Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Philips LEDs Contribute To A Higher Winter Production of Excellent Quality Cucumbers

LED systems clearly add value to year-round growth concepts for cucumbers. Jan Biemans of Tielemans Groentekwekerij from Boekel, the Netherlands and Eric van den Eynde from Kontich, Belgium have determined this after their first growth under a hybrid grow light solution.

July 21, 2021

LED systems clearly add value to year-round growth concepts for cucumbers. Jan Biemans of Tielemans Groentekwekerij from Boekel, the Netherlands and Eric van den Eynde from Kontich, Belgium have determined this after their first growth under a hybrid grow light solution. In 2020, they both upgraded their existing HPS installations with Philips LED toplighting systems from Signify. Despite the differences in their greenhouses, installations, and goals, their conclusions were unanimous: LED contributes to an efficient, high winter production of excellent quality.

Uniform distribution

Eric and Lander van den Eynde’s company close to Antwerp consists of 2 ha of unlit tomatoes and 2,1 ha of lit, high-wire cucumbers. “We have been growing under HPS lights for two years already, which complemented the natural light with 180 µmol/m²/s”, says Eric. “However, in winter the fruits did not reach the desired weight of 350 to 400 grams. Therefore, light had to be added and LED is the most efficient solution for that. Our question to Signify was how we could fulfill that in the smartest way.” Multiple light plans were calculated in consultation with their installer and the plant specialists from Signify. Because of the limited height of the greenhouse (gutter height 5 meters), the Philips GreenPower LED toplighting linear was chosen, because that gives the most uniform light distribution.

Half of the HPS lamps were removed, and for each removed lamp 2,9 linear LED modules were installed. This brought the total light intensity to 223 µmol/m²/s, divided between 87µmol/m²/s HPS and 136 µmol/m²/s LED in red, blue and a bit of white working light. The total installation gives 24% more PAR-light, while the energy usage (at equal lighting hours) is about 7% less.

“The light division is nice and equal, even when only the LED lights are on”, the grower continues. “The latter is the case every now and then in the Spring and Autumn especially, when the heat radiation from the HPS lights is not always wanted.”

More and heavier fruit

The new installation was ready in September of 2020. To take maximum advantage of the higher light level, a planting distance was chosen of 50 cm (2,5 plant/m2). Lighting was begun directly after planting on October 2nd. Van den Eynde: “The plants reacted well. Our goal is to have a growth speed of six new leaves per week, and we could keep up with that pace effortlessly. The higher density of the stalks did ask for an altered pruning policy, but that did not have any effect on our labor planning. The most important goal was a higher average fruit weight. That was realized right away. Furthermore, we cut more cucumbers and they were of a good color. Our customer is very satisfied, and therefore so are my son and I.”

Winter production

Tielemans Groentekwekerij consists of 12 ha of greenhouses at two locations in Boekel. Cucumber is the most important crop. The company realizes two high-wire growths per year, from the beginning of January till the end of November, which formerly received 95 µmol/m²/s extra PAR-light from HPS lamps during the lighting season.

“In 2020 we received the request from our producers’ association to adapt 3,0 ha for winter production”, says growth manager Jan Biemans. “In order to realize sufficient production, weight, and quality in the darkest period, quite some additional light had to be installed. We looked at different options and made calculations. The choice was made for Signify’s Philips GreenPower LED toplighting compact, in combination with the GrowWise control system. With that we can dim the LED installation and tune the light level even better to the crop’s needs.”

Longer light in the evening

According to the light plan, the toplighting compact grow lights (providing 2.600 µmol in red and blue for optimal efficiency) were attached to the trellis in between the rows of HPS lights, raising the light level with 144 µmol/m²/s to 240 µmol/m²/s. The stalk density was chosen at 2,25 stalks per m2. Biemans: “We are content with the achieved winter production, and I am happy with this hybrid solution’s flexibility. The LED installation enables us to continue lighting longer in the evening without the additional heat. The plants did fine and got through the winter well.”

The growth manager thinks he can get even more out of it by decreasing the width of the row distance. “In the future I think we can benefit even more by adding far-red light”, he adds. “One variety showed some contracted leaves in darker periods, but the other variety did not do this at all. Overall, we are happy with the results.” Erik Stappers, plant specialist at Signify adds: “Full LED with far-red has proven itself by now. The role of far-red light in a hybrid installation with more LED than HPS is being investigated at the moment. Indeed, we do see differences between the varieties there.”

Let me know in case you have any questions.

Infarm Expands Relationship With Sobeys In Canada

Infarm and Sobeys Inc. have announced a new agreement to accelerate the availability and distribution of fresh produce to an additional 4 of Canada’s 10 provinces by 2023.

July 26, 2021

Infarm and Sobeys Inc. BB #:116615 have announced a new agreement to accelerate the availability and distribution of fresh produce to an additional 4 of Canada’s 10 provinces by 2023.

The agreement builds on the success of a partnership launched in 2020 – the first of national scope between a Canadian retailer and a vertical farming company – to offer locally grown, Infarm produce to Sobeys Inc. consumers Canada-wide.

As part of the deal, Infarm will construct new Infarm Growing Centers – growth, production and distribution hubs with high-capacity vertical farms – at sites in Calgary, Halifax and Winnipeg, with Hamilton, Ontario, near Toronto planned to host the location for the largest Infarm Growing Center in North America with a growing capacity of 37,000 ft2.

In combination with existing Infarm Growing Centers in Vancouver and Victoria/Vancouver Island, the agreement allows the company to increase production volume in Canada more than sevenfold. The deal comes in response to the increasing demand by retailers, including Sobeys, Safeway and Thrifty Food for fresh Infarm produce, and will supply more than 1000 stores in the retailer’s network alone.

With 97 employees on the ground today, Infarm’s Canadian team will grow by more than 50% to 160 by the end of the year, working from locations in British Columbia, Alberta, Ontario, Nova Scotia and Manitoba.

“We’re delighted with what has been an extremely positive and successful partnership with the Sobeys family of retailers,” said Erez Galonska, CEO at Infarm. “This expansion deal represents one of the largest rollouts of any vertical farming company in North America to date as we aim to offer local, high-quality produce to people everywhere.”

Niluka Kottegoda, Vice President Customer Experience at Sobeys Inc. said, “We are passionate about bringing Canadian families the best, freshest, most delicious produce every single day. The expansion of our exclusive partnership with Infarm demonstrates our commitment to delivering that in a technologically advanced and sustainable way.”

Reflecting on the current offer and expansion plan, she said, “We received overwhelmingly positive feedback from our customers and our store teams about the current Infarm product grown in our stores. We are thrilled to expand into the Infarm Growing Centres as they allow us to exponentially offer these great local products to a multitude of communities across Canada all year-round.”

Infarm’s growing centers integrate farming units that can each save up to 10,000,000 liters of water per year compared to soil-based agriculture for similar crops, while producing the equivalent of up to 100,000 ft2 of land. In line with the company’s goal of utilizing 100% renewable or green-certified energy, 90% of electricity used throughout the Infarm network will be from green-certified sources by September 2021.

Over the next five years, Canadian consumers can expect to select from a range of new Infarm produce to the current selection of herbs, leafy greens and microgreens now available in the retailer’s grocery aisles including tomatoes, strawberries, peppers, mushrooms, convenient cut salads and even potted plants. By 2025 Infarm plans to scale to 100 growing centers with a growing capacity of 3 million ft2.

For further information, please visit here.

About Infarm

Infarm was founded in Berlin in 2013 by Osnat Michaeli and the brothers Erez and Guy Galonska. Passionate to become self-sufficient and eat better, they were growing their own food, enjoying all the flavor and nutrients, without the chemical pesticides and transport kilometers. With the aim to share the goodness of self-grown produce with everyone, they developed a smart modular farming system that allows distribution of vertical farms throughout the urban environment, growing fresh produce in practically any available space and fulfilling practically any market demand. Today, with cutting edge R&D, patented technologies and a leading multi-disciplinary team, Infarm is growing a worldwide farming network helping cities become self-sufficient in their food production, while significantly improving the safety, quality, and environmental footprint of our food.

