Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

[Webinar] Airing It Out: Clean Production Room Environment

You won't want to miss our next Indoor Ag-Conversations webinar session as our expert panel talks about creating a healthy environment for people and plants

JOIN OUR NEXT CONVERSATION

MARCH 24, 2021 | 2:00 - 3:00 PM EDT

You won't want to miss our next Indoor Ag-Conversations webinar session as our expert panel talks about creating a healthy environment

for people and plants

MODERATOR:

Dr. Nadia Sabeh, Ph.D., President|Founder, Dr. Greenhouse

PANELISTS INCLUDE:

Trent Thiel, Industrial Molecular Filtration Product Manager for North and South America, Camfil Americas

Jeremy Shechter, Director of Cultivation, Buckeye Relief

During the program, our panelists will touch on:

Air Filtration

Sanitation Best Practice

Covid Safety

Much More!

LEARN MORE & SAVE YOUR FREE SPOT!

SPECIAL THANKS TO INDOOR AG-CON MEDIA ALLIES, EXHIBITORS & SPONSORS

Indoor Ag-Con, 950 Scales Road, Building #200, Suwanee, GA 30024, United States

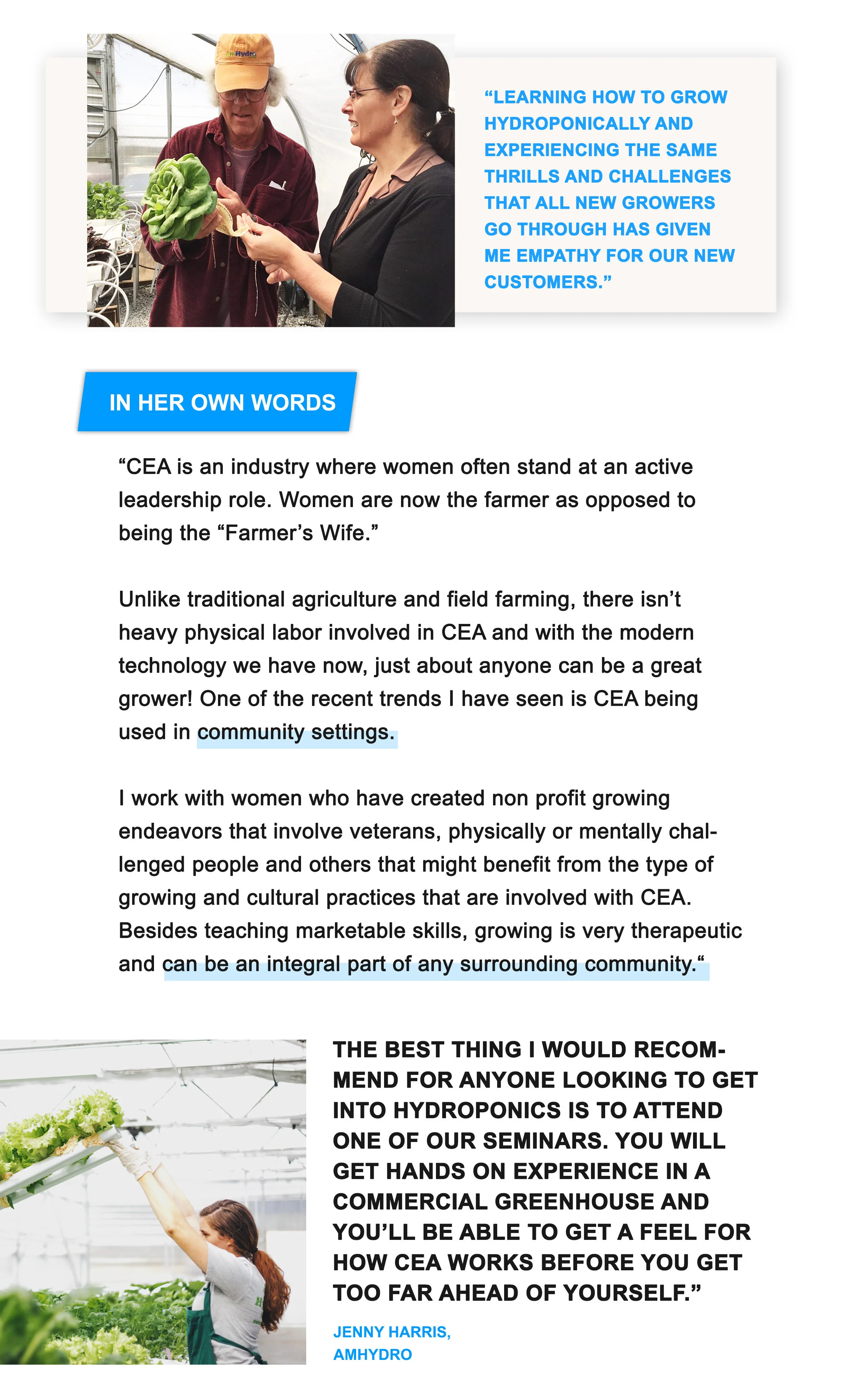

Women In CEA

Are you a woman in CEA, or do you know someone who is? Let us know, we love learning about growers who are working to bring fresh, local produce to their communities!

Are you a woman in CEA, or do you know someone who is?

Let us know, we love learning about growers who are working to bring fresh, local produce to their communities!

You can reach us by email at info@amhydro.com,

or by phone at 1.800.458.6543

Find AmHydro Online, on Facebook, and on Instagram!

SweGreen Becomes Partner In Viable Cities

Viable Cities is an innovation program for smart and sustainable cities. The aim is to accelerate the transition to inclusive and climate-neutral cities by 2030 with digitalization and citizen engagement as enablers

03-03-2021 | Swegreen

SWEDEN- Farming as a Service becomes a new tool in the fight against climate change as the FoodTech enterprise SweGreens joins the Swedish Strategic Innovation Program, Viable Cities.

Viable Cities is an innovation program for smart and sustainable cities. The aim is to accelerate the transition to inclusive and climate-neutral cities by 2030 with digitalization and citizen engagement as enablers.

SweGreen is an innovation company based in Stockholm focused on futuristic, smart, and circular solutions for controlled-environment urban farming. SweGreen own technologies which enables integration of smart vertical farming solutions into real-estate properties. Recently SweGreen has introduced a service for urban production of leafy greens, called Farming as a Service (FaaS), which allows clients to produce greens under their license and close to the city population.

Sweden inspires many other nations and has a leading position in the transition of urbanization context and fighting the climate change through smart and sustainable solutions that could be implemented in cities, says Sepehr Mousavi, member representative, and Chief Sustainability Officer at SweGreen.

Smart urban farming in infrastructure-integrated settings and by harnessing urban resources could be an exponential factor in localizing the food chains in Sweden and cutting back the carbon footprint associated with our food production and supply, he continues.

Viable Cities is growing steadily and new members like SweGreen are joining the current member pool, the likes of Swedish municipalities, Swedish universities and research institutes and other leading innovation companies. Running from 2017 to 2030, the program gathers partners from industry, academia, public and civil society organizations, and jointly funded by the Swedish Innovation Agency (Vinnova), the Swedish Energy Agency and Formas with a total investment of 1 billion SEK (about 100 million EUR).

Viable Cities is coordinated by KTH Royal Institute of Technology.

Together with our member organizations and other stakeholders, we aim to accelerate the transition to climate-neutral cities by 2030 with a good life for all within planetary boundaries, says Olga Kordas, Program Director of Viable Cities and a researcher at KTH Royal Institute of Technology.

Transforming our food systems are one of the key challenges, Olga Kordas continues, and we are happy to be joined by SweGreen to co-create solutions for the future.

Andreas Dahlin, CEO of SweGreen, highlights:

We are honored to be part of such a committed and influential strategic program and partner pool as Viable Cities’. We hope to contribute with innovations around the concept of Farming as a Service, which really could impact food production today and in the future. The ability to produce fresh and nutrient food close to the consumer will be one of the big missions for the food industry in the upcoming decades.

