Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Large-Scale Automated Vertical Farm Near Tokyo by Spread And ENEOS Partnership

Techno Farm Narita is Spread’s first partnership project and the first to be located in Eastern Japan

July 14, 2021, Spread Co., Ltd. (HQ: Kyoto, Japan; CEO: Shinji Inada, hereinafter “Spread”)’s partner, and a member of ENEOS Group, J Leaf Corporation (HQ: Chiba, Japan; President: Jun Uehara, hereinafter “J Leaf”) started operating the automated vertical farm “Techno Farm Narita” (Chiba, Japan) on 30th of June.

Spread’s Large-Scale Vertical Farming Partnership with ENEOS Group’s J Leaf Starts Operations near Tokyo

Spread owns and operates two vertical farms in Western Japan (Kyoto), the Kameoka Plant and Techno Farm Keihanna. Techno Farm Narita is Spread’s first partnership project, and the first to be located in Eastern Japan. The most significant feature of Techno Farm Narita is the increased efficiency in the use of land. This has been achieved by increasing the number of cultivation racks levels to 28, double that of Techno Farm Keihanna. Techno Farm Narita will produce 30,000 heads of lettuce daily, building on the know-how accumulated through the operation of Techno Farm Keihanna to deliver increasingly sustainable food production.

Unique Features of Techno Farm Narita

Even more efficient land saving through 28-level cultivation rack system (roughly 2 times more efficient than Techno Farm Keihanna)

Located in the Greater Tokyo Area, allowing for local production and consumption

Transforming idle land to efficient and sustainable agriculture ・

The utilization of renewable energy generated from solar panels

Techno Farm Narita also retains other features of Spread’s next-generation food production system, Techno Farm™, including pesticide-free, stable cultivation, integrated automation, specialized LED lighting, and Spread’s proprietary IoT-based cultivation management system, Techno Farm Cloud.

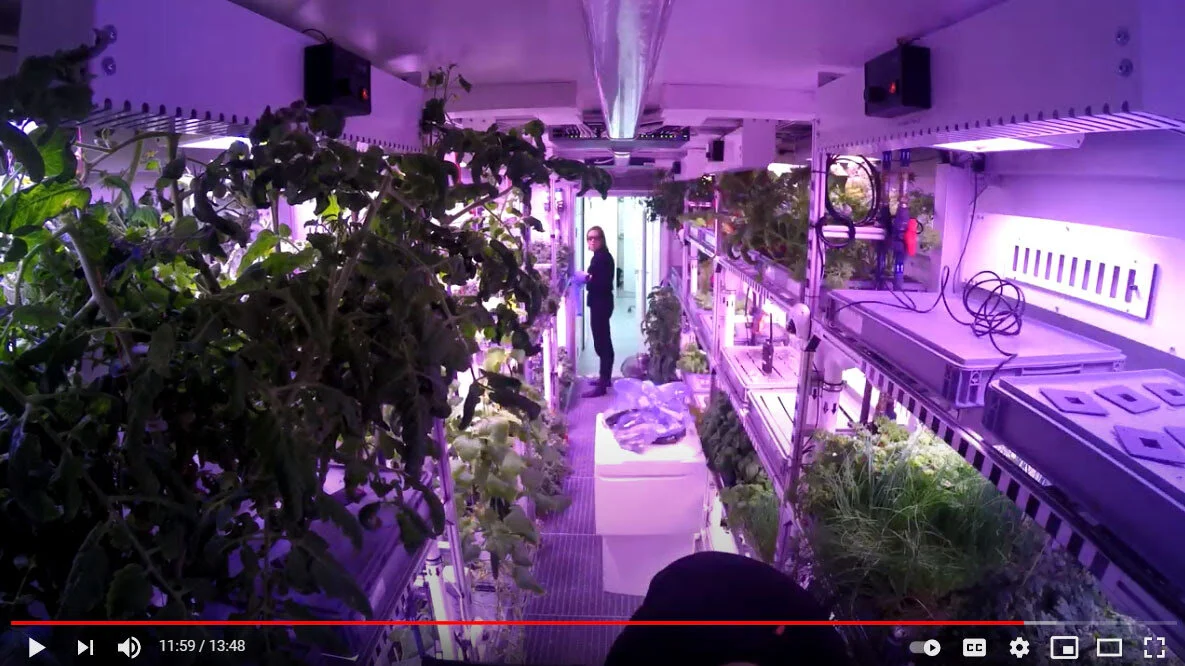

Techno Farm Narita’s Cultivation Room Opening Ceremony

About the Partners

ENEOS Group is one of Japan's leading corporate groups, with revenue in excess of 10 trillion yen. *1

The Group has the largest market share in oil refinery and petrochemicals distribution in Japan and is centered around ENEOS Holdings.

Spread’s vision is to create a sustainable society where future generations can live with peace of mind. On the way to this objective, Spread plans to reach a total production capacity of 100 tons per day domestically by 2030, through the expansion of its Techno Farm™. With the collaboration at Techno Farm Narita as a foundation, both parties are considering further partnership projects. The green business market is expected to continue growing, and Spread strives to become a leading vertical farming company globally.

Spread will continue to pursue further business opportunities through technological innovation both in Japan and overseas. Spread aims to provide solutions for the global problems of climate change and food security and the delivery of a truly sustainable society.

*1 FY2019 results (announced on May 20, 2020)

*2 ENEOS Techno Materials Corporation is a member of ENEOS Group

BASF Venture Capital Invests In Indian Startup UrbanKisaan

With the investment from BASF, UrbanKisaan plans to further expand its market presence in India, deploy its farming technology to work with thousands of farmers, and bring fresh, local, sustainable produce to urban dwellers

Startup optimizes sustainable agriculture without soil in tropical climates

■ BASF Venture Capital’s first investment in this early stage Indian business strengthens AgTech activities in Asia

Hyderabad, India, and Ludwigshafen, Germany, July 13, 2021 – BASF Venture Capital GmbH (BVC) is investing in the Indian startup UrbanKisaan, which specializes in hydroponic cultivation of various types of vegetables, greens and herbs in tropical urban environments. This is BVC’s first investment in an early stage business focusing on India. Conceptualized in 2017, UrbanKisaan operates several suburban greenhouses and vertical indoor farms in Hyderabad and Bangalore. The company sells the fresh produce, some of which is grown directly in the shops, in its franchise-owned brick-and-mortar stores and via an app and website. Both parties agreed not to disclose financial details of the investment.

UrbanKisaan has optimized hydroponics technology for use in tropical climates such as India. With only one tenth of the costs, the proprietary technology is significantly more efficient than conventional global standards in hydroponics cultivation. The company is also capitalizing on the trend of online food retailing, which is booming on the subcontinent. “Our approach in hydroponics enables us to produce our food cost-effectively and with relatively little effort,” said Vihari Kanukollu, co-founder and CEO at UrbanKisaan. “Our produce also contributes towards sustainability as it is grown in clean, hygienic farms in and around the city, thus minimizing the total carbon footprint. Use of IoT (Internet-of-Things)-enabled technology for monitoring the farms ensures pesticide-free produce. The growing demand from our customers shows that our idea is well-received,” he added.

UrbanKisaan’s farms are managed through their proprietary technology. Nutrient content, pH levels, atmospheric humidity, CO2 concentration, light concentration and other important parameters are controlled and adapted to the needs of the particular plants with an app.

“UrbanKisaan, as a pioneer in the hydroponics space, has developed a unique growing method and combines this with a compelling business model for sales,” commented Markus Solibieda, Managing Director of BASF Venture Capital GmbH. He added: “AgTech is one of our key investment focus areas worldwide. This includes, in particular, our goal of supporting innovative agricultural and food-related businesses in Asia. We look forward to learning more about hydroponic farming and exploring its potential through a close collaboration between UrbanKisaan and BASF’s agriculture experts.”

With the investment from BASF, UrbanKisaan plans to further expand its market presence in India, deploy its farming technology to work with thousands of farmers, and bring fresh, local, sustainable produce to urban dwellers.

Hydroponic farming – an efficient way to use limited resources

The world’s population is expected to reach 10 billion by 2050 1 while the area available for farming and freshwater reserves are becoming increasingly scarce. Hydroponics offers a sustainable way to grow crops without soil and using vertically stacked layers while reducing water usage by about 90 percent 2. Especially in densely populated urban areas, this presents a more efficient way to use limited resources like water, space and manpower. Water that is not absorbed by the plants is captured, purified and fed back into the farm’s water circulation system, minimizing wastage significantly.

