Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

SINGAPORE - VIDEOS: How IoT And Machine Learning Are Automating Agriculture

A new generation of farmers is tapping the internet of things and machine learning to operate self-sustaining urban farms with minimal supervision

A New Generation of Farmers Is Tapping The internet of Things And Machine Learning To Operate Self-Sustaining Urban Farms With Minimal Supervision

By Aaron Tan, TechTarget

21 Jul 2021

A new generation of farmers is turning to technologies such as the internet of things (IoT) and machine learning to automate agricultural production, alleviating the need to toil on the land while keeping a watchful eye on their crops.

Joining their ranks is Phoebe Xie, director, and co-founder of Singapore-based agrotechnology startup AbyFarm. Teaming up with technology service provider SPTel, Xie is building a smart hydroponics farm in a greenhouse that uses a plethora of IoT sensors, including video cameras, to keep the farm humming around the clock.

“To run a self-regulating farm at the optimal temperature with optimal water and nutrient supply, and to control the quality and taste of vegetables and fruits, we need IoT sensors,” she said, adding that the farm and its sensors collect and monitor thousands of data points, including humidity and temperature.

With the data and in certain environmental conditions, processes and actions are automatically triggered to protect crops from the elements. For instance, if the temperature or humidity gets too high, fans, water curtains, and roof shades are activated in the greenhouse.

Xie said the smart farm, located at a rooftop carpark in Singapore, is also equipped with sensors that monitor the pH and electrical conductivity levels of water. Among the sensors, which are connected to a Lora low-power wide area network, is a dozer that automatically releases acidic or alkaline nutrients to maintain optimal pH levels.

Whereas the farmers of old had to physically inspect their crops, AbyFarm’s agronomists and farmers can do so remotely using video cameras and image recognition technology to identify crops that might be succumbing to disease.

“If the image recognition finds that a plant is likely to be sick, the farmer will be alerted to go onsite to check how the plant is right now,” said Xie, adding that agronomists will also advise farmers on taking corrective actions to prevent disease or restore the health of their crops.

Like any machine learning system, AbyFarm’s algorithms get smarter over time. Each time a crop is affected by disease, data about the occurrence and corrective action is fed into the system, enabling its algorithms to formulate solutions for other farmers with similar crop issues – without consulting an agronomist.

With that, said Xie, even those who are new to the field can use the system to guide them on treating diseased crops, which can be isolated from other crops to prevent cross-infections.

AbyFarm’s automated farming system, which is hosted on SPTel’s private cloud, can also advise farmers on the best time to transplant their crops after germination and harvest them later for sale, said Xie.

Heng Kwee Tong, vice-president for engineering and customer solutions at SPTel, said the company has built up a software-defined platform to help companies like AbyFarm overcome the challenges of deploying applications such as IoT.

“The common struggle that companies like AbyFarm face with building an IoT solution is that it is quite intensive in terms of ICT infrastructure,” said Heng. “You’ve got to find the radio connectivity like Lora, subscribe to a service provider, and connect your sensors to a sensor collector.

“We make it easy by investing in a platform and because we are a service provider with edge hub assets for deploying radio connectivity, all AbyFarm needs to do is to bring their sensors onboard.”

Going forward, Heng said SPTel is looking to support next-generation video analytics capabilities through edge cloud services that can be used to crunch workloads closer to where they reside, reducing latency.

AbyFarm was one of six companies to win contracts from the Singapore Food Agency last year to build urban farms at nine rooftop carparks in public housing estates across Singapore.

The goal is to collectively produce about 1,600 tonnes of vegetables a year in a bid by the city-state – where less than 1% of the land is used for agriculture – to become more self-sufficient in meeting the nutritional needs of its people.

That could well be achievable with technology that makes farming more efficient, scalable, and less labor-intensive than before. “We are willing to train and educate the next generation in agrotechnology because now you don’t need 10 farmers to take care of one farm,” said Xie. “It’s just looking at the dashboard and, with the alerts, doing what is required.”

Farm Merges With Food Retail Spaces

Canadians have started to notice that grocers have begun to sell plants in miniature greenhouses

By Sylvain Charlebois

July 29, 2021

Opinion

Canadians have started to notice that grocers have begun to sell plants in miniature greenhouses.

We’ve seen gardens on rooftops, vertical farms close to stores, and even some selling gardening equipment to gardeners who are shopping for food. The farm is essentially merging with food retail spaces.

We’re slowly witnessing the rise of the “grow-cer.”

For years, customers accepted the myth that food just magically shows up at the grocery store. But COVID-19 got many of us to think differently about supply chains.

With the addition of new farmgate features, grocery stores are becoming the gateway to a world most of us rarely see: farming.

Sobeys has provided one recent example of what’s going on. The second-largest grocer in Canada recently signed a partnership agreement with German-based Infarm to get greenhouses into many outlets across the country. Infarm units were installed last year in British Columbia and can now be found in many other locations across the country.

In-farm units enable Sobeys to offer fresh herbs and produce grown hydroponically, which requires 95 percent less water, 90 percent less transportation, and 75 percent less fertilizer than industrial agriculture. As well, no pesticides are used.

Produce grown inside the store includes leafy greens, lettuce, kale, and herbs such as basil, cilantro, mint, and parsley. Expansion plans include chili peppers, mushrooms, and tomatoes. The growing cycle for most of these averages five weeks.

It’s not just Sobeys. Other grocers also have decent-sized vertical farms inside their stores or nearby.

For many consumers, gardening remains a luxury due to the lack of space or time. But now grocers are bringing the farm to the store so consumers can have both the farming and the retail experience at once.

Before COVID, farmers desperately tried to get closer to city dwellers so their work could be appreciated. Campaigns over the years brought mixed results. Farming is still largely misunderstood.

City dwellers have always respected farmers and the hard work they do, but many consumers who were looking for natural and organically produced goods have grown leery of farming in general.

Grocers are starting to bridge the worlds of farmers and urban consumers.

For years, we saw pictures of farmers on packages and posters. It was nice, but it wasn’t real. The hard work, and everything else that comes with farming, can only be properly conveyed when visiting a farm or working on one for a while.

The pictures likely won’t disappear from grocery stores but they don’t really tell the whole story.

The new grow-cer brings the imagery of farming in retail to a new level. Grabbing a living plant or produce off a living plant is real and increasingly valuable for Canadians longing for local and freshness. It just can’t get more local than growing it in the grocery store.

COVID-19 eliminated many rules for grocers. Previously, every business played a part. Grocers sold food, processors manufactured it and restaurants provided ready-to-eat solutions. Lines between sectors were already becoming blurred before COVID, but the pandemic blew up the blurred lines.

Grocers are becoming brokers, connecting various functions of the supply chain. Farming connects with retail by way of new initiatives that we’re now seeing everywhere.

For example, restaurants are selling meal kits through grocers’ apps. Few saw that coming.

Food brokering for grocers is no doubt the next frontier of growth.

Whether it will last is unknown. But grocers are embracing the fact they have the privilege of interacting with consumers every day. That privilege comes with a responsibility to show consumers the true value of food by being knowledge brokers.

If that means growing more food in stores, so be it.

Dr. Sylvain Charlebois is senior director of the agri-food analytics lab and a professor in food distribution and policy at Dalhousie University.

Lead photo: An employee of the urban farming start-up Infarm checks an indoor growing system at the company’s showroom in Berlin, Germany. Sobeys is working with the German company to put greenhouses into its Canadian stores. | REUTERS/HANNIBAL HANSCHKE PHOTO

Investors Eye Growth In Vertical Farms

Vertical farming is taking root. The market share of large-scale farms was estimated at $3.3 billion by Precedence Research in 2020 and is anticipated to increase nearly ten-fold, reaching $31.6 billion by 2030

Source: Streetwise Reports (7/29/21)

AeroFarms grows leafy greens in vertical farms using data science and technology; its upcoming acquisition by SPAC Spring Valley could grow its equity value.

Vertical farming is taking root. The market share of large-scale farms was estimated at $3.3 billion by Precedence Research in 2020 and is anticipated to increase nearly ten-fold, reaching $31.6 billion by 2030.

