Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Temasek Backs US $30m Firm For Vertical Farming Innovation to Boost Singapore's Food Supply

Called Unfold, it is a tie-up between Singapore state investment firm Temasek and a unit of German pharmaceutical and life sciences giant Bayer

Temasek Is Partnering With A Unit of Bayer To Form A US $30 Million

Company To Develop Breakthroughs In Vertical Farming.

August 12, 2020

SINGAPORE - A new US $30 million (S$41.2 million) company has been formed to develop breakthroughs in vertical farming, a move that will help to further reinforce Singapore's food supply.

Called Unfold, it is a tie-up between Singapore state investment firm Temasek and a unit of German pharmaceutical and life sciences giant Bayer.

The Straits Times understands that they will have an equal share of the company, which is incorporated in the United States.

Its primary focus is on improving the quality and variety of food as well as boosting the efficiency of its production, including that of popular vegetables such as lettuce and spinach.

In doing so, it will ensure the safe and reliable supply of food, something that is vital for countries with little arable land and in times of crisis like the Covid-19 pandemic, said Bayer on Wednesday (Aug 12), when announcing the union between its investment unit Leaps by Bayer and Temasek.

Temasek's head of agribusiness, Mr. John Vaske, noted that food security is a priority for Singapore, pointing to the country's "30 by 30" goal, which is to produce 30 percent of its nutritional needs locally by 2030.

He also told The Straits Times that Singapore has been formative in developing vertical farming. "So, we have insights and knowledge of the industry that Unfold can benefit from through the set-up of its commercial, research, and development operations here."

These operations will also be established in California, where Unfold will be headquartered in the city of Davis.

The focus on the genetic potential of vertical farming also sets the company apart from most vertical farming start-ups, which invariably concentrate on developing more efficient infrastructures, Bayer said.

The aim of the venture is to improve the quality and variety of food as well as boost the efficiency of its production. PHOTO: BAYER STOCK PHOTOS

Unfold has already entered into an agreement for specified rights to germplasm, or seed genetics, from Bayer's vegetable portfolio, a move that will enable it to develop new varieties of seeds. It also plans to come up with agronomic advice that is tailored for growing crops in the unique indoor environment of vertical farms.

These farms, also known as indoor farms, leverage on artificial light to grow crops, are less dependent on man-made chemicals, and optimize the use of water.

The company's chief executive officer is Dr. John Purcell, who was previously Bayer Crop Science's head of vegetable seeds research and development, said Bayer in its statement.

Dr. Purcell said that Unfold's investment in germplasm and crop growth models is timely as the two fields are "largely underserved"."

Some technology companies do not have access to germplasm resources. The power of Unfold is that we will combine the expertise and 100 percent focus on the genetics for vertical farming, with access to the best in class germplasm of the Bayer vegetable seed business," he added.

www.bayer.com

www.leaps.bayer.com

www.temasek.com.sg

unfold.ag

Lead Photo: PHOTO: BAYER STOCK PHOTO

Could Three Bristol Graduate’s LettUs Grow Sow The Seeds For a Second Green Revolution?

LettUs Grow, a Bristol-based company, founded in 2015 by Charlie Guy, Jack Farmer and Ben Crowther, utilizes a unique ‘aeroponic’ irrigation system, which may hold the key to solving the global food crisis

July 25, 2020

By Hana Azuma, Third Year, Biology

LettUs Grow, a Bristol-based company, founded in 2015 by Charlie Guy, Jack Farmer, and Ben Crowther, utilizes a unique ‘aeroponic’ irrigation system, which may hold the key to solving the global food crisis. The three University of Bristol graduates hope to tackle core issues surrounding food security, along with decreasing CO2 emissions and ecosystem collapse in the process.

By 2050, the global population is predicted to reach 10 billion. In order to ensure sustainable and nutritious diets for everyone, we must increase food production by 70%. This proves to be a difficult challenge as, along with the rapid, exponential population growth, agricultural land and resources worldwide are decreasing.

Since the first drop in crop production during the 1950s, followed by the onset of the first ‘Green Revolution’, we are in the midst of another major halt in the growth of food production.

Fortunately, despite the omnipresence of food insecurity and waste, we are currently producing enough food to feed the world. The main challenge is the unequal geographic distribution of adequate agricultural land.

LettUs Grow was founded in 2015 by three Bristol University graduates: Charlie Guy, Jack Farmer and Ben Crowther | Jack Wiseall

Nearly 80% of fertile land has some extent of soil erosion. Due to the changing climate, extreme weather events are predicted to occur more frequently and intensely. Together with population growth, it will be extremely tough to meet the global demand with the current practice.

LettUs Grow hopes to help farmers who are in such situations, to be able to grow their food regardless of the environmental conditions, feeding themselves and earning stable income all-year-around in the process

LettUs Grow were able to reduce water usage by 95%, whilst boosting the crop production by 70%

LettUs Grow has developed aeroponic irrigation systems for indoor vertical farming, which are not only easy to install in cities, but also use zero soil and little water. Crops are grown on a rack, where their roots are exposed to nutrient-rich mist and water spray.

When compared to hydroponics (another soil-free agricultural system), LettUs Grow were able to reduce water usage by 95%, whilst boosting the crop production by 70%. Additionally, neither pesticides nor fertilizers are needed and the whole growth condition is automated by LettUs Grow’s own management software, Ostara.

In June 2020, LettUs Grow, the University of Bristol, and John Innes Centre collaborated on a paper published to the New Phytologist Trust. It revealed the high efficacies of aeroponics and identified the key knowledge gaps that must be explored to accelerate further development. Moreover, the senior author and the former staff at the University of Bristol, Dr. Antony Dodd, mentioned the possibility of using this new system in space.

‘Vertical systems allow us to extend the latitude range on which crops can be grown on the planet, from the deserts of Dubai to the 4-hour winter days of Iceland. In fact, if you were growing crops on Mars you would need to use this kind of technology because there is no soil’, said Dr Dodd.

Aeroponic farming has proved to produce high-quality salads, pak choi, herbs, and more. LettUs Grow is now tackling more challenging crops, such as strawberries and potatoes, as well as the propagation of trees for both fruits and forestry.

It is thrilling to see how this award-winning aeroponic system is evolving as an efficient and sustainable candidate to combat food security. Could this be the start of the Second Green Revolution?

Featured: Jack Wiseall / LettUs Grow

Rooftop Farming: Another Contribution To The Modern-Day Green Revolution

Green roofs are a growing trend in urban areas because of their unique ability to address several urban challenges at once

This article was written by Camilla Stanley, a guest writer for Green Roofs for Healthy Cities

Green roofs are a growing trend in urban areas because of their unique ability to address several urban challenges at once. These benefits include lowering a building’s energy costs, reducing the urban heat island effect, improving air quality, boosting urban biodiversity, having a positive impact on mental health, and, for businesses, strengthening a company’s marketing and increasing property value. But there is one co-benefit that is rarely taken advantage of… food production! In particular, rooftop farms and gardens provide the added benefit of being a source of locally grown produce.

The demand for locally and sustainably grown food is a growing trend as consumers become more interested in knowing where their food is coming from. There are growing concerns around the distance food travels before it reaches our plates (on average fruits and vegetables travel 1,500 miles / 2500 km), and the usage of hormones, pesticides, and GMOs in meat, dairy products and eggs. What the grocery industry is seeing now is a wave of consumers more willing to ‘vote with their dollar’ to ensure that food companies take the necessary steps to effectively reduce their environmental impact.

Rooftop urban farming is a great way to meet these growing demands as consumers are beginning to understand the importance of reconnecting and taking care of nature and the many ecosystem services that nature provides. Green roofs utilized to produce food present a great opportunity for property managers and community leaders to transform the built environment and better serve their communities. This is why Green Roofs for Healthy Cities (GRHC) has put together an informative course on rooftop farming – Introduction to Rooftop Urban Agriculture – a comprehensive review of the benefits, importance, and potential of rooftop agriculture. GRHC is also hosting an Urban and Rooftop Agriculture Virtual Symposium on Thursday, July 23 from 1:00 to 4:30 pm est. The event is bringing together professionals from diverse backgrounds involved in mainstreaming urban agriculture.

The increase in events and resources are coming at a good time as urban agriculture is one of the fastest-growing sectors of the agricultural industry. Rapid technological innovation in areas like vertical farming is allowing entrepreneurs to take advantage of underutilized spaces in cities for food production. This is great for produce that is not well-suited for long-distance transport like leafy greens. Fruits and vegetables that travel long distances also lose flavor and nutrients the longer they are in transit. Urban agriculture helps reduce food waste along the supply chain, supports the growing demand for local and transparent supply chains, and improves the quality of the food available at supermarkets!

Community leaders seeking to address challenges such as poverty, environmental degradation, air and water quality, waste production and disposal and energy consumption would greatly benefit from integrating urban agriculture into their strategies as it is a proven solution in which communities can improve their ecological footprint while garnering social benefits.