With a multinational team of 1000 people globally, Infarm has partnered with more than 30 major food retailers including Aldi Süd, Amazon Fresh, Auchan, Carrefour, Casino, E.Leclerc, Edeka, Empire Company Ltd (Safeway, Sobeys, ThriftyFoods), Farmdrop, Intermarché, Irma, Kaufland, Kinokuniya, Kroger, Marks & Spencer, Metro, Migros, Selfridges, Selgros and Whole Foods Market in Canada, Denmark, France, Germany, Japan, Luxembourg, the Netherlands, the United Kingdom, the United States and Switzerland, deployed more than 1300 farms in stores and Infarm Growing Centers, saved more than 16,000,000 gallons of water and 600,000 square feet of land, while harvesting 1,000,000+ plants monthly and growing.

Lead Photo: An Infarm Growing Center (IGC) with multiple state-of-the-art production modules

Agrify Announces Launch of Innovative, Project-Based Learning Program, Agrify University

Agrify Corporation, a developer of highly advanced and proprietary precision hardware and software cultivation solutions for the indoor agricultural marketplace, today announced the opening of Agrify University, a brand new 3,500 sq. ft. state-of-the art indoor vertical farming facility featuring Agrify’s latest technology and advanced cultivation methods.

July 19, 2021

Introduces immersive program to assist Agrify customers and next-generation growers in cultivating high-value cannabis with efficiency at scale

Agrify Corporation (NasdaqCM:AGFY) (“Agrify” or the “Company”), a developer of highly advanced and proprietary precision hardware and software cultivation solutions for the indoor agricultural marketplace, today announced the opening of Agrify University, a brand new 3,500 sq. ft. state-of-the art indoor vertical farming facility featuring Agrify’s latest technology and advanced cultivation methods. We believe this new immersive, hands-on project-based learning experience will empower Agrify customers and next-generation growers with the knowledge and education to successfully cultivate cannabis with efficiency at scale by leveraging the power of Agrify’s vertical farming units (“VFUs”) and the Agrify Insights software solution.

Located in Billerica, MA, Agrify University, led by David Kessler, Agrify’s Chief Science Officer, and a team of industry experts, horticulturists, and scientists, will provide participants with in-classroom, on-site, and on-demand learning options. The immersive, multi-sensory curriculum will enable customers and growers to expand their knowledge of how to apply novel scientific research, interpret cultivation data, and leverage Agrify’s technology to improve their indoor cannabis cultivation practices.

“The cultivation methods used by many operators have not evolved as quickly as the industry itself, and we see an opportunity to use the power of data and cutting-edge techniques to dramatically improve the quality and yields from indoor cultivation,” said Mr. Kessler. “Agrify University utilizes our vast cannabis research data sets and technological innovation to provide a curriculum that we believe will support the long-term growth of our industry. We’re proud to add this valuable resource to our comprehensive Agrify ecosystem, and we look forward to welcoming our first cohorts.”

Agrify University classes are available now to all customers. For more information on how to apply and on available program resources, please contact Agrify at info@agrify.com.

About Agrify (NasdaqCM:AGFY)

Agrify is a developer of premium grow solutions for the indoor agriculture marketplace. The Company uses data, science, and technology to empower its customers to be more efficient, more productive, and more intelligent about how they run their businesses. Agrify’s highly advanced and proprietary hardware and software solutions have been designed to help its customers achieve the highest quality, consistency, and yield, all at the lowest possible cost. For more information, please visit Agrify’s website at www.agrify.com.

Forward-Looking Statements

This press release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended, concerning Agrify and other matters. All statements contained in this press release that do not relate to matters of historical fact should be considered forward-looking statements, including, without limitation, statements regarding Agrify University. In some cases, you can identify forward-looking statements by terms such as "may," "will," "should," "expects," "plans," "anticipates," "could," "intends," "targets," "projects," "contemplates," "believes," "estimates," "predicts," "potential" or "continue" or the negative of these terms or other similar expressions. The forward-looking statements in this press release are only predictions. We have based these forward-looking statements largely on our current expectations and projections about future events as well as the curriculum and plans that have been developed for Agrify University. Forward-looking statements involve known and unknown risks, uncertainties and other important factors that may cause our actual results, performance or achievements to be materially different from any future results, performance or achievements expressed or implied by the forward-looking statements. You should carefully consider the risks and uncertainties that affect our business, including those described in our filings with the Securities and Exchange Commission (“SEC”), including under the caption “Risk Factors” in our Annual Report on Form 10-K for the year ended December 31, 2020 filed with the SEC, which can be obtained on the SEC website at www.sec.gov. These forward-looking statements speak only as of the date of this communication. Except as required by applicable law, we do not plan to publicly update or revise any forward-looking statements, whether as a result of any new information, future events or otherwise. You are advised, however, to consult any further disclosures we make on related subjects in our public announcements and filings with the SEC.

Bringing Energy Management And Automation Opportunities To Indoor Farming

“We can’t be the most sustainable company in the world if we don’t work on the world’s biggest sustainability challenges,” says Travis Graham, international account manager at Schneider Electric. Schneider provides a vast array of digital technologies to multiple sectors, including horticulture

By Rebekka Boekhout

July 14, 2021

“We can’t be the most sustainable company in the world if we don’t work on the world’s biggest sustainability challenges,” says Travis Graham, international account manager at Schneider Electric. Schneider provides a vast array of digital technologies to multiple sectors, including horticulture. However, the company recently decided to strategically address the indoor farming segment and partner with growers to improve energy efficiencies within the sector.

As a global specialist in energy management and automation, Schneider’s goal is to empower the global population to improve their energy and resource use efficiency. This purpose, coined “Life is On”, aligns strongly with the spirit of indoor agriculture whose goal is to produce food and medicinal crops in an environmentally sustainable manner.

Named the world’s most sustainable company in 2021 by Corporate Knights, Schneider holds sustainability at its core and uses its century-long experience in energy management to help growers improve the energy efficiency of their facilities.

Read the rest of the article here

For more information:

Schneider Electric

www.se.com

FI Report Preview: Vertical Farming Concept Experiencing Immense Growth

Vertical farming is growing by leaps and bounds. In fact, the evolving form of agriculture has become a multibillion-dollar industry and is expected to reach $12.77 by 2026, growing at a compound annual growth rate of nearly 25%, according to Allied Market Research.

By Kelly Beaton

July 19, 2021

Vertical farming is growing by leaps and bounds. In fact, the evolving form of agriculture has become a multibillion-dollar industry and is expected to reach $12.77 by 2026, growing at a compound annual growth rate of nearly 25%, according to Allied Market Research.

Quite simply, the concept “has gone viral,” said Dr. Dickson Despommier, a professor at Columbia University.

And Despommier should know. After all, he’s credited with conceiving the concept, back in 1999, during an especially spirited Medical Ecology course.

The Food Institute recently interviewed Despommier at length, in advance of its in-depth report on vertical farming, which is set to be published Tuesday (you can eventually download the report here). Here’s some exclusive content from that interview, which discussed numerous aspects of indoor farming, also known as controlled-environment agriculture (or CEA):

HOW WOULD YOU PERSONALLY DEFINE INDOOR FARMING AND VERTICAL FARMING?

Despommier: “Indoor farming includes all indoor farms, including vertical farms, and it also includes greenhouses. The only difference between a vertical farm and a greenhouse is height, because you can’t just set greenhouses on top of each other.

“Vertical farms have grow lights. If you use grow lights … you get more nutritious plants as a result of that, because you can tweak those lights to cause the plants to produce more things that we need, like vitamins.”

IN YOUR OPINION, WHAT’S A KEY BENEFIT PROVIDED BY VERTICAL FARMING?

Despommier: “By manipulating the indoor lighting systems … you can create plants that you could never grow outside. That’s one of the advantages.”

WHICH COUNTRIES ARE EMBRACING VERTICAL FARMING THE MOST?