For more information:

Sepehr Mousavi, CSO SweGreen, sepehr.mousavi@swegreen.se +46(0)73-3140043

Andreas Dahlin, CEO SweGreen, andreas.dahlin@swegreen.se +46(0)70-9240032

Åsa Minoz, Head of Communications, Viable Cities, asa.minoz@viablecities.se +46(0)722108826

SweGreen is a Swedish GreenTech company that offers digital, efficient, and circular solutions for urban cultivation in a closed and controlled environment. By combining computer science, advanced technology, and plant sciences, SweGreen contributes to the development of urban sustainable food production. The company was established in 2019 and provides consumer products such as various leafy greens and herbs under the brand of Stadsbondens. www.www.swegreen.com

Source and Photo Courtesy of Swegreen

Advanced Container Technologies, Inc. Joins Clean Food Initiative

Through the use of the company’s GrowPods, ACTX can provide farmers, community groups, investors, and non-profit agencies with a turnkey system to grow ultra-clean and nutritious food that can not only benefit the ecology of the planet and bolster community food security but can also provide new jobs and economic opportunities

March 03, 2021 | Source: Advanced Container Technologies Inc.

Company joins movement toward sustainable alternatives to traditional food production.

CORONA, Calif., March 03, 2021 (GLOBE NEWSWIRE) -- Advanced Container Technologies, Inc. (Ticker: OTC:ACTX) stated it is joining the Clean Food Initiative and intends to become a leading force in the drive toward sustainable agriculture.

The Clean Food Initiative is focused on bringing clean, fresh, healthy food to children throughout the world, that is free from pesticides, herbicides, or harmful chemicals. Along with the practice of implementing Sustainable Agriculture Systems (SAS), the aim is to develop a global food system that uses half the water and half the soil as it does today – yet produces twice as much food.

Through the use of the company’s GrowPods, ACTX can provide farmers, community groups, investors, and non-profit agencies with a turnkey system to grow ultra-clean and nutritious food that can not only benefit the ecology of the planet and bolster community food security but can also provide new jobs and economic opportunities.

GrowPods are automated indoor micro-farms that can provide a sustainable supply of affordable safe, clean, nutritious food, while also providing jobs at a local level by promoting the growth of a skilled agricultural workforce in non-traditional settings.

Doug Heldoorn, CEO of Advanced Container Technologies, Inc., said the company’s objectives are to make agriculture sustainable, investable, manageable, scalable, and transparent.

“There is a substantial difference between meeting basic food requirements and meeting optimum nutrition requirements,” he said. “People need access to high quality foods that are rich in nutritional value. Future generations deserve access to a healthy and sustainable food supply, not a diet filled with preservatives, pesticides or chemicals.”

SAS and the Clean Food Initiative represents one of the greatest challenges of the 21st century, as well as a tangible investment opportunity with sound business growth prospects and consistent annual income generation.

“There are few problems facing mankind that are as massive as our need to change our methods of food production and distribution,” Mr. Heldoorn stated. “Fortunately, there are innovative solutions to these challenges, and we are extremely proud to be a vital participant in this agricultural and social evolution.”

For more information, call (951) 381-2555 or visit: www.advancedcontainertechnologies.com.

About Advanced Container Technologies, Inc.

Advanced Container Technologies, Inc. is in the businesses of selling and distributing hydroponic containers called GrowPods; and designing, branding, and selling proprietary medical-grade containers that can store pharmaceuticals, herbs, teas, and other solids or liquids, and can grind and shred herbs; as well as selling other products and accessories, such as humidity control inserts, odor-proof bags, lighters, and plastic lighter holders; and provides private labeling and branding for purchasers of the Company’s containers and the other products. For more information visit: www.advancedcontainertechnologies.com.

Forward-Looking Statements

This release includes predictions or information considered "forward-looking" within securities laws. These statements represent Company's current judgments but are subject to uncertainties that could cause results to differ. Readers are cautioned to not place undue reliance on these statements, which reflect management's opinions only as of the date of this release. The Company is not obligated to revise any statements in light of new information or events.

Company Contact:

(951) 381-2555

info@advancedcontainertechnologies.com

Investor Relations:

Stuart Smith

SmallCapVoice.Com, Inc.

512-267-2430

ssmith@smallcapvoice.com

Related Articles

More articles issued by Advanced Container Technologies Inc.

More articles related to: Product / Services Announcement Food

Hydroponics Farming: Why Hydroponic Farms Are Trending In India?

As per reports, India’s hydroponics market is expected to grow at a compound annual growth rate of 13.53% between 2020 and 2027.

Hydroponics is slowly gaining popularity in India and attracting more and more farmers. Basically, hydroponics is a type of horticulture and a subset of hydroculture, which is a method of growing plants, usually crops, without soil, by using mineral nutrient solutions in an aqueous solvent.

Hydroponic farming can be done in a small space also like a balcony which is a soil-less, water-based farming process. Rather than using soil for plant nutrition, crops are fed nutrient-rich water, negating a lot of the baggage that comes with soil-based methods.

Hydroponics is the practice of growing plants in a nutrient-rich solution, skipping the soil. “It has been practised for centuries, so it is not a new technology," points out Akhila Vijayaraghavan, the founder-director of Coimbatore’s Parna Farms, adding the Hanging Gardens of Babylon are believed to have been hydroponically grown. “The Aztecs created vast hydroponic systems using rafts called chinampas," she says.

The film piqued Gopal’s interest, and he began reading about the method to grow plants without soil. “We started working with hydroponics as a project in 2012. At that time, we didn’t know much about the plight of farmers and how a technology like this could add value," said Gopal. The idea was to create awareness among the right audience and sell “through prototypes and hobby kits."

Urban farmers are taking to hydroponics, a water-smart solution to grow pesticide-free produce on rooftops and terraces. As per reports, India’s hydroponics market is expected to grow at a compound annual growth rate of 13.53% between 2020 and 2027.

What is Hydroponics

Hydroponics is a branch of hydroculture, in which plants are grown without soil by using water solvent which consists of minerals nutrient solution. Terrestrial plants may be grown with their roots only, roots are exposed to the nutritious liquid, or roots may be supported physically by a medium like gravel.

Plants are also grown through a process called photosynthesis, in which plants use sunlight and a chemical inside their leaves called chlorophyll to convert carbon dioxide and water into glucose and oxygen, as shown in reaction.

6CO2 + 6H2O → C6H12O6(Glucose)+ 6O2

The nutrients we use in hydroponic systems may come from different sources, such as fish excrement, duck manure, or chemical fertilisers.

1Advantages of Hydroponics

Plantation without soil

We can grow plants in places where the land is limited, doesn't exist, or is contaminated. In the early time period, Hydroponics was a successful technique used to supply fresh vegetables for troops in Wake Island. It has been considered as the future farming to grow foods for astronauts in space by NASA.

Better use of space and location

All those plants need are provided and maintained in a system, you can grow plants in a small apartment, bedrooms or kitchen as long as you have some spaces.

Roots of plants usually expand and spread out in search of foods, and oxygen in the soil but in the case of Hydroponics, roots are sunk in a tank full of oxygenated nutrient solution and are directly in contact with vital minerals. This means that you can grow your plants closer, and consequently huge space savings.

Climate control

Hydroponic growers can have total control over climate, temperature, humidity, light, the composition of the air. This means you can grow foods all year, regardless of the season. Farmers can produce foods at the right time to maximize their profits.

Water-saving

Plants grown by the process of hydroponically can use 10% of water, as compared to one grown on the field because water is recirculated, in this method. Plants will take up the water they need, while run-off water will be captured and return to the system. Water loss in this system will only occur in two forms - evaporation and leaks from the system.

Use of nutrients

You can have 100% control of the nutrients (foods) that plants need in this method. Before planting, growers can check what are plants requirement and what amounts of nutrients needed at particular stages and at what percentage they should be mixed with water.

Better growth rate

Do hydroponic plants grow faster than in soil? Yes, because you can set conditions favourable to the plant’s growth like temperature, lights, moisture, and especially nutrients. As plants are placed in favourable conditions, nutrients are provided in sufficient amounts and come into direct contacts with the root systems. Therefore, plants do not waste valuable energy in the search for diluted nutrients in the soil and put their complete focus on growth.

A Fully Automated Three-Dimensional Vertical Farm Comes Into Operation

Eponic Agriculture Co. Ltd is a supplier of indoor farming equipment. Alice, the company's director, introduced the recently fully automated production system of a stereochemical vertical farm

Eponic Agriculture Co. Ltd is a supplier of indoor farming equipment. Alice, the company's director, introduced the recently fully automated production system of a stereochemical vertical farm.

"The current three-dimensional indoor farms on the market are based on semi-automated workflow, with some links requiring additional equipment configuration and no continuity in the whole planting system. In order to solve this problem, we developed and designed a complete automated planting system, including the processes from sowing to planting, full-spectrum planting light control, fertilization, harvesting, and cleaning. Which are all done by automated equipment. Whereas all procedures can be controlled by intelligent software with real-time monitoring, data collection, and many other functions."

