Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

CALS Researchers Imagine Future of Urban Farming

Making the case for urban agriculture, Cornell researchers have presented a vision for greener cities and a more equitable future for farmers

March 26, 2021

By Rory Sheppard

Making the case for urban agriculture, Cornell researchers have presented a vision for greener cities and a more equitable future for farmers.

The Cornell Small Farms Program, housed in the College of Agriculture and Life Sciences, is responsible for a body of research that advocates for the development of viable small farms throughout New York State.

Cornell Small Farms continues to advocate for urban agriculture through emerging projects such as Urban Ag, which focuses on highlighting the considerations farmers need to make to farms in urban environments and cites examples of successful urban farming.

As part of the program’s mission to ensure a future of rural and urban agriculture through research and educational opportunities, Director of the Cornell Small Farms Program, Dr. Anusuya Rangarajan and Urban Agriculture Specialist of the Cornell Small Farms Program, Molly Riordan published “The Promise of Urban Agriculture” in 2019.

The authors argue in the report that urban farms have the potential to become commercially viable, adding that up to now, much of the existing research has focused on the impact of urban agriculture on social indicators, such as community development and educational attainment.

According to Riordan, the make of a viable urban farm depends on factors such as the laws and regulations of a municipality, the availability and affordability of land, and opportunities available for season extension.

To produce a more comprehensive picture of the future of urban agriculture, Rangarajan and Riordan started by collecting data, speaking to an active network of growers.

“Every time we spoke with someone, we asked, ‘Who else should we speak with about commercial farming in cities?’” Riordan said in an email. “Inevitably that led us to more conversations that broadened and deepened our understanding. We spoke with over 160 individuals in the course of the study.”

Since publication, the multiple findings and recommendations of the report have started to take effect. Partnering with Rooted, an urban agriculture training organization, Cornell Small Farms has been working to introduce training for urban farmers to help improve commercial viability.

Riordan said that the farms, specifically those in controlled environments, have been known to generate considerable finances and interest from venture capital, alongside the development of more technology-focused urban farms. Likewise, technical assistance, research, and training will be essential in increasing the number of urban farms in the coming years.

As the researchers envisioned the future of urban agriculture, they were acutely aware of the concerns that still impact the field. One of the major challenges for urban farmers is, despite the typically smaller nature of the farms, urban land access.

“Knowing that urban growers struggle for access to land, especially Black, Indigenous, immigrant and other farmers of color, institutions can do more to lift up their voices and put the weight and the funding of the

Lead photo: Ben Parker/Sun Senior Photographer -

Housed in CALS, the Cornell Small Farms Program seeks to build more diverse, equitable, and sustainable food systems.

Hydroponics Farming: Why Hydroponic Farms Are Trending In India?

As per reports, India’s hydroponics market is expected to grow at a compound annual growth rate of 13.53% between 2020 and 2027.

Hydroponics is slowly gaining popularity in India and attracting more and more farmers. Basically, hydroponics is a type of horticulture and a subset of hydroculture, which is a method of growing plants, usually crops, without soil, by using mineral nutrient solutions in an aqueous solvent.

Hydroponic farming can be done in a small space also like a balcony which is a soil-less, water-based farming process. Rather than using soil for plant nutrition, crops are fed nutrient-rich water, negating a lot of the baggage that comes with soil-based methods.

Hydroponics is the practice of growing plants in a nutrient-rich solution, skipping the soil. “It has been practised for centuries, so it is not a new technology," points out Akhila Vijayaraghavan, the founder-director of Coimbatore’s Parna Farms, adding the Hanging Gardens of Babylon are believed to have been hydroponically grown. “The Aztecs created vast hydroponic systems using rafts called chinampas," she says.

The film piqued Gopal’s interest, and he began reading about the method to grow plants without soil. “We started working with hydroponics as a project in 2012. At that time, we didn’t know much about the plight of farmers and how a technology like this could add value," said Gopal. The idea was to create awareness among the right audience and sell “through prototypes and hobby kits."

Urban farmers are taking to hydroponics, a water-smart solution to grow pesticide-free produce on rooftops and terraces. As per reports, India’s hydroponics market is expected to grow at a compound annual growth rate of 13.53% between 2020 and 2027.

What is Hydroponics

Hydroponics is a branch of hydroculture, in which plants are grown without soil by using water solvent which consists of minerals nutrient solution. Terrestrial plants may be grown with their roots only, roots are exposed to the nutritious liquid, or roots may be supported physically by a medium like gravel.

Plants are also grown through a process called photosynthesis, in which plants use sunlight and a chemical inside their leaves called chlorophyll to convert carbon dioxide and water into glucose and oxygen, as shown in reaction.

6CO2 + 6H2O → C6H12O6(Glucose)+ 6O2

The nutrients we use in hydroponic systems may come from different sources, such as fish excrement, duck manure, or chemical fertilisers.

1Advantages of Hydroponics

Plantation without soil

We can grow plants in places where the land is limited, doesn't exist, or is contaminated. In the early time period, Hydroponics was a successful technique used to supply fresh vegetables for troops in Wake Island. It has been considered as the future farming to grow foods for astronauts in space by NASA.

Better use of space and location

All those plants need are provided and maintained in a system, you can grow plants in a small apartment, bedrooms or kitchen as long as you have some spaces.

Roots of plants usually expand and spread out in search of foods, and oxygen in the soil but in the case of Hydroponics, roots are sunk in a tank full of oxygenated nutrient solution and are directly in contact with vital minerals. This means that you can grow your plants closer, and consequently huge space savings.

Climate control

Hydroponic growers can have total control over climate, temperature, humidity, light, the composition of the air. This means you can grow foods all year, regardless of the season. Farmers can produce foods at the right time to maximize their profits.

Water-saving

Plants grown by the process of hydroponically can use 10% of water, as compared to one grown on the field because water is recirculated, in this method. Plants will take up the water they need, while run-off water will be captured and return to the system. Water loss in this system will only occur in two forms - evaporation and leaks from the system.

Use of nutrients

You can have 100% control of the nutrients (foods) that plants need in this method. Before planting, growers can check what are plants requirement and what amounts of nutrients needed at particular stages and at what percentage they should be mixed with water.

Better growth rate

Do hydroponic plants grow faster than in soil? Yes, because you can set conditions favourable to the plant’s growth like temperature, lights, moisture, and especially nutrients. As plants are placed in favourable conditions, nutrients are provided in sufficient amounts and come into direct contacts with the root systems. Therefore, plants do not waste valuable energy in the search for diluted nutrients in the soil and put their complete focus on growth.

Aquaponics In The Heart of Zurich

Umami creates microgreens in the city centre

They produce greens, but they travel to work by streetcar and don't need to put on weatherproof clothing. That's because Umami employees will harvest vegetables and herbs already in the early growth stages, as so-called microgreens. And they do so in a largely self-built facility, on the 4th floor of an office building in Zurich's Kreis 4 district.