Despommier: “The country that’s really got the most [vertical farming facilities] is Japan – Japan now has hundreds of vertical farms throughout the country, and they’re doing quite well. Taiwan has about 150, last I heard. Singapore has countrywide demand for locally produced food. The United States has a fair number, I would say in the neighborhood of 100, to 150.

HOW DO YOU ENVISION VERTICAL FARMING GROWING IN THE NEXT 5-10 YEARS?

Despommier: “I think the next issue will be, how can we franchise ourselves into a complete grocery store. And I know companies that are already doing that, so that’s in the wings. And, I think in another 5 years you’re going to see a versatility of crop selection that will force everything else into competition, and therefore [vertical farming] will succeed. That’s in the next 5 to 10 years.”

Light Science Technologies Launches Sustainable nurturGROW LED Lighting Range

Leading UK AgTech company Light Science Technologies (LST) has launched nurturGROW to the market, its new sustainable grow lighting product range, offering an innovative, high-performance and cost-effective solution for indoor farming, covering greenhouses, vertical farming, polytunnels and medicinal plants.

July 21, 2021

90% recyclable and interchangeable design enables growers to simply upgrade and replace

Leading UK AgTech company Light Science Technologies (LST) has launched nurturGROW to the market, its new sustainable grow lighting product range, offering an innovative, high-performance and cost-effective solution for indoor farming, covering greenhouses, vertical farming, polytunnels and medicinal plants.

Created with four core component parts, the patent-pending nurturGROW range is made of high-quality, durable materials to give growers the ideal balance between strength and optimal performance. 90% of the components are recyclable, minimizing the amount of materials needed to drastically cut down on waste and reduce carbon footprint. Thanks to its sustainable, future-proof design, 85% of nurturGROW is also reusable, allowing growers to easily upgrade components, cost-effectively and with no downtime, making nurturGROW easy to maintain. Backed by a 25-year product lifecycle, it ensures indoor farmers maximize the use of every element over a longer lifespan to generate maximum yields and save them a third on future costs.

Built for scale and sustainability

Thanks to its modular structure, the nurturGROW range consists of more than 30 different options with variable lengths of up to 2.78m, making it the longest luminaire on the market. It provides the scale needed to commercialize the right recipe and cut down on waste with both energy and space. With a high efficacy of up to 3.0 umol/J and up to 30-degree variance, growers can choose from 1000s of different light recipes to improve plant performance, from one of the widest ranges of recipes available on the market.

What’s more, nurturGROW enables you to give back to the environment. As proud reforestation partners of One Tree Planted, they plant one tree for every LST product sold, as part of a mutual commitment to champion global reforestation efforts and raise awareness of the importance of ecosystem restoration.

In-house UK scientific and manufacturing expertise

nurturGROW features industry-leading, high performing LED lighting innovation by drawing on its own in-house manufacturing capabilities, assuring growers of nothing

less than high quality and high performance grow lighting. This is supported by a successful tried and tested approach in real environments to prove nurturGROW’s long-lasting lighting technology.

Backed by science, LST works with growers to create the perfect recipe for crop growth. Using light testing equipment and data gathered from LST’s purpose-built laboratory, its in-house team of scientists can help identify the right spectral waveforms and PPFD levels by recreating various environment scenarios in one of its accredited grow chambers.

Grow more, with less

Founded in 2019, LST’s approach from the beginning was to create a bespoke, fully integrated lighting solution that met key criteria for CEA farmers and growers: sustainability, cost-effectiveness, and high performance. Knowing that each growing environment has its own set of unique requirements, nurturGROW gives growers optimum control over their crops with the potential to deliver optimal yield and minimize both CAPEX and OPEX costs.

Craig Price, Operations Director at Light Science Technologies, said: “Being customer-focused by design means that as an experienced LED grow light partner, we understand every variable and can help indoor growers to design a sustainable solution that fits their unique growing parameters.

“This extends to adjusting the light recipe for growers, as nurturGROW will allow you to increase, decrease or change the recipe depending on preference, thanks to an interchangeable luminaire body.

“The unique aspect of our design also means that we have already allowed for future integration of sensor technologies, offering significant added value. By choosing to add in our new sensor technology, which is under development, indoor growers and farmers can look to control their environment in much more granular detail. This will enable them to reduce any sub-optimal performances, whether that be in any environmental controls or from the light itself.”

Why Are Microgreens Often Referred To As Cash Crops?

Microgreens sell at high prices to specific niches: chefs, foodies or just people who pursue a healthy lifestyle because their exceptionally high nutrient density attracts customers who choose a healthy lifestyle. They contain higher vitamin, mineral, and antioxidant levels than mature vegetables

July 14, 2021

Food prices have been dropping for a couple of decades. These days they are barely covering the costs of a farming business. Microgreens in particular are an exception to this paradigm. If you grow smart, these little shoots can help create a very profitable operation.

Smart Farmers elaborates on how growing microgreens can be profitable.

Microgreens sell at high prices to specific niches: chefs, foodies, or just people who pursue a healthy lifestyle because their exceptionally high nutrient density attracts customers who choose a healthy lifestyle. They contain higher vitamin, mineral, and antioxidant levels than mature vegetables. In fact, research comparing microgreens to their mature counterparts report that nutrient levels can be up to 40x higher.

Besides, the flavor of microgreens is so intense that chefs and foodies go nuts over these babies. In addition, they are perfect to use as plate decorations and come in many different varieties. If you decide to only grow microgreens, you’ll still be able to offer a wide variety of products. There are at least 25 types that are commercially popular, and the market still allows for more exploration.

A big advantage for growers is that they can provide up to 35 harvests per year. Depending on the variety, microgreens only need 1 to 2 weeks to grow. Even if for some reason, something goes wrong with a batch, you won’t miss out on an entire seasonal income.

Read the complete article at: Vertical Farm Daily:

For more information:

Smart farmers

www.smartfarmers.eu

Four Vertical Growers Collaborating To Deliver Social-Impact Projects in Wales

Four UK vertical farming companies, LettUs Grow, Digital Farming, Farm Urban and GrowStack, are collaborating to bring the benefits of CEA to Welsh communities

July 9, 2021

Four UK vertical farming companies, LettUs Grow, Digital Farming, Farm Urban, and GrowStack, are collaborating to bring the benefits of CEA to Welsh communities. This is one of the widest collaborations between leading CEA tech providers in the UK to date, with a focus on delivering vertical farms across different locations in Wales as part of a social impact and community-focused project called Crop Cycle.

Crop Cycle is looking to bring the benefits of vertical farming directly to communities that could benefit most and is being funded by the Welsh Government through the Foundational Economy Challenge Fund. The project is being led by Social Farms and Gardens, supported by Welsh Government's NutriWales CEA Special Interest Group and BIC Innovation.

The project enables multiple different CEA systems to be tailored to fit different community settings, whilst also allowing them to be assessed in coordination across the pilot sites. This approach is unique, facilitating the testing of new socially focused business models, the engagement of the local communities and businesses with CEA and the development of new technical solutions. LettUs Grow, Digital Farming, GrowStack and Farm Urban are working together to share their specialisms and apply different technologies to where they are best suited within four sites in Wales, two of which are in the Valleys.

This project will introduce year-round food growing right into the heart of Welsh communities, where they’ll be connected to the particular dynamics of the local area. Activities will test new community-based engagement models, focusing on social well-being, local entrepreneurship and environmental impact. In this way, the project will be bringing together community, businesses and local public sector organizations.

Gary Mitchell, the Wales Manager for Social Farms and Gardens who is leading the project team stated, "we are excited to be running the pilot project across a diverse set of sites to gain insight and further knowledge into how new agricultural systems can successfully support communities in delivering local, fresh and nutritious foods as well as important social benefits in a sustainable manner."

