priced red LEDs, full-spectrum LEDs can help lower the costs of a grower’s entire lighting system.

“Samsung’s full-spectrum-based horticulture LEDs present a new way of using LED lighting to improve plant cultivation at reduced system costs,” said Un Soo Kim, senior vice president of LED Business Team at Samsung Electronics. “We plan to further expand our horticulture offerings by integrating the latest in smart LED lighting technology, including Samsung’s leading sensor and connectivity solutions.”

In addition to its full-spectrum white LEDs, Samsung has added blue, red and far-red LEDs to its horticulture family to offer an extensive variety of wavelength combinations and meet the different design needs of horticulture lighting manufacturers.

Built on Samsung’s market-proven LED technologies, the new full spectrum and color LED lineups feature a high degree of reliability, making them well-suited to withstand high temperatures and humidity levels as well as agricultural chemicals used in greenhouses and vertical farming.

Samsung’s horticulture LED packages are now in mass production for lighting manufacturers and growers worldwide. The modules will become available in the first quarter of 2019.

* Vertical farming is the practice of growing crops in vertically stacked layers and usually takes place in controlled, indoor environments.

** PPF (photosynthetic photon flux) indicates the total amount of photons in the photosynthetically active radiation (PAR) range – a spectral range between 400 and 700nm – that can enhance plant photosynthesis and is measured in micromoles per second (μmol/s).

*** PE (photon efficacy) indicates the light efficacy level for photosynthesis in plants and is measured in micromoles per joule (μmol/J).

Propagating Floriculture Crops Under Sole-Source Lighting

This production method allows growers to strictly control the growing climate to best meet the needs of a given plant throughout the day.

September 18, 2018

Leontiene van Genuchten

In the last 10 years, many companies have sprung up to grow herbs and greens in climate-controlled vertical farm or city farm facilities which are daylight-free. As a plant specialist for floriculture with Signify(formerly known as Philips Lighting), I’ve watched these developments with great interest. But I have wondered if a vertical farm can also benefit cultivation of young plants from floriculture crops.

Cultivating floriculture crops without daylight

Growing plants under daylight is the standard practice in conventional greenhouses. But as the popularity of vertical farms has increased, we as plant specialists have been asking ourselves if it is possible to grow floriculture crops without the influence of daylight. Why would growers want to do this? In a greenhouse, the sun affects both the amount of light that the plant receives as well as the temperature and humidity of the growing environment. A controlled environment removes the influence of daylight on the plant’s growth. This would allow growers to strictly control the growing climate to best meet the needs of each plant throughout the day.

Cultivating in a controlled environment also allows growers to optimize other factors, like plant quality and growth speed, and reduce water usage. Since fewer diseases and bacteria come into the controlled environment, vertical farming can also help stop the use of insecticides and fungicides.

Set-up of floriculture trial

These benefits prompted us to conduct a floriculture trial in our climate-controlled test facility at BrightBox in Venlo, The Netherlands. Most of the requests we receive are from growers of young plants, so we ran a trial on the propagation phase of flowers. We chose a wide range of annual and perennial plants, including begonias, petunias, calibrachoas, dianthus, gerberas, celosias, alternatheras and impatiens.

For this trial, we translated the cultivation conditions of a greenhouse to a climate-controlled environment and added the experience of our colleague City Farm plant specialists. Light levels were chosen based on the reference greenhouse environment with daylight, as well as scientific literature and the experience of growers. The light spectra used in the test were aligned with a number of growers to meet their quality standards for the different varieties of flowers. Growth speed is one requirement from growers, but good plant quality is the first priority. In this case, a plant is considered good if it has a compact shape, enough leaves and branches and a good root system. In addition, a good plant should be able to quickly establish roots and bloom as it moves to its next growth phases.