Property managers would be interested to know that rooftop urban farming is a great way to earn LEED credits and maintain peak LEED performance. Sites that have on-site vegetable gardens are eligible for up to 6 LEED credits in the following categories: local food protection (1 credit), social equity within the community (1 credit), heat island reduction (2 credits) and site development: protect or restore habitat (2 credits).

Municipalities are taking initiative and investing in the development of sustainable communities and repurposing unused spaces. For example, in New York City on April 18, 2019, the city council passed The Climate Mobilization Act to reduce greenhouse emissions from buildings and includes a requirement for the installation of green roofs and/or solar panels on newly constructed buildings. A similar by-law was passed in Toronto, Canada back in 2009 where all buildings over 2,000 sq. meters must install a green roof. The city now has over 700 green roofs! Other cities that have adopted green roof mandates in recent years include San Francisco, Portland, and Denver! On a larger scale, initiatives such as the C40 Good Food Cities Declaration where fourteen cities around the world committed to achieving the “‘Planetary Health Diet’ by 2030 which aims to address both environmental and human health through better food choices.

For examples of some rooftop urban farms around North America, check out the list below:

- Brooklyn Grange in Brooklyn, NY

- Ryerson Urban Farm in Toronto, ON

- Boston Medical Center Rooftop Farm in Boston, MA

- Chicago Botanical Gardens in Chicago, IL

- Uncommon Ground in Chicago, IL

- STEM Kitchen Garden in San Francisco, CA

- Top Leaf Farms in Oakland, CA

Tagged: urban agriculture, rooftop farm, Brooklyn Grange, Ryerson Urban Farm, Uncommon Ground, C40 Cities, green infrastructure, urban farming, green roof benefits, Toronto Green Roof By-law, climate mobilization act, LEED

Microgreens Launched By Vertical Farmer April Sun

Just in time for this year’s winter season, vertical farmer April Sun launched its range of sustainably grown microgreens from its new commercial-sized micro-farming facility in Melbourne

Food & Beverage | June 4, 2020

Just in time for this year’s winter season, vertical farmer April Sun launched its range of sustainably grown microgreens from its new commercial-sized micro-farming facility in Melbourne.

With a philosophy of true sustainability and paired with cutting-edge technology, the local farm wants to provide the community with a range of nutrient-packed microgreens available year-round to their nearby community.

Co-founder Darren Nichol, April Sun visionary of Australia’s cleanest and highest nutritional food supply who has a wealth of knowledge due to his agricultural background, says, “This is a particular focus of the Darebin Council. They have an actual goal to increase food production within its municipality.”

These super foods are grown without pesticides and utilise 95 percent less water than traditional farming methods due to a hydroponic based (closed loop) watering system. Co-founder Ty Dickson, April Sun technologist and facility designer, said this system guarantees the plants do not receive too little or too much water.

“The watering targets each individual plant or root system and is drained back to the holding tanks,” he said. “Traditional farming methods would see water being lost to the ground and you would use more water to achieve the same level of fertigation without the ability to recapture the excess.”

With custom-spectrum lights developed in-house, the microgreens are grown in their ideal conditions, allowing for year-round production and minimal waste.

“We use a combination of specific wavelengths of blue, red, far red and full spectrum light to stimulate the chlorophyll A and B of the plants, while giving the right signals to ensure proper colour, increased nutrients through stress and, above all, a very healthy plant,” Dickson said.

“We are a non-single use plastics company; we opt for PLA compostable packaging. Our facility uses the highest efficiency components and equipment available. We do run on electricity, although we are engaging in using 100% renewables, and are in preliminary talks with the Darebin Council to implement 100kW of solar panels on our warehouse roof.” said Dickson.

In traditional farming, external factors such as drought, pollution, soil erosion and more can impact crop success. However, the world of vertical farming is “most often done indoors in a controlled environment”, he adds. “Vertical farming when done sustainably has less impact on the environment, there are significant reductions in water usage, land usage, gas usage and many other resources. This is all achieved whilst controlling the indoor growing environment with minimal impact to it outside.”

“By controlling every factor in the plant’s environment, you end up with a high-quality product on a number of levels,” said Nichol.

“We can grow to a timeline and the removal of variables such as the weather allows us to more accurately forecast and grow to our customers’ demands. This can reduce the amount of waste and also increase consistency of supply to customers. This is a huge problem for traditional farming and is the cause for the large price jumps and shortages of produce on the market.”

To see more, click here.

UAE Farm Tech To The Fore

New technologies are helping the country make more of its own produce

New technologies are helping the country make more of its own produce

Over a span of just six months, Covid-19 has not only changed the way we work, celebrate occasions and stay healthy but also forced countries to take a hard look at how they feed their residents. “I believe the current pandemic has provided us the opportunity to completely reimagine the global food system,” says Tony Hunter, a global food futurist.

Going urban

One of the factors pushing the global agri-tech agenda is the growth and increasing density of cities. “By 2050, more than two thirds of the world’s population is forecasted to live in cities,” explains Smitha Paresh, Executive Director of Greenoponics, a UAE-based retailer of commercial and consumer hydroponics systems, adding that urban agriculture will be crucial for feeding burgeoning urban populations.

“On a macro level, we will see a rise in urban farming, mostly using high-tech farming methods such as hydroponics, aeroponics or aquaponics.” Paresh cites Singapore’s conversion of car parks into urban farm centres as an example. “In the UAE, as per the national food security strategy for 2017-2021, we have already witnessed a huge increase in climate-controlled greenhouses all over the country.”

Arable environments

For Hunter, who spoke about potential silver linings of Covid-19 at a recent Gulfood webinar, new technologies present the best means of achieving domestic self-sufficiency. “They can release countries from the tyrannies of arable land and water stress.” He singles out algal products that rely on low rainfall and can use seawater; cultivated meat and biomass products; cell-based products such as milk proteins; and synthetic biology that can manufacture a range of food products.

Over the long term, Ravindra Shirotriya, CEO, VeggiTech, believes there are three critical areas for sustainable farming in the UAE. The first is precision agriculture, which focuses on growing conditions for plants using hyperbaric chambers and nanotechnology-based organic nutrition. Photo bio-reactors, meanwhile, can cultivate food-grade algae such as spirulina. Finally, Shirotriya cites smart farms, which work with smart cities to create harvest plans based on real-time data on food demand and consumption within communities. “This will address our current broken food ecosystem, where we waste 35 percent of food while 15 percent of the world population goes to sleep hungry.”

VeggiTech’s primary focus is on setting up LED-assisted hydroponics for indoor vertical farms and protected hydroponics for sustainable farming in the UAE.

In terms of crop production, Avinash Vora, Co-founder of Aranya Farms, says new technologies aim to boost yields, reduce waste and grow produce entirely. “Technology is being applied at every stage, whether for plant seeding, monitoring growth, managing water, energy conservation, harvesting and packaging. “We are making huge strides adapting all of them here in the UAE; the interest and investments in agriculture prove that.”

For Philippe Peguilhan, Country Manager of Carrefour UAE at Majid Al Futtaim Retail, the UAE had already been seeking self-reliance in food production, but coronavirus amped up its importance. “The disruption that Covid-19 caused to the supply chain highlighted the importance of local produce and presented an excellent opportunity for local farmers to grab a greater share of the market.” Majid Al Futtaim recently made headlines for opening the UAE’s third, and Dubai’s first, in-store hydroponics farm.

Hydroponic hope

Hydroponics is one agri-tech that’s attracting keen investor interest. “As an indicator, Madar Farms’ 7,000-sq-m factory will produce 365 tons of tomatoes a year, and about 14,000 tons of cherry vine tomatoes were consumed in the UAE in 2019,” says Hunter. “There’s therefore the market opportunity for 38 Madar farms in the UAE for tomatoes alone. Add in other nutrient-dense crops such as cucumbers, peppers and leafy greens. Depending upon their size, we could be looking at several hundred businesses.”

On an individual level, more people are leaning towards home farming, especially towards soil-less cultivation since it is simple and easy, according to Paresh. “It guarantees a certain amount of yield. Home farming will be on the rise, considering the disruption we may face in trying times like this.”

As with most technologies, Hunter says the biggest challenge of hydroponics is profitability. “Fortunately, the costs of technology inputs required to optimise hydroponic production efficiencies are falling rapidly. This drop, together with simultaneous increases in performance, is driving down the costs of hydroponics, making acceptable ROIs much easier to achieve.” He adds that economies of scale can help achieve good ROIs. “Currently most farms are in the 1-2 ton per day range but farms of 50 tons per day are being projected by as early as 2025.”

Sustainability challenges

“Challenges in building our own farm were access to sufficient and cost-effective electricity; renewable sources of water; and the availability of locally made raw materials, specifically growing media, nutrients and seeds. With seeds we are adapting — we have been growing our own seeds but having a library of seeds to choose from that are suitable for our climate and environment would be a huge boon to all farmers.”

