Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

SPAIN: HPGen™ Improves Crop Yields, Reduces Irrigation System Maintenance In Almeria Greenhouse

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions

Located in the highly productive greenhouse area in the Almeria region in southern Spain, a greenhouse grower with cucumbers in winter and watermelons in summer ran into some irrigation issues: the soil in the region is dry, the climate warm and the operators use organic fertilizers. The plants are grown in the typical Almeria sandy soil (enarenado) and are irrigated with a modern drip irrigation system using pressure compensating non-leakage drippers.

When HPNow’s precision irrigation and agronomy experts assessed the site, it was clear that clogging of drippers leads to non-uniform irrigation and insufficient water and fertilizer delivery to part of the crop. To mitigate this, farm personnel were going through the drippers frequently to “unclog”, a manual process highly costly in man-hours.

Organic matter

Soil quality was also analyzed and the amount of organic matter in the soil, a critical parameter for the healthy growth of the plants, was very low at 0.33%. This is due to poor dissolution of organic matter fertilizers in water, which further exacerbates dripper clogging and decreases crop productivity. To overcome these issues, an HPGen™ system was installed and integrated with the drip irrigation system. The HPGen™ was installed in the irrigation room and set to automatically fill a buffer tank with Peroxide UltraPure™. Dosing was done through a proportional dosing pump, which is both simple and effective.

Improved yields

After a season of cucumber crop with HPGen™, yields were compared to previous seasons. The results with HPGen™ were of 17 kg/m2, a record for this grower, substantially higher than the average for the past 5 years of 12 kg/m2. In addition, the grower observed the quality of the fruit improved, and the fruit could remain on the plant longer, allowing for optimization in harvesting depending on market prices.

The improvement in >40% in production is explained by two factors:

· Better irrigation uniformity: After two weeks of installing the HPGen™ all drippers showed a uniform water flow, which allows for an optimal distribution of water and fertilizer throughout the field.

· Increase of soil organic content, which increased by a factor of 10 (from 0.33 to 4 %), which contributed to improving plant nutrition.

Both factors are due to the high oxidizing power of the Peroxide UltraPure™ generated by the HPGen™ system, which oxidizes organic matter in the irrigation system and makes it available to the crop. This results in better health and vigor of the plants, and in an improvement in yields.

About HPNow

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions. Headquartered in Copenhagen, and with representation across Europe, the Americas, and Asia, they address their clients’ water treatment needs in market segments ranging from agriculture and aquaculture, to industrial and drinking water treatment. HPNow is a technology and market leader in on-site generation of hydrogen peroxide and is continuously striving to further advance its technology and products in order to meet growing market needs and rising global demand.

Stay in the loop by following HPNow on LinkedIn and Facebook.

VIDEO: On Tour With Little Leaf Farms

If you've ever wondered what a commercial scale, hydroponic grower of leafy greens in the New England area is like, wonder no longer

By AMY SOWDER

March 22, 2021

If you've ever wondered what a commercial scale, hydroponic grower of leafy greens in the New England area is like, wonder no longer.

And if you haven't wondered, you'll still enjoy this virtual tour of an example of a growing sector of the produce industry: agtech and indoor growing.

Founder and CEO Paul Sellew of indoor grower-packer-shipper Little Leaf Farms, Devens, Mass., leads us on a tour of his expanded facility.

The greenhouse grows green leaf, red leaf, arugula, and other lettuces harnessing the power of the sun. When the sunshine isn't doing its thing, then there are LED and other lights to fill in.

See how a freshly seeded row comes in, and all the greens at different stages of growth shift along the line to keep the process moving.

Sellew said it's part of the future of agriculture and enables consumers along the East Coast to buy lettuce grown closer to home during all seasons.

Gotham Greens Goes West To Unlock Next Growth Chapter: ‘The Indoor Environment Is Relatively Unexplored But Offers Fantastic Opportunities’

Expanding to Solano, California, where the greenhouse will be co-located with the University of California-Davis (UC Davis), is a significant milestone for the company that has thus far built greenhouses in its home state of New York, Rhode Island, Maryland, Illinois, and Colorado

By Mary Ellen Shoup

02-Mar-2021

Photo Credit: Gotham Greens

Using funding from its recent $87m Series D capital raise, indoor agriculture company Gotham Greens has expanded operations to Northern California – its first West Coast greenhouse location – opening a 10-acre facility, which will bring its total annual production to 40 million heads of lettuce and herbs.

Expanding to Solano, California, where the greenhouse will be co-located with the University of California-Davis (UC Davis), is a significant milestone for the company that has thus far built greenhouses in its home state of New York, Rhode Island, Maryland, Illinois, and Colorado.

“California is a significant contributor to the nation’s produce industry in several ways. Not only is California responsible for growing one-third of the country’s vegetables and two-thirds of the nation’s fruits, but also it is home to numerous research institutes, industry groups, and suppliers,” Gotham Greens co-founder and CEO Viraj Puri told FoodNavigator-USA.

While working to produce hydroponic indoor lettuce on a mass scale for West Coast consumers is a major goal with the new greenhouse facility, Puri added that its partnership with UC Davis will help drive the next wave of innovation in controlled environment agriculture (CEA).

“The location of this new greenhouse uniquely enables opportunities for Gotham Greens to play a greater role in the produce industry as well as collaborate on research and innovation with the University of California system focused on advancing the science, workforce, technology, and profitability of indoor agriculture globally,” he said.

'Over time, we’ve increased the use of automated systems'

As the top producing state of lettuce, the California agriculture industry has battled with many issues such as heavy rains and flooding to months-long drought periods that have resulted in supply shortages and price increases.

Indoor agriculture such as the greenhouse hydroponic solution Gotham Greens has brought to market could provide a viable solution to all these issues, it claims.

Gotham Greens grows its greens uses natural sunlight and hydroponic systems which uses 95% less water and 97% less land than conventional farming.

“Over time, we’ve increased the use of automated systems to ensure that temperature, humidity and light levels, as well as air composition, are exactly the right balance,” said Puri.

The end product is packaged fresh greens which are beginning to reach cost parity with commoditized field-grown lettuce. A 4.5-ounce package of Gotham Greens Romaine lettuce for example costs $3.49 on average compared to a head of conventional Romain lettuce which retails for $2.28 (in Chicago), according to USDA market price data.

Consumers also have the extra security of knowing that the lettuce they purchased is fresh since the produce traveled a much shorter distance and passed through fewer hands than is typically required for field-grown lettuce, noted Gotham Greens.

Gotham Greens Product Shot_Photo Credit Gotham Greens

Size of the prize

Puri noted that while just a small fraction of the overall lettuce category, the potential addressable market for indoor-grown, packaged leafy greens and herbs in the US and Canada is $15bn.

"While indoor farming currently represents a small portion of the salad and leafy greens market, Gotham Greens is growing +70% year over year and the indoor farming sector is growing more than +50% year over year*, far outpacing the overall category (+15% YoY) as well as the organic segment (+9% YoY)," he said.

*Nielsen Total US xAOC Lettuce and Pre Packaged Salads, Dollar Sales, Latest 52 weeks ending 1/23/21

Advantages of greenhouse farming

Asked whether the company would ever explore a vertical farming model, which in theory could use less land to produce equal amounts of lettuce, Puri noted that its greenhouse method mixed with technology is a more flexible and economic solution.

“Vertical farming is an exciting extension of modern greenhouse farming with many shared principles, but it is still a relatively young industry with open questions around technology and financial sustainability. Fully indoor environments that rely on artificial light and HVAC systems can theoretically offer much higher yields and levels of climate control, pest management, and food safety. However, these benefits currently come with significantly higher capital and operating costs,” said Puri.

Plant varieties optimized for indoor growing

The company has proved its system can work at a large scale (Gotham Greens products are available in 40 states and at 2,000 retail stores), but there are many new areas it can explore to further optimize its growing methods.

