Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Optimizing Resource Use Efficiency In CEA System

An important factor affecting the profitability of vertical farming is a grower’s ability to consistently deliver a predictable product

Date: July 29, 2021

Time: 2 p.m. - 3 p.m. EDT

Presented by: Murat Kacira (The University of Arizona)

Click Here To Register

Webinar Description

An important factor affecting the profitability of vertical farming is a grower’s ability to consistently deliver a predictable product. To achieve this, growers must create an environment that supplies all the crop’s needs over its entire growth cycle by identifying and co-optimizing environmental variables such as CO2, light, humidity, airflow, and other parameters. This presentation will focus on real-time sensing, monitoring, and climate control strategies with system designs for environmental uniformity leading to enhanced resource use efficiency in CEA system.

Dr. Murat Kacira (Professor)

Murat Kacira is director of the Controlled Environment Agriculture Center and he is a professor in the Biosystems Engineering Department at the University of Arizona. He received his B.S. degree in Agricultural Engineering in Cukurova University in Turkey and M.Sc. and Ph.D. degrees from Food, Agricultural and Biological Engineering from The Ohio State University in USA. His research involves automation, environmental control, alternative energy integrated CEA systems and resource use optimization in controlled environment agriculture systems including greenhouses and vertical farming-based plant factories with artificial lighting. He is a member of American Society of Agricultural and Biological Engineers (ASABE), American Society of Horticultural Sciences (ASHS), and International Society for Horticultural Science (ISHS). He serves as Chair of the Division Precision Horticulture Engineering under ISHS.

Special thanks to our Industry partners

Join Today

If you have any questions or would like to know more about GLASE, please contact its executive director Erico Mattos at em796@cornell.edu

Inside Natural Grocers' Hydroponic Produce Container

Inside, more than 4,000 heads of organic lettuce are grown every month across roughly 320 square feet — just a fraction of the roughly 1 acre worth of land it would take to conventionally grow the same amount, said Michael Boardman, manager of the grow unit, which the grocer calls GardenBox

Catherine Douglas Moran

July 7, 2021

Eighty-two steps away from the produce aisle of Natural Grocers store in Lakewood, Colorado, sits a shipping container filled with hydroponic produce.

Inside, more than 4,000 heads of organic lettuce are grown every month across roughly 320 square feet — just a fraction of the roughly 1 acre worth of land it would take to conventionally grow the same amount, said Michael Boardman, manager of the grow unit, which the grocer calls GardenBox.

"Within this small space, there's a lot of possibilities," Boardman said while giving a recent FaceTime tour of the shipping container.

The GardenBox pilot marks Natural Grocers' first foray into organic hydroponic farming and furthers its commitment to sell 100% organic produce and invest in hyper-local production. Starting Wednesday, July 7, customers can buy the lettuce at the store for $1.99 per head.

GardenBox grows seven to eight varieties of lettuce, including Hampton, Brentwood, Alkindus, Tropicana, Muir, Marciano and Truchas. Unlike seasonal greens, the lettuce in GardenBox can be grown year-round, meaning it's always in season.

"We're seeing consistency in the product, whether it's snowing 2 feet outside or it's 90 degrees outside," Boardman said. "The box does a really good job of regulating this temperature."

Courtesy of Natural Grocers

From seed to salad

A portion of the container is dedicated to seedlings and can hold 2,400 plants at a time, with roughly 700 to 800 organic seeds planted each week in organic-friendly peat and coconut husk.

Around the three-week mark, the plants get transferred to the three vertical grow walls. The walls are double-sided and on rollers so that the plants can get spread out for equal access to LED lights that mimic sunlight, Boardman said. After about eight weeks after the seeds are planted, most varieties of the lettuce are ready for harvest.

The feeding, nutrients and water are automated through a computer system inside the box. The system also measures air temperature, humidity, vapor pressure deficit and pH levels. If any issues arise, the system sends Boardman an email. "The computer and box kind of run itself," Boardman said. "It's just us troubleshooting and then coming in planting and harvesting."

Lasting lettuce

The GardenBox lettuce, which is certified organic by Where Food Comes From Organic and has the Clean Hydroponic Produce seal, is sold with roots intact, which Boardman said lengthens its shelf life and provides a better flavor and more nutrients.

"They taste amazing," Boardman said. "The taste is a really big selling point for me. You get a much stronger flavor out of all of them."

Courtesy of Natural Grocers

In some cases, the lettuce may get sweeter when the roots are kept in the water following the harvest. Fresh living greens also provide a more nutrient-dense product than traditional lettuces that have been shipped to the store, Boardman noted.

After getting harvested, the produce is sold loose on a spinning display with water in the middle of the store's produce department. Shoppers can then bag it with plant-based produce bags.

Growing more greens

The idea for the hydroponic farm came from the Isely family, which started Natural Grocers in 1955, said Boardman, who joined the project in October.

The trickiest part of the operation has been figuring out the nutrients formula, which includes magnesium, cobalt, copper, manganese, zinc and iron, along with the organic growing process. "It took us several months to really dial in the organic nutrients. There's not a lot of organic hydroponic growers out there," Boardman said.

Courtesy of Natural Grocers

The first harvest happened in June, though Boardman said experimentation is continuing with different types of lettuce. Not all lettuce is prime for hydroponic farming, but the varieties in the box now, including butter lettuce, red romaine, and green and red oak leaf, are doing well, Boardman said. "I love [the oak leaf lettuce]. It comes out beautiful ... It just really thrives in the box," Boardman said.

Typically, hydroponic farming produces crops faster and saves more water than traditional farming. As part of the Clean Hydroponic Produce Standards certification, the grocer will be participating in scientific research studies on nutrient density and energy use.

GardenBox plans to eventually grow herbs for Natural Grocers, though for now, the focus is on perfecting its leafy greens, Boardman said.

Natural Grocers aims to bring GardenBox containers to more stores. "Right now, we've got one more store that we're planning on opening up with a box shortly within the next few months. But beyond that, I'm still not sure what the steps will be," Boardman said.

Lead Photo: The grocer's first foray in the futuristic farming technology, GardenBox, grows 4,000 lettuce heads per month and sits just steps away from a Colorado store's produce department.

Harvesting Cherries At Night To Protecting Apples With Nets, Record Heat Takes Toll On Fruit Crop

Record-breaking heat that blasted the West over the weekend is also proving to be lethal to crops. Even with the heat breaking a bit on Monday, daily records were tied or broken over the weekend across California, Nevada and Arizona, with extreme heat also hitting Idaho and portions of the Pacific Northwest

By Tyne Morgan

July 12, 2021

Record-breaking heat that blasted the West over the weekend is also proving to be lethal to crops. Even with the heat breaking a bit on Monday, daily records were tied or broken over the weekend across California, Nevada and Arizona, with extreme heat also hitting Idaho and portions of the Pacific Northwest.

Much of the West and Southwest have been under a heat warning for more than a week, with more than 28 million Americans seeing triple-digit heat, including Arizona, Nevada, California’s Central Valley and even parts of Washington State. The relentless heat comes just more than a week after the Pacific Northwest saw a “thousand year” heat wave that killed hundreds.

The heat and extreme drought conditions are also fueling wildfires, as well as causing orchards and farm workers to change their schedules in order to beat the heat. That’s as the National Oceanic and Atmospheric Administration (NOAA) says last month was officially the hottest June on record.

Trying to Beat the Heat with Nighttime Harvest

According to Reuters, the hottest days last month forced farm laborers to start picking cherries at 1 a.m., earlier than the normal 4 a.m. start. According to Reuters, headlamps and roving spotlights were used to aid the workers in an earlier start time in order to beat the daytime heat that threatened the workers’ safety. The extreme heat also made the fruit too soft to harvest during the day.