India is the second-largest producer of fruits and vegetables in the world, with a production value of about $64 billion3. It is also a large consumer of fruits and vegetables, and while much of this is through unorganized channels (local vegetable markets, hand-pulled carts and neighborhood stores), organized channels (modern trade and online retail) account for a little over 20 percent of the market4. Thus, hydroponics is a fast growing and efficient alternative to traditional supply chains in the organized fresh produce market.

About UrbanKisaan

UrbanKisaan was conceptualized in 2017 in Hyderabad, India. The company began as a farming enterprise but wanted to grow more than just fresh and nutritious food. They wanted to create a sustainable future for farming and feed the world in a way that is good for both people and planet. Today, with its hyper-local urban farms the company is creating a transparent supply chain with a low carbon footprint, leveraging on proprietary growing technology that helps save 90% of water yet grow 30 times more crops compared to traditional farms of similar area. Further information at www.urbankisaan.com.

About BASF Venture Capital

At BASF, we create chemistry for a sustainable future. BASF Venture Capital GmbH (BVC) also contributes to this corporate purpose. Founded in 2001, BVC has offices in Europe, the U.S., China, India, Brazil, and Israel. BVC’s goal is to generate new growth potential for current and future business areas of BASF by investing in young companies and funds. The focus of investment is on new materials, AgTech, Digitization and new, disruptive business models. Further information at www.basf-vc.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. More than 110,000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €59 billion in 2020. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S. Further information at www.basf.com.

3 Fruits & Vegetables Production value at Current Prices for 2015-16, Horticultural Statistics at a Glance 2018, Government of India, Ministry of Agriculture and Farmers Welfare

4 Avalon Consulting - http://www.fruitnet.com/asiafruit/article/178572/india-on-the-move

PODCAST: This Weeks Episode - Season 3 Episode 35

Join Harry Duran, host of Vertical Farming Podcast, as he welcomes to the show, co-founder and Chief Marketing Officer at AeroFarms, Marc Oshima. AeroFarms is an award-winning indoor farming company that is on a bold mission to grow the best plants possible for the betterment of humanity

Join Harry Duran, host of Vertical Farming Podcast, as he welcomes to the show, co-founder and Chief Marketing Officer at AeroFarms, Marc Oshima. AeroFarms is an award-winning indoor farming company that is on a bold mission to grow the best plants possible for the betterment of humanity.

Today, Harry and Marc talk about Marc’s background in marketing and how it has impacted his work at AeroFarms. Marc provides his thoughts on the concept of ‘speed breeding,’ speaks to his passion for food, and expounds on the concept of utilizing business as a force for good

Listen & Subscribe

1200% Increase In Production At ENOGROW In Times of A Pandemic!

One step closer to food sovereignty in New Brunswick Canada. 1200% increase in production at ENOGROW in times of a pandemic!

July 11, 2021

One step closer to food sovereignty in New Brunswick Canada. 1200% increase in production at ENOGROW in times of a pandemic!

Thanks to an equipment investment upgrade valued at nearly $250,000. ENOGROW, an indoor vertical hydroponic farm, located in Saint-Léolin NB, will see a production increase of leafy vegetables from 7,500 to

nearly 100,000 heads grown per year by the end of 2021. Due to the owners Chantal and Daniel Ratté hard work, perseverance and imagination, this amazing production surge occurs after less than 18 months of operation and in the midst of a worldwide pandemic.

Cultivation in a controlled environment takes place inside the former Le Maillon school, a 2280sqm building on 4 acres of land 12 month a year! ENOGROW currently offers their products to grocery stores, restaurants and on-site to the local population. With the above upgrades, along with a new refrigerated truck, the company will expand its customer’s network to Miramichi and Campbellton areas, and soon to southern New Brunswick as well.

Due to climate change, supply issues and the ever-growing demand for fresh local produce, this indoor hydroponic farm takes NB residents one step closer to food sovereignty year long!

This innovative indoor hydroponic farm grows nearly 20 different products year round, including 4 kinds of lettuce, various herbs and microgreens from organic seeds. All of this healthy produce is grown without soil, pesticides, herbicides or chemical residue, using 90% less water in only 10% of the space required by conventional cultivation.

The company is already working on their new goal for 2022, with expectations of 200,000 heads produced, a step closer to the final goal of 750,000 heads annually by 2025. This would create nearly 20 permanent jobs and serve New Brunswick, Prince Edward Island, Nova Scotia and Newfoundland with fresh and local leafy vegetables 12 months per year.

This is quite a challenge for Chantal and Daniel, whose company began their operations in November 2019, less than 3 months before the start of the pandemic. They work almost 80 hours a week. “We never thought

we had the ability to work this hard, especially me at 62 years old, says Dan. Advice to anyone thinking of beginning this kind of agricultural that request a high production volume to be profitable. This is real farm work, and it is year round, Dan explains!

The final commissioning of the new equipment is scheduled for end of July.

Daniel Ratté Pres.

Enogrow Inc.

916 Boul. Saint-Joseph,

Saint-Léolin, NB E8N 2P8

danielr@enogrow.com

Off: 506-604-4400 Cell:506-720-2007 FB: Enogrow

FRANÇAIS

06 Juillet 2021

Plus près de la souveraineté alimentaire au NB. Augmentation de 1200% de la production de légumes à feuilles chez Enogrow en temps de pandémie!

Grace à un investissement en équipements d’une valeur de près de $250,000, la ferme hydroponique verticale intérieure ENOGROW de Saint-Léolin verra sa production de légumes à feuilles passer de 7500

à près de 100,000 têtes cultivées par année d’ici la fin de 2021. C’est grâce au travail acharné, persévérance et imagination, des deux propriétaires Chantal et Daniel Ratté que cette incroyable augmentation de production se produit après moins de 18 mois d'exploitation et au milieu d'une pandémie mondiale.

Dû au changement climatique, problèmes en approvisionnement et ses coûts, ainsi qu’à la forte demande en produits frais local sans cesse grandissante, cette ferme hydroponique intérieure permet aux résidents du NB de franchir un pas de plus vers la souveraineté alimentaire.

La culture sous environnement contrôlée, se fait à l’intérieur de l’ancienne école Le Maillon, un bâtiment de 2280mc sur 4 acres. Ils offrent présentement leurs produits aux marchés d'alimentation, restaurants et sur place pour la population locale. Par cet ajout d’équipement et d’un camion réfrigéré, l’entreprise peux maintenant étendre son réseau de clients vers Miramichi et Campbellton et bientôt le sud du nouveau Brunswick.

La ferme hydroponique intérieure d’avant garde cultive près de 20 produits différents, dont 4 sortes de laitue incluant la romaine, fines herbes et micro-pousses à partir de graine graines organiques, sans terre, insecticides, herbicides ou résidus de produits chimique, en utilisant 90% moins d'eau en utilisant seulement 10% de l’espace requis par la culture conventionnelle et ce 12 mois par année!.

L'entreprise travaille déjà sur leur nouvel objectif pour 2022 qui devrait être près des 200,000 têtes produites en route vers son but final de 750,000 produites annuellement d'ici 2025. Ceci créera près de 20 emploies permanents et pourra servir le Nouveau Brunswick, Ile du Prince Edward, la Nouvelle-Écosse et Terre neuve en légumes à feuilles frais et local.

C’est tout un défi à relever pour Chantal et Daniel dont l’entreprise a démarré ses opérations en novembre 2019, soit moins de 3 moins de mois avant le début de la pandémie. Ils y travaillent près de 80 heures par semaine. ‘’ On ne pensait jamais avoir à travailler autant spécialement moi à 62 ans. C’est un pensez y bien avant, pour ceux et celles qui désirent se lancer dans ce genre d’agriculture qui demande un haut volume pour atteindre la rentabilité. C’est un travail de ferme mais à longueur d’année explique t-il!

La mise en service des nouveaux équipements est prévue fin juillet.

Daniel Ratté Prés.

Enogrow Inc.