“One area of particular interest for UC Davis is the breeding of improved crop varieties for indoor agriculture. For several centuries, plant breeders have focused on selecting and breeding crops suited to outdoor conditions, where they have been successful. The indoor environment, in contrast, is relatively unexplored but offers fantastic opportunities to use lights and nutrients to modify plant development, nutritional quality, yield, and shelf-life,” said Professor Gail Taylor, chair of the UC Davis Department of Plant Sciences.

“Much remains to be explored over the coming years to ensure safer, cleaner, and more sustainable food.”

‘We are interested in the complementary nature of indoor and outdoor agriculture’

Gabe Youtsey, chief innovation officer, UC Agriculture, and Natural Resources, believes the CEA industry a new and exciting frontier for agriculture.

“New genetics, data-driven intelligent farming, farm automation, energy optimization, and other technologies can all be brought together to create a range of new tasty, healthy, and sustainable food products. We are interested in the complementary nature of indoor and outdoor agriculture, and the opportunity to help expand a local footprint of food production that is less resource-intensive and create a new generation of diverse young farmers,” Youtsey told FoodNavigator-USA.

The greenhouse will generate 60 new full-time jobs and create a new type of opportunity for UC Davis students that want to pursue CEA as a career.

Copyright - Unless otherwise stated all contents of this web site are © 2021 - William Reed Business Media Ltd - All Rights Reserved - Full details for the use of materials on this site can be found in the Terms & Conditions

RELATED TAGS: indoor farming, greenhouse farming, Gotham Greens

Is Controlled Environment Agriculture Addressing The Issues Facing The Agriculture Industry?

As chairman of the USDA Fruit and Vegetable Industry Advisory Committee, Paul Lightfoot at BrightFarms is looking for ways to make major improvements in food production, sustainability and consumption

BrightFarms founder and president Paul Lightfoot, who is chairman of the USDA Fruit and Vegetable Industry Advisory Committee, said controlled environment agriculture could play a major role in helping to solve some of the significant issues facing the ag industry and U.S. Photos courtesy of BrightFarms

As chairman of the USDA Fruit and Vegetable Industry Advisory Committee, Paul Lightfoot at BrightFarms is looking for ways to make major improvements in food production, sustainability, and consumption.

When Paul Lightfoot founded BrightFarms in January 2011 he had no experience in commercial food production. Ten years later he is president of one of the fastest-growing controlled environment agriculture companies in the United States. Starting with one 54,000-square-foot greenhouse facility in Pennsylvania in 2013, BrightFarms has expanded with greenhouse operations in four states with a total production area of 700,000 square feet.

“I had a background in retail supply chain improvement,” Lightfoot said. “I was running a supply-side software company for about nine years and was thinking about whether I could create an opportunity that would combine my career with my personal interest in healthy sustainable food. I studied different opportunities and came across the leafy greens supply chain as one that was ripe for destruction.

“At the time, all salads in North America basically came from the West Coast, either Salinas, Calif., in the summer or Yuma, Ariz., in the winter. I identified a very centralized, very industrialized supply chain that wasn’t benefitting consumers.”

Paul Lightfoot said an increasing amount of growth in the leafy greens market is coming from controlled environment agriculture.

Lightfoot said the concentrated field production locations and long-distance shipping required to deliver leafy greens to East Coast markets was not good for the product.

“Most leafy greens are five to seven days old when they arrive at retailers’ distribution centers, and that shows in the quality, nutrition, and taste,” he said. “I also thought field food production had some Achilles heals’ in terms of food safety and sustainability, which I thought would become more important, providing BrightFarms with a terrific market opportunity.

“I knew that consumers would continue to focus on healthy eating and that the demand for salads was going to rise. I grew confident that BrightFarms could disrupt a supply chain that was fragile and vulnerable.”

After opening its first greenhouse facility in 2013, Lightfoot said by the end of 2014 the company had figured out its operating model.

“We began to raise serious capital,” he said. “We graduated from venture capital to private equity in 2016 as we hit the national stage. We opened much larger greenhouses, one in Virginia to serve the Washington, D.C., market and one in Illinois to serve the Chicago and Milwaukee markets. Those were in partnership with Ahold Delhaize and Kroger.

“Before then I don’t think the produce industry had taken controlled environment salad production seriously. After 2016 we established ourselves as a contender to continue winning market share.”

Lightfoot said just about every major retailer in the U.S. now has an indoor-grown salad program on its shelves.

“There are billions of dollars of market share to be captured with leafy greens,” he said. “It’s a big and growing segment and by far the lion’s share of the growth is coming from controlled environment local production like ours.”

Helping to solve ag industry, societal issues

In October 2020 Lightfoot was elected chair of the USDA’s Fruit & Vegetable Industry Advisory Committee (FVIAC). Formed in 2001, the purpose of the committee is to examine issues that impact the fruit and vegetable industry and to provide recommendations and ideas to the Secretary of Agriculture on how the USDA can tailor programs to better meet the needs of the produce industry. FVIAC currently has four working groups: food safety, production, labor and trade.

“During our committee meetings the members develop a series of recommendations on the matters that are within the preview of the USDA,” Lightfoot said. “These recommendations are relevant to fruit and vegetable companies in the U.S., including growers, shippers, distributors, retailers and other organizations that have a stake in this space.”

Controlled environment vegetable production could be instrumental in providing consumers with healthier, more nutritious, better-tasting produce that is locally grown.

Lightfoot said the U.S. agriculture industry has an opportunity to help tackle some of the most pressing issues facing the U.S., including climate change and nutrition.

“We have a society where the majority of Americans are obese or nearly obese and an extremely high percentage is diabetic or pre-diabetic,” he said. “The leading cause of death in the U.S. is from chronic diseases that are a result of our diets.

“We don’t need fancy technology to see the solution. Only about one in 10 Americans eat the recommended servings of fruits and vegetables. Shifting our diets away from highly processed foods and toward more fruits and vegetables would reduce diet-related chronic diseases, reduce the costs of healthcare, and even improve our military readiness.”

Another area where Lightfoot said the agricultural industry could help resolve issues is related to climate change.

“It is well understood that the energy and transportation sectors are huge contributors to climate change,” he said. “In general, as a world, we are making progress on those fronts. I’m not alone in driving an electric car and powering my home with wind-powered electricity.

“Less well understood is that the U.S. agriculture industry emits 10 percent of our country’s greenhouse gases. It is also one of the most vulnerable sectors to more volatile weather that results from climate change.”

Lightfoot is particularly concerned about the impact the agriculture industry is having on the country’s top soil and water resources.

“We’re mining our soil,” he said. “If we continue to degrade our soils, we only have about 50 seasons of soil left in the Midwest. Farming practices in the Midwest and California have also had a major impact on waterways, reducing sources of potable water.

Paul Lightfoot said just about every major retailer in the U.S. now has an indoor-grown salad program on its shelves.

“More biodiversity needs to be introduced into the areas of the West Coast that currently grow our salads. It has become a monoculture, which has removed the life from the soil and disrupted the water cycles. One idea would be to provide incentives to those farmers to “re-wild” some of that land, adding biodiversity to restore the soils and water cycles. That lost production capacity could be offset with the growth in high intensity indoor farms.”

Taking the CEA industry seriously

Lightfoot said his participation with FVIAC is beneficial to BrightFarms and to the CEA industry.

“It is important to remember that I am representing the entire fruit and vegetable industry in my role with FVIAC,” he said. “I care about BrightFarms like I care about a child, but in this role I will be speaking for the entire industry.

“The U.S. should be doubling the per capita annual consumption of fruits and vegetables. Because Americans are not eating enough fruits and vegetables, our country is suffering.”

Lightfoot said his participation with FVIAC, along with being a board member of the United Fresh Produce Association, reflects the changes occurring in the CEA industry and how it is viewed overall by the agriculture industry.

“The CEA industry was considered fairly new and only recently has it become a bigger player,” he said. “These ag organizations recognize that and want our representation. We are glad to have it. We think we have an important voice and I’m glad to be able represent the CEA industry.”

For more: BrightFarms, Farm Support Center, Irvington, NY 10533; (866) 857-8745; info@brightfarms.com; BrightFarms

This article is property of Urban Ag News and was written by David Kuack, a freelance technical writer in Fort Worth, Texas.