— Avinash Vora, Co-founder of Aranya Farms

By Riaz Naqvi, Staff Writer | Gulf News | May 28, 2020

WEBINAR - JUNE 3: USDA $3M In Grant Money Available for Urban Agriculture and Innovative Production Projects

The Office of Urban Agriculture and Innovative Production will hold a webinar on June 3, 2020, from 4 to 6 p.m. Mountain Standard Time. It will provide an overview of the grants’ purpose, project types, eligibility and basic requirements for submitting an application.

The U.S. Department of Agriculture (USDA) is encouraging communities and families to create gardens on rooftops, indoors, traditional, non-traditional and other urban farms to be successful at their craft. They recently announced grants to help establish community gardens and compensate people for start-up costs.

The USDA allocated $3 million for grants through its new Office of Urban Agriculture and Innovative Production.

The Office for Urban Agriculture and Innovative Production was organized after the 2018 Farm Bill was passed by both the house and senate and signed into law by President Trump.

The competitive grants are intended to support the development of urban agriculture and innovative production projects. They will accept applications on their website Grants.gov until midnight, July 6, 2020.“

These grant opportunities underscore USDA’s commitment to all segments of agriculture, including swiftly expanding areas of urban agriculture,” Under Secretary for Farm Production and Conservation Bill Northey said. “Such projects have the potential to address important issues such as food access and education and to support innovative ways to increase local food production in urban environments.”

We are proud to be able to offer support through this cross-agency effort,” said Under Secretary for Marketing and Regulatory Programs Greg Ibach. “In creating this grant opportunity, USDA will build upon its years of experience providing technical support, grant funding and research to help farmers and local and urban food businesses grow.”

USDA has made available $1 million for Planning Projects that initiate or expand efforts of farmers, gardeners, citizens, government officials, schools and other stakeholders in urban areas and suburbs. Projects may target a variety of agriculture areas.

USDA made available $2 million for Implementation Projects that accelerate existing and emerging models of urban, indoor, and other agricultural practices that serve multiple farmers. Projects should improve access to local food and collaborate with other organizations that may support infrastructure needs, emerging technologies, educational endeavors and urban farming policy implementation.

The Office of Urban Agriculture and Innovative Production will hold a webinar on June 3, 2020, from 2 to 4 p.m. Eastern Standard Time. It will provide an overview of the grants’ purpose, project types, eligibility and basic requirements for submitting an application.

Information on how to register for and participate in the webinar, or listen to the recording, will be posted at farmers.gov/urban.

More information is available at farmers.gov/urban.

Additional resources that may be of interest to urban agriculture entities include AMS grants to improve domestic and international opportunities for U.S. growers and producers and FSA loans.

Aquaponics Can Have Both Environmental And Cost Benefits

Although aquaponics systems, which combine conventional aquaculture with hydroponics, have become a hotly debated topic in future food production, data on the economic feasibility of aquaponics is relatively limited

Aquaculture is the farming of fish and other aquatic animals, while hydroponics involves growing plants without any soil. Both approaches have been successful on their own, however, combining fish and vegetable production — so-called aquaponics — could also be profitable, according to a new analysis published on 19 May in the journal Aquaculture Research (1).

Although aquaponics systems, which combine conventional aquaculture with hydroponics, have become a hotly debated topic in future food production, data on the economic feasibility of aquaponics is relatively limited.

To figure out how realistic the approach might be, researchers from the Leibniz-Institute of Freshwater Ecology and Inland Fisheries (IGB) analyzed one year of real production data from an existing aquaponics system — the “Mueritzfischer” — located in Waren (Müritz) in Germany. The research system was build as part of INAPRO, an EU-funded project led by IGB aimed at demonstrating the viability of an innovative aquaponics system.

The 540-square-meter facilities produce fish and vegetables on a large scale in a combined recirculating system. The fish and plants are grown separately within the two recirculating systems and sensors are used to continuously monitor can connect the two systems when needed to create optimal growth conditions.

The authors examined two different scenarios and performed an extensive profitability analysis. One scenario showed that the aquaponics approach can be profitable if facilities are sufficiently large. Using this scenario, the researchers developed a model case, which they used to calculate figures for different sized facilities.

Under the right conditions, aquaponics can have both environmental and cost benefits, according to the authors. The main barriers to the commercialization of aquaponics are the high investment costs and high operating costs such as for fish feed, labor, and energy, particularly in countries like Germany. Another challenge is that profitability largely depends on the market environment and the production risks, which can be difficult to predict.

Lead author Goesta Baganz believes there might be huge potential for aquaponics in urban areas: “The already profitable model case would cover an overall space of about 2,000 square meters. This would mean that professional aquaponics would also be possible in urban and peri-urban areas, where space is scarce and often relatively expensive.”

“If, therefore, urban aquaponics can make a profit on such a scale, there is even greater opportunity for local food production, which is becoming increasingly important throughout the world as urbanization progresses”, Baganz explained.

In a global context, Professor Werner Kloas, who led the project, said: “Considering current problems like climate change, population growth, urbanization as well as overexploitation and pollution of natural resources, global food production is the largest pressure caused by humans on Earth, threatening ecosystems and the stability of societies. Consequently, one of the key societal goals is to achieve eco-friendly, efficient food production,”

(1) Baganz, G. et al. Profitability of multi‐loop aquaponics: Year‐long production data, economic scenarios and a comprehensive model case. Aquaculture Research (2020). DOI: 10.1111/are.14610

Modular Micro Farms: A New Approach To Urban Food Production?

One key tenet of the “urban resilience” idea is local food production. If fruits, veggies, and herbs are grown in cities, they’ll reduce the runoff, emissions, perishability and transport costs of produce

November 25, 2019

Nov 25, 2019,

Scott Beyer Contributor

A micro-farm installation creates farm-to-salad-bar food. BABYLON MICROFARMS

One key tenet of the “urban resilience” idea is local food production. If fruits, veggies, and herbs are grown in cities, they’ll reduce the runoff, emissions, perishability and transport costs of produce. They’ll also make cities more self-sustaining, rather than having to fully rely on food grown elsewhere.

The problem is that urban agriculture doesn’t always seem like a practical concept. Urban land is expensive, and the prospect of making it farmland - even in distressed cities - could present long-term opportunity costs if these cities later revive. Furthermore, the vertical farming idea - where structures are built to grow produce at large scales - seems premature, since this brick-and-mortar infrastructure must compete with cheap, horizontal farmland. As fellow Forbes contributor Erik Kobayashi-Solomon writes, vertical farming is still a largely untested concept that receives limited capital compared to standard farming.

An urban agriculture technique that seems more practical, though, is micro-farming, which involves fitting small farms into tight spaces, sometimes ad hoc. The website Lexicon of Food defines micro-farming as “small-scale farming that takes place in urban or suburban areas, usually on less than 5 acres of land.”

Modular micro-farming is a subset within this niche, using small, automated modular food-growing equipment, often contained within a few square feet. Modular farms are easier to use and possibly more scalable, since they can fit into almost any home or apartment.

One example of this modular approach is Babylon Micro-Farms, a startup based in my hometown of Charlottesville, VA. The company sells 32” x 66” x 96” tall machines that use controlled environment hydroponics to grow leafy greens, herbs, and edible flowers. The farms don’t have soil, sunlight or standard seeds. Instead, Babylon places seed pods onto its trays. Depending on the seed variety (Babylon has 227 of them), the machines use remotely-managed equipment to cast the appropriate water and light. This causes produce to generate significantly more per-acre yield than standard farms. Babylon’s 15sqft micro-farms are capable of producing as much produce as 2000 sqft of outdoor farmland.

Babylon's latest modular micro-farm model. BABYLON MICROFARMS

These modular farms can be connected together to create indoor farms of different scales that can work within existing buildings. Their operations are remotely managed via the cloud with real-time data collection on all aspects of the growing environment. This is an exciting development in a space that has remained out of reach for businesses and consumers due to high capital costs and complex technology with a steep learning curve.

Babylon sells these machines the way some green energy companies sell solar panels. Customers agree to a minimum 2-year lease, paying a fixed monthly fee. Babylon installs the machines, provides a subscription of growing supplies, and remotely manages the crop growth via the cloud using a proprietary software platform. This lets customers enjoy the produce without needing a “green thumb or any real expertise,” says Alexander Olesen.

Olesen co-founded the company with Graham Smith, when they were at the University of Virginia and participating in the iLab Accelerator at Darden School of Business. They incorporated in 2017, and now work in a small warehouse-style space near downtown Charlottesville. Babylon has 14 employees and $3 million in seed funding, including a grant from the National Science Foundation, and venture capital from Virginia, Washington, DC and Silicon Valley. They have dedicated these first couple years to building and testing the product, landing a few early clients for feedback. These include UVA, Dominion Energy, and some local restaurants, schools and country clubs.

