Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

AUSTRALIA - VIDEO: Shipping Container Farm Teaching TAFE Students More Than Just Agriculture

Nestled beside a building on a TAFE campus in Toowoomba is an ugly metal shipping container, but it's no ordinary storage shed

August 16, 2021

By Lucy Cooper

Nestled beside a building on a TAFE campus in Toowoomba is an ugly metal shipping container, but it's no ordinary storage shed.

Key points:

TAFE is using a shipping container farm to teach students about alternative farming

All features of the farm are controlled by an app

Agriculture, hospitality, and IT students are using the "grow pod" in their studies

Step inside and it's bursting with greenery.

Packed floor to ceiling with vegetables and herbs like basil, kale, mint and mustard, this state-of-the-art modular farm is changing the future of agriculture, all with the push of a button.

TAFE Queensland school manager Elaine Wallace said the "grow pod" aimed to change students' perspectives on traditional farming.

"Often when people think about agriculture, they think, 'Oh, I don't want to go stand in the sun all day picking vegetables, that's a bit too dirty for my liking," Ms. Wallace said.

"This is just one of those technologies that really enables students to get involved in something different and something up and coming."

Student Kallia Stebbins said when she first saw the vertical farm she was amazed by the technology.

"I didn't realise that you can grow crops like this, compared to just out in the middle of a field," she said.

"Now that I've seen this, it's very cool. I'm very interested to learn more about it."

A farm controlled from the palm of a hand

The container farm is controlled remotely with an app.

To switch the lights on inside, Ms Wallace simply whips out her phone.

"If we have a look at our monitors, it tells us that our irrigation cycle has started up, so we can set the cycle to however long or short we need it," she said.

"It's drip irrigation from the top filter through to the bottom and it's caught in the gutter that is at the bottom.

"We have pumps that will feed nutrients into the water and then, of course, we've got our lights, which are LED lights, and they are also set on a timer, so they are grow lights."

'Absolutely no limits'

It's not just agricultural students reaping the benefits of the multidisciplinary project.

Information technology students studied the app controlling the farm, while electrical students looked at how the farm kept running.

Hospitality and cookery teacher Nev Siebenhausen said his students also gained valuable first-hand experience in paddock to plate catering.

"For our students, it's a great opportunity to obviously shorten up the duration and travel on the product," he said.

"It's great for our guys to see different ways it can be grown."

Mr Siebenhausen said the walk up the hill from the grow pod to the hospitality school reduced carbon miles and cut waste by 70 percent for produce like basil, which had a short lifespan.

Any leftover produce is donated to the food relief charity, Oz Harvest.

Talks are also underway to trial sensory herbs for community service students to study the calming effects on people.

"The possibilities are endless," Ms. Wallace said.

Where Does Our Lettuce Really Come From?

“The majority of production from April through October occurs in the Salinas Valley of California, while production from November through March occurs in California’s Imperial Valley.”

According to www.keepcaliforniafarming.com, more than 90% of the U.S. production of lettuce comes from either California or Arizona. The website also tells us: “The majority of production from April through October occurs in the Salinas Valley of California, while production from November through March occurs in California’s Imperial Valley.”

This shouldn’t really come as much of a surprise to folks who understand that the majority of leafy greens, and indeed most vegetables need a warm climate to thrive and grow. And that’s why California, Arizona, Texas, Florida, and states with similar climates are successful in agriculture.

The U.S. is the second-largest user of lettuce after only China (which makes complete sense based on population), but when we look at lettuce consumption and production as an example, we can see why vertical indoor farming can be such a great way to supplement what we eat.

The same website gives us quite a few facts about lettuce that we may never have thought of including that Americans consume on average, 30 pounds of lettuce each per year. That’s because lettuce is healthy, used in a variety of ways, and well, it just plain tastes good to a LOT of consumers both here in America and almost everywhere else. It’s nutritious, low in calories, generally healthy, and has a lot of varieties that can be consumed in a number of salads and other dishes. Americans have also become more accustomed to having choices in both restaurants and supermarkets. The days of relying just on iceberg lettuce are long gone. Today consumers are aware of less mainstream varieties or cultivars and they want to not only experience those cultivars but enjoy them on a routine basis. We have, in a word become “picky” about something as simple as a leafy green lettuce.

So let’s say that 90+% of the U.S. lettuce production is in California and Arizona, but we know that those two states only account for a small percentage of the U.S. population. How does the rest of America get their lettuce? The answer for most folks is by truck. So, the lettuce, like many vegetables in the U.S., is grown in California and shipped across the country - usually by a tractor-trailer. Of course, this has historically been the way to do things, and likely will be for the near term, but that transportation comes with its own set of challenges and increasing costs. For example, we read all the time about shortages of qualified truck drivers, the increasing cost of fuel that we can all see, the increase in salaries due to the worker shortage, and so on. What this means is that supplies to other parts of the country coming from the west coast may be inadequate to meet demand - especially if demand is increasing due to people wanting to eat healthier.

The USDA Specialty Crops Truck Rate Report published August 4, 2021, showed slight shortages of lettuce in Atlanta, Baltimore, Boston, Chicago, Dallas, Miami, New York, and Philadelphia. Keep in mind that this may only be termed as “slight shortage” but also this is a report for August and August is a month when it should be relatively easy to produce large amounts of lettuce - even outside of Arizona and California. So why the shortage? And, if a slight shortage now, what happens at other times of the year when the growing season isn’t exactly peak for other parts of the U.S. outside of California and Arizona?

Of course, the answer is that the “slight shortage” can very easily become more of a real shortage during times when other areas can’t produce lettuce to supplement that which comes out of Arizona and California. Factor in the increased cost of transportation, spoilage that is inevitable when a food source is harvested and then must be transported long distances, and other factors that can be catastrophic in nature and may include droughts, fires, floods, etc. and it becomes a compelling argument that growing indoors more closely to where a product is consumed can be very appealing.

Also, growing vertically in a controlled environment will help to lessen the chances for something to be introduced into the crop that isn’t wanted. Think about the E.coli scares that we have seen in the past several years. While diseases can be introduced into a crop at the seed level and so indoor farming is not 100% a safeguard against something like E.coli, it does help to mitigate many of the factors that might influence such a malady.

Vertical farming then can play a significant role in where our lettuce or other vegetables or plants come from both now and well into the future. By growing products close to the source of consumption, the product is fresher, should theoretically be cheaper over time, and should taste better with much less spoilage. As an added bonus, the lettuce can be grown year-round without herbicides and pesticides so it actually can be a cleaner form of plant than even something termed “organic.”

So, where does our lettuce come from today and where will it come from tomorrow? At HYVE they are helping to construct an infrastructure that hopefully answers that question in a way that will lead to great outcomes for all within the supply chain and also those ultimately eating the lettuce.

Visit www.growhyve.com to learn more about the indoor farming systems being produced. While they are not likely to supplant traditional farming in the short term, the systems are compelling for their advanced automation, accelerated ability to produce crops, and mostly for their ability to make growing local something that can happen anywhere. Again, we ask the question - Where does our lettuce really come from? We should also bookmark that question to ask a few years down the road because the answer may be very different.

ANCHORAGE, ALASKA - CityFarms Is Hiring!

We are in need of another Operations Associate! The job mostly entails running the ongoing operations of the farm

We are in need of another Operations Associate! The job mostly entails running the ongoing operations of the farm.

Things like harvesting, packaging, planting, delivering to stores, and managing the crops.

We are always trying to continuously improve what we do and are hoping to find great people with that same drive.

Our goal is to become the largest food producer in Alaska and we have a long way to go!