USA - ARIZONA: UA-CEAC 2021 Online Short Course

Only a few weeks away from the 2021 Online Greenhouse Crop Production and Engineering Design Short Course put on by the University of Arizona's Controlled Environment Agriculture Center

Only a few weeks away from the 2021 Online Greenhouse Crop Production and Engineering Design Short Course put on by the University of Arizona's Controlled Environment Agriculture Center. This virtual program will be hosted through Zoom on Wednesdays- March 3rd, 10th, & 17th from 10 am-3 pm (MST). Come expand your knowledge, sharpen your skills, and hear innovative presentations given by industry leaders and academia experts in Controlled Environment Agriculture. Click here to register. Registration will close on February 26th.

For more information, visit ceac.arizona.edu/events/cea-short-course or email ellenworth@email.arizona.edu

Pure Flavor® Receives International Taste Award For New Cloud 9® Tomato

Strategically grown in high-tech greenhouses in Canada, USA, and Mexico, Cloud 9® Bite-Sized Fruity Tomatoes are available year-round

Leamington, ON (February 1st, 2021) – While consumers continue to look for more healthy snacks in the fresh produce aisle, greenhouse vegetable grower Pure Flavor® is launching their new Cloud 9® Bite-Sized Fruity Tomatoes to help meet the growing demand for consistently flavorful options. After extensive product trials and consumer taste testing, many are heralding the new tomato variety as an everyday snack game changer.

“We taste hundreds of tomatoes every year searching for something special - unique colors, shapes, sizes, but most importantly flavor. From the first taste of the Cloud 9® variety, we knew we had found it”, said Jamie Moracci, President. With fruit like flavor, the new Cloud 9® Tomatoes are going to redefine what snacking tomatoes should taste like as an everyday item, not just as color in a salad. “We have created the Cloud 9® Standard for quality and look forward to consumers enjoying this premium and hand-selected bite-sized tomato every day”, said Moracci.

Strategically grown in high-tech greenhouses in Canada, USA, and Mexico, Cloud 9® Bite-Sized Fruity Tomatoes are available year-round. With a distinct color, unique shape, and a fruit-like flavor profile, Pure Flavor® has conducted extensive product trials in key growing regions to create the appropriate growing formula to consistently produce an exceptional snacking tomato.

“From the first bite, you know this will be memorable: it’s a fresh snacking experience that comes from an unwavering commitment to quality”, commented Matt Mastronardi, Executive Vice-President. Available in a variety of formats, Pure Flavor®’s award-winning Cloud 9® Tomato is available starting February 1st to be shipped throughout North America. “We hand-select a limited quantity of the most vibrant tomatoes so you can enjoy bold, balanced flavor that sweetens any snack or homecooked meal”, said Mastronardi.

Pure Flavor® recently received the prestigious Superior Taste Award Certification from the International Taste Institute (Brussels, Belgium) for the Cloud 9® Tomato. The reviewing Jury, consisting of more than 200 renowned European Chefs & Sommeliers from over 20 countries, critically tested & analyzed the Cloud 9® Tomato and highlighted these characteristics to award the product the Superior Taste designation:

Very clear, ripe tomato flavor with a marked sweetness; the taste lingers for a long time on your palate

These tomatoes have an original shape, and the size makes them ideal as a snack or for use in the kitchen

An intense red color with a soft texture and sweet taste; nice and juicy – good balance between sweetness & acidity

The product is very versatile; can be used in numerous different recipes and types of cuisines, suitable as a snack, in pasta, salads, stews, with various proteins (beef, poultry, fish), or even a Gazpacho

“It’s a strict process where all products are blind tasted; this means that the samples are anonymized, we do not see the packaging and do not know the brand name nor the producers’ name - we don’t even know from which country the product comes from. This forces us to be completely objective as we do the sensory analysis. Only truly good products are certified”, stated Stijn Roelandt – Sous-Chef at Hof van Cleve, 3 Michelin stars and member of the Jury, International Taste Institute.

The launch of a sweeter snacking tomato comes at a time when consumers are looking to enjoy a wider variety of healthy foods to eat at home. Cloud 9® offers consumers a healthy new snack option that will “make life’s sweetest moments even sweeter” – figuratively and of course, quite literally.

Video #1: https://youtu.be/CrsCQTszdp0

Video #2: https://youtu.be/hQIwq8M2Tfs

“The award-winning Cloud 9® tomatoes burst with a fruity sweetness that enriches any dish or eating occasion, every recipe you create deserves to be a showstopper”, said Chris Veillon, Chief Marketing Officer.

In anticipation of the new product launch, Pure Flavor® spent the last 16+ months developing the Cloud 9® brand to ensure that consumers could go beyond the package to enjoy all aspects of the tomato.

“Our team has developed dozens of recipes, conducted in person tasting surveys before the pandemic and hundreds of digital preference surveys during the Love For Fresh campaign late last fall, to creating engaging web & social content in lifestyle situations – we needed to effectively communicate that Cloud 9® is not just another salad topper, it’s the sweetness you crave with the quality you deserve. We think it’s a tiny taste of heaven™”, said Veillon.

To learn more about Cloud 9® Bite-Sized Fruity Tomatoes, please visit: https://www.pure-flavor.com/cloud9/

-30-

About Pure Flavor® -

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise.

We are the next generation of vegetable growers, inspired to put quality, flavor, and customers first by providing greenhouse-grown vegetables from our farms that are strategically located throughout North America.

About the International Taste Institute –

The International Taste Institute, founded in 2005 and based in Brussels, Belgium, evaluates and certifies the taste of food and drink from all over the world. Its jury is composed of over 200 renowned Chefs and Sommeliers from 15 European culinary or sommeliers associations.

The Taste Institutes performs objective sensory evaluation: its jury follows a rigorous blind tasting methodology in which product samples are anonymized to avoid any bias in the scoring. In addition to the scoring of the various sensory analysis criteria, the jury provides comments and eventually suggestions for further product improvement or food pairing suggestions.

(Assistant) Professor Crop Modelling In Greenhouses And Vertical Farms (Tenure Track)

Are you keen to contribute to the sustainable production of healthy fresh vegetables? We have a vacancy for an Assistant professor of Crop modelling in Greenhouses and vertical farms. Do you like to supervise students? Do you want to combine modelling and data analytics with plant experimentations? Then this position could be a perfect fit for you!

The chair group Horticulture and Product Physiology of Wageningen University & Research (WUR) is keen to hire an Assistant Professor (0.7-1.0 ft). As an Assistant Professor, you will take a leading role in developing research and education and the opportunity to establish your own research and education in crop modeling in greenhouses and vertical farms.

This position also involves experimental physiological work at the plant organ, whole plant or whole crop level, which is necessary to build, calibrate and validate models.

In this challenging career trajectory:

You will perform research on modeling, combined with experimentation, of growth, development, and quality of horticultural crops and products (vegetables, fruits, cut flowers, and/or pot plants).

You acquire, lead and implement together with the chair holder and other staff members innovative and creative (inter-)national research projects for our group. Once acquired you also implement and lead these projects.

You supervise Ph.D., MSc, and BSc students, and you will develop and teach courses (lectures, practicals) on the modeling of key plant processes in greenhouses and vertical farms.

Your work will focus on the development of models, which are a combination of multiscale Spatio-temporal data-driven, as well as knowledge-based models. Model applications may include predictions of yield, plant development and growth, quality, post-harvest behavior, resource use and running costs for crops grown in greenhouses and vertical farms

You collaborate with colleagues and establish a personal research portfolio that is embedded in the Horticulture and Product Physiology group

You undertake research on modeling and data analytics, combined with experimentation, that leads to high-quality research output.

You will perform research on modeling, combined with experimentation, of growth, development, and quality of horticultural crops and products (vegetables, fruits, cut flowers, and/or pot plants).

Tenure Track is a career path for scientists who pursue to excel in education and research. We seek to attract scientific talent and to stimulate and support their development.

Requirements:

You hold a Ph.D. degree in plant science, mathematical science, biological science, data science, or similar.

You have experience in modeling and data analytics, as well as a keen interest in combining these activities with experimentation with plants.

