Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Understanding The Key Tech Required In Vertical Farming

Staff Reporter Jan 25, 2021

Vertical farming involves; growing crops indoors under artificial temperature and lighting conditions. This technology focuses on increasing productivity in small places. It utilizes soil-free methods like aeroponics, aquaponics, and hydroponics. Read on to understand the main tech you need for your vertical farm.

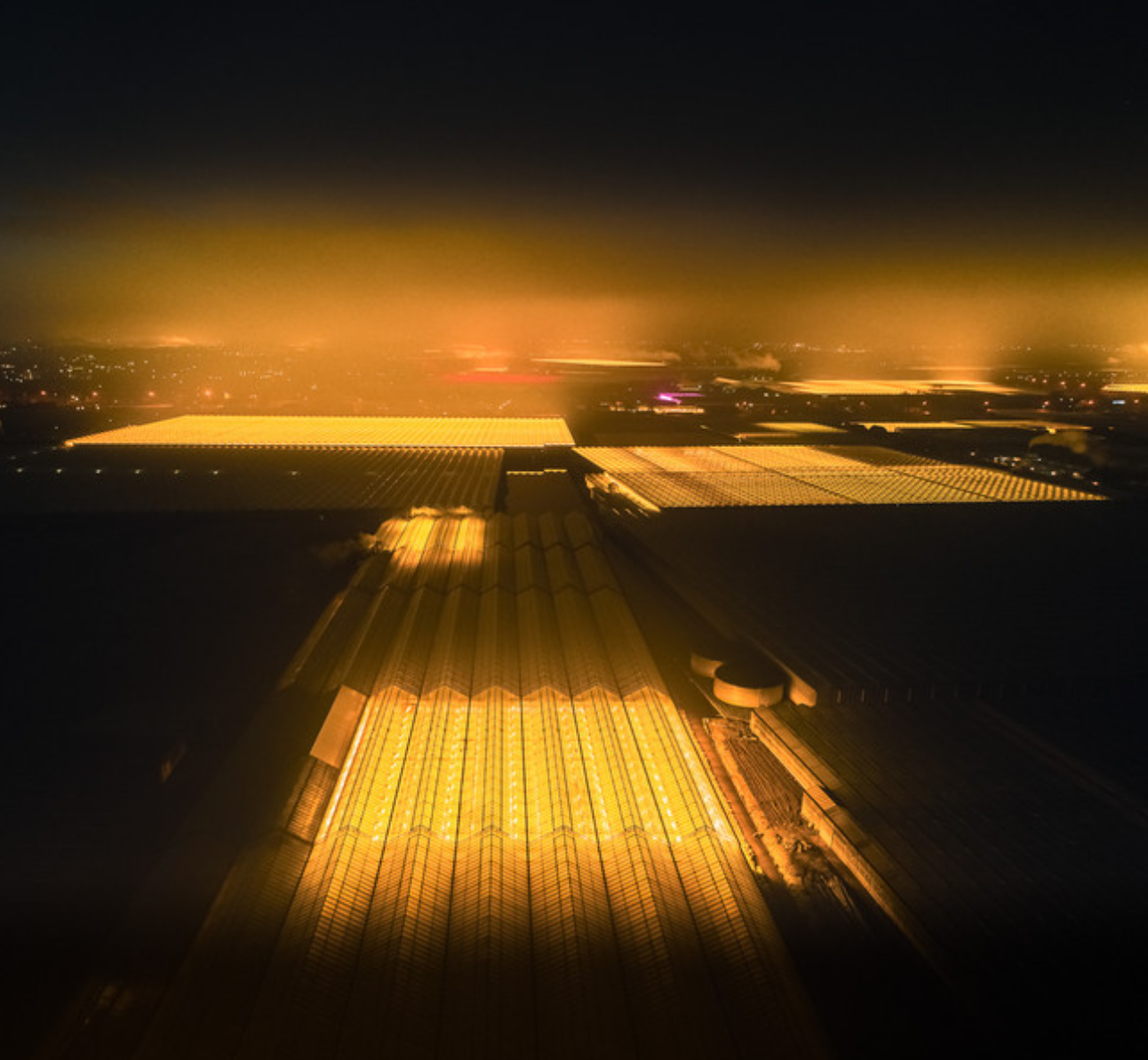

(Photo : Valcenteu Wikimedia Commons)

Lighting systems

Covered agriculture, which is the traditional method of farming uses HPS (High-Pressure Sodium) vapor lamps. These units generate a warm light, which appears as an orange-yellow glow in areas with many glasshouses. LED technologies have evolved, becoming more energy-efficient and cheaper.

LED vertical farming lighting dictates the next generation controlled environment agriculture (CEA). While HPS lamps generate orangey-yellow light, LEDs can be designed to generate light in any color or combination of choice. Today, more LED lights are specially designed for the CEA industry.

Researchers are working with manufacturers to manufacture crop-specific lights to enhance photosynthesis, guarantee crop quality, and boost yield production. When growing crops in an indoor environment without a natural or external light source, the quality and quantity of artificial vertical farming lighting for your crops is critical.

Heating, Ventilation and Air Conditioning (HVAC)

Controlling the heating, ventilation, and air conditioning is crucial in managing a vertical farm. Remember, the HVAC can influence the yield, health, and quality of your crops. Smart regulating systems are crucial for the management and maintenance of ventilation, temperature, and humidity. Installing smart enabled HVAC systems that can be incorporated into a general control system is critical.

Nutrients

Controlled environment agriculture allows farmers to regulate the frequency, levels, and nutrients they use on the crops. Commercial nutrient mixes are not only readily available but are also easy to use for your vertical farm. However, you can improve the quality of your crops and increase production with a crop-specific nutrient mix. Research and knowledge help you produce efficient nutrient mixtures for your vertical farm.

Control Systems

Control systems audit, and manage all elements of a controlled environment. Doing so allows the farmer to make proper decisions for crop-specific growing conditions. Advanced control systems give farmers crucial data on crop health, development, and the environment.

With this data, the farmer can develop different features of the growing conditions. Further, control systems facilitate the implementation of nutrient mixes and light that can change throughout growing, light intensity, and delivery of supplementary C02 (carbon dioxide).

Future vertical farms should come with integrated control systems and inline crop monitoring systems to facilitate disease management. These components will help boost conditions, enhance energy-efficiency, and increase yield.

Growing Systems

Vertical farming involves various hydroponic systems, making soil and other growing media unnecessary. Farmers can use different substrates, as seen below.

NTF (Nutrient Film Technique)

The NTF comprises narrow troughs or channels where flowing small amounts of nutrient and water solution drains to the bottom of the troughs. This process creates a thin film. Plants are hanged over the trough in net containers. They receive small amounts of the nutrient solution often per day.

