Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

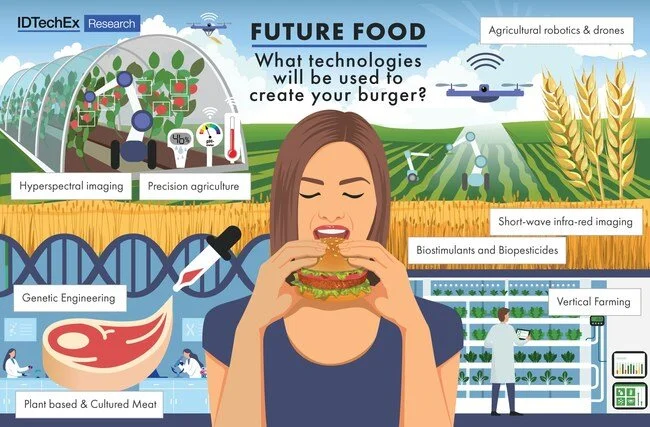

No Lives At Steak, IDTechEx Predicts How Food Will Be Made In The Future

A successful vertical farming future could see people buying their veggies at markets mere meters from where they were grown. Food miles could become a thing of the past

BOSTON, July 6, 2021

Syntheti bolognese

From free-range chicken to food miles on alfalfa, eating ethically is becoming more and more of a head-scratcher. Even for vegans, there are the questions of how sustainably agave was sourced, or whether environment-damaging pesticides were used to grow kale – and all that is without even considering how the food tastes.

Advances in the food and agriculture industry could answer every one of these questions, plus some of the regular consumers hadn't yet thought to ask.

For a slaughter-free spaghetti bolognese, a beef burger where no cows were harmed, and fresh produce growing from the walls of skyscrapers, food technology is turning science fiction into science fact one innovation at a time.

Plant-based burgers are on a roll

Meat alternatives are not new. Tofu and seitan have been around for over 1000 years and veggie burgers have been on supermarket shelves for decades. However, these have typically only appealed to vegans and vegetarians, a niche market perhaps prepared to compromise on how meat-like the product is for their own ethical reasons. With the advancement of new food technologies, that may no longer be a compromise that needs to be made; plant-based food is becoming increasingly convincing as meat. One example of plant-based food appealing to a more carnivorous palette is Impossible Foods, who used genetically modified yeast to make a vegetarian burger that bleeds.

But could the search for sustainable, guilt-free burgers go further? Cultured meat says yes.

Culture shock: meat the new burger on the block

A burger, made from 100% real beef, but no cows were harmed in its making? New technologies in cultured meat offer a potential solution for the burger-lover who feels bad about it.

Cultured meat involves directly culturing the same (or very similar) animal cells that make up conventional meat. Therefore, it is theoretically possible to create meat products completely indistinguishable from conventional meat, and without the need for slaughter.

Since the world's first cultured burger was produced in 2013, the industry has grown at a rapid pace, with start-ups around the globe competing to be the first company to commercialize a cultured meat product.

In December 2020, the industry received a major boost when Singapore became the first region in the world to grant regulatory approval for commercial sale of a cultured meat product, a hybrid product made from plant protein and cultured chicken cells produced by Eat Just. Many in the industry are hoping this will be the first of many approvals over the next few years, helping cultured meat transition from the prototype stage to consumer products.

For more information on how cultured meat is made, and promising companies in this area, see the IDTechEx report "Cultured Meat 2021-2041: Technologies, Markets, Forecasts".

Vertical farming takes agriculture to new heights

Let's not forget the lettuce and tomatoes! A successful vertical farming future could see people buying their veggies at markets mere meters from where they were grown. Food miles could become a thing of the past.

Vertical farming is a method of growing crops indoors under controlled environmental conditions, with crops grown in vertically stacked layers to save space. This could enable yields 20-30 times higher per acre than normal agriculture. By using advanced growing methods such as hydroponics and LED lighting tailored to the exact photosynthetic needs of the crops, vertical farming can achieve yields hundreds of times higher than the same space of conventional farmland.

Because it doesn't need large amounts of arable land to grow crops, it's possible to do vertical farming in urban areas, closer to population centers. This both frees up arable land and reduces the distance that food must travel to reach consumers.

Almost any location can be used for vertical farming, with companies operating out of old shipping containers (Freight Farms), disused warehouses (AeroFarms uses a warehouse in New Jersey for its indoor farming) and the walls of skyscrapers. The only limitations are being able to get resources in and harvested plants out.

Precision agriculture

Increasing agricultural yields in a sustainable manner will be crucial in feeding the world's growing population. Precision farming is a promising emerging approach, in which individual plants (or at least regions of a field) can receive targeted treatment. Furthermore, planting and harvesting can be tailored to ground conditions in a particular area and to the status of a particular fruit or plant.

Achieving this technological transition from the incumbent, broad-brush farming methodologies requires multiple new technologies, spanning robotics, imaging, machine vision and low-cost sensors. Indeed, this revolution in farming practices provides a substantial market opportunity for technologies perhaps more commonly associated with industrial automation.

Hyperspectral imaging

One technology that can monitor plant health and catch diseases early, minimizing the risk of wastage and lost crops, is hyperspectral imaging. Insight into plant health can be gained through hyperspectral imaging. Rather than expressing an image as red, green, and blue (RGB) values at each pixel location, hyperspectral imaging instead records a complete spectrum at each point, creating a full 3D data set. By obtaining a complete reflection spectrum for each pixel, far more information can be gained than from a standard image, enabling supervised machine learning to quantify chemical composition more precisely and hence determine ripeness or disease.

Extensive details of the wide range of competing technologies for SWIR and hyperspectral imaging, along with other emerging image sensor technologies and market forecasts for their adoption in different industries can be found in the IDTechEx report "Emerging Image Sensor Technologies 2021-2031: Applications and Markets".

Agricultural robotics and drones

Once agriculturally relevant data has been harvested and converted via AI into actionable insights, these need to be carried out. This will require agricultural robots, which can use this data to deliver precision-targeted planting, fertilizing, weedkilling and harvesting. Imagine varying planting densities across a field in response to soil conditions or targeting specific areas of a field with pesticides.

Short-wave infra-red imaging

To appropriately target fertilizer and/or weedkillers, the attributes of individual plants need to be ascertained. While this can be done via algorithmic image analysis, conventional cameras in the visible spectrum cannot necessarily identify subtle differences between leaves or fruit at different stages of ripeness.

Short-wave infrared (SWIR, 1000 to 2000 nm) imaging resolves some of these challenges since surfaces that look similar under visible light can show substantial differences under SWIR light – bruised fruit is an excellent example. An additional advantage of SWIR imaging is that scattering by clouds, dust, or mist decreases as wavelength increases, thus facilitating imaging in otherwise adverse conditions.

Biostimulants and biopesticides

Synthetic chemical pesticides and mineral fertilizers are growing less and less sustainable. They are responsible for greenhouse gas emissions and environmental damage, with the overuse of certain pesticides leading to the growing problem of resistance. However, much of the world's food supply still depends on them.

Agricultural biologicals – crop inputs derived from nature – could form part of the solutions. Biostimulants could boost crop yields while reducing the need for fertilizers and boosting soil health and biodiversity, while biopesticides could provide much-needed new modes of action, without causing environmental damage.

One other solution to the pesticide problem would be to genetically engineer plants to withstand certain common pests and diseases.

Genetic engineering

Although many aspects of agricultural biotechnology remain controversial, the technology has enormous potential as a way of improving food security.

Crop biotechnology is a set of tools and disciplines that modify organisms for a particular purpose, e.g. increasing yields, or developing an innate resistance to certain diseases in order to reduce crop losses and pesticide requirements.

The basis of agricultural biotechnology is genetics, with scientists using an understanding of DNA to develop methods to improve agriculture. The ability to identify genes that can confer advantages to certain crops and the ability to work precisely with these genes can significantly enhance breeders' abilities to improve crops and livestock.

IDTechEx, a leading market intelligence provider, offers a wide range of technical market research on the food and agricultural technology industry. For more details visit www.IDTechEx.com/Research/AgTech.