Benefits of an automated farm

When talking about the advantages of the automated equipment, Alice said, "Take our recently built 20-layer vertical farm as an example. First of all, the mechanical sowing time is 10 times-30 times faster than manual sowing. And on top of that, the use of automated equipment can realize precise planting and efficient communication of multi-layer planting surfaces. The 20-layer vegetable trays are automatically transferred to the ground for uniform watering, harvesting, and cleaning. This greatly improves productivity.

Secondly, the use of lift trucks is required when handling high-level crops. There are certain safety hazards in using lift trucks in a small space. While operating the automated equipment, only a tablet computer is needed to control the whole planting process, which is much safer and more convenient."

Although automated vertical farm systems have many advantages, their application in China is not yet popular. "In terms of production design, we have gone through countless experiments to design the most suitable software program. As well as hardware equipment for practical planting applications. Luckily after a long period of research, we finally chose the most cost-effective and suitable materials. The R&D investment is large and time-consuming.”

From a cost point of view, according to Alice, a fully automatic system is 2-3 times higher in costs than the semi-automatic system which is currently used more often. Most traditional agricultural companies find it difficult to accept such high initial costs. Thirdly, the automated system requires high technical requirements for farm managers. Managers need to have an understanding of both planting technology and software. Alice adds: “It is for these three reasons that the application of fully automated stereoscopic systems is not very common in China and other countries."

Automated planting

"Although the application is not yet widespread, I think fully automated stereoscopic planting is a trend. Urbanization has led to a reduction in arable land and soil pollution has triggered problems with pests and pesticide residues in fruits and vegetables, and the development of three-dimensional agriculture is the only way to maximize and optimize output in a limited area. Currently, stereoscopic planting plants still require a lot of manual labor to operate. As labor costs rise and planting techniques require more precision, the use of automated equipment will be a future trend," Alice notes.

"Automated systems are a trend, not only in China but also globally. Urbanization has been moving forward, in the face of soil pollution, pesticides and pests, etc. The planting area is gradually reduced and three-dimensional agriculture must be developed in order to quantify planting. Three-dimensional agriculture can be located near the city, and reduce the transport distance, people can eat the freshest vegetables, to achieve local supply. Therefore it is necessary to promote automated, intelligent planting systems in order to achieve efficient planting and sustainable development." Alice said.

Industry experience

Eponic Agriculture Co. Ltd's head office, Dahua Intelligent Electronics, has a twenty-five-year history division. The team has been focusing on the development and production of intelligent control systems and industrial lighting. Alice said that based on years of technical foundation, we developed full-spectrum LED planting lights which have been approved and applied by the USDA. Over the years, we have received technical support and affirmation from several agricultural doctors from Europe and the United States, focusing on the development and production of automated stereoscopic planting equipment.

According to Alice, the company has laboratories and showrooms in the US, Australia and Africa. This year, the company is planning on opening new showrooms and laboratories in Europe. “We are expanding our global reach and continue to optimize our growing systems to be a better supplier of fully automated growing equipment."

For more information:

Eponic Agriculture Co. Ltd

Alice Ou, Director

aliceou@eponicagriculture.com

www.eponicagriculture.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

US: TELEVISION - Today Show Will Feature Vertical Harvest Co-Founders For International Women’s Day

The segment will air on March 8 during the third hour of the show, which is 9 a.m. in most time zones. “We are so proud of our women-led team and hope you will tune into NBC and virtually watch with us!” Vertical Harvest reps said in a press release

March 6, 2021

Vertical Harvest employee Michele Dennis deposits sweet mix in Vertical Harvest’s revolving planters in May of 2019. The co-founders of the business, Nona Yehia and Caroline Croft Estay, will be part of a Today Show segment celebrating International Women's Day on March 8.

BRADLY J. BONER/ / NEWS&GUIDE

The Today Show will be celebrating International Women’s Day with a feature on Vertical Harvest’s two female co-founders, Nona Yehia and Caroline Croft Estay, and a few of their employees. The segment will air on March 8 during the third hour of the show, which is 9 a.m. in most time zones.

“We are so proud of our women-led team and hope you will tune into NBC and virtually watch with us!” Vertical Harvest reps said in a press release.

Vertical Harvest, which opened its doors in 2016, is the first vertical hydroponic greenhouse in the United States. It stands three stories high on the side of Jackson’s parking garage, using minimal space to grow produce for the community. In a year, the greenhouse grows as many vegetables as 10 acres of regular farming would produce.

Vertical farming may hold the key to the future of food supply, according to the organization’s website.

“The increasing frequency of natural disasters and the rising global temperature are putting outdoor agricultural productivity at risk,” the organization wrote on its website. “Vertical farming can contribute to reducing hunger in the future by ensuring a stable and constant supply of food that is not weather-dependent.”

Yehia, who grew up with a brother with developmental disabilities, also seeks to employ people with developmental disabilities in the greenhouse. Vertical Harvest strives to help “those who struggle to find meaningful work and upwardly mobile career opportunities” find purposeful work within the greenhouse.

All in all, Vertical Harvest is a testament to Yehia’s dedication to building a better world.

“Vertical Harvest Farms has been an opportunity to explore a new type of civic building, one that can address food, job and now housing insecurity, rooted in community resiliency,” Yehia wrote in a LinkedIn post two weeks ago.

Contact Victoria Lee at 732-5901 or vlee@jhnewsandguide.com.

Tags The Today Show Nbc Harvest Opportunity Greenhouse Agriculture Co-founder Farming Work Today Show

CubicFarms Appoints Former Microsoft GM As New Chief Technology Officer

“I want to use my experience to help make a meaningful impact on the world, something that my children and future generations will be proud of

As CTO, Edoardo De Martin will support the Company’s innovative growing technologies and an ambitious goal to feed a changing world

VANCOUVER, B.C., March 2, 2021 – CubicFarm® Systems Corp. (TSXV:CUB) (“CubicFarms” or the “Company”), a local chain agricultural technology company, announced today that Edoardo De Martin has joined its senior leadership team as Chief Technology Officer.

Prior to joining CubicFarms, De Martin spent 10 years at Microsoft working in various roles including General Manager of the Microsoft Vancouver Development Centre, as well as driving innovation as GM of Dynamics Mixed Reality Applications on HoloLens.

As a proven technology leader with more than 20 years of experience in the technology industry, De Martin will bring significant experience to advancing artificial intelligence (AI), robotics, and mixed reality technologies supporting the Company’s innovative growing technologies and an ambitious goal to feed a changing world.

“I want to use my experience to help make a meaningful impact on the world, something that my children and future generations will be proud of. I was inspired by the world of AgTech through my role as a mentor at Creative Destruction Lab in Vancouver,” De Martin said. “The path then led me to CubicFarms where I was blown away by their innovative solution to indoor automated growing. In my opinion, this company has really focused on what is the most important: understanding what growers need. My job will be creating the digital technology to further accelerate innovation and scale. I am excited to start this next journey in my career.”

“We’re thrilled to welcome Edo De Martin, a strong Canadian technology leader, as our CTO. Under Edo’s leadership, we’re confident that he will accelerate the growth of our systems and create the next generation of indoor growing technologies,” said Dave Dinesen, CEO, CubicFarms.

De Martin’s broad software experience across video games, holographic, and enterprise solutions, coupled with his leadership ability in leading technical innovation teams, will bring a unique perspective to Ag-Tech.

A graduate of Simon Fraser University, De Martin began his career in telecommunications before transitioning to roles in the video game industry where he is known for creating highly sought-after games. He delivered Need for Speed Underground, the franchise-leading, number-one selling game worldwide, and earned back-to-back ‘Best Company’ honours for operational excellence at Next Level Games, which was recently acquired by Nintendo.

In 2010, De Martin joined Microsoft to lead an innovation studio in Victoria, B.C. for HoloLens, the world’s first holographic computer.

In his role as General Manager of Microsoft Vancouver, De Martin grew the development centre from 400 to 1,200 employees onsite. He played a key role in global operations as well, overseeing site strategy and heading up a Dynamics 365 product team focused on Mixed Reality applications for frontline workers. As an advocate for British Columbia’s tech industry, he has served on the board of BC Tech, Cascadia Innovation Corridor, and was Co-Chair of the Canadian Digital Supercluster.