But their ambitions go well beyond central Virginia. Olesen said the first major act of scaling is currently underway, with Babylon installing their farms in major corporate restaurants, cafeterias, resort hotels, and grocery stores. Because such institutions thrive on b-to-c relations, they would benefit from the experiential component of a modular farm. Rather than just saying they use organic food, they can show customers where and how it’s being grown.

“This has the additional value of being able to show your customers that you care about those things,” said Smith. “If it’s growing 10 feet from the table, that’s pretty clear.”

Babylon believes that their technology can increase the biodiversity of produce available to consumers in urban areas, so they place a lot of emphasis on the underlying plant science required to grow crops using their machines.

“One of the most exciting things about hydroponics is the amount of blue ocean space, it’s theoretically possible to grow any plant this way, yet only a handful of crops have successfully been commercialized,” said Olesen.

Babylon has a controlled environment test facility in Charlottesville where plant scientists run trials on seed varieties from around the world, dialing in tailored growth recipes to produce higher yields and consistent flavors. Their technology consists of an array of sensors and utilizes camera vision to create an automated feedback loop that analyzes the data to increase the rate at which growth recipes can be developed. In doing so, they plan to learn how to grow heirloom crop varieties and reintroduce them to the supply chain, leading to more options for chefs and consumers alike.

In the long run, Babylon plans to use their modular vertical farming platform to build larger farms capable of growing the majority of fresh produce for their clients. They envision micro-farming becoming an amenity in urban areas located in, or adjacent to, all grocery stores, foodservice operations, and food distribution hubs. These companies now get their supply from different farms nationwide, then process, package and sell it to consumers. The benefit to them of growing it onsite would be to significantly reduce perishability, which now wipes out 50% of food, much of it during the transport process, which can be over 1500 miles from farm to fork in the U.S. Not to mention the emissions generated by such a long supply chain.

Users scan crops into the farm, and Babylon remotely manages the growth cycle for them through... [+]

“Initially, we’re focused strictly on the b-to-b market, and utilizing these farms to grow food for companies with a known means of consumption or distribution,” said Olesen, while walking me through the facilities. “The next step…is creating these farms as a means for people to sell.”

This latter vision makes modular micro-farming seem like a viable future urban food source. Land owners in dense cities struggle to find the right surface lots to convert into vertical or horizontal farms. But Babylon’s 15sqft machine provides an adaptable solution that can work with existing infrastructure by slotting into unused space throughout urban areas.

Other companies have, for this reason, embraced small modular micro-farming. Ones like Cityblooms and Zipgrow focus on slightly larger, more commercialized modular units. However, small scale urban farms have faced a scalability issue; the technology that is commercially available only allows for basic automation, but lacks any feedback that would enable these farms to learn how to operate more efficiently. The most direct competitor to Babylon is InFarm, a Berlin-based startup that operates in Europe. They have created a system similar to Babylon’s, which has gathered momentum with installations in grocery stores across Europe. It’s an exciting prospect to think of indoor farms in grocery stores here in the U.S.

If any or all of these companies can make modular micro-farms a standard provider of fresh produce, it has the potential to disrupt the current supply chain - from manufacturers down to individual households. It would be an environmentally-friendly way to increase crop yields, reduce emissions, and feed people in the future. If it becomes a city phenomenon, in particular, it could be key to improving urban resilience across the U.S.

I am the owner of a media company called The Market Urbanism Report. It is meant to advance free-market policy ideas in cities. The Report features multiple articles daily, along with a video series that explains urban issues from street level. I’m also a roving urban affairs journalist who writes columns for Forbes, Governing Magazine and HousingOnline.com. For three years, I'm circling America to live for a month each in 30 cities, starting from Miami and ending in New York City. The point is to write a book about revitalizing cities through this Market Urbanism concept. But my articles cover other city subjects too. I have also written for the Wall Street Journal, Atlantic, American Interest and National Review. You can find my work at MarketUrbanismReport.com.

