Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

How Do We Build Sustainable Local Food Systems?

Food Tank, in partnership with the Danone Institute North America, is hosting a very special virtual event, "One Planet. One Health," to discuss solutions to build more sustainable local food systems on Thursday, May 6, 2021, at 12 p.m. ET

Let's Work Together to Build Sustainable,

Local Food Systems With a Global Impact

Food Tank, in partnership with the Danone Institute North America, is hosting a very special virtual event, "One Planet. One Health," to discuss solutions to build more sustainable local food systems on Thursday, May 6, 2021, at 12 p.m. ET.

We’ve curated a terrific lineup of speakers, including luminaries like N. Diane Moss (Project New Village), Dariush Mozaffarian (Friedman School of Nutrition Science & Policy, Tufts University), Jose Oliva (HEAL Food Alliance), A-dae Romero-Briones (Cochiti/Kiowa, First Nations Development Institute), Tambra Raye Stevenson (WANDA), and more.

I’ll be moderating. You can register here.

Also, I strongly urge eligible nonprofits to apply for the Danone Institute North America grant program to help local communities live the "One Planet. One Health" vision.

Danone Institute North America will award a total of up to $160,000 for this initiative. Individual team grants of $30,000 plus a $10,000 incremental award for the team with the strongest communications plan will be awarded for work to be conducted over a two-year period. The call for entries is open now through June 6, 2021. For information and to submit an application, visit Danone Institute North America here.

Danone Institute North America launched the "One Planet. One Health" Initiative grant program in 2019 to support local projects that strengthen food systems, reflecting Danone’s belief that the health of people and the health of the planet are interconnected.

"The pandemic has not only sparked a health crisis but also has emerged as one of the most destructive economic and societal challenges of our time," says Leslie Lytle, President of Danone Institute North America and professor at the Gillings School of Global Public Health at the University of North Carolina, Chapel Hill.

Please let me know if you apply for the grant, and join me for free on May 6 by registering HERE.

All the very best,

Dani

How Image Data Is Changing Agriculture

Anyone who wants to realize applications in which objects with a wide variety of characteristics – such as vegetables or fruit – are to be reliably recognized, cannot afford to ignore image processing with artificial intelligence

Anyone who wants to realize applications in which objects with a wide variety of characteristics – such as vegetables or fruit – are to be reliably recognized, cannot afford to ignore image processing with artificial intelligence.

Article from | IDS Imaging Development Systems

04/27/21

Being able to control processes more easily and design them more efficiently – these requirements also play an important role for agriculture and the food industry. Factors such as increasing demand from consumers, high standards regarding sustainability and security of supply, as well as the need to produce efficiently, come into direct conflict. Connected devices and automation are therefore becoming more and more prevalent in these sectors. Cameras play an important role here. They support from the optimal application of fertilizers to the visual monitoring of products and growth phases to the processing of food.

A key technology is an artificial intelligence. Organic products with different shapes and colors are difficult to describe in the corset of standardized algorithms with which industrial cameras usually work. Anyone who wants to realize applications in which objects with a wide variety of characteristics – such as vegetables or fruit – are to be reliably recognized, cannot afford to ignore image processing with artificial intelligence. Intelligent vision systems for collecting and analyzing information are also valuable tools when it comes to detecting conditions, making decisions, and triggering follow-up processes. To make the best use of this technology, AI vision systems that are equally flexible, easy to handle, and powerful are required. This is where IDS NXT ocean comes into play.

IDS NXT ocean (www.ids-nxt.com) is a particularly user-friendly end-to-end solution that allows users to create AI-based image processing applications – even with little previous knowledge. Vision apps help to flexibly control which task the embedded vision system should solve; from simple barcode reading to complex AI-based object detection. Thanks to their compact industrial-grade housing and interfaces such as OPC UA, the intelligent IDS NXT cameras can be easily integrated into factory automation. Image processing takes place directly on the camera and can then be transmitted as a result, for example to a machine control system.

Customers are provided with coordinated workflows and all the necessary tools so that they can easily develop applications on their own. With the IDS-hosted, cloud-based AI training system IDS NXT lighthouse, they can train a neural network with their own images without any prior deep learning knowledge and without having to install any hardware or software. This is remarkable because although automation is a defining topic in the agriculture and food sector, only a few all-in-one packages for embedded vision with deep learning are available. In many cases, this is still project work, with customers building the systems themselves step by step. IDS Imaging Development Systems removes these hurdles so that even companies without dedicated AI specialists can benefit from the current technical state of the art and keep their competitive edge.

For more information and application examples, please visit

https://en.ids-imaging.com/smart-farming.html.

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

IDS Imaging Development Systems Inc.

IDS is a leading manufacturer of industrial cameras "Made in Germany" with USB or GigE interfaces. Equipped with state-of-the-art CMOS sensors, the extensive camera portfolio ranges from low-cost project cameras to small, powerful models with PoE functionality or robust cameras with housings that fulfill the prerequisites for protection code IP65/67. For quick, easy, and precise 3D machine vision tasks IDS offers the Ensenso series. With the novel vision app-based sensors and cameras of IDS NXT the company opens up a new dimension in image processing. Whether in an industrial or non-industrial setting: IDS cameras and sensors assist companies worldwide in optimizing processes, ensuring quality, driving research, conserving raw materials, and serving people. They provide reliability, efficiency, and flexibility for your application.

Monitoring & Growing, Precision Farming | IDS Imaging Development Systems Inc. | Imaging, machine vision

VIDEO: Ottawa Startup Plantaform Hopes To Harvest Profits From Indoor Gardening Technology

Ottawa biotech startup Plantaform's system, dubbed Rejuvenate, uses a concept called fogponics to grow herbs and leafy vegetables indoors

Ottawa biotech startup Plantaform's system, dubbed Rejuvenate, uses a concept called fogponics to grow herbs and leafy vegetables indoors.

A Carleton University business grad says his new startup is planting the seeds of a flourishing global horticulture enterprise with a soil-free system that grows herbs and leafy vegetables in a container small enough to sit on a kitchen countertop.

Alberto Aguilar launched fledgeling biotech startup Plantaform last spring with longtime friend Kiwa Lang, an industrial designer who attended high school with Aguilar in Dubai and now lives in Australia.

Lang was looking for sustainable alternatives to traditional horticulture and discovered a concept called fogponics, a technique pioneered by NASA that nourishes plants with nutrient-enriched water vapour rather than soil. He immediately reached out to his old pal, and a truly international startup was born.

“It’s extremely efficient,” Aguilar says of the technology, explaining that it uses 95 per cent less water than traditional soil-based horticulture operations.

Unlike more well-established hydroponics systems, Plantaform’s product – dubbed Rejuvenate – doesn’t submerge plant roots in water. Rather, it circulates a fine mist loaded with nutrients throughout an egg-shaped device roughly 60 centimetres high by 60 centimetres wide.

The high-tech indoor garden can grow up to 15 plants at a time, ranging from herbs such as basil and oregano to leafy greens including lettuce and kale.

35-day growing cycle

Customers set the proper lighting and nutrient mix on a smartphone app. Aguilar says the system can effectively run itself for up to three weeks before the water supply needs to be replenished, and it takes roughly 35 days to harvest a crop from the time seeds are “planted” in the device.

Plantaform’s own growth path has been a little rockier.

Backed by about $100,000 in funding from the founders’ family and friends as well as investors in Aguilar’s previous startups, the company stumbled out of the gate early last year.

The initial design for Rejuvenate failed, and it’s taken about half a dozen iterations to get the concept just right. In addition, Aguilar notes ruefully, the firm’s original team “collapsed” after several employees quit last summer because the founders couldn’t afford to pay them full-time salaries.