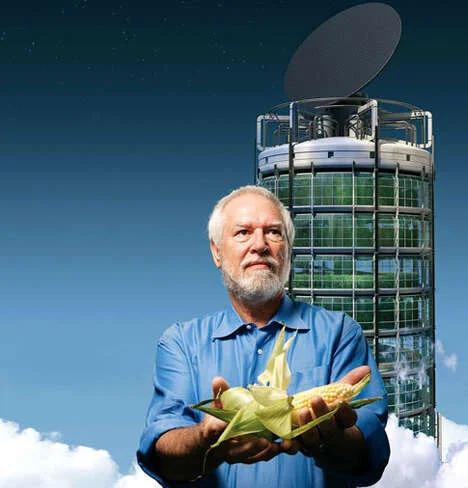

One vertical farm enterprise, AeroFarms, plans to go public in a special purpose acquisition company (SPAC) business combination in mid-2021. The company got started in 2004 and was cofounded by CEO David Rosenberg along with Chief Marketing Officer Marc Oshima and Chief Science Officer Ed Harwood, PhD. It is a certified B Corporation and public benefit corporation and has earned spots on Fast Company's World's Most Innovative Companies, Time Inc.'s Best Inventions, INC magazine's 25 Most Disruptive Companies, and a first-place ranking on the FoodTech 500 list.

Click here for more information on SPACs.

A pioneer in the vertical farming space, AeroFarms is on a mission "to grow the best plants possible for the betterment of humanity," with a focus on doing more with less by growing produce using fewer resources, zero pesticides, and less spoilage. "We look for inefficiencies and solve them using data science. We use our proprietary, fully controlled technology platform to better understand plants, optimize farms, improve quality and reduce costs," Rosenberg said.

AeroFarms leafy greens are grown in an approximately 70,000 square-foot facility—a former steel mill—in Newark, New Jersey. Its wide variety of greens are sold throughout the Northeast U.S. at major retailers, including Whole Foods Market, ShopRite, Amazon Fresh, and FreshDirect. In April 2021, AeroFarms broke ground in Danville, Virginia, on a new 136,000 square foot commercial farm that, according to the company, will be the world's largest indoor aeroponic vertical farm of its kind.

According to the company, it has a $1.9 trillion total addressable market and is expanding that through strategic partnerships, such as one with Chile's Hortifrut S.A. Together, the two companies will explore blueberry and cranberry production. "New Jersey is where blueberries were first domesticated in 1910," Rosenberg said. "With Hortifrut, we will be pioneering the next chapter by domesticating blueberries again in New Jersey—this time in a fully controlled environment."

International interest is demonstrated by AeroFarms' inclusion in Abu Dhabi Investment Office's $150 million investment in agricultural technology. AeroFarms' research center in Abu Dhabi will feature an advanced speed-breeding center and laboratories dedicated to R&D in precision phenotyping—studying the observable characteristics of an organism—machine vision and machine learning, robotics, and automation.

AeroFarms is also doing more with less in its entry into the public market. Rather than a time- and resource-consuming IPO, it will go public through a business combination with Spring Valley Acquisition Corp. (SV:NASDAQ), a SPAC. Click here for more information on SPACs.

Vertical Farming Attracts Investor Interest

"Our banker at J.P. Morgan introduced us to Spring Valley. A SPAC made sense for us because it gives us an easier platform to tell our story to investors," said Rosenberg. "We share a long-term vision regarding sustainability and align in our concern for environmental issues." In addition, he notes that Spring Valley has a track record of bringing other companies public at a stage similar to AeroFarms.

Spring Valley (NASDAQ:SV), sponsored by Pearl Energy Investments, was formed for the purpose of acquiring a $1+/- billion enterprise value company in the sustainability sector. The total gross proceeds of Spring Valley's own IPO in 2020 were $230 million (23 million units at $10 per unit). J.P. Morgan Securities LLC is acting as the exclusive financial advisor to AeroFarms, while Cowen & Co. is the financial advisor to Spring Valley. It would not be unusual for these firms to initiate coverage on AeroFarms after the completion of the SPAC transaction.

AeroFarms has roughly $75.5 million in cash and will be 65% owned by existing shareholders after the merger. Revenue of $13 million is anticipated in fiscal 2022, jumping to $553 million by fiscal 2026, when EBITDA is expected to reach $193 million. All stockholders will roll 100% of their equity holdings into the new public company, according to Investor Place.

The business combination with Spring Valley is expected to provide up to $357 million in gross proceeds to AeroFarms, composed of Spring Valley's $232 million cash held in trust (assuming no redemptions by its shareholders) and a $125 million fully committed public investment in private equity (PIPE) at $10 per share. This includes investments from leading institutional investors, AeroFarms insiders and Pearl Energy Investments, Spring Valley's sponsor.

The "de-SPACing" is expected in summer 2021, at which point AeroFarms will have an estimated pro forma equity value of $1.2 billion. It will remain listed on Nasdaq under the new ticker symbol ARFM.

Lake Street Capital Markets initiated coverage on AeroFarms on June 15 with a Buy rating and $20 price target. Senior research analyst Ben Klieve wrote, "Representing a leader in next-generation production methods with a significant sustainability benefit, we view AeroFarms as a high conviction Buy opportunity for investors targeting investments redefining food production for decades to come."

The analyst noted that AeroFarms "will enter the public market following a SPAC merger with considerable upside potential from the current level. We see multiple expansion and capacity ramp as alpha drivers."

Venture capital interest in the controlled environment agriculture space—which includes greenhouses or container farms, in addition to vertical farms—has exploded. The Food Institute estimates, using data from PitchBook, that global VC investments in the sector tripled from 2019 to 2020, nearing $2 billion. Investor Place recently named several leading stocks in the space, including Kalera (OTCMKTS:KSLLF), Appharvest (NASDAQ:APPH), Hydrofarm Holdings (NASDAQ:HYFM), Village Farms International (NASDAQ:VFF), GP Solutions (OTCMKTS:GWPD) and Cubicfarm Systems (OTCMKTS:CUBXF), as well as Spring Valley–AeroFarms.

Cutting Edge Technology

AeroFarms grows plants using aeroponics, where a plant's roots are misted with water, nutrients and oxygen. Instead of dirt or water, the plants are grown on a cloth that can be sanitized and reused. Grown indoors under LED light, the controlled environment stymies pests, eliminating the need for pesticides, herbicides and fungicides. Rosenberg says the company can harvest in one acre what would require up to 390 acres outdoors by a farm in New Jersey, using up to 95% less water.

"We are the most vertically integrated tech company in the space," Rosenberg said. "Our proprietary agSTACK technology creates a fully connected and digitally controlled farm that integrates hardware, automation, intelligent controls and sensors, machine vision, supervisory control and data acquisition, and our manufacturing execution system to create a powerful data loop." The company holds 15 patents and has 38 more pending. "The result is clean, nutritious, flavorful produce grown year-round that is ready to eat with no washing needed."

The lure of vertical farming—the practice of growing crops in vertically stacked layers, typically in a controlled environment—has both economic and environmental benefits. Traditional field agriculture produces significant greenhouse gases, takes up half the U.S. landmass, and accounts for more than half of the country's fresh-water usage. A recent report by EY highlighted some of the economic reasons for the sector's growth, ranging from higher yields per acre to reduced transportation costs for crops grown closer to consumers in cities, to the availability of consistent supply at predictable prices.

A recent report by McAlinden Research Partners contends that efficient vertical farming is poised to surge as an increasingly popular investment as a result of the mounting pressures on traditional agriculture. "A report from Big Think recently found that vertical farms are incredibly efficient when it comes to water usage, requiring 95% less irrigation than soil-grown plants. Nate Storey, co-founder of vertical farming startup Plenty, Inc., has highlighted the efficiency of vertical farming, noting that 99% of moisture transpired by plants can be recaptured and reused in a vertical farming system. . . As climate shifts continue to affect the global agriculture industry, indoor farming provides an efficient and sustainable way to produce more crops with fewer resources," the report stated.

McAlinden noted that AeroFarms is "rapidly expanding its distribution operations in the Northeast, collaborating with Whole Foods Market, Amazon Fresh, and FreshDirect, according to Supermarket News."

"It will likely be several years before vertical farming technologies begin tapping their true potential, but a scaling of the industry is becoming increasingly likely as a counter to climate change and diminishing water availability," McAlinden concluded.

