Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

No Sun, No Soil, And Robot Farmers: Is This Tomorrow’s Food Crop?

Even by the unconventional standards of modern-day urban agriculture, Geert Hendrix’s set-up is unorthodox. It is in an Alphington warehouse, with no windows and no soil, and is filled with the most diminutive of crops

By Megan Backhouse

July 2, 2021

Even by the unconventional standards of modern-day urban agriculture, Geert Hendrix’s set-up is unorthodox. It is in an Alphington warehouse, with no windows and no soil, and is filled with the most diminutive of crops.

Tiny purple radish stems, miniscule basil leaves and microscopic watercress seedlings are the heavy hitters here. Their stems strain towards LED lights and their roots stretch down through hemp fibre and coconut coir into fish-tanks.

Geert Hendrix with one of his indoor growing systems. CREDIT: JUSTIN MCMANUS

Other leafy greens are growing on illuminated shelves that have nutrient-rich water recirculating inside them. Lettuces are being cultivated – in a sealed glass cabinet – on nothing but air and a regular misting of another nutrient solution. Other plants are tended by robot.

Freewheeling, this place is not. Space is carefully allocated, lighting is monitored and close tabs are kept on waste. Nothing is left to chance. Hendrix, part of a growing band of people working to make food production more sustainable and reliable, is using his indoor farm at the Melbourne Innovation Centre to help turn traditional methods of food production on their head.

He says the range of growing systems – some of which are at more experimental stages than others – is predominantly aimed at showing high-school students what is possible.

Purple radishes growing in trays of hemp fibre atop a fish tank. CREDIT: JUSTIN MCMANUS

As anyone growing vegetables as microgreens in trays of soil in a sunny spot in their kitchen will tell you, growing baby plants doesn’t have to be high-tech. You need to be rigorous with your twice-daily rinsing, but then, in little more than a week, you will invariably have a good yield of aromatic, nutritionally dense miniature greens at the ready.

Hendrix says it’s the very ease and speed of growing microgreens that makes them such a powerful educational tool. “I see them as a gateway to help people become full-spectrum farmers in the future.” He expects that, over the next 10 years, big shifts in agricultural processes will create new opportunities for farming, and he wants to inspire young people to take advantage of them.

Lead photo: Lettuces growing in a sealed glass cabinet. CREDIT: JUSTIN MCMANUS

A Fully Automated Three-Dimensional Vertical Farm Comes Into Operation

Eponic Agriculture Co. Ltd is a supplier of indoor farming equipment. Alice, the company's director, introduced the recently fully automated production system of a stereochemical vertical farm

Eponic Agriculture Co. Ltd is a supplier of indoor farming equipment. Alice, the company's director, introduced the recently fully automated production system of a stereochemical vertical farm.

"The current three-dimensional indoor farms on the market are based on semi-automated workflow, with some links requiring additional equipment configuration and no continuity in the whole planting system. In order to solve this problem, we developed and designed a complete automated planting system, including the processes from sowing to planting, full-spectrum planting light control, fertilization, harvesting, and cleaning. Which are all done by automated equipment. Whereas all procedures can be controlled by intelligent software with real-time monitoring, data collection, and many other functions."

Benefits of an automated farm

When talking about the advantages of the automated equipment, Alice said, "Take our recently built 20-layer vertical farm as an example. First of all, the mechanical sowing time is 10 times-30 times faster than manual sowing. And on top of that, the use of automated equipment can realize precise planting and efficient communication of multi-layer planting surfaces. The 20-layer vegetable trays are automatically transferred to the ground for uniform watering, harvesting, and cleaning. This greatly improves productivity.

Secondly, the use of lift trucks is required when handling high-level crops. There are certain safety hazards in using lift trucks in a small space. While operating the automated equipment, only a tablet computer is needed to control the whole planting process, which is much safer and more convenient."

Although automated vertical farm systems have many advantages, their application in China is not yet popular. "In terms of production design, we have gone through countless experiments to design the most suitable software program. As well as hardware equipment for practical planting applications. Luckily after a long period of research, we finally chose the most cost-effective and suitable materials. The R&D investment is large and time-consuming.”

From a cost point of view, according to Alice, a fully automatic system is 2-3 times higher in costs than the semi-automatic system which is currently used more often. Most traditional agricultural companies find it difficult to accept such high initial costs. Thirdly, the automated system requires high technical requirements for farm managers. Managers need to have an understanding of both planting technology and software. Alice adds: “It is for these three reasons that the application of fully automated stereoscopic systems is not very common in China and other countries."