This research makes up part of the extensive research portfolio from IDTechEx covering many emerging technologies, building on a long history of analyzing these technologies, markets, and applications. All reports include a detailed analysis of established and emerging technologies, their potential adoption barriers and suitability for different applications, and an assessment of technological and commercial readiness. These reports also include multiple company profiles based on interviews with early-stage and established companies, along with 10-year market forecasts. A full list of IDTechEx reports and services can be found at www.IDTechEx.com or contact research@IDTechEx.com for more information.

Lead photo: Creating a burger with future food technologies

About IDTechEx

IDTechEx guides your strategic business decisions through its Research, Subscription and Consultancy products, helping you profit from emerging technologies. For more information, contact research@IDTechEx.com or visit www.IDTechEx.com.

Images download:

https://www.dropbox.com/sh/q3nb5075de1hzhc/AAC9IVpxzUVm5gDU4TuuwQ5-a?dl=0

Media Contact:

Natalie Moreton

Digital Marketing Manager

press@IDTechEx.com

+44(0)1223 812300

Social Media Links:

Twitter: https://www.twitter.com/IDTechEx

LinkedIn: https://www.linkedin.com/company/idtechex/

Facebook: https://www.facebook.com/IDTechExResearch

SOURCE IDTechEx

BrightFarms Launches “BrightLabs” Innovation Hub

BrightFarms, the leading grower of indoor leafy greens, today announced the formation of BrightLabs, a world-class innovation and research hub launching at its Ohio growing facility

BrightFarms Accelerates Indoor Farming Innovation Tenfold with the Formation of R&D Hub Led by Bayer Veteran and Greenhouse Expert “BrightLabs” will expand the company’s focus on the development of biotechnologies that increase the profitability of its indoor farming operations and deliver breakthrough product innovations

IRVINGTON, N.Y. – BrightFarms, the leading grower of indoor leafy greens, today announced the formation of BrightLabs, a world-class innovation and research hub launching at its Ohio growing facility. Matt Lingard, PhD, a former Bayer plant scientist with over 15 years of experience working at the intersection of biotechnology and greenhouse science, will lead the BrightLabs team as Vice President of Agriculture and Science.

“The indoor farming industry is at an inflection point as local, indoor-farmed produce becomes a priority for retailers and consumers. Among competitors, we’ve developed the most profitable model for the production of indoor leafy greens, but it’s essential that we maintain our market advantage to stay ahead of the curve,” said Steve Platt, BrightFarms CEO. “We’ve built up a team of the best minds in indoor agriculture to officially launch BrightLabs, where we’ll develop the next phase of game-changing products and technology solutions for our operations.”

BrightLabs is one of the most advanced biotechnology ventures in the indoor farming industry, with a key focus on developing proprietary & patented ecosystems for plants to thrive, increasing their flavor, yields and texture in the process. The team will be comprised of the strongest minds from the food and agriculture industry, bringing together experts in technology, microbiology and plant science to deliver breakthrough innovations in the salad category and beyond.

“No other indoor farming company is studying a plant’s microbiome, the naturally occurring bacteria that help determine its health, to the same degree that we are,” said Lingard. “Instead of pouring dollars into artificial lighting research, we’re developing cutting-edge biotechnology solutions to out-maneuver our competition with the most productive indoor farms in the industry. There’s no question that high-tech greenhouses that leverage natural sunshine have emerged as the most promising new generation of agriculture technologies, and optimizing the microbiome will allow us to unlock even more of a plant’s natural potential in our indoor farms.”

This multi-million dollar R&D investment is launching as part of the company’s $100MM Series E Fundraise led by Cox Enterprises, and represents a tenfold increase in the company’s research capabilities. Ten percent of the company is now dedicated to developing complex, patented growing solutions to be applied to BrightFarms’ burgeoning network of greenhouses.

Already known for proprietary research on growing spinach in a hydroponic system, BrightLabs aims to double its production of the crop, which is the industry’s best-selling tender leaf variety. BrightFarms will also build on the success of its best-selling Sunny Crunch variety with a new, industry-first antioxidant-rich lettuce, NutriGreens, set for release this June. BrightOS, the company’s award-winning proprietary data system, will help the BrightLabs team accelerate their research with machine learning and advanced data analysis.

BrightFarms’ five greenhouses – located in Ohio, Virginia, Illinois, Pennsylvania, and North Carolina – cover 1.2 million square feet and produce 9 million pounds of fresh lettuce annually. By the end of 2021, BrightFarms leafy greens will be available at over 3,500 stores, more than any indoor farming company in the industry.

To learn more about BrightFarms and their fresh produce offerings, visit www.brightfarms.com.

About BrightFarms

BrightFarms is the leading provider of locally grown packaged salads, serving the freshest, tastiest and most responsibly grown produce to consumers nationwide. BrightFarms operates hydroponic greenhouse farms in the communities it serves, enabling it to eliminate time, distance, and costs from the food supply chain. BrightFarms’ growing methods, a model for the future of scalable, sustainable local farming, use far less energy, land, and water than long-distance, field-grown agriculture. Forbes has recognized BrightFarms as one of the “100 Most Consumer-Centric Companies” and Fast Company has recognized BrightFarms as “One of World’s 50 Most Innovative Companies” and one of the “Top 10 Most Innovative Companies in Food.” BrightFarms is funded by leading investors Cox Enterprises, Catalyst Investors, WP Global Partners and NGEN Partners. For more information, please visit www.brightfarms.com.

Urban Crop Solutions SpaceBakery Project Wins First Place At Global Space Exploration Conference

The winning SpaceBakery project is an interdisciplinary cooperative research project between seven partners, of whom, Urban Crop Solutions is the lead vertical farming technology and research partner

The Global Space Exploration Conference (GLEX) took place in St. Petersburg in June 2021. The conference brought together several leaders and decision-makers in the international science and space exploration community. Urban Crop Solutions and partners were selected to present two projects of the 250 that were presented during the conference. The SpaceBakery project was awarded the first-place prize.

Organised by the International Astronautical Federation (IAF) and Roscosmos (the Russian space agency responsible for space flights and aerospace research), the conference gathered several international stakeholders from the science and space exploration community, on a year which marks the 60th anniversary of Yuri Gagarin’s spaceflight.

The winning SpaceBakery project is an interdisciplinary cooperative research project between seven partners, of whom, Urban Crop Solutions is the lead vertical farming technology and research partner. The objective of the consortium is to develop the next generation of bread products to support future space missions and aid the long-term survival of settlers on Mars, in addition to being applicable for modern agriculture. The overall goals and objectives of the consortium were presented by the Puratos Group (Belgium), the leading commercial partner of the SpaceBakery project.

Urban Crop Solutions also presented another joint project, the ‘variable climate biosphere’ that they have designed. The variable climate biosphere is a macro life support system that aims to create the best-suited environment for humans and plants to thrive together during extended periods of isolation, either on another planet – namely, the moon and Mars – or on earth in an underground shelter. The presentation showcased the 3D renderings, as well as the results that have so far been obtained.

“Our approach to partner with ambitious global industrial groups and research institutions for controlled indoor farming solutions is finally paying off. We feel that we are at the cutting-edge with our technology, products and services in the fast-emerging urban farming industry – whether it is in space, in cities, on the surface or beneath it.” – Maarten Vandecruys, CTO and co-founder of Urban Crop Solutions

ABOUT UCS

Urban Crop Solutions is a Belgium-based pioneer in the fast-emerging technology of indoor vertical farming. It has developed over the past six years, 220+ plant growth recipes in its research centre in Waregem, Belgium. To date, UCS has delivered over 25 projects in multiple global locations. Their farms are being operated both for commercial and research purposes. Uses range from the production of leafy greens, microgreens, and herbs for food retail, service and industrial use, and scientific research across multiple institutions.

Website: www.urbancropsolutions.com

Facebook: www.facebook.com/urbancropsolutions

Twitter: www.twitter.com/U_C_Solutions

LinkedIn: www.linkedin.com/company/urbancropsolutions

For more information on this press release, on Urban Crop Solutions and their products and services, or the SpaceBakery project, you may contact Maarten Vandecruys, Serge Ameye or Lucie Beckers.