We are currently a team of six and are excited to find people who are passionate about the same things we are.

If you are interested, click the button below and message us! We look forward to hearing from you.

Contact Us!

Pinduoduo Launches 2021 Smart Agriculture Competition To Spearhead Agriculture Modernization And Sustainability

Contestants will take a multidisciplinary approach, applying nutrition science, precision farming, and other relevant technology to cultivate tomatoes. The winners will be judged on yield, nutritional value, environmental sustainability, and commercial viability

August 09, 2021

Source: Pinduoduo Inc.

SHANGHAI, China, Aug. 09, 2021 (GLOBE NEWSWIRE) -- Pinduoduo (NASDAQ:PDD), China Agricultural University, and Zhejiang University jointly announced the launch of the 2021 Smart Agriculture Competition, an agricultural technology competition with the aim of fostering innovation and promoting agricultural modernization.

Contestants will take a multidisciplinary approach, applying nutrition science, precision farming, and other relevant technology to cultivate tomatoes. The winners will be judged on yield, nutritional value, environmental sustainability, and commercial viability. The competition is open to young agronomists and computer scientists from around the world and offers a total prize pool of more than 1 million yuan ($154,000).

Registration for the competition will end on Sept. 9, 2021. Teams can register through the competition website (https://smartagricompetition.com/register). A total of 15 teams will be shortlisted by the judging panel to present their plans. The four teams with the highest scores will proceed to the final round of the competition.

Now in its second year, the Smart Agriculture Competition is led by Pinduoduo, China Agricultural University and Zhejiang University, with technical guidance from the Food and Agriculture Organization of the United Nations (FAO) and Wageningen University & Research. The Yunnan Academy of Agricultural Sciences and representative agencies from the Netherlands, Switzerland, and Denmark have also provided strong support. Leading agritech companies including Bayer Crop Science, Ridder Group, and Omron have lent their industry expertise and advanced solutions to the competition.

Pinduoduo is organizing the annual competition as part of its support for global efforts to improve and modernize the agri-food system through technology. As China’s largest agriculture platform serving 824 million consumers, the company has made agriculture a central part of its mission to improve the way food is grown, transported, and sold.

“The driving force for the improvement of the agricultural industry comes from the development and application of cutting-edge technologies,” said Andre Zhu, Senior Vice President at Pinduoduo. “As China’s largest platform for agriculture, we want to play our part to improve food security and quality in a sustainable way.”

For the 2021 Smart Agriculture Competition, the judging panel is composed of leading experts and growers with diverse backgrounds including horticulture, crop modeling, algorithm design and policymaking. Tomato experts from China, the Netherlands, and Denmark will provide guidance to the participating teams.

The competing teams will be judged not just on yield but also on the nutritional value and environmental impact of their farming methods. This is in line with Pinduoduo's strong commitment to environmental sustainability, food quality and food safety.

“The Smart Agriculture Competition plays a unique role in that it aims to foster innovation that is usable by smallholder farmers, who produce around 80% of the food in China,” said Tian Jianhui, Vice President of China Agricultural University. “It is an important platform for the different stakeholders in the agri-food ecosystem to come together to develop practical, cost-effective, and environmentally sustainable solutions for working farms.”

In last year’s inaugural competition, the four technology teams employed data analysis, intelligent sensors and greenhouse automation to grow strawberries, producing 196% more fruit by weight on average compared with experienced farmers. Two of the technology teams have started to commercialize their technology after the competition, resulting in real-life gains in productivity for local farmers.

"China’s farming sector will undergo tremendous change, making the leap from traditional agriculture to modern agriculture,” said He Yong, Dean of Biosystems Engineering and Food Science College of Zhejiang University. “The Smart Agriculture Competition has encouraged more forces to push the industry forward together.”

Pinduoduo has gone from zero to over 800 million customers in just six years, making it the world's largest agri-focused tech platform. It is unique among other large internet companies to make digitizing the agriculture industry a core and strategic priority. Pinduoduo is also actively evaluating global opportunities to solve food safety and food security issues.

"Technology is transforming agriculture and food production. It is extremely important to implement the digital transformation of agriculture and improve food safety," said Carlos Watson, the FAO Representative to China. “FAO provided technical support to the Smart Agriculture Competition last year. We are looking forward to another successful collaboration to bring farmers real benefits through digitalization."

About Pinduoduo Inc.

Pinduoduo is a mobile-only marketplace that connects millions of agricultural producers with consumers across China. Pinduoduo aims to bring more businesses and people into the digital economy so that local communities can benefit from the increased productivity and convenience through new market opportunities.

For more information on Pinduoduo news and industry trends, please visit the content hub at https://stories.pinduoduo-global.com.

For media inquiries, please contact internationalmedia@pinduoduo.com

USA - FLORIDA: Brick Street Farms Was On A Podcast!

What an exciting opportunity we had this week to sit down with Feeding Tampa Bay to record a podcast episode about how we grow our produce and our dedication to sustainability

Farm in a Box with Shannon and Maddy of Brick Street Farms

What an exciting opportunity we had this week to sit down with Feeding Tampa Bay to record a podcast episode about how we grow our produce and our dedication to sustainability.

We also got a chance to discuss how our non-profit organization, Desert Farms, is partnering with them to work towards a hunger-free Tampa Bay. Click below to listen to the full podcast.

Listen

A Manufacturer And A Food Caterer Among New Players Feeding Singapore’s Urban Farming Boom

“We want to bring indoor farming into something more precise, where you calculate the least input for the best output. That is precision farming,”

Tang See Kit

@SeeKitCNA

11 Aug 2021

SINGAPORE: In a small room tucked away on the second floor of a precision engineering factory in Tuas, pots of kale and lettuce stacked in vertical racks grow under the glow of pink-purple lights.

These light-emitting diode (LED) lights have been designed to shine at a customized spectrum that will help crops grow better. Smart sensors also keep tabs on temperature and humidity in the room, while a special water treatment system reduces bacteria growth.

In here, the goal is to find the best way to farm vegetables indoors, all with the use of technology.

“You can control everything, even how much nutrients or water is being used for each plant,” said Mr. Nelson Lim, co-founder of I.F.F.I, which stands for Indoor Farm Factory Innovation.

“We want to bring indoor farming into something more precise, where you calculate the least input for the best output. That is precision farming,” he told CNA.

Mr. Lim is also the chief executive of precision engineering firm TranZplus Engineering, which is the parent company of I.F.F.I. TranZplus’ two-story office in Tuas now houses both a manufacturing facility for semiconductor components and a farming showroom.

“A lot of people ask me: ‘Nelson, are you crazy? You’re in engineering, why suddenly do farming?’ Actually, the two are not unrelated. We can put our engineering skills to good use in indoor farming,” Mr. Lim said while demonstrating the farming racks that can be adjusted according to height and size.

Robotics is another expertise that the company has incorporated into its farming solutions to not just improve the yield and quality of crops, but also workflow efficiencies.

For instance, automated machines that can perform seeding, transplanting, potting and harvesting tasks will be put to work at I.F.F.I’s mega indoor farm when ready at the end of this year.

(Left to right) I.F.F.I's general manager Veronica Lee, chief operating officer Kelvin Ng, and co-founder Nelson Lim. (Photo: Tang See Kit)

SEEDING A DIVERSIFICATION

TranZplus’ venture into agriculture was first seeded in 2016 when it became one of the vendors for Panasonic’s indoor farm in Singapore.

“Initially, they just wanted to have a rack. Then we thought why not have racks that can be customized, why not put in an irrigation system and other types of automation?” Mr Lim recalled. “We worked out a prototype and they were impressed.”