Automated planting

"Although the application is not yet widespread, I think fully automated stereoscopic planting is a trend. Urbanization has led to a reduction in arable land and soil pollution has triggered problems with pests and pesticide residues in fruits and vegetables, and the development of three-dimensional agriculture is the only way to maximize and optimize output in a limited area. Currently, stereoscopic planting plants still require a lot of manual labor to operate. As labor costs rise and planting techniques require more precision, the use of automated equipment will be a future trend," Alice notes.

"Automated systems are a trend, not only in China but also globally. Urbanization has been moving forward, in the face of soil pollution, pesticides and pests, etc. The planting area is gradually reduced and three-dimensional agriculture must be developed in order to quantify planting. Three-dimensional agriculture can be located near the city, and reduce the transport distance, people can eat the freshest vegetables, to achieve local supply. Therefore it is necessary to promote automated, intelligent planting systems in order to achieve efficient planting and sustainable development." Alice said.

Industry experience

Eponic Agriculture Co. Ltd's head office, Dahua Intelligent Electronics, has a twenty-five-year history division. The team has been focusing on the development and production of intelligent control systems and industrial lighting. Alice said that based on years of technical foundation, we developed full-spectrum LED planting lights which have been approved and applied by the USDA. Over the years, we have received technical support and affirmation from several agricultural doctors from Europe and the United States, focusing on the development and production of automated stereoscopic planting equipment.

According to Alice, the company has laboratories and showrooms in the US, Australia and Africa. This year, the company is planning on opening new showrooms and laboratories in Europe. “We are expanding our global reach and continue to optimize our growing systems to be a better supplier of fully automated growing equipment."

For more information:

Eponic Agriculture Co. Ltd

Alice Ou, Director

aliceou@eponicagriculture.com

www.eponicagriculture.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

Delivering The Optimal Growing Parameters

“Especially in the pharmaceutical or supplemental industry, you need an extremely strict batch control that leaves no room for variation,” says Dr Alexis Moschopoulos, Managing Director at Grobotic Systems.

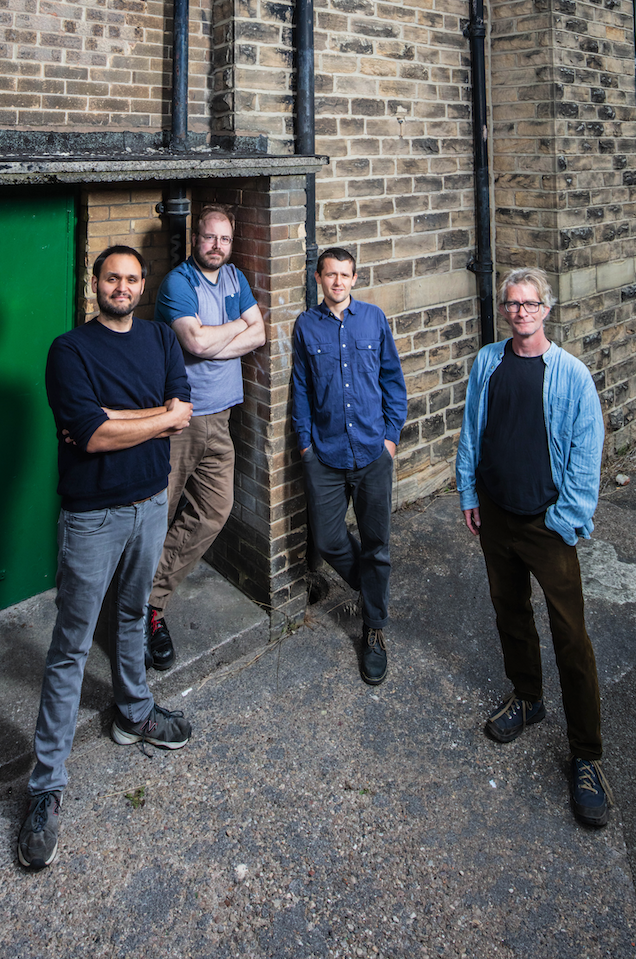

The Grobotic Systems team shows off an early prototype Grobotic chamber. From left to right: Gareth Coleman (Software Developer), Richard Banks (Chief Technology Officer), Dr Alexis Moschopoulos (Managing Director), and Andrew Merson (Mechanical Engineer). Credit: UKRI.