Maarten Vandecruys

Founder & CTO, UCS

maarten.vandecruys@urbancropsolutions.com

Serge Ameye,

Space, Tunnels & Special Projects, UCS

serge.ameye@marsbakingsociety.space

Lucie Beckers,

Research Manager Agronomy, Puratos Group

LBeckers@puratos.com

USA - GEORGIA - Giant Photovoltaic Canopy Tops Net-Positive Kendeda Building In Atlanta

US firms Miller Hull Partnership and Lord Aeck Sargent have designed a highly sustainable building at Georgia Tech university that generates more electricity and recycles more water than it uses.

US firms Miller Hull Partnership and Lord Aeck Sargent have designed a highly sustainable building at Georgia Tech university that generates more electricity and recycles more water than it uses.

The project – officially called The Kendeda Building for Innovative Sustainable Design – is located at the Georgia Institute of Technology, a public research university in central Atlanta.

The Kendeda Building for Innovative Sustainable Design is in Georgia

The educational building was designed by Seattle's Miller Hull Partnership in collaboration with local firm Lord Aeck Sargent, which was purchased by tech startup Katerra in 2018.

The project was backed by the Kendeda Fund, a private family foundation that supports a range of social and environmental initiatives. Skanska served as the general contractor.

The project is a highly sustainable building

The facility recently earned certification from the Seattle-based International Living Future Institute under its Living Building Challenge – one of the most rigorous green-building certification programmes in the world. The facility is considered to be a "regenerative building."

"Regenerative buildings create more resources than they use, including energy and water," the team said.

Classrooms and a design studio are included in the design

"The project's goal is to support the educational mission of Georgia Tech while transforming the architecture, engineering and construction industry in the Southeast US by advancing regenerative building and innovation."

The facility – which totals 47,000 square feet (4,366 square metres) – holds a range of spaces for students and faculty.

These include a design studio, two large classrooms, several laboratories, a seminar room, an auditorium and office space. There also is a rooftop garden with an apiary and pollinator garden.

The building's rooftop garden

Certain areas of the building are open to the public for special events.

While designing the facility, the team took inspiration from vernacular architecture – in particular, large porches that are commonly found on Southern homes.

"The project reimagines this regionally ubiquitous architectural device for the civic scale of the campus," said Miller Hull.

Rectangular in plan, the building is topped with a giant white canopy supported by steel columns. On the west elevation, the roof extends 40 feet (12 metres) to form a large, shaded area below with steps and seating.

A white canopy tops the building

In addition to providing shade, the canopy generates electricity. Its 900-plus solar panels form a 330-kilowatt array that produces enough power to exceed the building's energy needs.

For the exterior cladding, the team incorporated a mix of accoya wood, metal, glass and recycled masonry. The foundation walls are made of concrete.

Materials such as metal form the exterior cladding

Mass timber was used for the structural system due to it having a smaller embodied carbon footprint compared to concrete and steel, the team said.

In large-span areas of the building, the team used glue-laminated trusses with steel bottom chords.

Details on the building's exterior

"This hybrid approach reduces the quantity of wood required while making routing of building services more efficient," the team said.

For the structural decking, nail-laminated timber panels were made off-site and craned into place. A local nonprofit organisation, Lifecycle Building Center, sourced the lumber from discarded movie sets in Georgia.

Large windows flood spaces with natural light

Structural elements, along with mechanical systems, were left exposed so they could serve as a teaching tool.

Salvaged and recycled materials are found throughout the facility. For instance, stairs in the building's atrium are made of lumber off-cuts, and countertops and benches are made of storm-felled trees.

Mechanical systems were left exposed

Water recycling is also part of the building's sustainable design. Rainwater is captured, treated and used in sinks, showers and drinking fountains. In turn, that greywater is channelled to a constructed wetland, where it is treated and used to support vegetation.

The facility is also fitted with composting toilets, which nearly eliminate the use of potable water. The human waste is turned into fertilizer that is used off-site.

The rooftop has a pollinator garden

The building recently earned its Living Building Challenge (LBC) certification following a year-long assessment, in which it needed to prove it is net-positive for energy and water usage.

"It generates more energy from onsite renewable sources than it uses," the team said. "The building also collects and treats more rainwater onsite than it uses for all purposes, including for drinking."

The LBC programme evaluates buildings in seven categories – place, water, energy, health and happiness, materials, equity and beauty.

The Kendeda Building is the 28th building in the world to achieve LBC certification and the first in Georgia. The state's warm and humid climate poses a particular challenge when it comes to energy efficiency, the team said.

A large classroom

A communal workspace

"In spite of this, over the performance period the building generated 225 per cent of the energy needed to power all of its electrical systems from solar panels on its roof," the team said.

"It also collected, treated, and infiltrated 15 times the amount of water needed for building functions."

Students gather under the canopy outside

Other American projects that are designed to meet the LBC standards include the wood-clad Frick Environmental Center in Pittsburgh, designed by Bohlin Cywinski Jackson. It achieved certification in 2018.

Photography is by Jonathan Hillyer and Gregg Willett.

Project credits:

Design architect: The Miller Hull Partnership, LLP

Collaborating and prime architect: Lord Aeck Sargent, a Katerra Company

Contractor: Skanska USA

Landscape architect: Andropogon

Civil engineer: Long Engineering

Mechanical, electrical and plumbing engineer: PAE and Newcomb & Boyd

Structural engineer: Uzun & Case

Greywater systems: Biohabitatssolar panels

Kalera – Curtis McWilliams Proposed As A New Member of The Board of Directors

McWilliams, the former President and CEO of the nation’s largest restaurant REIT and a seasoned independent director of a number of publicly-traded corporate boards, brings a wealth of experience as Kalera prepares for rapid domestic and international expansion

June 28, 2021

McWilliams, the former President and CEO of the nation’s largest restaurant REIT and a seasoned independent director of a number of publicly-traded corporate boards, brings a wealth of experience as Kalera prepares for rapid domestic and international expansion

ORLANDO, Fla., June 28, 2021 (GLOBE NEWSWIRE) -- Kalera (Euronext Growth Oslo ticker KAL, Bloomberg: KSLLF), one of the fastest-growing and largest vertical farming companies in the world and a leader in plant science for producing high-quality produce in controlled environments, today announced the proposed appointment of Curtis McWilliams to its Board of Directors. In addition, it is expected that McWilliams will chair Kalera’s Audit Committee responsible for oversight of the financial reporting and disclosure process. An executive with deep experience in mergers & acquisitions, real estate, corporate governance as well as financial accounting and analysis, McWilliams brings nearly 40 years of executive leadership and experience to the Kalera board. After an extended career in investment banking with Merrill Lynch, McWilliams transitioned to the CEO of Trustreet Properties where over the course of the following 10 years, he oversaw the growth of the company from under $100 million to over $3 billion when it was sold to GE Capital in 2007. He presently is the non-executive chair of Ardmore Shipping Corporation (NYSE: ASC), an independent director for Braemar Hotels & Resorts (NYSE: BHR), and lead independent director for Modiv Inc. McWilliams has previously chaired the audit committee for CNL Bank and presently serves as chair of the audit committee for Braemar Hotels as well as serving on the audit committee for Ardmore Shipping.

The addition of McWilliams to the board coincides with Kalera’s rapid expansion into several new markets and its acquisition of Vindara Inc., the first company to develop seeds specifically designed for use in vertical indoor farm environments as well as other controlled environment agriculture (CEA) farming methods.

“We are thrilled and honored to have Curtis McWilliams join Kalera’s Board,” said Bjørge Gretland, Chairman. “Curtis has been tremendously successful as a CEO and has extensive experience chairing Audit Committees. He also brings valuable expertise doing M&A deals. I am confident he will be a strong contributor to Kalera’s success.”

In addition to his aforementioned business experience, McWilliams also has served on numerous civic and non-profit boards including the Orlando Museum of Art and Young Life. McWilliams received his BSE in Chemical Engineering from Princeton University and his MBA from the University of Chicago with a concentration in finance.