Reuters reports Northwest Cherry Growers still expects to see an average-sized cherry harvest this year.

"We think we probably lost about 20% of the crop," B.J. Thurlby, president of the Northwest Cherry Growers, a grower-funded trade group representing top cherry producer Washington and other Western states, told Reuters.

As reported on "The Packer" earlier this month, the Northwest Cherry Growers said the heat will force some growers to abandon a portion of their crop due to the damage caused by the heat. The issue surrounds quality. The Northwest Cherry Growers says fruit exposed to such a prolonged period of intense heat wouldn’t meet the stringent standards upheld by the Northwest growers. Unfortunately, that means that a few growers lost some or all of their crop this season.

The hot weather taking a toll on the cherry crop comes as USDA's latest sweet cherry production forecast showed production higher than 2020, but down 6% from what producers saw in 2019. USDA says the later blooming varieties were well behind the rest of the crop, which is already leading to lower yields.

Shipping Concerns

Also according to "The Packer," with temperatures topping 105 degrees for several days from June 27-30 in Wenatchee, Wash., shipping was also impacted by the extreme heat. Shippers said the heat wave could reduce the crop volume some and hold back sizing temporarily but expressed confidence there will be plenty of high-quality Washington cherries for retailers to promote in July and into August. Some are even hydro cooling cherries and taking other steps to take the heat out of fruit and using advanced sorting technology to send only strong fruit to market.

Eyes on the Apple Crop

But it’s also adding uncertainty to what the Washington apple crop will produce this year. Apples are Washington’s most valuable crop, with an estimated revenue of $2 billion each year. Apple harvest is still six weeks away, but the heat has caused the apples to stop growing for now.

"We really don't know what the effects are. We just have to ride it out," Todd Fryhover, president of the Washington Apple Commission, told Reuters.

The Washington Apple Commission says growers are doing what they can to protect their fruit against sunburn. That includes using expansive nets and spraying water vapor above the trees.

USDA's meteorologist Brad Rippey expects the heat to continue in the West for the remainder of July. View his forecast here.

Lead Photo: Heat and extreme drought are causing orchards and farmworkers to change their schedule in order to beat the heat. NOAA says last month was officially the hottest June on record, as heat continues to blast the West.

The Global Food Security & Sustainability Virtual Summit 2021 "Towards A Future Safe Global Food System"

The food crisis faced during the pandemic is a wake-up call for both developed and developing countries of the looming crisis facing the world when the next major crisis hits us, be it climate change, pandemics, etc

Overview

The Global food system is at a critical stage and made worse by the COVID-19 pandemic. As many as 265 million people are threatened by famine, up 50% on last year; 700 million suffer from chronic hunger; and 2 billion more from malnutrition, with obesity and associated diet-related diseases increasing in all world regions. During the height of the pandemic with lockdowns, we have witnessed the collapse of the global food system with reports of food producers resorting to dumping their produce.

The food crisis faced during the pandemic is a wake-up call for both developed and developing countries of the looming crisis facing the world when the next major crisis hits us, be it climate change, pandemics, etc.

Website link: https://pinnaclegroup.global/gfsss/

Website Registration Link https://pinnaclegroup.global/gfsss/delegate-attendance-opportunities/

Linkedin event: https://www.linkedin.com/events/theglobalfoodsecurity-sustainab6786907097511669760/

Although the world has progressed significantly in terms of technology advancements in food production, food is not distributed in an equitable manner to regions, countries, households, and individuals. Government policies, availability of investments and technological know-how, and improved access to food supplies are key issues that meet the urgent food needs of the world’s growing population. New and innovative farming technologies such as high-tech agriculture and aquaculture methods that produce more yields inland and urban conditions offer hope for the future.

The Global Food Security & Sustainability Virtual Summit 2021 held on the 17th of September 2021, would be one of the most important events ever held to address the critical issues of food security from the local level to the global level, and from an interdisciplinary and systemic food systems perspective. The summit will invite multi-stakeholders from governmental organizations, private sector businesses, and NGOs to address the current disruptions and possible solutions on the world food supply chain. Discussions will also include issues surrounding sustainability issues and how societies and businesses can design more sustainable solutions in their entire food chain to minimize impact to the environment and reduce food waste

See You At This Landmark Event

LettUs Grow, GrowStack, Digital Farming & Farm Urban Collaborating To Deliver Four Social-Impact Vertical Farming Projects In Wales

Vertical farming, a way of growing crops indoors on stacked shelves, can be beneficial for people, plants and the planet. It allows growers to provide fresh, healthy produce to their local area 365 days of the year and can help to supplement outdoor growing

Source: LettUs Grow

07/12/21

Four major UK vertical farming companies, LettUs Grow, Digital Farming, Farm Urban and GrowStack, are collaborating to bring the benefits of controlled environment agriculture (CEA) to Welsh communities. This is one of the widest collaborations between leading CEA tech providers in the UK to date, with a focus on delivering vertical farms across different locations in Wales as part of a social impact and community-focused project called Crop Cycle.

Vertical farming, a way of growing crops indoors on stacked shelves, can be beneficial for people, plants and the planet. It allows growers to provide fresh, healthy produce to their local area 365 days of the year and can help to supplement outdoor growing. It diversifies our supply chains and boosts local food security. It also has a long stream of environmental benefits, such as using fewer resources including land or water, removing the use of chemical pesticides and reducing the need to transport food across seas. However, a common criticism of vertical farming is that it’s not always accessible or affordable to areas under-served by our food networks.

Crop Cycle is looking to bring the benefits of vertical farming directly to communities that could benefit most and is being funded by the Welsh Government through the Foundational Economy Challenge Fund. The project is being led by Social Farms and Gardens, supported by Welsh Government's NutriWales CEA Special Interest Group and BIC Innovation.

The project enables multiple different CEA systems to be tailored to fit different community settings, whilst also allowing them to be assessed in coordination across the pilot sites. This approach is unique, facilitating the testing of new socially focused business models, the engagement of the local communities and businesses with CEA and the development of new technical solutions. LettUs Grow, Digital Farming, GrowStack and Farm Urban are working together to share their specialisms and apply different technologies to where they are best suited within four sites in Wales, two of which are in the Valleys.

This project will introduce year-round food growing right into the heart of Welsh communities, where they’ll be connected to the particular dynamics of the local area. Activities will test new community-based engagement models, focusing on social well-being, local entrepreneurship and environmental impact. In this way, the project will be bringing together community, businesses and local public sector organisations.

Gary Mitchell, the Wales Manager for Social Farms and Gardens who is leading the project team stated, "we are excited to be running the pilot project across a diverse set of sites to gain insight and further knowledge into how new agricultural systems can successfully support communities in delivering local, fresh and nutritious foods as well as important social benefits in a sustainable manner."

Welcome To Our Woods

Welcome To Our Woods in Treherbert is nestled in the heart of the Rhondda Valleys, where LettUs Grow and GrowStack will be delivering an aeroponic and hydroponic vertical container farm. This proactive community group has been actively engaging with its communities through partnerships with the Green Valleys CIC and their joint ‘Skyline’ project. This partnership has led to several funding investments in the region, exploring community ownership of land and the benefits of allowing the community to utilise their surrounding natural green assets.

Chris Nelson, director of GrowStack said: “Growstack are delighted to be working alongside LettUs Grow and Digital Farming as part of this important social enterprise. It is always fantastic to be part of a project that champions vertical farming and really shares in the values of what this approach to food production can offer, including the benefits to the local community. Working in partnership with innovative farming companies is always a pleasure, as together we can combine our expertise to deliver outstanding results.”

Ian Thomas from Welcome To Our Woods said, “We are excited to be bringing such an innovative and progressive project to our local high street. We have already been engaging with the Upper Rhondda community to explore the projects that actively use our woodlands for the benefit of those they surround, and initiatives such as this help give local people an idea of what can be achieved."