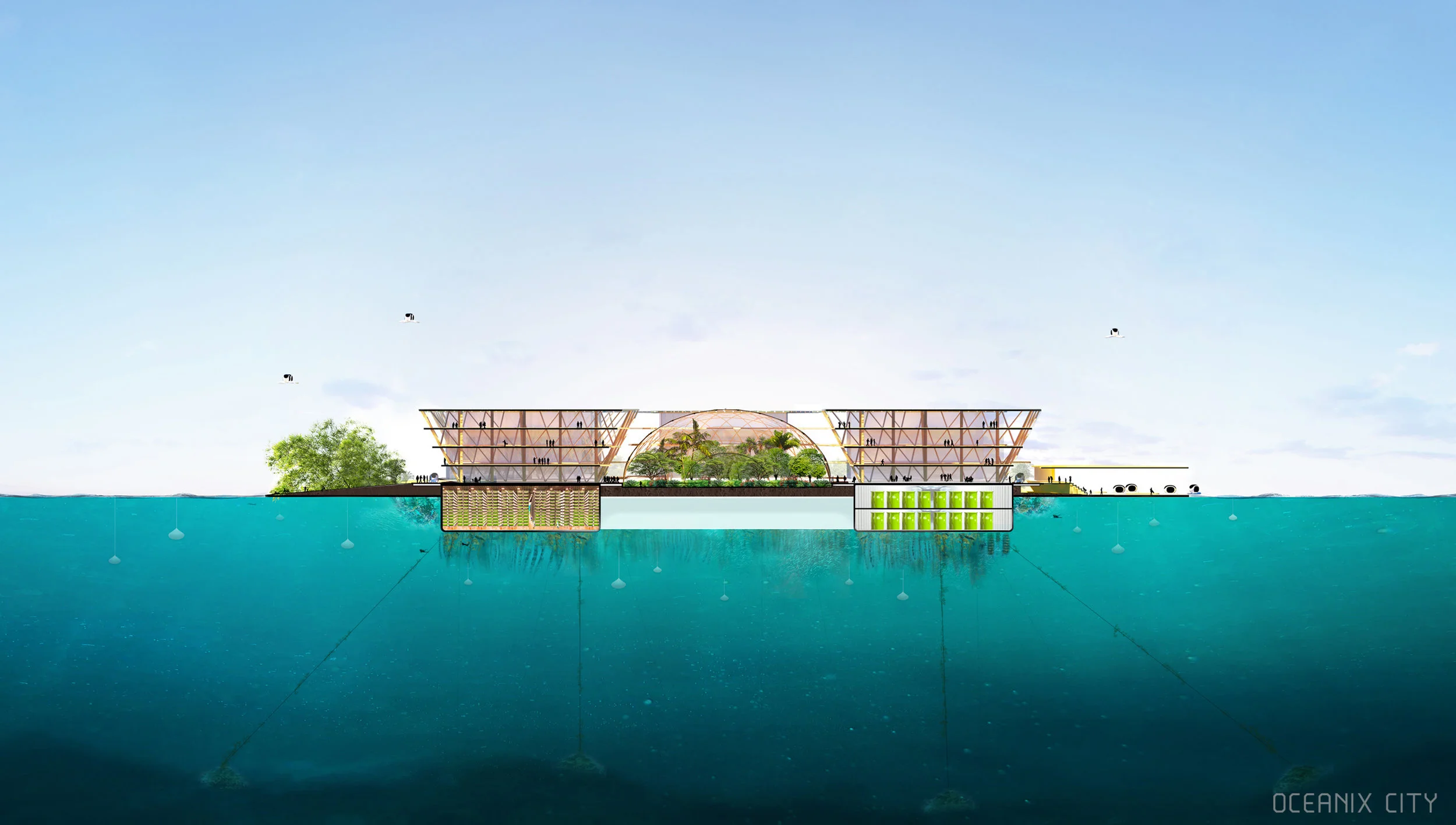

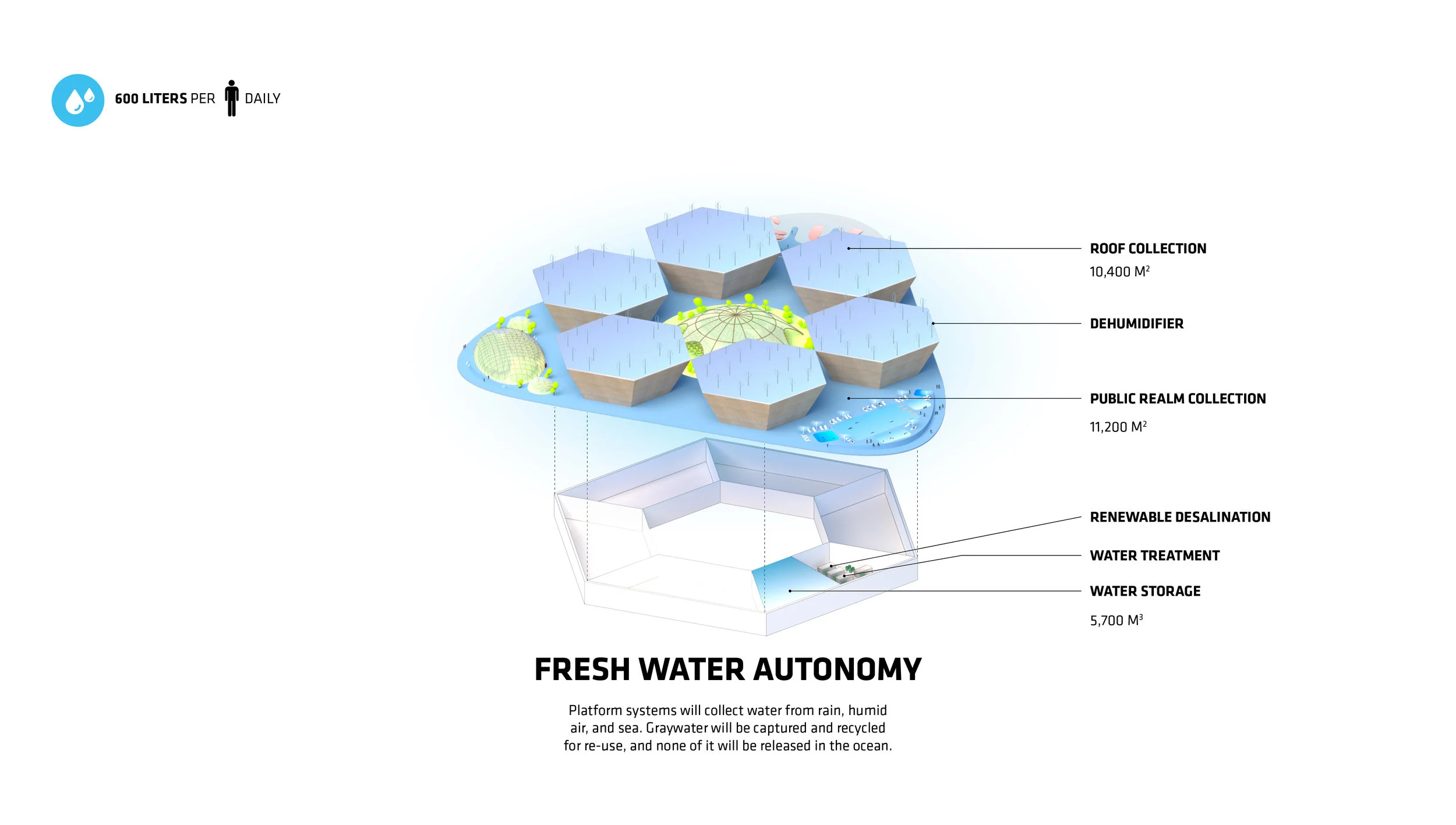

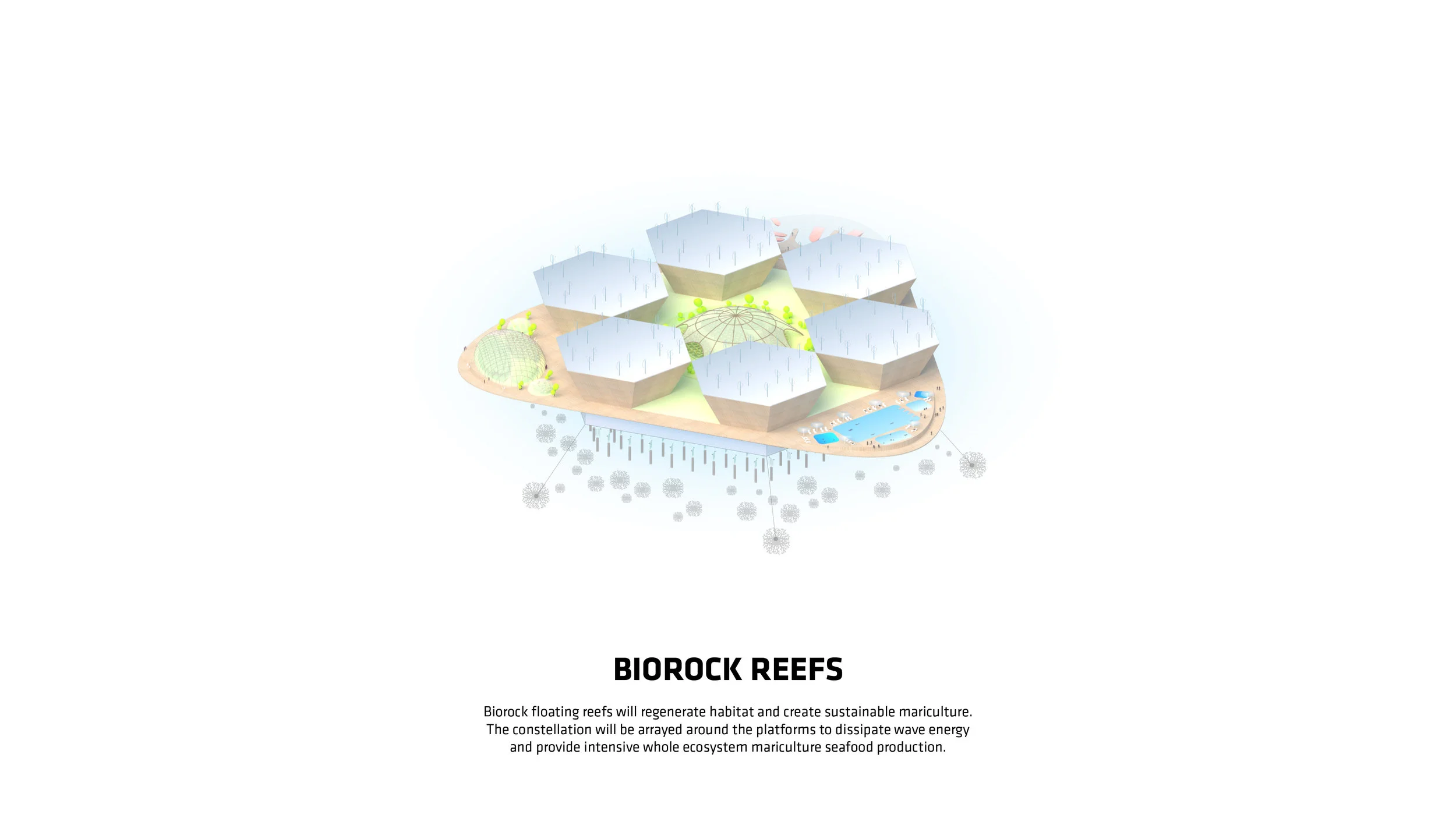

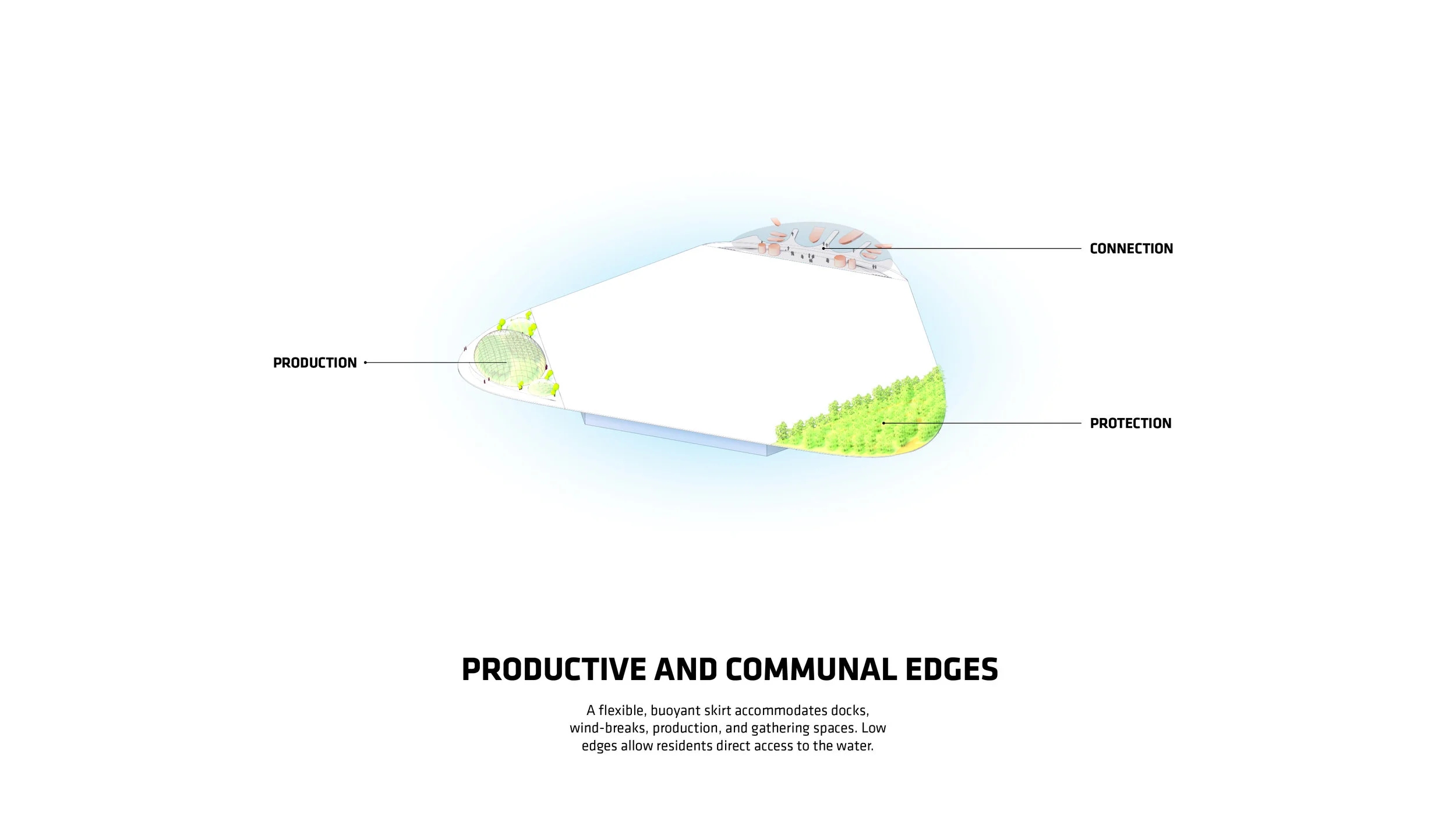

Oceanix City: This Concept Of