Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

EAT LOCAL + HEALTHIER + GREENER + FRESHER

As Americans increasingly reject cheap, processed food and embrace high-quality, responsibly-sourced nutrition, hyper-local farming is having a moment

EAT LOCAL

EAT FRESHER

EAT HEALTHIER

EAT GREENER

Photo: AeroFarms

image taken by photographer Holly Challinor, Jones Food Company Ltd.

HELIPONIX

TOP USAGE OF FARMLAND BY STATE

ALL OF THE AG LAND IN THE WORLD

Vertical Farming Comes to Edinburgh

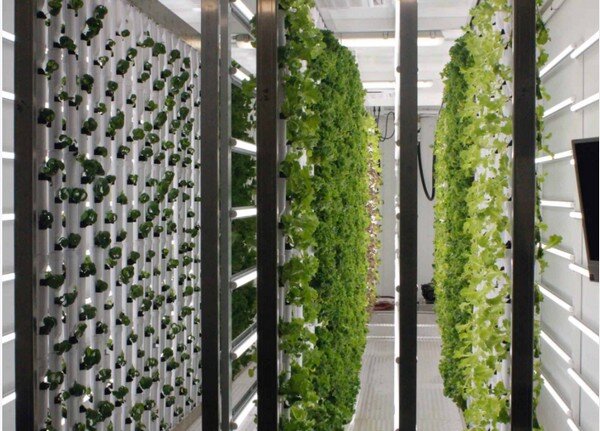

Scotland’s Rural College is to be the first higher education institute in Scotland to open its own vertical farm for research and education.

By Gordon Davidson

August 10, 2021

Scotland’s Rural College is to be the first higher education institute in Scotland to open its own vertical farm for research and education.

The half million-pound facility is to be built at the SRUC's King’s Buildings campus in Edinburgh next year, with the backing of a £200,000 grant from the Scottish Government. It will enable key research into plant and crop science, growing nutrient-dense fruit and vegetables with specific human health qualities, while analysing crop yield and growth rates – with all inputs recorded in the closed environment – to compare their carbon footprint to other production systems.

SRUC's vertical farm will operate on renewable energy sources from the national grid, supported by battery technology to manage peaks in energy demand.

With only a handful of commercial vertical farms in Scotland so far, it is envisaged that the facility will be important for demonstration and knowledge exchange with farmers, growers and small businesses. It will also be used by SRUC students as part of their educational activities, looking to a future when such systems will be far more common places of work.

Cabinet Secretary for Rural Affairs and Islands, Mairi Gougeon, said: “As we look to produce more fruits and vegetables locally, vertical farming could provide us with a way to make better use of our land. It’s an exciting and innovative field that could bring us real benefits and it is important that we have the skills in Scotland to take advantage of this technology.

“By supporting the industry at an early stage, we can assess these benefits and help to focus our long-term strategy. We will also be reaching out to the wider industry to explore in further detail the opportunities low-carbon vertical farming offers. We will work together to establish the future of vertical farming in Scotland.”

Principal and chief executive of SRUC, Professor Wayne Powell, said: “One of the most critical challenges we face is how to feed a growing global population. We have been teaching farmers for generations but, as the population increases, it is important that we look at growing different, more nutritious crops to support healthy diets and local access to food.

“Not only will this vertical farming unit be a valuable asset to our students, but it will also provide us with important data to help optimise and promote innovation into this expanding industry.”

Lead Photo: A new vertical farm at SRUC will be used for education and research.

Flashfood, Price Rite to Boost Fresh Sales, Cut Waste

Flashfood, an app-based marketplace that strives to eliminate retail food waste by connecting consumers with discounted food nearing its best by date, is adding more stores to its U.S. footprint through a new pilot program with Price Rite Marketplace.

August 12, 2021

Flashfood, an app-based marketplace that strives to eliminate retail food waste by connecting consumers with discounted food nearing its best by date, is adding more stores to its U.S. footprint through a new pilot program with Price Rite Marketplace. Price Rite Marketplace customers in the western New York area can now save up to 50 percent off select groceries that would otherwise go to waste.

The Flashfood app allows shoppers to browse and purchase fresh food, including produce, meat, deli and bakery products, nearing its best before date at significantly reduced prices. Shoppers can find great deals and purchase through the app, then simply pick up their items at the Flashfood zone located at their selected Price Rite store.

“We’re thrilled to work with Price Rite Marketplace as our newest partner committed to fighting food waste while helping their customers save significantly on their groceries,” said Josh Domingues, CEO of Flashfood. “Flashfood is a triple-win for our partners, the planet and people. We look forward to connecting Price Rite Marketplace shoppers with great deals while helping them make sustainable choices.”

In addition to helping customers shop more affordably with Flashfood, Price Rite Marketplace also supports local communities by donating to charitable organizations such as Feed the Children, contributing nearly 3 million pounds of food across 49 cities since 2015.

“Partnering with Flashfood is a natural next step as we continue to create environmentally-friendly neighborhoods and exceptional value for shoppers,” said Jim Dorey, president of Price Rite Marketplace. “We are proud of the concerted efforts our stores have made over the years to minimize our environmental footprint and look forward to seeing the impact of our new partnership with Flashfood.”

To date, Flashfood has partnered with grocery chains across the U.S. and Canada to divert more than 25 million pounds of food from landfills.

“We’ve Built a Controller That Works With Any Horticultural Lighting"

GrowFlux’s participation in the IN2 will provide up to $250,000 in non-dliutive funding from Wells Fargo as well as the opportunity to collaborate with the Donald Danforth Plant Science Center and National Renewable Energy Laboratory

August 12, 2021

In July 2021, the Wells Fargo Innovation Incubator (IN2) announced the five start-ups selected to participate in the initiative’s ninth cohort, with agtech company GrowFlux among the participants. The program is targeting the development of sustainable technologies for controlled environment agriculture. GrowFlux specializes in horticultural lighting control, having developed brand-agnostic wireless controllers that allow growers to control both HPS and LED lights. The controllers work with nearly all LED lights, while most HPS lights with dimming capabilities are compatible with the controller.

GrowFlux’s participation in the IN2 will provide up to $250,000 in non-dliutive funding from Wells Fargo as well as the opportunity to collaborate with the Donald Danforth Plant Science Center and National Renewable Energy Laboratory.

The GrowFlux Dimmer. Picture by GrowFlux.

According to CEO and founder Eric Eisele, GrowFlux will use the opportunity to enhance its Precision PAR® branded software controls, which will offer growers the ability to use PAR sensors to control any light according to grower defined lighting targets. The intelligent controls will also incorporate energy management features that will analyze natural light conditions in real time, compare it with historical data and electricity prices, then define the best time to light the greenhouse accordingly.

Coupling lighting control

“Utility companies are challenged to meet the demand of the rapidly expanding lighting loads within the CEA industry. By coupling our lighting control technology with real-time sensor and energy pricing data, we can define the best time to light a crop to optimize for energy savings,” Eric explains.

GrowFlux plans to address the largest addressable market possible and is doing so by focusing on small- and medium-sized operations. As Alex Roscoe, chief technology officer, explains, these operations are focused on efficiency, ease of use and the eliminating the need for technicians where possible. However, growers’ reliance on proven technologies has previously made it difficult to implement new technologies in the industry. Through IN2, GrowFlux will be able to continue developing its technology and prove it in a near-production setting.

“Right now, we’re in the development phase and once we reach the field deployment phase, which will happen shortly after the program, we’ll be looking for participants to help us scale our technology and ensure that the technology is accessible to the majority of the market. Different cultivators have different priorities; some are light-centric while others lead with temperature and humidity. We want to work with all of these strategies,” says Alex.

Ensuring accessibility and reliability

GrowFlux controllers are wireless and cloud-based, allowing growers to control their lighting system from any device. GrowFlux has also built redundancies into the platform to continue running the light plan should any Internet issues arise. With most facilities having back-up generators, power outages can quickly be mitigated and the redundancies allow the grower to quickly resume its lighting strategy. Cybersecurity has also become a main focus, alongside reliability, to ensure that growers can easily use the controllers and fully benefit from the peace of mind offered.

