Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

London Food Bank Is Going Greener With Greenhouse

CTV's Nick Paparella check in on the progress as the food bank aims to grow some of its own fresh produce for use during the winter months.

Nick Paparella CTV News London Reporter

Inside the London Food Bank's greenhouse in London, Ont. on Friday, Jan. 29, 2021. (Nick Paparella / CTV News)

LONDON, ONT. -- The outdoors may be covered in a blanket of white in January, but at the London Food Bank these days everything seems to be coming up green.

After a year of planning and with donations from the community, the new greenhouse is bearing fruit - or in this case vegetables.

“This is what Londoners a few years ago wanted more than anything else, to donate funds towards fresh fruits, fresh produce and that's what they have done,” says Glen Pearson from the London Food Bank. “So we've just taken it to a different level so we can grow our own as well.”

The man with the green thumb here is horticulturalist Luis Reyes.

“A couple of weeks ago we received the heaters and since then you can see the growth in only a couple of weeks,” says Reyes.

Like many from the food bank, Reyes is passionate about helping those in need.

“I am a grower and that's what I like to do and now to do it directly to people makes me proud,” he says.

The greenhouse is expected to grow about 15,000 plants a year which amounts to about four tons of food.

“You're not going to get anything fresher than this in a supermarket,“ says Reyes. “So probably you're going to harvest today here and the people or clients are going to receive it tomorrow or the same day.”

In the winter months, they are growing cold-weather plants like lettuce, spinach and even kale, but once summer arrives they will switch to tomatoes, cucumbers and fruit-bearing plants.

Adds Pearson, “It just expands the nutrition we're able to give to other people.”

Advice For New Vertical Farmers: Grower Spotlight on Andrew Worrall

Andrew is LettUs Grow’s Farm Manager, he manages two of our sites across Bristol and has brought a wealth of knowledge into the company through his previous experience in indoor farming roles across the UK including at Grow Up, Raynor Foods & RootLabs. In this three part interview, we explore what it’s been like to move from animal husbandry to indoor farming, the lessons he’s learned along the way, what it’s like working at LettUs Grow and his advice for those new to indoor growing.

Last week we spoke about running a farm at LettUs Grow. What excites you about vertical farming?

It’s the future of the industry. Also, the amount of salad that these farms can produce for their local community. We want to be able to eat salad all year round and we import to make that happen. However, just a small farm can easily provide for its local community, very efficiently and all year round. The sustainability element is also exciting: with our salad there’s no food miles, it’s very minimalistic. You could use an electric van or bike to distribute this crop if you wanted to. It’s a step forward in terms of what we need to do to take care of our planet.

What do you think are the biggest downsides to vertical farming?

It’s still a new technology and it can be expensive. The biggest roadblock facing the industry is that we need more people and companies to collaborate together to make sure we can build these farms at a sensible rate, so we can provide farms to anyone. We want to be able to provide farms to people, communities and countries that don’t have a lot of money, so that they can provide affordable fresh produce to local people.

How has vertical farming impacted your life?

Massively! I wanted to find my passion, a job that I loved - that was very important to me. It’s satisfying to be in a position now where I’m very happy to be doing what I do and I look forward to going into work. I was happy to make the move from London to Bristol. I would have moved even further if it meant being able to continue working within this industry.

Image from: LettUs Grow

How do you see vertical farming playing a part in the future?

When indoor farming first came about, it had a reputation of being competition for outdoor farming, which just isn’t the case. There’s so much we can’t grow that outdoor farming can provide, such as cereal crops. I’m glad we’re at a stage where indoor and outdoor farms can start to work together to optimise both methods. With these new relationships, there should be a good increase in the amount of indoor farms you’ll be seeing. What LettUs Grow offers with DROP & GROW™ is an exciting project because that’s a 40ft shipping container which can be placed pretty much anywhere. It’s not that big - it could go in a car park or behind a restaurant, but actually provide quite a lot of salad to that area.

How much of our food should be grown this way?

Good question. If you had asked me a while back I would have just said salad, but now I’ve changed my mind. Indoor farming can have a massive impact on propagation, especially aeroponics, because of how we aerate and nourish our roots. We could start lettuce for greenhouse projects and we can also propagate tomatoes, strawberries and tree whips. Propagating trees in this way could potentially be hugely beneficial and it’s something we want to do more of.

We can also quickly grow large amounts of microgreens, baby leafs, herbs and we can grow fruiting crops like strawberries. We are slowly chipping away and it’s really exciting. I’m waiting to see if I can ever say I’ve grown or propagated every crop that can be grown in these farms!

What do you think are the biggest benefits of vertical farming?

How fast these crops can grow! The turnover can be as short as 5 days from seed, depending on the crop. Also how clean it can be - I’m very dedicated to making sure these farms are built to ensure they are easy to be maintained and clean. The most exciting part is the crop growth rate though - it’s incredible how fast our crop grows from seed to plate. In a very well maintained growing calendar, which Ostara® is great for supporting, you can optimise your beds so that the day you harvest can also be the day you germinate onto that same bed. Your farms can be forever providing salad at very fast rates.

Image from: LettUs Grow

What was the biggest change you encountered during your years indoor farming?

Moving from being a production grower to an R&D grower. It has been a great change! As a production grower I knew what I needed to know about growing the plant safely and getting it onto a plate so it was good for the consumer. Now I’m fully optimising, learning and understanding the plants completely, so that I can help the grower that I used to be. We spend a lot of time on crop recipes to make sure that whoever we sell our farms to can start up very quickly and they won’t have to spend months developing their crops. If they have the customers and clients behind them, they can buy DROP & GROW and start producing salad as soon as it's been commissioned.

What was the biggest change you encountered in the industry?

More and more people are speaking about what’s going on in the industry and getting involved. I get so many messages on LinkedIn with people who want to get into this career. It’s exciting to see that indoor growing is a career people can access now. When I was developing my skills I didn’t know I would end up in indoor farming. There are more opportunities than ever before. For example, our Crop Technician is doing a placement here for 2 years. The aim is that they can gain the skill sets and knowledge they need to then go off and do the same practice in any farm they want.

What advice do you have for people who are looking to start a career in growing?

Reach out to companies who are already out there. You could start off part-time or as an assistant. If you are patient and dedicated then it’s a journey I promise you won’t regret. It takes a lot of work, but the outcome is amazing - you’ll be learning so much about this new technology. You’ll also build great relationships: there are so many amazing people in this industry who are so interesting, with different backgrounds, who are willing to share their knowledge. You can always learn more and other people are a great source of that.

What about for those looking to start a vertical farming business?

Do your homework. There are people out there who you can reach out to and it’s very easy to get information. It’s very easy to get excited about the idea and jump straight into it, because it is exciting and can be very rewarding, but it’s really important to do it step by step. Know how to scale properly, learning the differences between a small and larger farm. Understand how many people you’ll need and the logistics. I’d also advise people to get some practical work experience before you buy. You want to start the company knowing the tricks of the trade.

Image from: LettUs Grow

LettUs Grow Blog: www.lettusgrow.com/blog/advice-for-vertical-farmers

Delivering The Optimal Growing Parameters

“Especially in the pharmaceutical or supplemental industry, you need an extremely strict batch control that leaves no room for variation,” says Dr Alexis Moschopoulos, Managing Director at Grobotic Systems.