You have published research in high-quality journals and are willing to develop your skills in teaching and grant proposal acquisition.

You are strong in stakeholder management because you need to communicate the importance and significance of your research.

This position requires excellent English language proficiency (a minimum of CEFR C2 level). For more information about this proficiency level, please visit our special language page.

The chair group Horticulture & Product Physiology

The chair group Horticulture and Product Physiology conduct high impact research and educate students providing the scientific basis required to answer questions that are of utmost importance for sustainable crop production and product quality in horticulture.

The research focus is on how physiological processes in crops, plants, and plant organs interact with the abiotic environment and how this affects crop production and product quality. Questions arising from horticultural practice are translated into fundamental research topics, aiming to explain mechanisms. The research and education contribute to sustainably feeding the World with healthy high-quality products.

The chair group is an international team consisting of 15 permanent staff members, about 25 Ph.D. candidates and postdocs, and a number of guest researchers. Each year about 40 MSc students conduct their thesis study (6-month research) at our group. We organize and participate in a variety of courses for BSc and MSc students to transfer knowledge on horticulture (pre-and post-harvest), environmental physiology, and product quality.

More info about the chair group can be found at www.hpp.wur.nl or see the video below:

Salary Benefits:

Wageningen University & Research offers excellent terms of employment. A few highlights from our Collective Labour Agreement:

sabbatical leave, study leave, and paid parental leave;

working hours that can be discussed and arranged so that they allow for the best possible work-life balance;

the option to accrue additional flexible hours by working more, up to 40 hours per week;

there is a strong focus on vitality and you can make use of the sports facilities available on campus for a small fee;

a fixed December bonus of 8.3%;

excellent ABP pension regulations.

In addition to these first-rate employee benefits, you will be offered a fixed-term, 7-year contract which, upon positive evaluation based on criteria elaborated in the University's Tenure Track policy, can lead to a permanent employment contract as a professor. Depending on your experience, we offer a competitive salary of between € 3.746,- and € 5.127,- (assistant professor position) for a full-time working week of 38 hours in accordance with the Collective Labour Agreements for Dutch Universities (CAO-NU) (scale 11). The position can be part-time or full-time (0.7-1.0 ft).

Wageningen University & Research encourages internal advancement opportunities and mobility with an internal recruitment policy. There are plenty of options for personal initiative in a learning environment, and we provide excellent training opportunities. We are offering a unique position in an international environment with a pleasant and open working atmosphere.

You are going to work at the greenest and most innovative campus in Holland, and at a university that has been chosen as the "Best University" in the Netherlands for the 16th consecutive time.

Coming from abroad

Wageningen University & Research is the university and research center for life sciences. The themes we deal with are relevant to everyone around the world and Wageningen, therefore, has a large international community and a lot to offer to international employees. Applicants from abroad moving to the Netherlands may qualify for special tax relief, known as the 30% ruling. Our team of advisors on Dutch immigration procedures will help you with the visa application procedures for yourself and, if applicable, for your family.

Feeling welcome also has everything to do with being well informed. Wageningen University & Research's International Community page contains practical information about what we can do to support international employees and students coming to Wageningen. Furthermore, we can assist you with any additional advice and information about helping your partner to find a job, housing, schooling, and other issues.

Work Hours: 38 hours per week

Address: Droevendaalsesteeg

The Capital Expenses For Vertical Farms And Greenhouses

Here at Agritecture, we have performed side-by-side analyses of vertical farms and greenhouses. For most US markets, the greenhouse model comes out ahead on both capital and operational costs

28-01-202 | Agritecture

Written By: Djavid Amidi-Abraham

Breaking down the differences in CapEx between Vertical Farms and Greenhouses. If we peer into the portfolios of some venture capital investors with funds dedicated to agriculture investments, we see a hesitance to invest in vertical farms.

Here at Agritecture, we have performed side-by-side analyses of vertical farms and greenhouses. For most US markets, the greenhouse model comes out ahead on both capital and operational costs.

Let’s look at an example located in a New York Metropolitan market scenario with two similarly sized facilities having similar amounts of bed space (production capacity). The below tables indicate their differing costs per lb of leafy greens grown in the first year.

This analysis focuses on production systems and has thus excluded costs relating to installation and land acquisition, but includes an additional distribution cost for the greenhouse model, as this greenhouse is likely to be located outside of an urban area but still within the “local” range. In the interest of equating production conditions, the greenhouse model also includes additional capital and operational costs for the integration of supplemental lighting in order to bring the daily light integral to equal quantities provided by most vertical farms.

While we may see different scenarios in the future, this assessment draws on current prices and equipment performance.

Greenhouses draw a lot of their value from the fact that the production surfaces are mostly illuminated by the sun, a free resource. Vertical farms, on the other hand, have to pay for the light that their crops see, a significant added cost that often occupies high percentages of operational costs.

In addition, a specialized HVAC system must be designed and implemented to neutralize the heat emitted by the lights. Additional dehumidification capacity is also required with design setpoints relative to the transpiration rate of the crops being grown. HVAC is often the second-highest, non-labor expenditure for VF operations and when dehumidification is added into the mix, overall HVAC operational costs can even exceed lighting electricity costs.

As LEDs become more efficient, less power will be required to cool the space and the economic scenario for VFs becomes more attractive as two of the highest operational costs have been reduced.

To date, the introduction of LEDs to the agriculture industry has made VFs possible. In the future, the continued improvement of LEDs will make VFs more competitive against other modes of controlled environment crop production. It’s hard to say if VFs will outcompete greenhouses on their costs of production as greenhouses similarly benefit from lighting efficiency improvements that will enable them to serve more northern markets at lower operational costs.

While greenhouses outcompete vertical farms today, there may be a future where those tables are turned.

It should be considered that the efficacy of either of these approaches to CEA will be informed by local market conditions. In relation to both the revenue generated and the costs of operation, markets around the world provide differing contexts for the production of crops in protected agriculture scenarios, and these varying costs and opportunities create a unique scenario in every market.

Agritecture’s consultants have a deep understanding of these costs and opportunities and have provided these insights to over 100 clients in more than 20 countries. If any of our readers would like to explore the possibilities in their local region, reach out to Agritecture and we can assess this opportunity through our unique approach and assessment methodology.

This is the second of a two-part series on how vertical farming compares to other farming methods, from our Lead Systems Designer, Djavid Amidi-Abraham. To read Part 1, click here.

Source and Photo Courtesy of Agritecture

VIDEO: Take A Virtual Tour Of The New Controlled Environment Ag Center At The Ohio State University

Dr. Chieri Kubota, the Director of the new center focusing on controlled environment agriculture and protected cultivation hosted this event to introduces the programs and membership

Dr. Chieri Kubota, the Director of the new center focusing on controlled environment agriculture and protected cultivation hosted this event to introduces the programs and membership.

What OHCEAC is unique about is that we are an integrative, interdisciplinary, and inclusive team conducting collaborative research to respond to CEA stakeholder needs. Our focus inclusively covers various production systems and crop types. We use the terminology of CEA as having a very broad meaning including soil-based or soilless systems under various types of climate control or modification structures.

Boost Operational Efficiencies With Lighting Control System

Signify has expanded its GrowWise Control System, allowing for higher levels of automation and reducing manual labor and operational costs

"Signify’s expanded GrowWise Control System helps growers boost operational efficiencies. This allows for full dimming for Philips toplighting compact in greenhouses. Besides, it enables growers to plan and automate light recipes one year ahead and to control the grow lighting through their climate computer or greenhouse management system. This will result in lower manual labor costs and improved operational efficiency," the company announces.

Signify has expanded its GrowWise Control System, allowing for higher levels of automation and reducing manual labor and operational costs. This can be achieved by automating the lighting planning for their crop’s full growth cycle, up to one year ahead. The software tool brings dynamic lighting to greenhouses and vertical farms and fits seamlessly with modern climate computers and greenhouse management systems. This enables growers to automatically adjust light levels to maintain consistent levels on cloudy days, save energy on sunny days and simulate sunrise and sunset throughout the day or season.