“With visionaries like Edo, we’re continuously attracting the best talent in the world to our team,” continued Dinesen. “We’re committed to building an exceptional team with people who are passionate about revolutionizing agriculture now, and for future generations.”

NEITHER THE TSX VENTURE EXCHANGE NOR ITS REGULATION SERVICES PROVIDER (AS THAT TERM IS DEFINED IN THE POLICIES OF THE TSX VENTURE EXCHANGE) ACCEPTS RESPONSIBILITY FOR THE ADEQUACY OR ACCURACY OF THIS RELEASE.

About CubicFarms

CubicFarms is a local chain, agricultural technology company developing and deploying technology to feed a changing world. Its proprietary ag-tech solutions enable growers to produce high quality, predictable produce and fresh livestock feed with HydroGreen Nutrition Technology, a division of CubicFarm Systems Corp. The CubicFarms™ system contains patented technology for growing leafy greens and other crops onsite, indoors, all year round. CubicFarms provides an efficient, localized food supply solution that benefits our people, planet, and economy.

For more information, please visit www.cubicfarms.com.

Media Contact:

Andrea Magee

T: 236.885.7608

E: andrea.magee@cubicfarms.com

Investor Contact:

Adam Peeler

T: 416.427.1235

E: adam.peeler@cubicfarms.com

Hydroponics Greenhouse Provides Hands-On Learning At Hudson High School

A $20,000 grant was given by The Kiwanis Club of Hudson to support the project, and this money was used to purchase greenhouse equipment.

Yeji Kim

Special to the Hudson Hub-Times

A Jan. 15 tour led by HHS AP Environmental Science teacher Matthew Kearns offered members of The Kiwanis Club of Hudson insight into the hydroponic greenhouse. The club donated a $20,000 grant to help fund the project. Submitted Photo

Project-based learning is a learning model where students work together to engage in real-world questions and problems, and the Hudson High School hydroponics greenhouse centres around this approach to education.

The hydroponics greenhouse started roughly two years ago, and Phillip Herman, Superintendent of the Hudson City School District, and Christina Wooley, HCSD Curriculum Coordinator, are credited with most of the original idea.

Herman first learned about hydroponics gardening and greenhouses from a community member and thought there may be a way to better utilize the HHS greenhouse space to create learning opportunities for students. He began by discussing the idea with teachers, visiting an operating hydroponics greenhouse and exploring areas of the curriculum that could be enhanced.

The first year consisted largely of planning, strategizing and raising money, and this past year was when equipment started to come in and crops began to grow.

A hydroponics greenhouse differs from a traditional greenhouse in that no soil is required. Instead, the plants draw up nutrient-rich water. Less water is used since the water is recycled, and because of the absence of soil, hydroponics greenhouses take up less space — the plants can be stacked vertically. The HHS hydroponics greenhouse also includes a monitoring computer system that measures what is currently in the water and what will be needed.

A $20,000 grant was given by The Kiwanis Club of Hudson to support the project, and this money was used to purchase greenhouse equipment.

CropKing, an Ohio-based hydroponics equipment company, was the supplier for the equipment, seeds and fertilizer, and the firm also aided in setting up the equipment and trained those involved with the greenhouse.

Two other grants, an ADAR grant and a grant from the Hudson Parent-Teacher Organization supplemented the Kiwanis grant money. The greenhouse itself is located off of HHS biology classes and has been there before the hydroponics greenhouse was started.

Students are faced with real-world questions, such as how to sustain crops in regions without sufficient access to water, ways to use the land effectively and properly, impacts on the environment and how to grow sustainably and locally.

Science teacher Matthew Kearns said students have been seeing the benefit of this project, which includes those in the AP Environmental Science class he teaches, special education students who work with Intervention Specialist Kristin Stonestreet and biology classes taught by Ron Wright. Students visit at least once a week to monitor the crops.

Currently, the greenhouse is growing its first round of crops, which includes lettuce, tomatoes and cucumbers.

Stonestreet and Kearns are considering adding cilantro, basil and peppers as well. The diversification would enhance the project-based learning aspect, as students will need to work together to figure out how much additional lighting and heat every crop needs.

The long term goal is to get involved with the community; through connecting with the business department and forming a club, students plan to sell produce from the greenhouse at the Hudson Farmers Market in the summertime and sell to HCSD faculty and staff when school is in session, engaging aspects of science, business and team-work. Several potential products for sale in the future include a salsa kit, tomato sauce and fresh herbs.

Herman notes how this greenhouse works to enhance classroom activity and curriculum.

“Over recent years, we have continued to learn more about and explore opportunities for project-based learning. Project-based learning enables students to learn course content and develop other essential success skills by beginning with a challenging problem or question and conducting a sustained inquiry to explore solutions to the problem and answers to their questions. Together, Christina Wooley, Mr Kearns and Mrs Stonestreet dug in and worked collaboratively to do the hard work to bring an idea to implementation.”

BONAFIDE Will Continue To Develop It's Concept On Decentralized Agriculture And Food Supply Systems

The trend for decentralization is growing all the time and we trust that agricultural policies will follow suit to support local farmers and a new generation of young entrepreneurs that find their ideology in creating new markets

Over the last 6 years, we have seen technology advance to facilitate urban vertical farming embracing entrepreneurial opportunities, the supply of fresh food daily, and secure cultural kitchens requirements for raw materials anytime anywhere.

At the same time conflicts, natural resource competition, and climate change have had adverse effects on food security that local production using new technology can alleviate.

The trend for decentralization is growing all the time and we trust that agricultural policies will follow suit to support local farmers and a new generation of young entrepreneurs that find their ideology in creating new markets.

thomas.tapio@gmail.com

Thomas Tapio (LION) • Consultant (retired)

Strasbourg 27th February 2021, 🇫🇷🇪🇺

Saudi Farmer Has Built The Region’s First Vertical Farm

“My aim is to make sure we truly become self-sufficient,” he said.

The Saudi farmer Omar Al-Jundi even he is not related to farming by degree. But that is exactly where the industrial engineer found his calling, when he built the region’s first vertical farm in the heart of Dubai. Born in Egypt to Saudi parents, Al-Jundi spent his early years in Alkhobar due to his father’s engineering firm.

The family moved to Jeddah when he was 12 years old. His last two years of schooling were spent at Bahrain School in Manama. “I wanted to graduate with an American high school diploma,” Al-Jundi said. “At the time, as a Saudi, you couldn’t attend private foreign schools.” Upon graduation, he left the region to study industrial engineering, followed by an MBA at the University of Miami in Florida. Although his father is an engineer and his mother an architect, Al Jundi delved into the world of banking for two and a half years when he moved back to Jeddah upon graduating.

“I then shifted to the hospitality industry, opened the first lounge in Jeddah along with other restaurants with my friends, and ended up selling my share and joining my father’s company,” he said. “You learn that you’re better off doing something on your own than having partners because you end up changing directions.”

After 10 years of “paying his dues” in the family business, he felt compelled to change directions. “As an Arab, you’re always closely tied to the family,” he said. “We’re blessed my father started a business and there’s a place for us in that business, but luckily, my younger brother was a lot more interested in it — I always felt my calling was somewhere else.”

In search of his true passion, he started his journey as an entrepreneur. The field he specialized in had yet to be determined. “I felt that there was a meaning for something else,” Al-Jundi said. “I was free and my family was very supportive.”

Countless research and books later, he became intrigued by the tech space, admitting he believed he would start the next Amazon. “That didn’t follow through,” he said. “Then I thought it would be in mining, but I always looked for something that was away from my comfort zone such as engineering, contracting, real estate and consulting. Just something different. It was a process.”

The young Saudi had reached a point in his life where he felt the need to do something impactful, something which added true value to the region. Eventually, two of his friends introduced him to the concept of modern farming. “I visited some orange farms in Egypt and I was in exploration research mode,” he said. “I enjoyed seeing nature — you’re a lot more relaxed. Here, when you go in and see the plants growing every day, there’s definitely a connection, because you’re seeing the end product, you’re feeling it, and I connect to them.”

The more research he immersed himself in, the more driven his interest became. At the time, the Saudi Government was focused on addressing food security and self-sufficiency. “It’s always been a big topic,” he said. “When you fly out of Riyadh, you find these big circular green spots as they’re trying to green and farm the desert, which was successful, but on the other hand, it depleted our water resources.” According to the Food and Agriculture Organization, agriculture represents around 70 per cent of water consumption in most of the GCC countries. But Al-Jundi did not give up on the thought.