Supply-chain disruptions

Meanwhile, the pandemic wreaked havoc with the startup’s supply chain, forcing Aguilar and Co. to abandon foreign suppliers in China and elsewhere and manufacture the bulk of the components for the prototypes in their own homes on 3D printers.

But the plucky grow-op persevered, overhauling its development staff and bringing on veteran Ottawa-based engineer Georges Hamoush as chief operating officer. Plantaform eventually signed a Chinese contractor to manufacture most of the components, which will be assembled locally at Stittsville’s L-D Tool & Die.

If all goes according to plan, the first units will be shipped to customers this fall – and Aguilar plans to personally deliver as many as he can.

“We’ve made a lot of mistakes, but you know what? We’re not giving up,” says the budding biotech magnate, who grew up in Barcelona, spent some of his teenage years in Dubai and moved to Ottawa in 2014 to finish high school at Lisgar Collegiate before studying international business at Carleton.

"I’m really trying to put Ottawa on the map."

Alberto Aguilar - CEO and co-founder of biotech startup Plantaform

“We’re confident that if we keep trying, it’ll eventually work out.”

The 24-year-old Aguilar boasts an accomplished entrepreneurial resume. Plantaform is already his third startup, and he earned spots in Invest Ottawa’s pre-accelerator and Ottaw’’s Startup Garage with his previous ventures.

He’s hoping to secure additional seed funding for Plantaform later this year, with an eye to landing a series-A round early in 2022. The company also has its sights set on even bigger markets – it’s currently working with the Vineland Research and Innovation Centre, a non-profit organization based near Niagara Falls, on a system to grow cannabis using fogponics technology.

The worldly Aguilar says he’s hoping his venture can elevate his adopted hometown on the international biotech stage.

“I’m really trying to put Ottawa on the map,” he says. “We want to go global.”

This Weeks Episode - Season 3 Episode 32

Join Harry Duran, host of Vertical Farming Podcast, as he welcomes to the show co-founders of Vertical Harvest, Nona Yehia, and Caroline Croft Estay

Join Harry Duran, host of Vertical Farming Podcast, as he welcomes to the show co-founders of Vertical Harvest, Nona Yehia, and Caroline Croft Estay. An architect and entrepreneur, Nona conceptualized and built Vertical Harvest, the first vertical hydroponic greenhouse in the world. Combining her expertise in behavioral health and experience in training and case management, Caroline crafted and implemented the innovative “Grow Well” employee model at Vertical Harvest.

In today’s episode, Harry, Nona, and Caroline discuss the inspirational work they are doing to bring architectural, economic, and social innovation to communities nationwide. Their mission is to bring meaningful employment to underserved populations and educate communities on how good jobs help differently-abled individuals to thrive.

Listen & Subscribe

AeroFarms Breaks Ground on World’s Largest Aeroponic Indoor Vertical Farm

AeroFarms, a certified B Corporation and leader in indoor vertical farming, today announced the groundbreaking of its second commercial indoor vertical farm in Danville-Pittsylvania County, Virginia

April 30, 2021

Coming online in the second quarter of 2022, AeroFarms’ next-generation Model 5 farm will be the largest and most technologically advanced aeroponic indoor vertical farm in the world.

NEWARK, N.J.–(BUSINESS WIRE)–AeroFarms, a certified B Corporation and leader in indoor vertical farming, today announced the groundbreaking of its second commercial indoor vertical farm in Danville-Pittsylvania County, Virginia.

Elected officials from Pittsylvania County and the City of Danville, along with Virginia Governor Ralph Northam, Virginia Secretary of Agriculture Bettina Ring and other state and community leaders, will join AeroFarms representatives for a groundbreaking ceremony this morning to celebrate the beginning of construction of the 136,000 square foot farm.

“We congratulate AeroFarms on launching construction of its state-of-the-art facility in Cane Creek Centre,” said Governor Ralph Northam. “The Commonwealth’s history is rooted in agribusiness, and the completion of the world’s largest and most advanced indoor vertical farm will enhance this booming industry. We thank AeroFarms for choosing Southern Virginia, and look forward to supporting its success.”

“Innovation and new technologies have always been the driving forces behind the success of Virginia’s largest private sector industry, agriculture,” said Secretary of Agriculture and Forestry Bettina Ring. “By choosing to establish their largest production facility to date here in the Commonwealth, AeroFarms is ensuring that Virginia is a leader in indoor vertical farming.”

Coming online in the second quarter of 2022, AeroFarms’ next-generation Model 5 farm will be the largest and most technologically advanced aeroponic indoor vertical farm in the world. Strategically located in close proximity to more than 1,000 food retailers in the region, the Danville farm will provide access to approximately 50 million people located within a day’s drive. The new farm will advance AeroFarms’ leadership in plant science and technology and expand its leafy greens business to the Mid-Atlantic region with brick-and-mortar retail and e-commerce partners, building upon existing relationships that include Whole Foods Market, ShopRite, Baldor, Amazon Fresh and FreshDirect.

Danville, Virginia, near the North Carolina border

“The science, technology, and innovation that underpin our platform allows us to drive superior unit economics and scale up our business to deliver on our mission of growing the best plants possible for the betterment of humanity,” said David Rosenberg, Co-Founder and Chief Executive Officer of AeroFarms. “Our customers love our leafy greens, which consistently win on quality, flavor, taste and texture. We are excited to break ground on our new farm, expand our retail presence in the region and bring our exceptional, great-tasting products to more customers.”

The Danville farm will feature AeroFarms’ proprietary and cutting-edge agSTACK technology, creating a fully connected and digitally controlled farm that integrates hardware, automation, intelligent controls and sensors, machine learning, machine vision, supervisory control and data acquisition (SCADA), and manufacturing execution systems to create a powerful data loop. By collecting and analyzing data through its 26 crop turns per year, AeroFarms’ team of engineers, plant scientists, and programmers gather insights about plants and apply these learnings for the continuous improvement of its farms, which yield annual productivity up to 390 times greater than traditional field farming, while using up to 95% less water and zero pesticides.

An AeroFarms vertical farm. - File photo

Rosenberg continued, “Danville-Pittsylvania County is the perfect location to introduce our next-generation Model 5 farm that will be able to serve the more than 1,000 food retailers in the region. Our new farm will deepen our established retailer partnerships even further and make our sustainably-grown, pesticide-free, and always fresh leafy greens available throughout the Mid-Atlantic region, while also creating high-quality jobs in the area. This new facility represents an inflection point in our growth trajectory as we scale our technology and expand our retail distribution footprint and customer reach.”

About AeroFarms

Since 2004, AeroFarms has been leading the way for indoor vertical farming and championing transformational innovation for agriculture. On a mission to grow the best plants possible for the betterment of humanity, AeroFarms is a Certified B Corporation Company with global headquarters in Newark, New Jersey, United States. Named one of the World’s Most Innovative Companies by Fast Company two years in a row and one of TIME’s Best Inventions, AeroFarms patented, award-winning indoor vertical farming technology provides the perfect conditions for healthy plants to thrive, taking agriculture to a new level of precision, food safety, and productivity while using up to 95% less water and no pesticides versus traditional field farming. AeroFarms enables local production to safely grow all year round, using vertical farming for elevated flavor. In addition, through its proprietary growing technology platform, AeroFarms has developed multi-year strategic partnerships ranging from government to major Fortune 500 companies to help uniquely solve agriculture supply chain needs. For additional information, visit: https://aerofarms.com/.