Growers, like the Italian vertical farm, Planet Farms, and the Belgium greenhouse, De Glastuin, are already using the expanded system providing additional value within their growing facility.

“Using the GrowWise Control System is ideal for us,” says Luca Travaglini, co-founder of Planet Farms. “We want to automate as many aspects of our operations as possible to become more cost efficient. Now we can easily create custom light recipes and set them to run year-round to provide the right light recipe with the right light intensity at the right time throughout the crop’s growth cycle. By automating our full light strategy during the growth cycle, for the whole year, we can run our operations very efficiently and keep our manual labor costs low. That makes it easier for us to maintain consistent quality as we scale up our production.”

The demand for the GrowWise Control System is increasing for greenhouse applications as well. “The lighting can be used much more efficient, since it gives us the flexibility to reduce light levels at any moment we need to,” says Wouter de Bruyn, owner at De Glastuin. Lettuce grower De Glastuin is using the GrowWise Control System to control the Philips GreenPower LED toplighting compact grow lights via its climate control system. “The climate computer is equipped with a daylight sensor that sends actual light measurements to the GrowWise Control System so we can adapt our light levels automatically to ensure an even light level throughout the day and season. This results in a continuous high-quality crop. In case the electricity is the limiting factor, we are still able to use the LEDs evenly for the whole greenhouse in a lesser intensity.”

“Dynamic lighting in a greenhouse is the next step in improving the cost-efficiency and quality for the cultivation process,” says Udo van Slooten, Business leader Horticulture LED solutions at Signify. “It allows growers to effortlessly maintain a consistent level of light throughout the day to produce the best possible crops. The system compensates for cloudy weather and creates a more controlled growing environment for your crop.”

Offering The Complete Package, Thinking From A Plant Perspective

KG Systems has about any solution to vertical farming that can be thought of

“Nowadays, there’s very little growing space. Many growers have to grow in several places at the same time, moving their products around,” says Floris Berghout, International business development manager at KG Systems. “Therefore, when taking this problem into account, vertical farming is a valuable addition to horticulture. However, I do not think that vertical farming will replace traditional greenhouse growers.”

Over 15 years ago, KG Systems became involved with vertical farming. In 2006, the company constructed its first vertical farm inside a greenhouse, used for Lilly production, soon after that, a propagation cell followed for orchids. KG Systems has about any solution to vertical farming that can be thought of. This thanks to the experience they gained because of their involvement in many diverse projects over the years.

(F.l.t.r.) Matthias Haakman and Floris Berghout

“Many growers are involved with researching the propagation process in vertical farms as this cultivation process delivers stronger plants and better performance in the greenhouse,” Matthias Haakman, Account manager at KG Systems. “We always sit down with the client to analyze what the most appropriate solution would be for them. Here, we’re looking at the plants and what they need. We’re basically building a product around the plant the grower aims to grow. In terms of seeds, the system, etc.”

Floris says that the great thing about KG Systems’ technique is that they’re able to adjust any system to the plants. The team is working closely with flora, tomato, etc. growers. These systems are one big puzzle, but the company can deliver either one piece of it or more. “We’re working with many customers that are either upgrading their systems or wanting to install a complete new farm inside a warehouse, or elsewhere. In all these cases the same knowledge is implemented,” he says.

“The more projects we have done, the more we have been taught about the market. It has enabled us to see what techniques are available and that’s in our benefit. Therefore we can offer the best tailored solutions to our customers nowadays,” says Matthias.

KG Systems' installation at a tulip grower

According to Floris, it’s the trick to outline the situation. Meaning, what does the customer have in mind and then reason back to the plant. The client has its eye on a certain market where the product will be sold at a certain price. Therefore we need to know the following things in order to create the best solution for them. Such as, what does the plant need in order to grow, and how do we fit this into a multiple layer system, using what technique? Then we’ll draw up a balance in terms of budget.

KG’s technology is scalable in complexity. In other words, the company can deliver any system at any price, depending on the growers’ end goal. “We are there to help out with their market, potential buyers, you name it. If clients lack of market-, product- or customer knowledge, etc., the company directs them to a consultancy agency,” says Floris. This agency will educate them in every area needed and guide them into the right direction.

For more information:

KG Systems

Matthias Haakman, Account manager

Floris Berghout, International business development manager

info@kgsystems.nl

www.kgsystems.nl

Author: Rebekka Boekhout

© VerticalFarmDaily.com

The One Thing You’re Probably Overlooking In Your Greenhouse

We often overlook the value of light in southern parts of the continent.

The cost of natural sunlight is an important thing for producers to understand because there is an economic value that they should be placing on sunlight. It’s one of the main inputs to production!

If you ask a good greenhouse operator, “What is your cost of natural gas? Electricity? Building cost per square foot? Operational cost per square foot?”, he’ll give you detailed answers.

Ask him, “What is the value of the light you receive?” and you’ll get a different response.

“…Uh, what?” he might respond.

You clarify. “The light, the sunlight. What is the value of the sunlight?

“I don’t know.” He will be taken off guard because he’s never thought about it before. Why?

Because people take light for granted. After all, sunlight is free. Why place a value on it?

But light is a “free” resource!

The cost of natural sunlight is an important thing for producers to understand because there is an economic value that they should be placing on sunlight. It’s one of the main inputs to production! If they’re placing an economic value on supplemental lighting, then they should be placing an economic value on natural light.

Why do they make that mistake? Because it’s free. Most people don’t put a value on free things.

And if a person places no value on a thing, they’re not going to use it efficiently. When something is free you don’t think about trying to use it in the most economical sense. When something is free you just use it.

Why would you try to conserve something that’s free? Why would you try to maximize the value of something that’s free? In your mind, it has no value.

This is true with sunlight. Because it’s (supposedly) a free resource, people don’t place an economic value on it and then they don’t build their model to maximize that value. The problem with this is that light does have a cost that can act as a limiting factor on your operation. This inefficiency poses a significant problem.

For instance, say you want to grow in Alaska. You want to grow year round but in the middle of the winter you might only have an hour of daylight – all of a sudden the economic value of that light becomes alarmingly apparent. Because you actually have to pay to replace it in the wintertime. So if you’re growing in Alaska in the wintertime, you’re freaking out about how you get the maximum value out of that light. You’re may choose to use red and blue LEDs instead of white because you can get more efficiency from them – even if it’s at a higher initial cost. You’re going to do everything you can to maximize the value of that resource.

We often overlook the value of light in southern parts of the continent.

And that’s why, even though light is a resource like everything else, no one actually figures it into any of their calculations, including the cost of goods sold. This mistake often limits growers to much lower production, or missing out on key observations that inform their model. (Among other things.)

In reality, the value of light is high

Note that the value and the cost of light are very comparable here. The value of something can be defined by it’s cost. Keep that in mind.

If you did think about light use efficiency, you would probably find yourself at the same destination that we did: volumetric farming, and much higher production because of it.

How to Place a Value on Light

If you don’t have light, then the easiest way to calculate it is by calculating the cost of replacing that light. What is the cost of replacing it with LEDs or HID or whatever supplemental lighting you choose?

If you do have light, then you’re probably growing in a greenhouse. In that case, you can find the cost of light by comparing the cost of growing in a greenhouse (which is how you are acquiring that light) with the cost of growing in a facility without that sunlight. (So the value of the sunlight is essentially the difference in operational cost between a warehouse of the same size and a greenhouse.)

These operating costs are going to include things like replacing a covering, heating (heating a greenhouse is always a lot more expensive), and maybe things like building permits.

Those costs can add up, and you’ll find that light is a costly resource even if you don’t think about it much. When you understand the costs of light, you will begin to use it more efficiently. You’ll start thinking about maximizing light use the same way that you maximize water and electrical and natural gas and other resources.

Initially this will result in lower overall costs, but we think you’ll find that your efforts toward efficiency will lead to even more benefits.

Once you do understand the value of your light, how do you get more out of it?

To increase light use efficiency, you first have to identify the main areas of waste and eliminate them. To do that, you start by identifying what’s happening with most of the light that enters your greenhouse: absorption and reflection.

ZipGrow Towers were designed to reflect light through the mass of towers to reduce shadowing and light waste.