Growing a new variety

Indoor farming has numerous growing parameters to take into account. Particularly when growing a new variety, all variables should be perfected in order to reach an optimum yield. In an indoor space, experimenting with these environmental parameters might, however, seem tricky. But what about trying out this environment in a smaller setting, such as an experimental growth chamber?

Alexis is fully aware of the challenges that vertical farmers face. The environmental control needs to be as precise as possible, as the effect of different light spectra or nutrients may have a significant impact on crop yield and quality. With this challenge in mind, Grobotic Systems brings a new solution to the market: a compact and highly instrumented growth chamber. “It’s an experimental chamber rather than a farming chamber. Therefore, you won’t use it to grow vegetables, but you can use it to identify which growing parameters are best suited to your crops,” Alexis says.

The Grobotic Systems team outside their workshop in Sheffield, England. From left to right: Dr Alexis Moschopoulos, Richard Banks, Andrew Merson, and Gareth Coleman. Credit: UKRI.

On your desk or under your bench

According to Alexis, the chamber fits on your desk or under your bench. It can apply any environmental condition preferred, including light spectra and temperature. Internet connection via the growth chambers allows users to monitor plants on their cellphones via integrated cameras and other sensors inside the chamber.

Another advantage of the chambers’ size is that they can be stacked in an array, adjusting variables in each chamber. In this way, a multi-variable experiment can help users identify which environment works most optimally for their intended crop. “When using a large cultivation room, it is hard to split the room into different temperatures. A smaller cultivation space, such as our growth chambers, can be placed anywhere, just like a personal computer. Moving away from the large expensive capital equipment and machinery to small and stackable experimental chambers saves a lot of space and money.”

Alexis first came up with the concept of the growth chamber during his PhD and postdoctoral work in plant genetics. Several prototypes are currently being used at research institutes and start-up companies. Grobotic Systems is working on a more advanced growth chamber that will be launched in the summer of 2021: “We are integrating feedback from the deployed prototypes into the design of the advanced chamber, and we will start marketing the advanced chamber later this year.”

Richard Banks designs a control system circuit board for an early prototype Grobotic chamber. Credit: UKRI.

Large-scale farms

Not only new farmers can benefit from running small-scale experiments in a growth chamber, but also large-scale, established farms, since the chamber allows them to experiment with new varieties, creating the optimal yield. This will in turn enable them to upscale their production. “Not all farmers like to invest their time in carrying out experiments, as some trust that the vertical farming technologies they buy will always work for them. However, in the end it could save them a lot of money. No one needs to use productive farm space to do the experiments, just a few manageable boxes can suffice.”

Gareth Coleman works on the chamber imaging and control systems. Credit: UKRI.

For more information:

Grobotic Systems

Dr Alexis Moschopoulos, Managing Director alexis@groboticsystems.com

www.groboticsystems.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

BrightFarms Promotes Jackie Hawkins To Director Of Food Safety & Quality

Hawkins will oversee all aspects of food safety and quality assurance as the company continues its rapid growth into new markets

BrightFarms, a leading supplier of locally grown packaged salads, recently announced that Jackie Hawkins has been promoted to director of food safety & quality. She will report directly to Josh Norbury, BrightFarms’ senior vice president of operations.

Jackie Hawkins

Hawkins will oversee all aspects of food safety and quality assurance as the company continues its rapid growth into new markets. Her responsibilities will include the development and execution of BrightFarms’ food-safety protocols across five facilities, as well as the coordination of customer, regulatory and third-party audits.

“Under Jackie’s leadership, BrightFarms is delivering the safest and freshest leafy greens to the nation’s largest retailers,” said Josh Norbury, senior vice president of operations. “She has built an industry-leading food safety program for the indoor production of leafy greens, and our rigorous protocols have set the standard for other companies in our space. We are fortunate to have her leadership and expertise as we continue to grow.”

Since joining BrightFarms in 2016, Hawkins contributions have been critical to the success of the company’s world-class operations team. She has designed and implemented the most comprehensive food-safety program in the indoor farming industry and maintains close working relationships with leading food-safety experts in the produce industry.

In 2018, Hawkins led the development of the Controlled Environment Agriculture (CEA) Food Safety Coalition, an independent and member-governed organization whose membership is comprised of controlled environment leafy greens growers who subject their production processes to external audit. She also led BrightFarms’ early adoption of IBM’s Food Trust platform to enhance traceability with blockchain technology.