On March 26, 2021, AeroFarms announced a definitive business combination agreement with Spring Valley Acquisition Corp. (Nasdaq: SV). Upon the closing of the business combination, AeroFarms will become publicly traded on Nasdaq under the new ticker symbol “ARFM”. Additional information about the transaction can be viewed here: https://aerofarms.com/investors/

No Offer or Solicitation

This press release does not constitute an offer to sell or a solicitation of an offer to buy, or the solicitation of any vote or approval in any jurisdiction in connection with a proposed potential business combination among Spring Valley and AeroFarms or any related transactions, nor shall there be any sale, issuance or transfer of securities in any jurisdiction where, or to any person to whom, such offer, solicitation or sale may be unlawful. Any offering of securities or solicitation of votes regarding the proposed transaction will be made only by means of a proxy statement/prospectus that complies with applicable rules and regulations promulgated under the Securities Act of 1933, as amended (the “Securities Act”), and Securities Exchange Act of 1934, as amended, or pursuant to an exemption from the Securities Act or in a transaction not subject to the registration requirements of the Securities Act.

Forward-Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “will,” “estimate,” “continue,” “anticipate,” “intend,” “expect,” “should,” “would,” “plan,” “predict,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this presentation, regarding Spring Valley’s proposed acquisition of AeroFarms, Spring Valley’s ability to consummate the transaction, the benefits of the transaction and the combined company’s future financial performance, as well as the combined company’s strategy, future operations, estimated financial position, estimated revenues and losses, projected costs, prospects, plans and objectives of management are forward-looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of the respective management of AeroFarms and Spring Valley and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AeroFarms and Spring Valley. These forward-looking statements are subject to a number of risks and uncertainties, including changes in domestic and foreign business, market, financial, political, and legal conditions; the inability of the parties to successfully or timely consummate the proposed transaction, including the risk that any regulatory approvals are not obtained, are delayed or are subject to unanticipated conditions that could adversely affect the combined company or the expected benefits of the proposed transaction or that the approval of the stockholders of Spring Valley or AeroFarms is not obtained; failure to realize the anticipated benefits of the proposed transaction; risks relating to the uncertainty of the projected financial information with respect to AeroFarms; risks related to the expansion of AeroFarms’ business and the timing of expected business milestones; the effects of competition on AeroFarms’ business; the ability of Spring Valley or AeroFarms to issue equity or equity-linked securities or obtain debt financing in connection with the proposed transaction or in the future, and those factors discussed in Spring Valley’s final prospectus dated November 25, 2020 under the heading “Risk Factors,” and other documents Spring Valley has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. There may be additional risks that neither Spring Valley nor AeroFarms presently know, or that Spring Valley nor AeroFarms currently believe are immaterial, that could also cause actual results to differ from those contained in the forward-looking statements. In addition, forward-looking statements reflect Spring Valley’s and AeroFarms’ expectations, plans, or forecasts of future events and views as of the date of this press release. Spring Valley and AeroFarms anticipate that subsequent events and developments will cause Spring Valley’s and AeroFarms’ assessments to change. However, while Spring Valley and AeroFarms may elect to update these forward-looking statements at some point in the future, Spring Valley and AeroFarms specifically disclaim any obligation to do so. These forward-looking statements should not be relied upon as representing Spring Valley’s and AeroFarms’ assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Tagged aerofarms, indoor farm, indoor farming

Sustainably Goals Urges Architect To Build A Greenhouse Around Former Fruit Farm

As decided by the municipality of Gooik, visitors can now see the refurbished agricultural buildings enclosed within a greenhouse-like structure, this way learning more about the countryside of Belgium

Is it a greenhouse, is it an educational center, is it a former fruit farm? It is all in one. A former fruit farm in Gooik, Belgium, is now functioning as an educational center. As decided by the municipality of Gooik, visitors can now see the refurbished agricultural buildings enclosed within a greenhouse-like structure, this way learning more about the countryside of Belgium. Architect Jo Taillieu: "We wanted a generous building that could provide the necessary comfort to all users of the center, even in bad weather, and provide an anchor point for exploring the Pajottenland.”

The old farmhouse had been used as an education center already for years, but the project became to big to be run by volunteers completely. That’s why the municipality bought it and realized further expansion plans.

Interwoven

"Paddenbroek is by no means inconspicuous. In the hilly Pajottenland region, landscape, nature, heritage, and culture have been closely interwoven for centuries. Maintaining that balance was one of the major goals," architect Jo Taillieu explains. "The farmstead and especially the outbuildings were in a bad state and unsuitable for achieving the intended objectives. The link with the context was almost non-existent. The first idea - a classic renovation - was discarded, as was a new building, because it was unrealistic and did not meet the task that could be expected of an educational and tourist center. We, therefore, opted for a roof that would cover the farmstead, the historic baking oven, and the space around it."

Photo courtesy Jo Tailleu

Sustainability was one of the main goals of the construction. The dilapidated outbuildings were dismantled and the farmstead and the baking oven incorporated, restored, and insulated with moisture-regulating wood-wool cement boards and loam. Only these rooms and the offices can be heated. Thus, heating costs are sustainably limited to a few cores in the building and not everything needs to be air-conditioned. Inside the unheated greenhouse, therefore, there is an intermediate climate. Visitors are sheltered from rain and wind and can still enjoy the magnificent view of the surroundings. Upstairs are two more multi-purpose rooms that can be used as meeting rooms.

According to Stefan De Clerq, one of the business managers of the greenhouse construction company, the challenge was mostly the size and complexity of the project, as the features of this construction did not allow for a basic model. We created a unique truss and steel construction where each step was carefully monitored. All steel components were produced in our own workshops. This challenge was brought to a successful conclusion by the close cooperation between our draftsmen, our production team, and the external architects. Our own typical aluminum profiles and glass, applied in the roof and wall, also contribute to the elegant appearance of this nevertheless quite robust realization."

The construction of a complex like that of Paddenbroek in a rural area is not obvious and initially met with the necessary reservations, as could be expected. The fact that the municipality was prepared to go along with the story of architect Jo Taillieu and project manager Dries Deleye, therefore, shows vision and insight. Now that the construction is complete, everyone agrees that Gooik has gained a valuable multipurpose center that responds to ecological sustainability and from which the residents can also derive maximum benefit.

Lead photo: Photo courtesy Jo Tailleu

Publication date: Thu 29 Apr 2021

© HortiDaily.com / Contact

HECTAR Offers Free Design Plans For Open Source Hydroponics Unit

Felix Wieberneit from the Royal College of Art and Imperial College London imagined a way for U.K. citizens with a limited amount of indoor space to build their own vertical garden and is now making the design free for anyone to download

Among all of the new hobbies picked up during the COVID-19 lockdowns, gardening has to be one of the most popular. Felix Wieberneit from the Royal College of Art and Imperial College London imagined a way for U.K. citizens with a limited amount of indoor space to build their own vertical garden and is now making the design free for anyone to download.

Described as an open-source hydroponics unit, the HECTAR vertical farm is designed especially for interiors to help more people grow healthy food from home. Sponsored by multinational technology company Huawei, the unit is inspired by open-source electronic and 3D printing companies. Open-source describes a type of computer software that’’s released under a special license made to be accessible to the public. HECTAR has since been selected as one of 25 companies in the Imperial College Venture Catalyst Accelerator, a competition for local entrepreneurs.

It looks like a simple shelf, but the innovative hydroponics unit can grow a whopping 120 plants confined to a space the size of a cupboard. Even better, the design is fully modular and can be built using standard parts found in almost any hardware store. Wieberneit hopes the free plans will educate and empower regular people to grow their own food at home, without relying on pricey smart growing systems or seed subscription services. In theory, the unit can save users money in the long run as they cultivate their own edible plants like arugula, lettuce or herbs.

Plans include an instructional video, a bill of materials, and suggestions on where to find the parts. There is also a dedicated forum where users can ask questions if they get stuck or connect with others. The plans officially launched on March 16, and the company is still looking for U.K.-based beta testers to try the designs out for themselves. Those who are interested can download the plans from the HECTAR website, linked below.