916 Boul. Saint-Joseph,

Saint-Léolin, NB E8N 2P8

danielr@enogrow.com

Off: 506-604-4400 Cell:506-720-2007 FB: Enogrow

It’s All In The Mix – ams-Osram Presents White LED For Highly Efficient Horticulture Lighting

ms-OSRAM (SIX: AMS), a global leader in optical solutions, is expanding its comprehensive horticulture portfolio with the Osconiq S 5050

June 24, 2021

Premstaetten, Austria — ams-OSRAM (SIX: AMS), a global leader in optical solutions, is expanding its comprehensive horticulture portfolio with the Osconiq S 5050. There is an ideal light recipe for each plant that includes "ingredients" such as the required wavelengths, intensity, average illumination duration and much more. Operators of greenhouses and so-called indoor farms naturally want to be as energy-efficient as possible in addition to maximizing yields. ams-Osram’s Osconiq S 5050 addresses a key problem of often used white LEDs resulting in lower energy costs and more efficient lighting to luminaire manufacturers and indoor farmers.

In indoor farming, red and blue or alternatively red and white LEDs are the predominate combinations found today. Standard white LEDs used to grow plants also emit light in the red wavelength range, which could be covered by direct emitting red LEDs in the lighting system instead. In addition, classic white LEDs require considerably more energy than a directly red-emitting LED would for a comparable number of red photons. “Our new Osconiq S 5050 now enables a higher system efficacy of red-white spectra by reducing the share of phosphor converted red photons. With this concept, growers are now able to save energy costs significantly,” explains Thomas Grebner, Marketing Manager at ams-Osram. The special phosphor used in the Osconiq S 5050 cuts the red part of the spectrum, so to speak. The red component in the white light of the LED is therefore considerably lower.

The Osconiq S 5050 enables compact luminaire designs for manufacturers thanks to its space-saving dimensions of just 5.0 mm x 5.0 mm x 0.7 mm. The mid-power LED also boasts an efficiency of 2.86 µmol/J and an optical output of 630 mW. In addition, the device, which can be operated in a range of 180 to 1050 mA depending on the target application, is protected against overvoltages of up to 8 kV.

Horticulture technologies from ams-Osram not only help to produce food independently of location, in a space-saving manner and without the addition of pesticides, they also make it easy for consumers in urban areas to obtain fresh and healthy food quickly.

Further information about horticulture lighting can be found on our website.

The Osconiq S 5050 expands ams-Osram's comprehensive horticulture lighting portfolio and significantly increases the energy efficiency of lighting solutions thanks to a new type of phosphor. Image: Osram

Combined with red LEDs for horticulture lighting, white LEDs provide the right spectrum for the growth of various plants.

About ams-OSRAM

The ams-OSRAM Group, including the listed companies ams AG as parent company and OSRAM Licht AG, is a global leader in optical solutions. By adding intelligence to light and passion to innovation, we enrich people’s lives. This is what we mean by Sensing is Life.

With over 110 years of combined history, our core is defined by imagination, deep engineering expertise and the ability to provide global industrial capacity in sensor and light technologies. We create exciting innovations that enable our customers in the consumer, automotive, healthcare and industrial sectors maintain their competitive edge. We thereby drive innovation that meaningfully improves the quality of life in terms of health, safety and convenience, while reducing impact on the environment.

Our around 30,000 employees worldwide focus on innovation across sensing, illumination and visualization to make journeys safer, medical diagnosis more accurate and daily moments in communication a richer experience. Our work creates technology for breakthrough applications, which is reflected in over 15,000 patents granted and applied. Headquartered in Premstaetten/Graz (Austria) with a co-headquarter in Munich (Germany), the group achieved well over USD 5 billion combined revenues in 2020 (pro-forma).

ams AG is a listed company on the SIX Swiss Exchange (ISIN: AT0000A18XM4). OSRAM Licht AG remains a listed company on the XETRA market in Germany (ISIN: DE000LED4000).

To find out more about us on https://ams-osram.com

ams is a registered trademark of ams AG. In addition many of our products and services are registered or filed trademarks of ams Group. All other company or product names mentioned herein may be trademarks or registered trademarks of their respective owners. Information provided in this press release is accurate at time of publication and is subject to change without advance notice.

Please note: The ams brand is owned by ams AG, the OSRAM brand is owned by OSRAM GmbH. ams group and OSRAM group are in the process of integration. The combination of the ams and OSRAM brand is not representing a new brand. This is a visual symbol of the two companies coming together, representing the aspiration of our future joined group.

2021 Global CEA Census Will Measure The Impact of Sustainability

This is the third year the Census has run with an increasing participation each year from greenhouse, indoor vertical, and tunnel house growers. Past Census reports have brought forward key information on the state of the industry, tactics being used, and the people behind its many operations

7 July 2021: The 2021 Global CEA Census has launched with a focus on growers’ perspectives on sustainability and how they are measuring specific ESG (environmental, social, and governance) outcomes.

This year Agritecture Consulting will partner with AgTech leader WayBeyond who has taken over the responsibility of the Census from automation business Autogrow.

“Our WayBeyond ethos for sustainable crop production technology fits perfectly with this year’s Census. Understanding the impact of CEA (Controlled Environment Agriculture) on the planet allows us to continue highlighting the growers doing remarkable work to reduce environmental impact while producing quality crops.

There’s clear evidence showing consumers, particularly Gen-Z, are making decisions based on the sustainability factor of not only the food they eat but also the packaging, distribution and producers themselves. This Census will give a clear view of the role CEA can play in creating a more sustainable planet.”

— WAYBEYOND CEO & FOUNDER DARRYN KEILLER

This is the third year the Census has run with increasing participation each year from greenhouse, indoor vertical, and tunnel house growers. Past Census reports have brought forward key information on the state of the industry, tactics being used, and the people behind its many operations. For example, the 2020 report showed that there was plenty of optimism despite the pandemic, with 95% of respondents having an “excellent” or “good” outlook for the 12 months ahead, and only 5% indicating that the business’ future was uncertain.

“We work hard to encourage as many growers to participate as possible and, with a focus on sustainability, we hope to gain an even better uptake this year, especially from large-scale operations.

This is the most comprehensive global survey of CEA operations running, and the published findings will provide valuable insights that may affect policy, financing options, operational practices, and new technology. That is a benefit for all of us in the industry.”

— AGRITECTURE CONSULTING FOUNDER AND CEO HENRY GORDON-SMITH

The 2021 Global Census will run from 7 July 2021 until 20 August 2021.

Take the survey: Global CEA Census

Survey Terms and Conditions can be found here.

Manage Only The Environment That Matters: The Canopy

AgricUltra is a Canadian company that designs and develops turnkey, multi-layer grow platforms that are engineered to optimize inter-canopy control and management. The company also conducts research and development related to UV lighting.

July 5, 2021

“We offer a completely integrated product and take all of the guesswork out, whether it relates to chillers, controls, air handling units, adjustable nozzles, etc.,” says Emil Breza, co-founder, president and CEO of AgricUltra Advancements.

AgricUltra is a Canadian company that designs and develops turnkey, multi-layer grow platforms that are engineered to optimize inter-canopy control and management. The company also conducts research and development related to UV lighting.

AgricUltra Advancements was officially incorporated in August 2018 and specializes in four keys areas: controlled environment agriculture, computational fluid dynamics analysis (CFD), systems design & engineering and photobiology. While the company designed its systems for medical cannabis production, AgricUltra believes that its system can be applied to any vertical farm and will be trialing berry production at its new research center and unit.

Decisions rooted in CFD analysis

As Emil explains, computational fluid dynamics modeling allows the company to accurately model airflow in an existing or proposed grow room. AgricUltra can visualize how heat, humidity and temperature interact to create humidity pockets, temperature stratifications or impeded airflow.

“At AgricUltra, we create a very accurate representation of the physical environment (from room level to canopy level) as well as the environmental setpoints (Temp, RH, CFM, heat inputs, etc) and let the software compute the complex interactions that result. Then we can identify problem areas and come up with viable solutions. That’s the power of CFD analysis. It helps you find mistakes that you can’t otherwise see,” says Emil.

Read the complete article at: Vertical Farm Daily

For more information:

Emil Breza, Co-Founder, President and CEO

AgricUltra Advancements

www.agricultra.com

yanna@agricultra.com

Hong Kong's Urban Farms Sprout Gardens In The Sky

Invisible to those below, a sprawling garden of radishes, carrots and rhubarb is flourishing at the top of the 150-metre tall Bank of America tower, a stark and colourful contrast to the monotone shades of concrete, steel and glass of the city's financial district.