“We’ve built a controller that works across the entire industry and with any horticultural lighting. At the end of the day, we want to make energy saving controls as accessible as possible and see our industry grow sustainability,” says Eric.

For more information:

GrowFlux

info@growflux.com

www.growflux.com

Lead Photo: The GrowFlux Dimmer. Picture by GrowFlux.

Women in AI: How Does the Future of Horticulture Will Look?

But what skills are needed to work in AI tech? And what does the future of working with AI look like? Britta Meixner, Saheli De and Gosia Piekarska of Blue Radix answer these questions, and suggest how we can encourage more women to aim for tech jobs in AI or IT

August 11, 2021

Getting the best from your crop and greenhouse will increasingly become a computer responsibility. We need to make better decisions, to get better results and fix the global food problems and expertise shortages. Artificial Intelligence can help us with this. But what skills are needed to work in AI tech? And what does the future of working with AI look like? Britta Meixner, Saheli De and Gosia Piekarska of Blue Radix answer these questions, and suggest how we can encourage more women to aim for tech jobs in AI or IT.

What’s your job at Blue Radix?

Britta: “My name is Britta Meixner, and I’m a Scientific Data Engineer. I advise the Blue Radix management team on technical implementations. I keep track of new technologies enabling us to introduce innovative products to customers. I also design, build and maintain a scalable and future-proof IT environment. Other tasks include implementing proof of concepts for new technologies and setups; I design and realize solutions when we start using these new technologies. One of these is the Azure IoT Hub, which lets us send results from the Data Science Team to greenhouses, steering installations autonomously.”

“A day in a data scientist’s life entails a range of tasks,” explains Saheli De, who works as a Data Scientist at Blue Radix. “Developing new functionalities for our customers involves preparing, cleaning and analyzing the data that comes from the climate computers and other data platforms. In this phase we work closely with our product development team to understand the dynamics and strategies involved in the greenhouse. Then there’s extensive discussion of strategies to solve the business requirement, leading to building models using cutting-edge AI technologies like machine learning. The essence of the job lies in translating the horticulture industry’s business requirements into data science solutions.”

Gosia Piekarska works as a Blue Radix Test Engineer and is responsible for implementing testing procedures, shaping the testing process, and software testing. “My job is to check the quality of the infrastructure and components in both Crop Controller and the energy domain. My work is my hobby; I’m always trying to improve my software testing knowledge in my spare time. I’m particularly interested in Test Automation, Data Analysis and DevOps.”

What do you like about working with new AI tech solutions for horticulture?

Britta: “There’s often no standard way of doing something when creating new AI solutions. Every new project requires new skills and technology knowledge. I can never stop learning in my job. Staying up to speed on new developments and technologies is the key to success. This makes my job demanding, but at the same time it never gets boring.”

Adds Saheli: “The tech industry is growing rapidly, and being the flag-bearer of AI in horticulture lets you design unique and sustainable solutions. Imagine walking into a supermarket picking up a tomato that was produced with the help of your algorithms! That’s powerful!”

“I always love working on the cutting-edge technology solutions, because they introduce the innovations which are so desperately needed in our world,” says Gosia. “I think that sustainable technology in the food-growing industry is critical for people’s well-being.”

What skills are needed to work in the AI tech-field?

“You need a broad spectrum of knowledge to make our solutions work in the greenhouse, from network protocols and operating systems, databases and APIs, to data pipelines. It’s only the combination of these which enables us to steer a greenhouse autonomously,” explains Britta. “Because the IT infrastructure differs in every greenhouse, we must be able to create solutions that quickly adjust to a wide range of situations. So alongside a very broad technical knowledge, you also need to be flexible, and to understand new situations and requirements quickly.”

Saheli adds: “Data Science in particular is a mix of mathematics, statistics, and computer science skills. Horticulture-related skills are a benefit, but not mandatory in my role.”

Gosia: “Constant learning of both broad technologies and tools.. On top of that, don’t forget soft skills.”

How do you think the future of working with AI will look?

Britta: “Data Scientists now focus mainly on a deep understanding of algorithms and data sets to be able to get the most accurate results for steering the greenhouse. This is often done in controlled offline setups. But there’s still a large gap before these algorithms are ready to be integrated into production environments to produce real-world data for the greenhouse. Data science and data engineering have to work together early in the development process to close this gap. That lets us deliver new features and improvements to existing functionalities faster.”

Saheli: “As we say at Blue Radix: ‘Algorithms can feed the world’. We believe that algorithm-based solutions, like our Crop Controller, offer growers worldwide a digital brain for their greenhouse. The dream is to work towards a symbiotic utopia of growers and AI-driven solutions.”

Gosia adds: “The key will be the AI-human interaction and how to deliver AI solutions to customers who don’t necessarily have a deep technical understanding of AI systems. This is important in horticulture, because advanced controlled systems are relatively new in this industry.”

How can we generate enthusiasm among women for tech jobs in AI or IT?

Britta: “Women have different styles of working, thinking and communicating than men. While that might cause confusion here and there, it can really help a team to reach their goals faster, and to find better solutions. If we are to encourage more women to take up AI or IT jobs, it’s important to reach true equality in opportunities and pay in every job out there. We need to remove gender stereotypes in daily work, while also avoiding them in early childhood and at schools.”

Saheli: “I completely agree with Britta,; we need to generate opportunities for both genders to be able to access and experience meaningful interaction with technology from a very young age. I strongly believe that curiosity is the key to science. Stay curious and keep asking questions!”

Gosia: “We can’t shape our world if we’re not involved. Working in IT offers enormous opportunities for women to make their mark. I also believe there are great career prospects if you choose a future working in AI, IT and sustainability. There are so many great challenges, and you can really contribute to a better world. The best would be to provide successful examples and stories of women working in AI, to encourage young girls to join the field.”

California Drought Continues to Cause Irrigation Cutbacks

California, which has already reduced water deliveries received through the State Water Project to zero or near zero levels, has now stopped water diversions for thousands of farmers and other users in the Sacramento-San Joaquin Delta watershed

By Tom Linden

August 11, 2021

California, which has already reduced water deliveries received through the State Water Project to zero or near zero levels, has now stopped water diversions for thousands of farmers and other users in the Sacramento-San Joaquin Delta watershed.

In early August, the California State Water Resources Control Board unanimously voted 5-0 to put new limitations on 5,700 water right holders, including farmers and landowners, preventing them from diverting more than 55 gallons per day from their adjacent water sources without prior approval. These users have long term water rights based on the location of their land adjacent to these water sources. In addition, all water use has to be reported by those who have water rights in the region. Failure to comply will result in significant fines, including penalties as high as $1,000 per day, as well as up to $2,500 for each acre-foot of water diverted without expressed permission.

The new diversion ban is expected to be approved by California’s Office of Administrative Law by mid-August.

This action stems from California’s worsening drought situation as a very dry winter has been followed by high summer temperatures adding to the state’s dire situation.

While more cutbacks to farmers are not a welcome sight, representatives of agriculture and the state’s many water districts were not summarily opposed to the State Water Board’s action. Many groups weighed in on the proposed diversion ban with many of their comments concerning the length of the ban and the mechanics of it. Western Growers, which represents many growers in the state, officially commented on the regulations as a signee of a letter generated by like associations in California.

Gail Delihant, senior director of state government affairs and a water expert for the association, agreed the state is in bad shape and efforts to better manage water use are needed. In fact, she said, “Rules mandating large amounts of water to be released from reservoirs and flushed out to the ocean in prior months and years have gotten us into this current situation. The state water system was designed for dry periods like this. We are in dire straits because of implementation of environmental rules from the State Water Board and the environmental rules due to the federal and state Endangered Species Acts.”

She said the excess use of stored water for unattainable environmental goals has depleted the resources to a critically low level.

She noted this particular ban of water diversion was ordered because the state is not achieving the environmental results it expected with the amount of water it has released from the state’s Shasta and Oroville reservoirs that was pumped through the delta and out to sea to curb salt intrusion. She said the state’s water officials are theorizing that more water is being diverted from the delta by adjacent users than is being reported. Hence, the board is banning water diversions to ensure water quality standards are able to be met.

