Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Vertical Farming Startup Oishii Raises $50m In Series A Funding

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone.”

By Sian Yates

03/11/2021

Oishii, a vertical farming startup based in New Jersey, has raised $50 million during a Series A funding round led by Sparx Group’s Mirai Creation Fund II.

The funds will enable Oishii to open vertical strawberry farms in new markets, expand its flagship farm outside of Manhattan, and accelerate its investment in R&D.

“Our mission is to change the way we grow food. We set out to deliver exceptionally delicious and sustainable produce,” said Oishii CEO Hiroki Koga. “We started with the strawberry – a fruit that routinely tops the dirty dozen of most pesticide-riddled crops – as it has long been considered the ‘holy grail’ of vertical farming.”

“We aim to be the largest strawberry producer in the world, and this capital allows us to bring the best-tasting, healthiest berry to everyone. From there, we’ll quickly expand into new fruits and produce,” he added.

Oishii is already known for its innovative farming techniques that have enabled the company to “perfect the strawberry,” while its proprietary and first-of-its-kind pollination method is conducted naturally with bees.

The company’s vertical farms feature zero pesticides and produce ripe fruit all year round, using less water and land than traditional agricultural methods.

“Oishii is the farm of the future,” said Sparx Group president and Group CEO Shuhei Abe. “The cultivation and pollination techniques the company has developed set them well apart from the industry, positioning Oishii to quickly revolutionise agriculture as we know it.”

The company has raised a total of $55 million since its founding in 2016.

The Stock Market Discovers Indoor Ag In A Big Way

Special purpose acquisition companies are a faster cheaper way to raise company funds than the traditional IPO process. What role may they play in our ever growing vertical farming industry?

Robinhood antics aside, there’s no hotter topic in finance right now than SPACs (special purpose acquisition companies), and even indoor agriculture has become caught up in the buzz.

SPACs, or special purpose acquisition corporations, are a shell company that lists itself on a stock exchange and then uses the listing proceeds to acquire or merge with another company. It’s an attractive route to raising funds for companies looking for a faster and cheaper way to list than the rigours of the traditional IPO process.

Though SPACs have been around since the 1990s, they have had a reputation for being “the buyer of last resort”, primarily owing to a spate of failures in the early 2000s. The approach has once more taken off in recent years. There was nearly 8x as much raised in 2020 as in 2018, and 2021’s total has already surpassed last year’s[1]. The approach has become so hot that even Goldman Sachs junior investment bankers recently complained that they were burned out by the sheer volume of SPACs they’re working on[2].

This newfound enthusiasm is generally traced to a combination of tighter SEC regulations, efforts by cash-rich private equity companies to exit portfolio companies and fewer traditional IPO listings. Higher quality sponsors, such as 40-year old private equity firm Thoma Bravo, lead some to believe that things are different this time around. The lustre of famous SPAC participants – such as baseball player A-Rod and basketball legend Shaquille O’Neal – has helped things along.

Detractors point to post-listing underperformance by SPACs, high fees to sponsors and opaqueness around the acquisition of companies. SPAC rules mean that institutional investors sometimes get to see information on potential acquisitions ahead of retail investors.[3] On a recent Clubhouse chat, one investor compared SPACs to the risky no-revenue internet listings of the late 1990s. Another questioned whether retail investors’ appetite for such vehicles would cause greater market volatility[4].

Dan Bienvenue, the interim CEO of mega public pension fund CALPERs, recently described SPACs as “fraught with potential misalignment, potential governance issues”.[5] That said, similar dire warnings have accompanied the rise of many a new approach in finance, most recently equity crowdfunding, and have proven wrong as often as right.

As is so often the case in indoor agriculture, cannabis companies have led the way when it comes to SPACs, generally listing in Canada owing to the US federal prohibition on the crop. One example is Choice Consolidation Corp, which raised $150mm in February, and says that it plans to acquire “existing strong single-state operators”[6].

Historically, food-focused indoor agriculture companies have sourced little of their capital from public markets, preferring instead to work with private equity and strategic investors. To be sure, there is a small cadre of listed CEA firms, such as Canadian greenhouse operator Village Farms (TSE: VFF) and Canadian grow system tech company CubicFarm Systems Corp (TSXV: CUB) are exceptions to this rule.

All of that changed last month when Kentucky-based greenhouse company AppHarvest raised $475mm through NASDAQ listed SPAC Novus Capital. The funds will fuel the expansion of up to a dozen new farms through 2025.

Naturally, the move has led to speculation that vertical farms and greenhouses will follow suit, though it’s worth noting that the rules that govern SPACs aren’t necessarily friendly to CEA companies. They favour large, highly valued companies that easily capture the attention of retail investors, and those are not plentiful in CEA.

Regardless of whether the SPAC trend becomes a permanent feature of the indoor farm fundraising landscape, one more method of accessing capital for CEA can only be a good thing. For the moment at least.

For more information:

Contain

www.contain.ag

Note: None of the above constitutes investment advice.

Sources:

[1] SPACInsider figures

[2] “Goldman’s junior bankers complain of crushing workload amid SPAC-fueled boom in Wall Street deals”, CNBC, March 18, 2021

[3] For instance, where a PIPE is being considered by the SPAC

[4] “SPACS: IPO 2.0 & Agrifoodtech Exits”, March 4, 2021

[5] “CalPERS’ Bienvenue: SPACs are fraught with potential misalignment”, Private Equity International, March 16, 2021

[6] “New cannabis SPAC raises $150 million in IPO for US acquisitions”, Marijuana Business Daily, February 19, 2021

Publication date: Wed 24 Mar 2021

Author: Rebekka Boekhout

© VerticalFarmDaily.com

Kosher Certification & Controlled Environment Agriculture

Kosher Certification Evolves With The Continuous Technological Changes in Food Production

February 25, 2021

Kosher Certification Evolves

With The Continuous Technological

Changes In Food Production

Since the OU’s first product certification of Heinz vegetarian baked beans in 1923, the OU’s processes for certification evolved with food production technology. A deep understanding of food production, technology, and science have made it possible to meet our customers where they are. The Controlled Environment Agriculture (CEA) Industry, an industry sector at the leading edge of agriculture has seen tremendous growth recently. It shows promise in the production of bug-free food vegetables which are in high demand by kosher consumers.

As background, most of us are familiar with pigs as not being Kosher as this is expressly forbidden for Kosher consumption in the Torah (bible). However, it is stated many more times that insects are forbidden to be eaten as well. As a result, the Kosher Consumer has to be very careful when preparing fresh produce because of the potential presence of insects such as Thrips and Aphids. This entails the consumer’s washing the produce at home, checking and, if clean (otherwise would have to restart the process) dry before consumption. Needless to say, this can be an arduous task when preparing any meal.

The Unique Nature of the Kosher Vegetable Market

This is where the Kosher Vegetable market is unique because kosher certified produce provides a critical convenience factor (often translating into higher premiums) for the consumer who is careful about not eating insects. Interestingly enough, consumers who do not keep the dietary restrictions of Kosher will nonetheless prefer kosher-certified produce because of the fear/perceived disgust of eating insects. A well-known resort was recently sued for serving lettuce wraps that contained Aphids by non-kosher consumers.

With many farms now going indoors, to allow control of humidity, lighting, and nutrients for the plants, there is a greater potential of being insect-free with the benefits of minimal to no pesticide use. This is in addition to the freshness of the product as many of these farms are more local since they are not bound by outdoor constraints. Some companies can deliver their produce within 24 hours of harvest. Due to this technology, the consumer can now have access to a greater variety of produce that can be insect-free and never has to be washed, a process that reduces the product’s quality.

This does not mean that indoor farms are automatically clean as it has been our experience that there are plenty of farms that have an insect infestation. Also, since many farms want to advertise that they are pesticide-free, this will translate into an Integrated Pest Management that requires the release of beneficial insects to consume the more detrimental ones.

The kosher certification of insect-prone vegetables is carefully supervised and navigated by the OU. Standard OU procedure will require an assessment of the facility. In addition, substantial samples of vegetables or final product are checked for insects prior to granting certification. The dynamic of OU certification of vegetables is undoubtedly highly involved but the OU has created a system of supervision to certify vegetables prone to insect infestation.

Through meeting many demands and developing an excellent working partnership with companies, the OU always strives to provide its certified companies with an unparalleled level of supervision.