High Tech And Ancient Methods Meet At The Vertical Fields of Nabo Farm

In a former auto repair shop in the outskirts of Copenhagen, a farm has found its unlikely grounds. Fresh coriander, pea sprouts, and edible flowers are grown at the vertical farm – and sold to some of the finest restaurants in Denmark

21 April 2021

In a former auto repair shop in the outskirts of Copenhagen, a farm has found its unlikely grounds. Fresh coriander, pea sprouts, and edible flowers are grown at the vertical farm – and sold to some of the finest restaurants in Denmark.

There is no soil at Nabo Farm. And the Sun never shines on the crops. Layer upon layer of sprouts are growing in the purple fluorescent light. Rocket sprouts, pea sprouts, coriander, red mustard, nasturtium, and dill all thrive at the vertical farm specialized in microgreens – in the outskirts of Copenhagen.

For almost three years Nabo Farm has been a so-called vertical farm. Technology is at the core of the production. LED lights make sure that the plants get the perfect sunny day every day without ever seeing the sun. A hydroponic watering system makes soil superfluous and saves 90 percent of water consumption at the same time. This technology combined makes it possible to grow multiple layers of crops. To create a farm in the middle of the city. And to save valuable farmland for other crops.

The name “Nabo Farm” can loosely be translated to “the farm next door”. And during the relatively short time, Nabo Farm has existed the company has managed to get customers such as Aamands and Denmark’s first and only two Michelin starred restaurant Alchemist. All products are grown specifically to order – and delivered by bicycle.

Cucumbers on the fourth floor

It all started with a home-built watering system for a few vegetables grown on Jens Juul Krogshede’s fourth-floor balcony. He was going away on holiday for a few weeks and didn’t want to see all his hard work amount to nothing.

“I had worked in the tech industry for many years and had burned out a bit. That’s when I started growing tomatoes and cucumbers on my balcony. When we had to go away for a few weeks – I build my own watering system in the living room. And that started all of this,” says Jens Juul Krogshede.

“One thing quickly led to another, and I learned about hydroponics – how to grow plants without soil. A core element of vertical farming. That took me to the next level – and I no longer had to carry big bags of soil up five flights of stairs,” he tells.

Hydroponics is a technique that dates back to the Hanging Gardens in Babylon, he adds.

At about this time Jens Juul Krogshede meets the soon-to-be co-founder of Nabo Farm, Sebastian Dragelykke, who was already working with developing the future of foods at a think tank in Copenhagen.

“Together we saw the technology – the opportunity – and went with it,” says Jens Juul Krogshede.

Sustainability is the driving force

From the very beginning, sustainability has been at the core of Nabo Farm. On several levels. The two founders want to be a part of the solution when it comes to feeding the growing population on planet Earth. They want to be a part of the solution to the climate challenges we all face.

“There are more and more people on the planet who eat more and more food. With vertical farming we can create a fundamental change in the way we produce food. A great addition to traditional farming. With vertical farming we can produce food in old basements, inside old factories and on rooftops in the cities without causing further damage to the climate. This is something we have to do. In the long run we might even be able to take out traditional farmland to develop biodiversity,” says Jens Juul Krogshede.

“Nabo Farm helps to solve a different sustainability issue as well. In the food supply chain. The first year we existed we found out that many restaurants in Copenhagen have a demand for fresh coriander during the winter. At this time of the year, coriander must be imported from Spain or The Netherlands. By growing crops our way, we can supply local coriander all year round – and we deliver by bicycle – not by truck.”

Rapidly developing technology

Every day is a perfect summer day inside Nabo Farm thanks to the fluorescent LED lights. The conditions are optimal for the microgreens.

It’s all possible because the LED technology has been going through a rapid development in the last couple of years. Where the lights used to be extremely expensive, the technology is now affordable.

“Not that many years ago, the only products you could grow this way with a profit were of a shadier kind. However, the rentability is still the main challenge for vertical farming, and a lot of vertical farms still struggle to make a profit. There are still many unknowns, and the technology is still developing rapidly,” says Jens Juul Krogshede.

Next step in Copenhagen

Vertical farming is a part of the future of food production. Therefore Food & Bio Cluster Denmark is now establishing a new network for vertical farming. Here the high-tech farmers can meet, share knowledge, hear from industry experts and scholars. Nabo Farm is already a part of that network.

“Denmark is a farming country by tradition. We are great farmers. We also have a great tradition for knowledge and academia. If we can bring the two together, I believe Denmark can be an industry-leading country in vertical farming. That’s why we’ve joined the new network,” says Jens Juul Krogshede.

As for Nabo Farm, the company has just received a new investment that will take the company to the next level and scale the business to turn it into a franchise that can thrive sustainably in other Northern European cities.

Square Roots Opens New Indoor Farm, Produces First Harvest

The farm’s first locally grown harvest of herbs and greens that includes basils, arugula and radish microgreens will be available for consumers to purchase on e-commerce platforms, restaurants and grocery stores across the Great Lakes region in the coming weeks

April 15, 2021

New York-based Square Roots, an urban indoor farming company, opened a two-story indoor farm located at Gordon Food Service headquarters in Wyoming.

The farm’s first locally grown harvest of herbs and greens that includes basils, arugula and radish microgreens will be available for consumers to purchase on e-commerce platforms, restaurants and grocery stores across the Great Lakes region in the coming weeks.

Construction on the indoor farm began in December and the first seeds were planted in March. The farm is cloud-connected and is managed by Square Roots’ farmers and in-house software.

“COVID-19 exposed major weaknesses in the industrial food supply chain and accelerated the already fast-growing local farming movement,” said Kimbal Musk, co-founder and executive chair of Square Roots. “Square Roots can now deploy commercial-scale, controlled-climate farms, fast, in locations across America to meet the demand for local food, all year-round. My wider mission is to bring responsibly grown, local food to everyone in America.”

A farmer harvest basil. Courtesy Square Roots

The farm’s proprietary OS, otherwise known as The Square Roots Farmer Toolbelt, provides day-to-day guidance to farmers while capturing millions of data points throughout growing cycles. The data can then be analyzed to determine how changes in certain environmental parameters impact factors like yield, taste, and texture.

In addition to the technology that drives its operation, there also are cold storage, biosecurity, climate-controlled packaging space, and distributor loading docks, among other things in the farm that ensures food safety.

The new indoor farm is Square Roots’ third commercial facility.

Lead photo: Construction on Square Roots' indoor farm began in December and the first seeds were planted in March. Courtesy Square Roots

How To Be A Hydroponic Farmer: Expert Advice From Agricultural Entrepreneur

For a decade, Sharaff worked in the finance, nonprofit, and hospitality industries, struggling to find a calling

“Everything I’ve learned, I’ve learned the hard way,” laughs Hassan Sharaff, BE’07, gesturing to, well, everything: the polyethylene greenhouse walls with a soaring aluminum frame, torqued by last year’s derecho winds, and tray after tray of arugula, basil, kale, and lettuce shoots, drinking in diffuse winter sunlight, tropical humidity and ever-flowing water.

“Water is fascinating. We still understand so little about it,” says Sharaff, the owner of HydroHouse Farms, a commercial hydroponics business in Mount Juliet, Tennessee, that supplies leafy greens to many restaurants and businesses in Nashville—including Vanderbilt Campus Dining. He’s a man with many interests. As a boy growing up in the United Kingdom, Switzerland, and New York, Sharaff loved car engines, airplanes, and spaceships. At Vanderbilt, he studied mechanical engineering. Then he headed home to New York to start a career in finance—following in his dad’s professional footsteps.

For a decade, Sharaff worked in the finance, nonprofit, and hospitality industries, struggling to find a calling. After college, he’d prioritized making money. But as he got older, his values began to shift. “I wanted to make a positive contribution to society,” he says. “I believed in kindness and philanthropy, things my parents instilled in me.”