What Western Growers and other groups are lobbying for are mitigation efforts to increase storage as soon as possible once the rainy season begins, if it does.

More water restrictions in California are expected in the coming weeks as the drought intensifies.

AeroFarms and Nokia Bell Labs Partner to Further AI-Plant Technology

AeroFarms and Nokia Bell Labs have unveiled a multi-year partnership. The goal is to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels

By Johnny Eppich

August 11, 2021

AeroFarms and Nokia Bell Labs have unveiled a multi-year partnership. The goal is to combine their expertise and expand their joint capabilities in cutting-edge networking, autonomous systems, and integrated machine vision and machine learning technologies to identify and track plant interactions at the most advanced levels.

As part of this partnership, AeroFarms, a global leader in indoor vertical farming, contributes its commercial growing expertise, comprehensive environmental controls, an agriculture-focused data platform, and machine vision core foundation.

Nokia Bell Labs, the industrial research arm of Nokia, contributes its autonomous drone control and orchestration systems, private wireless networks, robust image and sensor data pipelines, and innovative artificial intelligence (AI) enabled mobile sensor technologies.

AeroFarms and Nokia Bell Labs have been working together since 2020. They have reached a milestone of achieving a proof of concept for this state-of-the-art integrated system and testing the technologies with AeroFarms’ current commercial crop varieties.

Together, they plan to scale this system to all of AeroFarms’ crops and future indoor vertical farms, including the next ones in Danville, VA, and Abu Dhabi.

The integration of Nokia Bell Labs’ AI-enabled drone-based sensors and advanced machine learning, computer vision, and data analytics technologies with AeroFarms’ existing machine vision tools enhances and elevates AeroFarms’ position as an agriculture platform and capabilities organization dedicated to solving food and agriculture supply chain challenges.

“With Nokia Bell Labs, we have developed the next-generation system that can image every plant every day in a cost-effective way at scale,” says David Rosenberg, CEO at AeroFarms. “This level of detailed imaging and insights helps us be better farmers by monitoring our plant biology dynamically and allowing us to course-correct as needed to ensure the highest level of quality all year round.”

Nokia Bell Labs’ machine vision technology has enabled the most precise data capture yet, down to the level of individual plants, using leaf size segmentation, quantification, and pixel-based scanning to identify consistency and variation.

Going beyond what even the human eye can perceive, this state-of-the-art imaging technology enables the gathering of immense insights about a plant, including its leaf size, stem length, coloration, curvature, spotting, and tearing.

The end-to-end system is flexible and robust, built to take advantage of Nokia’s 5G private wireless network with cloud processing technology. The network is designed for low latency and high privacy in an on-premises network. It also provides intelligent industrial analytics capabilities as an integrated service that can be deployed quickly and efficiently anywhere.

“Nokia Bell Labs is driven to solve hard and impactful problems, and together with AeroFarms, we are building the ability to see and identify plant interactions at unprecedented levels,” says Thierry Klein, Vice President of Integrated Solutions and Experiences Research Lab at Nokia. “The fundamental technologies of this partnership are our strength, and vertical farming is just the beginning. With the AeroFarms platform, we are exploring the power of network-driven intelligence for industrial outcomes. These capabilities can expand into a multitude of indoor industrial operations, including logistics, warehousing, distribution hubs, and manufacturing.”

Mastronardi, AppHarvest Form New Indoor Farming Venture: FarmCo

Mastronardi Produce Ltd. BB #:115453 and AppHarvest have announced a new endeavor that will further strengthen their relationship and cement their leadership as true visionaries in the AgTech sector

August 11, 2021

KINGSVILLE, ON and MOREHEAD, Ky., /PRNewswire/ – Mastronardi Produce Ltd. BB #:115453 and AppHarvest have announced a new endeavor that will further strengthen their relationship and cement their leadership as true visionaries in the AgTech sector. The companies have signed a non-binding letter of intent to form FarmCo, a joint venture to develop a portfolio of controlled environment agriculture (CEA) facilities to expand supply of fruits and vegetables including leafy greens to Mastronardi’s existing fresh produce marketing and distribution business.

FarmCo is planned to have its own leadership team, and calls for the two partners to contribute equity and assets of over $100M. The venture would use the equity contributed from both companies to raise additional capital to fund its growth, targeting to build over 750 acres of CEA Facilities in the United States to grow fresh fruits and vegetables including leafy greens.

“We are extremely pleased to be entering into this letter of intent with AppHarvest,” says Paul Mastronardi, President and CEO of Mastronardi Produce Ltd. “We have seen the demand for locally-grown produce skyrocket, particularly over the past 18 months as more people are cooking from home, and this partnership will allow us to significantly increase our ability to get more fresh, flavorful locally-grown produce to tables across America.”

“Mastronardi is the unquestionable leader in marketing and distributing CEA-grown produce to top grocers and restaurants in North America, and partnering more closely with them to fulfill the growing demand for quality local, fresh produce across the United States positions us together to make an even greater impact to establish a climate-resilient, sustainable food system to ensure food security,” adds Jonathan Webb, AppHarvest Founder and CEO.

About Mastronardi Produce Ltd.®

A pioneer and industry leader in the gourmet greenhouse industry, Mastronardi Produce grows and markets nationally recognized products under the SUNSET® brand, including Campari®, Flavor Bombs®, and Angel Sweet® tomatoes. Mastronardi Produce has been family-owned for over 70 years and prides itself on producing consistently flavorful gourmet tomatoes, peppers, cucumbers, and berries.

About AppHarvest

AppHarvest is an applied technology company in Appalachia developing and operating some of the world’s largest high-tech indoor farms, designed to grow non-GMO, chemical pesticide-free produce, using up to 90 percent less water than open-field agriculture and only recycled rainwater while producing yields up to 30 times that of traditional agriculture on the same amount of land without agricultural runoff. The company combines conventional agricultural techniques with cutting-edge technology including artificial intelligence and robotics to improve access for all to nutritious food, farming more sustainably, building a domestic food supply, and increasing investment in Appalachia. The company’s 60-acre Morehead, Ky. facility is among the largest indoor farms in the world. For more information, visit https://www.appharvest.com/.

Lead Photo: Mastronardi Produce Ltd (SUNSET) and AppHarvest partnering to form new AgTech venture (CNW Group/Mastronardi Produce Ltd.)

Fluence by OSRAM Reveals Multiyear Global Research Results on Broad-Spectrum Lighting Strategies for Cannabis and Food Crops

Fluence by OSRAM (Fluence), a leading global provider of energy-efficient LED lighting solutions for commercial cannabis and food production, announced today the results from a series of multiyear global studies analyzing the effects of broad-spectrum white light on cannabis, Merlice tomatoes and bell peppers.

August 12, 2021

AUSTIN, Texas—Fluence by OSRAM (Fluence), a leading global provider of energy-efficient LED lighting solutions for commercial cannabis and food production, announced today the results from a series of multiyear global studies analyzing the effects of broad-spectrum white light on cannabis, Merlice tomatoes and bell peppers.

The studies found that while spectrum sensitivity is cultivar-dependent, broad-spectrum lighting strategies—which include green light and other wavelengths largely absent in narrow-band spectra—improved crop yield, morphology and overall performance in selected cultivars when compared to narrow-band spectra with high ratios of red and far-red wavelengths.

“The results from our global studies show how effective broad-spectrum white light can be in improving crop performance for many cultivators around the world,” said Dr. David Hawley, principal scientist at Fluence. “Broad-spectrum strategies are about balance and flexibility in the spectrum itself as well as the overall cultivation approach. While there are certain scenarios in which narrow-band spectra, or pink light, may make sense from an energy efficiency or crop production perspective, we’ve found that many cultivars simply perform better under broad spectra across the KPIs cultivators care about most: yield, morphology and overall quality. Our latest research empowers us with new insights to assess each grower’s objectives, weigh those objectives against a facility’s unique financial, environmental and energy parameters, and then ultimately derive a tailored solution for each cultivator.”