Have any questions, comments, or want to explore Kosher Certification?

Please contact Rabbi Daniel Sharratt at: sharrattd@ou.org

Rabbi Daniel Sharratt

Rabbi Sharratt comes to the OU with experience working with many agencies across various industry sectors within the Food & Beverage Industry. Receiving a BS in Mechanical Engineering from the University of Notre Dame with a concentration in Industrial Design and receiving Rabbinic Ordination from Mesivta Torah Vodaath, he has become a valuable asset to the OU. As a Rabbinic Coordinator, he ensures that the Rabbis in the field are able to conduct their inspections, review formulas, manufacturing processes, and acts as the Accounts Executive. He currently specializes in Beverages and Produce (with a keen interest in Controlled Environment Agriculture). Rabbi Sharratt at one point even owned and operated a Kosher Fresh Vegetable company, developing a unique perspective into the Kosher Vegetable market. He is actively involved with ASK OU, where he provides classes for consumers on how to wash and check vegetables at home for kosher consumption. In addition, he works with many companies in Latin America due to his ability to speak Spanish.

This article originally appeared on OUkosher.org

A New FEZ "Karakalpak-Agro" Established In Uzbekistan

“….increasing the production of agricultural products, expanding its deep processing and increasing exports, effectively using the production potential of the region…”

Tashkent, Uzbekistan (UzDaily.com) - The Cabinet of Ministers adopted a resolution”On measures to organize the activities of the free economic zone “Karakalpak-Agro”.

In accordance with the decree of the President “On measures for the comprehensive socio-economic development of the Republic of Karakalpakstan in 2020–2023” on an area of 875.4 hectares in Amu Darya, Buzatausky, Kegeili, Konlikul, Kushgirot, Muynak, Nukus , Takhiatash, Turtkul, Khodjeyli, Shumanai and Ellikala districts, the SEZ "Karakalpak-agro" was created.

The functions of managing the activities of the FEZ "Karakalpak-Agro" are assigned to the State Unitary Enterprise "Directorate of the free economic zone" Nukus ".

The main tasks and directions of the SEZ "Karakalpak-Agro":

- attracting direct foreign and domestic investments for organizing modern greenhouses on a cluster basis, including hydroponic ones, as well as organizing the production of structures, equipment and other components for the construction of modern energy-efficient greenhouses;

- increasing the production of agricultural products, expanding its deep processing and increasing exports, effectively using the production potential of the region;

- encouraging the organization of the complete process of agricultural production from seeds to delivery to the market;

- introduction of effective mechanisms for providing greenhouses with seeds and seedlings of high-yielding crops demanded by the market, by creating conditions for organizing nurseries, as well as seed production;

- formation of a modern infrastructure for the provision of logistics services, assistance to agricultural producers in organizing the export of their products;

- widespread introduction of modern resource-saving technologies, the use of alternative sources of thermal energy in the organization of greenhouses;

- creation of research and production centers to assess the compliance of products with international standards.

The Council of Ministers of Karakalpakstan, together with the Ministry of Investments and Foreign Trade, the Chamber of Commerce and Industry and commercial banks, was instructed to develop a targeted program of facilities for the production of structures for greenhouses on the territory of Karakalpak-Agro within two months, with the allocation of vacant non-agricultural land.

"We’re Retrofitting With The Variables We Have In Place"

Planted Detroit introduces new 20.000 sq. ft. growing facility

“The Square Room is a big block of pink lights with eight levels, where all our growing is done. Everything after germination is done in the same room, both harvesting of our baby greens and microgreens. Because we’re almost done with our PARS (Planted Automated Racking System), which is the big automation,” says Megan Burritt, Managing partner at Planted Detroit.

From a mix-fused downtown neighborhood in Detroit, daily deliveries of ready-to-eat salads and fresh greens are transported to local retailers and restaurants. Planted Detroit makes a large contribution to the city’s share of fresh produce.

New facility

Planted Detroit has been in the middle of the construction of its new 20.000 sq. ft growing facility. The growing space has been a massive update to the company compared to its previous 6-level growing facility which was between 1500-2000 sq. ft. The same room was used for processing, packaging, harvesting, and so on. “It was rather crowded, says Megan, but the main goal was to keep everything tight for the construction to continue in the near surrounding. We’re very serious about biosecurity and we have a daily procedure for everyone who sets foot in our grow room to go through. Making sure our greens don’t come into contact with pathogens is our top priority.

The new growing room

The Square Room, one of our growing rooms, is highly automated, including an automatic harvester to ensure work-efficiency. Once everything is big enough to be transplanted out of their plug trays, PARS (Planted Automated Racking System) will be transplanted with gutters and then go into harvesting. On the other side of PARS, the gutters are taken down and harvested through Planted’s new automatic harvester.

Delivering directly to consumers

The company wants to reach a higher volume of customers as it’s aiming to obtain a consumer brand status. Next to that, the company is always on the lookout for finding more customers through other venues. “We want to go directly to consumers via our web-store to shorten food miles as much as possible, delivering the freshest and most delicious greens,” Megan says. In order to do that the company needed to have a bit more scale, trying to maximize the space they already had.

She adds: “Our farm maybe isn’t the square footage which we could have built from scratch, but we’re retrofitting with the variables we have in place. That is why we have done a combination of a microgreen vertical nursery and PARS for baby greens. Our direct customers wanted meal solutions and we’ve been able to deliver them that. We’ve been doing everything from seed to plate basically.”

Megan Burritt, Managing partner

New projects coming up

On the same campus, 10 meters away, a new farm will be constructed, under the company's office space. In this farm herbs and edible flowers will be grown in response to different customers' demands. Megan says that Planted Detroit’s wholesale customers got them to this point as they were very interested in herbs and edible flowers. “However we weren’t able to perfect these as well in the systems that our baby greens were in perfectly. That’s why we’ve been leaning into R&D lately because once finishing the construction of Farm 2 it will have excellent growing conditions that are better than they have been for those crops.”

Edible flowers are an interesting thing, says Megan, but the company has gotten so much interest in it. According to Megan there aren’t many farms in the US that are growing them. “They’re high priced at this point. It sort of sticks to our original innovation, namely what exists here in the food system and what does not. Where can we fill the ‘does not exist niche’ and satisfy the needs of our customers.”

The company is rolling out a subscription program sometime this year and figuring out where it fits into the fresh food subscription system and how they can partner with other parties in order to get produce closer to society. “It’s great to have this ag job, applied science to be able to do. In all the things we’ve been doing is hiring these Detroiters and showing that we can really create a really great culture of work. It’s really great to see we’re contributing to a better Detroit and a better tomorrow,” Megan states.

Team expansion

During 2020 most of the team stayed on by moving around working hours, so the farm could come back in full force. By the time all equipment was in place, 10 to 12 people were added to the team to have them fully trained before the system would be functioning. “It has been really wonderful to expand the team to see what our capacity is,” says Megan.

“Luckily we’ve been able to develop systems that have been resilient. We’ve seen so many different patterns in consumer behavior but they seem to have fallen in our favor. People are eating more at home, shopping for groceries more, and that triggered our pivot focusing on direct consumers. But now, it’s perfectly in line with our strategy on how we go to market. As long as we can supply our customer needs we’ll be on the right path. Nothing but bright hopes for the future right now,” Megan affirms.

For more information:

Planted Detroit

Megan Burritt, Managing partner

megan@planteddetroit.com

www.planteddetroit.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

Eastern Kentucky Company Growing Local Economy By Growing Vegetables Year-Round

AppHarvest has created 300 jobs in Appalachia, an area not really known for growing tomatoes.

by GIL MCCLANAHAN

MOREHEAD, Ky. (WCHS) — Imagine growing fresh local tomatoes in the dead of winter. A company in Eastern Kentucky is using high-tech agriculture to grow vegetables indoors.

To View The Video, Please Click Here.

AppHarvest checks tomatoes growing inside the company's 60-acre indoor greenhouse.

(AppHarvest ) Courtesy Photo

AppHarvest opened in Rowan County, Ky. last October. They are growing more than just vegetables. They are growing the economy in an area that sorely needs it.

What's growing inside AppHarvest's 2.8-million square foot facility is capable of producing more food with less resources.