By Celia Cazale

July 9, 2021

With their heads in the clouds and their hands in the soil, a group of office workers are busy harvesting the fruits of their labour on the roof of a Hong Kong skyscraper.

Invisible to those below, a sprawling garden of radishes, carrots and rhubarb is flourishing at the top of the 150-metre tall Bank of America tower, a stark and colourful contrast to the monotone shades of concrete, steel and glass of the city's financial district.

The farm is among more than 60 that have sprouted across the space-starved city since 2015—on decommissioned helipads, shopping mall rooftops and public terraces—thanks to initiatives like Rooftop Republic, a local social enterprise which promotes urban farming.

Cofounder Andrew Tsui sees the rooftop farms as a way for people to reconnect with how sustainable food can be produced in what he calls the current "instant-noodle city lifestyle" that sees so much waste.

"What we are looking at is really how to identify underutilised spaces among the city and mobilise the citizens, the people, to learn about food," the 43-year-old told AFP during a blustery site inspection of the skyscraper's garden.

Tsui believes Hong Kongers need to re-establish a relationship with what they eat that has been broken "since we started outsourcing our food and relying so much on industrialised production."

Andrew Tsui of Rooftop Republic sees the farms as a way for people to reconnect with how sustainable food can be produced in what he calls the current "instant-noodle city lifestyle" that produces so much waste.

Piles of food waste

According to government statistics, Hong Kong throws out some 3,500 tonnes of food waste a day—the equivalent weight of 250 double-decker buses. Less than a quarter is recycled.

And around 90 percent of the food eaten by the city's 7.5 million inhabitants is imported, mostly from mainland China.

But while Hong Kong is one of the most densely packed places on earth, there is still considerable space to grow food locally.

Tsui said some seven million square metres of farmable area is currently cultivated. But more than six million square metres on the city's rooftops remain unused.

"So we could have the potential of doubling the supply of land for growing food," he said.

"The challenge for us is to design urban farming as a lifestyle to integrate into our daily life," he added. "And the first step for that, of course, is to be accessible."

Tsui believes Hong Kongers need to re-establish a relationship with what they eat that has been broken "since we started outsourcing our food and relying so much on industrialised production"

To incorporate urban farms into the blueprints for office buildings, Rooftop Republic closely collaborates with architects, developers and property managers.

Major companies are signing up.

As well as the Bank of America garden, financed by property consultancy giant JLL, Singaporean banking giant DBS has partnered with Rooftop Republic to set up an academy that runs workshops for beginners as well as professional courses.

"In Hong Kong, most of the people focus on the commercial value of the properties. But we want to promote the concept of sustainability," said Eric Lau, the group's senior director of property management.

New skills

Urban farmers say the projects also help build community spirit among those who cultivate the crops.

After retiring from the public service, Lai Yee-man said she turned to farming to connect with nature and her neighbours.

Around 90 percent of the food eaten by Hong Kong's 7.5 million inhabitants is imported, mostly from mainland China.

Hong Kong throws out some 3,500 tonnes of food waste a day—the equivalent weight of 250 double-decker buses.

While Hong Kong is one of the most densely packed places on earth, there is still considerable space to grow food locally.

Urban farmers say their projects help build community spirit among those who cultivate the crops.

The 60-year-old initially learned techniques and tricks from professionals to develop her farming plot in the New Territories region of Hong Kong—a rural area close to the border with mainland China.

But now she is passing on her knowledge to fellow residents working the Sky Garden, a 1,200 square-metre facility on top of a mall.

There residents cultivate edible flowers and fruit trees and can attend lifestyle classes like mindful gardening.

"People attach greater importance to their health now, they will buy organic food," said Lai.

"Here, we teach them not to waste... and to cherish their food," she explained, adding that the majority of what the mall farm grows goes to local food banks.

Tsui recognises that few young Hong Kongers currently have an interest in learning how to grow food.

But younger people are often concerned about the environment and climate change, so the opportunity to generate enthusiasm is there for the taking.

"If coding is the skill set to learn for the 21st century, growing your own food is a necessary new skill that we all need to learn to ensure a regenerative and green planet," he said.

Lead Photo: More than 60 urban farms have sprouted across space-starved Hong Kong since 2015—on decommissioned helipads, shopping mall rooftops and public terraces—thanks to initiatives like Rooftop Republic.

All You Need To Know About Hydroponic System

Hydroponics has existed in various forms for thousands of years, from Babylonian hanging gardens to ancient Mexican Chinampas

By: Harold Camaya

July 12, 2021

Many people use hydroponics to grow plants that use nutrient-rich solutions in water, so there’s no use of soil. Instead, some materials support plant roots, such as peat moss, rock wool, perlite, and clay pellets.

Hydroponics has existed in various forms for thousands of years, from Babylonian hanging gardens to ancient Mexican Chinampas.

Only in the past 70-80 years have we understood the science behind this technique. While we have practiced hydroponics in various forms for centuries, some places have sometimes been more developed than others. For example, people use ac infinity to ventilate their growing space.

In this article, you’ll learn all you need to know about hydroponic systems. We will aim to answer these questions that include:

What is hydroponics?

How do you set up your hydroponic systems?

What systems do people use in hydroponics?

What are the advantages of hydroponics?

What is hydroponics?

Hydroponics refers to any growing of terrestrial plants that delivers nutrients directly to the roots rather than having the roots seek them out by digging in a soil body.

We derive the word hydroponics from the Greek word hydros, which means water, and pon means work. The plant’s roots receive nutrients from water-based nutrient solutions.

How do you set up your hydroponic system?

Photo by Jatuphon Buraphon from Pexels

Depending on what your tastes are, your hydroponic system can be simple or very complex. It is possible to set up several approaches that require little effort and set up some that require a significant investment.

The three elements of hydroponic design include:

Growing containers

Sump tank

Pump

Systems used in hydroponics

Photo by Anna Tarazevich from Pexels

Selecting a hydroponic system involves choosing from six different types. They all revolve around the use of water and nutrients. Each design addresses the core elements but in slightly different ways.

Water culture

Water culture is a simple and inexpensive system. We place plants in a basket above reservoirs filled with nutrient solutions. After hanging in the solution for a while, the roots descend entirely into the soil. They will need regular aeration leading to faster growth to prevent suffocation because of constant submersion.

Nutrient Film Technique (NFT)

The system comprises a shallow, downward-sloping stream of nutrient solution. This stream contains roots that absorb nutrients from its steady flow. Growing lettuce, herbs, and baby greens in this system are excellent for plants with a short growth cycle.

Aeroponic

By creating an aeroponics system, we expose roots to as much oxygen as possible. Growing chambers without growing medium allow roots to hang upside down in midair, exposing their entire root system. As the roots grow, we mist them periodically with aeroponics misters within this section. It has proven successful commercially propagating seed potatoes, growing tomato plants, growing leaf crops, and growing microgreens using aeroponics techniques.

Ebb and Flow

A water pump runs on a timer in Ebb and Flow, also known as Flood and Drain. Water and nutrients flood and then drain the root system. The overflow tube allows the excess water to drain through. What’s left is a dry pond with soaking roots and an overflow tube to drain water away.

Drip

We use perlite or gravel as a drip system for supplying the roots with nutrients. We then pump water and nutrients into them via tubes from a reservoir. Soaking the growing medium and roots makes the solution drip back into the container and the pool.

Wicking

Plants grow in wicking media, such as vermiculite or perlite. You can find them in a container next to the water and nutrient reservoir. To connect a wicking medium to a solution, we use wicking ropes or strips of felt.

What are the advantages of hydroponics?

Hydroponic gardening offers many benefits. Among the most important are:

Total control over nutrient supply

Because the soil is not a source of minerals or nutrients, it is easy to adjust mineral or nutrient levels based on plant needs.

Climate or season is not a constraint

Regardless of the weather outside, you can grow hydroponically whenever during the year.

Better results and higher yields

If we calibrate the hydroponic system and maintain it well, it can effortlessly produce a higher product quality and quantity than a soil-based system.

Hydroponics offers significant environmental advantages

Not only does hydroponics take up much less space than traditional horticulture, but it also uses much less water. And it allows nutrient solutions to be recycled.

It is possible to grow all plants hydroponically

You can grow vegetables like potatoes, carrots, onions, etc., that grow on the earth using hydroponics.