Floating City Includes Food Production And Farming

Linked by Michael Levenston

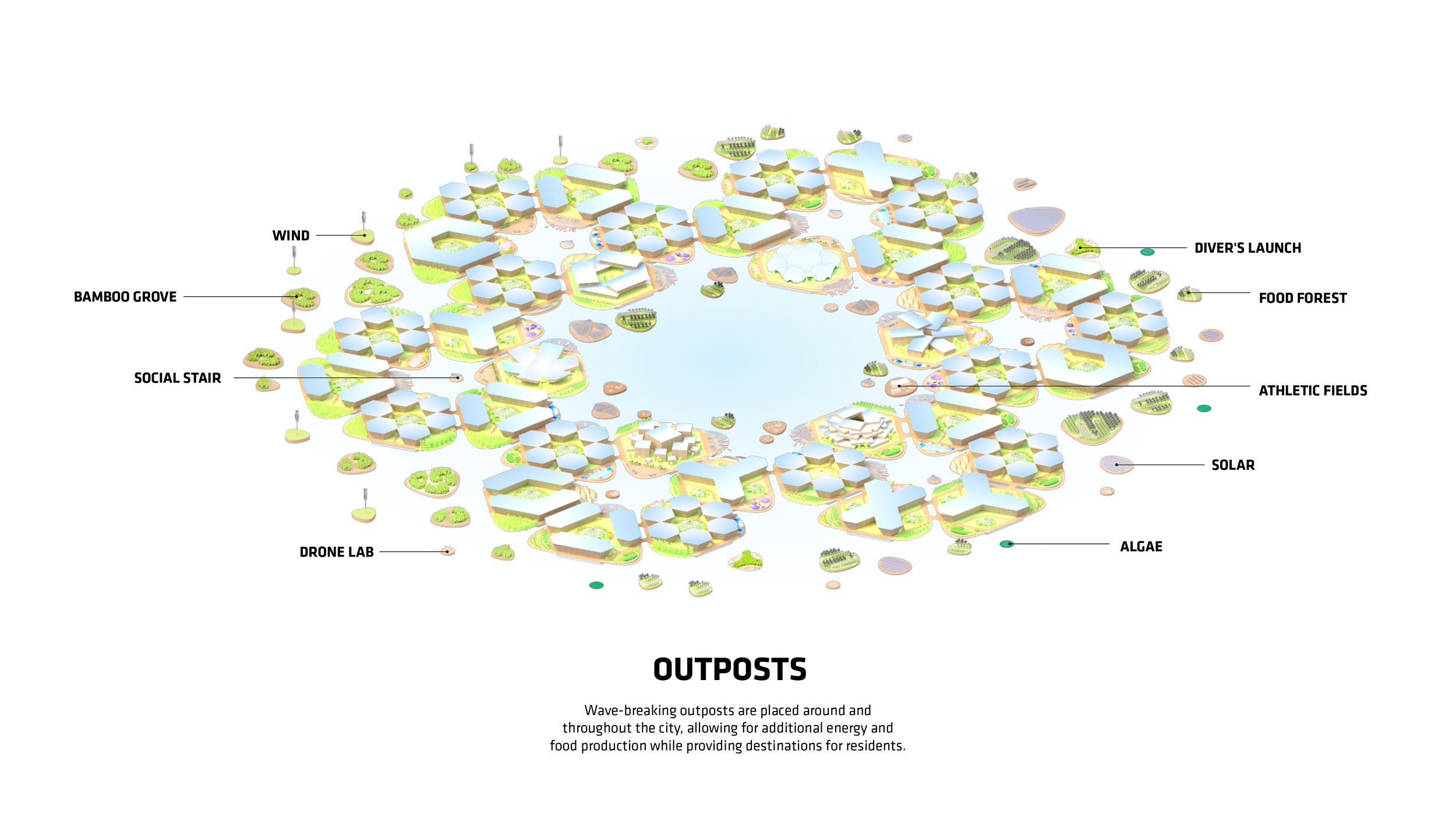

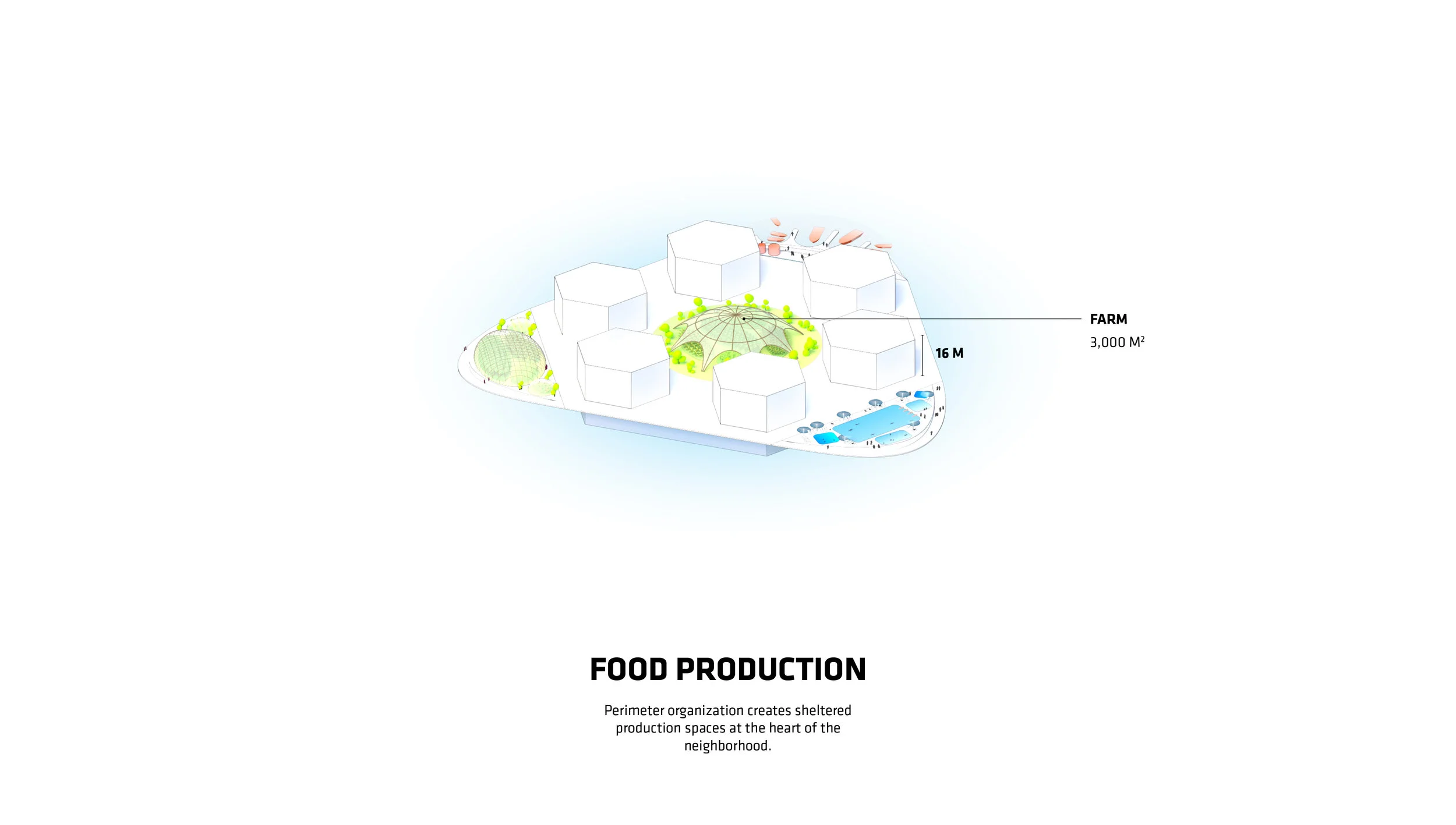

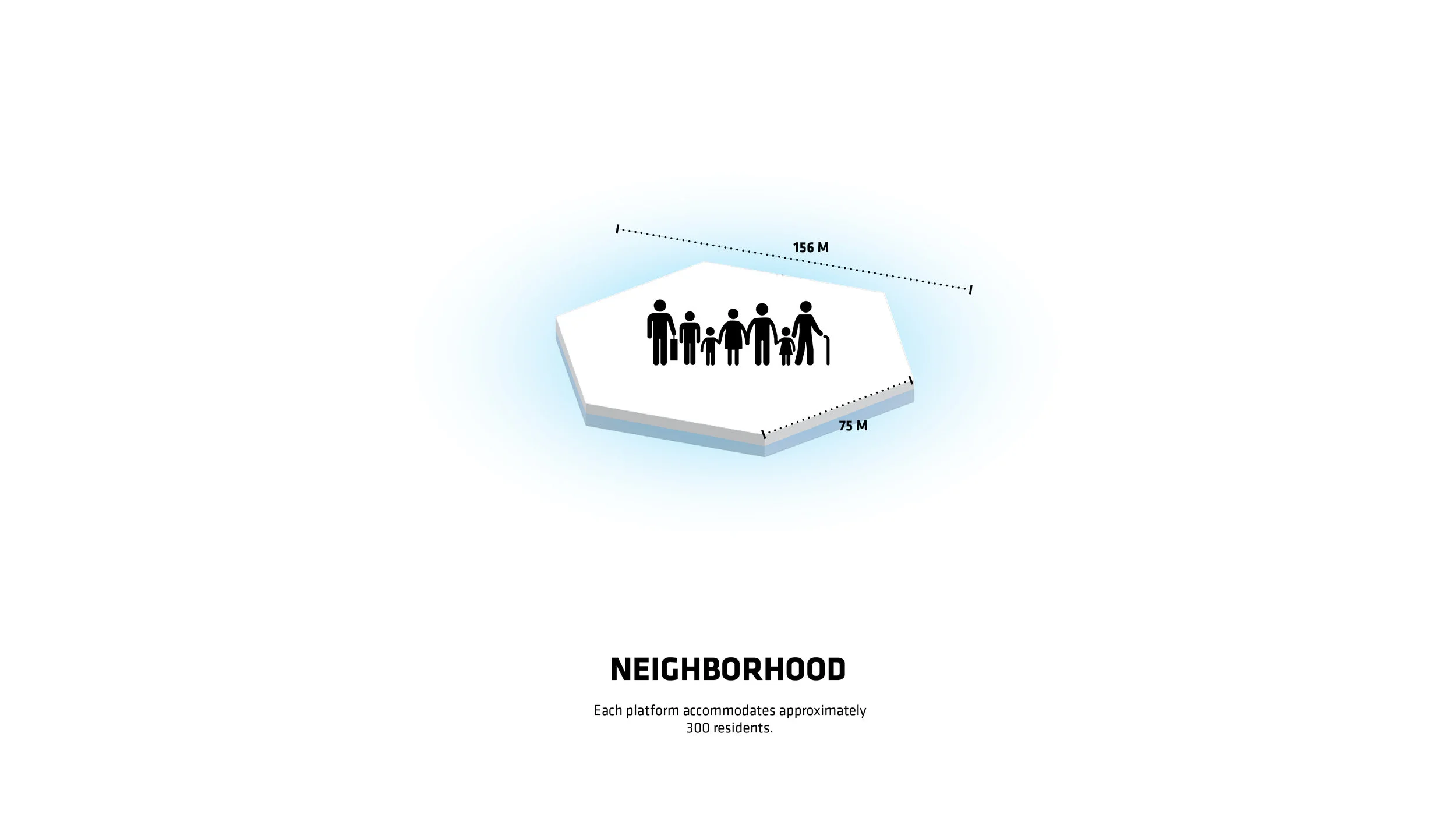

“Every island has 3,000 square metres of outdoor agriculture that will also be designed so that it can be enjoyed as free space,” said Ingels.

By Katharine Schwab

Fast Company

Apr 4, 2019

Excerpt:

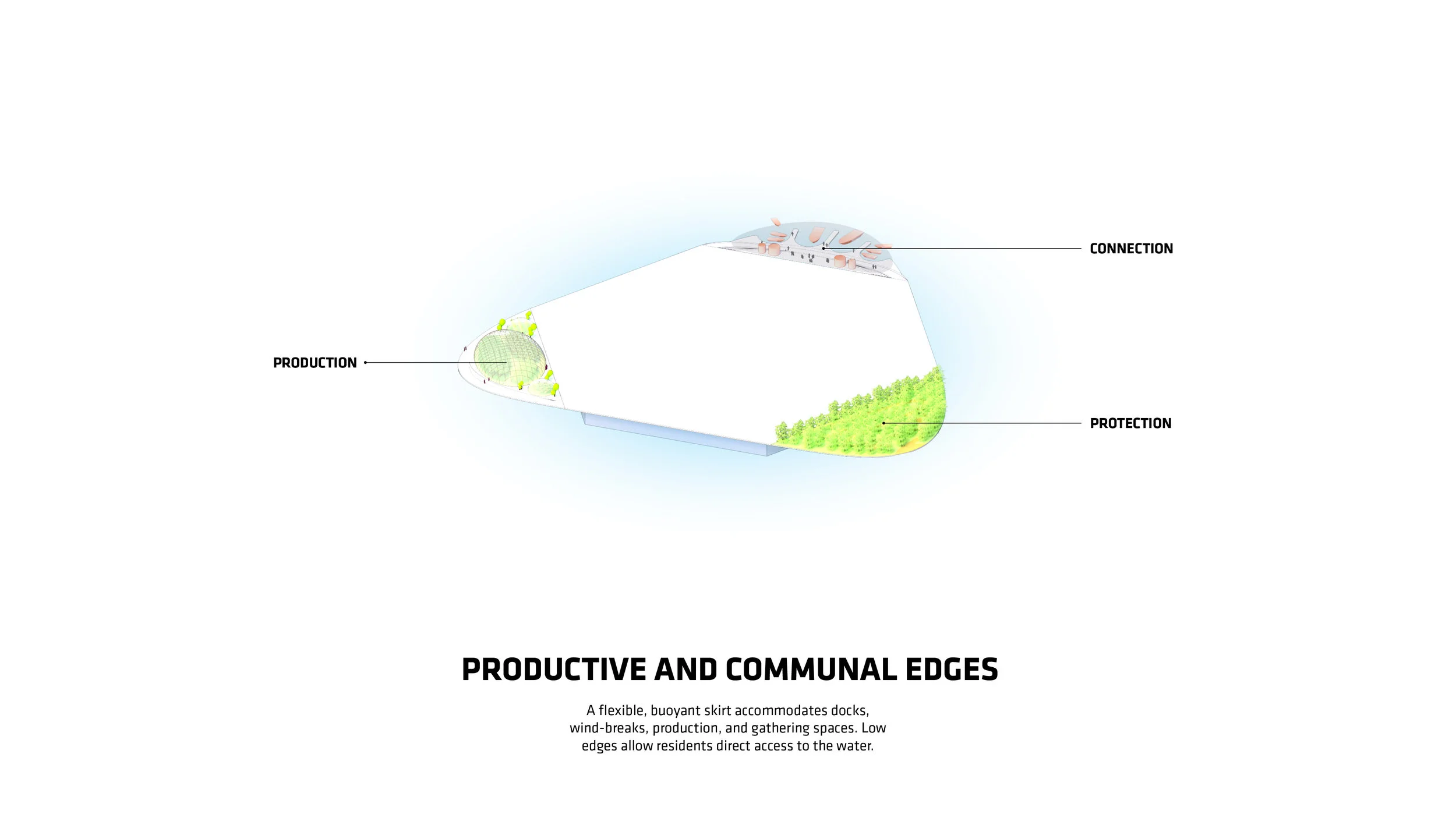

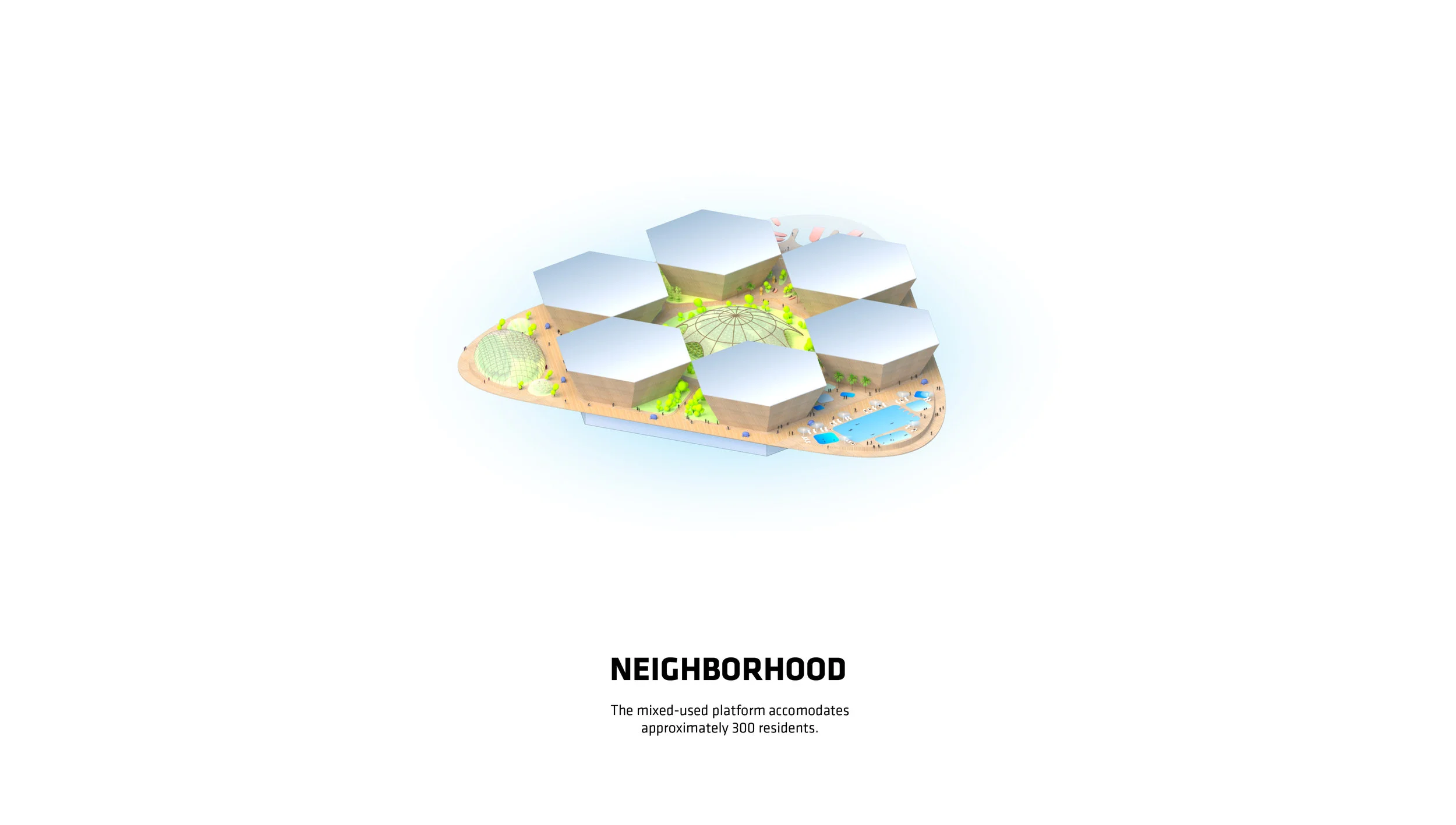

For Oceanix’s idea to work, all the food needed to feed every person living in the floating city would need to be grown there. What does that mean? There’s certainly no meat involved, mostly because beans are a far more efficient way of getting protein. Some crops would be grown outdoors–an estimated 32,000 square feet on each hexagon would be devoted to food cultivation. Much of that would be outdoors, since the sun uses the least amount of stored energy, and the crops would double as green space for residents.

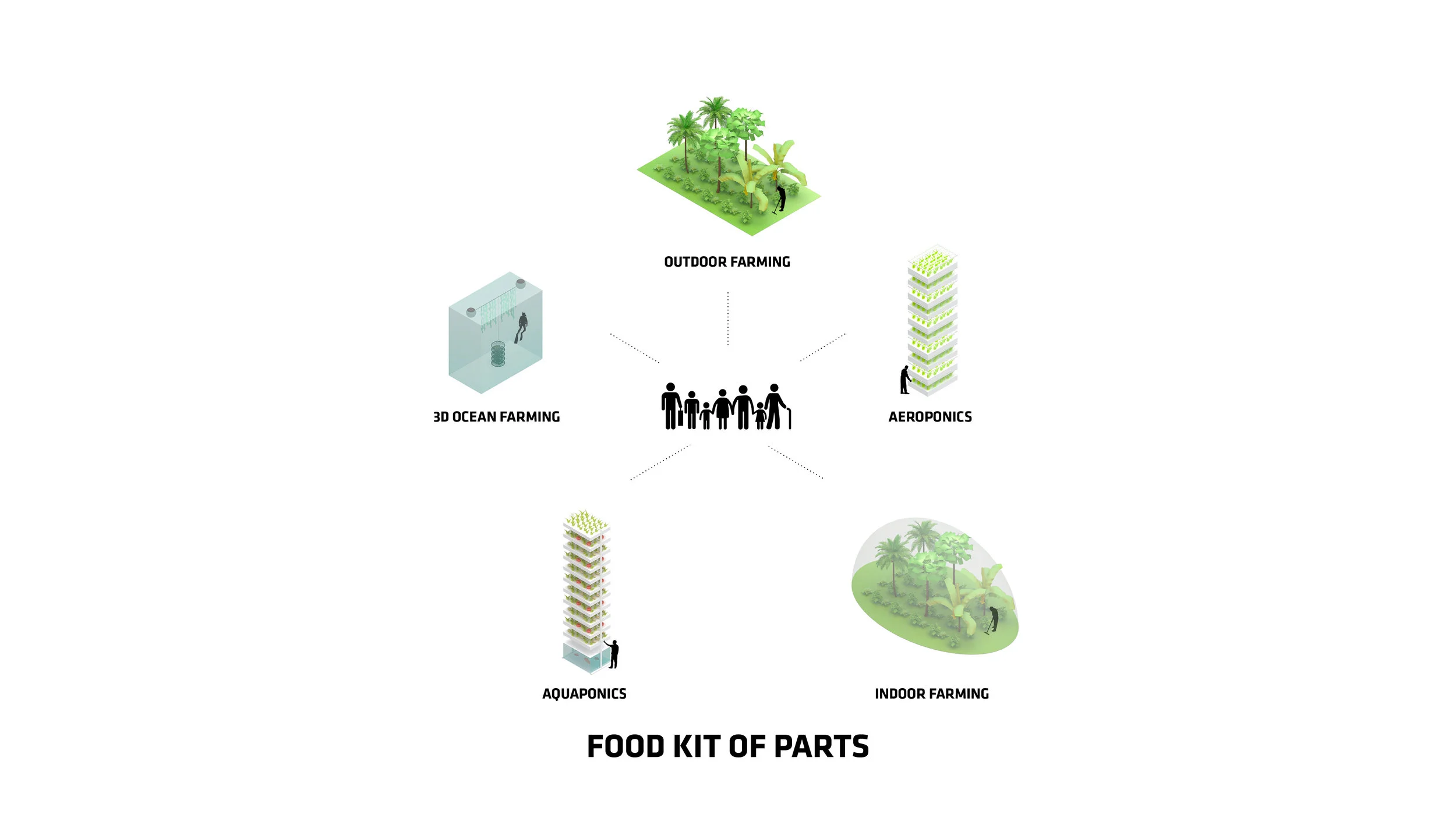

But according to Clare Miflin, the cofounder of the Center for Zero Waste Design, a floating city would also need to experiment with other ways of growing food. One possibility: outdoor vertical farming for crops like lettuce. Then there’s hydroponics and aeroponics, the latter of which uses 10 times less water than traditional farming simply by spraying plant roots with mist. Aquaponics, in which plants grow hydroponically and are fertilized with fish waste, has a deep precedent–the Aztecs used aquaponic farming on their own floating agricultural islands many centuries ago.

With food comes food waste. Miflin wants to create a circular system where all food waste is turned into nutrients for the soil through composting. Food waste would go through a pneumatic system of pipes directly to an anaerobic digester to start the composting process. But there’s also the problem of packaging. Miflin believes that it would be crucial for the floating city to only use reusable food containers, with centrally located drop-off points for people to put their empty containers; from there, they could be cleaned centrally and reused.