The fine nutrient film solution facilitates watering of the rear of the roots without getting soaked. The top part of the roots stays dry and consumes oxygen. The nutrient film technique is ideal for baby greens, salads, leaves, strawberries, and herbs.

Flood and Ebb System

The flood and ebb system is also known as drain and flood. It involves the use of trays filled with a nutrient solution for a few minutes before the water drains. The plant roots are swayed around the nutrient solution. Using flood like circumstances allows the plants to consume nutrients and oxygen, making them healthy and strong. The flood and ebb system is ideal for producing microgreens.

Finally

Vertical farming allows farmers to grow crops throughout the year, and this facilitates maximum crop production. This technology does not rely on the weather. You can grow your crops with the help of LED lighting. Apart from being eco-friendly, vertical farming allows you to farm within limited spaces, as is the case in cities.

University of Arizona Announces Greenhouse Engineering Course

Join the University of Arizona’s Controlled Environment Agriculture Center for their 20th Annual CEAC Greenhouse Crop Production & Engineering Design Short Course on March 3rd, 10th, and 17th via Zoom

Join the University of Arizona’s Controlled Environment Agriculture Center for their 20th Annual CEAC Greenhouse Crop Production & Engineering Design Short Course on March 3rd, 10th, and 17th via Zoom. This virtual conference will increase your knowledge in Controlled Environment Agriculture and hydroponic growing and will allow you to network with industry leaders.

Each day will be jam-packed with incredible presentations given by experts in academia and the CEA industry. Topics will include Greenhouse Structures and Environments, Managing Plant Nutrition, Lighting, Fertigation Systems, Pest Identification, and Control Strategies, Hemp and Mushrooms in CEA, Organic Hydroponic Food Production, and much more! Registration is open until February 26th, 2021.

Click here for the 2021 Online Greenhouse Crop Production & Engineering Design Short Course Schedule

For more information, visit ceac.arizona.edu.

Polygreens Podcast Episode: 010 - Hydroponic Nutrient Solution

In this podcast, we’re going to discuss watering plants so that you can apply the technique to your own crops

When it comes to hydroponic nutrient solution, there are various opinions saying it’s better to use carbon filter water while others claim it’s best to use reverse osmosis water. When it comes to feeding plants, the main goal is to avoid any chances of root rot. In this podcast, we’re going to discuss watering plants so that you can apply the technique to your own crops.

Listen

Nick Greens The Nick Greens Grow Team has participated in many changes since they started developing indoor controlled agricultural environments in 2010. Our goal is to expand the vertical farming industry by helping ag-entrepreneurs manage their businesses better, avoid common mistakes, and improve crop yields based on what we have observed and developed over the past decade.

YouTube

2020 Shone A New Light On The Need For Container Farming

For us here at Freight Farms, the COVID-19 pandemic became a pivotal moment

Even A Pandemic Couldn’t Stop Us!

When the COVID-19 pandemic came to a head in March, we all felt a deep sense of trepidation. At the time, the future looked beyond bleak. We were all at the forefront of a completely new experience and it was up to us to figure out how to stay safe and continue to thrive in the ‘new normal’ world. For us here at Freight Farms, the COVID-19 pandemic became a pivotal moment. Would people still care about their source of food in the midst of a health crisis? Would individuals be looking to shift careers and lifestyles during such uncertainty?

The answer came right away: yes. The pandemic shone a spotlight on the key flaws within our food system and the need for a workplace revolution. We saw a tremendous growth of interest from people looking to make a positive and needed impact on their communities. We reflect on the year with immense gratitude for our community of farmers that continue to help us address pressing issues of sustainability and food security–we can’t wait to see all we can accomplish together in 2021!

Coimbatore’s Hydroponic Farm Delivers Fresh Greens Within Three Hours of Harvest

I grab a leaf of peppermint from a bed of mint leaves and taste the intense freshness.

Sustainable farming and fresh, zero-carbon food are the philosophy behind the city’s first urban hydroponic farm, located inside an industrial building campus. To know more, MetroPlus makes a visit

I grab a leaf of peppermint from a bed of mint leaves and taste the intense freshness. Next, I look at thyme and smell the powerful aroma. A little away, purple basil with a beautiful, coppery glow beckon. I crush a lemon balm leaf and take in the uplifting, mild scent.

I am at Parna Farms, Coimbatore’s first urban hydroponic farm, located right in the heart of the city at an industrial building campus. Spread across 3,000 square feet, it grows 2,520 plants.

Akhila Vijayaraghavan | Photo Credit: S Siva Saravanan

“Our fresh lemon balm leaves impart a subtle flavour and fragrance, making it especially nice for custards, jam and jellies, cakes and tea,” says Akhila Vijayaraghavan, owner of the farm. “The purple basil is used for colour in salads. Except maybe amaranthus and palak (spinach), you can eat all the greens we grow here raw,” says Akhila pointing to varieties of lettuce, basil, bok choy, and kale.

Asian water spinach (kang kong), red gongura, mustard leaves and methi (fenugreek) are some of the new additions. “We also grow dill leaves, which are used as a garnish for fish and meat dishes and pasta. Fresh peppermint extracts are used in baking. We constantly try new crops based on demand, after rounds of trial-and-error.”

Peppermint grown at the hydrophonic Farm | Photo Credit: S Siva Saravanan

A graduate of Molecular Biology from the University of Glasgow, Akhila ran her own environmental consultancy for over 10 years before turning an urban farmer. “I worked with a lot of companies, from pharmaceuticals to FMCG, and learnt that the supply of quality end-product is a difficult task. Agriculture has always been one of my passions; I was interested in food crops. A herb can be used in cooking, to extract oil, extract nutrients in dry form, and maybe in alternative medicine, perfumery… the possibilities are exciting,” adds Akhila.

She researched hydroponic methodology and educated herself on farming before diving into it. “Anyone can do it, it is not rocket science,” she says.

“Hydroponics combines both sustainability and technology. In indoor hydroponic cultivation, the control on nutrient supply ensures more quality products, for example, improved oil content in herbs, as well as better crop yield. A hydroponic mint has more methanol content than a soil-grown one. The system also uses 80% less water than conventional agriculture. The water is upcycled for reuse.”

At Parna Farms, greens are grown using the nutrient film technique (NFT), where a thin ‘film’ of nutrient-rich water with macronutrients like nitrogen, potassium, phosphorous and calcium nitrate, and micronutrients like manganese and zinc nourish the roots of the plants.

Seedlings at the nursery at the hydroponic farm | Photo Credit: S Siva Saravanan

The farm has a germination area that uses coco peat to sprout plants and a nursery where net cups (small planters) are filled with clay pebbles. There is also the growing system, which involves metal stands and PVC pipes attached to a covered nutrient tank that pumps water to the plants. “We incubate the net cups in a plastic tray for a couple of weeks. Once the plant grows roots, it is transferred to the main system with higher nutrients in the water. This is where it is fully grown and harvested,” explains Akhila.