Determining Your Best Method

It would be best to have some ground understanding of each system’s strengths and weaknesses, as well as your hydroponic needs, before choosing one of these systems.

For example, wicks and water culture systems are excellent options for home growers who want an easy setup system.

Drip systems and NFT systems may be the right choice if you want to grow various plants. Examine each hydroponic system’s pros and cons to pinpoint the best one.

Conclusion

Growing your fruits and vegetables is a fun way to do so from the comfort of your own home using hydroponics.

The process can become complicated and expensive, but you do not have to make it so if you don’t want to. With all the essential information in this guide, you can better decide for yourself.

Lead photo: Photo by Anna Tarazevich from Pexels

Indoor Farming Is In Growth Mode

The future of indoor farming, including vertical farming, has nowhere to go but up. With parallel and perhaps inevitably colliding trends of sustainability, plant-based eating, food safety and labor-saving agricultural practices, produce grown in controlled environments is likely to become much more common in grocery stores.

By Lynn Petrak

July 9, 2021

The future of indoor farming, including vertical farming, has nowhere to go but up. With parallel and perhaps inevitably colliding trends of sustainability, plant-based eating, food safety and labor-saving agricultural practices, produce grown in controlled environments is likely to become much more common in grocery stores.

As a testament to the sunny future of the ag tech niche, the U.S. Department of Agriculture started a new Office of Urban Agriculture and Innovative Production last year. More than $3 million in initial grants were made available through that department in 2020.

Prognosticators have weighed in on a future of food that includes strategically located indoor farms throughout the country. In a report released late last year, Allied Market Research, whose Americas office is in Portland, Ore., projected that the global vertical-farming industry is expected to reach $1.38 billion by 2027, with a compound annual growth rate (CAGR) of 26.2% from 2021 to 2027.

Several grocers are already buying into this type of produce supply. Earlier this year, The Kroger Co., based in Cincinnati, began sourcing fresh produce from Hamilton, Ohio-based indoor grower 80 Acres Farms for the retailer’s stores in Ohio, Indiana and Kentucky. In 2020, Kroger partnered with German startup Infarm to add modular vertical farms to two of its Quality Food Centers in the Seattle area.

Also last year, Publix Super Markets said that it will invest more in hydroponic produce and added a new on-site trailer farm from a local hydroponic grower to its GreenWise Market store in the grocer’s hometown of Lakeland, Fla. Boise, Idaho-based Albertsons Cos. has collaborated with South San Francisco, Calif.-based Plenty and with Bowery Farming, based in New York, to provide its shoppers with fresh produce grown indoors. Natural and organic retailer Whole Foods Market, based in Austin, Texas, recently added a mini-farm from New York-based Farm.One to one of its Big Apple stores to provide herbs for prepared pizzas and drinks. In addition to these and other large grocery players, smaller chains and independents have teamed up with various greenhouses and growing operations near their locations.

Consumers have expressed their opinions about produce grown indoors. According to the 2021 “Power of Produce” report published by Arlington, Va.-based FMI – The Food Industry Association, and conducted by San Antonio-based 210 Analytics, 43% of shoppers don’t have a preference for produce coming from indoor versus outdoor farms. Those most likely to prefer indoor growing include urbanites, consumers with above-average spend per person, members of the Generation Z age demographic, higher-income households, core value-added shoppers, organic produce buyers and men. Those more likely to prefer outdoor-grown produce include consumers in rural areas and conventional produce buyers, the report found.

AeroFarms uses aeroponic methods to grow healthy plants, using up to 95% less water and no pesticides.

Greener Pastures

One of the biggest drivers of the move to produce more food in indoor-farming facilities is sustainability. From an environmental standpoint, indoor-grown produce may be part choice, part necessity, depending on the area and the circumstances.

Necessity is born of conditions wrought by continual weather extremes that are often attributed to a changing climate. Unusual weather patterns resulting in droughts, floods, storm damage and harmful freezes take a toll on traditional farms and on the farmers who grow fresh fruits and vegetables.

Weather extremes have always happened, but are becoming more frequent. For example, coming off last summer’s devastating derecho event, a drought that began in late 2020 in Iowa and has continued through early summer is stressing that state’s corn and soybean crops. Earlier this year, rare heavy snow, ice and frigid temperatures in Texas hurt winter wheat and some citrus crops.

At the same time, there’s an overall push to produce food in a more sustainable way. More than two-thirds (64%) of American consumers say that they’re willing to pay a premium for environmentally friendly products. “There is a trend – not a fad – of consumers who appreciate the benefit of getting produce soon after it’s harvested,” says David Rosenberg, co-founder and CEO of vertical-farming leader AeroFarms, based in Newark, N.J., “and more and more customers are realizing that they want products with no pesticides, because those are not meant for human beings.”

On the business side, sustainability is a central part of many CPGs’ and grocers’ corporate- responsibility platforms as they pledge to reduce their use of resources like water and energy. Many manufacturers and retailers have also revealed goals to cut down on or eliminate the use of pesticides in their products.

Other Seeds of Change

In addition to the pursuit of sustainable growing practices, other factors are contributing to interest in this method of agriculture. The need to shore up food security in the face of a booming global population and the problem of urban food deserts are notable catalysts. So is consumers’ penchant for eating more fresh plant-based foods, and foods grown in a more sustainable way.

Meanwhile, as evidenced in ubiquitous “Now hiring” signs, it can be tough to find workers to plant, care for and harvest crops. Indoor farms run with several automated controls and tasks are less affected by fluctuations and stresses in the labor market.

The global COVID-19 pandemic also contributed to the acceleration of indoor farming. When some retailers faced supply chain issues and had difficulty sourcing fresh products, they turned to new vendor partners that operated indoor farms with more controlled conditions and inventories. Indoor farms typically can be built faster and are also versatile operations that allow for pivots in the event of changing circumstances.

There are additional practical reasons for sourcing produce from indoor growers. “Right now, retailers want consistency in price, quality and delivery. At its core, we are delivering consistency,” notes Rosenberg, citing other profit-driven benefits such as reduced shrink and spoilage.

Modern indoor farms combine technology and agriculture to provide fresh produce in a more sustainable way.

Indoor-Farm Tour

Generally, plants in indoor-farming facilities are grown in cells stacked for space savings and efficiency. In lieu of the sun, LED lights are used to facilitate growth.

Watering techniques vary. In hydroponic farms, plant roots are placed in nutrient-rich solutions instead of soil. With aeroponics, exposed roots hang down from the plant and receive nutrients via a system that sprays nutrient-filled water.

Indoor farms take different forms in the United States and around the world. Some indoor farms are massive in size and almost industrial in their setup. Others are smaller and hyperlocal, using locations like repurposed shipping containers or greenhouses. Some farms are constructed vertically to minimize the physical footprint or to use existing buildings, while others are more spread out in their design. Farms are being built in urban areas, often in former manufacturing facilities, warehouses or multilevel stores, and in more rural areas, where they are run by longtime family farm owners who are looking for ways to reinvent their businesses in the wake of competition from big farms.

One thing is for sure: There are more of these types of growing operations. AeroFarms is one grower on the march, with a l36,000-square-foot aeroponics farm under construction in Virginia, set to be finished sometime in 2022.

In June, Vertical Roots, a Charleston, S.C.-based hydroponic container farm that’s part of Amplifed Ag, opened its third indoor farm in Atlanta at a facility run by two large produce suppliers in the Southeast. According to the company, the new farm will eliminate the need for transportation to the distributor and will enable produce to be delivered to local customers the same day that it’s harvested.

In mid-June, Morehead, Ky.-based grower AppHarvest revealed that it’s adding two large indoor farms in the Bluegrass State. With a completion date of the end of 2022, the farms will produce non-GMO leafy greens and fruits for shipment to grocers and restaurants.

Also in 2021, Irvington, N.Y.-based BrightFarms opened its newest indoor farm, in Hendersonville, N.C., a 6-acre greenhouse that will deliver to retailers in nearby areas in that state, as well as in South Carolina and Georgia.

Startup Bowery Farms is opening an R&D hub called “Farm X” that will help expand product development. The facility includes a new sensory lab and innovation center.

In another sign of the health of this sector, there’s major seed money – no pun intended – going toward indoor farming. Berlin-based Infarm, for example, is said to be going public following a reported merger with Kernel Group Holdings Inc., of San Francisco. In May, Bowery Farming revealed a new round of funding to the tune of $300 million that lifted the company’s estimated value to about $2.3 billion. Indoor-farming company Gotham Greens, based in Brooklyn, N.Y., revealed $87 million in new funding in December 2020.