Cultivate

Two linked sites will be in Newtown, one within the established community growing space attached to the Newtown Campus of the Neath Port Talbot College Group, and one within a new town centre ‘Circular Economy’ shop. The two CEA systems, provided by LettUs Grow and Digital Farming, are being integrated into an active college site and managed by a community group, with a cafe and kitchen, shop, deli and veg box scheme in place. The site is supported by Cultivate, which is a membership cooperative linking food and community. Cultivate aims to address many of the issues associated with the modern food system, and focus on creating sustainable local food solutions.

Charlie Guy, co-founder and CEO of LettUs Grow said this about the collaborations: “LettUs Grow is delighted to be working alongside these leaders of the UK vertical farming ecosystem and inspiring community projects. The UN Sustainable Development Goals (SDGs) were implemented the same year as our foundation and have never been far from our minds. SDG 17 ‘Partnerships for the Goals’ rings especially true for us. We believe a brighter future can only be realised with inclusive partnerships and strong cooperation, built on shared values and a vision which places people and the planet at its epicentre.”

Greenmeadow Community Farm

Greenmeadow Community Farm in Cwmbran is being delivered by Digital Farming. It is one of only two ‘city farms’ in Wales and one which connects people to food and farming in a very public way. It is owned and operated by Torfaen County Borough Council, bringing with it a high-level partnership. The farm already welcomes thousands of visitors through its gates and connects locally through a number of schools and college partnerships – making it an ideal ‘showcase’ location for this pilot. Digital Farming were commissioned to deliver the Digital Farm in a container for pilot production of high nutrition greens and herbs. The system uses V-Farm patented growing systems linked to Digital Farming’s smart digital management system powered by solar PV.

Dr Gareth Jones, CEO of Digital Farming, said, “we were delighted to be awarded this project and have been enjoying working with the team at Social Farms and Gardens and Greenmeadow to bring together a new concept to explore the business of growing locally using controlled environment agriculture to enhance nutrition for communities.”

Xplore! Science Discovery Centre

The final site is in Xplore! Science Discovery Centre, situated in the centre of Wrexham: a brand new science centre that will support the promotion of urban agriculture in north Wales’ largest urban area. The vertical farming system is provided by Farm Urban. It will reach out to all generations, showcasing new technology and modern horticulture methods, blended with traditional growing experience. Xplore! welcomes public visitors, school groups and provides a range of educational workshops.

Paul Myers, Managing Director of Farm Urban said: “We are thrilled to be able to offer our hydroponic Edible Wall systems, Produce Pod aquaponic systems and learning programmes across all four sites involved in the Crop Cycle project. The team at Farm Urban have loved working alongside the four community organisations, they are all so enthusiastic and engaged which is exactly what we need for the social and environmental benefits of CEA to be shared across the UK and beyond. It has been a privilege to work alongside industry leaders GrowStack, LettUs Grow and Digital Farming learning more about their systems and approach. One of the many highlights of this project has been the openness and willingness to share and collaborate between all partners which is so important to drive the industry forward.”

To follow the progress of the community grow sites, you can follow Crop Cycle on social media, and technology providers LettUs Grow, Digital Farming, GrowStack and Farm Urban.

Tags: Indoor & Vertical Farming, Processing & Supply Chain | AgTech

Earth911 Podcast: Freight Farms’ Jake Felser On Hydroponic Agriculture & Container Farming

Earth911 talks with Jake Felser, chief technology officer at Freight Farms, about the company’s “complete farming system inside a box.”

By Earth911

JULY 14, 2021

Earth911 talks with Jake Felser, chief technology officer at Freight Farms, about the company’s “complete farming system inside a box.” It’s a very big box that includes climate controls and monitoring systems to make farming easy for anyone to do. Freight Farms builds and delivers shipping containers converted into highly efficient hydroponic farms that use LED lighting to grow and deliver fresh produce year-round.

Jake discusses the cost of getting started, how many people are needed to run the farm, and how the built-in automation helps farmers plan a profitable business. Grocers, restaurants, communities, and small farms are using Freight Farms installations at 350 farms in 49 states and 32 countries. The company says most of its customers are new to agriculture and operate right in the urban and rural communities they serve.

Jake Felser, CTO at Freight Farms, visits Sustainability in Your Ear to talk about automated hydroponic gardening in shipping containers.

Growing and distributing vegetables locally is one of the most effective ways to lower our society’s carbon footprint. While agriculture contributes about 10% of the U.S. greenhouse gas emissions each year, the majority of that is from raising animals. By increasing our consumption of locally grown vegetables, we can improve local health and reduce overall emissions from transportation. It’s not easy to grow food in most cities using traditional methods. The introduction of container farms and vertical farming inside buildings can reshape food deserts and create economic opportunities.

To learn more, visit FreightFarms.com.

Subscribe to Sustainability in Your Ear on iTunes and Apple Podcasts.

Follow Sustainability in Your Ear on Spreaker, iHeartRadio, or YouTube

Tags: container farming, Freight Farms, hydroponics, reinventing agriculture

Polygreens Podcast Episode: 34 Vijay Rapaka - Oasis Company

Skilled in Research and New Product Development, Strategic Planning, and Research Management. Successfully developed and launched several groundbreaking technologies

In this episode, Joe and Nick interview Vijay Rapaka, an experienced technical professional, passionate and motivated to deliver commercial value through research and innovation. Skilled in Research and New Product Development, Strategic Planning, and Research Management. Successfully developed and launched several groundbreaking technologies.

Latest Episode

Growfoam Welcomes New Chief Financial Officer

Growfoam, world leader in biodegradable foams for controlled environment agriculture, announced today that drs. Janet Koolman RA, a seasoned financial expert, has joined the company’s executive team as Chief Financial Officer.

July 1, 2021

Growfoam, the world leader in biodegradable foams for controlled environment agriculture, announced today that Drs. Janet Koolman RA, a seasoned financial expert, has joined the company’s executive team as Chief Financial Officer.

Koolman brings over 20 years of experience in management, accounting, and controlling. Before joining Growfoam, she worked in various roles at the Dutch Accell Group, most recently as Senior Holding Controller. Accell Group is a publicly owned company with a position on the EURONEXT Amsterdam Stock Market and is the European market leader in e-bikes. Their portfolio includes brands such as Koga, Raleigh, and Batavus. Koolman’s impact on the mobility sector is not to be underestimated. During her career at Accell, the company grew from a European player to a multinational with branches all over the world. Koolman and her team were instrumental in initiating the immense professionalization and growth of the Accell finance department.

“Koolman’s impressive background and career make her a great fit for her new role at Growfoam,” said Growfoam CEO Martin Tietema. “As well as her financial management expertise, she shares our mission and vision of making the world better for future generations, and enabling reliable and safe food production.”

Koolman’s hire follows Growfoam’s strong growth perspective since its market introduction at Greentech 2019. The company’s growth is fuelled by a financial injection from venture capitalists SHIFT Invest and Future Food Fund, alongside a global portfolio of CEA clients that has rapidly expanded over the last few months.

“I am excited to join the executive team at Growfoam,” said Koolman. “I am impressed by the team’s commitment to positively impacting the world by enabling their clients to grow greener, safer and faster, which is a core priority of the company. The time for making a big impact on food safety and quality is now. I am determined to contribute to that and, in my field of expertise, the difference between making an impact in mobility or food production is not as big as one might think. And I still commute to work by bike. Old habits die hard.”

Koolman’s hire is effective starting July 1st.

Farmers Already Forced To Abandon Crops As Additional Water Restrictions Loom

Bringing into focus some of the California crop losses caused by the 2021 drought, Western Growers has released a series of videos called “No Water = No Crops”

By Tom Karst

July 12, 2021

Bringing into focus some of the California crop losses caused by the 2021 drought, Western Growers has released a series of videos called “No Water = No Crops.”