Hydroponic agriculture, she says, has existed for over 3,000 years, with the Hanging Gardens of Babylon being one of the often-quoted examples of this technique. “It is one of the more accessible forms of modern agriculture, tackling the dual problems of water scarcity and shortage of farmland. It reduces soil-borne pests and diseases.”

Akhila says the objective is to ensure that customers get fresh, pesticide-free produce within three hours of harvest. “Though a palak bunch from here costs ₹130, they are willing to pay the premium to enjoy good health,” says Akhila, adding, “You are what you eat. In hydroponics farming, every day is a learning curve.”

Follow @parnafarms on Instagram to know more

IPO Planned To Improve Revenues Indoors

Light Science Technologies has gained the funding from Intuitive Investments Group plc (IIG), ahead of going public on the London Stock Exchange in the next six months.

8-01-2021| Business Live

“We believe that there is no better time to be involved in both agritech and medtech." A company which makes technology to improve indoor crop yields has received a £1 million investment ahead of a planned IPO.

Light Science Technologies has gained the funding from Intuitive Investments Group plc (IIG), ahead of going public on the London Stock Exchange in the next six months.

The business, based on the Hilton Business Park, Derby, provides lighting and plant growing and monitoring technology for agriculture in partnership with university research teams.

Its agricultural tech can be used in three main indoor settings – vertical farming (where crops such as tomatoes are grown in vertically stacked layers), greenhouses and medicinal plants.

Its patent-pending, sustainable light unit combines interchangeable LEDs, power and technology to help reduce costs and generate maximum yields over 25 years.

Its real-time monitoring and control technology can also be used to link technicians, farmers, and facility managers with their crops to provide instant production data.

Management said that with better light quality and energy savings, its light, science and technology products increase cycles.

It also supplies technology to clients in the electronics, audio, automotive, AI technology and pest control sectors.

The move to become a publicly listed company follows significant investment in its team and operations over the past few years which, the business said, has “brought to market a fully updateable, bespoke and intelligent lighting solution that provides optimal yield”.

The company is also due to launch its own in-house growth and laboratory service in the spring, focusing on plant growth and performance to help farmers with their crops.

Chief executive Simon Deacon said: “We believe that there is no better time to be involved in both agritech and medtech as two rapidly expanding sectors which are going to be responsible for spearheading some of the most significant global developments over the coming decade and beyond.

“IIG’s investment is not just a reflection of its commitment to LSTH as a fast-growing business backed by almost 30 years’ expertise in light technology but also of its awareness of the importance in achieving a better, more sustainable approach to agricultural production as well as pioneering potential life-saving solutions in digital health innovation.”

Light Science Technologies is IIG’s first investment following its own successful IPO and admission to AIM in December, as it seeks to attract investors with its life sciences portfolio.

IIG chairman David Evans said: “LSTH has the key ingredients for success; it has an excellent management team, a deep knowledge of the light spectrum and the application of that knowledge to areas where substantial growth can be obtained.

“I am personally excited about the potential diagnostic applications in the digital health sector, such as non-invasive haemoglobin measurement, as well as the developments in vertical farming technology that will underpin the long-term growth of LSTH.”

The investment follows recent funding for Light Science Technologies from Innovate UK which will see it work over the next six months with Nottingham Trent University to develop a growing sensor and transmission node for vertical farms.

Photo: Light Science Technologies designs lighting, science and plant monitoring technology.

Source and Photo Courtesy of BusinessLive

Combining Hydroponic And Aeroponic In Vertical Farming

Growers are finding new ways to drive the efficiency up and the cost down, and one of these solutions is vertical farming.

Generally speaking, horticulture operations can be quite expensive to operate; yet, growers can rely on hundreds of years of knowledge to improve the efficiency, so that those costs go down. At the same time, indoor farming cannot rely on such knowledge, and it is not uncommon to see cultivation facilities with huge bills at the end of the month. As the industry matures, growers are finding new ways to drive the efficiency up and the cost down, and one of these solutions is vertical farming.

LED technology

Nowadays, LED technology has made a huge leap forward, and Alvis Ma, the CEO of GrowSpec claims they are the industry standard. “Growers generally make the switch from HPS to LED for three reasons: increased yield, improved cannabinoid, and terpene content, and energy efficiency,” he explains. Thus, LEDs allow for vertical cultivation, which has a host of benefits, especially when it comes to space optimization.

“The VetriAero Planter system uses a mobile planting rack that reduces the ‘required’ indoor grow space area and extends the plant cultivation space by multiple tiers, maximizing growth space, increasing the yield and thus the profit,” Alvis Ma points out. “And if a grower wants to use one rack only initially, other tiers can be added later on: the helves can be connected to one another so that growers can modify the VetriAero Planter system length according to the size of the room.”

A very peculiar feature of this system is the integration of both aeroponic and hydroponic methods. “Instead of growing in soil, the roots are suspended in mid-air and surrounded by oxygen,” he adds. “The plant roots get misted directly with a nutrient-dense solution that gets sprayed to the roots every 3-5 minutes. At the same time, the remaining liquid at the bottom of our container ensures that, in the event of an emergency, there is still enough nutrient-dense liquid to sustain your plants for up to 48 hours.”

“Commercial indoor cultivation operations can be very expensive,” says Alvis Ma with GrowSpec. “And if you look at the cost of the real estate, added on top of substantial

power bills and staffing requirements, it becomes critical to find a way to increase profit and reduce overhead costs.” Exactly to respond to such a demand, GrowSpec has developed the VertiAero Planter system, a new vertical growing system. “One of the primary reasons why vertical farming is so attractive for growers is the improved performance of current LEDs,” Alvis Ma continues. “This is something that could not happen back in the day, as HPS has been the go-to lights for decades, and they produce a lot of heat; generally speaking, the plants have to be placed a couple of feet away from light to stay safe and healthy.”

Controlling the environment

Indoor growing, especially vertical growing, requires a particularly efficient airflow system to guarantee healthy growth for the plants. This has direct consequences on the growing environment. “Maintaining optimum temperature, humidity, and air circulation is challenging for all cannabis operations,” Alvis Ma remarks. “But in vertical growing, there is even more variability in macro and micro environmental conditions, because more plants make control more difficult.

That’s why the GrowSpec VertiAero’s multi-layer airflow solution improves the airflow rate in the micro-environment of the plant canopy by maintaining consistent plant canopy temperature and humidity, reducing the cultivation potential of harmful pathogens, and increasing the rate of photosynthesis by evenly distributing CO2 over the plant canopy. The system utilizes various sensors to detect crucial data points such as moisture change, for instance.”

Although such a system might sound complicated to use, user-friendliness and easiness of use are very well implemented. “The VertiAero Planter system integrates intelligent control and touchscreen control system so that your business can save up exponentially on overhead costs,” Alvis Ma points out. “At our core, we operate according to the highest standard, combining this with technology that respects our planet.”