Absorption is happening either when the light hits photosynthesizing plants or when it hits another absorptive surface and is either used by plants or turns to heat. Reflection happens when light hits a surface and bounces back. This is what you want, because if it’s not being absorbed by plants, then we reflect it to be absorbed by plants. (The less light energy that’s converted to heat, the more is conserved for use by your plants.)

The most obvious way to promote reflectance is to use reflective surfaces wherever possible. This doesn’t necessarily mean using silver or mirror finish, but it does mean white finishes to reflect that light. It also means that we think about growing plants on multiple planes, and arranging the production apparatus to conserve light within the greenhouse through reflection as opposed to reflecting it out of the greenhouse.

If you’re growing on a horizontal plane, know that if that light doesn’t hit a plant, oftentimes light will just be reflected back up and out of your greenhouse. When we switch the plane around so that the photons are conserved to the bottom of the mass, our absorption rates are higher, we have more plants absorbing energy rather than energy just being reflected up and out of the greenhouse. That’s the idea behind volumetric farming with ZipGrow™ Towers.

Source and Photo Courtesy of Agritech Tomorrow

IPO Planned To Improve Revenues Indoors

Light Science Technologies has gained the funding from Intuitive Investments Group plc (IIG), ahead of going public on the London Stock Exchange in the next six months.

8-01-2021| Business Live

“We believe that there is no better time to be involved in both agritech and medtech." A company which makes technology to improve indoor crop yields has received a £1 million investment ahead of a planned IPO.

Light Science Technologies has gained the funding from Intuitive Investments Group plc (IIG), ahead of going public on the London Stock Exchange in the next six months.

The business, based on the Hilton Business Park, Derby, provides lighting and plant growing and monitoring technology for agriculture in partnership with university research teams.

Its agricultural tech can be used in three main indoor settings – vertical farming (where crops such as tomatoes are grown in vertically stacked layers), greenhouses and medicinal plants.

Its patent-pending, sustainable light unit combines interchangeable LEDs, power and technology to help reduce costs and generate maximum yields over 25 years.

Its real-time monitoring and control technology can also be used to link technicians, farmers, and facility managers with their crops to provide instant production data.

Management said that with better light quality and energy savings, its light, science and technology products increase cycles.

It also supplies technology to clients in the electronics, audio, automotive, AI technology and pest control sectors.

The move to become a publicly listed company follows significant investment in its team and operations over the past few years which, the business said, has “brought to market a fully updateable, bespoke and intelligent lighting solution that provides optimal yield”.

The company is also due to launch its own in-house growth and laboratory service in the spring, focusing on plant growth and performance to help farmers with their crops.

Chief executive Simon Deacon said: “We believe that there is no better time to be involved in both agritech and medtech as two rapidly expanding sectors which are going to be responsible for spearheading some of the most significant global developments over the coming decade and beyond.

“IIG’s investment is not just a reflection of its commitment to LSTH as a fast-growing business backed by almost 30 years’ expertise in light technology but also of its awareness of the importance in achieving a better, more sustainable approach to agricultural production as well as pioneering potential life-saving solutions in digital health innovation.”

Light Science Technologies is IIG’s first investment following its own successful IPO and admission to AIM in December, as it seeks to attract investors with its life sciences portfolio.

IIG chairman David Evans said: “LSTH has the key ingredients for success; it has an excellent management team, a deep knowledge of the light spectrum and the application of that knowledge to areas where substantial growth can be obtained.

“I am personally excited about the potential diagnostic applications in the digital health sector, such as non-invasive haemoglobin measurement, as well as the developments in vertical farming technology that will underpin the long-term growth of LSTH.”

The investment follows recent funding for Light Science Technologies from Innovate UK which will see it work over the next six months with Nottingham Trent University to develop a growing sensor and transmission node for vertical farms.

Photo: Light Science Technologies designs lighting, science and plant monitoring technology.

Source and Photo Courtesy of BusinessLive

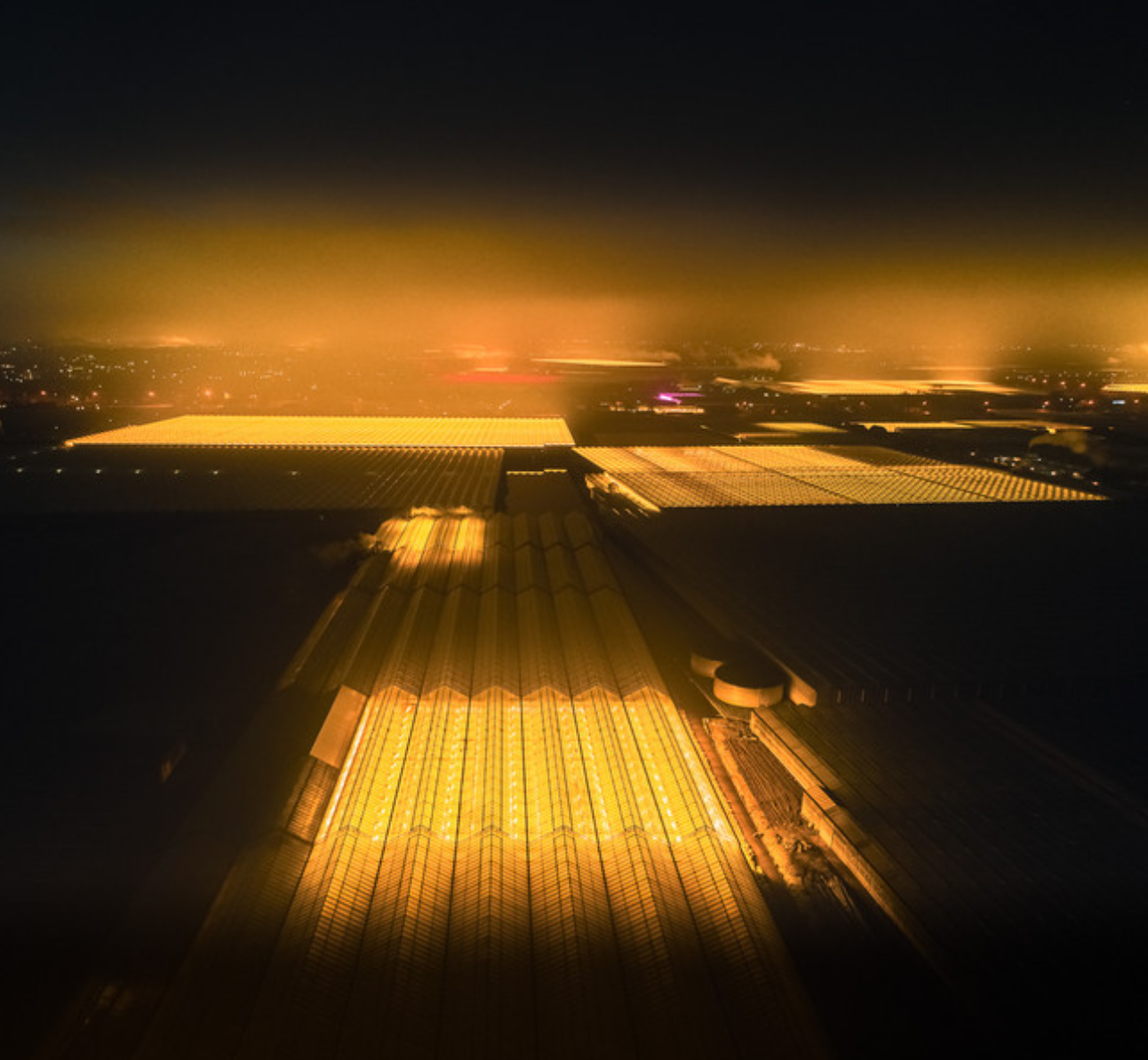

Leamington Greenhouse Growers Struggle With Venting With Light Pollution Limits

Venting limits are imposed by local municipalities to address light pollution concerns

A recent Horti Daily article discussed the problems with limited venting experienced by many greenhouses in the Leamington, Ontario area. Venting limits are imposed by local municipalities to address light pollution concerns. Venting is a strategy used by greenhouses to remove warm air from the greenhouse as temperatures rise, especially in the warmer months. Venting limits make it difficult for greenhouses to remove warm air and maintain optimal temperatures in greenhouses. An unintended consequence with artificial lights is that opening greenhouse side walls and roofs allows light escaping, causing light pollution to the neighboring area outside.