Full-time producers instead of restaurant operators

In the beginning, the three friends Manuel Vock, Robin Bertschinger and Denis Weinberg wanted to open a restaurant. They wanted to produce half of the products themselves. At the same time, Manuel Vock was researching aquaponics systems for his bachelor's thesis. He introduced the principle to his friends, and the team began building a prototype set-up in a former archive in 2016.

That was the end of their restaurant plan and at the same time the beginning of completely self-produced food. The guys grew several varieties of microgreens and sold them to restaurateurs who were excited to have a regional product. "Up to that point, microgreens from the Netherlands were the only alternative," says Luca Grandjean, who joined the team of Umamigos (as Umami employees call themselves) in 2019.

The aquapinic facility / Image: Umami

Microgreens

Microgreens, unlike sprouts, grow on a substrate or in soil, require light and nutrients, and are consumed without roots. They are vegetables or spice plants that are harvested immediately after their cotyledons develop. As a result, microgreens contain a high concentration of vitamins and trace elements. The small plants are used as nutritional supplements and can add sweetness and spice to different dishes.

Fish excrement as fertilizer

Regionality is not the only plus of the little plants. Umami grows the microgreens in a cycle based on nature; the only input is fish feed. But even this is actually food waste and, additionally, insects that Umami produces via scraps.

African cichlids (tilapias) and other fish species swim in various tanks, and their excretions enrich the water with nitrogen and other micronutrients. The enriched water flows into the system to the tray on which the microgreens thrive.

These are sown on a hemp-based substrate and positioned in hard trays so that their roots can touch the water, absorbing the nutrients. The water, now purified by the plants, flows back to the fish, who recharge it. Thanks to this recirculation system, only about 1% of the water needs to be replaced with fresh drinking water each month. "That's about two bathtubs full of water. Just what is lost to evaporation," Grandjean says.

Aquaponics

Aquaponics refers to a process in food production that combines raising fish in aquaculture and cultivating crops in hydroponics. There are various combinations, such as the cultivation of tomatoes and the production of tilapias, as described in this article.

Not just fish and microgreens are part of the 'ecosystem', as the Umamigos like to call their jungle. Mussels, shrimp, snails, algae and many other plants also contribute to the Umami ecosystem. "We are copying nature. Yet we have learnt that the more players there are in the cycle, the better the system works," says Luca Grandjean. This might seem to be a contradiction, but he explains: "If there are just two actors in the system and something happens to one of them, the system is quickly unbalanced."

Nomen est omen

Their most important element, he says, is Zurich's tap water; it sets the pace. "We have no soil percolation, 95% less water loss than conventional agricultural systems," Grandjean says.

Environmentally-friendly production, free of chemicals, strikes a chord with consumers. Above all, however, the products have to taste right, says Luca Grandjean. It's no coincidence that the three friends named their startup Umami when they founded it in 2015. The Japanese word means tasty or spicy, and is one of the five basic tastes, alongside sweet, sour, bitter and salty.

"The glutamate found in meat, for example, tastes umami," Grandjean explains. He adds: "The microgreens are very palatable and don't contain glutamate, but our fish do." He is referring to the license to sell fish that the Umamigos recently obtained.

For more information: https://www.eat-umami.ch/

CGTN Conversations: Chinese Firms Add Strength To Dubai's Future Tech Ecosystem

CGTN Digital's International Editor Abhishek G. Bhaya spoke with Faisal Al Hawi, the head of Accelerator and Incubators at the Dubai Future Foundation, and Stuart Oda, the founder and CEO of Alesca Life.

Over the decades, the Gulf city of Dubai has emerged as a land of innovation and a place where the future could be felt right now in the present. The city is actively encouraging global collaborations to drive innovation and future technology in the United Arab Emirates and internationally through its Dubai Future Accelerators (DFA) initiative that was launched in 2016 under the aegis of Dubai Future Foundation.

In recent years, many Chinese tech firms and start-ups – which are known for their technological prowess – have partnered with DFA to contribute to their mission of imagining, designing and co-creating solutions for future challenges.