Want to be the first to know about interesting Special Situations and Technology investment ideas? Sign up to receive the FREE Streetwise Reports newsletter. Subscribe

Disclosure:

1) Diane Fraser compiled this article for Streetwise Reports LLC and provides services to Streetwise Reports as an independent contractor. She and/or members of her household own securities of the following companies mentioned in the article: None. She and/or members of her household are paid by the following companies mentioned in this article: None. Her company has a financial relationship with the following companies referred to in this article: None.

2) The following companies mentioned in this interview are billboard sponsors of Streetwise Reports: None. Click here for important disclosures about sponsor fees.

3) The interview does not constitute investment advice. Each reader is encouraged to consult with his or her individual financial professional and any action a reader takes as a result of information presented here is his or her own responsibility. By opening this page, each reader accepts and agrees to Streetwise Reports' terms of use and full legal disclaimer. This article is not a solicitation for investment. Streetwise Reports does not render general or specific investment advice and the information on Streetwise Reports should not be considered a recommendation to buy or sell any security. Streetwise Reports does not endorse or recommend the business, products, services, or securities of any company mentioned on Streetwise Reports.

4) From time to time, Streetwise Reports LLC and its directors, officers, employees, or members of their families, as well as persons interviewed for articles and interviews on the site, may have a long or short position in securities mentioned. Directors, officers, employees, or members of their immediate families are prohibited from making purchases and/or sales of those securities in the open market or otherwise from the time of the decision to publish an article until three business days after the publication of the article. The foregoing prohibition does not apply to articles that in substance only restate previously published company releases. As of the date of this article, officers and/or employees of Streetwise Reports LLC (including members of their household) own securities of AeroFarms, a company mentioned in this article.

Additional Disclosures:

Lake Street Capital Markets, AeroFarms, June 15, 2021.

RESEARCH DISCLOSURES

Lake Street Capital Markets, or its affiliates, intends to seek or expects to receive compensation for investment banking services from the subject issuer in the next three months.

The authoring analysts who are responsible for the preparation of this investment research are eligible for compensation based on the total revenue and general profitability of Lake Street Capital Markets, which includes investment banking revenue.

However, such authoring analyst will not receive compensation that is directly based on or linked to specific investment banking transactions.

ANALYST CERTIFICATION – REGULATION AC

Each authoring analyst of Lake Street Capital Markets whose name appears on the front page of this investment research hereby certifies that (1) the recommendations and opinions expressed in this investment research accurately reflect the authoring analyst's personal, independent, and objective views about any and all of the subject investments or issuers discussed herein; and (2) no part of the authoring analyst’s compensation was, is, or will be, directly or indirectly, related to the specific recommendations or views expressed by the authoring analysts.

Lake Street Capital Markets may effect transactions as a principal or agent in the securities mentioned herein.

McAlinden Research Partners:

This report has been prepared solely for informational purposes and is not an offer to buy/sell/endorse or a solicitation of an offer to buy/sell/endorse Interests or any other security or instrument or to participate in any trading or investment strategy. No representation or warranty (express or implied) is made or can be given with respect to the sequence, accuracy, completeness, or timeliness of the information in this Report. Unless otherwise noted, all information is sourced from public data.

McAlinden Research Partners is a division of Catalpa Capital Advisors, LLC (CCA), a Registered Investment Advisor. References to specific securities, asset classes and financial markets discussed herein are for illustrative purposes only and should not be interpreted as recommendations to purchase or sell such securities. CCA, MRP, employees and direct affiliates of the firm may or may not own any of the securities mentioned in the report at the time of publication.

Freight Farm To Teach Youth About Sustainable Agriculture

Beyond School Bells is partnering with the Bay in Lincoln for a new after-school program that will teach students about sustainable ag technology. "We really see Freight Farm as kind of that key, climate-change impervious tool that young people need to know about as we face an uncertain future," said Jeff Cole, Network Lead for Beyond School Bells

by Nicole Weaving

July 24th, 2021

LINCOLN, Neb. — Beyond School Bells is partnering with the Bay in Lincoln for a new after-school program that will teach students about sustainable ag technology.

"We really see Freight Farm as kind of that key, climate-change impervious tool that young people need to know about as we face an uncertain future," said Jeff Cole, Network Lead for Beyond School Bells.

An old shipping container in the parking lot of the Bay has been transformed in a self-contained hydroponic farm.

Using red and blue LED lights, this Freight Farm, known as the Greenery, creates a climate-controlled environment, where the plants grow vertically without a need for soil.

"We enrich the water with nutrients that would normally be in the soil," said Colton Harper, Organizing Manager for The Greenery. "And then in these grow walls, we've got spickets that come right through these foam and it's directly onto the roots of the plants."

Inside of the Greenery with the red and blue LED lights on. (KHGI)

According to Harper, there are currently about 6,000 plants growing in the Freight Farm, but at full capacity, it can hold 13,000 plants between the seeding area and that walls. That would produce the equivalent of a 2.5-acre farm year-round.

"Even in the winter, if there are shortages anywhere, we can turn on a dime, 7-week grow cycle and be able to provide those crops for local markets," said Harper.

The Greenery arrived in Lincoln in April, and Harper has led to two teams to get it up and running. They are currently preparing for their first harvest with items like basil, lettuce, and radishes.

"We're at about Week 7, and in 2-3 weeks, we'll have our produce at a farmer's market," said Harper.

After a few more grow cycles, the program will open to local students to teach them all aspects of sustainable farming.

"From the electrical side, the growing, the programming, computer science to the irrigation, the HVAC system, there's so many elements," said Harper. "And we're particularly well-placed with the Bay and their digital design area of focus, the students will also be able to design the packaging, design the labeling, so it's really a full-circle, interdisciplinary opportunity for the students to get involved."

The Greenery plans to hold a Harvest Party to celebrates the farm's success in the coming weeks

Remembering Ed Harwood: AeroFarms Co-Founder, Chief Science Officer

Ed Harwood, co-founder, and emeritus chief science officer at AeroFarms, has died, leaving a legacy of patented innovative agriculture technology and expansion beyond his expectations

By AMY SOWDER

July 26, 2021

Ed Harwood, co-founder, and emeritus chief science officer at AeroFarms, has died, leaving a legacy of patented innovative agriculture technology and expansion beyond his expectations.

A framed photo of Harwood’s smiling face greets those who arrive at the indoor, vertical aeroponic farm company’s headquarters in Newark, N.J., said Marc Oshima, chief marketing officer, and co-founder with Harwood and David Rosenberg. The company began in 2004.

Whenever someone schedules a meeting in the conference room, they do so at “Ed’s Garage.”

It was in his dining room and then garage where Harwood tinkered with the nozzles that transport water and nutrients to leafy greens. He patented a way to keep them unclogged, Oshima said.

Harwood also patented a new clean, inert, reusable growing medium: cloth. It’s lighter than water and soil, making it more suitable for vertical farming in urban areas where space is scarce. And it’s a growing medium made from recycled water bottles plucked from the waste stream.

“Ed’s early work led us on that path of a circular economy, sanitary design, performance and measuring that performance. Ed’s spirit of inquiry helped foster the same in our team and in our practices,” Oshima said. “His legacy is part of our culture today.”

Harwood’s focus and early discoveries helped commercialize the urban vertical farming movement, he said.

Today, AeroFarms is a Certified B Corporation striving to feed more people on less arable land by using breakthroughs in indoor agtech, artificial intelligence, and plant biology to improve the food system’s way of growing and distributing produce, locally and globally. The company is on its way to going public and has expanded with several locations including commercial farms, community farms and research and development farms, like the newest one in Abu Dhabi, United Arab Emirates.

The company’s awards surpass the dozens. Harwood won United FreshTEC Achievement Award in 2018, a kind of lifetime achievement award for driving innovation in agriculture.

“I was really excited for Ed to be recognized for that by the broader produce community,” Oshima said. “I mean, 15 years ago he was having these conversations.”

Harwood’s training and prior experience provided the foundation of this success.

He earned his doctorate degree in dairy science with a minor in artificial intelligence. He was able to translate the dairy sector’s leading food safety principles and practices into procedures that work for indoor agriculture at AeroFarms, Oshima said.