Merlice tomatoes

A collaborative study with Wageningen University and Research (WUR)—led by researchers Leo Marcelis and Ep Heuvelink—evaluated differences in yield, morphology, development and quality for Merlice tomatoes grown with the VYPR top light series under four light spectra: PhysioSpecTM BROAD R4, PhysioSpec TM BROAD R6, PhysioSpecTM BROAD R8 and PhysioSpecTM DUAL R9B. BROAD R4, R6 and R8 all contain significant fractions of green light and other photosynthetically active wavelengths, while DUAL R9B is a narrow-band spectrum that contains almost no green light.

As researchers increased the ratio of red light in the overall spectrum, they recorded a linear decrease in yield. Compared to spectra with higher blue, red and far-red wavelengths, Merlice grown under broader spectrum lights yielded increases in fruit weight as high as 13 percent. Other tomato cultivars grown under broad-spectrum saw yield increases up to 14 percent.

Cannabis

Fluence conducted individual studies with WUR and Texas Original Compassionate Cultivation (TOCC), respectively. In the TOCC study, researchers studied Type I, Type II and Type III cannabis response to broad-spectrum R4, R6 and R8 under high PPFD. In each case, broad-spectrum R4 generated the most dry weight per plant. In Type I cannabis, PhysioSpecTM BROAD R4 generated 17 percent higher yields than the next highest yielding spectral solution, R6. Cannabis grown under broad-spectrum R4 also significantly improved morphology compared to plants cultivated under R6 or R8. Plants grown under broad-spectrum R4 were free of photobleaching in their upper buds, a development that typically occurs in plants grown with a higher fraction of red light.

In the WUR study, researchers found that in some cultivars, monoterpene and cannabinoid content, including THC, CBD and CBG, is significantly inversely proportional to the fraction of red light in the production spectrum. With these cultivars, R4 induced a 20 percent increase in cannabinoid compounds compared to spectra with red light ratios as high as 90 percent or more.

“The results of the TOCC and WUR intensity and spectrum studies are important for cannabis cultivators for two reasons,” Dr. Hawley said. “First, there is rarely a scenario in which they should grow cannabis under low PPFD. Our research continues to emphasize how much more beneficial it is to grow cannabis under higher PPFDs. Second, watch your red light ratio. There are a couple very specific cultivars and production situations that could benefit from narrow-band or high red/far-red and blue wavelengths. But it can also have detrimental effects on cannabinoid content, terpene ratios, yield and morphology, and would raise the risk of significant photobleaching of the canopy. That’s why we generally recommend growing cannabis with broad-spectrum under high PPFD.”

Bell pepper

Fluence also conducted studies with bell peppers at the Harrow Research and Development Centre in Ontario, Canada led by Dr. Xiuming Hao and Dr. Jason Lanoue. The collaborative research on bell pepper found that fruit quality significantly increased in Gina and Eurix cultivars under broad-spectrum lighting. Peppers grown under broader spectrum light increased average fruit size by up to 15 percent compared to others with higher blue and red wavelengths. An increase in the dry matter content—which is largely associated with fruit quality—also increased with increasing green light. It was also found that broad-spectrum lighting strategies proved the consistency of week-to-week production by leveling out a traditionally flush-prone crop cycle.

“Time and time again, our research with leading institutions around the world is proving that there is no universal spectral strategy for cultivators,” said David Cohen, CEO at Fluence. “For many crops and cultivars, however, it’s also showing the holistic benefits of broad-spectrum white light not just for the crop, but for a cultivator’s entire operation. That’s why we at Fluence have a multilayered approach to how we work with our cultivators. We continue to invest heavily in industry-leading research around the world. We provide cultivators with boots-on-the-ground expertise and experience in the form of our horticulture services team, and we identify the right light fixture and spectral strategy to help cultivators achieve their most important goals.”

Fluence’s ongoing global research initiatives include additional studies on strawberry, lettuce and cucumber cultivation. To learn more about Fluence and discover its latest research results, visit www.fluence.science.

About Fluence by OSRAM

Fluence Bioengineering, Inc., a wholly-owned subsidiary of OSRAM, creates powerful and energy-efficient LED lighting solutions for commercial crop production and research applications. Fluence is a leading LED lighting supplier in the global cannabis market and is committed to enabling more efficient crop production with the world’s top vertical farms and greenhouse produce growers. Fluence global headquarters are based in Austin, Texas, with its EMEA headquarters in Rotterdam, Netherlands. For more information about Fluence, visit www.fluence.science.

"Using Variable Spectrum Luminaries Allows us to Grow a Wide Range of Plants"

Bringing food closer to consumers is no longer an option but rather a necessity, given the strain traditional agriculture and transportation place on the environment.

August 11, 2021

Bringing food closer to consumers is no longer an option but rather a necessity, given the strain traditional agriculture and transportation place on the environment. Czech grow tech company GreeenTech teamed up with Hungary’s Tungsram to provide vertical farming solutions that pave the way for sustainable crop production.

Prague-based GreeenTech was born out of this realization. The company specializes in the research and development of hydroponic technologies to be used in container farms and vertical farms set up in buildings. Established in 2000, the business aims to enable people to grow agricultural crops anytime and anywhere in the world.

They are involved in developing innovative solutions for the local production of leafy vegetables, herbs, and small fruits through their own hydroponic cultivation technology complete with an IOT control system created in cooperation with Siemens. The uniqueness of the solution provided by GreeenTech lies in the development of tailor-made hydroponic farming technology.

Finding the perfect lighting solution

"Hydroponic systems are soil-less, water-based farming processes. The technology is based on growing plants in a controlled environment where crops are fed nutrient-rich water. Crop cultivation takes place in an enclosed growing space, where sensors control conditions such as humidity, temperature, or light cycle. The result is quality crops that have not been subjected to treatment with pesticides and herbicides and the farm uses about 90% less water than conventional agriculture," the GreeenTech team explains.

Given that crops are not exposed to natural light, selecting the right lighting solution in these farms is of utmost importance. GreeenTech’s quest for the best lighting solution provider-led them to Tungsram, whose variable spectrum LED luminaries proved to be the perfect match as the light sources have been designed and created only for the purposes of a growing container.

“We were searching for a lighting solution and we realized that Tungsram’s luminaries and the automation solutions provided by them are ideal for our needs because they are well suited for research purpose. Using variable spectrum luminaries allows us to grow a wide range of plants. In addition, customers have a high degree of flexibility in deciding what kind of plants they want to grow or in switching from one crop to the other,” said Karolína Pumprová, CGO at GreeenTech.

LED lights

"Our four-channel LED lights offer the highest performance in their category and are extremely easy to install," the Tungsram team says. "The luminaries are controlled remotely and allow users to adjust the color spectrum and light intensity independently for each growing rack, which is a game-changer for large-scale urban farms."

In addition to the lights, Tungsram also provided a tailor-made lighting design with the help of the company’s engineers and designers. "Variable spectrum luminaries are a powerful tool for growers in terms of adopting a “dynamic light recipe approach,” which is a rather unique offering in the market."

Compatible with software

“Another factor that weighed heavily in favor of Tunsgram was the fact that the lighting solution developed together with them was compatible with the software and system we already had in place,” said Milan Souček, CTO at GreeenTech.

GreeenTech will use the Tungsram luminaries at the expo in Dubai, which will run from September through March. The cultivation container will be set up in a restaurant and the plants will be used in the restaurant. As part of a cooperation with the Technical University in Prague, Tungsram lights will be installed at a small hydroponic farm set up by GreeenTech where students will be conducting research and testing.

For more information:

Tungsram

Keith Thomas, Commercial Leader

keith.thomas2@tungsram.com

agritech.tungsram.com

Kalera AS to Acquire &ever GmbH to Form a Global Leader in the Vertical Farming Industry

Kalera AS (Euronext Growth Oslo: KAL, Bloomberg: KSLLF), one of the fastest-growing and largest vertical farming companies in the world, announces today that it has entered into a share purchase agreement for the acquisition of all shares in &ever GmbH, a global leader in baby leaf indoor farming, for a total consideration reflecting an enterprise value for &ever GmbH of EUR 130 million on a cash and debt free basis as of 1 July 2021. T

August 11, 2021

&ever has been represented on the global market since 2015 and operates a large vertical farming facility in Kuwait, in addition to in-store grow-towers in Germany. It is also currently constructing a mega-facility in Singapore.