The videos feature three California farmers who talk about the losses they are suffering this year.

“This is one of the most difficult decisions I’ve had to make in a long time,” Joe Del Bosque of Del Bosque Farms, Firebaugh, Calif., who sacrificed his asparagus field that still had five years’ productivity left, said in one video. “Seventy people are going to lose their jobs here. Next year, there will be no harvest here. Those 70 people lose two months of work. It’s a very difficult hit for them.”

Another video features Ross Franson of Fresno, Calif.-based Woolf Farming.

“Around this time of year, we’d normally be prepping for harvest,” Franson said in the video.

The farm has started knocking down almond trees in its 400-acre orchard, he said.

“But due to the dire drought that’s going on in the state of California right now, we made the decision to pull these trees out simply because we didn’t have the water to irrigate them.”

“These trees are all dead, and they shouldn’t be,” Jared Plumlee of Booth Ranches said in one video. The company produces citrus in Orange Cove, Calif., and destroyed 70 acres of trees because of the drought.

“It’s just a shame. This block had probably 20 years of productive life, and we were forced to push it out.”

Western Growers president and CEO Dave Puglia said in a news release that the future of agriculture in California is being compromised by the regulatory uncertainty of water deliveries to farms.

“Is that really what you want? Do you want a bunch of dust blowing through the center of the state interrupted by fields of solar panels, which don’t employ many people?” Puglia said in the release.

“It is a question that needs to be posed to Californians, generally, and their political leaders. Is that what you want? Because that is the path you are on.”

Lead Photo: Joe Del Bosque of Del Bosque Farms, Firebaugh, Calif. points to a melon field that was plowed under because of the drought.

Netled Signs €15 Million Contract With Oh My Greens To Deliver Vera Vertical Farm To Sweden

Netled and Oh My Greens (OMG) have signed a contract for a three-year investment programme that will see Netled deliver its Vera vertical farm to OMG, a Swedish supplier of potted herbs

July 13, 2021

Netled has signed a contract worth €15 million with Swedish herbs supplier, Oh My Greens.

Netled and Oh My Greens (OMG) have signed a contract for a three-year investment program that will see Netled deliver its Vera vertical farm to OMG, a Swedish supplier of potted herbs. The contract was signed in June 2021 and is worth a total of 15 million euros over three years. The contract also includes a five-year maintenance and cultivation consultancy service, and is estimated to be one of the largest turn-key technology deals specifically between the technology providers and farm operators in the indoor agriculture market to date.

The first delivery for the project is underway and is valued at 3.2 million euros; it is due in Q2 of 2022. After commissioning, Netled will continue to provide technical and consultancy services while OMG will focus on producing and supplying vegetables to retailers in Stockholm. The second phase of the investment plan is due to start in Q4/2022.

OMG is a farm operator company providing consumers with potted herbs and has ambitions to achieve a major market share in Sweden by the end of the investment program.

OMG is part of Applied Value Group, a Swedish-American investment, management consultancy, and social impact firm. OMG operates in Sweden together with its sister company, Bake My Day (BMD). BMD is a 25 million USD revenue company serving 800 customers with daily deliveries including around 400 grocery stores. Working together, BMD and OMG can offer a wide range of the highest quality fresh food products to retail throughout Stockholm and the Mälardalen region, covering 40% of the Swedish population.

“We considered 17 different vertical farming technology providers and came to the conclusion that, in terms of its technology, know-how, and delivery capabilities, Netled is years ahead of the competition,” says CEO of OMG, Moses Isik.

“Netled’s technical and horticultural knowledge, and decades of experience of growing technologies, combined with OMG’s superb logistic network and existing customer relationships, creates an unbeatable competitive advantage which will allow us to quickly increase our market share and supersede traditional herb production with sustainable and ecological vertical farming that will disrupt the existing supply structures.” he continues.

“Netled’s Vera vertical farming technology will allow us to provide customers throughout Sweden with fresher herbs and leafy greens, grown hyper-locally and with a significantly reduced carbon footprint”, Moses adds. “Not only does the customer benefit, but the planet does too!”

Netled Ltd. is the leading vertical farming technology provider in Finland. Netled’s Vera technology offers turn-key indoor farming systems which include a dynamic spacing system, LED lighting, HVAC, and a nutrition system. It also includes automation software, production management and horticulture intelligence software. The Vera family of growing systems range from the Instore growing cabinets to massive-scale Industrial systems.

“The cooperation with OMG and its sister company, BMD, creates a huge opportunity for Netled to increase its market presence in Sweden. It also solidifies our position as the global leader in vertical farming technology,” says CEO of Netled, Niko Kivioja. This contract is the first industrial-scale operation for Netled, which was previously focused on an urban farm scale.

“This contract not only allows OMG to produce fantastic products for customers throughout the whole of Sweden, but it also functions as a clear example to other farm operators of the industrial-scale applications and opportunities our Vera vertical farming technology is capable of.” Kivioja continues.

“Netled is now the premier provider of vertical farming technology globally and we intend to keep it that way.” he concludes.

More information:

Niko Kivioja

CEO, Netled Ltd.

+358 50 360 8121

Moses Isik

CEO, Applied Industries Holding AB

+46 704 269 267

Robert Brooks

Investor Relations & Communications Manager

+358 50 484 0003

What Flooding In London And New York Tells Us About The Future of Climate Change

With America and parts of Europe already experiencing erratic weather patterns, such as record-breaking night temperatures, climate scientists are increasingly worried over the future of weather patterns like this in the coming years

By Hope Talbot

July 13, 2021

Yesterday, parts of London experienced one month’s worth of rain within a day, causing severe flash floods across various areas of the city. Similar incidents of flash flooding have also been reported across several parts of Europe, with Bulgaria, France, and Switzerland all experiencing similar flooding.

This comes after New York experienced similarly severe flooding last Thursday as a result of Storm Elsa, with subways and highways flooded throughout the state.

With America and parts of Europe already experiencing erratic weather patterns, such as record-breaking night temperatures, climate scientists are increasingly worried over the future of weather patterns like this in the coming years.

How is climate change affecting flooding?

The likelihood of flooding is significantly increased due to the extreme weather patterns caused by global climate change. Changes in the geography of the land, resulting from climate change, also have a part to play in increasing flooding.

With certain vegetation and other land barriers being broken down as a result of changing temperatures and freak weather patterns, many of the natural preventative measures against flooding are no longer there.

Higher temperatures mean higher rainfall

With America experiencing its hottest June on record, temperatures have soared dramatically. As a result of these higher temperatures, we’re experiencing higher air and water temperatures, increasing evaporation.

With increased evaporation comes increased rainfall, with longer durations as well as higher intensity and frequency of rainfall, too.

Evidence also suggests that temperatures increase at a higher rate above the equator, meaning countries in the Northern Hemisphere, such as America and the UK, are likely to experience more significant temperature changes.

How can flooding be prevented?

Although flash floods may seem uncontrollable, there are several possible steps to ensuring that cities and towns are protected against flooding, with rainwater being distributed in a sustainable way.

Sponge cities

Through ingenious urban planning, cities have been able to use strategic green spaces to absorb excess rainwater for future use, therefore reducing flood risk. In China, the concept of ‘sponge cities’ has become popular, with irrigating gardens and urban farms acting like sponges to soak up excess water.

Urban greenery

As seen in the recent London floods, sewage management became a big issue, with sewage pipes bursting due to flooding. In Europe, green roofs are another innovative solution to reducing flooding risk, with greenery absorbing stormwater run-off, and thereby preventing sewage overflow.

Permeable pavements

A common issue seen within urban flooding is the lack of drainage away from walking paths and roads, with cement being unable to absorb water. An ingenious solution to this is installing permeable pavements, which can absorb water and transfer it to other sources, such as urban green spaces.