Harwood was the associate director for agriculture at Cornell Cooperative Extension, where he worked for nine years.

Preferring to be called "Ed" rather than "Edward," Harwood was a man with a sense of fun, a soccer coach, and a family man.

Family members were by Harwood’s side when he died from cancer. He had stepped back from his duties gradually in recent years, serving as emeritus chief science officer and continuing to consult with the company, the U.S. Department of Agriculture, and in academia.

Harwood lived with a positive outlook, a smile, and a sense of wonderment about the world, Oshima said.

“He was not one for titles or pretenses. It was just about the work. It was about ‘How can we do something for the greater good, have a greater impact?’” Oshima said. “He would say where we’ve gone has blossomed far beyond his dreams.”

“But it was his principles of curiosity, acting with a sense of urgency and responsibility — those have been the hallmark of our organization.”

Those who wish to send anecdotes or photos can do so at EdHarwoodTribute@AeroFarms.com.

Lead Photo: (Photo and logo courtesy AeroFarms; graphic by Amy Sowder)

Investment Projects On Construction And Modernisation of Greenhouse Complexes Will Be Presented At the 6th Annual International Forum Greenhouse Complexes Russia & CIS 2021

6th Annual International Forum Greenhouse Complexes Russia & CIS 2021 is an established professional international platform for attracting investment in the Greenhouse Industry of Russia, discussion of industry development strategies, exchanging experience between key market players, and signing new win-win contracts

Date: 1-3 December 2021

Place: Moscow, Baltschug Kempinski

Organized by: Vostock Capital

Tel.: +44 207 394 3090

E-mail: Events@vostockcapital.com

Website: https://www.greenhousesforum.com/en/

6th Annual International Forum Greenhouse Complexes Russia & CIS 2021 is an established professional international platform for attracting investment in the Greenhouse Industry of Russia, discussion of industry development strategies, exchanging experience between key market players, and signing new win-win contracts.

The Forum is supported by the Ministry of Agriculture of the Russian Federation.

Silver sponsors: Svetogor, Gavita. Bronze sponsor: Hortilux.

Industry partner: the Association “Greenhouses of Russia”.

Onsite Visit Partners: Agrokombinat Moskovsky, Podosinki greenhouse complex.

You have the opportunity to become a part of a unique business conference.

Please Note! Vostock Capital company, an organizer of the International Forum in Moscow, assists foreigners interested in the industry development with entering Russia for event participation on the basis of a “green list”. Foreign delegates will be included in this list if they register for the event and submit their documents before August 10.

The event annually brings together over 500 delegates from the largest federal and regional agro holdings, heads of retail chains and service companies, presidents of national unions and associations. Just to name a few: ECO-Culture, Stavropol Flavour, Greenhouse, Ovoschevod, Grow Group Azerbaijan, Yagodnaya Dolina, Tander, X5 Retail Group, Agricultural Complex Gorkovskiy, Agrocombine Moskovskiy, MC AgroPark Plody s Gryadki, Yug-Agro, ECO-farm Mazilovo, Trading House Vyborgec, Green Farmer, Sun Valley, Growth Technology, Yagodnaya Dolina, Udmurt Flowers, FITO, MWM RUS, Horti XS BV, Pylot, AgroBioTechnology and many others.

Among the speakers and honorary guests 2020: Dzhambulat Khatuov, First Deputy Minister, the Ministry of Agriculture of Russian Federation; Dmitry Aveltsov, CEO, Ministry of Agriculture of the RF Center of Agroanalytics Federal state budgetary organization; Inna Rykova, Head of the Sectorial Economy Centre, The Federal State Budgetary Institution Financial Research Institute of the Ministry of Finance of the Russian Federation; Dmirty Lashin, Chairman of the Board of Directors, Lipetskagro; Alexey Shemetov, Vice-President, Production Operation, Agricultural Holding ECO-Culture; Dmitry Lisnevskiy, Minister, Ministry of Investment Policy of Sakhalin Region; Sharip Sharipov, First Deputy Minister, Ministry of Agriculture and Food of the Republic of Dagestan; Alexander Belkovets, General Director, Trading House Vyborgec, Agrofirma Vyborgec; Andrey Chigin, General Director, Stavropol Flavour and many others.

Forum Highlights 2021:

· 500+ executives of flagship greenhouse complexes and agro holdings from Russia and the CIS – Belarus, Armenia, Kazakhstan, Uzbekistan, Azerbaijan, as well as investors, government representatives, chief agronomists, managers of retail chains and service companies

· NEW! 2 TECHNICAL VISITS to state-of-the-art greenhouse complexes – Agrokombinat Moskovsky (vegetable farming) and Podosinki (flower cultivation)

· Leaders' debates: the Ministry of Agriculture of the Russian Federation, agro holdings, investors, initiators. Post-pandemic status of the greenhouse industry

· Greenhouse investment projects on modernization and construction with the implementation period of 2021-2025 from all Russian regions and the CIS countries

· NEW! HYDROPONICS AND VERTICAL FARMING. What is the difference from traditional industrial cultivation? Technology development prospects

· FOCUS SESSION: STRATEGIES TO INCREASE SALES. How to establish interaction between suppliers and retailers for the benefit of all?

· HOW TO OPTIMISE PRODUCTION WITH THE HELP OF INNOVATIVE GREENHOUSE TECHNOLOGIES. How do innovations boost the development of the greenhouse industry?

· IMPORTANT! POWER SUPPLY IN THE GREENHOUSE INDUSTRY. Cost optimization methods

· INCREASE IN YIELD AND RESISTANCE – MODERN APPROACHES TO CULTIVATION. Parallel round tables for agronomists in the following areas: fruit and vegetable and lettuce greenhouses, mushroom complexes, berry greenhouses

· Presentation of modern equipment and technologies for greenhouse complexes from top companies from the Netherlands, Israel, Germany, Italy, Spain, and other countries

· Fast and efficient! Roadshow of innovative technologies and equipment by the global leaders

· EVENING COCKTAIL

Register Now

Step Away From That Screen And On To Our Expanded Expo Floor

There's nothing like an in-person event for getting a first-hand look at the latest product innovations. So step away from that computer screen, step onto our expo floor and see live product demonstrations...Touch new products...Ask questions and gather feedback from company execs and peers in the booth

BIGGER, BETTER EXPO FLOOR OFFERS PERFECT ZOOM FATIGUE FIX!

(And some pretty great solutions for your business, too)

There's nothing like an in-person event for getting a first-hand look at the latest product innovations. So step away from that computer screen, step on to our expo floor and see live product demonstrations...Touch new products...Ask questions and gather feedback from company execs and peers in the booth.

We've significantly expanded our expo floor to bring you even more top names, established best-sellers and promising start-ups. See the latest in lighting, operating, automation and control systems, growth chambers, seed treatments, plant nutrition, greenhouse & hydroponic supplies, substrates, pest control, irrigation, equipment & design resources and so much more from companies like:

LEARN MORE

YOUR TWO-DAY INDOOR AG-CON EXPERIENCE PACKAGE

Indoor Ag-Con is so much more than an event. It's an experience! And one you don't want to miss. Hear from 70+ speakers, network with industry peers, see the latest product innovations. Then, head back to your operation armed with actionable ideas and profitable strategies that promise to grow your business!

Register before our Early Bird Rates end on August 16, 2021 to save up to $300 on our full access pass. And if your plans change, no worries! Passes are completely refundable prior to September 27, 2021, and include:

All Keynotes, Morning Conference Sessions, Afternoon Panels

Expo Floor Access

Welcome Gift Bag

Complimentary On-Demand Access to In-Depth, 2-Day "Financing Indoor Ag Seed To Scale" webinar

White Paper From The Packer & PMG presenting the latest research on indoor growing & sustainability

Lunch Daily

Show Floor Cocktail Receptions

Event App

Access to Indoor Ag-Con Library

REGISTER NOW & SAVE UP TO $300

OUR SAFETY PROMISE

Your health and safety are priority one at Indoor Ag-Con Orlando.

Rest assured that the Indoor Ag-Con team is closely monitoring the

guidelines issued by the CDC, state and local officials. We're working with our venue partner, Hilton Orlando, to provide you with a safe and

productive environment to conduct business.