Kalera will become the only company with capabilities to serve every segment within the leafy green industry solidifying Kalera’s position as the overall indoor farming market leader.

Through the combination with &ever’s existing portfolio of vertical farms, Kalera will own the largest portfolio of farming systems from small in-store or on-property farms to megafarms.

ORLANDO, Fla., (GLOBE NEWSWIRE) -- Kalera AS (Euronext Growth Oslo: KAL, Bloomberg: KSLLF), one of the fastest-growing and largest vertical farming companies in the world, announces today that it has entered into a share purchase agreement for the acquisition of all shares in &ever GmbH, a global leader in baby leaf indoor farming, for a total consideration reflecting an enterprise value for &ever GmbH of EUR 130 million on a cash and debt free basis as of 1 July 2021. The consideration will consist of a combination of cash and Kalera shares. Under the terms of the agreement, &ever GmbH shareholders will receive EUR 21.6 million in cash and 27,856,081 Kalera shares at a subscription price of NOK 36.68.

The cash consideration will be financed through a debt facility provided by DNB or by other financing sources available to Kalera. Kalera shareholders will own an 87% stake in the combined company, while current &ever GmbH shareholders will own 13%, on a fully-diluted basis.

&ever is a vertical farm company headquartered in Germany with operations in the Middle East, Asia and Europe. The acquisition will transform Kalera into a global vertical farming leader, accelerating its plans for international growth and broadening its product line to include several cut leaf baby greens in high demand.

The company will be wholly owned by Kalera AS upon closing of the transaction. &ever GmbH will be renamed to Kalera GmbH.

Leading Technology and Capabilities for Baby Leaf Production

Founded in 2015 to grow select baby leaf produce and herbs including spinach, kale, endive, arugula, watercress, cilantro and bok choy, &ever has developed a proprietary approach for seeding, germination, propagation, harvesting, and delivery of fresh baby leaf products that optimize the entire production cycle through unique growing methods and technologies.

&ever has operations in Europe, Asia, and the Middle East and has designed production facilities of various sizes, ranging from small scale installations to mega-farms. Large-scale installations or mega-farms allow for mass scale production of baby leaf greens in facilities that can be built in less than 10-months and that can produce up to 1,500 MT of produce per year.

&ever has a large-scale farm in Kuwait that is currently in ramp-up phase, built in partnership with NOX Management. A second mega-farm is under construction in Singapore with support from a major competitive government grant and is expected to start operations during Q1 2022.

Small scale production facilities include an on-site Grow Box® for small retail stores and an on-site Grow Tower® for larger retail stores allowing the company to grow on-site in a local grocery store.

In addition, the company has unique growth solutions that include Dryponics® and Bestponics®, which are exclusive to &ever and expand the existing alternatives for growing leafy greens. Additional capabilities include advanced climate cells for perfect climate conditions for each product and an automated intra-farm bench movement system that significantly reduces operating expenses for high volume/short cycle growing methods, developed in partnership with German engineering firms Viessmann and Kardex Mlog, and Italy-based Modula.

Transformational Acquisition Creating a World Leader in Vertical Farming

"With Kalera’s farms in North America and &ever’s operations in Asia, the Middle East and Europe, we will jointly revolutionize the global vegetable production industry and further expand our market leadership in vertical farming,” says Daniel Malechuk, CEO of Kalera. “In addition, we see &ever's climate cell technology and their high degree of automation as excellent additions to our advanced nutrient management system, which will further increase the productivity of our production facilities."

“From the beginning, our vision has been to offer communities worldwide hyperlocal high-quality salads and herbs year-round. Together with Kalera, we have now come a big step closer to this goal,” says Dr. Henner Schwarz, CEO of &ever who will serve as Managing Director of EMEA and Asia for the combined entity. "We share very similar visions, core values, and goals and are eager to immediately begin the integration of the companies together."

“The merger is an important milestone for the global future of vertical farming. We are very much looking forward to the next steps with &ever as a new, stronger Kalera,” says Daniel Malechuk who will serve as CEO of the combined company. “This acquisition, combined with our previous acquisition of Vindara, the only seed company dedicated specifically for controlled environment agriculture, continues to complement and accelerate Kalera’s now global industry-leading position.”

The Largest Portfolio of Indoor Farming Systems

Through the combination with &ever’s existing portfolio of vertical farms, Kalera will own the largest portfolio of farming systems from small in-store or on-property farms to mega-farms, allowing Kalera to serve all market segments through a full spectrum of indoor farming systems that require low CAPEX and can deliver all products ranging from baby leaf, full head, cut leaf, or teen leaf to serve all segments and customer preferences.

Ability to Produce the Full Array of Leafy Green Products from Whole-Head to Baby Leaf

The indoor farming industry has been highly fragmented into different product segments between microgreens, baby leaf, cut leaf, teen leaf, and full head. Kalera will become the only company with capabilities to serve every segment within the leafy green industry solidifying Kalera’s position as the overall indoor farming market leader. This will provide retailers and foodservice customers with a single source to serve all their leafy green needs, a value proposition in the marketplace that no other company has been able to offer until now.

Accelerate Global Expansion

Kalera will accelerate its international rollout plan with the addition of two international facilities and a strong pipeline of opportunities especially in the Middle East and Asia. The &ever facility in Kuwait is a partnership with NOX Management, an investment arm of IFA Group, an owner of food markets, restaurant chains, retail chains, and food distributors. The &ever farm in Singapore is under construction and will launch operations by the end of Q1 2022. These two farms will become Kalera’s first international operations accelerating Kalera’s rollout schedule. Additional rapid international expansion at strategic locations throughout Asia, Middle East, and Europe, will be driven by Kalera’s and &ever’s combined business plan with an ability to offer the widest product portfolio to customers.

World-class Management Team to Join Kalera

&ever’s management team will join Kalera to strengthen Kalera’s international business development initiatives and operational capabilities. In addition, one member of &ever’s Board will join Kalera’s Board, adding to a team of world-class professionals that will help to drive the company’s future.

Technology and Partnerships are Highly Complementary

With &ever, Kalera adds grow technologies and strong German engineering partnerships. Kalera’s best-in-class hydroponic grow systems have been used to-date for growing whole-head lettuce and microgreens, whereas Dryponics® and Bestponics® technology is more flexible and productive for growing baby leaf including certain product varieties such as spinach and arugula. &ever’s technology also allow for a more effective offering of smaller in-store growing systems. These technologies can be combined to produce a wider variety of products with maximum efficiency. &ever’s partnerships with Viessmann and Kardex Mlog, and Modula add outstanding expertise in climate control and in-farm bench movement systems, respectively.

Transaction Terms

Under the terms of the agreement, &ever GmbH shareholders will receive EUR 21.6 million in cash and 27,856,081 Kalera shares at a subscription price of NOK 36.68. The consideration shares will be subject to a twelve-month lock-up after closing except for management who will be subject to a three-year lock-up.

The cash consideration will be financed through a debt facility provided by DNB or by other financing sources available to Kalera.

Kalera shareholders will own an 87% stake in the combined company, while current &ever GmbH shareholders will own 13%, on a fully-diluted basis.

By continuing to own shares of the combined company, &ever GmbH shareholders will have the opportunity to participate in the enlarged Kalera’s long-term value creation potential.

The current &ever shareholders will propose Faisal Al-Meshal as a new Kalera Board member and Dr. Klaus Bader as an observer to the Kalera Board, both to be proposed for election at a Kalera general meeting. The election is expected to take effect upon completion of the contemplated merger between Kalera and the new Luxembourg parent for the group, which has previously been announced. In the period between completion of the &ever acquisition and such merger, Faisal Al-Meshal and Dr. Klaus Bader will be invited to participate in Kalera Board meetings.

Up to 2.2 million Kalera share options will be granted to &ever management in connection with the transaction. The options will have a strike price of NOK 36 and will vest over four years with the following schedule: 0% at the end of year one, 25% at the end of year two, 25% at the end of year three, and 50% at the end of year four.