Lead Photo: Recent flooding across the UK

The Collaborative Farm: Where Agriculture Meets The Entertainment World

The Collaborative Farm is an emerging destination in Milwaukee that survives as the rebrand of an organization formally known as Growing Power. The Farm is redefining urban agriculture and how the entertainment industry can impact its operations remarkably to sustain several communities

By GetNews

July 13, 2021

The Collaborative Farm is an emerging destination in Milwaukee that survives as the rebrand of an organization formally known as Growing Power. The Farm is redefining urban agriculture and how the entertainment industry can impact its operations remarkably to sustain several communities. The new and improved organization was made possible by Tyler Schmitt, best known to his peers as Tymetravels. His phenomenal vision to put together agriculture and music to expand urban farming has been making waves, making his novel initiative an extraordinary breakthrough.

Schmitt majored in Entrepreneurship with a minor in Sustainability at the University of St. Thomas then later moved to live in the national parks in Wyoming. When Growing Power collapsed, Schmitt came home from Jackson Hole to lend a hand to Will Allen and his father Tom Schmitt to solve the intricate issues involved in urban farming—from solar aquaponics to increasing food production while keeping operations sustainable.

Schmitt developed Ultimate Farm Collaborative to redesign not just farms but also cities in the near future. Collab Official, on the other hand, is the record label he created in order to unite various music artists under the umbrella of an extraordinary cause. The Farm Music Festival is its annual event, which is designed to generate funds to sustainably operate the farm.

This coming October 1–3, Milwaukee’s last remaining farm will be hosting a music festival to create awareness on the value of urban farming through hip-hop and EDM music. Schmitt hopes that the upcoming event will make a difference in the lives of urban farmers. The upcoming event will also give the good people of Milwaukee an opportunity to experience The Collaborative Farm up close. When music meets agriculture, the possibilities are out of this world.

The Collaborative Farm has a whole lot of surprises in store for the future as it is in the process of developing and recruiting a solid and hardworking team that will help it realize its goals. In the coming months, it will open an art studio, which will also be a coffee shop. The coffee shop will be the front store to increase foot traffic day in and out long-term. Additionally, it is working on establishing the vertical farm that Growing Power was positioned to pursue in the past.

Moreover, the founder of Ultimate Farm Collaborative sees the company staying with The Collaborative Farm long-term. In the next couple of years, it will either purchase or design a second facility. The annual music festival at The Collaborative Farm will continue and expand as a creative label through the efforts of Collab Official.

The novel idea behind The Collaborative Farm serves as an inspiration to those who have been supporting urban farming and those who wish to try sustainable living by growing their own produce. As the entertainment aspect of the whole operation continues to fund the needs of the farm that provides produce for locals, Tyler Schmitt hopes to continue to make promising collaborations that will impact the community significantly in the coming years.

Media Contact

Company Name: Ultimate Farm Collaborative Inc.

Contact Person: Tyler Schmitt

Email: Send Email

Phone: 4145874320

Country: United States

Website: http://www.ultimatecollab.com

RMA Authorizes Emergency Procedures To Help Drought-Impacted Producers

The USDA’s Risk Management Agency is working with crop insurance companies to streamline and accelerate the adjustment of losses and issuance of indemnity payments to crop insurance policyholders in impacted areas, according to a news release

By TOM KARST

July 13, 2021

The U.S. Department of Agriculture is authorizing emergency procedures to help agricultural producers impacted by extreme drought conditions.

The USDA’s Risk Management Agency is working with crop insurance companies to streamline and accelerate the adjustment of losses and issuance of indemnity payments to crop insurance policyholders in impacted areas, according to a news release.

The agency said the new crop insurance flexibilities are part of USDA’s broader response to help producers impacted by drought, in the West, Northern Great Plains, Caribbean and other areas.

“Crop insurance helps producers weather natural disasters like drought,” RMA Acting Administrator Richard Flournoy said in the release. “We recognize the distress experienced by farmers and ranchers because of drought, and these emergency procedures will authorize insurance companies to expedite the claims process, enabling them to plant a new crop or a cover crop.”

Emergency procedures allow insurance companies to accept delayed notices of loss in certain situations, streamline paperwork, and reduce the number of required representative samples when damage is consistent, according to the release.

Producers should contact their crop insurance agent as soon as they notice damage, the agency said.

The insurance company must have an opportunity to inspect the crop before the producer puts their crop acres to another use. If the company cannot make an accurate appraisal, or the producer disagrees with the appraisal at the time the acreage is to be destroyed or no longer cared for, the insurance company and producer can determine representative sample areas to be left intact and maintained for future appraisal purposes, according to the release. Once an insured crop has been appraised and released, or representative strips have been authorized for later appraisal, the producer may cut the crop for silage, destroy it or take any other action on the land including planting a cover crop, the release said.

Additional information on these emergency procedures is available on RMA’s Crop Insurance and Drought Damaged Crop webpage.

Farming During The Dry Age

The period of 2000 to 2018 was the second driest 19-year period in over a thousand years. Let that sink in for a few moments. Global warming drives increased evaporation, causing droughts to become more likely and more severe where they already exist

The period of 2000 to 2018 was the second driest 19-year period in over a thousand years. Let that sink in for a few moments. Global warming drives increased evaporation, causing droughts to become more likely and more severe where they already exist.

The past 10 to 20 years have been some of the driest on record, especially for the west coast of the United States. 70% of the land in the West is already in severe drought, and the National Weather Service estimates that the area is closer to 90%. Water demand is expected to rise by 55% by 2050, so planning how to provide more water with a diminishing supply is not a matter of whether one believes in climate change, it’s a crisis.

These climate events in the west have economic impacts worth noting water shortages during the 2015 droughts in California resulted in almost $2 billion in direct costs. On average, one drought event causes a 0.8% decrease in agricultural GDP, let alone the cost to the population.

With California responsible for a large portion of the country’s produce and experiencing extremely dry conditions, indoor farming is the only option. CEA (controlled environment agriculture) where environmental factors are manipulated can help keep the west coast's agricultural sector intact.

Greenhouses, whether traditional or vertical uses methods such as drip irrigation that save up to 30-50% of the water it would take to conventionally grow using surface irrigation. Up to half the amount of an outdoor farm. Overall, reports indicate that greenhouses create around a 60% water savings during crop cultivation.

Droughts affect not only the direct air and soil of an open farm, but also the types of pests and pathogens living in them. When a climate drastically changes, the organisms that thrive there adapt much quicker than the plant’s ability to resist them. With the U.S. already using over one billion pounds of pesticides per year, as drier environments invite new pests and pathogens that native crops are ill-equipped to handle on their own either crops will die, or pesticide use will increase.

The agricultural economy along the West Coast and indeed across the U.S. and the world will need to adapt their growing techniques to meet the demand of a growing population and conserve water. Indoor growing saves water during growing cycles and significantly reduces crop loss, pesticide use, and GHG’s.

Droughts along the West Coast are already transforming the farming landscape as we watch farmers plow crops under knowing that there won’t be enough water to sustain them throughout the summer. Crops grown indoors can be both protected and hydrated with indoor technologies that are more secure for feeding people and sustaining the planet.

Hallie Cordingley, Intern

Carl Silverberg, Sr. VP Outreach & Public Affairs

844 746 4868

Is Hydroponics The Future of Farming In Bangladesh?

Bangladesh is known to have flat fertile land which is exceptionally good for cultivating crops and vegetables all year round, but with the rise in water levels, the southern regions of the delta are becoming less cultivation friendly.