SPECIAL THANKS TO OUR INDOOR AG-CON SPONSORS,

MEDIA & MARKETING ALLIES

Indoor Ag-Con, 3834 Silvestri Lane, Las Vegas, NV 89120, United States

UAE’s “Green Sheikh” Visits Green Bronx Machine, Gotham Greens And CS55

Green Bronx Machine founder Stephen Ritz and his students welcomed yesterday His Royal Highness Sheikh Abdulaziz bin Ali Al Nuaimi, to their classroom at the National Health and Wellness Learning Center (NHWLC) at CS 55 in the Bronx

22-July-2021

Green Bronx Machine founder Stephen Ritz welcomes the "Green Sheikh," His Royal Highness Sheikh Abdulaziz bin Ali Al Nuaimi to GBM's National Health, Wellness and Learning Center at CS 55 in the South Bronx.

Green Bronx Machine founder Stephen Ritz welcomes the "Green Sheikh," His Royal Highness Sheikh Abdulaziz bin Ali Al Nuaimi to GBM's National Health, Wellness and Learning Center at CS 55 in the South Bronx.

Green Bronx Machine

The "Green Sheikh," His Royal Highness Sheikh Abdulaziz bin Ali Al Nuaimi tours Green Bronx Machine's National Health, Wellness and Learning Center at CS 55 in the South Bronx.

Gotham Green Co-Founder and CEO Viraj Puri (r) hosts the "Green Sheikh," His Royal Highness SheikhAbdulaziz bin Ali Al Nuaimi, along with Green Bronx Machine Founder Stephen Ritz and former GBM student and current Gotham Greens employee Corey Gamble at their Brooklyn-based greenhouse.

Senior officials from NYC Department of Education, the Office of the Brooklyn Borough President, NYS Senator Gustavo Rivera, and other staff and community from CS 55 greet His Royal Highness Sheikh Abdulaziz bin Ali Al Nuaimi at Green Bronx Machine's National Health, Wellness and Learning Center.

Newswise — BRONX, NY, July 22, 2021 – Green Bronx Machine founder Stephen Ritz and his students welcomed yesterday His Royal Highness Sheikh Abdulaziz bin Ali Al Nuaimi, to their classroom at the National Health and Wellness Learning Center (NHWLC) at CS 55 in the Bronx.

A member of the ruling family of Ajman of the United Arab Emirates and an environmental adviser to the Ajman Government, HRH is a globally acclaimed humanitarian and philanthropist whose work focuses on mindfulness, well-being, spirituality, sustainability, and nutrition, particularly in children and those living in marginalized communities.

During the visit, HRH, known as the “Green Sheikh,” and Ritz, often called “America’s Favorite Teacher,” had a chance to catch up on all things ag education-related and see what GBM students are growing and learning during the Summer Rising school program that is currently in session. In fact, GBM’s students hosted a luncheon for HRH, preparing and serving him a vegan meal made from vegetables grown by them right in their NHWLC classroom. Prior to arriving at CS 55, Ritz accompanied HRH on a tour of Brooklyn-based Gotham Greens, a longtime GBM supporter, and partner. Gotham Greens, a pioneer in sustainable indoor farming with the largest network for hydroponic greenhouses in North America, brings a fresh perspective to how businesses can operate with a triple bottom line.

"The power of friendship between the UAE and USA started many years ago via multiple platforms. Events like these help that friendship to continue to blossom and grow. Today, we all come together for sustainability, stewardship, and the best interests of all children. Today, we celebrate education and possibilities,” said His Royal Highness Sheikh Abdulaziz bin Ali Al Nuaimi. “After many years of working together overseas, to be able to visit my dear friend, Stephen Ritz, and see the work of Green Bronx Machine personally, in his home country and home community is beyond exciting. To see this classroom and to visit Gotham Greens is to truly understand what is possible when people work together with innovation and dedication to change lives. This is what community looks like. This visit helps to share our work, our commitment, and our shared vision for the future and the planet for everyone to see - all around the world. I want to thank the NYC Department of Education, the residents of the Bronx, Stephen's family, colleagues, and the community at Community School 55 and the staff at Gotham Greens for their gracious hospitality. I look forward to continuing our sharing, our learning, and our working together."

Longtime sustainability allies, the two green leaders met years ago in UAE via government officials with The Knowledge and Human Development Authority (KHDA) of Dubai. KHDA is responsible for the growth and quality of private education in Dubai. The two quickly became friends, sharing their passion for impact work, philanthropy, sustainability, education, and wellness initiatives.

Stephen continues to work in UAE with ESOL Education. Based on the model of Green Bronx Machine's National Health, Wellness, and Learning Center, ESOL launched the International Health, Wellness and Learning Center at Fairgreen International School located in the heart of Dubai’s The Sustainable City – the first net-positive city in the world. Fairgreen International School is considered a Top Twenty School in the UAE and is known for innovation globally.

“It has been an honor hosting His Royal Highness Sheikh Abdulaziz bin Ali Al Nuaimi, our dear friend, colleague, and fellow believer in the power of the plant to grow successful people, communities and economies,” said Ritz. “We look forward to our continued work with HRH. We are always ready to bring the Bronx to the world and make epic happen for millions more across the globe.”

Over the coming months, HRH and Ritz will embark on a series of joint projects including a series of books for young people about bringing the farm to the desert, as well as building farms throughout the UAE to address food insecurity, agricultural innovation, workforce development, and overall health and wellness.

“We built our first greenhouse in New York City in 2011 with the mission to reimagine how and where fresh food is grown,” said Viraj Puri, Co-Founder, and CEO of Gotham Greens. “His Highness, Green Bronx Machine, and Gotham Greens all share a passion for environmental advocacy and building a more sustainable future for our planet and for people around the world. We believe business can be a force for good, so we plant roots in the neighborhoods surrounding our greenhouses through long-standing partnerships with community groups and non-profit organizations like Green Bronx Machine, bringing nutritious, local food and STEM education to cities across America. We know that the impact from these programs extends beyond the borders of our neighborhoods and are proud to share learnings from our experience over the past decade.”

About Green Bronx Machine

Founded in 2011 by Global Teaching Prize finalist and life-long educator Stephen Ritz, Green Bronx Machine (GBM) is an impact-driven, for-purpose organization with 501(c)(3) status. GBM builds healthy, equitable, and resilient communities through inspired education, local food systems, and 21st Century workforce development. Dedicated to cultivating minds and harvesting hope, its school-based model and propriety curriculum uses urban agriculture aligned to key school performance indicators, to grow healthy students and healthy schools. Simultaneously, GBM also transforms once fragmented and marginalized communities into neighborhoods that are inclusive and thriving. For more information, visit www.greenbronxmachine.org.

Follow us on social media:

Facebook: https://www.facebook.com/green.BX.machine/

Instagram: https://www.instagram.com/greenbronxmachine/

Twitter: https://twitter.com/greenBXmachine

USA - VIDEO: Could Hydroponic Farms In Shipping Containers Promote Water Conservation?

Dozens of red leaf lettuce heads grew without ever seeing the actual light of day with the help of Freight Farms "ag tech," a repurposed shipping container, and students from La Sierra University

JULY 21, 2021

RIVERSIDE, Calif. — Dozens of red leaf lettuce heads grew without ever seeing the actual light of day with the help of Freight Farms "ag tech," a repurposed shipping container and students from La Sierra University. One of the students was Max Proebstle, who never thought he would find a personal interest in hydroponic farming.

"As soon as you transplant them into the growth panels after about a week, they're already like a full head of lettuce; it's pretty amazing to see," the graduate student said.

What You Need To Know

More than 20 La Sierra students are working together to study hydroponic farming inside a repurposed shipping container

The Freight to Table program used Freight Farms "ag-tech" to grow leafy greens with the help of high-intensity lights, circulating water, and plant nutrients

The system uses at least 90% less water than traditional farming, according to La Sierra University project director Marvin Payne

The program will utilize harvested crops in the university dining halls and provide locally sourced produce for the surrounding area

Proebstle and about 20 other students have been volunteering their time inside the repurposed shipping container turned indoor hydroponic farm on campus. This method of growing crops replaces the need for soil with plant nutrients, artificial light, and recirculating water. After working with the new tech system, Proebstle believes it could be a game-changer for the future of farming.