"For our first harvest to be on a day where there was a snowy mountainside could not have been any more timely. The fact that we are able to grow a great juicy flavorful tomato in the middle of January and February is what we have been working to accomplish," AppHarvest Founder and CEO Jonathan Webb said.

Webb said five months after opening its Morehead indoor farm facility, the company shipped more than a million beefsteak tomatoes to several major supermarket chains, including Kroger, Walmart and Publix. Those large bushels and bushels of tomatoes are grown using using the latest technology, no pesticides and with recycled water in a controlled environment using 90% less water than water used in open-field agriculture.

"We're just trying to get that plant a consistent environment year round with the right amount of light and the right amount of humidity and the right temperature just to grow, and the vines of our crops the tomato plant end up being 45 feet and we grow them vertically so that is how we can get so much more production," Webb said.

One of the company's more well-known investors is Martha Stewart.

"I said Martha, can I get five minutes and I told her what we are doing. She was like, look we need good healthy fruits and vegetables available at an affordable price. I love the region you are working in," Webb said.

A couple of weeks later, Webb met with Stewart at her New York office, and she decided to become an investor in the company. Some local restaurants are looking forward to the day when they can buy their vegetables locally from AppHarvest. Tim Kochendoerfer, Operating Partner with Reno's Roadhouse in Morehead, buys his vegetables from a company in Louisville.

"It will be another selling point to show that we are a local restaurant," Kochendoerfer said.

Webb points out AppHarvest is not trying to replace traditional family farming. "Absolutely not. We want to work hard with local farmers," he said.

Webb said by partnering with local farmers, more local produce can get on grocery store shelves, because last year 4 billion pounds of tomatoes were imported from Mexico.

"What we are working to replace is the imports from Mexico where you got children working for $5 a day using illegal chemical pesticides in the produce is sitting on a truck for 2-3000 miles," Webb said.

AppHarvest has already started influencing the next generation of farmers by donating high tech container farms to local schools. Students learn to grow crops, not in the traditional way, but inside recycled shipping containers. The containers can produce what is typically grown on 4 acres of land. Rowan County Senior High School was the second school to receive one. It arrived last fall.

"We sell that lettuce to our food service department and it's served in all of our cafeterias in the district," said Brandy Carver, Principal at Rowan County Senior High School.

"When we talk about food insecurity and young people going home hungry, what better way can we solve these problems by putting technology in the classroom. let kids learn, then let the kids take the food home with them and get healthy food in the cafeterias," Webb said.

AppHarvest has created 300 jobs in Appalachia, an area not really known for growing tomatoes. Local leaders believe the company will attract more business to the area.

"I fully expect in time we'll see more and more activity along that line like we do in all sectors," said Jason Slone, Executive Director of the Morehead-Rowan County Chamber of Commerce.

"We will eventually be at the top 25 grocers. Name a grocer. We've been getting phone calls from all of them," Webb said.

AppHarvest has two more indoor farming facilities under construction in Madison County, Ky., with a goal of building 10 more facilities like the one in Rowan County by the year 2025.

To find out more about AppHarvest click here.

Fresh Impact Farms Awarded Arlington's First Agriculture Grant

Arlington County received its first-ever agriculture fund grant from the state, money that will go to county-based Fresh Impact Farms.

Operating since 2018, Fresh Impact Farms uses hydroponic technology to grow a variety of speciality herbs, leafy greens, and edible flowers indoors. (Mark Hand/Patch)

ARLINGTON, VA — Arlington County received its first-ever agriculture fund grant from the state, money that will go to Fresh Impact Farms, an Arlington-based company that plans to double production at its indoor growing facility.

Virginia Gov. Ralph Northam announced Monday that he had awarded an Agriculture and Forestry Industries Development, or AFID, Fund grant to Arlington totalling $15,000 to be given to Fresh Impact Farms. The company will receive a total of $30,000 from the government, with Arlington County matching the state grant with local funds.

"Agriculture continues to be a key driver of our economic recovery in both rural and urban areas of our commonwealth," Northam said Monday in a statement. "Innovative, dynamic businesses like Fresh Impact Farms are demonstrating how exciting new opportunities can grow out of pandemic-related challenges."

"I congratulate the company on their success and am thrilled to award the first-ever AFID grant to Arlington County to support this expansion," the governor said.

In recent decades, Arlington County has grown into one of the most densely populated counties in the nation. Up until World War II, Arlington still had plenty of farmland. But over the past 60-plus years, the only farming in the county has been of the backyard and patio variety or in the community gardens in the Four Mile Run area.

Operating since 2018, Fresh Impact Farms uses proprietary hydroponic technology to grow a variety of specialty herbs, leafy greens, and edible flowers indoors.

"Governor Northam's award to Fresh Impact Farms, Arlington's only commercial farm, is an innovative way to celebrate unique uses of technology to help a small business pivot during the pandemic," Arlington County Board of Supervisors Chairman Matt de Ferranti said. "I am thrilled that Fresh Impact Farms is growing and looking to the future of a sustainable food supply."

The company will invest a total of $137,500 as part of the expansion, which will include a second grow room, a larger production facility, and an educational hub where customers, after the pandemic, will be able to see how their food is harvested.

Fresh Impact Farms' community-supported agriculture or CSA, program focuses on leafy greens and home kitchen-friendly herbs and has grown them steadily since the program's creation last April. Along with residential customers, the company now has smaller wholesale clients in the Washington, D.C., area.

The future is bright for urban agriculture, said Ryan Pierce, founder of Fresh Impact Farms, located in the back of a Lee Highway strip mall. (Mark Hand/Patch)

After the start of the pandemic, Fresh Impact Farms decided to shift its business model to a CSA delivery service in order to continue generating revenue.

"Seizing the opportunity created by more people cooking at home, the company initiated a Community Supported Agriculture program targeting area residents," the governor's office said.

"Now, with vaccinations underway and the restaurant industry poised to rebound, Fresh Impact Farms is expanding, which will allow the company to resume supplying their restaurant customers, while also meeting new demand through their CSA program," the governor's office said.

Over the next three years, the company expects to grow an additional 10,500 pounds of Virginia-grown leafy greens, herbs, and edible flowers for restaurant and CSA customers.

The future is bright for urban agriculture, said Ryan Pierce, founder of Fresh Impact Farms, located in the back of a Lee Highway strip mall.

"The support and generosity from the Commonwealth and Arlington County will be valuable as we expand our production and move towards a hybrid model of serving both the needs of restaurants and consumers," Pierce said in a statement. "As the owner of a local food business, nothing gets me more excited than seeing the community come together in support of local food."

The funds from the Arlington County Industrial Development Authority, together with the state grant, represent "an important investment in urban agriculture, sustainability, and technology," Arlington County IDA Chair Edwin Fountain said in a statement. "This project will advance the County's innovative and forward-thinking approach to developing new sectors of economic activity in Arlington."

Vertical Farms vs Greenhouses – The First Consideration: Location

When and where to use a vertical farm versus a greenhouse, and what factors – both economic and environmental – make the difference.

In just the past decade or so, sustainable farming has seen a high-tech makeover in the form of Controlled Environment Agriculture, or CEA, which consists of two main technologies: Vertical farms and greenhouses.

When it comes to feeding the world, it’s not a choice between vertical farms or greenhouses. We’ll need both to feed our growing global population with healthy, sustainable food, and we need to understand the ideal situation for each.

But as a business decision, it often is a choice between the two – and that’s what we hope to explain in this five-part series of articles: When and where to use a vertical farm versus a greenhouse, and what factors – both economic and environmental – make the difference.

In this first post, we’ll cover the basic differences between vertical farms and greenhouses, and why location matters so much when deciding between the two. Then stay tuned because, in the next articles, we’ll dive deeper into energy and lighting costs, automation and other expenses, environmental and crop considerations, and finally, the future of farming.

Vertical Farms vs Greenhouses: The Basics

The two technologies are often confused, but there are significant differences between them in resource use, cost, output, and, perhaps most importantly, the ideal locations for each.

Greenhouses are the more traditional technology that you’re probably familiar with: A single layer of crops, planted inside an enclosed space with walls and a ceiling made of glass or plastic to allow natural light in. They’re semi-controlled environments.

Vertical farms, on the other hand, are a much more recent invention using trays of usually hydroponic plants, stacked in floor-to-ceiling towers, with LED lights illuminating each layer, and climate control constantly adjusting the temperature, humidity and more.