After moving to Dubai in 2014, he learned about King Abdullah’s Initiative for Saudi Agricultural Investment Abroad. Half the capital needed for agricultural projects was offered to Saudis who invested in a list of 31 countries abroad to purchase land, set up a project and export the food back to the Kingdom. It gave him an idea to start his own vertical farm. “I knew it was a big topic,” he said. “I’d never heard we could grow food with no soil. I thought it was intriguing and fascinating. It was enough for me to know there was something there to explore it further.”

With more than 90 per cent of the region’s land unsuitable for agriculture, Al-Jundi set out to find a solution. He spent the following 12 weeks taking courses in aquaponics, aquaculture, hydroponics and horticulture in California and the Netherlands. He even spent time working in a cucumber greenhouse at the Delphy facility in Holland, where he acquired valuable experience in the field. “It was really professional and a great learning experience,” he said. “That’s when I knew what I wanted to do. And I knew I had to completely immerse myself in it.”

The team of Badia Farms, which he founded in Al Quoz in December last year, consists of 12 people, all of whom have experience in farming. “It took 18 months to get it up and running because we didn’t work with any technical partner,” Al-Jundi said. “I knew I was in it for the long haul, so I worked with different growers and learned.”

The 850-square-meter facility includes a “fertigation” room, which fertilizes and irrigates the 18 varieties of crops he currently grows. Gourmet seeds, some of them hybrids, such as lemon basil, cinnamon kale, wasabi, green radish, mustard, micro kale, edible flowers and cinnamon basil, are flown in from the United Kingdom and the United States every three months — from 50 to 300 kilograms at a time. The farm plans on introducing as many as 26 varieties, including sunflowers.

The seeds are placed on a type of mat made of recycled carpet that is food-certified. LED lights flood the room in a pink atmosphere, with each UV light containing a certain spectrum that is beneficial for the plants.

In the tank room, feed and water is scheduled through a computer-based on the crop, with a unique nutrient recipe for each type, including potassium, calcium, magnesium, and ammonium. UV and concentrated oxygen are also able to kill any potential bacteria or pathogens in recycled water. Once the seeds sprout, they are moved to the five stacks in the vertical farm. Four dehumidifiers regulate the humidity in the air, providing each on average with 70 litres of water a day. The eco-system created by Badia Farms uses 90 percent less water than open-field farming and recycles its water up to nine times.

“We’re using hydroponics,” Al- Jundi said. “The biggest advantage is that we do not spray pesticides, which are messing up our health. In fact, we extensively use stickers to attract insects away from the crops.” Different levels of lighting are provided for each stage of the plants before they are sent out as they were grown. “They’re intense in flavor and it’s the freshest you can get that way,” he said. “My personal favourite is chocolate mint.” With 60 clients so far, serving hotels, restaurants, and cafes, the model is a first for the region, which made it challenging to set up. “All the ones abroad are designed for different climatic conditions so none of them are applicable here, where there is extreme humidity and high temperatures,” he said. “And to convince a chef to give you his time, when you don’t have the track record, was a big challenge. I wasn’t a known farmer yet.”

The system’s structure was manufactured in Riyadh, with a plan to set up the next facility by 2020 in Jeddah. Until then, the plan is to cater to Saudi as well as the UAE. “Dubai is a good testing ground and Saudi’s vision now is to support our type of sustainable growing and ecological farms, so it’s perfectly in line with what we want to do,” Al-Jundi said. “The government is now delegated to move into sustainable growing and find viable solutions to address self-sufficiency, so it’s not a slogan anymore: it’s the real deal.”

He hopes to develop similar projects across the Kingdom in the future. “My aim is to make sure we truly become self-sufficient,” he said. “Vertical farming is one solution but it’s not the full one — the ideal solution lies in all models of modern farming. What’s close to my heart is giving people healthy food while preserving our resources, and I believe the new generations of Saudis are ambitious and want to evolve our country. We were just waiting for the opportunity and it has finally come.”

Source: Arab News

UPDATE - Vertical Farming Leader Kalera Welcomes Maria Sastre to Board of Directors

Sastre brings world-class customer service and operations experience as Kalera prepares for rapid domestic and international expansion.

A seasoned executive with experience in the food, travel, and tourism industries, Sastre brings with her over 25 years of executive leadership and experience and currently sits on the boards of esteemed, Fortune 500, multibillion dollar public and private companies, including General Mills and O’Reilly Auto Parts.

ORLANDO, Fla., Feb. 24, 2021 (GLOBE NEWSWIRE) -- Kalera (Euronext Growth Oslo ticker KAL, Bloomberg: KSLLF), one of the fastest-growing and largest vertical farming companies in the world and a leader in plant science for producing high-quality produce in controlled environments, today announced the appointment of Maria Sastre to its Board of Directors. A seasoned executive with experience in the food, travel, and tourism industries, Sastre brings with her over 25 years of executive leadership and experience and currently sits on the boards of esteemed, Fortune 500, multibillion dollar public and private companies, including General Mills and O’Reilly Auto Parts. The addition of Sastre to the board coincides with Kalera's rapid expansion into several new markets and its acquisition of Vindara Inc., the first company to develop seeds specifically designed for use in vertical indoor farm environments as well as other controlled environment agriculture (CEA) farming methods.

“We are thrilled that someone of Maria’s caliber has chosen to join Kalera’s board,” said Daniel Malechuk, Kalera CEO. “Her resume is beyond impressive, with extensive experience leading highly successful international and growing companies, and is a strong complement to our industry-leading management team and board of directors. She has proven time and again that she is invaluable in helping scale businesses, and will be an incredible asset to Kalera during this time of rapid growth, both domestically and abroad.”

In addition to her aforementioned business experience, Sastre also served on numerous civic and non-profit boards such as the Greater Miami Visitors and Convention Bureau(Chair), the Executive Advisory Board of Florida International University School of Hospitality,and the Executive Board of the United Way of Miami-Dade County. She has been recognized as one of the Top 80 U.S. Hispanics and Top 20 Latinas and has received numerous awards in the travel and hospitality industry sectors. Sastre's education includes a Bachelor's degree and a Master's in Business Administration, both from New York Institute of Technology.

“As someone with a passion for optimizing customer experiences, I am proud to join Kalera’s board as I fully believe their product is a category leader,” said Maria Sastre, new Kalera board member. “Kalera has the opportunity to serve diverse customer segments and increase accessibility to a product that is inherently safer, cleaner, fresher, more sustainable, and more nutritious and flavorful. In a world where brands are looking for ways to differentiate their products and services to their discerning customers, the Kalera portfolio is well positioned to offer the best vertical farming product solution. I trust my years of experience in operations and customer service will prove beneficial as Kalera expands into new markets.”

Sastre previously served as the President and Chief Operating Officer for Signature Aviation, the largest worldwide network of fixed-based operations and maintenance centers for private aviation. Before joining Signature, she spent eight years at Royal Caribbean Cruises LTD, where she held the positions of Vice President, International, Latin America, Caribbean and Asia; and Vice President of Hotel Operations. Her roles included strategic growth across emerging markets as well as managing all aspects of operations and the guest experience onboard Royal Caribbean's fleet of vessels. Previously, Sastre served as Vice President of Worldwide Customer Satisfaction for United Airlines, where she led the newly created customer-satisfaction division charged with refining the customer-service experience.

Kalera currently operates two growing facilities in Orlando, and is building facilities in Atlanta, Houston, Denver, Columbus, Seattle, and Hawaii. Kalera is the only controlled environment agriculture company with coast-to-coast facilities being constructed, offering grocers, restaurants, theme parks, airports and other businesses nationwide reliable access to locally grown clean, safe, nutritious, price-stable, long-lasting greens.Kalera uses a closed-loop irrigation system which enables its plants to grow while consuming 95% less water compared to field farming.

About Kalera

Kalera is a technology driven vertical farming company with unique growing methods combining optimized nutrients and light recipes, precise environmental controls, and clean room standards to produce safe, highly nutritious, pesticide-free, non-GMO vegetables with consistent high quality and longer shelf life year-round. The company’s high-yield, automated, data-driven hydroponic production facilities have been designed for rapid rollout with industry-leading payback times to grow vegetables faster, cleaner, at a lower cost, and with less environmental impact. To learn more visit www.Kalera.com.