"If you have a connection to a water system and electricity, you can basically grow produce sustainably and organically, anywhere and anytime," he said.

The Enactus team on campus recently harvested more than 500 heads of red leaf lettuce, with more on the way. The program is helping students get a hands-on approach in STEM and agriculture while also introducing them to a way to create their urban farms in the future.

Project Director Marvin Payne, who oversees the Freight to Table program on campus, explained that this model allows hydroponic farms to be placed just about anywhere for year-round harvesting.

"The entire footprint of this container is basically 320 square feet, and so with this, you can turn out thousands of plants in a fairly short period of time," he said.

The tech allows growers to monitor nutrient levels, production and light schedules remotely. Since it's inside a container, the amount of artificial daylight for the crops can be increased to about 16 hours each day. Doing so means more growth but also a higher electricity output.

As drought conditions worsen, at least 94% of California is considered to be in a severe drought. There will be more pressure on the farming industry for water conservation, and this model — according to Payne — uses at least 90% less water.

"You are using electricity, but we're getting creative in producing electricity these days, and it uses only a very small fraction of the water that any traditional farming is going to use," he said.

After plucking the leafy greens from growth panels inside the controlled agriculture environment, Proebstle and the team have brought their harvest from a hydroponic farm to the table with a new passion for farming.

"In my personal life, I can totally see this being a part of my life, something that I'll be interested in and involved in for the rest of my life," Proebstle said.

Until then, the Enactus team at La Sierra University will continue exploring how this growing method could bring sustainability and locally sourced produce where it's needed most.

Central Minnesota Research Project Growing Kale Indoors

The project is a partnership with Todd-Wadena Electric Cooperative, Central Lakes College, Lakewood Health System, Great River Energy and the Electrical Power Research Institute

The project is a partnership with Todd-Wadena Electric Cooperative, Central Lakes College, Lakewood Health System, Great River Energy, and the Electrical Power Research Institute.

Written By: Rebecca Mitchell

July 21, 2021

Central Lakes College research analyst Noah Boetler shows a panel of kale plants in the Sota Grown pod during a virtual tour on July 13, 2021. Rebecca Mitchell/Pioneer Journal

STAPLES, Minn. — A community research project in Staples involving indoor gardens is set to continue growing.

The hydroponics project started in 2020 with Great River Energy, Todd-Wadena Electric Cooperative, and the Electrical Power Research Institute hoping to learn new technology and increase access to fresh produce. And even with kale as the chosen plant, local organizations rooted for the success of the hydroponics pod. The pod, planted at the Central Lakes College Staples campus, is a shipping container with room for 5,820 kale plants.

“I didn’t know how things were going to grow in here, it’s kind of a weird concept with there being no sunlight and things like that, so just seeing it go from a little seed to your big plant and harvesting it, I think that has been the coolest aspect,” CLC research analyst Noah Boelter shared with Minnesota educators in a virtual tour on July 13.

The partnership is called "'Sota Grown" and has helped develop a fully enclosed hydroponic container for growing fresh plants all year long — to supplement existing agriculture practices in communities across the state.

The pod, equivalent to one acre of crops, is a supplement to traditional farming, not a replacement, as TWEC member service manager Allison Uselman said. Although kale is the focus of the two-year project, the team has experimented with growing basil, swiss chard, lemon balm, and chives. Romaine lettuce, butterhead lettuce, and salad mixes are next on the list — and after a year of only kale, Boelter is excited for the new opportunities.

Each kale seed, planted by hand, starts in the nursery before being transplanted to vertical panels. The kale takes 12 weeks to reach maturity. The team of four staff members and interns plant and transplant on Wednesdays and harvest on Mondays.

“Kale is pretty forgiving, which is very fortunate for us,” Boelter said after sharing about a frozen pump during the winter. The kale wilted and bounced back in a matter of days. The team is also learning about flooding and nutrient dosing in the pod.

With the expected growth of indoor agriculture, Uselman said electrical companies will need to prepare for the change. For example, the pod uses the most energy when most other customers could have off-peak rates. The light and water systems run from 4 p.m. to 8 a.m. daily. The kale is watered for five minutes every 45 minutes. The electricity is about $600 a month.

“It’s education with students, it’s giving back and feeding our communities, and Todd-Wadena has the opportunity then to research all the electrical side of things and really understand this industry before it grows to a larger state,” Uselman said.

The pod’s water usage depends on the humidity levels outside, with the most water used in the winter — about 10.5 gallons every day—and about five gallons a day in the summer. The two water tanks deliver water above the panels and water behind the plants. There are also several different nutrients added, such as one to adjust pH levels.

“In the summertime, the pod does not use a whole lot of water because the HVAC unit has a dehumidifier built into it and that’s recirculating around a gallon of water an hour that gets dumped back into the pod, so it’s really efficient in the summer,” Boelter explained. “But when it’s winter, the air is so dry that’s when we use the most water.”

The indoor pod means the ability to regulate the temperature, which is a cool 65-68 degrees and having no pesticides or herbicides used on the plants since most bugs remain outside. There are some drain flies due to the algae.

The red LED lights in the Sota Grown pod at Central Lakes College are the only source of heat. The lights and water run from 4 p.m. to 8 a.m. daily. Rebecca Mitchell/Pioneer Journal, July 2021

As for sunlight, the LED lights are the only heat source in the pod, as Boelter said, though it is also insulated. The red and blue lights support stem growth and leaf density.

The process yields about 20 pounds of kale a week — and on a record week 43 pounds — or over 1,000 pounds as of July 5. All of the kale is donated to Lakewood Health System, who shares the kale through the Food Farmacy and Hilltop Regional Kitchen. The Kitchen uses the kale in specific meals for those who have tested positive for COVID-19 and people being discharged from the hospital. People can also receive free kale at the summer farmer’s market on Thursdays.

As Lakewood’s Community Health Coordinator, Amy Wiese works with about 70-100 bags of kale a week to find where it can best be served. She said the kale lasts about two weeks in the fridge.

People also receive kale recipes for new ways to enjoy the vegetable. Wiese enjoys massaging the kale to break down the bitterness and then eating it in a salad. Other favorites are kale chips and soups.

“We just see the benefits of this project and recognize the positive impact that healthy food can have on individuals and in the community,” Wiese said. The organizations also hope to address local food deserts. “It’s really amazing that we are able to provide fresh produce all year with this pod” even with snow on the ground for six months of the year.

The seeds grown and sown in the community have finished their process with new seeds set to germinate, grow to maturity, and be harvested and packaged in four to eight hours for their short drive up the road.

Photo: 1 - The kale seeds are planted in peat moss plugs and stored in the nursey for three weeks before being transplanted to the indoor panels. The planting process takes about an hour. Submitted photo

Photo: 2 - The shipping container contains an acre of kale growing hydroponically with LED lights. Photo courtesy Todd-Wadena Electric Coop

Photo: 3 - Each section has 22 panels with space for 5,820 kale plants or the resemblance of one acre of crops. Rebecca Mitchell/Pioneer Journal, July 2021

Scale Microgrid Solutions Brings Indoor Farm Microgrid Online

Scale Microgrid’s modular microgrid for Fifth Season, a startup indoor farming company, uses 160 kW of photovoltaic solar panels, 200 kW of lithium ion batteries and a 1,200-kW natural gas generator outfitted with advanced emissions control technology

July 16, 2021

Scale Microgrid Solutions brought a 1.75-MW microgrid online for a major indoor farm near Pittsburgh, Pennsylvania.

By ESstock/Shutterstock.com

Scale Microgrid’s modular microgrid for Fifth Season, a startup indoor farming company, uses 160 kW of photovoltaic solar panels, 200 kW of lithium-ion batteries, and a 1,200-kW natural gas generator outfitted with advanced emissions control technology.

The microgrid provides ancillary services to the electric grid and is expected to cut greenhouse gas emissions by 470,000 pounds a year, or the equivalent of taking 39 passenger cars off the road, according to Scale.

Fifth Season’s Braddock indoor farm uses 97% less land and up to 95% less water than traditional farming, according to Scale. Fifth Season uses robotics and artificial intelligence to grow leafy vegetables and herbs year-round.

Fifth Season needs cheap, clean and reliable power to create the ideal indoor farming environment, the Ridgewood, New Jersey-based company said.