“Food safety is a personal passion that I’ve dedicated my career to, and I couldn’t be more thrilled to step into my expanded role,” said Hawkins. “I’m thrilled that I have the opportunity to work for a company that places food safety at the centre of everything we do. I look forward to continuing to advance our leading protocols and providing our consumers with the safest, freshest and most nutritious greens on the market.”

Hawkins graduated from Oregon State University in 2016 with a B.S. in Environmental Science.

For more information about BrightFarms, visit www.brightfarms.com.

Coimbatore’s Hydroponic Farm Delivers Fresh Greens Within Three Hours of Harvest

I grab a leaf of peppermint from a bed of mint leaves and taste the intense freshness.

Sustainable farming and fresh, zero-carbon food are the philosophy behind the city’s first urban hydroponic farm, located inside an industrial building campus. To know more, MetroPlus makes a visit

I grab a leaf of peppermint from a bed of mint leaves and taste the intense freshness. Next, I look at thyme and smell the powerful aroma. A little away, purple basil with a beautiful, coppery glow beckon. I crush a lemon balm leaf and take in the uplifting, mild scent.

I am at Parna Farms, Coimbatore’s first urban hydroponic farm, located right in the heart of the city at an industrial building campus. Spread across 3,000 square feet, it grows 2,520 plants.

Akhila Vijayaraghavan | Photo Credit: S Siva Saravanan

“Our fresh lemon balm leaves impart a subtle flavour and fragrance, making it especially nice for custards, jam and jellies, cakes and tea,” says Akhila Vijayaraghavan, owner of the farm. “The purple basil is used for colour in salads. Except maybe amaranthus and palak (spinach), you can eat all the greens we grow here raw,” says Akhila pointing to varieties of lettuce, basil, bok choy, and kale.

Asian water spinach (kang kong), red gongura, mustard leaves and methi (fenugreek) are some of the new additions. “We also grow dill leaves, which are used as a garnish for fish and meat dishes and pasta. Fresh peppermint extracts are used in baking. We constantly try new crops based on demand, after rounds of trial-and-error.”

Peppermint grown at the hydrophonic Farm | Photo Credit: S Siva Saravanan

A graduate of Molecular Biology from the University of Glasgow, Akhila ran her own environmental consultancy for over 10 years before turning an urban farmer. “I worked with a lot of companies, from pharmaceuticals to FMCG, and learnt that the supply of quality end-product is a difficult task. Agriculture has always been one of my passions; I was interested in food crops. A herb can be used in cooking, to extract oil, extract nutrients in dry form, and maybe in alternative medicine, perfumery… the possibilities are exciting,” adds Akhila.

She researched hydroponic methodology and educated herself on farming before diving into it. “Anyone can do it, it is not rocket science,” she says.

“Hydroponics combines both sustainability and technology. In indoor hydroponic cultivation, the control on nutrient supply ensures more quality products, for example, improved oil content in herbs, as well as better crop yield. A hydroponic mint has more methanol content than a soil-grown one. The system also uses 80% less water than conventional agriculture. The water is upcycled for reuse.”

At Parna Farms, greens are grown using the nutrient film technique (NFT), where a thin ‘film’ of nutrient-rich water with macronutrients like nitrogen, potassium, phosphorous and calcium nitrate, and micronutrients like manganese and zinc nourish the roots of the plants.

Seedlings at the nursery at the hydroponic farm | Photo Credit: S Siva Saravanan

The farm has a germination area that uses coco peat to sprout plants and a nursery where net cups (small planters) are filled with clay pebbles. There is also the growing system, which involves metal stands and PVC pipes attached to a covered nutrient tank that pumps water to the plants. “We incubate the net cups in a plastic tray for a couple of weeks. Once the plant grows roots, it is transferred to the main system with higher nutrients in the water. This is where it is fully grown and harvested,” explains Akhila.

Hydroponic agriculture, she says, has existed for over 3,000 years, with the Hanging Gardens of Babylon being one of the often-quoted examples of this technique. “It is one of the more accessible forms of modern agriculture, tackling the dual problems of water scarcity and shortage of farmland. It reduces soil-borne pests and diseases.”