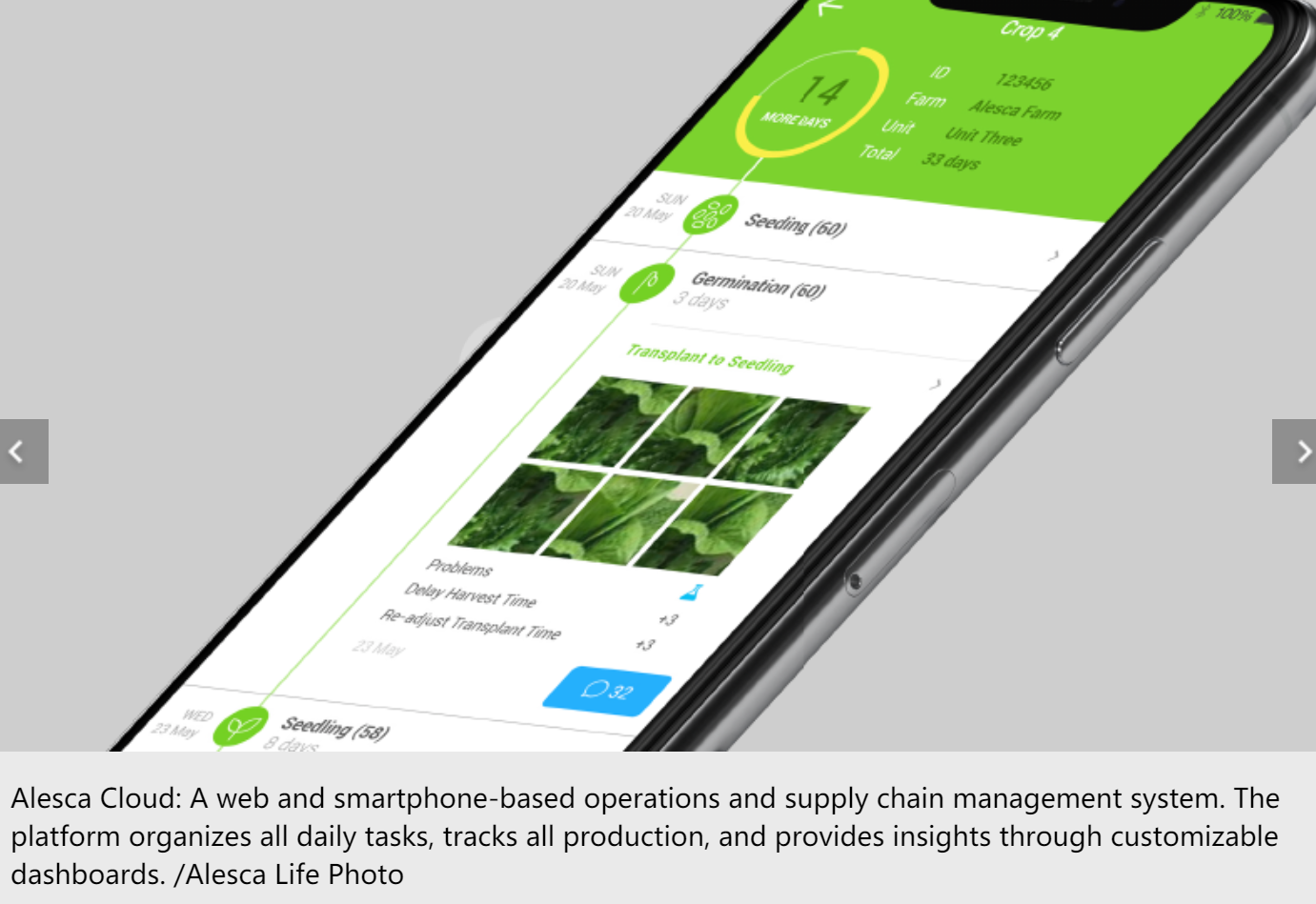

One such successful initiative has come from Beijing-headquartered Alesca Life, an agro-tech company that is creating next-generation urban farming solutions that consume five per cent water and 30 per cent energy vis-à-vis conventional farming.

To get an overview of DFA's future innovation agenda and how Chinese firms are contributing in making that vision a reality, CGTN Digital's International Editor Abhishek G. Bhaya spoke with Faisal Al Hawi, the head of Accelerator and Incubators at the Dubai Future Foundation, and Stuart Oda, the founder and CEO of Alesca Life.

Al Hawi is responsible for creating a myriad of programs that connect different stakeholders, government and private, with innovative startups and companies from around the world to experiment with and making Dubai the testbed for future ideas.

Oda is an investment banker-turned- urban farmer with a passion for innovation and sustainability. He founded Alesca Life in 2013 with an aim to make food production more localized and data-driven.

Edited excerpts:

Bhaya: Faisal, please tell us a bit about the vision of the DFA initiative and what it aims to achieve and also some of the main areas and technologies it has tasted success in the past four years?

Al Hawi: Dubai Future Accelerators is an initiative that was born four years ago under the Dubai Future Foundation. The vision was pretty much straightforward – to put Dubai as a leading city of the world when it comes to technology innovation. Our mission is to turn Dubai into a global testbed for innovations and technologies. The DFA looks around for all the start-ups in the global scene, trying to understand the technology needs, the partner needs, the local ecosystem needs, and trying to bridge the gap between these two players of the market.

We do this in what we call the Area 2071, which is like the heart of our ecosystem in Dubai and we've had tremendous success. Throughout the four years, we've run eight cohorts, the eighth cohort is ongoing as we speak. We've engaged with more than 300 start-ups and over 60 pilot projects were produced out of DFA and more than 150 memoranda of understanding or commercial agreements were signed with different government entities and private sector partners.

Dubai Future Accelerators is positioned in a way that basically bridges the gap between the big players, be it government or private sector, and the start-up innovators from around the world.

Bhaya: How many Chinese firms and start-ups have availed the DFA program so far? Please name some of the major projects the Chinese entities have undertaken in the UAE as part of the DFA initiative.

Al Hawi: We've worked with Chinese companies ever since Cohort 1 back in 2016. So, Alesca Life is one of them. Shellpay, which was a fintech company working with the General Directorate of Immigration in Dubai, was another company. There was another company called Future Trends, working with Dubai Health Authority on medical imaging, and utilizing the technologies of AI and machine learning to optimize the diagnosis of late-stage cancers.

Yitu Technology is another Chinese AI-based company which worked very closely with [UAE's largest telecom service provider] Etisalat on solving some of their telecom related issues. So these are just to name a few companies that worked with us.

We really understand the strength Chinese ecosystem brings to our ecosystem. And I think we complement each other in a lot of areas.

Another example, broader than just Dubai Future Accelerators, is within Area 2071, where SenseTime actually has an office here, and they work very closely with the AI office, in a couple of strategic projects.

So, the partnership is growing stronger and stronger, year after year. And we definitely believe that there are areas specifically in the fourth industrial revolution technologies, blockchain, AI and IoT and the likes that we will definitely materialize more and more outcomes and success moving forward.

Bhaya: Stuart, what is the story behind Alesca Life?

Oda: Seven years ago, I started Alesca Life here in Beijing. The vision of the company is to democratize access to fresh and nutritious food by democratizing the means and the knowledge of production.

And the more research that I was doing, it became very clear that one of the most pressing challenges over the next decades wasn't so much actually related to connectivity, as these things were becoming easier with the proliferation of smartphones and computers, but access to fresh and nutritious food. And so, my team and I wanted to find a way in which we can make this access a lot easier. And wherever it made sense to localize that fresh food production, and wherever food production currently existed to make it more data driven.

So we set on this journey seven years ago, and we currently have our teams and offices across Japan, China, and the United Arab Emirates and we have partnerships across many more countries. We're developing precision farming tools to accomplish, to increase the productivity, the profitability, and the predictability of food production by up to 10 times.

Bhaya: The urban farming technologies including vertical farms and data-driven food production are certainly relevant for an arid region like the Arabian Peninsula. How did your partnership with DFA come about and what has been the journey like in the UAE for Alesca Life?

Oda: In 2016, our team was selected into the DFA program as part of Cohort 1. It was actually our first entry into the Gulf region. We knew that the technology had huge promise and potential in the region, and we wanted to make a serious commitment to the region. The DFA program was kind enough to offer us a spot in Cohort 1.

It has been hugely transformational in two ways. You know, the way in which business is done in the Middle East is very different. And to be able to have an organization like DFA, both providing the meaningful introductions, reducing some of the barriers related to the company's formation, and then also just the credibility that is bestowed on some of the companies that get to go through the program. All three of these things contributed enormously to our success in the region.

Through this program we've also been able to find meaningful strategic partnerships to mitigate some of the challenges related to concentration of supply chain, for example, even being in a place like China, to have manufacturing bases and other places in other countries, is beneficial for us.

So, right after the DFA program, we had an opportunity to localize the manufacturing of our container farm in the Emirates of Ajman in the UAE, so that we can serve our customers and our base in the GCC (Gulf Cooperation Council) and also to showcase our commitment to the region that we're not just there to sell our systems, but that we are there for the long term.

Bhaya: The year 2020 has been a watershed in many ways for the world due to the COVID-19 pandemic, reinforcing our increasing reliance on digital and AI technologies without which we can't imagine a future. How did the global crisis impact the long-term vision of DFA?