In the upcoming articles in this series, we’ll dive into each part of these differences in more detail. But for now, let’s start with the first question entrepreneurs always need answering: The price tag.

Henry Gordon-Smith is the CEO of Agritecture, an independent consultancy and software creator that helps clients decide between the two technologies. As he puts it, “Vertical farming represents the most expensive, most controlled form of agriculture.”

At first blush, vertical farms are, in fact, shockingly more expensive than greenhouses – six to 10 times as costly. Gordon-Smith says vertical farming costs 2,200 to 2,600 Euro per square meter of cultivation bed space, while high-tech greenhouses cost 250 to 350 Euro per square meter of cultivation space.

Both offer a year-round source of fresh, pesticide-free, locally-grown produce, which provides better nutrition than the same foods that arrive from far away.

But what else do farmers, entrepreneurs, and investors get for all the added expense of vertical farming?

The answer is pretty simple: A more compact farm with more production per square meter, less water use, and more control over both quantity and quality. (With iFarm, this predictability is part of the package, in the form of a guaranteed yield within a precise time frame.)

For some entrepreneurs or municipalities, the cachet of implementing a high-tech farming technique that’s only been in use for less than a decade is also a factor in favour of vertical farming. But most often, the choice comes down to location.

The Ideal Location for a Vertical Farm versus a Greenhouse

The first step in determining the feasibility of building a vertical farm or greenhouse is to look at the drivers and constraints – many of which are simply location-based.

Places with limited space, such as dense urban areas, and limited access to fresh water are ideal for vertical farms. Doubly so if they have access to low-cost, renewable energy, and if they’re near a market with high demand for the crops vertical farms excel at producing: Leafy-greens, micro-greens, herbs and berries grown locally, without pesticides.

But in areas with unlimited space, lots of natural sunlight, and high-cost and/or high-carbon electricity, greenhouses may be the better option and the extra expenses of vertical farming might not make sense.

How these considerations apply in broad regions of the world is illustrated below:

A Fully Automated Three-Dimensional Vertical Farm Comes Into Operation

Eponic Agriculture Co. Ltd is a supplier of indoor farming equipment. Alice, the company's director, introduced the recently fully automated production system of a stereochemical vertical farm

Eponic Agriculture Co. Ltd is a supplier of indoor farming equipment. Alice, the company's director, introduced the recently fully automated production system of a stereochemical vertical farm.

"The current three-dimensional indoor farms on the market are based on semi-automated workflow, with some links requiring additional equipment configuration and no continuity in the whole planting system. In order to solve this problem, we developed and designed a complete automated planting system, including the processes from sowing to planting, full-spectrum planting light control, fertilization, harvesting, and cleaning. Which are all done by automated equipment. Whereas all procedures can be controlled by intelligent software with real-time monitoring, data collection, and many other functions."

Benefits of an automated farm

When talking about the advantages of the automated equipment, Alice said, "Take our recently built 20-layer vertical farm as an example. First of all, the mechanical sowing time is 10 times-30 times faster than manual sowing. And on top of that, the use of automated equipment can realize precise planting and efficient communication of multi-layer planting surfaces. The 20-layer vegetable trays are automatically transferred to the ground for uniform watering, harvesting, and cleaning. This greatly improves productivity.

Secondly, the use of lift trucks is required when handling high-level crops. There are certain safety hazards in using lift trucks in a small space. While operating the automated equipment, only a tablet computer is needed to control the whole planting process, which is much safer and more convenient."

Although automated vertical farm systems have many advantages, their application in China is not yet popular. "In terms of production design, we have gone through countless experiments to design the most suitable software program. As well as hardware equipment for practical planting applications. Luckily after a long period of research, we finally chose the most cost-effective and suitable materials. The R&D investment is large and time-consuming.”

From a cost point of view, according to Alice, a fully automatic system is 2-3 times higher in costs than the semi-automatic system which is currently used more often. Most traditional agricultural companies find it difficult to accept such high initial costs. Thirdly, the automated system requires high technical requirements for farm managers. Managers need to have an understanding of both planting technology and software. Alice adds: “It is for these three reasons that the application of fully automated stereoscopic systems is not very common in China and other countries."

Automated planting

"Although the application is not yet widespread, I think fully automated stereoscopic planting is a trend. Urbanization has led to a reduction in arable land and soil pollution has triggered problems with pests and pesticide residues in fruits and vegetables, and the development of three-dimensional agriculture is the only way to maximize and optimize output in a limited area. Currently, stereoscopic planting plants still require a lot of manual labor to operate. As labor costs rise and planting techniques require more precision, the use of automated equipment will be a future trend," Alice notes.

"Automated systems are a trend, not only in China but also globally. Urbanization has been moving forward, in the face of soil pollution, pesticides and pests, etc. The planting area is gradually reduced and three-dimensional agriculture must be developed in order to quantify planting. Three-dimensional agriculture can be located near the city, and reduce the transport distance, people can eat the freshest vegetables, to achieve local supply. Therefore it is necessary to promote automated, intelligent planting systems in order to achieve efficient planting and sustainable development." Alice said.

Industry experience

Eponic Agriculture Co. Ltd's head office, Dahua Intelligent Electronics, has a twenty-five-year history division. The team has been focusing on the development and production of intelligent control systems and industrial lighting. Alice said that based on years of technical foundation, we developed full-spectrum LED planting lights which have been approved and applied by the USDA. Over the years, we have received technical support and affirmation from several agricultural doctors from Europe and the United States, focusing on the development and production of automated stereoscopic planting equipment.

According to Alice, the company has laboratories and showrooms in the US, Australia and Africa. This year, the company is planning on opening new showrooms and laboratories in Europe. “We are expanding our global reach and continue to optimize our growing systems to be a better supplier of fully automated growing equipment."

For more information:

Eponic Agriculture Co. Ltd

Alice Ou, Director

aliceou@eponicagriculture.com

www.eponicagriculture.com

Author: Rebekka Boekhout

© VerticalFarmDaily.com

US: TELEVISION - Today Show Will Feature Vertical Harvest Co-Founders For International Women’s Day

The segment will air on March 8 during the third hour of the show, which is 9 a.m. in most time zones. “We are so proud of our women-led team and hope you will tune into NBC and virtually watch with us!” Vertical Harvest reps said in a press release

March 6, 2021

Vertical Harvest employee Michele Dennis deposits sweet mix in Vertical Harvest’s revolving planters in May of 2019. The co-founders of the business, Nona Yehia and Caroline Croft Estay, will be part of a Today Show segment celebrating International Women's Day on March 8.

BRADLY J. BONER/ / NEWS&GUIDE

The Today Show will be celebrating International Women’s Day with a feature on Vertical Harvest’s two female co-founders, Nona Yehia and Caroline Croft Estay, and a few of their employees. The segment will air on March 8 during the third hour of the show, which is 9 a.m. in most time zones.

“We are so proud of our women-led team and hope you will tune into NBC and virtually watch with us!” Vertical Harvest reps said in a press release.

Vertical Harvest, which opened its doors in 2016, is the first vertical hydroponic greenhouse in the United States. It stands three stories high on the side of Jackson’s parking garage, using minimal space to grow produce for the community. In a year, the greenhouse grows as many vegetables as 10 acres of regular farming would produce.

Vertical farming may hold the key to the future of food supply, according to the organization’s website.

“The increasing frequency of natural disasters and the rising global temperature are putting outdoor agricultural productivity at risk,” the organization wrote on its website. “Vertical farming can contribute to reducing hunger in the future by ensuring a stable and constant supply of food that is not weather-dependent.”

Yehia, who grew up with a brother with developmental disabilities, also seeks to employ people with developmental disabilities in the greenhouse. Vertical Harvest strives to help “those who struggle to find meaningful work and upwardly mobile career opportunities” find purposeful work within the greenhouse.

All in all, Vertical Harvest is a testament to Yehia’s dedication to building a better world.

“Vertical Harvest Farms has been an opportunity to explore a new type of civic building, one that can address food, job and now housing insecurity, rooted in community resiliency,” Yehia wrote in a LinkedIn post two weeks ago.

Contact Victoria Lee at 732-5901 or vlee@jhnewsandguide.com.