Read the complete article at: Vertical Farm Daily

For more information:

LettUs Grow

info@lettusgrow.com

lettusgrow.com

GrowStack

www.growstack.co.uk

Digital Farming

www.digitalfarming.io

Farm Urban

www.farmurban.co.uk

An Affordable Solution To Monitor And Optimize Food Production

Ecobloom, a startup based in Stockholm, provides two different solutions to the vertical farming space. The first solution is a B2B product, namely an AI solution ensuring automated growing of the plant and monitors plant food production at the same time

By Rebekka Boekhout

July 9, 2021

“We’re helping farmers optimize their food production through more efficient yield management,” says Hamza Qadoumi, CEO and founder of Ecobloom. “Also, cost reduction comes in through a significant reduction in labor and yield increases up to 2 times more per year through accurate predictions. The system allows us to reduce food waste up to 20% through yield prediction and our deviation analysis.”

Ecobloom, a startup based in Stockholm, provides two different solutions to the vertical farming space. The first solution is a B2B product, namely an AI solution ensuring automated growing of the plant and monitors plant food production at the same time. With already a successful consumer product on the market, their focus is to offer smart technology solutions for the indoor farming market.

The pilot farm

Smart sensor - EcoSense

The company provides a software-connected plug-and-play solution named EcoSense. EcoSense is a small box that can basically be placed anywhere on the farm, such as above shelves to monitor plant growth. EcoSense comes in two formats: a camera for growth and plant analysis, sensors for water analysis and sensors for air analysis. Next to that the sensors predict yield, so lots of data can be gathered to keep improving this. Hamza notes, “We’re now looking at venturing with flowers and fruit greenhouse growers in Spain, Holland, The UK and the Middle East region.

The core solution of the device is hardware, sensors and cameras. Through these elements, the environmental sensors and plant environment is captured by data collectors and cameras throughout the plant’s life cycle. According to Hamza, farmers need about 1 device per 100m2. The wifi-connected cameras and sensors are modular solutions, using machine learning to constantly monitor and analyze plant development, health and stress. Through camera recognition, a certain yield outcome and deviations can be predicted.

Read the rest of the article here

For more information:

Hamza Qadoumi, CEO and founder

Ecobloom

hamza@ecobloom.se

www.ecobloom.se

AeroFarms Expands Its Award-Winning Leafy Greens Product Assortment

AeroFarms, a Certified B Corporation and leader in indoor vertical farming, today announced that it is expanding its line of leafy greens to include 5 new items: Baby Bok Choy-The New SpinachTM, Micro Arugula, Micro Broccoli, Micro Kale, and Micro Rainbow Mix

July 13, 2021

NEWARK, N.J.–AeroFarms, a Certified B Corporation and leader in indoor vertical farming, today announced that it is expanding its line of leafy greens to include 5 new items: Baby Bok Choy-The New SpinachTM, Micro Arugula, Micro Broccoli, Micro Kale, and Micro Rainbow Mix.

AeroFarms® award-winning retail brand of leafy greens is prized for its elevated flavor and is grown using proprietary aeroponics and indoor vertical farming technologies, which yield annual productivity up to 390 times greater than traditional field farming while using up to 95% less water and zero pesticides.

There has been increased consumer interest in Asian greens and Future Fusebiquity – as outlined in Datassential’s Food Bytes 2021 Food Trends – that takes new generation products and combines them with well-known dishes. AeroFarms Baby Bok Choy-The New SpinachTM is reimagining how to create a better spinach experience that is juicier, more flavorful, and even more nutrient-dense with an ANDI (Aggregate Nutrient Density Index) score of 865 vs. spinach at 707, and it can be enjoyed in just about any spinach recipe for an updated new take on the dish.

Microgreens were recognized by The Today Show as one of the top health trends for 2021, and AeroFarms has been expanding this category at retail since 2019. Responding to consumer demand, AeroFarms has added Micro Arugula, Micro Broccoli, Micro Kale, and Micro Rainbow Mix to its core line of Micro Spicy Mix and Micro Super Mix. Produced year-round at the highest quality, AeroFarms microgreens offer great visual and flavor excitement, elevating the home cook into a chef. In addition, AeroFarms microgreens provide higher nutrient density than their mature green counterparts, offering a powerful way to provide a potent boost of vitamins, minerals, and phytonutrients.

AeroFarms starts by selecting the most flavorful varietals of microgreens and baby greens, then perfects them in its proprietary indoor vertical farms for optimal quality, yield, color, nutrition, texture, and taste. In fact, AeroFarms has trademarked Vertical Farming, Elevated Flavor™ to highlight to consumers not only where and how their food is grown, but also more importantly, the key growing benefits that AeroFarms uniquely brings to the market, setting a new culinary standard with millions of data points to prove it.

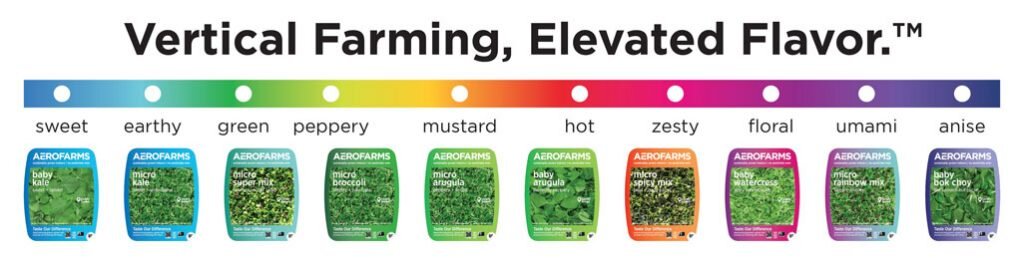

AeroFarms is able to grow its kale to be sweeter and its arugula to be perfectly peppery, and the Company has developed its signature FlavorSpectrum™ to represent the breadth of flavors and hundreds of varieties of leafy greens that it is able to grow. AeroFarms’ team of experts from horticulturists to engineers to data scientists to nutritionists paired each specific tasting note with a representative color to bring the FlavorSpectrum™ philosophy to life. Across its leafy greens packaging line, the cool blue tones represent sweet and mellow notes, while the intense reds represent bold and zesty flavors.

All AeroFarms leafy greens are safely grown indoors in New Jersey at one of AeroFarms’ state-of-the art commercial indoor vertical farms that is certified for USDA Good Agricultural Practices, SQF Level 2 Good Manufacturing Practices, Non-GMO Project Verification, and OU Kosher. AeroFarms leafy greens are completely pesticide free, and ready-to-eat without any need to wash, providing a major benefit to consumers looking for safety and convenience. AeroFarms leafy greens are available at major customers such as Amazon Fresh, Baldor Specialty Foods, FreshDirect, Morton Williams, ShopRite, Walmart, and Whole Foods.

“Our Company is committed to partnering with our retail partners to expand the entire category of leafy greens and drive consumption with our sustainably grown produce that is winning on taste,” said David Rosenberg, Co-Founder and Chief Executive Officer of AeroFarms. “We are excited to expand our line of microgreens, which we believe can move from just a garnish to center of the plate given their exceptional taste — microgreens can be enjoyed all of the time!”

About AeroFarms

Since 2004, AeroFarms has been leading the way for indoor vertical farming and championing transformational innovation for agriculture. On a mission to grow the best plants possible for the betterment of humanity, AeroFarms is a Certified B Corporation with global headquarters in Newark, New Jersey. Named one of the World’s Most Innovative Companies by Fast Company two years in a row and one of TIME’s Best Inventions in Food, AeroFarms patented, award-winning indoor vertical farming technology provides the perfect conditions for healthy plants to thrive, taking agriculture to a new level of precision, food safety, and productivity while using up to 95% less water and no pesticides ever versus traditional field farming. AeroFarms enables local production to safely grow all year round, using vertical farming for elevated flavor. In addition, through its proprietary growing technology platform, AeroFarms has developed multi-year strategic partnerships ranging from government to major Fortune 500 companies to help uniquely solve agriculture supply chain needs. For additional information, visit: https://aerofarms.com/.