Al Hawi: The pandemic has definitely affected everyone. At DFA, we realized that innovation is the way to be resilient for the future, prepared for the future and understanding exactly the problems of today that potentially, and unfortunately, led us into the pandemic. We had just a very short drop-in time in which everybody had to just realign ourselves, and that was around March. But we immediately resumed back in October.

Not just the DFA, I think all the government entities, as well as start-ups, realized how important a role they play in this ecosystem. And Cohort 8, that is currently ongoing and will last until the end of March, is specifically looking at challenges that will basically be more specific around life after COVID.

I'll share a couple of examples. The Dubai Roads and Transport Authority (RTA) is looking into new solutions of shared mobility. We are very much accustomed to the ride-hailing apps and public transport systems. But that has changed forever. So they (RTA) are really being proactive in trying to foresight what new models of public transport and shared mobility will be out there. And we're really excited to see what comes out as solutions in a couple of weeks' time.

Another entity which is really looking at how things might evolve in the health care sector is the Dubai Health Authority. They are focusing on preventive health care measures, solutions and products, but not only from a sense of being preventive or proactive but in a sense of also democratizing access to that device.

Bhaya: Food security is already a global concern and going to be a top challenge in the future. It did aggravate last year due to the supply-chain disruption caused by the pandemic. What are some of the innovative solutions that Alesca Life offers to meet this challenge and has COVID-19 triggered a sense of greater urgency?

Oda: This is a great point. Pre-pandemic, in 2018-19, a lot of the interest and investment from governments, companies and investors was in food tech, which was related to food delivery and meal kits at home. And it was really focused on one thing, which was consumer convenience. What has happened in 2020, with the pandemic and now that we're in 2021, is that the focus has shifted materially from food tech to agtech - agricultural technology, which is focused on resilience. It's about community resilience, as opposed to consumer convenience.

So, one of the solutions, the benefits or the outcomes of the pandemic, was a renewed interest in agtech. And by that, I mean, local food production is in control of your own supply chain for fresh and nutritious food. So, since the pandemic has happened, since the lockdowns have begun, I've probably spoken to individuals and government entities from over 30 countries that are interested in finding ways in which they can secure a minimum supply of local fresh food production in their own countries, in their own communities.

The shift has accelerated towards this localization, towards this decentralized form of food production that can happen almost anywhere. And one of the solutions that we're providing for this is to bundle all of our precision farming tools – our monitoring equipment, our automation systems, our farm management and software tools, and even our latest computer vision AI cameras – and bundle all these products together to create an incredibly capital efficient indoor farm. And this allows both governments, at large scale, and even community, at a smaller scale, to be able to be in control of their local food production needs.

Interviewer and script: Abhishek G Bhaya

Video editors: Meiyi Yan & Wu Chutian

Cover image: Du Chenxin

Infographics: Jia Jieqiong

Director: Mei Yan

Israel’s Vertical Field Inks Deal To Deploy Its Farming System In UAE

Ag-tech company to launch pilot in Emirates ahead of wider roll-out; its vertical farming system could lessen food insecurity in water-scarce Gulf state

By LUKE TRESS

Produce grown using Israeli start up Vertical Field's farming system. (Courtesy/Vertical Field)

Vertical Field, a startup that has developed a vertical farming system, has signed an accord with an Emirati company to deploy its products to the United Arab Emirates.

The Israeli ag-tech firm signed the agreement with Emirates Smart Solutions & Technologies, Vertical Field said in a statement on Wednesday.

Vertical Field will set up pilot vertical farms in the Emirate of Umm Al Quwain ahead of a wider roll-out in the UAE, the company said. The pilot will aim to determine which crops are best for the local market and will be supported and overseen by Vertical Field’s Israeli agronomists.

The firm expects the project to expand into a multimillion-dollar venture that will include distributing Vertical Field’s products to additional Gulf states, the company said.

Roughly 80 percent of agricultural food products in the UAE is imported from abroad, amounting to $10 billion in trade in 2018. The increasing cost of transporting food and concerns over food security played a part in the new partnership, Vertical Field said.

“Arid desert regions face many challenges surrounding the production of high-quality agricultural produce at low prices. With the help of various agricultural technologies and new developments, we believe that we can successfully align the demands of the market with competitive prices without compromising quality,” Guy Elitzur, Vertical Field’s CEO, said in a statement.

Maher Makalde, the CEO of Emirates Smart Solutions & Technologies, said, “We are excited for the opportunity to partner with Vertical Field and bring advanced Israeli vertical technology that enables the growth of produce in a controlled and predictable way, overcoming harsh outdoor climate conditions.

“Our goal is to establish food security that is independent of imports and to develop a high-quality agricultural infrastructure that reaches the retail market,” Makalde said.

An illustration of vegetables growing on walls by Vertical Field. (Courtesy)

Vertical Field’s soil-based installations are made up of separate blocks of plants that can be rearranged at will to produce locally sourced vegetables. This green wall of vegetation is suitable for growing vegetables in stores, offices and apartment buildings, or anywhere in urban areas, which have little space but many walls.

The firm, formerly called Green Wall Israel, said that products grown with its farming method are pesticide-free, generate less waste than conventional agriculture and utilize 90% less water, growing in precise quantities in a controlled environment with shorter growing cycles.

Produce in its containers can grow 365 days a year and is free of the limitations usually imposed by seasons, weather, climate and location.

The farms are modular, expandable and moveable, with fully automated crop management and a sterile environment that requires significantly less human contact. The crops that are currently offered include lettuce, basil, parsley, kale, mint and others, and are competitively priced, the firm said in a statement.

Israel and the oil-rich UAE signed a US-brokered normalization agreement in September, opening the way for business and tourism between the two countries, after years of covert trade exceeding $1 billion annually by some estimates.

The UAE, a federation of seven desert sheikdoms dependent on petrodollars, has been keen to cash in on the influx of Israeli investment and travel, particularly after the pandemic diminished demand for oil and hammered international tourism.

Earlier this month, Vertical Field signed an agreement with Moderntrendo S.R.O, an agricultural distributor in Ukraine, to deploy its plant installations in supermarket chains nationwide.

In December Vertical Field also signed a “multi-million dollar” agreement with Israeli discount supermarket chain Rami Levy for the installation of its vertical farming containers on the stores’ premises.

Vertical Field is based in Ra’anana in central Israel and was founded in 2006.

2-Acre Vertical Farm Run By AI And Robots Out-Produces 720-Acre Flat Farm

A San Fransisco start-up is changing the vertical farming industry by utilizing robots to ensure optimal product quality

Plenty is an ag-tech startup in San Francisco, co-founded by Nate Storey, that is reinventing farms and farming. Storey, who is also the company’s chief science officer, says the future of farms is vertical and indoors because that way, the food can grow anywhere in the world, year-round; and the future of farms employ robots and AI to continually improve the quality of growth for fruits, vegetables, and herbs. Plenty does all these things and uses 95% less water and 99% less land because of it.