Media Contact

Molly Antos

Phone: (847) 848-2090

Email: molly@dadascope.com

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/bb487877-0d3b-4e1c-9492-9ea280c217a1

INTERACTIVE WORKSHOP: How To Make Your Network Part of Your Net “Worth”

It doesn’t matter the industry, the gold coin of success is making your network “worth” something towards your career goals

Join Us Monday To Hear From

The Leaders of Ag In Europe

Register TODAY

It doesn’t matter the industry, the gold coin of success is making your network “worth” something towards your career goals. Discovering job opportunities, bridging industries, gaining product knowledge, climbing the ladder – they all can be pushed to new heights through strategically managing your connections.

How do you do this? It’s as easy as 1-2-3!

1. First, register for the interactive workshop How to Make Your Network Part of Your Net “Worth" on 8 March 2021 that is part of the annual Women in Agribusiness (WIA) Summit Europe.

2. Second, tune in (virtually, so this is very easy to do) to every word that accomplished speaker, Dorothy Dalton, CEO of 3Plus International Ltd., will share with you during the session.

3. Third, stay and attend the entire WIA Summit Europe (8-10 March) and put your new networking skills to practice by mingling with dozens of attendees from several countries!

Your net “worth” is in your hands.

Get strategic with your networking and achieve your career goals!

Learn More And Register Here

VIDEO: Signify Celebrates Five Years Anniversary of GrowWise Research Center

Over the past five years, we have helped hundreds of entrepreneurs and pioneers all over the world discover how they can feed tomorrow’s cities and grow plants faster, in a more sustainable way."

Five Years of Feeding Tomorrow’s Cities

Ellis Janssen, Director city farming at Signify explains: “At the GrowWise Center, we believe in vertical farming. Over the past five years, we have helped hundreds of entrepreneurs and pioneers all over the world discover how they can feed tomorrow’s cities and grow plants faster, in a more sustainable way."

Jarno Mooren, Signify's plant specialist vertical farming with tomato crops cultivated at the GrowWise Center

"We work closely with our customers and partners, looking at all aspects of the business case: whatever a grower’s needs are, we can translate them into a dedicated recipe for growth. To achieve this, our team of plant specialists, application engineers and key account managers look at the most important aspects that determine the set-up of a farm so they can give the grower dedicated advice in making the best decisions," Ellis states.

Ellis Jansen, director of city farming at Signify

She adds, "We have learned a lot over the past five years, and as we are evolving our customers are evolving as well. They want the best solutions for their specific needs. At the GrowWise Center, we support them wherever we can. The world continues to change, and we will change along with it. Through this all, and by combining the latest technology, business insights and plant expertise, we can help growers make their business successful and future-proof."

Jarno in between strawberry crops

"At the GrowWise Center, we are proud of all that has been accomplished in vertical farming over the past five years, and we are excited to see where we can take the dreams and ambitions in vertical farming in the future," Ellis notes.

Global Marcom Manager Horticulture at Signify

Daniela Damoiseaux

Tel: +31 6 31 65 29 69

E-mail: daniela.damoiseaux@signify.com

About Signify

Signify (Euronext: LIGHT) is the world leader in lighting for professionals and consumers and lighting for the Internet of Things. Our Philips products, Interact connected lighting systems and data-enabled services, deliver business value and transform life in homes, buildings, and public spaces. With 2020 sales of EUR 6.5 billion, we have approximately 38,000 employees and are present in over 70 countries. We unlock the extraordinary potential of light for brighter lives and a better world. We achieved carbon neutrality in 2020, have been in the Dow Jones Sustainability World Index since our IPO for four consecutive years and were named Industry Leader in 2017, 2018, and 2019. News from Signify is located at the Newsroom, Twitter, Linked In, and Instagram. Information for investors can be found on the Investor Relations page.

PODCAST: What Do Saltwater Vertical Farming And Sustainable Coastlines Have In Common?

In the podcast, Heron Farms, a sea beans cultivator, is featured. Heron Farms uses its vertical farm and is also restoring marshland from their home base in Charleston, South Carolina

A podcast by Evolve.ag

Recently Evolve.ag held a podcast on 'What do saltwater vertical farming and sustainable coastlines have in common?'. Their series focuses on what's trending in food and food tech.

In the podcast, Heron Farms, a sea beans cultivator, is featured. Heron Farms uses its vertical farm and is also restoring marshland from their home base in Charleston, South Carolina.

In this episode, Wendy Yared, a food anthropologist, speaks with Sam Norton, the founder of Heron Farms. Inspired by the marsh he grew up playing in, he started the first saltwater vertical farm in the US. Heron Farms grows a type of Salicornia, also known as a sea bean. This plant provides high levels of nutrients like vitamin A, vitamin C, and, not surprisingly, sodium chloride. Chefs sometimes use it as a replacement for salt on fish dishes, like Crudo or ceviche. Beyond the farm, they're also using Salicornia to remediate salt marshes.

They talk about the ecological benefits of Salicornia and how marshland restoration can help turn seawater into a resource instead of a concern for people living in coastal areas. During the podcast, they also dive into the challenges of starting a vertical farm. And how important it is to balance the negative aspects of controlled environment agriculture, like expensive lighting and plastic, with activities that support the ecosystem.

Click here to access the podcast.

For more information:

Wendy Yared, food anthropologist

26 Feb 2021

Jersey City Housing Authority To Host Vertical Farms

The partnership aims to provide more access to healthy food

Partnership Aims To Provide

More Access To Healthy Food

February 25, 2021

AeroFarms will construct and maintain 10 farming sites, the first of which will be built at the Curries Woods Community Resource Center as part of a new agreement between the city, AeroFarms, and the Jersey City Housing Authority.

Vertical farms will provide free nutritious food to residents in need now that the Jersey City Council has adopted a resolution approving an agreement between AeroFarms, the city, and the Housing Authority.

The new agreement means that vertical farms will be opened at Curries Woods and Marion Gardens.

The public housing farms, which will be funded by the city, will increase healthy food access where needed most and encourage residents to live healthier lifestyles.

The Jersey City Department of Health and Human Services (HHS), AeroFarms, and Jersey City Housing Authority will collaborate with the Boys & Girls Club and Head Start Early Childhood Learning programs to support produce distribution and healthy eating education.

“We’ve worked hard to keep the Vertical Farming Program a priority despite the impacts from this pandemic, which have disproportionately affected the more economically challenged areas and exacerbated societal issues such as healthy food access,” said Mayor Steven Fulop.

“We’re taking an innovative approach to a systemic issue that has plagued urban areas for far too long by taking matters into our own hands to provide thousands of pounds of locally-grown, nutritious foods that will help close the hunger gap and will have an immeasurable impact on the overall health of our community for years to come.”

City farming

AeroFarms will construct and maintain the farming sites. The first will be built at the Curries Woods Community Resource Center. The Boys & Girls Club and Head Start will integrate the vertical farm as a learning tool for youth within their educational programming.

Head Start, operated by Greater Bergen Community Action, plans to integrate greens into its early childhood meals.

AeroFarms indoor vertical farming technology uses up to 95 percent less water and no pesticides versus traditional field farming.

According to the city, the JCHA-Aerofarms Advisory Committee will be formed to provide strategic oversight and guidance throughout the program.

The steering committee will include Jersey City residents and stakeholders from the Boys & Girls Club and Head Start.

The city’s Vertical Farming Program will consist of eight additional vertical farms throughout Jersey City in senior centers, schools, public housing complexes, and municipal buildings.

The 10 sites will grow 19,000 pounds of vegetables annually using water mist and minimal electricity, according to the city.

The food is free to residents if they participate in five healthy eating workshops, and they will have the option of participating in a quarterly health screening.

“As a Certified B Corporation, we applaud Mayor Fulop’s leadership and advocacy to bring healthier food options closer to the community, and we are excited to launch together the nation’s first municipal vertical farming program that will have a far-lasting positive impact for multiple generations to come,” said Co-Founder and CEO of AeroFarms David Rosenberg.

The city’s Health and Human Service Department will run the program with a health-monitoring component to track participants’ progress under a greener diet, monitoring their blood pressure, cholesterol, diabetes, and obesity.

Crops will be integrated with other Healthy Food Access initiatives, including senior meal programs, according to the city.

“Access to healthy food and proper nutrition is directly linked to a person’s mental and physical health, and can decrease risks of chronic diseases while increasing life expectancy,” said Stacey Flanagan, director of Health and Human Service for Jersey City. “This past year has shed light on the health disparities that exist in urban areas nationwide, which is why we’ve remained focused on closing gaps where healthy food access is most needed, specifically for our low-income, youth, and senior populations.”