On March 26, 2021, AeroFarms announced a definitive business combination agreement with Spring Valley Acquisition Corp. (Nasdaq: SV). Upon the closing of the business combination, AeroFarms will become publicly traded on Nasdaq under the new ticker symbol “ARFM”. Additional information about the transaction can be viewed here: https://aerofarms.com/investors/

No Offer or Solicitation

This press release does not constitute an offer to sell or a solicitation of an offer to buy, or the solicitation of any vote or approval in any jurisdiction in connection with a proposed potential business combination among Spring Valley and AeroFarms or any related transactions, nor shall there be any sale, issuance or transfer of securities in any jurisdiction where, or to any person to whom, such offer, solicitation or sale may be unlawful. Any offering of securities or solicitation of votes regarding the proposed transaction will be made only by means of a proxy statement/prospectus that complies with applicable rules and regulations promulgated under the Securities Act of 1933, as amended (the “Securities Act”), and Securities Exchange Act of 1934, as amended, or pursuant to an exemption from the Securities Act or in a transaction not subject to the registration requirements of the Securities Act.

Forward Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “might,” “will,” “estimate,” “continue,” “contemplate,” “anticipate,” “intend,” “expect,” “should,” “would,” “could,” “plan,” “predict,” “project,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this presentation, regarding Spring Valley’s proposed acquisition of AeroFarms, Spring Valley’s ability to consummate the transaction, the benefits of the transaction and the combined company’s future financial performance, as well as the combined company’s strategy, future operations, estimated financial position, estimated revenues and losses, projected costs, prospects, plans and objectives of management are forward-looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of the respective management of AeroFarms and Spring Valley and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AeroFarms and Spring Valley. These forward-looking statements are subject to a number of risks and uncertainties, including changes in domestic and foreign business, market, financial, political, and legal conditions; the inability of the parties to successfully or timely consummate the proposed transaction, including the risk that any regulatory approvals are not obtained, are delayed or are subject to unanticipated conditions that could adversely affect the combined company or the expected benefits of the proposed transaction or that the approval of the stockholders of Spring Valley or AeroFarms is not obtained; failure to realize the anticipated benefits of the proposed transaction; risks relating to the uncertainty of the projected financial information with respect to AeroFarms; risks related to the expansion of AeroFarms’ business and the timing of expected business milestones; the effects of competition on AeroFarms’ business; the ability of Spring Valley or AeroFarms to issue equity or equity-linked securities or obtain debt financing in connection with the proposed transaction or in the future, and those factors discussed in Spring Valley’s Annual Report on Form 10-K, Quarterly Report on Form 10-Q, final prospectus dated November 25, 2020 and preliminary proxy statement/prospectus dated May 10, 2021 under the heading “Risk Factors,” and other documents Spring Valley has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. There may be additional risks that neither Spring Valley nor AeroFarms presently know, or that Spring Valley nor AeroFarms currently believe are immaterial, that could also cause actual results to differ from those contained in the forward-looking statements. In addition, forward-looking statements reflect Spring Valley’s and AeroFarms’ expectations, plans, or forecasts of future events and views as of the date of this press release. Spring Valley and AeroFarms anticipate that subsequent events and developments will cause Spring Valley’s and AeroFarms’ assessments to change. However, while Spring Valley and AeroFarms may elect to update these forward-looking statements at some point in the future, Spring Valley and AeroFarms specifically disclaim any obligation to do so. These forward-looking statements should not be relied upon as representing Spring Valley’s and AeroFarms’ assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Ocado To Fund New Vertical Farm Near Bristol As Sales Leap

Ocado is planning to “assist” with the building of a vertical farm near Bristol, it has announced. The online grocer said it had invested £5 million in Lincolnshire-based Jones Food Company (JFC) as part of a wider £25 million raise

By Holly Williams, Hannah Baker, David Laister

July 6, 2021

Ocado is planning to “assist” with the building of a vertical farm near Bristol, it has announced.

The online grocer said it had invested £5 million in Lincolnshire-based Jones Food Company (JFC) as part of a wider £25 million raise.

The funding will be used to help JFC - Europe’s largest vertical farm - to build a second site outside the South West city.

Ocado said its original stake in the Scunthorpe business, which uses hydroponics and renewable energy to grow herbs and leafy greens, was now worth “more than double” its initial investment, made in mid 2019.

JFC launched in early 2018 with a 5,000 sq m farm in an adapted coldstore, with an entrepreneur and expert agronomist at the helm.

Initial harvests saw enough produce grown for 11 million sandwiches.

The announcement was made as Ocado posted its half-year results on Tuesday. The company said in the six months to May 30, losses narrowed sharply as sales surged.

But the company said shoppers had begun returning to some pre-pandemic habits due to easing restrictions.

Jones Food Company is an energy intensive business, and has partnered with Flexitricity to participate in demand side response for the National Grid. (Image: HLC Creative)

Ocado posted a £23.6m loss before tax over the period - down from losses of £40.6m a year earlier. Underlying earnings – the company’s preferred measure – rose 41% to £61m.

Ocado said revenues for its retail joint venture with Marks & Spencer jumped 19.8% higher in the first half to £1.2bn

This comes as a marked slowdown on the 39.7% sales rise notched up in the first quarter to February

The online grocer also said its first UK mini Customer Fulfilment Centre (CFC) in Avonmouth, near Bristol, was “ramping faster” than any facility before it.

Lead Photo: Ocado has invested millions into Scunthorpe vertical farming start-up Jones Food Company

The Farm is Merging With Food Retail Spaces

We’ve seen gardens on rooftops, vertical farms close to stores and even some selling gardening equipment to gardeners who are shopping for food. The farm is essentially merging with the food retail spaces we roam as consumers. It’s quite interesting

July 13, 2021

Canadians have started to notice that grocers have begun to sell plants in miniature greenhouses.

We’ve seen gardens on rooftops, vertical farms close to stores and even some selling gardening equipment to gardeners who are shopping for food. The farm is essentially merging with the food retail spaces we roam as consumers. It’s quite interesting.

We’re slowly witnessing the rise of the ‘grow-cer.’

For years, customers accepted the myth that food just magically shows up at the grocery store. But COVID-19 got many of us to think differently about supply chains – how food is grown, produced, transported, packaged and retailed.

With the addition of new farmgate features for city dwellers, grocery stores are slowly becoming the gateway to an entire world most of us rarely see: farming.

Sobeys has provided one recent example of what’s going on. The second-largest grocer in Canada recently signed a partnership agreement with German-based Infarm to get greenhouses into many outlets across the country. Infarm units were installed last year in British Columbia and can now be found in many other locations across the country.

Infarm units enable Sobeys to offer fresh herbs and produce grown hydroponically, which requires 95 percent less water, 90 percent less transportation, and 75 percent less fertilizer than industrial agriculture. And no pesticides are used.

Available produce grown inside the store includes leafy greens, lettuce, kale, and herbs such as basil, cilantro, mint and parsley. Expansion plans include chili peppers, mushrooms, and tomatoes. The growing cycle for most of these averages five weeks.

While Sobeys doesn’t have to worry about infrastructure and extra capital to change a store’s allure, it can get rid of these miniature vertical farms if proven unpopular or unnecessary. That works well for Sobeys and the consumer.

But it’s not just Sobeys. Other grocers now have decent-sized vertical farms inside the store or close to them.

The gardening rate in Canada has gone up by more than 20 per cent since the start of the pandemic last year. For consumers, growing their own food was about pride and taking control of their supply chain in some way.

For many others, though, gardening remains a luxury due to the lack of space or time. Since a trip to the grocery store is inevitable for most of us, grocers are bringing the farm to the store so consumers can have both the farming and the retail experience at once.

Before COVID, farmers desperately tried to get closer to city dwellers so their work could be appreciated. Campaigns over the years brought mixed results. Farming is still largely misunderstood.

Debates on genetically modified organisms (GMOs) and the use of chemicals have also divided urban and rural communities. City dwellers have always respected farmers and the hard work they do. But many consumers who are/were looking for natural and organically-produced goods have grown leery of farming in general.

This has attracted the attention of environmental groups opposed to many farming practices.