For more information:

GrowSpec

Yuxin Industry Zone, Shishan Town, Nanhai, Foshan, Guangdong, China

+86-15914220731

Leamington Greenhouse Growers Struggle With Venting With Light Pollution Limits

Venting limits are imposed by local municipalities to address light pollution concerns

A recent Horti Daily article discussed the problems with limited venting experienced by many greenhouses in the Leamington, Ontario area. Venting limits are imposed by local municipalities to address light pollution concerns. Venting is a strategy used by greenhouses to remove warm air from the greenhouse as temperatures rise, especially in the warmer months. Venting limits make it difficult for greenhouses to remove warm air and maintain optimal temperatures in greenhouses. An unintended consequence with artificial lights is that opening greenhouse side walls and roofs allows light escaping, causing light pollution to the neighboring area outside.

Greenhouse growers are constantly juggling and adjusting growth parameters like light, temperature, and CO2 to create an optimal growth environment for their plants. Choosing to vent or not is always a double-edged sword. On the one hand, venting is an inexpensive way to manage air exchange in order to keep temperatures cooler in the warm months from spring through fall. On the other hand, venting with artificial lights on results in light pollution. Venting also makes it impractical to supplement the greenhouse grow area with CO2 by atmospheric enrichment (also known as CO2 gassing) since the CO2 gas quickly escapes outside.

The problem with venting is not usually an issue for Leamington greenhouses in the colder months when the vents are closed, thereby enabling CO2 gassing as the facility is sealed and reduces artificial light pollution. CO2 gas levels in the grow rooms can be maintained at 1200 parts per million (ppm) to optimize growth. However, in the warmer months when venting occurs, it is very difficult to maintain 400 ppm (the level of natural CO2 in the air) even if CO2 gas is pumped into the grow area since nearly all of it escapes outside during venting.

CO2 Delivery Solutions™ can help Leamington greenhouse growers solve the CO2 supplementing problem when venting.

CO2 Delivery Solutions™ enables Leamington greenhouses to provide their plants with added CO2 which enhances growth and yields. This capability is achieved by misting an aqueous CO2 solution directly on to the plants, with or without venting. This technology allows CO2 to be controlled independently, rather than its delivery being co-dependent on the control of other growth parameters like light and temperature. This enhances a grower’s ability to optimize environments in a simpler and more effective manner. While CO2 Delivery Solutions™ cannot solve the artificial light pollution problem when Leamington greenhouses need to vent, it can certainly solve the lack of optimal CO2 problem during those months and help tip the balance towards more optimal yields year-round.

Visit co2delivery.ca for more information.

AVF FREE PUBLIC WEBINARS: AVF Annual General Meeting Day

AVF members will convene at the annual general meeting on the 29th of January 2021 at 5 p.m. CET to review 2020 and plan for the new year

AVF members will convene at the annual general meeting on the 29th of January 2021 at 5 p.m. CET to review 2020 and plan for the new year. All members are required to register for this session:

Register For The Meeting (Only for Members)

On the same day, we plan to provide a platform for our members to present their innovations and introduce their companies to a wider audience in the format of roundtable talks and short presentations.

AVF members have time until the 25th of January to either send us a short recording (10-15 minutes) introducing your company’s vision or express their interest in presenting live for the second webinar.

Send Us Your Recordings (Only for Members)

Please bear in mind that if you wish to attend all sessions you need to register for them separately.

Webinars are free and open to the public

There are only a limited number of seats available

Webinar 1

AVF Roundtable: Vertical Farming Startups’ Challenges, Solutions & Opportunities in the Time of COVID-19

Friday, 29 January 2021, 11-12:30 CET

Featuring YASAI, Organifarms, and Urban Greens

Register for Webinar 1

Webinar 2:

AVF Focus on Leading Vertical Farming Innovations

Friday, 29 January 2021, 14-17 CET

Interested members: AgricUltra, IFCO Systems, VeggiTech, Seoul Semiconductor, iFarm, Innovation Agri-Tech Group, Urban Crop Solutions, CDVTA, and maybe your company!

Register for Webinar 2

Contact us for more information: re@vertical-farming.net

&Walsh Finds Comfort And Warmth In Rebrand For Plenty, A Sustainable IndoorVertical Farming Company

New York creative agency &Walsh is behind the rebrand for sustainable indoor vertical farming company, Plenty, featuring a bold and "approachable" custom font inspired by plants, and an identity and packaging influenced by the flavour of its produce

Written by Katy Cowan

21 January 2021

New York creative agency &Walsh is behind the rebrand for sustainable indoor vertical farming company, Plenty, featuring a bold and "approachable" custom font inspired by plants, and an identity and packaging influenced by the flavour of its produce.

It's a refreshing approach by Jessica Walsh and her team, who have avoided any of the clichéd "healthy green" visual cues like some of Plenty's competitors. With a bright and friendly colour palette and non-fussy, almost retro aesthetic, at its heart lies the crafted font, known as Plenty Custom – a humanist sans serif with leaf-like corners and terminals. "Wherever possible, the font avoids straight lines and is made up of curved and tapered strokes," as &Walsh puts it. "The stroke endings are sharp and the curves are as round as a ripe tomato."

There's a purpose behind Plenty that caught the attention of &Walsh: "What stood out to us was its commitment and desire to make the tastiest, freshest cleanest greens accessible to the masses," Jessica tells Creative Boom.

"Making greens and healthy foods flavorful and accessible to people is very important. Right now, many people turn to unhealthy, processed, and fast foods because of the price and accessibility. In the long term, this causes numerous health problems, which has become a public health issue in America."

In their research, Jessica and her team looked at what would make the brand feel more warm and accessible, while also evoking comfort and tastiness – and that's where nostalgia steps in: "Fast food companies (such as McDonald's and Wendys) often use red and yellow colours in their branding, which have been shown to make people feel hungry. Why not use this technique for healthy foods?" adds Jessica. "With the colours and type choices, we wanted to create a friendly and happy brand that also stood out on the shelf from the competition.

"Almost all greens brands use a similar design aesthetic, so we aimed for the Plenty packaging to pop off of the shelf and pique people's interest. We did extensive target audience testing on the logo and packaging throughout the process to test the new packaging and typeface design, with the final result of our work scoring higher for warmth and accessibility than the previous brand work."

Which Type Of Hydroponic System Is Better?

So why do I answer, “it all depends”?

Hint: They are all just irrigation systems.

One of the questions that I get most frequently is, “Which hydroponic system is the best?”

I am fairly sure that my standard answer of, “it all depends” annoys most of the people I am speaking to. From suppliers to growers and from researchers to hobbyists there is always a desire to know and understand which system is the best.

So why do I answer, “it all depends”?