Tags The Today Show Nbc Harvest Opportunity Greenhouse Agriculture Co-founder Farming Work Today Show

Gotham Greens Goes West To Unlock Next Growth Chapter: ‘The Indoor Environment Is Relatively Unexplored But Offers Fantastic Opportunities’

Expanding to Solano, California, where the greenhouse will be co-located with the University of California-Davis (UC Davis), is a significant milestone for the company that has thus far built greenhouses in its home state of New York, Rhode Island, Maryland, Illinois, and Colorado

By Mary Ellen Shoup

02-Mar-2021

Photo Credit: Gotham Greens

Using funding from its recent $87m Series D capital raise, indoor agriculture company Gotham Greens has expanded operations to Northern California – its first West Coast greenhouse location – opening a 10-acre facility, which will bring its total annual production to 40 million heads of lettuce and herbs.

Expanding to Solano, California, where the greenhouse will be co-located with the University of California-Davis (UC Davis), is a significant milestone for the company that has thus far built greenhouses in its home state of New York, Rhode Island, Maryland, Illinois, and Colorado.

“California is a significant contributor to the nation’s produce industry in several ways. Not only is California responsible for growing one-third of the country’s vegetables and two-thirds of the nation’s fruits, but also it is home to numerous research institutes, industry groups, and suppliers,” Gotham Greens co-founder and CEO Viraj Puri told FoodNavigator-USA.

While working to produce hydroponic indoor lettuce on a mass scale for West Coast consumers is a major goal with the new greenhouse facility, Puri added that its partnership with UC Davis will help drive the next wave of innovation in controlled environment agriculture (CEA).

“The location of this new greenhouse uniquely enables opportunities for Gotham Greens to play a greater role in the produce industry as well as collaborate on research and innovation with the University of California system focused on advancing the science, workforce, technology, and profitability of indoor agriculture globally,” he said.

'Over time, we’ve increased the use of automated systems'

As the top producing state of lettuce, the California agriculture industry has battled with many issues such as heavy rains and flooding to months-long drought periods that have resulted in supply shortages and price increases.

Indoor agriculture such as the greenhouse hydroponic solution Gotham Greens has brought to market could provide a viable solution to all these issues, it claims.

Gotham Greens grows its greens uses natural sunlight and hydroponic systems which uses 95% less water and 97% less land than conventional farming.

“Over time, we’ve increased the use of automated systems to ensure that temperature, humidity and light levels, as well as air composition, are exactly the right balance,” said Puri.

The end product is packaged fresh greens which are beginning to reach cost parity with commoditized field-grown lettuce. A 4.5-ounce package of Gotham Greens Romaine lettuce for example costs $3.49 on average compared to a head of conventional Romain lettuce which retails for $2.28 (in Chicago), according to USDA market price data.

Consumers also have the extra security of knowing that the lettuce they purchased is fresh since the produce traveled a much shorter distance and passed through fewer hands than is typically required for field-grown lettuce, noted Gotham Greens.

Gotham Greens Product Shot_Photo Credit Gotham Greens

Size of the prize

Puri noted that while just a small fraction of the overall lettuce category, the potential addressable market for indoor-grown, packaged leafy greens and herbs in the US and Canada is $15bn.

"While indoor farming currently represents a small portion of the salad and leafy greens market, Gotham Greens is growing +70% year over year and the indoor farming sector is growing more than +50% year over year*, far outpacing the overall category (+15% YoY) as well as the organic segment (+9% YoY)," he said.

*Nielsen Total US xAOC Lettuce and Pre Packaged Salads, Dollar Sales, Latest 52 weeks ending 1/23/21

Advantages of greenhouse farming

Asked whether the company would ever explore a vertical farming model, which in theory could use less land to produce equal amounts of lettuce, Puri noted that its greenhouse method mixed with technology is a more flexible and economic solution.

“Vertical farming is an exciting extension of modern greenhouse farming with many shared principles, but it is still a relatively young industry with open questions around technology and financial sustainability. Fully indoor environments that rely on artificial light and HVAC systems can theoretically offer much higher yields and levels of climate control, pest management, and food safety. However, these benefits currently come with significantly higher capital and operating costs,” said Puri.

Plant varieties optimized for indoor growing

The company has proved its system can work at a large scale (Gotham Greens products are available in 40 states and at 2,000 retail stores), but there are many new areas it can explore to further optimize its growing methods.

“One area of particular interest for UC Davis is the breeding of improved crop varieties for indoor agriculture. For several centuries, plant breeders have focused on selecting and breeding crops suited to outdoor conditions, where they have been successful. The indoor environment, in contrast, is relatively unexplored but offers fantastic opportunities to use lights and nutrients to modify plant development, nutritional quality, yield, and shelf-life,” said Professor Gail Taylor, chair of the UC Davis Department of Plant Sciences.

“Much remains to be explored over the coming years to ensure safer, cleaner, and more sustainable food.”

‘We are interested in the complementary nature of indoor and outdoor agriculture’

Gabe Youtsey, chief innovation officer, UC Agriculture, and Natural Resources, believes the CEA industry a new and exciting frontier for agriculture.

“New genetics, data-driven intelligent farming, farm automation, energy optimization, and other technologies can all be brought together to create a range of new tasty, healthy, and sustainable food products. We are interested in the complementary nature of indoor and outdoor agriculture, and the opportunity to help expand a local footprint of food production that is less resource-intensive and create a new generation of diverse young farmers,” Youtsey told FoodNavigator-USA.

The greenhouse will generate 60 new full-time jobs and create a new type of opportunity for UC Davis students that want to pursue CEA as a career.

Copyright - Unless otherwise stated all contents of this web site are © 2021 - William Reed Business Media Ltd - All Rights Reserved - Full details for the use of materials on this site can be found in the Terms & Conditions

RELATED TAGS: indoor farming, greenhouse farming, Gotham Greens

Aquaponics In The Heart of Zurich

Umami creates microgreens in the city centre

They produce greens, but they travel to work by streetcar and don't need to put on weatherproof clothing. That's because Umami employees will harvest vegetables and herbs already in the early growth stages, as so-called microgreens. And they do so in a largely self-built facility, on the 4th floor of an office building in Zurich's Kreis 4 district.

Full-time producers instead of restaurant operators

In the beginning, the three friends Manuel Vock, Robin Bertschinger and Denis Weinberg wanted to open a restaurant. They wanted to produce half of the products themselves. At the same time, Manuel Vock was researching aquaponics systems for his bachelor's thesis. He introduced the principle to his friends, and the team began building a prototype set-up in a former archive in 2016.

That was the end of their restaurant plan and at the same time the beginning of completely self-produced food. The guys grew several varieties of microgreens and sold them to restaurateurs who were excited to have a regional product. "Up to that point, microgreens from the Netherlands were the only alternative," says Luca Grandjean, who joined the team of Umamigos (as Umami employees call themselves) in 2019.

The aquapinic facility / Image: Umami

Microgreens

Microgreens, unlike sprouts, grow on a substrate or in soil, require light and nutrients, and are consumed without roots. They are vegetables or spice plants that are harvested immediately after their cotyledons develop. As a result, microgreens contain a high concentration of vitamins and trace elements. The small plants are used as nutritional supplements and can add sweetness and spice to different dishes.

Fish excrement as fertilizer

Regionality is not the only plus of the little plants. Umami grows the microgreens in a cycle based on nature; the only input is fish feed. But even this is actually food waste and, additionally, insects that Umami produces via scraps.

African cichlids (tilapias) and other fish species swim in various tanks, and their excretions enrich the water with nitrogen and other micronutrients. The enriched water flows into the system to the tray on which the microgreens thrive.

These are sown on a hemp-based substrate and positioned in hard trays so that their roots can touch the water, absorbing the nutrients. The water, now purified by the plants, flows back to the fish, who recharge it. Thanks to this recirculation system, only about 1% of the water needs to be replaced with fresh drinking water each month. "That's about two bathtubs full of water. Just what is lost to evaporation," Grandjean says.

Aquaponics

Aquaponics refers to a process in food production that combines raising fish in aquaculture and cultivating crops in hydroponics. There are various combinations, such as the cultivation of tomatoes and the production of tilapias, as described in this article.

Not just fish and microgreens are part of the 'ecosystem', as the Umamigos like to call their jungle. Mussels, shrimp, snails, algae and many other plants also contribute to the Umami ecosystem. "We are copying nature. Yet we have learnt that the more players there are in the cycle, the better the system works," says Luca Grandjean. This might seem to be a contradiction, but he explains: "If there are just two actors in the system and something happens to one of them, the system is quickly unbalanced."