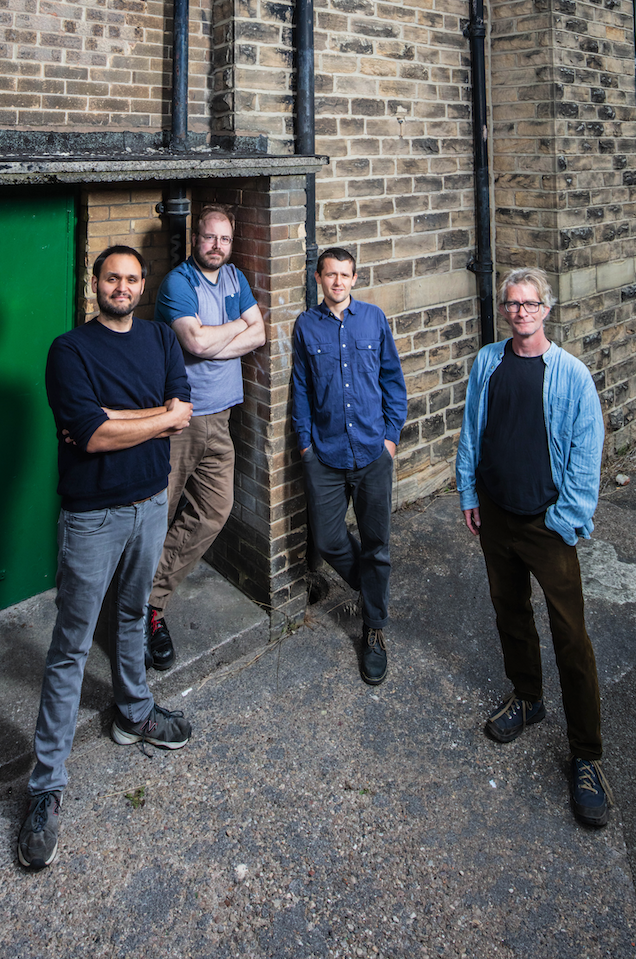

The Grobotic Systems team shows off an early prototype Grobotic chamber. From left to right: Gareth Coleman (Software Developer), Richard Banks (Chief Technology Officer), Dr Alexis Moschopoulos (Managing Director), and Andrew Merson (Mechanical Engineer). Credit: UKRI.

Growing a new variety

Indoor farming has numerous growing parameters to take into account. Particularly when growing a new variety, all variables should be perfected in order to reach an optimum yield. In an indoor space, experimenting with these environmental parameters might, however, seem tricky. But what about trying out this environment in a smaller setting, such as an experimental growth chamber?

Alexis is fully aware of the challenges that vertical farmers face. The environmental control needs to be as precise as possible, as the effect of different light spectra or nutrients may have a significant impact on crop yield and quality. With this challenge in mind, Grobotic Systems brings a new solution to the market: a compact and highly instrumented growth chamber. “It’s an experimental chamber rather than a farming chamber. Therefore, you won’t use it to grow vegetables, but you can use it to identify which growing parameters are best suited to your crops,” Alexis says.

The Grobotic Systems team outside their workshop in Sheffield, England. From left to right: Dr Alexis Moschopoulos, Richard Banks, Andrew Merson, and Gareth Coleman. Credit: UKRI.

On your desk or under your bench

According to Alexis, the chamber fits on your desk or under your bench. It can apply any environmental condition preferred, including light spectra and temperature. Internet connection via the growth chambers allows users to monitor plants on their cellphones via integrated cameras and other sensors inside the chamber.

Another advantage of the chambers’ size is that they can be stacked in an array, adjusting variables in each chamber. In this way, a multi-variable experiment can help users identify which environment works most optimally for their intended crop. “When using a large cultivation room, it is hard to split the room into different temperatures. A smaller cultivation space, such as our growth chambers, can be placed anywhere, just like a personal computer. Moving away from the large expensive capital equipment and machinery to small and stackable experimental chambers saves a lot of space and money.”

Alexis first came up with the concept of the growth chamber during his PhD and postdoctoral work in plant genetics. Several prototypes are currently being used at research institutes and start-up companies. Grobotic Systems is working on a more advanced growth chamber that will be launched in the summer of 2021: “We are integrating feedback from the deployed prototypes into the design of the advanced chamber, and we will start marketing the advanced chamber later this year.”

Richard Banks designs a control system circuit board for an early prototype Grobotic chamber. Credit: UKRI.

Large-scale farms

Not only new farmers can benefit from running small-scale experiments in a growth chamber, but also large-scale, established farms, since the chamber allows them to experiment with new varieties, creating the optimal yield. This will in turn enable them to upscale their production. “Not all farmers like to invest their time in carrying out experiments, as some trust that the vertical farming technologies they buy will always work for them. However, in the end it could save them a lot of money. No one needs to use productive farm space to do the experiments, just a few manageable boxes can suffice.”

Gareth Coleman works on the chamber imaging and control systems. Credit: UKRI.

For more information:

Grobotic Systems

Dr Alexis Moschopoulos, Managing Director alexis@groboticsystems.com

www.groboticsystems.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

US - NEW MEXICO: ‘Farm in a Box’ Coming To Grants

The Farm in a Box operates inside a 40-foot shipping container, shown here in Moffat County, Colo. A similar one will be set up at New Mexico State University branch campus in Grants. (Courtesy of Tri-State Generation and Transmission)

ALBUQUERQUE, N.M. — Fresh, locally produced vegetables will soon sprout from hydroponic beds in an enclosed, converted shipping container parked at New Mexico State University’s branch campus in Grants.

The 40-foot “Farm in a Box” will provide hands-on education and workforce training for local students and others interested in studying the emerging science of “indoor agriculture” as a new, potentially sustainable, enterprise that could offer fresh economic development opportunities and job creation in an area hard hit by the transition from fossil fuels to renewable energy.

NMSU, the Tri-State Generation and Transmission Association, and the National Electric Power Research Institute (EPRI) are collaborating on the project.

It’s one of several initiatives under development with local, state, and federal backing to diversify economic activity in Cibola, McKinley, and San Juan counties, where coal-fired power plants and associated mining have provided a financial mainstay for workers and communities for decades.

Both Cibola and McKinley counties are reeling from last year’s shutdown of the coal-fired Escalante Generating Station near Grants, plus the closure of Marathon Petroleum’s oil refinery in Gallup, which together eliminated hundreds of stable, high-paying jobs in those northwestern communities.

Unemployment hit 10.8% in Cibola County in December and 10.2% in McKinley County, according to the state Department of Workforce Solutions. That compares to an 8.2% average statewide unemployment rate.

To ease the impact of Escalante’s closure and assist in transitioning local communities, Tri-State provided $5 million in grants in January to four local economic development organizations. It is also now sponsoring the Farm in a Box initiative, providing $250,000 to set up and equip the high-tech container unit that houses the indoor agricultural operation, with forthcoming grants for NMSU faculty and student assistants to work on the project.

“We realize that closing such coal facilities as the Escalante plant that have traditionally employed significant workforces creates very difficult challenges for local communities to replace those jobs,” Tri-State spokesman Mark Stutz said. “Our goal is to find opportunities in support of economic development with new technologies when we can.”

Tri-State permanently closed the 253-megawatt Escalante power plant in Pruitt last summer as part of the association’s long-term plan to completely withdraw from coal generation over the next decade. It laid off about two-thirds of the plant’s 107 employees, Stutz said.

TriState also plans to close a much larger, 1.3-gigawatt coal facility in Craig, a municipality in Moffat County, Colorado, where the company sponsored another Farm in a Box project that EPRI set up last November.

“We don’t want to just walk away from these communities that we’ve been a part of for decades,” Stutz said.

High tech

EPRI has set up similar Farm in a Box projects in 13 states, said its principal technical leader Frank Sharp, project manager for the institute’s indoor agriculture-and-lighting research efforts.

It’s part of an emerging concept of indoor farming for urban areas and isolated rural communities where food could be grown year-round right where it’s consumed. It could lead to huge energy and water savings through efficient, high-tech growing processes, contributing to carbon reduction by using electricity rather than fossil fuels in agricultural operations and by eliminating long-haul transport of produce to market.

For economically stressed communities such as Cibola and McKinley counties, it could be scaled beyond shipping containers to retrofit under-used or abandoned buildings and to construct new facilities, such as greenhouses, on empty plots, Sharp said.

“It all translates into community impact, job creation, and beneficial use of electricity,” Sharp told the Journal. “Vacated buildings with the infrastructure already in place can be retrofitted, with opportunities to also build new facilities.”