A hydroponic farming enterprise ticked all the boxes of what he considered a calling: “Provide a valuable service, work on my feet, make a decent income and be proud of what I’m doing,” he says. Ten years after graduation, Sharaff, who’d never sowed a seed before, built a greenhouse with his dad in his parents’ backyard in suburban New York. He launched a mini hydroponic operation there to experiment with horticulture while he plotted his agribusiness venture. Location was a problem: He needed to plant himself on the fertile ground near a city full of chefs who wanted quality produce, but where real estate prices weren’t sky-high. New York was a non-starter. Portland, Oregon, didn’t feel right.

In early 2016, Sharaff flew to Nashville, his first trip back since college. He found a thriving culinary scene and affordable land east of the city. That September he closed on 17 acres in Mount Juliet, and he launched operations in May 2017. His business has survived hard-won lessons from nature and the marketplace. He shares a few of these here for prospective farmers—or for anyone who dreams of “providing more than you’ve taken” from the world.

For more information:

Vanderbilt University

www.vanderbilt.edu

26 Apr 2021

VIDEO: One Sure Way To Save Our Soil – Don’t Use Any

The advantage of container farming is the ability to create commercial-scale production within a small space the size of your standard 40-foot shipping container through vertical farming techniques

In the push for regenerative agriculture and soil rehabilitation, container farming has an important role to play.

The idea behind regenerative agriculture isn’t new, but this year it is front and center as one of the key initiatives of the official Earth Day 2021 campaign: Restore Our Earth™.

According to the Earth Day organization, overfarming has caused soil capacity in the U.S. to decline dramatically, losing soil 10 times faster than it can be replenished. The result is that in many places, the land has as few as 60 harvests left before it is completely depleted. Unfortunately, with ownership of farms increasingly concentrated in the hands of industrial or foreign producers, the promise of short-term profits wins out over long-term solutions that would prioritize soil health.

What is regenerative agriculture?

Regenerative farming takes an opposite position. As a school of thought, it is a method of farming that actively fights soil degradation by restoring carbon to the soil, which has a double benefit of renewing the viability of the land while simultaneously removing carbon dioxide from the atmosphere. There are many different types of regenerative agriculture, here’s a helpful video to explain the main three:

But between destroying the soil and saving the soil, there’s a third option: not using any soil at all. This is the premise behind container farming.

Container farming to save soil.

Container farming is a subset of the indoor farming industry, which includes everything from greenhouses and warehouses to at-home tabletop setups. The advantage of container farming is the ability to create commercial-scale production within a small space the size of your standard 40-foot shipping container through vertical farming techniques. Inside the container, plants are protected from the external elements and nurtured using nutrient-enriched water, powerful red and blue light, and optimal temperatures.

Notice anything missing? Oh yeah–soil!

Container farming with hydroponics completely eliminates the need for soil to grow food, which is great news for the whole regenerative agriculture movement. Since regenerative farming is based on the idea of protecting soil, container farming is able to take the whole idea to the logical extreme by not using any soil–period.

Not only does container farming prevent the further degradation of soil, but it actually frees up land to be actively regenerated. At Freight Farms, our containers (each capable of growing an average of 2 acres of food) have already saved 700 acres of land… which’s equal to about 530 football fields!

Additional sustainability benefits

Beyond regenerative agriculture, which is primarily focused on soil, container farming brings many additional sustainable benefits. The Greenery S is able to save:

Water: 99% less water than is used in conventional agriculture.

Food miles: we move the farms, not the food. Instead of trucking/shipping food from a centralized location, we put the farm as close to the final consumer as possible.

Carbon emissions: in addition to reducing food miles, we’ve partnered with Arcadia to make it easy and effective for our farmers to get onto the renewable energy grid and make their carbon footprint just one-quarter of what it would be if they were farming using industrial farming methods.

Regenerating communities

While regenerative agriculture may start with soil, the implications on climate change, food access, and food security are clear. In the same way, container farming is also more than just improving the sustainability of our agriculture system. In addition to saving soil, land, water and reducing food miles and carbon emissions, container farming unlocks many important social gains:

Independence: when we are not reliant on soil, land, and climate, we can make any place a farm. This makes it possible for us to create the distributed system we need to combat the harmful effects of industrial farming and centralized food systems.

Equality: independence from soil and land also creates more food equality, since individuals and communities need fewer resources (money & land) to create commercial-scale farms.

More farmers: Soil is complicated and nuanced, it takes huge amounts of experience and education to know how to do regenerative agriculture properly. With container farming, everyone can be a low-impact farmer.

More varieties: Conventional agriculture is beholden to monocropping, which improves the unit economics of growing food but also increases the risk of crop failure, blight, and soil degradation. Container farming makes it possible to grow hundreds of plant varieties, introducing people to new types of plants and growing public perception of the diversity you can have with fresh greens. This can have an overall positive effect on market demands and help move the whole system away from relying on mono-cropping.

Learn more about the Earth Day Restore Our Earth™ campaign and check out how Freight Farms is helping support the regenerative farming movement with container farming!

Freight Farms

Empowering anyone to grow food anywhere. Freight Farms makes local food accessible in any climate with the Greenery™ container farm.

April 23, 2014

Follow Earth Day Earth Day 2021 Sustainability Regenerative Agriculture Agriculture

Indoor AgTech Innovation Summit June 24-25

We can’t wait for the virtual Indoor AgTech Innovation Summit! From 65+ global speakers to 1-1 video networking opportunities and live-streamed panel discussions, this is one event you don’t want to miss on June 24-25

We can’t wait for the virtual Indoor AgTech Innovation Summit! From 65+ global speakers to 1-1 video networking opportunities and live-streamed panel discussions, this is one event you don’t want to miss on June 24-25.

Find Out More

Join iGrow News at the virtual Indoor AgTech Innovation Summit (June 24-25) and connect with global farm operators, retailers, and investors for two days of insights into how CEA and vertical farming can reach greater profitability and scale

Find Out More

Global farm operators, retailers, investors, and technology providers will host live panel sessions and interactive roundtable debates on new trends and technologies at the virtual Indoor AgTech Innovation Summit (June 24-25):

REGISTER

The virtual Indoor AgTech Innovation Summit will focus on CEA and vertical farming reaching greater profitability and scale in the USA and overseas.

Will You BeJoining The Conversation

On June 24-25?

VIDEO: Tortuga Raises $ 20m To Build Hundreds of Harvesting Robots

Last year Tortuga launched a strawberry harvesting robot. This platform is flexible, according to Tortuga it can be adapted to work on other crops like indoor-grown tomatoes or outdoor table grapes

23-04-2021

Harvest automation start-up Tortuga completed a $ 20 million Series A funding. The money will be used to build hundreds of robots to deploy in 2022.

Last year Tortuga launched a strawberry harvesting robot. This platform is flexible, according to Tortuga it can be adapted to work on other crops like indoor-grown tomatoes or outdoor table grapes.

Picking robots

“For many years, the story behind harvesting robotics has been a lot of promise but really companies have struggled to deliver on that promise for the customer. That’s because this is one of the hardest problems there is to solve,” Eric Adamson, co-founder of Tortuga AgTech told AgFunder News. “Not only are we doing autonomous robotics but we are also doing picking robotics and we are doing them together in really unstructured environments.”

Robots-as-a-service

The $ 20 million in new capital will be used to build hundreds of robots to deploy in 2022. Some of the funding will also go towards building out the operating model and making sure there are enough employees to operate the robot fleets.

Tortuga currently offers its technology through a robots-as-a-service model, getting paid by the kilo for the produce that its robots pick.

Additional services

“On top of that, as we provide other services that are close to harvest, like data-driven forecasting and other types of cultivation services, those will also be service-based although they may not be quite so specific to a kilogram. We are charging for some of these additional services on a monthly or per-hectare basis,” Adamson told AFN.