“Fifth Season is paving the way for indoor farming, and Scale is improving their energy efficiency and grid resilience, reducing their costs and mitigating their greenhouse gas emissions,” Ryan Goodman, Scale CEO, and co-founder, said July 13.

Scale owns and operates the microgrid at the 60,000-square-foot Braddock farm under an energy-as-a-service contract. Fifth Season didn’t have to pay upfront costs for the microgrid.

The project uses Schneider Electric’s EcoStruxure Microgrid Advisor (EMA), a cloud-based, demand-side energy management software platform. EMA uses predictive and learning algorithms, which will help Scale efficiently manage the production and use of its renewable energy.

Scale and Schneider previously worked together developing a microgrid for a Bowery Farming indoor farm in New Jersey. The microgrid, commissioned in 2019, includes 815 kW of natural gas-fired generation, 150 kW of solar, and 200 kW of battery storage, according to Scale.

Scale is backed by a $300 million equity commitment from global private equity firm Warburg Pincus.

"Precision Indoor Propagation For High Quality Transplants" - August 3rd Tuesday 11:00 AM Eastern Time

Indoor Ag Science Cafe is an open discussion forum, planned and organized by the OptimIA project team

August Indoor Ag Science Cafe

August 3rd Tuesday 11:00 AM Eastern Time

Please sign up, thank you!

by

Dr. Ricardo Hernandez

North Carolina State University

Please sign up to receive your Zoom link.

Indoor Ag Science Cafe is an open discussion forum, planned and organized by the OptimIA project team.

OptimIA (Optimizing Indoor Agriculture) is a project funded by the USDA Specialty Crop Research Initiative and supported by many of you receiving this email (thank you!).

Sign Up Here

VIDEO: Foundation Farms, Corp., Reports A Second Harvest Is Currently Underway

Following an overwhelmingly positive response from customers who purchased the first crop last month, the word is spreading throughout the surrounding communities and this second crop is already sold even before harvesting has been completed

NEW YORK, NY / ACCESSWIRE / July 15, 2021 / Foundation Farms, Corp., ('Foundation Farms') a subsidiary of GME Innotainment, Inc. (OTC PINK:GMEV) today reported that the second harvest is currently underway at the company's E-ROOTS CENTRE located in the Red Deer, Alberta area.

Following an overwhelmingly positive response from customers who purchased the first crop last month, the word is spreading throughout the surrounding communities and this second crop is already sold even before harvesting has been completed. Consumers have been delighted with the "no blemishes" produce and we have had numerous reports that the flavors and palatability of the vegetable greens are, "much better than anything that we have ever purchased at local supermarkets."

In response to the market demand, the company has expanded from an assortment of six basic leafy greens and herbs in the first crop to a total of 14 leafy greens and herbs, two fruits (strawberries and cayenne peppers), and four varieties of edible flowers in this second crop. Management and on-site staff also report the very successful functioning of the E-ROOTS system with minimal labor input.

When asked about these results, Ed Kroeker, CEO of Foundation Farms stated "I am pleased to report that, if anything, we may have under-estimated the expectations we have held until now. There is a lot of attention paid to tangible benefits of vertical farming including environmental sustainability, low water usage, ability to convert urban waste spaces to food production, and reduction of food transportation logistics. Our E-ROOTS CENTRES are demonstrating that we can produce plant-based food products whose culinary qualities supersede anything currently available in conventional food markets. We plan to have the same impact on the plant-based food market as Angus-beef branding has had on the red meat market. This will soon become even more evident as we are getting ready to announce several new joint ventures."

Yves R. Michel, CEO of GMEV further added, "In just a few short months of production at the Red Deer area vertical farm, Foundation Farms is demonstrating an ability to set a new standard of excellence in this industry and the demand for the products supports profitability projections. With product demand this high for smaller population centers, I am excited to see what happens once some of the larger population centers get hold of this technology.

CONTACT:

Yves R. Michel

Chief Executive Officer and Director

208 East 51st St., Suite 170

New York, NY 10022

www.srcorpgroup.com

OTCPink: GMEV

Forward-Looking Statements

Certain statements in this press release constitute forward-looking statements. These forward-looking statements are based on current expectations and assumptions that involve risks and uncertainties and on information available to the Company as of the date hereof. The Company's actual results could differ materially from those stated or implied, due to risks and uncertainties associated with its business, which include the risk factors disclosed in its latest Annual Report on OTCMarkets.com, it’s Regulation A+ Offering Statement, and other filings with the Securities and Exchange Commission, including the sections entitled "Risk Factors" and "Management's Discussion and Analysis of Financial Condition and Results of Operations" contained therein. Forward-looking statements include statements regarding the Company's expectations, beliefs, intentions or strategies regarding the future, and can be identified by forward-looking words such as "plans," "anticipate," "believe," "could," "continue," "estimate," "expect," "intend," "may," "should," "will" and "would" or similar words. The Company expressly disclaims any obligation or undertaking to disseminate any updates or revisions to any forward-looking statement contained herein to reflect any change in the Company's expectations with regard thereto or any change in events, conditions or circumstances on which any such statement is based.

SOURCE: GME Innotainment, Inc.

Malaysian, Smart Farm That Grows And Delivers Organic Vegetables

“The pandemic has underscored the urgency of building better food production, including fresh vegetables. Customers are increasingly aware that food choices influence both the health and the health of the planet,” the team concluded

July 15, 2021

7 years. It’s how long the farm lasts with 5G BoomGrow it has existed, but it has not always been so efficient. Founders Jay, Murali, and Shan had initially explored different cultivation methods, from simple hydroponics to aquaponics.

Image Credit: Founders of BoomGrow

“We grew our greens in small boxes. We even tried to grow them outdoors. Nothing worked, ”Jay recalled in an interview with Vulcan Post.

This trial and error lasted for five years until the co-founders discovered AI-driven vertical agriculture. With this method, they realized that they could also grow their greens in a controlled indoor environment that would make harmful chemicals such as pesticides unnecessary.

Finally, they had found it the method that allowed them to properly achieve their goals of producing clean, tasty greens.

Using 95% less resources to get the same performance

“Our systems detect how diverse contributions like the light, the water, and the pH affect the quality and the flavor of our plants. That’s what we call our plant recipes, ”said Shan.

“We then rely on machine learning and data analysis to tailor each entry to the respective plant, producing tastier greens.”

The team says its system equipped with technology is Machine Farm. It is used in all reused BoomGrow shipping containers where crops are grown on modular plant racks.

According to the team, five piles of crops on a 360-square-foot plot can produce a yield that is the equivalent of the traditional harvests of a 1-acre outdoor farm.

With this technology and efficient use of space, they can grow 20 varieties of leafy vegetables and herbs in a residential neighborhood of Ampang.

At the same time, Jay said Machine Farm uses 95% less land, water, and fuel than traditional outdoor farms.

Its technology-based agricultural approach has seen BoomGrow achieve multiple milestones, from being the country’s first 5G showcase farm to receiving benefits from government grants from SME Corp, PlaTCOM Ventures, and MDEC.

One of his most proud moments was the validation of renowned chefs working in 5-star hotels, who placed an order for their greens and have since been loyal followers.

Dedicated to clean processes and products

Clearly, there are already several agents in the precision and vertical farming industry with more union, but few are as gung-ho about clean produce as BoomGrow is.

Cleaning doesn’t just mean pesticide-free vegetables; the team decided that value should be reflected in the overall operation of their business.

Inside a Container / Image Credit: BoomGrow

As a former national athlete, Murali wanted to start BoomGrow because he knew the difference a good diet could make.

Meanwhile, Shan is a trained architect who had developed an interest in sustainable design throughout his career. Fascinated by the way modular structures had minimal impact on their environment, he wanted to explore other avenues for incorporating sustainability into everyday life.

He is the director of innovation at BoomGrow, designing and bringing its plant systems to life. On the other hand, Jay was inspired to co-found BoomGrow after many years in sustainability consulting.

He told Vulcan Post: “Throughout my career, I have had consulting experience for various agricultural and F&B manufacturing companies. This allowed me to evaluate the data around some of the practices, as well as the disconnection that people from these organizations had about sustainability. ”

Bringing the head together led the team to arrive at the current solution that is committed to implementing the 12th Sustainable Development Goal, responsible consumption, and production.