Nomen est omen

Their most important element, he says, is Zurich's tap water; it sets the pace. "We have no soil percolation, 95% less water loss than conventional agricultural systems," Grandjean says.

Environmentally-friendly production, free of chemicals, strikes a chord with consumers. Above all, however, the products have to taste right, says Luca Grandjean. It's no coincidence that the three friends named their startup Umami when they founded it in 2015. The Japanese word means tasty or spicy, and is one of the five basic tastes, alongside sweet, sour, bitter and salty.

"The glutamate found in meat, for example, tastes umami," Grandjean explains. He adds: "The microgreens are very palatable and don't contain glutamate, but our fish do." He is referring to the license to sell fish that the Umamigos recently obtained.

For more information: https://www.eat-umami.ch/

Agritech: Precision Farming With AI, IoT and 5G

For a company that grows and delivers vegetables, Boomgrow Productions Sdn Bhd’s office is nothing like a farm, or even a vertical farm. Where farms are bedecked with wheelbarrows, spades and hoes, Boomgrow’s floor plan is akin to a co-working space with a communal island table, several cubicles, comfortable armchairs, a cosy hanging rattan chair and a glass-walled conference room in the middle

Image from: Photo by Mohd Izwan Mohd Nazam/The Edge

For a company that grows and delivers vegetables, Boomgrow Productions Sdn Bhd’s office is nothing like a farm, or even a vertical farm.

Where farms are bedecked with wheelbarrows, spades and hoes, Boomgrow’s floor plan is akin to a co-working space with a communal island table, several cubicles, comfortable armchairs, a cosy hanging rattan chair and a glass-walled conference room in the middle.

At a corner, propped up along a walkway leading to a rectangular chamber fitted with grow lights, are rows of support stilts with hydroponic planters developed in-house and an agricultural technologist perched on a chair, perusing data. “This is where some of the R&D work happens,” says Jay Dasen, co-founder of the agritech start-up.

But there is a larger farm where most of the work behind this high-tech initiative is executed. Located a stone’s throw from the city centre in Ampang is a 40ft repurposed shipping container outfitted with perception technologies and artificial intelligence (AI) capabilities that mimic the ideal environment to produce more than 50,000kg of vegetables a year.

Stacked in vertical layers, Boomgrow’s vegetables are grown under artificial lights with Internet of Things (IoT) sensors to detect everything from leaf discolouration to nitrate composition. This is coupled with AI and machine learning algorithms.

Boomgrow is the country’s first 5G-connected vertical farm. With the low latency and larger bandwidth technology, the start-up is able to monitor production in real time as well as maintain key parameters, such as temperature and humidity, to ensure optimal growth conditions.

When Jay and her co-founders, K Muralidesan and Shan Palani, embarked on this initiative six years ago, Boomgrow was nowhere near what it is today.

The three founders got together hoping to do their part in building a more sustainable future. “I’ve spent years advising small and large companies on sustainability, environmental and social governance disclosures. I even embarked on a doctorate in sustainability disclosure and governance,” says Jay.

“But I felt a deep sense of disconnect because while I saw companies evolving in terms of policies, processes and procedures towards sustainability, the people in those organisations were not transforming. Sustainability is almost like this white noise in the background. We know it’s important and we know it needs to be done, but we don’t really know how to integrate it into our lives.

“That disconnect really troubled me. When we started Boomgrow, it wasn’t a linear journey. Boomgrow is something that came out of meaningful conversations and many years of research.”

Shan, on the other hand, was an architect who developed a taste for sustainable designs when he was designing modular structures with minimal impact on their surroundings between regular projects. “It was great doing that kind of work. But I was getting very dissatisfied because the projects were customer-driven, which meant I would end up having debates about trivial stuff such as the colour of wall tiles,” he says.

As for Murali, the impetus to start Boomgrow came from having lived overseas — while working in capital markets and financial services — where quality and nutritious produce was easily available.

Ultimately, they concluded that the best way to work towards their shared sustainability goals was to address the imminent problem of food shortage.

“By 2050, the world’s population is expected to grow to 9.7 billion people, two-thirds of whom will be in Asia-Pacific. Feeding all those people will definitely be a huge challenge,” says Jay.

“The current agricultural practice is not built for resilience, but efficiency. So, when you think of farming, you think of vast tracts of land located far away from where you live or shop.

“The only way we could reimagine or rethink that was to make sure the food is located closer to consumers, with a hyperlocal strategy that is traceable and transparent, and also free of pesticides.”

Having little experience in growing anything, it took them a while to figure out the best mechanism to achieve their goal. “After we started working on prototypes, we realised that the tropics are not designed for certain types of farming,” says Jay.

“And then, there is the problem of harmful chemicals and pesticides everywhere, which has become a necessity for farmers to protect their crops because of the unpredictable climate. We went through many iterations … when we started, we used to farm in little boxes, but that didn’t quite work out.”

They explored different methodologies, from hydroponics to aquaponics, and even started growing outdoors. But they lost a lot of crops when a heat wave struck.

That was when they started exploring more effective ways to farm. “How can we protect the farm from terrible torrential rains, plant 365 days a year and keep prices affordable? It took us five years to answer these questions,” says Jay.

Even though farmers all over the world currently produce more than enough food to feed everyone, 820 million people — roughly 11% of the global population — did not have enough to eat in 2018, according to the World Health Organization. Concurrently, food safety and quality concerns are rising, with more consumers opting for organically produced food as well as safe foods, out of fear of harmful synthetic fertilisers, pesticides, herbicides and fungicides.

According to ResearchAndMarkets.com, consumer demand for global organic fruit and vegetables was valued at US$19.16 billion in 2019 and is anticipated to expand at a compound annual growth rate (CAGR) of 6.5% by 2026.

Meanwhile, the precision farming market was estimated to be US$7 billion in 2020 and is projected to reach US$12.8 billion by 2025, at a CAGR of 12.7% between 2020 and 2025, states MarketsandMarkets Research Pte Ltd.

Malaysia currently imports RM1 billion worth of leafy vegetables from countries such as Australia, China and Japan. Sourcing good and safe food from local suppliers not only benefits the country from a food security standpoint but also improves Malaysia’s competitive advantage, says Jay.

Unlike organic farming — which is still a soil-based method — tech-enabled precision farming has the advantage of catering for increasing demand and optimum crop production with the limited resources available. Moreover, changing weather patterns due to global warming encourage the adoption of advanced farming technologies to enhance farm productivity and crop yield.

Boomgrow’s model does not require the acres of land that traditional farms need, Jay emphasises. With indoor farms, the company promises a year-round harvest, undisturbed by climate and which uses 95% less water, land and fuel to operate.

Traditional farming is back-breaking labour. But with precision technology, farmers can spend less time on the farm and more on doing other things to develop their business, she says.

Boomgrow has secured more than RM300,000 in funding via technology and innovation grants from SME Corporation Malaysia, PlaTCOM Ventures and Malaysia Digital Economy Corporation, and is on track to build the country’s largest indoor farms.

Image from: Boomgrow

The company got its chance to showcase the strength of its smart technology when Telekom Malaysia Bhd (TM) approached it to be a part of the telco’s Smart Agriculture cluster in Langkawi last October.

“5G makes it faster for us to process the multiple data streams that we need because we collect data for machine learning, and then AI helps us to make decisions faster,” Jay explains.

“We manage the farm using machines to study inputs like water and electricity and even measure humidity. All the farm’s produce is lab-tested and we can keep our promise that there are no pesticides, herbicides or any preserving chemicals. We follow the food safety standards set by the EU, where nitrate accumulation in plant tissues is a big issue.”

With TM’s 5G technology and Boomgrow’s patent-pending technology, the latter is able to grow vegetables like the staple Asian greens and highland crops such as butterhead and romaine lettuce as well as kale and mint. While the company is able to grow more than 30 varieties of leafy greens, it has decided to stick to a selection of crops that is most in demand to reduce waste, says Jay.

As it stands, shipping containers are the best fit for the company’s current endeavour as containerised modular farms are the simplest means of bringing better food to local communities. However, it is also developing a blueprint to house farms in buildings, she says.