Web editor for Future Farming

INDIA: VIDEO - University Student Runs Farm In Kuala Lumpur

Ah Pa, a well-known YouTube cook recently visited Sean, a university student living in Kuala Lumpur who runs his own farm. As Sean calls it, his E-farm is located in the middle of the city

Ah Pa, a well-known YouTube cook recently visited Sean, a university student living in Kuala Lumpur who runs his own farm. As Sean calls it, his E-farm is located in the middle of the city.

The self-built foil-greenhouse comprises 1000 sq. ft. and is filled with vertical growing towers and an aquaponic system. Currently, the farm has 1000 tilapia that are fed by the plants grown in Sean's greenhouse. "We're growing more than 20 plants here," says Sean, whereas we can grow up to 60 different plants and herbs."

Click on the video below to hear Sean's story.

23 Apr 2021

How Can 'Aquaponics' Farming Help Create Sustainable Food Systems?

Millions of people around the world go hungry every year, due to lack of access to healthy food and the effects of climate change on agricultural development

By Jaxx Artz

APRIL 23, 2021

Aquaponics has the potential to help people who are food insecure take control of the food system

Why Global Citizens Should Care

Millions of people around the world go hungry every year, due to lack of access to healthy food and the effects of climate change on agricultural development. Aquaponics is a sustainable growing method that has the potential to put food production into the hands of the people who experience food insecurity, giving them autonomy in controlling their access to safe and nutritious produce. Join us by taking action to strengthen our food systems and protect the planet here.

Global Citizens everywhere are increasingly recognizing the need for more sustainable career options to increase global food security.

According to a 2020 report from UNICEF on the state of food security and nutrition in the world, almost 690 million people went hungry in 2019, or 8.9% of the world population. This is due, in part, to the high costs associated with eating nutritiously, the lack of access to healthy food, and the effects of climate change devastating agricultural production systems.

As more government leaders commit to becoming carbon neutral by 2050, and more people choose to change their habits (like eating less meat) to reduce their carbon footprint, methods of food production that promote a harmonious relationship between humans and the environment are becoming more common.

One of these methods involves fish.

Aquaponics farming is a method of sustainable agriculture that forms a symbiotic relationship between fish and plants. It involves the use of a fish tank placed below a grow bed for plants, where the main input to the system is fish food.

When the fish produce waste, it is cycled out of the fish tank into the grow bed, where bacteria transform ammonia into nitrates that plants need to grow. The water is then filtered and returned to the fish tank, aiding in the highly optimized, zero-waste process of farming fish and plants together.

Yemi Amu, founder and director of Oko Farms in Brooklyn, New York, working on the outdoor aquaponics farm. Photo courtesy of Oko Farms.

The practice of aquaponic gardening can be traced back centuries. In central Mexico around 1000 AD, the Aztec people developed a technique known as chinampa to expand their growing efforts to the surface of lakes and ponds, according to the Permaculture Research Institute. By weaving together logs and sticks to create a “floating farm,” the Aztecs used water from the lakes and waste produced by fish to nourish crops.

Aquaponics also has roots in Southeast Asia, where farmers cultivated rice and fish concurrently, according to the United Nations' Food and Agriculture Organization. The practice of raising fish in rice fields became one of the best examples of polyculture farming as a method of sustainability.

Photo courtesy of Oko Farms.

In recent years, aquaponics has increasingly been chosen as a growing option for urban farmers, or those who practice agriculture in cities and must rely on vertical farming techniques when faced with less land area. Many of these aquaponics farmers choose to produce food for their communities, particularly in areas where economic inequalities threaten household food security.

Around the world, the environmental impacts of climate change are preventing low-income people from accessing sufficient, safe, and nutritious foods. To improve global food systems and decrease food insecurity, it is more important than ever for people to practice sustainable agricultural development.

To learn more about how aquaponics can aid in the production of sustainable food systems, Global Citizen spoke to Yemi Amu, founder, and director of Oko Farms, an aquaponics farm and learning center in Brooklyn, New York.

Global Citizen: Tell me a little about your background and how you became interested in agriculture.

Yemi Amu: My background is in nutrition and behavior modification. I spent a lot of my time at the beginning of my career really using a hands-on approach to guiding people to adopting healthy dietary habits and trying to understand what the barriers are. Things like knowing how to cook ... can be a barrier for people, and knowing what food to buy from the grocery store.

I also happened, at one point, to be working with a formerly homeless population, and for that particular group going out into the world — like leaving the neighborhood, going to the grocery store to shop — it was not practical for them. They are dealing with anxiety, and [going from] being chronically homeless to living in an apartment [is] a huge adjustment that most people don’t understand.

After working with them, I found that they were only eating well when I was preparing the food for them. When I wasn’t involved, they weren’t going on their own to get healthy food. And so after going back and forth with my colleagues, who were social workers, we decided, hey, you know what, the roof of the building where the residents lived would be a great place to grow food because it was intended to be a green roof. We decided, “Why not turn that into a farm?” and really that’s how my farming career started.

So how did your interest in aquaponics specifically come about?

I discovered aquaponics while I was on the roof. I learned how to farm along with the residents and had to learn about seasonal growing, what it’s like to grow in a soil-less environment, and how to grow in raised beds. I’m from Nigeria. I grew up in a city, in Lagos, and so the idea of people farming in a city wasn’t weird. But farming in New York City? It seemed so different, and so learning about aquaponics and how you don’t have to worry about watering plants, I just found it fascinating.

I started visiting farms around the country just to see how aquaponics works in practice and make sense of it. I saw how it could play a really big role in not just feeding people but also raising awareness about alternative agricultural methods. Around 2011, hydroponics [using nutrient-rich water for agriculture instead of soil] was becoming popular, and I thought it was so great to throw aquaponics in the mix. The system can work indoors or outdoors, it saves water, and Oko Farms was built a couple of years later.

Aquaponics is also a throwback to other cultures that have used it in the past. In Peru, in China — so many cultures around the world had these models that were rooted in the idea of raising animals and plants together. It was industrial agriculture that saw people no longer raising animals and plants in tandem, so it’s great that we can bring this centuries-old model back to the urban environment.

For people who experience drought, or live in an urban environment — can aquaponics improve food access, or be used in conjunction with other methods of sustainable agriculture?

I mean, this isn't a one-size-fits-all model. Aquaponics can absolutely be used in conjunction [with other methods of sustainable agriculture].

It’s not that there is anything wrong with soil, but we are living in a very complex environment. There are barriers for many communities to access food, like not having space to grow food, and aquaponics systems can be set up to address these barriers and ecological issues.

Aquaponics, in my experience, lends itself better to small-scale production. And I think that we can ultimately guarantee food security for those of us that live in urban areas. It doesn’t require a lot of land, it saves water. Water access is limited for a lot of people around the world, and we use a lot of water in agriculture specifically. Aquaponics can address this problem because it requires very little input of water.

Your work at Oko Farms emphasizes education, specifically around helping people learn to grow their own food, in food sovereignty. Can you speak to why that is important in the production of sustainable food systems?

I haven’t seen our current system support people, empower people, or ensure food security. Giving people the tools to [control their access to food] is important. Our workshop model supports people in building their own aquaponics system, and in an urban environment, it is important for us to have a space to teach the public about food systems.

At Oko, we donate some of the produce we grow, and then we sell some of it at farmers’ markets in the area. Sometimes people come to the farm and buy produce off the farm — they know it’s grown here. Aquaponics has helped us develop that system as we look to feed ourselves sustainably, or just feed ourselves, period.

This interview has been edited and condensed for clarity.