Electric Power Research Institute principal technical leader Frank Sharp, left, with Tri-State Generation and Transmission Association CEO Duane Highley, inside the Farm in a Box agricultural container that was set up in Moffat County, Colo., last November. (Courtesy of Tri-State Generation and Transmission)

Research needed

Research is still needed to maximize efficiency and production, measure benefits, make contained farming systems profitable, and train the workforce. That’s where NMSU comes in, said Jay Lillywhite, agricultural economics professor and co-director of NMSU’s center of Excellence in Sustainable Food and Agricultural Systems.

NMSU faculty and students will study the entire container system, which includes vertical, hanging plastic enclosures to grow crops connected to a closed-loop plumbing system to recycle all water. Researchers will monitor all energy and water use, plant productivity, the impact of red and blue LED lighting spectrums on plant growth, and the economics of the whole operation, Lillywhite said.

“We’ll record everything and transmit all the data wirelessly to EPRI,” Lillywhite said. “It needs to be profitable. Indoor agriculture has had mixed reviews in terms of profitability, so we’ll look at a model that makes sense for New Mexico and the Southwest.”

Other applications

Opportunities extend into many disciplines beyond agriculture, including electrical engineering focused on energy efficiency and renewable generation as alternative systems, such as solar panels, are added to indoor operations, said Rolando A. Flores, dean of NMSU’s College of Agriculture, Consumer, and Environmental Sciences.

“The project has excellent potential to address social, environmental, and economic facets of sustainability, and become a resource-efficiency model for urban agriculture, provided that renewable energy can be incorporated from the beginning,” he said.

State Rep. Patricia Lundstrom, D-Grants, said indoor agriculture can offer significant opportunities alongside other initiatives to diversify the local economy.

Lundstrom sponsored legislation last year that now allows counties with coal plants that are closing to set up special economic districts with bonding and taxing authorities to invest in infrastructure, business recruitment, and retention to create jobs and promote economic development.

That led to the launch in December of the McKinley County Electric Generating Facility Economic District, which is focused on converting the Escalante site in Pruitt into a new industrial zone to recruit more businesses to the area.

“Value-added agriculture is one of the opportunities we can work to develop there with help from the partners on this project,” Lundstrom said. “It can have a significant impact as we work to recruit new, sustainable industry to the local community.”

President Biden & The Future of Regenerative Agriculture In The US

With a new administration in Washington, the next few years could be interesting for efforts to improve agriculture production while addressing environmental issues at the same time

February 5, 2021

Editor’s note: Steve Groff is a farmer, a regenerative agriculture consultant, and the founder of Cover Crop Coaching, which educates farmers and farm advisors about effective cover crop use. The views expressed in this guest article are the author’s own and do not necessarily represent those of AFN.

With a new administration in Washington, the next few years could be interesting for efforts to improve agriculture production while addressing environmental issues at the same time.

President Joe Biden has expressed support for climate-friendly farming practices, but there are questions about what that ultimately will mean. Will helping American farms be a high priority for the new president or will it get lost amid other pressing concerns, including the Covid-19 pandemic? And just how open is a good portion of the agriculture community to the government getting involved in what they do?

Among other proposals, Biden has vowed to pursue policies that would expand and fortify the federal Conservation Stewardship Program. One desired result of this effort would be to make more money available for payments to farmers who reduce their carbon footprint through a variety of methods, including the use of cover crops.

While the big-business side of agriculture has been more willing to use government programs, grassroots farmers involved in regenerative agriculture tend to be leery of government programs and handouts. Most of them, in fact, suggest getting out of government-related programs – particularly the use of crop insurance.

Invest with Impact. Click here.

Those in the regenerative agriculture movement come from the perspective that we have ruined the resiliency of our soils and if we ‘regenerate’ them, they can better handle weather extremes brought on by climate change.

But one challenge for the regenerative agriculture movement is getting farmers educated on how to use these practices. That is a huge reason why I wrote my book, The Future Proof Farm. I wanted not only to educate but to inspire farmers to take their first step in that direction.

I firmly believe regenerative agriculture is scalable, as we now have large farms with thousands of acres that are successfully using these practices with little to no inputs such as fertilizers and pesticides.

And yes, most of those farms are doing it with no government help.

But on the other side are farmers drooling over the potential to get paid to use cover crops, no-till, and other soil health practices that can sequester carbon. Farmers are primed like never before to try those practices due to rising awareness over the past 20 years or so. In any business, it’s ‘all about the money’ – so if a farmer can get paid to engage in a good practice, it’s a favorable thing in their minds.

How do farmers feel about cover crops? We asked a cover crop coach – read more here

I am biased toward letting the market work, as we know there is a demand for food and fiber grown using regenerative agriculture – and we can accomplish what we need to without government help. With regenerative agriculture, we can lower our costs of production.

That being said, there are not enough resources to help farmers learn these methods. I believe we have an education hurdle – not a need for another handout. I also believe we need to take a deeper look at how regenerative agriculture actually leads to a more nutritious or nutrient-dense food product, whether it is fed to livestock or ends up on the kitchen table.

I do see some merit in the government helping farmers for a few years to get started in these carbon-sequestering practices, but more important are educational efforts to help farmers be effective in using those practices. The old adage applies: give a person a fish and you will be giving them fish for a lifetime; teach each person to fish, and they will meet their own needs for a lifetime.

If the Biden administration can somehow capture a holistic approach by supporting the education necessary for farmers to grow healthy food, it will be a win for producers, a win for the people, and a win for the planet.

Light Company LumiGrow Has Ceased Operations

The company has not shared specific information as to why operations have been ceased.

The lighting company LumiGrow has ceased operations and is now out of business.

LumiGrow was a company focused on LED lights, and it hit the headlines at the beginning of 2020 for the purple glow that illuminated the sky over Navajo County, Arizona, which was coming from a cannabis greenhouse where LumiGrow LEDs were installed.

The company has not shared specific information as to why operations have been ceased. For sure, the global pandemic together with the fierce competition in the LED sector of horticulture have had an impact.

Publication date: Tue 2 Feb 2021

Does Vertical Farming Actually Work?

Essentially, Bowery grows greens and other veggies in a nutrient-rich tray of water, which is consistently recycled in a closed-loop system

Feb. 03, 2021

In the outskirts of Newark, New Jersey, tucked between a packaging manufacturer and an aquatics center lies a farm. Except, if you're driving down the nearby highway you probably wouldn't be able to tell that this particular farm is churning out thousands of pounds of greens each year. In fact, all you'll see is a bunch of buildings, because this is a vertical farming operation called AeroFarms, which grows all their food in a warehouse. Like the owners of AeroFarms, tech enthusiasts across the world have embraced the dream of vertical farming, exclaiming that their operations are the answer to feeding a growing global population, combating climate change, and eradicating food deserts.

The many-shelved farming operation that is AeroFarms is just one of many companies that use vertical space to grow vegetables. What sets AeroFarms apart, however, is that it grows in a fine mist filled with nutrients instead of a typical growing environment like Rockwool and nutrient-rich water. But AeroFarms is an outlier in the vertical farming space. The typical vertical farm looks a lot more like that at Bowery, a company that uses a more traditional hydroponics system to grow their produce.

Essentially, Bowery grows greens and other veggies in a nutrient-rich tray of water, which is consistently recycled in a closed-loop system. This system is then replicated en masse and expanded not horizontally, but vertically to maximize space. But because all these plants are stacked on top of each other, access to light becomes a big obstacle, which means that each shelf is equipped with LED lights to act as artificial sunlight. Some operations like Plenty go even further by shining only the beneficial colors in the light spectrum for growth. While some of these large-scale vertical farms can quickly become laden with advanced technologies like robotic arms and AI monitoring systems, at their most basic, vertical farms use a combination of artificial sunlight and vertical space to maximize the amount of yield per acre. These food factories seem promising, but they also seem like a lot of work. So why are people so excited about them? For that answer and a deeper behind-the-scenes look at vertical farming, make sure to check out the video above.

Our Changing Climate is an environmental YouTube channel that explores the intersections of social, political, climatic, and food-based issues. The channel dives into topics like zero waste and nuclear energy in order to understand how to effectively tackle climate change and environmental destruction.