Healthy food initiatives

The Vertical Farming Program is part of the broader initiative from the World Economic Forum (WEF) toward partnerships with cities.

Jersey City is the first in the world to be selected by WEF to launch the Healthy City 2030 initiative, which aims to catalyze new ecosystems that will enable socially vibrant and health-centric cities and communities.

The vertical farming initiative is the latest and broadest effort Jersey City has launched around food access, including more than 5,000 food market tours for seniors to educate them on healthy eating, and the “Healthy Corner Store” initiative.

According to a 2018 city report, much of Jersey City could be described as a “food desert.”

The USDA defines a food desert as “a low-income census tract where either a substantial number or share of residents has low access to a supermarket or large grocery store.”

This means at least 500 people or 33 percent of the population live more than a mile from a supermarket or large grocery store.

According to the city, these deserts have led to an increased rate of diabetes, heart disease, obesity, and other diet-related illnesses in the more marginalized communities of Jersey City.

“We are thrilled that the vertical farms that will be installed at JCHA sites to enable some of our most vulnerable residents, including low-income households, children, and seniors, to have access to fresh, green produce that is nutritious, delicious, and easy to prepare,” said Vivian Brady-Phillips, director of the JCHA.

For updates on this and other stories check www.hudsonreporter.com and follow us on Twitter @hudson_reporter. Marilyn Baer can be reached at Marilynb@hudsonreporter.com.

Swegreen’s New In-Store Farming Service Will Be Scandinavia’s Biggest

Swegreen's innovative in-store service will make the Ica Maxi megamarket in Linköping, located in Mid-Sweden, the first of all Sweden’s megamarkets to offer fresh herbs and salad grown from seed to finished plant inside the store

March 01, 2021

Swegreen’s board member Pierre Mohlin meets up with Milleriine Axelsson who will be responsible for the in-store growing unit from Ica Maxi’s side.

Swegreen launches ‘NextGen’ of super-efficient in-store vertical farming service when Ica Maxi megastore in Linköping puts the company’s Farming-as-a-Service growing unit for leafy greens right at the entrance of the store. The new vertical farm will be Scandinavia’s largest in-store cultivation.

Swegreen's innovative in-store service will make the Ica Maxi megamarket in Linköping, located in Mid-Sweden, the first of all Sweden’s megamarkets to offer fresh herbs and salad grown from seed to finished plant inside the store. Every day, several hundred fresh leafy vegetables can be harvested for the store's customers.

- It won’t get more locally produced than this, says Ica Maxi Linköping's CEO Tomas Lundvall.

The actual cultivation facility, which takes place in the middle of the store entrance, will have glass walls from floor to ceiling. This, together with an eye-catching light from the plants' LED system, will leave a clear mark on the entrance to the store when the installation is ready later this spring.

- We have chosen a central place for cultivation to really clarify our commitment to a greener and more climate-smart food production. The cultivation will be a destination in itself for our customers, and once they get the opportunity to taste these crops, many will understand what fantastic quality such a cultivation system offers, says Tomas Lundvall CEO and owner of the megamarket.

- Our salad and our herbs will simply be the smartest greens in town, he adds.

The new in-store plant is based on hydroponic cultivation technology. Nutrition comes directly from the water, which can be recycled. The system can also recover energy, carbon dioxide and nutrients. Behind the innovation is the all-Swedish technology company Swegreen, which has developed both the cultivation room itself and the AI-based control system which, via a cloud service, controls and optimizes the environment in the cultivation.

- We are very proud to work with the team for Ica Maxi in Linköping for this installation, their commitment to hyper-local and climate-smart produced food shows that this is a megastore at the forefront, says Swegreen's CEO Andreas Dahlin.

- Ordinary vegetables sold in Swedish supermarkets have traveled an average of 3,000 kilometers, while these crops have not been transported at all. Of course, it gives better taste, better consistency and durability - and also better nutritional value, he continues.

The new in-store service will start delivering leafy greens in May, and it will then be able to supply the megastore with different kinds of herbs such as coriander, dill, and parsley, and also lettuce and cabbage. The crops will also be used for in-house production in the store's own kitchen, and in future, there will be the possibility of more types of vegetables.

Swegreen is an all-Swedish ESG AgTech company combining advanced technology with data and plant science to efficient produce high quality and climate smart leafy greens in urban environment. Swegreen offers a prescription based growing service called Farming-as-a-Service (FaaS). With it, any supermarket or restaurant owner can supply their customers with fresh, nutritious, well-tasting and hyper-locally produced leafy greens all year. See more at www.swegreen.com

ICA Maxi Stormarknad Linköping was established in 1993 as one of the ICA Groups first Maxi megamarkets in Sweden. It’s the largest of its kind in the region and one of the largest ICA-stores all categories. The total sales area is 8,000 sqm and it employs around 300 persons. See more at: www.ica.se/butiker/maxi/linkoping/maxi-ica-stormarknad-linkoping-8900/start/

GoodLeaf Farms Launches Aggressive Expansion Plans

GoodLeaf will bring its innovative and proprietary controlled-environment agriculture technology to more Canadian markets over the coming year

NEWS PROVIDED BY

McCain invests in a national network of vertical farms to bring tasty, local food to Canadians

GUELPH, ON, - With the closure of a successful new funding round, GoodLeaf Farms is embarking on an aggressive growth and expansion plan to build a national network of vertical farms that will bring fresh, delicious, nutritious and locally grown leafy greens to Canadians across the country.

Backed by a sizeable investment from McCain Foods Limited — which has increased its total investment in GoodLeaf to more than $65 million — GoodLeaf will bring its innovative and proprietary controlled-environment agriculture technology to more Canadian markets over the coming year, providing more Canadian consumers with year-round local food that is typically imported from the Southern United States or Mexico.

"From our start in Truro to our first commercial farm in Guelph, GoodLeaf has built a strong foundation for future growth," says Barry Murchie, Chief Executive Officer of GoodLeaf. "We want to be a global leader in vertical farming. Our first step to accomplishing that is ensuring we have a strong footprint in Canada, giving Canadians access to top quality, nutrient-dense, sustainably grown and pesticide-free leafy greens 365 days a year."

GoodLeaf opened its first commercial vertical farm in Guelph, Ont., in the fall of 2019. By the end of 2021, GoodLeaf is planning two more indoor vertical farms — one to serve the grocery and foodservice networks in Eastern Canada, and one for Western Canada.

The exact locations will be announced shortly.

"It is our intention to build farms that support the Canadian grocery store network, foodservice industry and consumers," says Mr Murchie. "We want to change what people are eating by providing a fresh, healthy and local alternative that, until now, hasn't been available in Canada. We are driving a new way to grow food, with disruptive technology that brings consumers leafy greens from their own backyard. This is a fundamental game-changer."

GoodLeaf's vertical farm grows to produce on hydroponic trays stacked in multiple horizontal levels. A proprietary system of specialized LED lights is engineered to emulate the spring sun, giving plants the light they crave to maximize photosynthesis. The indoor controlled environment is almost clinical, meaning there are no pesticides, herbicides or fungicides used. It is also immune to weather extremes, such as summer droughts or late spring frosts that can be lethal to crops.

Furthermore, having a local source of year-round food is vital to Canada's food security and sovereignty, concerns that were in the spotlight at the height of the COVID-19 pandemic as shoppers were faced with rapidly dwindling supplies on grocery store shelves.

At its 45,000-square-foot Guelph farm, every day GoodLeaf is harvesting microgreens (Spicy Mustard Medley, Asian Blend, Micro Arugula, Micro Radish and Pea Shoots) and baby greens (Ontario Baby Kale, Ontario Baby Arugula and Ontario Spring Mix) for Ontario grocery stores, ensuring a local supply of fresh, nutrient-dense leafy greens all year long.

GoodLeaf produce is exceptional in a salad, as a topping for burgers and sandwiches, as a kick of nutrients in a smoothie or as an ingredient to elevate your favourite dish.

Follow GoodLeaf Farms on Instagram @goodleaffarms and Like it on Facebook at /GoodLeafFarms.

About GoodLeaf Farms:

With a passion for delicious, nutrient-rich greens, GoodLeaf was founded in Truro, NS, in 2011. Using innovative technology and leveraging multi-level vertical farming, GoodLeaf has created a controlled and efficient indoor farm that can grow fresh produce anywhere in the world, 365 days of the year. The system combines innovations in LED lighting with leading-edge hydroponic techniques to produce sustainable, safe, pesticide-free, nutrient-dense leafy greens. GoodLeaf has ongoing R&D Programs in collaboration with the University of Guelph, Dalhousie University and Acadia University.