The transaction is subject to customary closing conditions, including a resolution of the Kalera general meeting to issue the consideration shares to the &ever shareholders.

It is expected that the transaction will be completed by the end of September 2021.

A presentation about the acquisition is attached here and is also available at the Kalera's website, www.kalera.com/investor.

About &ever:

&ever is a German indoor vertical farming company that combines technologies from the fields of software, mechanical engineering and agriculture. &ever has been represented on the global market since 2015 and operates a large vertical farming facility in Kuwait, in addition to in-store grow-towers in Germany. It is also currently constructing a mega-facility in Singapore. The company's focus is on building sustainable farms in cities around the world to provide more and more people with better tasting lettuce with higher nutrient content at the same time. The patented cultivation systems from &ever are easily scalable in shape and size so that indoor vertical farms of various sizes can be operated anywhere in the world, regardless of local climatic conditions. More information is available at www.and-ever.com.

About Kalera:

Kalera is an American vertical farming company based in Orlando, Florida. The company uses technology to ensure that more people around the world have access to the freshest, most nutritious, and cleanest products possible. It has spent several years optimizing plant nutrient formulas and developing an advanced automation and data acquisition system with Internet of Things, cloud, big data analytics and artificial intelligence. Kalera currently operates farms in Orlando, Florida, and Atlanta, Georgia. Kalera’s Houston, Texas farm will open soon, and the company has plans to open more farms in the US and also in both the Middle-East and Asia in the coming months. More information is available at www.kalera.com.

For more information, please contact:

Molly Antos

Phone: +1 847 848 2090

Email: kalerapr@dadascope.com

Important notice:

Matters discussed in this announcement may constitute forward-looking statements. Forward-looking statements are statements that are not historical facts and may be identified by words such as "believe", "expect", "anticipate", "strategy", "intends", "estimate", "will", "may", "continue", "should" and similar expressions. The forward-looking statements in this release are based upon various assumptions, many of which are based, in turn, upon further assumptions. Although the Company believes that these assumptions were reasonable when made, these assumptions are inherently subject to significant known and unknown risks, uncertainties, contingencies and other important factors which are difficult or impossible to predict, and are beyond their control. Actual events may differ significantly from any anticipated development due to a number of factors, including without limitation, changes in public sector investment levels, changes in the general economic, political and market conditions in the markets in which the Company operates, the Company's ability to attract, retain and motivate qualified personnel, changes in the Company's ability to engage in commercially acceptable acquisitions and strategic investments, and changes in laws and regulation and the potential impact of legal proceedings and actions. Such risks, uncertainties, contingencies and other important factors could cause actual events to differ materially from the expectations expressed or implied in this release by such forward-looking statements. The Company does not make any guarantee that the assumptions underlying the forward-looking statements in this announcement are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this announcement or any obligation to update or revise the statements in this announcement to reflect subsequent events. You should not place undue reliance on the forward-looking statements in this announcement.

The information, opinions and forward-looking statements contained in this announcement speak only as at its date, and are subject to change without notice. The Company does not undertake any obligation to review, update, confirm, or to release publicly any revisions to any forward-looking statements to reflect events that occur or circumstances that arise in relation to the content of this announcement.

Lead Photo: &ever is a German indoor vertical farming company that combines technologies from the fields of software, mechanical engineering and agriculture

Kalera CEO Makes an Impact on the Future of Farming

When he enrolled in North Carolina State University’s College of Management, Daniel Malechuk (’03) didn’t picture himself working in the food industry, but he couldn’t be more proud today of his role in the future of sustainable farming

By Lea Hart

August 10, 2021

When he enrolled in North Carolina State University’s College of Management, Daniel Malechuk (’03) didn’t picture himself working in the food industry, but he couldn’t be more proud today of his role in the future of sustainable farming.

Malechuk was named CEO of Kalera in 2019. Based in Orlando, Florida, Kalera grows leaf plants – mainly lettuce – in a vertical farming system inside clean room facilities. That means no pesticides or genetic modification, and the process uses five percent of the water that traditional farms use.

A video on Kalera’s website notes that 80 percent of land suitable for farming in the U.S. is already in use. Due to the growing population, it’s expected that the U.S. will need to produce 70 percent more food by 2050.

What’s more, the video goes on to point out that 95 percent of U.S. produce is grown in Arizona and California, and can take weeks to reach the consumer. That depletes vitamins, increases the risk of spoiling and the risk of contamination. Kalera’s approach localizes farming, bringing the product closer to the community.

From dreams of working in the sky to a career working for the planet

Malechuk enrolled at NC State with dreams of being an aviator. He was the recipient of a prestigious Park Scholarship and began a major in aerospace engineering. However, he enrolled prior to the Sept. 11, 2001, terrorist attacks and felt, post 9-11, that an aviation career didn’t look as promising.

At the same time, a mentor of his in the College of Management (now Poole College of Management), Professor Art Padilla, regularly encouraged him to consider a business degree instead. When he made the switch, Malechuk said he knew he’d made the right choice.

“I fell in love with the business degree,” he said.

Upon graduation, he went to work for Aldi USA as a district manager and quickly climbed the ladder to become director of corporate buying. While Malechuk didn’t plan to work in the food industry, he said he was excited by the management profile and career opportunities that it presented to him at such a young age.

His next role took him around the globe as vice president at Keysource Foods, a seafood company. He saw shrimp harvested in Vietnam and traveled on mussel boats off the coast of Ireland.

What’s so unique about a business degree and what I love about it is, it can open so many doors; it is one of the broader degrees

“What’s so unique about a business degree and what I love about it is, it can open so many doors; it is one of the broader degrees,” Malechuk said. “I don’t think I could have appreciated how true that is.”

During that time, Malechuk and his family had the opportunity to live in Apex, NC and he never forgot the Wolfpack, enjoying season tickets to athletic events.

He was recruited from there to run the retail division for Shamrock Foods, and his family moved to Arizona. During his time there, Malechuk pursued his executive MBA from the University of Arizona.

When the opportunity at Kalera presented itself, Malechuk admits he had never heard of vertical farming before, but he jumped at the opportunity for many reasons.

“This was a really exciting opportunity to, one, do something so cutting-edge, and two, to have that first opportunity to be CEO,” he said.

While his title is CEO, Malechuk calls himself something else most days.

“Right now, I call myself a farmer,” he says with a laugh.

But it’s fine with Malechuk, who ties it back to NC State’s roots as an agriculture school.

“I’m excited about feeding people,” he said. “It’s a noble cause and a great reason to get up in the morning.”

Demand and growth mean opportunity at Kalera

It’s also a great time to be leading Kalera. The company has a fascinating history. Its founders had initially worked on several different projects, including being a part of a sustainable city located in Florida, before pivoting to focus on indoor farming.

Daniel Malechuk in the Kalera facilities

“Historically, produce is farmed outside,” Malechuk said. “It’s susceptible to weather, fires, contaminants and more – it’s been a challenge.”

As sophisticated as the supply chain has become, he points out that there is also the issue of transporting and delivering it.

By growing produce locally, Kalera changes that business model. The company is currently expanding rapidly with facilities up and running in Orlando, FL and Atlanta, GA , where they have produced 12 times more leafy greens than the entire state of Georgia produced a year earlier. They’re expanding to Houston, Seattle and Honolulu to name just a few other locations, and recently took the company public on the European stock exchange, with plans for a NASDAQ IPO in the U.S. in the future.

I can’t imagine not having exposure and access to culture, people, learning and new experiences. I don’t know that I could have appreciated how much a business degree could give me those opportunities.

It’s been an opportunity for Malechuk professionally in more ways than one. The company was very small when he joined, and he’s had the opportunity to build a team and a culture from the ground up.

“It really has challenged me in a lot of ways,” he said. “It’s been a lot of neat and unique opportunities.”

Though it’s a very different path than the one he envisioned as a high school graduate enrolling at NC State, it fits Malechuk’s personality. As someone who has always had a sense of wanderlust, his various roles have taken him through all 50 states and 67 countries. While it’s not as a pilot, it still provides the same sense of satisfaction.