Peroxide UltraPure™ Produced Directly On-Site Improves Growth And Yield In Super-Intensive Olive Plantation

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions

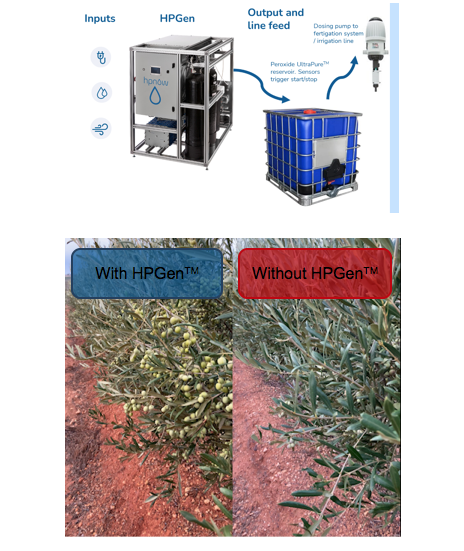

Successful Implementation of HPGen™

At 160 ha Olive Plantation In Alentejo, Portugal

The Alentejo region in Portugal is known for its long sunny days, which create ideal conditions for the growth of high-quality olives. Irrigation water in the region is sourced from the Alqueva dam, and especially in the summer months, it accumulates a high quantity of organic matter (algae, bacteria). This caused a problem for growers in the region specifically with drippers clogging, irrigation uniformity, and soil oxygenation. To address this situation, one of the largest olive plantation companies in the region, with more than 2000 ha, turned to NaanDanJain Ibérica and HPNow for help in a super-intensive plantation of young olive trees (2 years old) of 160 hectares.

HPNow, together with its channel partner NaanDanJain Ibérica, were able to identify this accumulation of organic matter from the dam in the drip irrigation lines which led to two main issues:

1. Organic matter was blocking a substantial amount of drippers, and as a consequence, the trees did not receive all water and fertilizer that they should.

2. The organic matter consumed dissolved oxygen in the water, another essential nutrient for proper tree development.

These two issues led to a slower tree development, which was very visible in this young plantation and threatened the viability of the operation.

To correct this situation, an HPGen™ system was installed at the plantation, producing Peroxide UltraPure™ that was injected in the drip lines of half of the plantation (80 ha). The other 80 ha did not receive any dosing.

Peroxide UltraPure™ had a dual effect in the olive field:

1. Oxidation of organic matter in the lines, which kept the drippers free of clogging and allowed plants to receive all the required water and fertilizer.

2. After Peroxide UltraPure™ is used for oxidation of organic matter, it becomes water and oxygen. This extra oxygen increases levels of dissolved oxygen in water, which acts as a nutrient and has a positive impact on the development of the root system and plant health.

The response of the trees was monitored for a full growing season. The trees in the section with Peroxide UltraPure™ clearly had more vegetative growth, and the coloration on the leaves was also deeper, indicating improved nutrient absorption. When comparing yields, Peroxide UltraPure™ resulted in higher production.

The farm manager expressed his enthusiasm about the solution: “With the HPGen system the olive trees look better, healthier, and all drippers are working. I noticed a much better irrigation uniformity, which translates to higher production”.

Better growth, higher yields

With those results, the olive trees are well irrigated and receive the nutrients they require, which clearly contributes to better growth and higher olive yields. The results are explained by the oxidizing power of Peroxide UltraPure™, which will keep irrigation lines clear, while oxidizing organic matter in the irrigation lines and making extra oxygen available to the crop. This ensures irrigation lines are clean and drippers flowing, getting water and fertilizer uniformly throughout the field while at the same time improving plant nutrition.

About HPNow

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions. Headquartered in Copenhagen, and with representation across Europe, the Americas, and Asia, they address their clients’ water treatment needs in market segments ranging from agriculture and aquaculture, to industrial and drinking water treatment. HPNow is a technology and market leader in the on-site generation of hydrogen peroxide and is continuously striving to further advance its technology and products in order to meet growing market needs and rising global demand.

Stay in the loop by following HPNow on LinkedIn and Facebook.

Kalera Announces The First Harvest For Atlanta Vertical Farming Facility That Will Produce Over 10 Million Heads of Lettuce Per Year

The new facility will supply schools, restaurants, grocery stores, hospitals, retailers, and more with safe, fresh, nutrient-dense, locally-grown greens

The new facility will supply schools, restaurants, grocery stores, hospitals, retailers, and more with safe, fresh, nutrient-dense, locally-grown greens

April 27, 2021

Source: Kalera

ATLANTA, April 27, 2021 (GLOBE NEWSWIRE) -- Kalera (Euronext Growth Oslo ticker KAL, Bloomberg: KSLLF), one of the fastest-growing US vertical farming companies in the world and a leader in plant science for producing high-quality produce in controlled environments, today celebrated their first harvest in their Atlanta-area facility. Its largest farm to date — and the largest vertical farm in the Southeastern United States — the facility is 77 thousand square-feet and has the capability of producing over 10 million heads of lettuce per year. Located in Forest Park, GA, the farm was built in just eleven months thanks in large part to the company’s modular building approach and has created dozens of new jobs in the Atlanta area.

“Our new Atlanta facility is open and performing in line with our expectations and we are eager to begin offering our local, fresh, safe, sustainable greens to the Georgia market,” said Daniel Malechuk, CEO of Kalera. “Our customers are telling us that there has never been a better time to ensure supply continuity, locally, than now and we are grateful Kalera can provide this.”

Kalera’s optimized nutrient and light recipes allow them to grow high-quality, pesticide-free, non-GMO produce at accelerated growth cycles. Planting at the Atlanta facility began in early March, and the first harvest began successfully last week. Kalera has so far experienced optimal operating efficiencies in Atlanta, particularly in terms of lighting productivity. All growth systems, environmental equipment, and technology have operated effectively since opening the facility on March 11. Due to strong sales indications in the region from both retail and foodservice customers, Kalera is implementing a faster ramp-up schedule than originally planned.

The facility’s location near the urban center of Atlanta cuts down on travel times for retailers, restaurants, and other customers who want access to the freshest, non-GMO, clean living lettuces and microgreens. Royal Food Service, a leading produce distributor in the state, is one of Kalera’s top partners bringing “pick-to-plate” greens to restaurants, hotels, schools, and other businesses including Ansley Golf Club, The Ritz-Carlton at Reynolds, Lake Oconee, The Georgia World Congress Center, several restaurants and many others. The lettuce is also available on the shelves of Publix Supermarkets.

“As the former Governor of Georgia, I could not be more excited that Kalera’s delicious greens are now available in the Atlanta area,” said Sonny Perdue, former U.S. Secretary of Agriculture, who joined Kalera’s Board of Directors earlier this year. “Kalera is leading the pack in a booming vertical farming industry. It’s a perfect example of the power of American innovation, creativity, and entrepreneurship to develop different, innovative ways to grow and provide food at home and around the globe.”

Kalera currently operates three growing facilities – two in Orlando and one in Atlanta and is building facilities in Houston, Denver, Columbus, Seattle, Minnesota, and Hawaii. Kalera is the only controlled environment agriculture company with coast-to-coast facilities being constructed, offering grocers, restaurants, theme parks, airports, and other businesses nationwide reliable access to locally grown clean, safe, nutritious, price-stable, long-lasting greens. Once all of these farms are operational, the total projected yield is several tens of millions of heads of lettuce per year. Kalera uses a closed-loop irrigation system which enables its plants to grow while consuming 95% less water compared to field farming.

Recently, Kalera also acquired Vindara, a seed company that uses genomics, machine learning, and computational biology along with traditional breeding methods to meet the market need for produce that is non-GMO, nutritious, high-yielding, and delicious. Explicitly intended for the new high-tech indoor growing environments, Vindara seeds offer growers the opportunity to capitalize on significantly higher yield potential, production efficiencies, and product customization — in a fraction of the time through reducing the grow cycle.