“There has never been a more pressing need for vertical farming than there is today. I’m honored and excited to have the opportunity to join the Board at Kalera, the leader in this innovative and disruptive industry,” said Curtis McWilliams. “I look forward to working with Kalera as they continue to grow and expand domestically and abroad.”

Kalera currently operates two growing facilities in Orlando and a newly opened facility in Atlanta and is building facilities in Houston, Denver, Columbus, Seattle, Minnesota, and Hawaii. Kalera is the only controlled environment agriculture company with coast-to-coast facilities being constructed, offering grocers, restaurants, theme parks, airports, and other businesses nationwide reliable access to locally grown clean, safe, nutritious, price-stable, long-lasting greens. Kalera uses a closed-loop irrigation system which enables its plants to grow while consuming 95% less water compared to field farming.

The appointment of Curtis McWilliams as a member of the Board of Directors will be presented for approval by Kalera’s shareholders at a general meeting and is expected to take effect upon completion of the contemplated merger between Kalera AS and the new Luxembourg parent for the group, which was announced previously.

For further information:

Bjørge Gretland, Chairman

Email: bgretland@kalera.com

About Kalera

Kalera is a technology-driven vertical farming company with unique growing methods combining optimized nutrients and light recipes, precise environmental controls, and cleanroom standards to produce safe, highly nutritious, pesticide-free, non-GMO vegetables with consistent high quality and longer shelf life year-round. The company’s high-yield, automated, data-driven hydroponic production facilities have been designed for rapid rollout with industry-leading payback times to grow vegetables faster, cleaner, at a lower cost, and with less environmental impact. To learn more visit www.Kalera.com.

This information is subject to the disclosure requirements pursuant to section 5-12 of the Norwegian Securities Trading Act.

The 5th AVF International Summit - The International Vertical Farming And New Food System Conference & Exhibition - 2nd - 3rd September, 2021 In Munich, Germany.

A hybrid event, it is designed to welcome back delegates and participants for in-person meetings, networking, and exchanges relating to innovations, investments, business opportunities, strategic partnerships, and cooperation in our vertical farming industry across the globe

The Association for Vertical Farming (AVF) in official partnership with the German State of Bavaria through its Ministry of Economy and Ministry of Food, Agriculture & Forestry announces the 5th AVF International Summit – The International Vertical Farming and New Food System Conference & Exhibition -- on 2-3 September 2021 in Munich, Germany.

A hybrid event, it is designed to welcome back delegates and participants for in-person meetings, networking, and exchanges relating to innovations, investments, business opportunities, strategic partnerships, and cooperation in our vertical farming industry across the globe.

We have prepared a two-day program of world-class keynotes, panels, roundtables, break-out sessions, and startup pitches to get everyone up to speed with the latest crucial developments and emerging trends in the various subsectors of our dynamic global industry. In addition, we are also organizing workshops on artificial intelligence, insect protein, robotics, automation, and sustainability certification.

And what’s more the city of Munich -- with its centuries-old culture, gastronomy, art, and architecture together with its vibrant, contemporary, and fun-loving modern incarnation – is eagerly awaiting your visit.

See You All In September

Click Here To Reserve Your Early Bird Tickets!

USA: VIRGINIA - Maker of Hydroponic Farming Systems Gets $1 Million Grant, Relocates Headquarters To Scott's Addition

The grant will help the company move further into commercialization. The company had been awarded a $225,000 Phase 1 grant in 2019 to conduct scientific trials of its technology

June 24, 2021

A startup company that makes indoor, hydroponic farming systems has opened its new headquarters and production site in the Scott’s Addition area of Richmond.

The opening of the Babylon Micro-Farms Inc. office comes after the company received a $1 million grant from the National Science Foundation with the potential for $750,000 in follow-on funding to continue development of BabylonIQ, its technology platform designed to operate decentralized, automated micro-farms.

The grant will help the company move further into commercialization. The company had been awarded a $225,000 Phase 1 grant in 2019 to conduct scientific trials of its technology.

Babylon Micro-Farms also completed a $3 million investment round in the first quarter of this year. Investors include Virginia’s Center for Innovative Technology, Hull Street Capital, Venture South, and the CAV Angels Group.

The capital raised “helped us move here [to Richmond] and build our team,” Alexander Oleson, the company’s CEO who co-founded the business with Graham Smith, said Thursday as Babylon Micro-Farms hosted an open house at the headquarters.

“A lot of it is about switching from an R&D organization to a sales organization,” Oleson said. “We have a backlog of orders to fill.”

Babylon Micro-Farms was founded in Charlottesville in 2017 by Oleson and Smith, who were University of Virginia students. The company announced plans to move its headquarters to Richmond earlier this year.

The company now has more than 30 employees working in a renovated 7,700-square-foot building on Carlton Street. The facility serves as the company’s main office as well as a research and development site for its indoor farming units designed to grow more than 40 different types of leafy greens, herbs and flowers.

From the Scott’s Addition site, the company staff also can remotely monitor the functioning of more than 40 of its indoor farming units that have been installed at customer sites including retirement communities, universities, and corporate cafeterias.

Several of the company’s 8-foot-tall, climate-controlled farming units stand in the main lobby of the headquarters, growing plants such as basil, kale, lettuce, and bok choy.

In a research area of the building, Babylon Micro-Farms is testing growing other produce such as strawberries and peppers in its hydroponic systems.

“Our hope is to be in hundreds of locations by the end of next year, mostly in Virginia, but really casting our footprint nationally,” Oleson said.

Photos: John Reid Blackwell

Karen Sizer, an account manager for Babylon Micro-Farms Inc., spoke with visitors on Thursday about the company’s hydroponic, indoor farming systems. The company, founded in Charlottesville in 2017, hosted an open house at its new headquarters in Scott’s Addition.

Alexander Oleson, co-founder, and CEO of Babylon Micro-Farms stands by one of the company’s 8-foot-tall, climate-controlled hydroponic farming units.

Babylon Micro-Farms Inc., a maker of indoor farming systems, has its headquarters and research facility on Carlton Street in the Scott’s Addition area of Richmond

(804) 775-8123

Is A Vertical Farm Cost Effective To Build And Operate?

A common question we’re often asked is a vertical farm cost effective to build and operate? There is no categorical answer to this complex question, which often requires a detailed feasibility study to resolve.

Author: Robert Colangelo.

Founding Farmer at Green Sense Farms Holding, INC.

A common question we’re often asked is a vertical farm cost-effective to build and operate? There is no categorical answer to this complex question, which often requires a detailed feasibility study to resolve.

The answer Starts With The 4 Cs -

Crop, Capacity, Climate, and Capital Budget.

Crop: What is the intended crop and how many varieties will be grown? At this time vertical farms can economically grow leafy greens (lettuces, baby greens, herbs, and microgreens), starter plants, and cannabis. To grow a cultivar well its best to design a farm with individual grow rooms where set points can be optimized to the monocrop. Many customers ask us to build farms that can grow a wide range of crops. We suggest specializing in growing large volumes of a few crops, that you can grow well and build a brand. This will also make production more efficient increasing the profitability.

Capacity: What is the desired output and frequency of harvest? The answer to this question is key to sizing a farm design. Understanding the production schedule and how many crop rotations a farm will hold will assist in laying out the farm. Capacity is also key to calculating the unit production cost. The bigger the farm typically the lower the unit cost.

Climate: One of the advantages of a vertical farm is that it can be built anywhere from the cold-dry climate in the South Pole to the hot- humid climate in Southeast Asia. The more humid the climate the more expensive mechanical equipment will be required to control Temperature and Relative Humidity. A good farm design can take into consideration the outside cool-dry climate and use it to reduce capital and operating expenses. In addition, cooler drier climates tend to have less bugs which will reduce operating costs when it comes to Integrated Pest Management (IPM) programs.

Capital Budget: A rule of thumb is that if you spend more on capital expense then you will reduce your operating expense. A well-built farm that is designed to optimize crop growth will lower the daily operating cost. To do this it greatly helps to have an anchor customer identified, define the crop (s) that will be grown, the harvest frequency/delivery and how it will be packaged so that these variables all be factored into the farm design.