Whether we are talking about nutrient film technique (NFT), deep water culture (DWC), drip irrigation systems, aeroponics systems, ebb and flow systems, or any other system we should agree that these are all just variations of irrigation systems.

Buffer capacity means security. Buffer capacity means you can leave for a day without fear of losing the crop.

Next let’s talk about the systems suppliers and their sales representatives. Suppliers of hydroponic systems will all tell you why theirs is better, but the conversation should really revolve around what factors cause their systems to fail. Every system has a weakness. Your crop, your budget, your facility and your geographic location will likely quickly highlight these weaknesses.

A large variety of hydroponic systems all at once – Big Tex Urban Farms

So, how do you determine what system is best for you?

Here are the things you should know, think about and research thoroughly before you invest.

What crop are you going to grow? If you are planning to grow tomatoes, it’s very unlikely that you will want to invest in a nft system or a dwc system. The needs of your crop will help direct you into the right direction. Likewise, a closed loop drip irrigation system is unlikely to be the answer for lettuce production.

Know your budget. Your budget will play a major role in this decision making process. Do not only think about the upfront costs of the system. Make sure to include the operational and labor costs associated with running the system 7 days a week 365 days per year.

Know your environment. Each crop type will respond to these 9 environmental variables (see diagram) in different ways. As a grower your ability to manage these variables will be a primary indicator of your ability to achieve your target yields. The irrigation systems primary function is to help you control the 4 variables surrounding the root zone (see diagram 0.0 to understand the variables.) Your geographic location and crop will determine which of these variables are most important.

Truly understand the design. In the recent Urban Ag News article, “Important Tips For Designing A Hydroponic Production Facility” I discussed the importance of buffer capacity. Buffer capacity in your irrigation system plays some very important roles. First, it will help you manage your nutrients. Second, it will help your crop deal with variations in temperature. Third and most importantly, it will be a primary indicator of how much time you can spend away from your farm.

Figure out your maintenance and spare parts plan. Irrigation systems break. Irrigation systems get clogged. Irrigation systems need to be serviced and fixed. Make sure you understand everything from how to access the most vulnerable and weak parts of the system to how long it will take you to get replacement parts and what parts you should plan to carry in case of an emergency. Think about redundancy!

Labor is KEY! Consider every aspect of labor. From the education requirements of running the labor, to the amount of labor needed to operate and maintain the system to the importance of labor needed to check on the system on a regular basis.

Budget • Scale • Access

Which brings me back to where we started. Which hydroponic system is the best? It truly all depends. All we know for sure is that if a supplier tells you, “you can grow every crop in our system”, be concerned. It might be true, but I can almost guarantee you that you cannot grow every crop profitably in their system. If a supplier struggles to help you clearly understand and answer the questions posed in this article, look for a new supplier. There are plenty that will.

Finally, focus on building a professional network with experience in the commercial hydroponics industries. Ask lots of questions and understand the full benefits and limitations of any system you choose.

Final hint: Aquaponics growers use one of these systems as well.

AppHarvest, USDA Partner To Expand Educational Container Farm Program

Located at Breathitt High School in Jackson, Ky., the retrofitted shipping container allows students to grow and provide fresh leafy greens to their classmates and those in need in their community

In partnership with the U.S. Department of Agriculture, we’ve opened a new high-tech educational container farm in Eastern Kentucky to offer students a hands-on AgTech experience.

Located at Breathitt High School in Jackson, Ky., the retrofitted shipping container allows students to grow and provide fresh leafy greens to their classmates and those in need in their community. The U.S. Department of Agriculture provided a majority of funding for the container farm through its Community Facilities grants program.

The Breathitt County container farm is the third in our program, which started in 2018 in Eastern Kentucky to excite students about growing their own food.

“This amazing project will not only put fresh vegetables on the table but, more importantly, it will teach tomorrow’s agribusiness leaders — and do all of that right here in Eastern Kentucky,” said U.S. Department of Agriculture Rural Development State Director Hilda Legg.

Click here to learn more and here for coverage of the container farm’s opening.

Valoya Announces Departure of CEO

The company will continue to execute its strategy of bringing high quality, research-based horticultural LED lighting solutions to its crop science, medicinal plant and vertical farming customers globally

Valoya's CEO, Mr. Lars Aikala will leave the company in early 2021, by which time he will have served it from its founding, a total of 12 years. A search for the new Chief Executive Officer is undergoing. The company will continue to execute its strategy of bringing high quality, research-based horticultural LED lighting solutions to its crop science, medicinal plant and vertical farming customers globally.

“Valoya has come a long way from when we founded it in 2009. We now have a unique position in the market with our research-based, proven horticultural lighting solutions, which are appreciated by our customers globally. Our innovations and over 600 plant trials have enabled us to pioneer this market for more than a decade. We have built an international patent portfolio of 100+ granted patents, which demonstrates and protects our innovation. Our amazing team and our great resellers serve our customers in more than 50 countries with commitment and dedication.”, says Mr Aikala. He continues “Naturally we have also had to overcome several challenges during the years. The latest one, COVID-19 has again proven that the team strongly pulls together to win. I am very proud of the fact that in these challenging times we managed to deliver revenue growth in 2020 and more importantly we also exceeded our profitability targets. Valoya now has a strong foundation and I am sure Valoya’s future will be very bright.”

The change comes from Lars’s desire to go back to the intensity, thrills and challenges of creating new business. The Board of Directors and Lars agree that now is a good time to make the change. To ensure a smooth transition, Mr Aikala will continue working as CEO until a successor is in place.

"With his passion, relentless drive and unique expertise Lars made Valoya into the great company it is today. On behalf of the Board of Directors and the owners, I would like to extend sincere and best thank you to Lars for his very valuable contribution to Valoya's development", says Christer Härkönen, Chairman of the Board at Valoya.

About Valoya

Valoya is a provider of high end, energy-efficient LED grow lights for use in crop science, vertical farming and medicinal plants cultivation. Valoya LED grow lights have been developed using Valoya's proprietary LED technology and extensive plant photobiology research. Valoya's customer base includes numerous vertical farms, greenhouses and research institutions all over the world (including 8 out of 10 world’s largest agricultural companies).

Additional information:

Valoya Ltd, Finland

Tel: +358 10 2350300

Email: sales@valoya.com

Web: www.valoya.com

Facebook: https://www.facebook.com/valoyafi/

Twitter: https://twitter.com/valoya

“Sharing Technology Is The Only Way The Industry Will Grow”

Lack of this might lead to farmers being susceptible to misleading information, using ineffective technologies, which I’ve seen many people suffering from.

“There is a lack of know-how amongst farmers to apply those techniques in a successful way,” says Joe Swartz, Vice president and Lead horticulturalists at AmHydro. In every situation, according to Joe, from geography to the skill of the grower or climate control, all play into what types of technology should be used. This requires a lot of experience and knowledge. Lack of this might lead to farmers being susceptible to misleading information, using ineffective technologies, which I’ve seen many people suffering from.