Columbia Vertical Farm Uses Technology To Cut Plastic Pollution And Boost Sustainability

The new packaging comes at no extra cost to the customer and will be cheaper in the long-run for Vertical Roots

Vertical Roots is the largest hydroponic container farm in the country. They grow and package lettuce varieties and have recently implemented a packaging process that reduces plastic with a resealable film. TRACY GLANTZ TGLANTZ@THESTATE.COM

With the use of agricultural technology, Vertical Roots farm in West Columbia created a packaging system for its leafy greens that cut down the company’s plastic usage by 30% and extends the shelf life of the lettuce.

In 2015, high school friends Andrew Hare and Matt Daniels created the idea for Vertical Roots, now the largest hydroponic container farm in the country. Hare is the general manager of the company and Daniels acts as the chief horticulturist.

The first Vertical Roots opened in Charleston and expanded with its second farm site in West Columbia in 2019. Vertical Roots parent company, AmplifiedAg, manufactures the container farms and farm technology of which Vertical Roots operates.

The farms are part of a growing industry called controlled environmental agriculture (CEA) that uses technology to ramp up nutrient-rich food production year around.

Hydroponics helps the farm uses 98% less water than traditional farming, according to Hare. Their technology creates an indoor environment to grow lettuce on the East Coast. Most lettuce in the U.S. comes from California and Arizona, where temperatures do not fluctuate much throughout the year, travelling 2,000 miles from farm to table. Vertical Roots offers a solution for local lettuce.

“Our mission is to revolutionize the way communities grow, distribute and consume food,” said Hare. As populations grow, Hare said the ability to produce enough food is a global concern.

VERTICAL ROOTS AGRICULTURAL INNOVATION

As a company committed to sustainability, Vertical Roots had to address its plastic usage and the consumer demand for environmentally friendly products.

“I think everyone can agree that the amount of plastic that’s consumed and used globally is a bit of a problem,” said Hare.

If Vertical Roots were to completely opt-out of using plastics, as much as 40% of the lettuce would be damaged in transportation to the retailers, Hare said. So the company decided to still use plastic containers in order to cut out food waste, but it changed the amount and type of plastic used.

By replacing the conventional “clamshell” plastic lids that you see on a container of lettuce at the grocery store, Vertical Roots cut down more than 30% of plastic usage by creating a resealable film lid. The new packaging comes at no extra cost to the customer and will be cheaper in the long-run for Vertical Roots, according to Hare.

The farm also uses recycled plastic that can also be recycled again after use. Tiny perforations in the film lid of the packaging allow air to leave the lettuce container and extends the product’s freshness, making Vertical Roots lettuce last around 14 days on the shelf.

“We tested respiration and condensation with each lettuce variety, and ultimately found that we could extend the freshness and shelf life of our salad mixes even more,” said Hare.

Vertical Roots, at the S.C. Farmer’s Market, is the largest hydroponic container farm in the country. They grow and package lettuce varieties. Tracy Glantz TGLANTZ@THESTATE.COM

GROWTH IN THE AGRICULTURAL TECHNOLOGY INDUSTRY

In the first three quarters of 2020, a record $754 million of venture capital was invested in the vertical farming industry, according to PitchBook data. This was a 34% increase from the entire previous year, Bloomberg reported in a January article.

A 2019 report from Global Market Insights showed that the vertical farming market size, or the number of potential customers or unit sales, surpassed $3 billion in 2018 and said it, “will exhibit a massive compound annual growth rate (CAGR) of over 27% from 2019 to 2026.”

In vertical farms, crops are harvested on several vertical layers indoors, where farmers can grow year-round by controlling light, temperature, water and other factors, according to the U.S. Department of Agriculture.

Vertical agriculture is also seen as a growing industry because it “could help increase food production and expand agricultural operations as the world’s population is projected to exceed 9 billion by 2050,” according to the USDA.

However, some are skeptical about the future of vertical farming for several reasons. The farms use LED light bulbs to grow crops, which require a lot of energy and money to operate.

Also, the farms mostly produce greens, which are low in calories because they take less water and light. The new farming technology is marketed as a way to combat world hunger, but in poorer countries, low-calorie greens are not as beneficial, according to Bloomberg.

THE FUTURE OF VERTICAL ROOTS

Despite a tough year due to COVID-19, Vertical Roots will open two more indoor, container farms in Georgia and Florida in 2021.

The company lost revenue from foodservice customers like restaurants, schools and universities during the pandemic, said Hare.

Those food service customers accounted for about half of Vertical Roots’ business, Hare said. Grocery store business stayed steady and even grew during the pandemic. As schools and restaurants are slowly reopening, Vertical Roots is gaining business back.

The West Columbia farm location produces about $1.5 million pounds of produce per year, said Hare. Vertical Roots lettuce is in 1,200 different grocery stores in 11 states, including Lowes Foods stores, Publix, Harris Teeter and Whole Foods Market chains.

Hare said the company is constantly working on sustainable initiatives, including figuring out a way to reduce light energy consumption by 20-25%, thinking about compostable packaging systems and finding ways to use less water at the farms.

In the future, Vertical Roots hopes to offer a larger variety of produce. The team is experimenting with growing foods like tomatoes, cucumbers, peppers, herbs and mushrooms to see if they could be viable products.

At 25,000 square feet, the world's first indoor vertical farm is also one of the largest farms. Located 120 miles south of Seoul, South Korea, fruits and vegetables grow without soil, bathed in light from pink LEDs. BY META VIERS

1 of 3

Vertical Roots, at the S.C. Farmer’s Market, is the largest hydroponic container farm in the country. They grow and package lettuce varieties. TRACY GLANTZ TGLANTZ@THESTATE.COM

Vertical Farming’s Sky-High Ambitions Cut Short By EU

Startups argue tough rules are blocking innovation in a sector that shares Brussels’ green goals

01-02-2021 | Politico

Startups argue tough rules are blocking innovation in a sector that shares Brussels’ green goals. Anders Riemann's indoor farm in the suburbs of Copenhagen is pesticide-free, chemical fertilizer-free, and promises not to emit any greenhouse gases into the environment. Indeed, his type of vertical farm — with greens stacked 14 levels deep — is often hailed as the future of food production in parts of the world where affordable farmland is scarce.

But under the EU’s strict rules, his company Nordic Harvest won’t be able to label its products as organic, which is precisely the premium market that eco-friendly vertical farmers want to sell into.

Supporters of more sustainable agriculture have high hopes of vertical farms not only because they save space but also because they often incorporate technology to save water and energy.

Vertical farms also work with hydroponic planting, which uses mineral nutrient solutions instead of soil. And it's the soil that's the problem, when it comes to being organic. EU regulation demands soil — which hydroponic production lacks by definition — as a feature of organic farming, meaning Nordic Harvest won't be able to use the term on labels when it begins deliveries of its produce next month.

“It’s ridiculous," said Riemann, the chief executive of Nordic Harvest, which is Europe’s largest vertical farm operation and recently raised 62 million Danish Kroner (€8.3 million) in its first investment round. "The EU regulation [has] slightly blocked our innovation by defining organic as being only produced in soil.”

That could make it harder for Nordic Harvest and a growing number of similar vertical farm startups to signal to shoppers their sustainable philosophy at a time when the EU is aiming to promote such green principles under its Farm to Fork food strategy.

Nordic Harvest plans to grow 1,000 metric tons of spinach, rucola, basil, mint, and coriander each year, powered by 100 percent certified wind energy. Riemann said that growing the same amount of produce using traditional farm practices would entail 467 hectares of land — land which Riemann said could be better put toward removing and storing carbon from the atmosphere.

Moreover, the former investment banker claims that vertical farming's potential is so great that it could cover all of Denmark’s salad and herb needs with just 20 urban farms.

An EU official said “organic plant production is based on nourishing the plants primarily through the soil ecosystem,” which means “plants should be produced on and in living soil in connection with the subsoil and bedrock. This is a fundamental principle of organic production.”