Many other factors play a role in setting and building a farm. This includes location, automation, and labor. The 4C’s will get you off to a good start and will allow the development of an initial financial proforma so that you can predict the size of the farm, output, and the capital required to build and operate the farm profitably. I have learned that sometimes the best projects are the “ones not done.” Building a farm too big or too small can be a disaster. Starting backwards to first identify and understand the customers’ needs is a good way to begin. With adequate research and planning a vertical farm can be built to operate profitably and be a project worth doing!

Vertical Roots Expands To Atlanta, Partners With Two Wholesalers

The company partnered with two of the leading Southeastern produce suppliers, Collins Brothers Produce BB #:128652 and Phoenix Wholesale Foodservice BB #:134241, to place the farm directly at their facilities

June 11, 2021

CHARLESTON, S.C., June 10, 2021 /PRNewswire/ — Vertical Roots, the largest hydroponic container farm in the U.S. sustainably growing fresh leafy greens year-round, opened its third indoor farm in Atlanta, Georgia this June.

The company partnered with two of the leading Southeastern produce suppliers, Collins Brothers Produce BB #:128652 and Phoenix Wholesale Foodservice BB #:134241, to place the farm directly at their facilities.

The new Atlanta farm site will eliminate the need for produce transportation to the distributor and allow Vertical Roots lettuce to be delivered to local customers the same day it’s harvested.

Located within the Atlanta State Farmers Market, this is phase one of the company’s Atlanta expansion. With farm production underway, Vertical Roots Georgia Grown™ lettuce will be available in grocery stores in July 2021.

Crisp, sweet, tender, or buttery, Vertical Roots lettuces are nutritious, pesticide-free, and come in a wide variety of flavors, colors, and textures for culinary masterpieces and everyday meals. With long lasting freshness, produce is in the hands of consumers within one to three days of being harvested and has up to a 21-day shelf life.

Vertical Roots’ mission is to revolutionize the ways communities grow, distribute, and consume food. Farming directly at distribution hubs is a part of Vertical Roots’ distinctive strategy to eliminate a massive leg of produce transportation in order to reduce emissions and provide communities with fresh, locally-grown produce.

The new Atlanta farmsite will reduce produce transportation by an estimated 300 miles per delivery and will help meet the company’s retail demand that services thousands of grocery stores across the Southeast and Mid-Atlantic, as well as restaurants, universities, and schools.

“A large part of our mission is to grow food as close to the point of consumption as possible, and this farmsite accomplishes just that,” said Andrew Hare, co-founder, and general manager of Vertical Roots. “The Collins family are esteemed produce industry leaders for three generations, and we’re ecstatic about the unique grower-supplier partnership that we’ve cultivated.”

David Collins, President of Collins Brothers & Phoenix Wholesale Foodservice, said, “At Collins Brothers and Phoenix Wholesale, we’ve had the privilege to work with dedicated farmers across the country for decades. We’re thrilled to partner with Vertical Roots as they bring an innovative way of farming to the agriculture industry. We look forward to this relationship as we share a like-minded mission in providing our customers with high quality, fresh, local produce.”

Vertical Roots’ state-of-the-art indoor farms are manufactured from upcycled shipping containers at the company’s headquarters in Charleston, SC. The farm containers made their way to Atlanta on June 8, where farmers started seeding and transplanting to produce Vertical Roots lettuce within weeks.

A small footprint with a large output, the new farm will produce half a million heads of lettuce this year. Each 320-square-foot container maximizes the growing space with 3,400 plants per harvest, and up to 17 harvests per year.

Vertical Roots farms operate with the highest globally recognized food safety standards, eliminating the need for pesticides of any kind.

An AmplifiedAg, Inc.® company, Vertical Roots operates farms with proprietary software and technology. The farms don’t rely on soil, use up to 95% less water and grow crops 25% faster, compared to traditional farming methods.

About Vertical Roots:

An AmplifiedAg, Inc. company, Vertical Roots is the country’s largest hydroponic container farm and is revolutionizing the ways communities grow, distribute and consume food. Sustainably-grown indoors and pesticide-free, Vertical Roots leafy greens are fresh, clean, nutritious, and delivered to your local grocery store within one to three days of being harvested. Vertical Roots produce is available at thousands of leading grocery stores in 12 Southeastern states, educational institutions, restaurants, and other food service organizations. Vertical Roots operates farms in Charleston, S.C., Columbia, S.C. and Atlanta, Ga.

Tagged greenhouse, lettuce, vertical farming

Click & Grow 25 Is An Efficient, Self-Monitoring Indoor Garden

“I started the company with a dream to make fresh food available and accessible for everyone and with the Click & Grow 25, we finally made it happen in a sustainable way,” said Mattias Lepp, founder, and CEO of Click & Grow

Written by Dawn Hammon

June 9, 2021

In a world struggling to find balance between busy lifestyles and healthy living, Click and Grow 25 aims to offer an easy-to-use way to grow organic food inside your home.

The smart indoor garden only takes up as much space as a microwave, yet with stacking trays, you can grow fresh produce for one person, two people or an entire family. With such a compact design, anyone can incorporate the Click & Grow 25 into their apartment, home or office.

The system is intuitive and does most of the work for you. Simply select your proprietary biodegradable Smart Soil plant pods, which are similar to the design used in single-serve coffee machines. Each pod is pre-loaded with seeds and soil. Once planted, the built-in technology takes over, monitoring the growth of leafy greens, fruits, and herbs.

This self-growing garden takes care of plants automatically by maintaining optimal levels of moisture, nutrients, root oxygen and pH. The device ensures perfect conditions needed to grow lush produce at a faster rate than you will find in an outdoor garden. Plus, the direct garden-to-table aspect offers a higher nutrient content than store-bought food, often pulled from the field weeks before. All plants are organic without the need for fertilizers and pesticides.

Click & Grow 25 not only provides convenience, but its energy-efficient design consumes just 200 kWh of electricity per year, which equates to about $40 in large urban areas. An associated app lets users know when it is time to add more water and offers harvesting tips as well as recipes.

“I started the company with a dream to make fresh food available and accessible for everyone and with the Click & Grow 25, we finally made it happen in a sustainable way,” said Mattias Lepp, founder and CEO of Click & Grow. “With the impact of population growth and the demand on our natural resources, it is inevitable for us to become more self-sufficient. I believe we are all going to be growing some of our food at home soon and I’m certain we’ve developed the best solution to do just that.”

Click & Grow 25 recently launched via Kickstarter, where it was fully funded in the first 20 minutes. At the time of writing, it had raised over $500,000 of the $35,000 goal.

Images via Click & Grow

Polygreens Podcast Episode: 30 - Richard Vollebregt - Part 1

In this episode Joe and Nick interview Richard Vollebregt, President & CEO of Cravo Equipment Ltd, a company that develops retractable roof production systems to enhance berry, cherry, cannabis, and vegetable production for growers worldwide

In this episode Joe and Nick interview Richard Vollebregt, President & CEO of Cravo Equipment Ltd, a company that develops retractable roof production systems to enhance berry, cherry, cannabis, and vegetable production for growers worldwide.

His background in economics combined with 30+ years of experience designing automated retractable roof greenhouses, knowledge of plant physiology and my worldwide experience in many crop industries allows me to be very effective in designing crop production systems and then creating financial models which benchmarking again conventional greenhouses, tunnels, and open field production.

Latest Episode

Green Skyscrapers That Add A Touch of Nature + Sustainability To Modern Architecture!

Polish designers Pawel Lipiński and Mateusz Frankowsk created The Mashambas Skyscraper, a vertical farm tower, that is in fact modular!

06/09/2021

Skyscrapers have taken over most of the major cities today. They’re symbols of wealth and power! And most of the skylines today are adorned with glistening glass skyscrapers. They are considered the face of modern architecture. Although all that glass and dazzle can become a little tiring to watch. Hence, architects are incorporating these tall towers with a touch of nature and greenery! The result is impressive skyscrapers merged with an element of sustainability. These green spaces help us maintain a modern lifestyle while staying connected to nature. We definitely need more of these green skyscraper designs in our urban cities!