Since the showcase, Boomgrow has started to supply its crops to various hotels in Langkawi. It rolled out its e-commerce platform last year after the Movement Control Order was imposed.

“On our website, we promise to deliver the greens within six hours of harvest. But actually, you could get them way earlier. We harvest the morning after the orders come in and the vegetables are delivered on the same day,” says Jay.

Being mindful of Boomgrow’s carbon footprint, orders are organised and scheduled according to consumers’ localities, she points out. “We don’t want our delivery partners zipping everywhere, so we stagger the orders based on where consumers live.

“For example, all deliveries to Petaling Jaya happen on Thursdays, but the vegetables are harvested that morning. They are not harvested a week before, three days before or the night before. This is what it means to be hyperlocal. We want to deliver produce at its freshest and most nutritious state.”

Plans to expand regionally are also underway, once Boomgrow’s fundraising exercise is complete, says Jay. “Most probably, this will only happen when the Covid-19 pandemic ends.”

To gain the knowledge they have today, the team had to “unlearn” everything they knew and take up new skills to figure what would work best for their business, says Jay. “All this wouldn’t have been possible if we had not experimented with smart cameras to monitor the condition of our produce,” she laughs.

How This Vertical Farm Grows 80,000 Pounds of Produce per Week

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process”

Bowery Farming uses technology to prioritize accessibility and sustainability in their produce growing operations

To some, the pristine growing conditions and perceived mechanical interference of a vertical farm can seem unnatural, but at Bowery Farming “interference” is actually not the goal at all. “We don’t really think about how people are involved in the growing process, but how to take people out of the growing process” says chief science officer Henry Sztul. “Our goal is actually to have as few people walking around our plants as possible.”

Bowery Farming is a network of vertical farms working to reengineer the growing process. Using a system of light and watering technology, Bowery is able to use 95 percent less water than a traditional outdoor farm, zero pesticides and chemicals, and grow food that tastes as good as anyone else’s.

Bowery Farming uses vertical farm-specific seeds that are optimized for flavor instead of insect resistance and durability. Seeds are mechanically pressed into trays of soil, and sent out into growing positions, or racks within the building that have their own lighting and watering systems. Each tray gets its own QR code so that they can be monitored and assigned a customized plan for water and light until they’re ready to be harvested.

Irving Fain, Bowery Farming’s founder and CEO contemplates the prediction from the United Nations that 70 to 80 percent of the world’s population will be living in and around cities in the next 30 years. “Figuring out ‘how do you feed and how do you provide fresh food to urban environments both more efficiently as well as more sustainably?’ is a very important question today, and an even more important question in the years to come.”

Video: Babylon Micro-Farms To Expand, Relocate To Richmond

Co-founded in 2017 by University of Virginia students Alexander Olesen and Graham Smith, Babylon Micro-Farms started when Olesen and Smith first designed a low-cost micro-farm to provide nutritious produce for food-insecure refugees in the Middle East

Richmond—Governor Ralph Northam today announced that Babylon Micro-Farms, a Virginia-based company that develops and produces remotely controlled, indoor hydroponic systems for growing fresh herbs, vegetables, and salad greens, will invest $140,000 to expand operations and relocate to the City of Richmond. Babylon’s new location in Scott’s Addition will enable the company to expand its capabilities in manufacturing, software development, and research and development so it can begin distributing nationally and internationally. Virginia successfully competed with Arizona and California for the project, which will create 24 new jobs.

“We are thrilled to celebrate the growth of innovative Virginia businesses like Babylon Micro-Farms,” said Governor Northam. “The company’s dynamic, high-tech systems are helping to address food insecurity during the pandemic and getting fresh, local produce into the hands of more people. This expansion demonstrates the success that entrepreneurs can find in our Commonwealth, while also maintaining a strong commitment to environmental sustainability.”

Co-founded in 2017 by University of Virginia students Alexander Olesen and Graham Smith, Babylon Micro-Farms started when Olesen and Smith first designed a low-cost micro-farm to provide nutritious produce for food-insecure refugees in the Middle East. Motivated by the desire to bring benefits of sustainable hydroponic farming to those who need it most, the pair set out to develop technology that would automate the complex aspects of indoor farming and in doing so, make this transformative method of crop production accessible to anyone. Babylon’s key innovation was developing a technology system that enables its own staff to remotely manage the light, water, and nutrients for its farming systems.

“The demand for Babylon Micro-Farms’ engineered indoor farming systems is growing in assisted living facilities, student centers, restaurants, and across the globe,” said Secretary of Commerce and Trade Brian Ball. “This expansion will enhance the company’s development and distribution of its products, and the addition of 24 new jobs is welcome as we work toward economic recovery amid this global health crisis.”

“Richmond is an exciting city with a rapidly expanding start-up and technology scene,” said Alexander Olesen, CEO, and Co-Founder of Babylon Micro-Farms. “We hope to attract some of the leading talent to our new headquarters in Scott’s Addition.”

The Virginia Economic Development Partnership worked with the City of Richmond to secure the project for Virginia. Babylon Micro-Farms is eligible to receive state benefits from the Virginia Enterprise Zone Program, administered by the Virginia Department of Housing and Community Development. Funding and services to support the company’s employee training activities will be provided through the Virginia Jobs Investment Program.

“Richmond has proven to be fertile ground for innovative companies, and Babylon Micro-Farms’ environmentally friendly, technology-driven, indoor farming methods provide healthy food options for many people,” said Richmond Mayor Levar Stoney. “We’re excited to welcome them to Richmond, and look forward to the company growing its product and its presence in our city.”

“Babylon Micro-Farms’ relocation to the City of Richmond and the expansion of its operations represents an exciting opportunity for the city,” said Senator Ghazala Hashmi. “Not only is the venture bringing new jobs, the company’s use of innovative technologies for indoor farming offers a model for fresh and healthy produce that is grown locally and within urban settings. I am delighted that the company will be a part of Scott’s Addition.”

“We are excited to welcome Babylon Micro-Farms to Richmond,” said Delegate Jeffrey Bourne. “We admire the company’s ingenuity and commitment to sustainability and food accessibility. Its presence will be a great addition to our community as well as create valuable new jobs.”