“I can’t imagine not having exposure and access to culture, people, learning and new experiences,” he said. “I don’t know that I could have appreciated how much a business degree could give me those opportunities.”

Tying it all back to NC State

Malechuk says his degree from NC State has been critical to his current success. He concentrated in marketing in his undergraduate, and said he’s applied everything he learned at NC State at some point during his career. And that includes experiences outside his degree framework as well.

“I don’t know that there was anybody that enjoyed their time at NC State more than I did,” he said.

He took extra Physical Education courses just because he enjoyed them, including scuba diving, and even put that to use during a business trip.

Malechuk was active with the Park Scholars. He calls that experience life-changing, noting the doors it opened and the opportunities it provided for mentorship and relationship-building. He’s hired and hopes to continue to hire NC State students and Park Scholars at Kalera as well.

He was president of the Bragaw Hall Council, served as a resident advisor, was active in the Catholic Campus Ministry, and participated in intramural sports, to name a few other activities.

“Through all of those things, the friendships that you develop and the maturing that you go through – that’s equally as important as the degree,” he said. “It helped me understand how to multi-task and become a dynamic leader in multiple different avenues.”

Malechuk and his wife of 15 years live in Florida currently with their four children, three girls and a boy.

While he is clearly invested in his career, Malechuk is also a big believer in balance and works as a team with his wife in that respect. He strives for balance among what he calls “the five F’s:” faith, family, friends, fitness and finances, saying he always tries to be cognizant that putting too much into one takes away from the others.

He and his family are active in their Catholic Church, and Malechuk enjoys fishing and boating. He got certified in Scuba Diving through NC State, still loves to travel and loves being active.

And, though he didn’t become a career aviator, he has his pilot’s license and enjoys flying.

While he’s committed to Kalera right now, Malechuk hopes things may come full circle one day in the future.

“I would love, perhaps someday, to become a professor in the business school at NC State,” he said. “I’d like to have that same experience of mentoring and leading students that I received, and to replicate what I had from some of the great professors there.”

Lead Photo: Daniel Malechuk, class of '03 graduate from Poole College

Genie Scissors Assist ‘Europe’s Largest’ Vertical Farm

Farming company Nordic Harvest has purchased a range of electric scissor lifts from Genie, for the construction and daily operations of its new vertical farming facility in Denmark.

By Leila Steed

August 10, 2021

Farming company Nordic Harvest has purchased a range of electric scissor lifts from Genie, for the construction and daily operations of its new vertical farming facility in Denmark.

A specialist in hydroponic cultivation, the company grows a variety of vegetables and herbs for wholesale in a 14-storey vertical farm near Copenhagen.

It added nine Genie scissors to its operations, specifically the GS-2632 and GS-2646. Flemming Dyring, Nordic Harvest’s sales director, said, “The scissor lifts had to provide a high level of stability for safe work. In addition, their handling had to be as easy as possible, including intuitive controls and the possibility of instant troubleshooting, all of which met our requirements.”

Five Genie GS-2632 electric scissor lifts helped build and set up the internal structures of its facility, which provides an area of 4,950m2 of growing space, and is said to be the largest indoor of its kind in Europe.

With a maximum working height of 9.8m and a platform capacity of 227kg, the GS-2632 slab scissors were used to install the farm’s cultivation trays at heights of up to 9m.

Genie GS-2646 electric scissor lift has a maximum working height of 9m and platform capacity of 454kg.

Due to the vertical nature of the sustainable farming technique, Nordic Harvest then added four Genie GS-2646 electric scissor lifts with platform capacities of 454kg.

The 9m models are now being used by the company’s staff to access all 14 storeys of cultivation trays, enabling employees to check the healthy growth of the plants and herbs before harvesting.

Nordic Harvest purchased the new scissor lifts through Genie’s authorised distributor Jøma Lift Teknik.

“For our work, a minimum working height of 8.80m (28ft 9in), a comfortable working space and high manoeuvrability in small spaces were imperatives”, said Dyring.

“Before making our decision, we took the opinion of our Taiwanese partners who recommended Genie scissor lifts to us for their design quality and proven reliability to effectively complete our assigned tasks: construction of the cultivation structures and control of the seedings and harvest.”

Lead Photo: Genie GS-2646 electric scissor lift at the Nordic Harvest vertical farm in Denmark.

Vertical Farming and the Future of Automation in Agriculture

Vertical farming is by no means a new idea. However, recent supply chain disruptions coupled with the falling price of produce, is opening new doors for a farming method previously deemed unviable by many.

August 10, 2021

Vertical farming is by no means a new idea. However, recent supply chain disruptions coupled with the falling price of produce, is opening new doors for a farming method previously deemed unviable by many. Here, John Young, APAC country manager at automation parts supplier EU Automation, highlights the renewed interest in vertical farming among a new generation of farmers, and explores the advantages it offers in tackling some of the biggest challenges facing the sector.

Turn the clock back approximately 1000 years, and less than four per cent of the world's habitable land was used for farming — that is the equivalent of four million square kilometres. Today, farmland takes up more than half of the world's habitable land, which equates to a landmass larger than South America.

Our World in Data reports the alarming facts associated with industrialized livestock farming, involving climate change, extinction of species, widespread destruction of habitat, and 80 per cent of cropland grown to feed livestock. With the population of the Asia Pacific region expected to reach 5 billion by 2050, the responsibility to supply food to an ever-growing population is becoming difficult.

A new generation of farmers are rising to the sustainability challenge. This agricultural revolution presents the transition from traditional farming to futuristic high-tech artificial intelligence (AI) and robotics. Whether it's weed-killing robots, harvesting and picking robots, or autonomous tractors, the farming landscape is evolving. In this age of robotic farming, producers believe incorporating automation and data will enable farmers to produce more, while damaging the environment less.

One major process change that is currently on the rise is the shift to vertical farming. Currently, 16.55 million square feet (sq ft) of indoor farms operate across the globe. However, the State of Indoor Farming report suggests this figure will increase to 22 million sq ft by 2022. The demand is high, and the AI journey is only getting started.

Why are farmers suddenly interested in vertical farming?

Vertical farming is the practice of producing food in vertically stacked layers. The climate-controlled indoor farms contain rows of plants situated next to each other, growing vertically, and hanging from the ceiling. Robotics help manoeuvre the products around, and AI can monitor the different parameters that are required for the crops to grow, such as the levels of water, temperature, and light.

Indoor agriculture is at an exciting point in its development. Key technologies used in farming systems today range from perception technologies which use cameras and sensors to detect and monitor various factors of the lifecycle. AI processes the data from sensors and provides solutions, while automated and autonomous mechatronics that use robotics and automated machines collect products when ready to dispatch to the market and recover the crops from ailments during the growing cycle.

Right now, the focus is to take vertical farming to the next level by developing smart robots which can increase precision and productivity, while minimizing environmental impact and risk. Agriculture, one of humankind’s oldest inventions, is merging with the latest technology, and farmers will soon be looking to pair with a reliable automation parts supplier to make the step up to vertical farming.

Vertical farming offers a unique set of advantages. Farmers understand there are many urgent and practical reasons to grow upwards rather than outwards. This farming method has huge potential for sustainability and food security, while protecting the environment, economy, and ecosystems.

In addition, the inclusion of AI and robotics ensures high-quality growth of products all year round, while preserving water, nutrients, and land consumption by 95 per cent. The controlled process of indoor farming with the help of AI and robotics also protects crops against pest invasions, and ensures they are well insulated — this is an aspect field farming cannot guarantee since it requires amenable weather conditions and labour.

Vertical farms can operate anywhere with no geographical constraints and are not subject to the limitations presented in outdoor farming, such as extreme conditions. This not only protects the crops, but also provides a safer working environment for labourers. What’s more, labour costs can be significantly reduced due to the automated indoor growing systems; thus, there is no longer a need for manual labour all year long.

In addition, energy consumption can be drastically reduced in vertical farming by implementing LED lighting to mimic the sun as a light source. A minor change like this can limit heat waste while increasing energy efficiency and cutting energy costs. Not only can LED lighting be used as an alternative, but renewable energy generated from wind turbines can be paired with vertical farming to ensure 100 per cent of its energy is produced from renewable sources. It is a win-win situation.