The company kept on with research and development after that, while being involved in setting up three other small-scale farms. In 2019, it decided it had gained enough experience to give it a shot.

Mr. Lim said the decision to venture into indoor farming was driven by “strong business potential”, partly on the back of Singapore’s “30 by 30” goal to produce 30 percent of the country's nutritional needs locally by 2030.

The COVID-19 pandemic has accentuated the potential, with global disruptions to the harvesting, shipping, and sale of food making it even more important for the country to have its own resources. Indoor farms can be the solution, he added.

Last September, I.F.F.I. became one of the nine urban farms to secure grants totaling S$39.4 million from the Singapore Food Agency.

Its 38,000 sq ft indoor farm, which remains under development at the JTC Space @ Tuas, will be using a soil-based cultivation method that allows more vegetable varieties to be planted.

When operational, the mega farm will be able to produce 800 to 1,000kg of vegetables, like nai bai and spinach, per day, said Mr Lim.

Another new player on the field is food caterer Kitchen Haus, which co-founded “farm-to-table” concept brand Frux Earth a few months ago.

With its core business facing a slow recovery amid the pandemic, the company has been diversifying actively in search of new opportunities over the past year.

Agriculture is “not unrelated territory”, chief executive Patrick Chan said. “It’s still part of the food ecosystem so when the opportunity came, I agreed instantly.”

It teamed up with home-grown urban farming company Metro Farm for the new venture. With the latter’s expertise, the farms under Frux Earth – three sites spanning 60,000 sq ft – are powered by an aquaponics system that converts fish waste into nutrients for the vegetables.

For instance, its 12,000 sq ft rooftop farm atop an industrial building in Bendemeer has eight fish tanks with red tilapia and jade perch. These fishes were chosen for their hardiness and ability “to produce more waste”, said Metro Farm’s director Chris Toh.

“We have a filter to separate the fish waste, which is then broken down by bacteria. Our system will then keep the nutrients flowing to the vegetables 24/7,” said the farm’s other director Brandon Toh, who added that the system is “self-sustainable” and keeps costs low.

The Bendemeer farm, with its 720 vertical plant towers, can harvest more than 30,000 stalks of vegetables, including purple lettuce and kale, a month. The fish will also be sold once they reach table size.

Mr. Chan said: “This is a breath of fresh air for us and we pivoted because we want to jump on the trend of food sustainability.

“I think Metro Farm sees the value in us having the know-how of food preparing, catering, and retail. And we partner them because it’s not easy to set up a farm and they are the experts.”

Metro Farm’s director Chris Toh (left) and Kitchen Haus' chief executive officer Patrick Chan (right) joined hands to form a new urban farming company Frux Earth. (Photo: Tang See Kit)

OPPORTUNITIES AND CHALLENGES

Metro Farm, which started its first farm in Kranji almost nine years ago, noted that the local agriculture sector has become “much more vibrant”.

While the presence of new and bigger players means greater competition, the increased attention has also made it easier for businesses to secure farming sites in land-scarce Singapore, including vacant rooftops on both public and private buildings.

“In the past, we have to explain what is a rooftop farm and what we are doing but now, more landlords are opening up to the idea,” said Mr. Brandon Toh, although he noted that not all rooftops are suitable given the need to take into consideration the additional loads of farming.

Frux Earth has plans to open three more urban farms over the next few months.

Its “farm-to-table” menu is in the works as it ramps up its crop production, while it is also gauging the interest for a weekly vegetable subscription service, said Mr. Chan.

These “culture boxes”, as they are called, will be filled with 1 to 2kg worth of freshly harvested organic vegetables and delivered to the doorsteps of customers every week. For now, it has started supplying a few restaurants located near its farm at the Marina Country Club.

Frux Earth is planning to launch a weekly vegetable box subscription service. (Photo: Frux Earth)

Over at I.F.F.I, the protracted pandemic and its impact on labour and supplies of raw materials have caused some delays at its mega indoor farm which was initially scheduled to open in the middle of this year.

“We are catching up and hopefully we can have everything ready soon,” said Mr. Lim. “Certainly, costs have also gone up with the increase in raw material prices, but we are managing that."

Meanwhile, the company is working on opening an “indoor farm pro-shop”.

“There will be a mini-farm set up for visitors to understand and raise awareness about indoor farming,” said I.F.F.I chief operating officer Kelvin Ng.

“If they like what they see and want to start their home cultivation system, they will also be able to purchase everything they need at the shop. We will even have consultants ready to guide you. It will be a one-stop shop about indoor farming.”

I.F.F.I. also sees opportunities beyond Singapore where they can serve as consultants or designers to those looking to set up indoor farms. For instance, in Russia where crop production is a challenge due to the cold climate.

Its technologies can also be deployed in “bite sizes” even in traditional food-producing countries as solutions to specific problems, such as water pollution.

Mr. Ng said: “There are many opportunities emerging in the space of indoor farming, and we want to be bold and seize them.”

Source: CNA/sk(cy)

Lead Photo: I.F.F.I, an affiliate of precision engineering firm TranZplus Engineering, is looking to open its mega indoor farm in Tuas by the end of this year. (Photo: Tang See Kit)

GLASE Webinar Series

This short presentation will cover the history of research on photosynthetic responses to light spectrum, recent work on the importance of far-red photons, and a discussion of the implication of (not) extending the definition of PAR

The photosynthetic activity of far-red photons was discovered 70 years ago, but has largely been ignored since then. Recent research has drawn new attention to the importance of far-red photons.

This short presentation will cover the history of research on photosynthetic responses to light spectrum, recent work on the importance of far-red photons, and a discussion of the implication of (not) extending the definition of PAR. There will be ample time for discussion following the presentation.

Register Here - August 26 • 2-3 p.m. EST

USA: VIDEO: Veteran Finds Peace, Purpose In Unique Kind of Farming

John Miller's routine may seem a bit "scaled-down" compared to his former life as a combat soldier. Miller spends much of his time in a 40-foot-long shipping container converted into a hydroponic farm field. Hydroponics involves growing plants without soil.

KENTUCKY

August 2, 2021

LOUISVILLE, Ky. — As John Miller prepared to leave the Air Force, the combat veteran admits he had no idea what he was going to do next.

What You Need To Know

John Miller served 14 years in the Air Force

The Louisville resident is the owner of Falls City Farms

Miller has found peace and purpose in hydroponic farming

In the future, Miller hopes to expand and employ fellow veterans

John Miller's routine may seem a bit "scaled-down" compared to his former life as a combat soldier. Miller spends much of his time in a 40-foot-long shipping container converted into a hydroponic farm field. Hydroponics involves growing plants without soil.

A close-up of Miller's baby kale. (Spectrum News 1/Jonathon Gregg)

“In essence, we sell a lot of things what we would consider baby," Miller explained. Little white turnips is just one crop of many growing inside Falls City Farms. “Right now I’m just pulling off the plug to turnips and then clean up any of the leaves."

The Iraq War combat veteran grows, prunes, packages, and sells a variety of greens to Louisville restaurants, online and at local markets.

“Here is our wasabi arugula, this is one of our fresh herbs, our dill, this would be our romaine trio," Miller said while touring his indoor farm.

Scaled-down? Maybe, but the hydroponic farm has helped Miller overcome what can be a sizable challenge for soldiers adapting to life after service.

“I got into this post-military, trying to find my next thing because I didn’t know what I was going to do when I got out," Miller said.