Akhila says the objective is to ensure that customers get fresh, pesticide-free produce within three hours of harvest. “Though a palak bunch from here costs ₹130, they are willing to pay the premium to enjoy good health,” says Akhila, adding, “You are what you eat. In hydroponics farming, every day is a learning curve.”

Follow @parnafarms on Instagram to know more

VIDEO: Agroz Aims To Build Malaysia’s Largest Indoor Vertical Farms

Agroz Group Sdn Bhd has announced that it’s building 100,000 square feet of indoor vertical farms in Malaysia throughout 2021, making it the largest of its kind in the country. When completed, the vertical farms can produce 3 tons of clean and fresh vegetables daily

30 DECEMBER 2020

Agroz Group Sdn Bhd has announced that it’s building 100,000 square feet of indoor vertical farms in Malaysia throughout 2021, making it the largest of its kind in the country. When completed, the vertical farms can produce 3 tons of clean and fresh vegetables daily.

The Malaysian-based agriculture technology (agritech) company was founded by serial technopreneuer, Gerard Lim Kim Meng, who has experience in the Malaysian technology and digital industry. The group aims to address the issue of Food Safety, Food Security, and Sustainability in Malaysia with its commercial large scale and industrial-grade indoor vertical farms.

Vertical farms are an efficient way of producing fresh vegetables as it uses less space and water compared to traditional farming on open land. The environment can be controlled accurately which include temperature, humidity and lighting. Since the vegetables are farmed in a well-controlled environment, it also eliminates the need for pesticides and additional chemicals.

According to the press statement from Agroz, it claims that most fresh vegetables including organic ones are several days or weeks old and are preserved “fresh” with large amounts of chemicals and preservatives.

It added that these vertical farms can be built within the community so that they are placed closer to where it’s consumed for a “farm to fork” supply chain. As a result, consumers will be able to enjoy clean, fresh, chemical-free and high quality food within hours.

Agroz will be using a myriad of advanced technologies to ensure that its farming process is repeatable, scalable, and traceable. This would include IoT, big data analytics, artificial and augmented intelligence, machine learning, blockchain, and in the future, 5G, to create a sustainable approach to modern precision agriculture through indoor vertical farming.

The group is seeking to raise RM100 million through issuance of Redeemable Convertible Preference Shares (RCPS), with exit plans in 5 years through a proposed initial public offering (IPO) or via a trade sale to a Special Purpose Acquisition Company (SPAC), if applicable.

According to its founder and CEO, Gerard Lim, they currently have over RM5 million worth of contracts in its order books with millions of dollars more in the pipeline to design, build, operate and manage various indoor vertical farms. He shared that they are currently growing 200kg per month and will soon have the capacity to grow 1 ton per day from their various farms that are already committed.

Gerard added that the indoor vertical farms will create hundreds of new high valued jobs and generate income for local communities in the post-COVID-19 era.

Those who are interested, may drop an email to gerard@agrozgroup.com or visit their official website.

Agrilution Brings Herb Gardens Into The Home With Their "Plantcube"

It will always be spring in your kitchen. That is what the "Plantcube" from Agrilution promises; a fully automated greenhouse that enables vertical farming even on a small scale

Closed Ecosystem In A Designer Cabinet

It will always be spring in your kitchen. That is what the "Plantcube" from Agrilution promises; a fully automated greenhouse that enables vertical farming even on a small scale. Maximilian Lössl, Co-Founder and CEO, spoke about the first experiments in his parents' basement, the new features of the second generation of "Plantcube" and why his personal mini-farm will never run out of basil. With a high-tech herb garden in a designer cabinet, the consumer gets a closed ecosystem where it's always spring. What could a mini-vertical farm like this do for us?

By mimicking the perfect spring conditions every day, the closed ecosystem grows herbs, lettuces, and micro-greens with up to 30 percent higher density of nutrients; all without transportation costs, cold chains or plastic waste. The harvest will also land directly on people's plates, retaining the all-important secondary plant compounds, vitamins, and minerals. It is a combination of special light frequencies, controlled climate, and hydroponic irrigation that will ensure optimal conditions throughout the year, all without pesticides or seasonal dependencies. In this way, technology and nature can work hand in hand.

You first started farm-to-table experiments in your parents' basement. How did the idea come about?