Grocers are starting to realize that bridging two worlds under one roof can help elevate their roles as ambassadors to an entire supply chain. Farmers can’t be replaced, of course, and they can’t be in stores.

For years, we saw pictures of farmers on packages and posters. It was nice, but it wasn’t real. The hard work, and everything else that comes with farming, can only be properly conveyed when visiting a farm or working on one for a while.

The pictures likely won’t disappear from grocery stores but they don’t really tell the whole story.

The new grow-cer brings the imagery of farming in retail to a new level. Grabbing a living plant or produce off a living plant is certainly real and increasingly valuable for Canadians longing for local and freshness. It just can’t get more local than growing it in the grocery store.

COVID-19 eliminated many rules for grocers. Every business played a part. Grocers sold food, processors manufactured it, and restaurants provided ready-to-eat solutions. Lines between sectors were already becoming blurred before COVID, given the crossing of concepts and elimination of lines between sectors.

For example, some of us have heard of the ‘grocerant’ concept, which has embedded food service into grocery stores. Consumers can relax, enjoy food before, during or after their grocery shopping.

But COVID blew up the blurred lines.

Grocers are becoming brokers, connecting various functions of the supply chain. Farming connects with retail by way of new initiatives that we’re now seeing everywhere.

For example, restaurants are selling meal kits through grocers’ apps. Few saw that coming.

Food brokering for grocers is no doubt the next frontier of growth.

Whether it will last is unknown. But grocers are embracing the fact they have the privilege of interacting with consumers every day. That privilege, more than ever, comes with a responsibility to show consumers the true value of food by being knowledge brokers.

If that means growing more food in stores, so be it.

Dr. Sylvain Charlebois is senior director of the agri-food analytics lab and a professor in food distribution and policy at Dalhousie University.

Grōv Technologies Signs Definitive Agreement With Superior Farms

Agtech and indoor farming company, Grōv Technologies, today announced a definitive agreement with California-based Superior Farms for the purchase of 10 Olympus Tower Farms that will produce fresh year-round feed for Superior’s upcoming Sheep Discovery Center™ in Central Utah

July 12, 2021

Vineyard — Agtech and indoor farming company, Grōv Technologies, today announced a definitive agreement with California-based Superior Farms for the purchase of 10 Olympus Tower Farms that will produce fresh year-round feed for Superior’s upcoming Sheep Discovery Center™ in Central Utah. Grōv is part of Superior Farms’ efforts to dramatically improve the sustainability and growth of US lamb production.

The ten Olympus Tower Farms will produce 60,000 pounds of Grōv’s fresh High-Density Nutrient (HDN) Superfeed wheatgrass a day using less than 5 percent of the water needed for field-grown fodder, without the use of pesticides or herbicides.

The Sheep Discovery Center is a new venture of Superior Farms. The goal of the Discovery Center is to showcase how sustainably focused science and technology can help farmers increase their flocks and consistently produce high-quality lamb.

“Our collaboration with Superior showcases how Grōv indoor ag technology can benefit farmers who want to improve production and sustainability, and minimize risk, especially as it relates to drought conditions that plague regions across the world,” says Steve Lindsley, president of Grōv Technologies. “The innovative thinking of Superior Farms is right in line with our efforts to provide feed security for animals and food security for growing populations.”

Leveraging Grōv’s indoor Olympus Tower Farms to grow fresh HDN feed, Superior Farms intends to optimize nutrition and environmental conditions to help support animal health during the lambing cycle. Superior Farms will also implement Grōv’s seasonal lighting technology as part of Superior’s efforts to improve the productivity of their sheep and provide a more consistent lamb supply throughout the year.

“The current Western U.S. megadrought is pushing farmers to ration their natural resources and find innovative ways to give their animals a more sustainable and nutrient-rich environment,” says Rick Stott, CEO of Superior Farms. “Feeding sheep with Grōv HDN opens up new opportunities for sheep farmers and gives them a way to overcome the water issues affecting their flocks.”

During the Covid pandemic, more consumers tried lamb for the first time and continued to purchase it throughout the year. The US lamb industry expects demand to keep rising as the number of new consumers who are more familiar with lamb continues to grow.

For more information about Grōv Technologies please visit www.Grōvtech.com.

About Grōv Technologies, LLC

Grōv Technologies is pioneering next-generation indoor agriculture technology and science to help meet the demand for global food and animal feed security. The company has developed enterprise-scale, automated controlled environment agriculture (CEA) systems to grow high-density nutrient animal feed and other crops using significantly less water and resources than traditional farming. These systems utilize patented low-heat LED technology, seed-to-harvest robotics, and data-driven scientifically proven indoor growing protocols. Grōv also operates an LED lighting and power management subsidiary, Stellar Smart Energy Solutions, using proprietary Wave Power Transformation and power management networking technology for commercial and agricultural facilities. Grōv is wholly owned by Nu Skin Enterprises, Inc. (NYSE: NUS), which develops and distributes a comprehensive line of premium-quality beauty and wellness solutions through a global network of sales leaders.

About Superior Farms

Superior Farms, the leading purveyor of sustainably raised, ranch-to-table American lamb. Proudly providing the highest quality natural lamb for a variety of recipes from weeknight dinners to Sunday brunch, lunches, and more, Superior Farms offers a range of premium cuts. From the mountains of Utah, the brisk winters of Minnesota, and the shores of California, Superior Farms prides itself on working exclusively with family ranchers who raise lambs with the best care and commitment to quality wellbeing and stable environment. Respecting a nutrient-rich land, maintaining a sustainable footprint, and working with dedicated family ranchers who raise flocks with the highest level of care, all are core values that make Superior Farms the leader in American lamb. From the plant floor to the corner office, Superior Farms is also proud to be 100 percent owned by its dedicated and talented employees. For more information, visit www.superiorfarms.com, order home delivery at www.superior-farms.com, or follow the brand on Instagram (@SuperiorFarms) and Facebook (@SuperiorFarms).

Ushio Germany Presents Horturion HPS 1000W de el Supra Plus "The Highest Light Output Ever Achieved By A 1,000 W Lamp"

With the Horturion HPS 1000W de el Supra Plus lamp, Ushio Germany GmbH presents another innovation in the field of plant growth lamps. "The Horturion Supra Plus is a 1,000 W lamp with a light output of 2180 µmol/s and therefore the most efficient 1,000 W lamp ever introduced in the market", the Ushio Germany team says.

July 5, 2021

With the Horturion HPS 1000W de el Supra Plus lamp, Ushio Germany GmbH presents another innovation in the field of plant growth lamps. "The Horturion Supra Plus is a 1,000 W lamp with a light output of 2180 µmol/s and therefore the most efficient 1,000 W lamp ever introduced in the market", the Ushio Germany team says. "It offers 3.8 % more light output compared to the standard Horturion 1000 W lamp and enables growers to achieve a noticeable increase in yield and thus higher income with the same energy input."

"The Horturion Supra Plus is the answer to the demand for a 1,000 W lamp with significantly increased light output, a result of many years of exchange and closest cooperation with our customers, especially in the Netherlands, the pioneer in horticulture in Europe, if not worldwide", they continue.

The Horturion Supra Plus is compatible with all standard 1,000 W luminaires for double-ended lamps on the market and will be available as early as August 2021.

More micromoles per square meter

At 2180 µmol per second, the Horturion Supra Plus offers 3.8 % more light output compared to its 1,000 W equivalent at 2100 µmol/s.

In-house labs for the highest quality HPS lamps

Just at the end of last year, Ushio Germany, formerly BLV Licht- und Vakuumtechnik GmbH, made a clear and bold statement by discontinuing its horticulture LED lighting solutions division and clearly focusing on the development, production, and distribution of HPS lamps for this sector.

Consistently following this strategic orientation, the company has further expanded its development capacities at the Steinhöring site. Ushio’s own laboratories, equipped with the latest technology and sophisticated equipment for precise measurements and tests, have for years provided ideal conditions for innovations and world premieres. All prototypes of the legendary BLV Horturion HPS series were developed here, including the Horturion Supra Plus.