Miller served 14 years in the Air Force. His wife Amy is still active with 17 years to her credit. In his pursuit to figure out the next chapter of his life, Miller learned about hydroponic farming from a marine veteran in San Diego.

Falls City Farm grows a lot of produce in just 320 square feet. (Spectrum News 1/Jonathon Gregg)

His operation encompasses 320 square feet and boasts 6,600 individual plant spaces. Crops grow thanks to a sophisticated watering system and good-old-fashioned artificial sunlight.

“Because we are in a shipping container, the plants and the crops don’t get any of the big yellow sun outside so we have to create that inside," he said. "So we do LED lighting because it is better from an energy standpoint as well as heat."

Miller has lots of time and enough room to think about his life as a soldier and his new career as a farmer.

“If I am being frank with you, I miss being surrounded by other airmen and folks I used to lead," he said. "But it is calming to be in here with the plants and at the end of the day, that’s one of the reasons I chose this path.”

He was after peace and a purpose, and now his purpose includes bringing other veterans aboard.

“A lot of veterans, as we know, suffer from trying to find that next mission. Hopefully, one day soon be able to bring fellow veterans in here to teach them the art of farming through hydroponics to help them find peace and purpose as well," Miller said.

At first, Falls City Farms may appear to be a small operation, it’s only until you spend time on the inside do you see all the big ideas growing.

“I fell in love with the sense of a day’s accomplishment of work, a sense of comfort of being inside a greenhouse," Miller said.

Roto-Gro Set To Blast Into Space With Food Production System

Roto-Gro is capitalizing on the space exploration boom, as it applies to a NASA challenge developing novel food production technologies to feed astronauts on long-term missions

Advanced Agritech Company Roto-Gro International (ASX: RGI) Is Aiming To Feed The World’s Astronauts.

August 9, 2021

Roto-Gro is capitalizing on the space exploration boom, as it applies to a NASA challenge developing novel food production technologies to feed astronauts on long-term missions.

Advanced agritech company Roto-Gro International (ASX:RGI) is aiming to feed the world’s astronauts as it capitalizes on innovations in food production systems and a boom in space exploration.

Roto-Gro World Wide (Canada), a wholly-owned subsidiary of Roto-Gro International, has applied to the Deep Space Food Challenge as part of its first step into the space agriculture sector.

Administered under an international collaboration between National Aeronautics and the Space Administration (NASA) and the Canadian Space Agency (CSA), the international competition aims to incentivize the development of novel food production technologies needed for long-development space missions and terrestrial applications.

Roto-Gro’s application highlight’s the technological diversification and adaptability of its patented proprietary indoor vertical farming technology.

Astronauts’ food needs changing as missions evolve

Astronauts currently receive food from spacecrafts regularly launching from Earth, for example to the International Space Station.

However, NASA and the CSA recognize that as the distance and duration of space exploration missions increase, the current method of feeding astronauts will no longer be sustainable.

Future astronauts will be required to use food production systems on their voyages and be self-sustaining. The challenge aims to inspire the agricultural industry to help bring innovative food production technologies to space, reducing the need for resupply from earth and ensuring astronauts have continuous safe and nutritious food supplies.

The ability to develop sustainable food production is considered the crucial next step for longer-term human presence on the lunar surface and the future missions to Mars.

The challenge is not only about space exploration but also missions in extreme arid and resource-scarce environments on Earth. Like space, input efficiency will be key, including the efficient use of water and electricity to reduce resources needed for food production here on Earth.

Adapting Roto-Gro’s existing models key to space success

A new Roto-Gro rotational garden system — branded Roto-Gro Beyond Earth — will be designed with engineering adapted-off components from its existing Model 420 and Model 710 rotational garden systems.

Roto-Gro Beyond Earth will be a smaller, more portable version of the Model 420 but feature the injection feed system from the Model 710, significantly reducing the required resource inputs while maximizing nutritional outputs when compared to other indoor farming technologies.

Roto-Gro CEO Michael Di Tommaso said Roto-Gro Beyond Earth will enhance the already existing, unique benefits of its rotational garden systems, optimizing both the operational efficiencies and yield per m2, which is crucial to the development and prospective use of food production systems in space.

“The technology developed to form the application to the challenge is astoundingly demonstrating the vast applicability and sheer innovation of the company’s technology,” Di Tommaso said.

He said the company had developed several key relationships with organizations currently providing food system solutions for long-duration space voyages, along with others focused on using space to solve problems we are experiencing on earth.

“We look to develop and foster these relationships moving forward, further strengthening our position in the sector,” Di Tommaso said.

He said entering the space agricultural sector was a natural progression for Roto-Gro, supporting its vision to provide sustainable technological solutions for agricultural cultivation, critical to ensuring global food security.

“Food system innovation is crucial to our progression in space, and we are excited with the prospect of moving to the next phase of the Deep Space Food Challenge, while also generating other opportunities to develop and implement Roto-Gro’s technology in the industry,” Di Tommaso said.

Roto-Gro global forecasts international growth

Established in 2015, Roto-Gro is continuing to attract interest on a global scale.

The company recently partnered with agriculture company Verity Greens Inc. who has signed a binding $10M Technology License to purchase 624 RotoGro Model 710 rotational garden systems, with the first, flagship indoor vertical farming facility to be built in Canada.

The deal is expected to generate long-term, sustained recurring revenue with Di Tommaso hailing it as not only a “win-win” for both companies but a venture that works on a socially responsible level by helping tackle global food shortages.

“RotoGro will introduce our revolutionary technology into the booming indoor vertical farming space, while Verity Greens, utilizing the RotoGro Garden Systems and supporting technology, will operate with a viable and cost-effective competitive advantage,” he said.

“Verity Green’s first facility also serves to further its objectives – to roll out indoor vertical farming facilities globally utilizing RotoGro’s technology, not only to generate substantial revenue for both companies but also to provide a truly sustainable solution to address the issues caused by food insecurity.”

Lead photo: Pic: Giphy

This article was developed in collaboration with Roto-Gro International, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Crazy Poet Discovers Solution To Vertical Farming Challenges

How on earth are we going to be able to make vertical farming a viable solution without disrupting the cities we live in

August 10, 2021

Lawrence Ip

Facilitating Workforce & Leadership Transformation Through Organisational Governance.

Keep Reading & The House Gets Bulldozed!

Dramatic I know (it's just one of those things). Nope, I won't be making myself homeless as I do actually need a roof over my head. What I also need is to get this crazy idea off my chest before I do actually lose my mind.

You see, I was watching a documentary a while back, about future cities, off the back of a few others that were about farming, global warming and the looming food crisis, and they got me thinking about vertical farming, and the issues the industry sector faces - namely scale.

That was the first thing that struck me.

How on earth are we going to be able to make vertical farming a viable solution without disrupting the cities we live in it, why heck, according to Pew Research world population is pitted to hit 10.9 Billion by 2100, with more and more folks migrating to cities. This begged a flurry of questions such as:

How are we going to feed everyone, and where on earth are we going to put the vertical farms that are supposed to feed them?

Will they really be able to provide the quantity of fruit and vegetables sustainably?

How much will they cost to build?

How much will they cost to run and maintain?

How do we store, pack and deliver the product?

What infrastructure does it require to make it work?

What about the effect on traffic?

What about the load bearing issues of weight on the structure of the farm, the actual building?

How on earth do we face the challenges facing vertical farming?

Don't get me wrong, I see incredible value in vertical farming and it could prove to be the answer to so many of the challenges we face ahead, because as we all know the way in which we produce the food we consume, and waste, is just not sustainable - not in the slightest. The globe's arable land is fast diminishing, and at the current rate the entire globe will be facing starvation soon after 2060 - it's a travesty just waiting to happen (if you haven't watched it yet I can highly recommend watching), Kiss The Ground, it's the documentary that got me started on the quest for answers.