Zaha Hadid Architects designed a pair of impressive skyscrapers that are linked by planted terraces, for Shenzhen, China. Named Tower C, the structure is 400 metres in height and is supposed to be one of the tallest buildings in the city. The terraces are filled with greenery and aquaponic gardens! They were built to be an extension of a park that is located alongside the tower and as a green public space.

Polish designers Pawel Lipiński and Mateusz Frankowsk created The Mashambas Skyscraper, a vertical farm tower, that is in fact modular! The tower can be assembled, disassembled and transported to different locations in Africa. It was conceptualised in an attempt to help and encourage new agricultural communities across Africa. The skyscraper would be moved to locations that have poor soil quality or suffer from droughts, so as to increase crop yield and produce.

The Living Skyscraper was chosen among 492 submissions that were received for the annual eVolo competition that has been running since 2006. One of the main goals of the project is to grow a living skyscraper on the principle of sustainable architecture. The ambitious architectural project has been envisioned for Manhattan and proposes using genetically modified trees to shape them into literal living skyscrapers. It is designed to serve as a lookout tower for New York City with its own flora and fauna while encouraging ecological communications between office buildings and green recreation centers. The building will function as a green habitable space in the middle of the concrete metropolis.

ODA’s explorations primarily focus on tower designs, in an attempt to bring versatility and a touch of greenery to NY’s overtly boxy and shiny cityscape. Architectural explorations look at residential units with dedicated ‘greenery zones’ that act as areas of the social congregation for the building’s residents. Adorned with curvilinear, organic architecture, and interspersed with greenery, these areas give the residents a break from the concrete-jungle aesthetic of the skyscraper-filled city. They act as areas of reflection and of allowing people to connect with nature and with one another.

Heatherwick Studio built a 20-storey residential skyscraper in Singapore called EDEN. Defined as “a counterpoint to ubiquitous glass and steel towers”, EDEN consists of a vertical stack of homes, each amped with a lush garden. The aim was to create open and flowing living spaces that are connected with nature and high on greenery.

Designed by UNStudio and COX Architecture, this skyscraper in Melbourne, Australia features a pair of twisting towers placed around a ‘green spine’ of terraces, platforms, and verandahs. Called Southbank by Beulah, the main feature of the structure is its green spine, which functions as the key organizational element of the building.

Mad Arkitekter created WoHo, a wooden residential skyscraper in Berlin. The 98-meter skyscraper will feature 29 floors with different spaces such as apartment rentals, student housing, a kindergarten, bakery, workshop, and more. Planters and balconies and terraces filled with greenery make this skyscraper a very green one indeed!

Algae as energy resources are in their beginnings and are seen as high potential. Extensive research work has dealt with algae as an energy source in recent decades. As a biofuel, they are up to 6 times more efficient than e.g. comparable fuels from corn or rapeseed. The Tubular Bioreactor Algae Skyscraper focuses on the production of microalgae and their distribution using existing pipelines. Designed by Johannes Schlusche, Paul Böhm, Raffael Grimm, the towers are positioned along the transalpine pipeline in a barren mountain landscape. Water is supplied from the surrounding mountain streams and springs, and can also be obtained from the Mediterranean using saltwater.

Tesseract by Bryant Lau Liang Cheng proposes an architecture system that allows residents to participate in not just the design of their own units; but the programs and facilities within the building itself. This process is inserted between the time of purchase for the unit and the total time required to complete construction – a period that is often ignored and neglected. Through this process, residents are allowed to choose their amenities and their communities, enhancing their sense of belonging in the process. Housing units will no longer be stacked in repetition with no relation whatsoever to the residents living in it – a sentimental bond between housing and men results.

In a world devoid of greenery, Designers Nathakit Sae-Tan & Prapatsorn Sukkaset have envisioned the concept of Babel Towers, mega skyscrapers devoted to preserving horticultural stability within a single building. The Babel towers would play an instrumental role in the propagation of greenery in and around the area. These towers would also become attraction centers for us humans, like going to a zoo, but a zoo of plants. Seems a little sad, saying this, but I do hope that we never reach a day where the Babel Tower becomes a necessity. I however do feel that having towers like these now, in our cities, would be a beautiful idea. Don’t you think so too?

Farm Tech Startup Iron Ox Appoints Impossible Foods and Tesla Veteran Rachel Konrad as First Independent Board Member

Iron Ox growing facilities use advanced robotics to precisely cultivate perfect, nutritious produce by giving each plant the specific attention it needs, and then getting it on a store shelf nearby within about a day of harvest

-- Konrad, who spent the past five years at Impossible Foods, joins the board of Iron Ox during a period of rapid manufacturing scale-up and retail expansion.

-- Iron Ox growing facilities use advanced robotics to precisely cultivate perfect, nutritious produce by giving each plant the specific attention it needs, and then getting it on a store shelf nearby within about a day of harvest.

-- The Series B-stage company, whose products are already a breakout seller in California, is also hiring plant scientists, engineers, greenhouse operators, and roboticists.

SAN CARLOS, Calif., June 10, 2021 /PRNewswire/ -- Iron Ox, a farming innovation company with deep expertise in robotics and artificial intelligence, has appointed former Impossible Foods and Tesla executive Rachel Konrad as its first independent board member. This appointment further demonstrates the food tech startup's growth trajectory as they scale up operations and expand their commercial footprint.

Iron Ox, which launched the world's first autonomous farm, has an industry-leading intellectual property portfolio to automate farming and produce that's fresher, cleaner, and locally grown. Thanks to the company's groundbreaking robotics, Iron Ox farms require 90% less water than traditional farms — generating 30 times more produce per acre of land.

Konrad joins Iron Ox after spending the past five years as Chief Communications Officer and a member of the senior leadership team at Impossible Foods, reporting directly to CEO Pat Brown. She previously held senior management roles at Renault-Nissan-Mitsubishi and Tesla, where she reported directly to Elon Musk as the company scaled up operations.

"We can't solve our planet's climate crisis without radical changes to the way we make food," said Konrad, who lives in the San Francisco Bay Area and enjoys cooking for her family and hiking with her rescue German Shepherd. "Iron Ox's intellectual property portfolio can usher in a new era of farming that produces food sustainably and ethically. But honestly, I was sold after my first whiff of Iron Ox basil."

"Rachel understands the unique power of disruptive startups to shift entire industries and force even the most entrenched incumbents to do the right thing for people and the planet," said Brandon Alexander, Iron Ox CEO and Co-Founder. "Her unique perspective will help Iron Ox refine and execute our ambitious strategy. As our first independent board member, we expect Rachel to help us set a new standard for inclusive governance in corporate America."

The Series B-stage company operates farms in Northern California and recently broke ground on a new 535,000 sq. ft. indoor farm in Lockhart, Texas. Today, California consumers can buy Iron Ox food throughout California at Whole Foods and at San Francisco Bay Area's upscale Biancchini's markets. Sales in Texas are expected to begin in late 2021.

The company is also hiring plant scientists, engineers, greenhouse operators and roboticists who are passionate about solving food insecurity, which is at the root of our environmental and public health crises.

For more information, and to view the job openings, visit the Iron Ox jobs page.

About Iron Ox:

Iron Ox is a farming innovation company with deep expertise in robotics and artificial intelligence, and a vision to solve global climate through food. Their approach redesigns every step of the farming process, achieving levels of precision that are impossible through traditional farming. Iron Ox produce is both local and sustainable by design, greatly reducing systemic food waste and minimizing the ecological impact of farming. For more information, visit www.ironox.com.

SOURCE: Iron Ox

Pontus Files International Patent Application For Automated Vertical Farm Harvesting Robot

Pontus' initial crop, water lentils, is the fastest-growing leafed plant.* Pontus' CEVAS helps accelerate the growth of Pontus' water lentils, requiring the plant to be harvested every 24 hours

NEWS PROVIDED BY

Jun 09, 2021, VANCOUVER, BC, June 9, 2021 /CNW/ - Pontus Protein Ltd. (TSXV: HULK) (OTCQB: HLKKF) (FSE: 8YC) ("Pontus" or the "Company"), is pleased to announce that it has filed an international patent application through the Patent Coordination Treaty with the World Intellectual Property Organization for Pontus' proprietary Harvesting Automated Robotic Vehicle or "HARV" for short. HARV is a vertical farm rack system and automated plant tending and harvesting robot designed to work alongside and assist Pontus' Closed Environment Vertical Aquaponics System or CEVAS system.