Expanded production capacities

In order to meet the increasing demand, even for high volumes, a new production facility with a total area of almost 6,000 m² was inaugurated at the Ushio Poland site back in 2017. At full capacity, one million lamps for professional greenhouse lighting can be produced here per year. With this capacity, Ushio is not only a trusted partner for lamps of the highest quality but is also able to reliably produce and deliver orders with very high quantities for large projects.

The Horturion® Supra Plus will be available from August 2021. Pre-orders are accepted as of now.

For more information:

Ushio

info@ushio.eu

www.ushio.eu

BLV

Muenchener Strasse 10

85643 Steinhoering

Germany

www.blv-licht.de

Inside Natural Grocers' Hydroponic Produce Container

Inside, more than 4,000 heads of organic lettuce are grown every month across roughly 320 square feet — just a fraction of the roughly 1 acre worth of land it would take to conventionally grow the same amount, said Michael Boardman, manager of the grow unit, which the grocer calls GardenBox

Catherine Douglas Moran

July 7, 2021

Eighty-two steps away from the produce aisle of Natural Grocers store in Lakewood, Colorado, sits a shipping container filled with hydroponic produce.

Inside, more than 4,000 heads of organic lettuce are grown every month across roughly 320 square feet — just a fraction of the roughly 1 acre worth of land it would take to conventionally grow the same amount, said Michael Boardman, manager of the grow unit, which the grocer calls GardenBox.

"Within this small space, there's a lot of possibilities," Boardman said while giving a recent FaceTime tour of the shipping container.

The GardenBox pilot marks Natural Grocers' first foray into organic hydroponic farming and furthers its commitment to sell 100% organic produce and invest in hyper-local production. Starting Wednesday, July 7, customers can buy the lettuce at the store for $1.99 per head.

GardenBox grows seven to eight varieties of lettuce, including Hampton, Brentwood, Alkindus, Tropicana, Muir, Marciano and Truchas. Unlike seasonal greens, the lettuce in GardenBox can be grown year-round, meaning it's always in season.

"We're seeing consistency in the product, whether it's snowing 2 feet outside or it's 90 degrees outside," Boardman said. "The box does a really good job of regulating this temperature."

Courtesy of Natural Grocers

From seed to salad

A portion of the container is dedicated to seedlings and can hold 2,400 plants at a time, with roughly 700 to 800 organic seeds planted each week in organic-friendly peat and coconut husk.

Around the three-week mark, the plants get transferred to the three vertical grow walls. The walls are double-sided and on rollers so that the plants can get spread out for equal access to LED lights that mimic sunlight, Boardman said. After about eight weeks after the seeds are planted, most varieties of the lettuce are ready for harvest.

The feeding, nutrients and water are automated through a computer system inside the box. The system also measures air temperature, humidity, vapor pressure deficit and pH levels. If any issues arise, the system sends Boardman an email. "The computer and box kind of run itself," Boardman said. "It's just us troubleshooting and then coming in planting and harvesting."

Lasting lettuce

The GardenBox lettuce, which is certified organic by Where Food Comes From Organic and has the Clean Hydroponic Produce seal, is sold with roots intact, which Boardman said lengthens its shelf life and provides a better flavor and more nutrients.

"They taste amazing," Boardman said. "The taste is a really big selling point for me. You get a much stronger flavor out of all of them."

Courtesy of Natural Grocers

In some cases, the lettuce may get sweeter when the roots are kept in the water following the harvest. Fresh living greens also provide a more nutrient-dense product than traditional lettuces that have been shipped to the store, Boardman noted.

After getting harvested, the produce is sold loose on a spinning display with water in the middle of the store's produce department. Shoppers can then bag it with plant-based produce bags.

Growing more greens

The idea for the hydroponic farm came from the Isely family, which started Natural Grocers in 1955, said Boardman, who joined the project in October.

The trickiest part of the operation has been figuring out the nutrients formula, which includes magnesium, cobalt, copper, manganese, zinc and iron, along with the organic growing process. "It took us several months to really dial in the organic nutrients. There's not a lot of organic hydroponic growers out there," Boardman said.

Courtesy of Natural Grocers

The first harvest happened in June, though Boardman said experimentation is continuing with different types of lettuce. Not all lettuce is prime for hydroponic farming, but the varieties in the box now, including butter lettuce, red romaine, and green and red oak leaf, are doing well, Boardman said. "I love [the oak leaf lettuce]. It comes out beautiful ... It just really thrives in the box," Boardman said.

Typically, hydroponic farming produces crops faster and saves more water than traditional farming. As part of the Clean Hydroponic Produce Standards certification, the grocer will be participating in scientific research studies on nutrient density and energy use.

GardenBox plans to eventually grow herbs for Natural Grocers, though for now, the focus is on perfecting its leafy greens, Boardman said.

Natural Grocers aims to bring GardenBox containers to more stores. "Right now, we've got one more store that we're planning on opening up with a box shortly within the next few months. But beyond that, I'm still not sure what the steps will be," Boardman said.

Lead Photo: The grocer's first foray in the futuristic farming technology, GardenBox, grows 4,000 lettuce heads per month and sits just steps away from a Colorado store's produce department.

Growfoam Welcomes New Chief Financial Officer

Growfoam, world leader in biodegradable foams for controlled environment agriculture, announced today that drs. Janet Koolman RA, a seasoned financial expert, has joined the company’s executive team as Chief Financial Officer.

July 1, 2021

Growfoam, the world leader in biodegradable foams for controlled environment agriculture, announced today that Drs. Janet Koolman RA, a seasoned financial expert, has joined the company’s executive team as Chief Financial Officer.

Koolman brings over 20 years of experience in management, accounting, and controlling. Before joining Growfoam, she worked in various roles at the Dutch Accell Group, most recently as Senior Holding Controller. Accell Group is a publicly owned company with a position on the EURONEXT Amsterdam Stock Market and is the European market leader in e-bikes. Their portfolio includes brands such as Koga, Raleigh, and Batavus. Koolman’s impact on the mobility sector is not to be underestimated. During her career at Accell, the company grew from a European player to a multinational with branches all over the world. Koolman and her team were instrumental in initiating the immense professionalization and growth of the Accell finance department.

“Koolman’s impressive background and career make her a great fit for her new role at Growfoam,” said Growfoam CEO Martin Tietema. “As well as her financial management expertise, she shares our mission and vision of making the world better for future generations, and enabling reliable and safe food production.”

Koolman’s hire follows Growfoam’s strong growth perspective since its market introduction at Greentech 2019. The company’s growth is fuelled by a financial injection from venture capitalists SHIFT Invest and Future Food Fund, alongside a global portfolio of CEA clients that has rapidly expanded over the last few months.

“I am excited to join the executive team at Growfoam,” said Koolman. “I am impressed by the team’s commitment to positively impacting the world by enabling their clients to grow greener, safer and faster, which is a core priority of the company. The time for making a big impact on food safety and quality is now. I am determined to contribute to that and, in my field of expertise, the difference between making an impact in mobility or food production is not as big as one might think. And I still commute to work by bike. Old habits die hard.”

Koolman’s hire is effective starting July 1st.

Netled Signs €15 Million Contract With Oh My Greens To Deliver Vera Vertical Farm To Sweden

Netled and Oh My Greens (OMG) have signed a contract for a three-year investment programme that will see Netled deliver its Vera vertical farm to OMG, a Swedish supplier of potted herbs

July 13, 2021

Netled has signed a contract worth €15 million with Swedish herbs supplier, Oh My Greens.

Netled and Oh My Greens (OMG) have signed a contract for a three-year investment program that will see Netled deliver its Vera vertical farm to OMG, a Swedish supplier of potted herbs. The contract was signed in June 2021 and is worth a total of 15 million euros over three years. The contract also includes a five-year maintenance and cultivation consultancy service, and is estimated to be one of the largest turn-key technology deals specifically between the technology providers and farm operators in the indoor agriculture market to date.