Greenhouse growers are constantly juggling and adjusting growth parameters like light, temperature, and CO2 to create an optimal growth environment for their plants. Choosing to vent or not is always a double-edged sword. On the one hand, venting is an inexpensive way to manage air exchange in order to keep temperatures cooler in the warm months from spring through fall. On the other hand, venting with artificial lights on results in light pollution. Venting also makes it impractical to supplement the greenhouse grow area with CO2 by atmospheric enrichment (also known as CO2 gassing) since the CO2 gas quickly escapes outside.

The problem with venting is not usually an issue for Leamington greenhouses in the colder months when the vents are closed, thereby enabling CO2 gassing as the facility is sealed and reduces artificial light pollution. CO2 gas levels in the grow rooms can be maintained at 1200 parts per million (ppm) to optimize growth. However, in the warmer months when venting occurs, it is very difficult to maintain 400 ppm (the level of natural CO2 in the air) even if CO2 gas is pumped into the grow area since nearly all of it escapes outside during venting.

CO2 Delivery Solutions™ can help Leamington greenhouse growers solve the CO2 supplementing problem when venting.

CO2 Delivery Solutions™ enables Leamington greenhouses to provide their plants with added CO2 which enhances growth and yields. This capability is achieved by misting an aqueous CO2 solution directly on to the plants, with or without venting. This technology allows CO2 to be controlled independently, rather than its delivery being co-dependent on the control of other growth parameters like light and temperature. This enhances a grower’s ability to optimize environments in a simpler and more effective manner. While CO2 Delivery Solutions™ cannot solve the artificial light pollution problem when Leamington greenhouses need to vent, it can certainly solve the lack of optimal CO2 problem during those months and help tip the balance towards more optimal yields year-round.

Visit co2delivery.ca for more information.

PODCAST: Season 2 Episode 20 - Founder And Chief Operating Officer (COO) of Ceres Greenhouse Solutions, Marc Plinke

Ceres designs and builds advanced, energy-efficient greenhouses that grow year-round while saving energy and water

Join Harry Duran, host of Vertical Farming Podcast, as he welcomes to the show Founder and Chief Operating Officer (COO) of Ceres Greenhouse Solutions, Marc Plinke. Ceres designs and builds advanced, energy-efficient greenhouses that grow year-round while saving energy and water.

In this episode, Harry and Marc dissect Marc’s career trajectory, from his time at Synergistic Building Technologies to his current role with Ceres. Marc breaks down his passion for bringing about positive change in the world, the inspiring work he’s doing with Ceres, and the state of food in our society.

Edible Garden To Expand With Ohio Greenhouse Purchase

The new facility is intended to accompany its Flagship Greenhouse in Belvidere, NJ, and partner farms the company contracts nationwide through a cooperative franchise farming model

Edible Garden to expand with Ohio greenhouse purchase

January 13, 2021

Edible GardenComing off of 2020 characterized by national demand and record sales, Edible Garden, Belvidere, N.J., announced today that it has signed a Letter of Intent to purchase a facility in Piqua, OH.

"This agreement is a great opportunity to build on our mission of Zero-Waste Inspired® farming, food safety, traceability, and the reduction of food miles," said Jim Kras, CEO of Edible Garden. "This acquisition aligns our facility with recent distribution wins at retailers including Meijer and Walmart, allowing us to supply fresh produce throughout the Midwest."

The Piqua, OH facility will increase Edible Garden's growing capacity with the introduction of the company's sustainability mandate, GreenThumb™ software technology and packaging innovation. The facility will go through an extensive renovation to accommodate Edible Garden's advanced processes and stringent food safety protocols. The company expects this acquisition will bring dozens of indoor farming and horticultural jobs to the area.

Courtesy Edible Garden

The new facility is intended to accompany its Flagship Greenhouse in Belvidere, NJ, and partner farms the company contracts nationwide through a cooperative franchise farming model.

Edible Garden produce includes USDA-Certified Organic Premium Fresh Cut Herbs, Hydro Fresh Basil, Organic 4" Living Herbs, and Premium Organic Living & Cut Lettuces that are currently available at major retailers including Meijer, Walmart, Kroger, Wakefern/ShopRite, Hannaford, Target, Sweetgreen, Weis, Hmart, among many others.

Edible Garden recently launched an equity crowdfunding campaign via crowd investment platform Republic to help fund the commercialization of advanced environmentally controlled greenhouses. More about the campaign is here: https://republic.co/edible-garden

Logo: Courtesy Edible Garden

Bowery Farming Expands With The Addition of A New Farm

“Adding our newest, most sophisticated, smart indoor farm in Bethlehem to our network is a critical next chapter in our growth,” said Founder and CEO Irving Fain

Jan. 6th, 2021

NEW BETHLEHEM, PA - If the new year has you thinking about all things bigger and better, you’re not alone. Bowery Farming announced its expansion with a new farm in Bethlehem, Pennsylvania, the company’s largest commercial farm yet.

Irving Fain, Founder and Chief Executive Officer, Bowery Farming“

Adding our newest, most sophisticated, smart indoor farm in Bethlehem to our network is a critical next chapter in our growth,” said Founder and CEO Irving Fain. “We’re proud to transform a former industrial site into productive, modern farmland, which will create year-round sustainable farming jobs for the community and expand access to a reliable source of traceable pesticide-free produce across the region.”

The farm, which is the most technologically advanced of Bowery’s farms, features industry-leading improvements like LED lighting that reduces energy consumption and a water transpiration system designed to recapture nearly all of the water from the plants, a press release revealed.

Bowery Farming announced its expansion with a new farm in Bethlehem, Pennsylvania, the company’s largest commercial farm yet

Bowery is working with the Commonwealth of Pennsylvania to transform the non-arable industrial site into useful, modern farmland. The grower is also partnering with the Pennsylvania Department of Community and Economic Development and Governor’s Action Team to bring the new farm to fruition. Because of its strategic location, the farm will bring local produce to the surrounding population of over 49 million consumers and provide year-round farming jobs.

Tom Wolf, Governor, Pennsylvania (Photo credit: National Governors Association)“

Pennsylvania welcomes Bowery Farming to our commonwealth’s rich and diverse agriculture industry and looks forward to supporting the company’s growth as it reimagines how farming can be more sustainable and impactful on our communities,” said Pennsylvania Governor Tom Wolf. “Bowery’s expansion will generate new opportunities by establishing this indoor vertical farm, and will create innovative farming practices, new jobs, and a chance to address food insecurity in the Bethlehem area.”

We at AndNowUKnow will keep our eye on the newswire as more and more growers continue to push for expansion in new markets.

Packaged Salads Value-Added Bowery Farming Expansion New Farm Farm Technology Water Transpiration System Lighting Sustainability New Jobs Facility Facilities Operation Growth Growing Expand Expanding Irving Fain Tom Wolf

COMPANIES IN THIS STORY

Bowery Farming

At Bowery, we're committed to growing the purest produce possible. To us, that means using zero pesticides and non-GMO...

AppHarvest Hires Impossible Foods’ David Lee As President

Lee brings track record capitalizing on innovative disruption to meet consumer demand

Lee brings track record capitalizing on innovative disruption to meet consumer demand

MOREHEAD, Ky., Jan. 7, 2021 – AppHarvest, the leading AgTech company building some of the country’s largest indoor farms and combining conventional agriculture techniques with cutting-edge technology to grow affordable, nutritious fruits and vegetables at scale, has appointed David Lee president, reporting to Founder & CEO Jonathan Webb effective Jan. 25.

In this newly created role, Lee will develop strategy and engage in operations management, leading the sales, marketing and finance functions as AppHarvest continues to grow as a sustainable fresh foods company.