Consequently, “vertical farming based on hydroponic production does not comply with the rules on organic production,” the official added.

The EU isn't alone in its strict definition of tying organic labels to soil requirements, and the U.S. is one of the few outlier countries where hydroponic production can be considered organic if producers comply with other criteria. Some in the traditional organic industry, which is already struggling to carve out a niche for its own more established and often costlier green practices, argue hydroponics don't capture the spirit of the movement as it's not directly rooted in the ecosystem.

Eric Gall, deputy director of the organic farm trade association IFOAM Organics Europe, said that calling something organic obliges the producer to follow certain rules regarding soil.

“It doesn’t mean vertical farming is not good — it’s probably great — but it can’t be called organic,” Gall said. “It’s not a matter of discrimination but of having clear principles to decide what is and what is not organic.”

Nordic Harvest now plans to use its own labels with phrases like “Where are my pesticides?” But when a nominally organic apple can be flown from New Zealand to Denmark and receive an instantly recognizable eco-label, Riemann says the EU’s organic rules are “cheating the consumer.”

Despite such limitations, Nordic Harvest aims to push ahead with plans for expansion across Scandinavia and to start growing strawberries and blueberries in Denmark by 2024.

Still, new EU public procurement rules that are supposed to bolster demand for organic foods as part of the Farm to Fork strategy may further dent the upstart sector's share in the eco-conscious market.

“It definitely discriminates against vertical farming,” Riemann said. “But nobody thought about it before vertical farming was established.”

Photo: A robot, used to plant seeds and check the plants while growing, moves past vertical racks at the vertical plant farm 'Nordic Harvest'. Credit: AFP

Source: Politico

VIDEO: Kentucky Greenhouse Company AppHarvest Goes Public On Nasdaq As It Prepares To Grow

AppHarvest has estimated it will generate net revenue of $21 million in 2021. The company is expected to produce 45 million pounds of tomatoes annually. AppHarvest employs 300 Eastern Kentuckians

FEBRUARY 03, 2021

AppHarvest has estimated it will generate net revenue of $21 million in 2021.

The company is expected to produce 45 million pounds of tomatoes annually. AppHarvest employs 300 Eastern Kentuckians.

David Wicks, Nasdaq’s vice president of new listings, said he was “incredibly proud to be your partner and look forward to supporting your innovation as a NASDAQ listing company” in a video message Monday.

Founder and CEO Jonathan Webb eats an AppHarvest tomato in a video message displayed in Times Square on Monday.

Two weeks ago, AppHarvest shipped its first bundle of tomatoes from its flagship location in Morehead.

“All this noise that is happening around us — listing on the Nasdaq and being shown in Times Square, selling our tomatoes to the largest grocers in the U.S. — all that is resonating back on the ground inside of our facility where our employees are feeling the positive impact of the work we’re all doing together,” Webb said.

The beefsteak tomatoes are selling out at grocers around the country.

“We can’t grow fast enough,” he said. “Our tomatoes are hitting store shelves and flying off the store shelves. It’s not just Kentucky, it’s everywhere from Indiana, all the way down to Florida.”

Webb said the company’s job now is to build faster and grow more vegetables to get on store shelves.

The company continues to look throughout Eastern Kentucky for building sites, Webb said, but there are challenges.

“We just have to find a place to build,” he said. “We have the capital. We want to build there, but building on these reclaimed coal mine sites are incredibly challenging and very expensive to try to make work. We would love to be there.”

The first greenhouse was originally planned for Pikeville, but AppHarvest said the site, a reclaimed strip mine, was not feasible for construction. After about two years of delays, AppHarvest announced its decision to relocate to a 350-acre parcel about two miles off I-64 near the Sharkey community of Rowan County.

Webb said they continue to invest in Pike County with a container farm at Shelby Valley High School. AppHarvest has two other farms at schools in Rowan and Breathitt counties.

The company aims to have 12 facilities growing and supplying fruits and vegetables by 2025. AppHarvest already announced a Berea facility to grow leafy greens and a Richmond facility to grow vine crops.

“One massive impact of 12 facilities is we’re going to have hundreds of millions of pounds of fresh fruits and vegetables pouring out of our region,” Webb said. “Not only the economic benefits of that, but the health benefits are tremendous. We’re in a situation where not many companies can say they feel incredibly proud of the product they produce and we do that.”

The first AppHarvest tomatoes will be in grocery stores by Wednesday, Jan. 20, 2021.

Photos: COURTESY OF APPHARVEST

Liz Moomey is a Reporter for America Corps member covering Eastern Kentucky for the Lexington Herald-Leader. She is based in Pikeville.

Pure Flavor® Receives International Taste Award For New Cloud 9® Tomato

Strategically grown in high-tech greenhouses in Canada, USA, and Mexico, Cloud 9® Bite-Sized Fruity Tomatoes are available year-round

Leamington, ON (February 1st, 2021) – While consumers continue to look for more healthy snacks in the fresh produce aisle, greenhouse vegetable grower Pure Flavor® is launching their new Cloud 9® Bite-Sized Fruity Tomatoes to help meet the growing demand for consistently flavorful options. After extensive product trials and consumer taste testing, many are heralding the new tomato variety as an everyday snack game changer.

“We taste hundreds of tomatoes every year searching for something special - unique colors, shapes, sizes, but most importantly flavor. From the first taste of the Cloud 9® variety, we knew we had found it”, said Jamie Moracci, President. With fruit like flavor, the new Cloud 9® Tomatoes are going to redefine what snacking tomatoes should taste like as an everyday item, not just as color in a salad. “We have created the Cloud 9® Standard for quality and look forward to consumers enjoying this premium and hand-selected bite-sized tomato every day”, said Moracci.

Strategically grown in high-tech greenhouses in Canada, USA, and Mexico, Cloud 9® Bite-Sized Fruity Tomatoes are available year-round. With a distinct color, unique shape, and a fruit-like flavor profile, Pure Flavor® has conducted extensive product trials in key growing regions to create the appropriate growing formula to consistently produce an exceptional snacking tomato.

“From the first bite, you know this will be memorable: it’s a fresh snacking experience that comes from an unwavering commitment to quality”, commented Matt Mastronardi, Executive Vice-President. Available in a variety of formats, Pure Flavor®’s award-winning Cloud 9® Tomato is available starting February 1st to be shipped throughout North America. “We hand-select a limited quantity of the most vibrant tomatoes so you can enjoy bold, balanced flavor that sweetens any snack or homecooked meal”, said Mastronardi.

Pure Flavor® recently received the prestigious Superior Taste Award Certification from the International Taste Institute (Brussels, Belgium) for the Cloud 9® Tomato. The reviewing Jury, consisting of more than 200 renowned European Chefs & Sommeliers from over 20 countries, critically tested & analyzed the Cloud 9® Tomato and highlighted these characteristics to award the product the Superior Taste designation:

Very clear, ripe tomato flavor with a marked sweetness; the taste lingers for a long time on your palate

These tomatoes have an original shape, and the size makes them ideal as a snack or for use in the kitchen

An intense red color with a soft texture and sweet taste; nice and juicy – good balance between sweetness & acidity

The product is very versatile; can be used in numerous different recipes and types of cuisines, suitable as a snack, in pasta, salads, stews, with various proteins (beef, poultry, fish), or even a Gazpacho

“It’s a strict process where all products are blind tasted; this means that the samples are anonymized, we do not see the packaging and do not know the brand name nor the producers’ name - we don’t even know from which country the product comes from. This forces us to be completely objective as we do the sensory analysis. Only truly good products are certified”, stated Stijn Roelandt – Sous-Chef at Hof van Cleve, 3 Michelin stars and member of the Jury, International Taste Institute.

The launch of a sweeter snacking tomato comes at a time when consumers are looking to enjoy a wider variety of healthy foods to eat at home. Cloud 9® offers consumers a healthy new snack option that will “make life’s sweetest moments even sweeter” – figuratively and of course, quite literally.