How will it boost the economy?

This sector is expecting a huge boom in investment and interest and manufacturers, suppliers and retailers are therefore preparing for this shift through early adoption. In the past, vertical farming was viewed as theoretical, but now the vertical farming market in the APAC region is expected to grow at a compound annual growth rate (CAGR) of 29 percent, rising from its current value of $0.78 billion to $2.77 billion by 2026. This is largely due to the advancement in technology such as sensors and smart energy systems that have improved the efficiency of growing products.

Although vertical farms will not replace traditional ways of farming, they hold great potential to revamp the future of agriculture in the APAC region by pushing towards a sustainable, environmentally conscious, tech savvy, economically rational, and health-sensitive world.

Source and Photo Courtesy of Agritech Tomorrow

AUSTRALIA - VIDEO: Shipping Container Farm Teaching TAFE Students More Than Just Agriculture

Nestled beside a building on a TAFE campus in Toowoomba is an ugly metal shipping container, but it's no ordinary storage shed

August 16, 2021

By Lucy Cooper

Nestled beside a building on a TAFE campus in Toowoomba is an ugly metal shipping container, but it's no ordinary storage shed.

Key points:

TAFE is using a shipping container farm to teach students about alternative farming

All features of the farm are controlled by an app

Agriculture, hospitality, and IT students are using the "grow pod" in their studies

Step inside and it's bursting with greenery.

Packed floor to ceiling with vegetables and herbs like basil, kale, mint and mustard, this state-of-the-art modular farm is changing the future of agriculture, all with the push of a button.

TAFE Queensland school manager Elaine Wallace said the "grow pod" aimed to change students' perspectives on traditional farming.

"Often when people think about agriculture, they think, 'Oh, I don't want to go stand in the sun all day picking vegetables, that's a bit too dirty for my liking," Ms. Wallace said.

"This is just one of those technologies that really enables students to get involved in something different and something up and coming."

Student Kallia Stebbins said when she first saw the vertical farm she was amazed by the technology.

"I didn't realise that you can grow crops like this, compared to just out in the middle of a field," she said.

"Now that I've seen this, it's very cool. I'm very interested to learn more about it."

A farm controlled from the palm of a hand

The container farm is controlled remotely with an app.

To switch the lights on inside, Ms Wallace simply whips out her phone.

"If we have a look at our monitors, it tells us that our irrigation cycle has started up, so we can set the cycle to however long or short we need it," she said.

"It's drip irrigation from the top filter through to the bottom and it's caught in the gutter that is at the bottom.

"We have pumps that will feed nutrients into the water and then, of course, we've got our lights, which are LED lights, and they are also set on a timer, so they are grow lights."

'Absolutely no limits'

It's not just agricultural students reaping the benefits of the multidisciplinary project.

Information technology students studied the app controlling the farm, while electrical students looked at how the farm kept running.

Hospitality and cookery teacher Nev Siebenhausen said his students also gained valuable first-hand experience in paddock to plate catering.

"For our students, it's a great opportunity to obviously shorten up the duration and travel on the product," he said.

"It's great for our guys to see different ways it can be grown."

Mr Siebenhausen said the walk up the hill from the grow pod to the hospitality school reduced carbon miles and cut waste by 70 percent for produce like basil, which had a short lifespan.

Any leftover produce is donated to the food relief charity, Oz Harvest.

Talks are also underway to trial sensory herbs for community service students to study the calming effects on people.

"The possibilities are endless," Ms. Wallace said.

Nearly 60,000 Pounds of Frozen Raw Chicken Products Sold at Aldi and Other Stores Recalled

Serenade Foods is recalling nearly 60,000 pounds of frozen, raw, breaded and pre-browned stuffed chicken products that could be contaminated with Salmonella Enteritidis, the USDA Food Safety and Inspection Service announced Monday.

By Christina Maxouris

August 10, 2021

View this video here

(CNN) Serenade Foods is recalling nearly 60,000 pounds of frozen, raw, breaded and pre-browned stuffed chicken products that could be contaminated with Salmonella Enteritidis, the USDA Food Safety and Inspection Service announced Monday.

The products were produced on February 24 and February 25, 2021, and were shipped to distributors across the country, the service said.

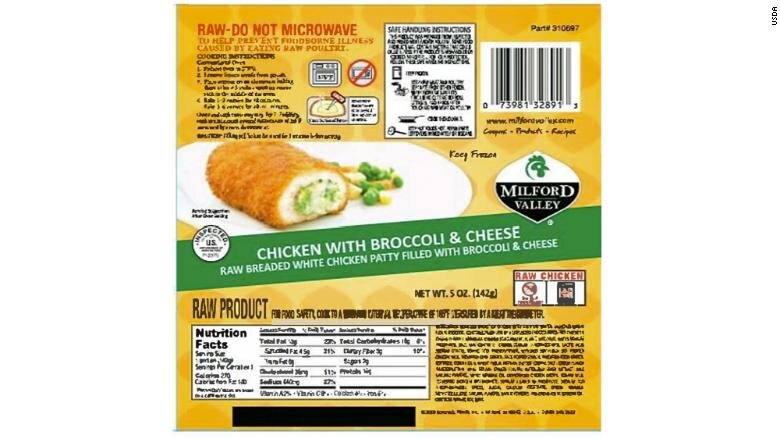

A label of one of the Serenade Foods products included in the recall

They include specific lots of the Dutch Farms Chicken with Broccoli & Cheese packages; Milford Valley Chicken with Broccoli & Cheese; Milford Valley Chicken Cordon Bleu; Kirkwood Raw Stuffed Chicken, Broccoli & Cheese; and Kirkwood Raw Stuffed Chicken Cordon Bleu, which is sold at Aldi.

The service said it was "concerned" that some of these products may be in Americans' freezers and urged consumers not to eat them.

"These products should be thrown away or returned to the place of purchase," it said.

The Service said it has been working with the US Centers for Disease Control and Prevention and other health officials to investigate an outbreak of 28 Salmonella Enteritidis illnesses across eight different states. The illnesses' timelines range from February 21 through June 28.

A second product involved in the recall

"Unopened intact packages of raw, frozen, breaded chicken stuffed with broccoli and cheese were collected from an ill person's home and tested positive for the outbreak strain of Salmonella Enteritidis," the service said. "FSIS continues to work with the CDC and state and local public health partners on this investigation."

Eating food that is contaminated with Salmonella can cause a bacterial food borne illness called salmonellosis which can cause diarrhea, abdominal cramps, and fever within 12 to 72 hours after eating the product.

"Most people recover without treatment. In some persons, however, the diarrhea may be so severe that the patient needs to be hospitalized. Older adults, infants, and persons with weakened immune systems are more likely to develop a severe illness. Individuals concerned about an illness should contact their health care provider," it said.

Vertical Farming: Turning Deserts Into Fresh Food Hubs

Deserts and arid lands are commonly perceived as worthless. Because of this image of the world’s drylands, agricultural investments and development initiatives pass these regions by. Moreover, with the new NASA food challenge, it seems like AgriTech enthusiasts would rather attempt to cultivate plants in space than in desert environments on their native planet.

August 10, 2021

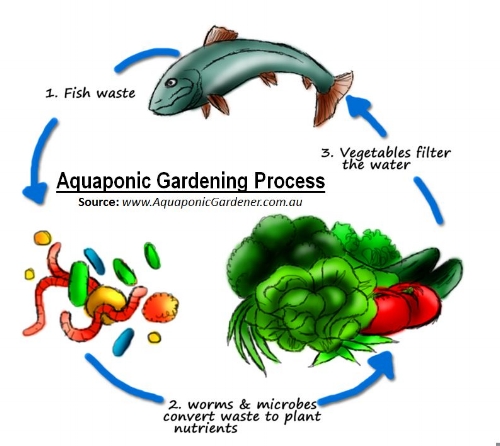

Vertical farming technologies allow for collecting the humidity produced by plants. With recirculating and recycling techniques, hydroponic and aquaponic systems can reuse 98% of water, which makes vertical farms feasible in deserts.