By Tanveer Mohiuddin

July 10, 2021

Hydroponics uses just nutrient-rich water to grow crops

Farmers across the Khulna region have not been able to make good use of the land for the cultivation of crops and vegetables. This is due to the region being flood-prone and the salinity of the soil. “We can neither cultivate crops nor fishes,” says a 45-year-old farmer from Satkhira district in the southwestern part of the country.

Bangladesh is known to have flat fertile land which is exceptionally good for cultivating crops and vegetables all year round, but with the rise in water levels, the southern regions of the delta are becoming less cultivation friendly.

Most parts of the region are becoming prone to floods and water-logging due to the Ganga-Brahmaputra River tributaries that flow through the country and often change their course. In addition to that, the saline soil makes it impossible to grow the necessary produce. In order to tackle such a problem, experts have come up with newer farming technologies to help cope with such problems.

Dr A F M Jamal Uddin, a renowned professor of the Department of Horticulture at Sher-e-Bangla Agriculture University, has given much hope with the use of hydroponics for growing crops in places where using soil can be challenging.

This method is also applicable for promoting urban farming where land is scarce and can sometimes be extremely expensive and unfeasible for cultivation. He mentions the challenges of pursuing this method as Bangladesh is yet very far off from using the method for commercial usage as the setup cost is very high.

In order to make sure the process gives sufficient dividends with its crop yields; the crops need to be grown inside a greenhouse made out of specialized polythene which helps control the temperature inside. Rain and rough weather can be a huge challenge in this respect as they can damage the setup.

More durable polythene can be used but that is only made in Israel, and bringing them here in Bangladesh is next to impossible with no diplomatic ties between the two. However, there are many high-value leafy crops that can easily be grown with this technique.

It’s most fitting for fodder cultivation for livestock farms around the urban areas as the year-round grass can ensure a steady feed for the cattle in places where empty land is difficult to find. Growing cattle feed or even leafy vegetables can easily be done with very little setup costs.

Floating gardens of Bangladesh

As the drylands become scarce in the region, farmers are forced to use Dhaps, a local name for floating garden agriculture practice better known as hydroponics. Hydroponics is a type of horticulture that involves growing plants and crops without the use of soil.

This is a method used by farmers for generations. But the technique is far more superior now and can yield crops in a larger quantity than before. Due to salinity, this method of growing farm produce has become ever more necessary as high-value crops can be cultivated all year round without the use of soil.

The Bangladesh government has been trying to promote such farming methods to be more widely used especially in these regions where monsoon rains can easily cause floods. In 2013, the government-sanctioned a project worth $1.6 million to promote floating agriculture, the project covered 12,000 families in eight districts across 50 locations.

A similar project was also recently started a couple of years back after the success of the initial one. Farmers in these low-lying regions are benefitting tremendously as vegetables such as spinach, eggplant, bitter gourd and even spices like turmeric and ginger can be grown easily.

“Last month we sold fish worth Tk 9,000 and spinach worth Tk 1,200 in the local market,” says Rani—a farmer who cultivates using the “Aqua-cage culture” method. This process does not require any fertilizers or insecticides, as a result, the vegetables are fully organic and financially more viable as no additional costs are incurred.

Challenges of Hydroponics Farm

According to experts who are trying to develop this method to become more efficient so that it can be used commercially, there are a few challenges that need to be taken care of such as, farmers need to be trained so that they can figure out how much cooling, dehumidification and heating are required to manage the temperature and humidity of the space for growing. This is a challenge that is difficult to overcome as most farmers lack proper literacy.

In order to properly set up a system that local company ACI is currently doing in Gazipur, huge amounts of money need to be invested as the system requires HVAC equipment. An HVAC equipment can include air conditioners, dehumidifiers, circulation fans, ductwork, chillers, boilers, pumps and pipes which all sums up to a huge cost of production, which is impossible for the ordinary Bangladeshi farmers to take on.

However, more and more people are coming into this method of cultivation, one such example is a Dohar-based Mizanur Rahman, who is a textile businessman and an amateur hydroponic vegetable grower. He has a setup of around 3000 sq ft greenhouse in which he cultivates tomatoes. In order to make the model more commercially viable, more expertise needs to be made available.

In order to tackle climate change and the rise of water levels and salinity of the soil in many regions across Bangladesh, new farming techniques need to be adopted by the farmers, which needs proper knowledge to do properly. With the help of government research and funding, these new methods can enable higher crop yields using up much lesser space.

AppHarvest: Firing On All Cylinders

AppHarvest has three quality characteristics that show it is stronger than most of its agtech competitors

Written by Jamie Louko

July 12, 2021

Summary

AppHarvest is trying to reimagine how consumers see produce.

With sustainability as one of their key focuses, AppHarvest separates itself from the pack of traditional farmers, and its size, scalability, and offering selection separate itself from other agtech players.

In this article, I am going to examine some of the most recent news AppHarvest has shared with investors, as well as looking back at AppHarvest compared with other agtech players.

AnnaStills/iStock via Getty Images

Investment Thesis

The agtech and sustainable farming industry has proved to be more efficient and sustainable compared to traditional farming. However, the difference and competitive edge lie between each sustainable farming business. These agtech businesses achieve similar sustainability and efficiency goals, so the competitive advantage comes in other forms. AppHarvest's (APPH) competitive advantage comes in the form of the size and scale potential of their farms, as well as their broad expansion of product offerings. Because of this, AppHarvest is one of the stronger players in the agtech space, and investors who want to play in this industry should be considering AppHarvest before other competitors.

Where We Last Left Off, and What's New

In my last article about AppHarvest, a large-scale indoor farming business operating in central Appalachia, I focused on the competitive advantages over traditional farming operations. Since then, other indoor farming businesses similar to AppHarvest have come out of the woodwork and announced plans to trade as public companies. Some of these businesses include AeroFarms (SV, will become ARFM), a sustainable farmer focused on vertical farming, Local Bounti (LIII, will become LOCL), an indoor farming business located in the pacific northwest, and Infarm, a German-based distributor who has become the world-leader in indoor farming. Infarm has rumored to becoming public via SPAC with Kernel Group Holdings Inc. (KRNL), but nothing definitive has been reached.

As these businesses show their superiority, they all claim similar sustainability and efficiency metrics. Most businesses claim that their use of water is extremely efficient, as is their optimization for crop growth, and their LEDs allow for optimal sunlight. Simply, all of these businesses have very similar technology that makes them superior to traditional farming, but this does not mean success for any individual business within the agtech industry. They all show that the agtech industry is superior, but rather they should focus on what makes their business superior to other agtech players.

Source: Investor Presentation

In my opinion, traditional farming is a dying industry, and it is sensible that sustainable farming and greenhouses will be the future of farming. Therefore, it is sensible that the agtech business should be demonstrating its competitive advantages over other agtech competitors, rather than traditional farming.

AppHarvest, even in this sense, does stand out from the competition. They are slowly becoming a bigger player in this space, and one that is starting to run ahead of the pack. While other agtech businesses are busy constructing their first farm, AppHarvest has jumped ahead with the production of its next 4 farms. While its competitors are starting small with only 1-2-acre farms, AppHarvest has positioned itself well with 15-60-acre farms. AppHarvest's competitors are currently focusing on one product category, yet AppHarvest is rapidly expanding its product offerings.

In an industry that is growing rapidly, AppHarvest is executing everywhere it needs to, and it is allowing for AppHarvest to set itself apart from the competition.

Competitive Advantages Over Agtech Businesses

AppHarvest has three quality characteristics that show it is stronger than most of its agtech competitors. Due to the size and scalability of its farms, expansion in offerings, and consistent execution, AppHarvest is proving to investors that they are one of the stronger players in this industry.

Size and Scale of Farms

One of AppHarvest's strongest competitive advantages within the agtech space is the size of its facilities. These facilities are absolutely massive, with their first facility 60 acres in size. This allows for mass production of sustainable-grown produce at a scale that no other agtech business has. These facilities can often take longer to construct, but once constructed, there is a long runway for growth and full-scale operations for it. It would take substantially less time to fully scale a farm this size compared to building and scaling 60 1-acre greenhouses.