Video #1: https://youtu.be/CrsCQTszdp0

Video #2: https://youtu.be/hQIwq8M2Tfs

“The award-winning Cloud 9® tomatoes burst with a fruity sweetness that enriches any dish or eating occasion, every recipe you create deserves to be a showstopper”, said Chris Veillon, Chief Marketing Officer.

In anticipation of the new product launch, Pure Flavor® spent the last 16+ months developing the Cloud 9® brand to ensure that consumers could go beyond the package to enjoy all aspects of the tomato.

“Our team has developed dozens of recipes, conducted in person tasting surveys before the pandemic and hundreds of digital preference surveys during the Love For Fresh campaign late last fall, to creating engaging web & social content in lifestyle situations – we needed to effectively communicate that Cloud 9® is not just another salad topper, it’s the sweetness you crave with the quality you deserve. We think it’s a tiny taste of heaven™”, said Veillon.

To learn more about Cloud 9® Bite-Sized Fruity Tomatoes, please visit: https://www.pure-flavor.com/cloud9/

-30-

About Pure Flavor® -

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise.

We are the next generation of vegetable growers, inspired to put quality, flavor, and customers first by providing greenhouse-grown vegetables from our farms that are strategically located throughout North America.

About the International Taste Institute –

The International Taste Institute, founded in 2005 and based in Brussels, Belgium, evaluates and certifies the taste of food and drink from all over the world. Its jury is composed of over 200 renowned Chefs and Sommeliers from 15 European culinary or sommeliers associations.

The Taste Institutes performs objective sensory evaluation: its jury follows a rigorous blind tasting methodology in which product samples are anonymized to avoid any bias in the scoring. In addition to the scoring of the various sensory analysis criteria, the jury provides comments and eventually suggestions for further product improvement or food pairing suggestions.

(Assistant) Professor Crop Modelling In Greenhouses And Vertical Farms (Tenure Track)

Are you keen to contribute to the sustainable production of healthy fresh vegetables? We have a vacancy for an Assistant professor of Crop modelling in Greenhouses and vertical farms. Do you like to supervise students? Do you want to combine modelling and data analytics with plant experimentations? Then this position could be a perfect fit for you!

The chair group Horticulture and Product Physiology of Wageningen University & Research (WUR) is keen to hire an Assistant Professor (0.7-1.0 ft). As an Assistant Professor, you will take a leading role in developing research and education and the opportunity to establish your own research and education in crop modeling in greenhouses and vertical farms.

This position also involves experimental physiological work at the plant organ, whole plant or whole crop level, which is necessary to build, calibrate and validate models.

In this challenging career trajectory:

You will perform research on modeling, combined with experimentation, of growth, development, and quality of horticultural crops and products (vegetables, fruits, cut flowers, and/or pot plants).

You acquire, lead and implement together with the chair holder and other staff members innovative and creative (inter-)national research projects for our group. Once acquired you also implement and lead these projects.

You supervise Ph.D., MSc, and BSc students, and you will develop and teach courses (lectures, practicals) on the modeling of key plant processes in greenhouses and vertical farms.

Your work will focus on the development of models, which are a combination of multiscale Spatio-temporal data-driven, as well as knowledge-based models. Model applications may include predictions of yield, plant development and growth, quality, post-harvest behavior, resource use and running costs for crops grown in greenhouses and vertical farms

You collaborate with colleagues and establish a personal research portfolio that is embedded in the Horticulture and Product Physiology group

You undertake research on modeling and data analytics, combined with experimentation, that leads to high-quality research output.

You will perform research on modeling, combined with experimentation, of growth, development, and quality of horticultural crops and products (vegetables, fruits, cut flowers, and/or pot plants).

Tenure Track is a career path for scientists who pursue to excel in education and research. We seek to attract scientific talent and to stimulate and support their development.

Requirements:

You hold a Ph.D. degree in plant science, mathematical science, biological science, data science, or similar.

You have experience in modeling and data analytics, as well as a keen interest in combining these activities with experimentation with plants.

You have published research in high-quality journals and are willing to develop your skills in teaching and grant proposal acquisition.

You are strong in stakeholder management because you need to communicate the importance and significance of your research.

This position requires excellent English language proficiency (a minimum of CEFR C2 level). For more information about this proficiency level, please visit our special language page.

The chair group Horticulture & Product Physiology

The chair group Horticulture and Product Physiology conduct high impact research and educate students providing the scientific basis required to answer questions that are of utmost importance for sustainable crop production and product quality in horticulture.

The research focus is on how physiological processes in crops, plants, and plant organs interact with the abiotic environment and how this affects crop production and product quality. Questions arising from horticultural practice are translated into fundamental research topics, aiming to explain mechanisms. The research and education contribute to sustainably feeding the World with healthy high-quality products.

The chair group is an international team consisting of 15 permanent staff members, about 25 Ph.D. candidates and postdocs, and a number of guest researchers. Each year about 40 MSc students conduct their thesis study (6-month research) at our group. We organize and participate in a variety of courses for BSc and MSc students to transfer knowledge on horticulture (pre-and post-harvest), environmental physiology, and product quality.

More info about the chair group can be found at www.hpp.wur.nl or see the video below:

Salary Benefits:

Wageningen University & Research offers excellent terms of employment. A few highlights from our Collective Labour Agreement:

sabbatical leave, study leave, and paid parental leave;

working hours that can be discussed and arranged so that they allow for the best possible work-life balance;

the option to accrue additional flexible hours by working more, up to 40 hours per week;

there is a strong focus on vitality and you can make use of the sports facilities available on campus for a small fee;

a fixed December bonus of 8.3%;

excellent ABP pension regulations.

In addition to these first-rate employee benefits, you will be offered a fixed-term, 7-year contract which, upon positive evaluation based on criteria elaborated in the University's Tenure Track policy, can lead to a permanent employment contract as a professor. Depending on your experience, we offer a competitive salary of between € 3.746,- and € 5.127,- (assistant professor position) for a full-time working week of 38 hours in accordance with the Collective Labour Agreements for Dutch Universities (CAO-NU) (scale 11). The position can be part-time or full-time (0.7-1.0 ft).

Wageningen University & Research encourages internal advancement opportunities and mobility with an internal recruitment policy. There are plenty of options for personal initiative in a learning environment, and we provide excellent training opportunities. We are offering a unique position in an international environment with a pleasant and open working atmosphere.

You are going to work at the greenest and most innovative campus in Holland, and at a university that has been chosen as the "Best University" in the Netherlands for the 16th consecutive time.

Coming from abroad

Wageningen University & Research is the university and research center for life sciences. The themes we deal with are relevant to everyone around the world and Wageningen, therefore, has a large international community and a lot to offer to international employees. Applicants from abroad moving to the Netherlands may qualify for special tax relief, known as the 30% ruling. Our team of advisors on Dutch immigration procedures will help you with the visa application procedures for yourself and, if applicable, for your family.

Feeling welcome also has everything to do with being well informed. Wageningen University & Research's International Community page contains practical information about what we can do to support international employees and students coming to Wageningen. Furthermore, we can assist you with any additional advice and information about helping your partner to find a job, housing, schooling, and other issues.

Work Hours: 38 hours per week

Address: Droevendaalsesteeg

Women In Agribusiness Announces WIA Europe, New Career Board And Meet Ups

Building off its successful 2020 virtual Women in Agribusiness (WIA) events, U.S.-based HighQuest Group has announced the lineup of events for 2021, starting with the Women in Agribusiness Summit Europe virtual conference on 8-10 March 2021

BOSTON, 2021 – Building off its successful 2020 virtual Women in Agribusiness (WIA) events, U.S.-based HighQuest Group has announced the lineup of events for 2021, starting with the Women in Agribusiness Summit Europe virtual conference on 8-10 March 2021.

The three-day virtual event, with live content from exceptional speakers, will continue the year-round agribusiness conversation among the Women in Agribusiness (WIA) community, which is thousands strong and growing each day. The Summit will include two virtual tours, an integrated platform that is the portal to knowledge and networking, and the promise of connecting with speakers and attendees from several countries.