ABOUT KALERA

Kalera is a technology-driven vertical farming company with unique growing methods combining optimized nutrients and light recipes, precise environmental controls, and cleanroom standards to produce safe, highly nutritious, pesticide-free, non-GMO vegetables with consistently high quality and longer shelf life year-round. The company’s high-yield, automated, data-driven hydroponic production facilities have been designed for rapid rollout with industry-leading payback times to grow vegetables faster, cleaner, at a lower cost, and with less environmental impact.

Media Contact

Molly Antos

Phone: (847) 848-2090

Email: molly@dadascope.com

USA: BALTIMORE - Hydroponic Operation Supplies High-End Restaurants

Growing vegetables in a shipping container have opened new marketing opportunities for a Baltimore County farm

Art Petrosemolo, Southeastern Pennsylvania Correspondent

Apr 23, 2021

Growing vegetables in a shipping container have opened new marketing opportunities for a Baltimore County farm.

The hydroponic growing system has allowed Karma Farm to sell fresh produce regardless of the season to high-end restaurants in Baltimore and Washington.

“Today we are delivering leafy greens and herbs year-round to a growing customer base,” said Jon Shaw, founder of the family operation.

The farm, which makes multiple weekly deliveries to 27 customers, has picked up clients through word of mouth and sampling visits arranged with chefs who find the farm on social media.

“Well-known chefs talk and move from restaurant to restaurant ... and they have brought us with them,” Shaw said.

The farm got its start just over a decade ago when Shaw was growing produce on 5 acres, both outside and in hoop houses, for retail sale as well as a nearly 100-member CSA.

Karma Farm purchased a freight container vertical hydroponics Leafy Green Machine from Freight Farms in Boston in 2017. Photo by Art Petrosemolo

Jon’s 28-year old son, Nat, learned the business from his dad as a teenager, and in the past few years he has helped Karma Farm pivot to the new customer base, embracing the new ag technologies.

Nat, now the farm’s hydroponic production manager, researched vertical growing in insulated shipping containers while he was studying entrepreneurship at the University of Baltimore and thought the year-round production method would be a good fit.

“Hydroponic container farming is still relatively new and is being introduced to farmers in parts of the country where short growing seasons, weather, and soil conditions make profitable, small family farming difficult,” he said.

With a feasibility study completed and a new focus for the business, the Shaws purchased a Leafy Green Machine container in 2017 from Freight Farms in Boston. The container is 40 feet long by 8 feet wide.

“These are the insulated type of refrigerated containers used to ship fresh produce across the country,” Nat said.

With delivery and setup, the container cost about $100,000.

Lead photo: Nat Shaw, left, and his dad, Karma Farm owner Jon Shaw, stand in their freight container.

USA: Zenat Begum Turned A Bustling Brooklyn Street Corner Into A Working Greenhouse

She reached out to Jasper Kerbs of the Cooper Union Garden Project and, with the help of several volunteers, the structure was erected in October of last year. The shop is utilizing one of the city’s outdoor vending permits and they’re in the midst of harvesting this month

The owner of Playground Coffee Shop transformed the cafe’s outdoor dining space into a project centered around care, creativity, and community

April 21, 2021

“I’m inviting people that I love to come and dress up the facade,” Zenat says of the greenhouse's verdant mural by artist Tiffany Baker. “I’m inviting people that I really respect to come and build these things because we deserve the best.”Image courtesy of Zenat Begum

To understand how a fully functioning greenhouse ended up at the busy intersection of Quincy Street and Bedford Avenue in Bed-Stuy, Brooklyn, it’s important to get to know Zenat Begum, the owner of Playground Coffee Shop.

Zenat opened the shop back in 2016, in a space that previously housed her father’s hardware store, and quickly expanded to include the Playground Annex, which houses a radio station and bookstore, as well as Playground Youth, a nonprofit organization dedicated to issues confronting the community, including literacy and food equity.

“I believe in Bed-Stuy. I believe in myself. I believe in the shop. I believe in the greenhouse,” says Playground Coffee Shop owner Zenat Begum. “These are things that are active radical attempts. We are imagining our futures because these things aren’t going to be built for us.”Image courtesy of Zenat Begum

Providing for the community is fundamental to each project that the Playground team takes on. “Every time we do something, we change and raise the bar of what should be done in our communities,” Zenat explains. “I’m talking about being able to keep implementing this really large notion and understanding of entrepreneurship into taking care of your communities.”

Shortly after the pandemic hit, Playground got to work on several mutual aid projects. The team established a take-one-leave-one library that distributes works exclusively by writers of color, assembled a network of volunteers distributing PPE and essential supplies at Black Lives Matter protests, and they worked with organizers to create a network of community fridges providing free produce 24 hours a day.

It was while working on the fridge project that the idea for the greenhouse began to crystalize, in realizing that fundamentally addressing the issues surrounding food sovereignty wasn’t, as she says, “as simple as just donating a fridge.”

Zenat cites the statistics: One in three kids in New York City are food insecure, and one in 10 in public schools experience homelessness. She probed further, looking at obesity and food deserts and gentrification. “Let’s reel it back: Why aren’t there programs that support Black and brown families who can’t support their children with adequate nourishment and nutrition?”

“It made me really frustrated. We need to have a plot of land that grows for this. We need to get an actual farm to be able to grow food for this,” Zenat says. And never having built a greenhouse before didn’t scare her off. “I don’t really have the tools,” she thought. “But I also know that, for the understanding that I have and the experience that I’ve had growing up in New York, I know what a New Yorker deserves, which is a lot more.”

She reached out to Jasper Kerbs of the Cooper Union Garden Project and, with the help of several volunteers, the structure was erected in October of last year. The shop is utilizing one of the city’s outdoor vending permits and they’re in the midst of harvesting this month.

When they’re able to resume programming, Zenat intends to teach kids in the neighborhood how to get involved and have plots so they can start growing together. “The most important thing about this is that this will be an opportunity for kids who live in Bed-Stuy to see food growing, to show them that there is life that starts at fertilizing and that we can be involved in the process of food distribution and food harvesting from the very beginning.”

“Our greenhouse is straight up on the street. I want people to see that these structures have to and should exist.”Image courtesy of Zenat Begum

And she acknowledges the responsibility and history that comes with this endeavor. “We’re on stolen land right now,” Zenat says. “We’re thinking about farming practices that date back to East Asia, which is where my family is from, and sharecropping that was implemented during the period just after slavery, which is one of the darkest times in history, period. But with all of those tragedies and travesties occurring, there is this sense of land and relationship that we have that we need to bring back to ourselves. It’s ancestral, of course, and it’s spiritual, but most importantly it’s territorial. Why is it that Black and brown people have a hard time with housing and food insecurity when we have literally created some of the most adequate and sophisticated food systems in the world? Our bodies are used to actually supply people with this type of food and nourishment.”

“So there’s many things that we’re addressing here, but I only hope that at surface level we’re talking about things that actually make a difference, which is ultimately feeding children.”

In true Playground style, the greenhouse is one of many initiatives in the works—from financial literacy courses and book clubs to bystander intervention trainings. Given Zenat’s dedication, there’s no doubt they’ll come to fruition. “The way that I love New York is so poetic. I’m like one of those gnarly girlfriends, ‘Did you eat today? Do you want water?’” She asks the city: “Did you eat today, New York? Do you want water? Do you want a pillow?”

If you’d like to support Playground Youth, there is a fundraiser underway for programming and operational costs.

CEA Food Safety Coalition Launches First-Ever Food Safety Standard For Indoor-Grown Produce

The CEA Food Safety Coalition was founded in 2019 to represent the interests of CEA leafy greens growers in developing credible and appropriate food safety standards while educating consumers and regulators alike on the value of controlled environment agriculture

The Coalition, founded by industry leaders in greenhouse and indoor farming, developed the food safety addendum to address the unique attributes of CEA-grown leafy greens