In recent years, farmers on flat farms have been using new tools for making farming better or easier. They’re using drones and robots to improve crop maintenance, while artificial intelligence is also on the rise, with over 1,600 startups and total investments reaching tens of billions of dollars. Plenty is one of those startups. However, flat farms still use a lot of water and land, while a Plenty vertical farm can produce the same quantity of fruits and vegetables as a 720-acre flat farm, but on only 2 acres!

Storey said:

“Vertical farming exists because we want to grow the world’s capacity for fresh fruits and vegetables, and we know it’s necessary.”

Plenty’s climate-controlled indoor farm has rows of plants growing vertically, hung from the ceiling. There are sun-mimicking LED lights shining on them, robots that move them around, and artificial intelligence (AI) managing all the variables of water, temperature, and light, and continually learning and optimizing how to grow bigger, faster, better crops. These futuristic features ensure every plant grows perfectly year-round. The conditions are so good that the farm produces 400 times more food per acre than an outdoor flat farm.

Storey said:

“400X greater yield per acre of ground is not just an incremental improvement, and using almost two orders of magnitude less water is also critical in a time of increasing environmental stress and climate uncertainty. All of these are truly game-changers, but they’re not the only goals.”

Another perk of vertical farming is locally produced food. The fruits and vegetables aren’t grown 1,000 miles away or more from a city; instead, at a warehouse nearby. Meaning, many transportation miles are eliminated, which is useful for reducing millions of tons of yearly CO2 emissions and prices for consumers. Imported fruits and vegetables are more expensive, so society’s most impoverished are at an extreme nutritional disadvantage. Vertical farms could solve this problem.

Storey said:

“Supply-chain breakdowns resulting from COVID-19 and natural disruptions like this year’s California wildfires demonstrate the need for a predictable and durable supply of products can only come from vertical farming.”

(Credit: Reuters)

Plenty’s farms grow non-GMO crops and don’t use herbicides or pesticides. They recycle all water used, even capturing the evaporated water in the air. The flagship farm in San Francisco is using 100% renewable energy too.

Furthermore, all the packaging is 100% recyclable, made of recycled plastic, and specially designed to keep the food fresh longer to reduce food waste.

Storey told Forbes:

“The future will be quite remarkable. And I think the size of the global fresh fruit and vegetable industry will be multiples of what it is today.”

Plenty has already received $400 million in investment capital from SoftBank, former Google chairman Eric Schmidt, and Amazon’s Jeff Bezos. It’s also struck a deal with Albertsons stores in California to supply 430 stores with fresh produce.

Ideally, the company will branch out, opening vertical farms across the country and beyond. There can never be too many places graced by better food growing with a less environmental cost.

Here’s a TechFirst podcast about the story behind Plenty:

Published by Dani Kliegerman for iGrow.News

VIDEOS: Vertical Farming: Hope or Hype?

Flurry of corporate activity has proponents hailing arrival of the future of agriculture

Flurry of corporate activity has proponents hailing arrival of the future of agriculture

Emiko Terazono - October 31, 2020

Vertical farming has become a hot topic during the coronavirus pandemic, as supply chain disruptions and labour shortages feed perennial fears over global food security.

The nascent sector, in which crops are grown in stacked indoor systems under artificial light and without soil, has enjoyed a flurry of activity this year.

Headline-grabbing developments have included the construction of Europe’s largest vertical farm, plans to build the world’s biggest indoor farm in the Abu Dhabi desert, and a $140m fundraising round by a SoftBank-backed start-up Plenty. Norway’s Kalera this week announced a $100m private placement ahead of its listing on the Oslo Stock Exchange’s Merkur Market on October 28.

Proponents believe that the technology represents the future of agriculture, hailing huge efficiency and environmental gains for the food industry, and about $1.8bn has flowed into the sector since 2014, according to data group Dealroom. However, agritech entrepreneurs and analysts warn that hype and lofty promises could undermine the sector’s credibility, putting off consumers and investors.

“There is a lot of BS coming from entrepreneurs,” said David Farquhar, chief executive of Scotland-based technology provider Intelligent Growth Solutions. “There are far too many unsubstantiated claims about energy use, the environmental benefits and quality of crops.”

High-cost, small-scale

The sector remains largely unprofitable and tiny. Vertical farming occupies the equivalent of 30 hectares of land worldwide, according to Rabobank analyst Cindy Rijswick, compared with outdoor cultivation of about 50m ha and 500,000 ha for greenhouses.

High initial capital investment and running costs mean it is hard to make a profit. Businesses must pay for specialised labour and face huge electricity bills for lighting and ventilation, while having to offer competitive prices to attract consumers.

Some operators in Japan are profitable while Nordic Harvest, the Danish start-up that has teamed up with Taiwan’s YesHealth Group to build Europe’s biggest vertical farm in Copenhagen, claims it will be profitable in its first year in 2021.

Keeping the faith

The industry is expected to grow over the next decade, with research group IDTechEx forecasting that annual sales of $700m will more than double to $1.5bn by 2030.

However, there is likely to be a cull of inefficient businesses in a sector that has always had a high level of failures.

“My big fear for this industry is that we will have some large failures,” said Mr Farquhar. “It’s not helpful for buyers’ confidence, for customers’ confidence and investors’ confidence.”

Vertical farming must also overcome perceptions among some consumers, often unfounded, that despite the various benefits it offers it cannot possibly match the taste of high-end produce grown with soil and sunlight.

Please click here to view the video - Can vertical farming feed cities of the future?

Tech challenge

Many vertical farms boast cutting-edge technology ranging from artificial intelligence and robotics to lighting and water filtration, and some companies, particularly in Asia, have established successful processes.

Stacked production systems allow the cultivation of produce in constrained spaces, including urban areas. That means food can be produced closer to its consumers, reducing transportation time and improving freshness at the point of sale.

But new entrants can face teething problems with automation and watering processes, leading to costs spiraling out of control. There have also been cases of black mold and pest infestations hitting the farms, which typically do not use pesticides, according to Michael Dent, an analyst at IDTechEx.

Taste test

Total control over the growing environment is one of vertical farming’s big selling points, ensuring reliable, high-quality crops. A reduction in “food miles” gives consumers access to fresher produce, giving further taste gains.

Skeptics are possibly associating the sector’s offerings with crops grown in greenhouses, which are often of low quality when growers prioritize yield over taste, according to Leo Marcelis, professor of crop production at Wageningen University in the Netherlands.

With many retailers only paying by volume, “growers think ‘I don't get extra money for the quality’ so they don’t pay much attention to that”, he said. Vertical farms may follow a similar path if and when they get to scale and price points of greenhouse rivals. However, for the moment, the sector’s reputation lies in higher-value, better-tasting produce.