The second option is what Local Bounti is doing, for their facilities are only 1-2-acre facilities. They plan on constructing 9 facilities by 2025, 8 of which will be roughly 5 acres, which would only lead to a maximum growing capacity of 42 acres. This goal of 42 acres would be less than AppHarvest's currently operating growing capacity.

Clearly, the size of AppHarvest's farms is a massive advantage for them. The scalability of these farms gives them an even greater lead. AppHarvest expects production of their first facility in Morehead, Kentucky to be fully scaled by the end of 2021, whereas Local Bounti's 42 acres would not be fully operational and scaled until at least 2025. AppHarvest would then have 4 years of fully-scaled operations to build a brand, strengthen the balance sheet, and fuel more growth for AppHarvest.

The scalability shows itself through guidance estimates for FY 2021 as well. By the year's end, at full-production, AppHarvest expects to make $21 million in revenue, whereas Local Bounti only expects to make $13 million by the end of 2022. The size and scalability of AppHarvest's farms are simply unmatched by its competitors, and as they build more farms (I will dive into that shortly), these size and scale advantages will only become more prevalent.

Offering Expansion

Compared to its competitors, AppHarvest is planning to expand its product offerings at a faster rate. One of the keys to success for these agtech businesses is having a successful brand, and one way to grow a brand is to put it in the eyes of more customers. One way to do this is by expanding the products offered. That way, both salad enthusiasts can eat the leafy greens and tomatoes produced, while berry lovers (like myself) can also recognize the brand. If a business were to only focus on leafy greens, then they would not achieve brand recognition from people like me as much.

AppHarvest's offering expansion is happening fast, and it will only be a matter of time before AppHarvest can offer products in various categories, rather than simply tomatoes. Their primary facility in Morehead, KY, solely produces tomatoes, but they have 4 facilities under operation that will be producing a wide variety of offerings. Here are the 4 facilities being constructed, along with what they will be producing:

Facility LocationProduction CategoryAcreageExpected Construction Completion DateBerea KYLeafy Greens15Q3 2022Richmond KYVine Crops60Q4 2022Somerset KYBerries30Q4 2022Morehead KYLeafy Greens15Q4 2022

Source: Press Release

Considering that AppHarvest currently focuses solely on tomatoes, expansion into 3 other product categories is a wonderful step in growing its brand recognition. This is something that few of its competitors are doing. Local Bounti does not have any structural plans on expansion out of leafy greens, and AeroFarms has plans to expand into berries for its primary leafy greens production.

As previously mentioned, I believe that offering expansion is important to the brand growth for these agtech businesses. As they expand their offerings, they will be able to get their products and their name in front of more consumers. AppHarvest has started showing signs of doing this well, where its competitors have failed to do the same.

Signs of Execution

One of the risks I mentioned in my last article was about the ability of management to meet or exceed guidance they put out for themselves. This included construction guidance. In their investor presentation, they expected to have 4 facilities up and running by the end of 2022, including their main facility in Morehead. Recently, they announced plans to construct two additional facilities, meaning that they are now expecting to have 5 facilities up and running by the end of 2022.

This seems small on the surface, but this is the exact type of execution proof that I look for in small businesses like AppHarvest. The fact that management was able to start construction on more farms than expected and thus increase their timeline shows that they are executing and exceeding the guidance they set out for themselves.

For investors, this should demonstrate that AppHarvest management can be trusted, for their guidance was beaten. Management was able to beat their own guidance, and that should show investors that AppHarvest is not just a pipe dream, but it actually has something tangible to run with and build.

A Look at My Risks: What Risks are Still Present, and What Risks Have Grown

In my last article, I noted many risks that are potential with the business:

AppHarvest is unable to grow its factories at or faster than projections.

Their Mastronardi partnership goes awry.

They are unable to educate the broader public on what makes them special.

AppHarvest is unable to lower prices.

Management leaves the company.

For the most part, all of these risks are still prevalent today, if not even more important. Although they have begun to prove they can beat their own guidance, they will still need to continue to prove this, both in quarterly and yearly financial estimates, but also through construction estimates.

Their Mastronardi partnership is still fragile, and if anything were to happen with that partnership AppHarvest would have no way of distributing its product to local grocers, which could potentially decimate this business.

Although the offering expansion will make it easier to gain brand recognition and thus educate the broader public about their business, this will likely always remain a risk as long as traditional farming produce dominates grocery store shelves. Gaining brand recognition will also go a long way in being able to lower prices. So, while their offering expansion has the potential to increase brand recognition for AppHarvest, risks still remain and likely will remain for a long time.

Even though management seems very happy at AppHarvest, and loss of a major figure, Jonathan Webb specifically, would greatly damage their business. Management is the face of the business until they are able to bring products to shelves at a very large scale, so management impressing investors is largely how they will gain capital to subsidize the financing of their farm construction. If the face of AppHarvest were to leave, it could hurt their ability to receive financing and thus their ability to develop their facilities.

After seeing many agtech businesses come to the market via SPAC, there has been more concern about competition in this space. Because of this, I would likely add competition as a risk to AppHarvest. While many of its competitors are pre-revenue and are not far along on facility construction, they do have a competitor that is much larger than AppHarvest. Infarm is a German-based sustainable food producer that sells its product internationally, with the U.S. being its most recent expansion area. They have expanded broadly in Europe, and they seem to have their eyes set on the United States. This could pose a tremendous risk for AppHarvest, for there is no agtech player that comes close to the size of Infarm. They have $19 million in sales across the world compared to AppHarvest's $2 million last quarter.

AppHarvest's competition is fierce, and there is no doubt that the competitive threats will slow as time goes on. Therefore, I am confident to say that AppHarvest will have to fight against fierce competition in order to gain market share in the U.S., but their competitive advantages listed above will be able to help them do so.

Recent Stock Decline: Buying Opportunity?

AppHarvest's stock price has plunged in recent months, falling roughly 58% since February 2021.

Data by YCharts

This has put AppHarvest's market cap roughly around $1.5 billion and dropped their valuation down from extremely high multiples to still high, but comparatively lower multiples. Currently, it is trading over 600x sales, but it is trading at 73x forward sales if investors are looking at FY 2021 revenue estimates.

A business that just got its first revenue in Q1 of 2020 is obviously going to have extremely high valuation multiples, but revenue is growing extremely fast, and it is expected to continue to do so. Considering that the stock price has had a tremendous fall from grace, and revenue is expected to grow rapidly, today could potentially be a wonderful time to invest in this business at a very low price.

Conclusion

As I have said before, an investment in AppHarvest is not for the faint of heart. It is valued at very high multiples, and the number of risks for this business is high. AppHarvest will need to continuously execute at a strong level, for there is little room for slip-ups. With plenty of competition in the agtech market, AppHarvest will need to hold onto its competitive advantages tight if it wants to be a market leader in this industry.

Despite all of this, AppHarvest is one of the better investments for investors who want to get in on the agtech industry. They are one of the few companies with strong competitive advantages, and there are very few companies that could construct what AppHarvest is constructing. Their valuation is high now, but as they grow revenue it is likely that it will rapidly decrease, and it will be much more reasonable in the future. The risks associated with this business are plenty, but management has begun to prove they can efficiently execute.

For risk-tolerant and volatility-tolerant investors who wish to capitalize on the sustainable produce transformation, AppHarvest is one of the best bets to make. Their competitive advantages are strong, and they are one of the only businesses that have proved they have the ability to accomplish what they say they can. Because of this, I am recommending that risk-tolerant and volatility-tolerant investors who wish to invest in agtech should consider AppHarvest before any other competitors.