The initial spark, the enthusiasm for vertical farming, came from a book by Dr. Dickson Despommier. On the author's recommendation, I actually went to Den Bosch in the Netherlands to study. But the theories were not enough for me. I became impatient and wanted to act. So I took the concept of vertical farming a step further; the idea of a "mini-vertical farm" in my own home was born. Philipp Wagner then joined me for the technical implementation. Our friendship goes back to our school days when we played basketball together. We started experimenting in my parents' garage and founded Agrilution together in 2013.

Which lettuces and herbs exactly do you grow in the "Plantcube"?

Our portfolio currently includes over 30 different plants - from common kitchen herbs to tatsoi, leaf lettuces, and mixes for pesto to more unusual microgreens such as bronze fennel. The selection is based on the needs of the market, but we also want to offer something unusual that is unavailable in the supermarket or organic market. In addition, growth speed is decisive so that our customers do not have to wait too long. Generally, the harvest time is between one and four weeks.

And what demand is the unit designed to meet?

Assuming a daily consumption rate, the capacity ranges from a single person to a small family - depending on how planting and planning is done. Our app provides insight on growth, advice on harvesting or maintenance, and also allows online ordering of new seedbars that carry the seed.

Won't we lose that particular feeling of taking care of your plants in the field, garden, or balcony?

We don't see ourselves as competing with people who want to have big gardens where they grow their own plants. Rather, we address city dwellers who do not have a balcony or garden in urban centers, are seasonally limited due to their location, or who simply lack a green thumb. Of course, we focus on vegetarians, vegans, and flexitarians, but we also address culinary connoisseurs who are looking for that special aroma. And technology-savvy early adopters who want to outfit their smart homes with the latest tech.

You recently launched the second edition of the "Plantcube". What exactly has been changed or improved?

What's new about the optimized "Plantcube", in addition to its black redesign, is the revised drawers system, which can now be equipped with nine seed bars each on two levels. This offers a much greater variety for planting and the new, portion-sized seedbars are even more aligned with daily needs/the daily harvest opportunity. We have also expanded our plant portfolio and divided it into three categories so that our customers can get a particularly quick overview: Dailies, Essentials and Chefs. In addition to all this, the Seedbar substrate is now 100 percent biodegradable thanks to the use of natural materials.

There is also a so-called "Cinema Mode". What is this in essence?

Cinema Mode is also one of the latest adjustments - it came about as a result of valuable customer feedback and allows the greenhouse to be set to silent and dark for up to two hours. Some users will position the "Plantcube" directly in the living room as a design statement. Its light can be disturbing when people are watching a movie, for example, which is why we have added this option.

You probably own a "Plantcube" yourself. What do you grow in it and why?

The "Plantcube" in our private home is always well-stocked. We eat our greens every day. Since I love Asian cuisine, we always have fresh cilantro for salads or as a topping for avocado bread. But our regular assortment also includes tatsoi and wasabi leaf mustard - nice and spicy. And don't forget the basil. My girlfriend is Italian.

Are there any recipes specifically using plants from the Plantcube?

We are constantly developing recipes with greens from the "Plantcube". Our website provides inspiration, as does the app. We also regularly cook together in our office, which is currently only possible to a limited extent. Otherwise, however, we always come up with highly recommendable creations. We also cooperate with KptnCook and chefs who use the "Plantcube" themselves. My favorite dish is "Asian Pak Choi Stir Fry", which I modify according to my mood.

What impact has the lockdown had on interest in your Plantcubes? Fresh greens from one's own home sounds like an enticing option right now.

Sales have really taken off; because customers will always have something fresh and healthy in the house, and for the first time it's becoming very clear to all of us that local cultivation can't always meet the demand for natural products. As a result, we're sometimes faced with empty vegetable shelves. Also, in general, a more conscious, healthier life is becoming more and more trendy right now.

Lead photo: "Plantcube" / Image: Agrilution.

Source: AD Magazin

23 Dec 2020

Indoor Agriculture, Challenges And Innovation

At Verde Compacto we want to share knowledge with you and make you part of the new era of agriculture

At Verde Compacto we want to share knowledge with you and make you part of the new era of agriculture.

That is why we developed a series of webinars where we will talk about the future, the challenges, and innovation in agriculture.

We look forward to your assistance and we invite you to register at the following link:

Greenhouse automation

September 22

18:00 hrs CDMX

Indoor growing systems: The new era of agriculture

24th September

18:00 hrs CDMX

REGISTRY

Our mailing address is:

Compact Green Cañada # 105 Col. Jardines de Moral

Leon De Los Aldama , Gua 37160

Mexico