Pontus' Harvesting Automated Robotic Vehicle or “HARV” for short. HARV is a vertical farm rack system and automated plant tending and harvesting robot (CNW Group/Pontus Protein Ltd.)

Pontus' initial crop, water lentils, is the fastest-growing leafed plant.* Pontus' CEVAS helps accelerate the growth of Pontus' water lentils, requiring the plant to be harvested every 24 hours. Pontus developed the HARV technology to allow the crop to be automatically harvested daily. In addition, due to its low profile, HARV will enable Pontus to stack nine levels of vertical farming at its Surrey, British Columbia production facility.

Steve McArthur, Chief Technology Officer, Pontus, stated, "Talking with the experienced team at Automation Experts (an automation and innovation company based in Calgary, Canada), we were able to identify that there was no robot out there that handled everything we needed it to do. By harvesting the crop in situ, using HARV, we will reduce the space between the water beds and increase the number of levels, increasing efficiency and the yield. We are beyond excited about pairing HARV with our CEVAS system, as we see CEVAS as a greener, more ecologically sustainable way of producing high nutrition food products."

Stephen Bruce Wong, CEO, Automation Experts, added, "HARV is more than a mechanical tool for harvesting. It will manage the farm and give us critical insight and data regarding the optimization of the growing environment. The robotics in HARV will allow Pontus to eliminate moving parts from the structure thus lowering the cost to build Pontus' vertical farms as the water beds can be dumb and do not need the technology built into them. It also uses machine learning and artificial intelligence to support all aspects of the growing process."

The patent filing is part of the technology leadership in the aquaponic space that Pontus continues to secure.

About Pontus Protein Ltd.

Pontus Protein Ltd. is a Vancouver, B.C. based technology company that grows water lentil protein for commercial use. Pontus is reinventing agriculture with their proprietary Closed Environment Vertical Aquaponic System (CEVAS) – the farming of the future. Pontus specializes in the indoor vertical farming of water lentils that use 95% less water than traditional agriculture and no pesticides or chemicals. Pontus is committed to solving the global food crisis by providing access to sustainable indoor biosecure pure plant-based proteins. Pontus' water lentils can be harvested every 24 hours, exceed organic certification, and can be grown in any climate in a relatively small area. Our water lentil protein is filled with antioxidants, minerals, vitamins, and all the amino acids, making a complete protein food source. Pontus aims to revolutionize the plant-based sector as the entire sector is currently based on two main protein sources: soy and pea. Water lentil protein is far superior to pea and soy protein. It contains over 40% protein vs. 5-36% protein*, and Pontus aims to be the base protein for nutrition-rich plant-based food products and nutraceuticals to support the movement transitioning the world from meat-based to plant-based proteins.

To learn more, please visit pontuswaterlentils.com.

*https://www.infood.net/visitor/collection/75?portion_size=100

*https://www.zmescience.com/science/fastest-growing-plant-02022021/

On behalf of the Board of Directors

"Connor Yuen"

Connor Yuen, CEO

Pontus Protein Ltd.

Contact Information

For more information, please contact:

Connor Yuen

Chief Executive Officer

https://pontuswaterlentils.com/company/#contact

Forward-Looking Information

Certain statements in this release are forward-looking statements, which reflect the expectations of management regarding the Company. Forward-looking statements consist of statements that are not purely historical, including any statements regarding beliefs, plans, expectations or intentions regarding the future, including but not limited to Pontus' ability to revolutionize the plant based sector. Such statements are subject to risks and uncertainties that may cause actual results, performance or developments to differ materially from those contained in the statements, including risks related to factors beyond the control of the Company. These risks include, but are not limited to, the following: the unknown magnitude and duration of the effects of the COVID-19 pandemic, the failure of Pontus to receive the necessary approvals from the Canadian Food Inspection Agency for its products and facilities, the inability to complete Pontus' Surrey-based production facility, as well as other general business, economic, or market related risks beyond the director control of the Company and which may affect the Company's business, operations, or products. No assurance can be given that any of the events anticipated by the forward-looking statements will occur or, if they do occur, what benefits the Company will obtain from them. The Company undertakes no obligation to update forward-looking information if circumstances or management's estimates or opinions should change, unless required by law. The reader is cautioned not to place undue reliance on forward-looking information.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

SOURCE Pontus Protein Ltd.

For further information: Investor Relations or Media enquiries: invest@pontuswaterlentils.com, (403) 589-7992

Organization Profile

Pontus Protein Ltd.

[Webinar] Financing Indoor Ag Seed to Scale

Get an in-depth look at financing -- the different stages and how it changes as you grow.

Indoor Ag-Con, FarmTech Society &

Brad McNamara Present

17 Indoor Ag Investors & Entrepreneurs.

2 Days. 6 Panels.

Countless Funding Insights!

Get an in-depth look at financing -- the different stages and how it changes as you grow. A one-of-a-kind opportunity to hear leaders from Artemis, Beta Hatch, Baywa, Rabobank, AccelR8, Anzu Partners, Equilibrium, Ceres Partners, Infinite Acres, Grey Matter LLC, Horizon11, Ara Partners, Barclays Investment Bank, Native and others!

Insights You Need To Build & Strengthen Your Successful Controlled Environment Agriculture Funding Strategy

Don't miss the chance to hear from successful entrepreneurs, investors, and others who will give you a crystal clear roadmap to build your own successful CEA funding strategy-- from seed to scale.

SEE FULL SCHEDULE & REGISTER!

USA - KENTUCKY: Elliott County High School Receives New Container Farm Through AppHarvest

The curriculum provided by AppHarvest will cover topics such as high-tech growing and an introductory course on local food systems and food resiliency

May. 29, 2021

SANDY HOOK, Ky. (WSAZ) - Some students at Elliott County High School will soon be able to help grow food -- not only for themselves but for the entire region.

The Elliott County High School container farm is the fourth addition to AppHarvest’s program in 2021 and the sixth educational container farm to date.

The container farm program was launched in 2018 and demonstrates AppHarvest’s ongoing commitment to cultivating interest in high-tech farming as it seeks to create America’s AgTech capital from inside Appalachia. Each retrofitted shipping container acts as a hands-on agricultural classroom for students, allowing them to grow and provide fresh leafy greens to their classmates and those in need in their communities.

AppHarvest has opened container farms in Eastern Kentucky at Madison Central High School in Richmond; Breathitt High School in Jackson; Shelby Valley High School in Pikeville; and Rowan County Senior High School and AppHarvest’s flagship farm at Rockcastle County High School in Morehead.

Elliott County High School’s container farm includes space to grow up to 2,760 seedlings and 2,960 mature plants, all at once in a nutrient film technique (NFT) system. NFT is a water-saving system in which plant roots are continuously fed all necessary water and nutrients by a shallow stream, also called “film.” Excess water drains to a holding tank and is then recirculated. This system of high-tech growing sets the Elliott County container apart from AppHarvest’s other educational containers, which have operated hydroponically and vertically.

“One of our goals at AppHarvest is to build an AgTech capital right here in Appalachia,” said Jonathan Webb, AppHarvest Founder, and CEO. “We want to see communities across the region use technology to bring farms to life. And in five years from now, it’ll be leaders from these very programs coming to us with ideas on how we continue to evolve and change agriculture.”

Makayla Rose, Elliott County High School agriculture teacher, will lead the newest container program.

The curriculum provided by AppHarvest will cover topics such as high-tech growing and an introductory course on local food systems and food resiliency.

“This is exciting. Some students who might not like to get in the dirt have a different way of growing vegetables,” said Garret Barker, president of Elliot County’s FFA chapter. “It’s different than my farm at home. It doesn’t depend on outside factors like the rain. It’s all controlled by an app.”

Lead Photo: Elliott County High School receives new container farm through AppHarvest (Kimberly Keagy/ WSAZ)

Indoor Vertical Farming Grows Up

Bryan Walsh, author of Future

Indoor vertical farming, where crops are raised in automated stacks, often in or near cities, offers a way to sustainably meet the growing demand for food — if its energy demand can be reduced.