Lead photo: Source: Investor Presentation

This article was written by

I am a college student who has found a deep thirst for learning and investing. Being very young, I have leaned toward very long-term investments and growth stocks, primarily in tech. I do, however, love consumer goods companies as well. Currently, I am studying International Business and Economics.

Long Only, Growth, Long-Term Horizon, Tech

Contributor Since 2021

Disclosure: I/we have no stock, option or similar derivative position in any of the companies mentioned, and no plans to initiate any such positions within the next 72 hours. I wrote this article myself, and it expresses my own opinions. I am not receiving compensation for it (other than from Seeking Alpha). I have no business relationship with any company whose stock is mentioned in this article.

Controlled Environment Agriculture Funding Breeds Optimism For Post-Pandemic Growth

Although the pace of announcements slowed slightly amid the coronavirus pandemic, we have covered quite a bit of research on plant science, optimization studies for horticultural lighting, and capital investment alike. And I am pleased to see prospects are growing for companies working toward technology integration in this sector

Carrie Meadows

July 9, 2021

Back in 2019, LEDs Magazine published a feature on investment pacing and market prospects for horticultural solid-state lighting (SSL) and products and systems for controlled environment agriculture (CEA) operations. We were really just beginning to see how venture capital funds and research grants were being distributed among CEA growers themselves in a wave hot investment for advanced farming methods. Indeed, as chief editor Maury Wright wrote regarding the early planning days of the former Horticultural Lighting Conference, “We suspected the primary interest would be investment in the companies supplying technology that could be deployed in vertical farms around the globe. Instead, the sector would soon witness huge investment in the farms themselves.”

Although the pace of announcements slowed slightly amid the coronavirus pandemic, we have covered quite a bit of research on plant science, optimization studies for horticultural lighting, and capital investment alike. And I am pleased to see prospects are growing for companies working toward technology integration in this sector.

For example, the Wells Fargo Foundation’s Wells Fargo Innovation Incubator (IN2), which is co-administered by the US National Renewable Energy Laboratory (NREL), just announced the latest cohort of startups that will benefit from its funding and partnerships with NREL and an independent research institute, the Donald Danforth Plant Science Center in St. Louis, MO. All of the companies in this phase are focused on enabling sustainable indoor agriculture.

GrowFlux CEO Eric Eisele was kind enough to point me to the program news, which you can read in the linked release on our site. For background, GrowFlux is a 2021 LEDs Magazine Sapphire Awards finalist for its GrowFlux Dimmer lighting controller. That product is designed with ease of use in mind to allow an end customer to easily deploy intelligent controls without programming experience or a technician to set up.

“With the growing complexity and evolving practices around horticultural lighting control, our user-friendly setup experience and app eliminates a lot of the frustration,” said Eisele. “We've been building out compatibility for all of the major manufacturers of horticultural lighting to make this energy-saving control technology as accessible as possible, especially for the many small and medium-sized businesses in the controlled environment agriculture industry.”

Each participating company in the IN2 cohort will receive $250,000 and will work at NREL and the Danforth center on R&D. When asked what GrowFlux plans to do with its funding, Eisele said that the company will partner with a sensor manufacturer to combine wireless controls and PAR sensors to determine real-time PAR levels in the indoor environment. The idea is to analyze the PAR data and program the lighting control system to evaluate and manage a Daily Light Integral (DLI) target.

The word “automation” came up. GrowFlux is not the first organization to explore the concept of bringing software intelligence, lighting, and systems controls together in a way that delivers both streamlined and adaptable operations to reduce energy consumption in a greenhouse or other CEA setting (refer to the Automatoes challenge and a presentation from AgEye in our past HortiCann Light + Tech insights). However, Eisele explained, the GrowFlux wireless dimmer is compatible with offerings from many well-known horticultural lighting providers (e.g., Fluence, GE Current, BIOS, Heliospectra, and more), and the company intends to maintain out-of-the-box installation and interoperability with the next generation of technology development, rather than pursue customized designs.

Funding placements like this will propel advances for CEA and AgTech, increase technology uptake, and prove out the return on investment for integrated horticultural systems.

Lead Photo: It’s an exciting time to watch engineers, scientists, and horticultural experts in the field receive the support and resources to collaborate and put new knowledge and technologies into action.

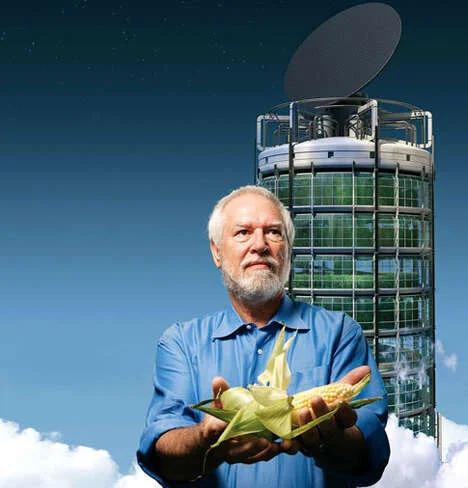

Green Sense Radio: Godfather of Vertical Farming - Dickson Despommier

Dickson Despommier has a Ph.D., in microbiology, is an ecologist, and emeritus professor of Public and Environmental Health at Columbia University, and coined the term vertical farm back in 1999

This week on Green Sense Radio Show: Grounding a tall vision in market reality an interview with the godfather of vertical farming!

Dickson Despommier has a Ph.D., in microbiology, is an ecologist, and emeritus professor of Public and Environmental Health at Columbia University, and coined the term vertical farm back in 1999. He’s one of the many respected experts who’ve contributed to the new book ‘The Economics of Sustainable Food - Smart Policies for Health and the Planet.’ We talk about the new book and the past, present, and future of vertical farming.

European And Asian Expansion For Equilibrium

Equilibrium, the company that this week closed the industry’s largest Controlled Environment Agriculture Fund at $1.022 billion, has established an office in Singapore and has Dutch master grower Godfried Dol and former Rabobank Asia & career agricultural investor John Baker manning it

July 9, 2021

Equilibrium, the company that this week closed the industry’s largest Controlled Environment Agriculture Fund at $1.022 billion, has established an office in Singapore and has Dutch master grower Godfried Dol and former Rabobank Asia & career agricultural investor John Baker manning it. Currently, the company is trying to develop the first high-tech glass greenhouse in Singapore. And there’s more. In the next year, Equilibrium is expecting to get several European greenhouse companies onboard.

“As the industry grows, capital and expertise are what’s needed. We’re in a great position to aggregate and consolidate as this industry matures,” Dave says. “In many countries in South East Asia, it is about food safety. In Singapore for example it is about food security: a small island nation that has little agricultural space. Yet, if it is safety, security, consistency, quality or the ability to manage climate volatility that is in demand and regardless of the order, they all contribute to the same demand for CEA facilities.”

David explains that he believes there to be plenty of opportunities in Asia – something that hasn’t developed at all since the industry grew out of Holland, and the current greenhouse crops mainly reflect the European diet. “Or as one policymaker said ‘We do not eat a lot of kale here.’ But they do eat a lot of vegetables. Bitter ones, different ones. There’s plenty of room to grow and innovate and that’s exciting.”

European market

And there’s more. Also in markets where the CEA industry has matured, Equilibrium sees opportunities. Earlier Dave shared his belief that access to capital is a competitive advantage and with this in mind, the company is also for operators in Europe. “We’re setting the tone for the Dutch industry,” Dave confirms. “When AppHarvest went public, we jokingly said that we listed a farm. When that happens, the family business balance sheet being the support for growth is likely no longer to be adequate. By now several companies have announced their listing, often through De-SPAC (Special Purpose Acquisition Company), and have seen also a significant rise of private capital. This will happen in Northern Europe in 2021 and 2022.”

Dutch greenhouse suppliers