Salad days

Mr. Dent believes boosterish claims that “we’ll all be eating food made in vertical farms” are “a red herring and not helpful for the industry”. While most things can technically be grown in a vertical farm, production costs mean offerings tend to focus on higher-value leafy greens, salad leaves, and herbs.

“Commodities like rice, corn, and soyabeans — crops that are cheaply grown in the field and stored easily, I don’t see as economic,” said Prof Marcelis.

Vertical farming was not going to replace banana groves or fields of wheat, said Mr Farquhar, who added that IGS was trialing fruit and root vegetables as well as seedlings for R&D.

As Ms Rijswick puts it, vertical farming will only ever be “part of the mix among various growing systems”.

Lead photo: The vertical farming industry is expected to grow over the next decade © Bloomberg

All rights reserved

Why Vertical Farming Is The Future of Agriculture

Can you imagine the possibility of harvesting yields equivalent to 3,000-4,000 sq. ft. of land in a 1,000 sq. ft. of land?

Utsav Patel

November 7, 2019

Although ‘do more with less’ is an age-old philosophy, it is still an ongoing mantra for many individuals and companies today. In other words, ‘do more with less,’ means produce more with less. The term ‘productivity’ in the 1800s and 1900s used to be the measurement of the output of goods and services available. While in the 2000s, it means squeezing every bit of output that we can from data.

When it comes to data, most of us cannot resist but think about data-driven technologies, from the Internet of Things, Artificial Intelligence, Machine Learning to Big Data. The adoption of such data-driven technologies has made possible for Harley Davidson to reduce its lead time from a fixed 21 days motorcycle production schedule to just 6 hours. BASF USA, the North American affiliate of BASF SE – the largest chemical producer in the world, reduced their unplanned downtime to 80%. Dr. Marcus Elliott, a Harvard-trained physician, established a P3 facility to assess and train athletes to revolutionize pro-sports. With so many transformations in other industries, agriculture is no exception.

Can you imagine the possibility of harvesting yields equivalent to 3,000-4,000 sq. ft. of land in a 1,000 sq. ft. of land? Vertical farming technology makes that possible. Essentially, this farming technology, based on such data-driven technologies, allows doing more with less. Less water. Less fertilizer. Less land. No soil. Fewer chances of crop failure. But the higher quantity and fresh quality of crops. That’s why iot based vertical farming is the future of greenhouse agriculture.

In this blog post, we’ll see what vertical farming is, what pushes the shift towards vertical farming from conventional agriculture, the types of vertical farming and the advantages of vertical farming.

What is vertical farming

Vertical farming is a method of growing plants in vertically stacked layers in fully controlled environments. By growing plants in vertically mounted shelves, it remarkably reduces the amount of land required for traditional farming methods. Since a vertical farming setup resembles a multi-storied building of plants, it is often associated with urban farming. Vertical farming can be either aeroponic, where without the use of soil, plants are grown by systematic spraying of water and nutrients on roots, or hydroponic, where plant growth is supported using a nutrient-dense bowl of water. Along with knowing what makes vertical farming productive, it is also vital to understand why vertical farming has become the need of the hour today.

Why there is no alternative to vertical farming

The population of the world has quadrupled over the last century. According to the United Nations, in 1915, there were 1.8 billion people. Today, that figure rises to 7.7 billion. And it may reach up to 9.8 billion by 2050. However, it’s not only the growing population but increasing incomes in developing countries, as well, which are driving up the global food demand.

While food demand is expected to increase 70% by 2050 to feed the expected 9.5 billion people, it is estimated that an approximate of 19.5 million hectares of agriculture land is converted annually into urban centers and industrial developments. Therefore, it has become evident that farmers must increase food production, either by increasing the amount of agricultural land or by enhancing productivity on existing agricultural lands. The first option is clearly not possible, while the latter is possible through vertical farming. Some more compelling reasons for vertical agriculture are as per the following:

To meet mounting demands for food, timber, fiber and fuel, since 1945, we have caused 50-1,000 times more extinctions than their natural rates. That’s higher than the extinctions that happened during the 18th and 19th centuries combined.

The average temperature of our planet has increased by 0.85 °C. Grain yields decrease by about 5% with the rise of each one-degree. Surprisingly, since 2001, annual averages have shown the warmest global temperatures than any time ever before on this planet.

According to the World Wide Fund for Nature (WWF), currently, 1.1 billion people in the world lack access to water. And around 2.7 billion go through water scarcity at least one month of the year. Imagine the scenario by 2050.

Overall, vertical farming can be promising to save the planet’s valuable resources and provide the common man with better opportunities for health and sustenance.

Types of vertical farming

Hydroponics

If you have ever put a plant clipping into a glass of water in the expectation that it will grow roots, you have practiced hydroponics. Hydroponics is an agricultural method where plants are grown without the use of soil Here, the nutrients which plants usually obtain from the earth are dissolved into water instead.

Hydroponic systems require only about 10% of the water than the water needed by soil-based farming. That’s because hydroponic systems allow water and nutrient solutions to be recycled, reused and because no water is wasted as well. Further, hydroponics needs little or no pesticides and needs only about 25% of soil-based plants’ nutrients and fertilizers. This not only reflects cost savings but also protects the atmosphere by not introducing any chemicals into the air as well as the produce. On a broader level, let’s also consider the transport’s environmental impacts. Because hydroponics allows local production and requires fewer areas to import their crops, both price and greenhouse gas emissions are reduced as a result of reduced transport requirements.

Moreover, since plants grown in hydroponic systems have easy access to water and nutrients, they are not required to establish complex root systems to get the nutrients they need. Therefore, hydroponics enables a shorter harvest time. The method saves time and yields better, lush plants in around half the time than conventional farming requires.

Aeroponics

Like hydroponic systems, the aeroponics system also allows the growth of plants without soil. Here, the roots are sprayed with water and/or nutrient solution. The dispersion of mist provides the roots with the necessary amount of moisture to allow the plants to grow.

Did you ever think that naked roots could not only survive, but thrive? With the aeroponics system, the roots get maximum oxygen. As a result, roots thrive and plants grow faster. Not only that, such closed-loop systems use 95% less irrigation than soil-grown crops. Also, it is easier to harvest, particularly for root crops.

Aquaponics

This system is the same as the hydroponic system, but it does have some additional benefits. The goal here is to create a symbiotic ecosystem that supports each other – plants and fish.

Water becomes nutrient-rich, when you grow fish in indoor pools. This water serves as a wholesome food for the plants growing in your vertical. On the other side, the water going through the hydroponic subsystem is cleaned, oxygenated and returned to the tanks of aquaculture for the fish. This saves a lot of time, efforts and money, as there is no need to recycle the pond’s water frequently.

This groundbreaking method is employed by many commercial vertical farms as aquaponics allow them to make more profits by producing two goods at the same time.