A few weeks ago I woke up in the middle of the night, I had an epiphany.

Prior to going to sleep, I asked myself, what is the single most pressing problem you could solve that would provide the best bang for the buck?

When I woke from that sleep the answer came to me, it came down to answering the last question, which fundamentally is a design question.

Having previously watched a documentary series on super-structures, and thinking about logistics and transportation, it dawned on me that it was not a, how on earth question, but rather a let's go to sea proposition.

I jotted down these two words on the trusty notepad I keep bedside...

"... container ships."

That's right, container ships!

Don't be fooled into thinking that what you see is what you get. What you see on the top deck is just part of the picture, container ships have just as much, if not more storage in their lower decks.

It was like WOW! It makes complete and total sense, well at least to me it does. Let's outline the reasons why container ships could be the perfect vertical farm.

Container ships are designed to bare the types of load required in the design of a vertical farm.

You can move container ships around.

Container ships can have desalination plants built in.

They are freaking massive.

They can be even more massive. Fun fact: when the size of a ship is doubled, it increases the surface area by only 25%.

Transportation logistics is a non-issue.

No need to reinvent the wheel. It wouldn't take much to repurpose container ships that have been decommissioned.

Repurposed ships equals no scrap metal.

Access to the energy required to run them is at hand.

Image Credit: Bernd Dittrich - UnSplash.

That pretty much sums it up, and hey, I'm no expert, but yes, I am a poet, and it really doesn't matter whether I'm certifiable or not, I have at the very least put the idea out there. All I ask of you, is that before you send the men with the straightjacket around, that you consider the idea as a viable solution before discarding it. If anything I hope it provides some inspiration, maybe a spark of some out-of-the-box thinking of your own and I sincerely hope you found the read entertaining too. Thank you for making it this far. I'd love to hear your thoughts and ideas. Do you have a crazy vertical farming solution you'd love to get off your chest? Please feel welcomed and leave your thoughts below. Peace ✌

Image Credit: Bailey Mahon - UnSplash.

#verticalfarmingchallenges #arablelandcrisis #foodcrisis #circulareconomy

Lead photo: Image Credit: Torben - UnSplash.

Published by: Lawrence Ip

Crazy Poet Discovers Solution To Vertical Farming Challenges. hashtag#verticalfarming hashtag#containerships hashtag#crazypoettimes hashtag#sustainability hashtag#agriculture hashtag#environment hashtag#innovation hashtag#climatechange hashtag#circulareconomy hashtag#design hashtag#energy hashtag#arablelandcrisis hashtag#foodcrisis hashtag#kisstheground hashtag#verticalfarmingchallenges

PODCAST: This Weeks Episode - Season 3 Episode 39

Join Harry Duran, host of Vertical Farming Podcast, as he welcomes to the show, CEO and co-founder of Fifth Season, Austin Webb

Join Harry Duran, host of Vertical Farming Podcast, as he welcomes to the show, CEO and co-founder of Fifth Season, Austin Webb. Fifth Season is a consumer tech company and indoor farming pioneer with Carnegie Mellon University roots that is creating a new era of fresh foods. Its commercial-scale indoor vertical farms use proprietary robotics, AI, and smart operations technology to grow leafy greens and herbs at affordable prices year-round.

Today, Harry and Austin talk about the origin story of Fifth Season, the relationship he has with the city of Braddock, and how Austin initially got involved in vertical farming. Austin expounds on the concepts of smart manufacturing and pest pressure and speaks to the learning curve he’s experienced as a first-time CEO. Finally, Austin speaks to the mission of Fifth Season and what excites him most about his future endeavors.

Listen & Subscribe

Projected Water Scarcity Prompts Need For Farming Ingenuity

Emerging technologies are quickly trying to find ways to get the most bang for each drop of water. Efficiencies have been identified, including vertical hydroponic farming, which drastically reduces the amount of water needed to grow crops

Posted by chrismichlewicz

July 31, 2021

The common refrain that freshwater is the next gold is ringing true as drastic changes in our climate are resulting in greater competition and a need for more efficient water uses, especially in the agricultural industry.

National Geographic points out that while the amount of fresh water on the planet has remained fairly constant over time — continually recycling through the atmosphere and back into our oceans, lakes, and rivers — the global population has exploded in the last century. This means that competition for a clean supply of water for drinking, cooking, bathing, and sustaining life intensifies every year. There is only so much water to go around.

Essentially, when taking saltwater into account, only about .007 percent of the Earth’s water supply is usable for the planet’s 6.8 billion (and counting) people, National Geographic says.

The vast majority of freshwater — about 70 percent by most estimates — is used for agriculture, and when you consider that feeding a planet of 9 billion people in 2050 will require an estimated 50 percent increase in agricultural production and a corresponding 15 percent increase in water withdrawals, the future becomes a lot clearer, according to World Bank.

Without proper governance, there is likely to be increased competition for water between sectors and an escalation of water crises of various kinds, triggering emergencies in a range of water-dependent sectors, according to a U.N. report.

Emerging technologies are quickly trying to find ways to get the most bang for each drop of water. Efficiencies have been identified, including vertical hydroponic farming, which drastically reduces the amount of water needed to grow crops. FarmBox Foods, a Colorado company that builds automated hydroponic farms inside repurposed shipping containers, has set its sights on creating a tangible shift in the approach to farming.

FarmBox Foods’ innovative, closed-watering system only uses 3-5 gallons of water per day and, almost as important, it does not contribute to groundwater contamination the way that traditional farming does. Furthermore, one farm is able to produce the same yield as 2 – 2.5 acres of farmland on an annual basis.

“Our container farms are built in such a way that it takes only a fraction of the amount of water to grow that same amount of produce,” said Rusty Walker, CEO of FarmBox Foods.

Climate change is projected to increase the number of water-stressed regions and exacerbate shortages in already water-stressed regions. It’s those regions that will realize the most benefit from vertical hydroponic farming and more efficient water usage in general.

An integrated view on water, the biosphere, and environmental flows is necessary to devise sustainable agricultural and economic systems that will allow us to decelerate climate change, protect us from extremes and adapt to the unavoidable at the same time, the U.N. says.

The automated hydroponic farms have a secondary benefit, as they can grow pine trees that contribute to the overall health of the environment by helping reduce the amount of carbon dioxide in the atmosphere. One container farm from FarmBox Foods can grow 35,000 tree saplings per year.

For more information, go to www.UNwater.org or www.FarmBoxFoods.com.

Posted by chrismichlewicz on July 31, 2021 in Arapahoe County Business, Douglas County, Douglas County Business, Featured, Greenwood Village Business

Tagged #farmboxfoods, agriculture, cleanwater, Colorado, containerfarm, containerfarming, environment, farmboxfoods, freshwater, indoorag, indoorfarming, UN, Water, waterscarcity, watershortage, watersupply, waterusage

Freight Farm To Teach Youth About Sustainable Agriculture

Beyond School Bells is partnering with the Bay in Lincoln for a new after-school program that will teach students about sustainable ag technology. "We really see Freight Farm as kind of that key, climate-change impervious tool that young people need to know about as we face an uncertain future," said Jeff Cole, Network Lead for Beyond School Bells

by Nicole Weaving

July 24th, 2021

LINCOLN, Neb. — Beyond School Bells is partnering with the Bay in Lincoln for a new after-school program that will teach students about sustainable ag technology.