Lee will join AppHarvest from Impossible Foods where he has served as chief financial officer since December 2015. He is credited with significant growth accomplishments at Impossible Foods including securing more than $1.3 billion in funding to accelerate manufacturing, product development and distribution into key national grocery, restaurant, and hospitality venues; and to expand in international markets. Additionally, Lee served as chief operating officer of Impossible Foods from 2015 to 2019, during a period of significant transformation for the company. Lee has served on the board of

directors of AppHarvest since August of 2020 and will continue to serve in that role after the closing of the previously announced business combination of AppHarvest with Novus Capital Corporation (Nasdaq: NOVS).

“David Lee brings decades of experience across retail and consumer industries driving business transformation and optimizing organizational effectiveness from Del Monte to Zynga to Impossible Foods,” said AppHarvest Founder & CEO Jonathan Webb. “His skillset will help us build AppHarvest into an iconic brand and sustainable foods company that disrupts traditional agriculture to deliver responsibly grown American products with social impact,” Webb said.

“AppHarvest offers a unique solution to building a more resilient and responsible food system. I have seen firsthand that when given sustainable options, consumers will be the market force that helps address climate change and food supply issues, ensuring success of companies that are putting the planet first, and I am eager to invest my time in a mission-driven company with so much potential to grow.”

In January, AppHarvest expects to begin the first harvest from its flagship farm – a 60-acre facility growing tomatoes – in Morehead, Ky. The company has two additional facilities under construction – a similar 60-plus acre facility outside Richmond, Ky., and a 15-acre facility to grow leafy greens in Berea, Ky. AppHarvest also is planning for more facilities across Kentucky and Central Appalachia, with nine potential projects in the pipeline through 2025.

AppHarvest grows produce using 100 percent recycled rainwater and zero chemical pesticides. Its indoor farms are designed to use 90 percent less water with yields that are up to 30 times higher compared to traditional open-field agriculture on the same amount of land. Its location in Appalachia allows it to deliver a strong social impact by building a diversified economy in economically distressed areas of the country, while enabling its products to reach about 70 percent of the U.S. population within a single day’s drive. As a result, AppHarvest expects to deliver fresher fruits and vegetables, ripened on the vine for peak flavor and nutrition, and an 80 percent reduction in diesel consumption required for transportation as compared to produce shipped from Mexico and the Southwest of the U.S.

Lee holds an MBA from the University of Chicago and a BA from Harvard.

How is AppHarvest different from traditional agriculture companies?

- The company’s controlled environment agriculture facilities are designed to reduce water usage

by 90% due to unique circular irrigation systems connected with large-scale rainwater retention ponds. The system is designed to eliminate harmful agricultural runoff, which contributes to toxic algae blooms.

- Strong relationships with leading AgTech universities and companies in the Netherlands position AppHarvest as a leading applied technology agriculture company. The Netherlands has developed a significant high-tech greenhouse industry, becoming the world’s second-largest agricultural exporter despite having a land mass roughly equal in size to Eastern Kentucky. Earlier this year, AppHarvest led a landmark 17-organization agreement uniting Dutch and Kentucky governments, universities, and private companies, with all committing to building America's AgTech capital from within Appalachia.

- AppHarvest puts the planet and people first as a registered Benefit Corporation and has also been certified as a B Corp by an independent organization.

In just over two years, AppHarvest has attracted more than $150 million in investment into Central Appalachia and announced on September 29, 2020, its entry into a definitive agreement for a business combination with publicly-traded special purpose acquisition company Novus Capital Corporation (Nasdaq: NOVS). The combination, which is anticipated to close early in the first quarter of 2021, is expected to provide $475 million of gross proceeds to the company, including $375 million from a fully committed common stock PIPE at $10.00 per share anchored by existing and new investors – including Fidelity Management & Research Company LLC, Inclusive Capital, and Novus Capital Corporation. Upon closing of the transaction, the combined company will be named AppHarvest and is expected to remain listed on Nasdaq under the ticker symbol APPH.

AppHarvest’s investors include Revolution’s Rise of the Rest Seed Fund, Inclusive Capital Partners, Equilibrium, Narya Capital, Lupa Systems, Breyer Capital and Endeavor Catalyst. Endeavor selected AppHarvest Founder & CEO Jonathan Webb as an Endeavor Entrepreneur in 2019.

Board members include food icon Martha Stewart, Narya Capital Co-Founder and Partner JD Vance and impact investor Jeff Ubben.

About AppHarvest

AppHarvest is an applied technology company building some of the world’s largest indoor farms in Appalachia. The company combines conventional agricultural techniques with cutting-edge technology and is addressing key issues including improving access for all to nutritious food, farming more sustainably, building a home-grown food supply, and increasing investment in Appalachia. The company’s 60-acre Morehead, Ky. facility is among the largest indoor farms in the U.S.

For more information, visit AppHarvest.

Forward-Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “will,” “estimate,” “continue,” “anticipate,” “intend,” “expect,” “should,” “would,” “plan,” “predict,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this press release, regarding Novus Capital’s proposed acquisition of AppHarvest, Novus Capital’s ability to consummate the transaction, the benefits of the transaction and the combined company’s future financial performance, as well as the combined company’s growth plans and strategy, future operations, estimated financial position, estimated revenues and losses, projected costs, prospects, plans and objectives of management are forward- looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of AppHarvest’s management and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AppHarvest. These forward-looking statements are subject to a number of risks and uncertainties, including those discussed in Novus Capital’s registration statement on Form S-4, filed with the SEC on October 9, 2020 (the “Registration Statement”), under the heading “Risk Factors,” and other documents Novus Capital has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. In addition, forward-looking statements reflect AppHarvest’s expectations, plans, or forecasts of future events and views as of the date of this press release. AppHarvest anticipates that subsequent events and developments will cause its assessments to change. However, while

AppHarvest may elect to update these forward-looking statements at some point in the future, AppHarvest specifically disclaims any obligation to do so. These forward-looking statements should not be relied upon as representing AppHarvest’s assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Important Information for Investors and Stockholders

In connection with the proposed transaction, Novus Capital has filed the Registration Statement with the SEC, which includes a preliminary proxy statement to be distributed to holders of Novus Capital’s common stock in connection with Novus Capital’s solicitation of proxies for the vote by Novus Capital’s stockholders with respect to the proposed transaction and other matters as described in the Registration Statement, as well as the prospectus relating to the offer of securities to be issued to AppHarvest’s stockholders in connection with the proposed transaction. After the Registration Statement has been declared effective, Novus Capital will mail a definitive proxy statement, when available, to its stockholders. Investors and security holders and other interested parties are urged to read the proxy statement/prospectus, any amendments thereto and any other documents filed with the SEC carefully and in their entirety when they become available because they will contain important information about Novus Capital, AppHarvest and the proposed transaction. Investors and security holders may obtain free copies of the preliminary proxy statement/prospectus and definitive proxy statement/prospectus (when available) and other documents filed with the SEC by Novus Capital through the website maintained by the SEC at http://www.sec.gov, or by directing a request to: Novus Capital Corporation, 8556 Oakmont Lane, Indianapolis, IN 46260. The information contained on, or that may be accessed through, the websites referenced in this press release is not incorporated by reference into, and is not a part of, this press release.

Participants in the Solicitation

Novus Capital and its directors and officers may be deemed participants in the solicitation of proxies of Novus Capital’s shareholders in connection with the proposed business combination. Security holders may obtain more detailed information regarding the names, affiliations and interests of certain of Novus Capital’s executive officers and directors in the solicitation by reading the Registration Statement and other relevant materials filed with the SEC in connection with the business combination when they become available. Information concerning the interests of Novus Capital’s participants in the solicitation, which may, in some cases, be different than those of their stockholders generally, is set forth in the Registration Statement.

Greenhouse Villages To Sprout In Metro Manila

The Agricultural Training Institute (ATI) recently partnered with four barangays in Caloocan and Quezon for the creation of greenhouse villages as part of the urban agriculture program of the government

Louise Maureen Simeon

12/22/2020

MANILA, Philippines — The Department of Agriculture will start establishing greenhouse villages in Metro Manila to help ensure a sustainable food supply in the country.