Joe adds, “Watching many good growers that have been led down a bad path in the industry, while investing so much into technologies that are not really effective, really breaks my heart. While providers know that they aren’t effective in this particular situation. With many years of industry experience, Joe is well aware of the challenges that the industry faces these days. Within the aquaponics sector there is not one singular technology, just as in conventional farming, rather various unique technologies can be combined for different outcomes.

Lack of know-how

When asked about the kind of growers that Joe educates, he notes that there are two kinds of growers contacting him. “We have two types of growers: either growers facing challenges or new growers wanting equipment and knowledge. Both of those approaches are interesting and it’s great to be able to help them become successful. It is great to see our system helping companies to grow and develop and become a worldwide provider. Growers like that keep coming back to us. They are the ones that move the industry”.

Joe Swartz, Vice president

An essential part of being a vertical farmer, in Joe’s opinion, is having experience with working on the ground floor. Only this will teach you what it takes to manage the equipment, crops and technology. “The best growers have started in the greenhouse. Hydro-experts will get nowhere with their college degree alone,” Joe states. For that reason, AmHydro offers grower seminars and even possesses a commercial greenhouse where growers can work in order to gain experience. “Some growers don’t think that they need it as they rely on technology, but my experience is exactly the opposite.”

Fake promises

Joe observes similar trends as in the 1980s when certain technologies were promoted as ‘the farming of the future’. People talked about automatic farming, in which no farmer would be needed, new techniques and new lightings. All things we hear today were said back then. What happened afterward, according to Joe, was that some techniques turned out disappointing. Millions of dollars invested were lost, leading to the industry losing its credibility.

“As a result, investors only valid projects that already have a positive cash flow, as they have become more cautious. Some growers struggled to get funding, even though they had a viable business model. In a certain way, negative events have closed off some appetite for investments in CEA, which is a shame. It is a good investment in general, but every time we see a less than a reputable company or a technology that fails, it holds the industry back.”

Misconception

Related to that, Joe says that vertical farming still has to overcome a somewhat negative public image. “The traditional consumer, at least in the USA, have an image of farmers working on the land using sustainable methods. Now, being a conventional farmer using hydroponics I know that it is a sustainable and safe way to produce food, but there’s a public perception of automatization, as robotic food. Some people even call it “Frankenfood”. In my opinion, the more we can promote CEA as what it is, sustainable growing techniques, people will be more accepting and investors will invest more easily”.

Joe strongly senses that the vertical farming industry needs more skilled farmers and growers to meet the demand. “A lot of my work is actually training people. We want to help especially young people, new to the industry, by giving them skills, experience and knowledge. I have been blessed to have mentors when I was young and I try my best to pass that knowledge as this will help the industry along. That’s one of the reasons why we now see some consultancy firms who see economic opportunities. Sharing technology is the only way in which the industry will grow,” says Joe.

“Despite the diversity amongst growers that I meet in over 66 countries, all growers face similar problems. Funny tech flitches, pipes that break and spray water all over the greenhouse, or water pumps that break down. It doesn’t matter whether it’s a technologically advanced greenhouse or a small low-tech one. It kind of goes across the board,” says Joe laughing.

For more information:

AmHydro

Joe Swartz, Vice president and Lead horticulturalist

joe@amhydro.com

www.amhydro.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

The Business Of Vertical Farming: What It Is And What It Isn’t

It’s definitely the future of agriculture but it’s also an opportunity for people to choose where they fit in and where they can make their most meaningful and important contribution

“Vertical farming is a tremendous opportunity,” says Glenn Behrman, founder and President of CEA Advisors, consultants and advisors to the global vertical farming industry and a 50-year veteran of the horticulture industry. It’s definitely the future of agriculture but it’s also an opportunity for people to choose where they fit in and where they can make their most meaningful and important contribution”.

Over the years, CEA Advisors has provided services for the development of indoor farming projects locally and internationally. They’ve worked on projects for growers, investors, universities, schools, food processors, vertical farm developers, pharmaceutical manufacturers and government agencies.

Fundraising business model

According to Glenn, many people enter the market without really doing their homework. They want to be in vertical farming, but they don’t know that there are many different industry entry points that are available that can really satisfy their interests. No questions are asked, no networking is done, and they do not drill down to a deeper level to see where their interest really is.

“Today, I see that many are only motivated with raising money but funding is not a business model. If money is your main motivation, you’re probably going to fail. There’s too much of a focus on raising money and not enough focus on making money. I believe a business should be cash flow positive, but we also need to be innovating and improving, not marketing concept systems to investors. New growers should first consider where they can make a difference in the market," says Glenn.

‘Go out there and start networking’

This highlights another big issue with vertical farming. According to Glenn, people don’t realize the relationship between the start-up vertical farmer and end-user, which is unbelievably important but fragile at the same time. A new farm cannot expect for institutional buyers to place orders just because they exist. When wanting to sell to retailers, Glenn says that it’s very unlikely for them to switch suppliers after being in business with them for many years. “Many growers overestimate their marketing capabilities because they don’t think the whole operational process out. The same problem with receivables, make sure you put away enough money to finance your receivables."

Glenn Behrmann

Glenn advises starting growers to first get involved with vertical farming by doing a lot of research. “Meaning, not only on the internet but go out there and talk to growers, visit farms, talk to produce buyers, restaurants and other end-users and get to know the industry. Get out in the field, visit trade shows, they’re thought-provoking, get active and do some networking. I also advise people to become a part of farming, grow things at home and get a better idea of what it’s all about. Then start focusing on the systems, machinery and equipment. But remember all growers need to look at the end result: the product.

Finding a balance

Every component, says Glenn, from seeds to sales involves many different processes. Every single process, every single link in the chain has room for improvement. “There are discussions about achieving a maximum yield in a sustainable manner. What isn’t realized is that maximum yield doesn’t only mean how much basil is grown in a specific time period, but it also dictates how less input should generate more output. Costs that are not controlled can render the most innovative system completely unsustainable.

It’s like an Excel spreadsheet, says Glenn. “Take every variable that goes into growing a crop, then continue to tweak, improve and change. At some point growers need to come up with the optimum result.” Glenn says that some might have the right component but not be in balance. Therefore, growers need to be always aware of all processes and keep them in balance. Too much light, too little light, wrong PH, bad air circulation, wrong fertilizer mix, high labor costs, wrong crop, humidity too high or too low? All need to be in balance to achieve success.

Don’t be afraid to ask

Glenn has more than 50 years of industry experience with a broad view of the market. “I don’t let myself get stuck in a corner, because I’m not afraid to ask when I don’t know or I’m not sure. During my early career in the foliage business, I asked a million questions, I watched how things were done, I took advice, I was like a sponge soaking up knowledge from those that came before me. Although I’ve been laser-focused on Vertical Farming for the past ten years, my attitude about acquiring knowledge hasn’t changed. Be curious and ask a lot of questions!"