Advantages of vertical farming

Vertical farming is, undoubtedly, a radical approach for producing quality fresh food in the least amounts of time and all year round. Though it does not rely on favorable weather conditions, skilled labor, high soil fertility and significant water usage, vertical farming technology delivers some extraordinary benefits.

It produces a harvest that is nutritious, environmentally friendly and affordable. As these harvests do not require long-distance transportation, it results in reduced fuel usage and decreases greenhouse gas emissions as well. In recent years, climate change has become the hottest topic. Amongst the industries that contribute to climate change, transportation is the second. By the way, due to limited transportation demand, consumers can get quality fresh vegetables at lower prices. And because of better access to healthy diet at affordable prices, the neighborhood is likely to lower their risk of diseases and witness an increase in their general health.

Moreover, vertical farming also enables more efficient use of waste. For example, a city’s grey, brown and black water can be used for irrigation after some minor treatment. Further, using anaerobic digesters, plant matter can be converted to methane gas, which can be used to generate electricity.

To know more about how data-driven technologies can help to monitor your vertical farming, contact our team of experts or stay tuned with us. We are in favor of promoting planet-friendly practices. How about you?

Categories:Blogs

KUALA LUMPUR, Malaysia: This Vertical Farm Was Born In The Pandemic. Sales Are Up

The Vegetable Co. in Kuala Lumpur, Malaysia, grows vegetables under LED lights in a shipping container. “We were a nascent product in an uncertain market,” one of its founders said

The Vegetable Co. in Kuala Lumpur, Malaysia, grows vegetables under LED lights in a shipping container. “We were a nascent product in an uncertain market,” one of its founders said.Credit...Ian Teh for The New York Times

The Vegetable Co. Sits In A Shipping Container On The Edge of A Malaysian Parking Lot. It’s One of Many Small Farms Around The World Selling Directly To Consumers.

By Ian Teh and Mike Ives

Sept. 3, 2020

KUALA LUMPUR, Malaysia — The setup of the two friends’ agricultural venture was unusual. Their farm sat next to a gas station, inside a shipping container where the plants grew in vertically stacked shelves. And the timing of their first sales — during the early days of Malaysia’s coronavirus outbreak — seemed less than ideal.

“We were a nascent product in an uncertain market,” said Shawn Ng, 28, a co-founder of the vertical farm, the Vegetable Co. “We weren’t too sure if it would take off.”

“But somehow,” he added, “the market kind of played in our favor. ”As in-person shopping wanes during the pandemic, Mr. Ng’s Malaysia-based operation is one of many small farms around the world that are selling fresh produce directly to consumers in ways that bypass brick-and-mortar grocery stores.

Some farms sell on e-commerce platforms like Amazon or Lazada, Alibaba’s online emporium for Southeast Asia, or through smaller ones like Harvie, a Pennsylvania-based website that connects consumers with individual farms across the United States and Canada.

ImageShawn Ng, one of the Vegetable Co.’s founders, loaded freshly harvested produce into a car for delivery.Credit...Ian Teh for The New York Times

Others, like the Vegetable Co., sell directly to customers. “I was very ‘kan cheong’ during the lockdown period,” said one of Mr. Ng’s regular customers, Ayu Samsudin, using a Cantonese word for anxious. “Having fresh vegetables delivered to your doorstep was such a relief.”

The Vegetable Co. consists of a 320-square-foot shipping container on the edge of a parking lot in Kuala Lumpur, Malaysia’s largest city. It opened for business, with just a handful of customers, about a month before the country’s restrictive lockdown took effect in mid-March.

Revenue grew by 300 percent in the first few weeks, and the shipping container is now approaching production capacity because of high demand, said Mr. Ng’s business partner, Sha G.P.Apart from the gas station, the shipping container’s other neighbors are a driving range and an oil palm plantation. Inside, tightly packed shelves with hydroponic lettuce, sprouts and other vegetables grow under LED lights.

Mr. Ng on a delivery run in Kuala Lumpur. Malaysia has weathered the pandemic relatively well, at least compared with other Southeast Asian countries.Credit...Ian Teh for The New York Times

The wallpaper outside the growing chamber shows blue sky and clouds, evoking the view from an old-fashioned farm. But employees pace the chamber’s narrow corridor wearing rubber gloves, surgical masks and white lab coats, as if it were a hospital ward.

The founders have scant experience with traditional farming, and they speak about their work with Silicon Valley-like jargon.

Mr. Sha, who has a master’s degree in management, said he first became interested in vertical farming after watching “The Martian,” the 2015 film in which an American astronaut played by Matt Damon is stranded on Mars and learns to grow his own food.

“I was lost in awe about the degree of precision in the technology along with the elegance of the solution to grow vegetables in a zero-gravity environment,” he said. “Since then, I have gone down the rabbit hole of independent research.”

Gudrun Olafsdottir, a Kuala Lumpur resident from Iceland, said the Vegetable Co. was one of the local businesses she was supporting with a “financial hug” during the pandemic.Credit...Ian Teh for The New York Times

The coronavirus took off in Malaysia in March, after an Islamic revivalist group’s gathering there became one of the pandemic’s biggest vectors in Southeast Asia. Since then, the country of about 32 million has weathered the outbreak relatively well, at least compared with some of its neighbors. As of Thursday, it had reported fewer than 10,000 confirmed cases since the pandemic began, according to a New York Times database.

Malaysia’s initial lockdown allowed only one person per household to go outside for essential errands, and the police enforced local travel restrictions with roadblocks.

But even though the rules were gradually loosened to let most businesses reopen, many urban Malaysians have maintained the online shopping habits they developed during the initial lockdown, said Audrey Goo, the founder of MyFishman, an e-commerce platform that connects fishermen from villages along the country’s west coast with consumers in Kuala Lumpur.

Gudrun Olafsdottir, a Kuala Lumpur resident from Iceland, said the Vegetable Co. was one of the local businesses she was supporting with a “financial hug” during the pandemic.Credit...Ian Teh for The New York Times

“Not many end users are willing to go back to the wet market,” said Ms. Goo, adding that her company’s sales had roughly doubled during the pandemic. “So I think the whole business model will continue to change.”

Mr. Ng said the Vegetable Co.’s parent company, Future Farms, was now seeking seed capital to finance an expansion into a larger facility. He recently hired an architect and a software developer to design it. For now, though, the operation remains modest. On a recent afternoon, Mr. Ng climbed into his car for a delivery run that snaked through low-rise residential neighborhoods, as the sun sank below Kuala Lumpur’s hazy downtown skyline.

One of the customers on the 40-plus-mile route, Gudrun Olafsdottir, said that along with yoga and meditation, greens from the Vegetable Co. were part of a routine that helped her keep physically and mentally fit during the pandemic.

Ms. Olafsdottir, who is from Iceland and works in retail, found the farm on Facebook through a local chef who specializes in raw and vegan cooking. She said it was one of several local businesses that she was supporting these days with a “financial hug.”