"We really see Freight Farm as kind of that key, climate-change impervious tool that young people need to know about as we face an uncertain future," said Jeff Cole, Network Lead for Beyond School Bells.

An old shipping container in the parking lot of the Bay has been transformed in a self-contained hydroponic farm.

Using red and blue LED lights, this Freight Farm, known as the Greenery, creates a climate-controlled environment, where the plants grow vertically without a need for soil.

"We enrich the water with nutrients that would normally be in the soil," said Colton Harper, Organizing Manager for The Greenery. "And then in these grow walls, we've got spickets that come right through these foam and it's directly onto the roots of the plants."

Inside of the Greenery with the red and blue LED lights on. (KHGI)

According to Harper, there are currently about 6,000 plants growing in the Freight Farm, but at full capacity, it can hold 13,000 plants between the seeding area and that walls. That would produce the equivalent of a 2.5-acre farm year-round.

"Even in the winter, if there are shortages anywhere, we can turn on a dime, 7-week grow cycle and be able to provide those crops for local markets," said Harper.

The Greenery arrived in Lincoln in April, and Harper has led to two teams to get it up and running. They are currently preparing for their first harvest with items like basil, lettuce, and radishes.

"We're at about Week 7, and in 2-3 weeks, we'll have our produce at a farmer's market," said Harper.

After a few more grow cycles, the program will open to local students to teach them all aspects of sustainable farming.

"From the electrical side, the growing, the programming, computer science to the irrigation, the HVAC system, there's so many elements," said Harper. "And we're particularly well-placed with the Bay and their digital design area of focus, the students will also be able to design the packaging, design the labeling, so it's really a full-circle, interdisciplinary opportunity for the students to get involved."

The Greenery plans to hold a Harvest Party to celebrates the farm's success in the coming weeks

Step Away From That Screen And On To Our Expanded Expo Floor

There's nothing like an in-person event for getting a first-hand look at the latest product innovations. So step away from that computer screen, step onto our expo floor and see live product demonstrations...Touch new products...Ask questions and gather feedback from company execs and peers in the booth

BIGGER, BETTER EXPO FLOOR OFFERS PERFECT ZOOM FATIGUE FIX!

(And some pretty great solutions for your business, too)

There's nothing like an in-person event for getting a first-hand look at the latest product innovations. So step away from that computer screen, step on to our expo floor and see live product demonstrations...Touch new products...Ask questions and gather feedback from company execs and peers in the booth.

We've significantly expanded our expo floor to bring you even more top names, established best-sellers and promising start-ups. See the latest in lighting, operating, automation and control systems, growth chambers, seed treatments, plant nutrition, greenhouse & hydroponic supplies, substrates, pest control, irrigation, equipment & design resources and so much more from companies like:

LEARN MORE

YOUR TWO-DAY INDOOR AG-CON EXPERIENCE PACKAGE

Indoor Ag-Con is so much more than an event. It's an experience! And one you don't want to miss. Hear from 70+ speakers, network with industry peers, see the latest product innovations. Then, head back to your operation armed with actionable ideas and profitable strategies that promise to grow your business!

Register before our Early Bird Rates end on August 16, 2021 to save up to $300 on our full access pass. And if your plans change, no worries! Passes are completely refundable prior to September 27, 2021, and include:

All Keynotes, Morning Conference Sessions, Afternoon Panels

Expo Floor Access

Welcome Gift Bag

Complimentary On-Demand Access to In-Depth, 2-Day "Financing Indoor Ag Seed To Scale" webinar

White Paper From The Packer & PMG presenting the latest research on indoor growing & sustainability

Lunch Daily

Show Floor Cocktail Receptions

Event App

Access to Indoor Ag-Con Library

REGISTER NOW & SAVE UP TO $300

OUR SAFETY PROMISE

Your health and safety are priority one at Indoor Ag-Con Orlando.

Rest assured that the Indoor Ag-Con team is closely monitoring the

guidelines issued by the CDC, state and local officials. We're working with our venue partner, Hilton Orlando, to provide you with a safe and

productive environment to conduct business.

SPECIAL THANKS TO OUR INDOOR AG-CON SPONSORS,

MEDIA & MARKETING ALLIES

Indoor Ag-Con, 3834 Silvestri Lane, Las Vegas, NV 89120, United States

Central Minnesota Research Project Growing Kale Indoors

The project is a partnership with Todd-Wadena Electric Cooperative, Central Lakes College, Lakewood Health System, Great River Energy and the Electrical Power Research Institute

The project is a partnership with Todd-Wadena Electric Cooperative, Central Lakes College, Lakewood Health System, Great River Energy, and the Electrical Power Research Institute.

Written By: Rebecca Mitchell

July 21, 2021

Central Lakes College research analyst Noah Boetler shows a panel of kale plants in the Sota Grown pod during a virtual tour on July 13, 2021. Rebecca Mitchell/Pioneer Journal

STAPLES, Minn. — A community research project in Staples involving indoor gardens is set to continue growing.

The hydroponics project started in 2020 with Great River Energy, Todd-Wadena Electric Cooperative, and the Electrical Power Research Institute hoping to learn new technology and increase access to fresh produce. And even with kale as the chosen plant, local organizations rooted for the success of the hydroponics pod. The pod, planted at the Central Lakes College Staples campus, is a shipping container with room for 5,820 kale plants.

“I didn’t know how things were going to grow in here, it’s kind of a weird concept with there being no sunlight and things like that, so just seeing it go from a little seed to your big plant and harvesting it, I think that has been the coolest aspect,” CLC research analyst Noah Boelter shared with Minnesota educators in a virtual tour on July 13.

The partnership is called "'Sota Grown" and has helped develop a fully enclosed hydroponic container for growing fresh plants all year long — to supplement existing agriculture practices in communities across the state.

The pod, equivalent to one acre of crops, is a supplement to traditional farming, not a replacement, as TWEC member service manager Allison Uselman said. Although kale is the focus of the two-year project, the team has experimented with growing basil, swiss chard, lemon balm, and chives. Romaine lettuce, butterhead lettuce, and salad mixes are next on the list — and after a year of only kale, Boelter is excited for the new opportunities.

Each kale seed, planted by hand, starts in the nursery before being transplanted to vertical panels. The kale takes 12 weeks to reach maturity. The team of four staff members and interns plant and transplant on Wednesdays and harvest on Mondays.

“Kale is pretty forgiving, which is very fortunate for us,” Boelter said after sharing about a frozen pump during the winter. The kale wilted and bounced back in a matter of days. The team is also learning about flooding and nutrient dosing in the pod.

With the expected growth of indoor agriculture, Uselman said electrical companies will need to prepare for the change. For example, the pod uses the most energy when most other customers could have off-peak rates. The light and water systems run from 4 p.m. to 8 a.m. daily. The kale is watered for five minutes every 45 minutes. The electricity is about $600 a month.

“It’s education with students, it’s giving back and feeding our communities, and Todd-Wadena has the opportunity then to research all the electrical side of things and really understand this industry before it grows to a larger state,” Uselman said.

The pod’s water usage depends on the humidity levels outside, with the most water used in the winter — about 10.5 gallons every day—and about five gallons a day in the summer. The two water tanks deliver water above the panels and water behind the plants. There are also several different nutrients added, such as one to adjust pH levels.

“In the summertime, the pod does not use a whole lot of water because the HVAC unit has a dehumidifier built into it and that’s recirculating around a gallon of water an hour that gets dumped back into the pod, so it’s really efficient in the summer,” Boelter explained. “But when it’s winter, the air is so dry that’s when we use the most water.”