“Nowadays, I see a lack of curiosity and a lot of over-confidence. Vertical farming needs to be taken one step at a time, meaning you cannot graduate college on the first day of high school, it’s a journey. Going into business is a risk and then there are more risks every day. Growers need to evaluate where they want to be in this equation. Nobody today promotes their vertical farming project as an R&D opportunity, but rather as the game-changing food supply of the future. The truth is with a technology that is constantly evolving, every single vertical farm operating today is still a work in progress."

Inside the Growtainer®

In addition to consulting and advising vertical farming CEA Advisors designs and builds custom Growtainers. “Each build is always interesting and challenging as they’re always built for a specific unique use and objective,” Glenn states. “I don’t believe that one size fits all in container farming and I don’t believe that plants were meant to grow sideways.

However, it is obvious that technology is constantly evolving and improving and each Growtainer must always provide what the end-user needs, whether it is for research or food production etc. Every unit must always be optimized. But Growtainers are technology-based and the end-user is always the most important part of the equation. And whether production takes place in a Growtainer or a Vertical Farm, it is always about balance.

For more information:

CEA Advisors LLC

Glenn Behrman, Founder and President

gb@cea-advisors.com

www.cea-advisors.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

Seattle Architect Is Helping The Fast-Growing Field of Indoor Ag Take Root

Seattle architect Melanie Corey-Ferrini is launching a controlled-environment business with assists from Sabey Corp., and Microsoft. The multifaceted, to-be-named enterprise includes a training program at Alan T. Sugiyama High School at South Lake in Seattle, where she is pictured in the cafeteria with a grow tower. Anthony Bolante | PSBJ

By Marc Stiles – Senior Staff Writer, Puget Sound Business Journal

January 16, 2021

Seattle architect Melanie Corey-Ferrini’s kiosk-style lobby pop-up concept called G2 is the ultimate in farm-to-fork dining. Protein-rich grains and greens are grown on-site in the unmanned, transparent kiosk and combined with other veggies, roots, spices and dairy to make custom bowls ordered on a mobile app. G2 last summer was named best pioneering food service concept in a national contest.

It’s one small example of the possibilities of controlled-environment agriculture (CEA), which is at the heart of Corey-Ferrini’s latest endeavor: a multifaceted, urban ag project largely centered in Tukwila, where Sabey Corp. is providing warehouse space for hydroponic growing equipment that Microsoft donated.

Corey-Ferrini will use space at Sabey’s Intergate East data center campus to build and launch CEA education and business development programs this year.

CEA is a technology-based approach to food production that allows indoor farmers to maximize use of water, energy and labor. Worldwide in the third quarter, venture capitalists invested $1.6 billion in ag tech companies, bringing the 2020 total to $4.2 billion, according to PitchBook. Alexandria Real Estate Equities, a developer of life science office and lab space, offers early-stage companies move-in-ready space at its Center for AgTech in Durham, North Carolina.

The sector has struggled to put down roots in the Seattle region, where there has been one unsuccessful attempt. Now comes not only Corey-Ferrini’s to-be-named enterprise but also Kalera, a Florida-based company that plans to open a facility in 70,000 square feet of leased space in Lacey this year.

Several years ago, Corey-Ferrini consulted with Microsoft on a CEA project in Redmond. Contract farmers used Microsoft’s PowerBI and Azure platforms to grow in hydroponic towers lettuce and micro-greens for company cafeterias.

“I was like, why aren’t more people doing this? It seems like it should be a programmatic feature in all food-related spaces,” said Corey-Ferrini. “I’ve learned it’s really a little bit of robotics, a little bit of AI, a little bit of automation.”

As a member of Soroptimist Seattle, which works to empower women and girls, she is establishing a program at Alan T. Sugiyama at South Lake, an alternative public high school in the Rainier Valley. She is working with other groups like New Roots, an International Rescue Committee program that provides land and other support in South King County to around 150 immigrant and refugee families.

Deepa Iyer, senior program coordinator for New Roots, said a pilot indoor ag tech and business class will be offered at the Sabey building through Corey-Ferrini’s enterprise. She said it will provide pathways not only to a year-round growing platform but training for tech careers.

The experience of a Seattle indoor ag business, UrbanHarvest, shows the challenges of such an endeavor. Six years ago, it worked with Seattle’s Millionair Club Charity (now Uplift Northwest) during its launch, but the program shut down after about a year when it couldn’t raise additional funds, said founder Chris Bajuk.

Corey-Ferrini is approaching it with a long-term view and plans to build a multipronged enterprise with multiple income streams. Kara Anderson, director of architecture at Sabey, said Corey-Ferrini has a good shot at pulling this off.

“She’s got endless energy,” said Anderson, who added that, like Sabey, Corey-Ferrini is known for outside-the-box thinking.

“She’s not afraid to pick up an idea without knowing really how she’s going to pull it together. She just starts marching down the path to get partners and grab people into her extensive network to brainstorm,” said Anderson.

Sabey, a developer and operator of data centers nationwide, sees opportunities in the project for both its business and community.

“We’re interested in what’s going on in our backyard and opportunities to help out and make some lives better if we can,” Anderson said “At some point these indoor facilities will be monitored by computers and that, in turn, ends up feeding into the data center world.”

Melanie Corey-Ferrini

Position: Chief experience architect

Company: Dynamik Space, a design and branding company

Founded: 2000

Career: Also currently CEO of 3.14DC, which programs food and retail spaces

Lessons Learned

Use your sense of humor.

Be curious.

Don’t fear failure.

Join Us For Global G.A.P. World Consultation Tour - Focused On Controlled Environment Agriculture (CEA)

Join the upcoming virtual meeting on January 25, 2021 13:00-14:30 EST

The GLOBAL G.A.P. World Consultation Tour goes into its second round! Join the upcoming virtual meeting on January 25, 2021 13:00-14:30 EST in collaboration with the Farm Tech Society. Together, we aim to deliver an impactful standard in line with producers’ practices. The unique challenges presented by vertical farming or produce grown in controlled environments will be addressed to ensure an appropriate user experience.

High-tech monitoring and control systems in commercial controlled environment agriculture farms and their supply chains enable the opportunity to capture automated measurements, support assessment and analyze a wide range of variables including water to energy to inputs, reducing costs and adding value for individual farms and across the industry. The ultimate goal of the partnership is the development and implementation of an impactful standard and certification process.

Participants will meet the expert working group behind the standard revision, and will have the opportunity to join the ongoing discussion and process.