While indoor farms are expanding, crops produced in such facilities are expected to grow, too. Most ag tech companies currently produce leafy greens and herbs in hundreds of different varieties. Tomatoes are also grown hydroponically in many places. Better technologies and a greater collective knowledge are spurring innovations in other types of crops grown indoors in an eco-friendlier way. AppHarvest, for its part, is growing strawberries in one of its new locations, and vine crops in another.

Implications for the Retail Produce Section

More and different types of indoor farms are transforming agriculture – and the retail produce department. Since many of these products are packaged on site, supermarket produce sections now feature a greater mix of packaged and bulk items. Offerings like packaged salads and tomatoes also help define and elevate a brand, whether it’s a store brand or a grower brand.

Coming off a year in which consumers prepared more foods and experimented with new products and varieties, several new products grown in indoor-farming facilities have hit the marketplace. Medford, Minn.-based Revol Greens recently rolled out new varieties of chopped romaine salads made with lettuces grown at its indoor farm in its home state. Revolution Farms, in Caledonia, Mich., is launching four new salad mixes. One of Bowery Farming’s latest products is a new Bowery Crispy Leaf Lettuce, deemed to be a “reinvigorated version” of iceberg lettuce. And that’s just the tip of the iceberg (lettuce).

Grocers can merchandise indoor-farmed produce in a creative way to distinguish their offerings and connect with shoppers. “We’ve worked in a process of co-creating with retailers,” observes AeroFarms’ Rosenberg. “It is an opportunity to deliver innovation and excitement for an exciting category.”

Lead Photo: Hydroponic farming company Vertical Roots is growing its footprint with a new indoor lettuce farm in the Atlanta area.

Philly Start-Up GrowFlux Tweaks Lighting For Growing Indoor Agriculture Industry

The University City company has received a $250,000 grant to conduct research at the National Renewable Energy Laboratory in Colorado.

The University City company has received a $250,000 grant to conduct research at the National Renewable Energy Laboratory in Colorado.

GrowFlux offer technology and software to control lighting for indoor farms. Shown here is Second Chances Farm in Wilmington, an early customer. GrowFlux

07-12-21

Crops in greenhouses — an increasingly popular way to supply year-round fresh greens and other produce to places with cold winters — are most productive when they receive the right amount of light at the right time.

But there’s a downside. Greenhouses are energy hogs and typically generate more gasses than traditional field agriculture because of their lighting and heating needs. Those are terrible characteristics for a burgeoning industry at a time of growing concern over global warming.

GrowFlux, a Philadelphia agricultural technology start-up that is trying to make the industry more efficient, won a $250,000 grant last week from the Wells Fargo Innovation Incubator for research at the National Renewable Energy Laboratory (NREL) in Colorado. The aim is to reduce energy consumption in greenhouses by fine-tuning the amount of artificial light that crops receive.

GrowFlux sells sensors that measure the amount of light, carbon dioxide, temperature, and humidity in indoor farms.GrowFlux

Simple timers are traditionally used to turn lights on and off in greenhouses, said Eric Eisele, GrowFlux’s chief executive, and cofounder. “They’re not dialing in the light in accordance with when the crop is actually using light most efficiently,” he said. “It results in a fair bit of energy that’s wasted.”

The GrowFlux system — to be further developed with the help of researchers at NREL and the Donald Danforth Plant Science Center in St. Louis — measures the natural light available and then adjusts the artificial light to add more when needed.

GrowFlux estimates that it can cut energy use by 20% to 30%.

While the grant, funded by the Wells Fargo Foundation, involves GrowFlux’s lighting controls, the University City company has a broader target with sensors that monitor carbon dioxide levels, humidity, temperature, and other factors that determine how well plants grow.

“They were one of the very first companies that were trying to essentially make farms like ours smart farms by using technology,” said Ajit Mathew George, founder and managing partner at Second Chances Farm in Wilmington, an indoor vertical farm that employs formerly incarcerated individuals.

“You don’t think of indoor vertical farms as being a place where technology plays an important part,” said George, who uses a GrowFlux app on his phone to monitor Second Chances Farm. “It does, and the more it does, the better our production is.”

Investor interest in indoor agriculture surged last year, with $929 million going into 41 deals in the United States, according to PitchBook Data Inc. That’s twice the amount invested the year before. Most of the money went into producers rather than into makers of components and technology like GrowFlux.

Eisele, 35, and Alexander Roscoe, chief technology officer, founded GrowFlux in 2017. Both are Drexel University graduates.

Eisele’s background is in interior lighting for humans. He worked for seven years in the research group at KieranTimberlake, a Philadelphia architecture firm. Rosco, 36, worked at Comcast on the build-out of national internet architecture.

GrowFlux’s first products, launched in 2018, were horticultural lights with built-in wireless technology. “The lighting space got very competitive in horticulture due to legalization of cannabis,” Eisele said.

The start-up, which now employs four, was competing with “the likes of Philips and General Electric and Osram,” Eisele said. GrowFlux dropped its lights in 2019 but kept developing its controllers.

Eisele and Roscoe declined to disclose their annual revenue but said they have raised close to $2 million from investors. The company has products in more than 100 farms, including indoor cannabis producers and greenhouses growing food like tomatoes and strawberries. The products are also used overseas, in Iceland and in an indoor vertical farm in Singapore that grows strawberries, Eisele said.

Trish Cozart, NREL’s program manager for the Wells Fargo Innovation Incubator, which in the past has worked with companies involved in traditional farming, said that over the next 30 years, global food production will have to increase by 60% to meet demand. NREL is part of the U.S. Department of Energy.

“It might not be possible to meet that demand through field-grown agriculture. Indoor agriculture is going to play a part. We don’t know how big of a part,” she said. But because indoor agriculture consumes so much energy, “we want to figure out how to combat that using innovative companies,” Cozart said.

Published July 12, 2021

I write about the business side of health care and the nonprofit sector.

Bucolic Kailash, An Agritech Startup, Brings “Computerized Farms” From The Future!

At the futuristic and smart agritech start-up “Bucolic Kailash”, a mission is becoming more real every day; the vision that soon in the very near future, starting and running farms profitably, will be as easy as downloading an app

July 6, 2021

At the futuristic and smart agritech start-up “Bucolic Kailash”, a mission is becoming more real every day; the vision that soon in the very near future, starting and running farms profitably, will be as easy as downloading an app.

Bucolic Kailash researches, manufactures and markets user-friendly life-growing computers. These computers are meant to enable economic and nutritional autonomy for its users. For example, one of the patented life-growing computers at Bucolic testing labs grows as much as Rs. 25 lakh worth of healthy produce annually in just 100 sq ft space with operational expenses of under Rs. 50,000/month for the user. Systems like these can be started with as low as 3 sq ft of space and scaled up with time.

Bucolic Kailash’s Vertical Garden and Vertical Farm System series are made to deliver super intensive and sustainable cultivation that is 100% organic, without soil and achieves more than 90% of water and energy saving. The smart agritech company has developed and acquired multiple patents on products and technologies that have shown promising results in the scope of personal, organized, and organic aquaponics farms. Their hydroponics computers grow up to 84 plants, vegetables, and salads in 1 sq ft. Their mushroom farming computers grow 50 Kgs of mushrooms in 3 sq ft every 45 days. Their fish-farming computer designs yield up to 800 Kgs of shrimps in just 10 sq mt every 150 days. All of this is achieved with IT, IoT and their custom developed life-growing AI. The Systems are engineered by closely working with its early customers and focusing on ease of use, AI & IoT powered automation and distribution. Engineering, Manufacturing, and IT has been the most guiding product shaper for the company’s early success.

Bucolic Kailash has unlocked a huge market for vertical farming, fish farming and hydroponic personal gardens.Their use of technological intervention empowers people to cultivate and harvest every day and in the comfort of their own homes through most efficient and effective ways. The company’s new offering under Vertical Garden system series ‘Tree of Wisdom – Eleganté’ is by far the most groundbreaking vertical hydroponics system the world has ever seen before. The product complies with ISO 9001:2015 for best in grade Quality Management and has been tested to meet the required hydroponics system parameter controls, as well as the state-of-art features. Tree of Wisdom - Eleganté has been doing well since its launch on 11th May 2021 at amazon.in.