Why it matters: With the global population still rising — albeit more slowly — and more people moving to urban areas, the world needs ways to produce more food without clearing land for conventional farms.

Driving the news: New York-based vertical farming startup Bowery Farming on Tuesday announced a new $300 million funding round — the largest in the industry's history — that values the company at $2.3 billion.

The deal accelerates the momentum in venture capital funding for vertical farming companies, which hit nearly $1.9 billion globally in 2020, almost tripling investment from the year before.

"We're going to need 50–70% more food over the next 30 years, according to the UN," says Irving Fain, the CEO, and founder of Bowery Farming, which has two commercial vertical farms in New Jersey and Maryland and sells its leafy greens to 850 grocery stores. "Indoor farming is not the only answer to that challenge, but it's part of the solution."

How it works: Food has been grown indoors in greenhouses for decades, and it's industrialized to the point that the Netherlands has become the second-largest vegetable exporter in the world chiefly through greenhouses.

Vertical farming takes greenhouses to the next level —literally — with crops grown in tower-like walls of plant-holding cells that require no soil. Like an apartment tower versus a suburban tract, that means more food can be grown on a smaller footprint, which is ideal for cities.

Water and nutrients are delivered to crops either aeroponically — via the air through misting — or hydroponically, in which the plants are grown in nutrient-rich water. "You get high density and high output, while using 90% less water" than conventional farming, says Micki Seibel, VP of product at the vertical farming startup Unfold.

Growing light is delivered via LED lamps. While more expensive than sunlight — which currently remains free — the LED lamps aren't weather-dependent, and like water, nutrients and temperature in the vertical farms, the light can be controlled precisely, vastly enhancing yield and reducing grow times.

Because vertical farming uses so little space, "we can move the farm to the people rather than the food," says James Woolard, chief marketing officer at Freight Farms, which develops mobile hydroponic freight containers modified for indoor farming.

By the numbers: There are more than 2,000 vertical farms in the U.S. Most are run by small growers with a few bigger players, including Bowery Farming, Newark-based AeroFarms, and Wyoming-based Plenty.

Internationally, says Seibel, "Japan has looked at vertical farming as a way to increase food security and reclaim production lost during the tsunami, while Singapore — which imports 90% of its food — is making significant investments in the sector to increase its own food security."

A recent report pegs the size of the vertical farming market at $240 million in 2019 and projects it will grow to over $1 billion by 2027.

The catch: Even with that growth, vertical farming will likely still remain a niche player — the output of U.S. farms alone was worth $136 billion in 2019.

In part because of the price of supplying artificial light, vertical farms have struggled to break even in the past, and they chiefly produce comparatively priced leafy greens rather than the commodity crops that make up the backbone of the food system.

What's next: Second-generation vertical farms are taking advantage of efficiency advances in LED technology, as well as automation and sensors that can reduce labor and setup costs and enhance yield.

The ability of vertical farms to maintain the ideal environment for high-quality crops like tomatoes or lettuce anywhere in the world at any time of the year is turning agriculture into a high-tech industry.

"All the externalities that have been uncontrollable [in farming] historically are now very much controllable," says Bowery's Fain.

What to watch: The development of AeroFarms's 136,000-square-foot Model 5 facility in Virginia, which is set to be the largest and most technologically advanced vertical aeroponic farm when it is scheduled to be completed in mid-2022.

The bottom line: Agriculture made cities possible. Now vertical farming holds out the possibility that cities could become farms themselves

Lead Illustration: Shoshana Gordon/Axios

Bowery Farming Unveils Research And Breeding Hub, Farm X

Farm X is one of the largest and most sophisticated vertical farming R&D facilities in the world, and will further accelerate the commercialization of products specifically designed for Bowery’s indoor system

May 18, 2021

NEW YORK, May 18, 2021 /PRNewswire/ — Bowery Farming, the largest vertical farming company in the United States, today announced the opening of Farm X, its newest state-of-the-art innovation hub for plant science in Kearny, N.J., adjacent to Bowery’s original R&D Center of Excellence and first commercial farm.

Farm X is one of the largest and most sophisticated vertical farming R&D facilities in the world, and will further accelerate the commercialization of products specifically designed for Bowery’s indoor system.

From the cultivation of strawberries, root vegetables, tomatoes, peppers and beyond, to the discovery of the next generation of wildly flavorful leafy greens, Farm X expands Bowery’s R&D capacity by nearly 300%.

“We’re proud to be the largest vertical farming company in the United States that is consistently and reliably delivering our customers a wide variety of high quality, flavorful produce that’s local, safe and sustainable,” said Irving Fain, founder, and CEO of Bowery Farming.

“From day one, our R&D team has been working tirelessly to unlock the next frontier in agriculture, and Farm X enables us to expedite the discovery of new vibrant crops and pioneering technological advancements that will further accelerate our momentum as the category leader.”

Bowery’s world-class team of plant breeders, plant physiologists, biochemists, and more, are constantly innovating from seed-to-shelf. At Farm X, they will be able to test more, faster—ultimately accelerating the discovery of new crops, growing recipes, and efficiency improvements that can be replicated at scale across the company’s network of commercial farms.

Featuring proprietary, highly customizable, modular growing environments managed and monitored by new technology developed in-house, Farm X will further unlock the next phase of Bowery’s growth.

Farm X also features a sensory lab where Bowery will continue its quest for the perfect cultivars for indoor growing, as well as launch the first-ever on-site breeding program at a vertical farming company.

Under the new breeding program, Bowery’s team will be able to develop varieties that thrive in its unique growing conditions and evaluate each one for optimal taste, quality and yield, rather than to survive outdoors, pest-resistance, and long-haul transportation. While a traditional breeding program takes up to ten years, Bowery’s controlled indoor environment and 24/7 monitoring of crops will enable the company to bring new groundbreaking products to market at scale in a fraction of the time.

Bowery’s R&D team works year-round to uncover flavor-packed produce and bring new and exciting culinary experiences to consumers. Beyond the cultivation of new fruits and vegetables at Farm X, they are also developing the next generation of greens.

The Farmer’s Selection category, which launched in January 2021, emerged as a way to let consumers in on the process, bringing the thrill of discovering a new ingredient at your local farm stand to the grocery store. Bowery is launching a new small-batch green every four months under this new category.

The first greens released, Bowery Mustard Frills — hearty mustard greens with a tingly start and a fiery, wasabi-style finish — were available through April 2021. Green Sorrel, bright, tart baby greens with a zing and the next release in the series, is now available from May through August 2021.

Farm X also serves as an experimental space for innovation in farm design, data science, computer vision, autonomous robotics, hardware, and software that can be deployed in Bowery’s growing network of commercial farms.

As Bowery continues to advance the integration of proprietary smart farming technology, it recently announced Injong Rhee (formerly VP at Google and CTO of Samsung Mobile) as its Chief Technology Officer. Rhee will ensure that every farm continues to benefit from the collective intelligence of the BoweryOS, the company’s proprietary operating system which integrates software, hardware, sensors, computer vision systems, machine learning models and robotics to orchestrate and automate the entirety of operations.

Rhee’s team is ensuring the advanced technological learnings discovered at Farm X will be seamlessly integrated and applied at scale across Bowery’s network.

Bowery has experienced more than 750% brick-and-mortar sales growth, and more than quadrupled sales with e-commerce partners, including Amazon, since early 2020. Bowery’s newest commercial farm in Bethlehem, Pennsylvania, will bring local, pesticide-free produce, harvested year-round at peak freshness, to a surrounding population of 50 million people within a 200-mile radius, and will be its largest and most technologically-advanced commercial farm yet, further automating the growing process from seed to store.

About Bowery Farming

Bowery Farming, the Modern Farming Company, was founded in 2015 with the belief that technology and human ingenuity can grow better food for a better future. Propelled by its proprietary software system, the BoweryOS, Bowery builds smart indoor vertical farms that deliver a wide variety of Protected Produce — in little time, near cities they serve, for a truly local approach.