The indoor pod means the ability to regulate the temperature, which is a cool 65-68 degrees and having no pesticides or herbicides used on the plants since most bugs remain outside. There are some drain flies due to the algae.

The red LED lights in the Sota Grown pod at Central Lakes College are the only source of heat. The lights and water run from 4 p.m. to 8 a.m. daily. Rebecca Mitchell/Pioneer Journal, July 2021

As for sunlight, the LED lights are the only heat source in the pod, as Boelter said, though it is also insulated. The red and blue lights support stem growth and leaf density.

The process yields about 20 pounds of kale a week — and on a record week 43 pounds — or over 1,000 pounds as of July 5. All of the kale is donated to Lakewood Health System, who shares the kale through the Food Farmacy and Hilltop Regional Kitchen. The Kitchen uses the kale in specific meals for those who have tested positive for COVID-19 and people being discharged from the hospital. People can also receive free kale at the summer farmer’s market on Thursdays.

As Lakewood’s Community Health Coordinator, Amy Wiese works with about 70-100 bags of kale a week to find where it can best be served. She said the kale lasts about two weeks in the fridge.

People also receive kale recipes for new ways to enjoy the vegetable. Wiese enjoys massaging the kale to break down the bitterness and then eating it in a salad. Other favorites are kale chips and soups.

“We just see the benefits of this project and recognize the positive impact that healthy food can have on individuals and in the community,” Wiese said. The organizations also hope to address local food deserts. “It’s really amazing that we are able to provide fresh produce all year with this pod” even with snow on the ground for six months of the year.

The seeds grown and sown in the community have finished their process with new seeds set to germinate, grow to maturity, and be harvested and packaged in four to eight hours for their short drive up the road.

Photo: 1 - The kale seeds are planted in peat moss plugs and stored in the nursey for three weeks before being transplanted to the indoor panels. The planting process takes about an hour. Submitted photo

Photo: 2 - The shipping container contains an acre of kale growing hydroponically with LED lights. Photo courtesy Todd-Wadena Electric Coop

Photo: 3 - Each section has 22 panels with space for 5,820 kale plants or the resemblance of one acre of crops. Rebecca Mitchell/Pioneer Journal, July 2021

Malaysian, Smart Farm That Grows And Delivers Organic Vegetables

“The pandemic has underscored the urgency of building better food production, including fresh vegetables. Customers are increasingly aware that food choices influence both the health and the health of the planet,” the team concluded

July 15, 2021

7 years. It’s how long the farm lasts with 5G BoomGrow it has existed, but it has not always been so efficient. Founders Jay, Murali, and Shan had initially explored different cultivation methods, from simple hydroponics to aquaponics.

Image Credit: Founders of BoomGrow

“We grew our greens in small boxes. We even tried to grow them outdoors. Nothing worked, ”Jay recalled in an interview with Vulcan Post.

This trial and error lasted for five years until the co-founders discovered AI-driven vertical agriculture. With this method, they realized that they could also grow their greens in a controlled indoor environment that would make harmful chemicals such as pesticides unnecessary.

Finally, they had found it the method that allowed them to properly achieve their goals of producing clean, tasty greens.

Using 95% less resources to get the same performance

“Our systems detect how diverse contributions like the light, the water, and the pH affect the quality and the flavor of our plants. That’s what we call our plant recipes, ”said Shan.

“We then rely on machine learning and data analysis to tailor each entry to the respective plant, producing tastier greens.”

The team says its system equipped with technology is Machine Farm. It is used in all reused BoomGrow shipping containers where crops are grown on modular plant racks.

According to the team, five piles of crops on a 360-square-foot plot can produce a yield that is the equivalent of the traditional harvests of a 1-acre outdoor farm.

With this technology and efficient use of space, they can grow 20 varieties of leafy vegetables and herbs in a residential neighborhood of Ampang.

At the same time, Jay said Machine Farm uses 95% less land, water, and fuel than traditional outdoor farms.

Its technology-based agricultural approach has seen BoomGrow achieve multiple milestones, from being the country’s first 5G showcase farm to receiving benefits from government grants from SME Corp, PlaTCOM Ventures, and MDEC.

One of his most proud moments was the validation of renowned chefs working in 5-star hotels, who placed an order for their greens and have since been loyal followers.

Dedicated to clean processes and products

Clearly, there are already several agents in the precision and vertical farming industry with more union, but few are as gung-ho about clean produce as BoomGrow is.

Cleaning doesn’t just mean pesticide-free vegetables; the team decided that value should be reflected in the overall operation of their business.

Inside a Container / Image Credit: BoomGrow

As a former national athlete, Murali wanted to start BoomGrow because he knew the difference a good diet could make.

Meanwhile, Shan is a trained architect who had developed an interest in sustainable design throughout his career. Fascinated by the way modular structures had minimal impact on their environment, he wanted to explore other avenues for incorporating sustainability into everyday life.

He is the director of innovation at BoomGrow, designing and bringing its plant systems to life. On the other hand, Jay was inspired to co-found BoomGrow after many years in sustainability consulting.

He told Vulcan Post: “Throughout my career, I have had consulting experience for various agricultural and F&B manufacturing companies. This allowed me to evaluate the data around some of the practices, as well as the disconnection that people from these organizations had about sustainability. ”

Bringing the head together led the team to arrive at the current solution that is committed to implementing the 12th Sustainable Development Goal, responsible consumption, and production.

Organic vegetable packages at competitive prices

With all the investment in technology growing their organic greens, it looks like a purchase of them should cost a bomb.

But because they are able to eliminate the need for extensive land located in remote areas and a long cold chain, they can offer their vegetables at a competitive price.

BoomGrow sells 5 to 6 varieties of vegetables depending on the package you want, priced between 45 and 65 RM per package. Free delivery is offered to subscribers of weekly or fortnightly plans. Otherwise, deliveries to the Klang Valley would cost 10 RMS for purchases over 45 RM or 15 RM for those under 45 RMS.

Young Greens Growing on Modular Racks / Image Credit: BoomGrow

Compared to another vegetable delivery service with a subscription model, Plant B, BoomGrow prices are reasonable.

Floor B offers 6 types of vegetables in a box and a two-week subscription would be RM37 / week, while a 4-week subscription would be RM34 / week. Shipping costs are offered at fixed rates of RM6-RM8 depending on where you are in the Klang Valley.

For both BoomGrow and Plant B, people may not be able to choose exactly what goes into their box, but Plant B customers will be informed of the variety they can expect depending on the season and availability. You can also contact the team for exclusions.

On the other hand, BoomGrow clearly lists each variety of vegetables in a package with the assigned weight, so you’ll know exactly what you’ll get. To add, plant B does not claim that its product is organic.

Improve your B2C services during the pandemic

When the pandemic first hit in 2020, BoomGrow saw a sharp drop in overall sales as hotels and restaurants had to cut back on their orders.

Conversely, their e-commerce orders increased as more people subscribed to their vegetable packages.

“The pandemic has underscored the urgency of building better food production, including fresh vegetables. Customers are increasingly aware that food choices influence both the health and the health of the planet,” the team concluded.

They were able to meet this demand thanks to the support of MaGIC, particularly as part of cohort 4 al Global Accelerator Program.

Through it, their technology pipelines became more focused and were able to expand their digital footprints, refine e-commerce offerings, and improve their automation. Now, BoomGrow is preparing a launch of its machine factories outside of Klang Valley to reach more customers.

Outside, they will come face to face with more players in the vegetable delivery space, but perhaps their technology and mission will differentiate them in the long run and attract a segment of customers with whom their mission resonates.