The agenda includes discussions on how upstream agriculture in the EU can be made more sustainable, opportunities in plant-based foods, supply chain challenges and possibilities, and a special two-hour strategic networking workshop. Speakers include Jaine Chisholm Caunt, director general of GAFTA; Geraldine Kutas, director general, European Crop Protection Association; and Dorothy Dalton, CEO of 3Plus International Ltd. Registration is now open, along with the chance to take a peek at the 2020 U.S. event to learn more about the conference.

“If the last year has shown anything, it is that staying connected is imperative to advancing your business,” said Joy O’Shaughnessy, event director and chief operating officer of HighQuest Group, the parent company of Women in Agribusiness. “Our commitment in providing networking opportunities to nurture and expand, as well as the knowledge and know-how to stay relevant, has not waivered during a year of unknowns, and we are grateful to continue to service the WIA community.”

Along those lines, WIA announced the start of its European WIA Meet Up dates for 2021. WIA Meet Ups are a night of networking from the comfort of one’s own home, while making new contacts and building new business relationships.

Admission is free to WIA members (US$10 for non-members), and one can join and register here: womeninag.com/membership.

2021 Virtual WIA Meet Up – Europe

· Thursday, 14 January – 6 p.m. CET

· Thursday, 11 February – 6 p.m. CET

Connect With Opportunity

In keeping with opening new doors within the ag sector, Women in Agribusiness has introduced the WIA Career Connector. The multi-tiered website offers opportunities for both employers and job seekers in its goal to connect talent with opportunity. Visitors to the site – careers.womeninag.com – can post new jobs, examine featured jobs, search by candidate, and get assistance with resume creation, job interview skills and much more. The world’s largest food and ag companies are already using the WIA Career Connector, and its contents will be freely shared with the WIA community of over 10,000.

Visit womeninag.com to make plans now to join the burgeoning WIA community in 2021. Also visit us @Womeninagri, on Facebook and LinkedIn.

# # #

About Women in Agribusiness

The annual Women in Agribusiness Summit in the U.S., which started in 2012, is renowned for annually convening close to 1,000 of the country’s female agribusiness decision-makers, with 30 percent at the CEO/executive level and another 25 percent at department management level. Women in Agribusiness Summit Europe debuted in Barcelona, Spain, in February 2015, which was praised by an executive in attendance for being “a solutions-oriented event that also brought up current trends in the market” and “a uniquely-focused agricultural event for women”.

WIA initiatives have grown to include the WIA Membership, WIA Demeter Award of Excellence, Scholarships, and the WIA Today blog. Learn more at womeninag.com.

This Startup Wants Vertical Farmers To Hire A Robot Gardener

“By automating the production with robotics and remote monitoring, we can lower labor costs and offer solutions for food producers that are economically viable and environmentally sustainable,” the company claims on their website.

Arugula micro greens are grown at AeroFarms on February 19, 2019, in Newark, New Jersey.

Photo: Photo by Angela Weiss (Getty Images)

In recent years, vertical farming has emerged as a futurist’s solution to the world’s agricultural problems. The growing trend seeks to use controlled environments to boost food production, leveraging indoor labs where temperature, light, and nutrients can be mechanically controlled.

Yet while vertical farms have gained in popularity, they are also still very expensive. When compared to conventional farming, these farms necessitate the purchase of pricey equipment to aid human labor—a fact that, when paired with other economic pressures, has apparently led to an industry “littered with bankruptcies.”

One company hopes to change this dire picture. Enter Watney the robot.

Watney was designed by start-up Seasony. The company, which was featured today at this year’s Alchemist Accelerator’s Demo Day, has sought to make the tech-farming trend more accessible by automating away some of the more difficult labor involved.

Image: Screenshot: Youtube/TV2LORRY

“By automating the production with robotics and remote monitoring, we can lower labor costs and offer solutions for food producers that is economically viable and environmentally sustainable,” the company claims on their website.

Indeed, Watney is designed to augment (and, in many ways, replace) a human labor force—currently one of the biggest expenditures for vertical farms. Essentially an intelligent, automated cart, the robot was designed to “move and transport plant trays” within a farming hub. In techno-jargon, it is an autonomous mobile manipulation robot (AMMR), a type of machine known for moving and manipulating items on its own. It is also equipped with a camera that captures image data and sends it back to farm management software for human analysis. Watney also gathers valuable horticultural data to help farmers optimize yields, said Christopher Weis Thomasen, Seasony’s CEO and Co-Founder, in an email.

From left to right: Erkan Tosti Taskiran, Servet Coskun and Christopher Weis Thomasen.

Photo: Photo from Seasony.

“We are doing for vertical farming what the integration of autonomous mobile robots did to amazon. We are able to decrease the costs of growing food in a vertical farm by alleviating the logistics pains of working from scissor lifts,” said Thomasen.

Thomasen, a mechanical engineer, and his two co-founders electrical engineer Servet Coskun and business specialist Erkan Tosti Taskiran, were inspired to create the business while brainstorming what it would take to sustain life in outer space (Watney the robot is named after Mark Watney, the astronaut in the movie The Martian, who, after being stranded on the Red Planet, fertilizes potatoes with his own poop to survive).

“It quickly evolved to Seasony setting up a vertical farming lab and exploring the technical challenges facing the new industry. Reducing the costs related to labor is key in order to scale vertical farming and make agriculture more sustainable,” Thomasen said.

There is, of course, some debate in the farming community about the social costs incurred through the large-scale displacement of human labor.

Presumably, we will have to wait to see what that cost-saving process looks like. Seasony, which is still getting off the ground, plans to do a pilot trial with the largest vertical farm in Europe in April. It has plans to conduct further testing with several smaller vertical farms, as well, Thomasen said.

Lucas Ropek

Staff writer at Gizmodo

Lumileds Addresses Industry Growth With LUXEON 3030 HE Plus Horticulture

The new LEDs are engineered for robust sulfur protection – critical for long and stable lifetime in warm and humid environments

Broad spectrum white LEDs are widely available

San Jose, CA – February 2, 2021 – Lumileds today announced immediate high quantity availability of its LUXEON 3030 HE Plus Horticulture LEDs. Based on the company’s leading 3030 LED portfolio and characterized for horticulture, the new options offer high PPF/W, broad-spectrum white light that enables grow lights that are productive and economical.

“In horticulture applications growers are looking for time tested, top performance and reliability, the LUXEON 3030 HE Plus Horticulture delivers the photons that enable consistent and high growth output with the highest of efficiencies,” said Mei Yi, Product Manager.

The new LEDs are engineered for robust sulfur protection – critical for long and stable lifetime in warm and humid environments – and are specified for horticulture at 65mA and Tj= 25°C with CCTs from 2200K to 6500K and CRI of 70, 80 or 90. When matched with LUXEON Deep Red and Far Red options a complete horticulture illumination solution is at hand.

LUXEON 3030 HE Plus Horticulture is available in manufacturing quantities today. It offers a 0.1V forward voltage bin, quadrant color bin inside 3SDCM, and a maximum drive current of 480mA. Detailed product information can be found at https://lumileds.com/3030Horticulture.

About Lumileds

For automotive, mobile, IoT, and illumination companies that require innovative lighting solutions, Lumileds is a global leader employing more than 7,000 team members operating in over 30 countries. Lumileds partners with its customers to push the boundaries of light.

To learn more about our portfolio of lighting solutions, visit lumileds.com.

For further information, please contact:

Steve Landau, Director Marketing Communications

+1 408 710 4090

AppHarvest Makes Initial Donation of 2,500 Pounds of Tomatoes To God’s Pantry Food Bank

AgTech leader AppHarvest today announced it has delivered 2,500 pounds of Beefsteak tomatoes from its first harvest this week to God's Pantry Food Bank, which will distribute them to those in need

Company designated portion of the first harvest of fresh, sustainably grown tomatoes to feed Kentuckians in need

JANUARY 22, 2021 — MOREHEAD, KY — AgTech leader AppHarvest today announced it has delivered 2,500 pounds of Beefsteak tomatoes from its first harvest this week to God's Pantry Food Bank, which will distribute them to those in need.