Organic vegetable packages at competitive prices

With all the investment in technology growing their organic greens, it looks like a purchase of them should cost a bomb.

But because they are able to eliminate the need for extensive land located in remote areas and a long cold chain, they can offer their vegetables at a competitive price.

BoomGrow sells 5 to 6 varieties of vegetables depending on the package you want, priced between 45 and 65 RM per package. Free delivery is offered to subscribers of weekly or fortnightly plans. Otherwise, deliveries to the Klang Valley would cost 10 RMS for purchases over 45 RM or 15 RM for those under 45 RMS.

Young Greens Growing on Modular Racks / Image Credit: BoomGrow

Compared to another vegetable delivery service with a subscription model, Plant B, BoomGrow prices are reasonable.

Floor B offers 6 types of vegetables in a box and a two-week subscription would be RM37 / week, while a 4-week subscription would be RM34 / week. Shipping costs are offered at fixed rates of RM6-RM8 depending on where you are in the Klang Valley.

For both BoomGrow and Plant B, people may not be able to choose exactly what goes into their box, but Plant B customers will be informed of the variety they can expect depending on the season and availability. You can also contact the team for exclusions.

On the other hand, BoomGrow clearly lists each variety of vegetables in a package with the assigned weight, so you’ll know exactly what you’ll get. To add, plant B does not claim that its product is organic.

Improve your B2C services during the pandemic

When the pandemic first hit in 2020, BoomGrow saw a sharp drop in overall sales as hotels and restaurants had to cut back on their orders.

Conversely, their e-commerce orders increased as more people subscribed to their vegetable packages.

“The pandemic has underscored the urgency of building better food production, including fresh vegetables. Customers are increasingly aware that food choices influence both the health and the health of the planet,” the team concluded.

They were able to meet this demand thanks to the support of MaGIC, particularly as part of cohort 4 al Global Accelerator Program.

Through it, their technology pipelines became more focused and were able to expand their digital footprints, refine e-commerce offerings, and improve their automation. Now, BoomGrow is preparing a launch of its machine factories outside of Klang Valley to reach more customers.

Outside, they will come face to face with more players in the vegetable delivery space, but perhaps their technology and mission will differentiate them in the long run and attract a segment of customers with whom their mission resonates.

HPNow And Kaneya Sign HPGen™ Distribution Agreement For Japanese High-Tech Horticulture Market

Agreement will provide Japan’s cutting-edge horticulture growers with access to HPGen™ benefits in autonomous, safe, and sustainable irrigation water treatment

COPENHAGEN, DENMARK, and MINAMICHITA, JAPAN (July 15, 2021) – HPNow, a global provider of HPGen™ Peroxide UltraPure™ on-site generation solutions, and Kaneya, Japan’s leading distributor of advanced horticulture inputs and solutions, are pleased to announce the signing of an HPGen™ distribution agreement for the Japanese market.

The Kaneya team with the HPGen™ system

Kaneya is a leader in the horticulture industry in Japan. The company has a large international network, and its mission as a distributor of high-end greenhouses and related equipment and inputs is to contribute to the future of advanced horticulture. The HPGen™ systems will play key role in supporting the company’s vision. Kaneya is active in 10 countries, and also operates its own high-tech greenhouse.

The distribution agreement will give Japan access to HPNow’s patented technology solution for autonomous, safe, and sustainable on-site generation of ultrapure hydrogen peroxide. HPGen has already proven strong effectiveness in agriculture operations around the world, providing for improved crop protection and reduced irrigation system maintenance across a wide range of crops, cultivation methods, and climates. Many HPGen customers further report increased crop yields.

“We’re very pleased to be working together with such an esteemed company as Kaneya,” comments Ziv Gottesfeld, CEO of HPNow. “Japan is at the forefront of controlled-environment agriculture, and this agreement is illustrative of the confidence the industry has in our products to support its cutting-edge cultivation methods.”

“We are looking forward to a strong collaboration with HPNow in the Japanese market,” adds Kazuta Aoyama, International Sales and Business Development Manager with Kaneya. “The HPGen technology offers exciting benefits to Japanese growers, which they will be eager to integrate into their operations.”

About Kaneya

Celebrating its golden anniversary, Kaneya is a leading horticultural and agricultural solution provider, selling and distributing products that range from its core, technologically advanced offering of plastic pots and trays, to a variety of other related products produced by leading horticulture companies around the world, including substrate, seeds, and plants, greenhouse equipment, fertilizer, etc. With more than 12,000 customers on record, and some 5,000 active, satisfied, and fiercely loyal active customers, Kaneya operates throughout Japan and exports its products to 10 countries, and has established itself as a global force in the horticulture industry.

About HPNow

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions. Headquartered in Copenhagen, and with representation across Europe, the Americas, and Asia, they address their clients’ water treatment needs in market segments ranging from agriculture and aquaculture, to industrial and drinking water treatment. HPNow is a technology and market leader in on-site generation of hydrogen peroxide and is continuously striving to further advance its technology and products in order to meet growing market needs and rising global demand.

Stay in the loop by following HPNow on LinkedIn and Facebook.

Optimizing Resource Use Efficiency In CEA System

An important factor affecting the profitability of vertical farming is a grower’s ability to consistently deliver a predictable product

Date: July 29, 2021

Time: 2 p.m. - 3 p.m. EDT

Presented by: Murat Kacira (The University of Arizona)

Click Here To Register

Webinar Description

An important factor affecting the profitability of vertical farming is a grower’s ability to consistently deliver a predictable product. To achieve this, growers must create an environment that supplies all the crop’s needs over its entire growth cycle by identifying and co-optimizing environmental variables such as CO2, light, humidity, airflow, and other parameters. This presentation will focus on real-time sensing, monitoring, and climate control strategies with system designs for environmental uniformity leading to enhanced resource use efficiency in CEA system.

Dr. Murat Kacira (Professor)

Murat Kacira is director of the Controlled Environment Agriculture Center and he is a professor in the Biosystems Engineering Department at the University of Arizona. He received his B.S. degree in Agricultural Engineering in Cukurova University in Turkey and M.Sc. and Ph.D. degrees from Food, Agricultural and Biological Engineering from The Ohio State University in USA. His research involves automation, environmental control, alternative energy integrated CEA systems and resource use optimization in controlled environment agriculture systems including greenhouses and vertical farming-based plant factories with artificial lighting. He is a member of American Society of Agricultural and Biological Engineers (ASABE), American Society of Horticultural Sciences (ASHS), and International Society for Horticultural Science (ISHS). He serves as Chair of the Division Precision Horticulture Engineering under ISHS.

Special thanks to our Industry partners

Join Today

If you have any questions or would like to know more about GLASE, please contact its executive director Erico Mattos at em796@cornell.edu

The Global Food Security & Sustainability Virtual Summit 2021 "Towards A Future Safe Global Food System"

The food crisis faced during the pandemic is a wake-up call for both developed and developing countries of the looming crisis facing the world when the next major crisis hits us, be it climate change, pandemics, etc

Overview

The Global food system is at a critical stage and made worse by the COVID-19 pandemic. As many as 265 million people are threatened by famine, up 50% on last year; 700 million suffer from chronic hunger; and 2 billion more from malnutrition, with obesity and associated diet-related diseases increasing in all world regions. During the height of the pandemic with lockdowns, we have witnessed the collapse of the global food system with reports of food producers resorting to dumping their produce.

The food crisis faced during the pandemic is a wake-up call for both developed and developing countries of the looming crisis facing the world when the next major crisis hits us, be it climate change, pandemics, etc.

Website link: https://pinnaclegroup.global/gfsss/

Website Registration Link https://pinnaclegroup.global/gfsss/delegate-attendance-opportunities/

Linkedin event: https://www.linkedin.com/events/theglobalfoodsecurity-sustainab6786907097511669760/

Although the world has progressed significantly in terms of technology advancements in food production, food is not distributed in an equitable manner to regions, countries, households, and individuals. Government policies, availability of investments and technological know-how, and improved access to food supplies are key issues that meet the urgent food needs of the world’s growing population. New and innovative farming technologies such as high-tech agriculture and aquaculture methods that produce more yields inland and urban conditions offer hope for the future.