The Company was founded by Mr. Utkarsh Sinha in March 2020 and now the company is a community of 18 carefully selected and nurtured members. During our interview with the founder, we found him very engaged and excited about the road ahead. Utkarsh graduated in MCIT-Computing from The University of Melbourne and B. Tech from MIT, Manipal. According to him, having worked with Godrej's R&D, Honeywell Aero HTS, Fagerhult OR Tech teams in India and Australia, helped him manage the company’s departments, processes, and make shipments possible from concept-to-product, even during the pandemic. The company runs its fully functional aquaponic devices manufacturing facility in Manipal on lean manufacturing and quality control principles.

On further talking with the founder, we found that the company’s mission with its life-growing computers is to ultimately enable community empowerment and economic development. The company believes that such life-changing science and technology should be available as user-friendly products. In the founder’s words, “It was a contrasting journey that I took back home to India in 2019 while having employment opportunities from companies in Australia that made me reflect upon my priorities and self-actualization needs. I wish to make communities exchange value through healthy food and money that can make coexistence wholesome.” We believe that Bucolic Kailash is a futuristic company that understands the needs of today's communities and a fast-changing world. They develop and market environmentally friendly agritech computers. The company has raised partial seed-funding after a year of setting up its manufacturing factory and distribution channels and they plan to expand their life-growing computers reach to a wider niche and the tap global market in the next 6 months.

Visit www.bucolic.ltd for more inspiration and information

Solar Firm To Convert Shipping Containers To Urban Greenhouses

CEO James DiPrima said: “We also felt that inner city urban areas also needed a way to get fresh fruits and vegetables grown right in their own neighborhood. Reimagining old shipping/cargo containers as the structural framework for our soar technology would greatly reduce the costs of building greenhouses

July 9, 2021

New York, New York, July 09, 2021 (GLOBE NEWSWIRE) — Green Stream Holdings Inc. (OTC PINK: GSFI) (“the Company”) (http://www.GreenRainSolar.com), an emerging leader in the solar utility and finance space, which had previously announced that it would be entering the rapidly growing urban gardening sector with solar greenhouses dedicated primarily to rooftop farming, today announced that it is also moving forward with its previously announced project to convert old shipping/cargo containers into inexpensive greenhouses for urban and inner city neighborhoods.

Last year, on October 6, 2020, the Company previously announced that it had entered into a non-binding agreement with Aoki Group Inc. (“Aoki”) and famed restauranter, Kevin Aoki, who wanted to ship his famous mushrooms to his various sites around the world. The mushrooms would grow inside the container while being shipped to their destination.

Blondie’s specializes in custom urban landscapes including roof decks, terraces, courtyards and entry gardens, and is now utilizing that expertise in designing the irrigation systems for our Cargo container Solar Greenhouses. Blondie’s transforms concept and vision into realized functional design.

Blondie’s is experienced in specifying, installing, renovating and maintaining green wall systems. They are famous for their interior and outside Green Walls.

For more information go to: https://blondiestreehouse.com.

CEO James DiPrima said: “We also felt that inner city urban areas also needed a way to get fresh fruits and vegetables grown right in their own neighborhood. Reimagining old shipping/cargo containers as the structural framework for our soar technology would greatly reduce the costs of building greenhouses. Less room, less labor and less panels was a marriage made in heaven for underserved communities. Communities can get one, ten or 100 containers… whatever amount of land is available… and since each container has a small footprint, there is a lot of flex flexibility for each situation.

Using solar energy has two main benefits: Solar energy systems do not produce air pollutants or carbon dioxide, and Solar energy systems on buildings have minimal effects on the environment… OUR Solar Greenhouses combine the two creating a physical structure that produce electricity, with the ability to capture the sun from many different angles.”

About Green Stream Finance, Inc.

Green Stream Finance, Inc., a solar utility and finance company with satellite offices in Malibu, CA and New York, NY, is focused on exploiting currently unmet markets in the solar energy space, and is currently licensed in California, Nevada, Arizona, Washington, New York, New Jersey, Massachusetts, New Mexico, Colorado, Hawaii, and Canada. The Company’s next-generation solar greenhouses constructed and managed by Green Rain Solar, LLC, a Nevada-based division, utilize proprietary greenhouse technology and trademarked design developed by world-renowned architect Mr. Antony Morali. The Company is currently targeting high-growth solar market segments for its advanced solar greenhouse and advanced solar battery products. The Company has a growing footprint in the significantly underserved solar market in New York City where it is targeting 50,000 to 100,000 square feet of rooftop space for the installation of its solar panels. Green Stream is looking to forge key partnership with major investment groups, brokers, and private investors in order to capitalize on a variety of unique investment opportunities in the commercial solar energy markets. The Company is dedicated to becoming a major player in this critical space. Through its innovative solar product offerings and industry partnerships, the Company is well-positioned to become a significant player in the solar space.

SOURCE: Green Stream Holdings Inc.

Tagged indoor farming

There is No Soil. There Is No Growth Period. Just Add Water and Technology.

Inside, nearly £3 million of beefsteak tomatoes grow on 45-foot-high vines without a teaspoon of soil, and their roots are submerged in nutrient-rich rainwater. Other vines hold thousands of small, juicy snack tomatoes with enough pepper to impress Martha Stewart on the board. AppHarvest, a start-up company that harvests its first crop here in January and plans to open 11 more indoor farms in Appalachia by 2025.

Scott Krantz

July 10, 2021

Morehead, Kentucky — In this beautiful town on the edge of the coal country, a high-tech greenhouse large enough to cover 50 soccer fields glows pink and yellow with 30,600 LEDs and high-pressure sodium lamps.

Inside, nearly £3 million of beefsteak tomatoes grow on 45-foot-high vines without a teaspoon of soil, and their roots are submerged in nutrient-rich rainwater. Other vines hold thousands of small, juicy snack tomatoes with enough pepper to impress Martha Stewart on the board. AppHarvest, a start-up company that harvests its first crop here in January and plans to open 11 more indoor farms in Appalachia by 2025.

In a much more industrial environment near the Hackensack River in Kearny, NJ, trays filled with sweet baby butterhead lettuce and sorrel flavored with lemon and green apple are piled up in a windowless warehouse. This is known as vertical farming. Bowery, The largest vertical farming company in the United States, manipulates light, humidity, temperature and other conditions to grow produce and is funded by investors such as: Justin Timberlake, Natalie Portman, chefs Jose Andre and Tom Colicchio.

“If you taste arugula, it’s sold,” said Koricchio, who has turned to people who claim to grow delicious hydroponic produce for years. “It was very spicy and lively and surprised me.”

The two operations use technological advances such as machine learning algorithms, data analysis, and proprietary software systems to create accurate growing conditions and bring out customized flavors and textures from fruits and vegetables in a new generation of hydroponics. It is part of a cultivation farm. And they can do it almost anywhere.

These farms arrive at crucial moments. The country’s strips have withered due to the heat and drought of climate change, partly supported by certain forms of agriculture. Demand for locally sourced foods is higher than ever, and pandemics have shown that many people are not as resilient as their food supply chains may have been.

However, not everyone is participating. These huge farms grow their produce in nutrient-rich water, rather than in healthy soil, which many believe is central to both deliciousness and nutrition. They can be consumed A huge amount of electricity. Their most ardent opponents say that the claims made to hydroponics are misleading and even dangerous.

“At this point, I think the bad guys are winning,” said a Vermont farmer. Real organic project.. “Hydroponics isn’t growing because it produces healthier foods. It’s growing thanks to money. Anyone who sees this as food for people or the environment is lying. I’m just there. “

The jargon of hydroponics is controlled environmental farming, but business people call it indoor farming. What used to be simply called a farm is now called an onshore farm or field farming.

“We have perfected Mother Nature indoors by combining science and technology with agriculture,” said Daniel Malechuk, CEO of. Carrera, A company that sells whole lettuce in plastic clamshells, leaving the roots intact, at about the same price as other washed lettuce.

In March, the company opened a 77,000-square-foot facility south of Atlanta, capable of producing more than 10 million lettuce annually. Similar indoor farms in Houston, Denver, Seattle, Honolulu St. Paul, Minnesota.

According to Malechuk and other executives, the beauty of this process is not limited by the seasons. You can accurately predict the cost and growth period of your crops and build farms wherever people need fresh produce.