About FTS:

The Farm Tech Society (FTS) is an international non-profit industry association that unites and supports the Controlled Environment Agriculture (CEA) industry, seeking to strengthen the sector through the development and implementation of resilient and future proof methods and technologies for indoor growing. The FarmTech Society is enlisted in the EU Transparency Register with #469686733585-87

About GLOBAL G.A.P.:

GLOBAL G.A.P. is a leading global certification program whose mission is to bring farmers and retailers together to produce and market safe food, to protect scarce resources, and to build a sustainable future.

Join the FarmTech Society in 2021

The Farm Tech Society (FTS) is an international non-profit industry association that unites and supports the Controlled Environment Agriculture (CEA) industry, seeking to strengthen the sector through the development and implementation of resilient and future proof methods and technologies for indoor growing. We look forward to continuing to grow and drive #CEA4CriticalChallenges with members like you.

Israel’s Vertical Field Inks Deal To Deploy Its Farming System In UAE

Ag-tech company to launch pilot in Emirates ahead of wider roll-out; its vertical farming system could lessen food insecurity in water-scarce Gulf state

By LUKE TRESS

Produce grown using Israeli start up Vertical Field's farming system. (Courtesy/Vertical Field)

Vertical Field, a startup that has developed a vertical farming system, has signed an accord with an Emirati company to deploy its products to the United Arab Emirates.

The Israeli ag-tech firm signed the agreement with Emirates Smart Solutions & Technologies, Vertical Field said in a statement on Wednesday.

Vertical Field will set up pilot vertical farms in the Emirate of Umm Al Quwain ahead of a wider roll-out in the UAE, the company said. The pilot will aim to determine which crops are best for the local market and will be supported and overseen by Vertical Field’s Israeli agronomists.

The firm expects the project to expand into a multimillion-dollar venture that will include distributing Vertical Field’s products to additional Gulf states, the company said.

Roughly 80 percent of agricultural food products in the UAE is imported from abroad, amounting to $10 billion in trade in 2018. The increasing cost of transporting food and concerns over food security played a part in the new partnership, Vertical Field said.

“Arid desert regions face many challenges surrounding the production of high-quality agricultural produce at low prices. With the help of various agricultural technologies and new developments, we believe that we can successfully align the demands of the market with competitive prices without compromising quality,” Guy Elitzur, Vertical Field’s CEO, said in a statement.

Maher Makalde, the CEO of Emirates Smart Solutions & Technologies, said, “We are excited for the opportunity to partner with Vertical Field and bring advanced Israeli vertical technology that enables the growth of produce in a controlled and predictable way, overcoming harsh outdoor climate conditions.

“Our goal is to establish food security that is independent of imports and to develop a high-quality agricultural infrastructure that reaches the retail market,” Makalde said.

An illustration of vegetables growing on walls by Vertical Field. (Courtesy)

Vertical Field’s soil-based installations are made up of separate blocks of plants that can be rearranged at will to produce locally sourced vegetables. This green wall of vegetation is suitable for growing vegetables in stores, offices and apartment buildings, or anywhere in urban areas, which have little space but many walls.

The firm, formerly called Green Wall Israel, said that products grown with its farming method are pesticide-free, generate less waste than conventional agriculture and utilize 90% less water, growing in precise quantities in a controlled environment with shorter growing cycles.

Produce in its containers can grow 365 days a year and is free of the limitations usually imposed by seasons, weather, climate and location.

The farms are modular, expandable and moveable, with fully automated crop management and a sterile environment that requires significantly less human contact. The crops that are currently offered include lettuce, basil, parsley, kale, mint and others, and are competitively priced, the firm said in a statement.

Israel and the oil-rich UAE signed a US-brokered normalization agreement in September, opening the way for business and tourism between the two countries, after years of covert trade exceeding $1 billion annually by some estimates.

The UAE, a federation of seven desert sheikdoms dependent on petrodollars, has been keen to cash in on the influx of Israeli investment and travel, particularly after the pandemic diminished demand for oil and hammered international tourism.

Earlier this month, Vertical Field signed an agreement with Moderntrendo S.R.O, an agricultural distributor in Ukraine, to deploy its plant installations in supermarket chains nationwide.

In December Vertical Field also signed a “multi-million dollar” agreement with Israeli discount supermarket chain Rami Levy for the installation of its vertical farming containers on the stores’ premises.

Vertical Field is based in Ra’anana in central Israel and was founded in 2006.

VIDEO INTERVIEW: Fork Farms Experiences “Growth” In Vertical Farming

January 12, 2021

GREEN BAY, Wis. (WBAY) - Hydroponic farming is a way to grow fresh food year-round indoors.

Fork Farms in Green Bay is one company leading the way on vertical farming. You may have seen their hydroponic walls growing fresh greens at the Appleton International Airport. The company has more than 600 installations and just expanded into the overseas market.

On Action 2 News at 4:30, Fork Farms President Alex Tyvink talked about the growth (pun intended) in this industry and how vertical farming can make a difference in communities.

International Webinar On Urban Farming - Soilless Cultivation

27th January 2021, between 9 am to 1 pm IST

organised by the

Department of Botany, Sri Venkateswara University, Tirupati, Andhra Pradesh, INDIA

in collaboration with

Universitas Bengkulu, Indonesia

Universiti Malaysia Kelantan, Malaysia

Industrial Technology Institute (CISIR), Sri Lanka

With the support of

CropG1 ,dFarms USA, Hydrilla, SAM Agro Biotech, SRC Malaysia, Sujay Biotech, Veggitech UAE and Urban Kisaan

on 27th January 2021, between 9 am to 1 pm IST.

Speakers are

1. A perspective of Hydroponics by Mr Vijay Bhaskar Noti, dFarm Inc., USA

2. Sustainable Farming with Multiloop Aquaponics by Mrs Mamatha, Hydrilla

3. Aeroponics: A versatile research tool in modern Agriculture by Dr Jagadeesh, SAM Agro Biotech

4. Diversity in Hydroponics by Prof. G. Sudarsanam, Sri Venkateswara University

5. Application of ARBUSCULAR MYCORRHIZAL FUNGI In Hydroponics and Aeroponics by Dr M. Lakshmi Prasad, Sujay Biotech

6. Hydroponics Scope and Opportunities by Bhaskar Rao, VeggiTech, UAE

7. Plant Health in Soilless Cultivation: Management of Deficiencies, Diseases and Pests By Dr Purushottam Dewang, CropG1

8. Hydroponic Urban Farming in Malaysia under MITRA by Chandrasekar, Sai Ram Capital, Malaysia

9. Entrepreneurship in Urban Farming by Dr P. Sairam, Urban Kisaan

Please fill Free Registration form and submit using the following link

https://forms.gle/52WaVECrqpEFQh4w8

*eCertificates & webinar link will be provided to the registered participants only

*Organisers are not responsible for network failures

For more information please contact

Prof.G.Sudarsanam

Convener of the Webinar

Head, Department of Botany

Sri Venkateswara University

Tirupati -517503

E-mail: sudarsanamg@gmail.com

WhatsApp: +91-9989053632