Through its 400-plus distribution partners, God’s Pantry Food Bank provides food to residents of 50 Kentucky counties, focused on Eastern and Central Kentucky. The organization, which operates a distribution center in Morehead — the home of AppHarvest’s 60-acre indoor farm — distributed nearly 14 million pounds of fresh fruits and veggies and more than 41 million pounds of food overall during its most recent fiscal year.

“The faith and grit of Eastern Kentuckians has built one of the world’s largest high-tech greenhouses, and we appreciate the opportunity to share what we’re growing with those in need as we all work to create a resilient food system,” said AppHarvest Founder & CEO Jonathan Webb in delivering the donated tomatoes on Friday. “We’re working to create America’s AgTech capital here in Appalachia to provide affordable, nutritious, and delicious fruits and veggies that will help reduce hunger and food deserts.”

“God’s Pantry Food Bank is thrilled to engage with AppHarvest to nourish more lives through sustainable agriculture,” said CEO Michael Halligan. “There are more than 250,000 kids, adults, and seniors across Central and Eastern Kentucky who are not sure when they might have their next meal. Imagine the impact of now having a sandwich with a fresh, Kentucky-grown slice of tomato on the top.”

The donation is one of many steps AppHarvest is taking to address America’s food crisis. In Kentucky alone, 20 percent of children and nearly 15 percent of adults experience food insecurity.1 Nationally, the U.S. Centers for Disease Control and Prevention has found only one in 10 adults eat enough fruits and veggies.2

By building closer to consumers, AppHarvest provides fresher fruits and vegetables at affordable prices. The company is also focused on helping students grow their own food through its high-tech educational container farm program. Started in 2018 prior to the company’s operations commencing at its indoor farm in Morehead, the program retrofits shipping containers with high-tech farming equipment to teach students to grow healthy leafy greens. The program started at Shelby Valley High School in Pike County and has since expanded to Rowan and Breathitt counties, with additional units planned. AppHarvest also recently partnered with Save the Children to provide more than 1,600 leafy green growing kits to Kentucky kids in need.

1 Feeding America

2 U.S. Centers for Disease Control and Prevention

“AppHarvest was founded as a benefit corporation and has also been certified as a B Corp by the independent non-profit B Lab, because we believe companies should be in the business of doing good,” said Amy Samples, AppHarvest’s Director of Community Outreach and People Programs. “We’re building America’s AgTech capital from within Appalachia and know that education is core to achieving that.”

Shipments from AppHarvest’s first harvest this week are now available at select national retailers such as Kroger, Publix, Walmart, Food City, and Meijer. The company’s Morehead facility alone is expected to produce about 45 million pounds of tomatoes annually from about 720,000 tomato plants, a mix of Beefsteak and “Tomatoes on the Vine.”

AppHarvest has two more facilities under construction—a similar 60-plus acre facility outside Richmond, Ky., and a 15-acre facility to grow leafy greens in Berea, Ky. AppHarvest also is planning for more facilities across Kentucky and Central Appalachia, with the goal of 12 total farms by the end of 2025.

About AppHarvest

AppHarvest is an applied technology company building some of the world’s largest indoor farms in Appalachia. The Company combines conventional agricultural techniques with cutting-edge technology and is addressing key issues including improving access for all to nutritious food, farming more sustainably, building a home-grown food supply, and increasing investment in Appalachia. The Company’s 60-acre Morehead, KY facility is among the largest indoor farms in the U.S. For more information, visit https://www.appharvest.com/.

Forward-Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “will,” “estimate,” “continue,” “anticipate,” “intend,” “expect,” “should,” “would,” “plan,” “predict,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this press release, regarding Novus Capital’s proposed acquisition of AppHarvest, Novus Capital’s ability to consummate the transaction, the benefits of the transaction and the combined company’s future financial performance, as well as the combined company’s growth plans and strategy, future operations, estimated financial position, estimated revenues and losses, projected costs, prospects, plans and objectives of management are forward-looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of AppHarvest’s management and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AppHarvest. These forward-looking statements are subject to a number of risks and uncertainties, including those discussed in Novus Capital’s registration statement on Form S-4, filed with the SEC on October 9, 2020 (the “Registration Statement”), under the heading “Risk Factors,” and other documents Novus Capital has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. In addition, forward-looking statements reflect AppHarvest’s expectations, plans, or forecasts of future events and views as of the date of this press release. AppHarvest anticipates that subsequent events and developments will cause its assessments to change. However, while AppHarvest may elect to update these forward-looking statements at some point in the future, AppHarvest specifically disclaims any obligation to do so. These forward-looking statements should not be relied upon as representing AppHarvest’s assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Plants Talk: Creating The Perfect Environment For Growth

There’s more to growing the greatest greens on the planet than just using less water.

Nate Klingler

It is well known that plants grow best when the weather is just right. Traditional farming methods have developed ways to combat mother nature by using an abundance of water, pesticides, herbicides, and chemical fertilizers. Crops are also transported, typically from California to Arizona, in the Fall and Winter months due to the changes in climate at that time of year. While these methods can help us adapt and grow crops in less than ideal conditions, they present potential problems, from resource consumption to introducing bacteria and disease into the crop. At Living Greens Farm, we have developed the perfect environment for our plants.

Hi, I’m Michelle Keller, Head Grower at Living Greens Farm. If you’ve been following along, you’ve seen how our non-GMO seeds grow into seedlings and eventually move from the nursery into our grow rooms. We recently showed you how we use 95% less water with our trolly mist system. But there’s more to growing the greatest greens on the planet than just using less water. Things like temperature, light, and air affect the plant’s growth.

Temperature is an easy element to control when you grow indoors. As the world’s largest indoor aeroponic farm, we have the responsibility to ensure that our grow rooms are highly regulated. That is why we continually monitor the temperature, not just for the health of our plants, but to make sure our energy consumption is at a responsible level.

Creating the Perfect Taste

We grow indoors to regulate the perfect amount of light given to the plants at just the right time. Our technology utilizes low energy LED lights that simulate sunlight and allow the plants to perform photosynthesis without being overwhelmed. This is one of the reasons our plants are known for their color and flavor. We’ve harnessed the energy of the sun and we give it to our plants right when they need the energy.

And we wouldn’t be an aeroponic farm without harnessing the power of the air. Our plants are grown in vertical grow racks and are challenged with the force of air which makes them stronger. When people eat Living Greens Farm salads for the first time, we are often asked how our greens are so crisp. Well, it’s because we grow our plants to be the strongest they can be.

Bringing Mother Nature Indoors

Controlling mother nature will always be a losing battle for traditional farmers. As the next generation of farming, we’ve brought mother nature indoors and can control the elements to grow the tastiest, healthiest greens on the planet.

VIDEO: Potato Seeds Made Without Soil With Little Help From Peru

Scientists say that in aeroponics technique, potato seeds are grown in mist environment. Potato seeds grown through this technology are free from soil-borne diseases. Potato Technology Centre has established three units which have the capacity to grow 10 lakh minitubers

Parveen Arora

Potato Technology Centre, (PTC) Shamgarh, in the district in collaboration with Central Potato Research Institute (CPRI) in Shimla and International Potato Centre (CIP), Peru, has started producing potato seeds in the air with the help of aeroponic technique.

Scientists show a potato breed at Potato Technology Centre at Shamgarh village in Karnal district. Sayeed Ahmed

In this technique, there is no need for soil and other growing media like coco-peat for production. The scientists say that in aeroponics technique, potato seeds are grown in mist environment. They claim potato seeds grown through this technology are free from soil-borne diseases.

“We have started the process of growing minituber (potato seed) plants with the help of aeroponic technique. It is the latest technique for growing plants and potato seed production in an air or mist environment. There is no need for soil and this technology is free from soil-borne diseases,” said Dr Prem Chand Sindhu, Deputy Director, PTC, Shamgarh.