CGTN Conversations: Chinese Firms Add Strength To Dubai's Future Tech Ecosystem

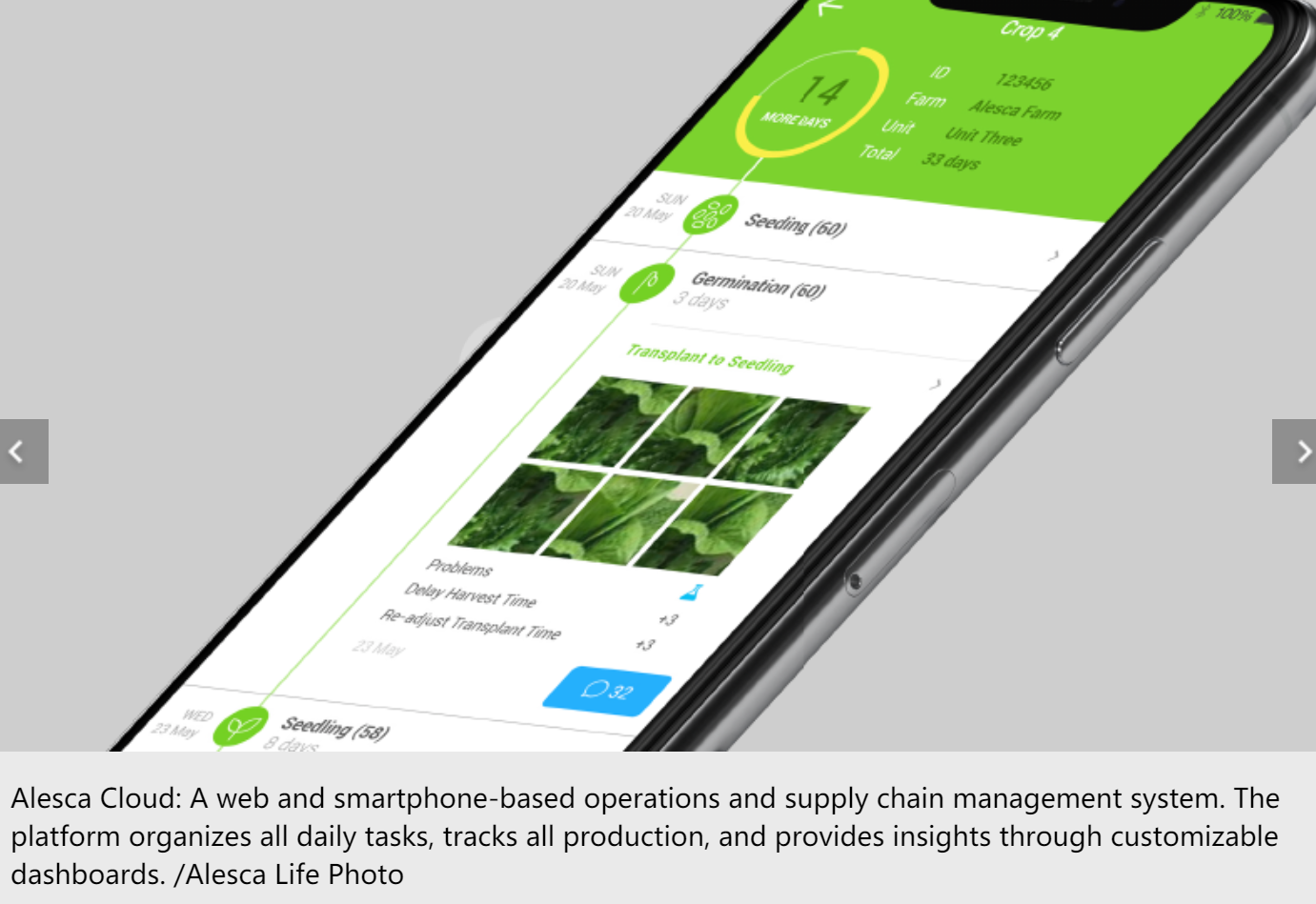

CGTN Digital's International Editor Abhishek G. Bhaya spoke with Faisal Al Hawi, the head of Accelerator and Incubators at the Dubai Future Foundation, and Stuart Oda, the founder and CEO of Alesca Life.

Over the decades, the Gulf city of Dubai has emerged as a land of innovation and a place where the future could be felt right now in the present. The city is actively encouraging global collaborations to drive innovation and future technology in the United Arab Emirates and internationally through its Dubai Future Accelerators (DFA) initiative that was launched in 2016 under the aegis of Dubai Future Foundation.

In recent years, many Chinese tech firms and start-ups – which are known for their technological prowess – have partnered with DFA to contribute to their mission of imagining, designing and co-creating solutions for future challenges.

One such successful initiative has come from Beijing-headquartered Alesca Life, an agro-tech company that is creating next-generation urban farming solutions that consume five per cent water and 30 per cent energy vis-à-vis conventional farming.

To get an overview of DFA's future innovation agenda and how Chinese firms are contributing in making that vision a reality, CGTN Digital's International Editor Abhishek G. Bhaya spoke with Faisal Al Hawi, the head of Accelerator and Incubators at the Dubai Future Foundation, and Stuart Oda, the founder and CEO of Alesca Life.

Al Hawi is responsible for creating a myriad of programs that connect different stakeholders, government and private, with innovative startups and companies from around the world to experiment with and making Dubai the testbed for future ideas.

Oda is an investment banker-turned- urban farmer with a passion for innovation and sustainability. He founded Alesca Life in 2013 with an aim to make food production more localized and data-driven.

Edited excerpts:

Bhaya: Faisal, please tell us a bit about the vision of the DFA initiative and what it aims to achieve and also some of the main areas and technologies it has tasted success in the past four years?

Al Hawi: Dubai Future Accelerators is an initiative that was born four years ago under the Dubai Future Foundation. The vision was pretty much straightforward – to put Dubai as a leading city of the world when it comes to technology innovation. Our mission is to turn Dubai into a global testbed for innovations and technologies. The DFA looks around for all the start-ups in the global scene, trying to understand the technology needs, the partner needs, the local ecosystem needs, and trying to bridge the gap between these two players of the market.

We do this in what we call the Area 2071, which is like the heart of our ecosystem in Dubai and we've had tremendous success. Throughout the four years, we've run eight cohorts, the eighth cohort is ongoing as we speak. We've engaged with more than 300 start-ups and over 60 pilot projects were produced out of DFA and more than 150 memoranda of understanding or commercial agreements were signed with different government entities and private sector partners.

Dubai Future Accelerators is positioned in a way that basically bridges the gap between the big players, be it government or private sector, and the start-up innovators from around the world.

Bhaya: How many Chinese firms and start-ups have availed the DFA program so far? Please name some of the major projects the Chinese entities have undertaken in the UAE as part of the DFA initiative.

Al Hawi: We've worked with Chinese companies ever since Cohort 1 back in 2016. So, Alesca Life is one of them. Shellpay, which was a fintech company working with the General Directorate of Immigration in Dubai, was another company. There was another company called Future Trends, working with Dubai Health Authority on medical imaging, and utilizing the technologies of AI and machine learning to optimize the diagnosis of late-stage cancers.

Yitu Technology is another Chinese AI-based company which worked very closely with [UAE's largest telecom service provider] Etisalat on solving some of their telecom related issues. So these are just to name a few companies that worked with us.

We really understand the strength Chinese ecosystem brings to our ecosystem. And I think we complement each other in a lot of areas.

Another example, broader than just Dubai Future Accelerators, is within Area 2071, where SenseTime actually has an office here, and they work very closely with the AI office, in a couple of strategic projects.

So, the partnership is growing stronger and stronger, year after year. And we definitely believe that there are areas specifically in the fourth industrial revolution technologies, blockchain, AI and IoT and the likes that we will definitely materialize more and more outcomes and success moving forward.

Bhaya: Stuart, what is the story behind Alesca Life?

Oda: Seven years ago, I started Alesca Life here in Beijing. The vision of the company is to democratize access to fresh and nutritious food by democratizing the means and the knowledge of production.

And the more research that I was doing, it became very clear that one of the most pressing challenges over the next decades wasn't so much actually related to connectivity, as these things were becoming easier with the proliferation of smartphones and computers, but access to fresh and nutritious food. And so, my team and I wanted to find a way in which we can make this access a lot easier. And wherever it made sense to localize that fresh food production, and wherever food production currently existed to make it more data driven.

So we set on this journey seven years ago, and we currently have our teams and offices across Japan, China, and the United Arab Emirates and we have partnerships across many more countries. We're developing precision farming tools to accomplish, to increase the productivity, the profitability, and the predictability of food production by up to 10 times.

Bhaya: The urban farming technologies including vertical farms and data-driven food production are certainly relevant for an arid region like the Arabian Peninsula. How did your partnership with DFA come about and what has been the journey like in the UAE for Alesca Life?

Oda: In 2016, our team was selected into the DFA program as part of Cohort 1. It was actually our first entry into the Gulf region. We knew that the technology had huge promise and potential in the region, and we wanted to make a serious commitment to the region. The DFA program was kind enough to offer us a spot in Cohort 1.

It has been hugely transformational in two ways. You know, the way in which business is done in the Middle East is very different. And to be able to have an organization like DFA, both providing the meaningful introductions, reducing some of the barriers related to the company's formation, and then also just the credibility that is bestowed on some of the companies that get to go through the program. All three of these things contributed enormously to our success in the region.

Through this program we've also been able to find meaningful strategic partnerships to mitigate some of the challenges related to concentration of supply chain, for example, even being in a place like China, to have manufacturing bases and other places in other countries, is beneficial for us.

So, right after the DFA program, we had an opportunity to localize the manufacturing of our container farm in the Emirates of Ajman in the UAE, so that we can serve our customers and our base in the GCC (Gulf Cooperation Council) and also to showcase our commitment to the region that we're not just there to sell our systems, but that we are there for the long term.

Bhaya: The year 2020 has been a watershed in many ways for the world due to the COVID-19 pandemic, reinforcing our increasing reliance on digital and AI technologies without which we can't imagine a future. How did the global crisis impact the long-term vision of DFA?

Al Hawi: The pandemic has definitely affected everyone. At DFA, we realized that innovation is the way to be resilient for the future, prepared for the future and understanding exactly the problems of today that potentially, and unfortunately, led us into the pandemic. We had just a very short drop-in time in which everybody had to just realign ourselves, and that was around March. But we immediately resumed back in October.