“I think that we could do so many things to support those in need if we just consciously choose how we spend our time and money,” she has written on her blog. “A hug and a squeeze.”

The farm is in a 320-square-foot shipping container near a gas station, a driving range and an oil palm plantation.Credit...Ian Teh for The New York Times

Ian Teh reported from Kuala Lumpur and Mike Ives from Hong Kong.

VIDEO: Will This Y Combinator-Backed Startup’s Urban Home Farms Take Root In India?

UrbanKisaan leverages hydroponic technology for home growing kits, as well as a network of urban farms for online delivery and retail channels

Inc42 Staff

27 Aug'20

UrbanKisaan leverages hydroponic technology for home growing kits, as well as a network of urban farms for online delivery and retail channels

During the lockdown phase, the company claimed to have seen 10x growth in terms of demand for its fresh produce, compared to pre-Covid times.

Based in Hyderabad, UrbanKisaan has installed close to 30+ vertical farms and plans to expand to Bengaluru, Chennai among other cities

There’s a minor revolution underway in many of India’s biggest cities. We are talking about hydroponic farming and this soil-less method is fast becoming the answer to solving the problem of carbon footprint in food. Call it hydroponic farming, soilless farming, vertical farming or anything else — for many it is the long-awaited answer to responsible eating.

In this backdrop, agritech and hydroponics startups are quickly finding niches in various produce categories and cities. Despite their shared ethos for sustainable food production, the likes of UrbanKisaan, Barton Breeze, Hydrilla, Simply Fresh, Acqua Farms, Letcetra Agritech, BitMantis Innovations, Future Farms, Ela Sustainable Solutions, Agro2o, Junga FreshnGreen, Pindfresh are working in this field through different models and targeting different niches — from large-scale hydroponics farming in rural areas to small home farms for the cities.

Working on the philosophy of bringing farms closer to home is Hyderabad-based UrbanKisaan. With the vision of making hydroponic technology more affordable and accessible for the masses, UrbanKisaan offers home-grow kits or vertical hydroponic farms. And by creating mini-farms in cities and revitalizing farmlands with hydroponic technology, the startup also supplies fresh produce to customers through Swiggy, Zomato, Dunzo, and other retail channels as well as in the D2C model on subscription and on-demand basis.

“We are the only startup in the hydroponic landscape to have taken a hybrid approach, where we have 20,000 sq. ft. research and development facility, along with 15+ in-house scientists working on newer innovations and products,” claimed cofounder and CEO Vihari Kanukollu elaborating on how the company is looking to differentiate itself in the burgeoning hydroponic market.

However, UrbanKisaan is not alone in the game, Simply Fresh, another Hyderabad based agritech startup, also grows and supplies a line of medicinal plants and fresh produce from its greenhouses. Similarly, Chennai-based Future Farms works on hydroponic technology at a commercial level, where it designs integrated full-stack solutions for alternative farming in the country. The vibrancy of the hydroponic models and the large ground area that needs to be covered across cities and villages has made it possible for multiple startups to thrive in this space.

Needless to say, the market opportunity is huge, as ‘urban farming’ is catching up at a rapid pace globally. According to MarketsandMarkets, the global hydroponics market is expected to reach $16.6 Bn by 2025, growing at a compound annual growth rate of 11.9% from $9.5 Bn in 2020. The growth of the sector is said to be driven by the increase in population and the need for food security through alternative high-yield farming techniques, given the depletion of water across the globe.

Plus, the rise in awareness and demand for a healthier lifestyle is said to have opened doors for a plethora of possibilities for hydroponic startups to reap the benefits in the long run.

UrbanKisaan earns revenue from its multiple channels which allow it to reach all kinds of consumers — from those who want a taste of the hydroponic produce to those who want to grow it themselves. Its urban farms are strategically located next to retail stores to facilitate hyperlocal deliveries and its DIY home kits are for the latter set. Additionally, it is also supplying its technology to local farmers to reutilise farmland.

The startup was founded in 2017 by Kanukollu, Srinivas Chaganti, Dr Hari, Shiva Prasad and Dr Sai Ram, a scientist who has been instrumental in developing the nutrient solution for their state-of-the-art vertical farming technique. In March 2020, the company also raised $1.5 Mn in seed funding from Y Combinator.

Home Farming In The Times Of Covid

During the lockdown phase, the company claimed to have witnessed 10x growth in terms of demand for its fresh produce, compared to pre-Covid levels. Further, cofounder Kanukollu said that the disruption in the supply chain and consumers leveraging on the hyperlocal delivery modes, along with the change in consumer lifestyle, for the consumption of fresh, organic produce has resulted in the surge in demand.

The Covid-19 pandemic temporarily halted the movement of produce across India and highlighted the gap in the food supply chain. This allowed agritech startups such as UrbanKisaan that specialise in hydroponic farming to tap a tremendous opportunity and bring efficiency in the supply chain.

With its hyperlocal urban farms model, Kanukollu claimed UrbanKisaan is not only bringing transparency to the vegetable supply chain but also lowering the carbon footprint, reducing food waste. Most importantly, their farming technique also claimed to save 95% water, and grow the produce 30x compared to traditional farms.

Its home kits are priced anywhere between INR 9,900 and INR 19,900 with about 50+ varieties of leafy vegetables and exotic vegetables supported by these kits, including spinach, coriander, mint, basil, bok choy, lettuce, parsley, fenugreek, capsicum, tomato and kale among others.

Further, the company claimed to have semi-automated the entire process and has designed the kits in such a way that it requires limited resources to manage it. “Once installed, it requires 15 min/week of effort to take care of the plants, thereby making it seamless for consumers to grow their own fresh produce,” said Kanukollu.

A Tech Upgrade For Rural Farmers

In addition to this, UrbanKisaan also works with local farmers who own greenhouses, where it helps them in setting up vertical farms from scratch to producing and supplying fresh fruits and vegetables.

Cost-wise, the poly house or greenhouse setup would typically cost farmers anywhere between INR 35 to INR 50 Lakhs per acre, of which, the government may subsidise up to 80%. Once this is installed, which is a fixed cost, for setting up of hydroponic setup, it would cost the farmer additionally INR 50 Lakhs. But, UrbanKisaan told Inc42 that it looks to reduce this cost at INR 15 to INR 20 Lakhs.

UrbanKisaan claims to have installed close to 30+ hydroponics farms in the state, across its various offerings. In the coming days, it plans to expand into other cities, including Bengaluru, Chennai among others, along with growing its team, adding newer varieties of hydroponic seeds, fruits and vegetables, and enhancing its technology capabilities.

Kanukollu is looking at creating a centralised monitoring system through UrbanKisaan for these various hubs and farms. “We are heavily investing in artificial and machine learning tools, where once the network of the urban farm increases, we will be able to monitor and control their farms remotely and provide a real-time update to customers.”