Earth911 Podcast: Freight Farms’ Jake Felser On Hydroponic Agriculture & Container Farming

Earth911 talks with Jake Felser, chief technology officer at Freight Farms, about the company’s “complete farming system inside a box.”

By Earth911

JULY 14, 2021

Earth911 talks with Jake Felser, chief technology officer at Freight Farms, about the company’s “complete farming system inside a box.” It’s a very big box that includes climate controls and monitoring systems to make farming easy for anyone to do. Freight Farms builds and delivers shipping containers converted into highly efficient hydroponic farms that use LED lighting to grow and deliver fresh produce year-round.

Jake discusses the cost of getting started, how many people are needed to run the farm, and how the built-in automation helps farmers plan a profitable business. Grocers, restaurants, communities, and small farms are using Freight Farms installations at 350 farms in 49 states and 32 countries. The company says most of its customers are new to agriculture and operate right in the urban and rural communities they serve.

Jake Felser, CTO at Freight Farms, visits Sustainability in Your Ear to talk about automated hydroponic gardening in shipping containers.

Growing and distributing vegetables locally is one of the most effective ways to lower our society’s carbon footprint. While agriculture contributes about 10% of the U.S. greenhouse gas emissions each year, the majority of that is from raising animals. By increasing our consumption of locally grown vegetables, we can improve local health and reduce overall emissions from transportation. It’s not easy to grow food in most cities using traditional methods. The introduction of container farms and vertical farming inside buildings can reshape food deserts and create economic opportunities.

To learn more, visit FreightFarms.com.

Subscribe to Sustainability in Your Ear on iTunes and Apple Podcasts.

Follow Sustainability in Your Ear on Spreaker, iHeartRadio, or YouTube

Tags: container farming, Freight Farms, hydroponics, reinventing agriculture

RMA Authorizes Emergency Procedures To Help Drought-Impacted Producers

The USDA’s Risk Management Agency is working with crop insurance companies to streamline and accelerate the adjustment of losses and issuance of indemnity payments to crop insurance policyholders in impacted areas, according to a news release

By TOM KARST

July 13, 2021

The U.S. Department of Agriculture is authorizing emergency procedures to help agricultural producers impacted by extreme drought conditions.

The USDA’s Risk Management Agency is working with crop insurance companies to streamline and accelerate the adjustment of losses and issuance of indemnity payments to crop insurance policyholders in impacted areas, according to a news release.

The agency said the new crop insurance flexibilities are part of USDA’s broader response to help producers impacted by drought, in the West, Northern Great Plains, Caribbean and other areas.

“Crop insurance helps producers weather natural disasters like drought,” RMA Acting Administrator Richard Flournoy said in the release. “We recognize the distress experienced by farmers and ranchers because of drought, and these emergency procedures will authorize insurance companies to expedite the claims process, enabling them to plant a new crop or a cover crop.”

Emergency procedures allow insurance companies to accept delayed notices of loss in certain situations, streamline paperwork, and reduce the number of required representative samples when damage is consistent, according to the release.

Producers should contact their crop insurance agent as soon as they notice damage, the agency said.

The insurance company must have an opportunity to inspect the crop before the producer puts their crop acres to another use. If the company cannot make an accurate appraisal, or the producer disagrees with the appraisal at the time the acreage is to be destroyed or no longer cared for, the insurance company and producer can determine representative sample areas to be left intact and maintained for future appraisal purposes, according to the release. Once an insured crop has been appraised and released, or representative strips have been authorized for later appraisal, the producer may cut the crop for silage, destroy it or take any other action on the land including planting a cover crop, the release said.

Additional information on these emergency procedures is available on RMA’s Crop Insurance and Drought Damaged Crop webpage.

Farming During The Dry Age

The period of 2000 to 2018 was the second driest 19-year period in over a thousand years. Let that sink in for a few moments. Global warming drives increased evaporation, causing droughts to become more likely and more severe where they already exist

The period of 2000 to 2018 was the second driest 19-year period in over a thousand years. Let that sink in for a few moments. Global warming drives increased evaporation, causing droughts to become more likely and more severe where they already exist.

The past 10 to 20 years have been some of the driest on record, especially for the west coast of the United States. 70% of the land in the West is already in severe drought, and the National Weather Service estimates that the area is closer to 90%. Water demand is expected to rise by 55% by 2050, so planning how to provide more water with a diminishing supply is not a matter of whether one believes in climate change, it’s a crisis.

These climate events in the west have economic impacts worth noting water shortages during the 2015 droughts in California resulted in almost $2 billion in direct costs. On average, one drought event causes a 0.8% decrease in agricultural GDP, let alone the cost to the population.

With California responsible for a large portion of the country’s produce and experiencing extremely dry conditions, indoor farming is the only option. CEA (controlled environment agriculture) where environmental factors are manipulated can help keep the west coast's agricultural sector intact.

Greenhouses, whether traditional or vertical uses methods such as drip irrigation that save up to 30-50% of the water it would take to conventionally grow using surface irrigation. Up to half the amount of an outdoor farm. Overall, reports indicate that greenhouses create around a 60% water savings during crop cultivation.

Droughts affect not only the direct air and soil of an open farm, but also the types of pests and pathogens living in them. When a climate drastically changes, the organisms that thrive there adapt much quicker than the plant’s ability to resist them. With the U.S. already using over one billion pounds of pesticides per year, as drier environments invite new pests and pathogens that native crops are ill-equipped to handle on their own either crops will die, or pesticide use will increase.

The agricultural economy along the West Coast and indeed across the U.S. and the world will need to adapt their growing techniques to meet the demand of a growing population and conserve water. Indoor growing saves water during growing cycles and significantly reduces crop loss, pesticide use, and GHG’s.

Droughts along the West Coast are already transforming the farming landscape as we watch farmers plow crops under knowing that there won’t be enough water to sustain them throughout the summer. Crops grown indoors can be both protected and hydrated with indoor technologies that are more secure for feeding people and sustaining the planet.

Hallie Cordingley, Intern

Carl Silverberg, Sr. VP Outreach & Public Affairs

844 746 4868

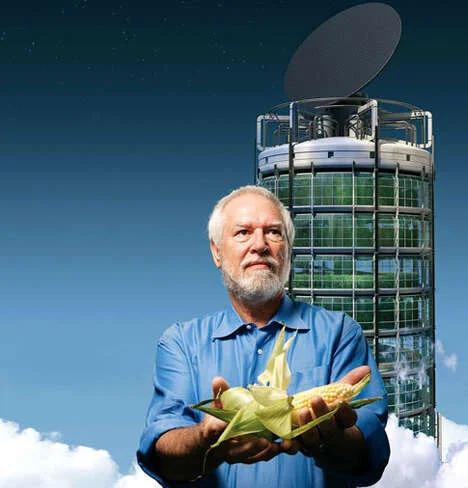

Green Sense Radio: Godfather of Vertical Farming - Dickson Despommier

Dickson Despommier has a Ph.D., in microbiology, is an ecologist, and emeritus professor of Public and Environmental Health at Columbia University, and coined the term vertical farm back in 1999

This week on Green Sense Radio Show: Grounding a tall vision in market reality an interview with the godfather of vertical farming!

Dickson Despommier has a Ph.D., in microbiology, is an ecologist, and emeritus professor of Public and Environmental Health at Columbia University, and coined the term vertical farm back in 1999. He’s one of the many respected experts who’ve contributed to the new book ‘The Economics of Sustainable Food - Smart Policies for Health and the Planet.’ We talk about the new book and the past, present, and future of vertical farming.