The first delivery for the project is underway and is valued at 3.2 million euros; it is due in Q2 of 2022. After commissioning, Netled will continue to provide technical and consultancy services while OMG will focus on producing and supplying vegetables to retailers in Stockholm. The second phase of the investment plan is due to start in Q4/2022.

OMG is a farm operator company providing consumers with potted herbs and has ambitions to achieve a major market share in Sweden by the end of the investment program.

OMG is part of Applied Value Group, a Swedish-American investment, management consultancy, and social impact firm. OMG operates in Sweden together with its sister company, Bake My Day (BMD). BMD is a 25 million USD revenue company serving 800 customers with daily deliveries including around 400 grocery stores. Working together, BMD and OMG can offer a wide range of the highest quality fresh food products to retail throughout Stockholm and the Mälardalen region, covering 40% of the Swedish population.

“We considered 17 different vertical farming technology providers and came to the conclusion that, in terms of its technology, know-how, and delivery capabilities, Netled is years ahead of the competition,” says CEO of OMG, Moses Isik.

“Netled’s technical and horticultural knowledge, and decades of experience of growing technologies, combined with OMG’s superb logistic network and existing customer relationships, creates an unbeatable competitive advantage which will allow us to quickly increase our market share and supersede traditional herb production with sustainable and ecological vertical farming that will disrupt the existing supply structures.” he continues.

“Netled’s Vera vertical farming technology will allow us to provide customers throughout Sweden with fresher herbs and leafy greens, grown hyper-locally and with a significantly reduced carbon footprint”, Moses adds. “Not only does the customer benefit, but the planet does too!”

Netled Ltd. is the leading vertical farming technology provider in Finland. Netled’s Vera technology offers turn-key indoor farming systems which include a dynamic spacing system, LED lighting, HVAC, and a nutrition system. It also includes automation software, production management and horticulture intelligence software. The Vera family of growing systems range from the Instore growing cabinets to massive-scale Industrial systems.

“The cooperation with OMG and its sister company, BMD, creates a huge opportunity for Netled to increase its market presence in Sweden. It also solidifies our position as the global leader in vertical farming technology,” says CEO of Netled, Niko Kivioja. This contract is the first industrial-scale operation for Netled, which was previously focused on an urban farm scale.

“This contract not only allows OMG to produce fantastic products for customers throughout the whole of Sweden, but it also functions as a clear example to other farm operators of the industrial-scale applications and opportunities our Vera vertical farming technology is capable of.” Kivioja continues.

“Netled is now the premier provider of vertical farming technology globally and we intend to keep it that way.” he concludes.

More information:

Niko Kivioja

CEO, Netled Ltd.

+358 50 360 8121

Moses Isik

CEO, Applied Industries Holding AB

+46 704 269 267

Robert Brooks

Investor Relations & Communications Manager

+358 50 484 0003

What Flooding In London And New York Tells Us About The Future of Climate Change

With America and parts of Europe already experiencing erratic weather patterns, such as record-breaking night temperatures, climate scientists are increasingly worried over the future of weather patterns like this in the coming years

By Hope Talbot

July 13, 2021

Yesterday, parts of London experienced one month’s worth of rain within a day, causing severe flash floods across various areas of the city. Similar incidents of flash flooding have also been reported across several parts of Europe, with Bulgaria, France, and Switzerland all experiencing similar flooding.

This comes after New York experienced similarly severe flooding last Thursday as a result of Storm Elsa, with subways and highways flooded throughout the state.

With America and parts of Europe already experiencing erratic weather patterns, such as record-breaking night temperatures, climate scientists are increasingly worried over the future of weather patterns like this in the coming years.

How is climate change affecting flooding?

The likelihood of flooding is significantly increased due to the extreme weather patterns caused by global climate change. Changes in the geography of the land, resulting from climate change, also have a part to play in increasing flooding.

With certain vegetation and other land barriers being broken down as a result of changing temperatures and freak weather patterns, many of the natural preventative measures against flooding are no longer there.

Higher temperatures mean higher rainfall

With America experiencing its hottest June on record, temperatures have soared dramatically. As a result of these higher temperatures, we’re experiencing higher air and water temperatures, increasing evaporation.

With increased evaporation comes increased rainfall, with longer durations as well as higher intensity and frequency of rainfall, too.

Evidence also suggests that temperatures increase at a higher rate above the equator, meaning countries in the Northern Hemisphere, such as America and the UK, are likely to experience more significant temperature changes.

How can flooding be prevented?

Although flash floods may seem uncontrollable, there are several possible steps to ensuring that cities and towns are protected against flooding, with rainwater being distributed in a sustainable way.

Sponge cities

Through ingenious urban planning, cities have been able to use strategic green spaces to absorb excess rainwater for future use, therefore reducing flood risk. In China, the concept of ‘sponge cities’ has become popular, with irrigating gardens and urban farms acting like sponges to soak up excess water.

Urban greenery

As seen in the recent London floods, sewage management became a big issue, with sewage pipes bursting due to flooding. In Europe, green roofs are another innovative solution to reducing flooding risk, with greenery absorbing stormwater run-off, and thereby preventing sewage overflow.

Permeable pavements

A common issue seen within urban flooding is the lack of drainage away from walking paths and roads, with cement being unable to absorb water. An ingenious solution to this is installing permeable pavements, which can absorb water and transfer it to other sources, such as urban green spaces.

Lead Photo: Recent flooding across the UK

The Collaborative Farm: Where Agriculture Meets The Entertainment World

The Collaborative Farm is an emerging destination in Milwaukee that survives as the rebrand of an organization formally known as Growing Power. The Farm is redefining urban agriculture and how the entertainment industry can impact its operations remarkably to sustain several communities

By GetNews

July 13, 2021

The Collaborative Farm is an emerging destination in Milwaukee that survives as the rebrand of an organization formally known as Growing Power. The Farm is redefining urban agriculture and how the entertainment industry can impact its operations remarkably to sustain several communities. The new and improved organization was made possible by Tyler Schmitt, best known to his peers as Tymetravels. His phenomenal vision to put together agriculture and music to expand urban farming has been making waves, making his novel initiative an extraordinary breakthrough.

Schmitt majored in Entrepreneurship with a minor in Sustainability at the University of St. Thomas then later moved to live in the national parks in Wyoming. When Growing Power collapsed, Schmitt came home from Jackson Hole to lend a hand to Will Allen and his father Tom Schmitt to solve the intricate issues involved in urban farming—from solar aquaponics to increasing food production while keeping operations sustainable.

Schmitt developed Ultimate Farm Collaborative to redesign not just farms but also cities in the near future. Collab Official, on the other hand, is the record label he created in order to unite various music artists under the umbrella of an extraordinary cause. The Farm Music Festival is its annual event, which is designed to generate funds to sustainably operate the farm.

This coming October 1–3, Milwaukee’s last remaining farm will be hosting a music festival to create awareness on the value of urban farming through hip-hop and EDM music. Schmitt hopes that the upcoming event will make a difference in the lives of urban farmers. The upcoming event will also give the good people of Milwaukee an opportunity to experience The Collaborative Farm up close. When music meets agriculture, the possibilities are out of this world.

The Collaborative Farm has a whole lot of surprises in store for the future as it is in the process of developing and recruiting a solid and hardworking team that will help it realize its goals. In the coming months, it will open an art studio, which will also be a coffee shop. The coffee shop will be the front store to increase foot traffic day in and out long-term. Additionally, it is working on establishing the vertical farm that Growing Power was positioned to pursue in the past.

Moreover, the founder of Ultimate Farm Collaborative sees the company staying with The Collaborative Farm long-term. In the next couple of years, it will either purchase or design a second facility. The annual music festival at The Collaborative Farm will continue and expand as a creative label through the efforts of Collab Official.

The novel idea behind The Collaborative Farm serves as an inspiration to those who have been supporting urban farming and those who wish to try sustainable living by growing their own produce. As the entertainment aspect of the whole operation continues to fund the needs of the farm that provides produce for locals, Tyler Schmitt hopes to continue to make promising collaborations that will impact the community significantly in the coming years.

Media Contact