“We can grow in Antarctica,” he said. “We can be on the island. We can be on the moon or on the space station.”

It’s easy to imagine. There are new breeds of young farmers on the farm who wear lab coats instead of overalls and prefer computers to tractors.

Today, more than 2,300 farms growing hydroponic crops in the United States make up just part of the country’s $ 5.2 billion fruit and vegetable market. But investors who are crazy about smart farming are betting big on them.

In 2020, $ 929 million was invested in US indoor farming ventures, more than double the investment in 2019. PitchBook data. The grocery chain and California’s largest berry producer Alliance with vertical farming, also.

“There is no doubt that we are reinventing agriculture, but what we are doing is reinventing the fresh food supply chain,” said Manhattan-based indoor farm in New Jersey. Irving Fain, founder and chief executive officer of Bowery, said. One is under construction in Maryland and the other in Pennsylvania, and two research farms are in New Jersey.

Mr. Fine said his farm is 100 times more productive than traditional farms and uses 95% less water. Other companies claim that one acre can grow as much food as a traditional farm can grow at 390.

Vertical farming can be built next to the city center, so lettuce, for example, doesn’t have to sit in a truck for days when heading from California to the east coast, losing both quality and quality. Nutritional value. Vegetables are grown for flavor, not storage and yield.

The new system was designed to produce pesticide-free sanitary crops in computer-monitored sanitary buildings, forcing a major recall of Romain Lettuce in 2019 and 2020. There is little risk of contamination by bacteria such as E. coli.

Still, many farmers and scientists remain unconvincing. Chapman of the Real Organic Project was engaged in hydroponics at the US Department of Agriculture Taskforce. Five years ago, he led an effort to encourage distributors not to allow hydroponics farmers to certify their produce as organic produce. According to him and others, the very definition of organic farming depends on creating healthy soil. May, Food Safety Center, Environmental groups, led Appeal of Federal Court Decision. It upheld the policy of government agencies.

The nutritional profile of hydroponics continues to improve, but no one yet knows what long-term health implications for fruits and vegetables grown without soil. No matter how many nutrients an indoor farmer puts in water, critics say that an indoor farmer can rival the taste and nutritional value that comes from a combination of sun, healthy soil microbes, and common phytobiology. They can’t and claim they can’t offer environmental benefits-run an organic farm.

“What are the health consequences of the second generation?” Chapman asked. “This is a huge live experiment and we are mice.”

The gap between soil lovers and ag-tech futurists has spread on a much closer scale between two influential brothers, Dan and David Barber, who found and own organic farms. Masu Blue Hill Restaurants in Greenwich Village and Stoneburn, Pocantico Hills, NY

Created by David Barber in 2018 Investment fund To support new food technology companies, including Bowery. But the 2014 book “Third plate: Field notes on the future of food” dedicates the entire section to the soil and believes that truly delicious food can only come from Earth.

“I haven’t bought it,” said Dan Barber about the heat of hydroponics.

It is virtually impossible to try to fortify water with nutrients to mimic what the soil does, he said.

“We know more about the stars and the sky than the soil,” he said. “In fact, we don’t know much about nutrition.”

There are also cultural costs. For centuries, he said, cooking has been developed based on what the land and plants demand. The Mexican diet in the corn and bean-based region was born out of farmers’ awareness that corn grows better in the presence of beans that fix nitrogen in the soil.

“The technological agricultural revolution is changing this equation head-on,” Barber said. It helps efficiency in the name of feeding more people but divorces food from nature.

His brother, David, was also skeptical of hydroponics for a long time. “Most of my career has been that good soil leads to good agriculture, good systems, and ultimately good flavors,” said David Barber.

But the environmental benefits of next-generation hydroponics cannot be ignored, he said. It also does not taste better than previous hydroponic produce. “They combine outdoor and indoor thinking, and science and history to create something special,” he said. “There aren’t many winners in this area, but they will be part of our food system.”

Indoor farmers see competition as a large industrial producer producing fruits and vegetables grown to withstand processing and shipping, rather than small farmers using more natural cultivation techniques. They say the fight is against monoculture, not the farmers who maintain healthy soil and feed the community. Hydroponic farms can help develop new and more diverse plants and reduce the overall use of pesticides.

“All we’re trying to do is be as good as a farmer 100 years ago,” said hydroponic lettuce grower Malechuk.

Kentucky-born founder and CEO of App Harvest, Jonathan Webb, said indoor farming is a bet on national farming.

“American farmers are already out of date,” he said, noting that the United States imports £ 4 billion of tomatoes from Mexico each year. “Our hope is to be able to bring farmers back to US shelves.”

Coriccio also leads the campaign opposed to genetically modified foods and long advocate for smallholders, he said the two farming styles could coexist. “The toolbox needs a lot of tools,” he said.

Uita Michel Kentucky chef App Harvest likes App Harvest because the company creates jobs and grows tomatoes that they are happy to use in restaurants.

But technology will never beat the magic of the soil, she said. “There is no substitute for my summer Kentucky tomatoes.”

There is no soil. There is no growth period. Just add water and technology.

"Resilience Is Going To Become A Key Element of Food Security"

A little over two years ago they formed AgroUrbana, a startup dedicated to vertical agriculture, which consists of producing food in vertically stacked layers, in their case using LED lights and hydroponic cultivation, to provide the light and water necessary to harvest vegetables with nutrition. very accurate in spaces with controlled climates.

July 5, 2021

When it comes to rethinking agriculture to create better products with much less impact 365 days a year on a large scale, Cristián Sjögren and Pablo Bunster, two professionals from the renewable energy sector, left their jobs behind to bring sustainable farming to cities.

A little over two years ago they formed AgroUrbana, a startup dedicated to vertical agriculture, which consists of producing food in vertically stacked layers, in their case using LED lights and hydroponic cultivation, to provide the light and water necessary to harvest vegetables with nutrition. very accurate in spaces with controlled climates.

In 2020, despite the fact that its creators consider that much more work needs to be done to advance in a country where traditional agriculture prevails, they have managed to expand their distribution channels. “Our investors and clients are excited. We have seen a very positive reception from the markets ”explains Bunster, who points out that last August they began to sell their vegetables in Jumbo, and since last week they have been in the North American multinational Walmart.

“The new generations read the label in the supermarket more than any other. The sophistication of the consumer is demanding more from the producers, and the way agriculture has been done until today has not been able to cope with these consumption conditions. This is part of the value of bringing vertical agriculture to Chile ”, says Pablo Bunster, who sees in the startup a possible solution by automating food production.

In March 2020, AgroUrbana closed its second round of financing, which was led by the CLIN fund of ChileGlobal Ventures, the Venture Capital area of Fundación Chile. To date, the startup adds USD 1.5 million in financing, in which funds from Venture Capital, Family Offices, and individuals have participated, which has allowed them to reach an advanced stage of the AgroUrbana Series A round for USD $ 4 million, to finance the construction of a much larger scale vertical farm.

Read the complete article at: Vertical Farm Daily

Nature Fresh Farms And The University of Windsor Looks To Bring Clean Transportation In New Partnership

Nature Fresh Farms joins the University of Windsor in their long-haul vehicle transportation sustainability project to help achieve new advancements in energy efficient shipping.

July 5, 2021

Leamington, ON – Nature Fresh Farms joins the University of Windsor in their long-haul vehicle transportation sustainability project to help achieve new advancements in energy efficient shipping.

The purpose of this $160,000 project is to determine the impact of long-haul electric vehicles (LHEV) on Ontario’s electric grid. They will create an archetypal routing network by determining the most frequently traveled routes and then overlay the electric grid which will help determine how it will perform when managing a fleet of electric trucks. Being battery operated the trucks will look, haul, and perform similarly to diesel trucks but with zero emissions. By drawing power from the electric grid, the transport trucks would not only be able to sustainably deliver goods but also allow for the transferring of electrons back to the grid at strategic locations and times.

The project is spearheaded by Dr. Rupp Carriveau, of the Environmental Energy Institute, and his associate Dr. Hanna Maoh, of the Cross Border Institute, with the assistance of several graduate students. In addition, they are developing various industry related partnerships that will assist in different facets of their project, including Nature Fresh Farms.

“We needed a partner to help pilot our project and potentially test and Nature Fresh Farms came to mind. They are a very progressive company and are calculated risk takers that push boundaries with new technologies.” – Rupp Carriveau