Learn more at goodleaffarms.com.

About McCain Foods (Canada)

McCain Foods (Canada) is the Canadian division of McCain Foods Limited, an international leader in the frozen food industry. McCain Foods is the world's largest manufacturer of frozen potato specialities, and also produces other quality products such as appetizers, vegetables and desserts that can be found in restaurants and retail stores in more than 160 countries around the world. In Canada, the company has eight production facilities with approximately 2,400 employees and, in addition to its famous French fries and potato specialities, makes frozen desserts, snacks and appetizers.

SOURCE GoodLeaf Farms

For further information: Michelle Hann, Senior Consultant, Digital and Communications, Enterprise Canada, mhann@enterprisecanada.com, 613-716-2118

LEDs Light the Way to Efficient Urban Farming

The global pandemic has turned the world upside down, bringing unprecedented change to the way we live, work and play. But the crisis has also paved the way for important new innovations

By Mike Martens, Senior Manager, Illumination Marketing at Osram Opto Semiconductors, North America

The global pandemic has turned the world upside down, bringing unprecedented change to the way we live, work and play. But the crisis has also paved the way for important new innovations. For instance, massive disruption to the global supply chain is now compelling many nations to ramp up their indoor and urban farming efforts to secure their food supply and feed their people.

Take the desert nation of the United Arab Emirates. Amid the ongoing pandemic, the country is experiencing something of a food crisis. That’s why it recently announced a $100 million investment in cutting-edge indoor farming facilities that can help feed its population. The effort will include the creation of the world’s largest vertical farm to help solve the challenge of local food production.

A key component of vertical farming is LED technology. In places across the globe where farmland is limited, innovative LED lighting solutions offer a major advantage because they can provide the exact light composition that various plants need for ideal growth or to develop certain characteristics. Plants can also be grown in a very space-saving manner and with considerably higher yields thanks to these lighting solutions.

LEDs are more efficient

For decades, traditional high-pressure sodium (HPS) lamps were commonly used for greenhouses and other horticultural purposes but they bring with them many challenges. They have a short lifespan and are often only suitable for top lighting in greenhouses due to their high heat output.

This is a big problem for greenhouse owners because efficient energy use is essential to economic production. In traditional greenhouse and urban farming setups, HPS lights are often inefficient. They do provide light for plants, but it is often not the most efficient wavelength range because the lamps cannot be customized to provide ideal growing conditions for different types of plants.

HPS lights often generate a lot of heat , causing considerable evaporation and ultimately limiting crop yield. What’s more, due to this heat production, HPS fixtures often cannot be placed very close to plant canopy, preventing more efficient vertical-farm setups. After all, you don’t want to singe your produce.

The good news is that innovative LED technologies can alleviate many of these concerns. For starters, LEDs produce almost no radiated heat, allowing for the light fixtures to be placed closer to plants and for plants to be stacked much higher, enabling farmers to grow more produce in smaller spaces while simultaneously reducing water costs.

LED lights also offer customizable wavelengths for different plants’ needs, allowing greenhouse operators and urban farmers to grow specific plants in their optimal conditions. For instance, LEDs can be tailored to supply light with a higher amount of red or blue content, generating exactly the wavelengths the plant, such as iceberg lettuce, tomatoes and basil need for optimal growth.

Urban farming is not a new phenomenon, but LEDs have the power to take it to the next level and more efficiently feed the world. In terms of sheer numbers, LEDs have an average lifespan of 50,000 hours compared to 8,000 hours for HPS lamps, making LEDS much more economical (and better for the environment). Indeed, vertical farms that leverage LED technology can achieve 40% energy savings compared to traditional lighting methods like HPS lamps. And due to the optimized light spectrum at 450, 660 and 730 nanometers, LEDs can provide the perfect lighting for all types of plants, allowing growers to adjust the lighting exactly to the needs of various crops.

LEDs grow healthier produce

LED are the most efficient lighting technologies to date for growing produce. They not only help produce fresh food in smaller spaces without the use of pesticides, they also make it easier for consumers in urban areas to obtain fresh and healthy food quickly, a must, considering the planet’s ever-growing population and ever-decreasing farmland.

Consumers in urban areas often rely on produce grown in faraway places that is brought to them on trucks using fossil fuels. This produce is often grown with pesticides to keep insects away, as well as fertilizers, so plants can be grown throughout the year, even in suboptimal conditions. All of these factors contribute to climate change and more polluted water sources. With horticultural LEDs, these issues can be mitigated.

LEDs also provide optimal growing conditions in any environment with minimal water waste, while reducing the need for pesticides in indoor growing environments. Communities then have the ability to grow produce closer to home, which allows consumers to learn more easily what exactly goes into their food and greatly reduces the fossil fuel usage to get produce from the (urban) farm to their tables. Urban farming has great potential to make positive impacts on local environments and communities. It’s more sustainable and decreases communities’ reliance on foods shipped in at great cost from around the globe.

LEDs light the way

As we grapple with the many concerns facing our modern society, it is imperative to invest in efficient and time-saving technology of all types. LEDs are one of these technologies. Indeed, they light the way to the farms of the future. They will have an enormously beneficial impact on agriculture by dramatically increasing crop production and putting food on every table more efficiently.

Elevate Farms To Expand In New Zealand And New Jersey By Late 2021

Other than building high-tech production facilities and growing leafy greens, Elevate is also in the business of proving its detractors wrong as the company is on track to produce 1 million pounds of leafy greens in one of its 5,000-square foot facilities in Niagara, Ontario

Producing 1 million lbs of Leafy Greens Per Year

Other than building high-tech production facilities and growing leafy greens, Elevate is also in the business of proving its detractors wrong as the company is on track to produce 1 million pounds of leafy greens in one of its 5,000-square foot facilities in Niagara, Ontario.

Elevate is a vertical farming company located in Toronto, Ontario and

producing leafy greens in state-of-the-art facilities. With its Niagara facility spanning 20,000 square feet with a cultivation area spanning 5,000 square feet, it can produce as much food as 100 acres of land-based agriculture. This, according to chief strategy officer Travis Kanellos, is critical to people’s understanding of vertical agriculture and its benefits over other conservation agriculture methods. While organic agriculture strives to improve soil health and conserve biodiversity, the global agricultural land base still cannot support the growing population.

Travis Kanellos, Chief Strategy Officer

Further, organic certifications do not necessarily prohibit the use of any and all chemicals, but instead, greatly restrict the list of certified agrochemicals. Organic agriculture is thus only part of a global agricultural solution, while vertical farming should also play an increasingly important role as it does not use any agrochemicals and demonstrates unparalleled planting density.

Elevate primarily produces leafy greens but has also successfully grown tomatoes, strawberries, beans, and various plant proteins during research trials. With many vertical farms producing crops with low caloric value, such as microgreens and herbs, Elevate is eager to broaden this range and include higher value, higher calorie crops. Nevertheless, Elevate has had significant success producing leafy greens and is reportedly one of few profitable vertical farming facilities that is actually delivering its forecasted yields, which Kanellos attributes to the company’s diligent approach and scientific partnerships.

“Typically we’ve seen the industry of indoor farming; secure funding, build the farms and expect everything to come to them. But building it then trying to figure it out is backwards to us. We’ve spent years of research and commercialized production with intellectual property. When you build a company through 15 years of R&D, along with our core team’s execution track record and all of the experience from our academic partners, we feel that is a pretty good recipe for success.”

The company’s most important partnership is with Intravision, a Norwegian agtech company with additional offices in Toronto and Shanghai. The company’s products include controlled environment systems, LED lighting, and research tools. However, Intravision does not limit itself to simply supplying products; the company also develops partnerships to continuously research and improve production methods in indoor agriculture. So while Intravision does supply much of the hardware for Elevate farms, the two companies have a strong partnership and collaborate throughout project implementation, crop production and aligned business interests.

Looking ahead, Elevate aims to have its pilot facility operating at 100% capacity in the coming months. Also, the company plans to build and begin operating facilities in New Zealand and New Jersey by late 2021.

“Our pilot facility in Toronto allowed us to reach out and develop global relationships. What started in Canada with the 1,000 square foot pilot facility in Toronto has led to agreements across Canada and New Zealand for the construction of more than 10 facilities, with each slated to produce 1 million pounds of produce annually,” says Kanellos.